Amana AVPTC37B14, AVPTC33C14, AVPTC37C14, AVPTC31C14, AVPTC39C14 Installation & Operating Instructions Manual

...Page 1

AVPTC**14**

®

AIR HANDLERS

INSTALLATION & OPERATING INSTRUCTIONS

Contents

© 2018 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com - or - www.amana-hac.com

P/N: IOA-4030 Date: May 2018

1 Important Safety Instructions ................................... 2

2 Shipping Inspection ................................................... 3

3 Codes & Regulations ................................................. 3

4 Replacement Parts ..................................................... 3

5 Pre-Installation Considerations................................. 3

6 Installation Location................................................... 3

7 Refrigerant Lines........................................................ 5

8 Condensate Drain Lines ............................................ 8

9 Ductwork .................................................................... 9

10 Return Air Filters ........................................................ 9

11 Achieving 1.4% and 2.0% Airflow Low

Leakage Rate .............................................................. 9

12 Electric Heat ............................................................... 9

13 Electrical and Control Wiring .................................. 10

14 AVPTC Motor Orientation .........................................11

15 Cool Cloud HVAC Phone Application ........................11

16 Quick Start Guide for Communicating

Outdoor Units........................................................... 12

17 Quick Start Guide for Non-Communicating

Outdoor Units........................................................... 12

18 Dehumidification ....................................................... 14

19 Auxiliary Alarm Switch ............................................. 14

20 Start-Up Procedure.................................................. 14

21 Accessories .............................................................. 14

22 Ramping Profiles ...................................................... 15

23 Electric Air Cleaner Warning ................................... 15

24 Start-Up Procedure.................................................. 16

25 Regular Maintenance ............................................... 16

26 Air Handler Troubleshooting Matrix ........................ 17

27 Air Handler Display .................................................. 19

28 Airflow Label ............................................................. 22

29 Wiring Diagram ........................................................ 23

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE OR

REPAIR (HEREINAFTER

SHOULD SERVICE THE EQUIP MENT

FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE OR

SERVICE PROCED URES

FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAY RESULT

JURISDICTIONS THAT REQUIRE ONE OR MORE LICENSES TO SERVICE THE EQUIPMENT

SPECIFIED IN THIS MANUAL, ONLY LICENSED PERSONNEL SHOULD SERVICE THE

EQUIPMENT

THE EQUIP MENT SPECIFIED IN THIS MANUAL, OR ATT EM PT ING TO INSTALL, ADJUST

SERVICE OR REPAIR THE EQUIP MENT SPECIFIED IN THIS MANUAL WITHOUT PROPER

TRAINING MAY RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH

, “

SERVICE

”)

THE EQUIPM ENT SPECIFIED IN THIS MANUAL

. THE

MANUFACTURER WILL NOT BE RESPONSIBLE

. IF

YOU SERVICE THIS UNIT, YOU ASSUME RESPONSIBILITY

. IN

ADDITION, IN

. I

MPROPER INSTALLATION, ADJUSTME NT, SERVICING OR REPAIR OF

.

,

RECOGNIZE THIS SYMBOL AS A

SAFETY PRECAUTION.

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation Manual. Observe all safety warnings. During installation or repair,

caution is to be observed. It is your responsibility to install the product

safely and to educate the customer on its safe use.

is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

-

Page 2

1 Important Safety Instructions

The following symbols and labels are used throughout this manual

to indicate immediate or potential safety hazards. It is the

owner’s and installer’s responsibility to read and comply with all

safety information and instructions accompanying these symbols.

Failure to heed safety information increases the risk of personal

injury, property damage, and/or product damage.

To prevent the risk of property damage, personal

injury, or death, do not store combustible materials or

use gasoline or other flammable liquids or vapors in

the vicinity of this unit.

This product is factory-shipped for use with

208/240/1/60 electrical power supply.

reconfigure this air handler to operate with any other

power supply.

To avoid property damage, personal injury or death

due to electrical shock, this unit MUST have an

uninterrupted, unbroken

electrical ground. The

electrical ground circuit may consist of an

appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel.

Other methods of grounding are permitted if performed

in accordance with the National Electric Code

(NEC)/American National Standards Institute

(ANSI)/National Fire Protection Association (NFPA) 70

and local/state codes. In Canada, electrical grounding

is to be in accordance with the Canadian Electric Code

(CSA) C22.1.

When installing or servicing this equipment, safety

clothing, including hand and eye protection, is

strongly recommended. If installing in an area that has

special safety requirements (hard hats, etc.), bserve

these requirements.

DO NOT

o

CO can cause serious illness includ ing permanent brain

dama ge or d eath.

Advertencia especial para la instalación de calentadores ó manejadoras

de aire en áreas cerradas c omo estacionamientos ó c uartos de servi cio.

Las emisiones de monóxido de carbono pueden circular a través

del aparato cuando se opera en cualquier modo.

El monóxido de carbono puede causar enfermedad es severas

como daño cerebral perma nente ó muerte.

RISQUE D'EMPOISONNEMENT AU

MONOXYDE DE CARBONE

Do not connect to or use any device that is not designcertified by the manufacturer for use with this unit.

Serious property damage, personal injury, reduced

unit performance and/or hazardous conditions may

result from the use of such non-approved devices.

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

Cette ventilation est nécessaire pour éviter le danger d'intoxication

au CO pouvant survenir si un appareil produisant du monoxyde

de carbone con tinue de fonctionne r au sein de la zone confinée.

2

Page 3

2 Shipping Inspection

Always transport the unit upright; laying the unit on its side or top

during transit may cause equipment damage. The installer should

inspect the product upon receipt for shipping damage and subsequent investigation is the responsibility of the carrier. The installer

must verify the model number, specifications, electrical characteristics, and accessories are correct prior to installation. The distributor or manufacturer will not accept claims from dealers for

transportation damage or installation of incorrectly shipped units.

2.1 Parts

Also inspect the unit to verify all required components are

present and intact. Report any missing components immediately to Goodman or to the distributor. Use only factory

authorized replacement parts (see Section 5). Make sure to

include the full product model number and serial number

when reporting and/or obtaining service parts.

2.2 Handling

Use caution when transporting/carrying the unit. Do not move

unit using shipping straps. Do not carry unit with hooks or sharp

objects. The preferred method of carrying the unit after arrival at the job site is to carry via a two-wheel hand truck from

the back or sides or via hand by carrying at the cabinet corners.

3 Codes & Regulations

This product is designed and manufactured to comply with applicable national codes. Installation in accordance with such codes

and/or prevailing local codes/regulations is the responsibility of

the installer. The manufacturer assumes no responsibility for equipment installed in violation of any codes or regulations.

The United States Environmental Protection Agency (EPA) has

issued various regulations regarding the introduction and disposal

of refrigerants. Failure to follow these regulations may harm the

environment and can lead to the imposition of substantial fines.

Should you have any questions please contact the local office of

the EPA and/or refer to EPA’s website www.epa.gov.

4 Replacement Parts

When reporting shortages or damages, or ordering repair parts,

give the complete product model and serial numbers as stamped

on the product. Replacement parts for this product are available

through your contractor or local distributor. For the location of

your nearest distributor consult the white business pages, the yellow page section of the local telephone book or contact:

HOMEOWNER SUPPORT

GOODMAN MANUFACTURING COMPANY, L.P.

19001 KERMIER ROAD,

WALLER, TX 77484

(877) 254-4729

5 Pre-Installation Considerations

5.1 Preparation

Keep this document with the unit. Carefully read all instructions for the installation prior to installing product. Make

sure each step or procedure is understood and any special

considerations are taken into account before starting installation. Assemble all tools, hardware and supplies needed to

complete the installation. Some items may need to be purchased locally. Make sure everything needed to install the

product is on hand before starting.

5.2 System Matches

The entire system (combination of indoor and outdoor sections) must be manufacturer approved and Air-Conditioning, Heating, and Refrigeration Institute (AHRI) listed. NOTE:

Installation of unmatched systems is not permitted. Damage

or repairs due to installation of unmatched systems is not

covered under the warranty.

5.3 Interconnecting Tubing

Give special consideration to minimize the length of refrigerant tubing when installing air handlers. Refer to Remote Cooling/Heat Pump Service Manual RS6200006, and TP-107 Long

Line Set Application R-410A for tubing guidelines. If possible,

allow adequate length of tubing such that the coil may be

removed (for inspection or cleaning services) from the cabinet without disconnecting the tubing.

5.4 Clearances

The unit clearance from a combustible surface may be 0".

However, service clearance must take precedence. A minimum of 24" in front of the unit for service clearance is required. Additional clearance on one side or top will be required for electrical wiring connections. Consult all appropriate regulatory codes prior to determining final clearances.

When installing this unit in an area that may become wet

(such as crawl spaces), elevate the unit with a sturdy, nonporous material. In installations that may lead to physical

damage (i.e. a garage) it is advised to install a protective

barrier to prevent such damage. Always install units such

that a positive slope in condensate line (1/4" per foot) is

allowed.

5.5 Horizontal Applications

If installed above a finished living space, a secondary drain

pan (as required by many building codes), must be installed

under the entire unit and its condensate drain line must be

routed to a location such that the user will see the condensate discharge.

6 Installation Location

NOTE: These air handlers are designed for indoor installation

only.

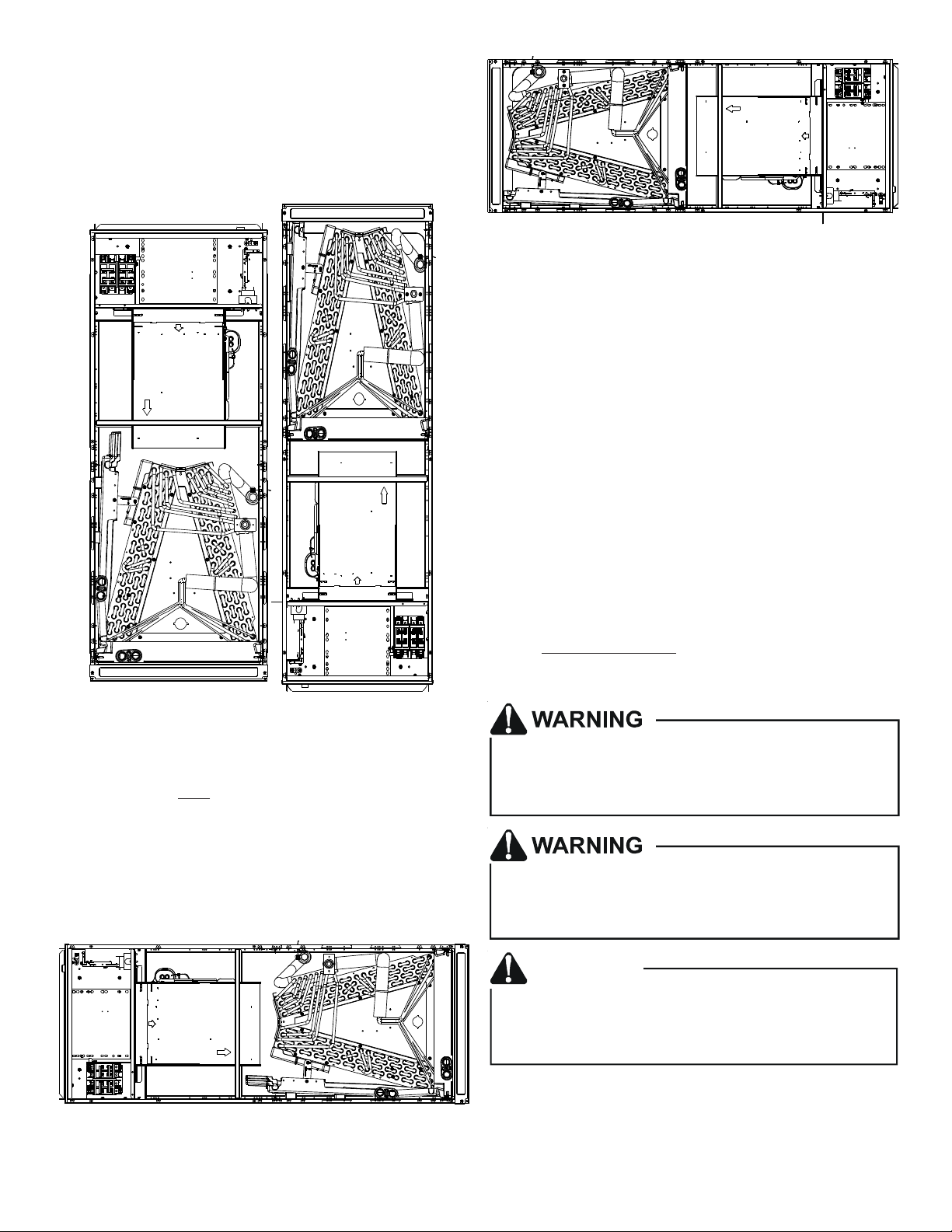

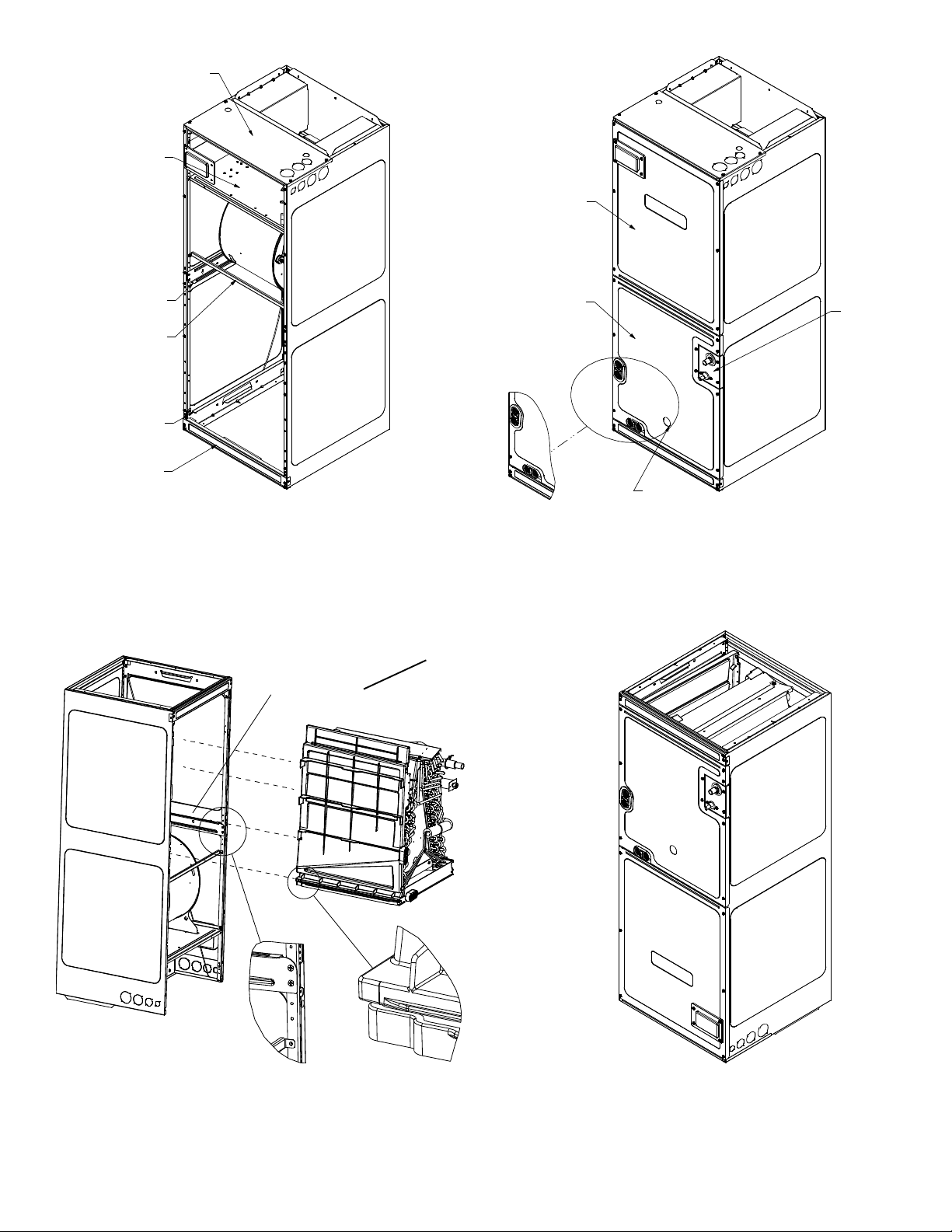

The AVPTC**14** product line may be installed in one of the

upflow, downflow, horizontal left or horizontal right orientations

as shown in Figures 2, 3, 4 and 5. The unit may be installed in

upflow or horizontal left orientation as shipped (refer to specific

sections for more information).

3

Page 4

Minor field modifications are necessary to convert to downflow

or horizontal right as indicated in below sections.

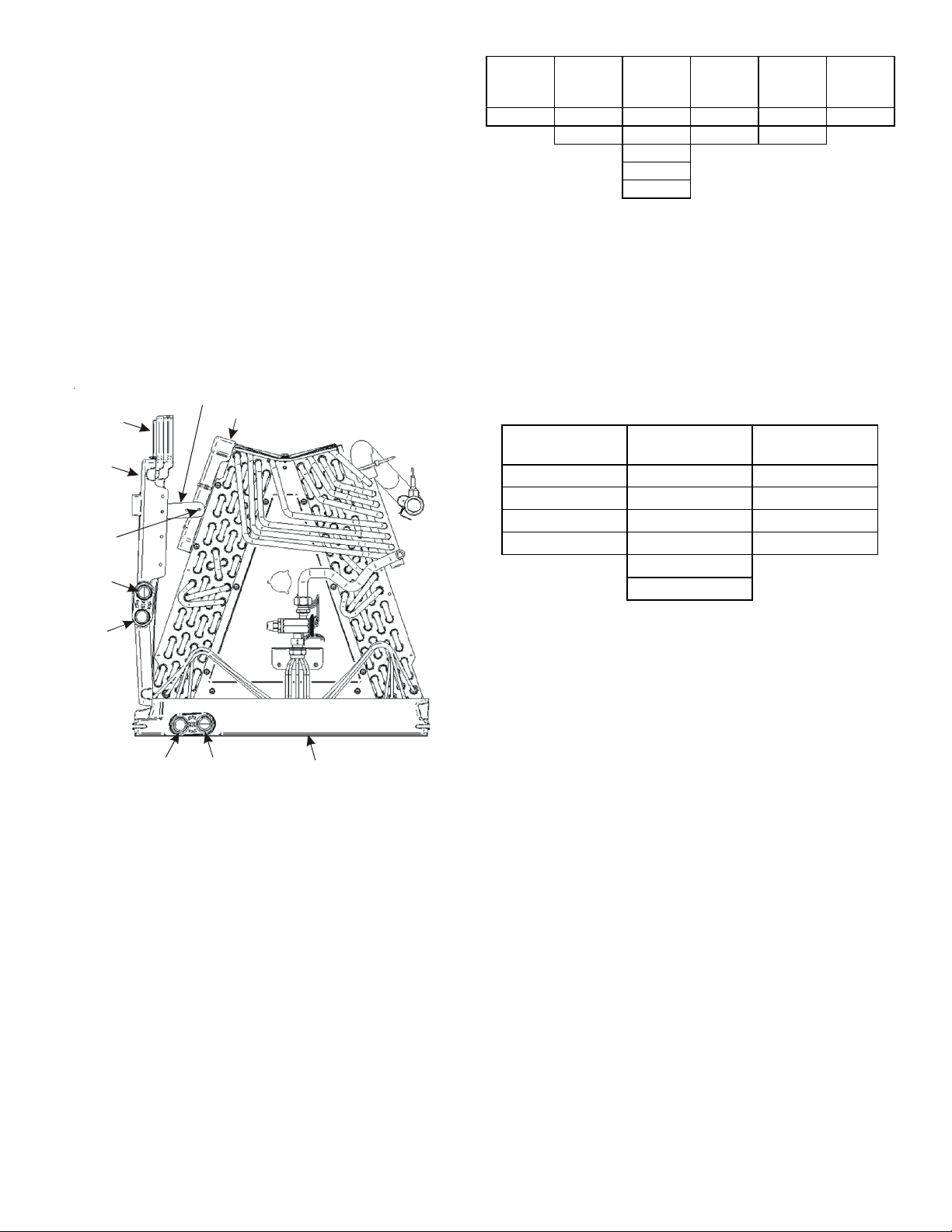

6.1 Upflow Installation

No field modifications are mandatory; however, to obtain

maximum efficiency, the horizontal drip shield, side drain pan

and drain pan extension can be removed.

Side Drain Pan and Extension Removal: Refer to Figure 1, remove the two (2) screws that secure the drip shield support

brackets to the condensate collectors (front and back). Unsnap the side drain pan from the main drain pan using a screw

driver or any small lever. The side drain pan, drip shield brackets and the drain pan extension may now be removed. From

Figure 1, drain port labeled (A) is the primary drain for this

application and condensate drain line must be attached to

this drain port. Drain port (a) is for the secondary drain line (if

used).

Drip Pan

Extension

Side

Drain

Pan

Screw

b

B

Drip Shield Bracket

Drip Shield

CMK0008

Condensate

Kit

AVPTC25B14 AVPTC29B14 AVPTC31C14 AVPTC49D14 AVPTC33C14 AVPTC49C14

CMK0009

Condensate

Kit

AVPTC37B14 AVPTC37C14 AVPTC61D14 AVPTC39C14

CMK0010

Condensate

Kit

AVPTC 37D 14

AVPTC59C14

AVPTC 59D 14

CMK0012

Condensate

Kit

CMK0013

Condensa te

Kit

CMK0014

Condensate

Kit

CONDENSATE KIT

TABLE 1

6.3 Downflow/Horizontal Right Installation

IMPORTANT NOTE: In the downflow application, to prevent

coil pan “sweating”, a downflow kit (DFK) is available through

your local Goodman distributor. The DFK is not supplied with

the air handler and is required by Goodman on all downflow

installations. See Table 2 for the correct DFK and follow the

instructions provided for installation.

MODEL LIST FOR DOWNFLOW KITS

DFK-B

Downflow Kit

DFK-C

Downflow Kit

DFK-D

Downflow Kit

AVPTC25B14** AVPTC31C14** AVPTC37D14**

AVPTC29B14** AVPTC37C14** AVPTC49D14**

AVPTC35B14** AVPTC59C14** AVPTC59D14**

AVPTC37B14** AVPTC33C14** AVPTC61D14**

AVPTC39C14**

AVPTC49C14**

DOWNFLOW KIT

TABLE 2

Pna

A

Main Drain Pan

SIDE DRAIN PAN REMOVAL

Figure 1

6.2 Horizontal Left Installation

No field modifications are permissible for this application.

The bottom right drain connection is the primary drain for

this application and condensate drain line must be attached

to this drain connection. The top connection of the three drain

connections on the drain pan must remain plugged for this

application. The bottom left drain connection is for the secondary drain line (if used).

In applications where the air handler is installed in the horizontal left position, and the return air environment see humidity levels above 65% relative humidity coupled with total

external static levels above 0.5” e.s.p., a condensate kit is

available for field application. Kit nomenclature can be found

in Table 1.

Refer to Figure 6 and 7 for the location of the components referenced in the following steps.

1. Before inverting the air handler, remove blower access

panel and coil access panel. The coil access panel and

tubing panel may remain screwed together during this

procedure. Remove and retain the seven (7) screws

securing the coil access panel to the cabinet and the six

(6) screws securing the blower access panel to the

cabinet.

2. Slide the coil assembly out using the drain pan to pull the

assembly from the cabinet.

NOTE: DO NOT USE MANIFOLDS OR FLOWRATOR TO

PULL THE COIL ASSEMBLY OUT. FAILURE TO DO SO MAY

RESULT IN BRAZE JOINT DAMAGE AND LEAKS.

3. Removal of the center support is required on units with

21" wide cabinet. Remove and retain the two (2) screws

that secure the center support to the cabinet. Remove

the center support.

4. Using the drain pan to hold the coil assembly, slide the

coil assembly back into the cabinet on the downflow

brackets as shown in Figure 8.

5. Re-install the center support (if removed) using the two

(2) screws removed in Step 4.

6. Re-install the access panels removed in Step 1 as shown

4

Page 5

in Figure 9.

7. The bottom left drain connection is the primary drain for

this application and condensate drain line must be

attached to this drain connection. The top connection of

the three drain connections on the drain pan must remain

plugged for this application. The bottom left drain

connection is for the secondary drain line (if used).

HORIZONTAL RIGHT

Figure 5

7 Refrigerant Lines

NOTE: Refrigerant tubing must be routed to allow adequate ac-

cess for servicing and maintenance of the unit.

7.1 Tubing Size

For the correct tubing size, follow the specification for the

condenser/heat pump.

7.2 Tubing Preparation

All cut ends are to be round, burr free, and clean. Failure to

follow this practice increases the chances for refrigerant leaks.

The suction line is spun closed and requires tubing cutters to

remove the closed end.

UPFLOW DOWFLOW

Figure 2 Figure 3

NOTE: If removing only the coil access panel from the unit, the

filter access panel must be removed first. Failure to do so may

result in panel damage.

Do not install the air handler in a location that violates the

instructions provided with the condenser. If the unit is located in

an unconditioned area with high ambient temperature and/or high

humidity, the air handler may be subject to nuisance sweating of

the casing. On these installations, a wrap of 2" fiberglass insulation

with a vapor barrier is recommended.

NOTE: To prevent possible damage to the tubing joints, do

not handle coil assembly with manifold or flowrator tubes.

Always use clean gloves when handling coil assemblies.

NOTE: The use of a heat shield is strongly recommended when

brazing to avoid burning the serial plate or the finish of the

unit. Heat trap or wet rags must be used to protect heat sensitive components such as service valves and TXV valves sensing bulb.

This product is factory-shipped with R410A and dry

nitrogen mixture gas under pressure. Use appropriate

service tools and follow these instructions to prevent

injury.

A quenching cloth is strongly recommended to prevent

scorching or marring of the equipment finish when

brazing close to the painted surfaces. Use brazing

alloy of 5% minimum silver content.

CAUTION

Applying too much heat to any tube can melt the tube. Torch

heat required to braze tubes of various sizes must be

proportional to the size of the tube. Service personnel must

use the appropriate heat level for the size of the tube being

brazed.

HORIZONTAL LEFT

Figure 4

5

Page 6

Upper Tie Plate

Control

Deck

Blower

Access

Panel

Downflow

Bracket

Center

Support

Filter

Bracket

Filter

Access

Panel

INTERNAL PART TERMINOLOGY

Figure 6

Coil Slides

on the downflow bracket

Access

Remove side drain pan

extension for

downflow application

Coil

Panel

Tubing

Panel

UV

Knockout

EXTERNAL PART TERMINOLOGY

Figure 7

IMPORTANT NOTE:

Ensure coil slides on the rails along the groove provided on the drain pan side walls.

Failure to do so will result in improper condensate drainage.

COIL INSTALLATION FOR DOWNFLOW

Figure 8

6

ACCESS PANEL CONFIGURAATION

FOR DOWNFLOW

OR HORIZONTAL RGHT

Figure 9

Page 7

7.3 Tubing Connections for TXV Models

TXV models come with factory installed TXV with the bulb

pre-installed on the vapor tube.

1. Remove refrigerant tubing panel or coil (lower) access

panel.

2. Remove access valve fitting cap and depress the valve

stem in access fitting to release pressure. No pressure

indicates possible leak.

3. Replace the refrigerant tubing panel.

4. Remove the spin closure on both the liquid and suction

tubes using a tubing cutter.

5. Insert liquid line set into liquid tube expansion and slide

grommet about 18" away from braze joint.

6. Insert suction line set into suction tube expansion and

slide insulation and grommet about 18" away from braze

joint.

7. Braze joints. Quench all brazed joints with water or a wet

rag upon completion of brazing.

NOTE: The sensing bulb must be permanently located. A heat

shield, heat trap, or wet rag must be used during brazing to prevent damage to the TXV valve.

8. Replace access panels, suction line grommet, insulation

and all screws.

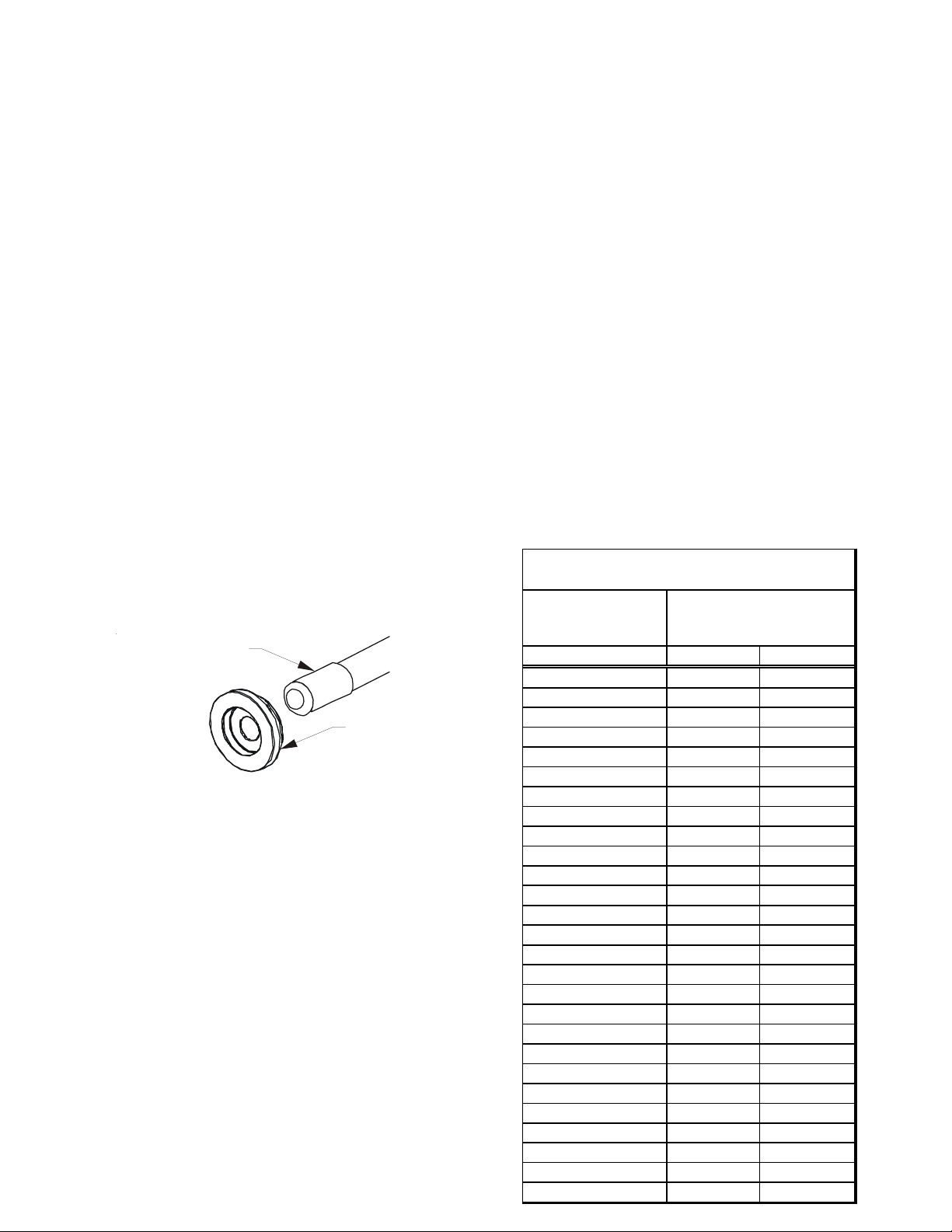

SUCTION LINE

WITH SPIN CLOSURE

RUBBER

GROMMET

Suction Line Grommet

Figure 11

7.4 Thermal Expansion Valve System Adjustment

Run the system at Cooling for 10 minutes until refrigerant

pressures stabilize. Use the following guidelines and methods to check unit operation and ensure that the refrigerant

charge is within limits. Charge the unit on low stage.

1. Purge gauge lines. Connect service gauge manifold to

base-valve service ports.

2. Temporarily install a thermometer on the liquid line at

the liquid line service valve and 4-6’’ from the compressor

on the suction line. Ensure the thermometer makes

adequate contact and is insulated for best possible

readings. Use liquid line temperatice to determine

subcooling and vapor temperature to determine superheat.

3. Check subcooling and superheat. Systems with TXV

application should have a subcooling of 7 to 9°F and

superheat of 7 to 9°F

a. If subcooling and superheat are low, adjust TXV to 7 to

9°F, and then check subcooling.

NOTE: To adjust superheat, turn the valve stem clockwise to increase and counter clockwise to decrease.

b. If subcooling is low and superheat is high, add charge to

raise subcooling to 7 to 9°F, and then check superheat.

c. If subcooling and superheat are high, adjust TXV valve to

7 to 9° superheat, then check subcooling.

d. If subcooling is high and superheat is low, adjust TXV valve

to 7 to 9° superheat and remove charge to lower the subcooling

to 7 to 9°F.

NOTE: Do NOT adjust the charge based on suction pressure unless there is a gross undercharge.

4. Disconnect manifold set, and installation is complete

NOTE: Check the Schrader ports for leaks and tighten valve cores

if necessary. Install caps finger-tight.

SUBCOOL FORMULA=

SAT. LIQUID LINE TEMP - LIQUID LINE TEMP

SUPERHEAT FORMULA=

SUCT. LINE TEMP - SAT. SUCT. TEMP

SATURATED SUCTION PRESSURE

TEMPERATURE CHART

SUCTION PRESSURE

PSIG R-22 R-410A

50 26 1

52 28 3

54 29 4

56 31 6

58 32 7

60 34 8

62 35 10

64 37 11

66 38 13

68 40 14

70 41 15

72 42 16

74 44 17

76 45 19

78 46 20

80 48 21

85 50 24

90 53 26

95 56 29

100 59 31

110 64 36

120 69 41

130 73 45

140 78 49

150 83 53

160 86 56

7

170 90 60

SATURATED SUCTION

TEMPERATURE ºF

Page 8

SATURATED LIQUID PRESSURE

TEMPERATURE CHART

CAUTION

LIQUID PRESSURE

PSIG R-22 R-410A

200 101 70

210 105 73

220 108 76

225 110 78

235 113 80

245 116 83

255 119 85

265 121 88

275 124 90

285 127 92

295 130 95

305 133 97

325 137 101

355 144 108

375 148 112

405 155 118

415 157 119

425 n/a 121

435 n/a 123

445 n/a 125

475 n/a 130

500 n/a 134

525 n/a 138

550 n/a 142

575 n/a 145

600 n/a 149

625 n/a 152

SATURATED LIQUID

TEMPERATURE ºF

8 Condensate Drain Lines

The coil drain pan has a primary and a secondary drain with 3/4"

NPT female connections. The connectors required are 3/4" NPT

male, either PVC or metal pipe, and should be hand tightened to a

torque of no more than 37 in-lbs. to prevent damage to the drain

pan connection. An insertion depth of approximately 3/8” to 1/2”

(3-5 turns) should be expected at this torque.

1. Ensure drain pan hole is not obstructed.

2. To prevent potential sweating and dripping on to finished

space, it may be necessary to insulate the condensate

drain line located inside the building. Use Armaflex® or

similar material.

A secondary condensate drain connection has been provided for

areas where the building codes require it. Pitch all drain lines a

minimum of 1/4" per foot to provide free drainage. Provide required support to the drain line to prevent bowing. If the secondary drain line is required, run the line separately from the primary drain and end it where condensate discharge can be easily

seen.

NOTE: Water coming from secondary line means the coil primary

drain is plugged and needs immediate attention.

If secondary drain is not installed, the secondary

access must be plugged.

Insulate drain lines located inside the building or above a finished living space to prevent sweating. Install a condensate trap

to ensure proper drainage.

NOTE: When units are installed above ceilings, or in other

locations where damage from condensate overflow may

occur, it is MANDATORY to install a field fabricated auxiliary

drain pan under the coil cabinet enclosure.

The installation must include a “P” style trap that is located as

close as is practical to the evaporator coil. See Figure 12 for

details of a typical condensate line “P” trap.

NOTE: Units operating in high static pressure applications may

require a deeper field constructed “P” style trap than is shown in

Figure 12 to allow proper drainage and prevent condensate overflow.

Drain

Connection

Air Handler

POSITIVE LIQUID

SEAL REQUIRED

AT T R AP

2" MIN.

3" MIN.

Figure 12

NOTE: Trapped lines are required by many local codes. In the

absence of any prevailing local codes, please refer to the requirements listed in the Uniform Mechanical Building Code.

A drain trap in a draw-through application prevents air from

being drawn back through the drain line during fan operation

thus preventing condensate from draining, and if connected to a

sewer line to prevent sewer gases from being drawn into the airstream during blower operation.

Use of a condensate removal pump is permitted when necessary.

This condensate pump should have provisions for shutting off the

control voltage should a blocked drain occur. A trap must be

installed between the unit and the condensate pump.

IMPORTANT NOTE: The evaporator coil is fabricated with oils

that may dissolve styrofoam and certain types of plastics.

Therefore, a removal pump or float switch must not contain any of

these materials.

Tip: Priming the “P” trap may avoid improper draining at the initial installation and at the beginning of the cooling season.

8

Page 9

9 Ductwork

This air handler is designed for a complete supply and return

ductwork system.

To ensure correct system performance, the ductwork is to be

sized to accommodate 350-450 CFM per ton of cooling with the

static pressure not to exceed 0.5" in w.c. Refer to ACCA Manual

D, Manual S and Manual RS for information on duct sizing and

application. Flame retardant ductwork is to be used and sealed

to the unit in a manner that will prevent leakage.

NOTE: A downflow application with electric heat must have an Lshaped sheet metal supply duct without any outlets or registers

located directly below the heater.

9.1 Return Ductwork

DO NOT LOCATE THE RETURN DUCTWORK IN AN AREA

THAT CAN INTRODUCE TOXIC, OR OBJECTIONABLE FUMES/

ODORS INTO THE DUCTWORK. The return ductwork is to

be connected to the air handler bottom (upflow configuration).

10 Return Air Filters

Each installation must include a return air filter. This filtering

may be performed at the air handler using the factory filter rails

or externally such as a return air filter grille. When using the

factory filter rails, a nominal 16x20x1”, 20x20x1” or 24x20x1”

(actual dimension must be less than 23-½”x20”) filter can be installed on a B, C and D cabinet respectively (the cabinet size is

the seventh letter of the model number).

11 Achieving 1.4% and 2.0% Airflow Low Leakage Rate

Ensure all the gaskets remain intact on all surfaces as shipped

with the unit. These surfaces are areas between the upper tie

plate and coil access panel, blower access and coil access panels,

and between the coil access and filter access panels. Ensure upon

installation, that the plastic breaker cover is sitting flush on the

blower access panel and all access panels are flush with each

other and the cabinet. With these requirements satisfied, the

unit achieves less than 1.4% airflow leakage @ 0.5 inch wc static

pressure and less than 2% airflow leakage @1inch wc static pressure when tested in accordance with ASHRAE Standard 193.

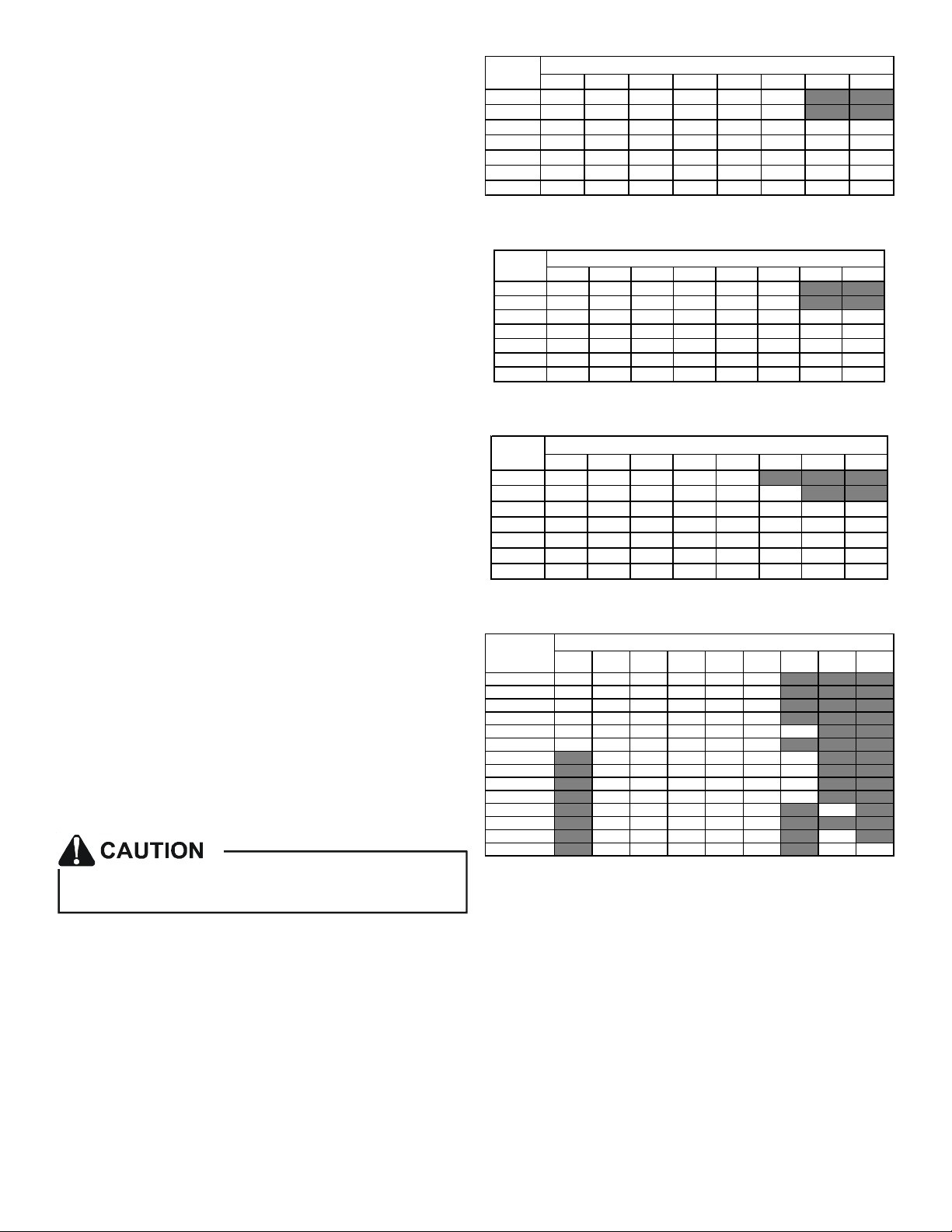

12 Electric Heat

Do not operate this product without all the ductwork

attached.

CFM

800 121923313756

1000 9 1519253044

1200 8 12152125374962

1400 7 11131821324253

1600 6 9 12 15 19 28 37 46

1800 5 8 10 14 16 25 33 41

2000 5 7 9 1215223037

3 5 6 8 10 15 19/20 25

HEAT KIT NOMINAL kW

230/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 2

CFM

800 111822303554

1000 9 1418242842

1200 7 12152024354759

1400 6 10131720304051

1600 6 9 11 15 18 27 35 44

1800 5 8 10 13 16 24 31 39

2000 4 7 9 12 14 21 28 35

3568101519/2025

HEAT KIT NOMINAL kW

220/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 3

CFM

800 1017212833

1000 8 1317222740

1200 7 11141922334556

1400 6 10121619293848

1600 5 8 10 14 17 25 33 42

1800 5 7 9 12 15 22 30 37

2000 4 7 8 11 13 20 27 33

3568101519/2025

HEAT KIT NOMINAL k W

208/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 4

Model

AVPTC25B14 550 650 700 800 850 875

AVPTC29B14 550 650 700 800 875 875

AVPTC35B14 550 650 700 800 875 1050

AVPTC37B14 550 650 700 800 875 1050

AVPTC31C14 600 700 770 880 97 0 1090 1280

AVPTC33C14 600 700 750 850 92 0 95 0

AVPTC37C14 700 770 880 970 1090 1280

AVPTC39C14 700 770 880 970 1090 1280

AVPTC49C14 800 800 950 1 090 1290 1345

AVPTC59C14 800 800 950 1 090 1290 1345

AVPTC37D14 870 970 1060 1120 1220 1250

AVPTC49D14 950 1060 1150 1220 1520

AVPTC59D14 990 1110 1200 1240 1520 1520

AVPTC61D14 1030 1150 1 250 1320 1 650 1690 1750

35681015192025

HEATE R (kW)

MINIMUM CFM REQUIREMENTS FOR HEATER KITS

Table 5

Refer to the installation manual provided with the electric heat

kit for the correct installation procedure. All electric heat must

be field installed. If installing this option, the ONLY heat kits that

are permitted to be used are the HKS series. Refer to the air handler unit’s Serial and Rating plate or the HKS specification sheets

to determine the heat kits compatible with a given air handler.

No other accessory heat kit besides the HKS series may be installed in these air handlers.

The heating mode temperature rise is dependent upon the system airflow, the supply voltage, and the heat kit size (kW) selected.

Use data provided in Tables 3, 4 and 5 to determine the temperature rise (°F).

NOTE: For installations not indicated above the following formula

is to be used:

TR = (kW x 3412) x (Voltage Correction) / (1.08 x CFM)

Where: TR = Temperature Rise

kW = Heater Kit Actual kW

3412 = Btu per kW

VC* = .96 (230 Supply Volts)

= .92 (220 Supply Volts)

= .87 (208 Supply Volts)

1.08 = Constant

CFM = Measured Airflow

VC* (Voltage Correction)

9

Page 10

NOTE: The Temperature Rise Tables can also be used to estimate

the air handler airflow delivery. When using these tables for this

purpose set the room thermostat to maximum heat and allow

the system to reach steady state conditions. Insert two

thermometers, one in the return air and one in the supply air.

The temperature rise is the supply air temperature minus the

return air temperature. Using the temperature rise calculated,

CFM can be estimated from the TR formula above. See Spec

Sheets and/or Service Manual for more information.

13 Electrical and Control Wiring

IMPORTANT: All routing of electrical wiring must be made

through provided electrical knockouts. Do not cut, puncture or

alter the cabinet for electrical wiring.

13.1 Building Electrical Service Inspection

This unit is designed for single-phase electrical supply only.

DO NOT OPERATE ON A THREE-PHASE POWER SUPPLY. Measure the power supply to the unit. The supply voltage must

be measured and be in agreement with the unit nameplate

power requirements and within the range shown.

• Wire used must carry the Minimum Circuit Ampacity

(MCA) listed on the unit’s Series and Rating Plate.

• Refer to the NEC (USA) or CSA (Canada) for wire sizing.

The unit MCA for the air handler and the optional electric

heat kit can be found on the unit Series and Rating Plate.

• Wire must be sized to allow no more than a 2% voltage

drop from the building breaker/fuse panel to the unit.

• Wires with different insulation temperature rating have

varying ampacities - be sure to check the temperature rating used.

Refer to the latest edition of the National Electric Code or

in Canada the Canadian Electric Code when determining

the correct wire size.

13.3 Maximum Overcurrent Protection (MOP)

Every installation must include an NEC (USA) or CEC

(Canada) approved overcurrent protection device. Also,

check with local or state codes for any special regional requirements.

Nominal Input Minimum Voltage Maximum Voltage

208-240 197 253

ELECTRICAL VOLTAGE

Table 6

13.2 Wire Sizing

Wire size is important to the operation of your equipment.

Use the following check list when selecting the appropriate

wire size for your unit.

FIRE HAZARD!

To avoid the risk of property damage, personal injury

or fire, use only copper conductors.

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

Protection can be in the form of fusing or HACR style circuit

breakers. The Series and Rating Plate provides the maximum overcurrent device permissible.

NOTE: Fuses or circuit breakers are to be sized larger than

the equipment MCA but not to exceed the MOP.

13.4 Electrical Connections – Supply Voltage

IMPORTANT NOTE: USE COPPER CONDUCTORS ONLY.

Knockouts are provided on the air handler top panel and

sides of the cabinet to allow for the entry of the supply

voltage conductors, as shown in Figure 13. If the knockouts

on the cabinet sides are used for electrical conduit, an

adapter ring must be used in order to meet UL1995 safety

requirements. An NEC or CEC approved strain relief is to

be used at this entry point. Some codes/municipalities require the supply wire to be enclosed in conduit. Consult

your local codes.

Top of

Cabinet

HIGH VOLTAGE!

To avoid property damage, personal injury or death

due to electrical shock, this unit MUST have an

uninterrupted, unbroken

electrical ground circuit may consist of an

appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel.

Other methods of grounding are permitted if performed

in accordance with the National Electric Code

(NEC)/American National Standards Institute

(ANSI)/National Fire Protection Association (NFPA) 70

and local/state codes. In Canada, electrical grounding

is to be in accordance with the Canadian Electric Code

(CSA) C22.1.

electrical ground. The

Side of

Cabinet

KNOCK-OUT FOR ELECTRICAL CONNECTIONS

Figure 13

10

Page 11

13.4.1 Air Handler Only (Non-Heat Kit Models)

A

A

The building supply connects to the stripped black and red

wires contained in the air handler electrical compartment

cavity. A ground screw is also contained in this area. Attach

the Supply wires to the air handler conductors as shown in

the unit wiring diagram using appropriately sized solderless

connectors or other NEC or CEC approved means.

13.4.2 Air Handler - Non-Circuit Breaker Heat Kits

A terminal block is provided with the HKS kit to attach the

power supply and air handler connections. Follow the HKS

Installation Manual and wiring diagram for complete wiring details.

13.4.3 Air Handler With Circuit Breaker Heat Kit

The air handler has a plastic cover on the upper access

panel that will require either one or both sections to be

removed to allow the heat kit circuit breaker(s) to be installed. The circuit breakers have lugs for power supply

connection. See the HKS Installation Instructions for further details.

14 AVPTC Motor Orientation

If the unit is in the upflow position, there is no need to rotate the

motor. If the unit is in the downflow position, loosen motor

mount and rotate motor as shown in the AVPTC Motor

Orientation figure below. Be sure motor is oriented with the

female connections on the casing down. If the motor is not

oriented with the connections down, water could collect in the

motor and may cause premature failure.

15 Cool Cloud HVAC Phone Application

Actual screens may look different based on the mobile device

being used.

FRONT VIEW

FEMALE CONNECTIONS

AVPTC Motor Orientation

Figure 14

SIDE VIEW

W

RNING

SOFTW

RE VER.

TOP

Figure 15

This air handler is Bluetooth ready and functions with the Cool

Cloud HVAC phone application designed to improve the

contractor’s setup / diagnostic experience. Users can see specific

model information, review active diagnostic error codes, observe

system menu testing of all operational modes (heat / cool / fan)

directly from the phone. The phone application is also capable of

directly updating the air handler software anytime updates are

available. The application will automatically notify the user.

NOTE: The software update may take up to 20 minutes to

complete.

11

Page 12

16 Quick Start Guide for Communicating Outdoor Units

EXTREMELY IMPORTANT: For all cooling calls the system only

requires a single Y input from the thermostat. For all heating

calls (including applications with backup electric heater kits) the

system only requires a single W input from the thermostat.

Internal algorithms will control all available cooling and heating

stages based on these inputs. Any single-stage 24VAC thermostat

can be used. For proper operation, the thermostat must be setup

to control a single stage AC outdoor unit and to control single

stage electric heat operation. The control board does not

accommodate an O wire thermostat input (reversing valve signal).

If a heat pump is installed, the thermostat should be setup as

stated above. Setting the thermostat for the heat pump control

or multistage control may result in incorrect performance.

1. Connect all necessary thermostat wires to the thermostat

connector on the air handler control as instructed by the

applicable wiring diagrams shown in this section.

2. Connect the 1 & 2 wires between the indoor and outdoor

unit for communicating operation.

Note: Verify two stage outdoor units include a 24VAC

transformer (for outdoor control board power). Two

stage outdoor units may not behave properly without

this 24 VAC transformer.

16.2 Electric Heater Kit Testing

1. Select the electric heat icon after entering the air handler

menus in the Cool Cloud HVAC phone application.

2. Select any value less than 50% for low stage operation

and any value greater than 50% for high stage operation.

3. Confirm thermostat heating and cooling calls function

properly with equipment.

17 Quick Start Guide for Non-Communicating Outdoor

Units

EXTREMELY IMPORTANT: For two stage electric heat kit control

the system only needs a single W input. Internal algorithms will

control staging automatically based on the single W input. For

non-communicating outdoor unit wiring, see instructions below:

1. Use the wiring diagrams on the next page to connect low

voltage thermostat wires.

NOTE: When installing the air handler with a noncommunicating heat pump, wire directly to the “O”

terminal on the non-communicating heat pump. See the

following figures.

Figure 16

3. Download the Cool Cloud HVAC phone application for

charging and to configure /test system.

NOTE: When new versions of Bluetooth Communication Software and Air Handler Control Software are available, the phone

application notifies the user. Software updates are classified as

either optional or mandatory and installed by using the phone

application. Ensure all mandatory software updates and install if

necessary.

16.1 Charging

1. Two-stage outdoor units using the Cool Cloud HVAC

application:

a. Using the cooling icon after entering the outdoor

unit menus, energize the outdoor unit at 100%

capacity.

b. Charge the outdoor unit as required using the

charging information provided with the outdoor

equipment.

Figure 17

FIgure 18

12

Page 13

Figure 19

4. Go to the Tonnage Units Menu () and select the

tonnage value that corresponds to the desired airflow for

the outdoor unit. See the following table.

NOTE: For the two stage non-communicating outdoor

units, system will stage airflow automatically for low

stage operation.

NOTE: The system will not provide airflows above the max Airflow

Value.

Figure 20

2. Download the Cool Cloud HVAC phone application.

Note: When new versions of Bluetooth Communication

Software and Air Handler Control Software are available,

the phone application notifies the user. Software updates

are classified as either optional or mandatory and

installed by using the phone application. Ensure all

mandatory software updates have been installed. Review

notes for optional software updates and install if

necessary.

3. Go to the Non-Comm Outdoor Setting Menu () using

the on board push buttons or the Cool Cloud HVAC

phone application. Selec t “” for single stage Air

Conditioners, “” for single stage Heat Pumps, “”

for two stage Air Conditioners and “” for 2 stage Heat

Pumps.

Model MAX CFM

AVPTC25B14

AVPTC29B14

AVPTC35B14

AVPTC37B14

AVPTC33C14 1300

AVPTC31C14

AVPTC37C14

AVPTC39C14

AVPTC37D14

AVPTC49C14

AVPTC49D14

AVPTC59C14

AVPTC59D14

AVPTC61D14

1200

1600

1800

1900

2100

5. Use the Cool Cloud HVAC phone application to configure/

test air handler operations.

NOTE: The phone application cannot test a non- communicating

outdoor unit. The thermostat will be required for outdoor unit

testing.

17.1 Electric Heater Kit Testing

1. Two-stage outdoor units:

a. Provide a second stage cooling call from the

thermostat and charge accordingly.

2. Single-stage outdoor units:

a. Provide a cooling call from the thermostat and

charge accordingly.

13

Page 14

17.2 Electric Heater Kit Testing

1. Select the electric heat icon after entering the air handler

menus while using the Cool Cloud phone application.

2. Select any value less than 50% for low stage operation

and any value greater than 50% for high stage operation.

3. Confirm thermostat heating and cooling calls function

properly for high stage operation.

18 Dehumidification

Dehumidification allows the air handler’s circulator blower to

operate at a reduced speed during a combined thermostat call

for cooling and a dehumidification call from the thermostat or

humidistat. This lower blower speed increases dehumidification

of the conditioned air as it passes through the indoor coil. The

control board is equipped with a 24 volt dehumidification input

(DH) located on the thermostat wiring connector. The terminal

can be configured to enable dehumidification when the input is

energized or de-energized. When using an external dehumidistat,

connect it between the R and DH terminals. If the humidistat

closes on humidity rise or the thermostat energizes this terminal

when dehumidifcation is required, set the control board Dehum

Logic Menu () to “” using the push buttons or Cool Cloud

HVAC phone application. If the humidistat opens on humidity or

the thermostat de-energizes this terminal when dehumidification

is required, set the Dehum Logic Menu to “” using the push

buttons or Cool Cloud HVAC phone application.

19 Auxiliary Alarm Switch

The control is equipped with a 24VAC Aux Alarm to be

used for a condensate switch install (designated by CON-DENSATE

IN/OUT on the control). By default, the connected

AUX switch is normally closed and opens when the

water level in the evaporator coil base pan reaches an

undesirable level. The control responds by displaying a “”

error code and turning off the outdoor condensing

unit. If the AUX switch is detected to be in the closed

position for 30 seconds, normal operation resumes and

the error message is no longer displayed.

enter into a main menu and to then permanently select

options within those menus.

NOTE: After scrolling to the desired option within a menu,

that option may be flashing on the 7-segment displays.

This indicates the option has not been officially selected.

Pressing the Center button two times will select that

option. The first press will stop the flashing. The second

will make the selection official and return you to the main

menu.

21 Accessory Control (Humidifiers, Dehumidifiers,

Ventilators)

If an external humidifier, dehumidifier or ventilator is installed,

it may require airflow from the HVAC system to

function properly.

1. Make sure the installed 24VAC thermostat is capable of

controlling the accessory or accessories.

2. Connect the appropriate accessory control wires to the

accessory devices from the thermostat (see thermostat

manual for connection and setup instructions).

3. If the thermostat is capable of providing a continuous fan

call (G signal) during accessory operation:

Make sure to connect the thermostat G terminal to the G

terminal on the indoor unit. Setup thermostat to ensure

G signal is energized during accessory operation.

20 Start-Up Procedure

Figure 21

The air handler includes three on-board push buttons allowing

users to navigate indoor and outdoor system menus.

The Right and Left buttons allow the user to scroll through

the main menus and to then scroll through available options

within specific menus. The Center button is used to

FIgure 22

4. Select the appropriate fan only airflow for the accessory

using the indoor unit push button menus or the Cool

Cloud HVAC phone application.

5. Using the thermostat, independently test each accessory

in addition to the independently testing continuous fan

mode.

14

Page 15

22 Ramping Profiles

The variable-speed circulator offers four different ramping

profiles. These profiles may be used to enhance cooling

performance and increase comfort level. Select the desired

ramping profile using the Cool Cloud phone application or the

push button menus.

23 Electric Air Cleaner Warning

The control is equipped with an Accessory Relay and a pair of ¼

inch accessory terminals which is normally open, labeled EAC-IN

and EAC-OUT (see accessory contacts graphic). The Accessory

Relay is configured to close anytime the blower is running. A

closed relay means the two terminals will have continuity between them (the control does not energize these contacts). It is

recommended to utilize 24VAC with these terminals and limit

the current to 1A.

Figure 23

FIgure 24

15

Page 16

24 Start-Up Procedure

• Prior to start-up, ensure that all electrical connections are

properly sized and tightened.

• All panels must be in place and secured. For Air Tight

application, neoprene gasket must be positioned at

prescribed locations to achieve low airflow as stated in

section 13.

• Tubing must be leak free.

• Unit should be elevated, trapped and pitched to allow for

drainage.

• Low voltage wiring is connected.

• Auxiliary drain is installed when necessary and pitched to

allow for drainage.

• Drain pan and drain tubing has been leak checked.

• Return and supply ducts are sealed.

• Unit is elevated when installed in a garage or where

flammable vapors may be present.

• Unit is protected from vehicular or other physical damage.

• Return air is not obtained from any areas where there may

be objectionable odors, flammable vapors or products of

combustion such as carbon monoxide (CO), which may

cause serious personal injury or death.

25 Regular Maintenance

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

The only item to be maintained on a regular basis by the user is

the circulating air filter(s). Filter should be cleaned or replaced

regularly. A certified service technician must perform all other

services.

NOTE: THESE INSTRUCTIONS ARE SPECIFICALLY FOR AVPTC

MODELS. DO NOT USE THESE DIAGRAMS FOR ANY OTHER

MODELS. SEE SEPARATE INSTALLATION AND OPERATING

INSTRUCTIONS FOR ATUF, ARUF, ARPT, ADPF, AND ASPF MODELS.

NOTICE: THIS PRODUCT CONTAINS ELECTRONIC COMPONENTS WHICH REQUIRE A DEFINITE GROUND. PROVISIONS

ARE MADE FOR CONNECTION OF THE GROUND. A DEDICATED

GROUND FROM THE MAIN POWER SUPPLY OR AN EARTH

GROUND MUST BE PROVIDED.

16

Page 17

26 Air Handler Troubleshooting Matrix

Symptoms of Abnormal Operation

Diagnostic /

Status LED

Codes

Fault Description Possible Causes Corrective Actions

Imp rop er low voltage wiring

No outd oor u ni t operati ons

No Ai r Hand ler operation Open fu se Shor t in low voltage wi ri ng

No Ai r Hand ler operation

No Ai r Hand ler operation Data not yet on network No network data

No Ai r Hand ler operation Invalid memory card data

Operation dif feren t than exp ected or n o

oper ation

No Ai r Hand ler operation

Invalid memory card data

Communication error with

outdoor u ni t

Auxilary switch (condensate

switch) open

Cir cu lator bl ower motor not

running with demand present

between the in door and outd oor u ni t

Outdoor control board lost power

duirng operation

High water level in the evaporation

coil

Air Handler blower does not contain

an ap pr opriate shared data set

Shared d ata set on memory card

has been rejected by integrated

control module

Loos e or di sconnected wirin g

connection at circulator motor power

leads

Open ci rcui t in i nductor or loose

wir in g con nection at indu ctor (3/4

Hp and 1 Hp models only)

Failed circu lator bl ower motor

Locate an d correct i mpr oper l ow vol tag e

wiri ng iss ue

Identi fy reason outdoor control board los t

power during operation

Locate and correct sh ort in l ow voltage

wiri ng

Replace fuse with 3-amp automotive type

Check evap orator drai n pan , trap, p ip in g

Populate shared data set using memory

card

Populate correct shared data using memory

card

Verif y shared data set is correct for th e

specifc model. Re-populate data using

correct memory card if required

Ti ghten or correct wiring connection

Verify continuous circuit through inductor.

Repl ace i f open or sh ort ci rcuit

Check ci rculator b lower motor

No Ai r Hand ler operation

No Ai r Hand ler operation

Ai r Handler oper ates at r edu ced

performance

Ai rf ow del iv ered is l ess than expected

Integrated control modul e has

lost communications with

ci rcu lator b lower motor

Cir cu lator bl ower motor horse

power in shared data set does

not match circulator blower

motor horse power

Cir cu lator bl ower motor is

oper atin g in a power,

temp eratu re, or sp eed l im iti ng

condition

Loos e wiring con necti on at

circulator motor control leads

Failed circu lator bl ower motor

Failed integrated control module

Incorrect circulator blower motor in

Air Handler

Incorrect sh ared data set in

integrated control module

Blocked flters

Restrictive or undersized ductwork

Hi gh amb ien t tem peratu res

Ti ghten or correct wiring connection

Check ci rculator b lower motor, repl ace i f

necessary

Check integ rated control module, replace i f

necessary

Verif y circ ul ator b lower if motor horse p ower

is th e same specifed for the specifc Air

Handler model, replace if necessary

Verif y shared data set is correct for th e

specifc model, re-populate data using

correct memory card if required

Check f il ters for bl ockage, cl ean flters or

remove obstruction

Check ductwork for blockage, remove

obstruction and verify all registers are fully

open

Verify ductwork is appropriately sized for

system and resize/replace ass needed

17

Page 18

26 Air Handler Troubleshooting Matrix (continued)

Symptoms of Abnormal Operation

Diagnostic /

Status LED

Codes

Fault Description Possible Causes Corrective Actions

No Ai r Hand ler operation

No Ai r Hand ler operation

No Ai r Hand ler operation

No Ai r Hand ler operation

Cir cu lator bl ower motor

senses a loss of rotor control

Cir cu lator bl ower motor

senses high current

Cir cu lator bl ower motor fails to

start 10 consecutive times

Cir cu lator bl ower motor sh uts

down for over or under voltage

condition

Cir cu lator bl ower motor sh uts

down du e to over temperature

condition on power module

Cir cu lator bl ower motor does

not have en oug h i nformati on

to operate pr oper ly

Motor fail s to start 40

con secu ti ve ti mes

Abnormal motor loading, sudden

change in speed or torque, sudden

blockage of air handler air inlet or

outlet

Obstruction in circulator blower

housing

Sei zed Circ ul ator b lower motor

bearings

Failed circu lator bl ower motor

High or low AC line voltage to air

handler

Hi gh amb ien t tem peratu res

Error with integrated control module

shared d ata

Check filters, filter grills/registers, duct

system an d ai r h and ler in let/outlet f or

blockages

Check ci rculator b lower for obstructions

Remove and repair/replace wheel/motor if

necessary

Check ci rculator b lower motor s haf t rotation

and motor, replace motor if necessary

Check power to air handler

Verif y l in e voltage i s wi thi n the ran ge

specified on the rating plate

Verify control is populated with the correct

sh ared data

Ai r Handler oper ates at r edu ced

per for mance or op erates on low stage

when hi gh stage is exp ected

Airflow is lower than

demanded

Blocked filters or restrictive

ductwork

Undersized ductwork

Check f il ters for bl ockage, cl ean fil ters or

remove obstruction

Check ductwork for blockage, remove

obstruction and verify all registers are fully

open

Verify ductwork is appropriately sized for

system, resize/replace ductwork if necessary

18

Page 19

27 Air Handler Display

LED Display Menu Description

View 6 most rec ent fault codes and Clear Fault Codes if desired

(furnace)

Restart communications between the indoor and outdoor unit.

Control Firmware Revision Number

Control Shared Data Revision Number

Constant Fan Speed as percent of maximum airflow. Default = 30%

Electric Heater Kit Wattage (kW )

Electric Heat Off Delay (seconds)

Electric Heat On Delay (seconds)

Electric Heat Airflow Trim (percentage)

Percentage of high stage electric heating airflow to run duirng low

stage electric heat operation

1 = system will try to satisfy the thermostat quickly.

5 (default) = system will try to satsify the thermostat more slowly.

Select "" to enable dehumidification when the thermostat DH

terminal is energized. Select "" to enable dehumidification when

the thermostat DH terminal is de-energized. (default = )

Select number of stages for the non-communicating outdoor unit.

( for single-stage Air Conditioners, for single stage Heat

Pumps, for two stage Air Conditioners or for two stage heat

pumps)

Indoor Airflow for non-communicating outdoor units. (values based

on 400CFM per ton) (default = 3.0 Ton)

Cooling Airflow Trim (default 0%)

Cooling Airflow Profile setting (default = profile D shown as 4)

Cooling Airflow On Delay Time (default = 5 seconds)

Cooling Airflow Off Delay Time. (default = 60 seconds)

Percentage of high stage cooling airflow to run during low stage

operation. (default = 70%)

Electric heat operation during defrost. 1 = low stage 2 (default) =

high stage

Heat Pump Indoor Airflow Trim (default = 0%)

Heat Pump Heating Airflow Off Delay Time (default = 60 seconds)

Heat Pump Heating Airflow On Delay Time (default = 5 seconds)

Percentage of high stage heat pump heating airflow to run during

low stage operation. (defaullt = 70%)

When heat pump heating and electric heat are running at the same

time, this percentage is used for additional airflow trim

Enables or disables dehumidification feature in the outdoor unit.

(default = Enabled)

Balance point temperature. The Compressor will not operate below

temperature. (Default = 0°F)

Backup Heat Balance Points

Compressor run time between defrost cycles. (default = 30 minutes)

(2 stage units)

Compressor off delay at the beginning and end of a defrost cycle.

(default = 30 seconds)

19

Page 20

27 Air Handler Display (continued)

LED Display Menu Description

View 6 most recent fault codes and Clear Fault Codes if desired

(outdoor communicating units)

Menu is enabled if the

the system will attempt to satisfy the thermostat.

Menu is enabled if the

past the target time when the system will enable electric heat

operation during heat mode.

Menu is enabled if the

the next heat call if the heat pump fails to satisfy the custom target

time for this number of consecutive cycles) (default = 20 cycles)

Menu is enabled if the

stage electric heat is able to consecutively satisfy the thermostat

under the set target time for this number of cycles, the system will

transition to the heat pump for primary heating)

Menu is enabled if the

help determine when switching back to heat pump only operation is

appropriate. Default = 20%. If target time = 20 minutes, the addtion

of low stage electric heat must staisfy the thermostat by less than 16

minutes. (target time - 20% default = 16 minutes).

menu is set to 6. Select the target time

menu is set to 6. Select the percentage

is set to 6. (Electric heat will run during

menu is set to 6. (if the additi on of low

menu is set to 6. (this percentage will

20

Page 21

27 Air Handler Display (continued)

LED Display Description of System Status

Idle

Constant Fan

Compressor Cooling, Single-Stage (non-comm units)

Compressor Cooling, Low Stage (non-comm units)

Compressor Cooling, High Stage (non-comm units)

Compressor Cooling, Low Stage (comm units)

Compressor Cooling, High Stage (comm units)

Compressor Heat, Single-Stage (non-comm. units)

Compressor Heat, Low Stage (non-comm units)

Compressor Heat, High Stage (non-comm units)

Compressor Heat, Low Stage (Comm Units)

Compressor Heat, High Stage (Comm Units)

Electric Heat, Single Stage

Electric Heat, Low Stage

Electric Heat, High Stage

Defrost, Single Stage Electric Heat

Defrost, Low Stage Electric Heat

Defrost, High Stage Electric Heat

Dehumidification

21

Page 22

28 Air Handler Label

Menu Navigation and Selection Instructions

Using Phone Application over Bluetooth Network:

1) Connect to the air handler (instructions provided by phone during

connection process).

2)

Select desired settings menu

3) Select item that requires adjustment and m

4) Submit Changes

Using On-Board Push Buttons:

1) Use the Right and Left Buttons to scroll between menus

2) Use the Center Button to select desired menu when menu code is

shown on 7-segment displays

3) Use the Left and Right Buttons to scroll through options within the

desired menu (the display will flash while scrolling through options for

selection)

4)

Use the Center Button to select the displayed option (when selected

the display will stop flashing

5) Use the Center Button to finalize selection and return to the main

menu

Profiles

1 -------- -------- 60 sec/100%

2 -------- 30 sec/50% 60 sec/100%

3 -------- 7.5 min/82% 60 sec/100%

4 30 sec/50% 7.5 min/82% 60 sec/100%

Airflow Settings Instructions

1) For non-communicating installations, select the type of unit installed

in the

1HP

2HP

2) Use the Tonnage Menu (

(non-communicating installation). Tonnage selection options and

correspo

[Airflow = Tonnage Selection x 400] Default selection is 6.0 tons.

3)

[Optional] Use the Cooling Trim Menu (

4) [Optional] Use the Heating Trim Menu(HtF) to adjust the heat pump

5) [Optional]

percentage of maximum airflow for continuous fan

6) [Optional] Use the Cooling Airflow Profile Menu (

between 5 cooling airflow profiles. Profile options 1-4 are listed above

(option 5 is adjustable). See installation manual for further details

Htr Kw

3

5

6

8

10

15

19

20

21

25

Selecting Heater Kit: Use the Electric Heating Wattage Menu (

above. Default selection is 0 (No Heat Kit). Select installed heater kit for heater kit operation.

NR - Not Rated

++ For match up with a 3 ton outdoor unit: Airflow for 5kW up to 15kW heater kits shall be set to 1220 CFM by selecting 10 in the

Electric Heating Wattage (

+++ For match up with a 3.5 ton outdoor unit: Heater kit application shall not exceed 20 kW. Airflow for 5kW up to 20kW heater kits

shall be set to 1320 CFM by selecting 10 in theElectric Heating Wattage (

menu (

0d5

= single-stage heat pump,

= 2 stage heat pump) Default =

nding airflow CFM can be found to the right.

airflow

from -10% to +10% (2% increments).

stage communicating outdoor units and single or 2 stage

non-communicating ou

outdoor units require an equipment relay board to function with this

system). For inverter

Intermediate and L

adjustment.

airflow

from -10% to +10% (2% increments).

stage communicating outdoor units and single or 2 stage

non-communicating ou

units require an equipment r

available). For inver

Intermediate and L

adjustment.

Use the Constant Fan Menu (

AVPTC25B14 AVPTC29B14

550

650

700

800

850

875

NR

NR

NR

NR

ake necessary selection

)

Pre-Run Short-Run OFF Delay

= single-stage air conditioner,

1AC

ow menus(

ow menus (

2AC

= 2 stage air conditioner,

OFF

(no outdoor unit).

ton

) to select Cooling/Heat Pump Airflow

CtF

) to adjust the cooling

This applies for 2

tdoor units (2 stage

outdoor units use Cooling Trim

CtH,Ct

tdoor units (all non-communicating outdoor

elay board for the trim option to be

ter outdoor units use Heating Trim Factor High,

HtH,Ht1

non-communicating

1

, and CtL) for trim

This applies for 2

,and

HtL

) for trim

F5d

) to select the

CAP

Factor High,

) to select

Electric Heat Airflow Table

550

650

700

800

875

875

NR

NR

NR

NR

AVPTC29B14

AVPTC29B14

EHt

) menu.

AVPTC31C14 AVPTC31C14

550

650

700

800

875

1050

NR

NR

NR

NR

600

700

770

880

970

1090

1280

NR

NR

NR

Tonnage Menu (t o n)

Tonnage

Selection

1.0 400

1.1 440

1.2 480

1.3 520

1.4 560

1.5 600

1.6 640

1.7 680

1.8 720

1.9 760

2.0 800

2.1 840

2.2 880

2.3 920

2.4 960

2.5 1000

2.6 1040

2.7 1080

2.8 1120

2.9 1160

3.0 1200

3.1 1240

3.2 1280

3.3 1320

3.4 1360

3.5 1400

Airflow

Tonnage

Selection

3.5 1400

3.6 1440

3.7 1480

3.8 1520

3.9 1560

4.0 1600

4.1 1640

4.2 1680

4.3 1720

4.4 1760

4.5 1800

4.6 1840

4.7 1880

4.8 1920

4.9 1960

5.0 2000

5.1 2040

5.2 2080

5.3 2120

5.4 2160

5.5 2200

5.6 2240

5.7 2280

5.8 2320

5.9 2360

6.0 2400

Maximum Airflow Output

AVPTC2 5B14

AVPTC2 9B14

AVPTC3 5B14

AVPTC3 7B14

*If

airflow is set above the model's maximum value, the output will be the

maximum value

AVPTC37C14

AVPTC39C14

600

700

750

850

920

950

NR

NR

NR

NR

EHt

NR

700

770

880

970

1090

1280

NR

NR

NR

) to select heater kit size. See "Menu Navigation and Selection Instructions"

AVPTC3 3C14

12001300 1600 1800 1900 2100

AVPTC49C14

AVPTC59C14

NR

800

800

950

1090

1290

1345

NR

NR

NR

EHt

) menu.

AVPTC3 1C14

AVPTC3 7C14

AVPTC3 9C14

AVPTC37D14

NR

870

970

1060

1120

1220

NR

1250

NR

NR

AVPTC3 7D14

AVPTC4 9C14

AVPTC49D14

++

NR NR

950

1060

1150

1220

1520

NR

NR

NR

NR

AVPTC4 9D14

AVPTC5 9C14

AVPTC59D14

990

1110

1200

1240

1520

NR

1520

NR

NR

22

Airflow

AVPTC5 9D14

AVPTC6 1D14

AVPTC61D14

++

NR

1030

1150

1250

1320

1650

NR

1690

NR

1750

0140A00615-A

Page 23

A

A

29 Wiring Diagrams

HIGH VOLTAGE!

WARNING

(SEE NOTE 4)

GROUND LUG

8456321

7

9

RD

BK

INSTALLING

WH

AUX ALARM

BR

(ALARM)

(SEE NOTE 7)

BL

HEATE R KIT

OUTPUT

AUX

~

~

OUT

AUX

IN

~

~

RELAY OUT

RELAY OUT

(EAC-OUT)

RELAY IN

RELAY IN

(EAC-IN)

NOTES:

1. PLACE RED WIRES ON 208 V TERMINAL OF 2 TRANSFORMERS (TR1/TR2)

FOR 208 VAC OPERATION.

2. MAN UFACTURER’S SPEC IFIED REPLA CEMENT PARTS MUST BE US ED

WHEN SERVIC ING.

3. IF ANY OF THE ORI GINAL WIRES AS SUPPL IED WITH THIS UNIT MU ST

BE REPLAC ED, IT MUST BE R EPLACED WITH WIRING MATERIAL

HAVING A TEMPERATURE RATING OF AT LEAST 105°C. USE COPPER

CONDUCTORS ONLY.

4. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO N.E.C

AND LOCAL CODES.

6. DISCARD CONNECTOR Pl1 WHEN INSTALLING OPTIONAL HEAT KIT.

7. REM OVE JUMPER TAB AND PUT AUX ALARM SWITCH W HEN

INSTALLING AUX ALARM SWITCH.

9. USE N.E.C CLASS

2 WIRE.

10. SEE M ANUAL FOR PUSH BU TTON OPERATION.

11. SEE MANUAL FOR 7-SEGMENT DIS PLAY DIAGNOSTIC C ODES AND

MENU CODES .

12. SEE MANUAL FOR LED FUNCTIONALITY.

13. R AND C TERMINALS (USED FOR 24VAC OUTDOOR CONTROL

VOLTAGE) ARE OPTIONAL FOR 2 STAGE COMMUNICATING AIR

CONDITIONERS. R AND C TERMINALS ARE NOT TO BE USED FOR 2

STAGE COMMUNICATING HEAT PUMP APPLICATIONS.

FOR COMMUN ICATING HEAT PUMPS OR IF ONLY TWO THERMOSTAT

WIRES ARE AVAILABLE, A SEPARATE TRANSF ORMER MUST BE

INSTALLED IN TH E OUTDOOR UNIT FOR CONTRO L BOARD POWER.

1 AND 2 WIR ES ARE REQUIR ED FOR ALL APPLICATIONS. SEE

INSTALLATION MANU AL FOR FULL SYST EM WIRING EXAM PLES.

208/230 VAC

TO

L2

BL

3

24

1

L1

RD BK

PL1

PL2

208

230

VAC

VAC

TR1

24VAC

(SEE NOTE 1)

RD

598710 11 12

6

AUX AL ARM

AUX AL ARM

(ALARM)

R

AUX

AUX

OUT

IN

EAC-OUT

TB6

COM

EAC-IN

Tb7

TB5

Th2

TR

Tb3

TB4

F2U

K1R

K2R

GND

NC

J4

(SEE NOTE 11)

J6

EEV

COIL

THERMISTOR

(HEAT EXCHANGER 1,2)

INTEGRAT ION TYPE

HEATER KIT

BK

RD

~

~

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

(SEE N OTE 6)

BK

BK

RD

J19

TH1Tr1

B1

SEG3

SEG2

SEG1

J7

TS

F1U

PS

PS

TC

PU YL

TB2

S

208

VAC

24VAC

(SEE NOTE 10)

Pb3

PB2

PB1

J20

DATA AC

TEMPERATURE)

VAC

TR2

(SEE

DH/Y2

FLASH WRITER

(RETURN AIR

RD

30

NOTE 1)

PL3

PL4

RD

THERMOSTAT

WH GR BL

PUGY

YGWCRC

LEGACY INPUT

J11

U

A

R

T

5

I

J13

J12

S

D

H

A

A

T

R

A

E

J8

RAT

BK

J14

J15

J

T

A

G

OUTDOOR UNIT

SEE NOTE 13)

GY BK

BL RD

RD

R21

CT COMM

J3

R

M

A

O

M

N

I

T

O

R

J5

MPU

LED

(SEE NOTE 12)

U10

J18

J9

SAT

PRESSURE

(SUPPLY AIR

SENSOR

TEM PERAT URE)

INTEGRATED CONTROL:

LOW VOLTAGE

LOW VOLTAGE FIELD

HIGH VOLTAGE

HIGH VOLTAGE FIELD

JUNCT ION

TERMINAL

INTERNAL TO

RESISTOR

OVERCURRENT

PROT. DEVICE

PLUG CONNECTION

EQUIPM ENT GND

FIELD GROUND

DISCONNECT ALL POWER BEFORE SERVICING.

L1

GRND

ECM MOTOR

DISCONNECT

FAN

MOTOR

INDOOR

IR

CIRCULATOR

BLWR

208/23 0 VAC

24 VAC

HEAT 1 COIL/R 1

HEAT 2 COIL/ R2

CONDENSATE AUX SWITCH

POWER/HEATER

CONNECTOR

TL

THERMAL LIMIT

TRANSFORMER

FUSE LINK

TRANSFORMER

CONNECTOR

J2J1

D

A

A

C

T

A

RD

INDO OR U NIT

PCB

BK

BL

GY

L1

FUSE 3 A

R

2

4

V

W

T

h

e

r

m

o

Y

s

t

a

t

C

o

n

n

e

c

t

i

o

n

s

DH/Y2

TO

MICRO

C

TH2

W1 (1)

W2 (2)

CAS (1)

CAS (2)

+VDC (1)

RX (2)

TX (3)

GRND (4)

TR2

COM

INTEGRATED CONTROL MODULE

COLOR CODES:

BL - BLUE

- RED

RD

YL - YELLOW

OR - ORANGE

BK - BL ACK

COMPONENT CODES:

PL1, PL2

TR

F1U, F2U

PL3, P L4

GY - GREY

BR - BROWN

GR - GREEN

PU - PURPLE

WH - WHITE

L2

GRND

40 VA

TRANSFORMER

INDOOR

IR

CIRCULATOR

BLWR

GRND

0140 A00613- A

L2

23

Page 24

29 Wiring Diagrams

3-Phase Heat Kit

WARNING

HIGH VOLTAGE!

MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

DISCONNECT ALL POWER BEFORE SERVICING.

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

24

Page 25

AIR HANDLER

AIR HANDLER HOMEOWNER’S ROUTINE MAINTENANCE RECOMMENDATIONS

We strongly recommend a bi-annual maintenance checkup be performed before the heating and cooling seasons begin by a qualified servicer.

REPLACE OR CLEAN FILTER

IMPORTANT NOTE: Never operate unit without a filter installed as dust and lint will build up on internal parts resulting in loss of

efficiency, equipment damage and possible fire.

An indoor air filter must be used with your comfort system. A properly maintained filter will keep the indoor coil of your comfort

system clean. A dirty coil could cause poor operation and/or severe equipment damage.

Your air filter or filters could be located in your furnace, in a blower unit, or in “filter grilles” in your ceiling or walls. The installer of your

air conditioner or heat pump can tell you where your filter(s) are, and how to clean or replace them.

Check your filter(s) at least once a month. When they are dirty, replace or clean as required. Disposable type filters should be replaced.

Reusable type filters may be cleaned.