Page 1

Part No. 12642704

Printed in U.S.A.

©2002 Maytag Appliances Sales Co.

Form No. B/07/02

Bottom Freezer

Refrigerator

Ordering parts and accessories?

Questions about your features?

Please contact us with your model and serial number:

Consumer Affairs Department

Amana Appliances

2800 - 220th Trail

Amana, Iowa 52204

Ph# 1(800)843-0304 in U.S.A.

1(866)587-2002 au Canada

Internet: http:// www.amana.com

Owner’s Manual

Keep instructions for future reference.

Keep this manual and your sales receipt together in a safe place

in case warranty service is required.

Contents

Introduction .................................................................2

Important Safety Information ......................................3

Installing Your Refrigerator .........................................4

How to Remove the Doors and Hinges....................4

How to Reverse Refrigerator Door...........................5

How to Install and Remove Handles........................6

How to Replace the Doors and Hinges....................7

How to Remove and Install Panels ..........................7

How to Remove and Install the Pullout Drawer .......8

How to Connect the Water Supply...........................9

How to Level Your Refrigerator ..............................10

How to Adjust the Temperature Controls................10

About Your Water Filter.............................................11

Fresh Food Features ................................................12

Primary Features....................................................12

Interior Shelves.......................................................12

Door Storage ..........................................................12

Accessories ............................................................12

Climate-Controlled Drawers ...................................13

Freezer Features ......................................................14

Primary Features....................................................14

Drawers ..................................................................14

Accessories ............................................................14

Hints and Care..........................................................15

How to Clean Your Unit..........................................15

How to Remove and Replace Light Bulbs .............16

Trouble Shooting.......................................................17

Water Filter Data.......................................................20

Warranty ...................................................................22

Page 2

2

Thank you for buying an Amana refrigerator!

Please read this Owner's Manual thoroughly. This manual provides proper maintenance

information.

Complete registration card and promptly return. If registration card is missing, call

the Consumer Affairs Department.

Warranty service must be performed by an authorized servicer. Amana also

recommends contacting an authorized servicer if service is required after warranty

expires. To locate an authorized servicer, call 1-800-NAT-LSVC (1-800-628-5782). You

may also contact us on the web at www.amana.com.

When contacting Amana, please provide the following information. Product information

is on the serial plate, located on ceiling of fresh food section.

Model Number ________________________________________________________

'P' Number ___________________________________________________________

Serial Number _________________________________________________________

Purchase Date ________________________________________________________

Dealer Name _________________________________________________________

Dealer Address ________________________________________________________

Dealer Phone _________________________________________________________

Asure™ extended

service plan

Amana offers long-term service protection for this new refrigerator. Asure™

Extended Service Plan is specially

designed to supplement Amana’s strong

warranty. This plan covers parts, labor,

and travel charges. Call 1(800)528-2682,

or contact us at www.amana.com for

more information.

Before calling service...

If something seems unusual, please

check “Trouble Shooting” section, which

is designed to help you solve problems

before calling service.

What if these features

are different from

mine?

This book is intended to show the variety

of features that are available in the product line. If your refrigerator does not have

all the options that are shown, many of

these options may be purchased by contacting the Consumer Affairs Department.

See contact information on the cover of

your manual.

Page 3

3

Important safety information

What you need to know

about safety

instructions

Warning and Important Safety

Instructions appearing in this manual are

not meant to cover all possible conditions

and situations that may occur. Common

sense, caution, and care must be

exercised when installing, maintaining, or

operating refrigerator.

Always contact your dealer, distributor,

service agent, or manufacturer about

problems or conditions you do not understand.

Save these instructions

DANGER – Immediate hazards which

WILL result in severe personal injury

or death.

DANGER

WARNING – Hazards or unsafe prac-

tices which COULD result in severe

personal injury or death.

WARNING

CAUTION – Hazards or unsafe prac-

tices which COULD result in minor

personal injury.

CAUTION

To reduce risk of fire, electric shock, serious injury or death when using your refrigerator, follow these basic precautions,

including the following:

WARNING

To reduce risk of injury or death,

follow basic precautions, including

the following:

IMPORTANT: Child entrapment and

suffocation are not problems of the

past. Junked or abandoned refrigerators are still dangerous – even if they

sit out for “just a few days.” If you are

getting rid of your old refrigerator,

please follow the instructions below to

help prevent accidents.

Before you throw away your old refrigerator or freezer:

➢ Take off the doors.

➢ Leave the shelves in

place so children

may not easily climb

inside.

DANGER

RECOGNIZE SAFETY

SYMBOLS, WORDS,

LABELS

1. Read all instructions before using the refrigerator.

2. Observe all local codes and ordinances.

3. Be sure to follow grounding instructions.

4. Check with a qualified electrician if you are not sure this

appliance is properly grounded.

5. DO NOT ground to a gas line.

6. DO NOT ground to a cold-water pipe.

7. Refrigerator is designed to operate on a separate 103 to

126 volt, 15 amp., 60 cycle line. DO NOT modify plug on

power cord. If plug does not fit electrical outlet, have proper

outlet installed by a qualified electrician.

8. DO NOT use a two-prong adapter, extension cord or power

strip.

9. DO NOT remove warning tag from power cord.

10. DO NOT tamper with refrigerator controls.

11. DO NOT service or replace any part of refrigerator unless

specifically recommended in Owner’s Manual or published

user-repair instructions. DO NOT attempt service if instructions

are not understood or if they are beyond personal skill level.

12. Always disconnect refrigerator from electrical supply before

attempting any service. Disconnect power cord by grasping

the plug, not the cord.

13. Install refrigerator according to Installation Instructions. All

connections for water, electrical power and grounding must

comply with local codes and be made by licensed personnel when required.

14. Keep your refrigerator in good condition. Bumping or dropping refrigerator can damage unit or cause unit to malfunction or leak. If damage occurs, have refrigerator checked by

qualified service technician.

15. Replace worn power cords and/or loose plugs.

16. Always read and follow manufacturer’s storage and ideal

environment instructions for items being stored in refrigerator.

Page 4

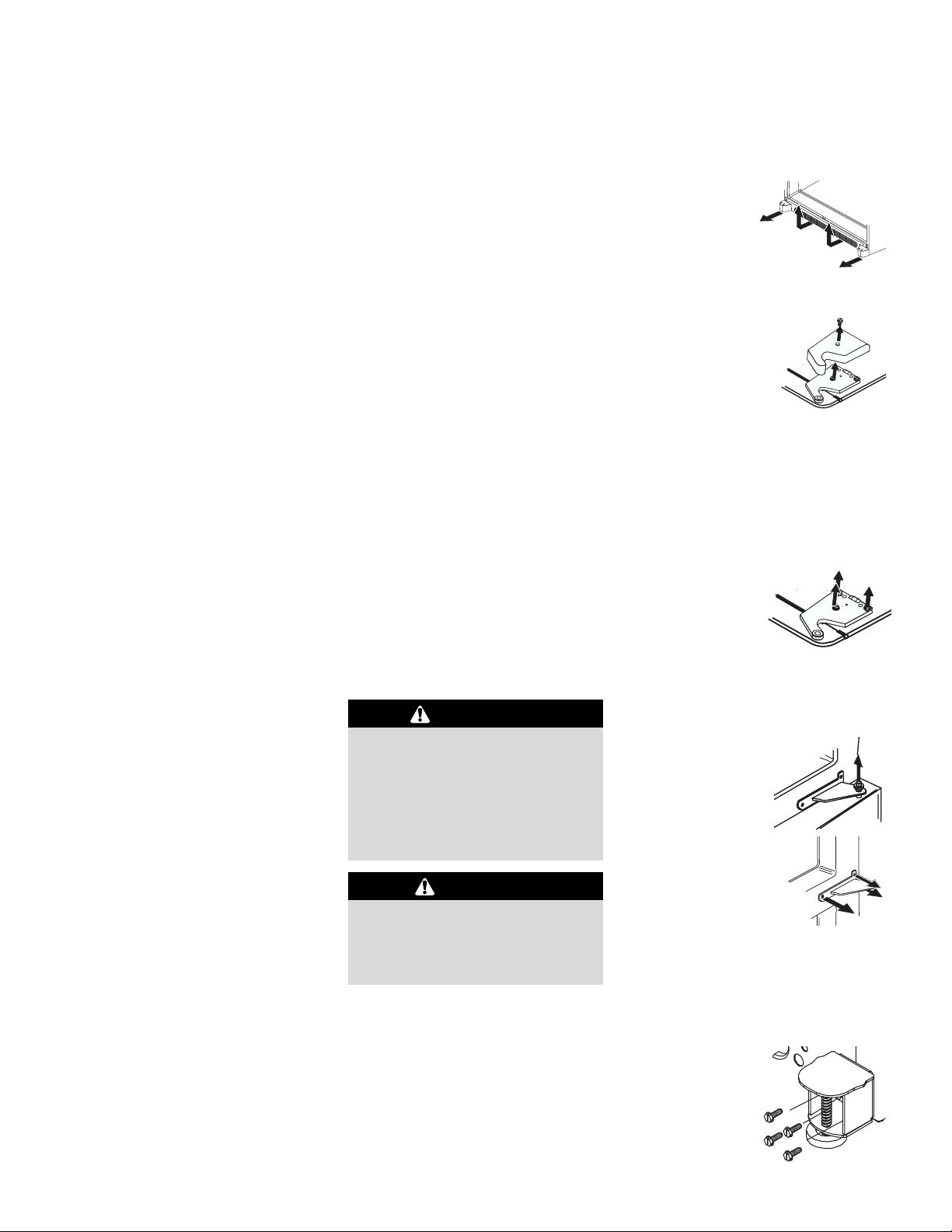

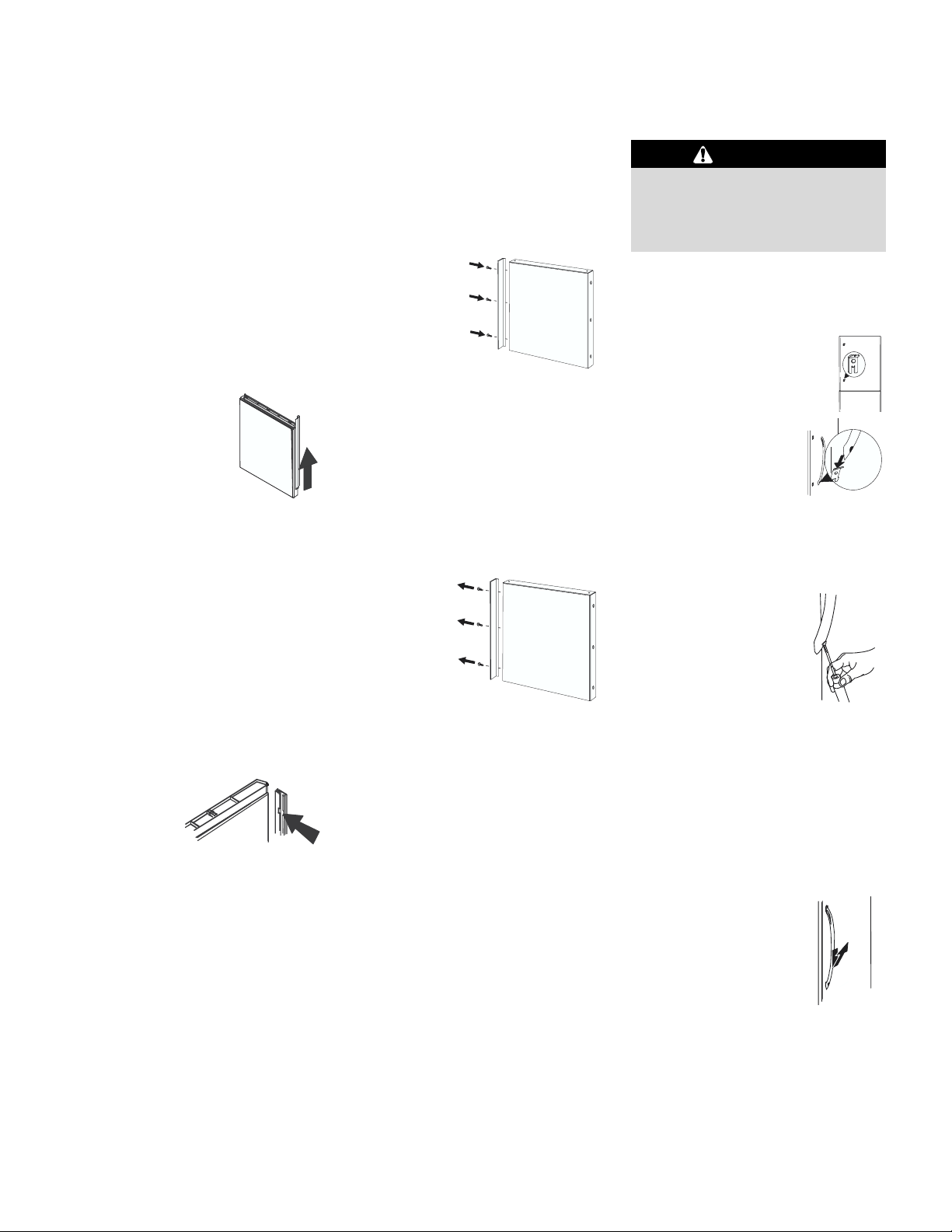

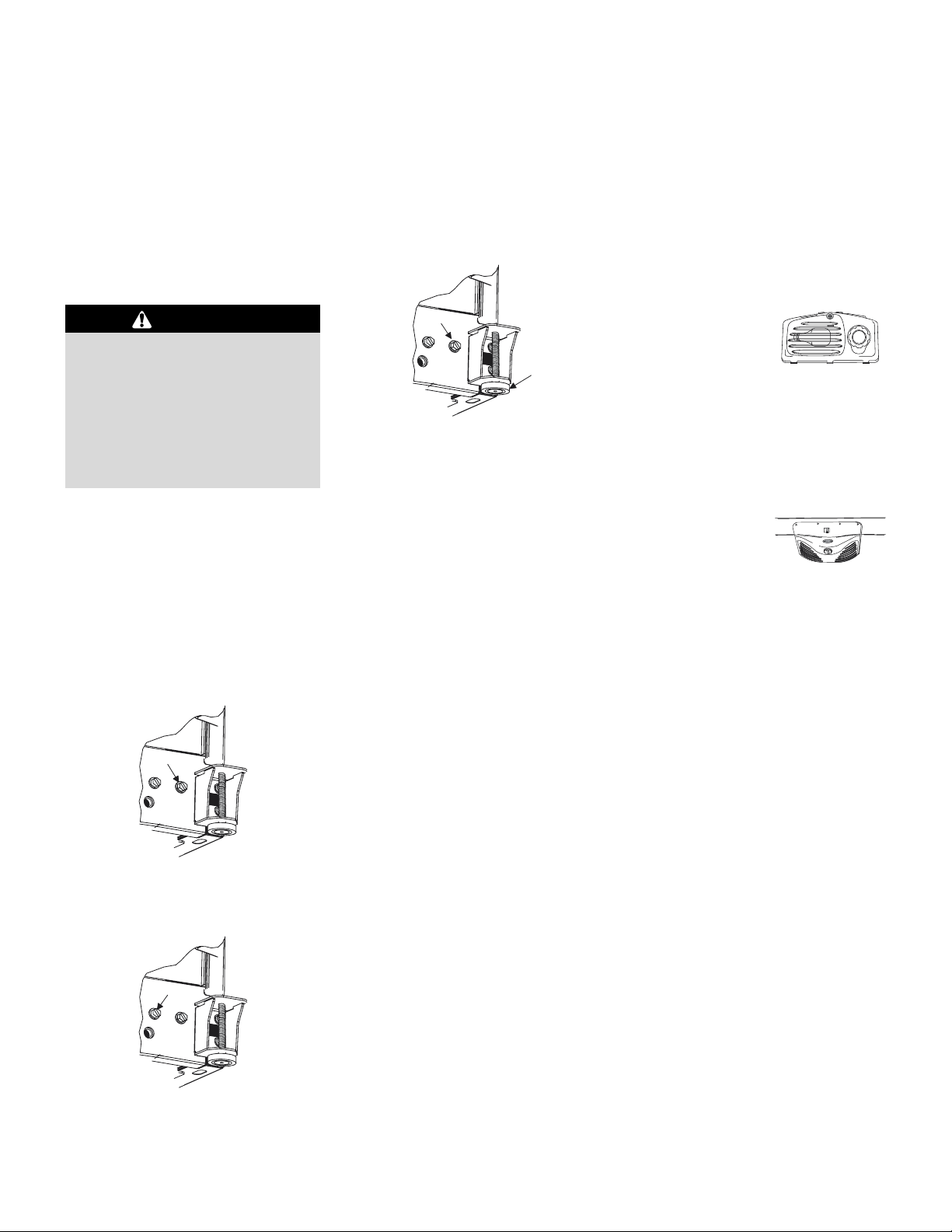

1. Unplug power cord from power

source.

2. Remove toe

grille and bottom bracket

cover.

• Open freezer door

(some models) as wide as possible.

3. Remove top hinge

cover from refrigerator door by removing Phillips screw

(non-trim models

only).

• Retain screw and cover for replace-

ment.

4. Remove top door trim with Phillips

screw (trim models only).

• Retain screw and trim for replace-

ment.

5. Unscrew

5

Ú16" hex

head screws from

top hinge to

remove hinge.

• Retain hinge and all screws for later

use.

6. Lift refrigerator door from center hinge

pin.

7. Remove center

hinge pin with a

5

Ú16" hex nut driver.

• Retain hinge pin

for later use.

8. Remove Phillips

screws to remove

center hinge.

• Retain hinge and all screws for later

use.

9. Remove both stabilizing brackets with

3

Ú8" hex head driver.

•Retain screws and brackets for later

use.

4

Installing your refrigerator

These instructions were provided to aid

you in the installation of your refrigerator.

Amana is not responsible for improper

installation.

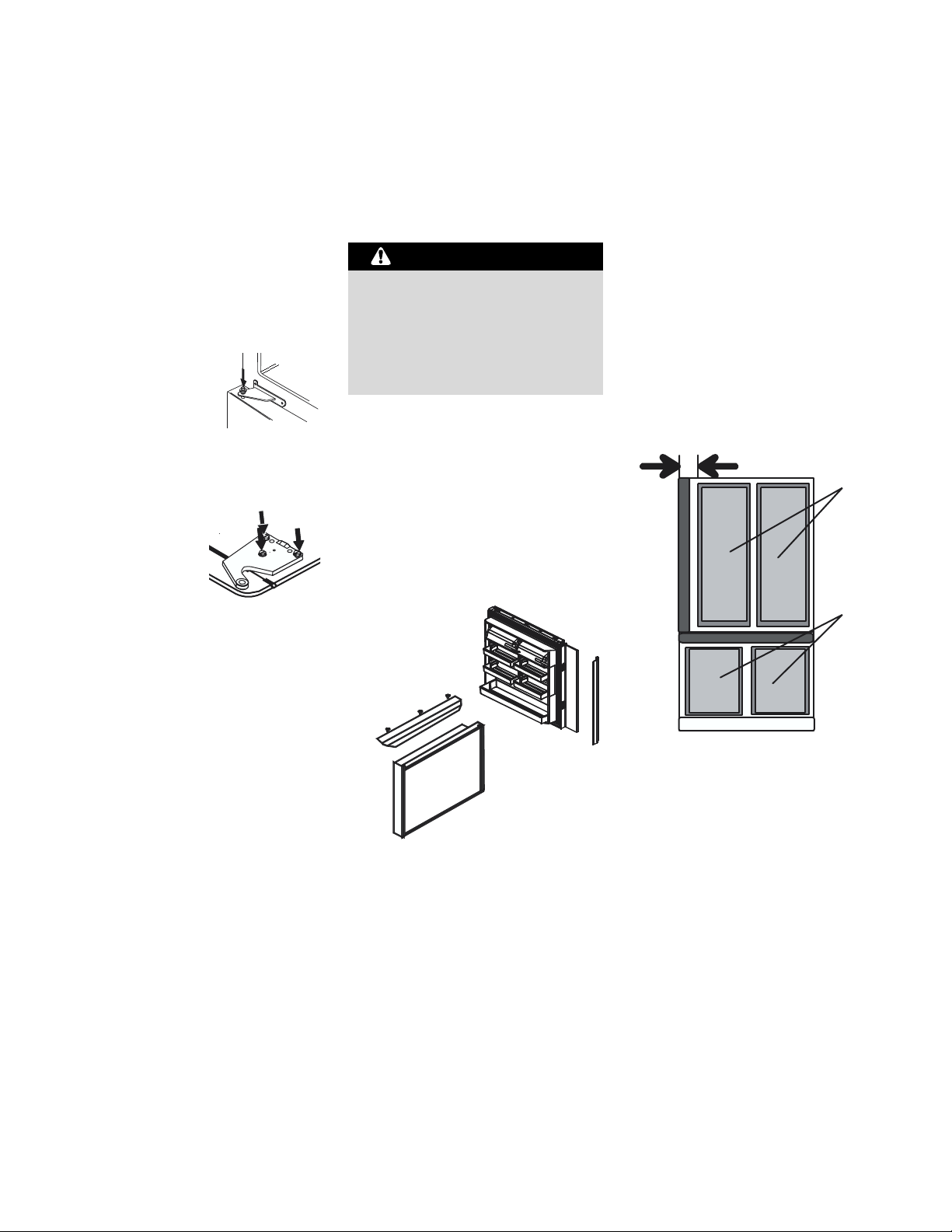

Measuring the opening

A

1

Ú2" of air space should be provided for

the top and back of the unit to allow for

proper air circulation. When installing

your unit, measure carefully.

Subflooring or floor coverings (i.e. carpet,

tile, wood floors, rugs) may make your

opening smaller than anticipated.

Some clearance may be gained by using

the leveling procedure under How to

Level Your Refrigerator.

IMPORTANT: If unit is to be installed into

a recess where top of unit is completely

covered, use dimensions from floor to top

of hinge cap to verify proper clearance.

Transporting your

refrigerator

Follow these tips when moving the unit to

final location:

➢ NEVER transport unit on its side. If an

upright position is not possible, lay unit

on its back. Allow unit to sit upright for

approximately 30 minutes prior to

plugging unit in to assure oil return to

the compressor. Plugging unit in

immediately may cause damage to

internal parts.

➢ Use an appliance dolly when moving

unit. ALWAYS truck unit from its

side–NEVER from its front or back.

➢ Protect outside finish of unit during

transport by wrapping cabinet in blankets or inserting padding between the

unit and dolly.

➢ Secure unit to dolly firmly with straps

or bungee cords. Thread straps

through handles when possible. DO

NOT overtighten. Overtightening

restraints may dent or damage outside

finish.

Selecting the best

location

Observe these points when choosing the

final location for your unit:

➢ DO NOT install refrigerator near oven,

radiator or other heat source. If not

possible, shield unit with cabinet

material.

➢ DO NOT install where temperature

falls below 55° F (13° C). Malfunction

may occur at this temperature.

➢ Make sure floor is level. If floor is not

level, shim rear wheels of unit with a

piece of plywood or other shim material.

➢ To assure proper door closure, verify

that the unit is leveled with a

1

Ú4" tilt to

the back.

How to remove the

doors and hinges

Some installations require door removal

to get refrigerator to final location.

To avoid electrical shock which can

cause severe personal injury or death,

observe the following:

➢ Disconnect power to refrigerator

before removing doors. Connect

power only after replacing doors.

WARNING

To avoid damage to walls and flooring,

protect soft vinyl or other flooring with

cardboard, rugs or other protective

material.

CAUTION

Page 5

5

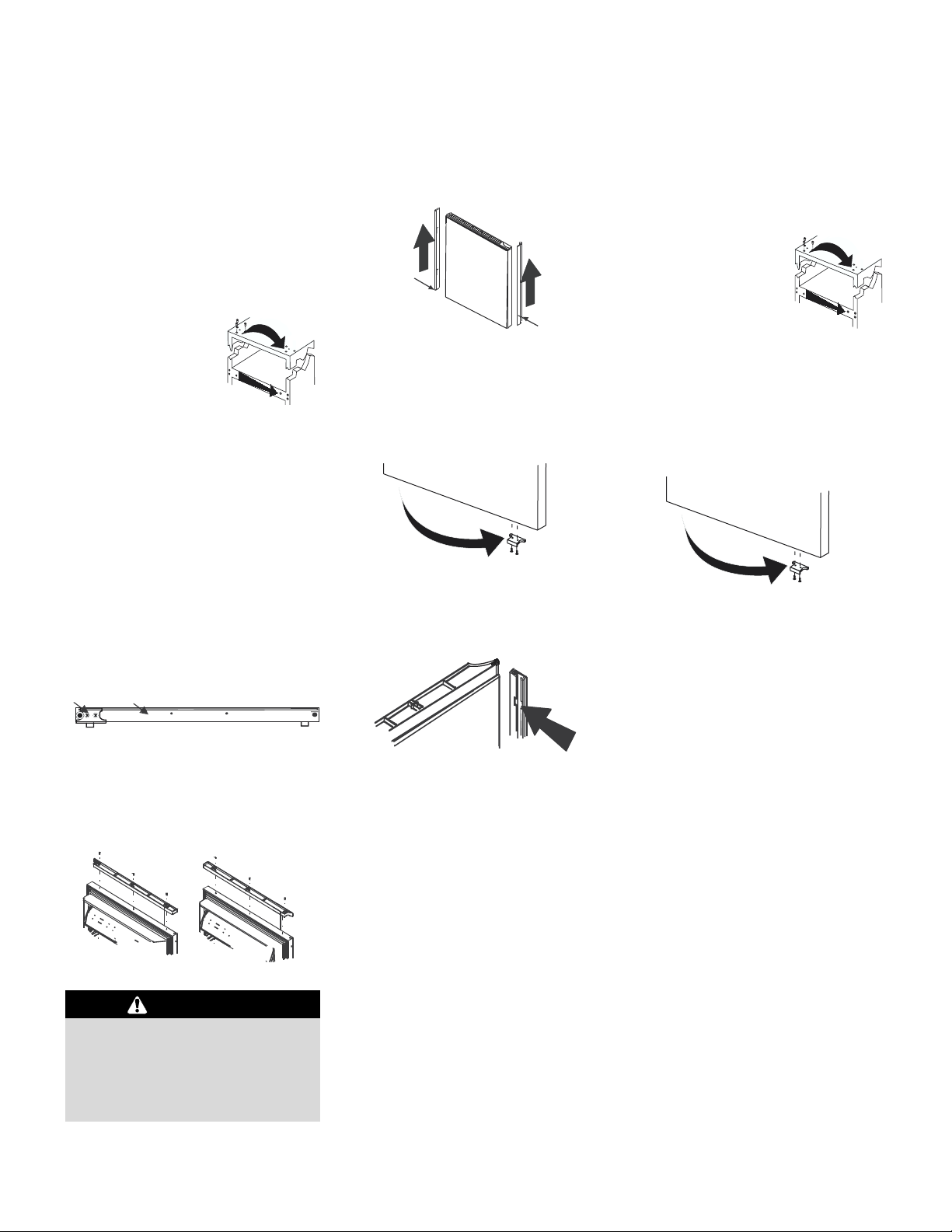

How to reverse

refrigerator door

DOORS WITH TRIM AND

PANELS

1. Perform all steps listed in How to

Remove the Doors and Hinges.

2. Transfer cabinet

plugs and screws to

opposite side of

cabinet.

3. Remove plugs with flat blade of screwdriver wrapped in masking tape.

4. Remove center mullion screws with

5

Ú16

" hex head driver.

IMPORTANT: When working directly on

doors, place doors on a nonabrasive surface protected by towels or rugs to avoid

damage to door finish.

5. Locate door stop (A) and door cap (B)

on bottom edge of fresh food door.

Remove with a Phillips screwdriver.

• Retain all items for later replace-

ment.

6. Remove top door extension with

1

Ú4"

hex head driver. Flip door extension

(A) so notched corner turns in toward

interior of door (B).

7. Remove side door trim (A) and handle

trim (B) from door by tapping bottom

edges upward with soft rubber mallet.

•Trim will slide up approximately

3

Ú4"

and release from door.

8. Replace bottom door cap removed

previously. Install door stop on opposite side of door.

9. Retrieve alternate side door trim

shipped with refrigerator. Install trim

by aligning notches of trim with metal

mounting tabs on side of door.

• Slide trim down until piece locks into

place.

•Tap top of trim with rubber mallet to

insure snug fit.

10 . Remove tape from panels.

11. Proceed to How to Install and

Remove Handles to reinstall handle.

To avoid possible injury and damage

to property, tape decorative panels

(some models) securely into place

before removing side door trim and

handles.

WARNING

STANDARD

REFRIGERATOR DOOR

1. Perform all steps listed in How to

Remove the Doors and Hinges.

2. Transfer cabinet

plugs and cabinet

screws to opposite

side of cabinet.

3. Remove cabinet

plugs with flat blade screwdriver tip

wrapped in masking tape.

4. Remove center mullion screws with

5

Ú16" hex head driver.

5. Transfer door stop to opposite edge of

door using Phillips screwdriver.

IMPORTANT: When working directly on

doors, place doors on a nonabrasive surface protected by towels or rugs to avoid

damage to door finish.

6. See How to Install and Remove

Handles to remove and reinstall

handles.

7. Proceed to How to Replace the

Doors and Hinges to mount doors.

B

A

B

A

A

B

Page 6

6

Installing your refrigerator,

cont.

How to install and

remove handles

REMOVING TRIM AND

PANEL FRESH FOOD

HANDLE

Removing handles is necessary when

removing panels, or when reversing the

door.

1. Remove top door cap using a Phillips

screwdriver.

2. Remove handle from

door by tapping

bottom edge upward

with soft rubber

mallet.

• Handle will slide up approximately

3

Ú4"

and release from door.

INSTALLING TRIM AND

PANEL FRESH FOOD

HANDLE

Installing handles may be necessary after

reversing door or installing a panel.

1. Make sure bottom door cap is installed

and top door cap is removed.

• Use a Phillips screwdriver for instal-

lation and removal.

2. Install handle by

aligning handle

notches with

metal mounting

tabs on side of door.

• Slide handle down until piece locks.

•Tap top of handle with rubber mallet

to insure snug fit.

IMPORTANT: If reversing trim and panel

door, use alternate top hinge shipped

with refrigerator.

3. Install top door cap with Phillips

screwdriver.

INSTALLING FRESH FOOD

SIDE-MOUNTED HANDLE

If installing handles for the first time, the

Fresh Food handles can be located on

the back of the refrigerator.

➢ Install handle

by fastening

with T-15

Torx®* screws

removed from

edge of door.

NOTE: If reversing door, remove door plugs from opposite side of door and insert in screw

holes.

REMOVING FRESH FOOD

SIDE-MOUNTED HANDLE

Removing handles may be necessary

when transporting unit through tight

spaces, or when reversing the door.

➢ Remove

handle by

removing

three

T-15 Torx®*

screws

from side of

door.

• Retain screws for later replacement.

* Torx

®

is a registered trademark of Textron Inc.

To avoid risk of serious personal injury

from sharp edges, use extreme

caution when removing and installing

handles.

WARNING

INSTALLING STAINLESS

STEEL FRONT -MOUNTED

HANDLES

1. Loosen door clip on door

with

1

Ú4" hex nut driver.

2. Locate predrilled hole at

base of handle, and fit

hollow end of handle

over door clip.

3. Fit other end of handle

over other door clip and

slide handle up as far as possible.

NOTE: If top of handle does not fit over

top clip, loosen lower clip further until fit

can be accomplished.

4. Insert

1

Ú4" hex nut driver

into predrilled hole at

base of handle to tighten screw. Insert screw

plug into hole.

REMOVING STAINLESS

STEEL FRONT-MOUNTED

HANDLES

1. Remove screw plug at base of handle

with a very small flat-blade screwdriver.

2. Insert

1

Ú4" hex nut driver into predrilled

hole to remove screw.

3. Slide handle down and

out to remove from

door clip.

Page 7

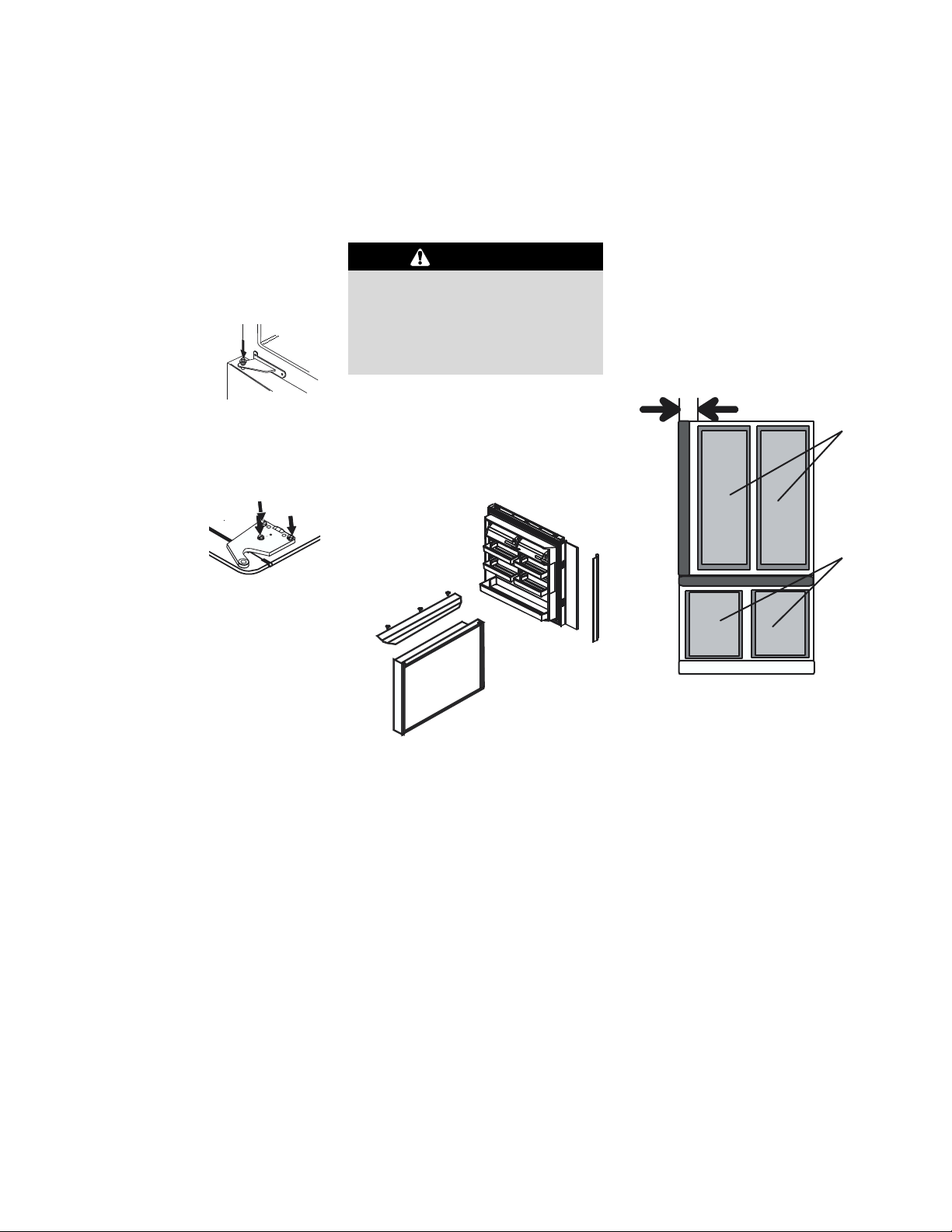

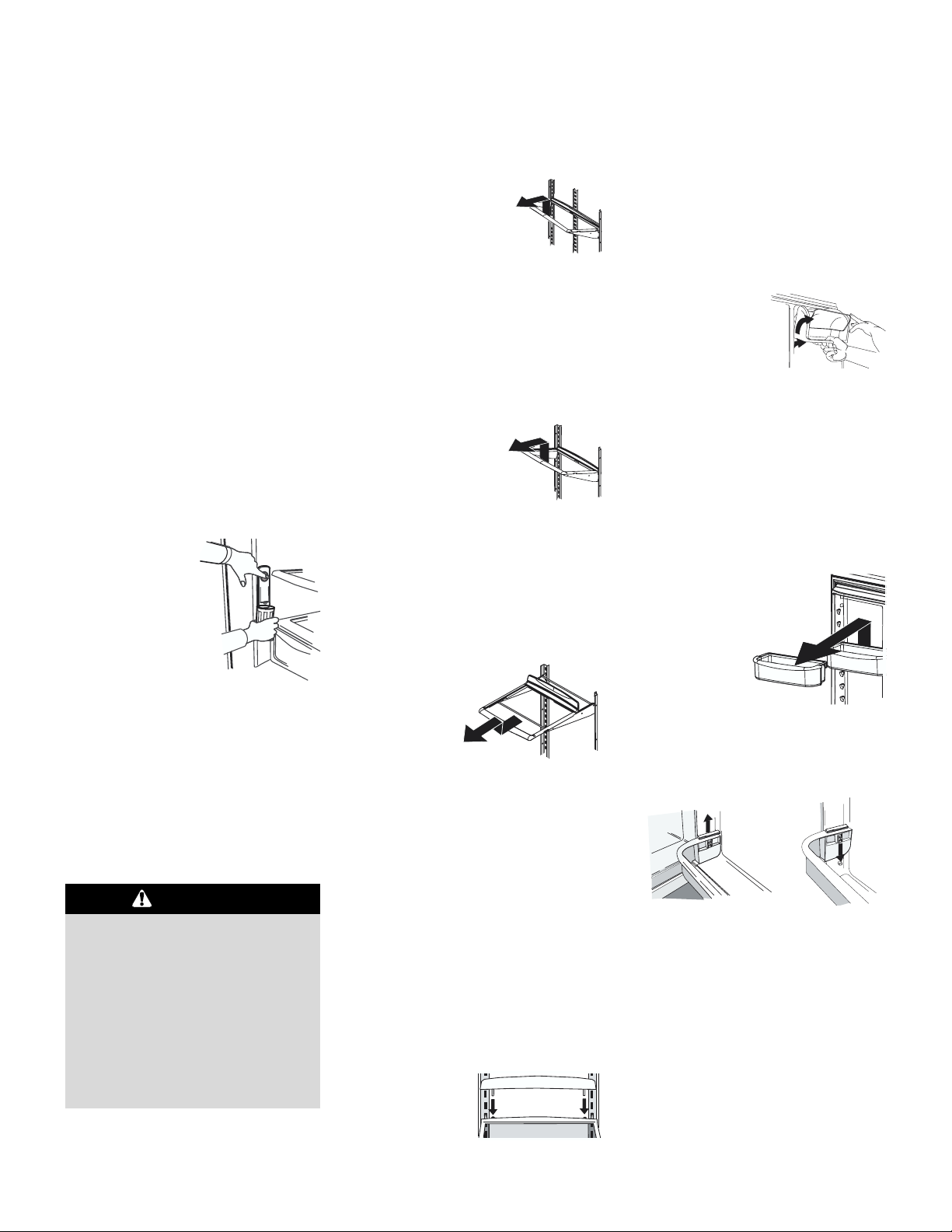

➢ To remove panels, remove door han-

dle and slide panel out the handle side

of door.

➢ Install panels by sliding panel in

grooves provided by bottom door cap

and side trim.

➢ Replace the

handles, when

completed.

7

How to replace the

doors and hinges

1. Install hinge assemblies.

2. Install center hinge with Phillips

screws.

3. Install stabilizing bracket with

3

Ú8" hex

head screws.

4. Install center

hinge pin with

5

Ú16"

hex head driver.

5. Place hinge side of refrigerator door

on center hinge pin.

6. While holding refrigerator door

upright, tighten down top hinge with

5

Ú16" hex head driv-

er. Replace hinge

cover (some models).

To avoid personal injury or property

damage, fresh food panel should not

weigh more than 30 lbs (14 kgs) and

freezer panel should not weigh more

than 15 lbs (7 kgs).

WARNING

How to remove and

install panels

(SOME MODELS)

WHAT IF I AM INSTALLING

RAISED PANELS?

If raised panels are used, allow 2

1

Ú2" (A)

minimum clearance between raised edge

of panel and handle.

Please see the recommended dimensions for panelling.

Raised Panel B – 42" x 35

5

Ú8"

(106.7 cm x 90.5 cm)

Raised Panel C – 23

1

Ú4" x 361Ú16"

(59.1 cm x 91.6 cm)

B

C

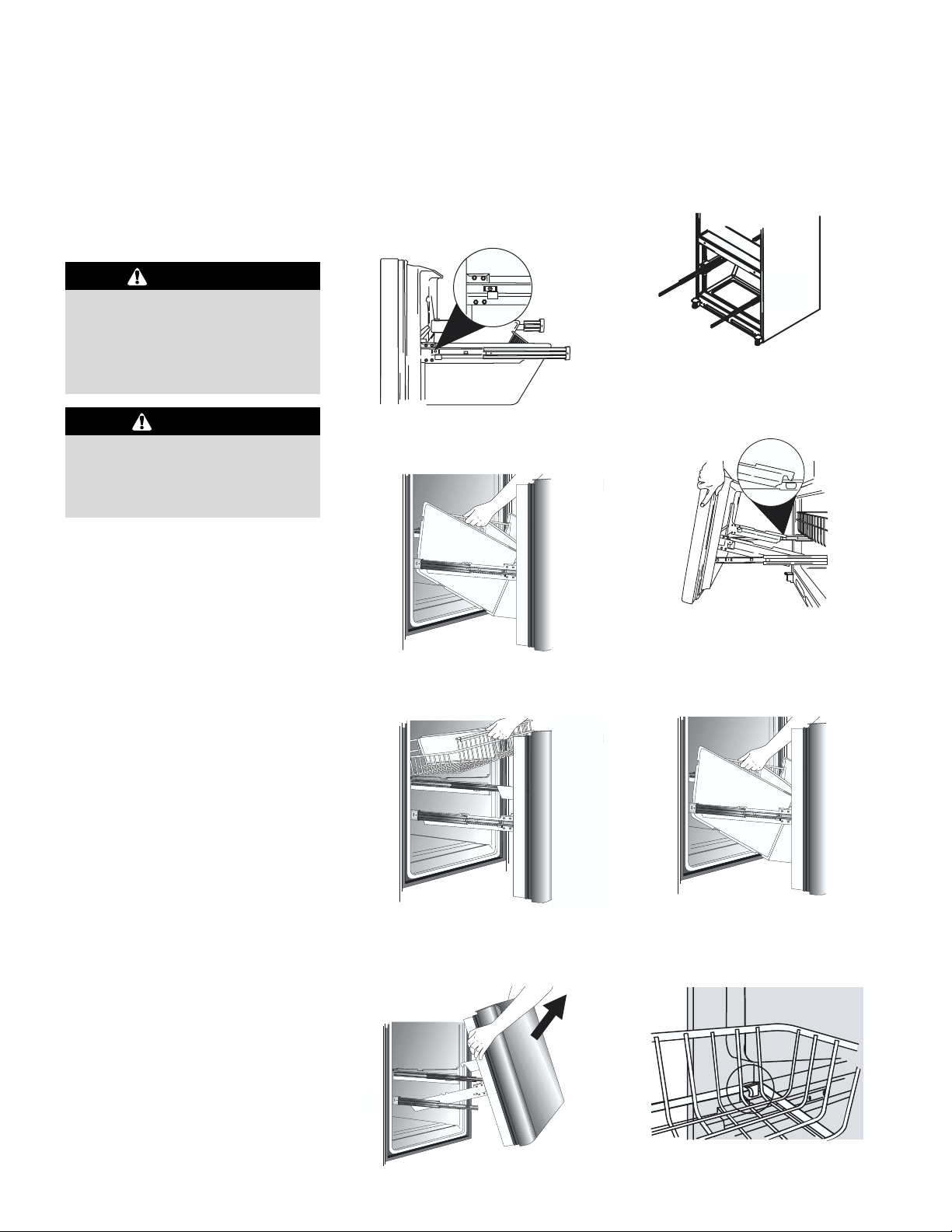

Page 8

8

Installing your refrigerator,

cont.

How to remove and

install the pullout

drawer

To avoid electrical shock which can

cause severe personal injury or death,

disconnect power to refrigerator

before removing doors. After replacing

doors, connect power.

WARNING

To avoid possible injury, product, or

property damage, you will need two

people to perform the following

instructions.

CAUTION

REMOVING PULLOUT

DRAWER

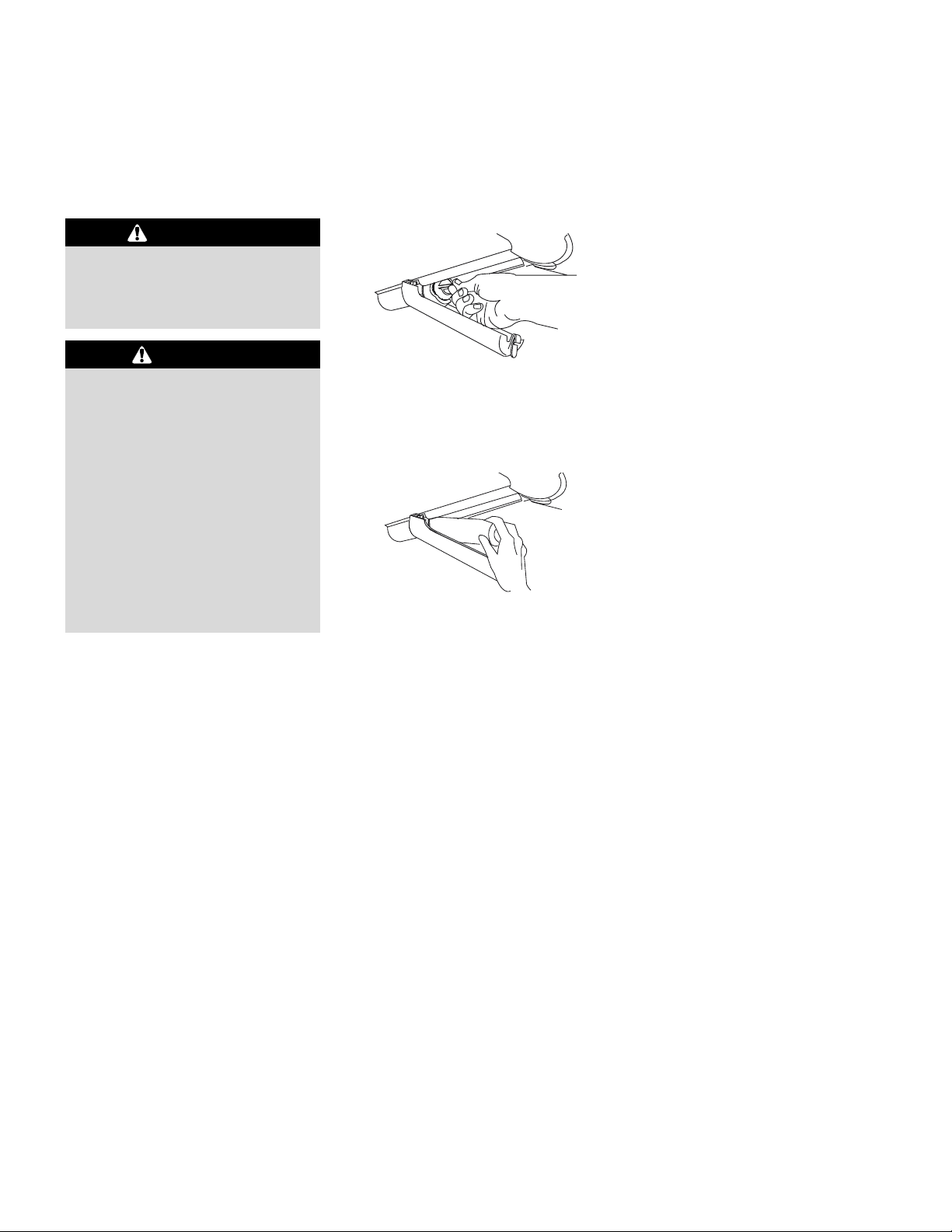

1. Pull drawer open to full extension.

Remove Phillips screw from each side

of rail system.

2. Remove lower basket by lifting basket

from rail system.

3. Pull upper basket out to full extension,

and lift out to remove.

4. Lift top of door to unhook door

supports from rail system. Lift door out

to remove.

INSTALLING PULLOUT

DRAWER

1. Pull both rails out to full extension.

2. Hook door supports into rail tabs, as

illustrated, and lower door into final

position.

3. With drawer pulled out to full extension, insert lower basket by aligning

tabs on both side of lower basket with

notches in rail assembly.

4. Slide upper basket into unit. Make

sure that rear of basket hooks behind

rail catch.

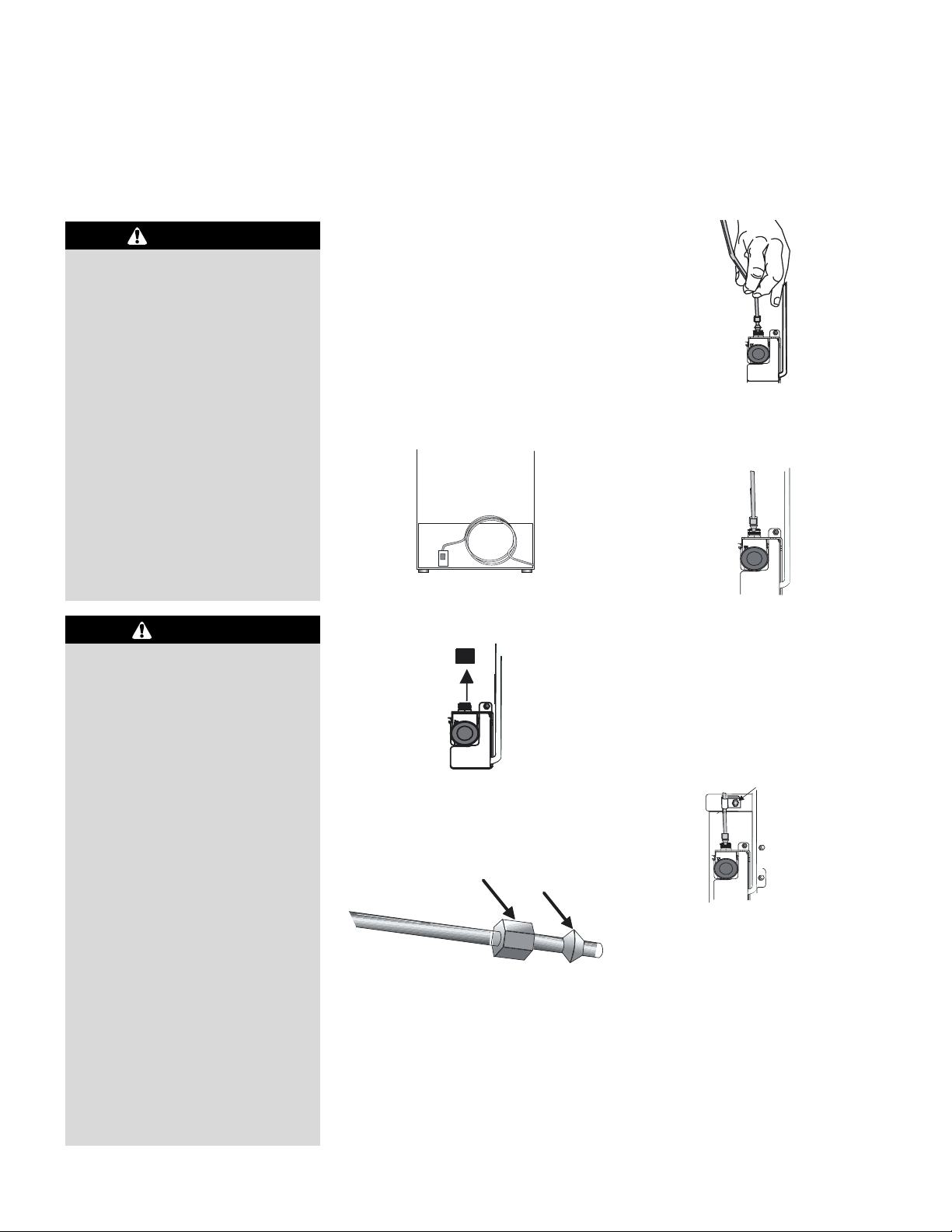

Page 9

4. Place end of copper tubing into water

valve inlet port. Shape tubing slightly –

DO NOT KINK – so that tubing feeds

straight into inlet port.

5. Slide brass nut over sleeve and screw

nut into inlet port. Tighten nut with

wrench.

IMPORTANT: DO NOT overtighten.

Cross threading may occur.

6. Pull on tubing to confirm connection is

secure. Connect tubing to frame with

water tubing clamp (C) and turn on

water supply. Check for leaks and

correct, if present.

7. Monitor water connection for 24 hours.

Correct leaks, if necessary.

9

How to connect the

water supply

To reduce the risk of injury or

death, follow basic precautions,

including the following:

➢ Read all instructions before

installing device.

➢ DO NOT attempt installation if

instructions are not understood or if

they are beyond personal skill

level.

➢ Observe all local codes and ordi-

nances.

➢ DO NOT service device unless

specifically recommended in

owner’s manual or published userrepair instructions.

➢ Disconnect power to unit prior to

installing device.

WARNING

To avoid property damage or possible injury, follow basic precautions,

including the following:

➢ Consult a plumber to connect

copper tubing to household plumbing to assure compliance with local

codes and ordinances.

➢ Confirm water pressure to water

valve is between 20 and 100

pounds per square inch. If water

filter is installed, water pressure to

water valve must be a minimum of

35 pounds per square inch.

➢ DO NOT use a self-piercing, or

3

Ú16"

saddle valve! Both reduce water

flow, become clogged with time,

and may cause leaks if repair is

attempted.

➢ Tighten nuts by hand to prevent

cross threading. Finish tightening

nuts with pliers and wrenches. Do

not overtighten.

➢ Wait 24 hours before placing unit

into final position to check and

correct any water leaks.

CAUTION

MATERIALS NEEDED

➢

1

Ú4" outer diameter flexible copper

tubing

➢ Shut-off valve (requires a

1

Ú4" hole to be

drilled into water supply before valve

attachment)

➢ Adjustable wrench

➢

1

Ú4" hex nut driver

NOTE: Add 8' to tubing length needed to

reach water supply for creation of service

loop.

1. Create service loop with tubing using

care to avoid kinks in tubing.

2. Remove plastic cap from water valve

inlet port.

C

3. Place brass nut (A) and sleeve (B) on

copper tube end as illustrated.

A

B

Page 10

10

Installing your refrigerator,

cont.

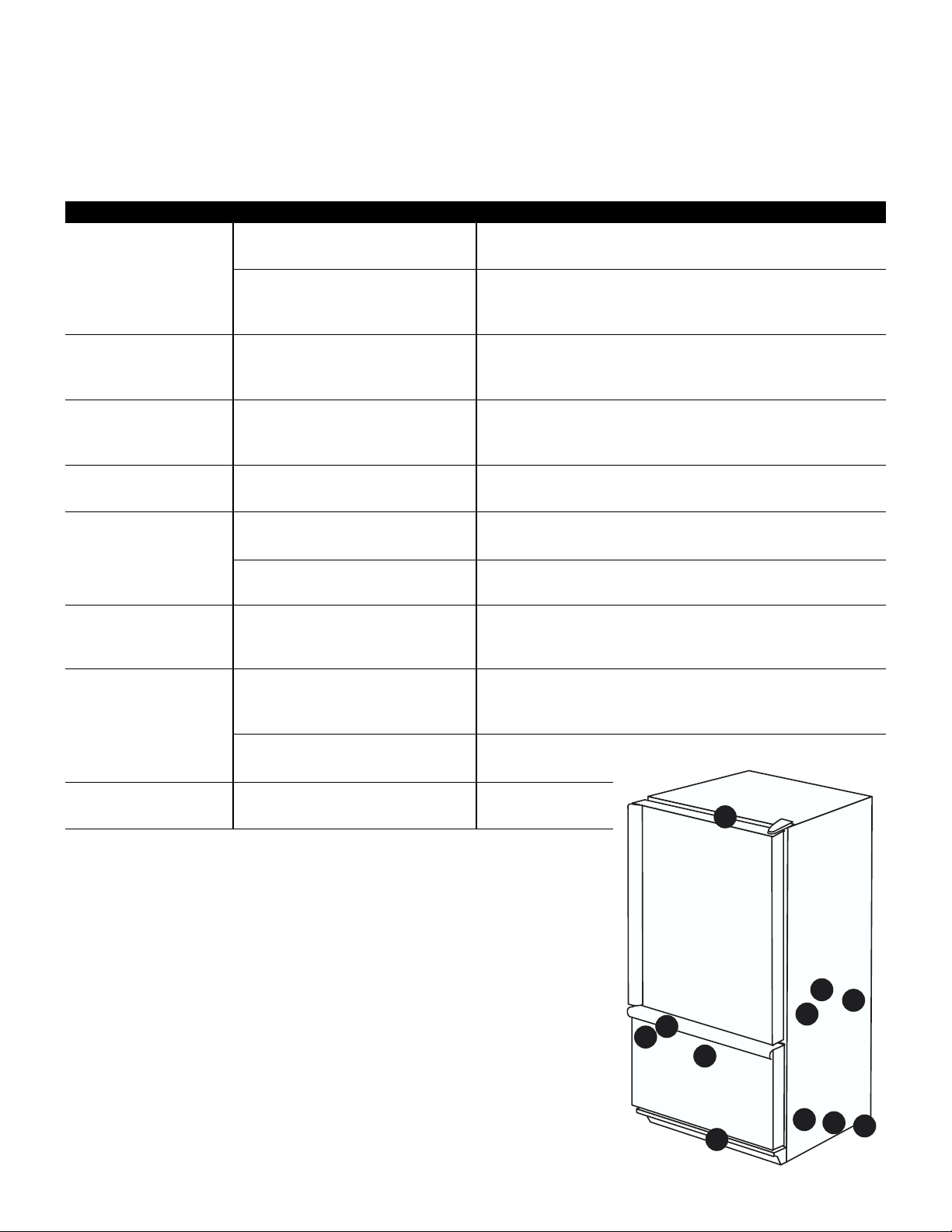

How to level your

refrigerator

If your refrigerator requires an ice maker

water supply connection, proceed to How

to connect the water supply section

before leveling your refrigerator.

To protect personal property or unit

from damage, observe the following:

➢ Protect soft vinyl or other flooring

with cardboard, rugs, or other

protective material.

➢ Do not use power tools when

performing leveling procedure.

CAUTION

MATERIALS NEEDED

➢

3

Ú8" hex head driver

➢ Level

1. Remove toe grille and bottom hinge

covers (see previous instructions).

2. Turn both front adjustment screws (A)

clockwise to raise and counterclockwise to lower.

3. Turn both rear adjustment screws (B)

clockwise to raise and counterclockwise to lower.

4. Turn stabilizing legs (C) clockwise

until firmly against floor.

5. Turn front roller adjustment screws (A)

2 to 3 times counterclockwise, so that

full weight of unit rests on stabilizing

legs (C).

6. Using a level, make sure front of

refrigerator is

1

Ú4" (6 mm) or 1Ú2 bubble

higher than back of refrigerator. See

leveling step 3 for assistance.

7. Replace toe grille and bracket

cover(s). See markings on inside of

toe grille to insure proper placement.

Snap bottom portion into place

first. Press down on top part of grille

until top portion snaps into place.

How to adjust the

temperature controls

This refrigerator is designed to operate at

a household temperature of 55° to 110° F

(13° to 43° C). For initial temperature

setting, follow all five steps listed below. If

doing a simple temperature modification

for an operational unit, only steps 3

through 5 are required.

A

B

A

C

1. Locate refrigerator controls at the top

of fresh food compartment and freezer

controls at top of freezer section. Set

both controls to 4.

IMPORTANT: Neither section will cool if

freezer control is set to Off.

2. Allow 24 hours for temperatures to

stabilize.

3. Check to see if

freezer temperature is 0° to 2° F

(-17° to -16° C).

➢ Turn control to next highest number

if too warm.

➢ Turn control to next lowest number

if too cold. Allow 5 to 8 hours for

adjustments to take effect.

4. Check to see that

fresh food section

is 38° to 40° F

(3° to 4° C).

➢ Turn control to next highest number

if too warm.

➢ Turn control to next lowest number

if too cold.

➢ Allow 5 to 8 hours for adjustments

to take effect.

5. Repeat steps 3 & 4, as necessary.

HOW DO I PERFORM A

TEMPERATURE TEST?

MATERIALS NEEDED

➢ 2 thermometers measuring -5° to

50° F (-21° to 10° C)

➢ 2 drinking glasses

For Freezer

➢ Place thermometer in glass of

vegetable oil in middle of freezer and

continue with step 3 of temperature

adjustment section.

IMPORTANT: Always start temperature

adjustments with freezer section.

For Refrigerator

➢ Place thermometer in glass of water in

middle of unit and continue with step 3

of temperature adjustment section.

Page 11

11

About your water filter...

Water filter removal and

installation

To avoid serious illness or death, do

not use unit where water is unsafe or

of unknown quality without adequate

disinfection before or after use of filter.

WARNING

➢ Bypass cartridge DOES NOT filter

water. Be sure to have replacement cartridge available when filter

change is required.

➢ If water filtration system has been

allowed to freeze, replace filter

cartridge.

➢ If system has not been used for

several months, and water has an

unpleasant taste or odor, flush

system by dispensing 2–3 glasses

of water. If unpleasant taste or odor

persists, change filter cartridge.

CAUTION

INITIAL INSTALL OF

WATER FILTER

1. Remove blue bypass cap and retain

for later use.

2. Remove sealing label from end of filter

and insert into filter head.

3. Rotate gently clockwise until filter

stops, and snap filter cover closed.

4. Reduce water spurts by flushing air

from system. Run water continuously

for 2 minutes through dispenser until

water runs steady.

➢ Additional flushing may be required

in some households where water is

of poor quality.

REPLACING WATER

FILTER

IMPORTANT: Air trapped in system may

cause water and cartridge to eject. Use

caution when removing.

1. Turn filter counterclockwise until it

releases from filter head.

2. Drain water from filter into sink, and

dispose in normal household garbage.

3. Wipe up excess water in filter cover

and continue with Initial Install of

Water Filter, steps 2 and 3.

WHEN DO I CHANGE THE

WATER FILTER?

The filter should be changed approximately every 6 months.

IMPORTANT: Condition of water and

amount used determines life span of

water filter cartridge. If water use is high,

or if water is of poor quality, replacement

may need to take place more often.

HOW DO I ORDER A

REPLACEMENT FILTER

CARTRIDGE?

Amana®Replacement Water Filter cartridge model WF 50 is available through

Amana®dealers and servicers. You may

also order through Amana®Consumer

Affairs by using the information on the

cover of your manual.

I'M TRYING TO DISPENSE

WATER TO FLUSH THE

SYSTEM. WHERE'S THE

WATER?

During initial use, allow about a 1 to 2

minute delay in water dispersal to allow

internal water tank to fill.

WHAT IF I CHOOSE NOT

TO USE THE WATER

FILTRATION SYSTEM?

Dispenser feature may be used without

water filter cartridge. If you choose this

option, replace filter with blue bypass

cap.

Page 12

12

Fresh food features

Primary features

HOW CAN I CLEAN OUT

MY WATER SUMP?

The sump has been designed for easyaccess cleaning.

The cup-style sump can be removed by

sliding straight up out of the sump frame.

It may be required to clean the sump to

remove water or mineral deposits. These

items ARE NOT dishwasher-safe. Sumps

may be washed with soap and water.

IMPORTANT: The sump does not

contain a drain.Spills must be wiped up

occasionally to remove water.

WATER DISPENSER

(SOME MODELS)

A water dispenser is

located on the left

side wall of the fresh

food section. This

design is for cold

water dispensing

only. A water sump

has been designed

below the dispenser to catch drips and

minor spills.

To dispense water:

➢ Hold container under spout and press

dispenser pad, as illustrated.

Interior shelves

To avoid personal injury or property

damage, observe the following:

➢ Confirm shelf is secure before

placing items on shelf.

➢ Handle tempered glass shelves

carefully. Shelves may break

suddenly if nicked, scratched, or

exposed to sudden temperature

change.

CAUTION

FULL-WIDTH SHELF

(SOME MODELS)

➢ To remove shelves,

unhook shelf from

rear ladder assembly

and pull out.

➢ To install shelves, insert shelf hooks

into rear ladder assembly and lower

into place.

SPILLSAVER™

STATIONARY SHELVES

(SOME MODELS)

Spillsaver™ stationary

shelves hold simple

spills for easier cleaning.

➢ To remove shelves, lift up

and out.

➢ To install shelves, reverse above

procedure.

SPILLSAVER™

EASYGLIDE™

(SOME MODELS)

Spillsaver™ EasyGlide™

shelves feature the

convenience of

easy cleaning

with a pullout

design to reach

items in the back. For ease of cleaning,

glass shelf may be removed by pulling to

full extension and lifting out of frame.

➢ To remove shelf and frame, see

instructions for Spillsaver™ stationary

shelves.

REAR SHELF

EXTENSIONS

(SOME MODELS)

Rear shelf extensions help prevent

articles from falling off the back of the

shelf.

To remove and install shelf extension:

➢ To remove,

pull extension

straight up

from rear of

shelf.

➢ To install, insert posts of the shelf

extension into holes in the shelf frame.

Door storage

DAIRY CENTER

The dairy center

provides convenient

storage for items

such as butter,

yogurt, cheese, etc.

This compartment is an adjustable

feature located in the door. It can be

moved to several different locations to

accommodate storage needs.

➢ To remove, open dairy door, pull

upward and tilt out.

➢ To install, reverse above procedure.

DOOR BUCKETS

Door buckets adjust to meet

individual storage needs.

➢ To remove, slide

bucket up and

pull straight

out.

➢ To install, reverse above procedure.

DOOR RETAINER

Door retainers remove for easy cleaning.

➢ To remove, slide retainer up and pull

straight out.

➢ To install, reverse above procedure.

Page 13

13

Climate-controlled

drawers

HUMIDITY-CONTROLLED

CRISPER DRAWERS

The crisper drawer keeps produce fresh

longer by providing an environment with

adjustable humidity.

Controls

The crisper

controls

regulate

the amount

of humidity in the crisper drawer. Use the

low setting for produce with outer skins.

Use the high setting for leafy produce.

To remove and install crisper drawers:

➢ To remove

drawer, pull

drawer out to

full extension. Tilt up

front of drawer and pull straight out.

➢ To install, insert drawer into frame rails

and push back into place.

TEMPERATURECONTROLLED DRAWER

Chef's Pantry™

The Chef's Pantry™ system provides a

drawer with a variable temperature

control that keeps the compartment up to

5° F (3° C) colder than refrigerator

temperature. This drawer can be used for

large party trays, deli items, or

beverages.

Control

The Chef's Pantry™

control regulates the air

temperature in the

drawer. Set control level

to cold to provide normal refrigerator temperature. Use the coldest setting for

meats or other deli items.

NOTE: Cold air directed to the Chef's

Pantry™ can decrease refrigerator temperature. Refrigerator control may need

to be adjusted.

Accessories

GRIP PADS

(SOME MODELS)

The Grip Pads prevents objects from sliding in

the door bucket. Grip Pads are removable and are top-rack dishwasher safe for

easy cleaning.

WINE TRIVET/CAN RACK

(SOME MODELS)

The Wine

Trivet/Can Rack

accessory fits in

the bottom of most

drawer assemblies.

Beer bottles can be laid crosswise, or a

single bottle may be laid in the center

depression. Cans may also be stored

horizontally.

PANTRY DIVIDER

(SOME MODELS)

The pantry divider is used

to organize the

Chef's Pantry™

into sections.

To remove and replace divider:

➢ To remove, raise front of divider to

unhook divider from rear wall of

pantry, and pull out.

➢ To install, hook back of divider over

rear wall of pantry and lower into

place.

NOTE: For easiest removal and replacement, remove pantry. If removal is not

possible, pull drawer open to its fullest

extension.

To remove and install pantry:

➢ To remove draw-

er, lift lid and pull

drawer out to full

extension. Tilt up

front of pantry and pull straight out.

➢ To install, push metal

glide rails to the back

of the unit. Place drawer onto rails and slide

drawer back until it falls into place.

HOW DO I REMOVE THE

GLASS AND CRISPER

FRAME IF I WANT TO

CLEAN IT?

1. Remove the drawers as instructed at

left.

2. Place hand beneath frame to push up

glass from underneath. Lift glass out.

3. Lift frame from refrigerator liner rails.

4. To install, repeat above instructions in

reverse order.

WHAT CAN I DO TO

PROLONG THE LIFE

OF MY PRODUCE?

Please observe the following rules when

storing produce in humidity-controlled

crisper drawers:

➢ DO NOT wash produce before placing

in crispers. Any additional moisture

added to the drawers may cause produce to prematurely spoil.

➢ DO NOT line crispers with paper

towels. Towels will retain moisture.

➢ DO NOT place leafy vegetables in the

temperature-controlled drawer. Colder

temperatures will damage leafy produce.

➢ Follow control instructions carefully.

Not setting controls correctly may

damage produce.

See chart below for assistance with

humidity drawer controls:

LOW • cauliflower • apples

• corn • oranges

• zucchini • grapes

• cucumbers

HIGH • lettuce • asparagus

• spinach • cabbage

• celery • broccoli

• fresh sprouts • fresh herbs

Page 14

14

Freezer features

Primary features

AUTOMATIC ICE MAKER

(SOME MODELS)

Using Ice Maker for the First Time

1. Confirm ice bin is in

place and ice maker

arm is down.

2. After freezer section reaches between

0° to 2° F (-18° to -17° C), ice maker

fills with water and begins operating.

3. Allow approximately 24 hours after

installation to receive first harvest of

ice.

4. Discard ice created within first 12

hours of operation to verify system is

flushed of impurities.

Operating Instructions

1. Confirm ice bin is in place and ice

maker arm is down.

2. After freezer section reaches 0° to 2° F

(-18° to -17° C), ice maker fills with

water and begins operating. You will

have a complete harvest of ice

approximately every 3 hours.

3. Stop ice production

by raising ice maker

arm until click is

heard.

4. Ice maker will remain in the off position until arm is pushed down.

To avoid property damage, observe

the following:

➢ Do not force ice maker arm down

or up.

➢ Do not place or store anything in

ice storage bin.

CAUTION

To prevent accidental child entrapment or suffocation risk, DO NOT

remove the divider in the top freezer

basket.

DANGER

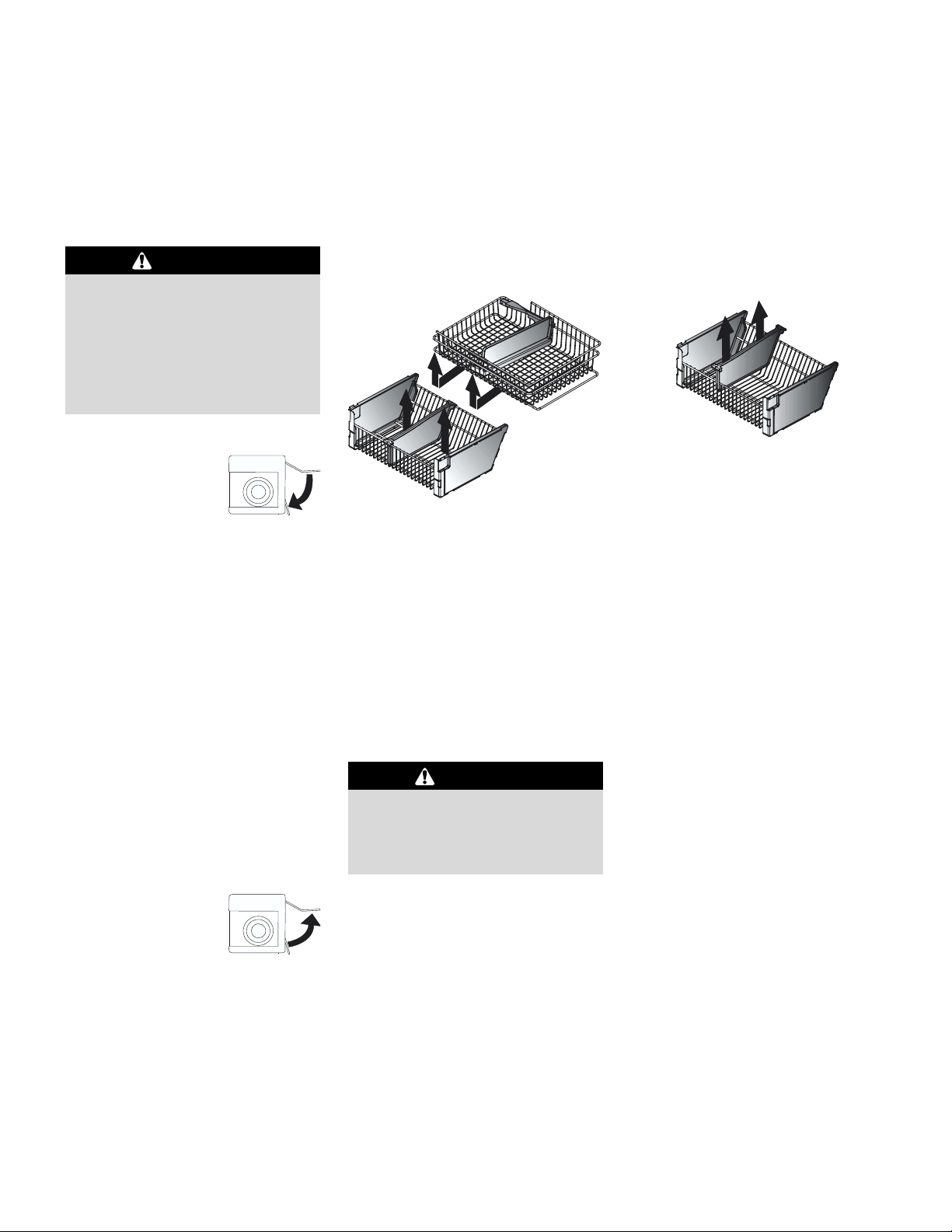

Drawers

PULLOUT DRAWER

BASKETS (SOME MODELS)

(Door assembly of drawer removed from

illustration for visual clarity)

To remove and replace top basket:

➢ Remove basket by pulling basket out

to its full extension and lift out.

➢ Replace basket by sliding into upper

molded railing.

To remove and replace bottom basket:

➢ Remove basket by lifting basket from

rail guides.

➢ Replace basket by placing into rail

guides.

Accessories

LOWER BASKET DIVIDER

(SOME MODELS)

The lower basket divider allows the

option to organize the basket area into

sections.

To remove and replace divider:

➢ To remove, pull divider straight up.

➢ To install, hook top corners of divider

over top horizontal basket rungs.

Page 15

15

Hints and Care

PART DO

➢ Use 4 tablespoons of baking soda dissolved in 1 quart (1 liter)

warm soapy water.

➢ Rinse surfaces with clean warm water and dry immediately to

avoid water spots.

➢ Use warm, soapy water and a soft, clean cloth or sponge.

➢ Rinse surfaces with clean warm water and dry immediately to

avoid water spots.

➢ Use a vacuum cleaner hose nozzle.

➢ Use a vacuum cleaner hose nozzle with brush attachment.

➢ Follow removal and installation instructions from appropriate

feature section.

➢ Allow items to adjust to room temperature.

➢ Dilute mild detergent and use a soft clean cloth or sponge for

cleaning.

➢ Use a plastic bristle brush to get into crevices.

➢ Rinse surfaces with clean warm water.

➢ Dry glass and clear items immediately to avoid spots.

DO NOT USE

➢ Abrasive or harsh cleaners

➢ Ammonia

➢ Chlorine bleach

➢ Concentrated detergents or

solvents

➢ Metal or plastic-textured

scouring pads

➢ Abrasive or harsh cleaners

➢ Ammonia

➢ Chlorine bleach

➢ Concentrated detergents or

solvents

➢ Metal or plastic-textured

scouring pads

➢ Vinegar-based products

➢ Citrus-based cleaners

➢ Abrasive or harsh cleaners

➢ Metal or plastic-textured

scouring pads

➢ A dishwasher

Textured Doors

and Exterior

Cabinet Interior

Stainless Steel Doors

and Exterior

IMPORTANT: Damage

to stainless steel finish

due to improper use of

cleaning products or

non-recommended

products is not covered

under this product’s

warranty.

Door Gaskets

Condenser Coil

Remove base grille to

access

Condenser Fan Outlet

Grille

See back of refrigerator

Accessories Shelves,

buckets, drawers, etc.

To avoid personal injury or property damage, observe the following:

• Read and follow manufacturer’s directions for all cleaning products.

• DO NOT place buckets, shelves or accessories in dishwasher. Cracking or warp-

ing of accessories may result.

CAUTION

To avoid electrical shock which can

cause severe personal injury or death,

disconnect power to refrigerator

before cleaning. After cleaning, connect power.

WARNING

How to clean your unit

Page 16

16

What cleaners does

Amana recommend for my

stainless steel product?

Amana has a cleaner available for purchase (Part # 31960801) through our

Consumer Affairs division.

For this, or a list of other recommended

cleaning products, please contact us at

Amana Consumer Affairs using the information on the cover of your Owner's

Manual.

Removing odors from

refrigerator

1. Remove all food.

2. Disconnect refrigerator.

3. Clean the following items using the

appropriate instructions in the Care

and Cleaning table.

–Walls, floor and ceiling of cabinet

interior

– Drawers, shelves and gaskets

according to the instructions in this

section.

4. Pay special attention to clean all

crevices by completing the following

steps.

– Dilute mild detergent and brush

solution into crevices using a plas-

tic bristle brush.

– Let stand for 5 minutes.

– Rinse surfaces with warm water.

Dry surfaces with a soft, clean

cloth.

5. Wash and dry all bottles, containers

and jars. Discard spoiled or expired

items.

6. Wrap or store odor-causing foods in

tightly sealed containers to prevent

reoccurring odors.

7. Connect power to refrigerator and

return food to unit.

8. After 24 hours, check if odor has been

eliminated.

If odor is still present:

1. Remove drawers and place on top

shelf of refrigerator.

To avoid personal injury or property

damage, observe the following:

➢ Allow light bulb to cool.

➢ Wear gloves when replacing light

bulb.

CAUTION

To avoid electrical shock which can

cause severe personal injury or death,

disconnect power to refrigerator

before replacing light bulb. After

replacing light bulb, connect power.

WARNING

2. Pack refrigerator and freezer sections

– including doors – with crumpled

sheets of black and white newspaper.

3. Place charcoal briquettes randomly on

crumpled newspaper in both freezer

and refrigerator compartments.

4. Close doors and let stand 24-48

hours.

Energy saving ideas

➢ When placing refrigerator into final

position, allow for

1

Ú2" clearance around

the top and sides of the unit to supply

ample ventilation for optimum energy

efficiency.

➢ Avoid overcrowding refrigerator

shelves. This reduces air circulation

around food and causes refrigerator to

run longer.

➢ Avoid adding too much warm food to

unit at one time. This overloads compartments and slows rate of cooling.

➢ Do not use aluminum foil, wax paper,

or paper toweling as shelf liners. This

decreases air flow and causes unit to

run less efficiently.

➢ A freezer that is

2

Ú3

full runs most effi-

ciently.

➢ Locate refrigerator in coolest part of

room. Avoid areas of direct sunlight, or

near heating ducts, registers or other

heat producing appliances. If this is

not possible, isolate exterior by using

a section of cabinet or an added layer

of insulation.

➢ Refer to Owner's Manual section on

temperature controls for recommended control settings.

➢ Clean door gaskets every three

months according to Owner's Manual

cleaning instructions. This will assure

that door seals properly and unit runs

efficiently.

➢ Take time to organize items in refriger-

ator to reduce time that door is open.

➢ Be sure your doors are closing

securely by leveling unit as instructed

in your Owner's Manual.

➢ Clean condenser coils as indicated in

the Owner’s Manual every 3 months.

This will increase energy efficiency

and cooling performance.

Remove and replace

light bulbs

Fresh Food Section

1. Slide shield toward

back of compartment

to release from light

assembly.

2. Remove light bulbs.

3. Replace with appliance bulbs no

greater than 40 watts.

4. Replace light bulb

cover by inserting

tabs on light shield

into liner holes on

each side of light

assembly. Slide shield toward front of

unit until it locks into place. DO NOT

force shield beyond locking point.

Doing so may damage light shield.

Freezer

1. Pinch rear tabs on

light cover and pull

straight down.

2. Remove light bulb.

3. Replace bulb with appliance bulb no

greater than 40 watts.

4. Insert front tabs of light cover into

freezer liner and snap rear portion

over light assembly until rear tabs

engage.

Hints and care,

cont.

A

B

Page 17

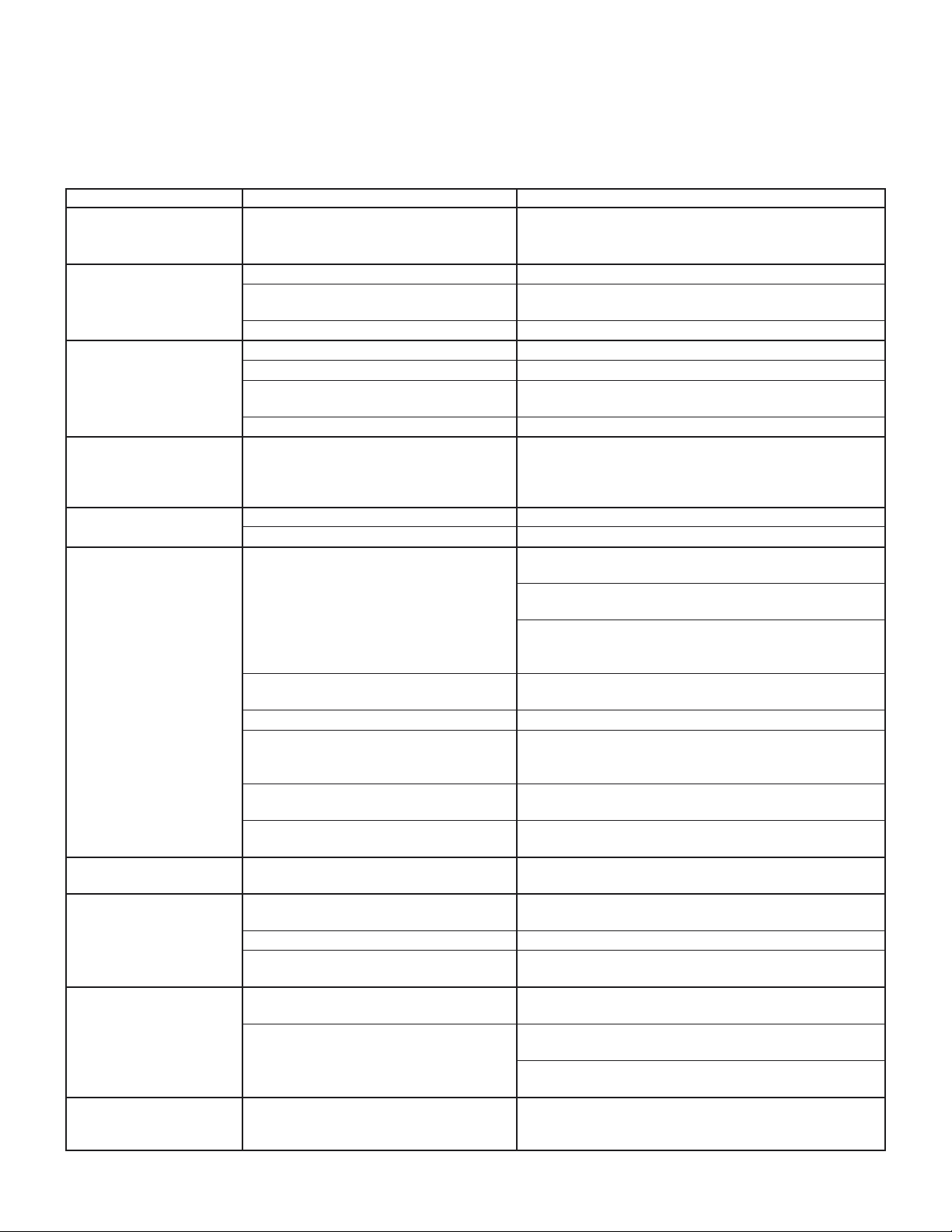

17

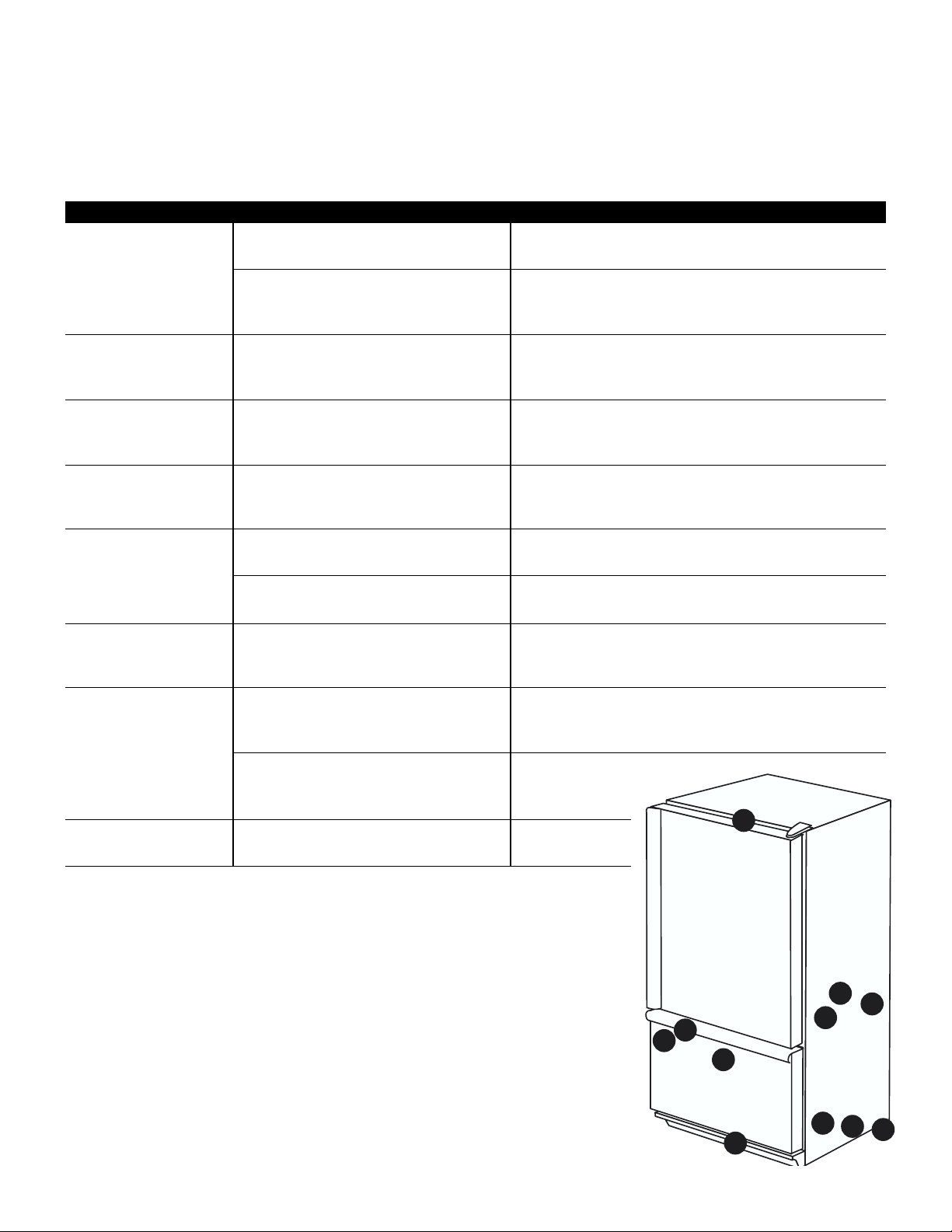

Trouble shooting

Today’s refrigerators have new features and are more energy efficient. Foam insulation is very energy efficient and has excellent insulating capabilities, however, foam insulation is not as sound absorbent. As a result, certain sounds may be unfamiliar. In time, these

sounds will become familiar. Please refer to this information before calling service.

B

J

G

A

F

C

I

E

K

D

H

SOLUTION

➢ Normal operation

➢ Normal operation

➢ Normal operation

➢ Normal operation

➢ Normal operation

➢ Normal operation

➢ See Installation Instructions for details on how to level your

unit.

➢ Normal operation

➢ Stop sound by raising ice maker arm to ‘off’ position. See

Automatic Ice Maker section in your Owner’s Manual for

details.

➢ Normal operation

➢ Normal operation

POSSIBLE CAUSE

➢ Freezer control (A) clicks when

starting or stopping compressor.

➢ Defrost timer (B) sounds like an

electric clock and snaps in and

out of defrost cycle.

➢ Freezer fan (C) and condenser

fan (D) make this noise while

operating.

➢ Evaporator (E) and heat

exchanger (F) refrigerant makes

this noise when flowing.

➢ Ice cubes from ice maker (select

models) drop into ice bucket (G).

➢ Compressor (H) makes a

pulsating sound while running.

➢ Refrigerator is not level.

➢ Ice maker water valve (I)

hookup (select models) buzzes

when ice maker fills with water.

➢ Ice maker (J) is in the ‘on’ posi-

tion without water connection.

➢ Compressor (H) can make a high-

pitched hum while operating.

➢ Defrost heater (K) hisses, sizzles

or pops when operational.

TOPIC

Clicking

Air rushing or whirring

Gurgling or boiling

sound

Thumping

Vibrating noise

Buzzing

Humming

Hissing or

popping

Page 18

18

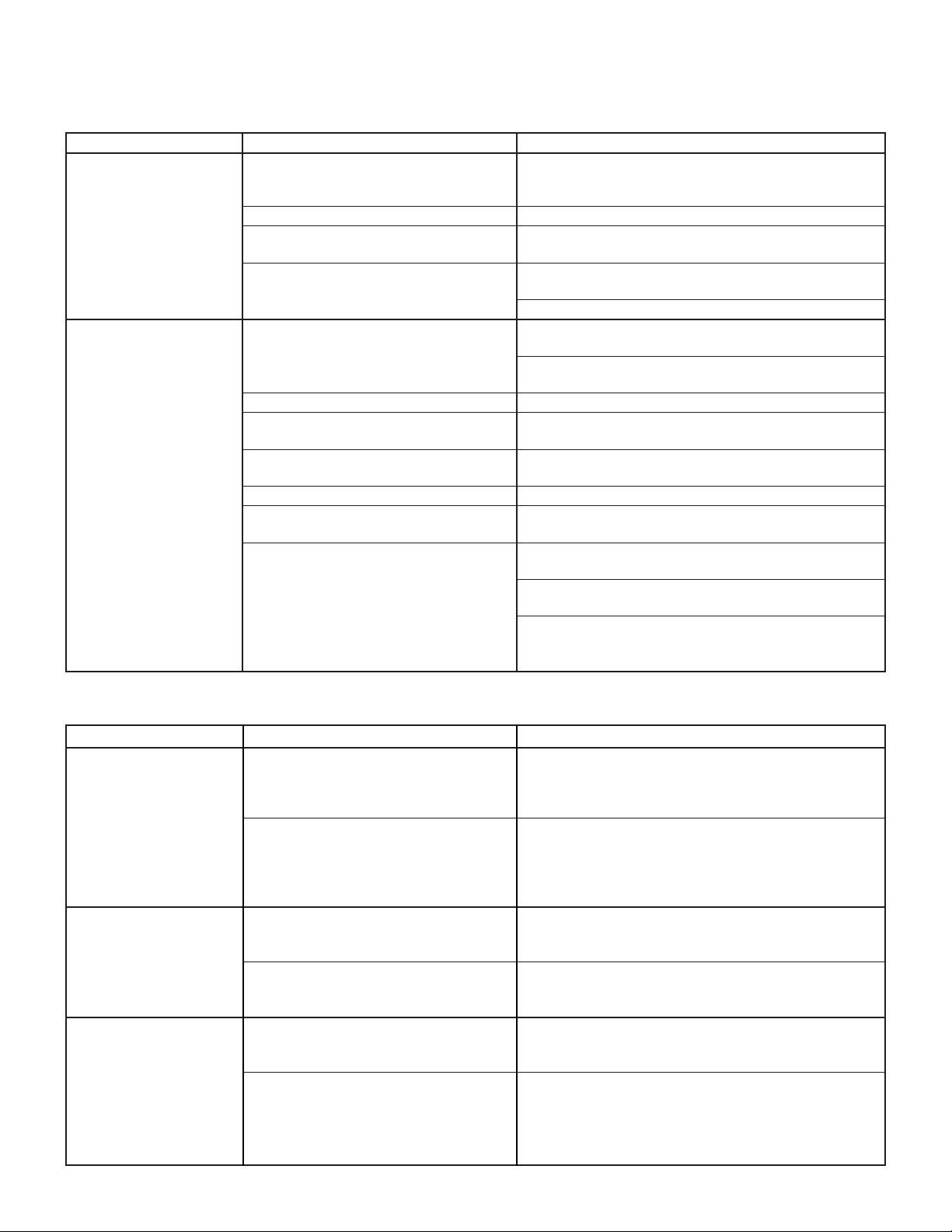

PROBLEM POSSIBLE CAUSES WHAT TO DO

Freezer control and lights Refrigerator is in defrost mode. Normal operation. Wait 40 minutes to see if refrigerator restarts.

are on, but compressor

is not operating

Crisper drawer Control settings are too low. See section on Crisper drawer to adjust controls.

temperature is too warm

Freezer controls are set too low. See controls section in Owner’s Manual on how to adjust your

controls.

Drawer is improperly positioned. See section on Crisper drawer to verify drawer positioning.

Refrigerator does not Refrigerator is not plugged in. Plug in unit.

operate

Freezer control is not on. See controls section in Owner’s Manual.

Fuse is blown, or circuit breaker needs to be Replace any blown fuses. Check circuit breaker and reset, if.

reset. necessary.

Power outage has occurred. Call local power company listing to report outage.

Refrigerator still won’t Unit is malfunctioning. Unplug refrigerator and transfer food to another unit. If another

operate unit is not available, place dry ice in freezer section to preserve

food. Warranty does not cover food loss.

Contact service for assistance.

Food temperature Condenser coils are dirty. Clean according to your Owner’s Manual.

is too cold

Refrigerator or freezer controls are set too high. See controls section in Owner’s Manual on how to adjust controls.

Food temperature Door is not closing properly. Refrigerator is not level. See How to Level Your Refrigerator

is too warm for details on how to level your unit.

Check gaskets for proper seal. Clean, if necessary, according to

cleaning instructions in Owner’s Manual.

Check for internal obstructions that are keeping door from closing

properly (i.e. improperly closed drawers, ice buckets, oversized

or improperly stored containers or foodstuffs, etc.)

Controls need to be adjusted. See the controls section in Owner’s Manual for assistance on

how to adjust your controls.

Condenser coils are dirty. Clean according to cleaning instructions in Owner’s Manual.

Rear air grille is blocked. Check the positioning of food items in refrigerator to make sure

grille is not blocked. Rear air grilles are located under crisper

drawers.

Door has been opened frequently, or has been Reduce time door is open. Organize food items efficiently to

opened for long periods of time. assure door is open for as short a time as possible.

Food has recently been added. Allow time for recently added food to reach refrigerator or freezer

temperature.

Refrigerator has an odor Compartment is dirty or has odor-causing food. Refer to Care and Cleaning in Owner’s Manual for odor removal

instructions.

Water droplets form on Check gaskets for proper seal. Clean, if necessary, according to cleaning instructions in

outside of refrigerator Owner’s Manual.

Humidity levels are high. Normal during times of high humidity.

Controls require adjustment. See the controls section in Owner’s Manual for assistance on

how to adjust your controls.

Water droplets form on Humidity levels are high or door has been See the controls section in Owner’s Manual for assistance on

inside of refrigerator been opened frequently. how to adjust your controls.

Check gaskets for proper seal. Reduce time door is open. Organize food items efficiently to

assure door is open for as short a time as possible.

Clean, if necessary, according to cleaning instructions in

Owner’s Manual.

Refrigerator or ice maker Normal operation. Refer to noise section of Normal Operating Sounds guide in

makes unfamiliar sounds Owner’s Manual.

or seems too loud

Operation

Trouble shooting,

cont.

Page 19

19

PROBLEM POSSIBLE CAUSES WHAT TO DO

Crisper drawers do not Contents of drawer, or positioning of items Reposition food items and containers to avoid interference with

close freely in the surrounding compartment could be the drawers.

obstructing drawer.

Drawer is not in proper position. See Crisper drawer section for proper placement.

Refrigerator is not level. See How to Level Your Refrigerator for details on how to level

your unit.

Drawer channels are dirty or need treatment. Clean drawer channels with warm, soapy water. Rinse and dry

thoroughly.

Apply a thin layer of petroleum jelly to drawer channels.

Refrigerator runs too Doors have been opened frequently or for Reduce time door is open. Organize food items efficiently to

frequently long periods of time. assure door is open for as short a time as possible.

Allow interior environment to adjust for period the door has

been opened.

Humidity or heat in surrounding area is high. Normal operation.

Food has recently been added. Allow time for recently added food to reach refrigerator or

freezer temperature.

Unit is exposed to heat by environment or Evaluate your unit’s environment. Unit may need to be moved to

by appliances nearby. run more efficiently.

Condenser coils are dirty. Clean according to cleaning instructions in your Owner’s Manual.

Controls need to be adjusted. See controls section in your Owner’s Manual for assistance

on how to adjust your controls.

Door is not closing properly. Refrigerator is not level. See How to Level Your Refrigerator

for details on how to level your unit.

Check gaskets for proper seal. Clean, if necessary, according

to cleaning instructions in Owner’s Manual.

Check for internal obstructions that are keeping door from closing

properly (i.e. improperly closed drawers, ice buckets, oversized

or improperly stored containers or foodstuffs, etc.)

PROBLEM POSSIBLE CAUSES WHAT TO DO

Unit is leaking water Plastic tubing was used to complete water The manufacturer recommends using copper tubing for installation.

connection. Plastic is less durable and can cause leakage. The manufac-

turer is not responsible for property damage due to

improper installation or water connection.

Improper water valve was installed. Check water connection procedure in your “Installing Your

Refrigerator.” Self-piercing and

3

Ú

16” saddle valves cause low water

pressure and may clog the line over time. The manufacturer is

not responsible for property damage due to improper

installation or water connection.

Ice forms in inlet tube to Water pressure is low. Water pressure must be between 20 to 100 pounds per square

ice maker inch to function properly. A minimum pressure of 35 pounds per

square inch is recommended for units with water filters.

Freezer temperature is too high. See controls section in chapter called Installing Your Refrigerator

on how to adjust your controls. Freezer is recommended to be

between 0 to 2° F (-18 to –17° C).

Water flow is slower than Water pressure is low. Water pressure must be between 20 to 100 pounds per square

normal inch to function properly. A minimum pressure of 35 pounds per

square inch is recommended for units with water filters.

Improper water valve was installed. Check water connection procedure in your “Installing Your

Refrigerator.” Self-piercing and

3

Ú16” saddle valves cause low water

pressure and may clog the line over time. The manufacturer is

not responsible for property damage due to improper

installation or water connection.

Ice

Page 20

20

Water filter data

GENERAL USE

CONDITIONS

Read this Performance Data Sheet and

compare the capabilities of this unit with

your actual water treatment needs.

DO NOT use this product where water

is microbiologically unsafe or of

unknown quality without adequate

disinfection before or after the system. System certified for cyst reduction may be used on disinfected water

that may contain filterable cysts.

Use only with cold water supply.

Check for compliance with the state

and local laws and regulations.

The retractable water filtration system

uses a WF50 replacement cartridge.

Timely replacement of filter cartridge is

essential for performance satisfaction

from this filtration system. Please refer to

the applicable section in this owner’s

manual for general operation, maintenance requirements and troubleshooting.

This system has been tested according to

ANSI/NSF 42 and 53 for reduction of the

substances listed below. The concentration of the indicated substances in water

entering the system was reduced to a

concentration less than or equal to the

permissible limit for water leaving the system, as specified in ANSI/NSF 42 and 53.

*Tested using a flow rate of 0.75 GPM (2.83 L/min.) and a maximum pressure of 120 psi (827 kPa) under

standard laboratory conditions, however, actual performance may vary. Health Claim Performance tested and certified by NSF International

** Particle size range classification of test. Particles used were 0.5 –1 microns.

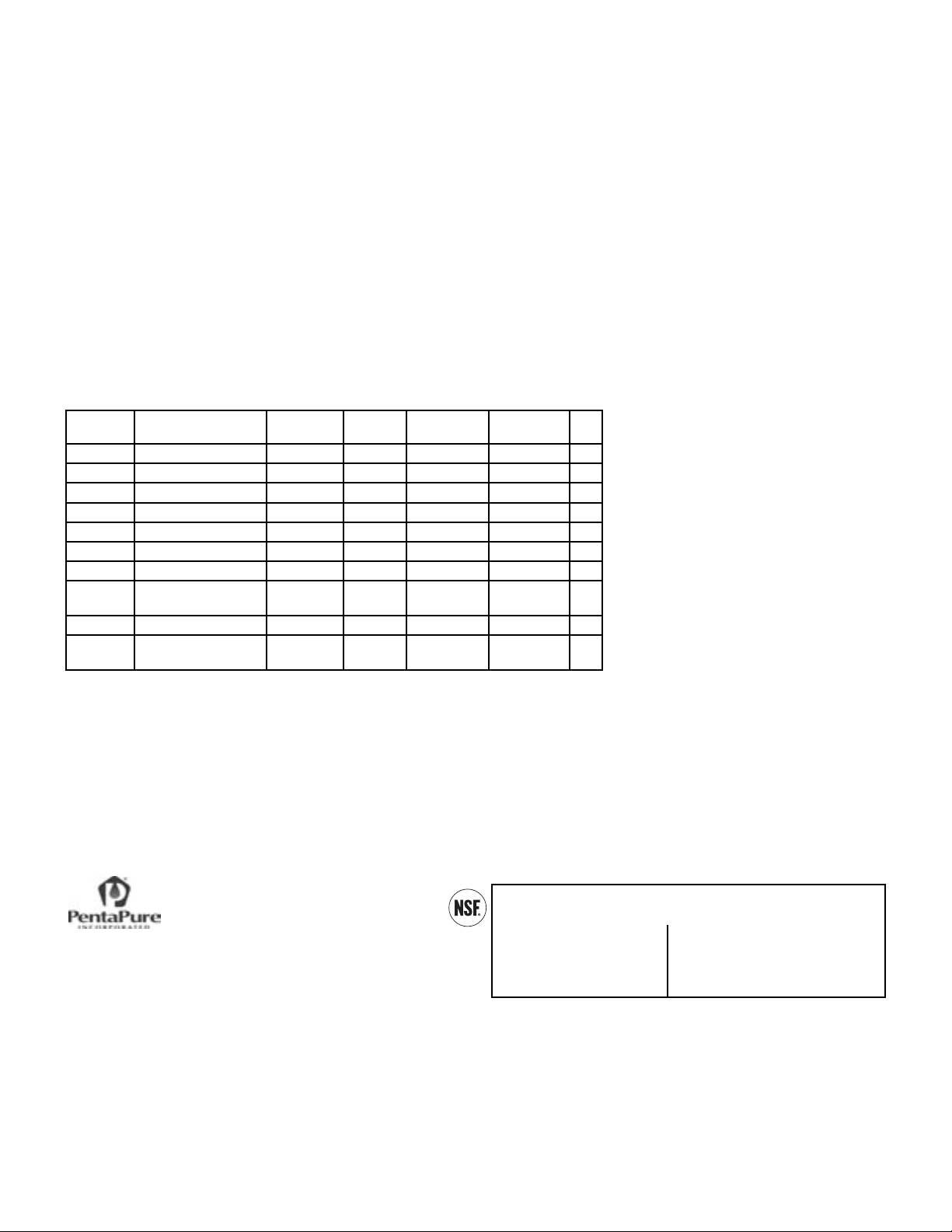

Influent Challenge Effluent Average % Maximum Min. Required Inlet

Substance Concentration Average Reduction Effluent Reduction pH

Lead 0.15 mg/L +/- 10% 0.001 mg/L 99.33% 0.001 mg/L 0.010 mg/L 6.5

Lead 0.15 mg/L +/- 10% 0.002 mg/L 98.66% 0.003 mg/L 0.010 mg/L 8.5

Cyst Minimum 50,000/L 1count/mL 99.99% 3 count/mL > 99.95% NA

Turbidity 11+/-1 NTU 0.12 NTU 98.98% 0.18 NTU 0.5 NTU NA

Lindane 0.002 mg/L +/- 10% 0.00005 mg/L 97.62% 0.00005 mg/L 0.00002 mg/L NA

Atrazine 0.009 mg/L +/- 10% 0.0002 mg/L 97.93% 0.0006 mg/L 0.003 mg/L NA

Chlorine 2.0 mg/L +/- 10% 0.09 mg/L 95.26% 0.17 mg/L ≥75% NA

Particulate** at least 10,000 900 count/mL 99.68% 2400 count/mL ≥85% NA

particles/mL

2,4-D 0.210 mg/L +/- 10% 45.45 ug/L 84.42% 100 ug/L 0.0017 mg/L NA

Asbestos

107to 108fibers/L; fibers greater

0.16 MFL/mL 99.96% 0.16 MFL/mL 99% NA

than 10 micometers in length

PERFORMANCE DATA

SYSTEM SPECIFICATION AND PERFORMANCE DATA

SHEET REFRIGERATOR WATER FILTER CARTRIDGE

MODEL WF50

Specifications

Service Flow Rate (maximum) ...............................................0.75 GPM (2.83 L/min)

Rated Service Life WF50-NI300 (maximum) .........................300 gallons/1135 liters

Rated Service Life WF50-WI500 (maximum) ........................500 gallons/1892 liters

Maximum Operating Temperature..........................................100° F/38° C

Minimum Operating Temperature...........................................33° F/1° C

Minimum Pressure Requirement............................................35 psi/138 kPa

Maximum Operating Pressure ...............................................120 psi/827 kPa

1000 Apollo Road

Eagan, Minnesota U.S.A.

EPA EST #35917-MN-1

Standard No. 53: Health Effects

Chemical Reduction Unit

Lead, Atrazine, Lindane and 2, 4-D Reduction

Mechanical Filtration Unit

Cyst, Turbidity and Asbestos Reduction

Te sted and certified by NSF International against ANSI/NSF Standards 42 and 53 in

models WI500 and NI300 for the reduction of:

Standard No. 42: Aesthetic Effects

Taste and Odor Reduction

Chlorine Reduction

Mechanical Filtration Unit

Particulate Reduction Class 1

Page 21

21

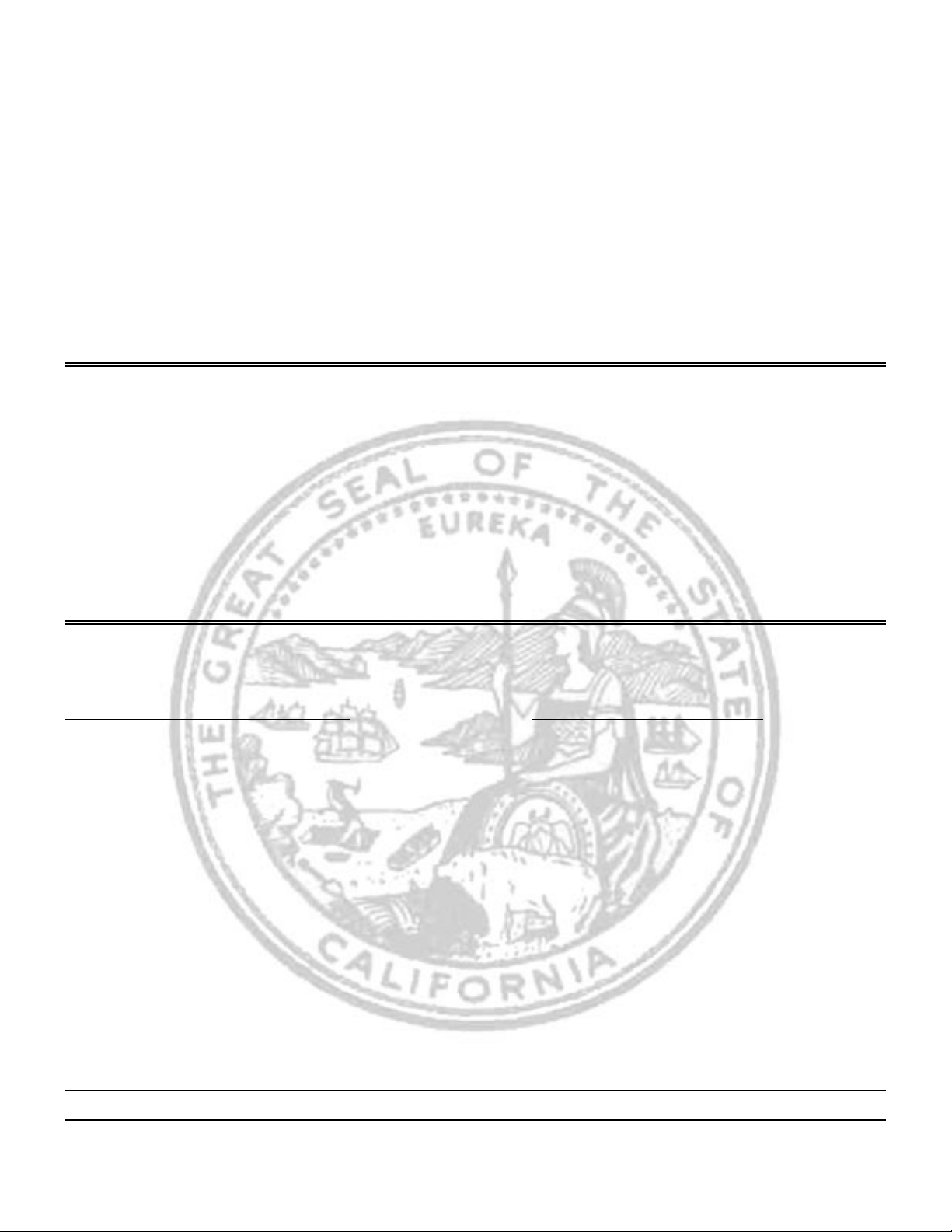

State of California

Department of Health Services

Water Treatment Device

Certificate Number

01 - 1486

Date Issued: September 21, 2001

Date Revised: March 20, 2002

T

rademark/Model Designa

tion Replacement Elements Rated Capacity

WF50-WI500 WF50 500 gal

WF50-NI300 WF50 300 gal

WF50-KWI500 46 9005 500 gal

WF50-KNI300 46 9005 300 gal

OWF50-WI500 OWF51 500 gal

OWF50-NI300 OWF51 300 gal

Manufacturer: PentaPure Incorporated

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section 116830 of the

Health and Safety Code for the following health related contaminants:

Microbiolo

gical Contaminants and Turbidity

Inoganic/Radiological Contaminants

Cysts Asbesos

Lead

Org

anic Contaminants

Atrazine

Lindane

Rated Service Flow: 0.75

Page 22

22

Amana

refrigerator warranty

Owner's responsibility

➢ Provide proof of purchase (sales receipt).

➢ Provide normal care and maintenance. Replace owner replaceable items

where directions appear in Owner's Manual.

➢ Make product reasonably accessible for service.

➢ Pay premium service costs for service outside technician's normal busi-

ness hours.

➢ Pay for service calls related to product installation and usage.

Amana Appliances Factory Service

1-800-628-5782 inside USA

For more information, Amana Appliances Consumer Services

Amana Appliances

2800 220th Trail

Amana, Iowa 52204

1-800-843-0304 inside USA

1-866-587-2002 au Canada

www.amana.com

First Year

Amana will replace, free of charge, any part

which is defective due to workmanship or

materials.

Second through Fifth Year

Amana will replace free of charge, any sealed

system component (compressor, condenser,

evaporator, drier and interconnecting tubing)

and repair any food compartment liner

(exclusive of door liner) which is defective due

to workmanship or materials.

Warranty Limitations

➢ Begins at date of original purchase.

➢ Excludes original and replacement water or

air filter cartridges (if equipped with the filtration system). Original and replacement

cartridges are warranted for 30 days, parts

only, against defects of material or workmanship.

➢ Service must be performed by an author-

ized Amana technician.

➢ Damage due to shipping and handling is

not covered by this warranty.

Warranty Is Void If

Repairs resulting from the following:

➢ Serial plate is defaced.

➢ Product is used on a commercial, rental, or

leased basis.

➢ Product has defect or damage due to prod-

uct accident, alteration, connection to an

improper electrical supply, fire, flood, lightning, or other conditions beyond the control of Amana.

➢ Product is improperly installed or used.

IN NO EVENT SHALL AMANA BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

This warranty gives you specific legal rights,

and you may have others which vary from state

to state. For example, some states do not

allow the exclusion or limitation of incidental or

consequential damages, so this exclusion may

not apply to you.

Page 23

Refrigerador con

congelador inferior

¿Necesita pedir piezas y accesorios?

¿Tiene preguntas acerca de las características?

Comuníquese con nosotros con el número de modelo y

de serie:

Departamento de Asuntos del Cliente

Amana Appliances

2800 – 220th Trail

Amana, Iowa 52204 EE.UU.

Tel. 1(800) 843-0304

1(319) 622-5511 fuera de EE.UU.

Internet: http://www.amana.com

Manual del propietario

Conserve las instrucciones para usarlas

como referencia futura.

Mantenga este manual y el recibo de compra juntos en un lugar

seguro por si fuera necesario solicitar servicio bajo la garantía.

Contenido

Introducción ..............................................................24

Información importante de seguridad.......................25

Instalación del refrigerador .......................................26

Cómo quitar las puertas y las bisagras..................26

Cómo invertir las puertas .......................................27

Cómo instalar y quitar las asas..............................27

Cómo volver a colocar las puertas y las bisagras .28

Cómo quitar e instalar el cajón deslizable .............29

Cómo conectar el suministro de agua....................30

Cómo nivelar el refrigerador...................................30

Cómo ajustar los controles de temperatura ...........31

Características del alimento fresco ..........................32

Parrillas interiores...................................................32

Almacenamiento en la puerta.................................32

Accesorios ..............................................................33

Cajones con clima controlado ................................33

Cajones de almacenamiento..................................33

Características de la sección del congelador...........35

Características principales .....................................35

Repisas...................................................................35

Cajones ..................................................................35

Almacenamiento en la puerta.................................36

Accesorios ..............................................................36

Consejos y cuidado ..................................................37

Cómo limpiar la unidad...........................................37

Cómo quitar y reemplazar los focos.......................38

Diagnóstico de averías .............................................39

Datos del filtro de agua ............................................42

Garantía....................................................................44

Page 24

24

¡Gracias por adquirir un refrigerador Amana!

Lea minuciosamente este manual del propietario. Éste le proporcionará la información de

mantenimiento apropiada.

Llene la tarjeta de registro y devuélvala enseguida. Si la tarjeta no está, llame al departamento

de asuntos del cliente.

El servicio de garantía debe realizarlo un técnico autorizado de servicio. Amana también

recomienda comunicarse con un técnico autorizado si se requiere de servicio después de que

caduque la garantía. Para localizar a un técnico autorizado llame al 1-800-NAT-LSVC (1-800-628-

5782). También puede comunicarse con nosotros mediante nuestro sitio en la red

www.amana.com.

When contacting Amana, please provide the following information. Product information is on the

serial plate, located on ceiling of fresh food section.

Model Number _________________________________________________________________

'P' Number ____________________________________________________________________

Serial Number __________________________________________________________________

Purchase Date _________________________________________________________________

Dealer Name __________________________________________________________________

Dealer Address _________________________________________________________________

Dealer Phone __________________________________________________________________

Plan de servicio

extendido Asure™

Amana Appliances ofrece un servicio de

protección a largo plazo para este nuevo

refrigerador. El Plan de servicio extendido

Asureä está diseñado especialmente para

complementar la excelente garantía de

Amana. Este plan cubre piezas funcionales,

mano de obra y cargos de transporte. Llame

al 1-800-528-2682 o comuníquese con

nosotros en www.amana.com para obtener

más información.

Antes de llamar para

solicitar servicio...

Si algo parece fuera de lo común, consulte la

sección “Diagnóstico de averías”, la cual está

diseñada para ayudarle a resolver problemas

antes de llamar para solicitar servicio.

¿Qué sucede si estas

características son

diferentes a las de mi

refrigerador?

Este libro tiene la finalidad de mostrar la

variedad de características que hay

disponibles en la línea de productos. Si su

refrigerador no tiene todas las opciones que

se muestran, muchas de estas opciones

pueden adquirirse comunicándose con el

Departamento de Asuntos del Cliente. Vea la

información para comunicarse contenida en la

portada del manual.

Page 25

25

Información importante de seguridad

Lo que necesita saber

acerca de las

instrucciones de

seguridad

Las advertencias y las instrucciones

importantes de seguridad que aparecen en

este manual no tienen el propósito de cubrir

todas las condiciones posibles que podrían

ocurrir. Debe usarse sentido común,

precaución y cuidado cuando se instale, se

realice mantenimiento o se opere el

refrigerador.

Siempre comuníquese con el distribuidor,

concesionario, agente de servicio o fabricante

para los asuntos relacionados con problemas

o condiciones que no entienda.

Conserve estas instrucciones

PELIGRO—Riesgos inminentes que

CAUSARÁN lesiones personales graves o

la muerte.

PELIGRO

ADVERTENCIA—Riesgos o prácticas

inseguras que PODRÍAN causar lesiones

personales graves o la muerte.

ADVERTENCIA

PRECAUCIÓN—Riesgos o prácticas

inseguras que PODRÍAN causar lesiones

personales menores o daños materiales o

del producto.

PRECAUCIÓN

Para evitar el riesgo de incendio, descarga eléctrica, lesiones graves o la muerte cuando use el refrigerador, siga estas precauciones

básicas:

ADVERTENCIA

Para reducir el riesgo de lesiones o la

muerte, siga las precauciones básicas,

incluyendo las siguientes:

IMPORTANTE: Los niños atrapados y

asfixiados en refrigeradores no es cosa del

pasado. Los refrigeradores que se

arrumban o abandonan; aun cuando sea

“sólo por unos cuantos días”, continúan

representando un peligro. Si desecha un

refrigerador viejo, sírvase seguir las

siguientes instrucciones para ayudar a

prevenir un accidente.

Anes de tirar su refrigerador o congelador

viejo:

➢ Quítele las puertas.

➢ Déjele las repisas

puestas para que los

niños no puedan

meterse con facilidad.

PELIGRO

RECONOZCA LOS SÍMBOLOS,

LAS PALABRAS Y LAS

ETIQUETAS DE SEGURIDAD

1. Lea todas las instrucciones antes de usar el refrigerador.

2. Observe todos los códigos y reglamentos locales.

3. Asegúrese de seguir las instrucciones de conexión a tierra.

4. Consulte a un electricista calificado si no está seguro que el

aparato está conectado a tierra correctamente.

5. NO lo conecte a tierra en una tubería de gas.

6. NO lo conecte a tierra en una tubería de agua fría.

7. El refrigerador está diseñado para funcionar en una línea

separada de 103 a 126 voltios, 60 ciclos. NO modifique la clavija

del cordón eléctrico. Si la clavija no cabe en el tomacorriente, haga

que un electricista calificado instale uno apropiado.

8. NO use un adaptador de dos clavijas, un cordón de extensión ni

una tira de enchufes de energía.

9. NO quite la etiqueta de advertencia del cordón eléctrico.

10. NO altere los controles del refrigerador.

11. NO repare ni reemplace ninguna pieza del refrigerador ni trate

realizar ningún tipo de servicio, a menos que se recomiende

específicamente en las instrucciones de mantenimiento del

usuario. NO intente darle servicio si no entiende las instrucciones

o si se requiere un mayor nivel de dresteza personal.

12. Siempre desconecte el refrigerador del suministro eléctrico antes

de realizar algún tipo de servicio. Desconecte el cordón eléctrico

sujetando la clavija, no el cordón.

13. Instale el refrigerador de acuerdo con las instrucciones de

instalación. Todas las conexiones de agua, energía eléctrica y

conexión a tierra deben cumplir con los códigos locales y debe

realizarlas personal con licencia cuando se requiera.

14. Mantenga el refrigerador en buenas condiciones. El golpear o

dejar caer el refrigerador puede dañar la unidad o causar un mal

funcionamiento o goteras. Si se daña, haga que un técnico

calificado de servicio lo revise.

15. Reemplace las clavijas y los cordones eléctricos desgastados.

16. Siempre lea y siga las instrucciones del fabricante de

almacenamiento y ambiente ideal para los artículos que se

almacenarán en el refrigerador.

Page 26

1. Desenchufe el cordón eléctrico de la fuente

de energía.

2. Quite la parrilla inferior

y las cubiertas del

soporte inferior.

• Abra la puerta del congelador

lo más posible (modelos selecos).

3. Quite la cubierta de la

bisagra superior quitando

el tornillo Phillips (para los

modelos con el ajuste en

las puertas solamente).

4. Quite el ajuste de la tapa de la puerta

usando un destornillador Phillips (modelos

con el ajuste solamente).

• Guarde los tornillos y el ajuste de la

puerta para instalar más adelante.

5. Destornille los tornillos hexagonalesde

5

Ú16

”

de la bisagra superior

para quitar la bisagra.

• Conserve todos los

tornillos para usarlos

después.

6. Quite la puerta del refrigerador. Sostenga la

puerta del congelador en su lugar mientras

quita el pasador de la bisagra central con

un destornillador

hexagonal de

5

Ú16”.

• Conserve el pasador

para usarlos

después.

7. Quite los tornillos Phillips para quitar la

bisagra central.

• Conserve todos los tornillos para usarlos

después.

8. Quite la bisagra inferior o el

soporte estabilizador con un

destornillador hexagonal de

3

Ú8”.

• Conserve todos

los tornillos para

usarlos después.

26

Instalación del refrigerador

Estas instrucciones tienen la finalidad de

ayudarle con la instalación de su unidad.

Amana no puede hacerse responsable

por una instalación incorrecta.

¿Cómo mido un hueco

para asegurarme que

quede bien ajustado?

Debe proporcionarse un espacio de aire de

1

Ú2"

(1.3 cm) en la parte superior y posterior de la

unidad para permitir la circulación de aire

apropiada. Cuando instale la unidad, tome las

medidas cuidadosamente. El sobrepiso o los

recubrimientos del piso (por ejemplo,

alfombras, mosaicos, pisos de madera,

tapetes) podrían hacer el espacio más

pequeño de lo que pensaba.

Podría obtenerse algo de espacio usando el

procedimiento de nivelación bajo Cómo

nivelar el refrigerador.

IMPORTANTE: Si la unidad se va a instalar

en un hueco en donde la parte superior del

refrigerador estará completamente cubierta,

use dimensiones de piso a la parte superior de

la parte superior de la cubierta de la bisagra

para comprobar el espacio libre correcto.

Cómo transportar la

unidad

Siga estos consejos cuando mueva la unidad

a su ubicación final:

➢

NUNCA transporte la unidad sobre un

costado. Si no es posible transportarla

verticalmente, colóquela sobre la parte

posterior. Permita que la unidad

permanezca en posición vertical durante

30 minutos aproximadamente antes de

enchufarla para asegurar que el aceite

regrese al compresor. Si enchufa la unidad

inmediatamente podrían causarse daños a

las piezas internas.

➢

Use una carretilla para electrodomésticos

cuando mueva la unidad. SIEMPRE

transporte la unidad sobre un lado,

NUNCA por la parte posterior ni el frente.

➢