Page 1

Service

Commercial

Microwave Oven

This Base Manual covers Commercial

Microwave Ovens with 120/230 V, 60 Hz.

Refer to individual Technical Sheet for

information on specific models.

This manual includes, but is not limited to

the following:

CRC18T2OG P1323006M, P1323015M

CRC21T2RL P1323007M, P1323017M

HDC10 P1323008M

HDC12 P1323009M

HDC18 P1323003M, P1323013M

HDC18SD P1323004M, P1323014M

HDC21 P1323005M, P1323016M

Service Manual for

Amana

®

This manual is to be used by qualified appliance

technicians only. Amana does not assume any

responsibility for property damage or personal

injury for improper service procedures done by an

unqualified person.

RS2240002

Revision 1

October 2000

Page 2

!

!

Important Product Information

!

WARNING

Precautions to be observed before and during servicing

to avoid possible exposure to excessive microwave

energy .

(A) Do not operate or allow oven to be operated with the

door open.

(B ) Make the following safety checks on all ovens to be

serviced before activating the magnetron or other

microwave source, and make repairs as necessary:

• Interlock operation

• Proper door closing

• Seal and sealing surfaces (arcing, wear, and other

damage)

• Damage to or loosening of hinges and latches

• Evidence of dropping or abuse

(C ) Before turning on microwave power for any service

test or inspection within the microwave generating

compartments, check the magnetron, wave guide or

transmission line, and cavity for proper alignment,

integrity , and connections.

(D ) Any defective or misadjusted components in the

interlock, monitor, door seal, and microwave

generation and transmission systems shall be

repaired, replaced, or adjusted by procedures

described in this manual before oven is released to

the consumer.

(E) Check microwave leakage to verify compliance with

the Federal Performance Standard should be

performed on each oven prior to release to the

consumer.

WIRING

Good service practice is to never route wiring over

terminals and/or sharp edges. This applies to any wiring

without regard to the circuit voltage. Wire insulation

material and thickness is designed and regulated for

electrical spacing purpose only , but cannot always be

relied upon because of possible cuts and/or abrasions,

which can occur during servicing.

WA RNING

To avoid risk of electrical shock, injury, or death, make

sure these grounding instructions are followed.

Grounding Instructions

WA RNIN G

Do not remove grounding prong when installing

grounded appliance in a home or business that does

not have three wire grounding receptacle, under no

condition is grounding prong to be cut off or removed. It

is the personal responsibility of the consumer to

contact a qualified electrician and have properly

grounded three prong wall receptacle installed in

accordance with appropriate electrical codes.

Should a two prong adapter plug be required temporarily

it is the personal responsibility of the consumer to have it

replaced with properly grounded three prong receptacle or

the two prong adapter properly grounded by a qualified

electrician in accordance with appropriate electrical

codes.

Servicing of Grounded Products

The standard accepted color coding for grounding wires

is GREEN or GREEN WITH YELLOW STRIPE. These

ground leads are NOT to be used as current carrying

conductors. It is extremely important that the technician

replace any and all grounds prior to completion of the

service call. Under no condition should ground wire be left

off causing a potential hazard to technicians and

consumer.

RS2240002 Rev. 1 2

Page 3

Table of Contents

Important Product Information ..................................... 2

Impo rtant I nform ation .................................................. 4

Important Safety Information ....................................... 5

Product Information

Antenna Blade ......................................................... 8

Blower/Fan Assembly.............................................. 8

Grease Shield.......................................................... 8

Door Interlock and Monitoring Switch....................... 8

Auto Transformer ..................................................... 8

Transformer High V oltage......................................... 8

High Voltage Capacitor ............................................ 8

High Voltage Diode (Rectifier) .................................. 8

Magnetron ............................................................... 8

Thermal Cutout Protectors....................................... 8

T ouch Panels........................................................... 8

Triac ........................................................................ 8

Antenna Motor(s) ..................................................... 8

Installation

Unpacking Oven ...................................................... 9

Oven Placement ...................................................... 9

Radio Interference ....................................................9

Grounding Instructions ............................................. 9

Care and Cleaning

Changing Oven Light Bulb...................................... 10

Cleaning Interior, Exterior , and Door....................... 10

Cleaning Splatter Shield ........................................ 10

Cleaning Air Intake Filter ....................................... 1 1

Cleaning Discharge Air Vents ................................ 1 1

Control Panel Features ............................................. 1 2

Displays

Cooking Methods................................................... 13

Cooking Displays................................................... 13

Programming Displays........................................... 13

Operation

Interrupting Operation ............................................ 1 4

Canceling Mistakes ............................................... 14

Operating Preprogrammed Pads............................ 14

Using X2 Pad......................................................... 1 4

Manual Time Entry ................................................ 14

Programming Instructions

Memory Pads ........................................................ 15

Multiple Cooking Stages ........................................ 1 5

X2 Quantity Feature ............................................... 15

User Options ......................................................... 16

Component T esting Procedures ................................ 17

T est Modes

Power T est............................................................. 21

Microwave Energy Leakage T esting

Equipmen t ............................................................. 2 2

Procedure for Measuring Radiation Leakage.......... 22

Measurement With the Outer Case Removed ........ 22

Measurement With a Fully Assembled Oven ......... 22

Record Keeping and Notification

After Measurement ................................................ 22

Troubleshooting

Initial Power Up .................................................. 23

Standby Condition .............................................. 24

Cook Condition................................................... 25

Disassembly

Door Removal ........................................................ 26

Inner Door/Window Removal .................................. 26

Door Disassembly ................................................. 2 6

Door Handle........................................................... 26

Hinge ..................................................................... 26

Interlock Switch Assembly .................................... 27

Switch Replacement / Door Adjustment ................ 28

Outer Case ............................................................ 29

Back Panel............................................................ 29

Grease Shield........................................................ 29

Antenna Assembly–T op......................................... 29

Antenna Motor–T op................................................ 29

Oven Tray Removal ................................................ 29

Antenna Assembly–Bottom ................................... 29

Antenna Motor–Bottom.......................................... 30

T ouch Panel Assembly.......................................... 3 0

Control Board ........................................................ 30

Interlock Switch Assembly .................................... 30

Magnetron Cutout (TCO) ........................................ 3 0

Triac ...................................................................... 30

Diodes ................................................................... 30

Magnetron ............................................................. 30

Cavity Thermal Cutout Replacement ...................... 3 1

Fuse ...................................................................... 31

Blower Wheel and Motor........................................ 31

Fan Blade .............................................................. 3 1

Auto Transformer ................................................... 31

High Voltage T ransformer ....................................... 3 2

Capacitor ............................................................... 3 2

Power Cord............................................................ 32

Lamp Receptacle................................................... 32

Replacing Oven Lamp ............................................ 3 2

Component Location

Figure 1 .............................................................. 33

Figure 2 .............................................................. 34

Figure 3 .............................................................. 35

Amana Appliances • 2800 220thTrail • Amana, Iowa • 52204-0001 • Printed in the U.S.A.

3 RS2240002 Rev. 1

Page 4

!

!

!

!

!

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE

APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

Important Notices for Consumers and Servicers

WARNING

T o avoid risk of serious injury or death, repairs should not be attempted by an unauthorized personnel, dangerous

conditions (such as exposure to electrical shock) may result.

CAUTION

Amana will not be responsible for any injury or property damage from improper service procedures. If prefroming

service on your own product, assume responsibility for any personal injury or property damage which may result.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER AFFAIRS DEPT. OR 1-319-622-5511

AMANA REFRIGERATION, INC. CALL and ask for

AMANA, IOWA 52204 Consumer Affairs

If outside the United States contact:

AMANA

ATTN: CONSUMER AFFAIRS DEPT

2800 220th Trail

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER - Immediate hazards which WILL result in severe personal injury or death.

WA RNIN G

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION - Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

RS2240002 Rev. 1 4

Page 5

!

Important Safety Information

CAUTION

Do not become exposed to radiation from the

microwave generator or other parts conducting

microwave energy .

Basic design of this microwave oven makes it an

inherently safe device to both use and service. However,

there are some precautions which should be followed

when servicing microwave oven to maintain this safety .

These are as follows:

1. Always operate unit from an adequately grounded

outlet. Do not operate on a two-wire extension cord.

2. Before servicing unit (if unit is operable) perform

microwave leakage test.

3. Oven should never be operated if door does not fit

properly against seal, hinge/hinge bearings are

damaged or broken; choke is damaged, (pieces

missing, etc.); or any other visible damage can be

noted. Check choke area to ensure that this area is

clean and free of all foreign matter. If any above

problems occur take the following steps:

• T ell the user not to operate the oven.

• Contact Amana immediately.

4. If oven operates with door open and produces

microwave energy , take the following steps:

• T ell the user not to operate the oven.

• Contact Amana immediately.

5. Always have oven disconnected when outer case is

removed except when making "live" tests called for in

the service manual. Do not reach into equipment

area while unit is energized. Make all connections

for the test and check them for tightness before

plugging cord into outlet.

6. Always ground capacitors on magnetron filter box and

H.V . capacitor with an insulated-handle screwdriver

before working in high voltage area of equipment

compartment. Some types of failures will leave a

charge in capacitors and the discharge could cause a

reflex action which could make you injure yourself.

7. In the area of the transformer, capacitor , diode, and

magnetron there is HIGH VOL T AGE. When unit is

operating, keep area clean and free of anything which

could possibly cause an arc or ground, etc.

8. DO NOT for any reason defeat interlock switches,

there is no valid reason for this action at any time;

nor will it be condoned by Amana.

9. Microwave oven should never be operated with:

• Any components removed and/or bypassed

• Any of the safety interlocks are found to be

defective

• Any of the seal surfaces are defective, missing, or

damaged

10.To ensure that unit does not emit excessive

microwave leakage and to meet Department of Health

and Human Services guidelines check oven for

microwave leakage using Narda Model 8100, 8200,

Holaday HI1500, HI1501, or Simpson 380M leakage

monitor as outlined in instructions. Maximum leakage

level allowed is 4mw/cm2 .

1 1.If servicer encounters an emission reading over 4mw/

cm2, servicer is to cease repair and contact Amana

Service Department immediately for further direction.

Amana will contact the proper government agency

upon verification of test results.

12.Install or locate this equipment ONLY in accordance

with the installation instructions in this manual.

13.Some products such as whole eggs and sealed

containers – for example, closed glass jars – may

explode and SHOULD NOT be HEA TED in this

equipment.

14.Use this equipment ONLY for its intended use as

described in this manual. Do not use corrosive

chemicals or vapors in this equipment. This type of

equipment is specifically designed to heat or cook. It

is not designed for industrial or laboratory use.

15.As with any equipment, CLOSE SUPERVISION is

necessary when used by CHILDREN.

16.DO NOT operate this equipment if it has a damaged

cord or plug, if it is not working properly , or if it has

been damaged or dropped.

17.This equipment, including power cord, must be

serviced ONL Y by qualified service personnel. Special

tools are required to service equipment. Contact

nearest authorized service facility for examination,

repair, or adjustment.

18.DO NOT cover or block any openings on the

equipment.

19.DO NOT store this equipment outdoors. DO NOT use

this product near water – for example, near a kitchen

sink, in a wet basement, or near a swimming pool,

and the like.

20.DO NOT immerse cord or plug in water.

21.Keep cord AWA Y from HEATED surfaces.

22.DO NOT let cord hang over edge of table or counter.

5 RS2240002 Rev. 1

Page 6

Important Safety Information

!

CAUTION

To avoid personal injury or property damage, observe the following:

1. Briskly stir or pour liquids before heating with

microwave energy to prevent spontaneous boiling

or eruption. Do not overheat. If air is not mixed

into a liquid, liquid can erupt in oven or after

removal from oven.

2. Do not deep fat fry in oven. Fat could overheat and

be hazardous to handle.

3. Do not cook or reheat eggs in shell or with an

unbroken yolk using microwave energy . Pressure

may build up and erupt. Pierce yolk with fork or

knife before cooking.

4. Pierce skin of potatoes, tomatoes, and similar

foods before cooking with microwave energy . When

skin is pierced, steam escapes evenly .

5. Do not operate equipment without load or food in

oven cavity .

6. Use only popcorn in packages designed and

labeled for microwave use. Popping time varies

depending on oven wattage. Do not continue to

heat after popping has stopped. Popcorn will

scorch or burn. Do not leave oven unattended.

7. Do not use regular cooking thermometers in oven.

Most cooking thermometers contain mercury and

may cause an electrical arc, malfunction, or

damage to oven.

8. Do not heat baby bottles in oven.

9. Do not use metal utensils in oven.

10. Never use paper, plastic, or other combustible

materials that are not intended for cooking.

11. When cooking with paper , plastic, or other

combustible materials, follow manufacturer's

recommendations on product use.

12. Do not use paper towels which contain nylonor

other synthetic fibers. Heated synthetics could melt

and cause paper to ignite.

13. Do not heat sealed containers or plastic bags

in oven. Food or liquid could expand quickly and

cause container or bag to break. Pierce or open

container or bag before heating.

14. To avoid pacemaker malfunction, consult physician

or pacemaker manufacture about effects of

microwave energy on pacemaker .

PRECAUTIONS TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWA VE ENERGY

a. DO NOT attempt to operate this oven with the door

open since open-door operation can result in harmful

exposure to microwave energy . It is important not to

defeat or tamper with the safety interlocks.

b. DO NOT place any object between the oven front

face and the door or allow soil or cleaner residue to

accumulate on sealing surfaces.

RS2240002 Rev. 1 6

c. DO NOT operater the oven if it is damaged. It

particularly important that the oven door close

properly and that there is no damage to the:

(1) door (bent), (2) hinges and latches (broken or

loosened), (3) door seal and sealing surface.

d. The oven should NOT be adjusted or repaired by

anyone except properly qualified service personnel.

Page 7

!

Important Safety Information

!

Recognize this symbol as a SAFETY message

WARNING

When using electrical equipment, basic safety precautions should be followed to reduce the risk of burns, electrical

shock, fire, or injury to persons.

1. READ all instructions before using equipment.

2. READ AND FOLLOW the specific “PRECAUTIONS

TO A VOID POSSIBLE EXPOSURE TO

EXCESSIVE MICROWA VE ENERGY”.

3. This equipment MUST BE GROUNDED. Connect

only to properly GROUNDED outlet. See

“GROUNDING INSTRUCTIONS”.

4. Install or locate this equipment ONL Y in accordance

with the installation instructions in this manual.

5. Some products such as whole eggs and sealed

containers – for example, closed glass jars – may

explode and SHOULD NOT be HEA TED in this

oven.

6. Use this equipment ONLY for its intended use as

described in this manual. Do not use corrosive

chemicals or vapors in this equipment. This type of

oven is specifically designed to heat or cook. It is

not designed for industrial or laboratory use.

7. As with any equipment, CLOSE SUPERVISION is

necessary when used by CHILDREN.

8. DO NOT operate this equipment if it has a damaged

cord or plug, if it is not working properly , or if it has

been damaged or dropped.

9. This equipment, including power cord, must be

serviced ONLY by qualified service personnel.

Special tools are required to service equipment.

Contact nearest authorized service facility for

examination, repair, or adjustment.

10. DO NOT cover or block filter or other openings

on equipment.

11. DO NOT store this equipment outdoors. DO NOT

use this product near water – for example, near a

kitchen sink, in a wet basement, or near a

swimming pool, and the like.

12. DO NOT immerse cord or plug in water.

13. Keep cord AWA Y from HEA TED surfaces.

14. DO NOT let cord hang over edge of table or counter.

15. See door cleaning instructions in “Care and

Cleaning” section.

16. For commercial use only.

CAUTION

To reduce the risk of fire in the oven cavity:

a. DO NOT overcook food. Carefully attend equipment

if paper , plastic, or other combustible materials are

placed inside the oven to facilitate cooking.

b. Remove wire twist-ties from paper or plastic bags

before placing bag in oven.

c. KEEP oven DOOR CLOSED, turn oven off, and

disconnect the power cord, or shut off power at the

fuse or circuit breaker panel, if materials inside the

oven should ignite. Fire may spread if door is

opened.

d. DO NOT use the cavity for storage. DO NOT leave

paper products, cooking utensils, or food in the

cavity when not in use.

7 RS2240002 Rev. 1

Page 8

!

Product Information

Antenna Blade

Distributes microwave energy throughout the cavity .

Blower/Fan Assembly

Circulates cooling air throughout the microwave oven

compartment and cavity .

Grease Shield

Covers and protects the antenna blade assembly .

Door Interlock and Monitoring Switch

NOTE: When the line fuse is open, Interlock Switch

Assembly must be replaced.

Interlock switch assembly mounts behind oven cavity

front bulkhead. Switches are actuated by the door

hooks.

Monitoring switch (contacts COM and NC) is actuated by

the top door hook.

The primary interlock switch (contacts COM and NO) is

actuated by the top door hook.

The logic switch (contacts COM and NO) is actuated by

the bottom door hook.

The secondary interlock switch (contacts COM and NO)

is actuated by the bottom door hook.

If a malfunction occurs in the primary interlock when door

opens, current will flow through the monitor switch

causing the oven fuse to open.

If a faulty door interlock switch has allowed current

through the monitor switch, the switch assembly must be

replaced (see interlock switch testing) before replacing

fuse.

Auto T ransformer

Auto transformer in this unit provides a voltage of 120,

208, or 230 V AC.

Transformer High Voltage

High voltage transformer is used in this unit, which

supplies high voltage A.C. for operation of the magnetron

tube.

High Voltage Capacitor

Doubles the A.C. output voltage from the high voltage

transformer.

High V oltage Diode (Rectifier)

Is connected at the output side of the high voltage

capacitor. It changes voltage from A.C. to D.C. It passes

current in one direction and blocks it in the other. Also

called a rectifier.

Magnetron

With filament voltage and high D.C. voltage from the

output of the H.V . capacitor/diode junction, the

magnetron will put out an electomagnetic radio frequency

of 2450 MHz to heat the food load in the oven.

Thermal Cutout Protectors

At a predetermined temperature, the thermal cut-outs will

open.

• Magnetron thermal cut-outs are mounted directly on

the body of the magnetron.

• Cavity thermal cut-out is mounted directly on the left

side of cavity exterior, inside the exhaust duct.

DANGER

T o avoid severe personal injury or death avoid

contacting any high voltage parts. The capacitors are

at high voltage (4000 volt) potential and it is extremely

important that they be grounded before handling.

RS2240002 Rev. 1 8

Touch Panels

Allows consumer operation and programming of oven.

Triac

Triac is controlled by control board. Triac controls one

side of the power line going to the high voltage power

transformer.

• Triac is mounted on blower bracket.

Antenna Motor(s)

Antenna motor(s) rotate(s) antenna assemblies.

Page 9

Installation

!

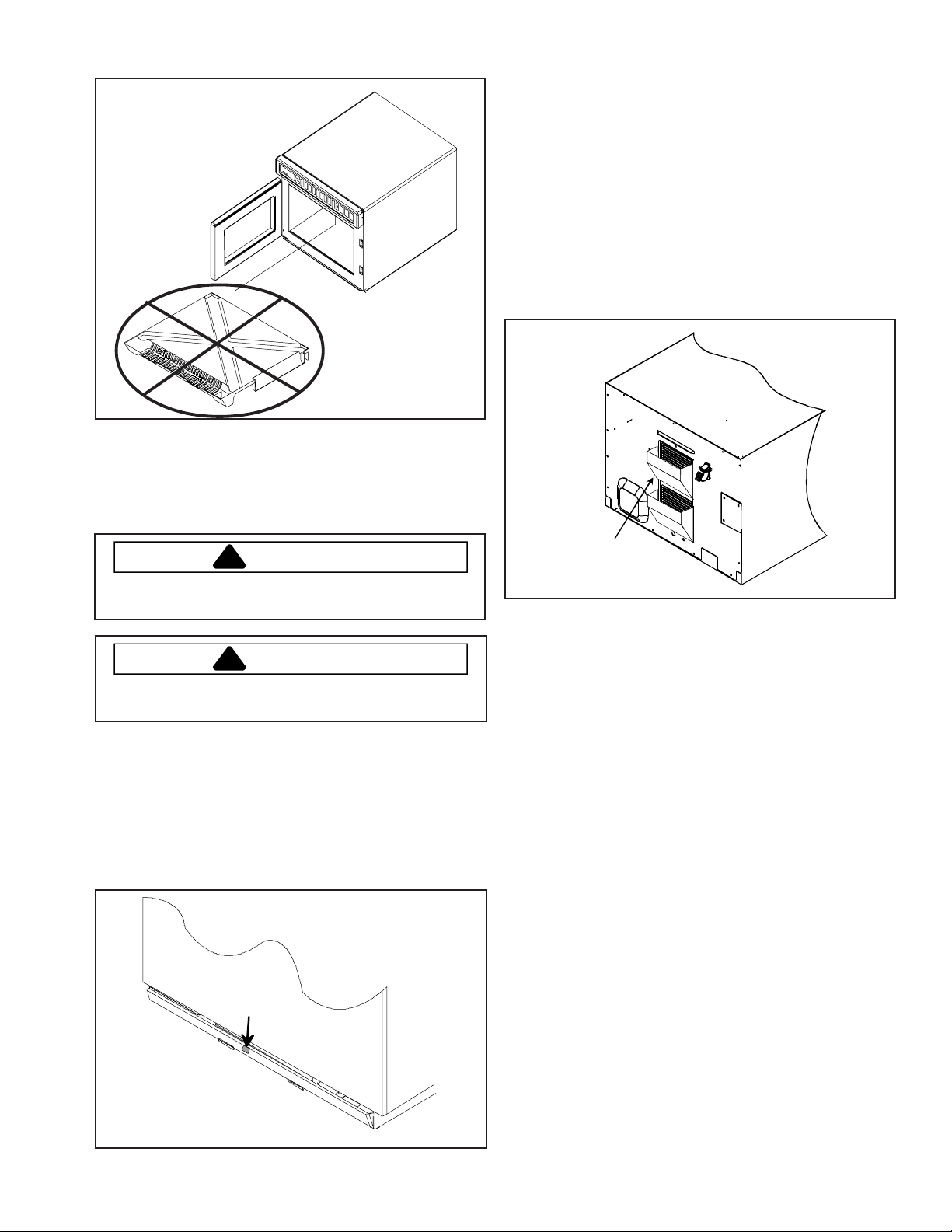

Unpacking Oven

• Remove packing and printed material from ovencavity .

• Inspect oven for damage such as dents

in door or inside oven cavity .

• Report any dents or breakage to source of

purchase immediately. Do not attempt to use oven if

damaged.

• If oven has been stored in extermely cold area, wait a

few hours before connecting power.

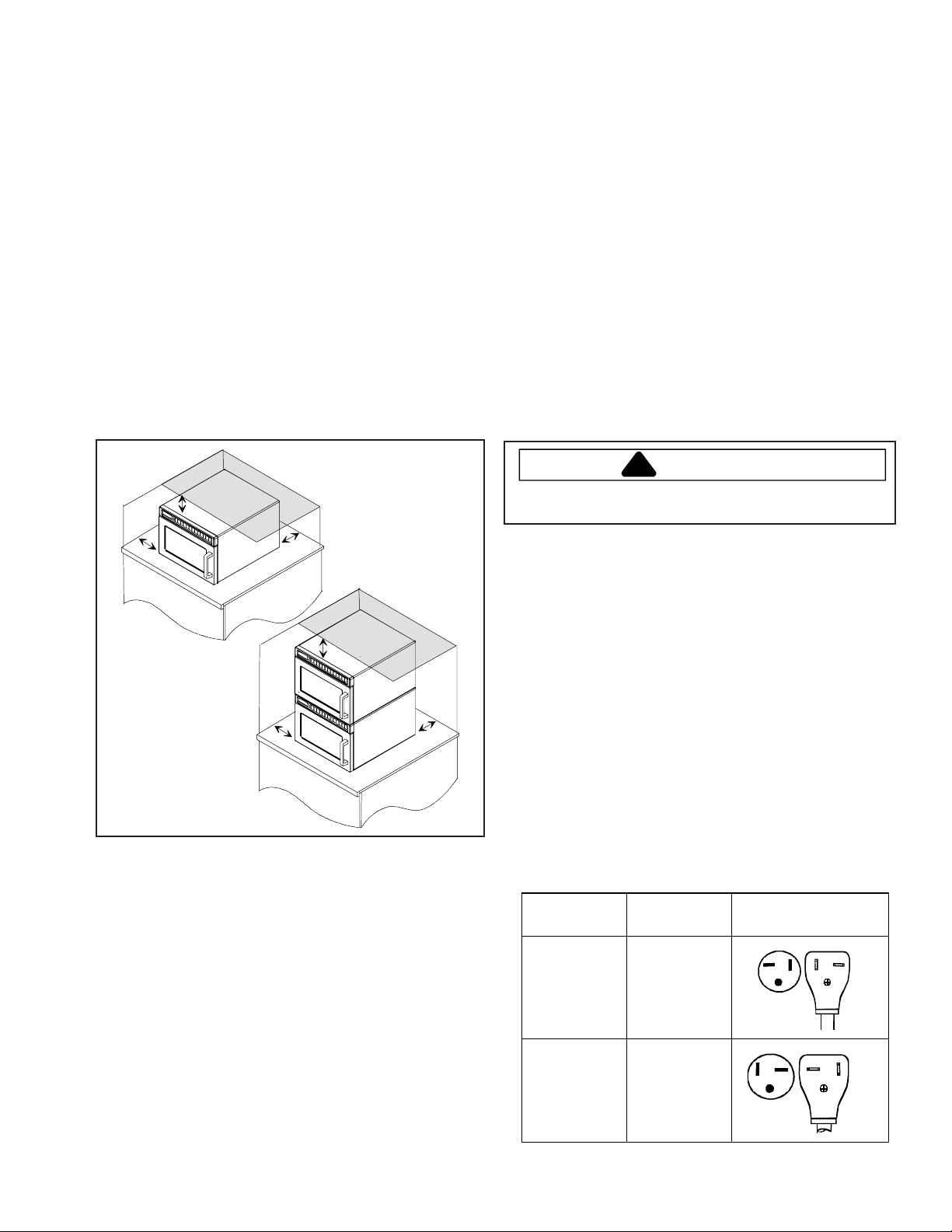

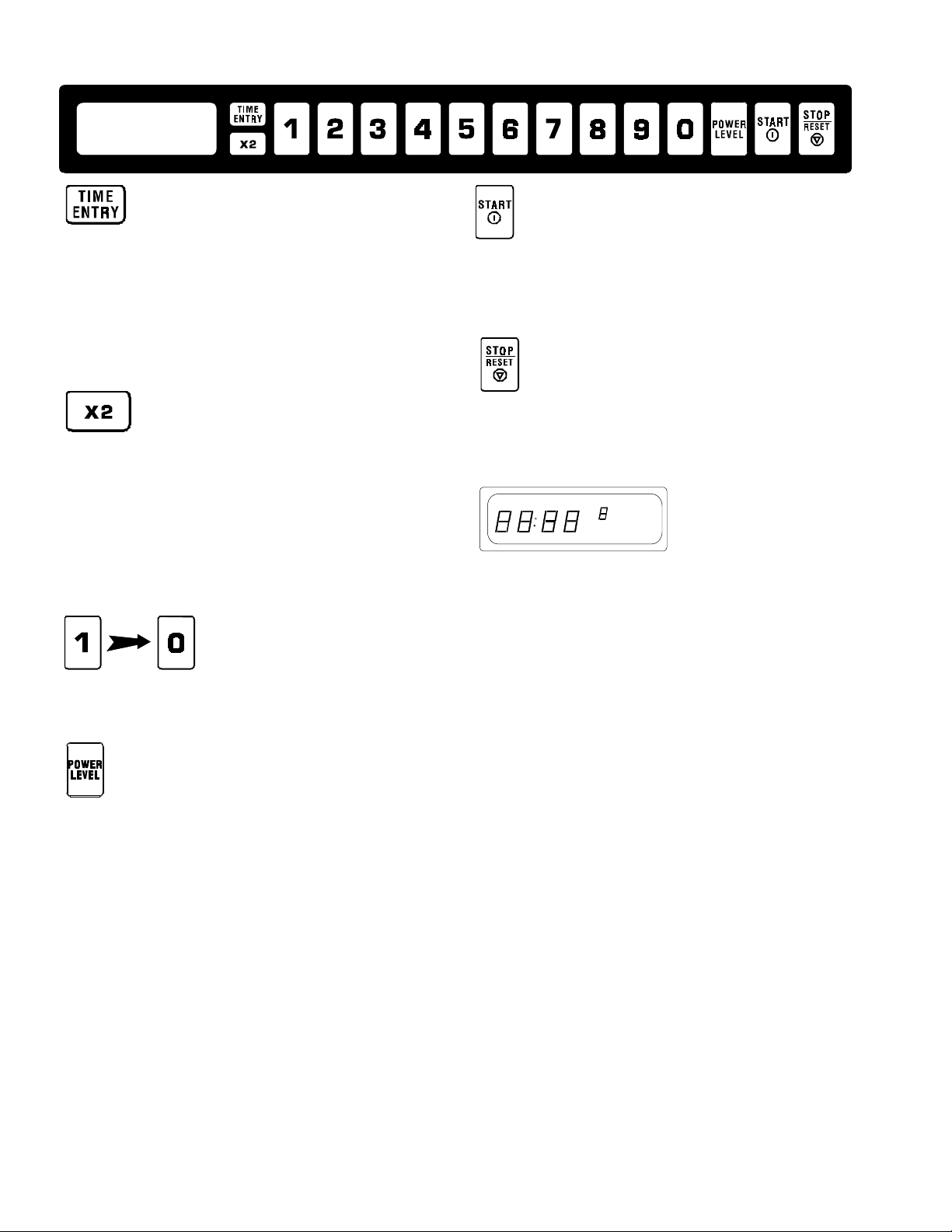

Oven Placement

• Do not install oven next to or above source of heat,

such as pizza oven or deep fat fryer. This could cause

microwave oven to operate improperly and could

shorten life of electrical parts.

• Do not block or obstruct oven filter. Allow access for

cleaning.

• Install oven on level countertop surface.

A

Radio Interference

Microwave operation may cause interference to radio,

television, or similar equipment. Reduce or eliminate

interference by doing the following:

• Clean door and sealing surfaces of oven

according to instructions in "Care and Cleaning"

section.

• Place radio, television, etc. as far as possible from

oven.

• Use properly installed antenna on radio, television, etc.

to obtain stronger signal reception.

Grounding Instructions

NOTE: Do not under any circumstances cut or remove

grounding prong from the plug or bend power

prongs to fit receptacle other than one shown for

your equipment. Such abuse of the plug can

result in electrical shock or overheating.

WARNING

Improper use of grounding plug can result in a risk of

electrical shock or death.

A

A—Allow at least 7" (17.8 cm) of clearance around top

and sides of oven. Proper air flow around oven cools

electrical components. With restricted air flow, oven

may not operate properly and life of electrical parts

is reduced.

B—Allow at least 2 9/16" (6.5 cm) between air discharge

on back of oven and back wall.

B

A

A

B

This equipment MUST be grounded. In the event of an

electrical short circuit, grounding reduces risk of electric

shock by providing an escape wire for electric current.

This oven is equipped with a cord having grounding wire

with a grounding plug. Plug must be plugged into an

outlet that is properly installed and grounded. DO NOT

use a two-prong adapter .

Consult a qualified electrician or servicer if grounding

instructions are not completely understood, or if doubt

exists as to whether the equipment is properly grounded.

Do not use an extension cord. If product power cord is

too short, have a qualified electrician install an

appropriate receptacle. This equipment should be

plugged into a separate 60 Hz circuit with the appropriate

electrical rating as shown in the drawings. When an oven

is on a circuit with other equipment, an increase in

cooking times may be required and fuses can be blown.

Model NEMA

Designation

HDC10

HDC12

NEMA

5-20R/5-20P

120V-20AMP

Receptacle and

Plug

HDC18

HDC18SD

HDC21

9 RS2240002 Rev. 1

NEMA

6-20R/6-20P

250V-20AMP

Page 10

Care and Cleaning

!

!

!

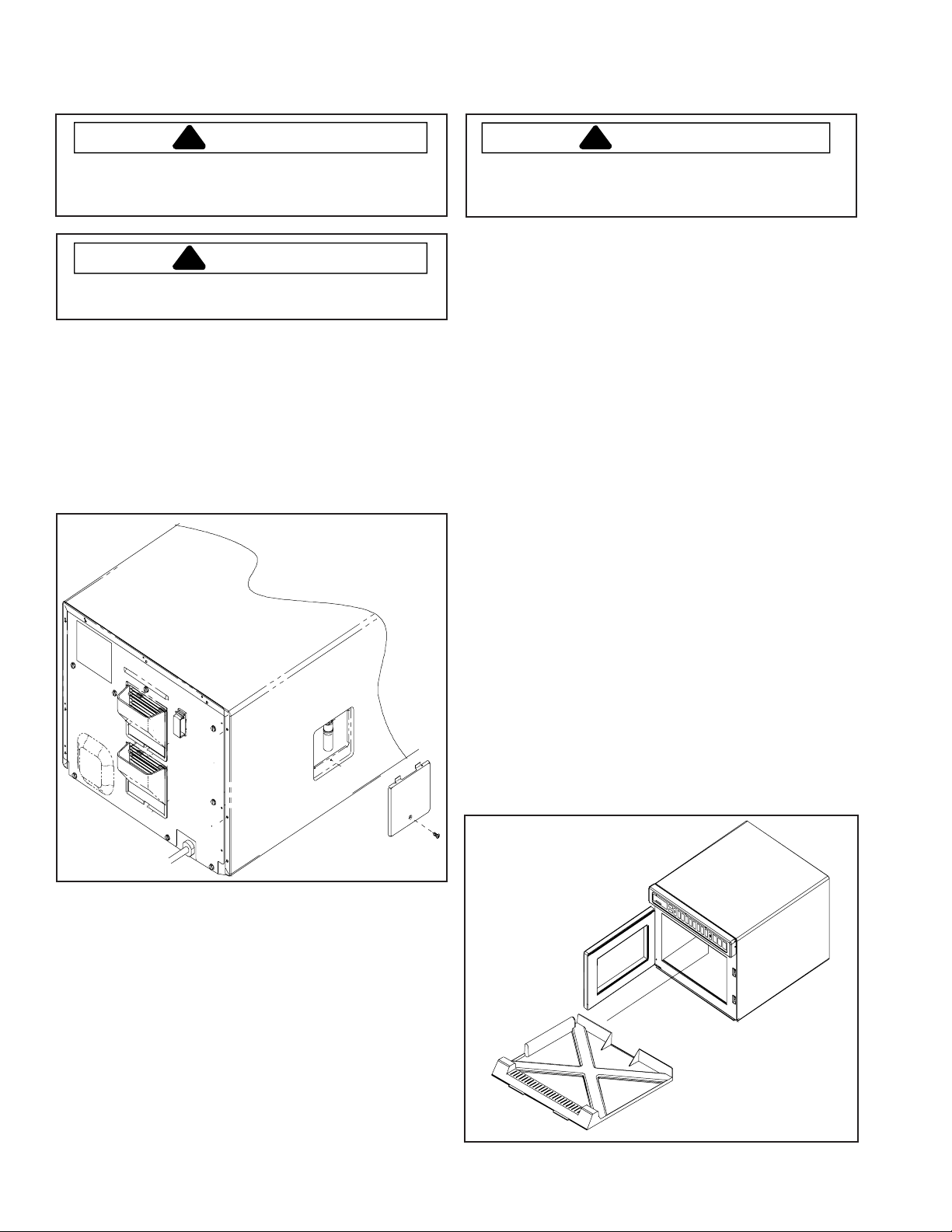

Changing Oven Light Bulb

CAUTION

T o avoid electrical shock hazard unplug power cord or

open circuit breaker to microwave oven before replacing

light bulb. After replacing light bulb, reconnect power .

CAUTION

T o avoid burns and cuts, wear gloves to protect hands

should bulb break. If hot, allow bulb to cool.

Tools and Bulb

• Protective gloves

• Standard screwdriver or ¼ inch socket

• Light bulb rated 120 volt, 25 watt

1. Unplug oven.

2. Remove screw from side of oven and remove access

cover.

Cleaning Interior , Exterior, and Door

WARNING

T o avoid electrical shock which can cause severe

personal injury or death, unplug power cord or open

circuit breaker to oven before cleaning.

Clean microwave oven with mild detergent in warm water

using soft sponge or cloth. Wring sponge or cloth to

remove excess water before wiping equipment. If desired,

boil a cup of water in microwave oven to loosen soil

before cleaning.

• Do not use abrasive cleansers or cleaners containing

ammonia. These could damage finish.

• Never pour water into microwave oven bottom.

• Do not use water pressure type cleaning systems.

Cleaning Splatter Shield

Splatter shield keeps top of microwave oven cavity and

antenna from becoming soiled. Clean soil from shield

with damp cloth or clean with mild detergent and water .

Remove splatter shield for easy cleaning.

1. Unplug oven before removing splatter shield to stop

antenna from rotating.

2. Place fingers behind shield, pull forward, and down.

• When removing and replacing splatter shield, be

careful not to bend antenna.

3. Wash shield in hot, soapy water . Rinse and

dry thoroughly .

• Do not wash splatter shield in dishwasher.

• Do not use abrasive cleaners.

4. Reinstall splatter shield by placing front portion of the

shield in first. Lift until shield slides into holes

located in back of oven.

3. Remove bulb by turning counterclockwise, being

careful not to burn fingers or break bulb.

• Replace with bulb rated 120 volt, 25 watt.

5. Reverse procedure to reassemble.

RS2240002 Rev. 1 10

Correct Installation

Page 11

!

!

Care and Cleaning

Incorrect Installation

(Shield in upside down)

NOTE: If splatter shield is installed upside down, shield

will interfere with antenna movement.

Cleaning Air Intake Filter

To replace filter

• Place bottom portion of filter into position first and push

in on the top portion of the filter, until filter is securely in

place.

NOTE: When placing filter back into position, verify

plastic tab is on the outside of the unit.

Cleaning Discharge Air V ents

Check for a buildup of cooking vapors along discharge

louvers in back of oven. Clean air vent with damp cloth to

ensure proper airflow . Dry thoroughly.

CAUTION

T o avoid overheating and oven damage, clean air filter

regularly.

CAUTION

T o avoid oven door damage, do not lift oven by oven

door.

Filter is located below oven door. Clean air intake filter

weekly for proper air flow. W ash filter in hot water and

mild detergent. Do not use oven without filter in place.

To remove filter

• Locate plastic tab in the center of filter and pull

downward (rolling the filter), to release filter from metal

holding tabs.

Plastic

Discharge

air vent

tab

11 RS2240002 Rev. 1

Page 12

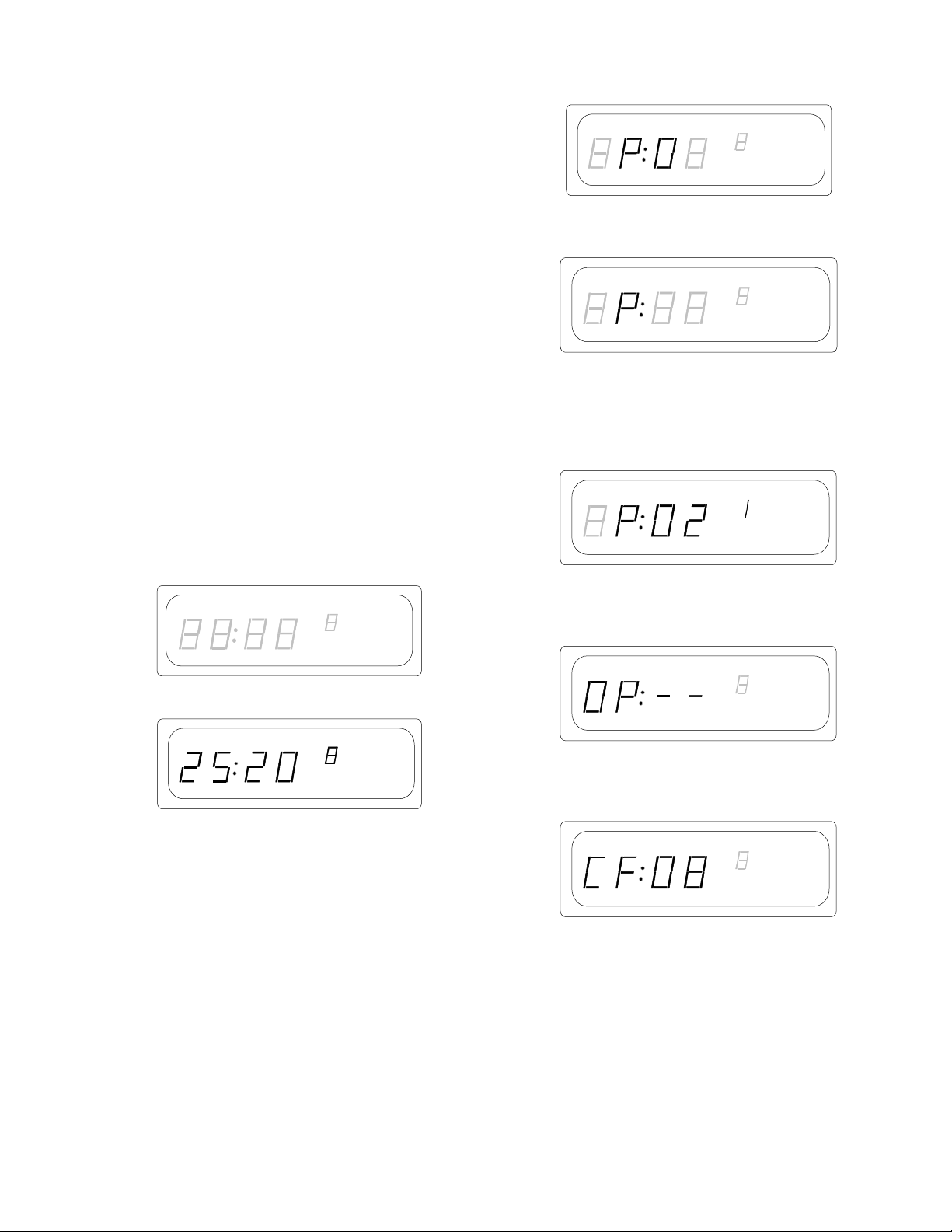

Control Panel Features

TIME ENTRY pad is used to enter cooking time for

either manual entry or programming. Cooking time

ranges from 1 second (00:01) to a total of 60 minutes

(60:00) over four stages. If more than 60 minutes of total

microwave cooking time is required, open door and

inspect food before beginning new cooking cycle.

X2 pad increases the cooking time when cooking more

than one item at a time is necessary . The amount of

added time when the X2 pad is pressed is a percent of

the original preprogrammed cooking time. The percent

can be set from 10% to 100% with the default at 80%.

The percent of the time added can be changed for

individual cooking sequences.

Numbered pads begin cooking programs or enter times

and power levels for “Manual Time Entry” cooking.

ST ART pad begins Manual T ime Entry cooking or

restarts an interrupted cooking cycle. When

programming, use to save time and power level, and to

advance to next user option.

STOP/ RESET pad exits programming mode and stop

cooking during cooking cycle.

MICRO DEFR WARM MEDHI POWER HOLD

COOK

LEVEL

TIMER

READY

CLOCK

DisplaySome items in display can be seen but will not

glow.

Stages

This oven can be programmed to run 4 cooking

sequences consecutively . Each sequence is called a

stage. For example, the first cycle could be programmed

to defrost at 60% power, the second to defrost at 30%

power, the third to heat at 100% power , and the fourth to

hold warm at 10% power. Total time for all cooking

stages counts down.

POWER LEVEL pad is used to set microwave power

level. When cooking, the power level can be decreased

for foods that require slower more even cooking.

Microwave power levels range from 0% to 100% in 10%

increments. If cooking time is set and ST ART pad

pressed, oven cooks at 100% power. When

programming, to reset power level to 100%, press

POWER LEVEL pad.

RS2240002 Rev . 1 12

User Options

User Options allow the user to program the oven to

perform in a way convenient to the user . The beeps,

maximum cooking time, and number of preprogrammed

cooking sequences can be changed.

Page 13

Displays

Cooking Methods

Memory Pads

This oven can of store either 10 or 100 cooking programs

in memory .

Single Pad Cooking

From the factory , it is programmed to store 10 cooking

programs. Each pad begins a cooking program.

Double Pad Cooking

The oven control can be changed to store up to 100

cooking programs. T o set the control to 100 cooking

programs, see the “User’s Options” section of this

manual. T o heat when the oven is set for 100 programs ,

press 2 memory pads. For example, to start the first

program, press pad 0, then pad 1. T o use the second

program, press pad 0, then pad 2. After the pads are

pressed, the oven starts automatically and time counts

down.

Manual Time Entry

Manual Time Entry feature allows the operator to heat

without changing the preprogrammed pads. Time must be

entered and power can be set before cooking. ST ART pad

must be pressed to begin cooking.

Programming Displays

MICRO DEFR WARM MEDHI POWER HOLD

This display indicates oven is in programming mode and

ready to program a numbered pad(s).

MICRO DEFR WARM MEDHI POWER HOLD

This display indicates oven is set to double pad entry and

2 pads must be pressed to enter a program. See

“Programming” section of manual for programming

procedure or “User Options” to change from single or

double pad entry .

MICRO DEFR WARM MEDHI POWER HOLD

COOK

LEVEL

COOK

LEVEL

COOK

LEVEL

TIMER

READY

CLOCK

TIMER

READY

CLOCK

TIMER

READY

CLOCK

Cooking Displays

MICRO DEFR WARM MEDHI POWER HOLD

READY shows when oven control will accept entries.

MICRO DEFR WARM MEDHI POWER HOLD

25:20 shows cooking time. When more than one cooking

stage is programmed, total time for all stages displays.

POWER Shows when microwave energy is generated.

COOK LEVEL shows when oven is operating. 8 indicates

the microwave power level used. If number does not

show, oven is cooking at 100% power .

COOK

LEVEL

COOK

LEVEL

TIMER

READY

CLOCK

TIMER

READY

CLOCK

This display shows briefly when programming more than

one stage. It indicates programming mode for pad 02.

The smaller “1” indicates stage 1 is being programmed.

MICRO DEFR WARM MEDHI POWER HOLD

COOK

LEVEL

TIMER

READY

CLOCK

This display indicates programming user options mode.

See “User Options” section of manual for programming

procedure.

MICRO DEFR WARM MEDHI POWER HOLD

COOK

LEVEL

TIMER

READY

CLOCK

This display indicates cooking factor of 80% when X2 pad

is pressed.

13 RS2240002 Rev . 1

Page 14

Operation

Interrupting Operation

Open oven door or press

operation. Display continues to show countdown time.

Close door and press

operation.

STOP/RESET

ST ART

pad to resume oven

pad to interrupt

Canceling Mistakes

If oven is not cooking, press

display . If oven is cooking, press

once to stop oven, then again to clear display . If oven

door is open and time shows in display, close oven door

and press

STOP/RESET

STOP/RESET

pad to clear

STOP/RESET

pad to clear display .

pad

Operating Preprogrammed Pads

From the factory , this oven can of store up to 10

preprogrammed cooking sequences in memory . To heat

using a preprogrammed sequence, press a numbered

pad. Oven starts to heat automatically . Example: Heat

using the third cooking sequence.

1. Open oven door, place food in oven, and close oven

door.

• Display shows “READY”.

• If pad is not pressed in 60 seconds, open and

close oven door again.

2. Press 3 pad.

• Oven operates and time counts down.

• Display shows cooking time, “POWER”, ”COOK

LEVEL”. Display shows “POWER” only when

microwave energy is present.

• If power level other than 100 percent power was

programmed, display shows “COOK LEVEL” and

power level.

• If additional cooking time is required, press

preprogrammed pads before or after cooking cycle

ends.

3. Oven stops cooking and oven signal sounds when

cooking timing elapses.

Preprogrammed Times and Cook Level

All preprogrammed pads arrive set at full power.

Pads Times Pads Times

1 10 sec . 6 1:30 min.

2 20 sec. 7 2 min.

3 30 sec. 8 3 min.

4 45 sec. 9 4 min.

5 1 min. 0 5 min.

Double Pad Programs

The oven control can be changed to store up to 100

cooking programs. See the “User’s Options” section of

this manual to change oven control.

T o start a double pad cooking program, press 2 memory

pads. For example, press pad 0 and pad 3 to start a

cooking program.

Using X2 Pad

X2 pad increases the cooking time when cooking more

than one item at a time is necessary . The amount of

added time when the X2 pad is pressed is a percent of

the original preprogrammed cooking time. The percent

can be set from 10% to 100% with the default at 80%.

The percent of the time added can be changed for

individual cooking programs.

Press X2 pad before pressing memory pad. For example,

press X2 pad and then memory pad 3. Pad 3 normally

cooks for 30 seconds. When the X2 pad is pressed

before memory pad 3, 54 seconds displays because it

added 24 seconds, (80% of 30 sec. =24 sec.).

Manual Time Entry

Manual Time Entry feature allows the operator to enter

time and power levels, and heat without changing the

preprogrammed pads. Example: Heat for 30 seconds at

80% power.

1. Open oven door, place food in oven, and close door .

• Display shows “READY”. Fan and light operate.

• If pad is not pressed in 60 seconds, open and

close oven door again.

2. Press TIME ENTRY pad.

• Display shows “0000” and “READY”.

3. Press 3 and 0 pad to enter cooking time.

4. Press POWER LEVEL pad to change power level.

• Display shows “COOK LEVEL” and current power

level if other than 100 percent power.

5. Press 8 pad to enter desired power level.

6. Press STAR T pad.

• Oven operates and time counts down.

• Display shows cooking time, “POWER”, “COOK

LEVEL”.

• Display shows “POWER” only when microwave

energy is present.

• If power level other than 100 percent power was

programmed, display shows “COOK LEVEL” and

power level. Display counts down cooking time.

7. Oven stops cooking and oven signal sounds when

cooking timing elapses.

RS2240002 Rev . 1 14

Page 15

Programming Instructions

Memory Pads

From the factory , this oven can of store up to 10 cooking

programs. Follow instructions below to program cooking

times and power levels for customized cooking.

Example: Program third cooking sequence to heat for 30

seconds at 80% power.

1. Open oven door.

• Display shows “READY”.

• If door is closed or RESET pad is pressed before

finishing programming sequence, oven exits

programming mode.

2. Press and hold pad 1 for approximately 5 seconds.

• After 5 seconds, signal sounds. Display shows

“P:0”.

3. Press 3 pad to select memory pad.

• Display shows cooking time, “COOK LEVEL” and

power level if other than 100 percent power.

4. Press 3 and 0 pad to enter desired cooking time.

5. Press POWER LEVEL pad to change power level.

• Display shows “COOK LEVEL” and current power

level if other than 100 percent power.

6. Press 8 pad to enter desired power level.

7. Press ST ART pad to save new cooking time and

power level in oven memory.

• Display shows “P:0”.

• Repeat step 3–8 to program additional pads.

8. Press STOP/RESET pad or close oven door to exit

programming mode.

Double Pad Programs

The oven control can be changed to store up to 100

cooking programs. See the “User’s Options” section of

this manual to change oven control.

T o create a double pad program, follow the instructions

above except for a change to step #3. When entering the

cooking program number, press 2 memory pads. For

example, press pads 0 and pad 3 to create a new

cooking program.

Multiple Cooking Stages

Follow instructions below to program oven to perform four

consecutive cooking cycles without interruption.

Example: Program third cooking sequence to heat for 30

seconds at 80% power, 40 seconds at 50% power , and

10 seconds at 100% power.

1. Open oven door.

• Display shows “READY”.

• If door is closed or RESET pad is pressed before

finishing programming sequence, oven exits

programming mode.

2. Press pad 1 for approximately 5 seconds.

• After 5 seconds, signal sounds. Display shows

“P:0”.

4. Press 3 pad to select memory pad.

• Display shows cooking time, “COOK LEVEL” and

power level if other than 100 percent power.

5. Press 3 and 0 to enter desired cooking time.

6. Press POWER LEVEL pad to change power level.

• Display shows “COOK LEVEL” and current power

level if other than 100 percent power.

7. Press 8 pad to enter desired power level.

8. Press TIME ENTRY pad.

• Display briefly shows "P:03

programming, pad 3, stage 2. Then cook time and

power level for stage show in display .

• Repeat steps 5–8 to create additional stages.

9. Press ST ART pad to save new cooking time and

power level in oven memory .

10.Press STOP/RESET pad or close oven door to exit

programming mode.

(1-4)

" indicating

X2 Quantity Feature

This feature allows the user to change the amount of time

added when the X2 pad and then the programmed pad is

pressed. Based on the original time, the X2 pad can add

from 10%-100% of additional cooking time. The default is

80%. Example: change cooking factor to 50% for third

cooking sequence.

1. Open oven door.

• If door is closed or

finishing programming sequence, oven exits

programming mode.

2. Press and hold pad 1 for approximately 5 seconds.

• After 5 seconds, signal sounds. Display shows

“P:--”.

3. Press 3 pad to select the cooking program.

4. Press 5 pad to change cooking factor.

• Display shows “CF:05”.

5. Press ST ART pad to save changes.

6. Press STOP/RESET pad or close oven door to exit

programming mode.

Double Pad Programs

The oven control can be changed to store up to 100

cooking programs. See the “User’s Options” section of

this manual to change oven control.

T o change the quantity for a double pad program, follow

the instructions above except for a change to step #3.

When entering the cooking program number , press 2

memory pads. For example, press pads 0 and pad 3 to

create a new cooking program. After the program is

saved, press pad 0 and pad 3 to start a cooking program.

RESET

pad is pressed before

15 RS2240002 Rev . 1

Page 16

Programming Instructions

User Options

Follow the instructions below to customized the

microwave oven’s operation. End-of-cycle signal,

maximum cooking time and other options can be

changed to meeting your cooking needs. Example:

Change setting to single digit pad operation.

1. Open oven door.

• If door is closed or

finishing programming sequence, oven exits

programming mode.

2. Press and hold pad 2 for approximately 5 seconds.

• After 5 seconds, signal sounds. Display shows

“0P:”.

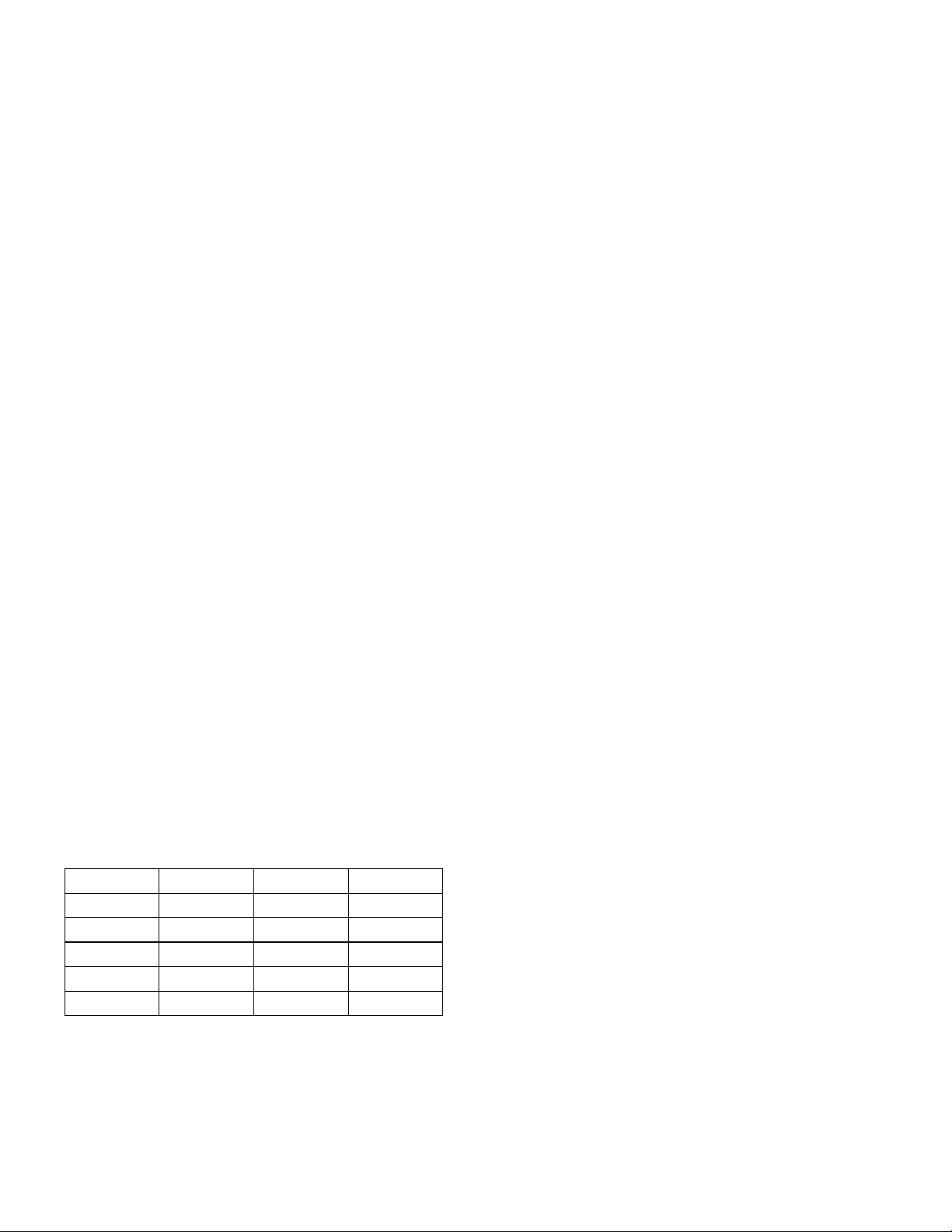

Numbered Pads Display Options (Factory Settings in Bold)

1

End of Cycle Beep

2

Speaker Volume

3

Key Beep

4

Keyboard Enable

Window

5

Add Time during

Heating

6

Reset Door Open

7

Maximum Heating

Time

RESET

OP:10

OP:11

OP:12

OP:20

OP:21

OP:22

OP:23

OP:30

OP:31

OP:40

OP:41

OP:42

OP:43

OP:50

OP:51

OP:60

OP:61

OP:70

OP:71

pad is pressed before

3 second continuous beep.

Continuous beep until door is opened.

5 beeps bursts until door is opened.

Eliminates beep.

Sets volume to low.

Sets volume to medium.

Sets volume to high.

Prevents beep when pad is pressed.

Allows beep when pad is pressed.

15 seconds after oven door is opened, keyboard disabled.

30 seconds after oven door is opened, keyboard disabled.

1 minute after oven door is opened, keyboard disabled.

2 minutes after oven door is opened, k eybo ar d dis abled.

Prevents adding heating time while oven is heating.

Allows he a t i ng time to be chang e d whi le ov e n is he a t i ng

when a memory pad is pressed.

Allows oven to resume heating time countdown after door is

opened during cycle.

Cancels heating time countdown after door is opened during cycle.

Allows 60 minutes of heating time.

Allows 10 minutes of heating time.

3. Press 9 pad.

• See table for options.

• Displays shows “OP:91”.

• “OP” represents optional program mode, first

number represents option number and second

number represents functions currently selected for

option.

4. Press 9 pad repeatedly to change setting.

5. Press ST ART pad to save changes.

• Repeat steps 3-5 to change additional options.

• Changes appear after door is closed or STOP/

RESET is pressed.

6. Press STOP/RESET pad or close oven door to exit

programming mode.

8

Manual Operation

9

Double Digit

Operation

RS2240002 Rev . 1 16

OP:80

OP:81

OP:90

OP:91

Allows use of preprogrammed pads only.

Allows use of manual time entry and preprogrammed pads.

Allows 10 (0-9) preprogrammed pads.

Allows 100 (00-99) preprogrammed pads.

Page 17

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires it.

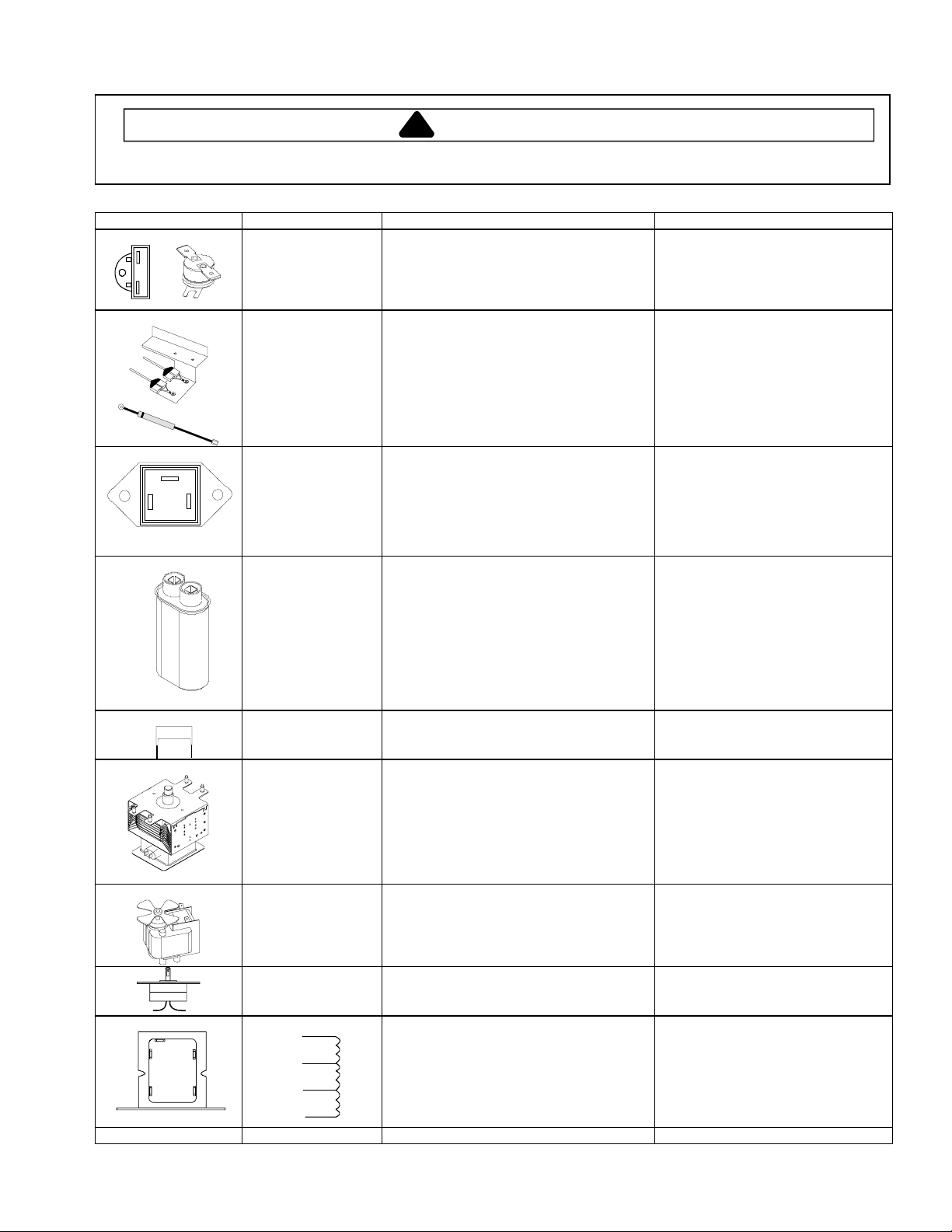

Illustration Component Testing Results

Thermal Cutout Disconnect all wires from TCO.

Diode Assembly

Measure resistance across terminals.

Cavity Thermal Fuse

Magnetron TCO

Discharge Capacitors

Remove diode lead from capacitor and

connect ohmmeter.

Reverse leads for second test.

Open at 219°F (104°C)

Open at 280°F (138°C) and closed at

180°F (82°C)

Infinite resistance should be

measured in one direction and 50K

or more in the opposite direction.

NOTE:

Analog meter must contain a

battery of 6 volts minimum.

Ω

Triac Disconnect wires to triac.

MT2

MT1 GATE

Capacitor

Snubber Assembly Disconnect wires to snubber.

Magnetron

Blower Motor Remove all wires from motor.

Measure resistance from:

MT1 to MT2

MT1 to Gate

MT2 to Gate

All terminals to ground

Discharge Capacitors

Remove wires from capacitor terminals and

connect ohmmeter, set on highest

resistance scale to terminals.

Also check between each terminal and

capacitor case.

Measure resistance across terminals. Infinite

Discharge Capacitors

Remove wires from magnetron and connect

ohmmeter to terminals. Also check

between each terminal and ground.

Caution - Do not operate oven with

wire to terminal MT2 removed.

Infinite

Approximately 40 Ω or more

Infinite

Infinite

Between Terminals: Meter should

momentarily deflect towards zero

then return to over 5 MΩ. IF no

deflection occurs, or if continuous

deflection occurs, replace capacitor.

Terminal to Case: Infinite resistance

Between Terminals: Less than 1

Each terminal to ground measures

Infinite resistance.

Note:

This test is not conclusive. If

oven does not heat and all other

components test good replace the

magnetron and retest.

Ω

Measure resistance across coil.

Antenna motor Remove all wires from motor.

Auto Transformer

230

COM

120

Wire Harness Test continuity of wires. Indicates continuity

208

230

208

120

0

Discharge Capacitors

Remove all wires from terminals.

Measure resistance from:

230 to 0

208 to 0

120 to 0

RS2240002 Rev. 1 17

Measure resistance across terminals.

Approximately 30

Circuitry

120 VACApproximately 3.4 K

230 VACApproximately 12 K

42.4

Ω

38.6

Ω

21.5

Ω

Ω

Ω

Ω

Page 18

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires it.

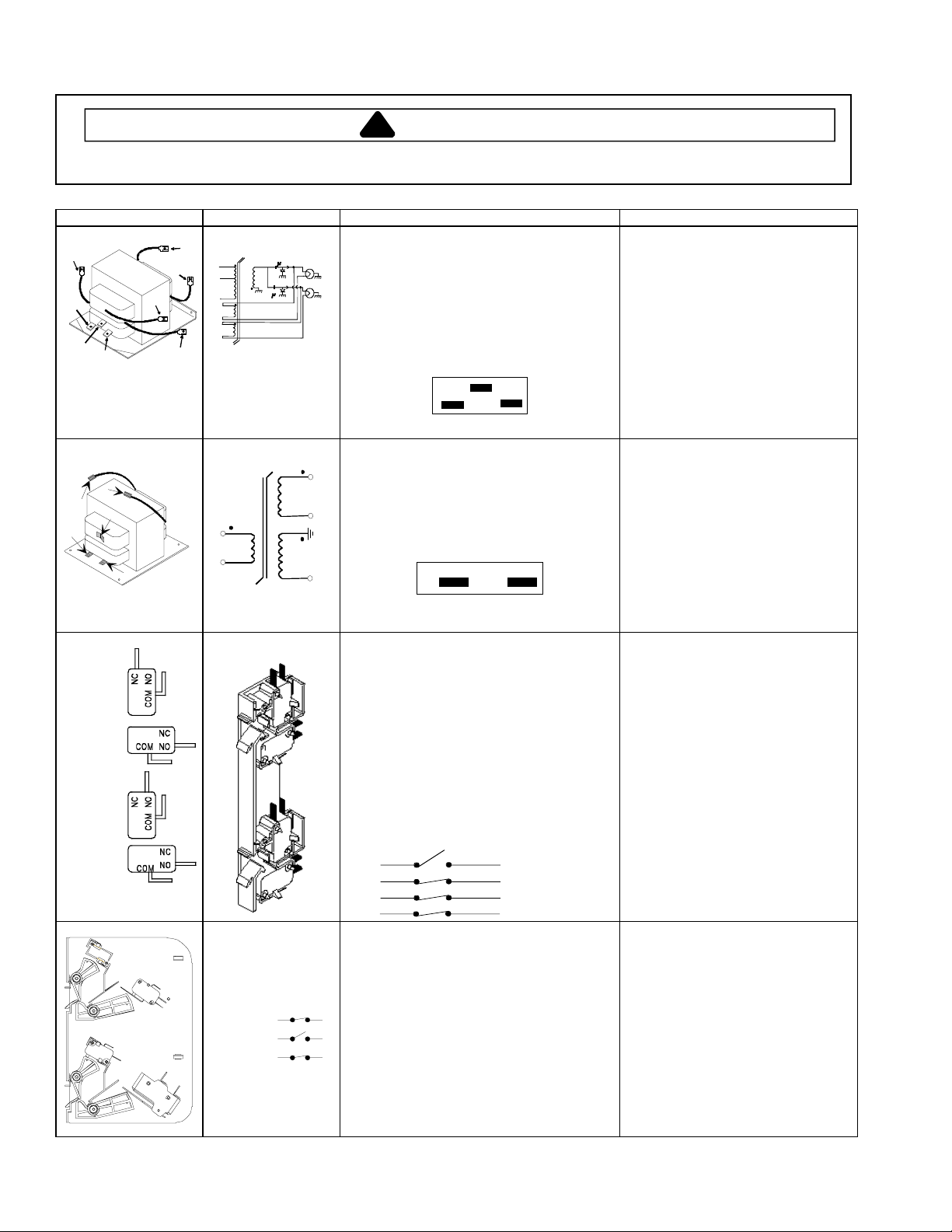

Illustration Component Testing Results

5

8

7

Transformer

# 4

# 1

# 3

# 2

# 5

# 6

# 7

# 8

1.0 F

HDC21,

HDC18SD,

HDC18

CRC18T2OG

CRC21T2RL

Transformer

1

2

1.0 F

-300 MA

-300 MA

Discharge Capacitors

Remove all wires from terminals.

Measure resistance from:

Terminal 1 to 2

Terminal 1 to 3

Terminal 5 to 6

Terminal 7 to 8

Terminal 4 to Ground screw on transformer

Terminal 4 to any other terminal

Violet

3

12

Gray

Red

Discharge Capacitor

Remove all wires from terminals, and

5

measure resistance from:

Terminal 1 to 2

Terminal 5 to 6

6

Terminal 4 to Ground screw on transformer

Terminal 4 to any other terminal

4

2

1

Gray Red

1.0

Ω

Less than 1

Less than 1

Less than 1

30

Ω

Ω

Ω

Ω

Infinite resistance should be

indicated, if not replace transformer.

Less than 1

Less than 1

78

Ω

Ω

Ω

Infinite resistance should be

indicated, if not replace transformer.

12136102

6

5

4

−

HDC10

−

HDC12

1

4

1

3

2

Terminal 1− 230 V

Terminal 2− Common

Terminal 3−208 V

10426609

10426610

6

2

Terminal 1−120 V

Terminal 2−Common

R0150154

Monitor

Primary

Logic

Secondary

12538901Q

Monitor

Primary /

Logic

Seconda ry

Interlock switch

assembly

Interlock switch

assembly

Door Closed

Primary / Logic

Monitor

Secondary

C

C

C

Disconnect wires to switch.

With door open measure resistance from:

Terminal C to NC Monitor

Terminal C to NO Primary

Terminal C to NO Logic

Terminal C to NO Secondary

With door closed measure resistance from:

Terminal C to NC Monitor

Terminal C to NO Primary

Terminal C to NO Logic

Terminal C to NO Secondary

Door Closed

NC

NO

NO

NO

Monitor

Primary

Logic

Secondary

C

C

C

C

Disconnect wires to switch.

With door open measure resistance from:

Terminal C to NC Monitor

Terminal C to NO Primary

Terminal C to NO Logic

NO

Terminal C to NO Secondary

NC

With door closed measure resistance from:

NO

Terminal C to NC Monitor

Terminal C to NO Primary

Terminal C to NO Logic

Terminal C to NO Secondary

Indicates continuity

Infinite

Infinite

Infinite

Infinite

Indicates continuity

Indicates continuity

Indicates continuity

Indicates continuity

Infinite

Infinite

Infinite

Infinite

Indicates continuity

Indicates continuity

Indicates continuity

RS2240002 Rev. 118

Page 19

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires it.

Illustration Component Testing Results

R0000277

Primary

Monitor

COM

N.O.

COM

Logic

N.O.

COM

N.C.

COM

Secondary

N.O.

Interlock switch

assembly

Door Closed

Logic

C

C

C

C

Primary

Monitor

Secondary

Disconnect wires to switch.

With door open measure resistance from:

Terminal C to NO Primary

Terminal C to NO Logic

Terminal C to NC Monitor

NO

Terminal C to NO Secondary

NO

With door closed measure resistance from:

NC

Terminal C to NO Primary

NO

Terminal C to NO Logic

Terminal C to NC Monitor

Terminal C to NO Secondary

Infinite

Infinite

Indicates continuity

Infinite

Indicates continuity

Indicates continuity

Infinite

Indicates continuity

Type 1

Pin #1

Type 2

Pin #1

P2

P2

P1

Pin #1

L

P1

Pin #1

H

Controller board

Type 1

CRC18T2OG

P1323006M

CRC21T2RL

P1323007M

HDC18

A B C D E F G

P1323003M

HDC18SD

P1323004M

HDC21

P1323005M

All Models

Line voltage to control board

P2 connector

Pin 1 — Pin 3 .......................................

Output drive voltage to triac

Triac terminals

Gate — T1............................................

208 VAC line voltage

Fan relay (controls blower motor, antenna

motor(s), and oven light)

Control board..........................................

Terminals C — D..................................

Line voltage sensing relay (automatically

switches for 208 or 230 VAC operation)

Control board..........................................

Terminals F — G..................................

Line voltage (All Condition)

0 VAC (Idle and Standby)

0.9 VAC (Cook)

Line voltage (Idle)

0 VAC (Standby and Cook)

Line voltage (Idle)

0 volts (Standby and Cook)

230 VAC line voltage

Fan relay (controls blower motor, antenna

H

Type 2

CRC18T2OG

P1323015M

CRC21T2RL

P1323017M

HDC18

P1323013M

A B C D E F G

HDC18SD

P1323014M

motor(s), and oven light)

Control board..........................................

Terminals C — E..................................

Line voltage sensing relay (automatically

switches for 208 or 230 VAC operation)

Control board..........................................

Terminals F — H ..................................

P2

1

10

Line voltage (Idle)

0 VAC (Standby and Cook)

Line voltage (Idle)

0 volts (Standby and Cook)

HDC21

P1323016M

10

P1 connector used for touch panel

ribbon

RS2240002 Rev. 1 19

P1

1

Page 20

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires it.

Illustration Component Testing Results

Type 3

HDC10, HDC12

P2

Pin #1

P1

Pin #1

Controller board

P2

A B C J F K

P1 connector used

for touch panel

ribbon

Touch Panel

Assembly

1

P1

All Models

Line voltage to control board

P2 connector

10

10

1

Pin 1 — Pin 3.......................................

Output drive voltage to triac

Triac terminals.......................................

Gate — T1 ...........................................

120 VAC

Fan relay (controls blower motor, antenna

motor(s), and oven light)

Control board.........................................

Terminals C — J..................................

Cook relay

Control board.........................................

Terminals F — K..................................

Continuity is indicated as 100 Ω and below.

Pin 1: is considered Ground

10

1

Line voltage (All Condition)

0 VAC (Idle and Standby)

0.9 VAC (Cook)

Line voltage (Idle)

0 VAC (Standby and Cook)

Line voltage (Idle)

0 volts (Standby and Cook)

Pad

1

2

3

4

5

6

7

8

9

0

Start

Stop/Reset

Power Level

X 2

Time Entry

Pin

8 & 10

7 & 10

6 & 10

5 & 10

4 & 10

3 & 10

8 & 9

7 & 9

6 & 9

5 & 9

4 & 9

4 & 8

5 & 8

6 & 8

7 & 8

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Conditions

Initial Power Up Condition:

Idle Condition:

Standby Condition:

Cook Condition:

Apply power to oven with door closed—see, “Troubleshooting” section.

Oven plugged in, display blank (no other components operating).

Open oven door, light and motors operate—see, “Troubleshooting” section.

Food load in oven, cook cycle initiated—see, “Troubleshooting” section.

RS2240002 Rev. 120

Page 21

Test Modes

Power Test (Traditional Test Method)

Test equipment required is Amana power test kit R0157397 (Fahrenheit), or

Menumaster power test kit M95D5 (Celsius).

1. Fill the plastic container to the 1000 ml. line with cool tap water.

2. Using the thermometer; stir the water, measure, and record the water temperature.

Initial water temperature should be approximately 60°F (16°C).

3. Place container on the center of the oven shelf and heat the water for

33 seconds for ovens with more than 1550 watts or 63 seconds for ovens with less than 1550 watts.

NOTE: Use a watch second hand, not the oven timer.

4. Stir the water , measure and record the temperature of the water after heating time is complete.

5. Subtract the starting water temperature (Step 2), from the ending water temperature (Step 4) to obtain the

temperature rise (DT).

6. See the Traditional Power Test Temperature Chart below.

NOTES: • The IEC-705 test method requires precision measurements and equipment. It is not practical to

perform the IEC test in the field. To convert the traditional power test results to the approximate IEC705 rating, take the traditional power test results and add 100 watts per magnetron for the unit being

tested.

Example: 1627 watts output using the traditional power test for model HDC18

+ 200 watts (2 magnetrons X 100 watts)

1827 Approximate IEC-705 results

• Always perform power test three times for accuracy, changing the water after each test is performed.

• Variation or errors in the test procedure will cause a variance in the temperature rise. Additional power

tests should be made if temperature rise appears marginal.

• Low line voltage will cause lower temperature rise.

Temperature Chart

ONE MINUTE, THREE SECONDS run time chart for units less than 1550 watts cooking power.

∆∆

∆T Cooking

∆∆

(°F) Power Output (°F) Power Output

16 620 26 1007

17 659 27 1046

18 697 28 1085

19 736 29 1124

20 775 30 1162

21 814 31 1201

22 852 32 1240

23 891 33 1279

24 930 34 1317

25 969

THIRTY THREE SECONDS run time chart for units more than 1550 watts cooking power.

∆∆

∆T Cooking

∆∆

(°F) Power Output (°F) Power Output

20 1550 25 1937

21 1627 26 2015

22 1705 27 2092

23 1782 28 2170

24 1860 29 2247

∆∆

∆T Cooking

∆∆

∆∆

∆T Cooking

∆∆

∆∆

∆T Cooking

∆∆

(°C) Power Output (°C) Power Output

7 490 15 1050

8 560 16 1120

9 630 17 1190

10 700 18 1260

11 770 19 1330

12 840 20 1400

13 910 21 1470

14 980 22 1540

∆∆

∆T Cooking

∆∆

(°C) Power Output (°C) Power Output

11 1540 14 1960

11.5 1610 14.5 2030

12 1680 15 2100

12.5 1750 15.5 2170

13 1820 16 2240

13.5 1890

21 RS2240002 Rev. 1

∆∆

∆T Cooking

∆∆

∆∆

∆T Cooking

∆∆

Page 22

!

Microwave Energy Leakage Testing

!

Measurement With the Outer Case

WA RN IN G

Removed

Check for radiation leakage after servicing. Should the

leakage be more than 4mW/cm2 inform Amana

immediately . After repairing or replacing any radiation

safety device, keep a written record for future

reference, as required by D.H.H.S. and HEW

regulations. This requirement must be strictly

observed. In addition, the leakage reading must be

recorded on the service repair ticket while at the

customer’s location.

Equipment

• Electromagnetic radiation monitor

• 600 cc glass beaker

Procedure For Measuring Radiation

Leakage

Note before measuring -

• Do not exceed meter full scale deflection. Leak

monitor should initially be set to the highest scale.

• To prevent false readings the test probe should be

held by the grip portion of the handle only .

• The scan speed is equal to one inch per antenna

revolution or one inch per second if antenna speed is

unknown.

• Areas to be checked are all door seal areas and any

venting parts.

• Leakage with the outer panel removed, 4mW/cm2 or

less.

• Leakage for fully assembled oven with door normally

closed, 4mW/cm2 or less.

• Leakage for a fully assembly oven (before the latch

switch (primary) is interrupted) while pulling the door,

4mW/cm2 or less.

DANGER

To avoid risk of personal injury or death avoid

contacting any high voltage components.

Whenever you replace the magnetron, measure for

radiation leakage before the outer case is installed and

after all necessary components are replaced or

adjusted. Special care should be taken in measuring

around the magnetron.

Measurement With a Fully Assembled Oven

After all components, including the outer panel are fully

assembled, measure for radiation leakage around the

door periphery , the door viewing window , the exhaust

opening, and air inlet openings.

Record Keeping and Notification After

Measurement

1. After any adjustment or repair to a microwave oven,

a leakage reading must be taken. Record this

leakage reading on the repair ticket even if it is zero.

2. A copy of the repair ticket and the microwave

leakage reading should be kept by the repair facility.

1 . Pour 275 ± 15 cc (9 oz ± 1/2 oz) of 20 ± 5°C. (68±

9°F.) water in a glass beaker which is graduated to

600 cc and place the beaker in the center of shelf.

2. Set the radiation monitor to 2450 MHz and use it

following the manufacturer’s recommended test

procedure to assure correct results.

3. While measuring the leakage, always use the two

inch (5 cm) spacer supplied with the probe.

4. Press the start pad or turn on the timer and with the

magnetron oscillating, measure the leakage by

holding the probe perpendicular to the surface being

measured.

RS2240009 Rev. 1 22

Page 23

T roubleshooting

Initial Power Up

Apply power with door closed.

Relays click.

YES

Which display is shown?

NO

Open line fuse.1.

Open cavity TCO.

2.

Inoperative control board.

3.

4.

Broken or improper wire connections.

Open magnetron TCO (only on models

5.

P1323013M thru P1323017M).

MICRO DEFR WARM MEDHI POWER HOLD

COOK

LEVEL

TIMER

READY

CLOCK

Proceed to "Standby" condition.

MICRO DEFR WARM MEDHI POWER HOLD

COOK

LEVEL

TIMER

READY

CLOCK

Blower, oven light, and antenna

all activate.

1.

Open magnetron TCO (only on models

P1323003M thru P1323009M).

Inoperative interlock switch assembly (logic ).

2.

3.

Broken or improper wire connections.

23 RS2240002 Rev. 1

Page 24

T roubleshooting

Standby Condition

Open ove n door.

Display

MICRO DEFR WARM MEDHI POWER HOLD

Yes

Oven light is on?

Yes

COOK

LEVEL

TIMER

READY

CLOCK

NO

NO

Inoperative interlock switch assembly (logic or primary).

1.

Inoperati ve contr ol board.

2.

Broken o r improper wire conn ections.

3.

Inoperati ve light bu lb.

1.

Inoperati ve light sock et.

2.

Inoperati ve auto- tra nsfo rmer .

3.

Inoperati ve contr ol board.

4.

5.

Broken o r improper wire conn ections.

Blower motor operates?

Yes

Antenna motor(s) operate?

Yes

"Standby Condition" normal - proceed to

"Cook Condition".

NO

NO

Inoperati ve blow er moto r.

1.

Inoperati ve auto- tra nsfo rmer .

2.

Broken o r improper wire conn ections.

3.

Inoperative antenna mot or.

1.

Binding gears (bottom a ntenna only).

2.

Grease shield installed upside down

3.

(top antenna only).

Inoperati ve auto- tra nsfo rmer .

4.

Broken o r improper wire conn ections.

5.

RS2240002 Rev. 1 24

Page 25

T roubleshooting

Cook Condition

Place cup of wa ter in

oven and close oven door.

Display

MICRO DEFR WARM MEDHI POWER HOLD

COOK

LEVEL

Push pad number 1.

Pad beeps when push ed?

Display

MICRO DEFR WARM MEDHI POWER HOLD

Yes

COOK

LEVEL

TIMER

READY

CLOCK

TIMER

READY

CLOCK

1.

Beep not programmed into oven.

NO

2.

Pad not programmed.

Inoperative touch panel .

3.

Inoperative control bo ard.

4.

Broken or improper wire connections.

5.

1.

Magnetron TCO opened in mid-cycle

(only on models P1323003M thru P1323009M).

2.

Logic switch op en ed in mid-cycle

(only on models P1323003M thru P1323009M).

3.

Primary switch opened in mid-cycle

(only on models P1323013M thru P1323017M).

Inoperative control bo ard.

4.

Symptoms of the above are as follows:

- Countdown time stops and remains displayed.

NO

- "POWER" indicator disappears.

- "READY" ind icator is displayed.

- Blow er and antenna m otors and lig ht continue t o operate.

After 2 m i nutes, all fun ctions stop and the display goe s blank.

After TCO or switch resets:

- "READY" ind icator is displayed.

Displa y s tarts counting down.

- Blower and antenna motors and light operate for 2 minutes.

Yes

Display counting down to "0" and

beep sounds.

Yes

Heats very slowly.

NOTE: Verify by performing power test.

One inoperative diode.

1.

One inoperative capacitor.

2.

One inoperati ve magnet ro n.

3.

Broken or improper wire connection.

4.

Inoperative or misadjusted interlock switch assembly.5.

No heat.

Open oven door, water i s prop erly he ated?

Yes

Oven is operating properly.

NO

Inoperative triac.

1.

Inoperative diodes.

2.

Inoperative capacitors.

3.

Inoperative high voltage transformer.4.

Inoperative control bo ard.

5.

Inoperative or misadjusted interlock switch assembly.

6.

7.

Broken or improper wire connections.

NOTE: Shut down after cook cycle - door closed - fa ctory preset at 60 seconds, but can be changed with user options.

Shut dow n, door open - approxima t ely 2 minute s .

After shut down, dis pl ay goes blank.

25 RS2240002 Rev. 1

Page 26

Disassembly

!

!

WARNING

Door Removal

1. Unplug power cord from power source.

2. Remove outer case cover .

3. Remove bolts securing door hinges.

4. Remove door from unit, and lay door on padded

surface.

Inner Door/Window Removal

1. Open oven door .

2. Remove screws on hinge side.

3. Beginning at the bottom, carefully insert 1” putty knife

between inner and outer door. Pry up on inner door

to release tabs, (2 tabs per side). Work in a

clockwise direction to release all tabs, see illustration

below.

3

To avoid the risk of electrical shock, personal injury, or

death, disconnect power to oven and discharge

capacitors before following any disassembly procedure.

Inner

door

Door

latch

linkage

Door

latch

bracket

Window

outer

0281

Door

outer

Hinges

0261

Retainer

lens

Door

ring

weld

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

2

Remove

screws

Tabs

4

1

CAUTION

When glass retainer is removed, be careful glass

does not fall out of frame.

Door Disassembly

1. Remove door from oven, see “Door Removal”

procedure.

2. Perform “Inner Door/Window Removal” procedures,

step 1 through step 3 above.

3. Remove door latch linkage plate from latch assembly .

4. Remove screws securing door ring weld, (2 screws

under latch linkage and 2 on hinge side of outer

door).

5. Remove door ring weld from door.

6. Remove lens retainer and outer window from door.

7. Remove screws securing handle/door latch bracket

to gain access to latch spring.

8. Reassemble in reverse order.

9. Proceed to “Interlock Switch Replacement / Door

Adjustment” procedure.

Door Handle

1. Follow “Door Disassembly” procedure through step 6.

2. Remove screws securing latch assembly to outer

door.

3. Reassemble in reverse order.

Hinge

1. Follow Door Disassembly procedure through step 6.

2. Replace hinge on door ring weld.

3. Reassemble in reverse order.

RS2240002 Rev. 1 26

Page 27

Disassembly

!

To avoid the risk of electrical shock, personal injury, or

WARNING

Interlock Switch Assembly

1. See “Component Location” Figure 1, for location.

2. Unplug power cord from power source.

3. Remove outer case.

4. Disconnect wiring.

5. Remove screws securing switch assembly to unit.

6. Install new switch assembly.

7. Install screws but do not tighten.

8. Proceed to “Door/Interlock Switch Adjustment” procedure.

NOTE: When the line fuse is blown replace interlock switch assembly.

death, disconnect power to oven and discharge

capacitors before following any disassembly procedure.

R0150154 Early Production Switch

Monitor

Primary

Mounting

screws

Logic

Secondary

12538901Q Later Production Switch

R0000277 Replacement for Early Production Switch

Primary

Logic

Mounting

screws

Monito r

Secondary

Primary /

Logic

Mounting

Screws

Monitor

Secondary

27 RS2240002 Rev. 1

Page 28

Disassembly

!

!

WARNING

To avoid the risk of electrical shock, personal injury, or

death, disconnect power to oven and discharge

capacitors before following any disassembly procedure.

Switch Replacement / Door Adjustment

WARNING

To avoid risk of electrical shock, personal injury or

death; disconnect electrical power before servicing.

1. Remove and retain two (2) screws securing switch to

cavity . Remove switch.

2. Position new switch assembly into cavity opening.

• First, insert bottom ramp of switch into bottom

opening.

• Tilt switch upward and insert top ramp of switch

into top opening.

• Be sure both ramps are fully protuded through the

front frame of cavity .