Page 1

Service

Series "D"

Plastic Tub Dishwashers

Models and manufacturing

numbers in this manual

CDU300DB P1307505W

CDU220DB P1307506W

ADU7000DWW P1307507W

ADU7000DBB P1307508W

ADU7000DLL P1307509W

ADU6000DWW P1307510W

ADU6000DB P1307511 W

ADU5000DWW P1307512W

ADU5000DB P1307513W

ADU3000DB P1307514W

ADU3000DWW P1307515W

CDU300DB P1309605W

CDU220DB P1309606B

ADU7000D P1309607W

ADU7000D P1309608B

ADU7000D P1309609L

ADU6000D P1309610W

ADU6000D P1309611B

ADU5000D P1309612W

ADU5000D P1309613B

ADU3000D P1309614W

ADU3000D P1309615B

This manual is to be used by qualified appliance technicians

only. Amana does not assume any responsibility for property

damage or personal injury for improper service procedures

done by an unqualified person.

RS3300002

Revision 0

August 1997

Page 2

!

Important Information

!

!

!

!

Pride and workmanship go into every product to provide our customers with quality products. It is possible,

however, that during its lifetime a product may require service. Products should be serviced only by a

qualified service technician who is familiar with the safety procedures required in the repair and who is

equipped with the proper tools, parts, testing instruments and the appropriate service manual. REVIEW ALL

SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

To avoid risk of serious injury or death, repairs should not be attempted by an unauthorized personal, dangerous

conditions (such as exposure to electrical shock) may result.

Amana will not be responsible for any injury or property damage from improper service procedures. If preforming

service on your own product, assume responsibility for any personal injury or property damage which may result.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Important Information

Important Notices for Consumers and Servicers

WARNING

CAUTION

CONSUMER AFFAIRS DEPT. CALL (1-800-843-0304) or

AMANA If no answer call 1-319-622-5511 and ask for

AMANA, IOWA 52204 Consumer Affairs

If outside the United States contact:

AMANA

ATTN: CONSUMER AFFAIRS DEPT.

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

RS3300002 Rev 0 August 1997

Page 3

Contents

Important Information ................................................ 2

Product Information

Models and Features.................................................4

Model Identification ................................................... 4

Service Information ................................................... 4

Mini-Manual Location ................................................4

Features and Specifications ...................................... 5

Installation Instructions

Buit-In Installation Instructions ..................................6

Preparing Cabinet Opening ................................6

Preparing Electrical Wiring .......................................6

Preparing Hot Water Line ..........................................7

Preparing Drain Plumbing .........................................7

Installing Dishwasher ................................................ 7

Use & Care Instructions

Dishwasher-Safe Items .............................................9

Loading Dishwasher ..................................................10

Preparing Dishes ................................................10

Top Rack.............................................................10

Cup Retainer (some models)..............................10

Cup Shelf (some models) ...................................10

Bottom Rack .......................................................10

Cutlery Basket ....................................................10

Automatic Dishwasher Detergent Dispenser .............11

Changing Color Panels .............................................12

Changing Door Panel..........................................12

Changing Access Panel ...................................... 12

Before Calling for Service .........................................12

Dishwasher Operation

Basic Operation.........................................................13

User Operation ..........................................................13

Basic Components ....................................................14

Basic Functions.........................................................14

Fill with Hot Water ..............................................14

Wash Action ........................................................14

Drain ...................................................................15

Dry ......................................................................15

Inlet, Tub, and Thermostat Temperatures .................16

120° Inlet Water Capability ....................................... 16

Water Temperature Boost...................................16

Operating Instructions

CDU220 ..................................................................... 17

CDU300 ..................................................................... 18

ADU3000 ................................................................... 19

ADU5000 ................................................................... 20

ADU6000 ................................................................... 21

ADU7000 ................................................................... 22

Service Information

Water Valve and Inlet System...................................23

Disassembly .......................................................23

Water Valve Operation .......................................23

Float Switch ...............................................................24

Disassembly .......................................................24

Recalibration.......................................................24

Motor/Pump Mechanism and Boots .......................... 25

Motor/Pump Mechanism Check..........................25

Motor/Pump Removal ......................................... 25

Motor/Pump Replacement Parts.........................26

Reassembly ........................................................26

Soft Food Disposer ...................................................26

Disassembly .......................................................26

Drain Solenoid...........................................................27

Racks ........................................................................27

Rotating Upper Shower Arm .....................................27

Spray Arm .................................................................27

Filter System ............................................................. 28

Drain Action ........................................................28

Filter and Drain ...................................................28

Calrod Heater ............................................................28

Sump Cover and Baffle Grid .....................................28

Tub Corner Baffles ....................................................29

Door Gasket Replacement ........................................29

Door Components .....................................................29

Detergent Cup Cover And Latch.........................29

Rinse Agent Injector ...........................................29

Drying Vent .........................................................30

Control Panel Assembly ............................................ 30

Push Button Switches ...............................................30

Servicing Push Button Switch.............................31

Push Button Switch Test............................................31

Switch Contact Chart ................................................31

Snap On Electrical Components Cover ....................32

Timer.........................................................................32

Timer Testing ......................................................32

Latch Interlock Switches ...........................................33

Door Latch.................................................................33

Strike Adjust .......................................................33

Aluminum Trim Panel ...............................................33

Testing ................................................................33

Repair ................................................................. 33

Schematic Diagrams

ADU3000...................................................................34

ADU5000...................................................................36

ADU6000...................................................................38

ADU7000...................................................................40

CDU220..................................................................... 42

CDU300..................................................................... 44

RS3300002 Rev. 0 3 August 1997

Page 4

Product Information

!

!

WARNING

Disconnect power and close water supply valve

before servicing dishwasher. Never energize

electrical power to dishwasher with any panels

removed.

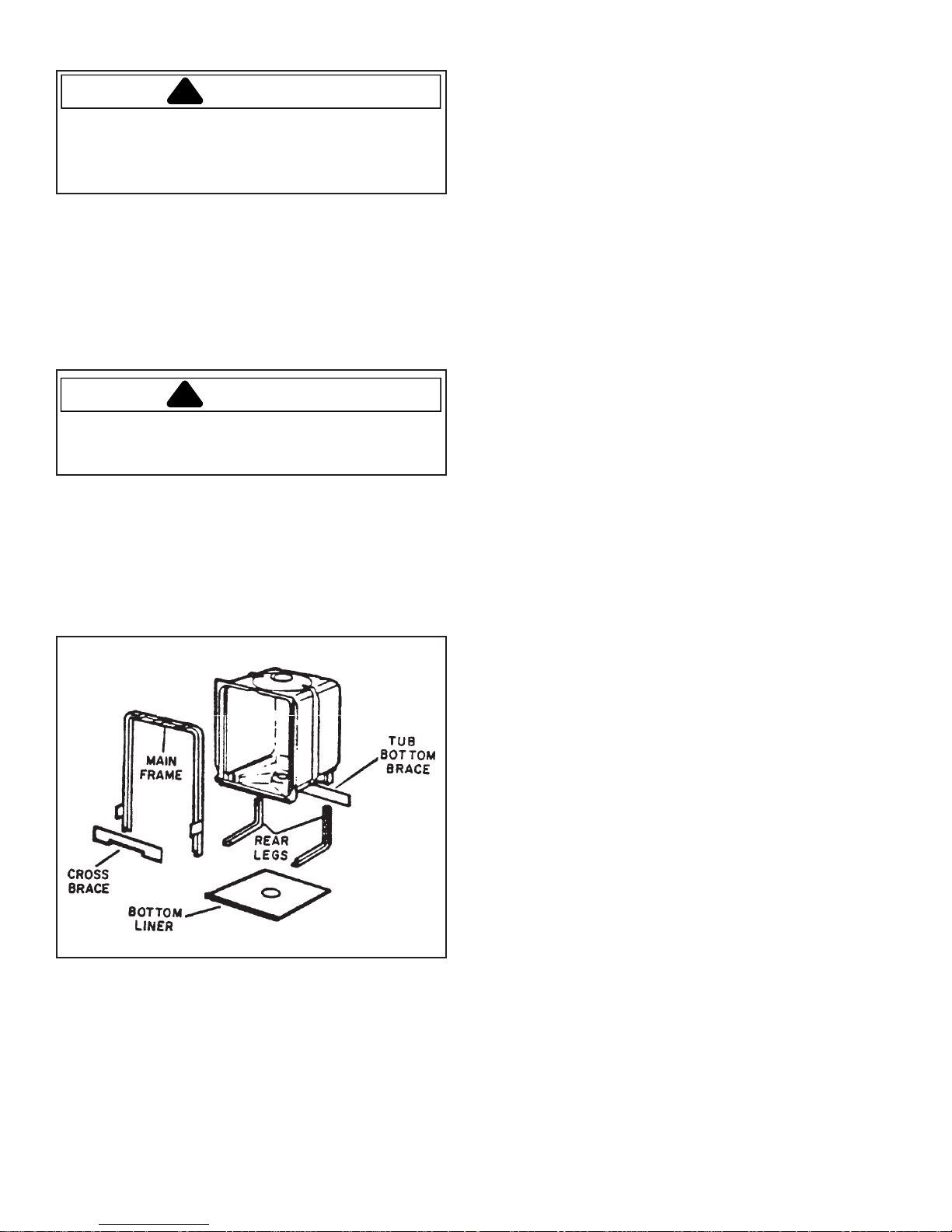

Models and Features

All dishwasher models use one piece of channel steel

as the main frame around tub and the two front legs.

Rear legs are channel steel, and a steel bottom liner

stiffens and supports tub bottom. A cross brace is

used at the front for stiffness. Tub bottom brace

supports the tub when filled with hot water and

prevents deformation.

WARNING

All ground wires removed during servicing must be

reconnected to insure dishwasher is properly

grounded.

Tub is not replaceable. If defective, the entire

dishwasher must be replaced.

The models all have 120°F inlet water capability.

Some models use a water heat thermostat and cycle

extender to extend cycle time for water temperatures

under 140°F. ADU3000, ADU5000, and ADU520 units

use a timed sytem.

Model Identification

Rating label, which gives the model number, is

located on the left side of the tub at the front, and is

visible when the door is opened. This series of models

will have "P" numbers which identify the product.

Service Information

Two different pieces of service literature will be

available. The mini-manual comes with the product.

This piece contains a schematic, cam chart, and

abbreviated service information.

This service manual will contain all pertinent service

reference information including schematics.

Mini-Manual Location

The mini-manual is accessible when the access panel

is removed.

The folded mini-manual is in a 6-inch x 3 1/4-inch

envelope, which is placed between the tub and metal

plate, on the right side.

RS3300002 Rev. 0 4 August 1997

Page 5

Product Information

Features and Specifications

BRAND AMANA CALORI C

MODE L ADU7 000 ADU6000 ADU500 0 ADU3000 CDU520 CDU300 CDU2 20

Colors

White

Black

Gold

Almond

Cup Shelf 2 Meta l 2 Plastic

Silverwa re Basket Super Super X X X X X

Timer

Rotary

Push Buttons

Cycles

Pots and Pans

Heavy Wash

Norma l Wash

Light Wash

China/Crystal

Short Wash

Rinse and Ho ld

Plate Warmer

Options

Delay Start

Heated Dry On

Water Heat Boost

Timer

Calrods Watts 500 500 500 500 500 500 500

Sound SofSound™ Premium Premium Standard Delux Standard

Washability

Wa sh Levels

Mid Level Wash

Rinse Aid Indicato r

Food Disposal

X

X

X

X

10

X

X

X

X

X

X

X

X

10 hours

X

X

X

3

Tower

X

X

X

X

X

X

X

7

X

X

X

X

X

X

X

6 Hours

X

X

X

3

Tower

X

X

X

X

X

X

5

X

X

X

X

X

X

X

X

3

Tower

X

X

X

X

X

X

2

X

X

X

X

X

X

X

3

Tower

X

X

X

X

X

X

X

X

X

X

6 Hours

X

X

X

3

Tower

X

X

X

2

X

X

X

X

X

X

2

Tower

X

X

X

5

X

X

X

2

Tower

August 1997 5 RS3300002 Rev. 0

Page 6

Installation Instructions

Buit-In Installation Instructions

Preparing Cabinet Opening

Dishwasher is designed to fit into a minimum 34 1/2"

height and 24" width and depth. A minimum of 2" is

required between dishwasher and perpendicular

cabinet or wall. Dishwasher must not be installed more

than 10' from sink for proper drainage.

Note: Complete enclosure is not provided with

dishwasher. Installer must provide top, bottom,

back and side enclosures.

Preparing Electrical Wiring

W ARNING

To avoid electrical shock which can cause severe

personal injury or death, open household circuit

breaker to dishwasher before installing or

servicing dishwasher. After installing or servicing

dishwasher, reconnect power.

Note: Electrical wiring must meet local codes and

ordinances. If wiring does not, contact a

licensed electrician.

1. Cut 1 1/2" maximum hole in cabinet for cable or

power cord. Wiring must enter within shaded area.

2. Connecting Dishwasher

Using Cable Direct Connection

Route cable as shown. Cable must extend a

minimum of 24" from back wall of cabinet.

Using Power Cord

Install a three-prong grounded receptacle

in rear of sink cabinet next to dishwasher.

Do not install receptacle in cabinet opening.

Receptacle must be installed at least 6" but not

more than 18" from cabinet opening.

Note:

Edges of cabinet opening for power cord must be

smooth and rounded. If cabinet is metal, edges of

opening must be covered with a rubber cord protector.

Receptacle

5"

4"

Electrical Wiring

5"

Alternate

Receptacle

4"

6"

3"

RS3300002 Rev. 0 6 August 1997

Page 7

Installation Instructions

Preparing Hot Water Line

Note:

• Plumbing must meet local codes and ordinances. If

plumbing does not, contact a licensed plumber.

• Hot water line must accommodate 3/8" copper

tubing or 1/2" plastic tubing. Manual shut-off in hot

water line is recommended.

1. Cut 1 1/2" hole in cabinet for hot water line. Hot

water line must enter within shaded area.

2. Flush water line to clean out debris.

5"

4"

6"

Hot

2"

5"

4"

Installing Dishwasher

W ARNING

To avoid electrical shock which can cause severe

personal injury or death, open household circuit

breaker to dishwasher before installing or

servicing dishwasher. After installing or servicing

dishwasher, restore power.

CAUTION

To avoid property damage, protect soft vinyl or

other flooring with cardboard, rugs or other

protective material during installation.

CAUTION

To avoid property damage, do not tilt dishwasher

forward.

1. Cut end of drain hose at pre-marked line as

necessary. Do not cut corrugated portion of drain

hose.

Preparing Drain Plumbing

Note:

• Plumbing must meet local codes and ordinances. If

plumbing does not, contact a licensed plumber.

• Edges of cabinet opening for drain hose must be

smooth and rounded. If cabinet is metal, edges of

opening must be covered with a rubber cord

protector.

• An air gap must be used if drain hose is connected

to house plumbing lower than 18" above floor level.

All air gap devices must be capable of passing 3/8"

steel ball to assure minimum drain line stoppages.

1"

3/4"

5/8"

August 1997 7 RS3300002 Rev. 0

Page 8

Installation Instructions

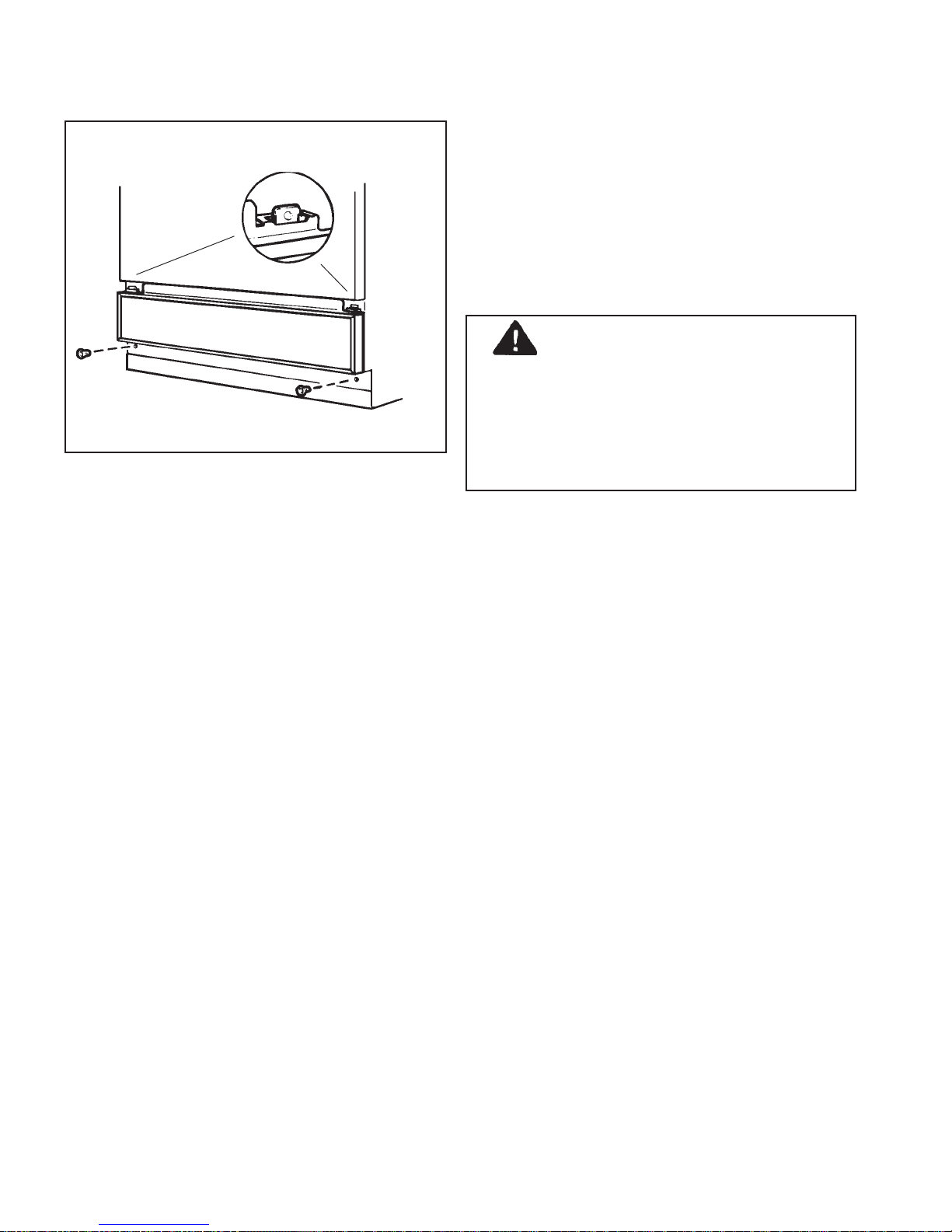

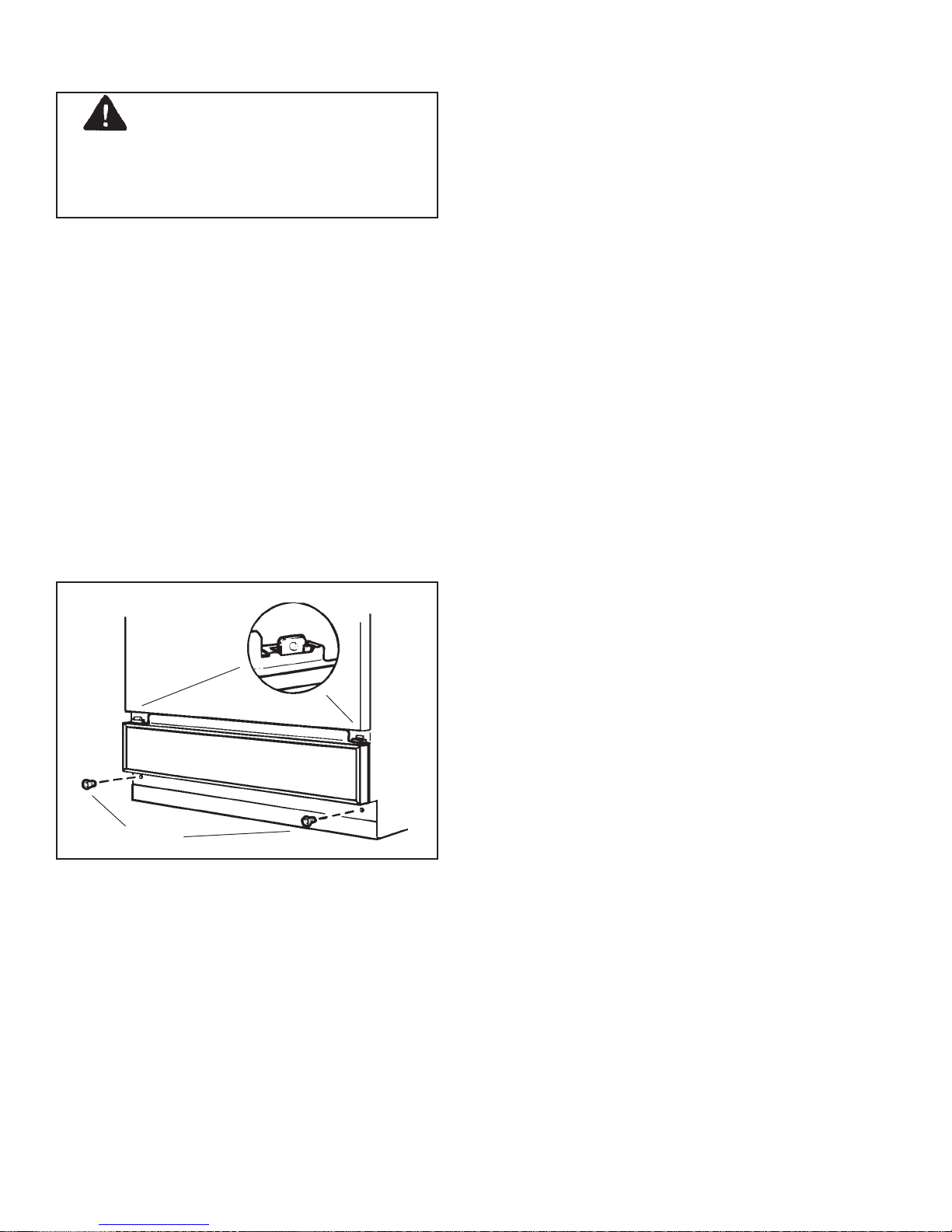

2. Remove access panel by removing screws then

lifting panel up and over tabs.

Tab

3. Confirm drain hose is connected to drain hose

valve.

4. Connect hot water line to water valve using a 90°

elbow. Dishwasher water valve has a 3/8" N.P.S.

internal thread.

5. Remove slotted hex head screws from

wooden base. Lift dishwasher off wooden base.

Discard wooden base and hex head screws.

6. Loosen leveling legs.

7. Push drain hose through opening in cabinet. Route

drain hose through plastic strain relief and connect

to disposer or drain using clamp. If connecting to a

disposer, remove disposer hopper plug before

making connection.

Note: If an air gap is not code required, drain hose

must have a high drain loop, which is 18"

minimum above floor level. This prevents back

flow of water into dishwasher or water siphoning

out during operation.

8. Attach power supply to rear of dishwasher

junction box using a strain relief (not supplied).

Connect wires using wire nuts (not supplied).

Connect incoming black wire to black wire inside

junction box. Connect incoming white wire to white

wire. Connect incoming ground wire to green ground

wire.

DANGER

To avoid electrical shock which can cause severe

personal injury or death, a ground wire must be

provided by installer if house wiring is not twowire with a ground wire. Otherwise dishwasher

will not be grounded. When house wiring is

aluminum, use U.L. approved antioxidant

compound and aluminum-to-copper connectors.

9. Route power cord (if applicable) through opening in

cabinet wall.

10.Slide dishwasher into position. Any excess drain

hose must be coiled under dishwasher.

11.Check front of door for correct vertical alignment. If

dishwasher is not aligned, adjust leveling legs until

dishwasher is aligned with cabinets.

12.Confirm door closes properly and latch engages. If

door strikes cabinets or latch fails to engage, adjust

leveling legs until properly aligned.

Note: Confirm dishwasher is flush with underside of

countertop to reduce sound level.

RS3300002 Rev. 0 8 August 1997

13.Fasten dishwasher to underside of countertop

byinserting screws and tightening. Screws must be

driven straight into countertop to avoid interference

with door.

14.Replace access panel by reversing step 2.

15. Plug power cord (if applicable) into outlet.

16.Pour two quarts of water into dishwasher tub prior to

starting dishwasher for the first time. Water acts as a

lubricant and will prevent possible motor damage.

17.Run dishwasher through a complete cycle to check

for leaks.

Page 9

Use & Care Instructions

Dishwasher-Safe Items

Material Usually Safe Exceptions Special Instructions

Aluminum Yes Some colored anodized aluminum

can fade.

China/Stoneware Yes Antique, metal trimmed,

hand-painted or over-the-glaze

patterns fade. Gold leaf will

discolor.

Crystal Yes Antique, metal trimmed,

hand-painted or over-the-glaze

patterns fade. Gold leaf will

discolor.

Glass Yes Milk glass may yellow.

Iron No

Non-dishware

such as filters,

etc.

Non-stick coatings Yes After washing, wipe non-stick

No Damage to dishwasher and

Some darkening or spotting

possible. Remove by scouring

with soap-filled steel wool pads.

If in doubt, check with

china/stoneware manufacturer or

test wash one piece daily for at

least a month. Compare with rest

of set.

Load securely to prevent

movement. Check crystal

manufacturer's instructions.

discoloration or staining of

dishwasher may result.

coating with vegetable oil to keep

coating from losing non-stick

quality.

Pewter No

Plastics Yes If plast ic does not say

"dishwasher - safe", test one piece

before washing entire set.

Stainless steel Yes Rinse if not washing immediately.

Salty or acid foods can stain if left

on.

Sterling silver and

silver plate

Tin No

Wood No

Yes Contact with stainless steel can

damage silver. Washing with

copper can leave a brown film.

Rinse if not washing immediately.

Salty or acid foods can stain if left

on. Powder detergent can cause

black spots. Avoid placing under

detergent dispe nse r.

August 1997 9 RS3300002 Rev. 0

Page 10

Use & Care Instructions

Loading Dishwasher

Preparing Dishes

Prerinsing of normal food soils is not necessary.

Remove foods such as mustard, mayonnaise, vinegar,

lemon juice that can cause discoloration of stainless

steel.

Caution

To avoid damage to pump, remove solids such as

bones, meat trimmings, rinds, seeds, skins, or

toothpicks.

Top Rack

Top rack is for delicate, plastic or small dishware.

Glasses fit best along the sides. Arrange stemware so

that stemware cannot move easily. Do not let glasses

or stemware touch each other.

Cup Retainer (some models)

Cup retainer secures tall cups and bowls in upper rack.

Cup Shelf (some models)

Cup shelf features a fold down shelf for two levels of

smaller dishware.

Bottom Rack

Bottom rack is best for heavily soiled dishware. Fit

plates and saucers between tines. Load dishware with

soiled side facing center. Prop broiler pans and racks

along edge.

Note: Do not load large dishware in front right corner

of bottom rack. Large dishware prevents

automatic dishwasher detergent from

circulating in wash cycle.

Do not block wash tower or load tall dishware

next to wash tower. Dishware must not

prevent wash tower from rotating freely.

WARNING

To avoid personal injury or property damage, do

not place plastic dishware in dishwasher unless

marked "dishwasher-safe" or equivalent. For

plastic dishware not marked, check

manufacturer's recommendations.

Place sauce pans, mixing bowls and other dishware

face down.

Do not let dishware extend through bottom

rack. This could block wash arm and cause

poor washing results.

Cutlery Basket

Load cutlery basket evenly with dishware mixed. Small

plastic dishware such as measuring spoons and lids

are not recommended for automatic dishwashing. If

placed in dishwasher, these items should be placed in

center compartment.

WARNING

To avoid personal injury or property damage, load

sharp knives so knives do not touch door seal.

Load knives in cutlery basket with handles up.

Note: Take out anything that might fall or extend

through the bottom of basket.

RS3300002 Rev. 0 10 August 1997

Page 11

Use & Care Instructions

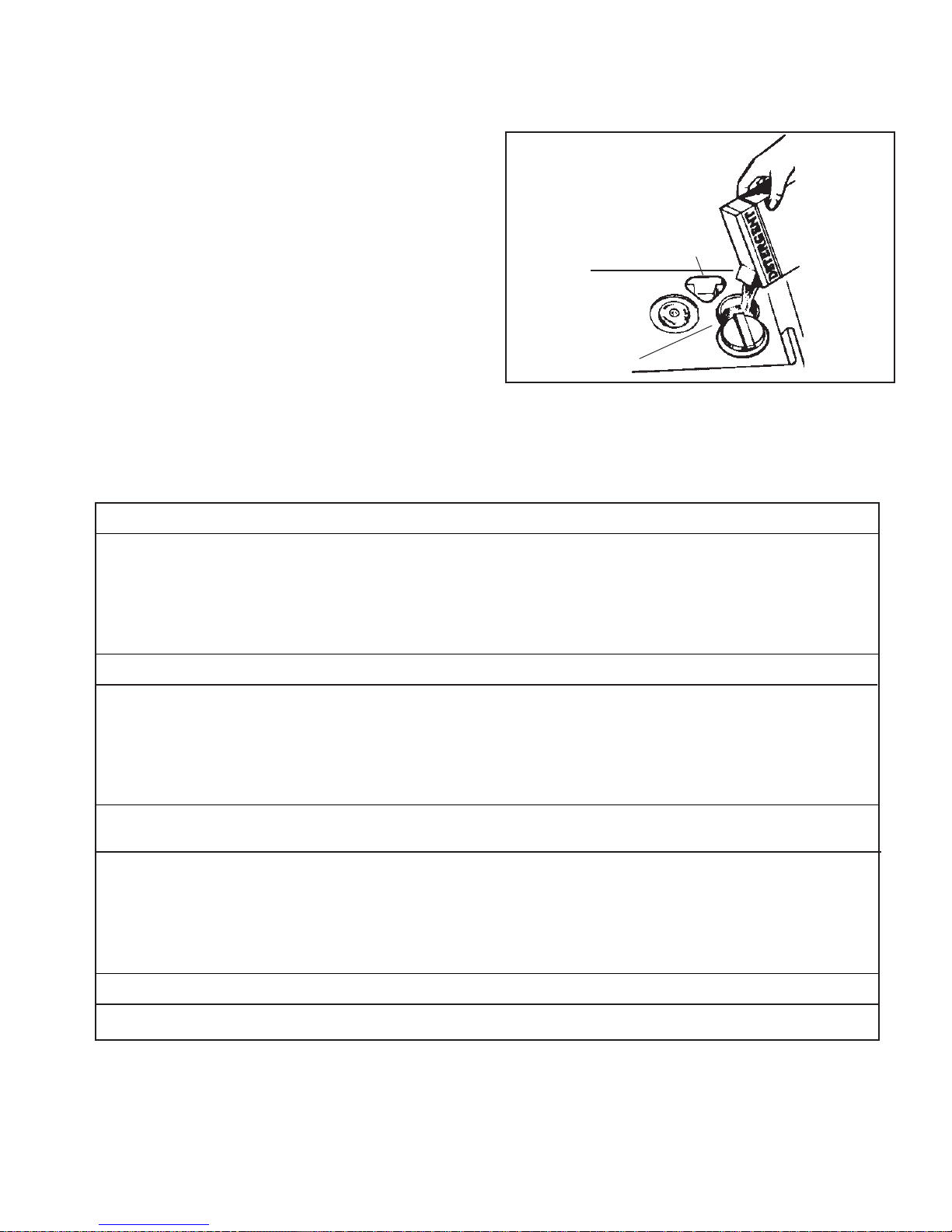

Automatic Dishwasher Detergent

Dispenser

Use main dispenser for all wash programs except

RINSE & HOLD. Reserve dispenser is for two cycle

washes and if extra detergent is necessary.

1. Confirm cycle indicator dial is in

otherwise main dispenser will not close properly.

Add automatic dishwasher detergent.

2. Close main dispenser.

Note: Open main dispenser after dispenser has

been closed by unlatching door and rotating

cycle indicator dial to

dispenser contains automatic dishwasher

detergent, partially open door before rotating

cycle indicator dial. This reduces amount of

spillage into tub.

Automatic Dishwasher Detergent Usage Guide (Cycles vary from model to model)

OFF

position. If

OFF

position,

Reserve Dispenser

Main Dispenser

Soft Water (0-3 Grains per Gallon)

Cycle s Main Dispenser Reserve Di spenser

POTS & PANS 1 Tablespoon minimum 1 Tablespoon minimum

HEAVY, NORMAL or LIGHT WASH 1 Tablespoon minimum 1 Tablespoon minimum

SHORT WASH 1 Tablespoon minimum Optional*

Hard Water (4-10 Grains per Gallon)

Cycle s Main Dispenser Reserve Di spenser

POTS & PANS 1 1/2 Tablespoons minimum 1 Tablespoon minimum

HEAVY, NORMAL or LIGHT WASH 1 1/2 Tablespoons minimum 1 Tablespoon minimum

SHORT WASH 1 1/2 Tablespoons minimum Optional*

Extremely Hard Water

(Over 10 Grains per Gallon)

Cycle s Main Dispenser Reserve Di spenser

POTS & PANS 3 Tablespoons (Full) 2 Tablespoon (Full)

HEAVY, NORMAL or LIGHT WASH 3 Tablespoons (Full) 2 Tablespoon (Full)

SHORT WASH 3 Tablespoons (Full) Optional*

A water softener should be installed if water hardness is over 19 grains per gallon.

*Add automatic dishwasher detergent to reserve dispenser if two wash, three rinse cycle is desired.

August 1997 11 RS3300002 Rev. 0

Page 12

Use & Care Instructions

Changing Color Panels

W ARNING

To avoid electrical shock which can cause severe

personal injury or death, unplug power cord or

open household circuit breaker to dishwasher

before changing panels.

Changing Door Panel

1. Remove door trim from one side of door by

removing screws.

2. Slide out door panel. Turn door panel around and

replace.

3. Replace trim by reversing step 1.

Changing Access Panel

1. Remove access panel by removing screws then

lifting panel up and over tabs.

2. Remove trim by removing screws.

3. Slide out access panel. Turn access panel around

and replace.

4. Replace trim by reversing step 2.

5. Replace access panel by reversing step 1.

Before Calling for Service

Dishwasher will not operate

• Check fuse or circuit breaker.

Automatic dishwasher detergent is left in dispenser

• Confirm dishwasher is loaded properly.

• Open dispenser and remove any hardened

automatic dishwasher detergent.

• Confirm automatic dishwasher detergent is not old

or wet.

Dishwasher makes unfamiliar sounds

• Confirm items are secure in dishwasher. Water

may be causing items to rattle.

• If dishwasher has not been used regularly, set

dishwasher to fill and pump out once every week.

This will keep seals moist.

Small amount of water is standing in tub

• This is normal and keeps water seal lubricated.

Water will not pump out of tub

• Check air gap.

• Confirm sink is draining well.

• Run disposer if dishwasher is connected to

disposal.

Screws

Suds are in tub

• Confirm detergent is for automatic dishwashers.

Remove suds by opening door and letting suds

evaporate. Add a gallon of cold water. Close and

latch door. Pump out water by turning control dial

until a drain period is reached.

• Confirm rinse aid dispenser is filled properly and

any spills are wiped up.

Dishwasher leaks

• Confirm automatic dishwasher detergent is for

automatic dishwashers.

• Confirm rinse aid dispenser is filled properly and

any spills are wiped up.

Cloudiness appears on dishware

• See spotting or filming section.

• Cloudiness may be etching. Etching cannot be

removed.

Dishware is chipped

• Confirm dishwasher is loaded properly.

Dishware is not dry

• Confirm water temperature is above 120°F.

• Confirm dishwasher is loaded properly.

• Unload bottom rack first. Water from dishes in top

rack may be spilling.

• Check level of rinse aid in dispenser.

RS3300002 Rev. 0 12 August 1997

Page 13

Operation

Basic Operation

For dishes to wash properly, consumer must load

dishwasher correctly as described in Use and Care

Section of this manual, and in more detail in the Use

and Care Manual.

Spraying water must be able to reach all dishware

surfaces. Dishes or utensils must not obstruct wash arm

of telescoping wash tower.

Next, detergent must be added to dispenser and

dispenser cover must be closed. Rinse aid dispenser

(RAD)

in final rinse.

To operate dishwasher, close door and push interlock

switch lever to the right. Turn timer knob to

models with push buttons, momentarily press in on

desired wash cycle push buttons. A timed fill of about 60

seconds will begin. During fill, pump and motor will run

in recirculation mode. First two or three fills (depending

on the cycle selected) are pre-washes—plain hot water

flowing over dishware. If extra detergent cup has been

filled, it dumps when door is closed to remove most of

food residue. After each fill and pre-wash, there is a

pumpout.

tank should contain enough rinse agent for dump

Start.

For

User Operation

1. Load dishes correctly—so spray gets to all surfaces.

2. Add dishwasher detergent.

3. Add rinse agent—if desired.

4. Close and latch door.

5. Select desired wash cycle and dry mode.

6. Turn timer knob to

Push in cycle buttons for models with push buttons.

7. For

8. If

Wash cycle follows pre-washes. Wash time will vary

with cycle selection. If model includes water heat

booster, heater is on during third pre-wash and during

wash to increase water temperature and improve

washability. Detergent cup cover opens approximately

two minutes into

After final rinse, wet portion of cycle is completed and

pump and motor stop. If

selected, heater will be on during drying. If

has been selected, heater will be off.

For

provides the two

continue to run to end of what would normally be

Dry

selection should be made. Applying heat to

Hold

and produce a washability complaint.

Normal

3 Pre-washes

1 Detergent Wash

3 Rinses

cycle:

Heated Dry

If

Normal Dry

Rinse and Hold

cycle. For

dishes could bake on any remaining food particles

Rinse and Hold

ON

on timer knob models.

, timer runs to

, timer runs to

Wash

cycle. Three rinses follow wash.

Heated Dry ON

cycle, turn to

Final Rinse

cycles only. Timer will

OFF

with heater on.

OFF

with heater off.

R & H

cycle, the

has been

Normal Dry

dot on dial. This

Heated

Normal Dry

Rinse and

August 1997 13 RS3300002 Rev. 0

Page 14

Operation

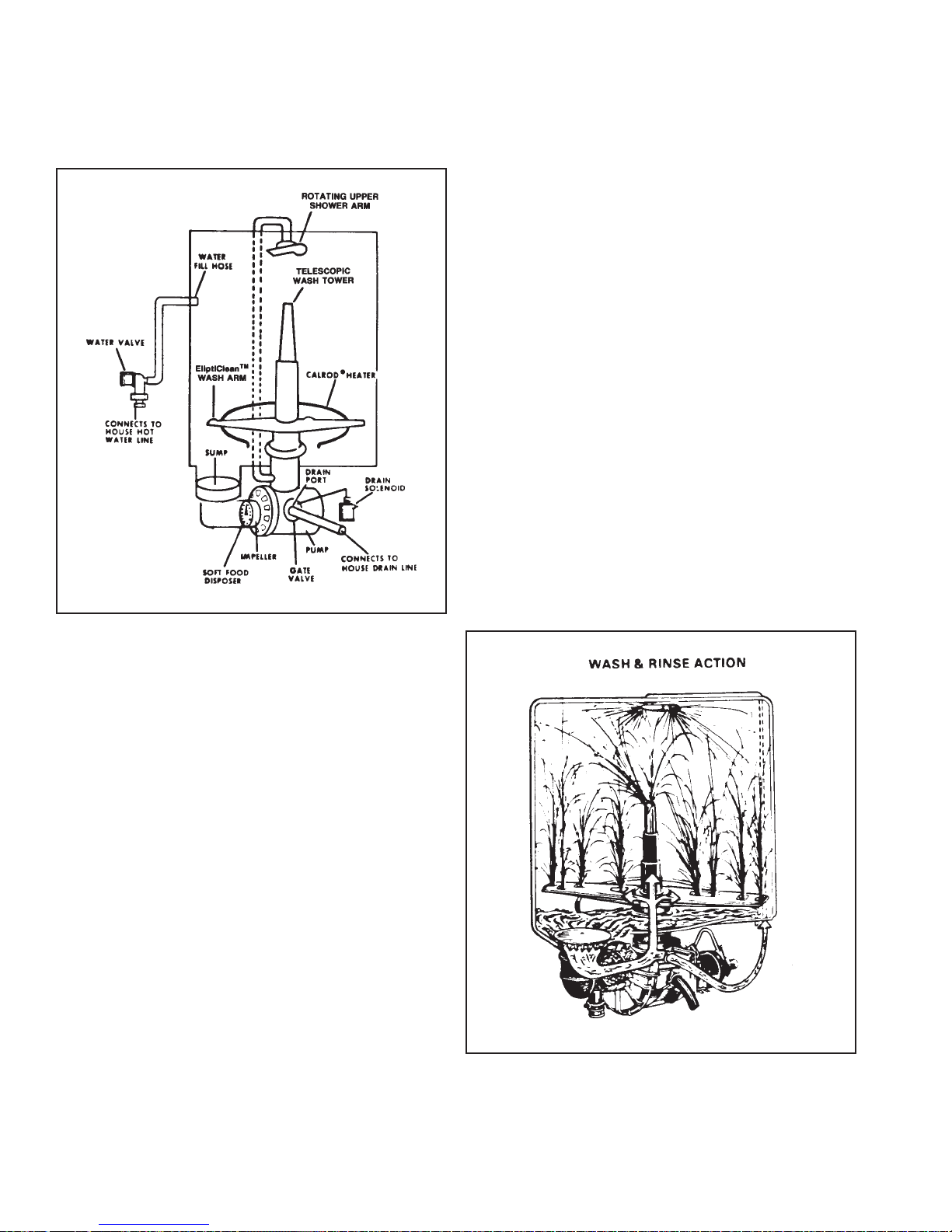

Basic Components

Illustration identifies the basic parts of the dishwasher.

Hot water supply connects to water valve which controls

flow through the water fill hose into side of tub.

When pump motor is energized, gate valve at the exit of

pump controls whether water is recirculated back into

tub (when drain solenoid is not energized) or out of drain

port (when drain solenoid is energized). Sump at bottom

of tub is connected to pump, so when pump motor is

energized water is either drained out or recirculated.

At entry to pump a

amounts of soft food which are pumped out of

dishwasher during drain periods. Soft food disposer

does not need to be cleaned by user.

Water recirculated into dishwasher tub goes up a hollow

tube connected to a rotating wash arm (sometimes

called spray arm) and telescoping wash tower. On some

models, a port off the pump housing channels water up

to enter the top of tub through the rotating upper shower

arm.

Calrod® sheathed heating unit is located at bottom of

tub.

Soft Food

disposer pulverizes small

Basic Functions

During normal wash cycle, dishwasher performs these

functions.

Fill with Hot Water

Enough water is necessary to enable good washing

action. Normal amount of water for a full fill is about 2.0

gallons. Some rinse fills are less.

Actual water level in dishwasher is controlled indirectly;

amount of water fill is determined by timer energizing

water valve solenoid for a specified length of time.

Water valve is designed to give a flow rate of 1.8

gallons per minute and is on for 1 minute. Fill would be

1.8 gallons under design conditions. Pump motor is

energized during the fill period.

Wash Action

Hot water is sprayed under pressure onto dishware. This

is accomplished by pumping water up a hollow tube

through tub bottom and into wash arm and three-section

telescoping wash tower fastened to wash arm.

These components rotate from 12 to 40 RPM. Wash

arm is powered by water jet at one end. Water sprayed

on dishware falls to the bottom of the tub and then goes

into sump and back to pump.

On some models there is a shower arm at top of tub. If

used, water comes out of port in pump housing through

a hose to upper shower arm. Water pressure rotates

upper shower arm at about 100 RPM.

RS3300002 Rev. 0 14 August 1997

Page 15

Operation

Action of wash system is exactly the same for washing

and rinsing periods except detergent is introduced

during wash period. A covered detergent cup is tripped

and detergent is dispensed during main wash period

(after fourth water fill in

First wash action period is usually called

Detergent can be used in the first wash period by filling

the open detergent cup. Detergent falls out into tub

when door is closed.

Drain

When drain solenoid is energized, water is pumped out

through drain hose into house plumbing. Pump motor

turns the same direction during wash and drain action,

but gate valve at exit of the pump is opened by drain

solenoid and recirculating opening in bottom center of

tub is closed.

Some water will always be visible in sump area at the

bottom of tub after drain to prevent pump water seal

from drying out.

Normal Wash

cycles).

Pre-wash

.

During heated dry, the calrod heater located in the

bottom of the tub is energized, unless

drying is selected.

For

Heated Dry

minutes.

For

Normal Dry

used in washing and rinsing starts the drying process.

However, it takes several hours for the dishes to

completely dry.

, the calrod heater is on for about 32

, the heat remaining from the hot water

Normal

no-heat

Dry

After last drain out during washing cycle, the pump

motor, which has run continuously until this point, is deenergized.

In convection drying systems, air enters tub at bottom of

door and, as it is warmed, rises and exits through vent

channel openings in top front of door. Vent opening is

closed during washing and rinsing.

August 1997 15 RS3300002 Rev. 0

Page 16

Operation

Inlet, Tub, and Thermostat Temperatures

Drawing shows locations where water temperature is

measured.

120°F inlet water temperature is, by definition, stabilized

temperature when hot water is run at a sink close to

dishwasher. The Use and Care Manual recommends a

candy thermometer to measure water temperature as it

runs into a glass.

120° Inlet Water Capability

Until 1983, most dishwashers required 140°F inlet water.

120°F capability means

1. saving energy by lowering water heater temperatures

to 120°F.

2. best possible washing job is accomplished when

water temperatures are above 120°F. Even if the

water heater is set for 140°F, actual inlet water

temperature is often less.

Water Temperature Boost

When hot water runs into dishwasher tub at room

temperature (normally 70°F), it cools down substantially

after the first fill because the water is sprayed on the

cold tub interior, racks, and dishware. During

subsequent fills tub is not as cool and water does not

cool down as much.

Highly featured models have

using calrod heater during wash periods. A timer is

used to extend wash period and heat water for a

specified time.

When calrod heater is on during wash or rinse, the water

temperature is raised about 0.6°F for each minute it is

on.

Water Temperature Boost

RS3300002 Rev. 0 16 August 1997

Page 17

Operating Instructions

OFF

RINSE

& HOLD

START

CDU220

HEATED DRY

NATURAL DRY

POWER

SAVER

Note:

Before operating dishwasher, read "Important Safety Instructions" section in User Maintenance Instructions.

1. Select

2. Turn knob to

HEATED DRY

Normal Wash

or

3. Latch door.

Cycle Sequence Water Used Cycle Time

NORMAL WASH

Use for average soiled items.

HEATED DRY

Use for fast drying.

NATURAL DRY

Use for no heat drying.

NATURAL DRY

.

Wash/Rinse, Rinse, Wash, Rinse,

Rinse, Rinse

.

(Gallons) (Minutes)

8.6 57

32

August 1997 17 RS3300002 Rev. 0

Page 18

Operating Instructions

POTS

NORMAL

& PANS

WASH

DRY/PLATE

WARMER

OFF

START

LIGHT

WASH

HEATED DRY

CDU300

POWER

SAVER

RINSE

& HOLD

NATURAL DRY

Note:

Before operating dishwasher, read "Important Safety Instructions" section in User Maintenance Instructions.

1. Push

2. Select

3. Select POTS & PANS or NORMAL WASH cycle by turning knob to

POTS & PANS

HEATED DRY

or

NORMAL WASH

or

NATURAL DRY

button, as desired.

.

START

.

or

Select LIGHT WASH, RINSE & HOLD or DRY/PLATE WARMER cycle by turning knob to appropriate setting.

4. Latch door.

Cycle Sequence Water Used Cycle Time

(Gallons) (Minutes)

POTS & PANS

Use for excessively soiled items.

NORMAL WASH

Use for average soiled items.

Wash/Rinse, Rinse, Rinse, Wash,

Rinse, Rinse, Rinse

Wash/Rinse, Rinse, Wash, Rinse,

Rinse, Rinse

10.3 96

8.6 96

LIGHT WASH

Use for lightly soiled items.

RINSE & HOLD

Use to prevent food from drying on

items.

DRY/PLATE WARMER

Use for drying and warming

HEATED DRY

Use for fast drying.

NATURAL DRY

Use for no heat drying.

RS3300002 Rev. 0 1 8 August 1997

Wash/Rinse, Rinse, Wash, Rinse,

Rinse

Rinse, Rinse

7.1 86

3.1 12

32

32

Page 19

Operating Instructions

WASH TEMP BOOST

ON OFF

DRY/PLATE

WARMER

OFF

START

SHORT

WASH

ADU3000

HOT DRY

RINSE & HOLD

COOL DRY

Note:

Before operating dishwasher, read "Important Safety Instructions" section in User Maintenance Instructions.

1. Push

2. Select

3. Select NORMAL WASH cycle by turning knob to

WASH TEMP BOOST ON

HOT DRY

or

COOL DRY

button, if desired.

.

START

.

or

Select SHORT WASH, RINSE & HOLD OR DRY/PLATE WARMER cycle by turning knob to appropriate

setting.

4. Latch door.

Cycle Sequence Water Used Cycle Time

(Gallons) (Minutes)

NORMAL WASH

Use for average soiled items.

SHORT WASH

Use for a quick cycle.

Wash/Rinse, Rinse, Wash, Rinse,

Rinse, Rinse

Wash/Rinse, Wash, Rinse, Rinse,

Rinse

8.6 63

7.0 53

RINSE & HOLD

Use to prevent food from drying on

Rinse, Rinse

4.3 12

items.

DRY/PLATE WARMER

Use for drying and warming

HEATED DRY

Use for fast drying.

32

32

NATURAL DRY

Use for no heat drying.

*

WASH TEMP BOOST

Increases water temperature for improved wash performance.

August 1997 19 RS3300002 Rev. 0

Page 20

Operating Instructions

POTS

& PANS

NORMAL

WASH

WATER TEMP BOOST

ON

OFF

WATER

HEAT

DRY/PLATE

WARMER

OFF

RINSE

& HOLD

START

ADU5000

SHORT

WASH

HEATED

DRYING

NATURAL

DRYING

Note:

Before operating dishwasher, read "Important Safety Instructions" section in User Maintenance Instructions.

1. Push

2. Select

3. Select POTS & PANS or NORMAL WASH cycle by pushing

WATER TEMP BOOST ON

HEATED DRYING

turning knob to

STAR T

button, if desired.

or

NATURAL DRYING

.

.

POTS & PANS

or

NORMAL WASH

or

Select SHORT WASH, RINSE & HOLD or DRY/PLATE WARMER cycle by turning knob to appropriate

setting.

4. Latch door.

Cycle Sequence Water Used Cycle Time

(Gallons) (Minutes)

POTS & PANS

Use for excessively soiled items.

NORMAL WASH

Use for average soiled items.

SHORT WASH

Use for a quick cycle.

RINSE & HOLD

Use to prevent food from drying on

items.

Wash/Rinse, Rinse, Rinse, Wash,

Rinse, Rinse, Rinse

Wash/Rinse, Rinse, Wash, Rinse,

Rinse, Rinse

Wash/Rinse, Wash, Rinse, Rinse,

Rinse

Rinse, Rinse

10.2 63

8.8 63

7.0 63

4.3 12

button then

DRY/PLATE WARMER

Use for drying and warming.

HEATED DRY

Use for fast drying.

NATURAL DRY

Use for no heat drying.

*WATER TEMP BOOST increases water temperature for improved wash performance.

RS3300002 Rev. 0 2 0 August 1997

32

32

Page 21

Operating Instructions

ADU6000

POTS

& PANS

HEAVY

WASH

NORMAL

WASH

LIGHT

WASH

WATER TEMP

BOOST

RESET

HEATED

DRYING

CLEAR/

CANCEL

WATER

HEAT

START

DELAY

HRS TO START

OFF

DRY/PLATE

WARMER

5

3

RINSE

& HOLD

1

START

SHORT

WASH

Note:

Before operating dishwasher, read "Important Safety Instructions" section in User Maintenance Instructions.

1. Push

2. Push

WATER TEMP BOOST

HEATED DRYING

button, if desired.

button, if desired.

3. If START DELAY is desired, turn knob clockwise to desired delay time.

4. If START DELAY is not desired, do one of the following:

• Select POTS & PANS, HEAVY WASH, NORMAL WASH or LIGHT WASH cycle by pushing

PANS, HEAVY WASH, NORMAL WASH

or

LIGHT WASH

button then turning knob to

START

POTS &

.

• Select SHORT WASH, RINSE & HOLD or DRY/PLATE WARMER cycle by turning knob to appropriate

setting.

5. Latch door.

Cycle Sequence Water Used Cycle Time

POTS & PANS

Use for excessively soiled items.

HEAVY WASH

Use for heavily soiled items.

NORMAL WASH

Use for average soiled items.

SHORT WASH

Use for a quick cycle.

LIGHT WASH

Use for lightly soiled items.

RINSE & HOLD

Use to prevent food from drying on

items.

DRY/PLATE WARMER

Use for drying and warming

HEATED DRY

Use for fast drying.

Wash/Rinse, Rinse, Rinse, Wash,

Rinse, Rinse, Rinse

Wash/Rinse, Rinse, Rinse, Wash,

Rinse, Rinse, Rinse

Wash/Rinse, Rinse, Wash, Rinse,

Rinse, Rinse

Wash/Rinse, Wash, Rinse, Rinse,

Rinse

Wash/Rinse, Rinse, Wash, Rinse,

Rinse

Rinse, Rinse

(Gallons) (Minutes)

9.9 63

9.9 63

8.4 63

6.9 55

7.7 63

3 9

32

32

CLEAR/CANCEL

Use for no heat drying.

August 1997 21 RS3300002 Rev. 0

Page 22

Operating Instructions

ADU7000

POTS

& PANS

HEAVY

WASH

NORMAL

WASH

LIGHT

WASH

CHINA

CRYSTAL

RINSE

WATER TEMP BOOST

& HOLD

ON OFF

HEATED

DRYING

NATURAL

DRYING

WATER

HEAT

START

DELAY

DRY/PLATE

WARMER

HRS TO START

5

7

9

OFF

START

1

3

Note:

Before operating dishwasher, read "Important Safety Instructions" section in User Maintenance Instructions.

1. Push

2. Select

WATER TEMP BOOST ON

HEATED DRYING

or

NATURAL DRYING

or

OFF

button as desired.

as desired.

3. If START DELAY is desired, turn knob clockwise to desired delay time.

4. If START DELAY is not desired, do one of the following:

• Select POTS & PANS, HEAVY WASH, NORMAL WASH, LIGHT WASH, CHINA/CRYSTAL or RINSE

& HOLD cycle by pushing

CRYSTAL

or

RINSE & HOLD

POTS & PANS, HEAVY WASH, NORMAL WASH, LIGHT WASH, CHINA/

button then turning knob to

START

.

• Select SHORT WASH, RINSing or DRY/PLATE WARMER cycle by turning knob to appropriate

setting.

5. Latch door.

SHORT

WASH

Cycle Sequence Water Used Cycle Time

POTS & PANS

Use for excessively soiled items.

HEAVY WASH

Use for heavily soiled items.

NORMAL WASH

Use for average soiled items.

SHORT WASH

Use for a quick cycle.

LIGHT WASH

Use for lightly soiled items.

CHINA/CRYSTAL

Use for delicate items.

RINSE & HOLD

Use to prevent food from drying on

items.

DRY/PLATE WARMER

Use for drying and warming

Wash/Rinse, Rinse, Rinse, Wash,

Rinse, Rinse, Rinse

Wash/Rinse, Rinse, Rinse, Wash,

Rinse, Rinse, Rinse

Wash/Rinse, Rinse, Wash, Rinse,

Rinse, Rinse

Wash/Rinse, Wash, Rinse, Rinse,

Rinse

Wash/Rinse, Rinse, Wash, Rinse,

Rinse

Wash/Rinse, Rinse, Wash, Rinse,

Rinse

Rinse, Rinse

(Gallons) (Minutes)

9.9 63

9.9 63

8.4 63

6.9 55

7.7 63

7.3 63

3 9

32

HEATED DRYING

Use for fast drying.

NATURAL DRYING

Use for no heat drying.

*WATER TEMP BOOST increases water temperature for improved wash performance.

RS3300002 Rev. 0 2 2 August 1997

32

Page 23

Service Information

Water Valve and Inlet System

Fill hose runs up left side of tub and is fastened by a

clamp to fill funnel. Plastic tub has plastic fill funnel

vibration-welded to the plastic tub. Plastic tub is not a

replacement part.

A special insulator block is snapped over two water

valve solenoid coil terminals. This block is anchored to

the bracket to prevent harness leads from being pulled

off solenoid terminals during installation.

Disassembly

1. Remove two screws mounting water valve to left

front frame.

2. To remove insulator block, unlatch two plastic tangs;

one at front and one at harness end of block.

• Solenoid De-energized: Plunger closes center hole in

diaphragm. Water through bleeder hole causes

pressure in plunger guide to push down diaphragm

and close valve.

Note: Water valve solenoid is controlled by switch

contacts in timer, not by float switch.

With a full water fill, water level in tub bottom should be

3/8 inch to 1 inch above the pedestal in bottom of tub.

Valve in Closed Plunger Raised to

Position Open Pilot Hole

Water in Valve

Guide Escapes

Fill Funnel is Welded to Plastic Tub

Water Valve Operation

A hose connects to the outlet of the water valve and

runs to a water inlet in the side of the tub. All inlets have

an air break. Water valve operation is shown in

drawings.

• Closed Position: Plunger closes center hole in

diaphragm. Bleeder hose lets water pressure equalize

in plunger housing.

• Solenoid Energized, Plunger Raised: Water flows out

of plunger housing.

• Water Flow: Water line pressure pushes diaphragm

up allowing water flow past diaphragm. Flow washer

controls amount of water flow at 15 to 175 P.S.I. to

constant 1.80 gallons/minute.

Incoming Water Plunger Drops Pressure Lifts Closes Pilot Hole

Diaphragm - Pressure in Valve

Valve Opens Guide Closes Valve

All water valves may be replaced as complete

assemblies. Screen and washer gasket for water line

connections are available in replacement kit.

Open solenoid coils and clogged or restricted screens

are the most common faults.

August 1997 23 RS3300002 Rev. 0

Page 24

Service Information

g

Chart shown below outlines plumbing corrections that

are recommended to reduce or eliminate water valve

noise.

POSSIBLE CA USE REPAIR

1. Drain air gap restricted. Clean air gap.

2. Kink in drain hose. Replace or reposition hose.

3. Disposer stopped up.

(Some installations don’t

have a drain air gap. Instead

dishwasher drains directly

into disp o se r.)

4. Pump gate valve did not

return after normal pump

out.

5. Drain sensor switch closed

or shorted.

6. Drain solenoid plunger stuck

down.

7. Food soil in filer chamber. Remove filter screen and check

8. Check valve in filter

chamber not sealin

9. Pump inlet partially clogged. Clean inlet sump.

.

Float Switch

The flood, or float, switch protects against overflow.

Switch itself is captured in a plastic housing mounted

underneath tub bottom by a torx-head screw. Housing

cover snaps into place holding switch in correct position.

Housing also serves as an insulator over switch

terminals.

Stem from float inside tub holds switch arm down in

closed position during normal operation. Float is

covered by a plastic domed cover at front left corner of

tub. When water rises above a certain level in tub, float

switch stem rises and switch contacts open to

disconnect power to water valve solenoid.

Float switch will not furnish flood protection if water

valve mechanically sticks in open position. It will furnish

flood protection if timer stalls during fill period or if

switch contacts in timer freeze closed.

Run the disposer to clean it out.

Clean out dishwasher port.

Replace motor pump

mechanism.

Replace switch.

Replace solenoid.

valv e assem bly in filter

chamber. Clean if required.

Swollen or distorted. Check

leakage around threads.

Disassembly

1. Float switch can only be accessed from under tub.

2. Open snap cover on housing to remove switch.

Recalibration

1. Hold scale or rule against bottom of switch bracket

and center of large hole in bracket.

2. Press switch arm down until switch trips.

3. Read the dimension on the scale or rule at the point

where switch trips. It should measure between 5/8

and 3/4 inch.

4. If adjustment is necessary, bend switch arm at point

between stiffening rib and button on switch.

RS3300002 Rev. 0 2 4 August 1997

Page 25

Service Information

!

Motor/Pump Mechanism and Boots

Pump mechanism is supported by wire hangers from

metal plate under dishwasher tub.

Notice flexible plastic heat shield clipped into slots in

metal plate under tub. Heat shield prevents some hot air

from motor from blowing onto the electrical junction box

so temperature does not rise above acceptable limits.

Because of the limited work space under tub, it is

recommended dishwasher be pulled and tipped back to

replace the pump mechanism.

Pump connector boot and sump boot are the same part

and mount the same on all models.

Drain solenoid bracket is very heavy gauge to lessen

chance of bracket being bent causing drain solenoid

problems

All models use same pump mechanism. ADU7000

model has an induction motor; disassembly procedures

are the same.

Snap insulator covers used on motor leads and drain

solenoid terminals.

A plastic insulator block covers the harness lead

terminals to the drain solenoid. Insulator block is

anchored to solenoid to prevent pulling leads off during

installation. Block is held together by two tangs, one on

top and one at the harness end of block.

Two plastic insulator cylinders are used over the

connector terminals on the black wire motor leads to

capture terminals and prevent them from being pulled

apart from harness leads. Limited vertical space can

make removal of insulator cylinders difficult.

Motor/Pump Mechanism Check

If motor hums but does not pump, the cause may

mechanical lockup or frozen bearings, check:

1. Remove power. Try to turn fan blade clockwise to

determine if seal is stuck and can be broken loose. If

motor shaft cannot be turned, cutter blade may be

blocked. Proceed to step 2.

2. On inside of dishwasher, remove sump cover.

Remove grid and reach down into sump. Check for

blockages such as bones, wire ties, glass or

toothpicks. Check “pocket” on left side of sump; if it

contains debris, clean thoroughly. If motor shaft still

cannot be turned, replace motor/pump mechanism.

Motor/Pump Removal

1. Remove sump cover and grid. With sponge or

syringe, remove all water from sump.

2. Remove harness leads to motor.

3. Hose clamps fasten the sump boot and spray arm

boot to the pump housing. Remove two 5/16" bolts

from hose clamps. Find and loosen 5/16" bolt

holding sump boot spring clamp. Loosen clamp from

spray arm connector boot.

4. Disconnect drain hose and rotating upper shower

arm hose.

5. Remove hanger that holds motor to tub.

6. Motor/pump mechanism can now be removed from

under dishwasher. Some water will probably still be

present in hoses or pump; protect floor and other

areas if necessary to prevent damage.

WARNING

Power must be disconnected before attempting to

measure electrical resistance.

Turn dishwasher on and attempt to run motor.

If motor does not run, and does not hum, check:

1. House fuse or circuit breaker.

2. Door switch.

3. Timer plug and harness connections at timer. Be

sure terminals are fully seated.

4. Disconnect harness plug to motor leads. Check for

120 VAC.

5. After removing power, check motor winding

continuity on RX1 scale.

August 1997 25 RS3300002 Rev. 0

Page 26

Service Information

Motor/Pump Replacement Parts

The entire mechanism, including drain solenoid and

associated parts, is available as a replacement part. In

addition, these repair parts are furnished:

Drain Solenoid and associated parts—cutter, grader,

seal impeller kit, slinger, pump housing, lip seal kit

(diverter valve shaft).

The diverter (or gate) valve inside the housing is not

replaceable.

Reassembly

If mechanism is replaced with dishwasher in place,

follow seven steps below in sequence. Following these

steps should give the most reliable results because the

mechanism can be moved around somewhat to

correctly position the two bolts and clamps.

1. Connect spray arm boot, clamp screw at left, head to

front.

2. Connect sump boot, clamp screw at bottom, head to

left.

3. Install motor hangers.

4. Connect power shower hose (if used).

5. Connect drain hose.

6. Replace wiring and insulator blocks.

7. Check for water leaks.

2. Remove pump impeller. Hold motor fan blades and

turn impeller with pliers.

3. Remove seal from impeller. Seal presses in place by

hand. Seal seat remains in place in housing.

Disassemble housing from motor to remove and

replace seal seat.

4. The plastic slinger on the motor shaft must be

replaced if slinger bulges out due to rust buildup on

shaft. If slinger is not replaced, it can contribute to

new seal leaking.

When reassembling housing, it is recommended

centering sleeve be used to center motor shaft

inside seal set in the housing. If centering sleeve is

not used, be very careful to visually center motor

shaft in seal seat when housing mounting screws are

tightened.

5. Seal kit is furnished for replacing the water seal on

diverter valve shaft where it enters pump housing.

Seal washer, stainless steel washer, and retaining

ring are included in kit.

Soft Food Disposer

A spring cutter is used on the soft food disposer

mechanism. A spring cutter is included in the cutter,

grader, seal, impeller kit.

Disassembly

1. Spring cutter: Remove grader nut, using flat-blade

screwdriver or similar tool. Lift grader over spring

cutter, and remove wear ring base and wear ring.

These parts are shown in the illustration.

If smaller seeds or other foreign objects get caught

between the wear ring and impeller, they can jam

pump. The wear ring floats with the impeller and

maintains water pressure around the circumference.

To remove the spring cutter, grasp the bottom edge

of the spring with a long-nose pliers and turn

counterclockwise.

RS3300002 Rev. 0 2 6 August 1997

Page 27

Service Information

!

Drain Solenoid

WARNING

Power must be disconnected before attempting to

measure electrical resistance.

1. Check continuity of solenoid coil on low ohm scale.

2. Check armature for binding. The armature should

bottom before the gate is completely closed.

Mounting plate must not be bent.

3. When replacing solenoid coil, both springs

in place.

must

be

Spray Arm

Spray arm speed should be between 12 and 35 RPM.

1. Spray arm must rotate freely. If it binds, remove

tower (right hand threads).

2. Lift out tower assembly.

3. Inspect spray arm for seeds, bits of china, etc., that

may clog holes—also check for slits or cracks along

sides of arm.

4. Spray arm hub and entire spray arm assembly is

removed and replaced as an assembly. Reverse to

reassemble.

Racks

The lower rack rollers are the same on all models.

Two slight depressions have been molded into inner

door liner to avoid roll in of lower rack when pulled out

for unloading. The two front rollers rest in these

depressions when lower rack is fully pulled out.

To remove upper rack, remove plastic retainer caps on

the ends of the slides. The retainer cap can be removed

with a flat blade screwdriver, by prying back the member

that fits into slide and then pivoting retainer cap inward.

Assemble cap in reverse order.

Rotating Upper Shower Arm

This option is not used on all models.

Hose to rotating upper shower arm connects to port in

pump housing supplying water during wash and rinse

periods. If upper shower arm is not used, a rubber cap is

clamped over this port on pump housing.

Nozzle is a single plastic part which snaps into power

shower spray arm. Studs on nozzle are inserted into top

of the tub (from inside of tub). Metal palnut fasteners

are then driven onto studs to secure plastic nozzle plate

to top of tub.

August 1997 27 RS3300002 Rev. 0

Page 28

Service Information

Filter System

Drawing shows filter system in operation during wash

action. Wash water splashes against and runs down

back of tub. Eventually all wash water does this during

wash period.

Soil-laden wash water flows through inlet into screened

off area at bottom rear of tub. This water must flow

through fine mesh screen filter to go back into tub sump

for recirculation.

Filter check valve is spring-loaded to be open and allow

heavy soil particles to go down into soil collection

chamber where they are trapped during wash action.

Back flow valve inside tub under filter screen is held

closed by being mechanically coupled to spring-loaded

filter check valve.

Jet in bottom of spray arm constantly sprays water on

filter screen to clean.

Drain Action

During pump out period, drain water flows through soil

collection chamber to flush out debris.

Water flow pressure pushes up filter check valve to seal

opening from pump; flows through the soil collection

chamber; then flows out to check valve mounted under

front of tub. External drain line is connected to

dishwasher at check valve. This check valve is mounted

with Torx-head screws.

Normally closed drain check valve is opened by water

pressure during pump out.

Note: If drain line is not 18 inches above floor level,

pressure of water in tub will cause drain check

valve to open and wash water will drain into

drain hose during wash action.

Filter and Drain

1. Remove filter screen. Check piston valve for

jamming by toothpick or other object. Remove valve

and check spring and rubber parts.

2. Check routing of hose system for kinks.

3. Drain line check valve must pass water in drain line

direction only. Check for partially blocked drain line.

Calrod Heater

Heater is mounted by nuts under the tub to legs or

braces so heater sheath does not come into contact with

tub.

Sump Cover and Baffle Grid

Remove two screws hold sump cover and lift baffle grid

out.

With sump cover and grid removed from inside tub,

reach down into the sump boot and feel soft food cutter

and grader screen at pump inlet. Remove foreign

objects that block grader.

RS3300002 Rev. 0 2 8 August 1997

Page 29

Service Information

Tub Corner Baffles

Two black baffles are used at front lower corners of tub.

Use waterproof rubber cement on surface contacting tub

and press baffles in place during installation.

Door Gasket Replacement

It is not necessary to remove door liner from dishwasher

to replace gasket. To replace gasket, proceed as

follows:

1. Open door and pull old gasket straight up and out of

retainer slot, beginning at one end located at bottom

of door liner. No clip or cement is used to hold

gasket in place.

2. Position one end of new gasket about one inch from

center line at bottom of door liner. Start pressing

new gasket into slot at side of door liner near

bottom.

3. Press gasket firmly into slot completely around two

sides and top of door liner. (Liquid soap or silicone

spray may be used to make this easier to do.)

4. Carefully bend gasket around lower corners of liner

and press remaining two ends of gasket into slot

along bottom edge of door liner.

5. There should be a one to two inch-gap between ends

of gasket along bottom of liner.

Detergent Cup Cover And Latch

The detergent cup is molded as part of inner door panel.

A cam on timer trips cup cover and rinse agent injector.

To remove detergent cup cover and handle shaft, push

in fingers at end of shaft with a 1/4 inch socket.

To access detergent cup trip lever and spring, remove

timer.

To replace detergent cup handle shaft and covers,

follow steps below:

1. Position latch spring on shaft hub as shown below.

Wind spring counterclockwise to hook end on

installation pin.

2. Position shaft and cup with handle pointing up (cover

open).

3. Position latch on handle shaft as shown below, then

press onto shaft until fingers snap in place.

4. Turn latch counterclockwise to position end of spring

onto latch tang.

Door Components

Remove screw under door latch. Close latch halfway.

Then door components are accessible by removing

three screws from each side of inner door and one

screw at the top near latch. Carefully separate inner

door panel from outer door panel and drop outer door.

Rinse Agent Injector

Rinse agent injector can easily be removed as follows:

1. Remove power lower assembly (left hand threads).

2. Using top end of center section, press fingers of

rinse agent injector inward while pulling injector off

door.

3. In reassembling, simply snap in place.

August 1997 29 RS3300002 Rev. 0

Page 30

Service Information

Drying Vent

The grid and baffle are welded together for a one-piece

assembly, mounted by two screws.

Inner door flange above vent is flame treated to keep

water beads from forming. Top inside surface of tub is

similarly treated.

During wash and dry it is normal to see water vapor

coming through vent.

During wash and rinse periods, vent opening in inner

door is sealed off by water splashing up into grooves in

vent assembly as shown in illustration below. At

beginning of dry cycle, when wash action stops, water in

these grooves drains off opening vent during dry.

Push Button Switches

Switch contacts are opened or closed when a specific

push button cycle selection is pressed in. Together with

switches in timer control, push button switches set up

specific electrical circuits for cycle selected.

For the push button switch, the switch contacts remain

closed or open throughout the cycle; the timer switch

contacts open and close as the timer cam turns through

360 degrees.

Control Panel Assembly

Remove cover by lifting tab at each end.

RS3300002 Rev. 0 3 0 August 1997

Page 31

Service Information

!

!

WARNING

Power must be disconnected before attempting to

measure electrical resistance.

Servicing Push Button Switch

1. Remove switch bracket assembly by prying open

tabs and sliding assembly back.

2. Pull off buttons to replace switches. Buttons are not

all put on in same position. Note position of each

button for reassembly.

Switch Contact Chart

A chart titled “Switch” is included with timer cam chart

and schematic wiring diagram in all mini-manuals. This

chart tells which switch contacts are open and closed

when each of the push buttons is depressed. For

example, when

5-6, 9-10, and 17-16 are closed. Each contact is

designated by a number, as opposed to a number and a

letter for timer switches.

NORMAL

is selected, switch contacts

Push Button Switch Test

WARNING

Power must be disconnected before attempting to

measure electrical resistance.

1. Remove power from dishwasher.

2. Remove all wire leads from switch terminals before

making check.

3. Press cycles indicated on pushbutton switch chart,

and check continuity of switch terminals as

indicated.

August 1997 31 RS3300002 Rev. 0

Page 32

Service Information

!

!

Snap On Electrical Components Cover

CAUTION

Always replace snap on electrical component

covers after service is completed.

Remove two screws at top of door. Disconnect plug and

snap off cover.

Timer

Timer mounting plate is fastened with two screws at top,

and two tabs at bottom.

The harness connector block plugs into timer. Two

harness connectors are used on models with rapid

advance timer.

With timer removed, detergent cup trip lever, spring,

timer trip cam and timer knob are accessible.

CAUTION

To prevent breaking knob, do not pry knob out

from front side of escutcheon.

Latch Interlock Switches

Two interlock switches are used and snap in place.

Assemble with flat end of coil spring pointing to left as

shown.

On some models, timer knob is captured in plastic

escutcheon by two tabs on knob. To remove knob, press

in on tabs.

Timer Testing

Close door and press

dishwasher.

1. Check advance of timer. If it doesn’t advance,

remove power and check continuity of timer drive

motor. If tests positive, restore power and check for

voltage at timer motor.

2. Turn control dial slowly through cycle, using coin in

slot of indicator dial. Listen for operation of water

valve, drain solenoid and detergent cup.

3. If any component fails to operate, remove power

from dishwasher and check continuity of component.

If tests positive, restore power and check for voltage

to component from timer control.

NORMAL WASH

button, to start

RS3300002 Rev. 0 3 2 August 1997

Page 33

Service Information

!

!

Door Latch

Door latch mechanism fits onto rear of inner door panel

and is replaceable as an assembly.

Mechanism can be left in place, and can be latched to

hold inner door panel in place while outer door panel

and escutcheon assembly is lowered to open position.

Dishwasher can then be operated with water by

manually closing door interlock switch contacts.

Door interlock switches mounted to back of control

panel escutcheon are closed when door latch is

closed—handle moved all the way to right.

Strike Adjust

Latch strike may be adjusted by loosening two mounting

screws and sliding strike toward rear of tub to increase

latching force and reduce the possibility of leaks around

door gasket. If latch closes too hard—slide strike out

slightly.

Harness leads go directly from timer connector plug or

push button switch terminals to components.

Testing

Check voltage at a component (such as water valve or a

pump motor) before replacing as being inoperative.

If no voltage at component, suspect harness connector

block as possible cause. Check for

• Terminal not secured in block.

• Connect plug halves not pushed together tightly.

• Arcing or burning at terminal.

Use ohmmeter to check for continuity through terminals in

circuit or use a voltmeter to check for voltage on one side

of block but not on other side.

Repair

Complete harnesses for dishwashers are not supplied as

replacement parts.

Use a wire crimper tool to securely fasten new terminals

onto wiring harness leads.

Aluminum T rim Panel

This trim is held onto plastic escutcheon by tabs which

are bent over. To remove, straighten tabs.

Wiring Harness and Connector Plug

WARNING

To avoid an open circuit by damaging or crimping

wires, do not pull on terminal block wires when

removing block from timer.

CAUTION

Disconnect power cord and close water supply

valve before servicing dishwasher. Never energize

electrical power to dishwasher with any panels

removed.

To insure dishwasher is properly grounded, always

replace any ground wires removed during

servicing.

Timer connector plug on wiring harness is covered in

timer section. Always check terminals are securely in

place in this plug when timer problem is suspected.

August 1997 33 RS3300002 Rev. 0

Page 34

Schematic Diagrams

RS3300002 Rev. 0 34 August 1997

ADU3000

Page 35

Schematic Diagrams

August 1997 35 RS3300002 Rev.0

ADU3000

Page 36

Schematic Diagrams

RS3300002 Rev. 0 36 August 1997

ADU5000

Page 37

Schematic Diagrams

August 1997 37 RS3300002 Rev.0

ADU5000

Page 38

Schematic Diagrams

RS3300002 Rev. 0 38 August 1997

ADU6000

Page 39

Schematic Diagrams

August 1997 39 RS3300002 Rev.0

ADU6000

Page 40

Schematic Diagrams

RS3300002 Rev. 0 40 August 1997

ADU7000

Page 41

Schematic Diagrams

August 1997 41 RS3300002 Rev.0

ADU7000

Page 42

Schematic Diagrams

RS3300002 Rev. 0 42 August 1997

CDU220

Page 43

Schematic Diagrams

August 1997 43 RS3300002 Rev.0

CDU220

Page 44

Schematic Diagrams

RS3300002 Rev. 0 44 August 1997

CDU300

Page 45

Schematic Diagrams

August 1997 45 RS3300002 Rev.0

CDU300

Loading...

Loading...