Amana ARG7302WW-P1143391NWW, ARG7302WW-P1143368NWW, ARG7302WW-P1143343NWW, ARG7302WW-P1143337NWW, ARG7200W-P1143316NW Owner’s Manual

...

Self-Cleaning

Gas Range

Owner's Manual

ARG7302*

ARG7102*

* Additional alphanumeric characters representing other

models in series may follow each model number.

Please Read Manual Before Operating

Range

English ........................................................................ 2

Fran£ais .................................................................... 30

Para recibir un manual en espaSol gratis, envie por correo

o por fax su nombre, direccion, y nQmero de modelo a:

Amana Appliances

Consumer Communications/Spanish Manual

2800 220th Trail

PO Box 8901

Amana, Iowa 52204-0001

USA

NQmerode fax 1-319-522-8158

Installer

Leave this manual and other literature with consumer for

future use.

Customer

Keep these instructions for future reference, tf appliance

changes ownership, besure this manual accompanies

range.

Contents

Model Identification ................................................. 2

Parts and Accessories ............................................ 2

Service .................................................................... 2

Asure TM Extended Service Plan .............................. 2

Important Safety Information

ALL APPLIANCES .................................................. 4

SELF-CLEANING OVEN ......................................... 4

OVEN ..................................................................... 4

SURFACE COOKING UNITS .................................. 4

Delayed Ignition ...................................................... 4

VENTILATION HOOD .............................................. 5

In Case of Fire ........................................................ 5

Precautions ............................................................ 5

Installation

Packing Material ..................................................... 5

Range Location ....................................................... 5

Cabinet Opening ..................................................... 5

Minimum Clearances to Combustible Surfaces ....... 6

Special Countertop Conditions ................................ 6

Electrical Connection Requirements ....................... 6

Electrical Connection Clearance ............................. 7

Gas Connection Requirements ................................ 7

Gas Supply Location ............................................... 7

Gas Supply Pressure .............................................. 7

Pressure Regulator Location ................................... 8

Oven Shutoff Valve .................................................. 8

Converting for Use with Natural Gas

or Propane Gas ....................................................... 8

Gas Connection ...................................................... 11

Testing for Gas Leaks ............................................. 12

Seal Openings ........................................................ 12

Anti-tip Bracket Installation ..................................... 12

Place Range ........................................................... 12

Removal and Reinstallation of Range ...................... 13

Place Grates and Burner Caps ................................ 13

Test and Adjust Surface Burner Flame .................... 13

Test and Adjust Oven Burner Flame ........................ 14

Broiler Flame .......................................................... 15

Operation

Oven Control ........................................................... 16

Setting Electronic Clock ......................................... 17

Setting Electronic Timer .......................................... 17

Oven Light ............................................................... 17

Automatic Oven Shutoff .......................................... 17

Service Tones and Codes ........................................ 17

Operating Surface Burners ...................................... 18

Operating Surface Burner during a Power Failure .... 18

Cooking Utensils ..................................................... 18

Prepare to Bake ...................................................... 19

Baking .................................................................... 20

Adjusting Factory Set Baking Temperature ............. 21

Broiling ................................................................... 21

Self-Cleaning ........................................................... 22

Cooking Guide

Baking Guide .......................................................... 23

Broiling Guide ......................................................... 23

Poultry Roasting Guide ........................................... 24

Beef and Pork Roasting Guide ................................ 24

Care and Cleaning

Removing Oven Door ............................................... 25

Replacing Oven Light .............................................. 25

Removing Storage Drawer ....................................... 25

Cleaning .................................................................. 26

Before Calling for Service ............................................ 27

Warranty .................................................................... 28

Quick Reference Instructions ..................................... 29

Model Identification

Complete enclosed registration card and promptly return.

If registration card is missing, call Consumer Affairs

Department at 1-800-843-0304 inside U.S.A.

319-622-5511 outside U.S.A. When contacting Amana,

provide product information located on rating plate. Rating

plate is located on the oven frame. Record the following:

Model Number:

Manufacturing Number:

Serial or SIN Number:

Date of purchase:

Dealer's name and address:

Parts and Accessories

Purchase replacement parts and additional accessories

(e.g., refrigerator shelves, dryer racks, or cooktop

modules) over the phone. To order accessories for your

Amana product, call 1-800-843-0304 inside U.S.A. or

319-622-5511 outside U.S.A.

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. Any questions or to

locate an authorized servicer, call 1-800-NAT-LSVC

(1-800-628-5782) inside U.S.A. 319-622-5511 outside

U.S.A. Warranty service must be performed by an

authorized servicer. Amana, also recommends contacting

an authorized servicer if service is required after warranty

expires.

Asure TM Extended Service Plan

Amana offers long-term service protection for this new

range. Asure TM Extended Service Plan is specially

designed to supplement Amana's strong warranty.

This plan covers parts, labor, and travel charges.

Call 1-800-528-2682 for information.

Important Safety Information

[ WARNING

To reduce the risk of the appliance tipping, it

must be secured by a properly installed anti-tip

bracket(s). To make sure bracket has been

installed properly, remove the storage drawer

and look under the range with a flashlight.

Bracket(s) must be engaged in the rear corner of

the range.

ALL RANGES CAN TIP

INJURY TO PERSONS

COULD RESULT

INSTALL ANTI-TIP

BRACKET(S) PACKED

WITH RANGE

SEE INSTALLATION

INSTRUCTIONS

] WARNING

To avoid death, personal injury or property damage,

information in this manual must be followed exactly.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's in-

structions.

• If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

WARNING

To avoid personal injury, do not sit, stand or lean on

oven door or oven drawer.

WARNING I

To avoid risk of electrical shock, personal injury, or

death, make sure your range has been properly

grounded and always disconnect it from main power

supply before any servicing.

CAUTION

Do not obstruct the flow of combustion or

ventilation air.

CAUTION

This appliance contains or produces a chemical or

chemicals which can cause death or serious illness

and which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

To reduce the risk from substances in the fuel or from

fuel combustion make sure this appliance is installed,

operated, and maintained according to the instructions

in this booklet.

Important Safety Information

ALL APPLIANCES

1. Proper Installation --Be sure your appliance is

properly installed and grounded by a qualified

technician.

2. Never Use Appliance for Warming or Heating the

Room.

3. Do Not Leave Children Alone--Children should not be

alone or unattended in the area where the appliance

is in use. They should never be allowed to sit or stand

on any part of the appliance.

4. Wear Protective Apparel--Loose fitting or hanging

garments should never be worn while using appliance.

5. User Servicing--Do not repair or replace any part of

the appliance unless specifically recommended in the

manual. All other servicing should be referred to a

qualified technician.

6. Storage in or on Appliance--Flammable materials

should not be stored in oven or near surface units.

7. Do Not Use Water on Grease Fires--Smother fire or

flame, or use dry chemical or foam-type extinguisher.

8. Use Only Dry Potholders--Moist or damp potholders

on hot surfaces may result in burns from steam. Do

not let potholder touch elements. Do not use a towel

or other bulky cloth.

SELF-CLEANING OVEN

1. Do Not Clean Door Gasket--The door gasket is

essential for a good seal. Care should be taken not to

rub, damage, or move the gasket.

2. Do Not Use Oven Cleaners--No commercial oven

cleaner or oven liner protective coating of any kind

should be used in or around any part of the liner.

3. Clean Only Parts Listed in Manual. See Cleaning

section.

4. Before Self-Cleaning the Oven--Remove broiler pan,

oven racks, and other utensils.

5. Remove all items from rangetop and backguard.

OVEN

1. Use Care When Opening Door--Let hot air or steam

escape before removing or replacing food.

2. Do Not Heat Unopened Food Containers--Build-up of

pressure may cause container to burst and result in

injury.

3. Keep Oven Vents Ducts Unobstructed.

4. Placement of Oven Racks--Always place oven racks

in desired location while oven is cool. tf rack is

removed while oven is hot, do not let potholder

contact hot heating element in oven.

SURFACE COOKING UNITS

1. Use Proper Pan Size--This appliance is equipped

with one or more surface burners of different sizes.

Select utensils having flat bottoms large enough to

cover the surface burner flame. The use of undersized

utensils will expose a portion of the burner flame to

direct contact and may result in ignition of clothing.

Proper relationship of utensil to burner will also

improve efficiency.

2. Never Leave Surface Burners Unattended at High

Heat Settings--Boilover causes smoking and greasy

spillovers that may ignite.

3. Protective Liners--Do not use aluminum foil to line

oven bottom except as suggested in the manual.

Improper installation of these liners may result in a

risk of electrical shock, or fire.

4. Glazed Cooking Utensils--Only certain types of

glass, ceramic, earthware, or other glazed utensils

are suitable for rangetop service without breaking due

to sudden change in temperature.

5. Utensil Handles Should be Turned Inward and Not

Extend Over Adjacent Surface Burners--To reduce

the risk of burns, ignition of flammable materials, and

spillage due to unintentional contact with the utensil,

the handle of a utensil should be positioned so that it

is turned inward, and does not extend over adjacent

surface units.

Delayed Ignition

Surface Burners

Burner should ignite within 4 seconds. If burner does not

ignite within 4 seconds turn control knob to OFF position

and follow directions in "Placing Grates and Burner Caps"

and "Before Calling for Service" section. Try burner again.

If burner still does not ignite in 4 seconds, contact an

authorized servicer.

Bake Burner Flame

Allow no more than 40-60 seconds before burner ignites

and heat is felt. To check for heat, open oven door to first

stop and place hand over oven door. If heat is not felt, turn

temperature knob to OFF position. If burner repeatedly

fails to ignite, contact an authorized servicer.

Broiler Flame

Allow no more than 40-60 seconds before burner ignites

and flame is seen. tf burner does not ignite turn

temperature knob to OFF position. If burner repeatedly

fails to ignite within 40-60 seconds contact an authorized

servicer.

Radiant screen style broiler flame should appear hazy or

fuzzy. Haze should be no more than 3/8inch thick. The

radiant screen should begin to glow red or orange within

1-2 minutes.

Installation

VENTILATION HOOD

1. Clean Ventilation Hood Frequently--Grease should

not be allowed to accumulate on hood or filter.

2. When flaming foods under hood, turn fan off. The fan,

if operating, may spread the flame.

In Case of Fire

Fires can occur as a result of over cooking or excessive

grease. Though a fire is unlikely, if one occurs, proceed

as follows:

Surface Burner Fire

1. Smother the fire with a nonflammable lidor baking

soda, or use a Class ABC or BC extinguisher. Not

water. Not salt. Not flour.

2. As soon as it is safe to do so, turn the surface

burner controls to OFF.

• As an added precaution, turn offgas supply and

power at main circuit breaker or fuse box.

Oven Fires

1. If you see smoke from oven, do not open oven door.

2. Turn oven control to OFF.

3. As an added precaution, turn off gas supply and

power at main circuit breaker or fuse box.

4. Turn on vent to remove smoke.

5. Allow food or grease to burn itself out in oven.

6. If smoke and fire persist, call fire department.

7. If there is any damage to components, call repair

service before using range.

Packing Material

Remove protective packing material from range. Tape

residue can be cleaned with a soft cloth and alcohol.

Range Location

Choose a location based on following factors.

• Drafts caused by home heating and air conditioning and

open doors or windows can disrupt ventilation air

pattern. Range should not be installed near windows or

doors.

• Make sure there is adequate space for proper

installation.

• Carefully read all instructions before beginning

installation.

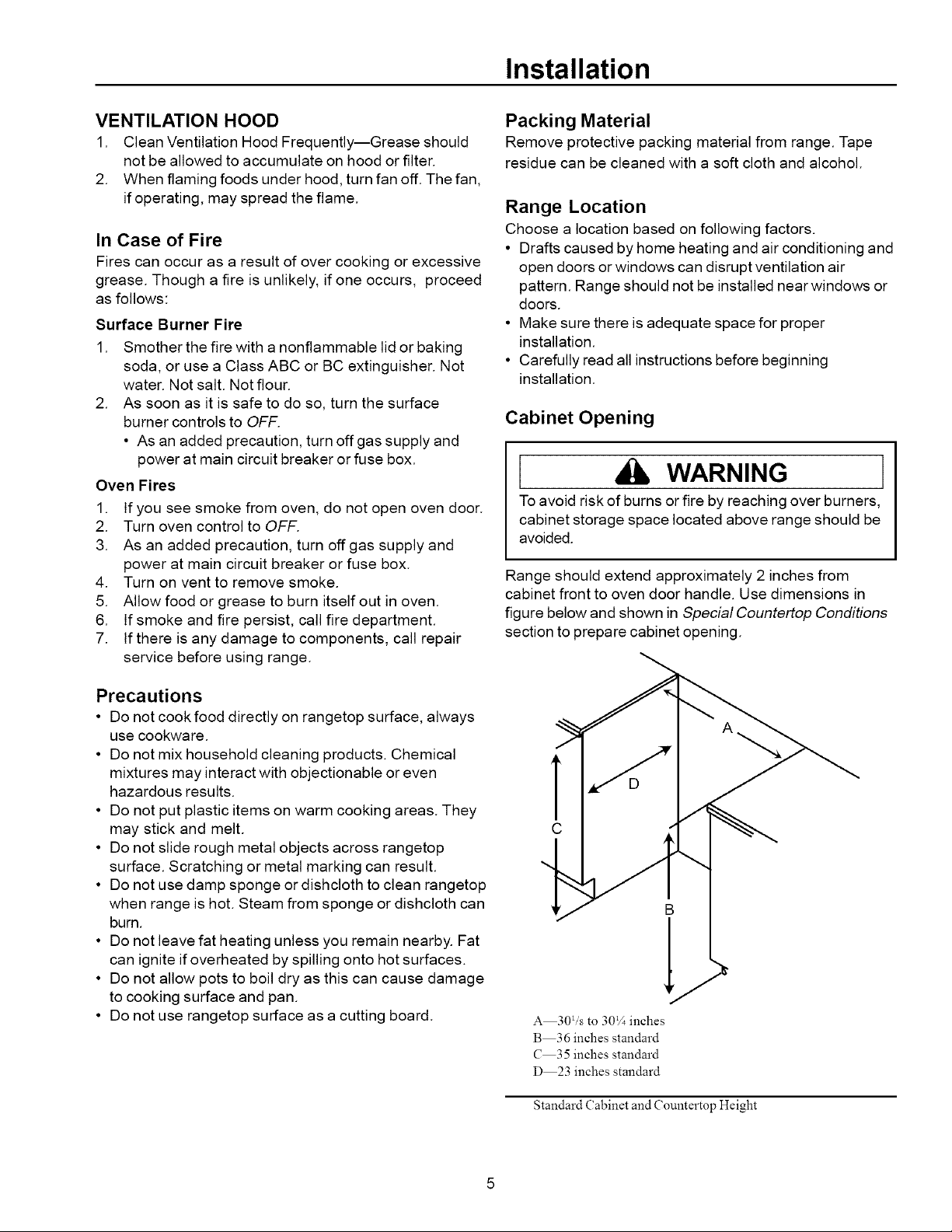

Cabinet Opening

WARNING

To avoid risk of burns or fire by reaching over burners

cabinet storage space located above range should be

avoided.

Range should extend approximately 2 inches from

cabinet front to oven door handle. Use dimensions in

figure below and shown in Special Countertop Conditions

section to prepare cabinet opening.

Precautions

• Do not cook food directly on rangetop surface, always

use cookware.

• Do not mix household cleaning products. Chemical

mixtures may interact with objectionable or even

hazardous results.

• Do not put plastic items on warm cooking areas. They

may stick and melt.

• Do not slide rough metal objects across rangetop

surface. Scratching or metal marking can result.

• Do not use damp sponge or dishcloth to clean rangetop

when range is hot. Steam from sponge or dishcloth can

burn.

• Do not leave fat heating unless you remain nearby. Fat

can ignite if overheated by spilling onto hot surfaces.

• Do not allow pots to boil dry as this can cause damage

to cooking surface and pan.

• Do not use rangetop surface as a cutting board.

T

C

B

A 301/8 to 30V4inches

B 36 inches standard

C 35 inches standard

D 23 inches standard

Standard Cabinet and Countertop Height

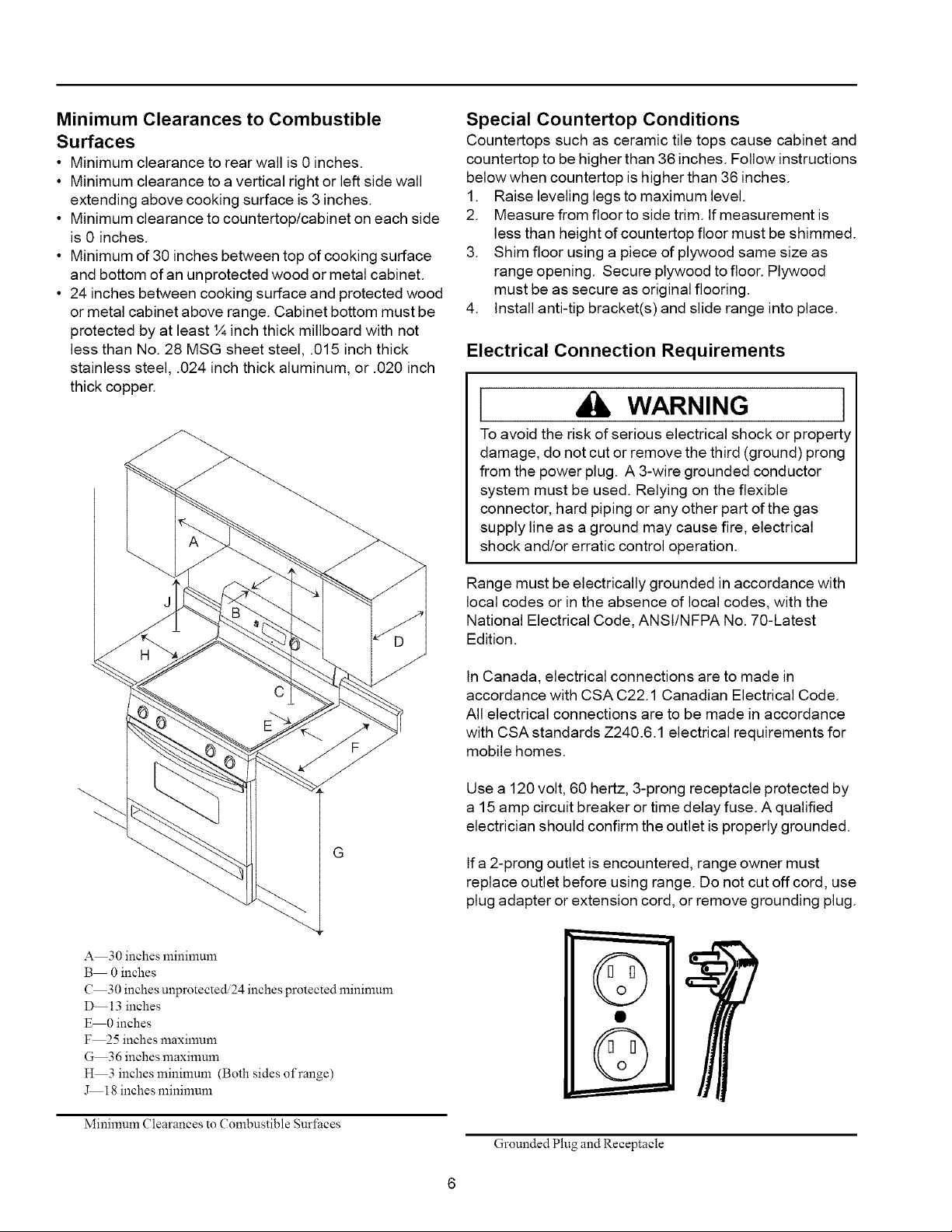

Minimum Clearances to Combustible

Surfaces

• Minimum clearance to rear wall is 0 inches.

• Minimum clearance to a vertical right or left side wall

extending above cooking surface is 3 inches.

• Minimum clearance to countertop/cabinet on each side

is 0 inches.

• Minimum of 30 inches between top of cooking surface

and bottom of an unprotected wood or metal cabinet.

• 24 inches between cooking surface and protected wood

or metal cabinet above range. Cabinet bottom must be

protected by at least 1/4inch thick millboard with not

less than No. 28 MSG sheet steel, .015 inch thick

stainless steel, .024 inch thick aluminum, or .020 inch

thick copper.

Special Countertop Conditions

Countertops such as ceramic tile tops cause cabinet and

countertop to be higher than 36 inches. Follow instructions

below when countertop is higher than 36 inches.

1. Raise leveling legs to maximum level.

2. Measure from floor to side trim. If measurement is

less than height of countertop floor must be shimmed.

3. Shim floor using a piece of plywood same size as

range opening. Secure plywood to floor. Plywood

must be as secure as original flooring.

4. Install anti-tip bracket(s) and slide range into place.

Electrical Connection Requirements

WARNING

To avoid the risk of serious electrical shock or property

damage, do not cut or remove the third (ground) prong

from the power plug. A 3-wire grounded conductor

system must be used. Relying on the flexible

connector, hard piping or any other part of the gas

supply line as a ground may cause fire, electrical

shock and/or erratic control operation.

A 30 inches mininmm

B 0 inches

C 30 inches unprotected/24 inches protected mininmm

D 13 inches

_0 inches

F 25 inches maximum

G 36 inches maximum

H 3 inches minimum (Both sides of range)

_18 inches nlininmm

Range must be electrically grounded in accordance with

local codes or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA No. 70-Latest

Edition.

In Canada, electrical connections are to made in

accordance with CSA C22.1 Canadian Electrical Code.

All electrical connections are to be made in accordance

with CSA standards Z240.6.1 electrical requirements for

mobile homes.

Use a 120 volt, 60 hertz, 3-prong receptacle protected by

a 15 amp circuit breaker or time delay fuse. A qualified

electrician should confirm the outlet is properly grounded.

Ifa 2-prong outlet is encountered, range owner must

replace outlet before using range. Do not cut off cord, use

plug adapter or extension cord, or remove grounding plug.

Minimum Clearances to Combustible Surfaces

Grounded Plug and Receptacle

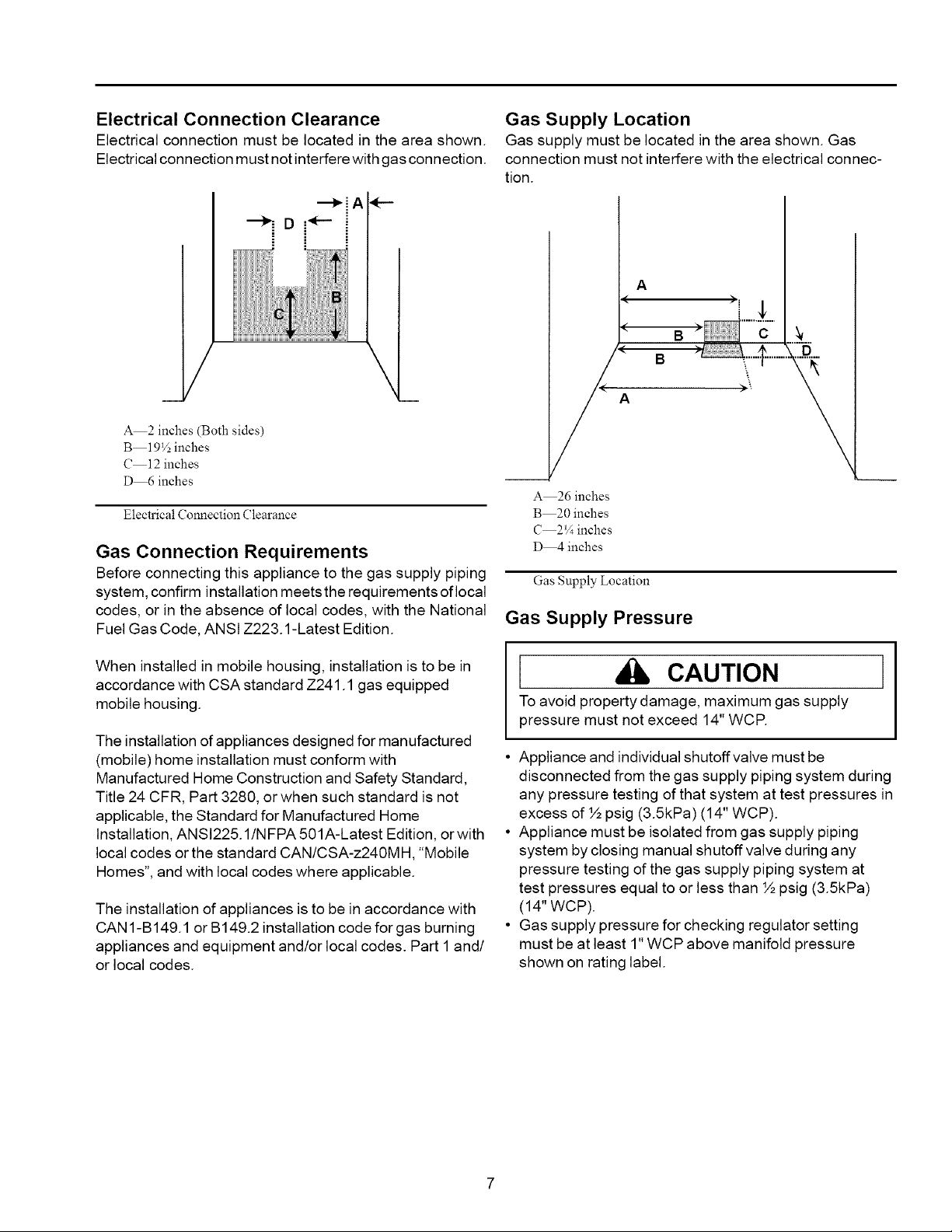

Electrical Connection Clearance

Electrical connection must be located in the area shown.

Electrical connection must not interfere with gas connection.

Gas Supply Location

Gas supply must be located in the area shown. Gas

connection must not interfere with the electrical connec-

tion.

A

(

_2 inches (Both sides)

B 19V2 inches

C 12 inches

D 6 inches

Electrical Connection Clearance

Gas Connection Requirements

Before connecting this appliance to the gas supply piping

system, confirm installation meetsthe requirements oflocal

codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1-Latest Edition.

When installed in mobile housing, installation is to be in

accordance with CSA standard Z241.1 gas equipped

mobile housing.

The installation of appliances designed for manufactured

(mobile) home installation must conform with

Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, or when such standard is not

applicable, the Standard for Manufactured Home

Installation, ANSI225.1IN FPA 501A-Latest Edition, or with

local codes or the standard CAN/CSA-z240M H, "Mobile

Homes", and with local codes where applicable.

The installation of appliances is to be in accordance with

CAN 1-B149.1 or B149.2 installation code for gas burning

appliances and equipment and/or local codes. Part 1and/

or local codes.

(

A

B

.,, ._. ....

D

/

A 26 inches

B 20 inches

C 2V4inches

D 4 inches

Gas Supply Location

Gas Supply Pressure

CAUTION

To avoid property damage, maximum gas supply

pressure must not exceed 14" WCR

• Appliance and individual shutoffvalve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of ½ psig (3.5kPa) (14" WCP).

Appliance must be isolated from gas supply piping

system by closing manual shutoff valve during any

pressure testing of the gas supply piping system at

test pressures equal to or less than ½ psig (3.5kPa)

(14" WCP).

Gas supply pressure for checking regulator setting

must be at least 1" WCP above manifold pressure

shown on rating label.

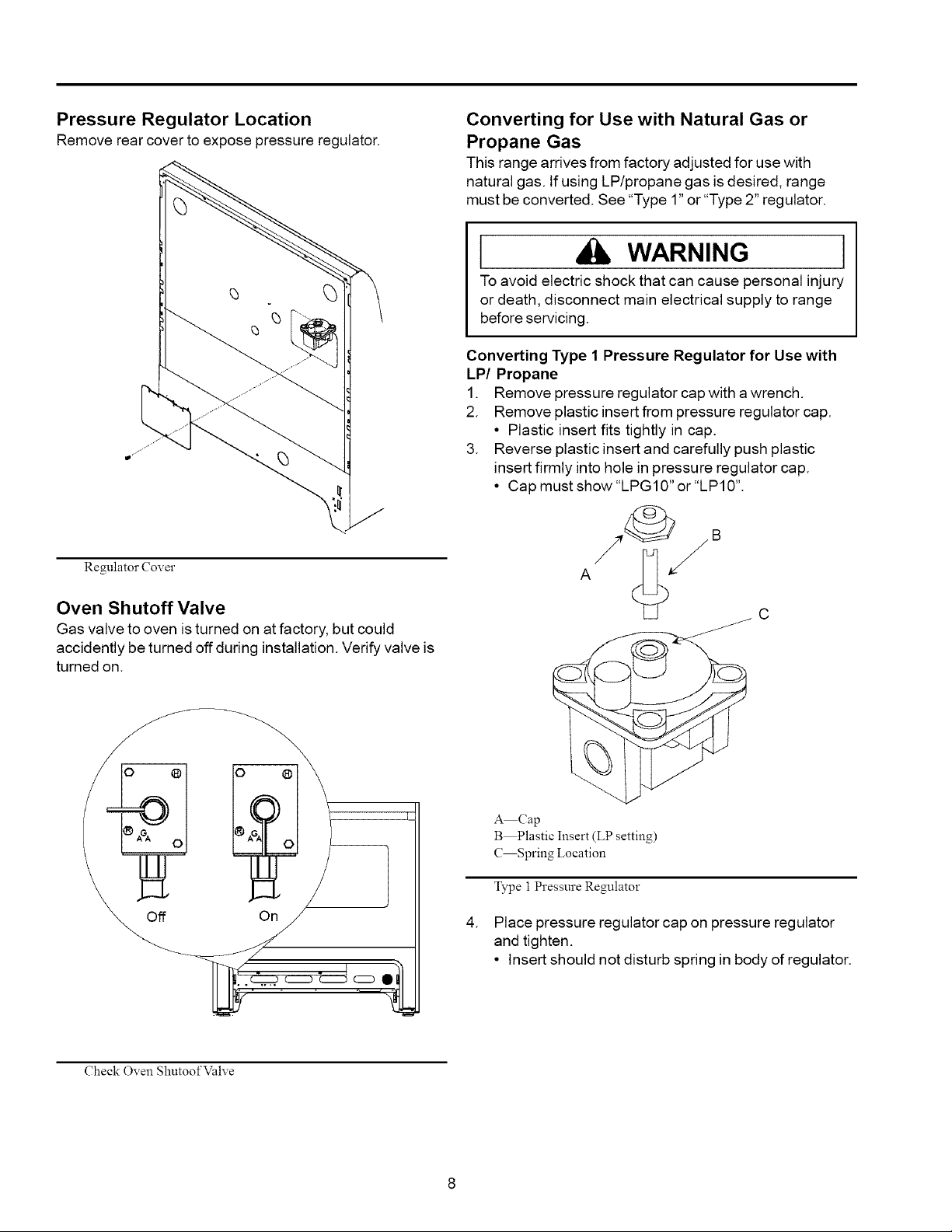

Pressure Regulator Location

Remove rear cover to expose pressure regulator.

Regulator Cover

Converting for Use with Natural Gas or

Propane Gas

This range arrives from factory adjusted for usewith

natural gas. If using LP/propane gas is desired, range

must be converted. See "Type 1" or "Type 2" regulator.

WARNING

To avoid electric shock that can cause personal injury

or death, disconnect main electrical supply to range

before servicing.

Converting Type 1 Pressure Regulator for Use with

LP/ Propane

1. Remove pressure regulator cap with awrench.

2. Remove plastic insert from pressure regulator cap.

• Plastic insert fits tightly in cap.

3. Reverse plastic insert and carefully push plastic

insert firmly into hole in pressure regulator cap.

• Cap must show "LPG10" or"LP10".

Oven Shutoff Valve

Gas valve to oven is turned on at factory, but could

accidently be turned off during installation. Verify valve is

turned on.

On/'

_Cap

B Plastic Insert (LP setting)

C Spring Location

Type 1 Pressure Regulator

.

Place pressure regulator cap on pressure regulator

and tighten.

• Insert should not disturb spring in body of regulator.

Check Oven ShutoofValve

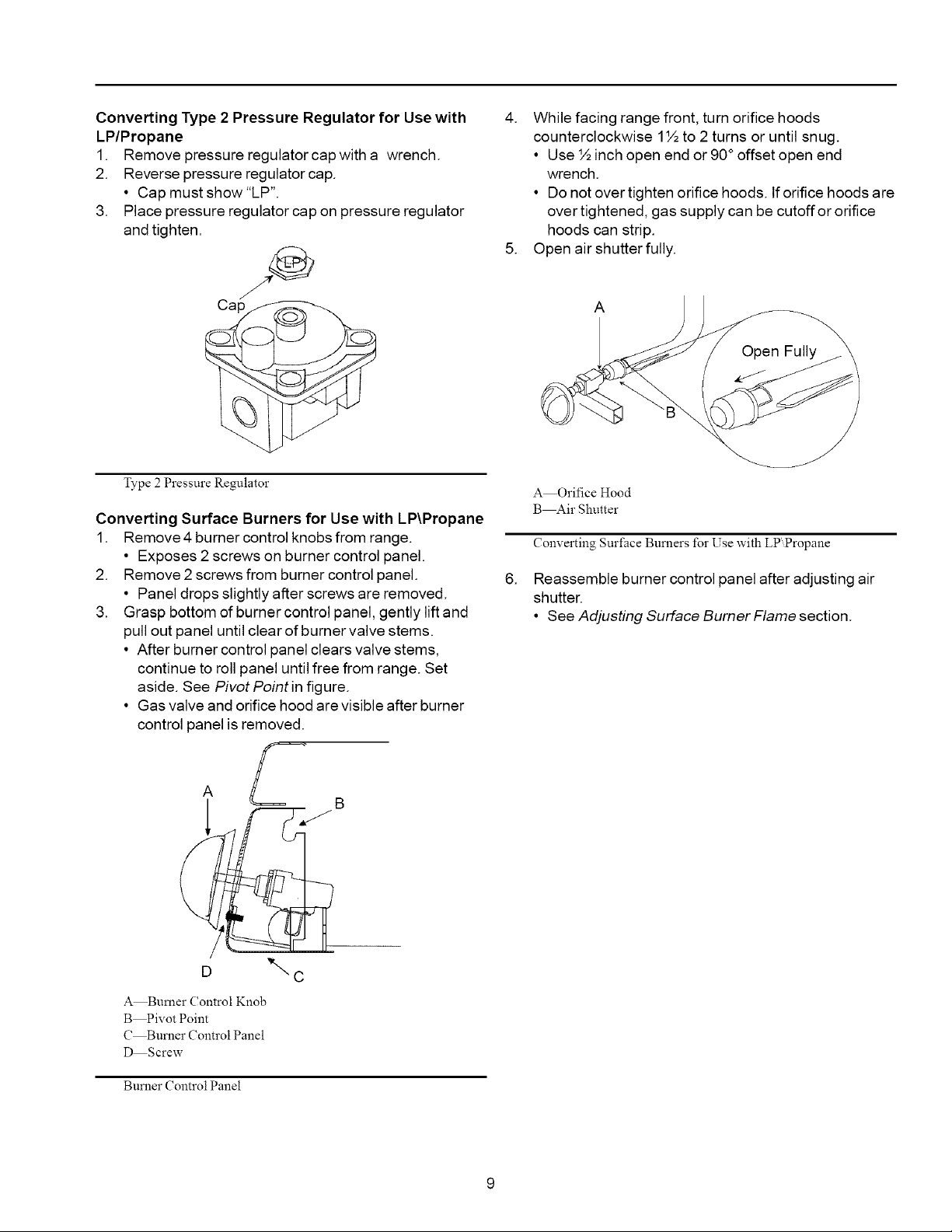

Converting Type 2 Pressure Regulator for Use with

LP/Propane

1. Remove pressure regulator capwith a wrench.

2. Reverse pressure regulator cap.

• Cap must show"LP'.

3. Place pressure regulator cap on pressure regulator

and tighten.

4. While facing range front, turn orifice hoods

counterclockwise 1½ to 2 turns or until snug.

• Use ½ inch open end or 90° offset open end

wrench.

• Do not over tighten orifice hoods. If orifice hoods are

over tightened, gas supply can be cutoffor orifice

hoods can strip.

5. Open airshutterfully.

Ca

Type 2 Pressure Regulator

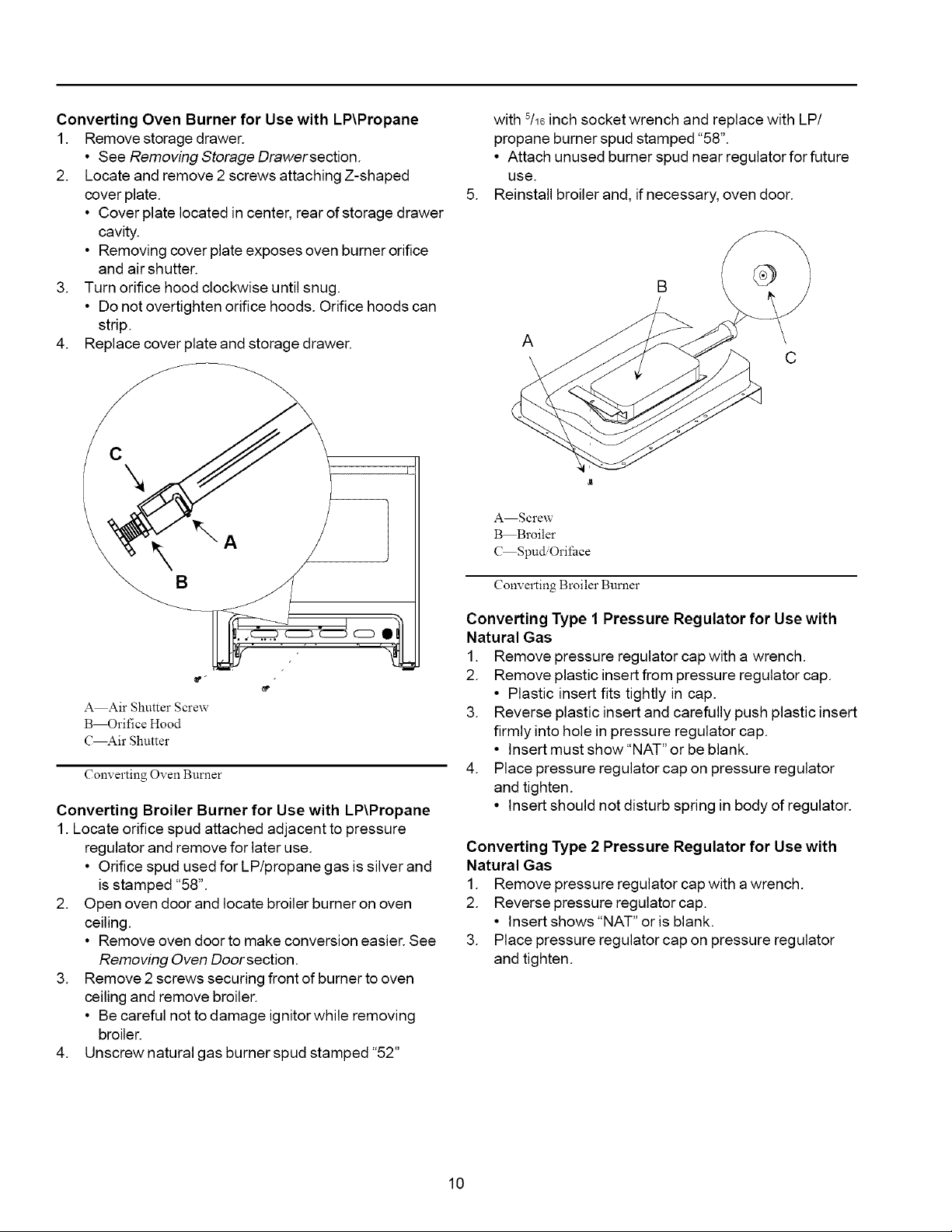

Converting Surface Burners for Use with LP\Propane

1. Remove 4 burner control knobs from range.

• Exposes 2 screws on burner control panel.

2. Remove 2 screws from burner control panel.

• Panel drops slightly after screws are removed.

3. Grasp bottom of burner control panel, gently lift and

pull out panel until clear of burner valve stems.

• After burner control panel clears valve stems,

continue to roll panel until free from range. Set

aside. See Pivot Point infigure.

• Gas valve and orifice hood are visible after burner

control panel is removed.

A

Open Fully

A Orifice Hood

B_ir Shutter

Converting Surface Burners for Use with LP Propane

.

Reassemble burner control panel after adjusting air

shutter.

• See Adjusting Surface Burner Flame section.

A

_Bumer Control Knob

B Pivot Point

C Burner Control Panel

D Screw

Burner Control Panel

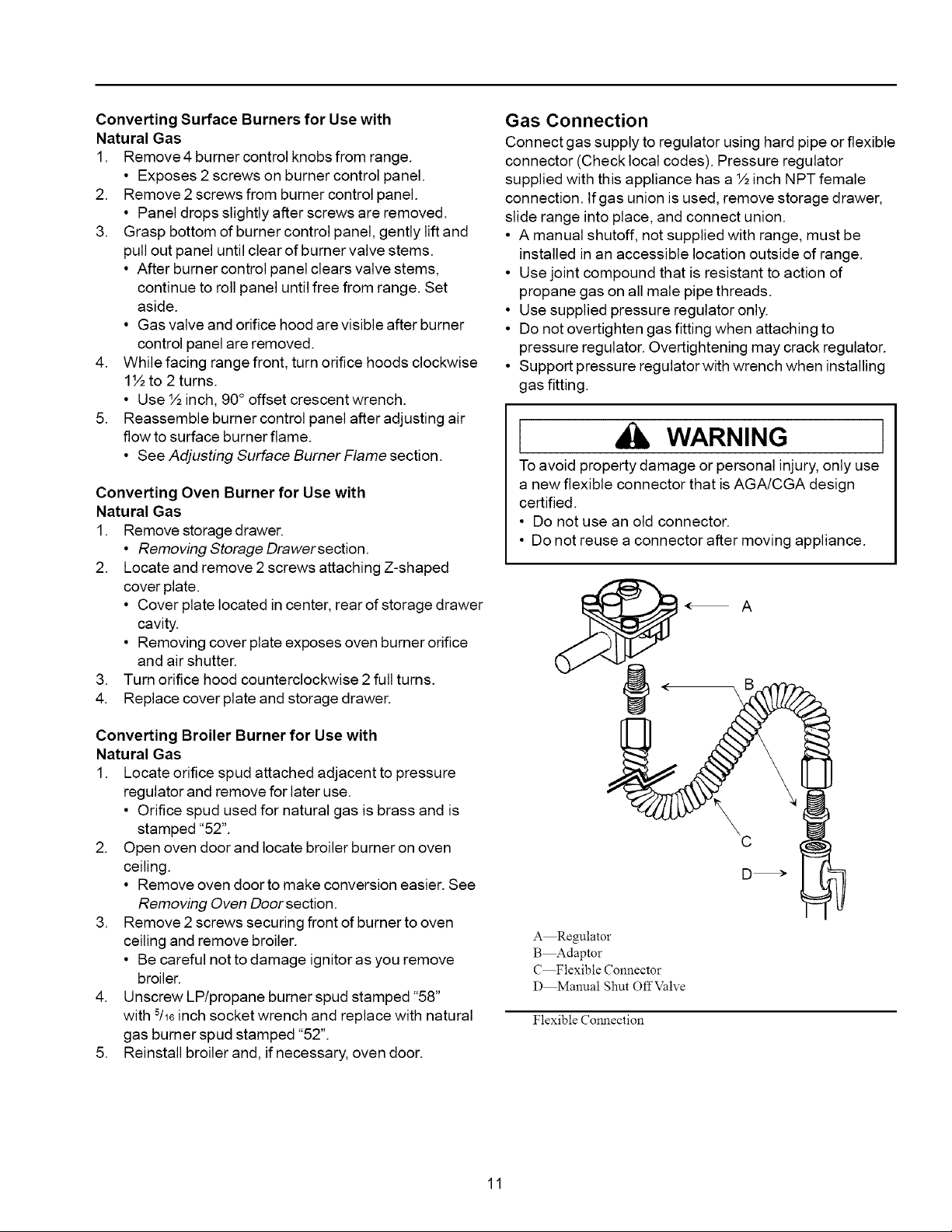

Converting Oven Burner for Use with LP\Propane

1. Remove storage drawer.

• See Removing Storage Drawersection.

2. Locate and remove 2 screws attaching Z-shaped

cover plate.

• Cover plate located in center, rear of storage drawer

cavity.

• Removing cover plate exposes oven burner orifice

and air shutter.

3. Turn orifice hood clockwise until snug.

• Do not overtighten orifice hoods. Orifice hoods can

strip.

4. Replace cover plate and storage drawer.

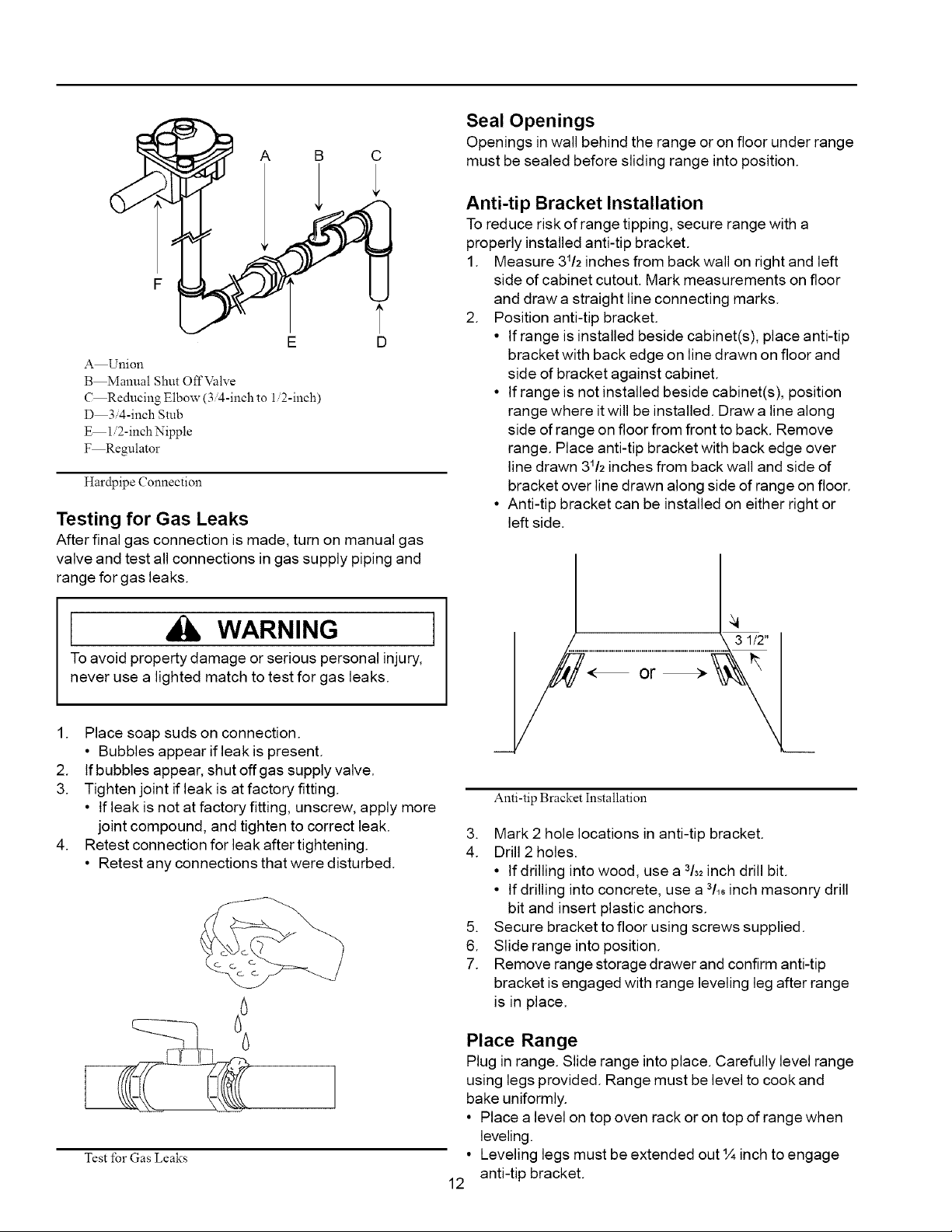

with 5/16inch socket wrench and replace with LP/

propane burner spud stamped "58".

• Attach unused burner spud near regulator for future

use.

.

Reinstall broiler and, if necessary, oven door.

A

C

A Screw

B Broiler

C SpudiOriface

B

A Air Shutter Screw

B Orifice Hood

C_ir Shutter

Converting Oven Burner

Converting Broiler Burner for Use with LP\Propane

1. Locate orifice spud attached adjacent to pressure

regulator and remove for later use.

• Orifice spud used for LP/propane gas is silver and

is stamped "58".

2. Open oven door and locate broiler burner on oven

ceiling.

• Remove oven door to make conversion easier. See

Removing Oven Door section.

3. Remove 2 screws securing front of burner to oven

ceiling and remove broiler.

• Be careful not to damage ignitorwhile removing

broiler.

4. Unscrew natural gas burner spud stamped "52"

Converting Broiler Burner

Converting Type 1 Pressure Regulator for Use with

Natural Gas

1. Remove pressure regulator cap with a wrench.

2. Remove plastic insert from pressure regulator cap.

• Plastic insert fits tightly in cap.

3. Reverse plastic insert and carefully push plastic insert

firmly into hole in pressure regulator cap.

• Insert must show "NAT" or be blank.

4. Place pressure regulator cap on pressure regulator

and tighten.

• Insert should not disturb spring in body of regulator.

Converting Type 2 Pressure Regulator for Use with

Natural Gas

1. Remove pressure regulator cap with a wrench.

2. Reverse pressure regulator cap.

• Insert shows "NAT" or is blank.

3. Place pressure regulator cap on pressure regulator

and tighten.

10

Converting Surface Burners for Use with

Natural Gas

1. Remove 4 burner control knobs from range.

• Exposes 2 screws on burner control panel.

2. Remove 2 screws from burner control panel.

• Panel drops slightly after screws are removed.

3. Grasp bottom of burner control panel, gently lift and

pull out panel until clear of burner valve stems.

• After burner control panel clears valve stems,

continue to roll panel until free from range. Set

aside.

• Gas valve and orifice hood are visible after burner

control panel are removed.

4. While facing range front, turn orifice hoods clockwise

1½ to 2 turns.

• Use ½ inch, 90° offset crescent wrench.

5. Reassemble burner control panel after adjusting air

flow to surface burner flame.

• See Adjusting Surface Burner Flame section.

Converting Oven Burner for Use with

Natural Gas

1. Remove storage drawer.

• Removing Storage Drawersection.

2. Locate and remove 2 screws attaching Z-shaped

cover plate.

• Cover plate located in center, rear of storage drawer

cavity.

• Removing cover plate exposes oven burner orifice

and air shutter.

3. Turn orifice hood counterclockwise 2 full turns.

4. Replace cover plate and storage drawer.

Gas Connection

Connect gas supply to regulator using hard pipe or flexible

connector (Check local codes). Pressure regulator

supplied with this appliance has a ½ inch NPT female

connection. If gas union is used, remove storage drawer,

slide range into place, and connect union.

• A manual shutoff, not supplied with range, must be

installed in an accessible location outside of range.

• Use joint compound that is resistant to action of

propane gas on all male pipe threads.

• Use supplied pressure regulator only.

• Do not overtighten gas fitting when attaching to

pressure regulator. Overtightening may crack regulator.

• Support pressure regulatorwith wrench when installing

gas fitting.

WARNING

To avoid property damage or personal injury, only use

a new flexible connector that is AGA/CGA design

certified.

• Do not use an old connector.

• Do not reuse a connector after moving appliance.

A

Converting Broiler Burner for Use with

Natural Gas

1. Locate orifice spud attached adjacent topressure

regulator and remove for later use.

• Orifice spud used for natural gas is brass and is

stamped "52".

2. Open oven door and locate broiler burner onoven

ceiling.

• Remove oven door to make conversion easier. See

Removing Oven Door section.

3. Remove 2 screws securing front of burner to oven

ceiling and remove broiler.

• Be careful not to damage ignitor as you remove

broiler.

4. Unscrew LP/propane burner spud stamped "58"

with s/16inch socket wrench and replace with natural

gas burner spud stamped "52".

5. Reinstall broiler and, if necessary, oven door.

\

C

A Regulator

B_daptor

C Flexible Connector

D Manual Shut OffValve

Flexible Connection

11

B C

E D

A Union

B Manual Shut OffValve

C Reducing Elbow(3i4-inchto 1/2-inch)

D 3/4-inch Stub

1/2 -inch Nipple

F Regulator

Hardpipe Connection

Testing for Gas Leaks

After final gas connection is made, turn on manual gas

valve and test all connections in gas supply piping and

range for gas leaks.

Seal Openings

Openings in wall behind the range or on floor under range

must be sealed before sliding range into position.

Anti-tip Bracket Installation

To reduce risk of range tipping, secure range with a

properly installed anti-tip bracket.

1. Measure 31/2inches from back wall on right and left

side of cabinet cutout. Mark measurements on floor

and draw a straight line connecting marks.

2. Position anti-tip bracket.

• Ifrange is installed beside cabinet(s), place anti-tip

bracket with back edge on line drawn on floor and

side of bracket against cabinet.

• Ifrange is not installed beside cabinet(s), position

range where it will be installed. Draw a line along

side of range on floor from front to back. Remove

range. Place anti-tip bracket with back edge over

line drawn 3V2inches from back wall and side of

bracket over line drawn along side of range on floor.

• Anti-tip bracket can be installed on either right or

left side.

WARNING

Toavoid property damage or serious personal injury,

never use a lighted match to test for gas leaks.

1. Place soap suds on connection.

• Bubbles appear if leak is present.

2. Ifbubbles appear, shut off gas supply valve.

3. Tighten joint if leak is at factory fitting.

• If leak is not at factory fitting, unscrew, apply more

joint compound, and tighten to correct leak.

4. Retest connection for leak after tightening.

• Retest any connections that were disturbed.

Test tbr Gas Leaks

Anti-tip Bracket Installation

3. Mark 2 hole locations in anti-tip bracket.

4. Drill 2 holes.

• Ifdrilling into wood, use a 3h2inch drill bit.

• Ifdrilling into concrete, use a 3/16inch masonry drill

bit and insert plastic anchors.

5. Secure bracket to floor using screws supplied.

6. Slide range into position.

7. Remove range storage drawer and confirm anti-tip

bracket is engaged with range leveling leg after range

is in place.

Place Range

Plug in range. Slide range into place. Carefully level range

using legs provided. Range must be level to cook and

bake uniformly.

• Place a level on top oven rack or on top of range when

leveling.

• Leveling legs must be extended out 1¼inch to engage

12 anti-tip bracket.

Removal and Reinstallation of Range

1. Unplug range cord.

2. Turn off gas valve and disconnect gas supply.

3. Remove range and place aside.

4. Remove anti-tip bracket and reinstall anti-tip bracket

into new location using instructions provided with

bracket.

5. To reinstall range, follow instructions in Installation

section of this manual.

• Do not reuse a flexible connector after moving

appliance.

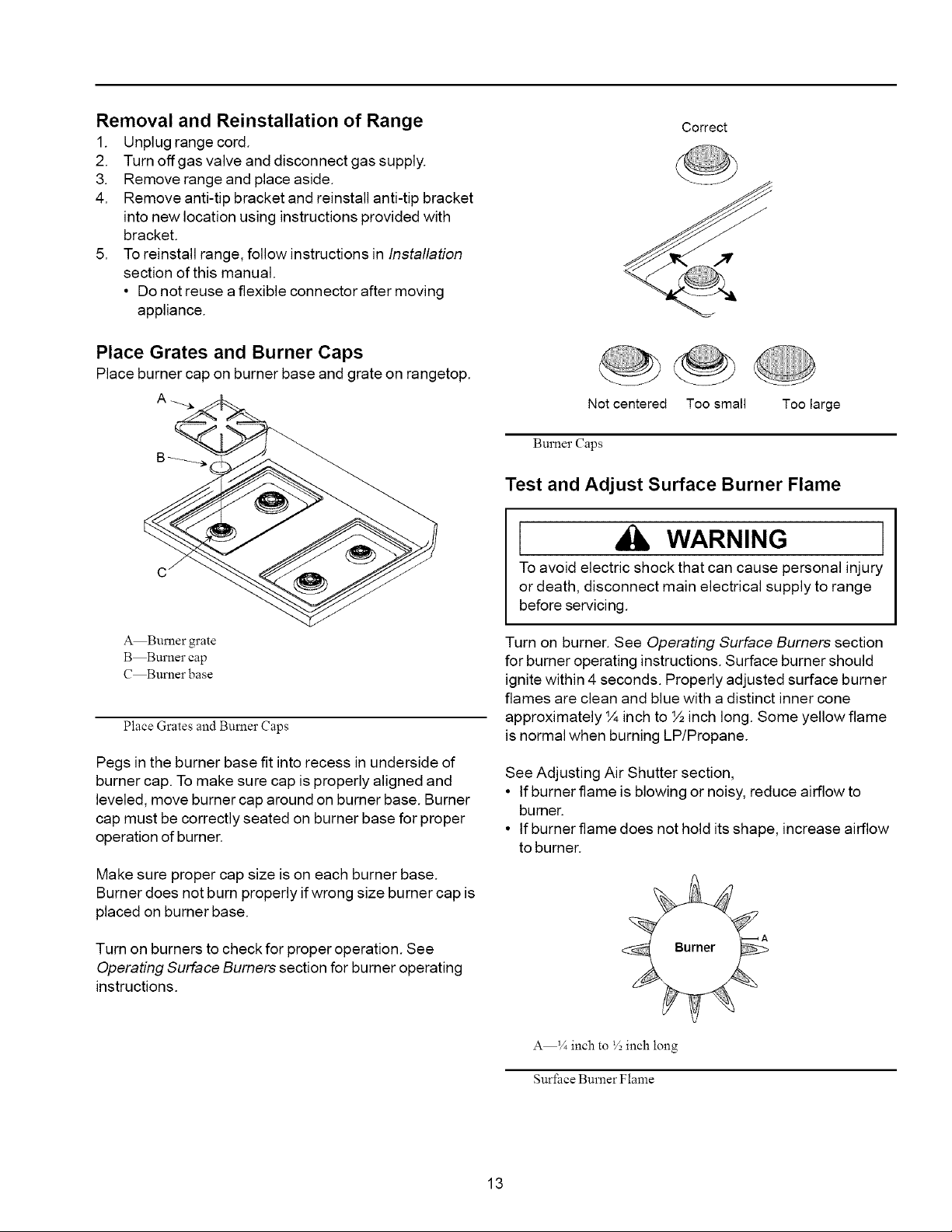

Place Grates and Burner Caps

Place burner cap on burner base and grate on rangetop.

Correct

Not centered Too small Too large

Burner Caps

Test and Adjust Surface Burner Flame

WARNING

To avoid electric shock that can cause personal injury

or death, disconnect main electrical supply to range

before servicing.

_Burner grate

B Burner cap

C Burner base

Place Grates and Burner Caps

Pegs in the burner base fit into recess in underside of

burner cap. To make sure cap is properly aligned and

leveled, move burner cap around on burner base. Burner

cap must be correctly seated on burner base for proper

operation of burner.

Make sure proper cap size is on each burner base.

Burner does not burn properly if wrong size burner cap is

placed on burner base.

Turn on burners to check for proper operation. See

Operating Surface Burners section for burner operating

instructions.

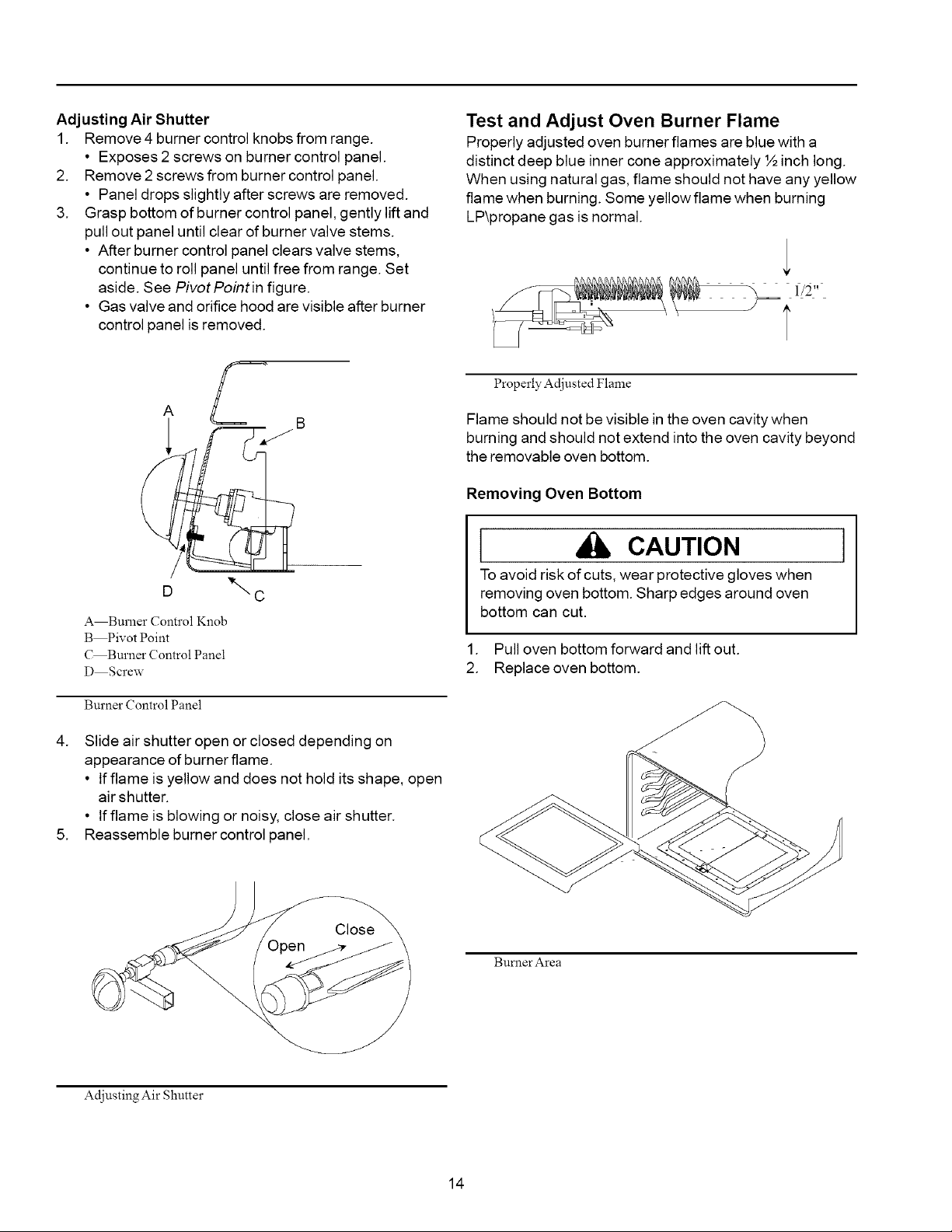

Turn on burner. See Operating Surface Burners section

for burner operating instructions. Surface burner should

ignite within 4 seconds. Properly adjusted surface burner

flames are clean and blue with a distinct inner cone

approximately 1/4inch to ½ inch long. Some yellow flame

is normal when burning LP/Propane.

See Adjusting Air Shutter section,

• If burner flame is blowing or noisy, reduce airflow to

burner.

• If burner flame does not hold its shape, increase airflow

to burner.

A V4 inch to V2inch long

Surface Burner Flame

13

Adjusting Air Shutter

1. Remove 4 burner control knobs from range.

• Exposes 2 screws on burner control panel.

2. Remove 2 screws from burner control panel.

• Panel drops slightly after screws are removed.

3. Grasp bottom of burner control panel, gently lift and

pull out panel until clear of burner valve stems.

• After burner control panel clears valve stems,

continue to roll panel until free from range. Set

aside. See PivotPointin figure.

• Gas valve and orifice hood are visible after burner

control panel is removed.

A

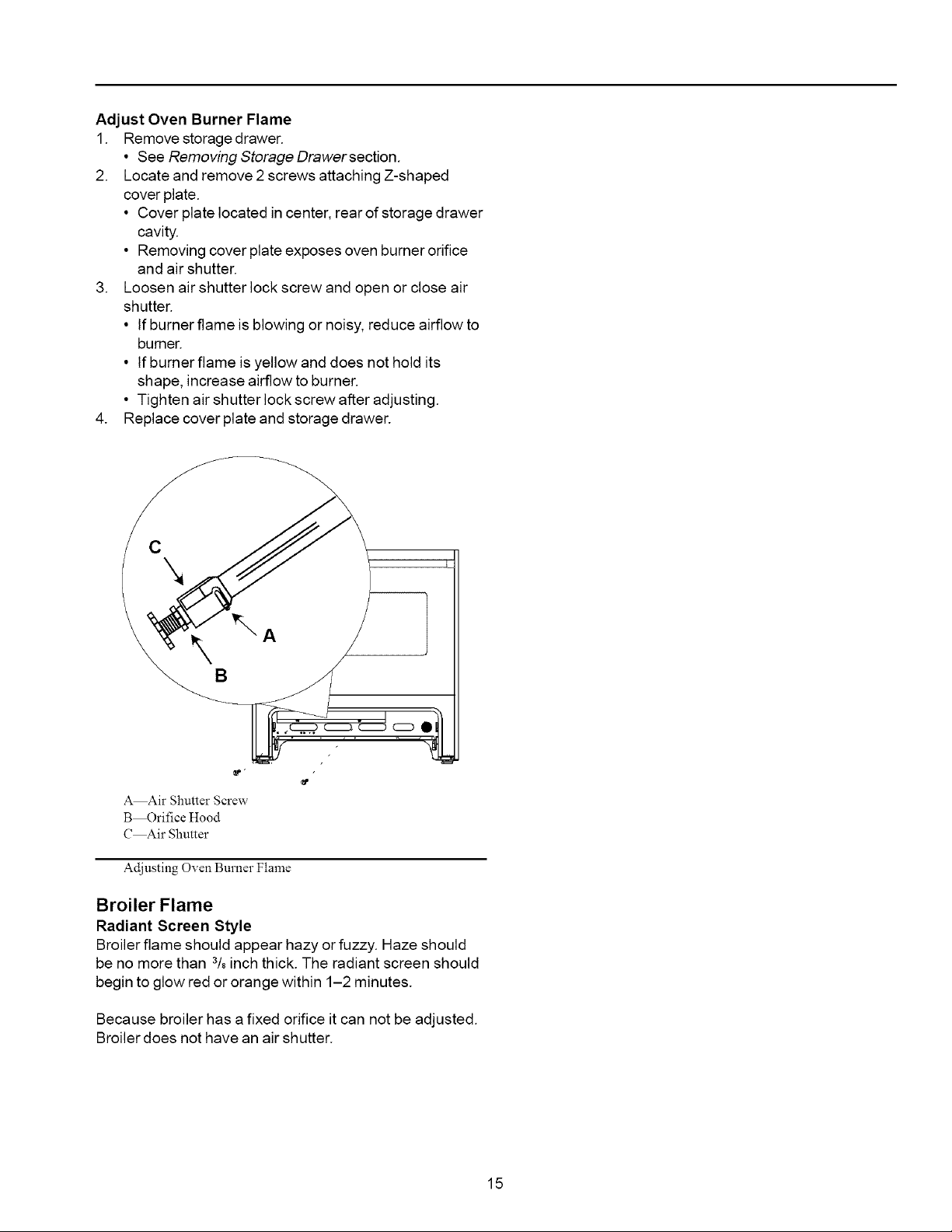

Test and Adjust Oven Burner Flame

Properly adjusted oven burner flames are blue with a

distinct deep blue inner cone approximately ½ inch long.

When using natural gas, flame should not have any yellow

flame when burning. Some yellowflame when burning

LP\propane gas is normal.

1/2"

T

Properly Adjusted Flame

Flame should not be visible in the oven cavity when

burning and should not extend into the oven cavity beyond

the removable oven bottom.

Removing Oven Bottom

CAUTION

A Burner ControlKnob

B Pivot Point

C Burner Control Panel

D Screw

Burner Control Panel

4. Slide air shutter open or closed depending on

appearance of burner flame.

• If flame is yellow and does not hold its shape, open

air shutter.

• If flame is blowing or noisy, close air shutter.

5. Reassemble burner control panel.

To avoid risk of cuts, wear protective gloves when

removing oven bottom. Sharp edges around oven

bottom can cut.

1. Pull oven bottom forward and lift out.

2. Replace oven bottom.

Burner Area

Adjusting Air Shutter

14

Adjust Oven Burner Flame

1. Remove storage drawer.

• SeeRemovingStorageDrawersection.

2. Locate and remove 2 screws attaching Z-shaped

cover plate.

• Cover plate located in center, rear of storage drawer

cavity.

• Removing cover plate exposes oven burner orifice

and air shutter.

3. Loosen air shutter lock screw and open or close air

shutter.

• If burner flame is blowing or noisy, reduce airflow to

burner.

• If burner flame is yellow and does not hold its

shape, increase airflow to burner.

• Tighten air shutter lock screw after adjusting.

4. Replace cover plate and storage drawer.

B

_Air Shutter Screw

B Orifice Hood

C Air Shutter

Adjusting Oven Burner Flame

Broiler Flame

Radiant Screen Style

Broiler flame should appear hazy orfuzzy. Haze should

be no more than 3/8inch thick. The radiant screen should

begin to glow red or orange within 1-2 minutes.

Because broiler has a fixed orifice it can not be adjusted.

Broiler does not have an air shutter.

15

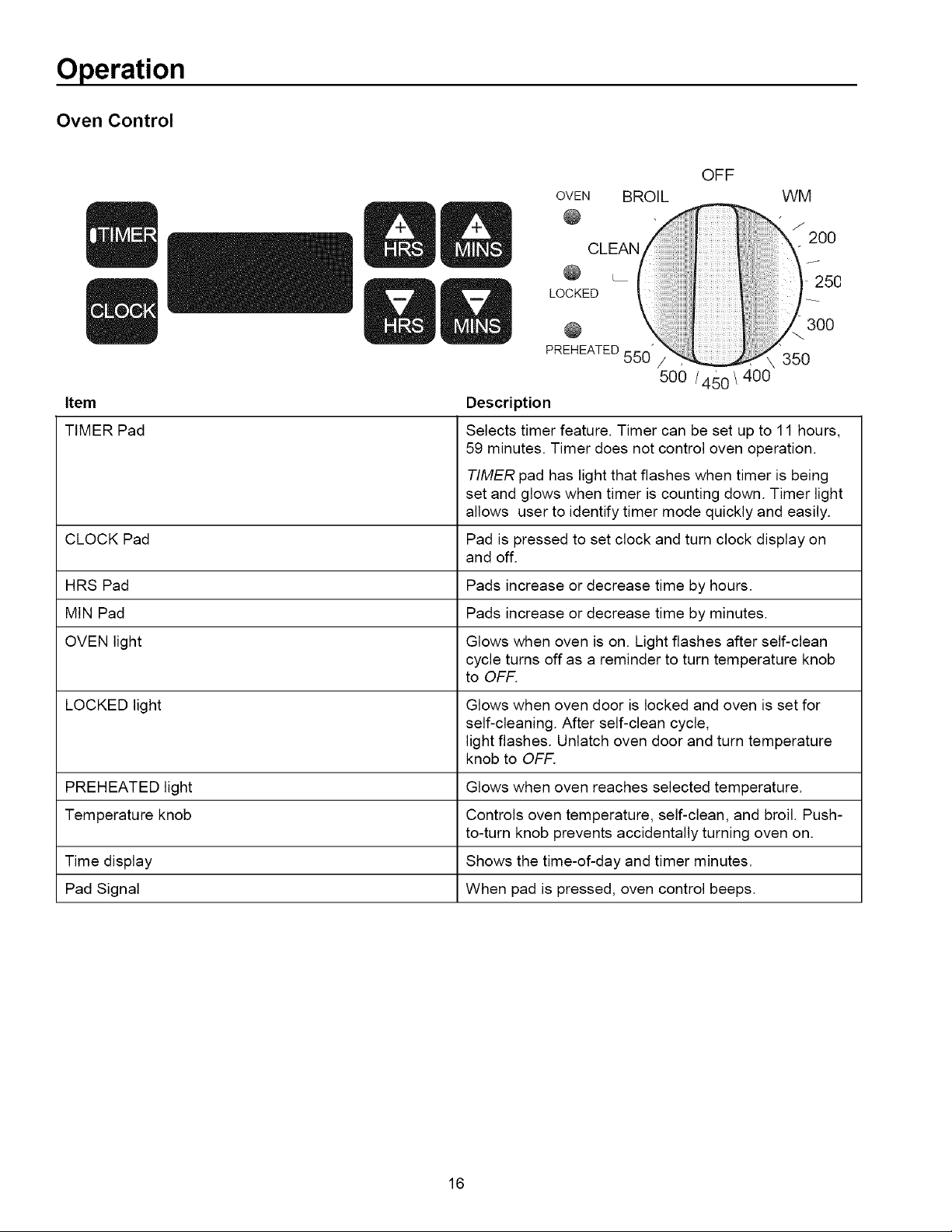

Operation

Oven Control

Item

TIMER Pad

OFF

OVEN BROIL WM

÷

PREHEATED550" / _ 350

500 /450 t 400

Description

Selects timer feature. Timer can be set up to 11 hours,

59 minutes. Timer does not control oven operation.

TIMER pad has light that flashes when timer is being

set and glows when timer is counting down. Timer light

allows user to identify timer mode quickly and easily.

CLOCK Pad Pad is pressed to set clock and turn clock display on

and off.

HRS Pad Pads increase or decrease time by hours.

MIN Pad Pads increase or decrease time by minutes.

OVEN light Glows when oven is on. Light flashes after self-clean

cycle turns off as a reminder to turn temperature knob

to OFF.

LOCKED light Glows when oven door is locked and oven is set for

self-cleaning. After self-clean cycle,

light flashes. Unlatch oven door and turn temperature

knob to OFF.

PREHEATED light Glows when oven reaches selected temperature.

Temperature knob Controls oven temperature, self-clean, and broil. Push-

to-turn knob prevents accidentally turning oven on.

Time display Shows the time-of-day and timer minutes.

Pad Signal When pad is pressed, oven control beeps.

16

Setting Electronic Clock

Electronic clock has 3 modes--Clock displayed, set

clock (flashing), and clock not displayed. Press CLOCK

pad to advance through modes.

Automatic Oven Shutoff

As a safety feature, oven control automatically shuts off

oven after 12 hours of operation. This feature can be

turned on or off.

When power is connected or restored, display flashes

until pad is pressed or temperature knob is turned. Reset

clock.

1. Verify display is flashing.

• If display does not flash, press CLOCKpad repeat-

edly until display flashes.

2. Press HRS + or - pad to set hours and MINS + or -

pad to set minutes.

3. Press CLOCKpad to save time-of-day.

• Clock saves time-of-day approximately 60 seconds

after time is entered if CLOCKpad is not pressed.

Turning Off/On Clock Display

Press CLOCKpad until display is blank. Clock retains

time while not displayed. To turn on display, press

CLOCKpad until time-of-day displays and is not flashing.

Setting Electronic Timer

The minute timer is a timer only. Electronic timer does not

control bake, broil, or self-clean function. Timer can be set

up to 11 hours and 59 minutes.

1. Press TIMER pad.

2. Press HRS + or - pad to set hours and MINS + or -

pad to set minutes.

• Timer begins counting down automatically after

time is entered.

• To view clock while timer counts down, press

CLOCK pad. To view timer again, press TIMER pad.

3. Press TIMER pad again to cancel.

• After time elapses, timer beeps approximatly once

a second until TIMER pad is pressed.

To allow the oven to operate for more than 12 hours,

confirm temperature knob is in OFF position. Then, press

and hold the MINS+ and - pads for approximately

4 seconds. Display will change from time-of-day and show

"OFF".

To set oven to shut off after 12 hours, confirm temperature

knob is in the OFF position. Then, press and hold the

MINS + and - pads for approximately 4 seconds. Display

will change from time-of-day and show "ON".

Service Tones and Codes

Electronic range control has a self-diagnostic system.

Self-diagnostic system sounds a series of short, rapid

beeps and shows an "F-code" in display when there is a

problem. When electronic range control signals a

problem, follow steps listed below.

1. Record "F-code" shown.

• FFF---control malfunction.

• F2--high oven temperature.

• F3--open temperature sensor or circuit malfunc-

tion.

• F4--shorted temperature sensor or circuit malfunc-

tion.

2. Disconnect electrical supply.

• Disconnecting electrical supply may eliminate "F-

code", tffailure continues, contact an authorized

servicer.

3. Contact an authorized servicer to check range.

Resetting and Canceling Timer

To reset or cancel timer, display must show remaining

time. If display does not show remaining time, press

TIMER pad.

To reset the time when remaining time is displayed, press

the HRS + or - pad to set hours and MINS + or - pad to

set minutes until new time displays.

To cancel timer when remaining time is displayed or

signal after time elapses, press TIMER pad.

Oven Light

Brightens oven cavity when oven door is opened or panel

switch (some models) is turned on.

17

Operating Surface Burners

WARNING

Toavoid risk of serious personal injury, property

damage, or fire, do not leave burners unattended while

in operation. Grease and spillovers can ignite causing

a fire.

1. Push burner knob in and turn control knob

counterclockwise to LITE position.

• Burner should ignite within 4 seconds, tf burner

does not ignite within 4 seconds turn control knob

to OFF position and follow directions in "Placing

Grates and Burner Caps" and "Before Calling for

Service" section. Try burner again. If burner still

does not ignite in 4 seconds, contact an authorized

servicer.

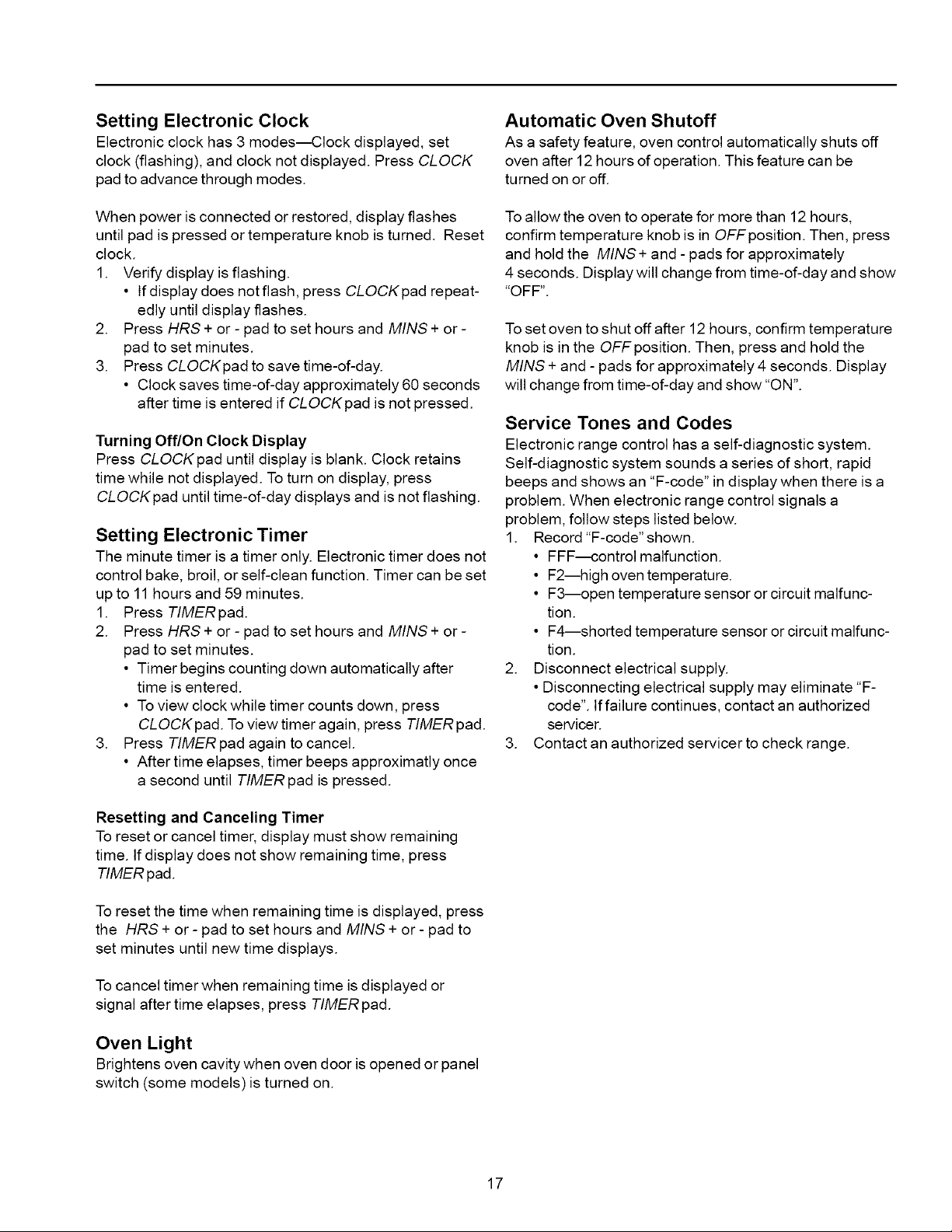

Adjusting Burner Flame Size

• While turning the burner control knob, watch the burner

flame.

• Flame size should match the size of the pan. Do not

allow the flame to extend up the sides of the pan.

Flames that extend up the sides of the pan can ignite

clothing, make handle hot, or burn.

Adjusting Burner Flame Size

...........

\

Burner Knob

2. After gas ignites, turn control to desired setting.

• Each control knob can be set to any required

cooking temperature. Burner settings do not have

distinct clicks.

• Use Hlto bring food to boiling temperatures. When

food is boiling temperature setting should be

reduced.

• After lighting burner do not operate burner for long

periods of time without cookware on the grate. The

finish on the grate can chip without cookware to

absorb heat.

3. Turn control knob to OFF position when finished

cooking.

Operating Surface Burner during a Power

Failure

Although the system that lights the burners is electric,

surface burners can be ignited during a power failure.

Never attempt to light bake or broil burners during power

failure.

1. Hold match at base of desired burner.

2. Push in burner control knob and turn to LITEposition.

3. After gas ignites, remove match from burner and turn

burner control knob to desired setting.

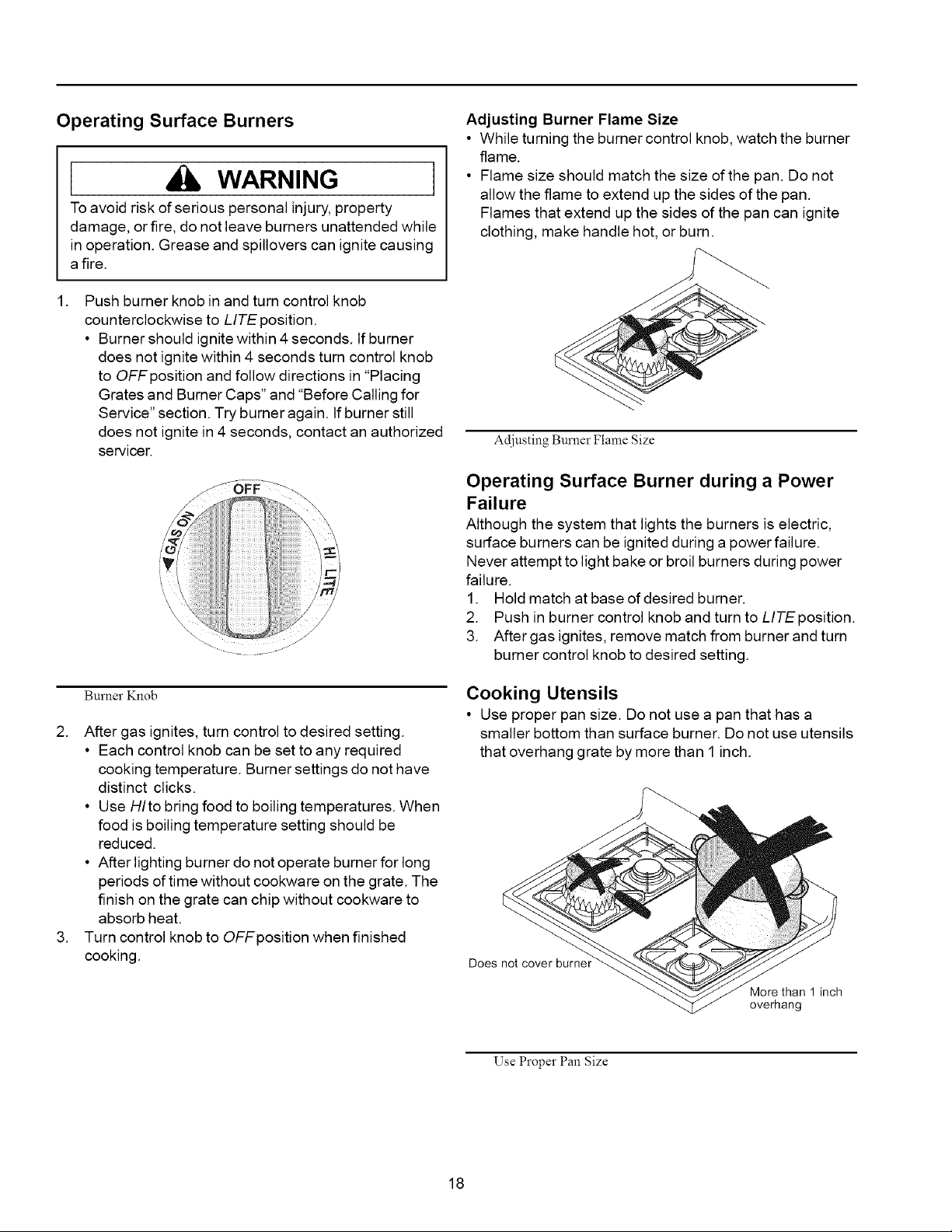

Cooking Utensils

• Use proper pan size. Do not use a pan that has a

smaller bottom than surface burner. Do not use utensils

that overhang grate by more than 1 inch.

Does not cover

Use Proper Pan Size

18

More than 1 inch

overhang

Loading...

Loading...