Page 1

Owner's Manual

Covering ,4 ana and ,dl a,,a Distinctions_Models

Side by Side

Refrigerator

Questions about your features?

Please contact us with your model and serial number:

Maytag Services sM

Attn: Amana CAIW _Center

RO. Box 39

403 West 4th Street North

Newton, Iowa 50208-0039

Ph# 1-800-843-0304 in U.S.A.

1-866-587-2002 au Canada

Internet: http://www.amana.com

Keep instructions for future reference.

Keep this manual and your sales receipt together in a safe place

in case warranty service is required.

Introduction .......................................................................................... 2

Important Safety Information ............................................................... 3

Installing Your Refrigerator ............................................................. 4-10

Measuring the Opening ..................................................................... 4

Transporting Your Refrigerator .......................................................... 4

Selecting the Best Location .............................................................. 4

How to Install and Remove Handles ................................................. 5

Removing the Doors and Hinges ...................................................... 7

Replacing the Doors .......................................................................... 7

How to Install and Remove Panels ................................................... 8

How to Connect the Water Supply .................................................... 9

How to Level Your Refrigerator ....................................................... 10

Setting and Maintaining Proper Temperatures .................................. 11

Initial Temperature Settings ............................................................. 11

Adjusting the Controls ..................................................................... 11

How to Perform a Temperature Test ............................................... 11

About Your Water Filter ..................................................................... 12

Water Filter Removal and Installation ............................................. 12

Water Filter Data ............................................................................... 13

Fresh Food Features .................................................................... 14-16

Interior Shelves ............................................................................... 14

Door Storage ................................................................................... 14

Climate-Controlled Drawers ............................................................ 15

Storage Drawers ............................................................................. 16

Accessories ..................................................................................... 16

Freezer Features .......................................................................... 17-18

Automatic Ice Maker ........................................................................ 17

Interior Shelves ............................................................................... 17

Door Storage ................................................................................... 18

Dispenser Features ...................................................................... 19-20

Dispenser Light ............................................................................... 19

Dispenser Pad ................................................................................. 19

Removable Tray .............................................................................. 19

Water Dispenser Operation ............................................................. 19

Control Features ............................................................................. 20

Hints and Care ............................................................................. 21-22

How to Clean Your Refrigerator ...................................................... 21

How to Remove Odors from Refrigerator ....................................... 22

Energy Saving Ideas ....................................................................... 22

How to Remove and Replace Light Bulbs ...................................... 22

Normal Operating Sounds ................................................................. 23

Troubleshooting ............................................................................ 24-26

As an Energy Star _Partner,

Amana _ has determined that this

product* meets the Energy Star _

guidelines for energy efficiency.

* This manualcovers several models. Please referto the feature

sticker on the interior of the fresh food door to verify that your

model number complies with Energy Sta(_standards.

!iiiiiii! ".........!i!iiiiiii ....!iiiiiii!4

Part No. 12591321 ©2003 Maytag Appliances Sales Co.

Form No.A/05/03

Page 2

Please read this Owner's Manual thoroughly.This manual provides proper

maintenance information.

Complete registration card and promptly return. If registration card is missing, see

contact information on the front cover of your manual.

Warranty service must be performed by an authorized servicer. Amana also

recommends contacting an authorized servicer if service is required after warranty

expires.To locate an authorized servicer, call 1-800-NAT-LSVC(1-800-628-5782). You

may also contact us on the web at www.amana.com.

When contacting Amana, please provide the following information. Product information

is on the serial plate, located on the interior of the fresh food section.

Model Number

Amana offers long-term service

protection for this new refrigerator.

Asure TM Extended Service Plan is

specially designed to supplement

Amana's strong warranty.This plan

covers parts, labor,and travel charges.

Call 1-866-232-6244,or contact us at

www.amana.com for more information.

'P' Number

Serial Number

Purchase Date

Dealer Name

Dealer Address

Dealer Phone

:}REGLLINGSERVI(E...

If something seems unusual, please

check Troubleshooting section, which

is designed to help you solve problems

before calling service.

This book is intended to show the

variety of features that are available in

the product line. If your refrigerator does

not have all the options that are shown,

many of these options may be

purchased. See contact information on

the front cover of your Owner's Manual.

2

Page 3

WHkTYOU£RDTOKNOW

ABOUT;kRTY

iN TRUCTJON

Warning and Important Safety

Instructions appearing in this manual are

not meant to cover all possible

conditions and situations that may occur.

Common sense, caution, and care must

be exercised when installing,

maintaining, or operating refrigerator.

Always contact your dealer, distributor,

service agent, or manufacturer about

problems or conditions you do not

understand.

RECOGNIZE SAFETY

SYMBOLS, WORDS,

LABELS

DANGER -Immediate hazards which

WILL result in severe personal injury

or death.

WARNING - Hazards or unsafe

practices which COULD result in

severe personal injury or death.

CAUTION - Hazards or unsafe

practices which COULD result in

minor personal injury.

To reduce risk of injury or death,

follow basic precautions, including

the following:

IMPORTANT: Child entrapment and

suffocation are not problems of the

past.Junked or abandoned

refrigerators are still dangerous -

even if they sit out for "just a few

days."Ifyou are getting rid of your old

refrigerator, please follow the

instructions below to help prevent

accidents.

Before you throw awayyour old

refrigerator or freezer:

>- Takeoff the doors.

Leavethe shelves in

place so children

may not easily climb

inside.

I

ill

i '1'

'Jl "

Ijr ',,

To reduce risk of fire, electric shock, serious injury or death when using your refrigerator,follow these basic

precautions, including the following:

,

Read all instructions before usingthe refrigerator.

2.

Observe all local codes and ordinances.

3.

Be sure to follow grounding instructions.

4.

Check with a qualified electrician if you are not sure this

appliance isproperly grounded.

5. DO NOT ground to a gas line.

6. DO NOT ground to a cold-water pipe.

7. Refrigerator is designedto operate on a separate 103 to

126 volt, 15 amp., 60 cycle line.DO NOT modify plug on

power cord. If plug does not fit electrical outlet, have

proper outlet installed by a qualified electrician.

8. DO NOT use a two-prong adapter, extensioncord or

power strip.

9. DO NOT remove warning tag from power cord.

10. DO NOTtamper with refrigerator controls.

11. DO NOTserviceorreplaceanypartof refrigeratorunless

specificallyrecommendedinOwner'sManualor published

user-repairinstructions.DO NOTattemptserviceif

instructionsarenotunderstoodor ifthey arebeyondpersonal

skill level.

12. Always disconnect refrigerator from electrical supply

before attempting any service. Disconnect power cord by

grasping the plug, notthe cord.

13. Install refrigerator according to Installation Instructions. All

connections for water,electrical power and grounding

must comply with local codes and be made by licensed

personnel when required.

14. Keep your refrigerator in good condition. Bumping or

dropping refrigerator can damage refrigerator or cause

refrigerator to malfunction or leak. If damage occurs, have

refrigerator checked by qualified service technician.

15. Replace worn power cords and/or loose plugs.

16. Alwaysread andfollow manufacturer'sstorage andideal

environmentinstructionsfor itemsbeing storedin

refrigerator.

;kViT!ll ilITII(TIIII

3

Page 4

These instructions were provided to aid

you in the installation of your refrigerator.

THEBEST

THEOPENING

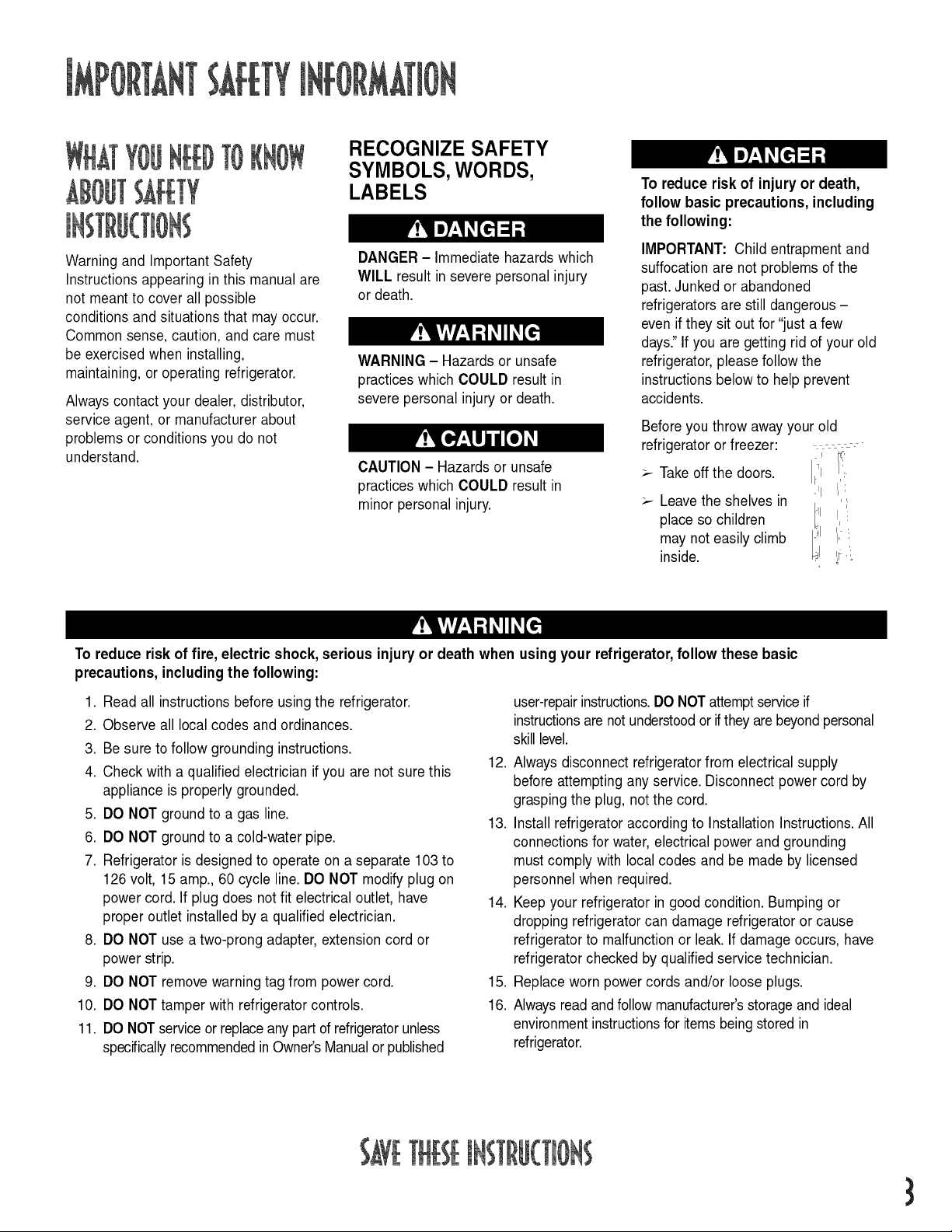

When installing your refrigerator, please

reference chart below for clearance

requirements.

Subflooring or floor coverings (i.e.

carpet, tile, wood floors, rugs) may make

your opening smaller than anticipated.

Some clearance may be gained by using

the levelingprocedure under

How to Level Your Refrigerator (page

10).

Recommended

UnitTotal

Volume

Less than

23 cu. ft.

Greaterthan

23 cu. ft.

IMPORTANT: If refrigerator isto be

installed into a recess where top of

refrigerator is completely covered, use

dimensions from floor to top of hinge

cap to verify proper clearance.

Clearance

Top Sides Rear

N/A N/A _"

Y_" N/A _"

Follow these tips when moving the

refrigerator to final location:

NEVER transport refrigerator on its

side. If an upright position is not

possible, lay refrigerator on its back.

Allow refrigerator to sit upright for

approximately 30 minutes prior to

plugging refrigerator in to assure oil

returns to the compressor. Plugging

refrigerator in immediately may cause

damage to internal parts.

Use an appliance dolly when moving

refrigerator.ALWAYStruck

refrigerator from its side or back-

NEVER from its front.

Protect outside finish of refrigerator

during transport by wrapping cabinet

in blankets or inserting padding

between the refrigerator and dolly.

Securerefrigeratortodollyfirmlywith

strapsorbungeecords.Threadstraps

throughhandleswhenpossible.DONOT

overtighten.Overtighteningrestraintsmay

dentor damageoutsidefinish.

Observe these points when choosing the

final locationfor your refrigerator:

DO NOT install refrigerator near

oven, radiator or other heat source. If

not possible, shield refrigerator with

cabinet material.

DO NOT install where temperature

falls below 55° F (13° C). Malfunction

may occur at this temperature.

Toassure proper door closure, follow

the leveling instructions in the

section, How to Level Your

Refrigerator (page 10).

4

Page 5

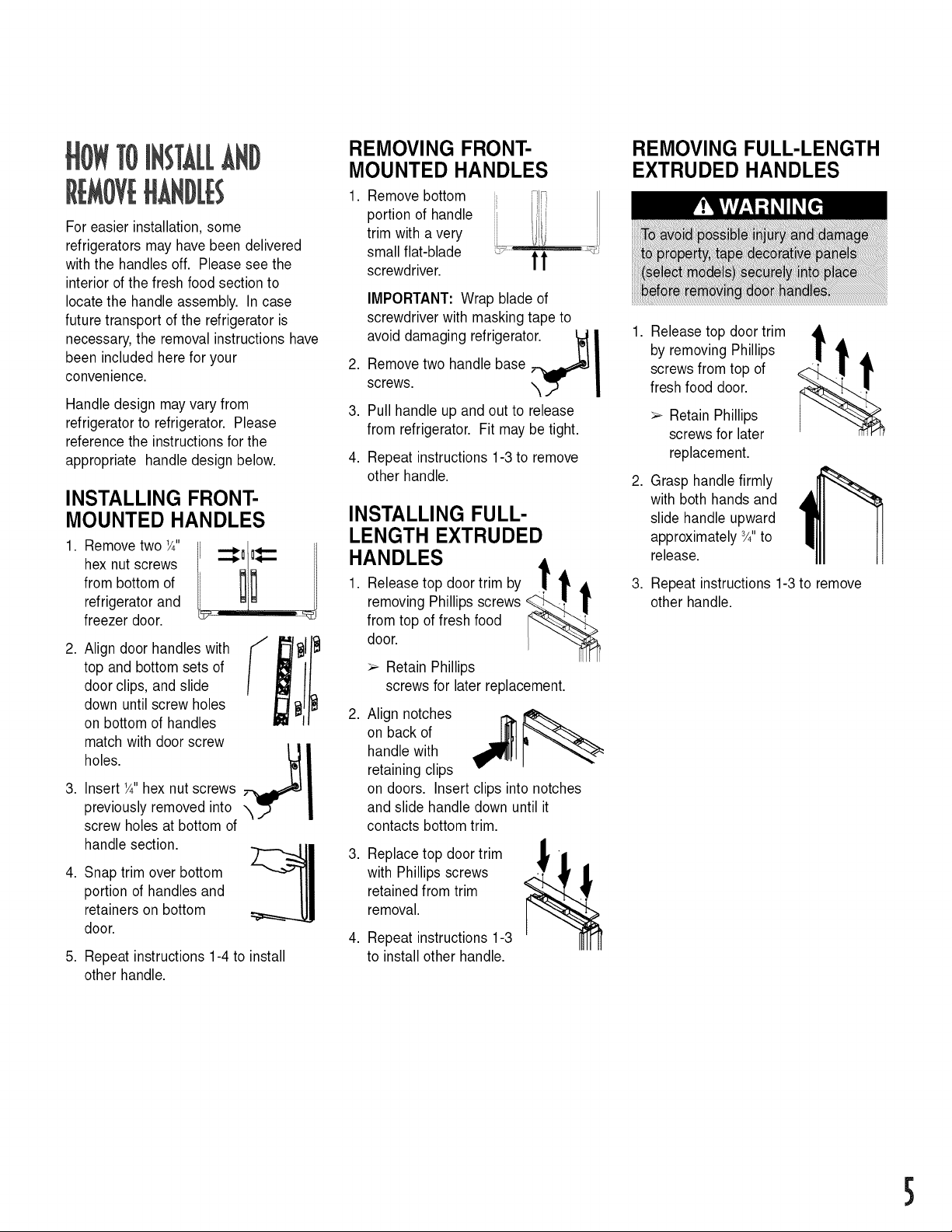

[}WTOINSTALLAN[}

For easier installation, some

refrigerators may have beendelivered

with the handles off. Please see the

interior of the fresh food section to

locate the handle assembly. In case

future transport of the refrigerator is

necessary,the removal instructions have

been included here for your

convenience.

Handle design mayvary from

refrigerator to refrigerator. Please

reference the instructions for the

appropriate handle design below.

INSTALLING FRONT-

MOUNTED HANDLES

1. Remove two ¼"

hex nut screws

from bottom of

refrigerator and

freezer door.

2. Align door handles with

top and bottom sets of

door clips, and slide

down until screw holes

on bottom of handles

match with door screw

3. Insert ¼"hex nut screws

holes.

previously removed into

screw holes at bottom of

handle section.

4. Snap trim overbottom

portion of handles and

retainers on bottom

door.

5. Repeat instructions 1-4 to install

other handle.

REMOVING FRONT-

MOUNTED HANDLES

1. Remove bottom

portion of handle

trim with a very

small flat-blade

screwdriver.

IMPORTANT: Wrap blade of

screwdriver with masking tape to

avoid damaging refrigerator. _-_ I

,

Removetwo handle base _ I

screws. ,,_ |

,

Pull handle up and out to release

from refrigerator. Fit may betight.

,

Repeat instructions 1-3to remove

other handle.

INSTALLING FULL-

LENGTH EXTRUDED

HANDLES

1. Release top door trim by [_ A,

removing Phillips screws

from top of fresh food

door.

> Retain Phillips

screws for later replacement.

,

Align notches ,_

handle with

on back of _IIPI

retaining clips

on doors. Insert clips into notches

and slide handle down until it

contacts bottom trim.

,

Replace top door trim

with Phillips screws

retained from trim

removal.

,

Repeat instructions 1-3

to install other handle.

,6.

REMOVING FULL-LENGTH

EXTRUDED HANDLES

Release top door trim

by removing Phillips

screws from top of

fresh food door.

> Retain Phillips

screws for later

replacement.

,

Grasp handle firmly

with both hands and

slide handle upward

approximately 3/4"to

release.

,

Repeat instructions 1-3to remove

other handle.

t

t

5

Page 6

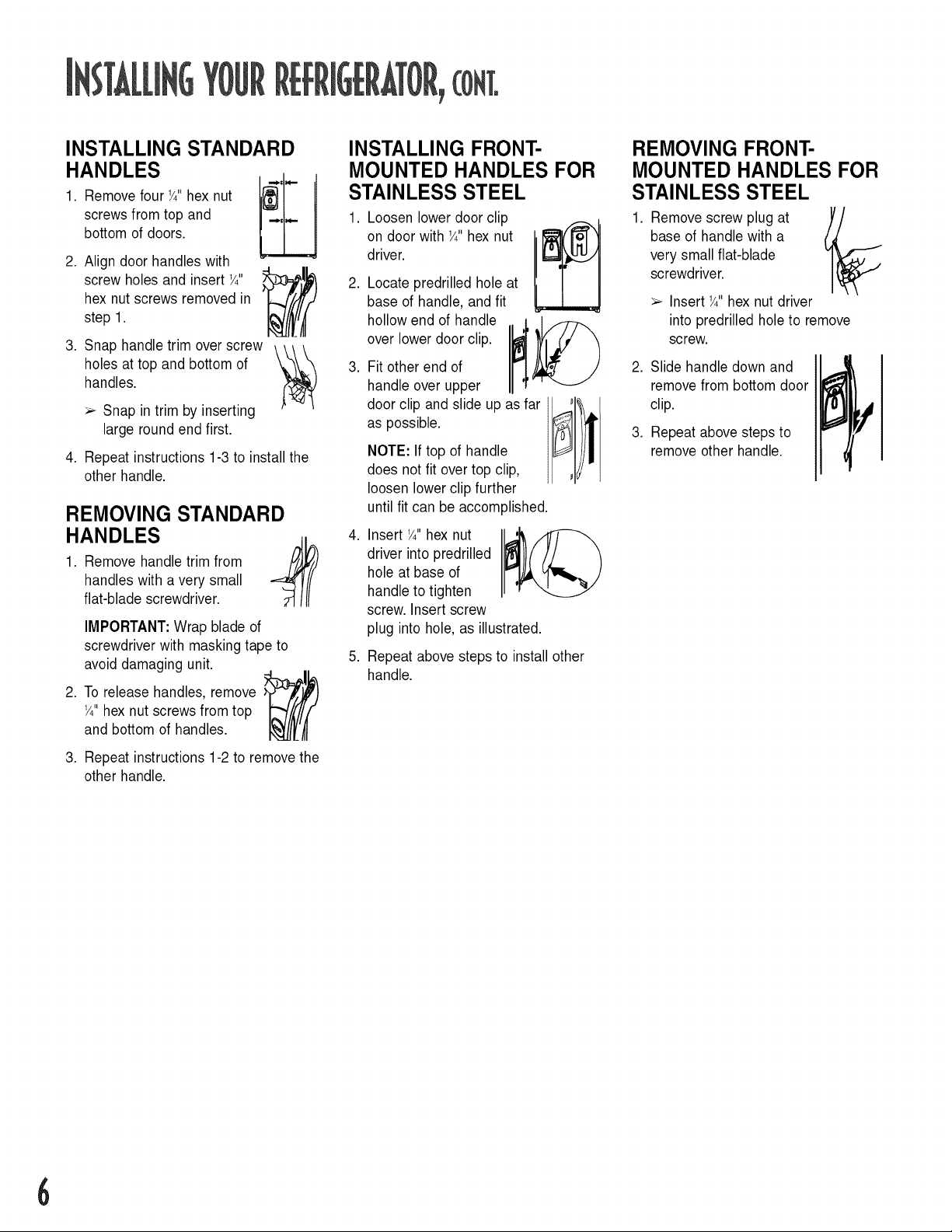

INSTALLING STANDARD

HANDLES

screws from top and _

1. Remove four Y,"hex nut ,LI_"*- _i

bottom of doors. E

2. Align door handles with

screw holes and insert _4" ;_=_lJ_

hex nut screws removed in

step 1.

3. Snap handle trim over screw ,\\\

holes at top and bottom of

handles.

> Snap in trim by inserting

large round end first.

4. Repeat instructions 1-3 to install the

other handle.

J ml

REMOVING STANDARD

HANDLES

1. Remove handle trim from

handles with a very small

flat-blade screwdriver.

IMPORTANT:Wrap blade of

screwdriver with masking tape to

avoid damaging unit.

,

Torelease handles, remove _'_,J_)

_4"hex nut screws from top

and bottom of handles.

INSTALLING FRONT-

MOUNTED HANDLES FOR

STAINLESS STEEL

1. Loosen lowerdoor clip

on door with _" hex nut

driver.

,

Locate predrilled hole at

base of handle, and fit

hollow end of handle

over lower door clip.

,

Fit other end of

handle over upper

door clip and slide up asfar

as possible.

NOTE: If top of handle

does not fit over top clip,

loosen lower clip further

until fit can be accomplished.

,

Insert _,"hex nut ,,_ ,,4[T---'_

driver into predrilled

hole at base of

handle to tighten

screw. Insert screw

plug into hole, as illustrated.

,

Repeat above steps to install other

handle.

REMOVING FRONT-

MOUNTED HANDLES FOR

STAINLESS STEEL

base of handle with a

very small flat-blade

1. Remove screw plug at

screwdriver.

> Insert _4"hexnut driver

into predrilled hole to remove

screw.

2. Slide handle down and

remove from bottom door

clip.

3. Repeat abovesteps to

remove other handle.

6

,

Repeat instructions 1-2 to remove the

other handle.

Page 7

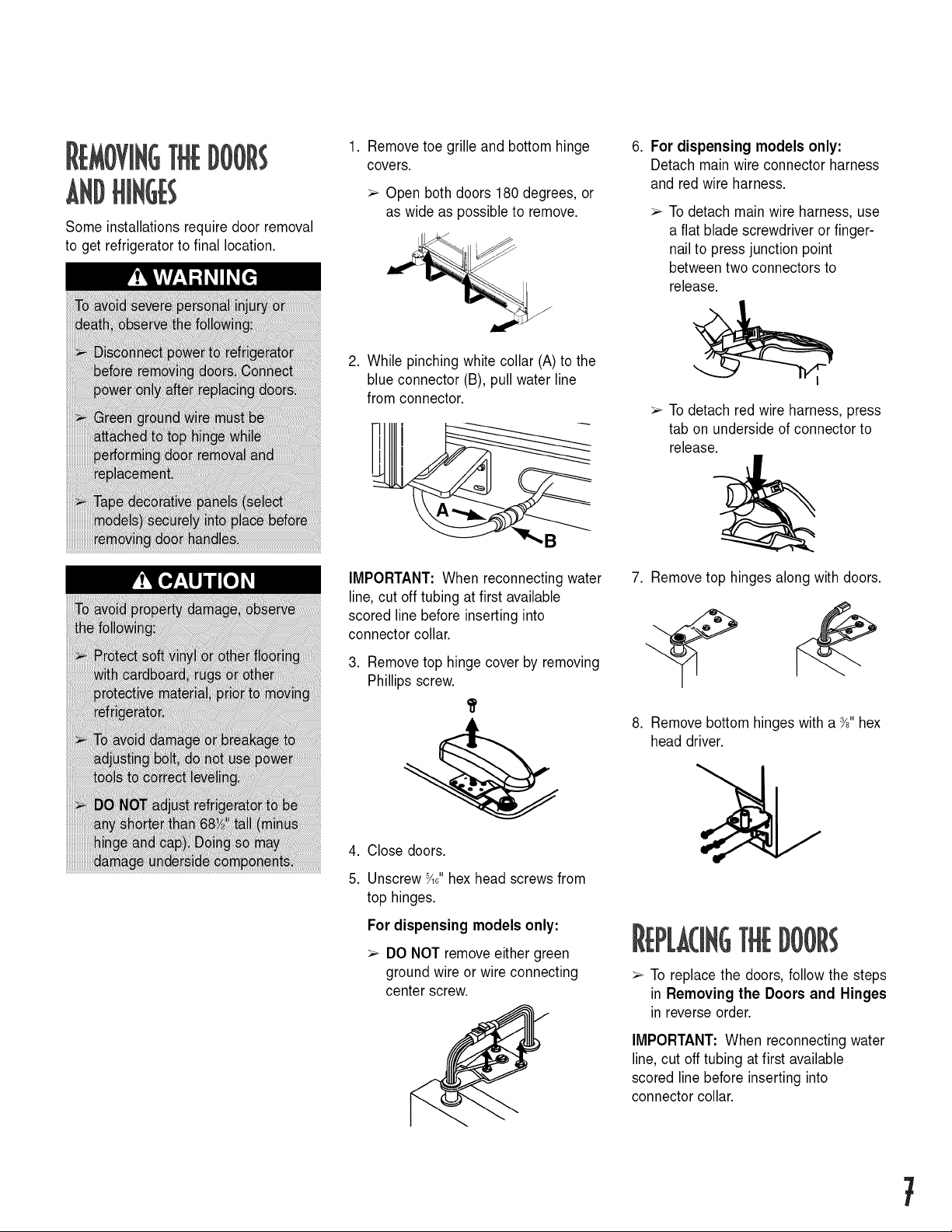

Some installations require door removal

to get refrigerator to final location.

1. Remove toe grille and bottom hinge

covers.

> Open both doors 180 degrees, or

as wide as possible to remove.

2. While pinching white collar (A) to the

blue connector (B), pull water line

from connector.

,

For dispensing models only:

Detach mainwire connector harness

and red wire harness.

> Todetach main wire harness, use

a flat blade screwdriver or finger-

nail to press junction point

between two connectors to

release.

> Todetach red wire harness, press

tab on underside of connector to

release.

IMPORTANT: When reconnectingwater

line, cut off tubing at first available

scored line before inserting into

connector collar.

3. Remove top hinge cover by removing

Phillips screw.

4. Close doors.

5. Unscrew %6"hex head screws from

top hinges.

For dispensing models only:

> DO NOT remove either green

ground wire or wire connecting

center screw.

7. Remove top hinges along with doors.

,

Remove bottom hinges with a 78"hex

head driver.

.A(INGTHE#{}ORS

> To replace the doors, follow the steps

in Removing the Doors and Hinges

in reverse order.

IMPORTANT: When reconnectingwater

line, cut off tubing at first available

scored line before inserting into

connector collar.

t

Page 8

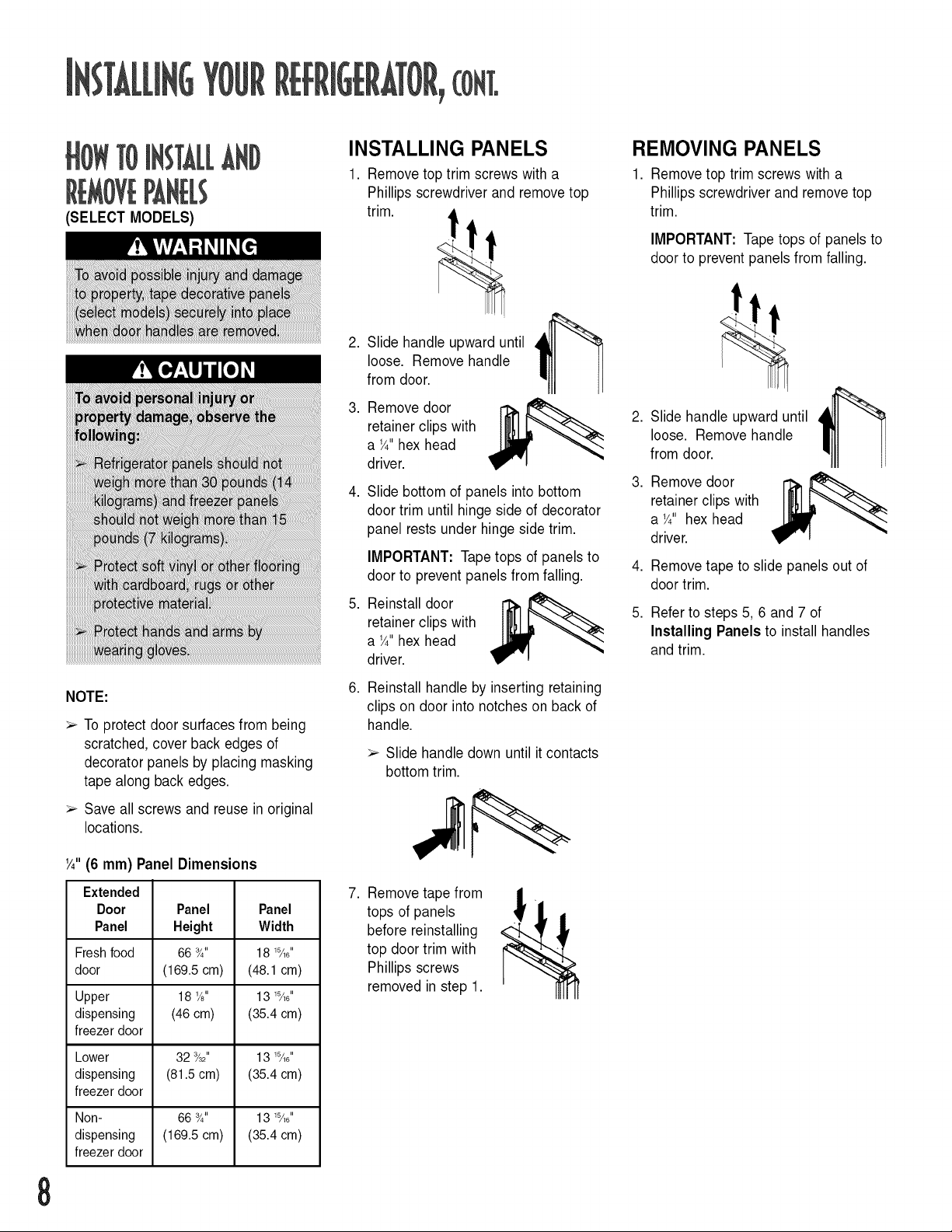

INSTALLING PANELS

REMOVING PANELS

[}WTOINSTALLAN[}

(SELECT MODELS)

1. Remove top trimscrews witha

Phillips screwdriver and removetop

trim.

1. Removetop trim screws with a

Phillips screwdriver and removetop

trim.

IMPORTANT: Tapetopsof panels to

door to prevent panels from falling.

t t

,

Slide handle upward until

loose. Remove handle

from door.

,

Remove door

retainer clips with

a ¼"hex head

driver.

,

Slide bottom of panels into bottom

door trim until hinge side of decorator

panel rests under hinge side trim.

IMPORTANT: Tapetopsof panels to

door to prevent panels from falling.

,

Reinstall door

iiiiiiiiiiii_i!_!i!!i!!i!!i_!_!!_!!_I_!_i!_i_i_!_i_i_i_i_i!_!_i!_!_!i_i_i_i_i_i¸_!iii!__i_!!_!!_!!_!!_!_!_!_!_!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!!_!_i_i_!!_

!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i_ _ii_!!ii!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!iii!_!i!i!

retainer clips with

a ¼"hex head

driver.

,

Slide handle upward until 4_1 "_

loose. Remove handle

from door.

,

Remove door

retainer clips with

a V_"hex head

driver.

,

Removetape to slide panels out of

door trim.

,

Refer to steps 5, 6 and 7 of

Installing Panelsto install handles

and trim.

NOTE:

> Toprotect door surfaces from being

scratched, cover back edges of

decorator panels by placing masking

tape along back edges.

> Save all screws and reuse in original

locations.

¼" (6 mm) Panel Dimensions

Extended

Door

Panel

Fresh food

door

Upper

dispensing

freezer door

Lower

dispensing

freezer door

Non-

dispensing

Panel Panel

Height Width

66 _" 18 15_611

(169.5 ore) (48.1 ore)

18 1/8" 13 15_6"

(46 ore) (35.4 ore)

32 _3_" 13 15_6"

(81.5 ore) (35.4 ore)

66 _4" 13 15_6"

(169.5 ore) (35.4 ore)

freezerdoor

,

Reinstall handle by inserting retaining

clips on door into notches on back of

handle.

> Slide handle down until it contacts

bottom trim.

7. Remove tape from

tops of panels

before reinstalling

top door trim with

Phillips screws

removed in step 1.

Page 9

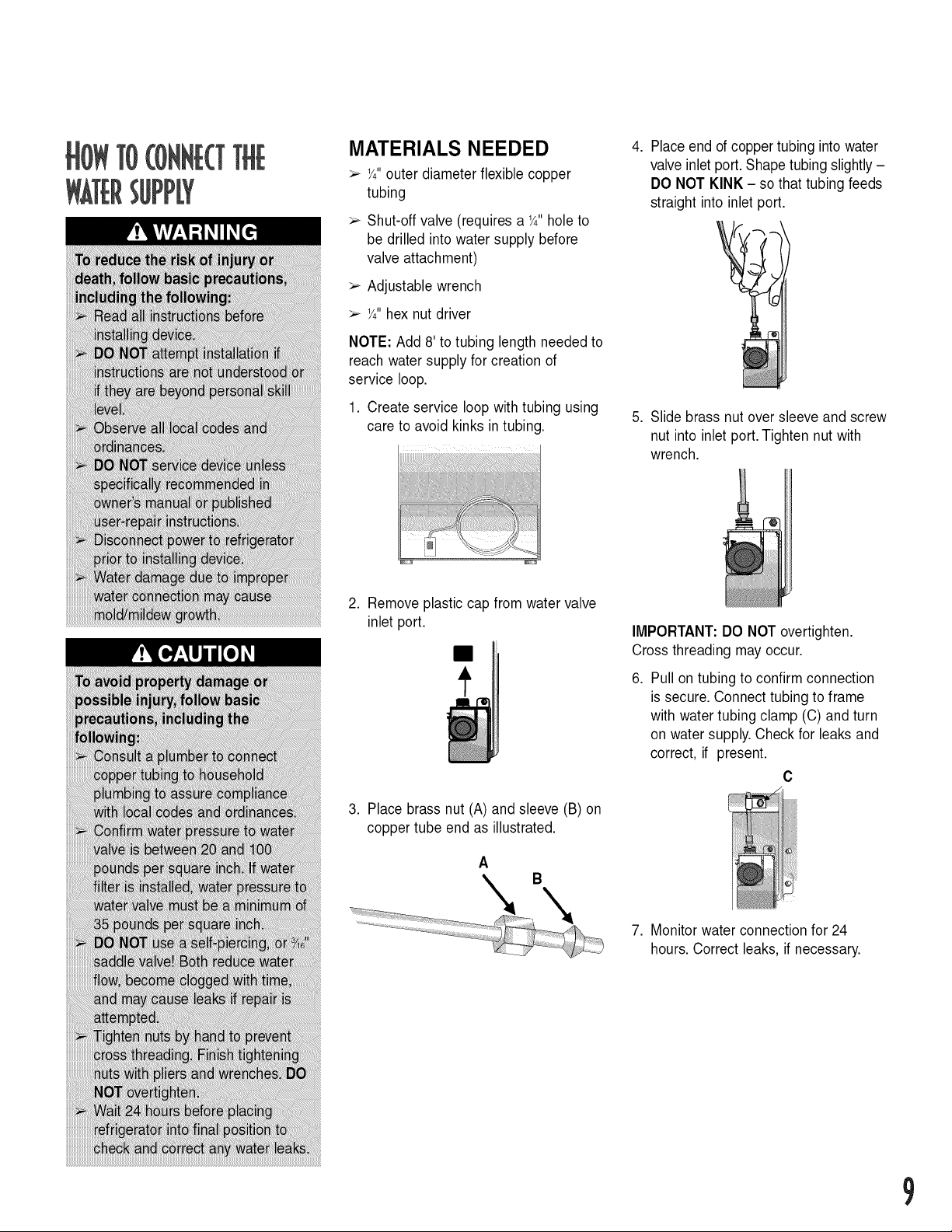

MATERIALS NEEDED

> ¼"outer diameter flexible copper

tubing

Shut-off valve (requires a ¼"hole to

be drilled into water supply before

valve attachment)

>- Adjustable wrench

> ¼"hex nut driver

NOTE: Add 8' to tubing length needed to

reach water supply for creation of

service loop.

,

Place end of copper tubing into water

valve inlet port. Shape tubing slightly -

DO NOT KINK - so that tubing feeds

straight into inlet port.

1. Create service loop with tubing using

care to avoid kinks in tubing.

2. Remove plastic cap from water valve

inlet port.

3. Place brass nut (A) and sleeve (B) on

copper tube end as illustrated.

,

Slide brass nutover sleeve and screw

nut into inlet port.Tighten nut with

wrench.

IMPORTANT: DO NOT overtighten.

Cross threading may occur.

,

Pull on tubing to confirm connection

is secure. Connect tubing to frame

with water tubing clamp (C) and turn

on water supply.Check for leaks and

correct, if present.

C

A

7. Monitor water connection for 24

hours. Correct leaks, if necessary.

Page 10

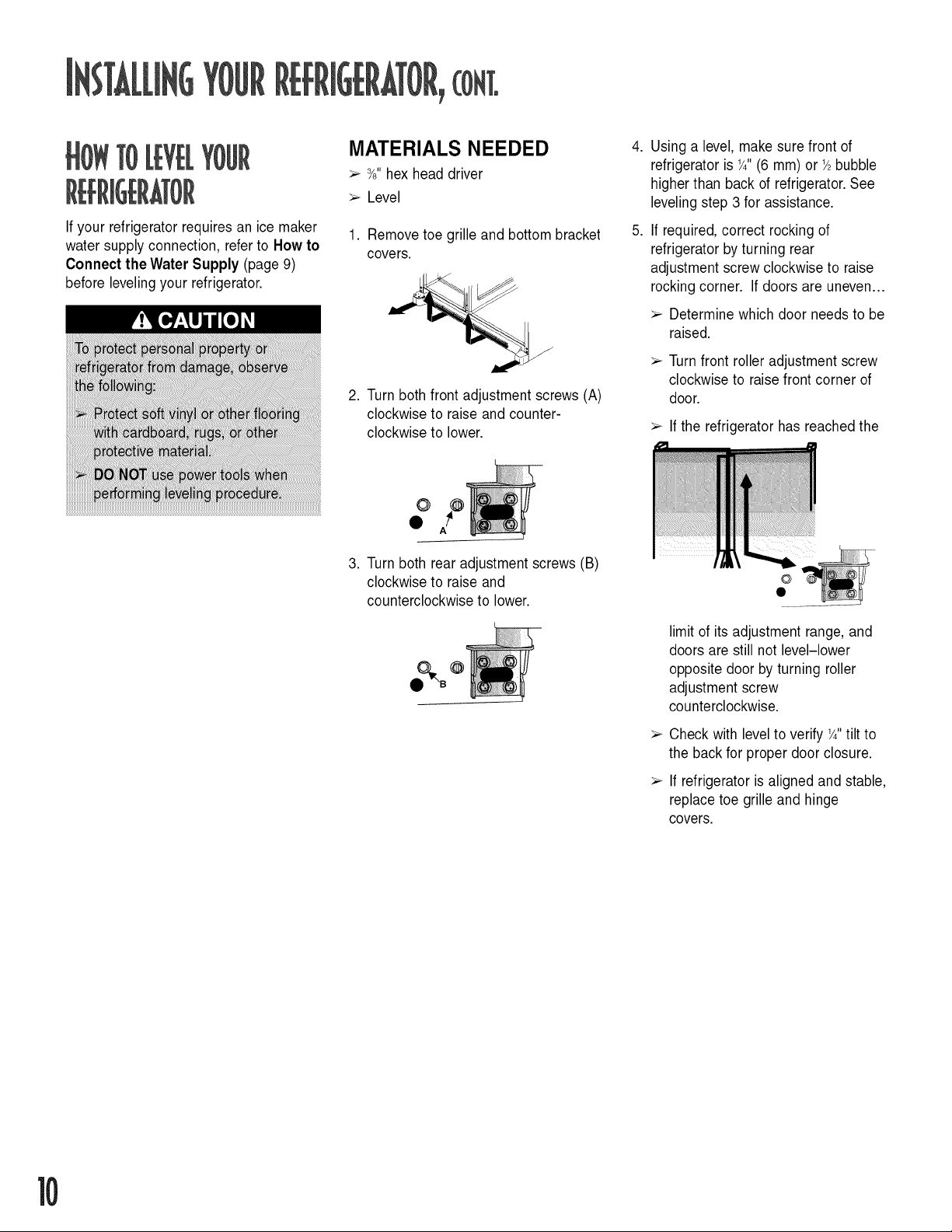

TOLEVELTOUR

If your refrigerator requires an ice maker

water supply connection, refer to How to

Connect the Water Supply (page 9)

before levelingyour refrigerator.

MATERIALS NEEDED

> _8"hex head driver

> Level

1. Remove toe grille and bottom bracket

covers.

f

2. Turn both front adjustment screws (A)

clockwiseto raise and counter-

clockwiseto lower.

@

3. Turn both rear adjustment screws (B)

clockwiseto raise and

counterclockwiseto lower.

,

Using a level, makesure front of

refrigerator is ¼"(6 mm) or h bubble

higher than back of refrigerator. See

levelingstep 3 for assistance.

,

If required, correct rocking of

refrigerator by turning rear

adjustment screw clockwise to raise

rocking corner. If doors are uneven...

> Determine which door needs to be

raised.

>- Turn front roller adjustment screw

clockwise to raisefront corner of

door.

> If the refrigerator has reached the

limit of its adjustment range, and

doors are still not level-lower

opposite door by turning roller

adjustment screw

counterclockwise.

Check with level to verify ¼"tilt to

the back for proper door closure.

If refrigerator is aligned and stable,

replace toe grille and hinge

covers.

]0

Page 11

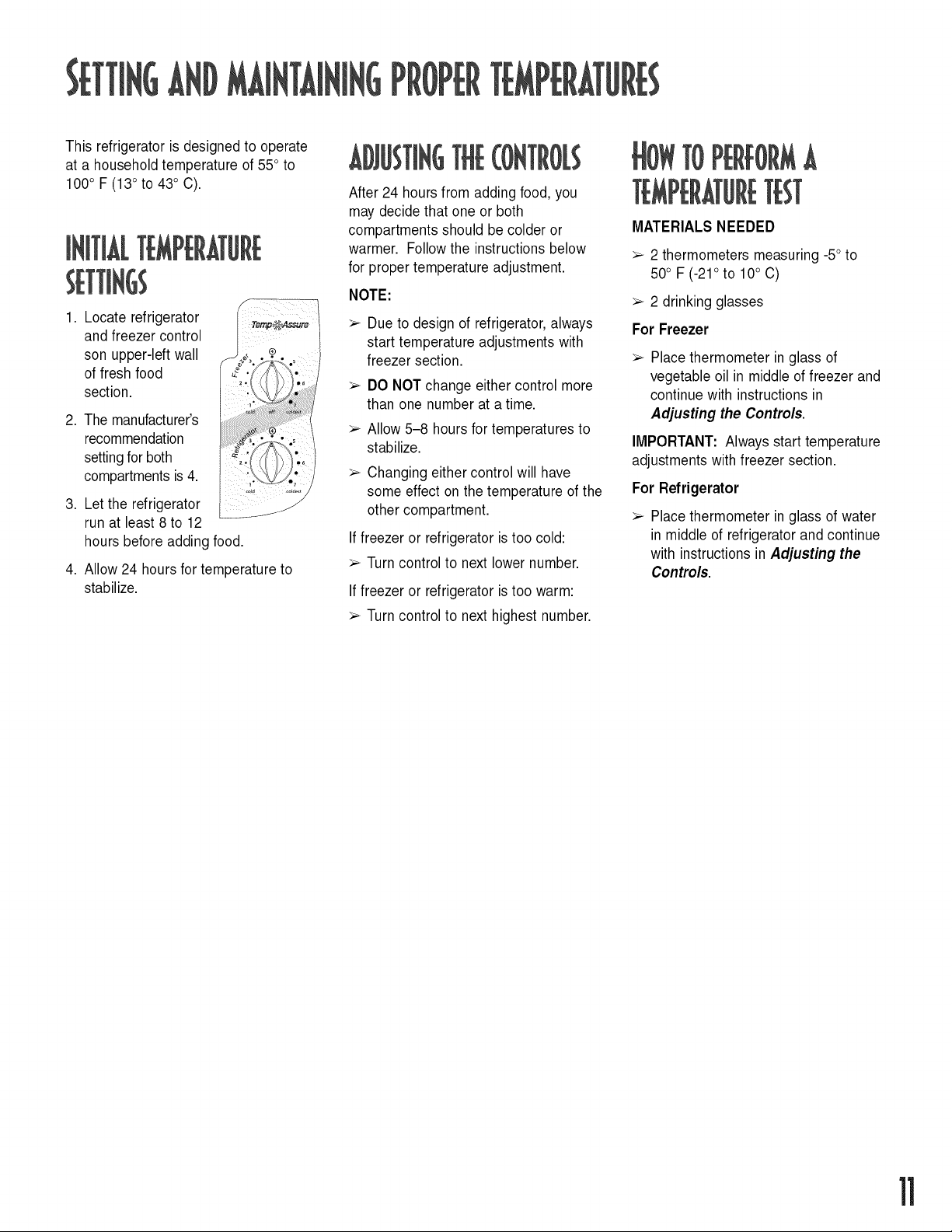

This refrigerator is designedto operate

at a household temperature of 55° to

100° F (13°to 43° C).

iNiTiALTEMPERATURE

1. Locate refrigerator

and freezer control

son upper-left wall

of fresh food

section.

2. The manufacturer's

recommendation

settingfor both

compartmentsis4.

3. Let the refrigerator

run at least 8 to 12

hours before adding food.

4. Allow 24 hours for temperature to

stabilize.

®

_t

_.1 _ ,o_

_. • " .,,_

2. a_

ADJUSTINGTHE(0NTR0[S

After 24 hoursfrom adding food,you

may decide that one or both

compartments should be colder or

warmer. Follow the instructions below

for proper temperature adjustment.

NOTE:

Due to design of refrigerator, always

start temperature adjustments with

freezer section.

DO NOT change either control more

than one number at a time.

Allow 5-8 hours for temperatures to

stabilize.

Changing either control will have

some effect on the temperature of the

other compartment.

If freezer or refrigerator is too cold:

> Turn control to next lower number.

If freezer or refrigerator is too warm:

Turn control to next highest number.

MATERIALS NEEDED

> 2 thermometers measuring -5° to

50° F (-21°to 10° C)

> 2 drinking glasses

For Freezer

> Place thermometer in glass of

vegetable oil in middle of freezer and

continue with instructions in

Adjusting the Controls.

IMPORTANT: Always start temperature

adjustments with freezer section.

For Refrigerator

> Place thermometer in glass of water

in middle of refrigerator and continue

with instructions in Adjusting the

Controls.

Page 12

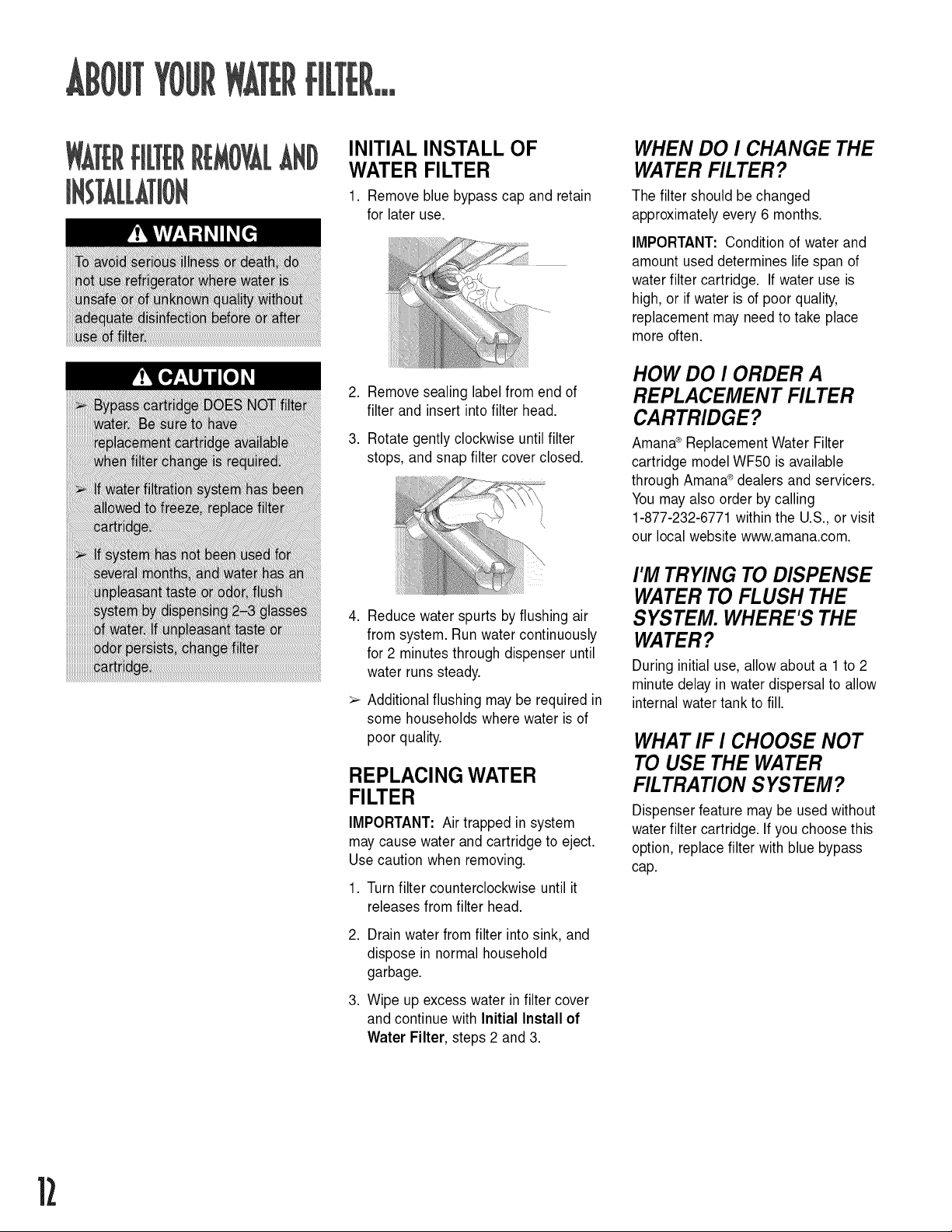

ilm

INITIAL INSTALL OF

WATER FILTER

1. Remove blue bypass cap and retain

for later use.

2. Remove sealing label from end of

filter and insert intofilter head.

3. Rotate gently clockwise until filter

stops, and snap filter cover closed.

4. Reduce water spurts by flushing air

from system. Run water continuously

for 2 minutesthrough dispenser until

water runs steady.

> Additional flushing may be required in

some households where water is of

poor quality.

REPLACING WATER

FILTER

IMPORTANT: Air trappedin system

may cause water and cartridge to eject.

Use caution when removing.

1. Turn filter counterclockwise until it

releases from filter head.

WHEN DO I CHANGE THE

WATER FILTER?

The filter should be changed

approximately every 6 months.

IMPORTANT: Condition of water and

amount used determines lifespan of

water filter cartridge. If water use is

high, or if water is of poor quality,

replacement may need to take place

more often.

HOW DO I ORDER A

REPLACEMENT FILTER

CARTRIDGE?

Amana_Replacement Water Filter

cartridge model WF50 is available

through Amana®dealers and servicers.

You may also order by calling

1-877-232-6771 within the U.S., orvisit

our local website www.amana.com.

I'M TRYING TO DISPENSE

WATERTO FLUSH THE

SYSTEM. WHERE'S THE

WATER?

During initial use, allow about a 1 to 2

minute delay in water dispersal to allow

internal water tank to fill.

WHAT IF I CHOOSE NOT

TO USE THE WATER

FILTRATION SYSTEM?

Dispenser feature may be used without

water filter cartridge. If you choose this

option, replace filter with blue bypass

cap.

]2

,

Drain water from filter into sink, and

dispose in normal household

garbage.

,

Wipe up excess water in filter cover

and continue with Initial Install of

Water Filter, steps 2 and 3.

Page 13

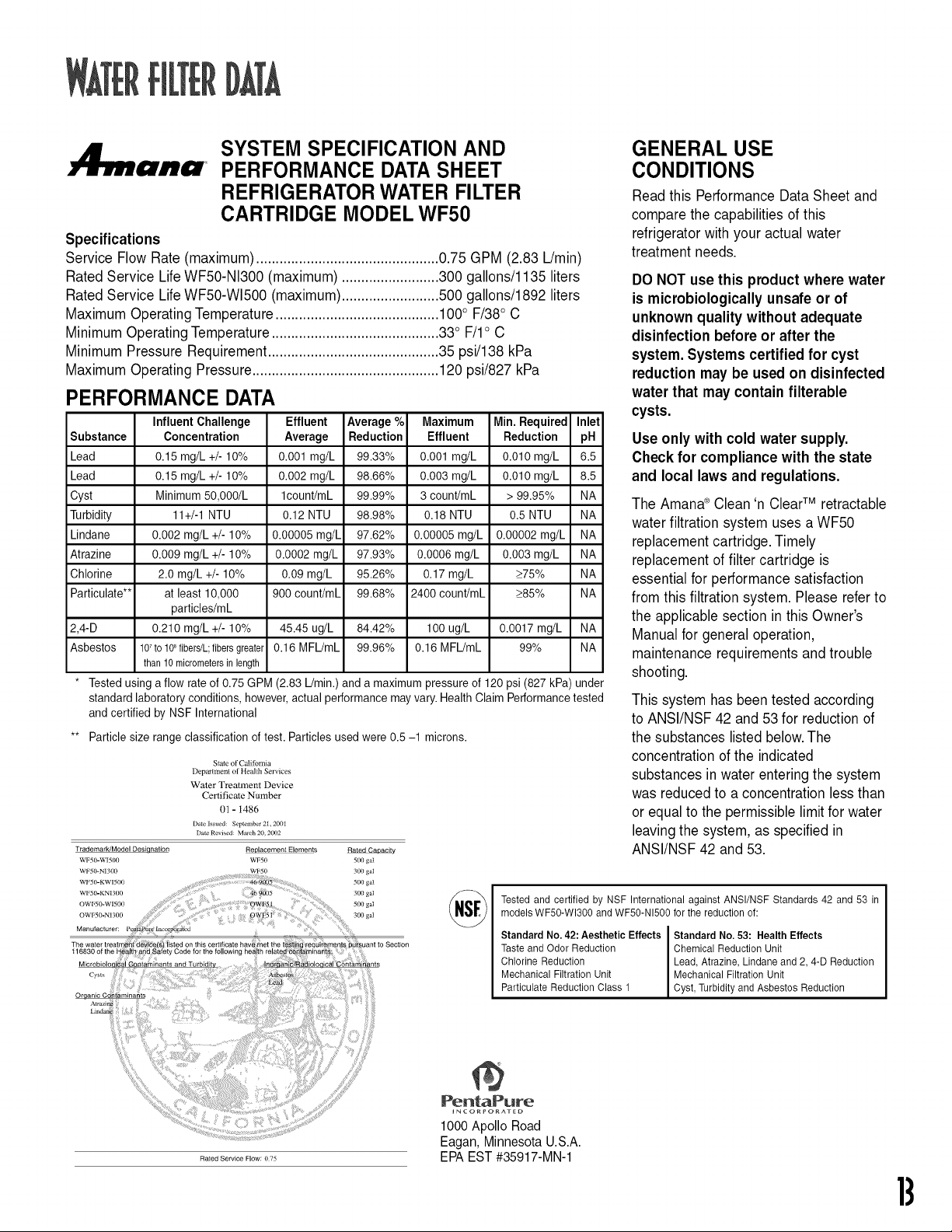

SYSTEM SPECIFICATION AND

PERFORMANCE DATA SHEET

REFRIGERATOR WATER FILTER

CARTRIDGE MODEL WF50

Specifications

Service Flow Rate (maximum)...............................................0.75 GPM (2.83 Umin)

Rated Service LifeWF50-NI300 (maximum).........................300 gallons/1135 liters

Rated Service LifeWF50-WI500 (maximum).........................500 gallons/1892 liters

Maximum Operating Temperature..........................................100° F/38° C

Minimum OperatingTemperature...........................................33° F/l° C

Minimum Pressure Requirement............................................35 psi/138 kPa

Maximum Operating Pressure................................................120 psi/827 kPa

PERFORMANCE DATA

Influent Challenge

Substance

Lead

Lead

Cyst

Turbidity

Lindane

Atrazine

Chlorine

Particulate**

2,4-D 0.210 mg/L +/- 10%

Asbestos 107to 108fibers/L;fibersgreater

* Tested using a flow rate of 0.75 GPM (2.83 L/rain.) and a maximum pressure of 120 psi (827 kPa) under

standard laboratory conditions, however, actual performance may vary. Health Claim Performance tested

and certified by NSF International

** Particle size range classification of test. Particles used were 0.5 -1 microns.

Trademark/Model Desiqnation Replacement Elements Rated C_

WFS0-WISO0 WFSO 500 ga/

WF50-NI300 WF50 300 gaI

WR50-KWI500 500 ga/

WFS0-KNt3(K) 300 gal

OWl 50-Nt300 300 gal

Manufacturer:

Concentration

0.15 mg/L +/- 10%

0.15 mg/L +/- 10%

Minimum 50,000/L

11+/-1 NTU

0.002 mg/L +/- 10%

0.009 mg/L +/- 10%

2.0 mg/L +/- 10%

at least 10,000

particles/mL

than 10 micrometersinlength

SlaIe of Caii fbmia

I)epartme_t ol Health Services

Water Treatment Device

Certificate Number

01 - 1486

Date Issued: Septcmi_r 21. 2001

Da_e Revised: Maldl 20, 20O2

Effluent Average % Maximum

Average Reduction Effluent

0.001 mg/L 99.33% 0.001 mg/L

0.002 mg/L 98.66% 0.003 mg/L

lcount/mL 99.99% 3 countJmL

0.12 NTU 98.98% 0.18 NTU

0.00005 mg/L 97.62% 0.00005 mg/L

0.0002 mg/L 97.93% 0.0006 mg/L

0.09 mg/L 95.26% 0.17 mg/L

900 count/mL 99.68% 2400 countJmL

45.45 ug/L 84.42% 100 ug/L

0.16 MFL/mL 99.96% 0.16 MFL/mL

500 gaI

Min. Required Inlet

Reduction pH

0.010 mg/L 6.5

0.010 mg/L 8.5

> 99.95% NA

0.5 NTU NA

0.00002 mg/L NA

0.003 mg/L NA

_>75% NA

_>85% NA

0.0017 mg/L NA

99% NA

Tested and certified by NSF International against ANSI/NSF Standards 42 and 53 in

models WF50-Wl300 and WF50-NI500 for the reduction of:

Standard No. 42: Aesthetic Effects

Taste and Odor Reduction

Chlorine Reduction

Mechanical Filtration Unit

Particulate Reduction Class 1

GENERAL USE

CONDITIONS

Read this Performance Data Sheet and

compare the capabilities of this

refrigerator with your actual water

treatment needs.

DO NOT use this product where water

is microbiologically unsafe or of

unknown quality without adequate

disinfection before or after the

system. Systems certified for cyst

reduction may be used on disinfected

water that may contain filterable

cysts.

Use only with cold water supply.

Check for compliance with the state

and local laws and regulations.

The Amana<_Clean 'n ClearTMretractable

water filtration system uses a WF50

replacement cartridge. Timely

replacement of filter cartridge is

essential for performance satisfaction

from this filtration system. Please refer to

the applicable section in this Owner's

Manual for general operation,

maintenance requirements and trouble

shooting.

This system has been tested according

to ANSI/NSF 42 and 53 for reduction of

the substances listed below.The

concentration of the indicated

substances in water enteringthe system

was reduced to a concentration lessthan

or equal to the permissible limit for water

leavingthe system, as specified in

ANSI/NSF 42 and 53.

Standard No. 53: Health Effects

Chemical Reduction Unit

Lead, Atrazine, Lindane and 2, 4-D Reduction

Mechanical Filtration Unit

Cyst, Turbidity and Asbestos Reduction

Rated Service Flow: 0 75

PentaPure

INCONPOR&TED

1000ApolloRoad

Eagan,MinnesotaU.S.A.

EPAEST#35917-MN-1

1}

Page 14

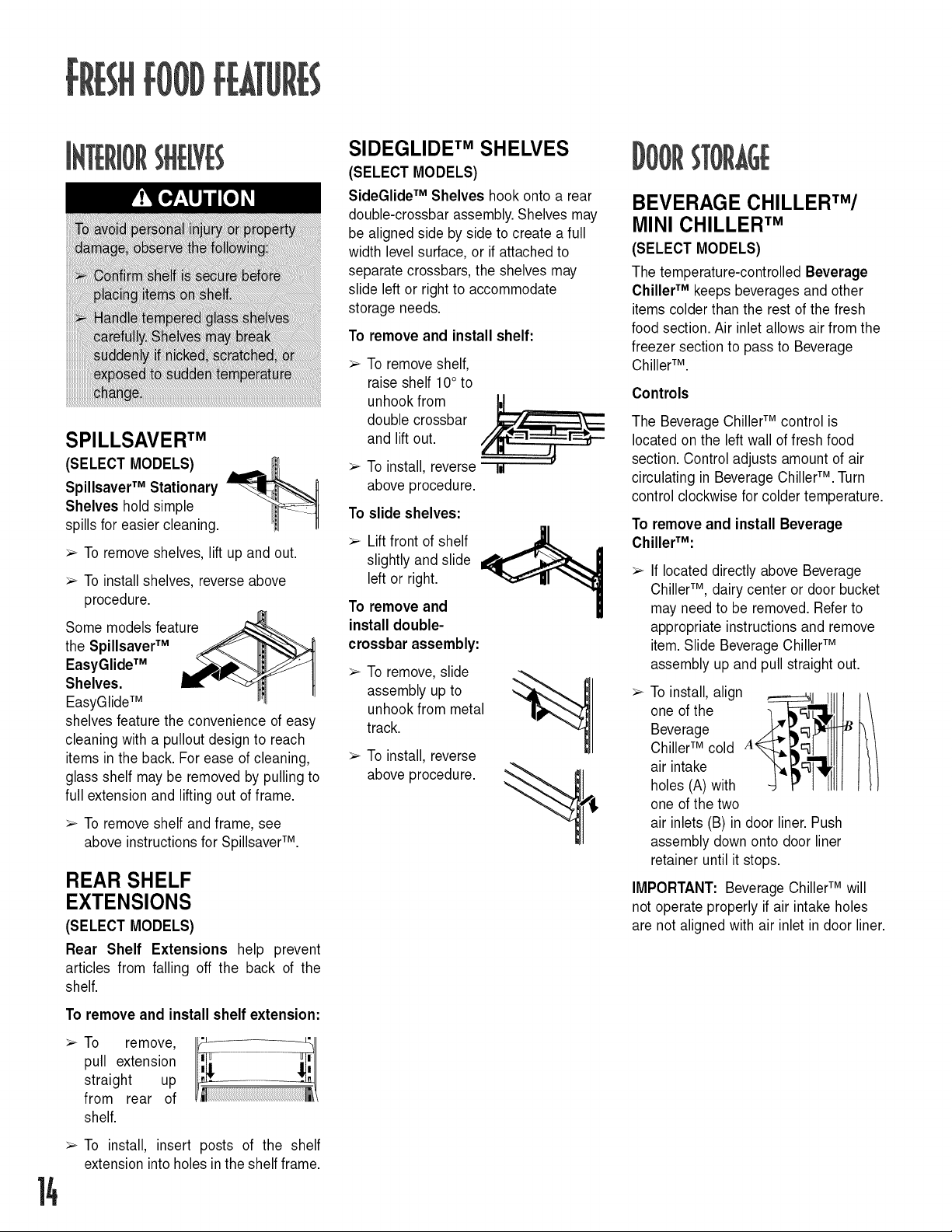

SPILLSAVER TM

(SELECT MODELS)

SpillsaverTM Stationary

Shelves hold simple

spills for easier cleaning.

> Toremove shelves, lift up and out.

> Toinstall shelves, reverse above

procedure.

Some models feature

the SpillsaverTM _

EasyGlide'M _il_'_._

Shelves. Be" "'-'_

EasyGlideTM _,_llj

shelves feature the convenience of easy

cleaning with a pullout design to reach

items in the back. For ease of cleaning,

glass shelf may be removed by pulling to

full extension and lifting out of frame.

> Toremove shelf and frame, see

above instructions for SpillsaverTM.

tr_

REAR SHELF

EXTENSIONS

(SELECT MODELS)

Rear Shelf Extensions help prevent

articles from falling off the back of the

shelf.

SIDEGLIDE TM SHELVES

(SELECT MODELS)

SideGlide TM Shelves hook ontoa rear

double-crossbar assembly,Shelves may

be aligned side by sidetocreateafull

width level surface, or if attached to

separate crossbars, the shelves may

slide left or right to accommodate

storage needs.

To remove and install shelf:

> To remove shelf,

raise shelf 10° to

unhook from

double crossbar

and lift out.

> To install, reverse

above procedure.

To slide shelves:

> Lift front of shelf

slightly and slide

left or right.

To remove and

install double-

crossbar assembly:

> To remove, slide

assembly up to

unhook from metal

track.

> To install, reverse

above procedure.

)ORS[O E

BEVERAGE CHILLERTM/

MINI CHILLER TM

(SELECT MODELS)

The temperature-controlledBeverage

ChillerTM keeps beveragesand other

items colder than the rest of the fresh

food section. Air inlet allows air from the

freezer section to pass to Beverage

ChillerTM.

Controls

The BeverageChillerTM control is

located on the left wall offresh food

section. Control adjusts amount of air

circulating in Beverage ChillerTM. Turn

control clockwise for coldertemperature.

To remove and install Beverage

ChillerTM:

> If located directly above Beverage

ChillerTM, dairy center or door bucket

may need to be removed.Refer to

appropriate instructions and remove

item. Slide Beverage ChillerTM

assembly up and pull straight out.

> Toinstall, align _::_;_z_l IlII1 I/

one of the "_,,_ _'_,_III,,

Beverage /iv" __

ChillerTM cold -4_:___=al IIIlt

air intake _ _]_'_IHI I

holes (A) with _ _" I Illll

one of the two

air inlets (B) in door liner.Push

assembly down onto door liner

retainer until it stops.

IMPORTANT: Beverage ChillerTM will

not operate properly if air intake holes

are not aligned with air inlet in door liner.

To remove and install shelf extension:

> To remove,

pull extension

straight up

from rear of

shelf.

> To install, insert posts of the shelf

extension into holesin the shelf frame.

]4

Page 15

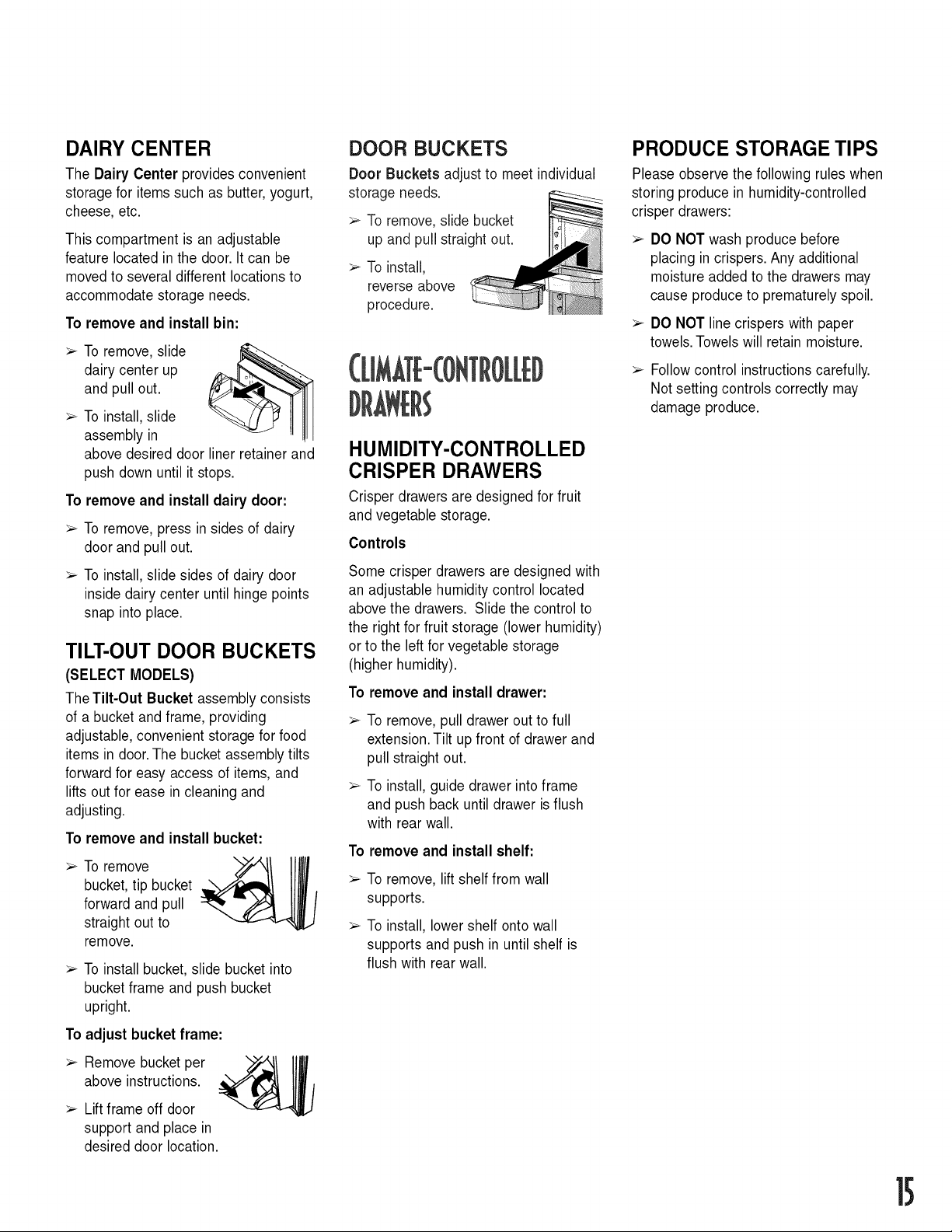

DAIRY CENTER

The Dairy Center provides convenient

storage for items such as butter, yogurt,

cheese, etc.

This compartment is an adjustable

feature located in the door. It can be

moved to several different locations to

accommodate storage needs.

To remove and install bin:

>- To remove, slide

dairy center up

and pull out.

> Toinstall, slide

assembly in

above desired door liner retainer and

push down until it stops.

To remove and install dairy door:

> Toremove, press in sides of dairy

door and pull out.

> Toinstall, slide sides of dairy door

inside dairy center until hinge points

snap into place.

TILT-OUT DOOR BUCKETS

(SELECT MODELS)

TheTilt-Out Bucket assembly consists

of a bucket and frame, providing

adjustable, convenient storage for food

items in door.The bucket assembly tilts

forward for easy access of items, and

lifts out for ease in cleaning and

adjusting.

To remove and install bucket:

>- To remove

bucket, tip bucket

forward and pull

straight out to

remove.

> Toinstall bucket, slide bucket into

bucketframe and push bucket

upright.

DOOR BUCKETS

Door Buckets adjust to meet individual

storage needs.

> To remove, slide bucket

up and pull straight out.

> To install,

reverse above

procedure.

HUMIDITY-CONTROLLED

CRISPER DRAWERS

Crisper drawers are designed for fruit

and vegetable storage.

Controls

Some crisper drawers are designed with

an adjustable humiditycontrol located

abovethe drawers. Slidethe control to

the right for fruit storage (lowerhumidity)

or to the left for vegetable storage

(higher humidity).

To remove and install drawer:

To remove, pull drawer out to full

extension.Tilt up front of drawer and

pull straight out.

To install, guide drawer into frame

and push back until drawer isflush

with rear wall.

To remove and install shelf:

To remove, lift shelf from wall

supports.

To install, lowershelf onto wall

supports and push in until shelf is

flush with rear wall.

PRODUCE STORAGE TIPS

Please observe the following rules when

storing produce in humidity-controlled

crisper drawers:

>- DO NOT wash produce before

placing in crispers.Any additional

moisture added to the drawers may

cause produce to prematurely spoil.

> DO NOT line crispers with paper

towels.Towelswill retain moisture.

> Follow control instructions carefully.

Not setting controls correctly may

damage produce.

To adjust bucket frame:

> Remove bucket per _/ II_

above instructions.

> Lift frame off door

support and place in

desired door location.

Page 16

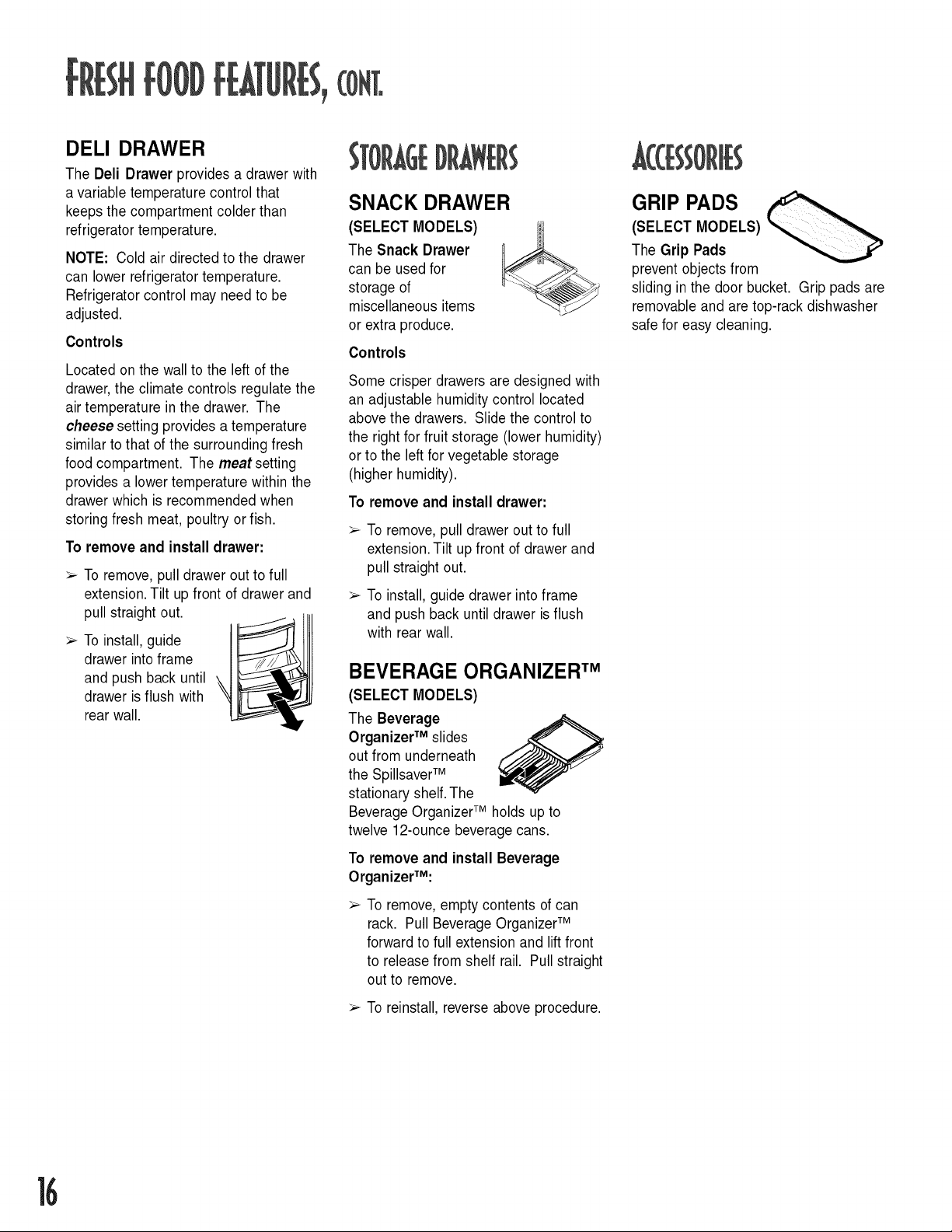

DELl DRAWER

The Deli Drawer provides a drawer with

a variable temperature control that

keeps the compartment colder than

refrigerator temperature.

NOTE: Cold air directed to the drawer

can lower refrigerator temperature.

Refrigerator control may need to be

adjusted.

Controls

Located on the wallto the left of the

drawer,the climate controls regulate the

air temperature in the drawer. The

cheese setting provides a temperature

similar to that of the surrounding fresh

food compartment. The meat setting

provides a lowertemperature within the

drawer which is recommended when

storing fresh meat, poultry or fish.

To remove and install drawer:

> Toremove, pull drawer outto full

extension.Tilt up front of drawer and

pull straight out.

> Toinstall, guide

drawer into frame

and push back until

drawer is flush with

rear wall.

SNACK DRAWER

(SELECT MODELS)

The Snack Drawer

can be used for

storage of

miscellaneous items

or extra produce.

Controls

Some crisper drawers are designed with

an adjustable humiditycontrol located

abovethe drawers. Slidethe control to

the right for fruit storage (lowerhumidity)

or to the left for vegetable storage

(higher humidity).

To remove and install drawer:

To remove, pull drawer out to full

extension.Tilt up front of drawer and

pull straight out.

To install, guide drawer into frame

and push back until drawer isflush

with rear wall.

BEVERAGE ORGANIZER TM

(SELECT MODELS)

The Beverage

OrganizerTM slides

out from underneath

the SpillsaverTM

stationary shelf.The

BeverageOrganizerTM holds up to

twelve 12-ounce beverage cans.

(SELECT MODELS)

GRIP PADS

The Grip Pads

prevent objects from

sliding in the door bucket. Grip pads are

removable and are top-rack dishwasher

safe for easy cleaning.

To remove and install Beverage

OrganizerTi:

> To remove, empty contents of can

rack. Pull BeverageOrganizerTM

forward to full extension and lift front

to release from shelf rail. Pull straight

out to remove.

> To reinstall, reverse above procedure.

Page 17

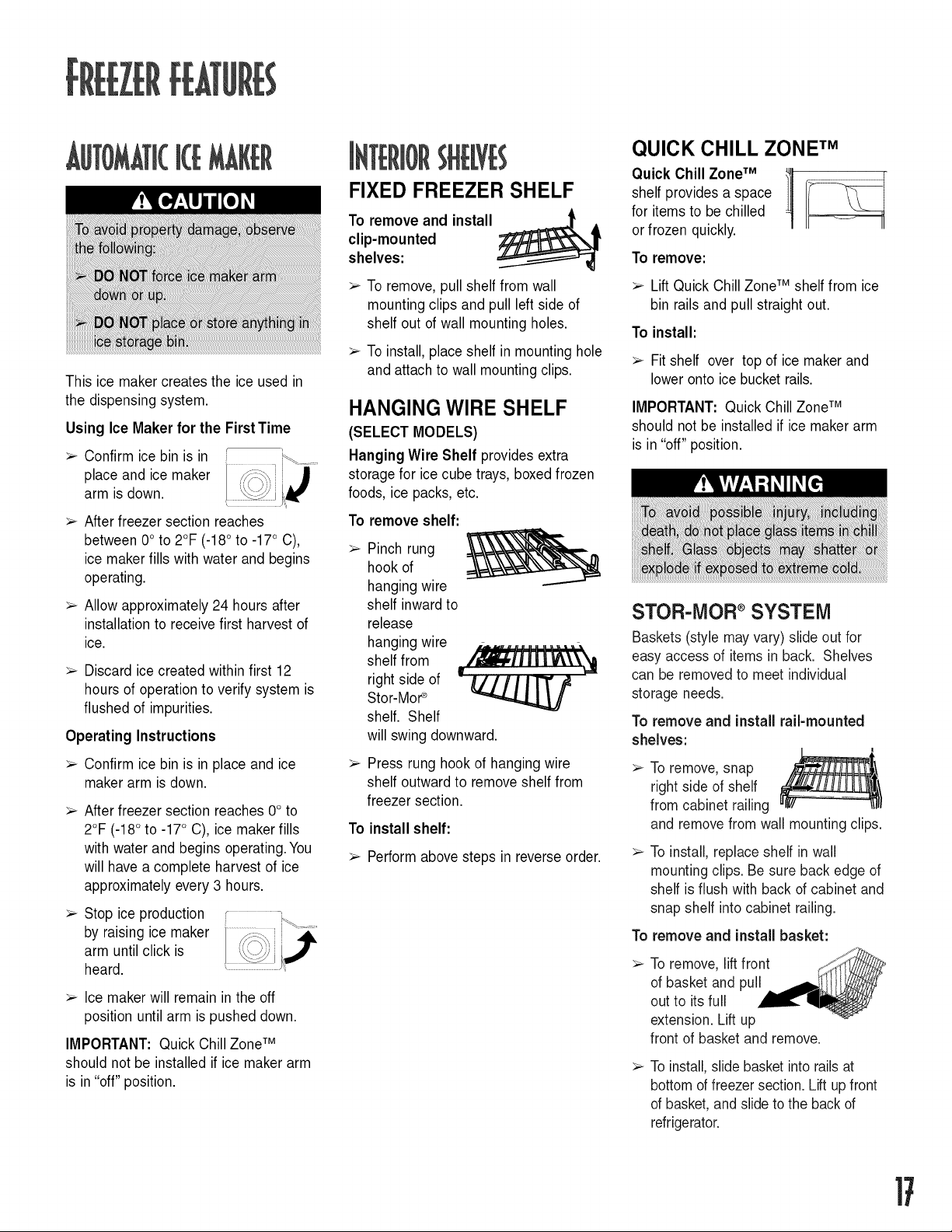

QUICK CHILL ZONETM

Thisicemakercreatestheiceusedin

thedispensingsystem.

Using Ice Maker for the FirstTime

>- Confirm ice bin is in

place and ice maker

arm is down.

> After freezer section reaches

between 0° to 2°F (-18° to -17° C),

ice maker fills with water and begins

operating.

> Allow approximately 24 hours after

installation to receive first harvest of

ice.

> Discard ice created within first 12

hours of operationto verify system is

flushed of impurities.

Operating Instructions

> Confirm ice bin is in place and ice

maker arm is down.

> After freezer section reaches 0° to

2°F (-18° to -17° C), ice maker fills

with water and begins operating. You

will have a complete harvest of ice

approximately every 3 hours.

>- Stop ice production - _ ....

by raising ice maker

arm untilclick is

heard.

> Ice maker will remain in the off

position until arm is pushed down.

IMPORTANT: Quick Chill ZoneTM

should notbe installed if ice maker arm

is in"off" position.

FIXED FREEZER SHELF

To remove and install J ,

clip-mounted

shelves:

> To remove, pull shelf fromwall

mounting clips and pull left side of

shelf out of wall mounting holes.

> To install, place shelf in mounting hole

and attach to wall mounting clips.

HANGING WIRE SHELF

(SELECT MODELS)

Hanging Wire Shelf provides extra

storage for ice cube trays, boxed frozen

foods, ice packs, etc.

To remove shelf:

hook of

Pinch rung

hanging wire

shelf inward to

release

shelf from

right side of w

hanging wire _

Stor-Mor_

shelf. Shelf

will swing downward.

Press rung hook of hanging wire

shelf outward to remove shelffrom

freezer section.

To install shelf:

> Perform above steps in reverse order.

shelf provides a space

Quick Chill ZoneTM t [_

for items to be chilled

or frozen quickly.

To remove:

> Lift Quick Chill ZoneTMshelf from ice

bin rails and pull straight out.

To install:

> Fit shelf over top of icemaker and

lower onto ice bucketrails.

IMPORTANT: Quick Chill ZoneTM

should notbe installed if ice maker arm

is in "off" position.

STOR-MOR ®SYSTEM

Baskets (style may vary) slide out for

easy access of items in back. Shelves

can be removed to meet individual

storage needs.

To remove and install rail-mounted

shelves:

> Toremove, snap __

right side of shelf

from cabinet railing

and remove from wall mounting clips.

Toinstall, replaceshelf in wall

mounting clips. Be sure back edge of

shelf is flush with back of cabinet and

snap shelf into cabinet railing.

To remove and install basket:

Toremove, lift front

of basket and pull

out to its full

extension. Lift up

front of basket and remove.

Toinstall,slide basketinto rails at

bottom offreezer section. Lift up front

of basket, and slideto the back of

refrigerator.

I !

]7

Page 18

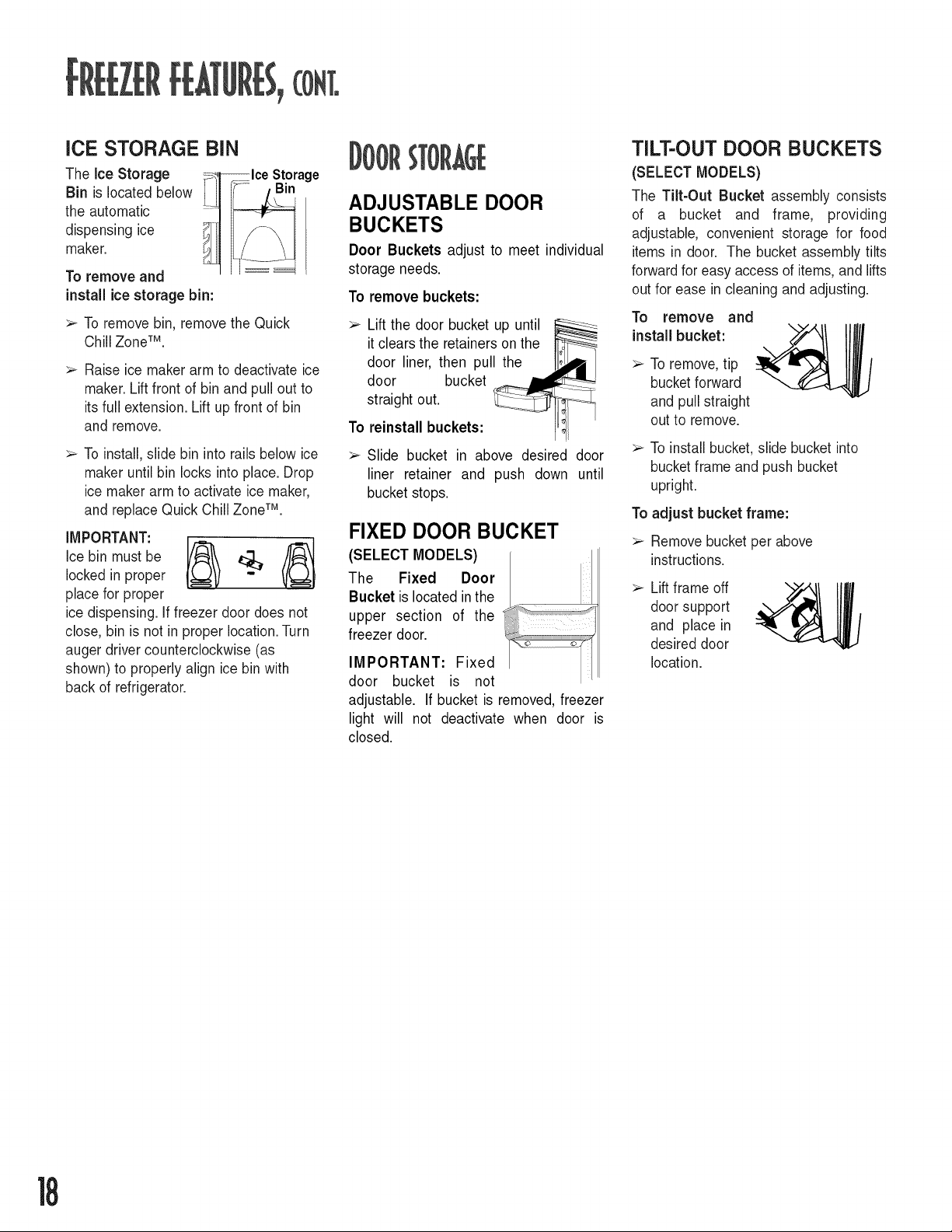

iCE STORAGE BiN

The ice Storage

Bin is located below

the automatic

dispensing ice

maker.

To remove and

install ice storage bin:

> Toremove bin, remove the Quick

Chill ZoneTM.

> Raise ice maker arm to deactivate ice

maker.Lift front of bin and pull out to

its full extension. Lift up front of bin

and remove.

> Toinstall, slide bin into rails below ice

maker until bin locks into place. Drop

ice maker arm to activate ice maker,

and replace Quick Chill ZoneTM.

Ice bin must be

IMPORTANT: 5 (_

locked in proper

place for proper

ice dispensing. If freezer door does not

close, bin is not in proper location.Turn

auger driver counterclockwise (as

shown) to properly align ice bin with

back of refrigerator.

}ORSTORAGE

ADJUSTABLE DOOR

BUCKETS

Door Buckets adjust to meet individual

storage needs.

To remove buckets:

> Lift the door bucket up until

it clears the retainers on the

door liner, then pull the

door bucket

straight out.

To reinstall buckets:

> Slide bucket in above desired door

liner retainer and push down until

bucketstops.

FIXED DOOR BUCKET

(SELECT MODELS)

The Fixed Door

Bucket is locatedinthe

upper section of the

freezer door.

IMPORTANT: Fixed

door bucket is not

adjustable. If bucket is removed, freezer

light will not deactivate when door is

closed.

TILT-OUT DOOR BUCKETS

(SELECT MODELS)

The Tilt-Out Bucket assembly consists

of a bucket and frame, providing

adjustable, convenient storage for food

items in door. The bucket assembly tilts

forward for easy access of items, and lifts

out for ease in cleaning and adjusting.

To remove and

install bucket:

> Toremove,tip

bucketforward

and pull straight

out to remove.

Toinstall bucket, slide bucket into

bucketframe and push bucket

upright.

To

adjust bucket frame:

Remove bucket per above

instructions.

> Lift frame off

door support

and place in

desired door

location.

\

\

Page 19

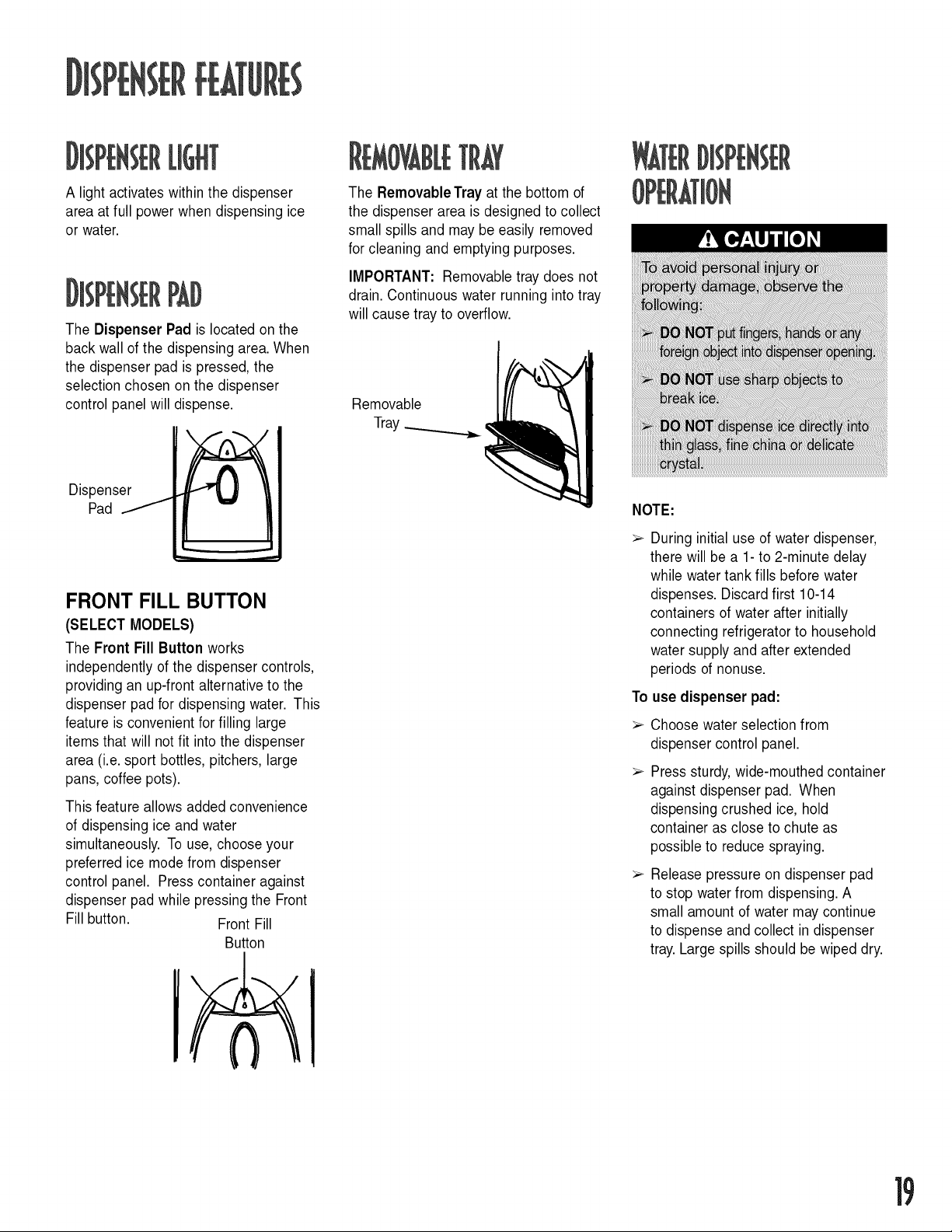

;PENSERLIGHT

A light activates within the dispenser

area at full power when dispensing ice

or water.

;PENSERPAl)

The Dispenser Pad is located on the

back wall ofthe dispensing area.When

the dispenser pad is pressed, the

selection chosen on the dispenser

control panel will dispense.

Dispenser

Pad

FRONT FILL BUTTON

(SELECT MODELS)

The Front Fill Button works

independentlyofthedispenser controls,

providing an up-front alternativeto the

dispenser pad for dispensing water. This

feature is convenient for filling large

items that will notfit intothe dispenser

area (i.e. sport bottles, pitchers, large

pans, coffee pots).

This feature allows added convenience

of dispensing ice and water

simultaneously. To use, choose your

preferred ice modefrom dispenser

control panel. Press container against

dispenser pad while pressing the Front

Fill button. Front Fill

Button

The RemovableTray at the bottom of

the dispenser area is designed to collect

small spills and may be easily removed

for cleaning and emptying purposes.

IMPORTANT: Removable tray does not

drain. Continuous water running into tray

will cause tray to overflow.

Removable

Tray

NOTE:

During initial use of water dispenser,

there will be a 1-to 2-minute delay

while water tank fills before water

dispenses. Discard first 10-14

containers of water after initially

connecting refrigerator to household

water supply and after extended

periods of nonuse.

To

use dispenser pad:

Choose water selection from

dispenser control panel.

Press sturdy,wide-mouthed container

against dispenser pad. When

dispensing crushed ice, hold

container as close to chute as

possible to reduce spraying.

Release pressure on dispenser pad

to stop water from dispensing. A

small amount of water may continue

to dispense and collect in dispenser

tray.Large spills should be wiped dry.

Page 20

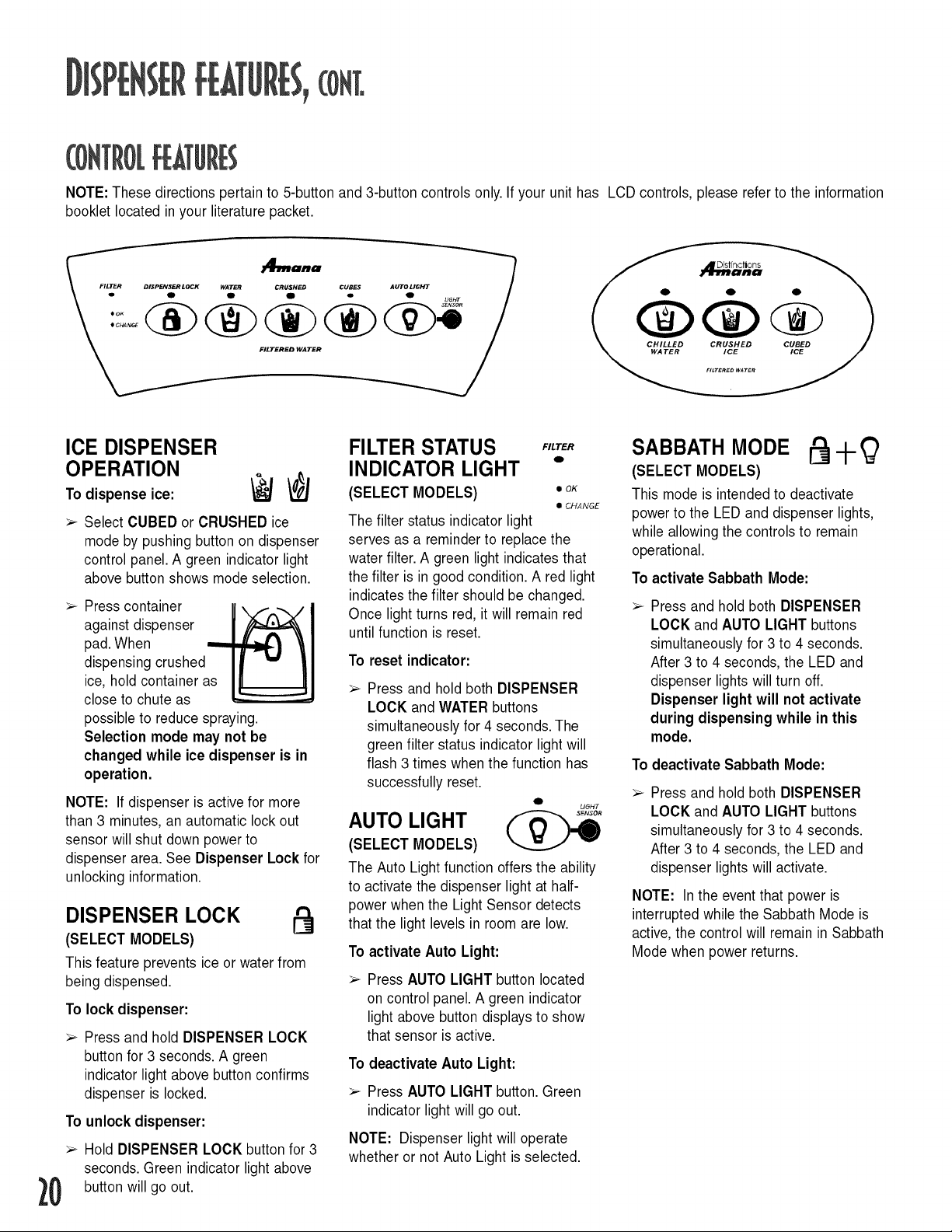

NOTE:Thesedirectionspertainto5-buttonand3-buttoncontrolsonly.IfyourunithasLCDcontrols,pleaserefertotheinformation

bookletlocatedinyourliteraturepacket.

IP_ndl 7FflJ'ER DISPENSER LOCK WATER CRUSHED CUBF._ AUTO LIGHT

ooK

ICE DISPENSER

OPERATION

To dispense ice: _J

Select CUBED or CRUSHED ice

mode by pushing button on dispenser

control panel. A green indicator light

above button shows mode selection.

Press container IIXf,-,_ I

against dispenser | _ I

pad.When _ _.dl_ '_1

dispensing crushed/r " !1

ice, hold container as I I I1|

close to chute as

possible to reduce spraying.

Selection mode may not be

changed while ice dispenser is in

operation.

NOTE: If dispenser is active for more

than 3 minutes, an automatic lock out

sensor will shut down powerto

dispenser area. See Dispenser Lock for

unlocking information.

DISPENSER LOCK

(SELECT MODELS)

This feature prevents ice or water from

being dispensed.

To lock dispenser:

> Press and hold DISPENSER LOCK

button for 3 seconds. A green

indicator light above button confirms

dispenser is locked.

To unlock dispenser:

> Hold DISPENSER LOCK button for 3

seconds. Green indicator light above

_0 buttonwill go out.

FILTER STATUS .,T.,,

INDICATOR LIGHT *

(SELECT MODELS) • oK

The filter status indicator light

serves as a reminderto replace the

water filter. A green light indicatesthat

the filter is in good condition. A red light

indicates the filter should be changed.

Once light turns red, it will remain red

until function is reset.

To reset indicator:

> Press and hold both DISPENSER

LOCK and WATERbuttons

simultaneously for 4 seconds.The

green filter status indicator light will

flash 3 times when the function has

successfully reset.

AUTO LIGHT

(SELECT MODELS)

The Auto Lightfunctionoffersthe ability

to activate the dispenser light at half-

power when the Light Sensor detects

that the light levels in room are low.

To activate Auto Light:

Press AUTO LIGHT button located

on control panel. A green indicator

light above button displays to show

that sensor is active.

To deactivate Auto Light:

> Press AUTOLIGHT button. Green

indicator light will go out.

NOTE: Dispenser light will operate

whether or not Auto Light is selected.

O

° CHANGE

LIGHT

SABBATH MODE

(SELECT MODELS)

This mode is intendedto deactivate

powerto the LED and dispenser lights,

while allowing the controls to remain

operational.

To activate Sabbath Mode:

Press and hold both DISPENSER

LOCK and AUTO LIGHT buttons

simultaneously for 3 to 4 seconds.

After 3 to 4 seconds, the LED and

dispenser lights will turn off.

Dispenser light will not activate

during dispensing while in this

mode.

To deactivate Sabbath Mode:

Press and hold both DISPENSER

LOCK and AUTO LIGHT buttons

simultaneously for 3 to 4 seconds.

After 3 to 4 seconds, the LED and

dispenser lights will activate.

NOTE: In the event that power is

interrupted while the Sabbath Mode is

active, the control will remain in Sabbath

Mode when power returns.

Page 21

TO( NYOURREFRIGERATOR

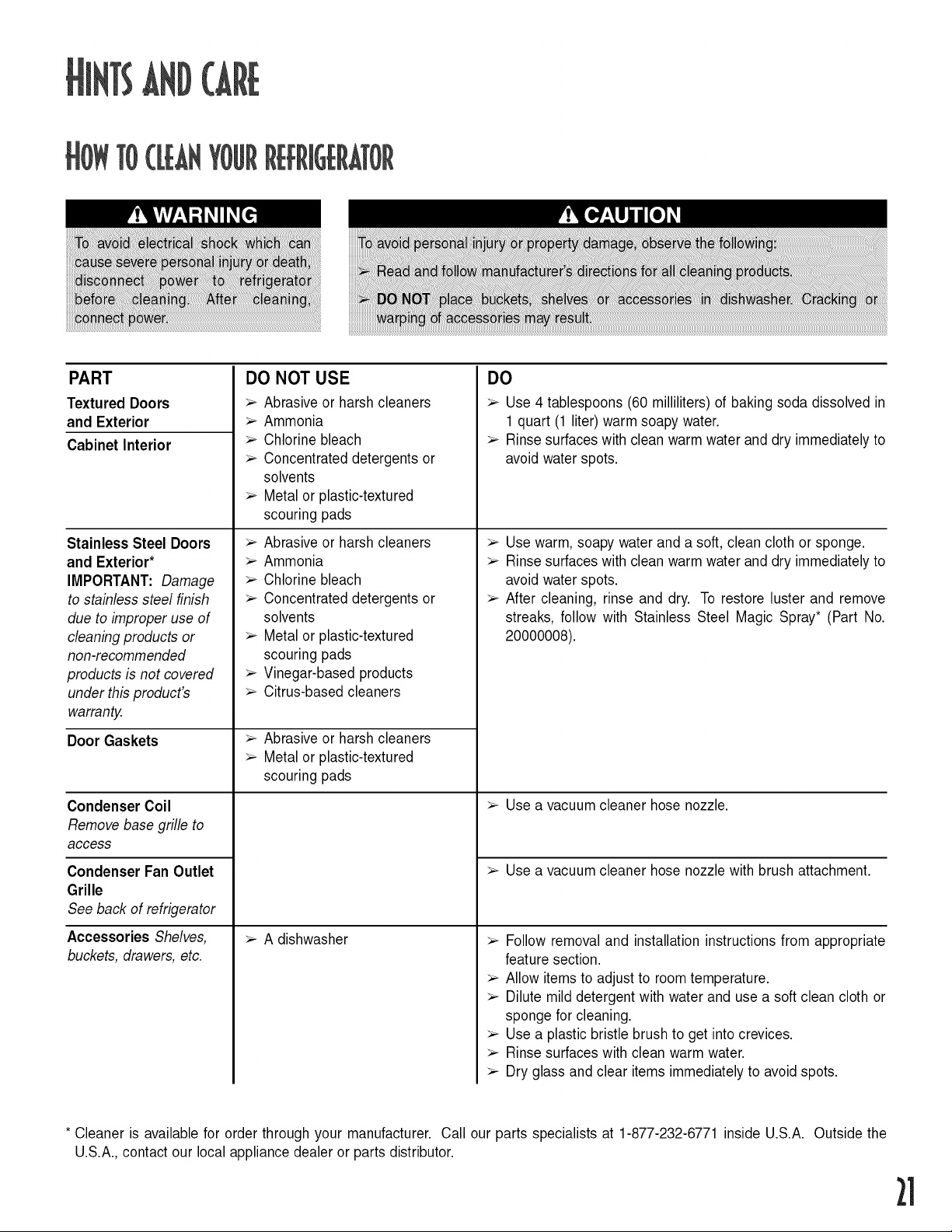

PART

Textured Doors

and Exterior

Cabinet Interior

Stainless Steel Doors

and Exterior*

IMPORTANT: Damage

to stainless steel finish

due to improper use of

cleaning products or

non-recommended

products is not covered

under thb product's

warranty.

Door Gaskets

Condenser Coil

Remove base grille to

access

Condenser Fan Outlet

Grille

See back of refrigerator

Accessories Shelves,

buckets, drawers, etc.

DO NOT USE

> Abrasive or harsh cleaners

> Ammonia

> Chlorine bleach

> Concentrated detergents or

solvents

> Metal or plastic-textured

scouring pads

> Abrasive or harsh cleaners

> Ammonia

> Chlorine bleach

> Concentrated detergents or

solvents

> Metal or plastic-textured

scouring pads

> Vinegar-based products

> Citrus-based cleaners

> Abrasive or harsh cleaners

> Metal or plastic-textured

scouring pads

> A dishwasher

DO

> Use 4 tablespoons (60 milliliters) of baking soda dissolved in

1 quart (1 liter) warm soapy water.

> Rinse surfaceswith clean warm water and dry immediately to

avoid water spots.

> Use warm, soapy water and a soft, clean cloth or sponge.

> Rinse surfaceswith clean warm water and dry immediately to

avoid water spots.

> After cleaning, rinse and dry. To restore luster and remove

streaks, follow with Stainless Steel Magic Spray* (Part No.

20000008).

> Use a vacuum cleaner hose nozzle.

> Use a vacuum cleaner hose nozzle with brush attachment.

> Follow removal and installation instructions from appropriate

feature section.

> Allow items to adjust to roomtemperature.

> Dilute mild detergent with water and use a soft clean cloth or

sponge for cleaning.

> Use a plastic bristle brush to get intocrevices.

> Rinse surfaces with clean warm water.

> Dry glass and clear items immediately to avoid spots.

* Cleaner is available for order through your manufacturer. Call our parts specialists at 1-877-232-6771 inside U.S.A. Outside the

U.S.A.,contact our local appliance dealer or parts distributor.

Page 22

1. Remove all food.

,

Disconnect refrigerator.

3.

Clean the following items-paying

special attention to crevices-using

the appropriate instructions in How to

Clean Your Refrigerator:

> Walls,floor, and ceiling of cabinet

interior.

> Drawers, shelves, and gaskets.

,

Wash and dry all bottles, containers,

and jars. Discard spoiled or expired

items.

,

Wrap or store odor-causing foods in

tightly-sealed containers to prevent

reoccurring odors.

,

Connect power to refrigerator and

return food.

7. After 24 hours, check if odor has

been eliminated.

If odor is still present...

,

Remove drawers and place on top

shelf of refrigerator.

,

Pack refrigerator and freezer

sections-including doors-with

crumpled sheets of black and white

newspaper.

,

Place charcoal briquettes randomly

on crumpled newspaper in both

freezer and refrigerator

compartments.

4. Closedoors and let stand24-48 hours.

5. Repeat steps 5 through 7 above.

ERGYSAVINGiDEAS

> Avoid overcrowding refrigerator

shelves.This reduces effectivity of air

circulation around food and causes

refrigerator to run longer.

> Avoid adding too much warm food to

refrigerator at one time. This

overloads compartments and slows

rate of cooling.

> DO NOTuse aluminumfoil,wax paper,

or papertowelingas shelf liners.This

decreasesair flow andcauses

refrigeratorto run less efficiently.

> A freezer that is _ full runs most

efficiently.

> Locate refrigerator in coolest part of

room. Avoid areas of direct sunlight,

or near heating ducts, registers, or

other heat producing appliances. If

this is not possible, isolate exterior by

using a section of cabinet or an

added layer of insulation.

> Refer to section on temperature

controls for recommended control

settings.

> Clean door gaskets as indicated in

the cleaning section every 3 months.

This will assure that door seals

properly and refrigerator runs

efficiently.

> Take time to organize items in

refrigerator to reduce time that door

is open.

> Be sure your doors are closing

securely by levelingrefrigerator as

instructed in levelingsection.

> Clean condenser coils off as

indicated in the cleaning section

every 3 months.This will increase

energy efficiency and cooling

performance.

UPPER FRESH FOOD

SECTION

Locate finger

gaps on each

side of clear light

shield. Insert

fingers and press in on each side of

shield. Pull shield down and remove.

2. Remove light bulbs.

3. Replace with appliance bulbs no

greater than 40 watts.

4. Replace light bulb cover by inserting

front tabs of light shield intoslots

directly infront of light assembly.

LOWER FRESH FOOD

SECTION B

Pinch bottom tabs

(A) on lightcover

and pull straight

out.

A

2. Remove light bulb.

3. Replace bulb with appliance bulb no

greater than 40 watts.

4. Insert top tabs (B) of light cover into

liner slots and snap bottom portion

over light assembly.

FREEZER SECTION

1. Remove ice bin by A

lifting front of bin

and pulling out.

2. Remove light bulb

cover by pinchingtop tab B

(A) and pulling cover out.

3. Removelightbulb.Replacewithappliance

bulbno greaterthan40 watts.

4. Insert bottomtab (B) of light cover

into liner slots and snap top portion

over light assembly.

5. Replace ice bin by sliding in until bin

locks into place.

ICE AND WATER

DISPENSER

1. Locate light bulb inside top edge of

dispenser frame. Unscrew to remove.

2. Replace light bulb with a J,

7-watt, 120 volt bulb.

22

Page 23

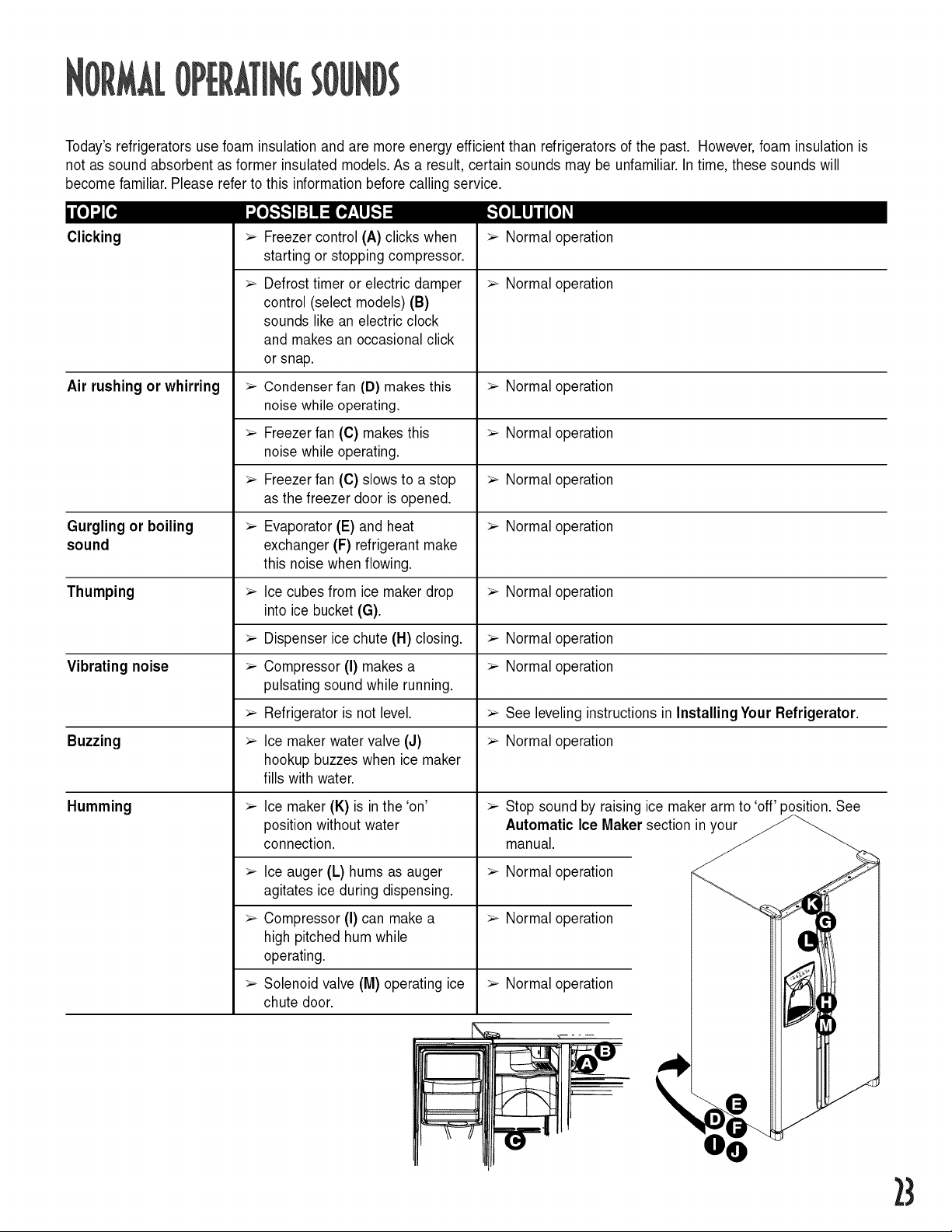

Today'srefrigeratorsusefoaminsulationandaremoreenergyefficientthanrefrigeratorsofthepast.However,foaminsulationis

notassoundabsorbentasformerinsulatedmodels.Asaresult,certainsoundsmaybeunfamiliar.Intime,thesesoundswill

becomefamiliar.Pleaserefertothisinformationbeforecallingservice.

"...,Te]...'._'.)I:t at::1(_7;_1_")Ii(e]'J[i

Clicking Freezer control (A) clicks when

starting or stopping compressor.

Defrost timer or electric damper

control (select models) (B)

sounds likean electric clock

and makes an occasional click

or snap.

Air rushing or whirring > Condenser fan (D) makes this > Normal operation

noisewhile operating.

> Freezerfan (C) makes this > Normal operation

noisewhile operating.

> Freezerfan (C) slows to a stop > Normal operation

as the freezer door is opened.

Gurgling or boiling > Evaporator (E) and heat > Normal operation

sound exchanger (F) refrigerant make

this noise when flowing.

Thumping > Ice cubes from ice maker drop > Normal operation

into ice bucket (G).

> Dispenser ice chute (H) closing. > Normal operation

_',[o]i.l//[o] _

> Normal operation

> Normal operation

Vibrating noise > Compressor (I) makes a > Normal operation

pulsating sound while running.

> Refrigerator is not level. > See leveling instructions in Installing Your Refrigerator.

Buzzing > Ice maker water valve (J) > Normal operation

hookup buzzes when ice maker

fills with water.

Humming >- Ice maker (K) is in the 'on'

position without water

connection.

Ice auger (L) hums as auger

agitates ice during dispensing.

Compressor (I) can make a

high pitched hum while

operating.

Solenoid valve (IVl)operating ice

chute door.

> Stop sound by raising ice maker arm to 'off' position. See

Automatic Ice Mlakersection in your

manual.

> Normal operation

> Normal operation

> Normal operation

23

Page 24

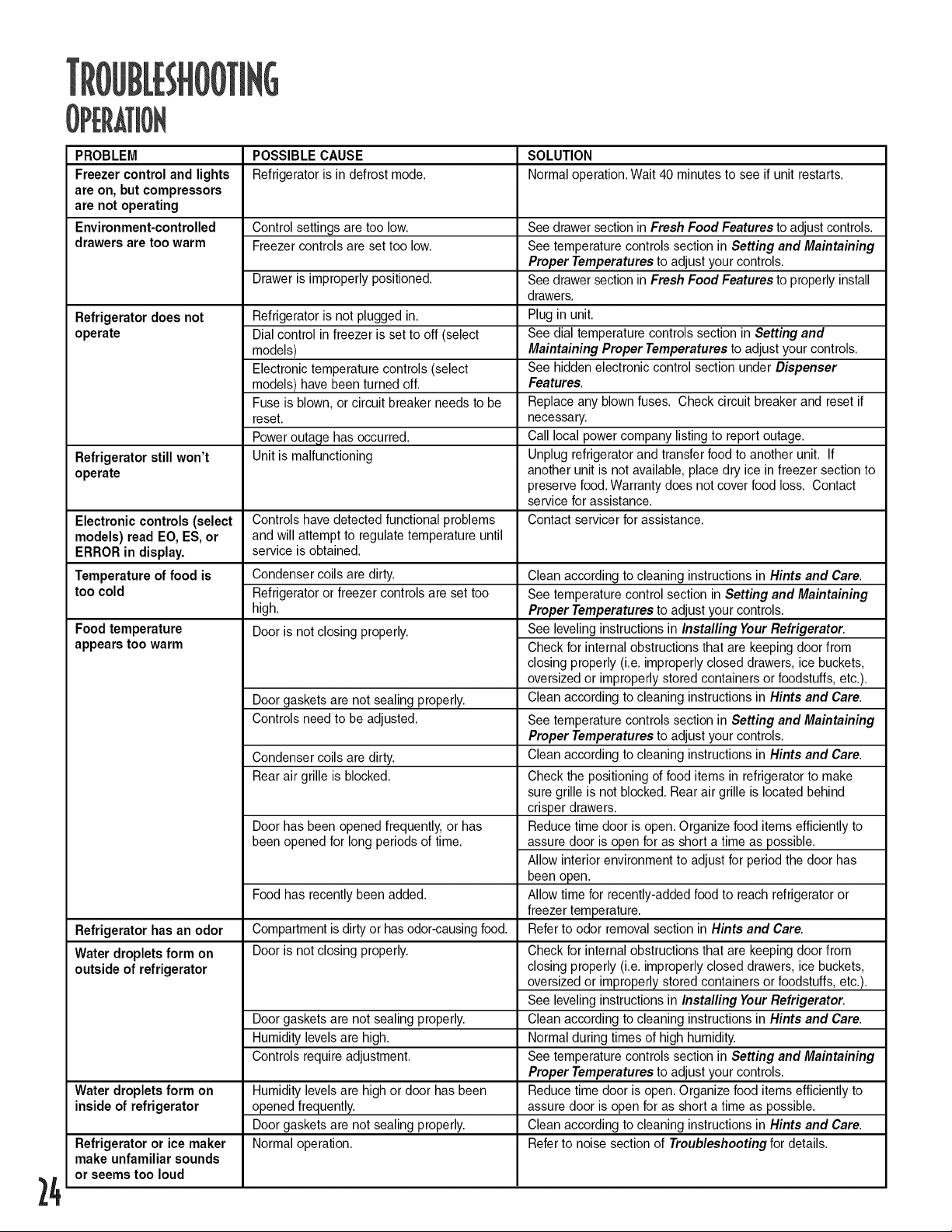

PROBLEM

Freezer control and lights

are on, but compressors

are not operating

Environment-controlled

drawers are too warm

Refrigerator does not

operate

Refrigerator still won't

operate

Electronic controls (select

models) read EO, ES, or

ERROR in display.

Temperature of food is

too cold

Food temperature

appears too warm

Refrigerator has an odor

Water droplets form on

outside of refrigerator

Water droplets form on

inside of refrigerator

Refrigerator or ice maker

make unfamiliar sounds

or seems too loud

24

POSSIBLE CAUSE

Refrigerator is in defrost mode.

Control settings are too low.

Freezer controls are set too low.

Drawer is improperly positioned.

Refrigerator is not plugged in.

Dial control in freezer is set to off (select

models)

Electronic temperature controls (select

models) have been turned off.

Fuse is blown, or circuit breaker needs to be

reset.

Poweroutage has occurred.

Unit is malfunctioning

Controls havedetected functional problems

and will attempt to regulate temperature until

service is obtained.

Condenser coils are dirty.

Refrigerator or freezer controls are set too

high.

Door is not closing properly.

Door gaskets are not sealing properly.

Controls need to be adjusted.

Condenser coils are dirty.

Rear air grille is blocked.

Door has been opened frequently, or has

been opened for long periods of time.

Food has recently been added.

Compartmentis dirtyor hasodor-causing food.

Door is not closing properly.

Door gaskets are not sealing properly.

Humidity levels are high.

Controls require adjustment.

Humidity levels are high or door has been

opened frequently.

Door gaskets are not sealing properly.

Normal operation.

SOLUTION

Normal operation. Wait 40 minutes to see if unit restarts.

See drawer section in Fresh Food Features to adjust controls.

See temperature controls section in Setting and Maintaining

Proper Temperatures to adjust your controls.

See drawer section in Fresh Food Features to properly install

drawers.

Plug in unit.

See dial temperaturecontrols section in Setting and

Maintaining Proper Temperatures to adjust your controls.

See hidden electronic control section under Dispenser

Features.

Replace any blown fuses. Check circuit breaker and reset if

necessary.

Call local power company listing to report outage.

Unplug refrigerator and transfer food to another unit. If

another unit is not available, place dry ice in freezer section to

preserve food.Warranty does not cover food loss. Contact

service for assistance.

Contact servicer for assistance.

Clean according to cleaning instructions in Hints and Care.

See temperature control section in Setting and Maintaining

Proper Temperatures to adjust your controls.

See leveling instructions in Instalfing Your Refrigerator.

Check for internal obstructions that are keeping door from

closing properly (i.e. improperly closed drawers, ice buckets,

oversized or improperly stored containers or foodstuffs, etc.).

Clean according to cleaning instructions in Hints and Care.

See temperature controls section in Setting and Maintaining

Proper Temperatures to adjust your controls.

Clean according to cleaning instructions in Hints and Care.

Check the positioning of food items in refrigerator to make

sure grille is not blocked. Rearair grille is located behind

crisper drawers.

Reduce time door is open. Organize food items efficiently to

assure door is open for as short a time as possible.

Allow interior environment to adjust for period the door has

been open.

Allow time for recently-added food to reach refrigerator or

freezer temperature.

Refer to odor removal section in Hints and Care.

Check for internal obstructions that are keeping door from

closing properly (i.e. improperly closed drawers, ice buckets,

oversized or improperly stored containers or foodstuffs, etc.).

See leveling instructions in Instalfing Your Refrigerator.

Clean according to cleaning instructions in Hints and Care.

Normal during times of high humidity.

See temperature controls section in Setting and Maintaining

Proper Temperatures to adjust your controls.

Reduce time door is open. Organize food items efficiently to

assure door is open for as short a time as possible.

Clean according to cleaning instructions in Hints and Care.

Refer to noise section of Troubleshooting for details.

Page 25

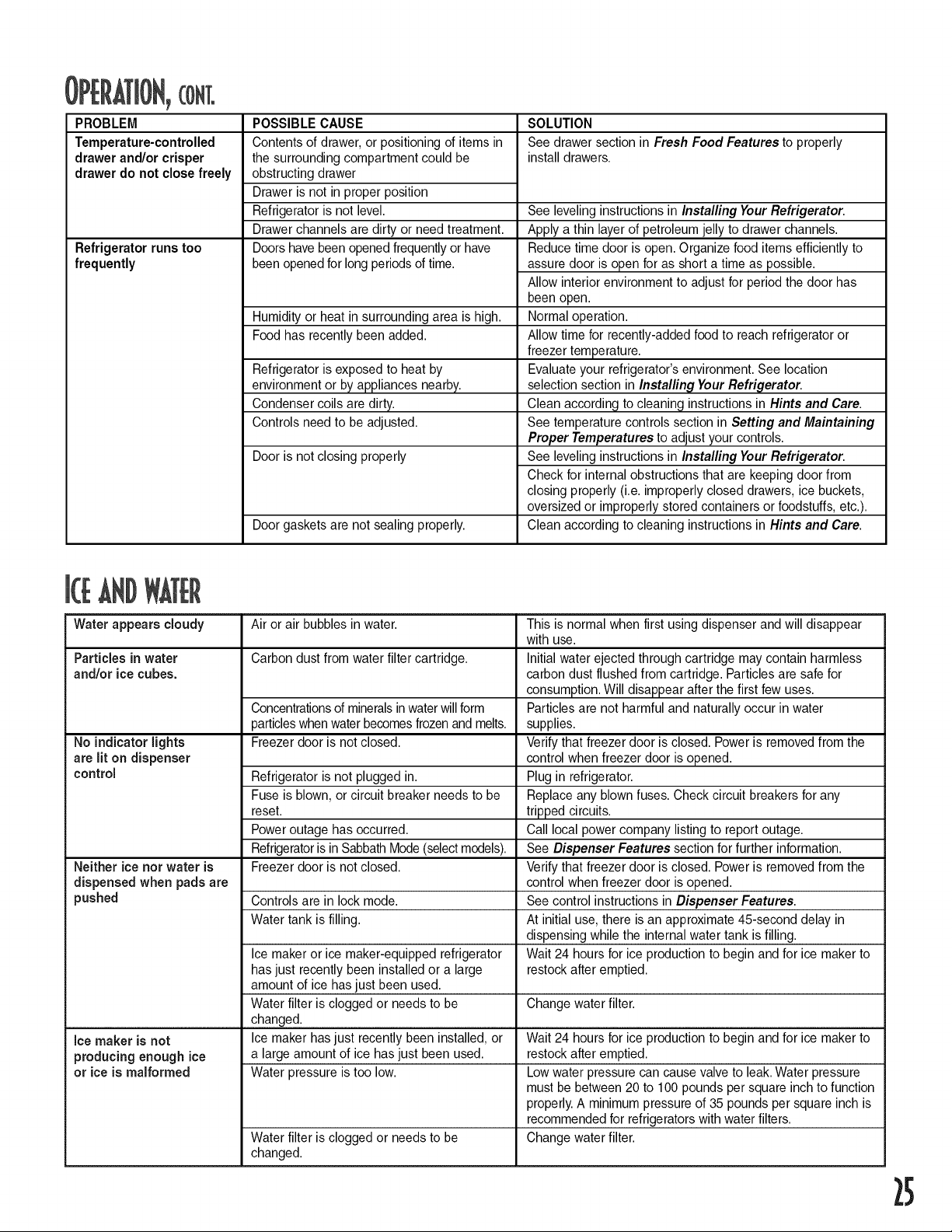

PROBLEM

Temperature-controlled

drawer and/or crisper

drawer do not close freely

Refrigerator runs too

frequently

POSSIBLE CAUSE

Contents of drawer, or positioning of items in

the surrounding compartment could be

obstructing drawer

Drawer is not in proper position

Refrigerator is not level.

Drawer channels are dirty or need treatment.

Doorshave been openedfrequently or have

been openedfor long periodsof time.

Humidity or heat in surrounding area is high.

Food has recently been added.

Refrigerator is exposed to heat by

environment or by appliances nearby.

Condenser coils are dirty.

Controls need to be adjusted.

Door is not closing properly

Door gaskets are not sealing properly.

SOLUTION

See drawer section in Fresh Food Features to properly

install drawers.

See leveling instructions in Instalfing Your Refrigerator.

Apply a thin layer of petroleum jelly to drawer channels.

Reduce time door is open. Organize food items efficiently to

assure door is open for as short a time as possible.

Allow interior environment to adjust for period the door has

been open.

Normal operation.

Allow time for recently-added food to reach refrigerator or

freezer temperature.

Evaluate your refrigerator's environment. See location

selection section in Instalfing Your Refrigerator.

Clean according to cleaning instructions in Hints and Care.

See temperature controls section in Setting and Maintaining

Proper Temperatures to adjust your controls.

See leveling instructions in Instalfing Your Refrigerator.

Check for internal obstructions that are keeping door from

closing properly (i.e. improperly closed drawers, ice buckets,

oversized or improperly stored containers or foodstuffs, etc.).

Clean according to cleaning instructions in Hints and Care.

AND

Water appears cloudy

Particles in water

and/or ice cubes.

No indicator lights

are lit on dispenser

control

Neither ice nor water is

dispensed when pads are

pushed Controls are in lock mode.

Ice maker is not Icemaker has just recently been installed, or Wait 24 hours for ice production to begin and for ice maker to

producing enough ice a large amount of ice has just been used. restock after emptied.

or ice is malformed Water pressure is too low. Lowwater pressure can cause valveto leak.Water pressure

Air or air bubbles in water.

Carbon dust from water filter cartridge.

Concentrationsofmineralsin water willform

particleswhenwater becomesfrozenand melts.

Freezerdoor is not closed.

Refrigerator is not plugged in.

Fuse is blown, or circuit breaker needs to be

reset.

Poweroutage has occurred.

Refrigeratorisin Sabbath Mode (selectmodels).

Freezerdoor is not closed.

Water tank is filling.

Icemaker or ice maker-equipped refrigerator

has just recently been installed or a large

amount of ice has just been used.

Water filter is clogged or needs to be Change water filter.

changed.

Water filter is clogged or needs to be Change water filter.

changed.

This is normal when first using dispenser and will disappear

with use.

Initial water ejected through cartridge may contain harmless

carbon dust flushed from cartridge. Particles are safe for

consumption. Will disappear after the first few uses.

Particles are not harmful and naturally occur inwater

supplies.

Verify that freezer door is closed. Power is removed from the

control when freezer door is opened.

Plug in refrigerator.

Replaceany blown fuses. Check circuit breakers for any

tripped circuits.

Call local power company listing to report outage.

See Dispenser Features section for further information.

Verify that freezer door is closed. Power is removed from the

control when freezer door is opened.

See control instructions in Dispenser Features.

At initial use, there is an approximate 45-second delay in

dispensing while the internal water tank is filling.

Wait 24 hours for ice production to begin and for ice maker to

restockafter emptied.

must be between 20 to 100pounds per square inch to function

properly.A minimum pressure of 35 pounds per square inch is

recommended for refrigerators withwater filters.

25

Page 26

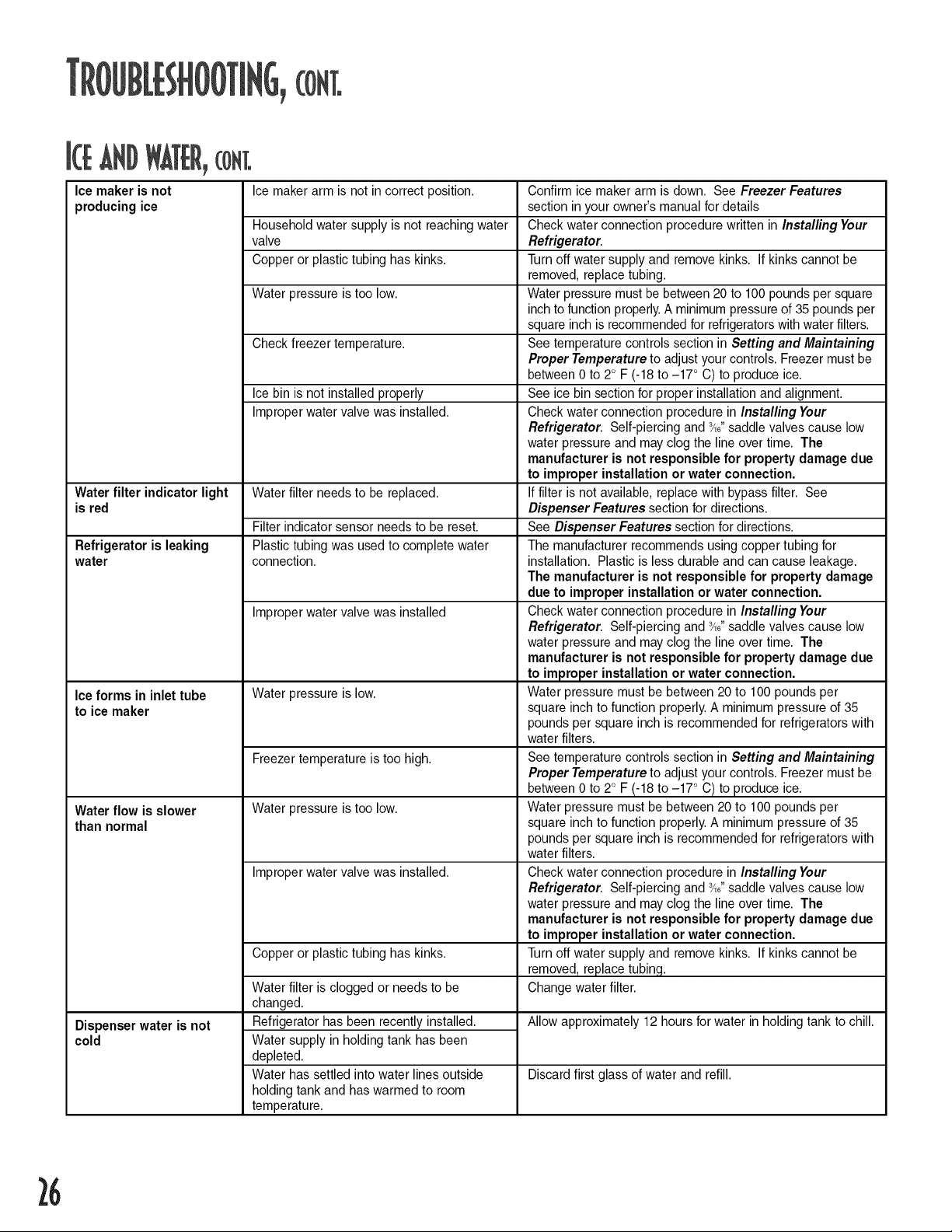

Icemakerisnot

producingice

Water filter indicator light

is red

Refrigerator is leaking

water

Ice forms in inlet tube

to ice maker

Water flow is slower

than normal

Dispenserwaterisnot

cold

Ice maker arm is not in correct position.

Household water supply is not reachingwater

valve

Copper or plastic tubing has kinks.

Water pressure is too low.

Check freezer temperature.

Ice bin is not installed properly

Improper water valve was installed.

Water filter needs to be replaced.

Filter indicator sensor needs to be reset.

Plastic tubing was used to complete water

connection.

Improper water valve was installed

Water pressure is low.

Freezer temperature is too high.

Water pressure is too low.

Improper water valve was installed.

Copper or plastic tubing has kinks.

Water filter is clogged or needs to be

changed.

Refrigerator has been recently installed.

Water supply in holding tank has been

depleted.

Water has settled into water lines outside

holding tank and has warmed to room

temperature.

Confirm ice maker arm is down. See Freezer Features

section in your owner's manual for details

Check water connection procedure written in Installing Your

Refrigerator.

Turnoff water supply and remove kinks. If kinks cannot be

removed, replace tubing.

Waterpressure must be between 20 to 100 poundsper square

inch to function properly.A minimum pressure of 35 pounds per

square inch is recommended forrefrigerators with water filters.

See temperature controls section in Setting and Maintaining

Proper Temperature to adjust your controls. Freezermust be

between 0 to 2° F (-18to -17 ° C) to produce ice.

See ice bin section for proper installation and alignment.

Check water connection procedure in Installing Your

Refrigerator. Self-piercing and _6"saddle valves cause low

water pressure and may clog the line over time. The

manufacturer is not responsible for property damage due

to improper installation or water connection.

If filter is not available, replace with bypass filter. See

Dispenser Features section for directions.

See Dispenser Features section for directions.

The manufacturer recommends using copper tubing for

installation. Plastic is less durable and can cause leakage.

The manufacturer is not responsible for property damage

due to improper installation or water connection.

Check water connection procedure in Installing Your

Refrigerator. Self-piercing and ¾6"saddle valves cause low

water pressure and may clog the line over time. The

manufacturer is not responsible for property damage due

to improper installation or water connection.

Water pressure must be between 20 to 100 pounds per

square inch to function properly.A minimum pressure of 35

pounds per square inch is recommended for refrigerators with

water filters.

See temperature controls section in Setting and Maintaining

Proper Temperature to adjust your controls. Freezermust be

between 0 to 2° F (-18to -17 ° C) to produce ice.

Water pressure must be between 20 to 100 pounds per

square inch to function properly.A minimum pressure of 35

pounds per square inch is recommended for refrigerators with

water filters.

Check water connection procedure in Installing Your

Refrigerator. Self-piercing and ¾_"saddle valves cause low

water pressure and may clog the line over time. The

manufacturer is not responsible for property damage due

to improper installation or water connection.

Turnoff water supply and remove kinks. If kinks cannot be

removed replace tubing.

Change water filter.

Allow approximately 12 hours for water in holding tank to chill.

Discard first glass of water and refill.

26

Page 27

21

Page 28

A.MA£i

III!I 1 I!;IilIili[iT'!

IIIil!liTOl IAIIAITY

FirstYear

Amana will replace, free of charge, any part

which is defective due to workmanship or

materials.

Second through Fifth Year

Amana will replace free of charge, any sealed

system component (compressor, condenser,

evaporator, drier and interconnecting tubing)

and repair any food compartment liner

(exclusive of door liner) which is defective due

to workmanship or materials.

Warranty Limitations

:-- Begins at date of original purchase.

_.-Excludes original and replacement water or

air filter cartridges (if equippedwith the

filtration system). Original and replacement

cartridges are warranted for 30 days, parts

only, against defects of material or

workmanship.

_--Service must be performed by an

authorized Amana technician.

_--Damage due to shipping and handling is

not covered by this warranty.

Warranty Is Void If

Repairs resulting from the following:

;-- Serial plate is defaced.

*- Provide proof of purchase (sales receipt).

Provide normal care and maintenance. Replace owner replaceable items

where directions appear in Owner's Manual.

Make product reasonably accessible for service.

Paypremium service costs for service outside technician's normal

business hours.

Payforservice calls related to product installation and usage.

Maytag ServicesSMFactory Service

1-800-628-5782 inside U.S.A.

To purchase accessories or replacement parts not covered by your

product warranty:

Please haveyour model and serial numbers ready and call our parts

specialists at 1-877-232-6771 inside U.S.A.from 7 a.m. to 7 p.m. central

time Monday through Friday. Outside the U.S.A.,contact your local

appliance dealer or parts distributor.

For more information:

Maytag Services_"

Attn: Amana CAIR Center

P.O.Box39

403 West 4th Street North

Newton, Iowa 50208-0039

Ph# 1-800-843-0304 in U.S.A.

1-866-587-2002 au Canada

Internet: http://www.amana.com

NOTE: Some ReverseOsmosis home water systems cause low water

pressure. Low water pressure can affect the water and ice dispensing

system by causing small or hollow ice cubes and slow water flow from the

dispenser.Service problems related to the home's ReverseOsmosis water

system are notcovered by the warranty.

_- Product is used on a commercial, rental, or

leased basis.

_- Product has defect or damage due to