Amana LGA90AW-PLGA90AW, LGA60AW-PLGA60AW, LGA60AL-PLGA60AL, LGA30AW-PLGA30AW, LGA50AL-PLGA50AL Installation Guide

...Page 1

Installation Instructions

Home Laundry Automatic l)ryers

(Electric and Gas. Models)

D3111E3A

KEEP THESE INSTt_UCTIONS FOR FUTURE REFERENCE. (If the dryer changes ownership, be

sure this manual accompanies the dryer.)

_1 WARNING

FOR YOUR SAFETY, the information in this manual must be followed to minimize the trisk of

fire or explosion or to prevent property damage, personal injury or death.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

• WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in your building.

- Clear the room, building or area of all occupants.

- Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

- If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

W033

W052

Part No. 503953

May 1997

Page 2

Table Of

Contents

Rei_lacement Parts ;,!2L_.,,L:.Z.2._I,I..I..,:_'........LI .............. ................ :.. 2

Roughing In Dimensions ..................................................................... 3

Before You Start

Tools ................................................................................................ 4

Exhaust ............................................................................................. 4

Electrical ........................................................................................... 4

Gas ..................................................................................................... 4

Location ............................................................................................. 4

Installing the Dryer

STEP 1 (Position and Level the Dryer) ........................................... 5

STEP 2 (Connect Dryer Exhaust System) ........... :............................. 5

STEP 3 (Connect Gas Supply Pipe) .................................................. 6

STEP 4 (Connect Electrical Plug) ,.................................................... 7

STEP 5 (Wipe Out Inside of Dryer) .................................................. 8

STEP 6 (Plug in the Dryer) ............................................................... 8

STEP 7 (Check Installation) .............................................................. 8

Heat Source Check ................................................................................ 9

Electric Dryers .................................................................................. 9

Gas Dryers ........................................................................................ 9

Reversing Door Procedure ................................................................. 10

Manufactured (Mobile) Home Installation ....................................... 11

Electrical Requirements (Electric Dryers) ....................................... 12

Electrical Plug Connection .................................................. ............... 13

Electrical Requirements (Gas Dryers) .............................................. 14

Gas Requirements .............................................................................. 15

Location Requirements ...................................................................... 16

Dryer Exhaust Requirements ........................................................... 17

Exhaust System Materials ............................................................... 17

Make UP Air Requirements ............................................................. 17

Exhaust System ............................................................................... 18

Exhaust Direction ............................................................................ 18

Exhaust System Maintenance .......................................................... 19

Dryer Airflow ................................................................................. 19

Reduced Clearance Elbow ............................................................... 19

User-Maintenance Instructions ......................................................... 20

Lubrication ............ ......................................................................... 20

Care of Your Dryer ......................................................................... 20

Exhaust System ............................................................................... 20

Information for Handy Reference .......................... Inside Back Cover

Installer Check .................................................................... Back Cover

Replacement Parts...

If replacement parts are required,

contact the source where you

purchased your dryer, or contact

© Copyright 1997, Raytheon Appliances

Alll rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the written permission of the publisher.

2 503953

Raytheon Appliances

Amana Home Appliance Division

2800 220th Trail

P.O. Box 8901

Amana, IA 52204-0001

Phone:

(800) 843-0304 in U.S.A.

(319) 622-5511 Outside U.S.A.

FAX: (319) 622-2977

for the name and address of the

nearest authorized Amana parts

distributor.

Page 3

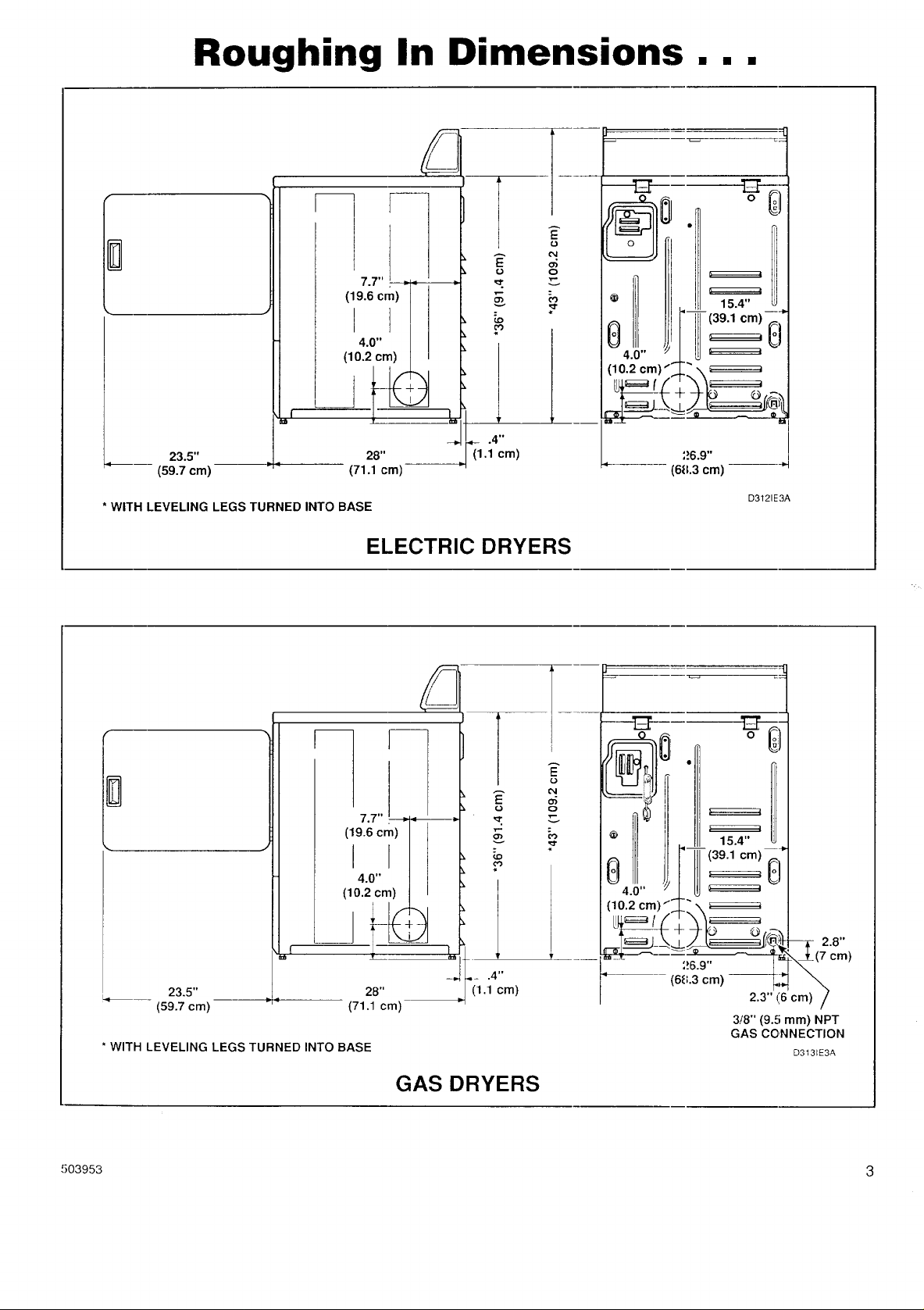

Roughing In Dimensions...

1--

E

o

v

23.5"

(59.7 cm)

* WITH LEVELING LEGS TURNED INTO BASE

(71.1 cm)

i

28"

ELECTRIC DRYERS

E

o

o_

26.9"

(6&3 cm) ---"

D3121E3A

!

E

o

o3

o

v

_ III 15.4"

4.0" _LW '===='

(10.2cm)/ L"\_

u_,=_ /,,'_',-_'_

.-__,,,,4(7 o_)

23.5"

(59.7 cm)

* WITH LEVELING LEGS TURNED INTO BASE

28"

(71.1 cm)

GAS DRYERS

503953 3

(68.3 cm) _2

2.3"(6c_) /

3/8" (9.5 mm) NPT

GAS CONNECTION

D3131E3A

Page 4

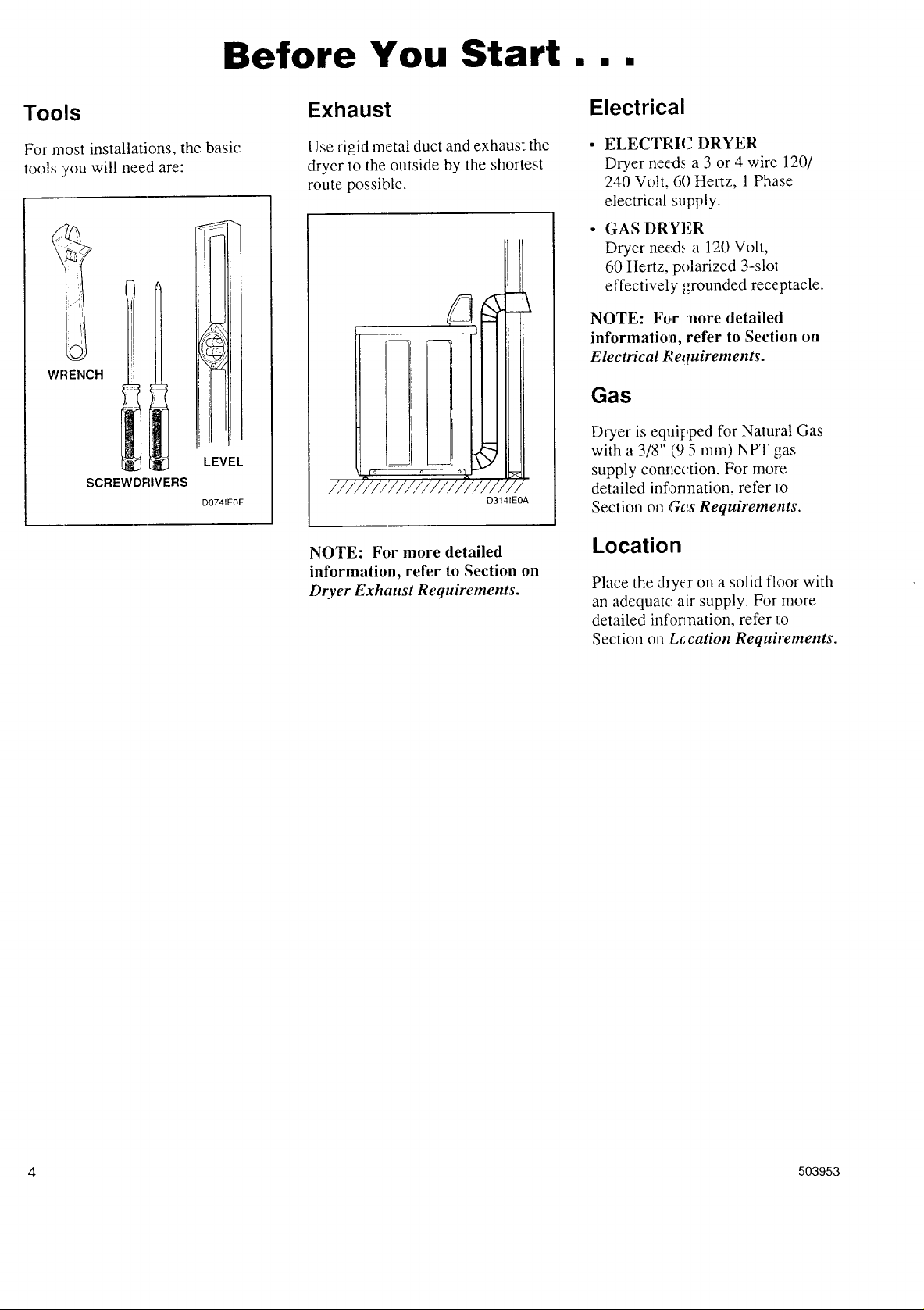

Before You Start...

Tools

For most installations, the basic

tools you will need are:

WRENCH

1'

i ii

LEVEL

SCREWDRIVERS

D0741EOF

Exhaust

Use rigid metal duct and exhaust the

dryer to the outside by the shortest

route possible.

o o o]

_///////////,r/ ////

///

NOTE: For more detailed

information, refer to Section on

Dryer Exhaust Requirements.

D3141EOA

Electrical

• • • (-1ELEC I RI _ DRYER

Dryer needs a 3 or 4 wire 120/

240 Volt, 60 Hertz, 1 Phase

electrical supply.

• GAS DRYER

Dryer need: a 120 Volt,

60 Hertz, polarized 3-slot

effectively _grounded receptacle.

NOTE: For :more detailed

information, refer to Section on

Electrical Requirements.

Gas

Dryer is equipped for Natural Gas

with a 3/8" (9 5 mm) NPT gas

supply connection. For more

detailed infarmation, refer lo

Section oll Gvs Requirements.

Location

Place the dryer on a solid floor with

an adequate air supply. For more

detailed information, refer I:o

Section on Lc.cation Requirements.

4 503953

Page 5

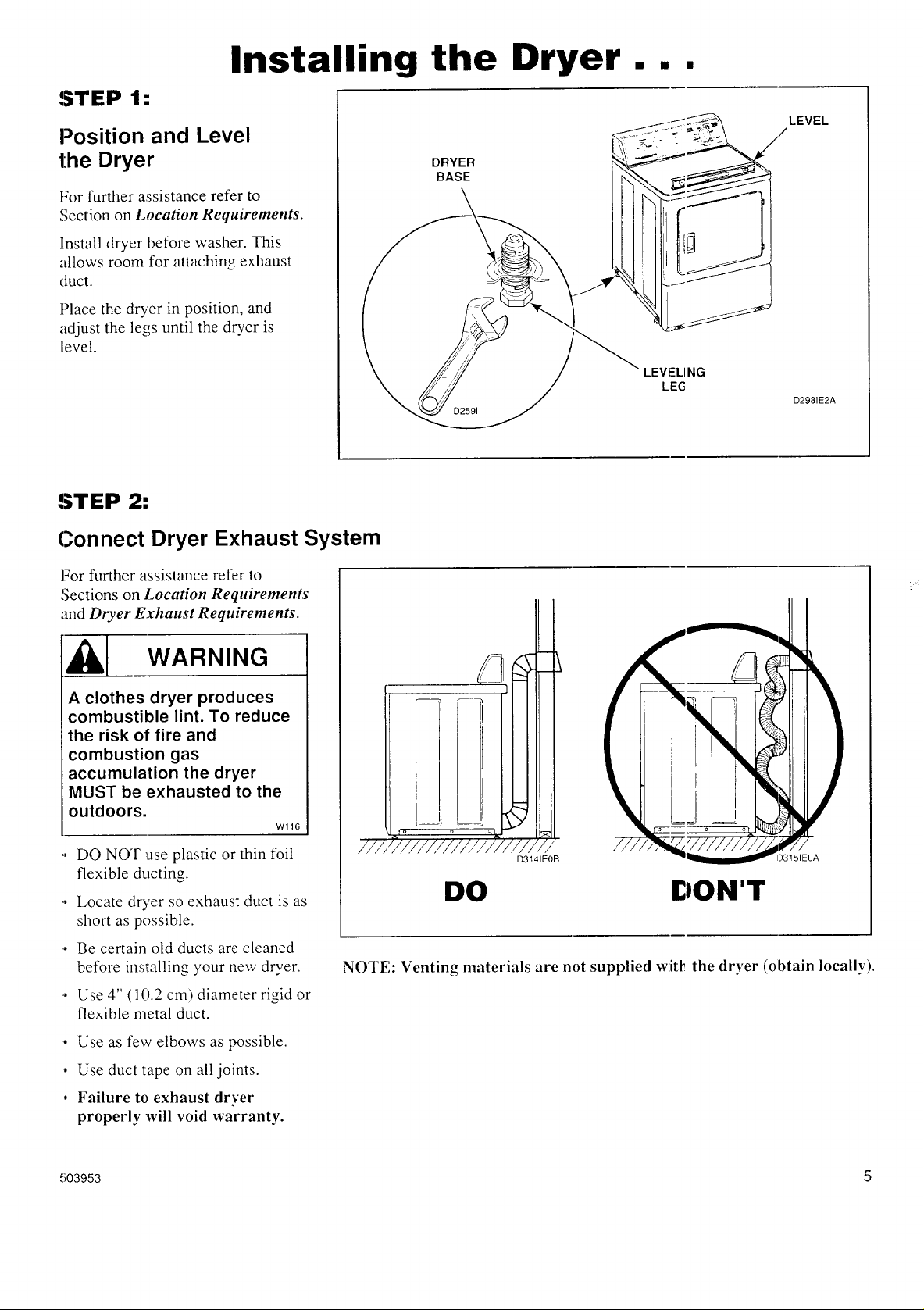

STEP 1 : ..........

Po., iti( ,n /

Position and Level

,nsta,,,n,Or,er

the Dryer

BASE

For f

For further assistance refer to

Section on Location Requirements.

Insta

Install dryer before washer. This

allo,_

allows room for attaching exhaust

duct.

Place the dryer in position, and [

adjust the legs until the dryer is

level.

LEVELING

LEG

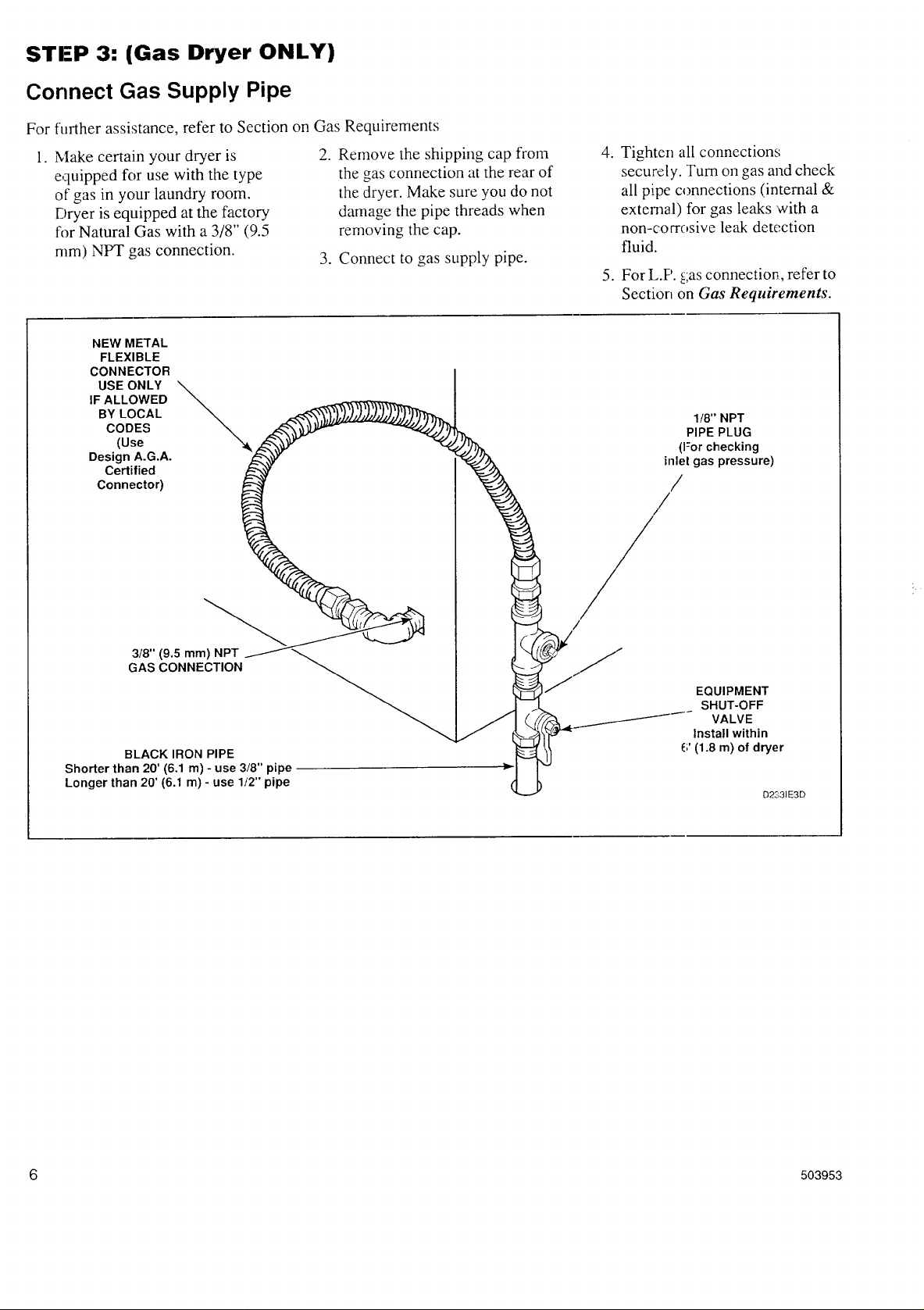

STEP 2:

Connect Dryer Exhaust System

For further assistance refer to

,_ecttons on Location Requirements

and Dryer Exhaust Requirements.

D2981E2A

-----_ WARNING

A clothes dryer produces

combustible lint. To reduce

the risk of fire and

combustion gas

accumulation the dryer

MUST be exhausted to the

outdoors.

Wl16

,. DO NOT use plastic or thin foil

flexible ducting.

,. Locate dryer so exhaust duct is as

short as possible.

,. Be certain old ducts are cleaned

before installing your new dryer.

,. Use 4" (l 0.2 cm) diameter rigid or

flexible metal duct.

• Use as few elbows as possible.

• Use duct tape on all joints.

. Failure to exhaust dryer

properly will void warranty.

D314]EOB

)3151EOA

DO DON'T

NOTE: Venting materials are not supplied w:itl!:the dryer (obtain locally).

503953 5

Page 6

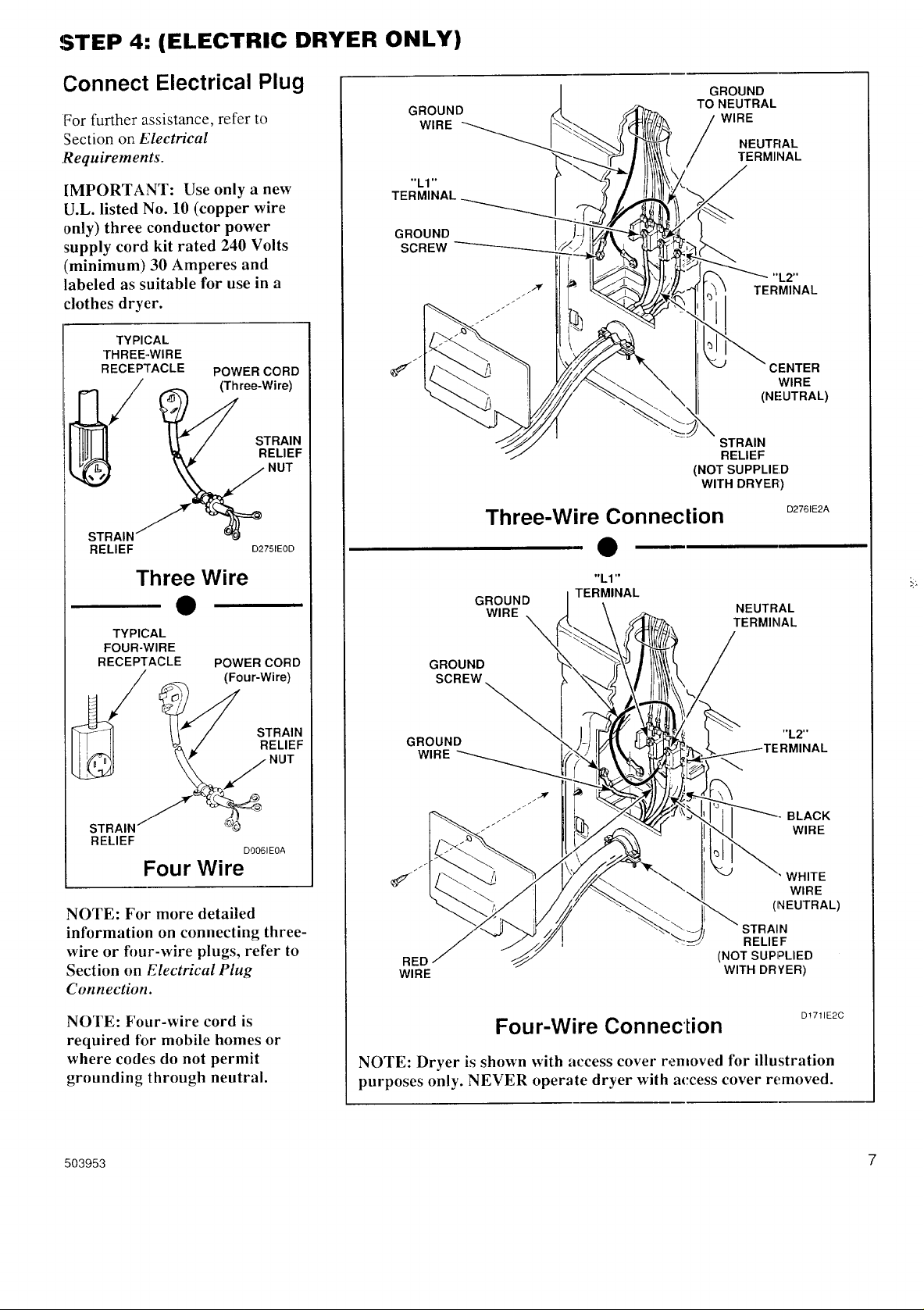

STEP 3: (Gas Dryer ONLY)

Connect Gas Supply Pipe

For further assistance, refer to Section on Gas Requirements

1. Make certain your dryer is

equipped fc)r use with the type

of gas in your laundry room.

Dryer is equipped at the factory

for Natural Gas with a 3/8" (9.5

mm) NPT gas connection.

NEW METAL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

2. Remove the shipping cap from

the gas connection at the rear of

the dryer. Make sure you do not

damage the pipe threads when

removing the cap.

3. Connect to gas supply pipe.

4. Tighten all connections;

securely. Turn on gas and check

all pipe connections (internal &

external) for gas leaks with a

non-cocrosive leak detection

fluid.

5. For L.P. gas connection,, refer to

Section on Gas Requirements.

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

/

3/8" (9.5 mm) NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 20' (6.1 rn) - use 3/8" pipe

Longer than 20' (6.1 m) - use 1/2" pipe

jr

.__....._/- VALVE

EQUIPMENT

SHUT-OFF

Install within

(i' (1.8 rn) of dryer

D2331E3D

6 503953

Page 7

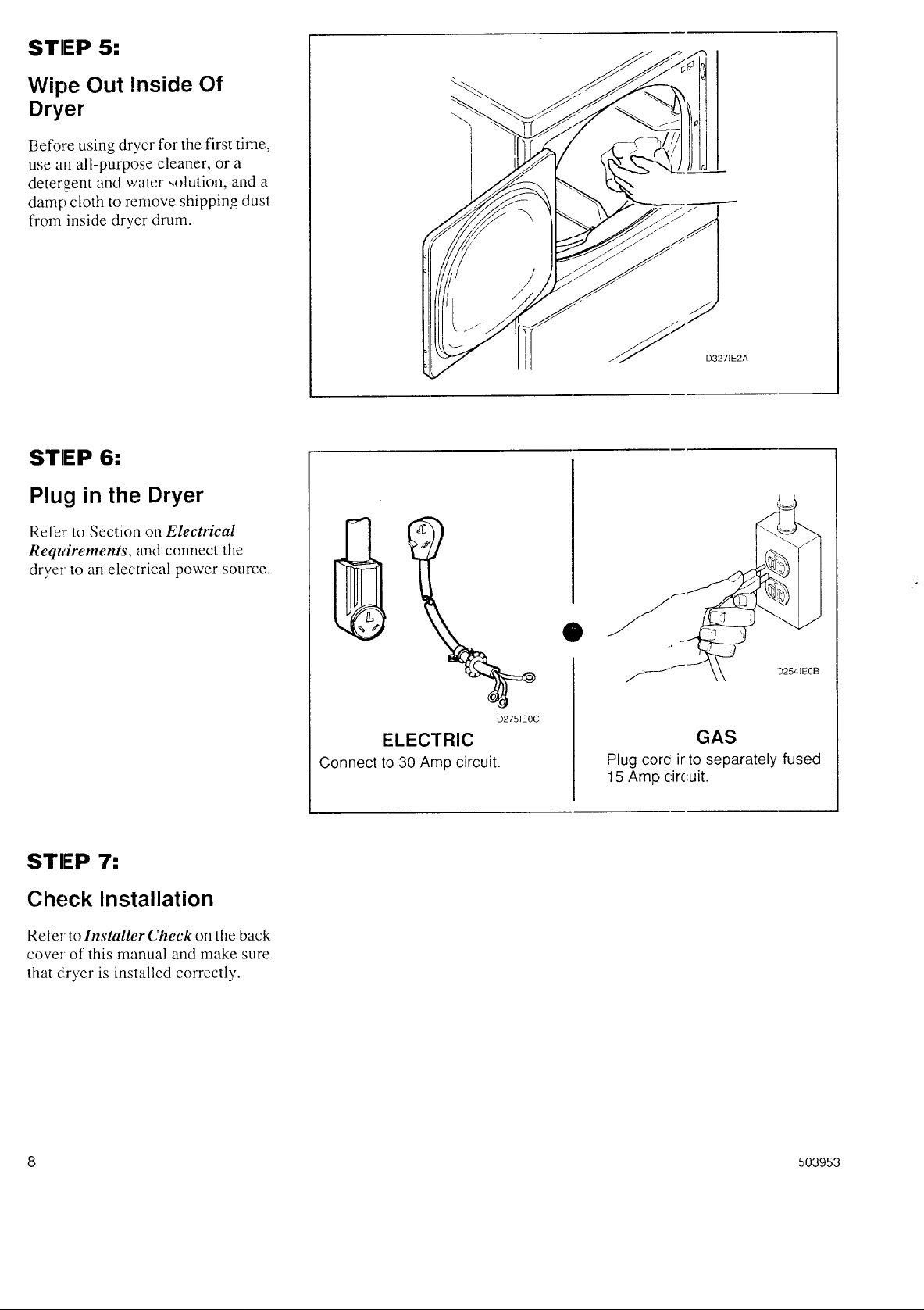

STEP 4: (ELECTRIC DRYER ONLY)

Connect Electrical Plug

For further assistance, refer to

Section on Plectrical

.Requirements.

IMPORTANT: Use only a new

U.L. listed No. 10 (copper wire

only) three conductor power

supply cord kit rated 240 Volts

(minimum) 30 Amperes and

labeled as suitable for use in a

clothes dryer.

TYPICAL

THREE..WIRE

RECEPTACLE POWER CORD

(Three-Wire)

RELIEF

NUT

S_FRAIN

STRAIN/f-m_ ===_

RELIEF D2751EOD

GROUND

WIRE

"L1"

TERMINAL

GROUND

SCREW

Three-Wire Connection

e

GROUND

TO NEUTRAL

NEUTRAL

WIRE

TERMINAL

TERMINAL

CENTER

(NFUTRAL)

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

"L2"

WIRE

D2761E2A

Three Wire

e

TYPICAL

FOUR-WIRE

RECEPTACLE POWER CORD

(Four-Wire)

__ STRAIN

RELIEF

Four Wire

NOTE: For more detailed

information on connecting three-

wire or four-wire plugs, refer to

Section on Electrical Plug

Connection.

NOTE: Four-wire cord is

required for mobile homes or

where codes do not permit

grounding through neutral.

D0061EOA

"L1"

GROUND

WIRE

TERMINAL

NEUTRAL

TERMINAL

\

GROUND

SCREW.

GROUND

WIRE

RED

WIRE

(NOT SUPPLIED

WITH DRYER)

Four-Wire Conneclion

NOTE: Dryer is shown with access cover removed for illustration

purposes only. NEVER operate dryer wilh access cover removed.

"L2"

BLACK

WIRE

WHITE

WIRE

(NEUTRAL)

AIN

RELIEF

D!711E2C

IAL

503953 7

Page 8

STEP 5:

Wipe Out Inside Of

Dryer

Befo_:e using dryer for the first time,

use an all-purpose cleaner, or a

detergent and water solution, and a

damp cloth to remove shipping dust

from inside dryer drum.

STEP 6;

Plug in the Dryer

D3271E2A

Ret'e_: to Section on Electrical

Requirements, and connect the

dryer to an electrical power source.

STEP 7:

Check Installation

Refer to Installer Check on the back

cover of this manual and make sure

that dryer is installed correctly.

ELECTRIC

Connect to 30 Amp circuit.

O

32541EOB

D2751EOC

GAS

Plug corc into separately fused

15 Amp circuit.

8 503953

Page 9

Heat Source Check...

Electric Dryers

Close the loading door and start the

dryer in a heat setting (refer to the

Use and Care Guide supplied with

the dryer). After the dryer has

To view the burner flame, remove

the lower front panel of the dryer.

Close the loading door, start the

dryer in a heat setting (refer to the

Use and Care Guide supplied with

the dryer); the dryer will start, the

igniter will glow red and the main

burner will ignite

][MPORTANT: If all air is not

purged out of gas line, gas igniter

may go off before gas is ignited. If

this happens, after approximately

two minules igniter will again

attempt gas ignition.

operated for three minutes, the

exhaust air or exhaust pipe shouhl

be warm.

Gas Dryers

After the dryer has operated for

approximately five minutes,

observe burner flame through lower

front panel. Adjust the air shutter to

obtain a soft, uniform blue flame. (A

lazy, yellow tipped flame indicates

lack of air. A harsh, roaring, very

blue flame indicates too much air.)

Adjust the air shutter as follows:

a. Loosen the air shutter

lockscrew.

b. Turn the air shutter to the left to

get a luminous yellow-tipped

flame, then turn it back slowly

to the right to obtain a steady,

soft blue flame.

c. ASter the air shutter is adjusted

for proper flame, tighten the air

shut :er lockscrew securely.

d. Reir stall the lower front panel.

WARNING

For personal safety, lower

front panel must be in place

during normal operation.

W046

After ::he dryer has operated for

approximately three minutes,

exhaust air or exhaust pipe should

be wa::m.

1/8" (3.1 mm) PIPE PLUG

(For checking

manifold pressure)

AIR SHUTTER

LOCKSCREW

/

APPLIANCE

MAIN GAS

VALVE

AIR

SHUTTER

D3161E3A

503953 9

Page 10

Reversing Door Procedure...

The, door on this dryer is completely reversible. To reverse door

proceed as follows:

D271PEOA

Remove four hinge attaching

screws.

®

I D272PEOA

I

&

Remove all nine screws.

®

®

P /

I

I

oIIJ.JiI]

Pull bottom of door liner out,

then pull down, removing door

liner from do3r panel.

®

/-js- [_

i,i ........

kL --"

Rotate door panel 180 degrees

as shown.

D273PEOA

$

D270PEOA

Reinstall nine screws removed

in S:ep 2.

D276PEOB

Remove door strike from door

liner and reinstall on opposite

side.

®

Using a screwdriver, remove

two door plugs, and reinstall on

opposite side of door opening.

< . 269PE0

Insert liner under flange on top

of door, then push bottom of

door liner nt3 place.

®

D275PEOA

Reinstall foL r hinge attaching

screws re-noved in Step 1.

10 503953

Page 11

Manufactured (Mobile) Home

Installation...

IMPORTANT: Installation must conform to "_

the Manufactured Home Construction and |

Safety Standards, Title 24 CFR, Part 32-80 or l

andard CAN/CSA-Z240 MH__p...J

The dryer can be installed in a

manufactured (mobile) home by

following these instructions:

1. IMPORTANT: Gas dryers

MUST be permanently

attached to the floor at the

time of installation. Order No.

526P3 Dryer Installation Kit

for a manufactured (mobile)

home installation. Follow the

instructions supplied with the

kit.

2. Electrical Connections (Electric

Dryer Only) must be a 4-wire

connection, refer to page 13.

3. Venting--Dryer MUST be

exhausted to the outdoors.

WARNING

To reduce the risk of fire and

combustion gas

accumulation, the dryer

MUST BE EXHAUSTED TO

THE OUTDOORS. Refer to

Section on Dryer Exhaust

Requirements.

W047

The dryer can be exhausted to the

outdoors through the back, left,

right or bottom panel. Gas dryers

cannot be exhausted out the left

side because of the burner

housing.

The dryer exhaust duct must be:

secured to the mobile home

structure.

Exhaust ducts MUST NOT be

connected with sheet metal

screws or fasteners which extend

into the duct.

Exhaust duct must not be

connected to any other duct, vent

or chimney.

Dryer exhaust duct MUST NO-['

terminate under the mobile home.

For proper operation, it is

important that tile dryer has an

ample amount of outside make-

up air. The free area of any

opening for the introduction ot

outside air must be at least 25 in2

( 163 cm2).

• When exhausting the, dryer to the

outdoors, the dryer can be

installed with "0" inch clearance

a! the sides and rear. Clearance of

the du =t from combustible

constraction must be a minimum

of 2 irlches (5.08 cm).

• Venting materials are not

supplied with the dryer (obtain

locally).

WARNING

To reduce the risk of fire, the

exhaust duct and weather

hood MUST be fabricated of

a material that will not

support combustion. Rigid

or flex ible metal pipe is

reconl mended for a clothes

dryer.

W048

503953 11

Page 12

Electrical Requirements...

NOTE: The wiring diagram is

located inside the control hood.

WARNING

To reduce the risk of fire,

electric shock, serious

injury or death, all wiring

and grounding MUST

conform with the latest

edition of the National

Electrical Code, ANSI/NFPA

70, or the Canadian

Electrical Code, CSA C22.1,

and such local regulations

as might apply. It is the

customer's responsibility to

have the wiring and fuses

checked by a qualified

electrician to make sure

your home has adequate

electrical power to operate

the dryer.

Grounding Instructions

This dryer must be connected to a

grounded metal, permanent wiring

system; or an equipment-grounding

conductor must be run with the

circuit conductors and connected to

the equipinent-grounding terminal

or lead on the dryer.

W113

(Electric Dryers)

POWER SUPPLY

_ CIRCUIT BREAKER

I [ ] NEUTRAL WtRE NEUTRAL WIRE

FUSE BOX

INTERMEDIATE _='_'_ /

(MAY BE METALLIC OR

OMITTED IF I _ I TM NON-MErALLIC

SERVICE I I_ _ • SHEATHED CABLE

ENTRANCE I I I I (COPPERWIRE

BOX IS WALLFUSED)_ _ ONLY)

RECEPTACLE _ PIGTAIL

L1 L2

PIGTAIL CONNECTION

/ 30-Amp

/ Three-wire

I i q_ A typical

240 _+12

VAC

NOTE: Use COPPER WIRE only.

Shorter than 15' (4.5 m) use 10 A.W.G.

Longer than 15' (4.5 m) use 8 A.W.G.

3-WIRE GROUNDED NEUTRAL

E ENTRANCE SWITCH BOX

120/240 VOLT, 60 HERTZ AC 1 PHASE

SEE NOTE BELOW) --'--_"

0 AMPERE ]:USES OR -----}

TO DRYER

S (SEE NOTE BELDW)

Receptacle

OOWER SUPPLY

INTERMEDIATE

SHUT-OFF BOX

(MAY OR MAY

NOT BE FUSED}

"RAL

L I L2

DIRECT CONNECTION

DOC31E2E

NOTE: The power cord (pigtail) is

NOT supplied with the electric dryer.

Type of pigtail ancl gauge of wire

must conform to local codes and

instructions.

The method of wiring the dryer is

optional and subject to local code

requirements,

NOTE: Connect the dryer to the power

:supply with the MAXIMUM RATED

'VOLTAGE listed on the nameplate.

12 503953

Page 13

Electrical Plug Connection...

-Three-Wire Plug Four-Wire Plug

I

D2841EOA

1. Remove access cover from

rear o1!dryer.

l. Remove access cover from rear

of dryer.

!

D2841EOA

GROUND

SCREW

4. Attach power cord ground

(greta:) wire to rear bulkhead

using ground screw removed in

Step 2.

"LI"

TERMINAL

WHITE

NEUTFIAL

TERMINAL

TERMINAL

BLACK

Use the three screws from the

.

envelope located in the cylinder

to attach the remaining power

cord wires to the terminal block

as tol tows:

"L2"

D2891EOC

D2851EOB

2. Use a strain relief and insert

end of power cord through

power supply hole.

"LI" /Ill 11 _ NEUTRAL

TERM ._._INAL

)y_ TERL2NAL

_f_ D2861EOA

. Use the three screws flom the

envelope located in the

cylinder to attach the power

cord wires to the terminal

block.

4. Tighten all screws and

reinstall access cover

removed in Step 1.

D2871EOC

2. Remove ground screw and save

for use in Step 4. Remove wire

and use in Step 5.

POWER

CORD

WIRE

D288;EOB

3. Use a strain relief and insert end

of power cord through power

supply hole.

a. Red wire to "LI" terminal.

b. BIack wire to "[,2" terminal.

c. White wire to Neutral

te[minal.

NOTE: When installing the white

wire, loop the free eyelet end of

the ground wire (removed in Step

2) and atlach along with the white

wire to the neutral (center)

terminal on the terminal block.

6. Tighten all screws ;and reinstall

access cover remo,,ed in Step 1.

503953 13

Page 14

Electrical

D..,, ; +

(Gas Dryers)

NOTE: The wiring diagram is

located inside the control hood.

WARNING

To reduce the risk of fire,

electric shock, serious

injury or death, all wiring

and grounding MUST

conform with the latest

edition of the National

Electrical Code, ANSl/NFPA

70, or the Canadian

Electrical Code, CSA C22.1,

and such local regulations

as might apply. It is the

customer's responsibility to

have the wiring and fuses

checked by a qualified

electrician to make sure

your home has adequate

electrical power to operate

the dryer.

• DO NOT

OVERLOAD

CIRCUITS

• DO NOT

USE AN

ADAPTER

• DO NOT

USE AN

EXTENSION

CCRD

DO091EOC

Wl!3

Grounding Instructions

The dryer must be grounded. In the

event of malfunction or breakdown,

grounding will reduce the risk of

electric shock by providing a path of

least resistance for electric cmTent.

The dryer is equipped with a cord

having an equipment-grounding

conductor and a 3-prong grounding

plug. The three-prong grounding

plug on the power cord should be

plugged directly into a polarized

three-slot effectively grounded

receptacle rated 110/120 Volts AC

(alternating current) 15 Amps.

WARNING

Improper connection of the

equipment-grounding

conductor can result in a

risk of electric shock. Check

with a qualified electrician

or service person if you are

in doubt as to whether the

dryer is properly grounded.

W038

Do not modify the plug provided

with the dryer--if it will not fit the

outlet, have a proper outlet installed

by a qualified electrician.

WARNING

STANDARD 120 VOLT,

60 HFRTZ, 3-WIRE

EFFECTIVELY GROUNDED CIRCUIT

L1 NEUTRAL

115 + 1;

V.A.C.

NEUTRAL_ -I

SIDE

ROUND

GROUNDING

PRONG

D0901EOD

NOTE: Have a qualified

electrician check the polarity of

the wall receptacle. If a voltage

reading is measured other than

that illustral ed, the qualified

electrician should correct the

problem.

Do not operale other appliances on

the same ci:cuit when this appliance

is operating.

WARNING

This dryer is equipped with

a three-prong (grounding)

plug for your protection

against shock hazard and

should be plugged directly

into a properly grounded

three-prong receptacle. Do

To reduce the risk of an

electric sh ock or fire, DO

NOT use an extension cord

or an adapter to connect the

dryer to the electrical power

source.

W037

not cut or remove the

grounding prong from this

plug.

W035

14 503953

Page 15

Gas Requirements...,

NOTE: The gas service to a gas

dryer must conform with the local

codes and ordinances, or in the

absence of local codes and

ordinances, with the latest edition

of the National Fuel Gas Code

ANSI Z223.1/NFPA 54 or the

CAN/CGA-B149, National Gas

_[nstallation Code.

Natural Gas service must be

supplied at 6.5 + 1.5 inch water

column pressure.

17orproper operatio n at altitudes

above 2,500 feet (760 m) the natural

gas valve spud orifice size must be

reduced to ensure complete

combustion. See table at right.

L.P. Gas service must be supplied at

10 + 1.5 inch water column

pressure.

NOTE: DO NOT connect the

dryer to L.P. Gas Service without

converting the gas valve. An

LPK1 Sales Accessory (L.P. Gas

Conversion Kit 649P3) must be

installed.)

(Gas Dryers)

WARNING

To reduce the risk of gas leaks, fire or explosion:

• The dryer must be connected to the type of gas as shown on

nameplate located in the door recess.

• Use a new flexible metal connector.

• Use pipe joint compound insoluble in LP Gas on all pipe

threads.

• Purge air and sediment from gas supply line before

connecting it to the dryer. Before tightening the connection,

purge remaining air from gas line to dryer until odor of gas is

detected. This step is required to prevent gas valve

contamination.

• Do not use an open flame to check for gas leaks. Use a non-

corrosive leak detection fluid.

Wl14

Altitude Orifice Size Part

m # Inches mm Number

3000 915 43 0.0890 2.26 503778

6000 !830 44 0.0860 2.18 58719

8000 2440 45 0.0820 2.08 503779

9000 2740 46 0.0810 2.06 503780

10000 3050 47 0.0785 1.99 503781

NOTE: The dryer and its

appliance main gas valve must be

disconnected from the gas supply

piping system during any

pressure testing of that system at

lest pressures in excess of 1/2 psi

(3.45 kPa). (See illustration on

page 10.)

The dryer must be isolated from the

gas supply piping system by closing

the equipment shut-off valve during

any pressure testing of the gas

supply piping system at test

pressures equal to or less than

[/2 psi (3.45 kPa)

NOTE: When connecting to a gas

line, an equipment shutoff valve

must be installed within 6' (1.8 m)

of the dryer. An 1/8" (3.1 ram)

N.P.T. pipe plug must be installed

as shown. See illustration.

NEW METAL \

FLEXIBLE

coN.EChO.\

USE ONLY _,,_ _.

IF ALLOWED _" _

BY LOCAL

CODES ,_

(Use

Design A.G.A. l_

Certified

Connector)

3/8" (9.5 ram) NPT / _

GAS CONNECTION

BLACK IRON PIPE

Shorter than 20' (6.1 m) - use 3/8" pipe ____-

Longer than 20' (6.1 m) - use 1_2" pipe

1/8" (3.1 mm) NPT

PIPE PLUG

._ (For checking

inlet gas; pressure)

QUIPMENT

1"-11 SHUT-OFF

.j] _ _ VALVE

_ _._2_)_ -_ Installed within

,_ 6' (1.8 m) of dryer

503953 15

Page 16

Location Requirements...

Select a location with a solid floor.

No other fuel burning appliance

should be installed in the same

closet with the dryer.

The dryer must not be installed or

stored in an area where it will be

exposed to water and/or weather.

:../

) /i

/i

Leveling legs can be adjusted from

inside the dryer with a 1/4" driver.

All four legs must rest firmly on the

floor so the weight of the dryer is

evenly distributed. The dryer must

not rock.

CLOSET

DOOR

/

__l__J __

-'--Am i

/

i,

The dryer neeJs sufficient clearance

and an adequate air supply for

proper operation and ventilation,

and for easLer installation and

servicing. (M inimum clearances are

shown below )

/ " -: i}

/"

1

CENTERED

AIR

OPENINGS (G)

(_ (20p,mings

Minimum)

**42"

l

•!'

l

i

]

" F

"*'C

SIDE VIEW OUTER

(w/o Closet Door)

AREA DESCRIPTION FREE STANDING / ALCOVE CLOSET INST._LLATION

INSTALLATION :(See Illustration)

(See Illustration)

A Dryer sides and rear clearance 0" (0 cm) 0" (0 cm)

B Dryer top clearance t2" (30.5 cm) 12" (30.5 cm)

C Dryer front clearance Not Applicable 2" (5.1 cm)

D Exhaust duct clearance to 2" (5.1 cm) 2" (5.1 cm)

combustible material

E Weather hood to ground clearance 12" (30.5 cm) 12" (30.5 cm)

F Distance from t]ooror ceiling to Not Applicable 3" (7.6 cm)

hole edge

G* Area of centered air openings m Nol Applicable 40 sq. in./open (260 sq. cm)

closet door

WALL OF

ENCLOSURE

FRONT VIEW

(Closet Door)

D317IE3A

*Louvered door with equivalent air openings is acceptable. (Minimum clearances are sh(,wn.)

** NOTE: For new installations, locate top of wall vent 42 inches above floor to make wmting easier to

connect.

16 503953

Page 17

Dryer Exhaust Requirements...

WARNING

A clothes dryer produces

combustible lint. To reduce

the risk of fire and

combustion gas

accumulation the dryer

MUST be exhausted to the

outdoors..

I

W1!6

This gas appliance contains

or produces a chemical or

chemicals which can cause

death or serious illness and

which are known to the

State of California to cause

cancer, birth defects, or

other reproductive harm. To

reduce the risk from

substances in the fuel or

from fuel combustion, make

sure this appliance is

installed, operated, and

maintained according to the

instructions in this manual.

W115

To reduce the risk of fire and

the accumulation of

combustion gases, DO NOT

exhaust dryer air into a

window well, gas vent,

chimney or enclosed,

unventilated area, such as

an attic, wall, ceiling, crawl

space under a building or

concealed space of a

building.

W045

To reduce the risk of fire, DO

NOT use plastic pipe or

flexible plastic pipe to

exhaust the dryer.

W041

i

_'////////////_/////

///

DO

Exhaust System

Materials

Exhaust duct must be four inches

(10.2 cm) in diameter having no

obstructions. Rigid metal duct is

recommended. Non-combustible

semi-rigid flexible metal duct is

acceptable. Do not use plastic pipe

or flexible plastic pipe, because il

contributes to poor drying

performance and collects lint, which

can lead to a fire hazard.

DO NOT use sheet metal screws on

exhaust pipe joints or other fasten mg

means which extend into the duc!

that could catch lint and reduce the

efficiency of the exhaust system.

Secure all joints with duct tape.

D3141EOB

:,3151EOA

DON'T

Make-Up Air

Requirements

For proper operation it is important

that you .ocate the drycr in an area

that hat an ample amount of make-up

air to replace the amount exhausted

by the dryer.

Energy efficient homes with low air

infiltration rates should be equipped

with an air exchanger that can

accommodate on demand inake-up

air needs in the home. These devices

can be obtained throug;h your

building contractor or building

material suppliers.

Never install flexible duct in

concealed spaces, such as a wall or

ceiling.

503953 17

Page 18

Exhaust System

Exhaust Direction

IMPORTANT: Keep exhaust

duct as short as possible.

NOTE: Be certain old ducts are

cleaned before installing your

new dryer.

For best drying results,

recommended maximum length of

exhaast system is shown below.

To prevent backdraft when dryer is

not in operation, outer end of

exhaust pipe must have a weather

hood with hinged dampers (obtain

locally).

NOTE: Weather hood should he

installed at least 12 inches (30.5

cm) above the ground.

Number of

90 ° Elbows Recommended

The dryer can be exhausted to the

outdoors through the back, left, right

or bottom of the dryer.

EXCEPTION: Gas dryers cannot

be vented out the left side because

of the burner housing.

Dryer is shipped from factory ready

for rear exhaust; no kits required.

Exhausting the dryer through sides

or bottom can be accomplished by

installing a DK1 Sales Accessory

(Directional Exhaust Kit 528P3)

available as optional equipment at

extra cost.

Weather Hood Type

Use only for short run

D3281EOA

528P;I Directional

Exhaust Kit

installations

(10.16 cm)

4"

(10.16 cm) o011E2o

2-1/2"

(6.35 cm)

DO1 [IE2E

Maximum length of 4" (10.2 cm) diameter rigid metal duct.

0

1

2

3

44 feet (13.4 m)

34 feet (10.4 m)

26 feet (7.9 m)

20 feet (6.1 m)

Maximum length of 4" (10.2

0 24 feet (7.3 m)

1 20 feet (6.1 m)

2 16 feet (4.9 m)

3 12 feet (3.7 m)

cm) diameter flexible metal duct.

34 feet (10.4 ra)

26 feet (7.9 rn)

120feet (6.1 rn)

14 feet (4.3 m)

20 feet (6. I m)

16 feet (4.9 m)

12 feet (3.7 m)

8 feet (2.4 no)

NOTE: Deduct 6 feet (1.8 m) for each additional elbow.

18 503953

Page 19

Exhaust System

Maintenance

The dryer interior and the complete

exhaust system should be inspected

after one year of use and cleaned if

necessary. Inspect and clean exhaust

duct every one to two years as

required thereafter. The weather

hood should be checked frequently

to make sure the dampers move

freely, dampers are not pushed in

and that nothing has been set against

them. This maintenance work

should be done by a qualified

service person.

WARNING

To reduce the risk of electric

shock, disconnect the

electrical service to the

dryer before cleaning.

W043

Dryer Airflow

Efficient dryer operation requires

proper dryer airflow. Proper dryer

airflow can be evaluated by

measuring the static pressure.

Static pressure in the dryer's

exhaust duct should be no greater

than that shown in the chart below.

(Check with dryer running and no

load.)

NOTE: This can be measured

with a manometer placed on the

exhaust duct approximately two

feet (61 cm) from the dryer, see

illustration below.

MAXIMUM STATIC

PRESSURE IN

WATER COLUMN

.6 INCHES (1.5 cm)

MANOMETER

Reduced Clearance

Elbow

Installirtg the dryer in shallow

closets ,:an be accomplished by

using an Elbow, Part No. 62688,

which i_;one inch narrower than a

standard venting elbow.

D3191

Reduced Clearance

Elbow

Exhausting the dryer in hard-to-

reach locations can be accomplished

by installing the 521P3 Flexible

Metal Vent Kit, available as

optional equipment at extra cost.

The kit comes in two halves that can

be separately attached to the dryer

and wall outlet. Once attached, the

dryer can be slid back into position

and the two halves can be connected

from the front.

EXHAUST

DUCT

Measuring Static Pressure

DO121EOA

521 P3 Metal

503953 19

Page 20

User.Maintenance Instructions...

• Lubrication

All moving parts are sealed in a

permanent supply of lubricant or

are equipped with oilless

bed.rings, Additional lubrication

will not be necessary.

• Care of Your Dryer

Clean the lint filter after drying

each load. The lint filter may be

washed if needed. Occasionally

reraove lint filter and vacuum the

area under it.

Ordinarily, the dryer cylinder will

need no care_

Wipe the dryer cabinet as needed.

If detergent, bleach or other

washing products have been

spilled on the dryer, wipe

immediately. Some products will

cause permanent damage if

spilled on the cabinet.

Do not allow sharp or rough

objects to lean against the dryer.

The finish could be damaged.

Use only a damp or sudsy cloth

for cleaning the control panel.

Some spray prewash products

may harm the finish on the control

panel.

NOTE: The wiring diagram is

located inside the control panel.

CAUTION

Label all wires prior to

disconnection when

servicing controls. Wiring

errors can cause improper

and dangerous operation.

W049

• Exhaust System

The exhaust duct should be

inspected after one year of use and

cleaned if necessary. Inspect and

clean exhaust duct every one to

two years _Lsrequired thereafter.

The weather hood should be

checked frequently to make sure

the dampers move freely, dampers

are not pushed in and that nothing

has been set against thern.

Keep drTer area clear and free

from coml:,ustible mater!Ms,

gasoline and other flammable

vapors and liquids.

Do no! ob.,:,truct the flow of

combustion and ventilation air.

NOTE: Verify proper operation

after servicing.

20 503953

Page 21

503953 21

Page 22

22 503953

Page 23

Information for Handy Reference...

Raytheon Appliances

Amana Home Appliance Division

2800 220th Trail

P.O. Box 8901

Amana, IA 52204-0001

Date Purchased

Model Numbe.r

Dealer's Name

Dealer's Address

Service Agency

Service Agency Address

NOTE: Record the above information and keep your sales slip. Model and serial numbers are located on

the nameplate.

Serial Number

Phone Numbe:

Phone Numbe:

503953 23

Page 24

Fast Track for Installing the Dryer

(Refer to the manual for more detailed information)

O. Position and Level

The Dryer.

(]]) LEVEL (_

Installer Check...

--ELECTRIC ONLY

O• Connecl Electrical Cord.

J

CHECK

• Connect Dryer Exhaust System.

!iii

CHECK CHECK

-- GAS ONLY

_). ConnectGas

Supply Pipe.

• Check for Gas

Leaks.

-N

J

O. Plug In The Dryer.

EL[__CTRL,

• Wipe Out

I aside Of Dryer.

GAS

"N

J

J

_ CHECK

CHECK

503953

Loading...

Loading...