Amana AVZC200241AA, AVZC200241AB, AVZC200241AC, AVZC200361AA, AVZC200361AB Installation Manual

...Page 1

HEAT PUMP UNIT

AVZC20 HEAT PUMP

INSTALLATION & SERVICE REFERENCE

Index

IMPORTANT SAFETY INSTRUCTIONS .......................................... 1

SHIPPING INSPECTION ............................................................ 2

CODES & REGULATIONS ........................................................ 2

FEATURES............................................................................ 2

INSTALLATION CLEARANCES .................................................... 2

ROOFTOP INSTALLATIONS........................................................ 3

SAFE REFRIGERANT HANDLING ............................................... 3

REFRIGERANT LINES .............................................................. 3

REFRIGERANT LINE CONNECTIONS........................................... 5

LEAK TESTING (NITROGEN OR NITROGEN-TRACED) ................... 5

SYSTEM START-UP PROCEDURE.............................................. 5

ELECTRICAL CONNECTIONS .................................................... 6

HEAT PUMP ADVANCED FEATURE MENU ............................... 22

WIRING DIAGRAM ............................................................... 25

CAPACITOR ........................................................................ 28

TROUBLESHOOTING .............................................................. 33

ETTING THE MODE DISPLAY ............................................... 38

S

7-S

EGMENT DISPLAY ........................................................... 44

START-UP CHECKLIST .......................................................... 47

I

MPORTANT SAFETY INSTRUCTIONS

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards. It is

the owner’s and installer’s responsibility to read and comply with

all safety information and instructions accompanying these symbols. Failure to heed safety information increases the risk of

personal injury, property damage, and/or product damage.

W ARNING

HIGH VOLTAGE !

D

ISCONNECT

M

ULTIPLE POWER SOURCES MAY BE PRESENT

TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE OR

REPAIR (HEREINAFTER

MANUAL SHOULD SERVICE THE EQUIPMENT

BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM

IMPROPER SERVICE OR SERVICE PROCEDURES

ASSUME RESPONSIBILITY FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAY

RESULT

LICENSES TO SERVICE THE EQUIPMENT SPECIFIED IN THIS MANUAL, ONLY

LICENSED PERSONNEL SHOULD SERVICE THE EQUIPMENT

INSTALLATION, ADJUSTMENT, SERVICING OR REPAIR OF THE EQUIPMENT

SPECIFIED IN THIS MANUAL, OR ATTEMPTING TO INSTALL, ADJUST, SERVICE OR

REPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL WITHOUT PROPER

TRAINING MAY RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

ALL

POWER BEFORE SERVICING

.

. F

AILURE

.

, “

SERVICE

”)

THE EQUIPMENT SPECIFIED IN THIS

. THE

MANUFACTURER WILL NOT

. IF

YOU SERVICE THIS UNIT, YOU

. IN

ADDITION, IN JURISDICTIONS THAT REQUIRE ONE OR MORE

. I

.

MPROPER

IOA-4013C

8/2016

“IMPORTANT – THIS PRODUCT HAS BEEN DESIGNED AND MANUFACTURED TO MEET ENERGY STAR CRITERIA FOR

ENERGY EFFICIENCY WHEN MATCHED WITH APPROPRIATE COIL COMPONENTS. HOWEVER, PROPER REFRIGERANT CHARGE

AND PROPER AIR FLOW ARE CRITICAL TO ACHIEVE RATED CAPACITY AND EFFICIENCY. INSTALLATION OF THIS PRODUCT SHOULD

FOLLOW THE MANUFACTURER’S REFRIGERANT CHARGING AND AIR FLOW INSTRUCTIONS. FAILURE TO CONFIRM PROPER

CHARGE AND AIRFLOW MAY REDUCE ENERGY EFFICIENCY AND SHORTEN EQUIPMENT LIFE.”

All information contained herein is subject to change without notice.

© 2015 - 2016 Goodman Manufacturing Company, L.P.

5151 San Felipe St., Suite 500, Houston, TX 77056

www.amana-hac.com

is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

Page 2

CAUTION

THE

UNIT HAS ITS OWN PUMP-DOWN MODE

MODE WHILE VACUUMING THE UNIT

CAUSE INTERNAL ELECTRICAL ARCING, RESULTING IN A DAMAGED OR

FAILED COMPRESSOR

S

HIPPING INSPECTION

.

. USE

THE PUMP-DOWN

. V

ACUUMING TOO LOW CAN

Always keep the unit upright; laying the unit on its side or top

may cause equipment damage. Shipping damage, and subsequent

investigation is the responsibility of the carrier. Verify the model

number, specifications, electrical characteristics, and accessories

are correct prior to installation. The distributor or manufacturer

will not accept claims from dealers for transportation damage or

installation of incorrectly shipped units.

C

ODES

& R

EGULATIONS

F

EA TURES

This heat pump is part of a system that uses inverter technology to

more efficiently remove or add heat with better efficiency and

achieve the target comfort conditions. System may ONLY be installed using a ComfortNet™ thermostat with model number

CTK04 as part of the digital communicating system. The

ComfortNet system reduces the number of required thermostat

wires, provides additional setup features and enhanced active

diagnostics. Due to components using inverter technology, the

heat pump will not function properly if used with a CTK03, 02 or

01 ComfortNet thermostat.

NOTICE

NOT

APPROVED FOR USE WITH A

I

NST ALLATION CLEARANCES

CTK01, CTK02 OR CTK03.

This product is designed and manufactured to comply with national codes. Installation in accordance with such codes and/or

prevailing local codes/regulations is the responsibility of the installer. The manufacturer assumes no responsibility for equipment installed in violation of any codes or regulations. Rated

performance is achieved after 72 hours of operation. Rated performance is delivered at the specified airflow. See outdoor unit

specification sheet for split system models or product specification sheet for packaged and light commercial models. Specification sheets can be found at www.amana-hac.com for Amana

brand products. Within the website, please select the residential or commercial products menu and then select the submenu

for the type of product to be installed, such as air conditioners

or heat pumps, to access a list of product pages that each contain links to that model’s specification sheet.

The United States Environmental Protection Agency (EPA) ha s

issued various regulations regarding the introduction and disposal of refrigerants. Failure to follow these regulations may

harm the environment and can lead to the imposition of substantial fines. Should you have any questions please contact the

local office of the EPA.

If replacing a condensing unit, heat pump or air handler, the system must be manufacturer approved and Air Conditioning, Heating and Refrigeration Institute (AHRI) matched.

NOTE: The installation of an inverter heat pump with unmatched

system units will not allow for proper operation.

NOTICE

I

NVERTER

AIR HANDLER OR

RESULTING FROM OPERATION WITH ANY OTHER COMBINATION IS NOT

COVERED BY OUR WARRANTIES

Outdoor inverter units are approved for operation above 0°F in

cooling mode and -20°F (RH10%) in heating mode with no additional kit necessary.

Damage resulting from operation of the units in a structure that

is not complete (either as port of new construction or renovation) is not covered by our warranties.

A/H

MODELS CAN ONLY BE MATCHED WITH AN

TXV-V**

EXPANSION VALVE KIT

.

. D

AV**PVC

AMAGE

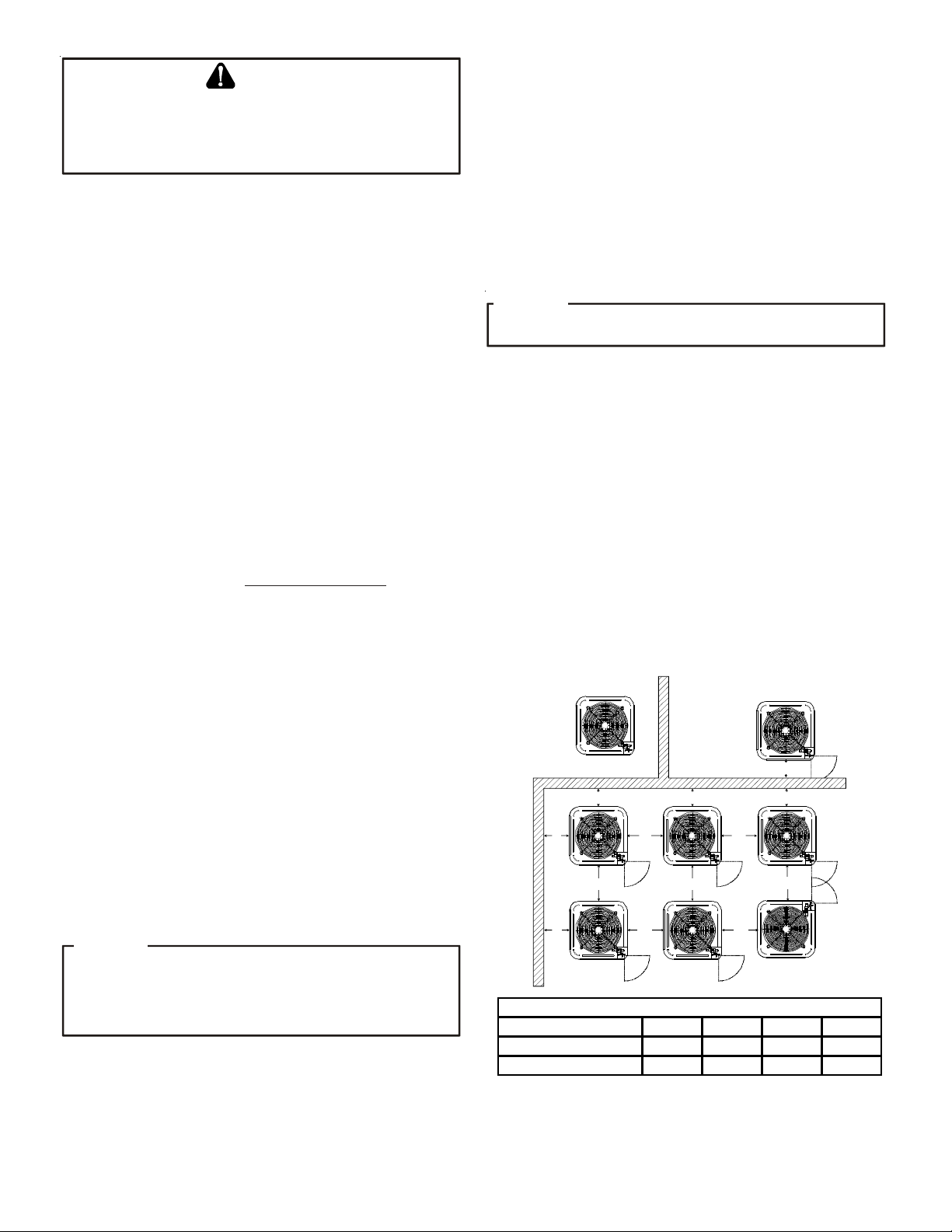

Special consideration must be given to location of the heat pump

unit(s) in regard to structures, obstructions, other units, and any/

all other factors that may interfere with air circulation. Where

possible, the top of the unit should be completely unobstructed;

however, if vertical conditions require placement beneath an ob-

struction there should be a minimum of 60 inches between the

top of the unit and the obstruction(s). The specified dimensions

meet requirements for air circulation only. Consult all appropriate regulatory codes prior to determining final clearances.

®

Another important consideration in selecting a location for the

unit(s) is the angle to obstructions. Either side adjacent the valves

can be placed toward the structure provided the side away from

the structure maintains minimum service clearance. Corner installations are strongly discouraged.

NOT

RECOMMENDED

B B B

AA AAA

C

AA

A

Model Type A B C AA

Residential

Light Commercia l

AA

Minim um Airflow Clear ance

10" 10" 18" 20"

12" 12" 18" 24"

AA

C

AA

CC

B

AA

OK!

OK!

OK!

OK!

OK!

OK!

This unit can be located at ground floor level or on flat roofs. At

ground floor level, the unit must be on a solid, level foundation

2

Page 3

that will not shift or settle. To reduce the possibility of sound

transmission, the foundation slab should not be in contact with

or be an integral part of the building foundation. Care should be

taken to ensure the unit is installed away from noise sensitive

locations such as bedrooms, windows and outdoor living areas.

Ensure the foundation is sufficient to support the unit. A concrete slab raised above ground level provides a suitable base.

R

OOFTOP INST ALLATIONS

If it is necessary to install this unit on a roof structure, ensure

the roof structure can support the weight and that proper consideration is given to the weather-tight integrity of the roof. Since

the unit can vibrate during operation, sound vibration transmission should be considered when installing the unit. Vibration absorbing pads or springs can be installed between the heat pump

unit legs or frame and the roof mounting assembly to reduce

noise vibration.

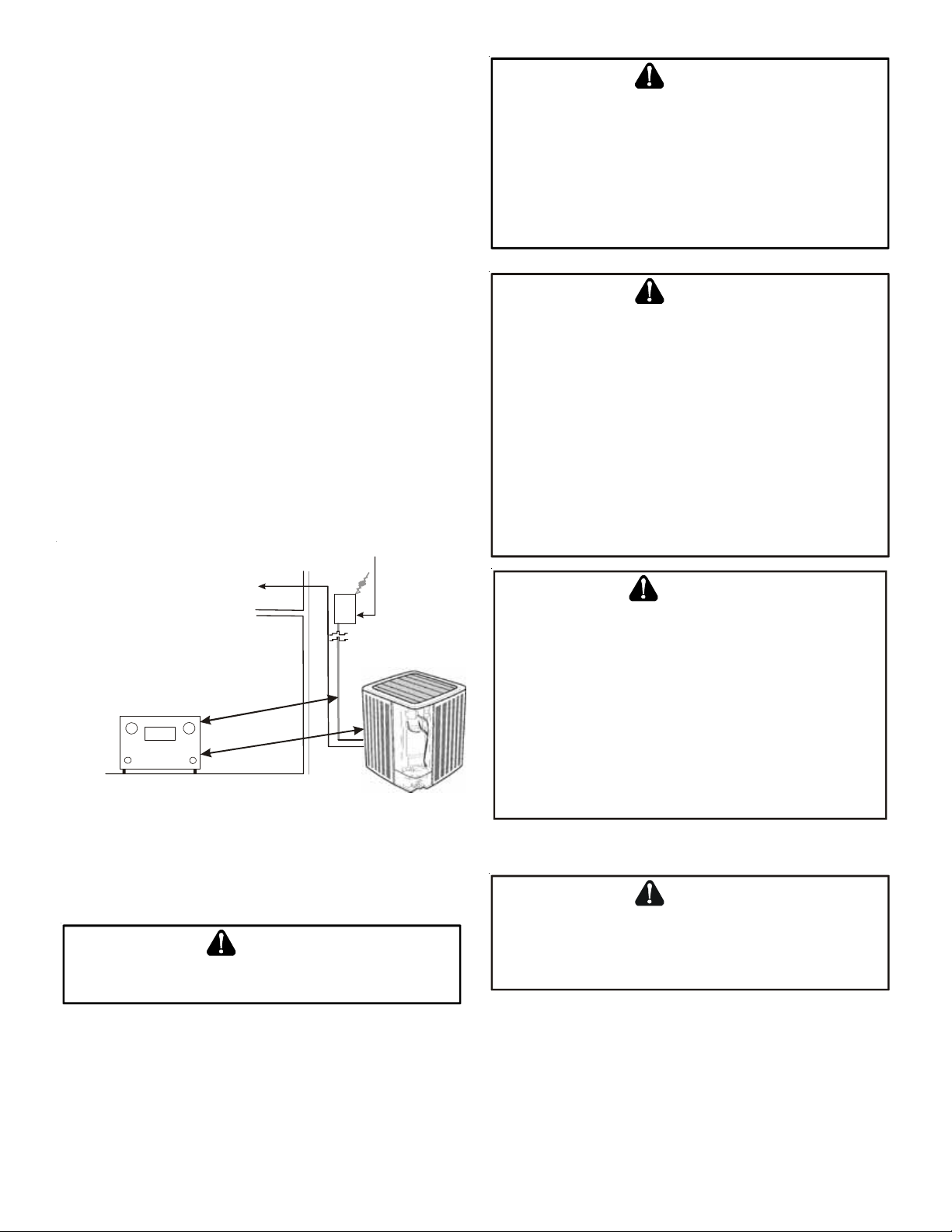

ELECTRICAL NOISE

The unit should be well grounded so that potential effects of

electrical noise from the inverter to surrounding equipment can

be minimized.

When selecting an installation location, keep sufficient distance

from the heat pump unit and wiring to radios, personal computers, stereos, etc., as shown in the following figure.

Circuit

Breaker

To Indoor Unit and Thermostat

WARNING

TO

AVOID POSSIBLE EXPLOSION, USE ONLY RETU RNABL E (NOT

DISPOSABLE) SERVICE CYLINDERS WHEN REMOVING REFRIGERANT FROM

A SYSTEM

• E

• E

• E

W

.

NSURE THE CYLINDER IS FREE OF DAMAGE WHICH COUL D LEAD TO A

LEAK OR EXPLOSION

NSURE THE HYDROSTATI C TEST DATE DOES NOT EXCEED

NSURE THE PRESSURE RATING MEETS OR EXCEEDS

HEN IN DOUBT, DO NOT USE CYLINDER

.

400

.

5

PSIG

YEARS

.

.

WARN ING

R

EFRIGERANTS ARE HEAVIER THAN AIR

OXYGEN IN YOUR LUNGS OR IN ANY ENCLOSED SPACE

POSSIBLE DIFFICULTY IN BREATHING OR DEATH

EVER PURGE REFRIGERANT INTO AN ENCLOSED ROOM OR SPACE

• N

LAW, ALL REFRIGERANTS MUST BE RECLAIMED

F AN INDOOR LEAK IS SUSPECTED, THOROUGHLY VENTILATE THE AREA

• I

BEFORE BEGINNING WORK

IQUID REFRIGERANT CAN BE VERY COLD

• L

OR BLINDNESS, AVOID CONTACT AND WEAR GLOVES AND GOGGLES

LIQUID REFRIGERANT DOES CONTACT YOUR SKIN OR EYES, SEEK MEDICAL

HELP IMMEDIATELY

LWAYS FOLLOW

• A

OISONOUS GAS WILL BE PRODUCED

P

EP A

.

.

REGULATIONS

. T

HEY CAN “PUSH OUT” THE

. TO

AVOID

:

.

. TO

AVOID POSSIBLE FROST BITE

. N

EVER BURN REFRIGERANT, AS

.

. BY

. IF

WARNING

Radio, TV

(In.)

Placement to Minimize Electronic Noise

S

AFE REFRIGERANT HANDLING

”

0

6

e

r

o

m

r

o

”

0

6

e

r

o

m

r

o

While these items will not cover every conceivable situation, they

should serve as a useful guide.

WARNING

TO

AVOID POSSIBLE INJURY, EXPLOSION OR DEATH, PRACTICE SAFE

HANDLING OF REFRIGERANTS

.

TO

AVOID POSSIBLE EXPLOSION

EVER APPLY FLAME OR STEAM TO A REFRIGERANT CYLINDER

•N

MUST HEAT A CYLINDER FOR FASTER CHARGING, PARTIALLY IMMERSE

IT IN WARM WATER

EVER FILL A CYLINDER MORE THAN

•N

REFRIGERANT

EVER ADD ANYTHING OTHER THAN

•N

R-410A

OR

•S

AS

R

EFRIGERANT LINES

CYLINDER

CERTIFIED FOR THE TYPE OF REFRIGERANT USE

TORE CYLINDERS IN A COOL, DRY PLACE

A

PLATFORM OR A ROLLER

.

.

. THE

:

. IF

YOU

80%

FULL OF LIQUID

R-410A TO A

SERVICE EQUIPMENT USED MUST BE LISTED

RETURNABLE

.

. N

EVER USE A CYLINDER

.

CAUTION

THE

COMPRESSOR

SUSCEPTIBLE TO MOISTURE ABSORPTION AND COULD CAUSE

COMPRESSOR FAILURE

ANY LONGER THAN NECESSARY FOR INSTALLATION

PVE

OIL FOR

R-410A

. DO

NOT LEAVE SYSTEM OPEN TO ATMOSPHERE

UNITS IS EXTREMELY

.

Use only refrigerant grade (dehydrated and sealed) copper tubing

to connect the heat pump unit with the indoor unit. After cutting

the tubing, install plugs to keep refrigerant tubing clean and dry

prior to and during installation. Tubing should always be cut

square keeping ends round and free from burrs. Clean the tubing

to prevent contamination. The liquid line must be insulated if

more than 50 ft. of liquid line will pass through an area that may

reach temperatures of 30 °F or higher than ambient in cooling

3

Page 4

mode and/or if the temperature inside the conditioned space may

reach a temperature lower than ambient in heating mode. Never

attach a liquid line to any uninsulated potion of the gas line.

Do NOT let refrigerant lines come in direct contact with plumbing,

ductwork, floor joists, wall studs, floors, and walls. When running refrigerant lines through a foundation or wall, openings

should allow for sound and vibration absorbing material to be

placed or installed between tubing and foundation. Any gap between foundation or wall and refrigerant lines should be filled

with a pliable silicon-based caulk, RTV or a vibration damping

material. Avoid suspending refrigerant tubing from joists and

studs with rigid wire or straps that would come in contact with

the tubing. Use an insulated or suspension type hanger. Keep

both lines separate and always insulate the gas line.

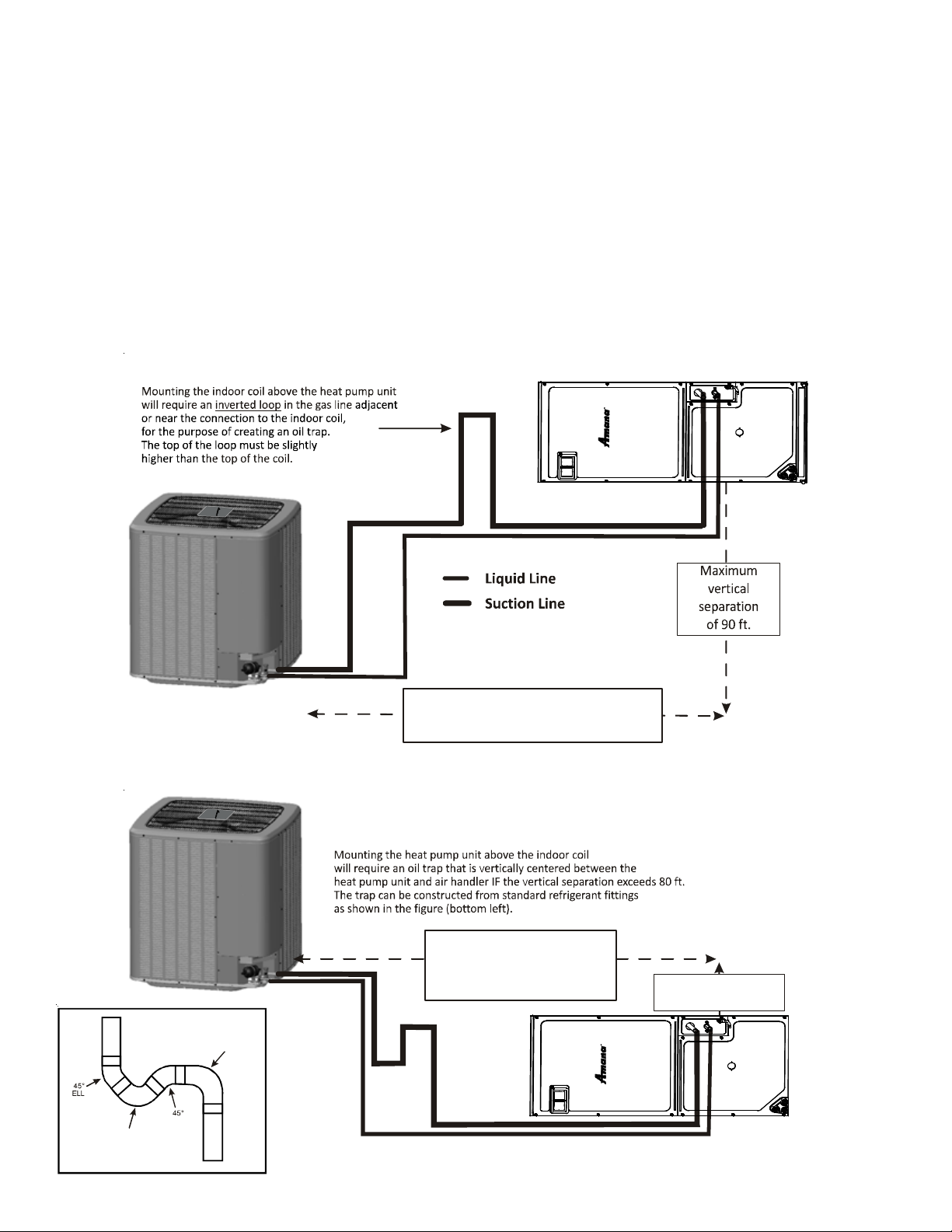

Heat Pump BEL OW Indoor Coil

Insulation is necessary to prevent condensation from forming

and dropping from the gas line. Armflex or satisfactory equivalent with 3/8” min. wall thickness is recommended. In severe

conditions (hot, high humidity areas) 1/2” insulation may be required. Insulation must be installed in a manner which protects

tubing and connections from damage and contamination.

Where possible, drain as much residual compressor oil from existing systems, lines, and traps; pay close attention to low areas

where oil may collect. NOTE: If changing refrigerant, the indoor

coil and metering device must be replaced. Only AV**PVC air

handlers or TXV** expansion valves are compatible and have been

manufacturer approved for use with these models. See unit specifications or AHRI for an approved system match.

Oil Trap Construction

SHORT RADIUS

STREET ELL

STREET

Maximum line set

equivalent length of 250 ft*.

The maximum line set actual length is 200 ft.

*Includes pressure losses of any elbow, bends, etc.

Heat Pump ABOVE Indoor Coil

Maximum line set

equivalent length of 250 ft.*

The maximum line set

actual length is 200 ft.

LONG RADIUS

STREET EL L

ELL

*Includes pressure losses of any elbow, bends, etc.

Maximum vertical

separation of 200 ft.

4

Page 5

RECOMMEND ED

INTERCONNECT ING TUB ING (Ft)

Line Set Length

0 - 250' Equivalent

Do NOT make final refrigerant line connection until plugs are

removed from refrigerant tubing.

L

EAK TESTING

(N

ITROGEN OR NITROGEN-TRACED

)

Heat Pump

Unit

& Li n e Diamet er (I n . OD)

Line Type

(Tons) Suct Liq

23/43/8

37/83/8

41 1/83/8

51 1/83/8

R

EFRIGERANT LINE CONNECTIONS

IMPORT ANT

To avoid overheating the service valve, TXV or filter drier

while brazing, wrap the component with a wet rag, or use a

thermal heat trap compound. Be sure to follow the

manufacturer’s instruction when using the heat trap

compound. Note: Remove Schrader valves from service

valves before brazing tubes to the valves. Use a brazing alloy

of 2% minimum silver content. Do not use flux.

Torch heat required to braze tubes of various sizes is

proportional to the size of the tube. Tubes of smaller size

require less heat to bring the tube to brazing temperature

before adding brazing alloy. Applying too much heat to any

tube can melt the tube. Service personnel must use the

appropriate heat level for the size of the tube being brazed.

NOTE: The use of a heat shield when brazing is recommended

to avoid burning the serial plate or the finish on the unit.

1. The ends of the refrigerant lines must be cut square,

deburred, cleaned, and be round and free from nicks or

dents. Any other condition increases the chance of a

refrigerant leak.

2. “Sweep” the refrigerant line with nitrogen or inert gas

during brazing to prevent the formation of copper-oxide

inside the refrigerant lines. The FVC oils used in R-410A

applications will clean any copper-oxide present from the

inside of the refrigerant lines and spread it throughout

the system. This may cause a blockage or failure of the

metering device.

3. After brazing, quench the joints with water or a wet cloth

to prevent overheating of the service valve.

4. A bi-flow filter drier is shipped with the unit as a separate

component and must be brazed on by the installer onsite. Ensure the bi-flow filter drier paint finish is intact after

brazing. If the paint of the steel filter drier has been

burned or chipped, repaint or treat with a rust

preventative.

The recommended location of the filter drier is before the

expansion device at the indoor unit.

WARNING

TO

AVOID THE RISK OF FIRE OR EXPLOSION, NEVER USE OXYGEN, HIGH

PRESSURE AIR OR FLAMMABLE GASES FOR LEAK TESTING OF A

REFRIGERATION SYSTEM

.

WARNING

TO

AVOID POSSIBLE EXPLOSION, THE LINE FROM THE NITROGEN

CYLINDER MUST INCLUDE A PRESSURE REGULATOR AND A PRESSURE

RELIEF VALVE

NO MORE THAN

. THE

PRESSURE RELIEF VALVE MUST BE SET TO OPEN AT

150

PSIG

.

To locate leaks, pressure test the system using dry nitrogen or

leak detector fluid per the manufacturer’s recommendation. If

you wish to use a leak detector, charge the system to 10 psi using the appropriate refrigerant then use nitrogen to finish charging the system to working pressure then apply the detector to

suspect areas. If leaks are found, repair them. After repair, re-

peat the pressure test. If no leaks exist, proceed to System Start-

up Procedure.

S

YSTEM START-UP PROCEDURE

GENERAL NOTES:

Adequate refrigerant charge for the matching indoor coil and 15

feet of line set is supplied with the heat pump unit. If liquid line

set exceeds 15 feet in length, refrigerant should be added at 0.6

ounces per foot of liquid line.

NOTICE

V

IOLATION OF

PENALTIES

EPA

REGULATIO NS MAY RESU LT IN FINES OR OTHER

.

NOTICE

ALL

UNITS SHOULD HAVE A HIGH VOLTAGE POWER SUPPLY CONNECTED

HOURS PRIOR TO STARTUP

2

.

WARNING

REFRIGERANT UNDER PRESSURE!

• DO

NOT OVERCHARGE SYSTEM WITH REFRIG ERANT

O NOT OPERATE UNIT IN A VACUUM OR AT NEGATIVE PRESSURE

• D

AILURE TO FOLLOW PROPER PROCEDURES MAY CAUSE PROPERTY

F

DAMAGE, PERSONAL INJURY OR DEATH

.

CAUTION

O

PERATING THE COMPRESSOR WITH THE GAS VALVE CLOSED WILL

CAUSE SERIOUS COMPRESSOR DAMAGE

COVERED BY OUR WARRANTIES

-

SUCH DAMAGE IS NOT

.

.

.

NOTE: Be careful not to kink or dent refrigerant lines. Kinked or

dented lines will cause poor performance or compressor damage.

5

Page 6

CAUTION

USE

REFRIGERANT CERTIFIED TO

MAY CAUSE COMP RESSOR DAMAGE, AND

WARRANTY

REFRIGERANT TO MEET

. M

OST PORTABLE MACHINES CANNOT CLEAN USED

AHRI

AHRI

STANDARDS

STANDARDS

. U

SED REFRIGERANT

IS NOT COVERED UNDER

THE

.

START-UP PROCEDURE DETAIL

Liquid and gas valves on heat pump unit are closed to contain the

charge within the unit. The unit is shipped with the valve stems

closed and caps installed. Do not open valves until the indoor coil

and line set is evacuated.

CAUTION

P

ROLONGED OPERATION AT SUCTION PRESSURES LESS THAN

FOR MORE THAN

SCROLLS AND PERMANENT DAMAGE TO THE SCROLL TIPS, DRIVE

BEARINGS AND INTERNAL SEAL

5

SECONDS WILL RESULT IN OVERHEATING OF THE

.

20

PSIG

E

LECTRICAL CONNECTIONS

WARNING

HIGH VOLTAGE!

D

ISCONNECT

M

ULTIPLE POWER SOURCES MAY BE PRESENT

TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH DUE TO ELECTRIC SHOCK

MUST CONFO RM WITH

CODES

EQUIPM EN T PERFORMANCE, EQUIPM EN T DAMAGE OR

FIRE

.

TO

AVOID THE RISK OF FIRE OR EQUIPM EN T DAMAGE, USE COPPER

CONDUCTORS

ALL

POWER BEFORE SERVICING

NEC OR CEC

. U

NDERSIZED WIRES COUL D CAUSE POOR

AND ALL LOCAL

WARNING

.

. W

.

. F

AILURE

IRING

1. Connect the vacuum pump with 250 micron capability to

the service valves.

2. Evacuate the system to 250 microns or less using gas and

liquid service valves. Using both valves is necessary as

some compressors create a mechanical seal separating the

sides of the system.

3. Close pump valve and hold vacuum for 10 minutes.

Typically pressure will rise during this period.

• If the pressure rises to 1000 microns or less and remains

steady the system is considered leak-free; proceed to

start-up.

• If pressure rises above 1000 microns but holds steady

below 2000 microns, moisture and/or noncondensibles

may be present or the system may have a small leak.

Return to step 2: If the same result is encountered check

for leaks as previously indicated and repair as necessary

then repeat evacuation.

• If pressure rises above 2000 microns, a leak is present.

Check for leaks as previously indicated and repair as

necessary then repeat evacuation.

5000

4500

4000

3500

3000

2500

2000

VACUUM IN MICRONS

1500

1000

500

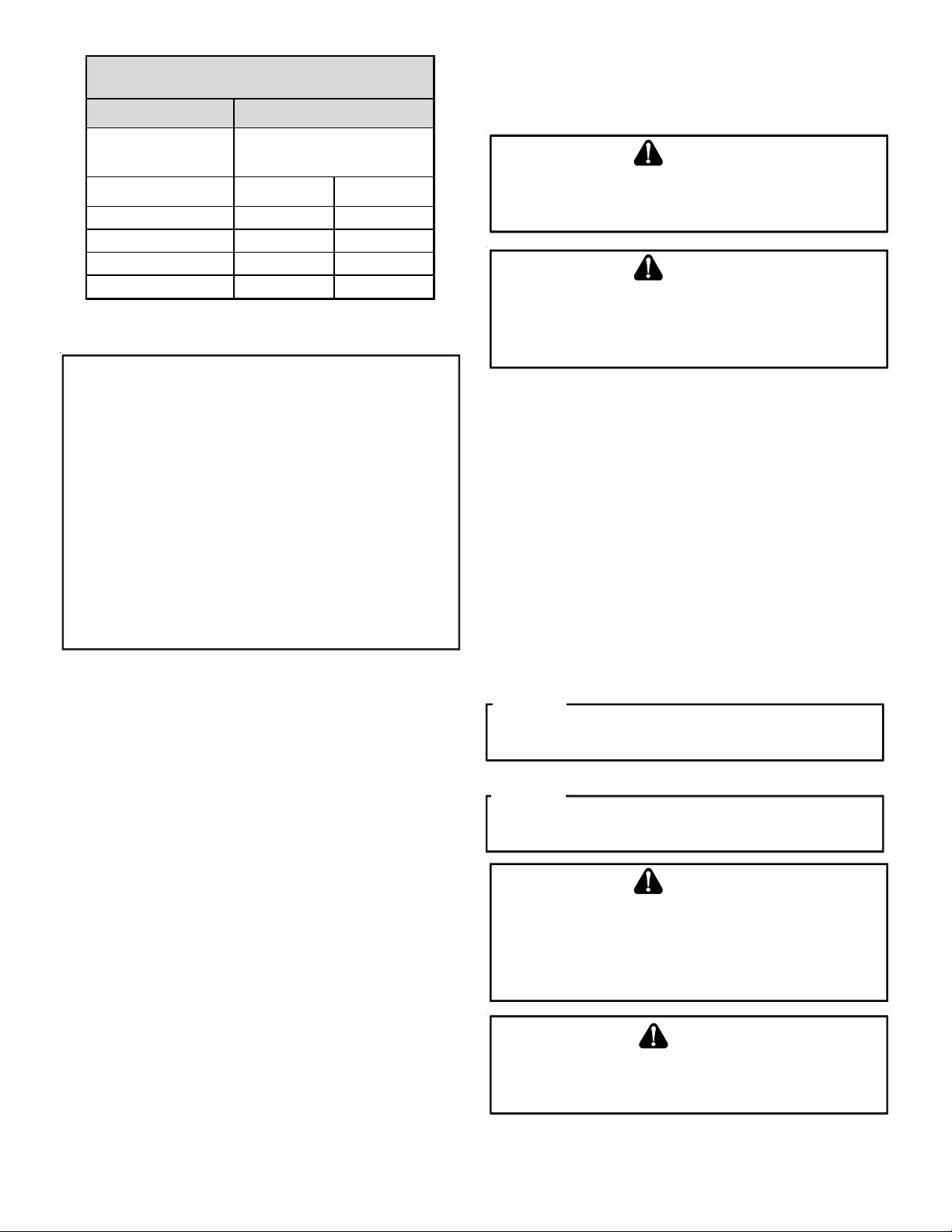

0 1 2 3 4 5 6 7 8 9

CONDENSIBLES OR SMALL

LEAK PRESENT

NO LEAKS

NO CONDE NSIBLES

MINUT ES

LEAK(S)

PRESENT

10

CAUTION

GROUNDIN G R EQUIRED!

LWAYS INSPECT AND USE PROPER SERVICE TOOLS

A

INSPECTION OR IMPROPER TOOLS MAY CAUSE EQUIPMENT DAMAGE OR

PERSONAL INJURY

RECONNECTED BEFORE INSTALLING OR SERVICING

COMPONENTS OF THIS UNIT MAY CONDUCT ELECTRICAL CURRENT

THESE ARE GROUNDED

OF GROUNDING WIRES, SCREWS, STRAPS, CLIPS, NUTS OR WASHERS

USED TO COMPLETE THE GROUND

ORIGINAL POSITION AND PROPERLY FASTENED

. ALL

DISCONNECTED GROUNDING DEVICES

. IF

SERVICING THE UNIT, ANY DISCONNECTION

MUST BE

. L

ACK OF

MUST BE

. M

ULTIPLE

RETURNED TO THEIR

.

;

The heat pump unit rating plate lists pertinent electrical data

necessary for proper electrical service and overcurrent protection. Wires should be sized to limit voltage drop to 2% (max.)

from the main breaker or fuse panel to the condensing unit.

Consult the NEC, CEC, and all local codes to determine the correct wire gauge and length.

Local codes often require a disconnect switch located near the

unit; do not install the switch on the unit. Refer to the installation instructions supplied with the indoor furnace/air handler

for specific wiring connections and indoor unit configuration.

OVERCURRENT PROTECTION

The inverter control system software provides sufficient time

delay to protect from overcurrent conditions and permit the compressor and fan motors to adjust their rotational speed.

HIGH VOLTAGE CONNECTIONS

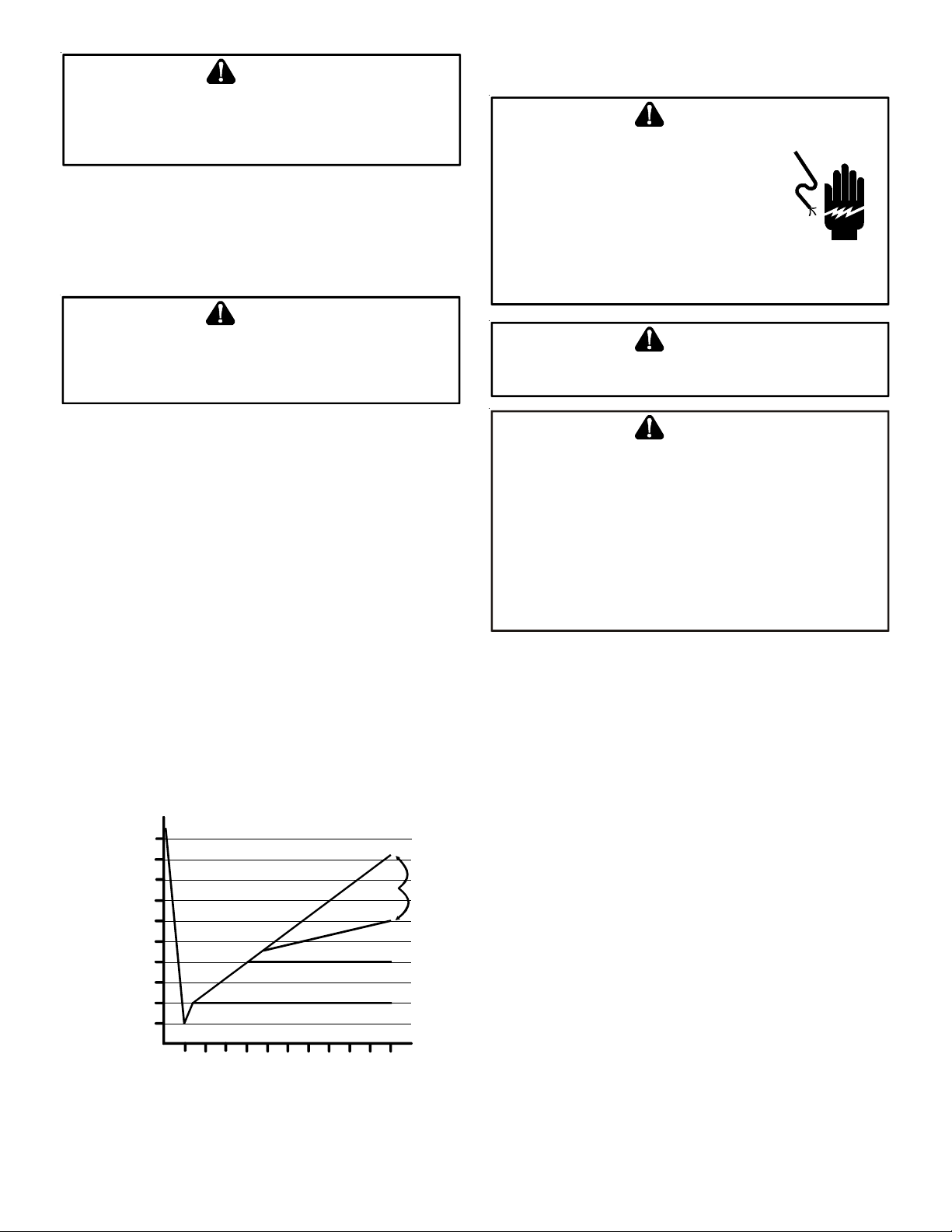

Route power supply and ground wires through the high voltage

port and terminate in accordance with the wiring diagram provided inside the control panel cover.

LOW VOLTAGE CONNECTIONS

The unit is designed to work as part of a fully communicating

HVAC system, utilizing a ComfortNet™ CTK04 thermostat,

ComfortNet compatible indoor unit, and up to four wires. Route

control wires through the low voltage port and terminate in accordance with the wiring diagram provided inside the control

panel cover.

6

Page 7

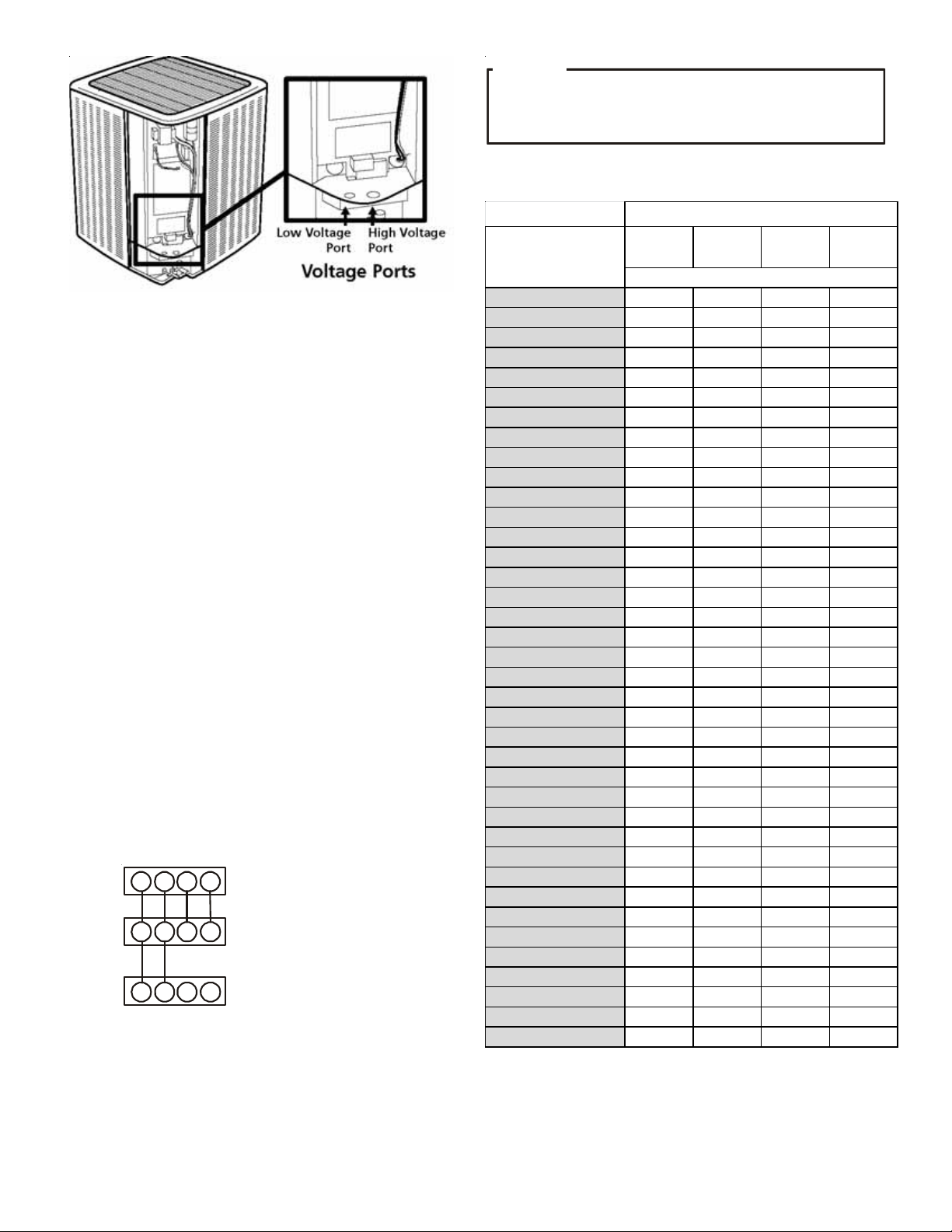

A

NOTICE

T

OTAL REFRIGERANT

F

ACTORY CHARGE

OF A

CTUAL LINE SET

The following table shows refrigerant amounts for every 5 feet of

line.

=

+ (0.6 OZ./FT. * A

).

DDITIONAL FEET

Unit Tonnage

Voltage Ports

NOTE: The communicating thermostat is able to search and iden-

tify the indoor and outdoor units when power is applied to the

system. Refer to the communicating thermostat’s installation

instruction manual for more information.

Connect low voltage communication wires (1, 2) to low voltage

pigtail provided.

THERMOSTAT WIRING

NOTE: A removable plug connector is provided with the control

to make thermostat wire connections. This plug may be removed,

wire connections made to the plug, and replaced. It is STRONGLY

recommended that you do not connect multiple wires into a

single terminal without mechanically twisting the tips together

with a set of pliers. Failure to do so may result in intermittent

operation.

Typical 18 AWG thermostat wire may be used to wire the system components. However, communications reliability may be

improved by using a high quality, shielded, twisted pair cable for

the data transmission lines. In either case, 250 feet is the maximum length of wire between indoor unit and outdoor unit, or

between indoor unit and thermostat.

TWO-WIRE OUTDOOR, FOUR-WIRE INDOOR WIRING

Low voltage wiring consists of two wires between the indoor

unit and outdoor unit and four wires between the indoor unit

and thermostat. The required wires are data lines 1 and 2, “R”

(24 VAC hot) and “C” (24 VAC common).

12RC

12RC

12RC

CTK04

Thermostat

Compatible

ir Handler/Furnace

Integrated Control Module

Compatible AC/HP

Integrated Control Module

System Wiring

Actual Line Set Length

(ft.)

15 (Factory Charge) 165 272 272 242

20 168 275 275 245

25 171 278 278 248

30 174 281 281 251

35 177 284 284 254

40 180 287 287 257

45 183 290 290 260

50 186 293 293 263

55 189 296 296 266

60 192 299 299 269

65 195 302 302 272

70 198 305 305 275

75 201 308 308 278

80 204 311 311 281

85 207 314 314 284

90 210 317 317 287

95 213 320 320 290

100 216 323 323 293

105 219 326 326 296

110 222 329 329 299

115 225 332 332 302

120 228 335 335 305

125 231 338 338 308

130 234 341 341 311

135 237 344 344 314

140 240 347 347 317

145 243 350 350 320

150 246 353 353 323

155 249 356 356 326

160 252 359 359 329

165 255 362 362 332

170 258 365 365 335

175 261 368 368 338

180 264 371 371 341

185 267 374 374 344

190 270 377 377 347

195 273 380 380 350

200 276 383 383 353

2-Ton 3-Ton 4-Ton 5-Ton

Refrigerant (Oz.)

STEP 1. CALCULATE REFRIGERANT CHARGE BASED ON LINE

SET LENGTH

The heat pump unit is shipped with a predetermined factory

charge level as shown below. For longer line sets greater than

15 feet, add 0.6 ounces of refrigerant per foot.

7

Page 8

STEP 2. CONNECT HEAT PUMP UNIT TO SYSTEM

OPEN THE LIQ UID VALVE FI R S T! IF

OPENED FIRST, OIL FROM THE COMPRESSOR MAY BE DRAWN INTO THE

INDOOR COIL OR

OPERATION OF THE SYSTEM

TXV

RESTRICTING REFRIGERANT FLOW AND AFFECTING

.

THE GAS SERVICE VALVE IS

CAUTION

POSSIBL E REFRIGER AN T LEAK!

TO

AVOID A POSSIBLE REFRIGERANT LEAK, OPEN THE SERVICE VALVES

UNTIL THE TOP OF THE STEM IS

1/8”

FROM THE RETAINER

.

CAUTION

E

NSURE VALVES ARE OPEN AND ADDITIONAL CHARGE IS ADDED PER

CHART BEFORE APPLYING POWER

.

ATTENTION INSTALLER - IMPORTANT NOTICE!

Please read carefully before installing this unit.

When opening valves with retainers, open each valve only until

the top of the stem is 1/8” from the retainer. To avoid loss of

refrigerant, DO NOT apply pressure to the retainer. When opening valves without a retainer, remove service valve cap and insert a hex wrench into the valve stem and back out the stem by

turning the hex wrench counterclockwise. Open the valve until it

contacts the rolled lip of the valve body.

NOTE: Units may utilize ball valves or front seating valves. These

are not back-seating valves. It is not necessary to force the stem

tightly against the rolled lip.

After the refrigerant charge has bled into the system, open the

liquid service valve. The service valve cap is the secondary seal

for the valves and must be properly tightened to prevent leaks.

Make sure cap is clean and apply refrigerant oil to threads and

sealing surface on inside of cap. Tighten cap finger-tight and then

tighten additional 1/6 of a turn to properly seat the sealing surfaces.

Do not introduce liquid refrigerant from the cylinder into the

crankcase of the compressor as this may damage the compressor.

Break vacuum by fully opening liquid and gas base valve.

• For AVZC20, do not install the 24 Volt Transformer that is included with the CTK04 Thermostat in the Heat

Pump Unit; it is not needed.

• Do not attach any wires to the R & C Terminals on the Heat Pump Unit, as they are not needed for inverter unit

setup.

•DATA LINE TERMINALS #1 AND #2 ARE POLARITY SENSITIVE. ONLY THE DATA LINES, 1 AND 2, ARE REQUIRED BETWEEN THE INDOOR AND

OUTDOOR

UNITS.

•DATA LINE TERMINAL #1 FROM OUTDOOR UNIT MUST CONNECT TO TERMINAL #1 ON INDOOR UNIT AND DATA LINE TERMINAL #2 FROM

OUTDOOR

UNIT MUST CONNECT TO TERMINAL #2 ON INDOOR UNIT. VERIFY WIRES ARE NOT REVERSED.

•IT IS STRONGLY RECOMMENDED TO USE WIRE NUTS AT THE INDOOR UNIT WHEN CONNECTING MULTIPLE DATA LINES OR LO W VOLTAGE WIRES

TOGETHER

. IT IS NOT RECOMMENDED TO USE THE TERMINAL BLOCK TO CONNECT TWO OR MORE WIRES.

• Calculate the Liquid Line Set length and weigh in 0.6 ounces per foot of R410A refrigerant for any length over

15 feet.

Or

• Charge by Sub-cooling.

Sub-cooling should be between 7° and 9°F. Allow 10 minutes of running in Charge Mode between each

amount of refrigerant added.

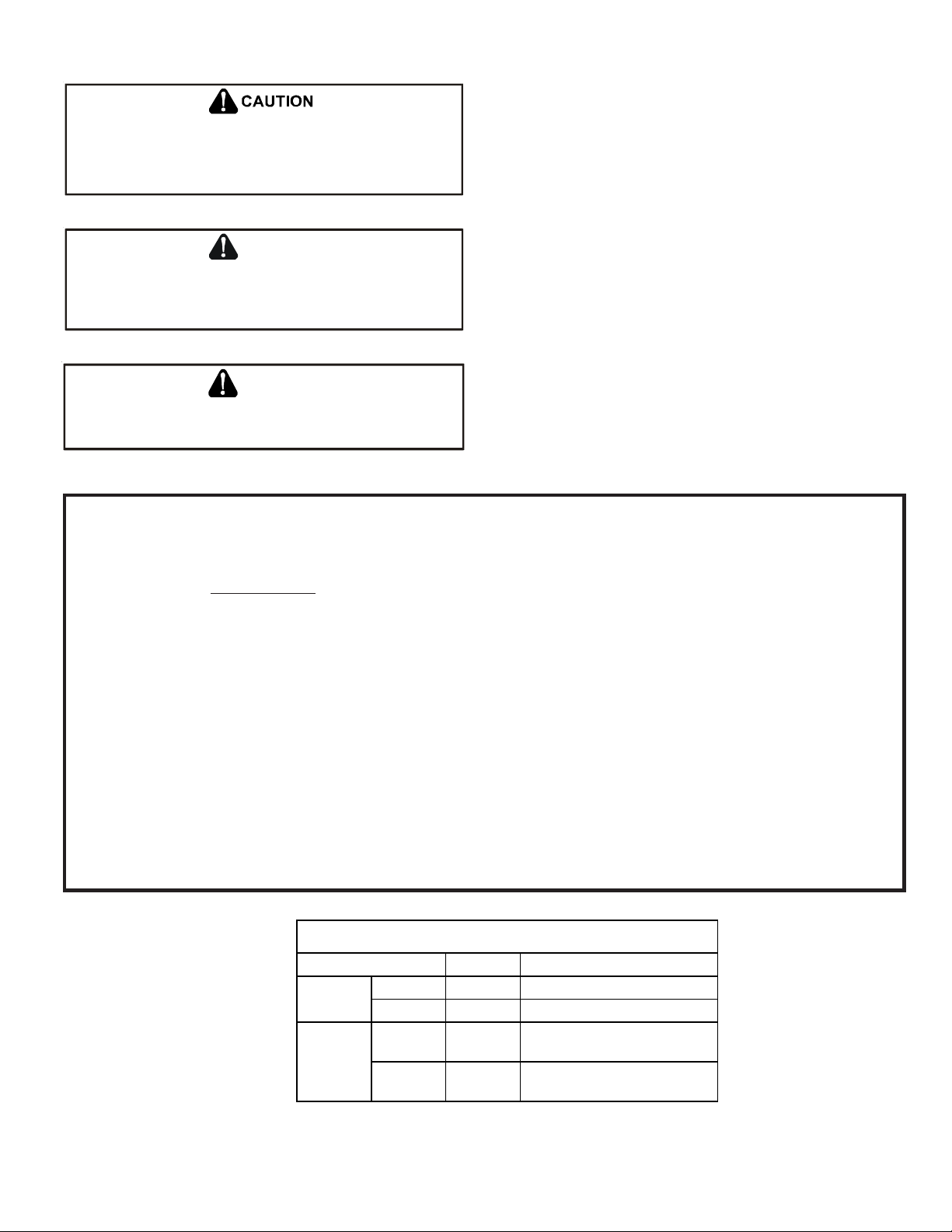

DIPSWITCH FAC TO RY DEFAULT SETTINGS

Switch #

OD DS1

OD DS2

* OD DS 2 s w i tch 1 and 2 bo th must be turned on

during normal operation mode

1 ON CT Communication Enabl ed

2 ON CT Communication Enabl ed

1ON

2ON

Setting Purpose

Cooling Emergency Mode

for Future Use *

Cooling Emergency Mode

for Future Use *

8

Page 9

STEP 3. SYSTEM START-UP TEST

NOTICE

ON

INITIAL POWER START-UP, THE OUTDOOR UNIT WILL DISPLAY CODE

E11,

SIGNALING THAT INITIAL

THE COMFORTNET™ SETUP SCREEN TO ENTER APPLICATION-UNIQUE

INFORMATION

DETAILED INFORMATION

. SEE C

A system test is now required to check the equipment

settings and functionality. Once selected, it checks the

equipment for approximately 5 - 15 minutes. System test

may exceed 15 minutes if there is an error. Refer to

the Troubleshooting section.

Before starting the SYSTEM TEST, turn off the electric heater

or gas furnace.

1. Ensure the thermostat is installed.

SYSTEM

OMFORTNET THERMOSTAT MANUAL FOR

TEST MUST BE RUN

. F

.

OLLOW

2. Apply power to outdoor and indoor units.

3. Start-up.

After the application information is entered,

the initial system test must be run.

NOTICE

FOR

INVERTER

TRANSFORMER

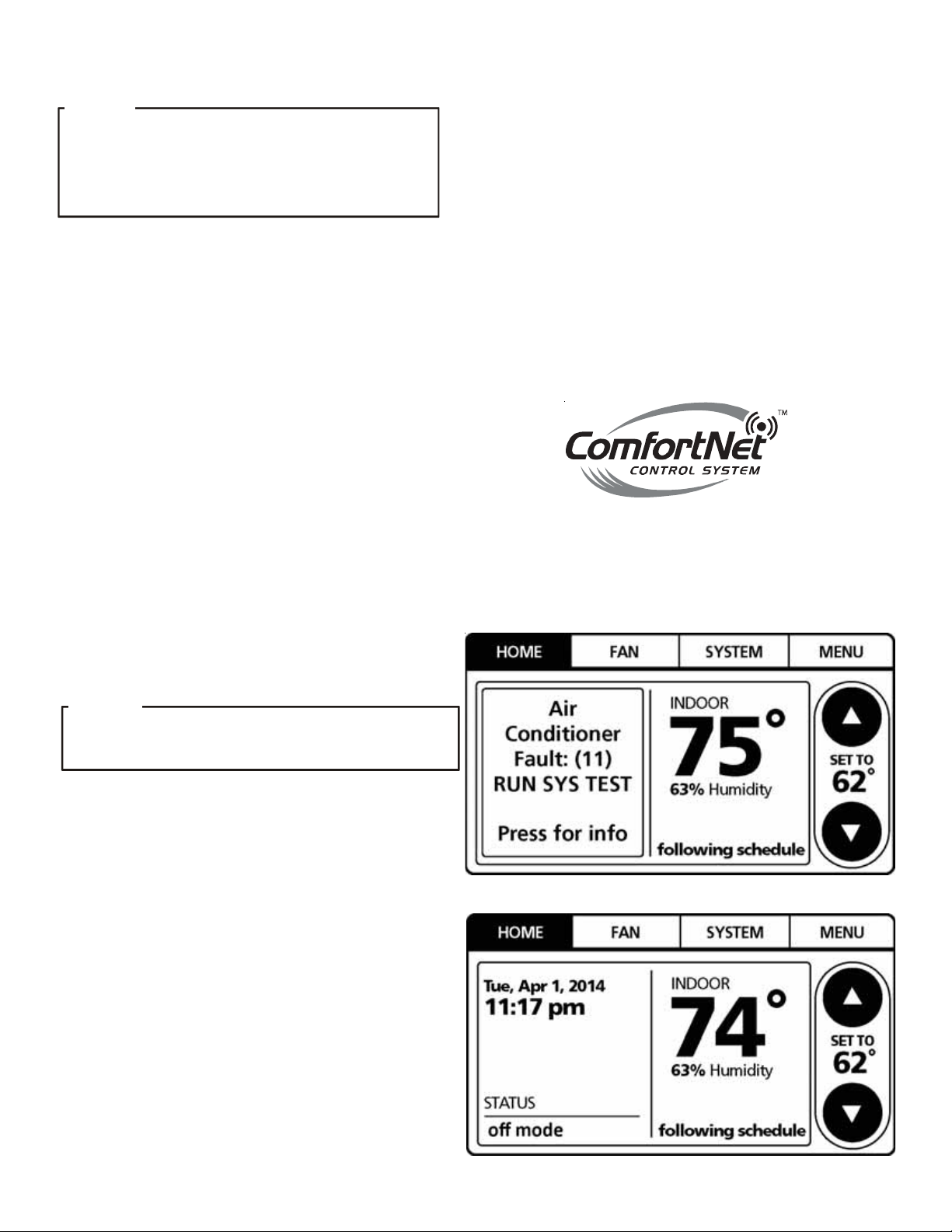

The HOME screen will be displayed showing

information similar to one of the adjacent screens.

Select MENU.

NOTE: Either screen may be displayed.

SYSTEM TEST must be run for all installations.

System will not operate without a completed initial

SYSTEM TEST.

NOTE: Ensure the thermostat is in OFF mode.

H/P

SYSTEM USING COMFORTNET, DO

.

NOT

INSTALL A

9

Page 10

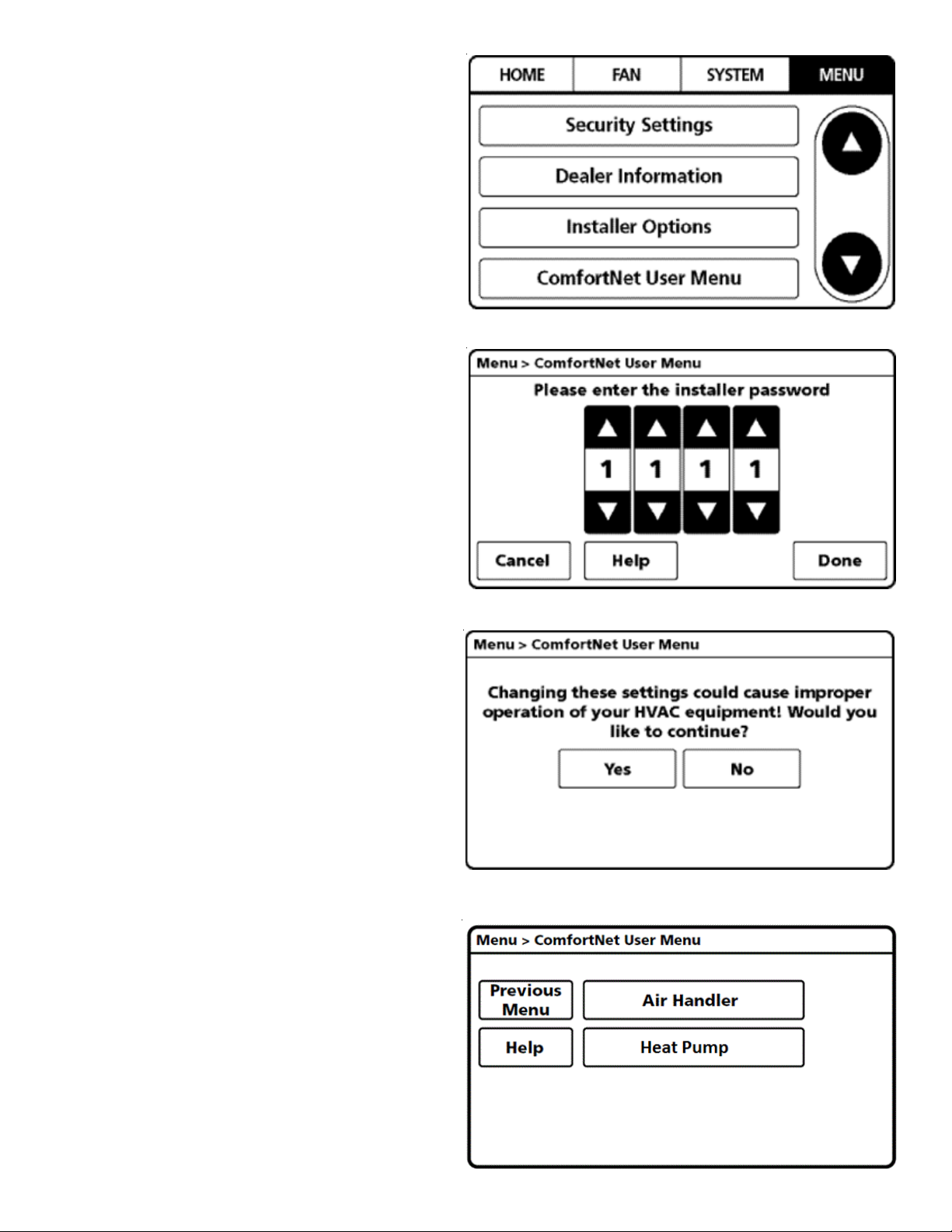

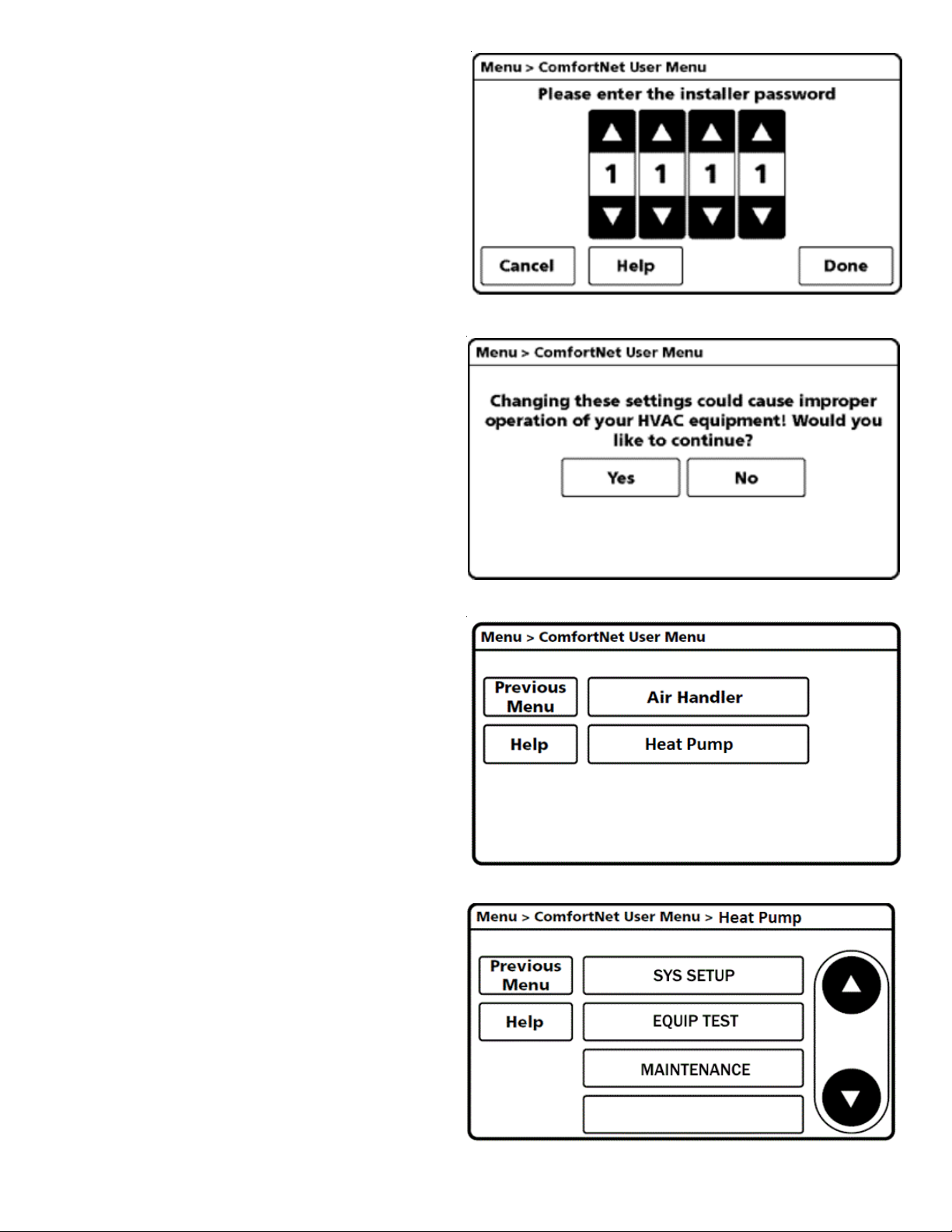

4. From the MENU screen, scroll down and select

COMFORTNET™ USER MENU.

5. Enter Installer password. (The password is the Date

Code located on the thermostat and is available by

entering the EQUIPMENT STATUS menu and

scrolling to the bottom.)

6. Select YES to continue.

7. From the ComfortNet USER MENU,

select HEAT PUMP.

NOTE: Screen may show air handler

or furnace depending on the type of system installed.

10

Page 11

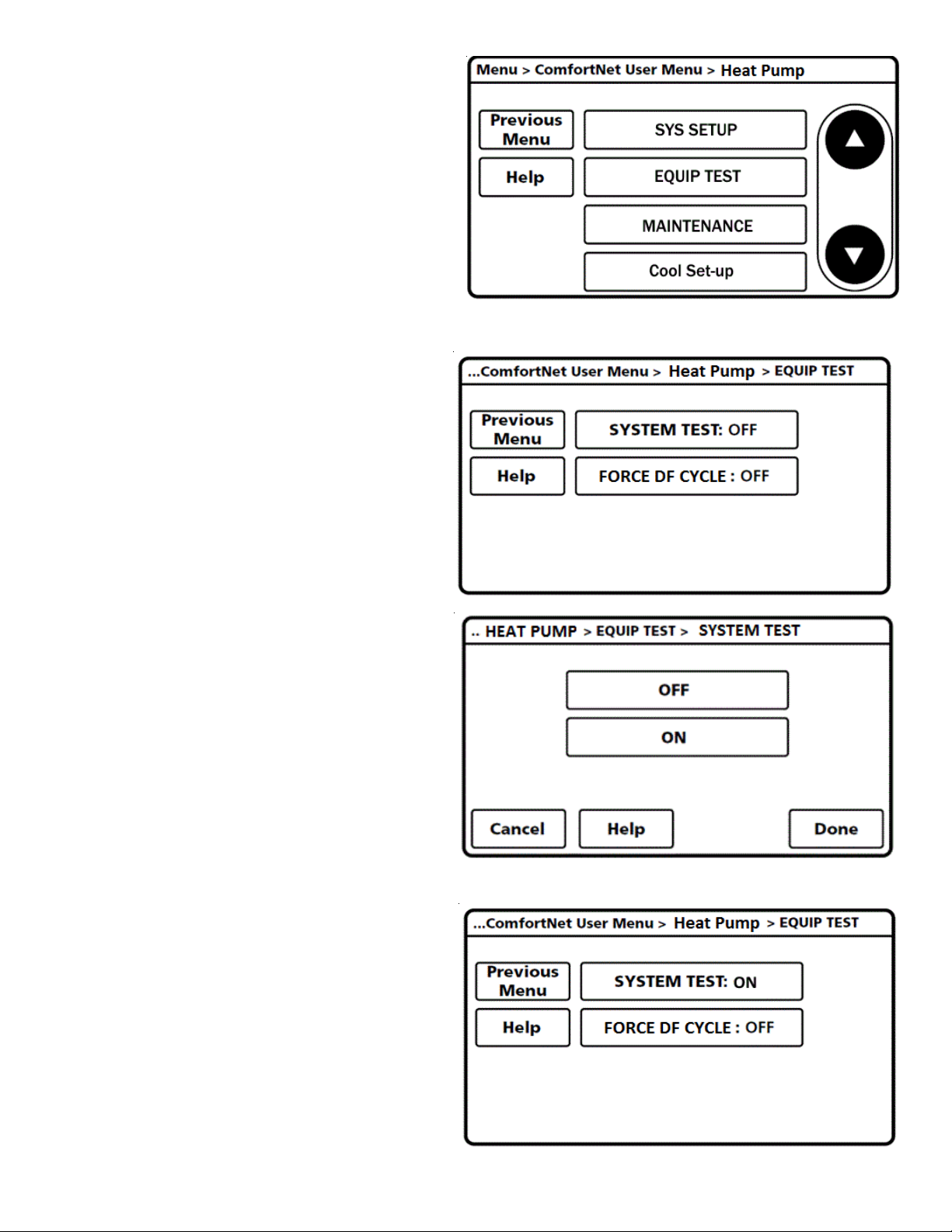

8. Next, scroll down and select EQUIP TEST.

9. Select SYSTEM TEST.

10. Select ON to run the SYSTEM TEST.

Press DONE to initiate test.

11. Allow the system test to run for its duration

(5-15 minutes). EQUIP TEST SCREEN will

show the system test is ON once selected.

System test will operate the outdoor unit and the

indoor unit through a series of startup tests.

Please proceed to the next step and allow for

startup tests to complete. Do not interrupt power

to outdoor unit, indoor unit, or thermostat

during system test.

11

Page 12

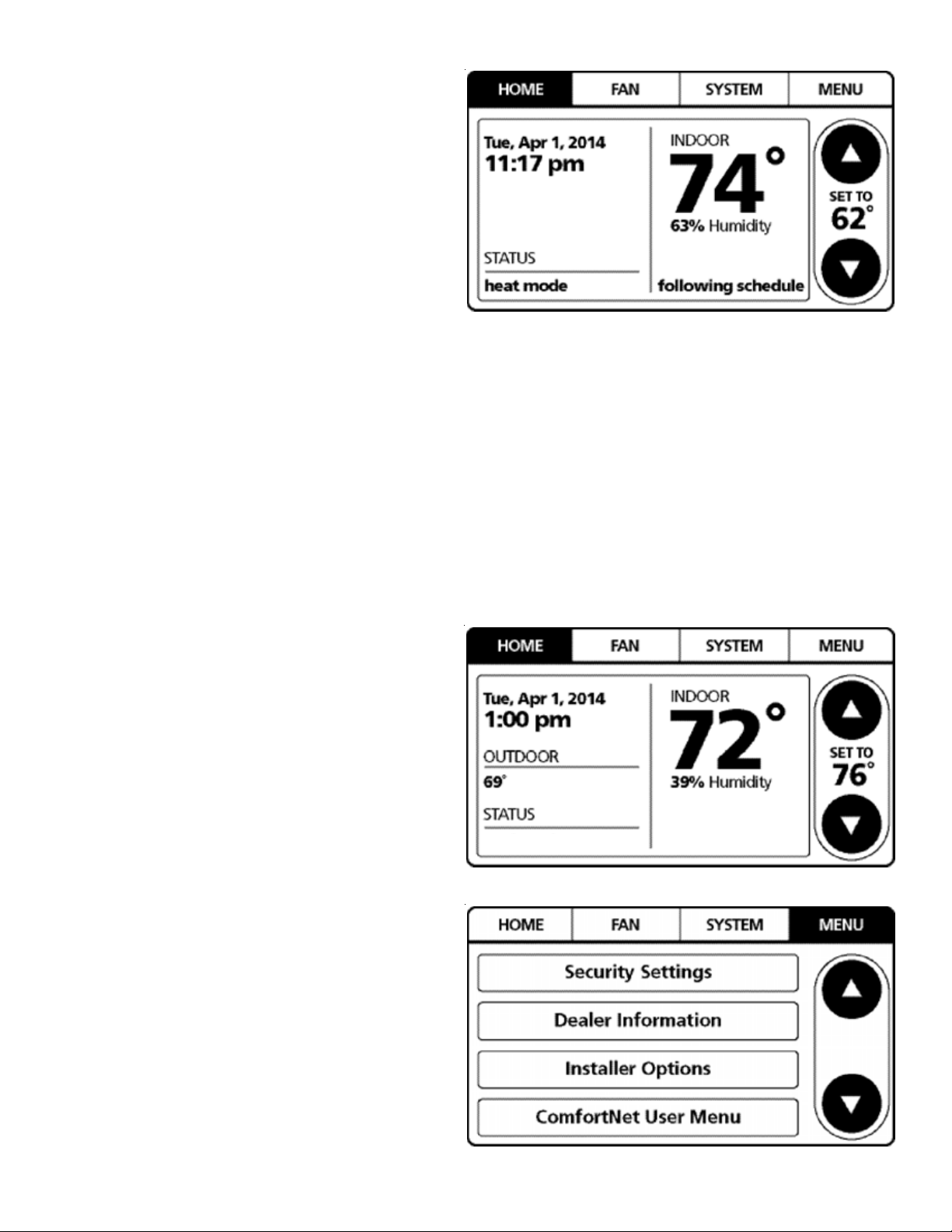

12. Press Previous Menu button and navigate to

HOME screen and allow test to finish. The display

similar to the one at the right will be displayed

after SYSTEM TEST completes. Test is complete

only when CODE 11 notice clears from BOTH the

thermostat display AND the seven segment LED

display on the outdoor unit. Please wait for test to

complete and for both codes to clear.

STEP 4. SET THERMOSTAT TO CHARGE MODE

Please follow the following sequence to enter CHARGE MODE.

CHARGE mode allows for charging of the system. System operates for a duration of approximately one hour while the

equipment runs at full capacity. After one hour, the CHARGE

MODE ends and the system resumes normal thermostat

operation.

Before starting the CHARGE MODE, turn off the electric

heater or gas furnace.

1. On the HOME screen, select MENU.

NOTE: Set COOL or HEAT MODE to OFF before starting

CHARGE MODE.

2. From the MENU screen, select

COMFORTNET™ USER MENU.

off

12

Page 13

3. Enter Installer password. (The password

is the Date Code located on the thermostat

and is available by entering the

EQUIPMENT STATUS menu and

scrolling to the bottom).

4. Select YES to continue.

5. Select HEAT PUMP.

6. Select MAINTENANCE.

13

Page 14

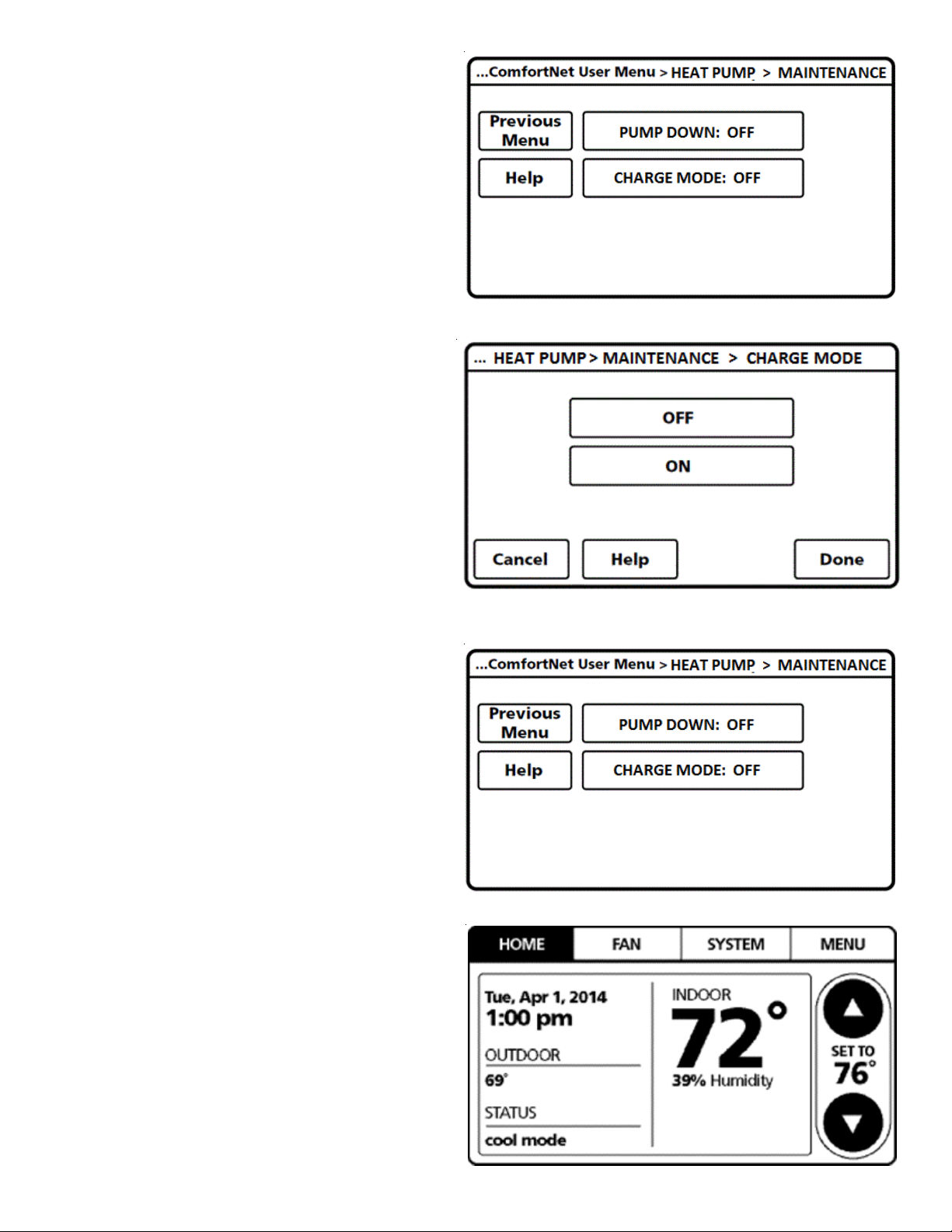

7. Select CHARGE MODE.

8. Select ON. Press DONE to initiate CHARGE mode. (System

will then run for 1 hour and either return to cooling or

heating mode depending on the mode thermostat is set

at COOL or HEAT, or stop if the thermostat is set for FAN

only mode.)

If charging is not complete after 1 hour, repeat

7. and 8.

Refer to STEP 5 and STEP 6 for refrigerant charge

level adjustment.

9. To terminate CHARGE MODE, select CHARGE

mode screen again. Press OFF. Press DONE to

terminate CHARGE MODE.

10. Once CHARGE MODE is complete and has been

terminated, navigate to HOME screen. Enter

normal operation with temperature offset or thermostat

schedule, as desired.

14

Page 15

STEP 5. ADJUST REFRIGERANT LEVEL

Using service equipment, add or recover refrigerant according to

the calculation in Step 1. Allow system to stabilize for 10 minutes

after adjusting charge level.

STEP 6. MEASURE SUBCOOLING TO VERIFY PROPER CHARGE

NOTE: Charging equipment must use dedicated PVE oil gauges

and hoses.

1. Purge gauge lines.

2. Connect service gauge manifold to base valve service ports.

3. Convert the liquid pressure to temperature using a

temperature/pressure chart.

4. Temporarily install a thermometer on the liquid line at

the liquid line service valve.

a. Ensure the thermometer makes adequate contact

and is insulated for best possible readings.

5. Subtract the liquid line temperature from the converted

liquid pressure to determine subcooling.

6. Before starting the Subcooling adjustment, make sure the

outdoor ambient temperature is in a below range and the

unit is operating at 100% capacity.

SUBCOOLING = (SA T. LIQUID TEMP .) - (LIQUID LINE

TEMP.)

SUPERHEA T = ( SUCT. LINE TEMP .) - (S AT . SUCT. TEMP .)

e. If subcooling and superheat are high, adjust the TXV

valve to 7 to 9°F superheat, then check subcooling.

f. If subcooling is high and superheat is 7 to 9°F, remove

charge to lower the subcooling to 7 to 9°F, then check

superheat.

g. If subcooling is high and superheat is low, adjust the

TXV valve to 7 to 9°F superheat and remove charge to

low the subcooling to 7 to 9°F.

h. If subcooling is 7 to 9°F and superheat is low, adjust the

TXV valve to 7 to 9°F superheat and remove charge to

lower the subcooling 7 to 9°F, then check the superheat.

NOTE: Not more than 0.5 lb. (8 Oz.) of refrigerant must

be added to the system in order to achieve the target

subcooling. It is recommended to add 4 oz. refrigerant

each time and try adjusting the TXV and let the system

stabilize.

NOTICE

C

HECK THE SCHRADER PORTS FOR LEAKS AND TIGHTEN VALVE CORES, IF

NECESSARY

. I

NSTALL CAPS FINGER-TIGHT

.

NOTICE

DO NOT

THERE IS A GROSS UNDERCHARGE

ADJUST THE CHARGE BASED ON SUCTION PRESSURE UNLESS

.

Chargi ng Tabl e

OD Ambie nt Tem p

(degF)

Subcooling

(degF)

Note: Subcooling information is valid only while the unit is operating

at 100% capacity or 100% of compressor speed in CHARGE MODE.

Compressor speed is displayed under STATUS menu in the thermostat.

< 65 °F 65°F to 105°F > 105 °F

Weigh in

Charge

7°F to 9°F

Weigh in

Charge

7. The system subcooling should be 7 to 9°F. If not in that

range, adjust subcooling and superheat according to the

following procedure.

a. If subcooling and superheat are low, adjust TXV to 7 to

9°F superheat, then check subcooling.

NOTE: To adjust superheat, turn the valve stem clockwise

to increase and counter clockwise to decrease.

b. If subcooling is low and superheat is 7 to 9°F, add charge

to rise subcooling to 7 to 9°F, then check superheat.

c. If subcooling is low and superheat is high, add charge to

rise subcooling to 7 to 9°F, then check superheat.

d. If subcooling is 7 to 9°F and superheat is high, adjust

the TXV valve to 7 to 9°F superheat, then check

subcooling.

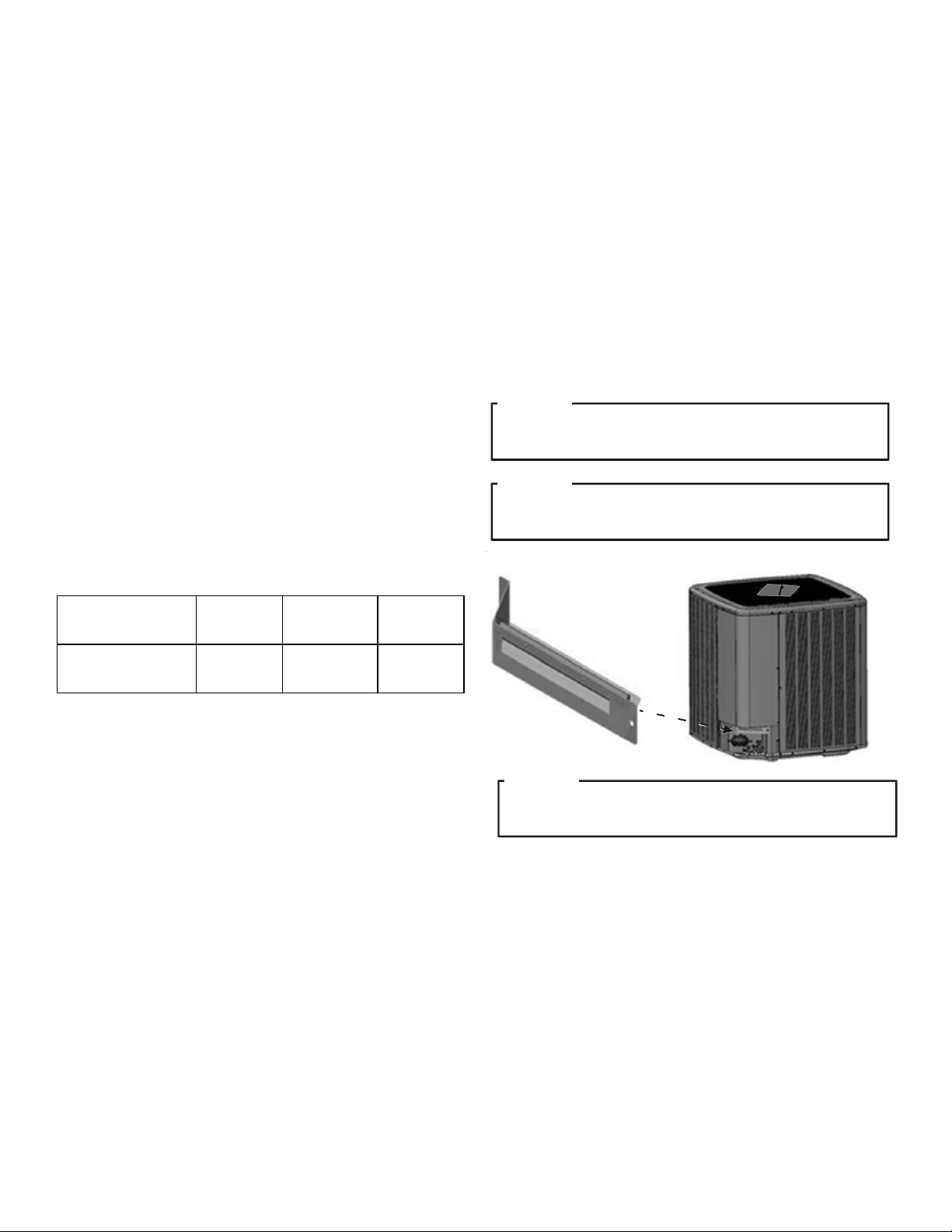

Rain

Shield

NOTICE

IF

THE RAIN SHIELD WAS REMOVED DURING THE INSTALLATION

PROCESS, BE SURE TO RE-INSTALL IT AFTER CHARGING THE UNIT

.

HEAT PUMP WITH OUTDOOR TEMPERATURE LOCKOUTS

It is recommended to set the outdoor temperature lockouts

during the initial thermostat set up. This will enable the compressor to be turned off and switch heating source from refrigeration to auxiliary/secondary heating under low ambient conditions.

15

Page 16

Backup heat lockout temperature will enable auxiliary/secondary heating to be turned on when outdoor temperature is

much higher than indoor temperature, compressor might stop

operating under this circumstance.

Line Set Length Range

(feet)

0 to 100 15

100 to 200 20

Compres sor Lo ck o ut T emperatu re

(°F)

In order to access temperature, the compressor lockout and

the backup heat lockout, press MENU and scroll down to

press INSTALLER OPTIONS. Enter the date code (password)

when prompted. Choose VIEW / EDIT CURRENT SETUP and

COMPRESSOR LOCKOUT / BALANCE POINT will be under

HEAT / COOL CONTROL OPTIONS. For more information

please refer to COMFORTNET™ CTK04 Communicating Thermostat SYSTEM INSTALLATION GUIDE.

BOOST MODE

BOOST MODE enables the system to operate at a higher compressor speed than rated maximum compressor speed and

satisfy the structural load more effectively during higher

ambient outdoor conditions. BOOST MODE is initiated by

an outdoor temperature sensor located in the outdoor unit.

Please note that outdoor equipment operational sound levels may increase while the equipment is running in BOOST

MODE. Disabling BOOST MODE will provide the quietest and

most efficient operation.

NOTE: BOOST MODE is applicable only for AVZC200**1AB

or later revision. BOOST MODE performance is most effective when paired with an electronic expansion valve enabled

indoor unit.

BOOST MODE is ON by default and is activated when the

outdoor temperature reaches 105°F. BOOST MODE can be

disabled and enabled and the activation temperature adjusted in the BOOST TEMP menu using the following procedure:

SATURATED SUCTI ON PRESS U RE

TEMPERATURE CHART

SUCTION PRESSURE LIQUID PRESSURE

PSIG PSIG

50 1 200 70

52 3 210 73

54 4 220 76

56 6 225 78

58 7 235 80

60 8 245 83

62 10 255 85

64 11 265 88

66 13 275 90

68 14 285 92

70 15 295 95

72 16 305 97

74 17 325 101

76 19 355 108

78 20 375 112

80 21 405 118

85 24 415 119

90 26 425 121

95 29 435 123

100 31 445 125

110 36 475 130

120 41 500 134

130 45 525 138

140 49 550 142

150 53 575 145

160 56 600 149

170 60 625 152

R-410A

°F

SATURATED L IQUID P RES SURE

TEMPERATURE CHART

R-410A

°F

1. On the CTK04 HOME screen, select MENU.

2. From the MENU screen, select COMFORTNET™ USER

MENU.

16

Page 17

3. Enter Installer password. (The password is the Date

Code located on the thermostat and is available by

entering the EQUIPMENT STATUS menu and scrolling

to the bottom).

4. Select YES to continue.

5. Select HEAT PUMP.

6. Select SYS SETUP.

17

COOL SET-UP

Page 18

7. BOOST MD turns BOOST MODE OFF or ON. BOOST

MODE is ON by default.

...Heat Pump > SYS SETUP > BOOST MD

8. BOOST TEMP adjusts the activation temperature

from 70°F to 105°F. “Always ON” option is also

available to permanently engage BOOST MODE.

Factory default is 105°F.

105F

...Heat Pump > SYS SETUP > BOOST TEMP

18

Page 19

9. Once satisfied with BOOST MODE adjustments, navigate

to the HOME screen by selecting the Previous Menu

button three times then selecting HOME.

DEHUMIDIFICATION

The thermostat reads the indoor humidity level from the CTK04

and allows the user to set a dehumidification target based on

these settings. The thermostat controls the humidity level of

the conditioned space using the cooling system. Dehumidification is engaged whenever a cooling demand is present and

structural humidity levels are above the target level. When this

condition exists, the circulating fan output is reduced, increasing system run time, over cooling the evaporator coil and ultimately removing more humidity from the structure than if only

in cooling mode. The CTK04 also allows for an additional

overcooling limit setting from 0°F to 3°F setup through the

Installer Option menu (directions following). This allows the

cooling system to further reduce humidity by lowering the temperature up to 3°F below the cooling setpoint in an attempt to

better achieve desired humidity levels.

By default, dehumidification needs to be turned ON at the thermostat via the Dehumidification Equipment menu. Dehumidification can be activated at the original equipment setup by

selecting the A/C with Low Speed Fan button in the Dehumidification Menu. Availability can be verified by pressing MENU

on the home screen. Scroll down and if a Dehumidification

button is present, dehumidification is activated.

If Dehumidification is not available in the menu then it must

be enabled through the Installer Options menu. Use the following procedure to enable and disable dehumidification:

1. On the CTK04 HOME screen select MENU.

2. From the MENU screen, scroll down and select Installer

Options.

3. Enter installer password if known.

a. The password is the thermostat date code and can

be obtained by selecting the red Cancel button and

selecting the Dealer Information button.

b. Once recorded, click the green OK button and re-

turn to the previous step.

4. Select YES to continue.

5. Select View / Edit Current Setup.

6. Scroll down and select Dehumidification.

7. Once open select Dehumidification Equipment: None.

8. From the Dehumidification Menu select A/C with Low Speed

Fan and click the green Done button.

9. Additional Dehumidification operational options can be

selected in the resulting window.

10. Once satisfied with the selection, navigate to the HOME

screen by selecting the Done button and selecting Yes to

verify the changes.

11. Select Previous Menu, then the HOME to return to the

main menu.

DEHUMIDIFICATION TIPS

For effective dehumidification operation:

• Ensure “Dehum” is ON through the Installer Options

menu and/or in the ComfortNet User Menu (COOL

SETUP).

- If ON, the Dehumidification menu should be visible in

the main menu.

• Verify the cooling airflow profile is set to “Profile D”.

- See the Cool Set-up section of the Installation Manual

for complete airflow profile details.

- By default, “Dehum” is ON and the cooling airflow pro-

file is set to “Profile D”.

• For additional dehumidification control, airflow settings

are field adjustable and can be fine-tuned to a value that

is comfortable for the application from a range of +15%

to -15%.

- See the Heat Pump Advanced Feature Menu section

of the Installation Manual for more detail.

19

Page 20

COMFORTNET™ SYSTEM

OVERVIEW

A ComfortNet inverter heating and air conditioning system uses

an indoor unit, outdoor unit and thermostat which digitally communicate with one another via a two-way communications path.

The thermostat sends commands to the indoor and outdoor

units. The thermostat may request and receive information from

both the indoor and outdoor units. This information may be displayed on the CTK04 thermostat. The indoor and outdoor units

also interact with one another. The outdoor unit may send commands to or request information from the indoor unit. This twoway digital communications between the thermostat and subsystems (indoor/outdoor unit) and between subsystems is the

key to unlocking the benefits and features of the ComfortNet

system.

Two-way digital communications is accomplished using only two

wires. The thermostat needs 24 VAC for power. 4 wires between

the indoor unit and thermostat plus two wires between the indoor unit and outdoor unit are all that are required to operate

the system.

COMFORTNET SYSTEM ADVANCED FEATURES

The ComfortNet™ system permits access to additional system

information, advanced set-up features, and advanced diagnostic/troubleshooting features. These advanced features are orga-

nized into a menu structure. See the HEAT PUMP ADVANCED

FEATURES MENU section for the menu layout.

DIRECTIONS TO HEAT PUMP ADVANCED FEATURE MENUS

Press MENU, scroll down and press COMFORTNET USER MENU.

Enter the date code (password) when prompted. The date code is

printed on the back of the thermostat; or press MENU > EQUIP-

MENT STATUS and scroll down to find the date code. After you

enter the password, select COMFORTNET USER MENU, answer YES

to the following menu and select HEAT PUMP to view the system

menus.

DIAGNOSTICS

The heat pump’s diagnostics menu provides access to the most

recent faults. The six most recent faults are displayed on the first

screen. Six additional faults are displayed under fault history.

Faults are stored in order from most recent to least recent. Any

consecutively repeated fault is stored a maximum of three times.

Example: A leak in the system, low refrigerant charge or an incompletely open stop valve can cause the unit to flash error code E15.

This error code suggests that the unit is experiencing operation at

low pressure. The control will only store this fault the first three

consecutive times the fault occurs.

NOTE: It is highly recommended that the fault list be cleared after

performing maintenance or servicing the system.

STATUS

This menu displays information about the systems current status.

This menu can be utilized to confirm correct functionality of the

equipment and for troubleshooting purposes. The following items

will be displayed:

TS Tim e Stamp

MD Mode

CRM Compressor Reduction Mode

RAD Requested and Actual % Demand

RAF Requested and Reported ID CFM

ATOF* Outdoor Air Temperature and Outdoor Fan RPM

DCT Discharge Temperature and Outdoor Coil Temperature

DLT Defrost Sensor and Outdoor Liquid Temperature

PSDST** Pressure Sensor and Outdoor Suction Temperature

* Only for AVZC200**1AB or later revision.

ATPRM is shown in AVZC200**1AA revision.

** Only for AVZC200**1AB or later revision.

PSD is shown in AVZC200**1AA revision.

Time Stamp: Provides compressor run time in hours.

Mode: Current system operational mode (COOLING, HEATING,

COOLING STARTUP, HEATING STARTUP, OIL RETURN, DEFROST,

STOP).

Compressor Reduction Mode: The compressor is running at a

speed lower than what is requested, based on the cooling load.

Requested and Actual % Demand: Compares the requested cool-

ing demand to what the equipment is providing. For steady state

operation, these numbers should match.

Requested and Reported ID CFM: Compares the requested in-

door airflow to what the indoor equipment has reported.

Outdoor Air Temperature and Outdoor Fan RPM: Displays the

outdoor air temperature as well as the outdoor fan speed (RPM).

Discharge Temperature and Outdoor Coil Temperature: Displays

the discharge temperature and outdoor coil temperature sensor

readings.

Defrost Sensor and Outdoor Liquid Temperature: Displays de-

frost sensor and outdoor liquid temperature sensor readings.

Pressure Sensor: Displays the pressure sensor reading.

20

Page 21

NOTE: Oil Return Mode: In order to properly return oil to the

compressor, compressor speed may periodically adjust to assist

oil circulation.

OFF

OFF

EQUIPMENT TEST

The mandatory system verification test is enabled from this menu,

which enables a functional check of the equipment, in addition

to ensuring proper stop valve position. The heat pump unit can

be set to manual defrost from this menu by selecting FORCE DF

CYCLE.

MAINTENANCE

Pump down and charge modes can be enabled within this menu.

COOL SET-UP

This menu allows for the adjustment of several cooling performance variables. Cool Airflow Trim (range from -15% to +15% in

3% increments), Cool Airflow Profiles, Cool Fan ON Delay, Cool

Fan OFF Delay and Dehumidification Select (enable or disable

dehumidification) can be adjusted in this menu. You can also

reset this entire menu to factory default settings. See the following images showing the four cooling airflow profiles.

• Profile A provides only an OFF delay of one (1) minute at 100%

of the cooling demand airflow.

OFF

• Profile B ramps up to full cooling demand airflow by first

stepping up to 50% of the full demand for 30 seconds. The

motor then ramps to 100% of the required airflow. A one (1)

minute OFF delay at 100% of the cooling airflow.

OFF

50% CFM

1/2 min

100% CFM 100% CFM

1 min

100% CFM

100% CFM

OFF

OFF

1 min

Airflow Tables

COOL RUN VALUES

Depending on the system configuration, adjusting the maximum

compressor RPS (revolutions per second) may be required. Necessary adjustments to the maximum compressor RPS are made

through the following sub-menus.

M

AXIMUM COMPRESSOR RPS RANGE FOR COOLING

Select the range that your maximum compressor RPS falls

within.

MAXIMUM COMPRESSOR RPS SELECTION FOR COOLING

Within the selected range, choose the specific maximum compressor RPS for the system configuration.

HEAT SET-UP

This menu allows for the adjustment of several heating performance variables. Heat Airflow trim (range from -15% to +15% in

3% increments), Heat Fan ON Delay, Heat Fan OFF Delay and

timed Defrost interval can be adjusted in this menu. Time interval of 30, 60, 90 and 120 minutes between two defrost cycles

can be set to suit the weather conditions and performance of

the unit.

HEAT RUN VALUES

Similar to cooling mode, the maximum compressor speed RPS

(revolutions per second) can be adjusted for heating mode under this menu.

MAXIMUM COMPRESSOR RPS RANGE FOR HEATING

Select the range that your maximum compressor RPS falls

within.

MAXIMUM COMPRESSOR RPS SELECTION FOR HEATING

Within the selected range, choose the specific maximum compressor RPS for the system configuration.

• Profile C ramps up to 82% of the full cooling demand airflow

and operates there for approximately 7 1/2 minutes. The

motor then steps up to the full demand airflow. Profile C also

has a one (1) minute 100% OFF delay.

OFF

100% CFM

• Profile D (default) ramps up to 50% of the demand for 1/2

minute, then ramps to 82% of the full cooling demand airflow

and operates there for approximately 7 1/2 minutes. The

motor then steps up to the full demand airflow. Profile D has a

1/2 minute at 50% airflow OFF delay.

OFF

21

Page 22

H

EAT PUMP ADVANCED FEATURE MENU

DIAGNOSTICS

SUBMENU ITEM

Clear Faults NO or YES Selecting "YES" clears the fault history.

Fault 1 Most recent HP f ault

Fault 2 2nd most recent HP fault

Fault 3 3rd most recent HP fault

Fault 4 4th mo st recent HP fault

Fault 5 5th mo st recent HP fault

Fault 6 6th mo st recent HP fault

SUBMENU ITEM COMMENTS

Time Stamp (TS)

Mode (MD)

Co mpressor Reductio n Mode (C RM)

Requested and Actual % Demand (RAD)

INDICATION/USER

MODIFIABLE OPTIONS

STATUS

Provides co mpresso r run time in ho urs.

Current system operation mode (COOLING, COOLING STARTUP, HEATING, HEATING STARTUP, DEFROST,

OIL RETURN, STOP).

Displays ON o r OFF status. ON indicates that the reduction mode is operating and the compressor is

running at a lower speed than the cooling load would normally require.

Displays a 0-100% value, based on a ratio of the requested cooling demand to what the system is actually

providing.

COMMENTS

Requested and Reported ID C FM (RAF)

Outdoo r Air Temperature and Outdoor Fan

RPM (ATOF*)

Discharge Temperature and Outdoor Coil

Temperature (DCT)

Def ro st sensor and Outdo or Liquid

Temperature (DLT)

Pressure Sensor (PSDST**)

* Only for AVZC200**1AB or later revision. ATPRM is shown in AVZC200**1AA revision.

** Only for AVZC20**1AB or later revision. PSD is shown in AVZC200**1AA revision.

Co mpares the requested indoor a irflo w to what the indo or equipment has repo rted.

Displays the outdoor air temperature as well as the outdoor fan speed (RPM).

Displays the discharge temperature and outdoor coil temperature sensor readings.

Displays the def rost temperature sensor and o utdo or liquid tempera ture sensor reading.

Displays the pressure sensor reading which is taken slightly upstream of the suction accumulator.

22

Page 23

H

EAT PUMP ADVANCED FEATURE MENU

SYSTEM SETUP (SYS SETUP)

SUBMENU ITEM USER MODIFIABLE OPTIONS COMMENTS

Reset System Setup Options to Facto ry

Defaults

SET MAX CURRENT N/A Future use.

VERTICAL RISE

BOOST MODE (BOOST MD) ON or OFF

BOOST MODE TEMPERATURE

(BOO ST TEMP)

SUBMENU ITEM

System Verification Test (SYSTEM TEST) ON or OFF

NO or YES Selecting "YES" resets this menu to factory default settings.

If the outdoor & indoor units are within +/- 15 ft. vertical distance,

Same Level, Outdoor Lower, or

Indoor Lower

Always ON, 70, 75, 80, 85,

90, 95, 100, 105F

EQUIPMENT TEST (EQUIP TEST)

INDICATION/USER

MODIFIABLE OPTIONS

select SAME LEVEL. If the outdoor unit is more than 15 ft. below the

indoor unit, select OUTDOOR LOWER. If the outdoor unit is more than

15 ft. above the indo or unit, select INDOOR LOWER.

BOOST MD turns BOOST MODE OFF or ON. BOOST MODE is ON by

default. See BOOST MODE section of this ma nual for more details.

BOOST TEMP adjusts the activation temperature from 70°F to 105°F.

An "Always ON" option is also available to permanently engage BOOST

MODE.

COMMENTS

System Verification Test must be run after installation. This is

approximately a 5-15 minute test. If the thermostat is set to COOL

mode, the system will enter CHARGE mode upon completion,

otherwise it will stop.

Force Def rost Cycle (FORCE DF CYCLE) ON or OFF This will make the unit run in defrost mode.

SYSTEM MAINTENANCE

SUBMENU ITEM USER MODIFIABLE OPTIONS COMMENTS

Ente r PU MP DOWN Mode. This pro cedure runs the equipment for

PUMP DOWN ON or OFF

CHARGE MODE ON or OFF

NOTE: BOOST MODE is applicable only for AVZC200**1AB or later revision.

approximately 15 minutes and allows accumulation of refrigerant at

the o utdoo r unit for purposes of removing & replacing the indoor unit

or outdoor unit.

Enter Charging Mode. This allows for a steady system operation for a

duration of approximately 1 hour to allow for refrigerant charging of

the system via the suction charge port. The system will stop af ter

completion.

23

Page 24

H

EAT PUMP ADVANCED FEATURE MENU

COOL SETUP

SUBMENU ITEM USER MODIFIABLE OPTIONS COMMENTS

CL Reset YES or NO Selecting to default factory setting.

Cool Airflow Trim Hi -15% to +15% in 3% increments Selects the cooling airflo w trim amount.

Cool Airflow Trim Int -15% to +15% in 3% increments Selects the cooling airflow trim amount.

Cool Airflow Trim Low -15% to +15% in 3% increments Selects the cooling airflow trim amount.

Cool Airflow Profile A, B, C, or D Selects the cooling airflow profile.

Cool ON Delay 5, 10, 20, 30 seconds Selects the indoor blower ON delay.

Cool OFF Delay 30, 60, 90, 120 seconds Selects the indoor blower OFF delay.

Dehumidif ic atio n Selec t ON o r OFF Sele cting OFF disables dehumidif icatio n; selecting ON

enables dehumidificatio n.

SET COOLING RUN VALUES (CL RUN VALUES)

SUBMENU ITEM USER MODIFIABLE OPTIONS COMMENTS

Maximum Compressor RPS Range for Cooling (COOL

RPS RANGE)

Maximum Compressor RPS Selection for C ooling

(COOL RPS SELECT)

Five different compressor RPS ranges

will be provided.

10 compressor RPS values will be

provided within the range selected in

the COOL RPS RANGE menu

Select the appropriate range for the installed system

configuration.

Select the appropriate compressor RPS for the installed

system c onfiguration.

HEAT S E T U P

SUBMENU ITEM USER MODIFIABLE OPTIONS COMMENTS

HT Reset YES or NO Selecting to default factory setting.

Heat Airflow Trim Hi -15% to +15% in 3% increments Selects the Heating airflow trim amount.

Heat Airflow Trim Int -15% to +15% in 3% increments Selects the Heating airflow trim amount.

Heat Airflow Trim Low -15% to +15% in 3% increments Selects the Heating airflow trim amount.

Heat ON Delay 5, 10, 15 seconds Selects the indoor blower ON delay.

Heat OFF Delay 30, 50, 70, 90 se conds Selects the indoor blower OFF dela y.

Maximum Defrost Interval 30 mins., 1 hr., 1.5 hrs. & 2 hrs. Se lects time def rost interval

SET HEATING RUN VALUES (HT RUN VALUES)

SUBMENU ITEM USER MODIFIABLE OPTIONS COMMENTS

Maximum Compressor RPS Range for Heating (HEAT

RPS RANGE)

Maximum Compressor RPS Selection for Heating (HEAT

RPS SELECT)

Five different compressor RPS ranges

will be provided.

10 compressor RPS values will be

provided within the range selected in

the HEAT RPS RANGE menu

Select the appropriate range for the installed system

configuration.

Select the appropriate compressor RPS for the installed

system c onfiguration.

24

Page 25

W

IRING DIAGRAM

- 2 TONS

AVZC200241**

HPS)

(

0140R00344-F

MOTOR

THERMI STOR/TEMPERATURE SENSO R

OMPONENT CODE

C

+

HIGH PRESSURE SWITCH

HIGH/ LOW PRESSURE TRA NSDUCER(H/LP T)

DS1/DS2 DIP SWITCH

SEG1-SEG 3 7- SEGMENT DISPLAY

Z1C-Z4 C F ERRITE CORE

TERMINAL

CONNECTOR

NOISELESS EARTH

ELECTRICAL GR OUND

HIGH VOLTAGE

LOW VOLTAGE

HIGH VOLTAGE FIELD

BS1-BS3 PUSH BUTTON SWITCH

RVC REVERSIN G VALVE COIL

M1C COMPRESSO R MOTOR

M1F FAN MOTOR

HP MODELS

W

U

V

COMP RESSOR

TERMINAL ORIENTATION

X12A

-

SHARE DATA

BS3

BS2

BS1

DS1

2

12R

BK

HPS

Z1C

BK

RD

V

X32A

C

UNIT

NOTE 1

X851A

W1Y1Y2

U

L

0

SEE NOTE 4

WH

X52A

OFF

ON

1

R

OO

GY

TO I ND

H/LPT

+

PU

RD

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. F AILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

POWER CON DITI ONER

AMBIENT

RVC

YL BL

BK

BK

TRANSFORMER

24V

1

2

RD

3

208/240 V

ON

OFF

2

DS2

EEV

RING

COLOR

X17A

1

NOTE 1

SEG3

SEG2

SEG1

X21A

X11A

C

C

R

O

L

C

U

I

I

T

I

T

D

O

R

S

E

F

D

I

L

N

I

L

Q

E

U

I

G

E

R

C

D

A

H

S

I

L

N

E

I

GR

M1C

YL

Z4C

W

HR2

HR4

INVERTER BOA RD

X25A

BK

M1F

BK

RD

WH

X108A

HR1 H R3

RD

BK

L1

L2

E1

TAB L E

EC13006-1 (2T) AVZC200241 DZ20VC0241

INVERTER MODEL

COLOR CODE:

RD------RED

BR------BROWN

GR------GREEN

BK-------BLACK

WH-----WHITE

YL------YELLOW

BL------BLUE

GY---- -GRAY

PU------PURPLE

BR

WH

UG

D L

SEE NOTE 3

GROUN

Z3C

TERMINAL BLOCK

208-230 V

60 HZ

FIELD WI RING

SEE NOTE 3

GR

RS ONLY.

TO

4. CLASS 2 WIRE

1.THE POSITION OF TH E SELECTOR SW ITCHES (DS1/DS 2) INDICATE FACTORY SETTING.

2. MOTOR OVERLOAD PROTECTION PROVIDED BY INVERTER : SEE TABLE

3. USE COPPER CONDUC

NOTES :

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

25

Page 26

WIRING DIAGRAM - 3 - 4 TONS

E TRANSDUCER(H/LPT)

UR

MOTOR

THERMISTOR/TEMPERATURE SENSOR

COMPO NENT CODE

HIGH/LOW PRESS

+

AVZC200361**; AVZC200481**

HPS)

(

0140R00345-G

TERMINAL

CONNECTOR

NOISE LES S EART H

ELECTRICAL GROUNDHIGH VOLTAGE

LOW VOLTAGE

HIGH PRESSURE SWITCH

-

COMPRESSOR

DS1/D S2 D IP SWITCH

SEG1-SEG3 7-SEGMENT DISPLAY

Z1C-Z3C FERRITE CORE

BS1-B S3 PUSH BUTTON SWITCH

RVC RE VERSING VALVE COI L

M1C C OMPRESS OR M OTOR

M1F FAN MOTOR

W

U

V

TER MINAL ORIE NTATION

Z1C

RD

HIG H VOLTAGE FI ELD

DZ20VC0481

DZ20V C0361

1

HP MODELS

200481

TABL E

EC13008 -1 (3T) AVZC20036

EC13008-1 (4T) AVZC

INVERTER MODEL

GR

M1C

Z2C

M1F

COLOR CODE:

RD------RE D

BR------BR OWN

GR---- --GREEN

BK-------BL ACK

WH-----WHITE

YL-- ----YELLOW

BL-- ----BLUE

BK

L1B

L2A L1A

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. F AILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

TRAN SFORME R

1

2

208/24 0 V

3

L2B

NOISE FILTER

BO ARD

X98A

GR

RD

BK

RVC

24V

BK

RD

L2C

BK

ON

OFF

L1C

BL

RD

EEV

X21A

X11A

AMBIENT

X17A

+

-

H/LPT

RING

COLOR

2

1

DS2

NOTE 1

BS3

BS2

SEG1 SEG2 SEG3

UIT

COIL CIRC

WH

BS1

OFF

DS1

2

ON

1

2

1

LIQUID LINE

DISCHARGE LINE

DEFROST

X12A

GY

RD

BL

BK

YL

BK

NOTE 1

R

OOR

TO IND

BK

U

SHARE DATA

X85 1A

C

U NIT

RD

V

W1Y1Y2

YL

W

L

SEE NOTE 4

BK

WH

RD

Z3C

X108A

INVERTER BOARD

TERMINAL BLOCK

X52A

X111 A

FIN THERMISTOR

X32 A

0

X99A

X25A

E1

GR

FIELD

WIRING

HPS

GND

SEE NOTE 3

NOTE 3

208- 230 V

60HZ

CH

E S (DS1/DS2) INDICATE FACTORY SETTING.

RS ONLY.

TO

NDUC

R CO

E

1. THE POSITION OF THE SELECTOR SWIT

2. MOTOR OVERLOAD PROTECTION PROVIDED BY INVERTER:SEE TABLE

3. USE COPP

4. CLAS S 2 WIR E

NOTES:

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

26

Page 27

WIRING DIAGRAM - 5 TONS

MOTOR

THERMISTOR/TEMPERATURE SENSOR

COMPONENT CODE

AVZC200601**

0140R00346-G

HIGH/LOW PRESSURE TRANSDUCER(H/LPT)

+

HIGH PRESSURE SWITCH(HPS)

-

COMPRESSOR

TERMINAL

WH

DS1/DS2 DIP SWITCH

SEG1-SEG3 7-SEGMENT DISPLAY

Z1C-Z2C FERRITE CORE

WH

V

W

U

ORIENTATION

TERMINAL

CONNECTOR

NOISELESS EA RTH

ELECTRIC AL GROUND

HIGH VOLTAGE

LOW VOLTAGE

HIGH VOLTAGE FIELD

CRANKCASE HEATER(CH)

C0601

V

20

BS1-BS3 PUSH BUTTON SWITCH

RVC REVERSING VALVE COIL

M1C COMPRESSOR MOTOR

M1F FAN MOTOR

WH

WH

CAPACITOR

M1C

Z1C

.

THESE WIRES GO

THROUGH THE

CURRENT SENSOR HOLE

DZ

1

HP MODELS

TA BL E

EC13042- 1 (5T ) A VZC 20060

INVERTER MODEL

TTING.

ES:

1. THE POSITION OF THE SELECTOR SWITCHES (DS1/DS2) INDICATE FACTORY SE

2. MOTOR OVERLOAD PROTECTION PROVIDED BY INVERTER: SEE TABLE

3. USE COPPER CONDUCTORS ONLY.

4. CLASS 2 WIRE

OT

N

YL

BK

POW ER

CONDITIONER

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. F AILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

BK

C

R

V

24V

BK

3 1

2

TRANSFORMER

208/240V

X301A

FIN THERMISTOR

HPS

GR

M1F

Z2C

BK

RD

WH

X108A

X302A

X111A

X32A

X202A

2

1

DS2

NOTE 1

ON

OFF

SEG

3

BS2 BS3

SEG

2

SEG

1

BS1

X21A

EEV

FAN CONTROL

BOARD

RD

U

V

W

X11A

AMBIENT

BK

COIL CIRCUIT

X17A

+

-

H/LPT

WH

GY

OR

N

P

L1D

X201A

SHARE DATA

X101A

LIQUID LINE

DISCHARGE LINE

DEFROS T

X12A

YL

RD

BL

RING

COLOR

L1E

X52A

2

1

DS1

NOTE 1

ON

OFF

X99A

X851A

1

2

R

C

W1

BK

GY

TO INDOOR

UNIT

X28A

L

0

Y1

Y2

SEE

BR

CH

NOTE 4

BK

CURRENT SENSOR

INVERTER B OARD

BK

L2C L1C

BL

X25A

RD

L1B

L2B

L1A

BK

GND

SEE NOTE 3

RD

RD

X98A

L2A

NOISE FILTER

BOARD

RD

GR

TERMINAL

BLOCK

NOTE 3

208-230 V

60 HZ

FIELD

WIRING

RD------RED

BR------BROWN

GR------GREEN

BK------ -BLACK

WH-----WHITE

YL------YELLOW

BL------BLUE

OR------ORANGE

COLOR CO DE:

GY------GRAY

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

27

Page 28

C

AP ACIT OR

2 TON

WARNING

A

VOID CONTACT WITH THE CHARGED AREA

EVER TOUCH THE CHARGED AREA BEFORE CONFIRMING THAT THE RESIDUAL VOLTAGE IS

•N

1. S

HUT DOWN THE POWER AND LEAVE THE CONTROL BOX FOR

AKE SURE TO TOUCH THE EARTH GROUND TERMINAL TO RELEASE THE STATIC ELECTRICITY FROM YOUR BODY (TO PREVENT

2. M

FAILURE OF THE

EASURE THE RESIDUAL VOLTAGE IN THE SPECIFIED MEASUREMENT POSITION USING A

3. M

TOUCH THE CHARGED AREA

MMEDIATELY AFTER MEASURING THE RESIDUAL VOLTAGE, DISCONNECT THE CONNECTORS OF THE OUTDOOR UNIT’S FAN

4. I

MOTOR

THE DANGER OF ELECTRICAL SHOCK

PC

BOARD

).

.

. (IF

THE FAN BLADE ROTATES BY STRONG WIND BLOWING AGAINST IT, THE CAPACITOR

.

50

10

MINUTES

VOLTS OR LESS

.

VOM

WHILE PAYING ATTENTION NOT TO

.

WILL BE CHA R GE D,

.)

CAUSING

DEFROST

ON

BK

RD

YL

C518

RECALL LEARN

TEST

VCT

7

1

6

ICT

FCT

C-

ƒRƒ“ƒfƒ“ƒT

–

{‘Ì i‹à‘®

j

Žæ•t‚¯‹à‹ï‚ª—L‚é

[

C

[

T

ƒ

“

ƒ

®

f

ƒ

“

ƒ

R

ƒ

L‚é

j

i‹à‘

{‘Ì

–

—

t‚¯‹à‹ï‚ª

•

Žæ

01

PU

RD

3

1

6

C

BK

()

1

2

1

6

C

WH

~~

BK

BR

WH

+-

C+

BK

ON

TERM

RD

DIP

C610

C609

C-

Capacitor Voltage

C+

28

Page 29

CAPACITOR

A

VOID CONTACT WITH THE CHARGED AREA

•N

1. S

2. M

3. M

4. I

3 - 4 TON

WARNING

.

EVER TOUCH THE CHARGED AREA BEFORE CONFIRMING THAT THE RESIDUAL VOLTAGE IS

HUT DOWN THE POWER AND LEAVE THE CONTROL BOX FOR

AKE SURE TO TOUCH THE EARTH GROUND TERMINAL TO RELEASE THE STATIC ELECTRICITY FROM YOUR BODY (TO PREVENT

FAILURE OF THE

EASURE THE RESIDUAL VOLTAGE IN THE SPECIFIED MEASUREMENT POSITION USING A

TOUCH THE CHARGED AREA

MMEDIATELY AFTER MEASURING THE RESIDUAL VOLTAGE, DISCONNECT THE CONNECTORS OF THE OUTDOOR UNIT’S FAN

MOTOR

THE DANGER OF ELECTRICAL SHOCK

PC

BOARD

).

.

. (IF

THE FAN BLADE ROTATES BY STRONG WIND BLOWING AGAINST IT, THE CAPACITOR

.)

10

MINUTES

.

50

VOLTS OR LESS

VOM

WHILE PAYING ATTENTION NOT TO

.

WILL BE CHA R GE D,

CAUSING

C+

Capacitor Voltage

C-

29

Page 30

CAPACITOR

A

VOID CONTACT WITH THE CHARGED AREA

•N

EVER TOUCH THE CHARGED AREA BEFORE CONFIRMING THAT THE RESIDUAL VOLTAGE IS

1. S

2. M

FAILURE OF THE

3. M

TOUCH THE CHARGED AREA

4. I

MOTOR

THE DANGER OF ELECTRICAL SHOCK

5 TON

WARNING

.

50

VOLTS OR LESS

HUT DOWN THE POWER AND LEAVE THE CONTROL BOX FOR

AKE SURE TO TOUCH THE EARTH GROUND TERMINAL TO RELEASE THE STATIC ELECTRICITY FROM YOUR BODY (TO PREVENT

PC

BOARD

).

EASURE THE RESIDUAL VOLTAGE IN THE SPECIFIED MEASUREMENT POSITION USING A

10

MINUTES

.

VOM

WHILE PAYING ATTENTION NOT TO

.

.

MMEDIATELY AFTER MEASURING THE RESIDUAL VOLTAGE, DISCONNECT THE CONNECTORS OF THE OUTDOOR UNIT’S FAN

. (IF

THE FAN BLADE ROTATES BY STRONG WIND BLOWING AGAINST IT, THE CAPACITOR

WILL BE CHA R GE D,

.)

CAUSING

30

C+C-

Capacitor Voltage

Page 31

HEATING ANALYSIS CHART

POSSI BLE CA USE

X IN ANALYSIS GUIDE INDICATE

"POSSIBLE CAUSE"

Comp discharge temp > 200F

Comp discharge temp < 105F

Comp discharge SH > 70F

Comp discharge SH < 20F

High pressure > 490psi

High pressure SSV< 270psi

High pressure LSV< 270psi

Liquid stop valve does not fully open

Gas stop valve does not fully open

Line set restriction

Line set length is too long

Blocked filter-dryer

OD EEV coil failure

OD EEV failure

Check valve failure – Leakage

High Pressure switch failure