Page 1

Training Manual

.6 − 50 Hz Compact Models

HDC−5 _ 50 Hz R2

MENUMASTER

C O M M E R C I A L M I C R O W A V E O V E N

R

June 2007

www.amanacommercial.com

1

Page 2

Model Number List

DEC11E..........(P1325203M)

(P1330512M)

DEC11E2........(P1331213M)

(P1331235M)

DEC14E..........(P1325207M)

(P1330516M)

DEC14E2........(P1331217M)

(P1331239M)

DEC18E..........(P1325211M)

(P1330520M)

DEC18E2........(P1331221M)

(P1331243M)

HDC511..........(P1325201M)

(P1330510M)

HDC511A .......(P1325213M)

HDC5112........(P1331211M)

MCHDC521 ....(P1331246M)

(P1331225M)

UC11E............(P1325204M)

(P1330513M)

UC11E2..........(P1331214M)

(P1331236M)

UC14E............(P1325208M)

(P1330517M)

UC14E2..........(P1331214M)

(P1331240M)

UC18E............(P1325212M)

(P1330517M)

UC18E2..........(P1331222M)

(P1331244M)

UHDC511 .......(P1325202M)

(P1330511M)

(P1331233M)

HDC514..........(P1325205M)

(P1330514M)

HDC514A .......(P1325214M)

HDC5142........(P1331215M)

(P1331237M)

HDC518..........(P1325209M)

(P1330518M)

HDC518A .......(P1325215M)

HDC5182........(P1331219M)

(P1331241M)

HDC5212........(P1331224M)

(P1331245M)

UHDC5112 .....(P1331212M)

(P1331234M)

UHDC514 .......(P1325206M)

(P1330515M)

UHDC5142 .....(P1331216M)

(P1331238M)

UHDC518 .......(P1325210M)

(P1330519M)

UHDC5182 .....(P1331220M)

(P1331242M)

CDEC14E2.....(P1331251M)

CDEC18E2 (P1331252M)

CDEC21E2.....(P1331253M)

CHDC5142 (P1331248M)

CHDC5182 (P1331249M)

CHDC5212 (P1331250M)

2

Page 3

Table of Contents

Model Number List...............................................................................................................2

Table of Contents.................................................................................................................3

Specifications.......................................................................................................................4

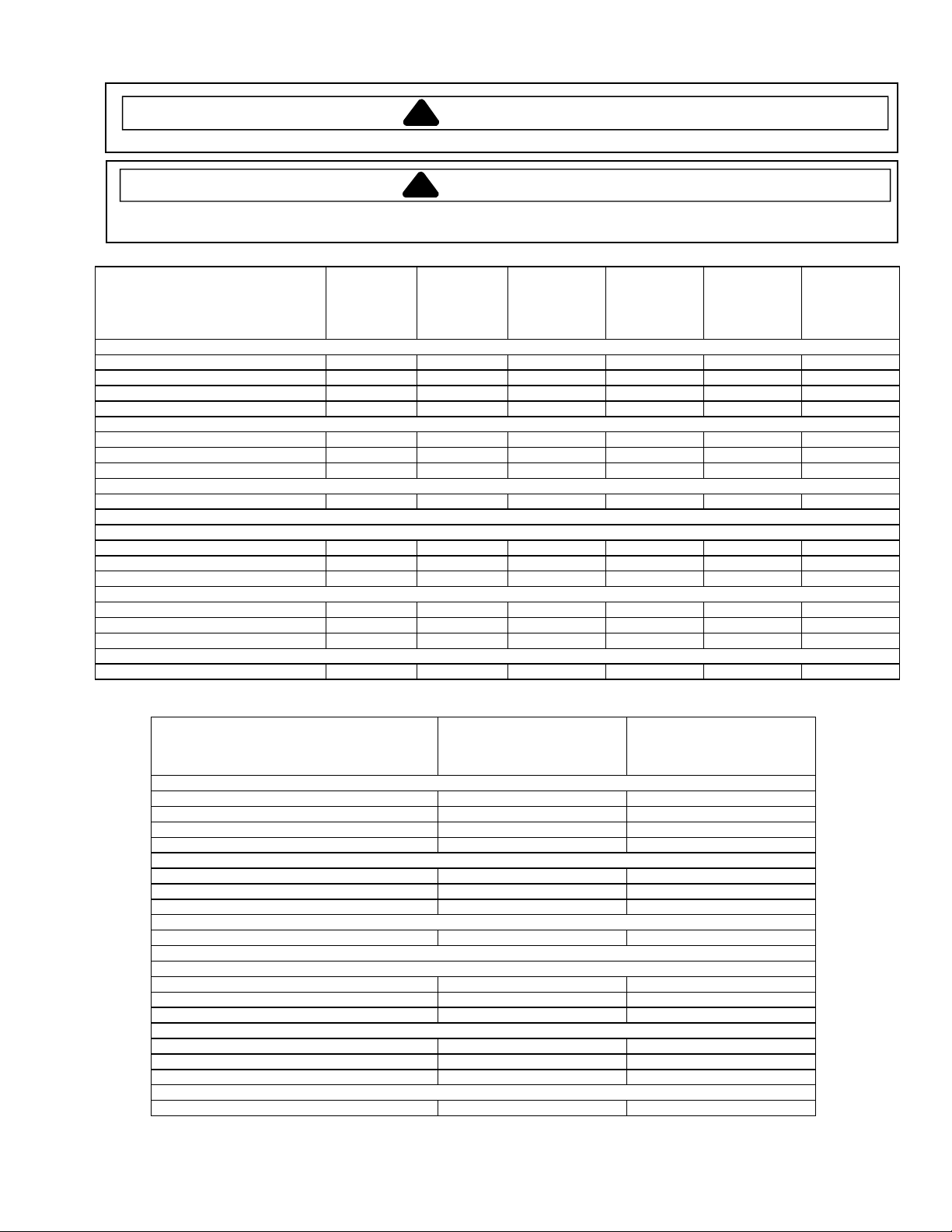

Quick Start Reference Guide...............................................................................................5

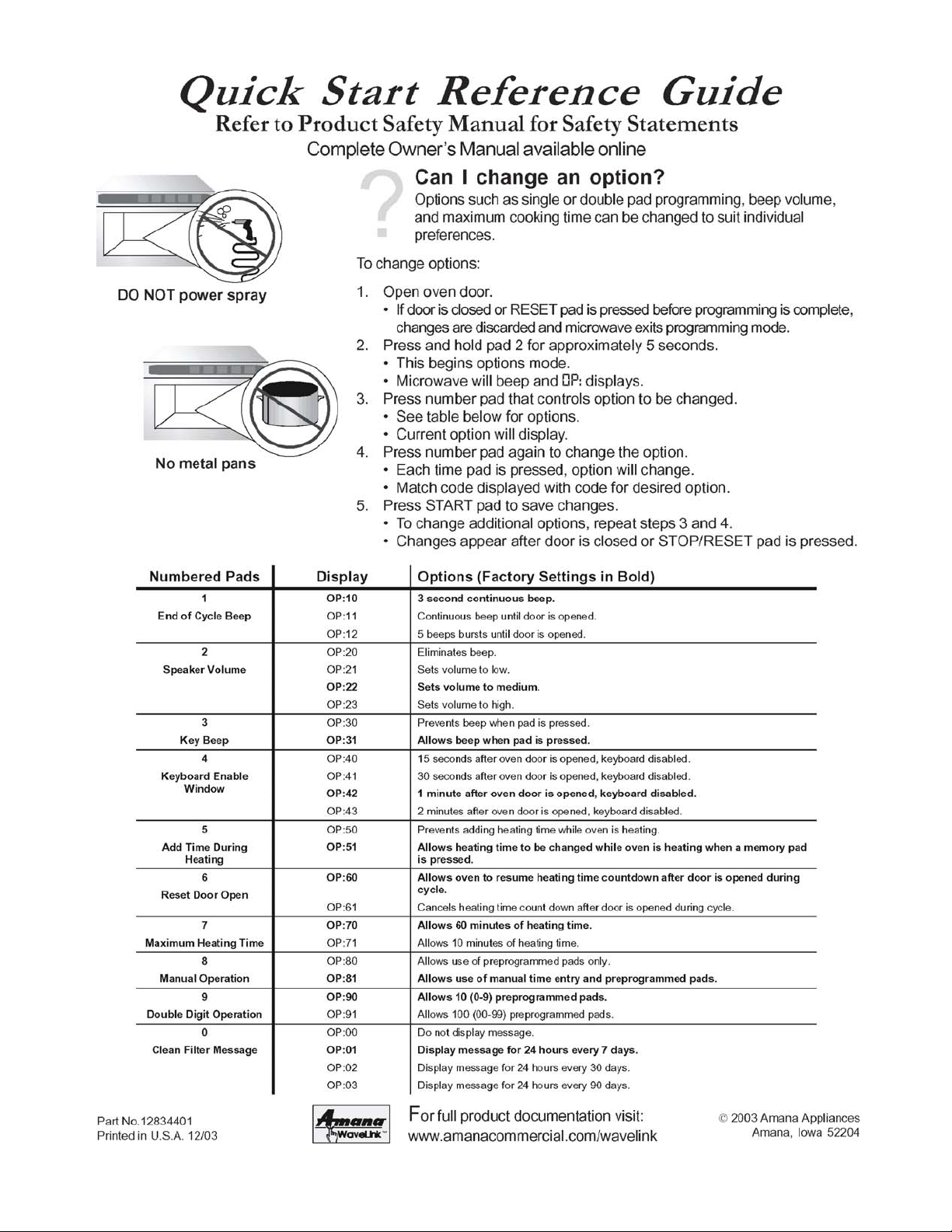

Inner Door/Window Removal...............................................................................................7

Technical Bulletin CR-236-B - Broken Tray........................................................................8

Air Flow.................................................................................................................................9

Improved Filter for .6 Compact Ovens..............................................................................10

Interlock Switches..............................................................................................................11

Switch Replacement / Door Adjustment...........................................................................12

Touch Panel and Control Board........................................................................................13

Disassembly ............................................................................................................... 14 – 16

Component Specifications........................................................................................ 17 – 19

Power Testing Procedure.................................................................................................. 20

Isolation Test – Two Magnetron Models...........................................................................21

Wiring and Schematic Diagrams................................................................................22 - 25

3

Page 4

CAUTION

!

All safety information must be followed as provided in Service Manual RS5320013.

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor before servicing, unless testing requires power.

Models

UHDC511*

UC11E*

Power Source

Voltage AC 230 VAC 230 VAC 230 VAC 230 VAC 230 VAC 230 VAC

Amperage (single unit) 13 A 13 A 13 A 13 A 13 A 13 A

Frequency 50 Hz 50 Hz 50 Hz 50 Hz 50 Hz 50 Hz

Single phase, 3 wire earthed X X X X X X

Power Output

Nominal microwave energy (IEC705) 1100 Watts 1100 Watts 1400 Watts 1400 Watts 1800 Watts 1800 Watts

Minimum temperature rise (∆T) 11º F / 5.5º C 11º F / 5.5º C 14º F / 7.5º C 14º F / 7.5º C 18º F / 10º C 18º F / 10º C

Operating frequency 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz

Power Consumption

Cook condition microwave 1800 W / 8 A 1800 W / 8 A 2300 W / 10 A 2300 W / 10 A 3000 W / 13 A 3000 W / 13 A

Dimensions

Cabinet

Width 423 mm 423 mm 423 mm 423 mm 423 mm 423 mm

Height 335 mm 335 mm 335 mm 335 mm 335 mm 335 mm

Depth 548 mm 548 mm 578 mm 578 mm 578 mm 578 mm

Oven Interior

Width 331 mm 331 mm 331 mm 331 mm 331 mm 331 mm

Height 175 mm 175 mm 175 mm 175 mm 175 mm 175 mm

Depth 305 mm 305 mm 305 mm 305 mm 305 mm 305 mm

Weight

Crated 29 kg 29 kg 31 kg 31 kg 31 kg 31 kg

HDC511*

HDC511A

DEC11E*

UHDC514*

UC14E*

HDC514*

HDC514A

DEC14E*

CHDC514

CDEC14E2

UHDC518*

UC18E*

HDC518*

HDC518A

DEC18E*

CHDC518

CDEC18E2

DEC21E2

Models MCHDC521

Power Source

Voltage AC 230 VAC 230 VAC

Amperage (single unit) 16 A 32 A

Frequency 50 Hz 50 Hz

Single phase, 3 wire earthed X X

Power Output

Nominal microwave energy (IEC705) 2100 Watts 2100 Watts

Minimum temperature rise (∆T) 21º F / 11.5º C 21º F / 11.5º C

Operating frequency 2450 MHz 2450 MHz

Power Consumption

Cook condition microwave 3100 Watts / 13.5 A 3100 Watts / 13.5 A

Dimensions

Cabinet

Width 423 mm 423 mm

Height 335 mm 335 mm

Depth 578 mm 578 mm

Oven Interior

Width 331 mm 331 mm

Height 175 mm 175 mm

Depth 305 mm 305 mm

Weight

Crated 31 kg 31 kg

HDC5212

CHDC5212

CDEC21E2

4

Page 5

5

Page 6

6

Page 7

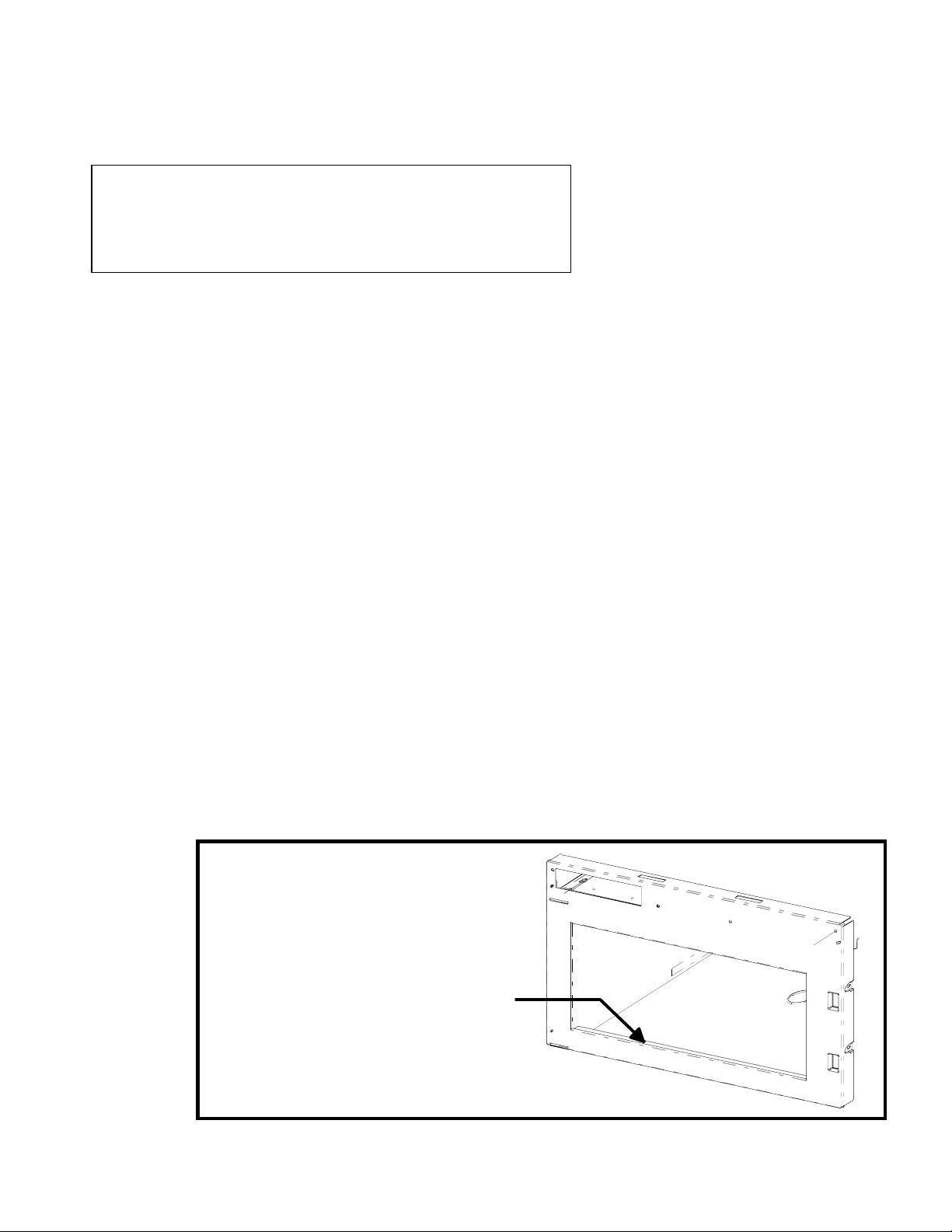

Inner Door/Window Removal

1. Open oven door.

2. Remove screws on hinge side.

3. Beginning at the bottom, carefully insert 1” putty knife between inner and outer door. Pry up on inner

door to release tabs, (2 tabs per side). Work in a clockwise direction to release all tabs, see illustration

below.

3

2

Remove

screws

Tabs

4

1

CAUTION

!

When glass retainer is removed, be careful glass does not fall out of frame.

7

Page 8

Bulletin

√ Comm. Microwave Dehumidifier Dishwasher

Domm. Microwave √ Export Comm. Heating Product

Laundry Product PTAC Products Range Product

Refrigerator/Fzr Room Air Cond.

Type Parts Manual Update

Policy Letter

√ Service Information

Attention Service Managers

√ Service and Parts Managers

Models CRC and HDC Compact Commercial Ovens

Issue Broken tray as a result of arcing at front lip of cavity.

Warranty Ceramic trays may be claimed under warranty only if damage was caused by

antenna failure (arcing).

Trays are not covered under warranty if there is evidence that damage was caused by impact,

thermal shock (frozen or refrigerated product placed on warm tray), oven operated with metal pans,

oven operated without a food load or lack of proper cleaning and maintenance.

NOTE: Typical symptoms of metal pan usage or empty cavity operation include arc spots on the

front lip of cavity, 1 to 2 inches from either side.

Date July 31, 2001

No CR−236−B

EXCMW-125-B

Page 1 of 1

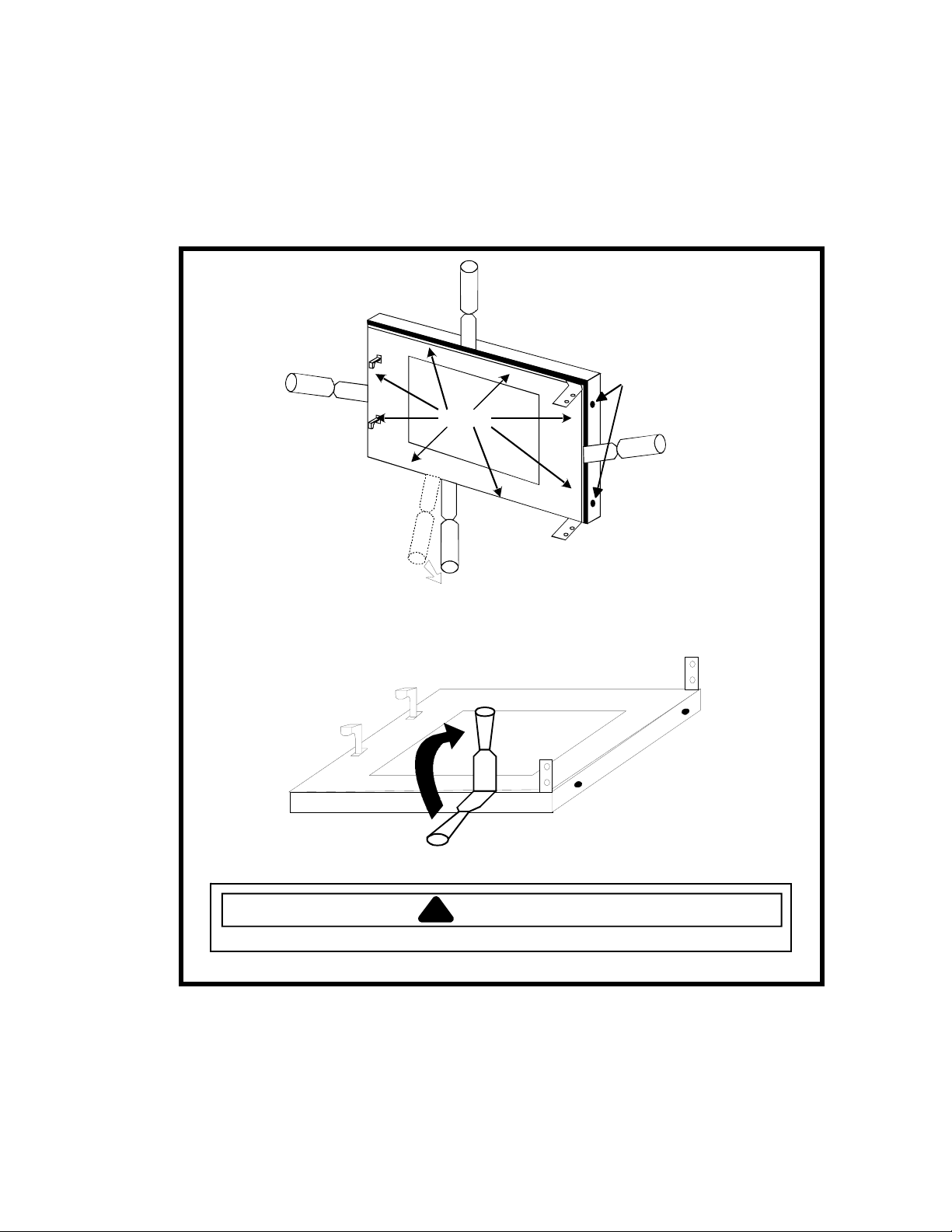

Action If encountering arcing at front lip of cavity, proceed as follows:

1. Check antenna operation – if either antenna is stalled, hot spots will occur.

2. Remove oven tray.

3. Thoroughly remove any carbon build-up from front lip using fine grade sandpaper.

4. Thoroughly clean cavity and front lip removing all old RTV.

5. Before installing new tray, apply a generous bead of RTV on the front lip of cavity, (see below).

6. Install new tray and reseal using instructions supplied with the tray.

7. If arcing has damaged the oven door, replace inner oven door and inspect door ring weldment

for arcing.*

8. Replace door ring weldment if it is damaged.*

*To ensure proper operation, use the instructions in the Service Manual when reinstalling the

oven door.

Apply a generous bead

of RTV along this lip

before installing oven tray

8

Page 9

A

Air Flow

On two tube ovens:

To ensure proper

spacing and air flow,

air ducts must be

in place if oven is

installed in a closed

back installation.

ir filter must be in place

and cleaned regularly.

9

Page 10

Improved Filter for .6 Compact Ovens

New improved filter kit 12002550, is now available from Maytag Services and in production ovens beginning

December 2003.

The new filter is more durable, easier to remove, clean, and reinstall.

New filter kit part number 12002550 will replace old filter part numbers 12135801, 12135802, 12135803 and

12135804.

When servicing microwave ovens, make sure to check the air intake and exhaust for obstructions and for a clean

filter. Remember, cool components last longer!

Side retainers on older units

Bottom retainers on newer units.

Tabs

New Filter 12002550 - December 2003 and later

NOTE: When installing new style filter on older units with side retainers, it will be necessary to remove the securing

tabs located on each side of the filter. No modification is necessary when installing on units with bottom

retainers.

Old Style Filter 12135801, 12135802, 12135803, 12135804

prior to December 2003

10

Page 11

INTERLOCK SWIT CHES

R0150154 Early Production Switch

Monitor

Primary

Mounting

screws

Secondary

Logic

R0000277 Replacement for

Early Production Switch

Mounting

screws

Primary

Logic

Monitor

Secondary

12538901Q Later Production Switch

Mounting

screws

OR

Primary /

Logic

Monitor

Secondary

11

Page 12

SWITCH REPLACEMENT / DOOR ADJUSTMENT

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect electrical power before servicing.

1. Remove and retain two (2) screws securing

switch to cavity. Remove switch.

2. Position new switch assembly into cavity opening.

• First, insert bottom ramp of switch into bottom

opening.

• Tilt switch upward and insert top ramp of

switch into top opening.

8. With door closed, loosen door hinge bolts 1/2

turn.

9. Lift upward on door, using the door handle.

10. With left hand, clamp door to cavity on hinge side

of door.

11. While holding door in place, tighten hinge bolts in

the order shown.

• Be sure both ramps are fully protruded

through the front frame of cavity.

3

1

P

r

i

m

ar

y

Cavity

Lo

gi

c

Front

M

on

i

t

or

S

e

cond

ar

y

4

2

3. Loosely install screws removed in step 1.

4. Push and hold switch assembly towards front of

oven and tighten screws.

5. Transfer wires to new switch.

6. Secure wires to switch bracket using plastic wire

ties.

IMPORTANT: It is necessary to adjust the door

assembly for correct switch function.

7. Tape shims 12382602 and 12019302 to door, as

shown.

12019302

Shim

.030 in. \ .75 mm

12382602

Shim

.060 in. \ 1.5 mm

12. Open and close door several times to check

switch operation.

NOTE: If switches do not activate, check

condition and alignment of door and hinges.

13. Remove shims.

12

Page 13

TOUCH PANEL and

CONTR OL BOARD

Error

Codes

F1

F2

F3

F4

F5

F6

Replace Board.

Replace Board.

Replace Board.

Replace Board.

Replace Touch Panel.

Replace Board.

13

Page 14

Disassembly

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Component Location

Screws

Diode location

single magnetron

ovens

Capacitor

T ouch panel

Tray supports

@MF SET #13

@MF SET #13

@MF SET #13

@MF SET #13

Diode location

2 magne tron

ovens

Oven Tray

Grease Shield

Interlock switch

assembly

High Voltage Components

14

Page 15

Disassembly

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Antenna

Motor

High Voltage Components

Magnetrons

Antenna

assembly

top

Antenna

assembly

bottom

Shaft

Washer

NOTE: Raised rib on edge of washer

must face away from cavity.

NOTE: Ribbed side of gear

must face oven cavity.

Gear

Antenna

Motor

Snap Ring

Original

Clip

Replacement

clip

15

Page 16

Disassembly

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Spill

shield

Cavity

thermal

cutout

Blower

motor

Snubber

Triac

Control

board

High Voltage

Transformer

Magnet r o n TCO

Power cord

High Voltage Components

Terminal

Block

Line filter

(Loc a ted be hind ex haust duct.)

Fuse

Capacitors

Lamp and

receptacle

Lamp

barrie r

Mounti ng bracket

16

Page 17

Component Specifications

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor before

servicing, unless testing requires power.

Illustration Component Testing Results

Thermal Cutout Disconnect all wires from TCO.

1100 Watt units

1400, 1800, and 2100

Watt units

MT2

MT1 GATE

Line

Wire Harness Test resistance of wires .................................. Continuity.

Load

Earth

Diode Assembly

Triac Disconnect wires to triac.

Capacitor

Snubber Assembly Disconnect wires to snubber.

Magnetron

Blower Motor Remove all wires from motor.

Line filter Measure resistance:

Measure resistance across terminals.

Cavity Thermal Fuse ...................................

Magnetron TCO...........................................

Discharge Capacitors

Remove diode lead from capacitor and

connect ohmmeter.

Reverse leads for second test.

Measure resistance from:

MT1 to MT2 .................................................

MT1 to Gate.................................................

MT2 to Gate.................................................

All terminals to ground.................................

Discharge Capacitors

Remove wires from capacitor terminals and

connect ohmmeter, set on highest

resistance scale to terminals.

Also check between each terminal and

capacitor case.

Measure resistance across terminals .............

Discharge Capacitors

Remove wires from magnetron and

connect ohmmeter to terminals. Also check

between each terminal and ground.

Measure resistance across coil ......................

Line to Line ..................................................

Load to Load................................................

Line to Load.................................................

Any terminal to Earth...................................

Open: 104° C (219° F).

Open: 138° C (280° F.

Closed: 82° C (180° F).

Infinite resistance should be

measured in one direction and 50KΩ

or more in the opposite direction.

NOTE: Test meter must contain a

battery of 6 volts minimum.

Caution - Do not operate oven with

wire to terminal MT2 removed.

Infinite.

Approximately 40 Ω or more.

Infinite.

Infinite.

Between Terminals: Meter should

momentarily deflect towards zero

then return to over 5 MΩ. If no

deflection occurs, or if continuous

deflection occurs, replace capacitor.

Terminal to Case: Infinite resistance.

Infinite.

Between Terminals: Less than 1 Ω.

Each terminal to ground measures

Infinite resistance.

NOTE: This test is not conclusive. If

oven does not heat and all other

components test good replace the

magnetron and retest.

Approximately 30 Ω.

.8 M Ω.

.8 M Ω.

Continuity.

Infinite.

17

Page 18

Component Specifications

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor before

servicing, unless testing requires power.

Illustration Component Testing Results

Discharge Capacitor

Remove all wires from terminals, and

measure resistance from:

5

220 to Common............................................

6

230 to Common............................................

Terminal 5 to 6..............................................

Terminal 4 to Earth screw on transformer....

Terminal 4 to any other terminal ..................

4

3

1

Gray Pink

Discharge Capacitor

Remove all wires from terminals, and

measure resistance from:

230 to Common............................................

Terminal 5 to 6..............................................

Terminal 7 to 8..............................................

Terminal 4 to Earth screw on transformer....

Terminal 4 to any other terminal ..................

Measure resistance across terminals ..............

This transformer is equipped with a

155° C thermal cutout.

1.3 Ω.

1.3 Ω.

<1 Ω.

70 Ω.

Infinite resistance. If not, replace

transformer.

1 Ω.

<1 Ω.

<1 Ω.

38 - 45 Ω

± 5%.

Infinite resistance. If not, replace

transformer.

Approximately 12 KΩ.

COM

220

6

COM

230

230

Transformer

1100 Watt

6

5

4

(COM)

3

(230V)

1

Transformer – 1400,

1800, and 2100

5

Watt

8

4

7

#

#

#

#

#

#

#

4

1

2

5

6

7

8

Stirrer motor Remove all wires from motor.

Interlock switch

assembly

Primary

Secondary

Monitor

Disconnect wires to switch.

With door open measure resistance from:

Terminal C to NO Primary .......................

Terminal C to NO Secondary ..................

Terminal C to NC Monitor........................

With door closed measure resistance from:

Terminal C to NO Primary .......................

Terminal C to NO Secondary ..................

Terminal C to NC Monitor........................

C

C

C

Door Closed

NC

NO

NO

Monitor

Primary

Secondary

Infinite.

Infinite.

Continuity.

Continuity.

Continuity.

Infinite.

18

Page 19

Component Specifications

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor before

servicing, unless testing requires power.

Illustration Component Testing Results

Line voltage to control board

P2 connector

Pin 1—Pin 3.....................................

Output drive voltage to triac

Triac terminals...................................

Gate—T1 .........................................

Fan relay (controls blower motor,

antenna motor(s), and oven light)

Control board.....................................

Terminals C—J................................

Cook relay

Control board.....................................

Terminals F—K................................

Line voltage (All Conditions)

0 VAC (Idle and Standby)

0.9 VAC (Cook)

Line voltage (Idle)

0 VAC (Standby and Cook)

Line voltage (Idle)

0 volts (Standby and Cook)

ERROR CODES

F1.......... Replace Control Board

F2.......... Replace Control Board

F3.......... Replace Control Board

F4.......... Replace Control Board

P2

Pin #1

P1

Pin #1

Controller board

K

F

J

C

B

A

P1 connector

used for touch

panel ribbon

P2

1

P1

10

10

1

F5.......... Replace Touch Panel

F6.......... Replace Control Board

Touch Panel

Assembly

Touch Panel

Assembly

Continuity is indicated as 100 Ω and

below.

Pin 1: Ground.

10

9

8

7

6

5

4

3

2

1

Split

Continuity is indicated as 100 Ω and

below.

Pin 1: Ground.

Pad

1

2

3

4

5

6

7

8

9

0

Start

Stop/Reset

Power Level

X 2

Time Entry

Pad

1

2

3

4

5

6

7

8

9

0

Start

Stop/Reset

Power Level

X 2

Time Entry

Trace

(measure both)

8 & 1, 10 & 1

7 & 1, 10 & 1

6 & 1, 10 & 1

5 & 1, 10 & 1

4 & 1, 10 & 1

3 & 1, 10 & 1

8 & 1, 9 & 1

7 & 1, 9 & 1

6 & 1, 9 & 1

5 & 1, 9 & 1

4 & 1, 9 & 1

4 & 1, 8 & 1

5 & 1, 8 & 1

6 & 1, 8 & 1

7 & 1, 8 & 1

Trace

(measure both)

8 & 1, 10 & 1

7 & 1, 10 & 1

6 & 1, 10 & 1

5 & 1, 10 & 1

4 & 1, 10 & 1

3 & 1, 10 & 1

8 & 1, 9 & 1

7 & 1, 9 & 1

6 & 1, 9 & 1

5 & 1, 9 & 1

4 & 1, 9 & 1

4 & 1, 8 & 1

5 & 1, 8 & 1

6 & 1, 8 & 1

7 & 1, 8 & 1

Measurement

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Measurement

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Continuity.

Conditions

Initial Power Up Condition: Apply power to oven with door closed.

Idle Condition: Oven plugged in, display blank (no other components operating).

Standby Condition: Open oven door, light and motors operate.

Cook Condition: Food load in oven, cook cycle initiated.

19

Page 20

Power Testing Procedure

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor before

servicing, unless testing requires power.

All Amana and Menumaster microwave oven power outputs are rated using the IEC705 standards. Using the

IEC705 test method requires precision measurements and equipment that is not practical to be performed in the

field. Using the test shown below will indicate if the oven performance is satisfactory.

WARNING

Test equipment required:

• 1000 ml test container and thermometer (Power test kit 1000100006).

• Digital watch / watch with a second hand for use on ovens with electromechanical timers.

Important Notes:

• Low line voltage will cause low temperature rise / power output.

• Ovens must be on a dedicated circuit, properly grounded, and polarized. Other equipment on the same

circuit may cause a low temperature rise / power output.

• This test and results are not a true IEC705 test procedures and are only intended to provide servicers with

an easy means of determining if the microwave oven cooking output is correct.

Procedure

1. Fill the test container to the 1000 ml line with cool tap water.

NOTE: Water temperature should be approximately 60° F / 16° C.

2. Using the thermometer, stir water for five to ten seconds; measure, and record the temperature (T1).

3. Place test container of water in the center of oven cavity and close door.

4. Heat the water for a 33-second full power cycle.

NOTE: Use a digital watch or a watch with a second hand for ovens with electromechanical timers.

5. At end of the cycle, remove test container. Using the thermometer, stir water for five to ten seconds and record

temperature (T2).

6. Subtract the starting water temperature (T1), from the ending water temperature (T2) to obtain the temperature

rise (∆T).

7. If the temperature rise (∆T) meets or exceeds the minimum, the test is complete. If the temperature rise (∆T)

fails to meet the minimum temperature rise, test the line voltage to verify it is correct. Then repeat steps 1-6

making sure to change the water. If the temperature rise (∆T) fails to meet the minimum temperature rise again

the oven will require service.

Minimum Temperature Rise at Thirty -Three (33) Seconds Run Time

∆T Cooking ∆T Cooking ∆T Cooking ∆T Cooking

(°F) Power Output (°F) Power Output (°C) Power Output (°C) Power Output

10..................1000 20 .................2000 5 ...............1000 11 ............2000

11..................1100 21 .................2100 5.5 ............. 1100 11.5 .........2100

12..................1200 22 .................2200 6.5 ............. 1200 12 ............2200

14..................1400 24 .................2400 7.5 ............. 1400 13 ............2400

17..................1700 25 .................2500 9.5 ............. 1700 13.5 .........2500

18..................1800 27 .................2700 10 .............. 1800 15 ............2700

19..................1900 30 .................3000 10.5 ........... 1900 16.5 .........3000

20

Page 21

Isolation Test – Two Magnetron Models

!

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

If the customer is complaining of low heat, it may be necessary to isolate the upper and lower high voltage systems.

WARNING

Method 1

1. Be sure outercase wrapper and back panel are installed on the oven.

2. Place a water load in the oven.

3. Confirm antennas are rotating.

4. Operate the oven for 60 seconds on full power.

5. Discharge air from both magnetrons should be warm.

6. If the discharge air from one magnetron is significantly cooler than the other, a problem may exist with the

cooler magnetron.

Method 2

1. Unplug oven and discharge capacitors.

2. To prepare oven for LOWER MAGNETRON high voltage system check, locate the Gray # 3 jumper wire

that connects between the capacitors.

3. Remove jumper wire connection from both capacitors and position wire to prevent any short to electrical

components.

4. Follow the guidelines for performance test (1000 ml. of 60º F (16º C) water for 33 seconds) and record the

temperature difference and confirm antenna is rotating.

5. To prepare oven for UPPER MAGNETRON high voltage system test check, unplug oven and discharge

capacitors.

6. Remove Red High Voltage Transformer wire # 4 from left hand capacitor (looking from the rear) and move

to the right hand capacitor.

7. Repeat step # 4 above.

Example using model HDC18:

Performance test with both magnetrons operating should be minimum of 18º F (10º C) Temperature rise. With either

magnetron operating individually, temperature rise should be a minimum of 9º F (4.5º C) for each system.

# 4 Wire

Red

# 3 Wire

Gray jumper

from LH to RH

capacitor

21

Page 22

Wiring and Schematic Diagrams

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

DANGER

!

HIGH VOLTAGE

Sample:

Oven Schematic, One (1) Tube (Magnetron)

22

Page 23

Wiring and Schematic Diagrams

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Sample:

Oven Wiring Diagram, One (1) Tube (Magnetron)

23

Page 24

Wiring and Schematic Diagrams

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

DANGER

!

HIGH VOLTAGE

Sample:

Oven Schematic, Two (2) Tube (Magnetron)

24

Page 25

Wiring and Schematic Diagrams

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Sample:

Oven Wiring Diagram, Two (2) Tube (Magnetron)

25

Loading...

Loading...