Page 1

A

t

GUD-X

®

Heating ¡ Air Conditioning

higher standard of comfor

High Efficiency

Gas Fired

Affix this Specification Sheet, Installation Instructions and

Warm Air Furnace

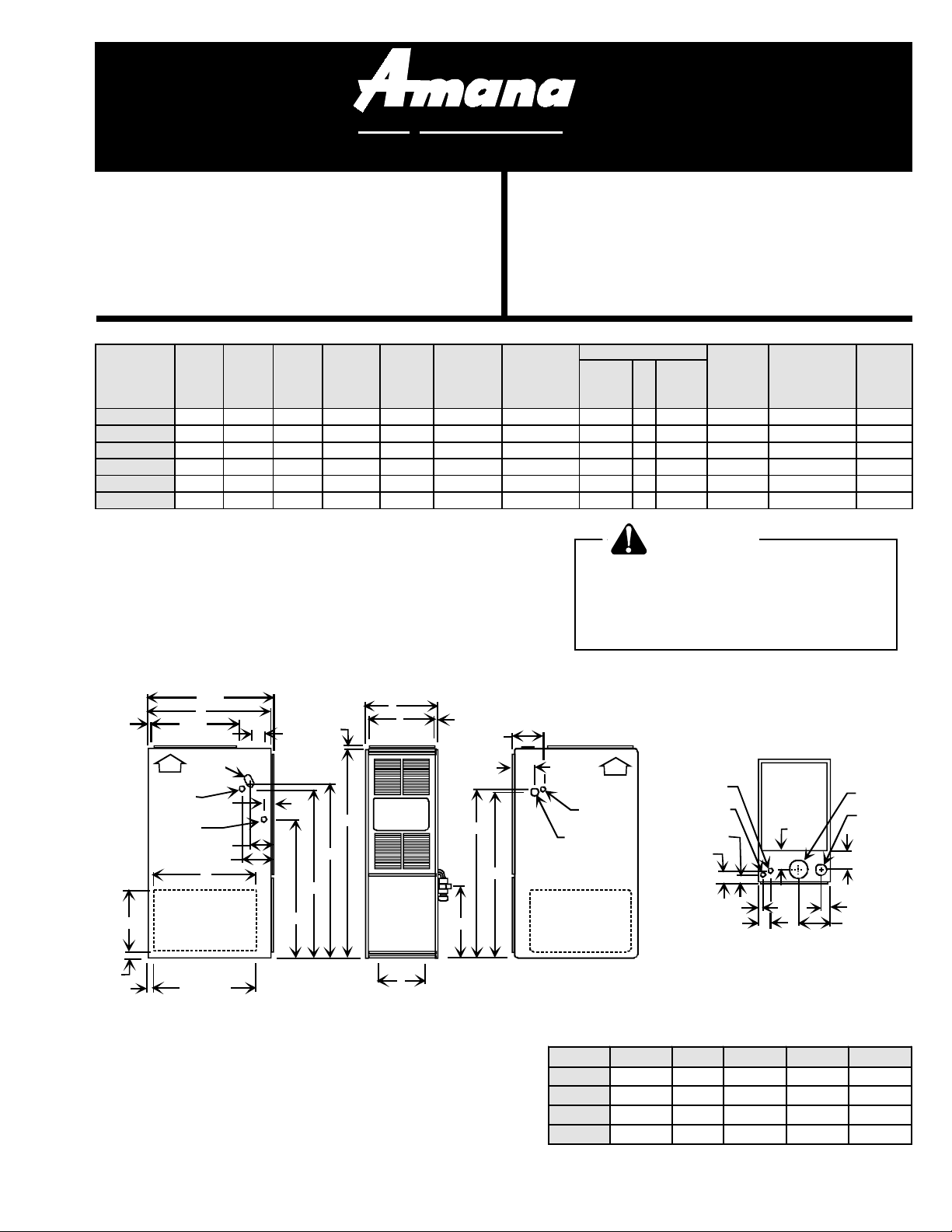

Model Number Input

GUD045X30B 45,000 43,000 95.6 25-55 2 11.3 15 10X8 1/3 3 2.0-3.0 -1.38 158

GUD070X30B 70,000 65,700 93.8 35-65 3 10.3 15 10X8 1/3 4 2.0-3.0 -1.38 194

GUD070X40B 70,000 65,700 93.8 35-65 3 14.1 15 10X10 3/4 4 3.0-4.0 -1.38 194

GUD090X35B 90,000 84,300 93.7 45-75 4 10.1 15 10X8 1/2 4 2.0-3.5 -1.57 216

GUD090X50B 90,000 85,100 94.6 35-65 4 15.1 20 10X10 3/4 4 3.5-5.0 -1.57 216

GUD115X50B 115,000 107,600 93.6 35-65 5 15.1 20 10X10 3/4 4 3.5-5.0 -1.38 231

1

Minimum Circuit Ampacity = (Circulating Blower Amps x 1.25) + I.D. Blower Amps

2

Maximum Overcurrent Protection refers to maximum recommended fuse or circuit breaker size.

3

As shipped for installations below 4,000 feet.

(BTUH)

Output

(BTUH) AFUE

Temp. Blower Pressure

Rise

Range, °F

Number

Burners

of

Minimum

Circuit

Ampacity

Maximum

Overcurrent

1

Protection

Specification Sheet

User Information manual adjacent to the unit.

Shipping

3

D" x W" HP Speeds

2

AC To ns @

.5 ESP

WARNING

Switch Setting

(Inches W.C.)

Weight

(lbs)

To avoid death, personal injury or

Dimensions

property damage due to fire, do not

exceed maximum recommended

fuse or circuit breaker size.

Left Side View

48

Front View

A

B

3/4

38-3/4

16-1/2

4-3/4

6-5/8

38-1/4

Right Side View

Supply

Electrical

Hole-Low

Voltage

Gas

Supply

Hole

Gas Supply H ole

Electrical Hol e

Line Volta ge

1-3/4

2

1-1/8

Top View

Combustion

Air Inlet

4-1/4

E

Flue Outlet

4-3/8

2-1/2

C

3/4

14

20-1/8

Supply

Electrical

Hole-Low

Voltage

Electrical

Hole-Line

Voltage

28-1/8

28

Gas

Supply

Hole

1-5/8

5-7/8

6-5/8

23

Side KO

2-3/8

28-3/4

3/4

40

38-3/4

1-5/8

1-5/8

23

Bottom KO

Due to continuous engineering design and development, the above

information is subject to change without notice.

January 1998

Condensate Drain

(Left or Right Side)

D

Bottom KO

Size A B C D E

45 16-1/2 15 7 10-1/2 2-5/8

70 20-1/2 19 11 14-1/2 2-5/8

90 24-1/2 23 10-1/2 18-1/2 4-5/8

115 24-1/2 23 12-1/2 18-1/2 2-5/8

Amana

Fayetteville, TN 37334

All dimensions are in inches.

11134620

Page 2

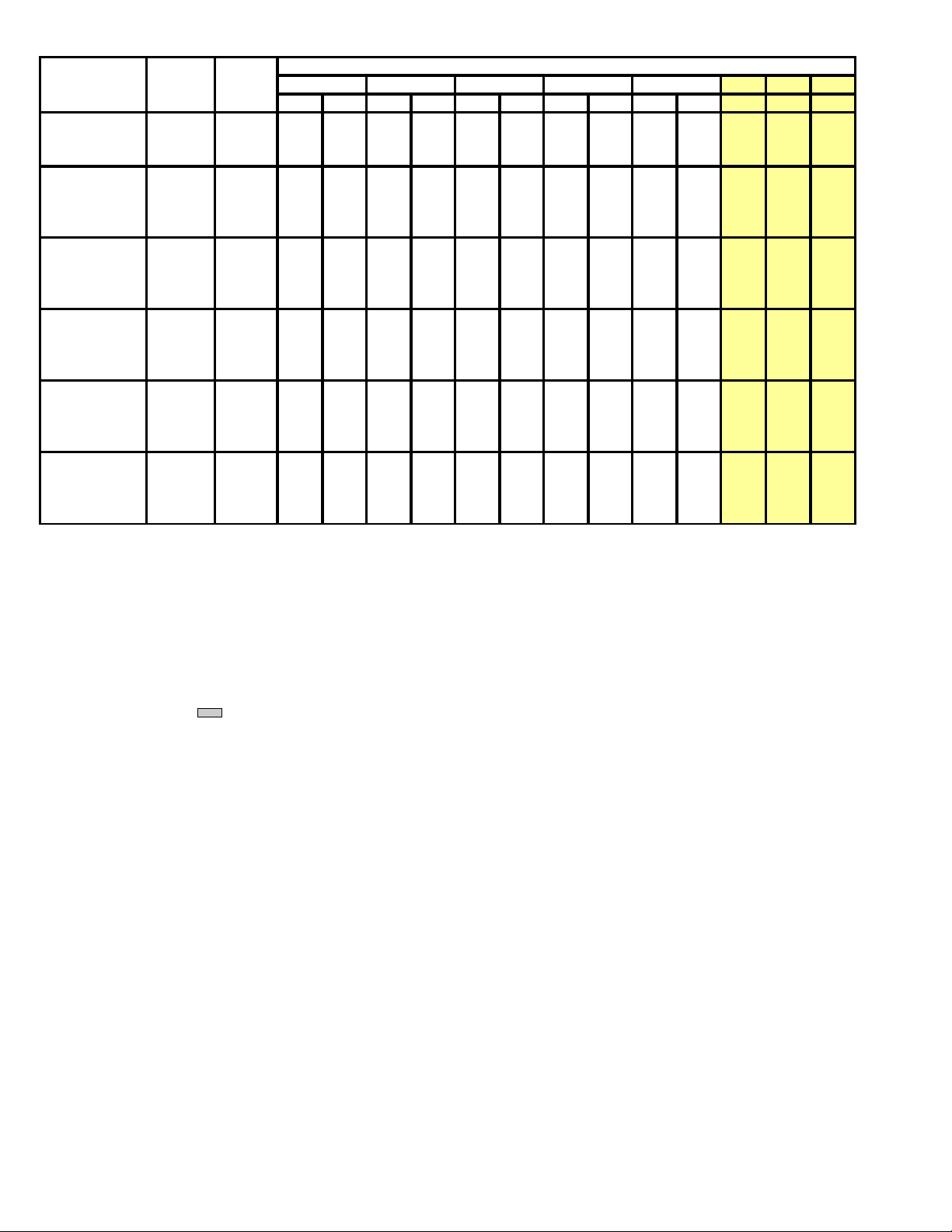

Model (Htg. Tons AC External Static Pressure, Inches Water Column

Speed As Motor at .5" 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Shipped) Speed ESP CFM RISE CFM RISE CFM RISE CFM RISE CFM RISE CFM CFM CFM

HIGH 3.0 1381 28 1319 29 1260 30 1197 32 1131 34 1055 960 847

GUD045X30B MED 2.5 1173 33 1142 34 1103 35 1055 36 998 38 931 848 736

(MED) LOW 2.0 908 42 901 43 884 43 855 45 815 47 760 688 602

HIGH 3.0 1458 41 1395 43 1334 45 1266 47 1188 50 1111 1015 895

GUD070X30B MED 2.5 1270 47 1229 49 1178 51 1122 53 1060 56 986 898 778

(HIGH) MED-LO 2.0 1019 59 1001 60 973 61 938 64 891 ----- 831 750 649

LOW 1.5 782 ----- 778 ----- 766 ----- 746 ----- 708 ----- 659 590 501

HIGH 4.0 1861 ----- 1803 ----- 1714 35 1647 37 1561 39 1457 1278 1063

GUD070X40B MED 3.5 1699 36 1643 37 1577 38 1512 40 1431 42 1312 1164 977

(MED-LOW) MED-LO 3.5 1519 40 1482 41 1439 42 1386 44 1316 46 1196 1063 903

LOW 3.0 1278 47 1277 47 1268 48 1227 49 1164 52 1069 937 839

HIGH 4.0 1664 47 1599 49 1532 51 1465 53 1395 56 1312 1234 1150

GUD090X35B MED 3.5 1465 53 1439 54 1395 56 1345 58 1288 60 1218 1145 1048

(MED) MED-LO 3.0 1089 71 1108 70 1106 70 1092 71 1059 73 1021 961 883

LOW 2.5 850 ----- 845 ----- 841 ----- 834 ----- 823 ----- 801 759 688

HIGH 5.0 2271 ----- 2184 36 2094 37 2000 39 1914 41 1810 1701 1552

GUD090X50B MED 4.5 1951 40 1889 41 1837 42 1770 44 1701 46 1598 1489 1353

(MED) MED-LO 4.0 1724 45 1695 46 1647 47 1598 49 1534 51 1412 1362 1236

LOW 3.5 1495 52 1474 53 1448 54 1407 55 1356 57 1289 1196 1036

HIGH 5.0 2358 42 2228 44 2094 47 1997 49 1896 52 1800 1680 1552

GUD115X50B MED 4.5 1922 52 1869 52 1810 55 1743 57 1688 59 1583 1488 1364

(HIGH) MED-LO 4.0 1699 58 1672 59 1630 61 1583 63 1526 65 1454 1369 1248

LOW 3.5 1475 ----- 1462 ----- 1441 ----- 1414 ----- 1369 ----- 1317 1232 1067

NOTES:

• CFM information in the above table is with high velocity, permanent filter(s) as shipped with the furnace. If the furnace is shipped with two

side return filters, this table assumes both filters are used.

• All furnaces ship as high speed for cooling. Installer must adjust blower speed as needed.

• For most jobs, about 400 CFM per ton when cooling is desirable.

• This chart is for furnaces installed at 0 - 4000 feet. At higher altitudes, a properly derated unit will have the same temperature rise at a particular

CFM, while the ESP at that CFM will be lower.

• The shaded area ( )indicates ranges in excess of maximum external static pressure allowable when heating. For satisfactory operation,

external static pressure should not exceed 0.5” W.C. The data for 0.6” W.C. to 0.8” W.C. is shown for air conditioning purposes only.

• The dashed (-----) areas indicate a temperature rise not recommended for this model.

• The installation must be adjusted to obtain a temperature rise within the range listed on the furnace nameplate.

2

Page 3

Accessibility Clearances (Minimum)

WARNING

To avoid death, personal injury or property

damage due to fire, clearances to combustible surfaces listed as below must be

observed.

36 inches front clearance is required for servicing or cleaning.

NOTE: In all cases, accessibility clearance must take

precedence over clearances from the enclosure where

accessibility clearances are greater.

CLEARANCES TO COMBUSTIBLE SURFACES

GUD_ MODEL FURNACES (Inches)

FRONT 3 TOP 1

RIGHT 1 FLUE 0

LEFT 1 FLOOR C

REAR 0 ---- ----

C = If placed on combustible floor, floor MUST be wood only.

High Altitude Installations

For installations above 4000 feet, please refer to your

Amana distributor for required kit(s).

Gas Al titude Ki t Orifice

Natural 0-4000 Ft. None #43 3.5" W.C.

Propane 0-4500 Ft. LPTK09 #55 10.0" W.C.

NOTE: In Canada, gas furnaces are certified to 4,500 feet

only.

IMPORTANT NOTES:

1. All furnaces have a redundant gas valve and blower

door interlock switch.

2. All furnaces are manufactured for use on 115 VAC, 60

Hz, single phase electrical supply.

3. IMPORTANT: While the data is presented as a guide,

it is very important to properly size fuses and wires and

make electrical connections in accordance with the

National Electrical Code and/or all existing local codes.

4. Performance figures are based on Department of Energy information and requirements under continuous

operating conditions. Performance will vary with weather

conditions and use.

Manif old

Pressure

5. Drain connections must conform to local codes.

6. Installer must supply the following gas line fittings

according to which entrance is used:

Top Two 90° Elbows

One Close Nippl e

Left

Right

One 90° Elbow

One 90° Elbow

One 45° Elbow

One Close Nippl e

Flame Sensor

Flame sensor output is 1 to 4 microamps at 115 volts.

Filters

Side Return Filters

Minimum Recommended Size

Size_Air Flow Disposable* Permanent*

045_30 1 - 24x24 (576) 1 - 16x25 (280)

070_30 1 - 24x24 (576) 1 - 16x25 (280)

070_40 2 - 16x25 (768) 1 - 16x25 (372)

090_35 2 - 14x25 (692) 1 - 16x25 (342)

090_50 2 - 20x25 (960) 2 - 16x25 (465)

115_50 2 - 20x25 (960) 2 - 16x25 (465)

* Quantity - Inches (Total Minimum Surface Area in Square Inches)

Permanent filter sizes are as shipped with furnace. The minimum

permanent filter size area is based on allowable face velocity of 620

feet per minute.

Bottom Return Filter Sizes

Model Filter Size (Inches) Type

45 14 x 25 x 1 P

70 16 x 25 x 1* P

90 20 x 25 x 1 P

115 20 x 25 x 1 P

P = Permanent

* As Shipped With Furnace

The figure below shows how the filter is retained over the

bottom return air opening.

Filter Retainer

Filter

Furnace Bottom

Filter Retainer

3

Page 4

WARNING

To prevent death, personal injury or property damage due to electrical shock, disconnect electrical power to this furnace

before servicing or performing maintenance.

THERMOSTAT

Y

CONNECTIONS

W

R

G

C

TERMINAL ORDER REARRANGED FOR CLARITY

L

E

E

H

H

I

A

A

U

U

N

C

C

M

M

E

H

H

N

H

N

O

O

E

O

E

T

T

U

T

U

120 V

TRANS-

FORMER

24 V

4

PS

CONTROL

X

X

F

F

M

M

R

R

H

N

H

O

E

T

P

L

T

T

U

H

S

I

R

NO

C

NC

5

**

*

C

H

P

H

O

E

A

L

M

M

O

A

R

O

V

V

L

T

K

L

I

M

I

T

GV

CAP ACB

C

NO

L1

DOOR

SWITCH

GND

6

C

P

A

R

K

L

I

I

N

R

E

I

N

I

G

N

N

E

E

G

F

N

D

U

U

N

P

D

S

F

E

L

N

A

S

M

O

E

R

CB

N

IGNITOR

WARNING:DISCONNECT POWER BEF ORE

SERVICING.WIRING TO UNIT MUST BE

PROPERLY POLARIZED AND GROUNDED.

PRIMARY

FACTORY WIRED BLOWER MOTOR TO CONTROL CONNECTIONS

HEATING BLOWER SPEEDFURNACE MODEL

* MANUFACTURER'S VARIABLE LETTER

GUX: 045X30*

GUC: 070X40* 4LOW RD-24

GUC: 045X30*

GUD: 045X30*

GUX: 070X40*

GUC: 090X50*

GUD: 070X40*

GUX: 070X30*,090X50*

GUD: 090X35*,090X50*

GUX: 090X35*,115X50*

GUC: 070X30*,115X50*

090X35*

GUD: 070X30*,115X50*

*

SPEED

LOW

MED 3BU-23

MED LOW 4OR-29

HI BK-26 4

R

R

0

0

2

1

FLAME S ENSOR

115V

FIELD

CONNECT

RL

MOTOR TO "HEAT"

3

P

2

C

1

M

GAS

VALVE

(GV)

COMBUSTION

BLOWER

(CB)

VT-14

BK

L1

N

GND

ELECTRI CAL BOX

RD-24

BU-23MED 4

PRIMARY

ROLLOU T

LIMIT (RL)

BR-21

GY-47

WH

VT

-55

MOTOR

SPEEDS

3

RD-44

RD-44

LIMIT

WH

**

COOLING

BLOWER SPEED

SEE

INSTALLATION

INSTRUCTIONS

TO DETERMINE

PROPER

COOLING

BLOWER SPEED.

LOW VOLTAGE FIELD

HI VOLTAGE FIELD

PRESSURE SWITCH (PS)

COM

NC

NO

OR

-16

BU-15

GN

YL

-11

CAPACITOR

(CAP)

WH-33

BU-36

RD-22

WH-

23

IGNITOR

BK-6

BK-3

DOOR SWITCH (CLOSED

WHEN D OOR IN PLACE )

WARNING:DISCONNECT POWER

BEFORE SERVICING.W IRING TO

UNIT MU ST BE PROPERLY

POLARIZED AND GROUNDED.

COLOR CODE

YL YELLOW

OR ORANGE

VT VIOLE T

GN GREE N

BK BLACK

BR BROWN

WH WHITE

BU BLUE

GY GRAY

RD RED

LOW VOLTAGE

HI VOLTAGE

115V FIE LD

CONNECT

ELECTRONIC

AIR CLEANER

VT

-55

RD

-22

5

BK-6

BK-1

**

*

L

T

K

K

E

R

E

R

OR-16

AIR

BR

CIRCULATION

BLOWER

BR

(ACB)

#26 BK (HI)

#23 BU (MED)

#29 OR (MED LOW)

#24 RD (LOW)

WH

BU-25

6

GY-47

THERMOSTAT

CONNECTIONS

WY

BR-21

BK-1

WH-2

LINE

TRANSFORMER

LOAD

115V FIE LD

CONNECT

HUMIDIFIER

BU-25

GY-25

OR-3

IMPORTANT:

READ BEFORE OPERATING OR SERVICING THIS UNIT.

1. SET HEAT ANTICIPAT OR ON ROOM THERMOSTAT AT 0.7 AMPS.

2. AMANA SPECIFIED RE PLACEMENT PARTS MUST BE USED WHEN SERVICING.

3. IF ANY OF THE ORIGIN AL WIRE AS S UP PLIED WITH THE FURNACE MUST BE

REPLACED, IT MUST BE REPLACED WI T H WIRING MAT ERIAL HAVING A TEMPERATURE RATI NG

OF AT LEAST 105C. USE COPPER CONDU CTORS ON LY.

4. UNUSE D BLOWER MOTOR LEADS MUST BE PLACE D ON "PARK" TERMINALS OF CONTROL OR TAPED.

5 IF HEATING AND COOLING BLOWER SPEEDS ARE NOT THE SA ME DISCARD JU M PER BEFORE

CONNECTING BLOWER LEADS.

6 DIAGNOSTIC LIGHT:STEADY=REPLACE CONTR OL;1 FLASH=LOCKOUT;2 FLASHES=PS ST UCK CLOSED;

3 FLASHES=PS STUCK OPEN;4 FLASHE S=OPEN HIGH LIMIT SWI TCH;

5 FLASHES=O PEN ROLLOUT CO NTROL ;

CONTINUOUS FLASHING=FLAME-NO CALL FOR HEAT

CIRCU LATOR BLO WER

COO

HEA

PAR

PAR

LIN

XFM

EAC

HUM

IND

IGN

CIR

LIN

XFM

EAC

HUM

R G C

HOT 120 VAC

NEUTRAL 120VAC

YL-11

CONTROL

MV GND HLI

RO1TR

PSRO2MV

12

11 8 5 2

GY

GN

-25

RD-44

11165501 REV . 0

TH FP HLO

369

OR-3

BU

-36

14710

VT

-14

RD-44

Loading...

Loading...