Page 1

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

IN

ON MANUAL

Electric 30-inch Wide

Free-standi

PLEASE KEEP THIS MANUALeFOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

CLEARANCE DIMENSIONS

For complete information in regard to installation of

Only qualified personnel should

install or service this range.

Read "Safety Instructions" in Use &

Care book before using range.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage,

CAUTION: This range has been designed in

accordance with the requirements of various safety

agencies and complies with the maximum allowable

wood cabinet temperatures of 194°F. If this range is

installed with cabinets that have a lower working

temperature than 194°F, discoloration, delamination

or melting may occur.

ENGLISH 0 PP. 1-7

freestanding range, see figures 1 and 2 on page 2. For

SAFETY CONSIDERATIONS do not install a range in

any combustible cabinetry which is not in accord with the

installation clearances shown in figure 1.

MOBILE HOMES

The installation of a range designed for mobile home

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, Part 280) or,

when such standard is not applicable, the Standard for

Manufactured Home Installations 1982 (Manufactured

Home Sites, Communities and Set-Ups), ANSI

A225.1-1atest edition, or with local codes.

LOCATING THE RANGE

Place range in a well lit area. Do not set range over

holes in the floor or other locations where it may be

subject to strong drafts. Any opening in the wall behind

the range and in the floor under the range should be

sealed. Make sure the flow of cooling/ventilation air is

not obstructed below the range.

ESPANOL 0 pag. 8-14

FRAN(_AIS i_ p. 15-21

8101 P506-60

(08-03-01)

Page 2

INSTALLATION DRAWINGS

PLEASE KEEP FOR THE USE OFTHE

LOCAL ELECTRICAL INSPECTOR,

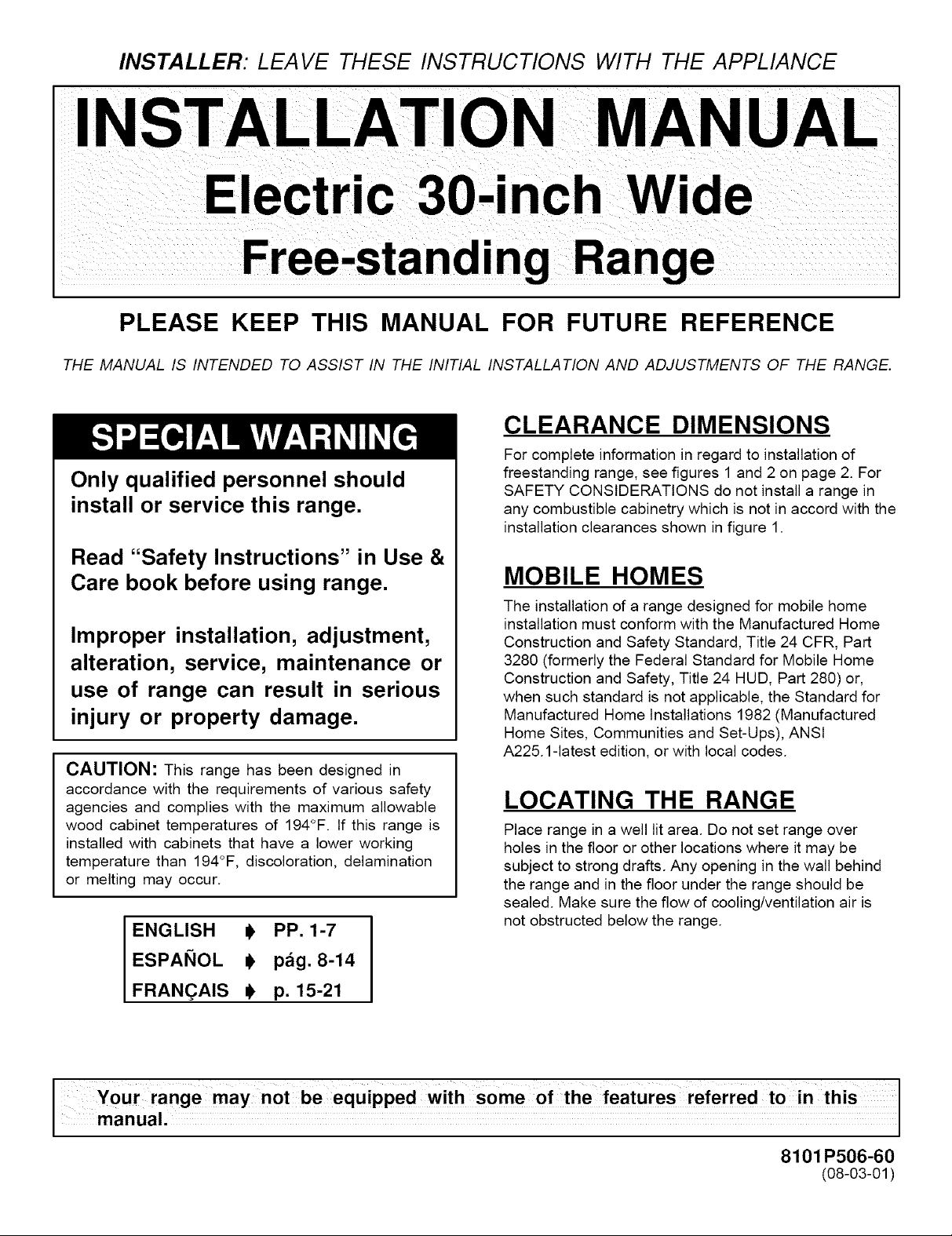

FIGURE 1

NOTE: Figure may not be representative of actual unit.

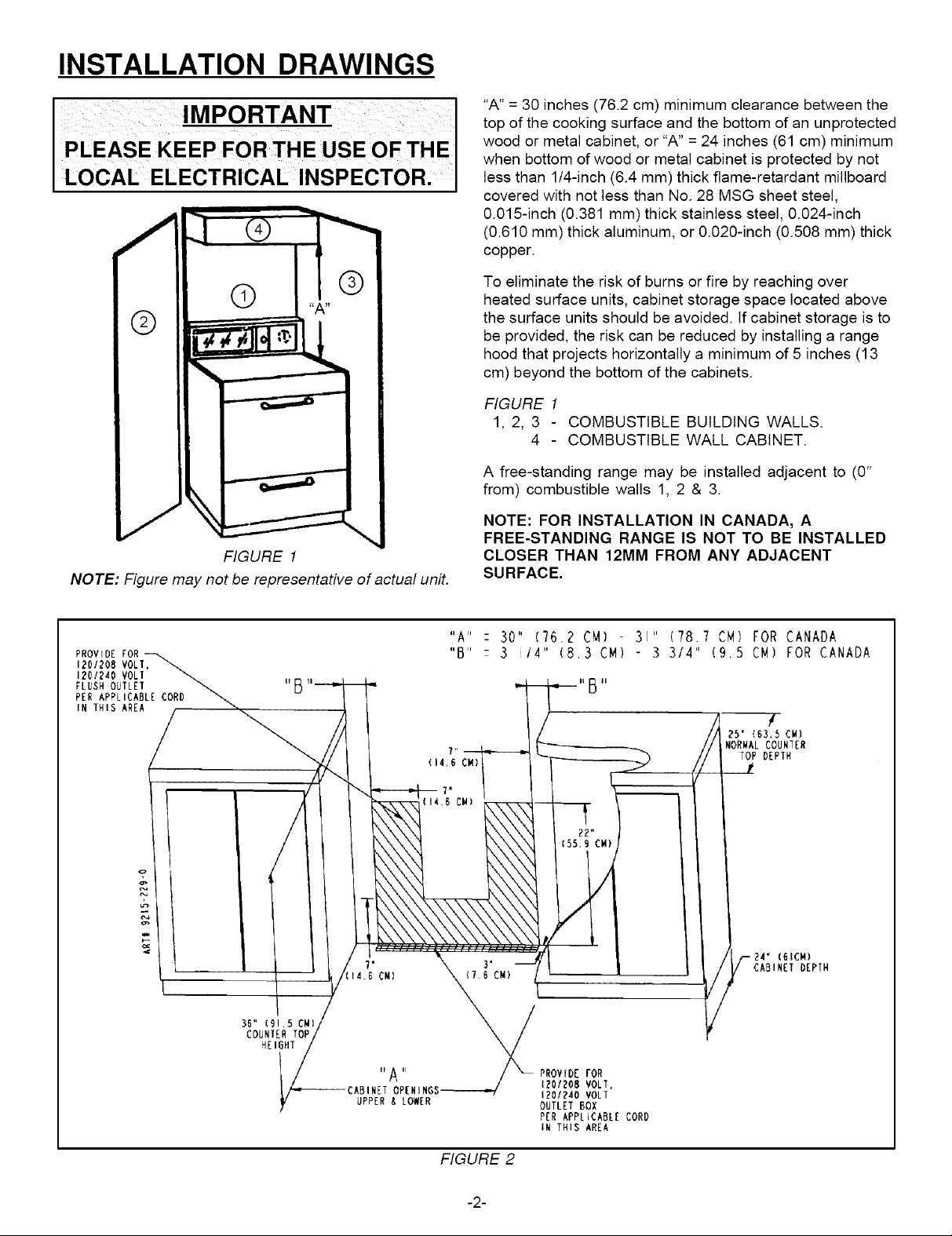

"A" = 30 inches (76.2 cm) minimum clearance between the

top of the cooking surface and the bottom of an unprotected

wood or metal cabinet, or "A" = 24 inches (61 cm) minimum

when bottom of wood or metal cabinet is protected by not

less than 1/4-inch (6.4 mm) thick flame-retardant millboard

covered with not less than No. 28 MSG sheet steel,

0.015-inch (0.381 mm) thick stainless steel, 0.024-inch

(0.610 mm) thick aluminum, or 0.020-inch (0.508 mm) thick

copper.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is to

be provided, the risk can be reduced by installing a range

hood that projects horizontally a minimum of 5 inches (13

cm) beyond the bottom of the cabinets.

FIGURE 1

1, 2, 3 - COMBUSTIBLE BUILDING WALLS.

4 - COMBUSTIBLE WALL CABINET.

A free-standing range may be installed adjacent to (0"

from) combustible walls 1, 2 & 3.

NOTE: FOR INSTALLATION IN CANADA, A

FREE-STANDING RANGE IS NOT TO BE INSTALLED

CLOSER THAN 12MM FROM ANY ADJACENT

SURFACE,

PROVIDE FOR

120/208 VOLT, "_.

120/240 VOLI_

FLUSH OUTLET"--...

PER APPLICABLE CORD

IN THIS AREA"

/

"A" = 30" (76,2 CM) - 31" (78.7 CM) FOR CANADA

"6" = 3 14" (8.3 CM) - 3 314" (9.5 CM) FOR CANADA

"B

/

/

la.G CR) CW)

36" (91.5CWI "X /

! "A'

(GICW)

CABINET DEPTH

FIGURE 2

-2-

PER APPLICABLE CORD

IN THIS AREA

Page 3

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

WARNING: A risk of range tip-over exists if the appliance

is not installed in accordance with the provided installation

instructions. The proper use of this device minimizes the

risk of TIP-OVER. In using this device the consumer must

still observe the safety precautions as stated in the USE

and CARE MANUAL and avoid using the oven door

and/or lower drawer as a step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall. The bracket may be installed

to engage the left or right rear leveling foot.

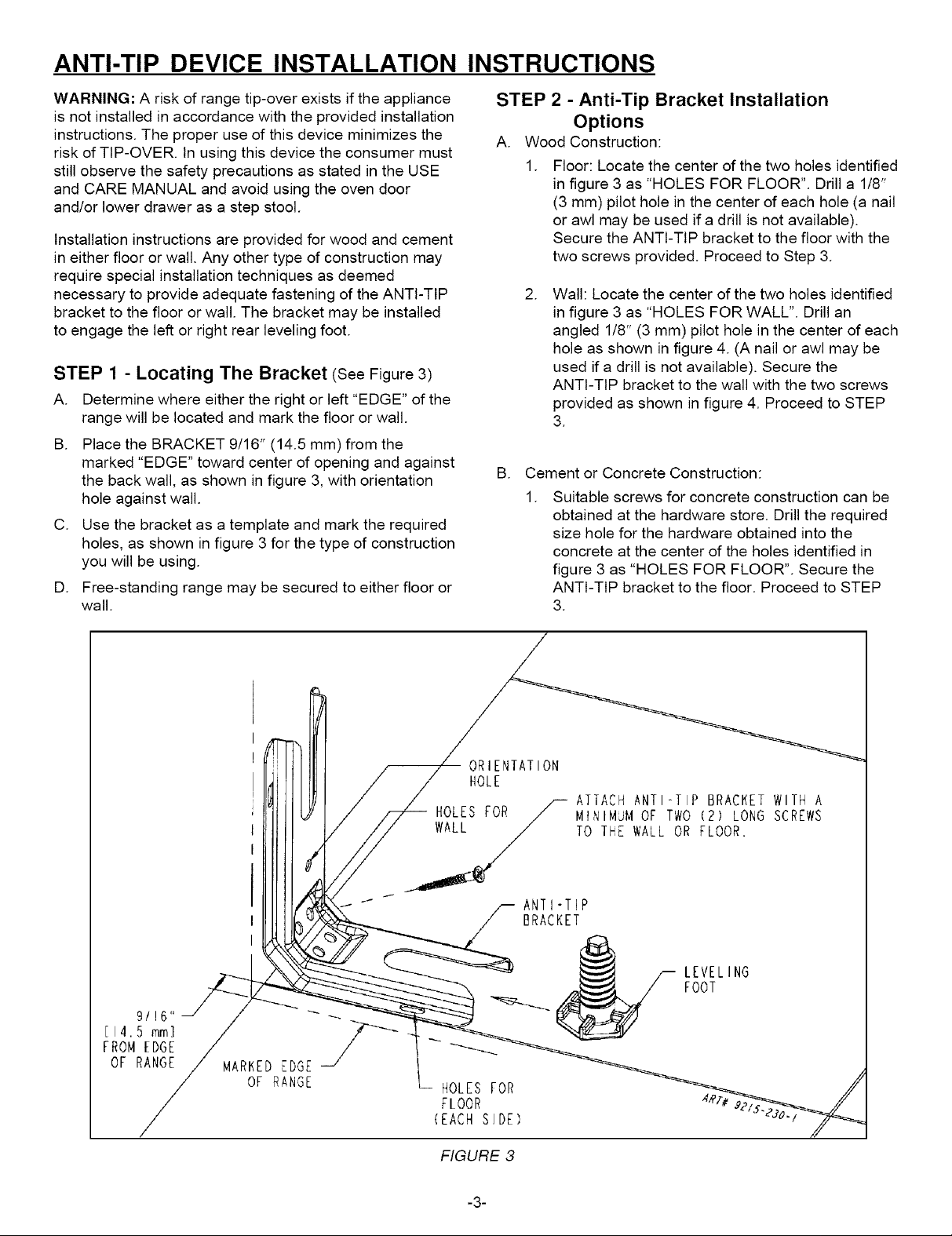

STEP 1 - Locating The Bracket (See Figure 3)

A. Determine where either the right or left "EDGE" of the

range will be located and mark the floor or wall.

B. Place the BRACKET 9/16" (14.5 mm) from the

marked "EDGE" toward center of opening and against

the back wall, as shown in figure 3, with orientation

hole against wall.

C. Use the bracket as a template and mark the required

holes, as shown in figure 3 for the type of construction

you will be using.

D. Free-standing range may be secured to either floor or

wall.

STEP 2 - Anti-Tip Bracket Installation

Options

A. Wood Construction:

1. Floor: Locate the center of the two holes identified

in figure 3 as "HOLES FOR FLOOR". Drill a 1/8"

(3 mm) pilot hole in the center of each hole (a nail

or awl may be used if a drill is not available).

Secure the ANTI-TIP bracket to the floor with the

two screws provided. Proceed to Step 3.

. Wall: Locate the center of the two holes identified

in figure 3 as "HOLES FOR WALL". Drill an

angled 1/8" (3 mm) pilot hole in the center of each

hole as shown infigure 4. (A nail or awl may be

used if a drill is not available). Secure the

ANTI-TIP bracket to the wall with the two screws

provided as shown in figure 4. Proceed to STEP

3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can be

obtained at the hardware store. Drill the required

size hole for the hardware obtained into the

concrete at the center of the holes identified in

figure 3 as "HOLES FOR FLOOR". Secure the

ANTI-TIP bracket to the floor. Proceed to STEP

3.

9/!6"

[14.5 mm]

FROM EDGE

OF RANGE

MARKEDEDGE__

OF RANGE

ORIENTATION

HOLE

ATTACHANTI-TIP BRACKETWITH A

MINIMUMOF TWO(2) LONGSCREWS

TO THE WALLOR FLOOR.

ANTI-TIP

BRACKET

LEVELING

FOOT

HOLES FOR

FLOOR

(EACH SIDE)

FIGURE 3

-3-

Page 4

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

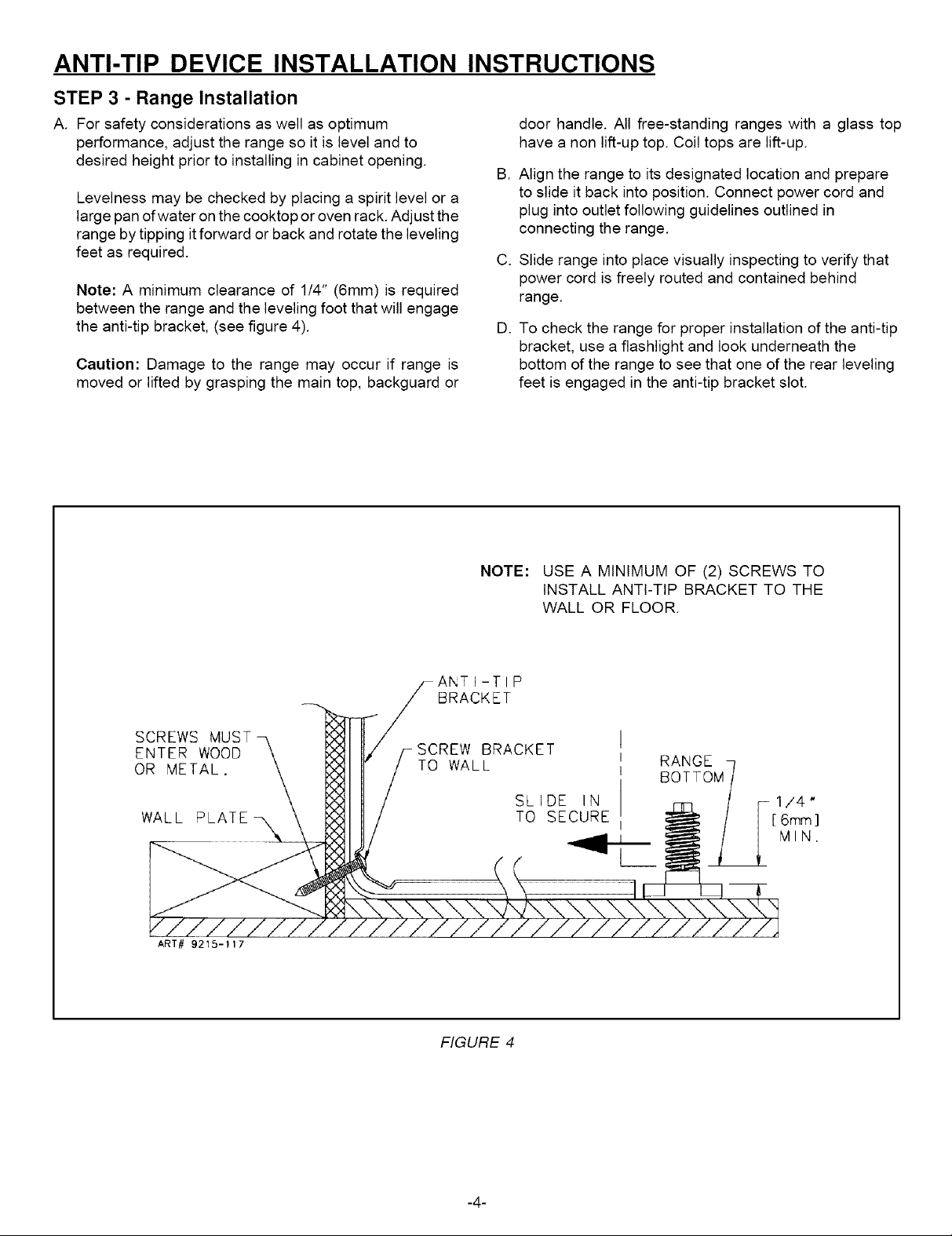

STEP 3 - Range Installation

A. For safety considerations as well as optimum

performance, adjust the range so it is level and to

desired height prior to installing in cabinet opening.

Levelness may be checked by placing a spirit level or a

large pan of water on the cooktop or oven rack. Adjust the

range by tipping it forward or back and rotate the leveling

feet as required.

Note: A minimum clearance of 1/4" (6mm) is required

between the range and the leveling foot that will engage

the anti-tip bracket, (see figure 4).

Caution: Damage to the range may occur if range is

moved or lifted by grasping the main top, backguard or

door handle. All free-standing ranges with a glass top

have a non lift-up top. Coil tops are lift-up.

a.

Align the range to its designated location and prepare

to slide it back into position. Connect power cord and

plug into outlet following guidelines outlined in

connecting the range.

C.

Slide range into place visually inspecting to verify that

power cord is freely routed and contained behind

range.

D.

To check the range for proper installation of the anti-tip

bracket, use a flashlight and look underneath the

bottom of the range to see that one of the rear leveling

feet is engaged in the anti-tip bracket slot.

SCREWS MUST

ENTER WOOD

OR METAL.

WALL PLATE

ART# 9215-117

NOTE: USE A MINIMUM OF (2) SCREWS TO

ANTI-TIP

BRACKET

SCREW BRACKET

TO WALL

SLIDE IN

TO SECURE

INSTALL ANTI-TIP BRACKET TO THE

WALL OR FLOOR.

[ 6mm]

MIN.

FIGURE 4

-4-

Page 5

CONNECTING THE RANGE

ELECTRIC SUPPLY

The range must be installed in accordance with Local and

National Electric Code (NEC) ANSI/NFPA No. 70-latest

edition. See rating plate for total connected KW rating.

ELECTRIC SUPPLY (Canada)

The range must be installed in accordance with Local and

Canadian Electric Code CSA STD.C22.1 latest edition.

See rating plate for total connected KW rating.

OUTSIDE WIRING

Your local utility company will tell you whether the present

electric service to your home is adequate. It may be

necessary to increase the size of the wiring to the house

and service switch to take care of the electrical load

demanded by the range. The kilowatt rating for the range

is specified on the rating plate located on front of range.

HOUSE WIRING

Most local Building Regulations and Codes require that all

electrical wiring be done by licensed electricians. All

wiring should conform to Local and National Electrical

Codes. This range requires a single phase three wire

120/240 or a 120/208 volt, 60 Hz, AC circuit. Wiring codes

require a separate circuit be run from the main entrance

panel to the range and that it be equipped with separate

disconnect switch and fuses, either in the main entrance

panel or in a separate switch and fuse box. tn some

communities, a solid or flexible continuous armored

conduit must be used from main entrance panel to the

terminal box on the rear of the range. Others will permit

the termination of the range circuit at a polarized three or

four wire plug-in outlet placed at a convenient point near

the back of the range. The range is then connected to this

outlet through an approved range connector (pigtail)

fastened securely to the terminal block with proper strain

relief at the range and a three or four pronged plug at the

opposite end.

by local code. USE COPPER OR ALUMINUM

CONDUCTORS. Main terminal block is recognized for

Copper or Aluminum conductors. Ifa flexible power cord

is required, it is recommended a cord no longer than 4 ft.

be used. Make connections as explained below and with

reference to the appropriate illustration (see figures 6 and

7). After installation, insure tightness of all electrical

connections and replace all covers.

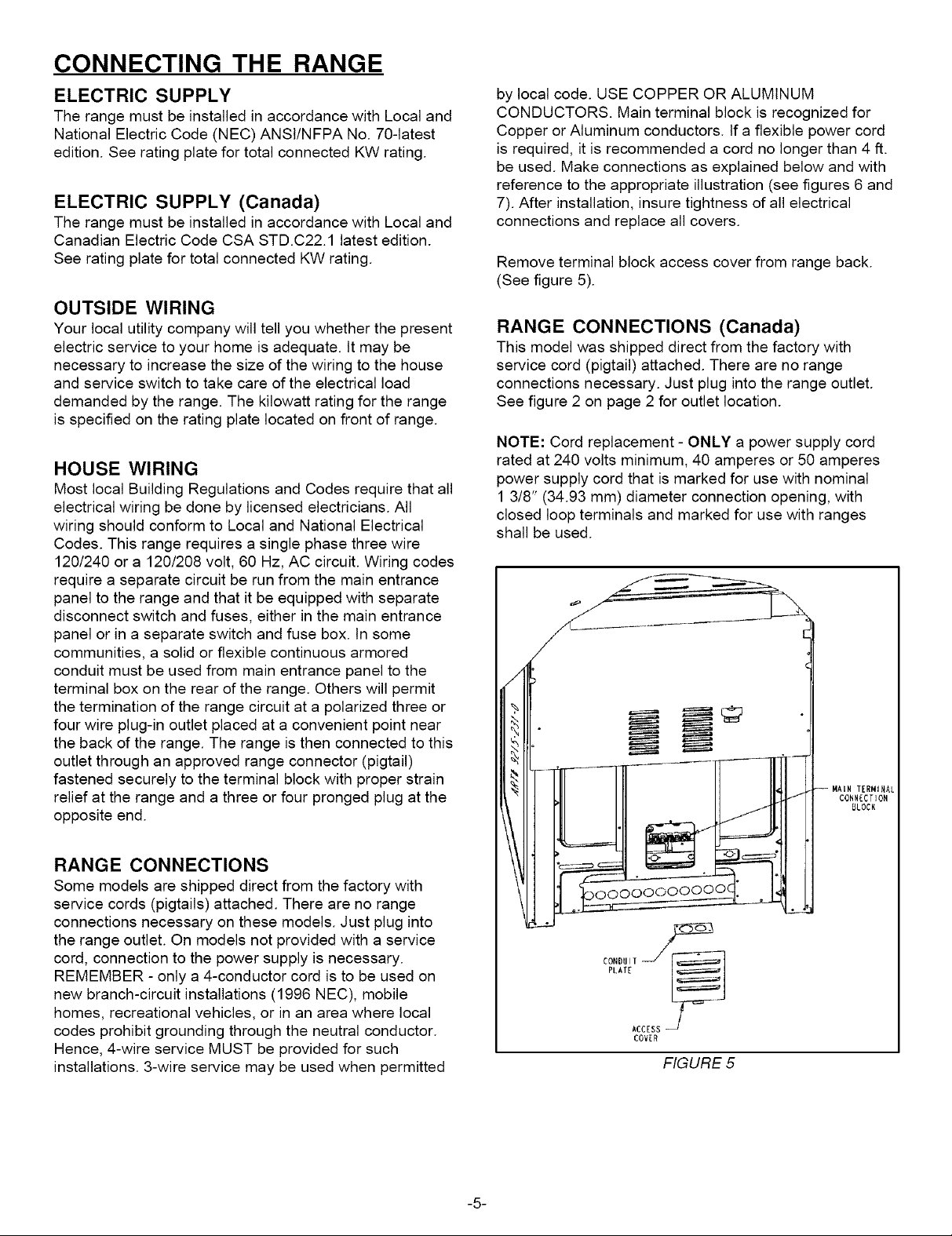

Remove terminal block access cover from range back.

(See figure 5).

RANGE CONNECTIONS (Canada)

This model was shipped direct from the factory with

service cord (pigtail) attached. There are no range

connections necessary. Just plug into the range outlet.

See figure 2 on page 2 for outlet location.

NOTE: Cord replacement - ONLY a power supply cord

rated at 240 volts minimum, 40 amperes or 50 amperes

power supply cord that is marked for use with nominal

1 3/8" (34.93 mm) diameter connection opening, with

closed loop terminals and marked for use with ranges

shall be used.

/

I

RANGE CONNECTIONS

Some models are shipped direct from the factory with

service cords (pigtails) attached. There are no range

connections necessary on these models. Just plug into

the range outlet. On models not provided with a service

cord, connection to the power supply is necessary.

REMEMBER - only a 4-conductor cord is to be used on

new branch-circuit installations (1996 NEC), mobile

homes, recreational vehicles, or in an area where local

codes prohibit grounding through the neutral conductor.

Hence, 4-wire service MUST be provided for such

installations. 3-wire service may be used when permitted

FIGURE 5

-5-

Page 6

CONNECTING THE RANGE

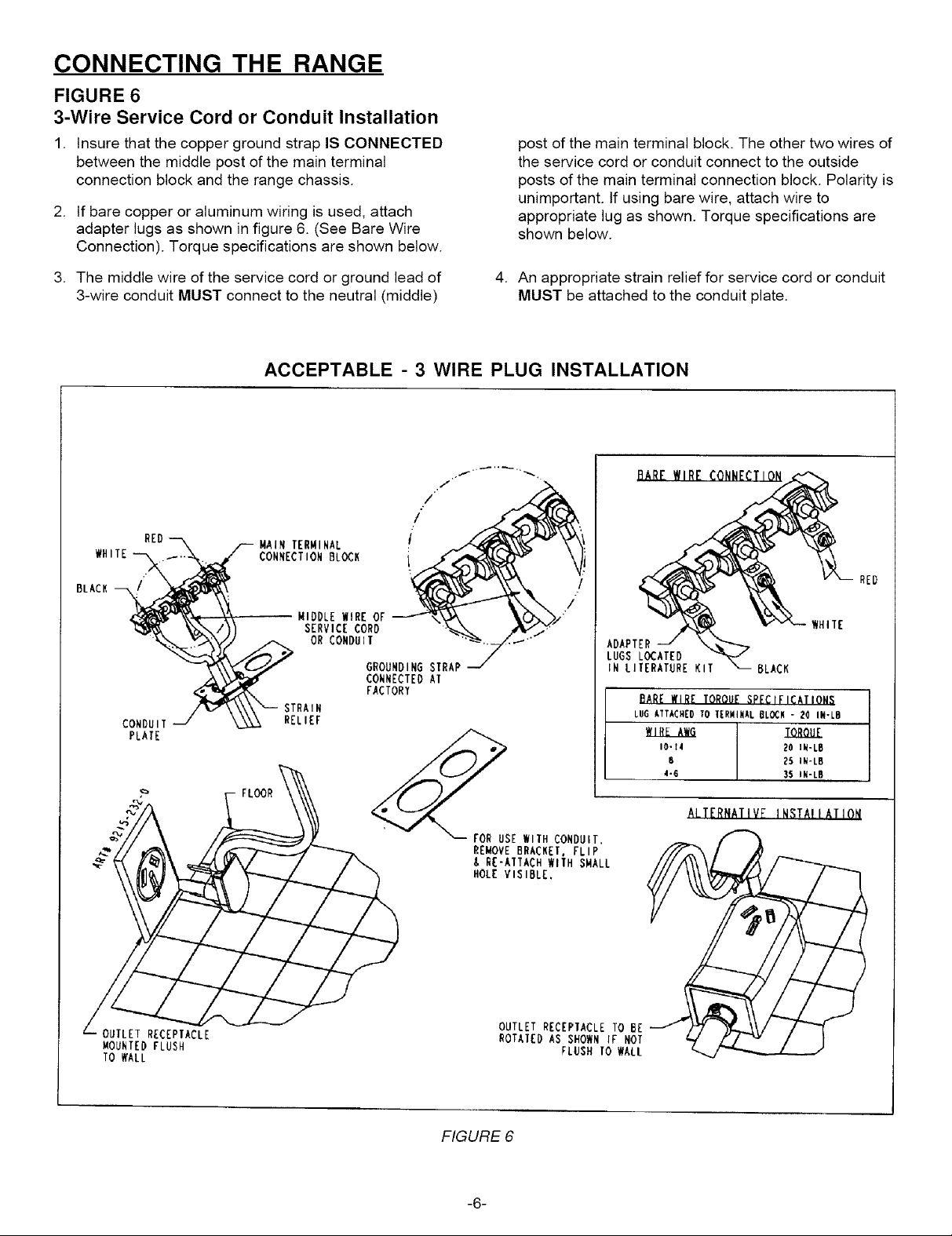

FIGURE 6

3-Wire Service Cord or Conduit Installation

1. Insure that the copper ground strap IS CONNECTED

between the middle post of the main terminal

connection block and the range chassis.

2. If bare copper or aluminum wiring is used, attach

adapter lugs as shown infigure 6. (See Bare Wire

Connection). Torque specifications are shown below.

post of the main terminal block. The other two wires of

the service cord or conduit connect to the outside

posts of the main terminal connection block. Polarity is

unimportant. If using bare wire, attach wire to

appropriate lug as shown. Torque specifications are

shown below.

3. The middle wire of the service cord or ground lead of

3-wire conduit MUST connect to the neutral (middle)

ACCEPTABLE - 3 WIRE PLUG INSTALLATION

/

MAIN TERMINAL /

CONNECTION BLOCK 1

MIDDLE WIRE OF WHITE

SERVICE CORD /.

OR CONDu(T ADAPTER

GROUNDING STRAP IN LITERATURE KIT BLACK

CONNECTED AT

STRAIN

CONDUIT

PLATE _ io.14 20 IE-LB

RELIEF LUG ATTA_H[D TO TERMINAL OLO_K - 20 IN-LB

FACTORY BAR[ W] RF TOROUF SPFC I F ICAT IONS

4. An appropriate strain relief for service cord or conduit

MUST be attached to the conduit plate.

,.-" "-. BARF WIRF CONNECTION

I"

/ RED

LUGS LOCATED

WIREA_G

8 25 IE-LB

,; ALTERNATIVE INSTAllATION

,,>'_ FOR USE WITH CONDUIT. _

REMOVE BRACKET.FLIP /,/./_._'_/ ,_

& RE-ATTACH WITH SMALL ////'_\_ \L ///_

Ol

OUTLET RECEPTACLE TO BE -_j

WOUNTED FLUSH FLUSH TO WALL "--

TO WALL

FIGURE 6

ROTATED AS SHOWN IF NOT _/ L'/

-6-

Page 7

CONNECTING THE RANGE

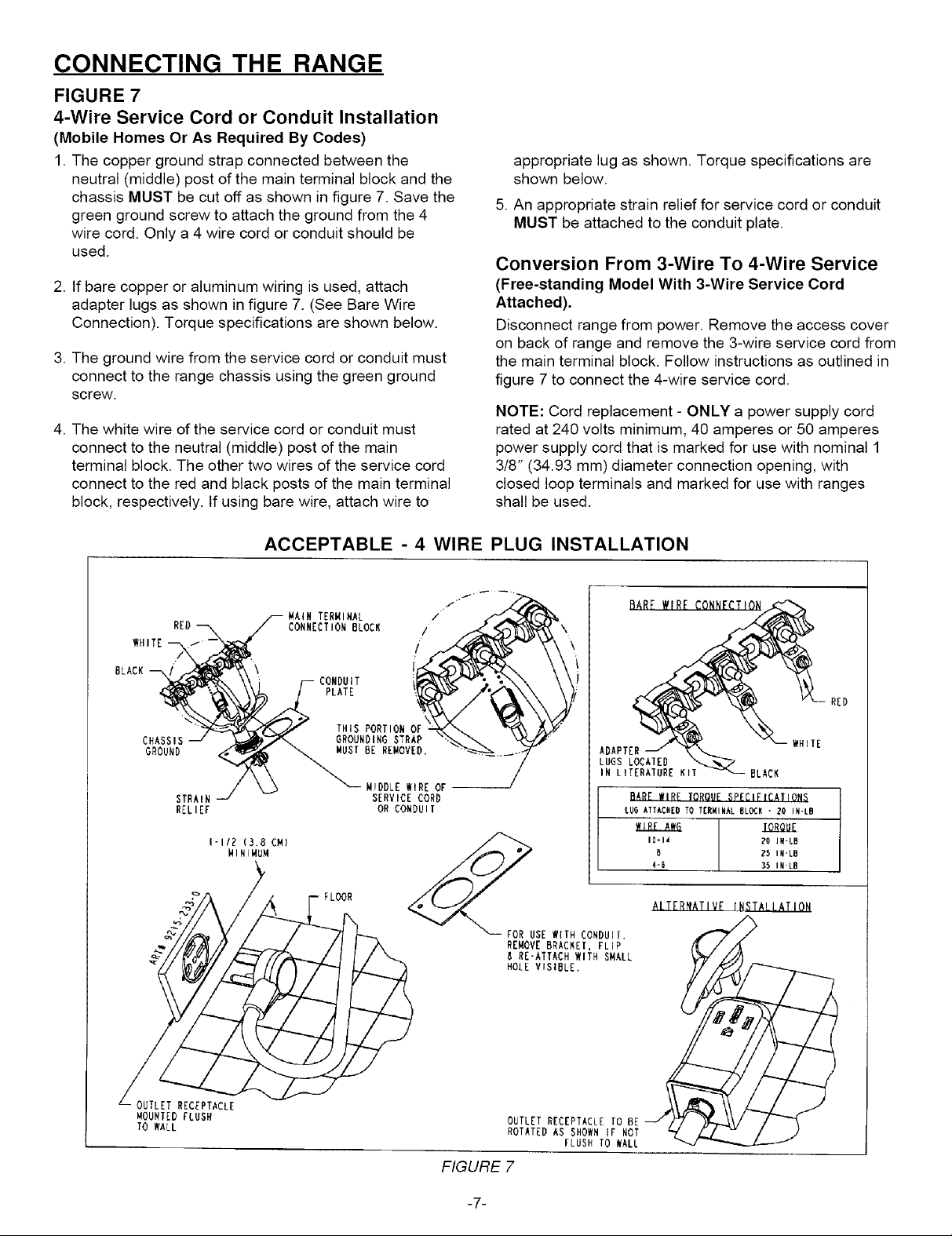

FIGURE 7

4-Wire Service Cord or Conduit Installation

(Mobile Homes Or As Required By Codes)

1. The copper ground strap connected between the

neutral (middle) post of the main terminal block and the

chassis MUST be cut off as shown in figure 7. Save the

green ground screw to attach the ground from the 4

wire cord. Only a 4 wire cord or conduit should be

used.

2. If bare copper or aluminum wiring is used, attach

adapter lugs as shown in figure 7. (See Bare Wire

Connection). Torque specifications are shown below.

3. The ground wire from the service cord or conduit must

connect to the range chassis using the green ground

screw.

4. The white wire of the service cord or conduit must

connect to the neutral (middle) post of the main

terminal block. The other two wires of the service cord

connect to the red and black posts of the main terminal

block, respectively. If using bare wire, attach wire to

appropriate lug as shown. Torque specifications are

shown below.

5. An appropriate strain relief for service cord or conduit

MUST be attached to the conduit plate.

Conversion From 3-Wire To 4-Wire Service

(Free-standing Model With 3-Wire Service Cord

Attached),

Disconnect range from power. Remove the access cover

on back of range and remove the 3-wire service cord from

the main terminal block. Follow instructions as outlined in

figure 7 to connect the 4-wire service cord.

NOTE: Cord replacement - ONLY a power supply cord

rated at 240 volts minimum, 40 amperes or 50 amperes

power supply cord that is marked for use with nominal 1

3/8" (34.93 mm) diameter connection opening, with

closed loop terminals and marked for use with ranges

shall be used.

WHITE

BLACK

CHASSIS

GROUND

RE8

STRAIN

RELIEF

ACCEPTABLE - 4 WIRE PLUG INSTALLATION

1-112 (3.8 CM)

MINIMUYl

TERM,MAL,

co,,E:T,O,BLOC,/ \

/ \

MLISTBE REMOVED. "_, _..--7'-

MIDDLE WIRE OF .... r

SERVICE CORD

OR CONOUI T

FLOOR

_USE WITH CONDUIT.

-/

REMOVE BRACKET, FLIP

& RE-ATTACH WITH SMALL

HOLE VISIBLE.

BARE WIRE CONNECTION

ADAPTER

LUGS LOCATED

IN LITERATURE KIT BLACK

BAR[ WIRE TORQUE SPECIFICATIONS

LUGATIACHED TO TZRNINkL BLOCK- _0 IN-LB

10"14 20 JN'LB

8 Z5 IN'LB

4-6 35 IN-LB

ALTER_ATIVF INSTALlATION

RED

WHITE

Z OUTLET RECEPTACLE

MOUNTED FLUSH

TO WALL

FIGURE 7

-7-

OUTLET RECEPTACLE TO BE

ROTATED AS SHOWN IF NOT

FLUSH TO WALL

Page 8

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL APARA TO

MANUAL DE INSTA ON

Estufa electrica individual de

30 pulgadas (76.2 cm) de ancho

CONSERVE ESTE MANUAL PARA REFERENCIA FUTURA

EL MANUAL TIENE LA FINALIDAD DE AYUDARLE EN LA INSTALACION Y AJUSTES INICIALES DE LA ESTUFA.

DIMENSIONES DEL HUECO

Para obtener la informaci6n completa relacionada con la

Solamente personal calificado debe

instalar o darle servicio a esta estufa.

Lea las "lnstrucciones de seguridad"

en el libro de Uso y cuidado antes de

utilizar la estufa.

instalacion de la estufa individual, vea las figuras 1 y 2

de las pagina 9. Por RAZONES DE SEGURIDAD no

instale la estufa en ningQn gabinete combustible que no

este de acuerdo con las dimensiones de los espacios de

instalacion que se muestran en la figura 1.

CASAS MOVILES

La instalacion, el ajuste, las alteracio-

nes, el servicio, el mantenimiento o el

uso incorrectos de la estufa pueden

causar lesiones graves o daSos

materiales.

PRECAUCION: Esta estufa se ha diseSado en

conformidad con los requisitos de varias agencias

de seguridad y cumple con las temperaturas

maximas permisibles de 194°F (90°C) para los

gabinetes de madera. Si se instala esta estufa en

gabinetes que tengan una temperatura de trabajo

menor de 194°F (90°C), podrian ocurrir decolora-

cion, perdida del laminado o podria derretirse.

ENGLISH 0 PP. 1-7

ESPANOL 0 p_lg. 8-14

FRAN(_AIS n) p. 15-21

La instalacion de una estufa dise5ada para casas

m6viles debe estar en conformidad con las Normas de

Seguridad y Construccion de Casas Prefabricadas

(Manufactured Home Construction and Safety Standard,

Titulo 24 CFR, Parte 3280 (anteriormente Federal

Standard for Mobile Home Construction and Safety,

Titulo 24 HUD, Parte 280)) o, cuando dichas normas no

correspondan, las Normas para tnstalaciones en Casas

Prefabricadas de 1982 (Manufactured Home Sites,

Communities and Set-Ups), ANSI A225.1-QItima edicion

o con los codigos locales.

UBICACION DE LA ESTUFA

Coloque la estufa en un area bien iluminada. No la

coloque sobre agujeros del piso ni en algQn lugar en

donde pueda recibir corrientes de aire fuertes. Deben

sellarse los orificios de la pared posterior y del piso

debajo de la estufa. AsegQrese que el flujo de

enfriamiento o el aire de ventilacion no esten obstruidos

debajo de la estufa.

-8-

Page 9

DIBUJOS DE INSTALACION

IMPORTANTE

SiRVASECONSERVARLOPARAOUELOI

USE EL INSPECTOR ELECTRICO LOCAL:

"A" = 30 pulgadas (76.2 cm) espacio minimo entre la

parte superior de la superficie de cocinar y la parte

inferior de un gabinete sin proteccion de madera o

metal, o "A" = 24 pulgadas (61 cm) cuando menos

cuando la parte inferior de un gabinete de madera o

metal esta protegido por de 1/4 de pulg. (6.4 mm) un

carton grueso recubierto con una hoja de acero cuando

menos del No. 28 MSG, una hoja de acero inoxidable de

0.015 pulg (0.381 mm) de espesor, aluminio de 0.024

pulg (0.610 mm) de espesor o una de cobre de 0,020

pulg (0.508 mm).

Para eliminar el riesgo de quemaduras o incendios por

alcanzar cosas por encima de las unidades superficiales

calientes, debe evitarse el espacio de almacenamiento

del gabinete que se ubica encima de las unidades

superficiales. Si se va a proporcionar almacenamiento

de gabinete, el riesgo puede reducirse instalando una

campana de estufa que sobresalga horizontalmente

cuando menos 5 pulgadas (13 cm) de la parte inferior de

los gabinetes.

FIGURA 1

1,2, 3 - PAREDES COMBUSTIBLES DEL EDIFIClO.

4 - GABINETE DE PAREDES COMBUSTIBLES.

Una estufa individual puede instalarse adyacente a (0"

de) las paredes combustibles 1, 2 y 3.

FIGURA 1

NOTA: La figura puede no ser representativa

de la unidad real

PROPORCIONE UN TOMACORRIENTE DE

120/208 VOLTIOS, ,120/240 VOLTIOS AL RAS

POR CADA CORDON CORRESPONDIENTE

EN ESTA AREA

"B

/

/

_(14"6 CM) __ _ 1"C ! / MOSTRADOR

7"

14.6CM) (7.6CM) _. ' !1/ _[ DELGABINETE

NOTA: PARA LA INSTALACION EN CANADA, UNA

ESTUFA INDIVIDUAL NO DEBE INSTALARSE MAS

CERCA DE 12 MM DE UNA SUPERFICIE

ADYACENTE,

"A" = 30" (76.2 CM)- 3!" (78.7 CM) PARA CANADA,

"B" = 3 1/4" (8.3 CM) - 3 3t4" (9.5 CM) PARA CANAD, g,

7" tS - /_ 25'T'

(14.6 CM) _-_ L__ // I (63.5 CM)

I I I _ // I f PROFUNDIDAD

I 1 i NORMAL DE LA

7" I t l "_ 1 I SUPERFICIE DEL

(51 CM)

, I/I/-PR°FUNDI°AD

l

86 _

(91.5 CM)

ALTURA DE LA PARTE /

SUPERIOR DEL MOSTRADOR /

/

ABERTURAS SUPERIOR E

INFERIOR DEL GABINETE

FIGURA 2

-9-

DE

120/208 VOLT!OS, 120/240 VOLTIOS AL RAS

POR CADA CORDON CORRESPONDIENTE

EN ESTA AREA

Page 10

INSTRUCCIONESDE INSTALACIONDELDISPOSITIVOESTABILIZADOR

ADVERTENCIA: Existe la posibilidad de que la estufa se

ladee si no esta instalada de acuerdo alas instrucciones

de instalaci6n que se proporcionan. El use correcto de

este dispositivo reduce el riesgo de LADEO. AI usar este

dispositivo el consumidor aun debe acatar las

precauciones de seguridad que se dictan en el MANUAL

DE USO Y CUIDADO y debe evitar utilizar las puertas del

horno come banquillo.

Las instrucciones de instalacion se proporcionan para

madera y cemento tanto en piso como pared. Cualquier

otro tipo de construcci6n podria necesitar tecnicas

especiales de instalacion segQn se determine necesario

para proporcionar la sujecion adecuada del soporte

ESTABILIZADOR al piso o a la pared. El soporte puede

instalarse para sujetar la pata niveladora posterior

IZQUIERDA o DERECHA.

PASO 1 -Ubicacion del soporte ESTABILIZADOR

(yea la figura 3)

A. Decida en d6nde se ubicara el "BORDE" derecho o

izquierdo de la estufa y marque el piso o la pared.

B. Coloque el SOPORTE del "BORDE" marcado a 9/16"

(14.5 mm) del centro de la abertura y contra la pared

posterior segQn se muestra en la figura 3, con el

orificio de orientacion hacia la pared.

C. Use el soporte como plantilla y marque los orificios

necesarios, segQn se muestra en la figura 3, para el

tipo de construcci6n que se utilizar&

D. La estufa individual puede asegurarse tanto al piso

como a la pared.

PASO 2 -Opciones para la instalacion del

soporte estabilizador

A. Construccion de madera:

1. Piso: Ubique el centro de los dos oriflcios que se

identifican en la figura 3 como "ORtFtClOS PARA

EL PISO". Taladre un agujero piloto de 1/8 (3

mm) en el centro de cada orificio (puede utilizarse

un clavo o una lezna si no tiene una broca).

Asegure el soporte ESTABILIZADOR al piso con

los dos tornillos que se proporcionan. ContinQe

con el PASO 3.

2. Pared: Ubique el centro de los dos orificios que

se identifican en la figura 3 como "ORIFtCIOS

PARA LA PARED". Taladre un agujero piloto en

angulo de 118" (3 mm) en el centro de cada

orificio segQn se muestra en la figura 4. (Puede

utilizarse un clavo o una lezna si no tiene una

broca). Asegure el soporte ESTABILIZADOR al

piso con los dos tornillos que se proporcionan

segQn se muestra en la figura 4. ContinQe con el

PASO 3.

a.

Construcci6n de concreto o cemento:

.

En una ferreteria pueden obtenerse los tornillos

adecuados para las construcciones de concreto.

Taladre un agujero del tama5o necesario para los

tornillos obtenidos, en el concreto en el centro de

los orificios que se identifican en la figura 2 como

"ORIFIClOS PARA EL PtSO". Asegure el soporte

al piso. ContinQe con el PASO 3.

9/16"

[14.5

desde el borde

de la estufa

de

orientacion

/_Sujete el soporte estabilizador con un

para J minimo de dos (2) tornillos largos a la

la pared /'pared o al piso.

aorte estabilizador

niveladora

Borde marcado j _

de la estufa Orificios para el piso

FIGURA 3

-10-

Page 11

INSTRUCCIONESDE INSTALACIONDELDISPOSITIVOESTABILIZADOR

PASO 3 - Instalacion de la estufa

A. Por razones de seguridad asi como para obtener el

desempefio 6ptimo, ajuste la estufa de manera que este

bien nivelada y a la altura deseada antes de instalarla en

el hueco del gabinete.

La nivelacion puede revisarse colocando un nivel de

burbuja de aire o un recipiente grande de agua en la

superficie para cocinar o en la parrilla del horno. Ajuste la

estufa ladeandola hacia delante o hacia atras y girando

la pata niveladora segQn sea necesario.

Nota: Se requiere un espacio libre de cuando menos

6 mm (1/4 pulg) entre la estufa y la pata niveladora que

se enganchara al soporte estabilizador (vea la figura 4).

Precaucion: La estufa puede dafiarse si se mueve o

levanta tomandola por la parte superior principal o por el

protector posterior o el asa de la puerta. Todas las

estufas individuales con la parte superior de vidrio tienen

la parte superior fija. La parte superior del serpentin se

puede levantar.

a.

Alinee la estufa en su ubicacion final y preparela para

deslizarla hacia atras en su lugar. Conecte la energia

electrica y enchQfela en un tomacorriente siguiendo

las directrices indicadas en la conexion de la estufa.

C.

Deslice la estufa en su lugar e inspeccionela

visualmente para comprobar que el cord6n electrico

este libre y bien acomodado detras de la estufa.

U.

Para revisar que el soporte estabilizador de la estufa

este bien instalado, use una linterna y vea por debajo

de la estufa para comprobar que una de las patas

niveladoras este enganchada en la hendidura del

soporte estabilizador.

LOS TORNILLOS

DEBEN ENTRAR

EN

EL METAL.

PLACA DE

PARED

ART# 9215-117

NOTA: USE CUANDO MENOS (2) TORNILLOS PARA

ESTABILIZADOR

INSTALAR EL SOPORTE ESTABILIZADOR A LA

PARED O AL PISO.

I

EL

PARTE

I

INFERIOR

I

DE LA

ESTUFA 1/4,

I

FIGURA 4

(6 MM)

MiN.

-11-

Page 12

CONEXION DE LA ESTUFA

SUMINISTRO ELC:CTRICO

La estufa debe instalarse de acuerdo a los C6digos

Electricos Locales y Nacionales (NEC) ANSt/NFPA No.

7O-Qltima edici6n. Yea la placa de clasificaci6n para

obtener la clasificaci6n total de KW conectados.

SUMINISTRO ELC:CTRICO (Canada)

La estufa debe instalarse de acuerdo a los Codigos

Electricos Canadienses y Locales CSA STD.C22.1 QItima

edici6n. Vea la placa de clasificacion para obtener la

clasificaci6n total de KW conectados.

CABLEADO EXTERIOR

La compa_ia local de servicios pQblicos le informara si es

adecuado el servicio electrico actual a su casa. Podria

ser necesario aumentar el tama_o del cableado a la casa

y el interruptor de servicio para poder con la carga

electrica que la estufa demanda. La clasificaci6n de

kilovatios para la estufa esta especificada en la placa de

clasificaci6n que se ubica al frente de la estufa.

CABLEADO DE LA CASA

La mayoria de los C6digos y Reglamentos locales para

edificios exigen que todo el cableado electrico Io instale

un electricista con licencia. Todo el cableado debe estar

en conformidad con los C6digos Electricos Nacionales y

Locales. Esta estufa requiere un circuito de CA

monofasico de tres o cuatro cables de 120/240 o de

120/208 voltios, 60 Hz. Los c6digos de cableado

requieren que se tenga un circuito separado del tablero

principal de entrada a la estufa y que este equipado con

fusibles y con un interruptor de desconexion, ya sea en el

tablero principal de entrada o en un interruptor y caja de

fusibles separados. En algunas comunidades, debe

usarse un conductor flexible o s61idoacorazado continuo

del tablero principal de entrada a la caja terminal en la

parte posterior de la estufa. Otros permitiran que el

circuito de la estufa termine en un tomacorriente de

conexion polarizada de tres o cuatro cables colocado en

un lugar conveniente cerca de la parte posterior de la

estufa. Entonces se puede conectar la estufa a este

tomacorriente mediante un conector de la clasificaci6n

aprobada (cable flexible de conexi6n) asegurado con

firmeza al bloque terminal, con el protector contra tirones

apropiado, a la estufa y a un enchufe de tres o cuatro

puntas en el otro extremo.

mediante el conductor neutro. Por Io tanto, DEBE

proveerse un servicio de 4 alambres en dichas

instalaciones. El servicio de 3 alambres puede usarse

cuando Io permitan los codigos locales. USE

CONDUCTORES DE COBRE OALUMINIO. El bloque

terminal principal esta indicado para uso con conductores

de cobre o aluminio. Si se necesita un cord6n de

suministro electrico, se recomienda usar un cord6n que

no sea mas largo de 4 pies. Haga las conexiones segQn

se explica a continuacion y consulte las ilustraciones

correspondientes (vea las figuras 6 y 7). Despues de la

instalacion, asegQrese de que todas las conexiones

electricas esten bien ajustadas y coloque todas las

cubiertas.

Quite la cubierta de acceso del bloque terminal de la parte

posterior de la estufa. (Vea la figura 5).

CONEXIONES DE LA ESTUFA (en Canada)

Este modelo se embarco directamente de fabrica con el

cordon de servicio (cable flexible de conexion). No es

necesario hacer ninguna conexion en la estufa.

Sencillamente conectela en el tomacorriente de la estufa.

Vea la figura 2 en la pagina 9 para saber la ubicacion del

tomacorriente.

NOTA: Reemplazo del cord6n, SOLAMENTE se debera

utilizar un cord6n de suministro electrico de clasificaci6n

minima de 240 voltios, 40 6 50 amperios que este

marcado para usarse con una abertura nominal de

conexi6n de 1 3/8" (34.93 mm) de diametro, con

terminales de lazo cerrado y que esten marcados para

utilizarse con estufas.

/

b

BLOQUE,DE

I

\

'111 III II __11" ] CONEXION

CONEXIONES DE LA ESTUFA

AIgunos modelos se envian directamente de fabrica con

los cordones de servicio (cables flexibles de conexi6n)

sujetos. No es necesario hacer ninguna conexion en

estos modelos de estufa. Sencillamente conectelos en el

tomacorriente de la estufa. En los modelos que no vienen

con el cord6n de servicio, es necesario hacer la conexi6n

al suministro de energia. RECUERDE - solamente debe

usarse un cord6n de 4 conductores en las instalaciones

nuevas de circuitos derivados (1996 NEC), areas en

donde los c6digos locales prohiben la conexion a tierra

•.E PRINCIPAL

PLAOACONDUCTOR

CUBIERTADEACCESO-u

FIGUR,45

-12-

Page 13

CONEXION DE LA ESTUFA

FIGURA 6

INSTALACION DEL CORDON DE SERVICIO DE 3 CABLES O DEL CONDUCTOR

Verifique que la tira de conexion a tierra de cobre

ESTE CONECTADA entre el poste medic del bloque

de conexion del terminal principal y del bastidor de la

estufa.

.

Si se usa alambrado desnudo de cobre o aluminio,

sujete la lengQeta de conexion del adaptador segQn

se muestra en la figura 6. (Vea Conexion de alambre

desnudo). Las especificaciones de torsion se

muestran a continuacion.

El alambre en medic del cord6n de servicio o la guia

de conexion a tierra del conductor de 3 alambres

INSTALACION ACEPTADA DEL ENCHUFE DE 3 CABLES

DEBE conectarse al poste neutro (central) del bloque

del terminal principal. Los otros dos alambres del

cordon de servicio o del conductor se conectan a los

postes de fuera del bloque de conexion del terminal

principal. La polaridad no es importante. Si va a usar

alambre desnudo, sujete el alambre a la lengQeta de

conexion correspondiente segQn se muestra. Las

especificaciones de torsion se muestran a

continuacion.

.

Debe instalarse un protector contra tirones apropiado

para el cord6n de servicio o del conductor a la placa

del conductor.

CONEXION DE

/

DE CONEXION !

BLANCO-_

NEGRO_

PLACA DEL CONTRA TIRONES

CONDUCTOR _ CALIBRE DELALAMBRE TORSION DE

DEL TERMINAL I

PRINCIPAL

ALAMBRE EN

MEDIC DEL

CORDON DE

SERVICIO O DEL

CONDUCTOR

PROTECCION

CORREA DE TIERRA

CONECTADA DE

FA,BRICA

J_i _ 10-14 20 PULG/UBRAB

ALAMB_

_v'-v"--B LANCO

iiiGDONAEpT_iiiX_ N"____ iXE E RO

MATERIALESIMPRESOS

ESPECIFICACIONES DE TORSION DEL ALAMBRE DESNUDO

LENGUETADE CONEXI6N SUJETAALBLOQUETERMINAL- 20 PULG/LIBRAS

/ (" _.// 0 2_PULG/UBRAS

*,"*,'_07 4-6 35PuLG,UBRAS

_. INSTALACION _ALTERNATIVA

v "_PARA EL USO CON

CONDUCTOR. QUITE EL _, it ,_

SOPORTE, VOLTEELO Y /////_ \_jf/_ _

VUELVA A SUJETARLO /-./'/// \\\ _-- /

CON EL ORIFIClO y/ _.--"_,_ _._:.._ /_,

EO .OA VSTA

RECEPT,_CULO DEL J /,_ _ r / --

TOMACORRIENTE

MONTADO AL RAS MUESTRA SINO ESTA AL

DE LA PARED RAS DE LA PARED

FIGURA 6

-13-

TOMACORRIENTE A _/' _ _ it

ROTARSE SEGUN SE -"-J _

Page 14

CONEXI()N DE LA ESTUFA

FIGURA 7

INSTALACION DEL CORDON DE SERVICIO DE 4

CABLES O DEL CONDUCTOR

(COMO LO REQUlEREN LAS CASAS MOVILES O LOS

CODIGOS LOCALES)

1. La tira de conexion a tierra de cobre que esta

conectada entre el poste neutro (medio) del bloque del

terminal principal y el bastidor DEBE cortarse segQn se

muestra en la figura 7. Conserve el tornillo verde de

conexion a tierra para sujetar la tierra del cord6n de 4

cables. Solamente debe utilizarse un cord6n de 4

cables o conductor.

2. Si se usa alambrado desnudo de cobre o aluminio,

sujete la lengQeta de conexion del adaptador segQn se

muestra en la figura 7. (Yea Conexion de alambre

desnudo). Las especificaciones de torsion se muestran

a continuacion.

3. El cable de conexion a tierra del cord6n de servicio o

del conductor debe conectarse al bastidor de la estufa

usando el tornillo verde de conexion a tierra.

4. El cable blanco del cordon de servicio o del conductor

debe conectarse al poste neutro (medio) del bloque del

terminal principal. Los otros dos cables del cord6n de

servicio o del conductor se conectan a los postes rojo y

INSTALAClON ACEPTADA DE UNA

negro del bloque del terminal principal, respec-

tivamente. Siva a usar alambre desnudo, sujete el

alambre a la lengQeta de conexion correspondiente

segQn se muestra. Las especificaciones de torsion se

muestran a continuacion.

5. Debe colocarse a la placa del conductor un protector

contra tirones apropiado en el cord6n de servicio o el

conductor.

CONVERSION DE SERVIClO DE 3 CABLES A 4

CABLES

(Modelo individual con cordon sujeto de servicio de 3

cables)

Desconecte la estufa de la energia electrica. Quite la

cubierta de acceso en la parte posterior de la estufa y

quite el cord6n de servicio de 3 cables del bloque del

terminal principal. Siga las instrucciones a continuacion

segQn se indica en la figura 7 para conectar el cord6n de

servicio de 4 cables.

NOTA: Reemplazo del cord6n, debera utilizarse

SOLAMENTE un cordon de suministro de energia con

clasificacion minima de 240 voltios, 40 6 50 amperios que

este marcado para utilizacion con aberturas nominales de

1 3/8" (34.93 mm) de diametro, con terminales de lazo

cerrado y marcados para utilizacion con estufas.

CLAVIJA DE CUATRO CABLES

NEGRO

CONEXION A

TIERRA DEL

CHASIS

PROTECCION

CONTRA TIRONES

BLOQUE DE CONEXION

DEL TERMINAL /- ....

PF SIPAL / /../"'

' ii

1 - 1/2" (3.8 _M)MiNIMO

DEL

CONDUCTOR

DEBE QUITARSE

ESTA PORCION

DE LA CORREA _ _ .--

)E TIERRA.

ALAMBRE EN I

MEDIO DEL I ESPEOIFICAOIONES DE TORSION DELALAMBRE DESNUDO

CORDON DE ILENGOETADECONEXtONSUJETAALBLOQUETERMINAL_20PULG/LISRAS

SERVICIO O DEL

CONDU_ I CALIBRE BELALAMBREf._/i_I TORSI6N DE

CONEXION DE

\

_! ALAMBRE

LENGUETASDECONEXION BLANCO

DEL ADAPTADORUBICADAS

ALES IMPRESOS

ENELPAQUETEDE MATERI- NEGRO

I 10-14 I 20 PULG/LIBRAS

I 8 I 25 PULG/LIBRAS

L 4-6 35 PULG/UBRAS

INSTALAClON ALTERNATIVA

_--PARA EL USO CON

CONDUCTOR. QUITE EL (_. / /"_

SOPORTE, VOLTEELO Y

VUELVA A SUJETARLO

CON EL ORIFIClO

PEQUENO A LA VISTA.

Z RECEPTACULO DEL

TOMACORRIENTE

MONTADO AL RAS

DE LA PARED

MUESTRA SI

FIGURA 7

-14-

RECEPT_,CULO DEL

TOMACORRIENTE A

ROTARSE SEEGsINSE

RAS DE LA PARED

Page 15

INSTALLATEUR : VEUILLEZ LAISSER CES INSTRUCTIONS A VEC L'APPAREIL

MAN

VEUILLEZ CONSERVER CE MANUEL POUR RI_FI_RENCE ULTI_RIEURE

CE MANUEL EST DESTINE A FACILITER LA MISE EN SERVICE ET LE REGLAGE INITIAUX DE LA CUISINIERE.

D#GAGEMENT N#CESSAIRE

Pour tous renseignements concernant la mise en service

La mise en service et le depannage

de cette cuisiniere doivent _tre

realises uniquement par du

personnel qualifi&

d'une cuisiniere amovible, voir les figures 1 et 2, page

16. Pour des RAISONS DE SECURITE, ne pas mettre la

cuisiniere en place dans des armoires en materiau

combustible qui ne satisfasse pas aux exigences de

degagement indiquees en figure 1.

Lire les <<Mesures de securite ,,

dans le manuel de I'utilisateur avant

d'utiliser la cuisiniere,

Une mauvaise realisation de la mise

en place, du reglage, de

modifications, de reparations ou de

rentretien de la cuisiniere ou son

usage incorrect peuvent entrainer

des blessures graves ou des deg_ts

materiels,

ATTENTION : Cette cuisiniere satisfait aux

exigences de divers organismes de protection et aux

normes relatives a la temperature maximum permise

de 194°F (90°C) pour les armoires en bois. Si cette

cuisiniere est adjacente a des armoires pouvant

supporter une temperature inferieure a 194°F (90°C)

seulement, celles-ci peuvent se decolorer, se

delaminer ou fondre.

ENGLISH I_ PP. 1-7

ESPANOL I) p_lg. 8-14

MAISONS MOBILES

La mise en service d'une cuisiniere prevue pour les

maisons mobiles dolt 6tre conforme aux normes <<

Manufactured Home Construction and Safety Standard

>>,titre 24 CFR, partie 3280 (precedemment <<Federal

Standard for Mobile Home Construction and Safety >>,

titre 24 HUD, partie 280) ou, Iorsque ces normes ne sont

pas applicables, les normes <<Standard for

Manufactured Home Installations1982 (Manufactured

Home Sites, Communities and Setu-Ups) >>,ANSI

A225.1-edition la plus recente, ou les codes de

construction Iocaux.

RACCORDEMENT DE LA

CUISINI#RE

Mettre la cuisiniere dans un endroit oQelle recevra un

bon eclairage. Ne pas monter la cuisiniere au-dessus de

trous dans le plancher ou en tout autre endroit oe elle

sera exposee a de forts courants d'air. Toute ouverture

dans lemur a I'arriere de la cuisiniere et dans le

plancher sous la cuisiniere doit 6tre bouchee. S'assurer

que le passage de I'air de refroidissement/ventilation

sous la cuisiniere n'est pas entrav&

FRAN(_AIS i1 p. 15-21

-15-

Page 16

SCHi:!:MAS DE MONTAGE

CONSERVER A L USAGE DE

I IMPORTANT I

L'INSPECTEUR EN I LECTRICITF_ LOCAL:

A = degagement minimum de 30 po (76,2 cm) entre la

table de cuisson et le bas d'une armoire non protegee en

bois ou en metal ;ou bien A = 24 po (61 cm) si le bas de

I'armoire en bois ou en metal est protege par du carton

ignifuge d'un minimum de 1/4 po (6,4 mm) d'epaisseur

couvert, au minimum, de t61ed'acier n° 28 MSG, d'acier

inoxydable de 0,015 po (0,381 mm) d'epaisseur,

d'aluminium de 0,024 po (0,610 mm) d'epaisseur ou de

cuivre de 0,020 po (0,508 mm) d'epaisseur.

Pour eliminer tout risque de brQlure ou d'incendie en

essayant d'atteindre un objet place au-dessus

d'elements brQlants, eviter d'avoir un espace de

rangement au-dessus de la table de cuisson. S'il doit y

avoir une armoire au-dessus de la table de cuisson,

I'installation d'une hotte depassant d'au moins 5 po (13

cm) de sa partie inf@ieure reduira les risques lies ace

type d'entreposage.

FIGURE 1

1,2, 3 - PAROIS EN MATERtAU COMBUSTIBLE.

4 - ARMOIRE EN MATERtAU

COMBUSTIBLE.

Une cuisiniere amovible peut 6tre directement contre (0

cm/po) les parois 1,2, 3 m6me si celles-ci sont en mate-

riau combustible.

FIGURE 1

REMARQUE : L'iflustration peut ne pas representer

exactement I'appareil.

PREVOIR UNE PRISE ENCASTREE

DE 120/208 V / 120/240 V PAR

CORDON D'ALIMENTATION DANS

CETTE ZONE

l

7 PO 3 PO--

[14,6 CM) (7,6 CM)

7 PO

CM)--_

7 PO }

REMARQUE : DANS LE CAS D'UNE MISE EN SER-

VICE AU CANADA, UNE CUISINIERE AMOVIBLE NE

DOlT PAS ETRE PLACEE .&.MOINS DE 12 MM DE

TOUTE SURFACE ADJACENTE.

A = 30 PO (76,2 CM) - 31 PO (78,7 CM) -- CANADA

B = 3 1/4 PO (8,3 CM) - 3 3/4 PO (9,5 CM) -- CANADA

T

PROFONDEUR DE

COMPTOIR NORMALE

DE 25 PO (63,5 CM)

221P0

D'ARMOIRE DE

24 PO(61 CM)

36 PO (9! ,5 CM)

DE HAUTEUR DE

DESSUS DE

COMPTOIR

OUVERTURE

ANS L'ARMOIRE

-- HAUT ET BAS

BO/TE DE SORTIE

DE 120/208 V / 120/240 V PAR

CORDON D'ALIMENTATION

DANS CETTE ZONE

FIGURE 2

-16-

Page 17

MISE EN PLACE DU SUPPORT DE STABILISATION

ATTENTION : La cuisiniere risque de basculer si elle

n'est pas mise en place conformement aux instructions

fournies. Si le support est utilise correctement, il reduit le

risque que la cuisiniere ne BASCULE. M6me si le support

est utilise correctement, le consommateur doit observer

les precautions indiquees dans le MANUEL

D'UTILISATION ET D'ENTRETIEN et eviter d'utiliser la

porte du four et/ou le tiroir inferieur comme un tabouret.

Les instructions sont prevues pour un plancher ou un mur

en bois ou en ciment. Tout autre materiau peut requerir

des techniques speciales, qu'il conviendra de determiner,

pour assurer la fixation du SUPPORT DE

STABILISATtON au mur ou au plancher. Le support de

stabilisation est prevu pour s'inserer a GAUCHE ou

DROITE du pied de mise a niveau.

ETAPE 1 - Emplacement du support de stabilisation

(voir figure 3).

A. Determiner o_ le <_BORD >>gauche ou droit de la

cuisiniere se trouvera une fois celle-ci en place et le

marquer d'un repere sur le plancher ou sur le mur.

B. Placer le SUPPORT a 9/16 po (14.5 mm) de la

marque du <<BORD >>en allant vers le centre de

I'ouverture et contre le mur arriere tel qu'indique a la

figure 3, le trou d'orientation etant contre lemur.

C. Utiliser le support comme gabarit et marquer

I'emplacement des trous pour le type de materiau sur

lequel le support doit 6tre fixe, tel qu'indique a la

figure 3.

D. La cuisiniere amovible peut 6tre fixee au plancher ou

au mur.

ETAPE 2 - Pose du support de stabilisation

A. Bois :

1. Plancher : Determiner le centre des deux trous

identifies par" TROUS POUR PLANCHER" a la

figure 3. Percer un trou de positionnement de 1/8

po (3 mm) au centre de chaque trou (un clou ou

un poingon peut egalement 6tre utilise si une

perceuse n'est pas disponible). Fixer le support

de STABILISATtON au plancher a I'aide des deux

vis fournies. Passer a I'€:TAPE 3.

2. Mur : Determiner le centre des deux trous

identifies par" TROUS POUR MUR" a la figure 3.

Percer un trou de positionnement de 1/8 po (3

mm) au centre de chaque trou (un clou ou un

poingon peut egalement 6tre utilise si une

perceuse n'est pas disponible) tel qu'indique a la

figure 4. Fixer le support de STABtLISATION au

mur a I'aide des deux vis fournies tel qu'indique

la figure 4. Passer a I'€:TAPE 3.

B. Ciment ou beton :

. On trouve des vis convenant au ciment ou au

beton dans les quincailleries. Percer les trous de

positionnement de la grandeur correspondante

celle des vis obtenues en quincaillerie au centre

des trous identifies" TROUS POUR PLANCHER"

la figure 3. Fixer le support de STABILISATION

au plancher. Passer a I'ETAPE 3.

9/16 po

[14,5

du bord de

la cuisiniere

Repere du bord _-

de la cuisiniere

/

ion

_z--.._ un minimum de deux (2)

longues vis

_ort de stabilisation

reglage

Trous pour le plancher

(de chaque c6te)

FIGURE 3

-17-

Page 18

MISE EN PLACE DU SUPPORT DE STABILISATION

ETAPE 3 - Mise en place de la cuisiniere

A. Pour des raisons de securite et pour obtenir des

resultats optimums a la cuisson, regler la cuisiniere de

fa£on ace qu'elle soit de niveau eta la hauteur voulue

avant de la mettre en place dans I'ouverture.

Pour verifier le niveau, mettre un niveau a bulle ou une

grande casserole d'eau sur la surface de cuisson ou sur

la grille du four. Regler le niveau en la basculant vers

I'avant ou I'arriere et en tournant les pieds de mise

niveau autant que necessaire.

Remarque : Un degagement minimum de 6 mm (1/4 po)

est exige entre la cuisiniere et le pied de mise a niveau

qui va s'inserer dans le support de stabilisation (voir

figure 4).

Attention : La cuisiniere peut se trouver abTmee si elle

est deplacee et soulevee par le dessus, a I'aide du

dosseret ou par la poignee de la porte.

Toutes les cuisinieres amovibles a dessus en

vitroceramique ont un dessus non relevable. Si elles

sont equipees d'elements chauffants tubulaires, le

dessus est relevable.

a.

Placer la cuisini¢re de fagon a ce qu'elle puisse entrer

dans I'ouverture oQelle sera encastree et se preparer

la pousser en place. Raccorder le cordon

d'alimentation et le brancher dans la prise en suivant

les directives fournies pour le raccordement de la

cuisiniere a I'electricit&

C.

Pousser la cuisiniere en place en verifiant visuellement

que le cordon d'alimentation n'est pas coince et qu'il

se trouve completement derriere la cuisiniere.

U.

Pour verifier si le support de stabilisation est

correctement en place, regarder sous la cuisiniere en

s'eclairant a I'aide d'une lampe de poche et s'assurer

que le pied arriere droit est bien insere dans la fente

du support.

LES VlS

D,OIV,ENT

DANS LE

BOIS OU LE

METAL

PLAC

MURALE

ART# 9215-117

REMARQUE : UTILISER AU MOINS 2 VlS POUR LA FIXATION

STABILISATION

VlSSER LE

DE

STABILISATION

AU MUR

DU SUPPORT AU MUR OU AU PLANCHER

BAS DE LA

CUISINIEREi

] [- 1/4 PO

/ / (6UU)

FIGURE 4

-18-

Page 19

RACCORDEMENT DE LA CUISINIERE

ALIMENTATION ¢:LECTRIQUE

Lors de la mise en service, la cuisiniere doit _tre installee

conformement aux normes NEC ANSI/NFPA n° 70-edition

la plus recente du code d'electricite local et national. Voir

la plaque signaletique de la cuisiniere pour en connaTtre la

puissance raccordee totale (en kW).

ALIMENTATION I_LECTRIQUE (Canada)

Lors de la mise en service, la cuisiniere doit _tre installee

conformement aux normes ACN STD.C22.1 de I'edition la

plus recente du code d'electricite canadien. Voir la plaque

signaletique de la cuisiniere pour en connaTtre la

puissance raccordee totale (en kW).

RACCORDEMENT AU SECTEUR

La compagnie d'electricite locale vous indiquera si votre

branchement est prevu pour fournir la puissance exigee

par I'appareil. 11pourra 6tre necessaire d'augmenter la

grosseur des c_bles amenant I'electricite a la maison et

au panneau de distribution electrique. La puissance

electrique de la cuisiniere (en kW) est specifiee sur la

plaque signaletique qui se trouve a I'avant de la

cuisiniere.

INSTALLATION ¢:LECTRIQUE DE LA

MAISON

La plupart des codes et reglements relatifs a la

construction exigent que I'installation electrique d'une

maison soit realisee par un electricien qualifi& Le c_blage

dolt 6tre conforme aux codes d'electricite local et national.

Cette cuisiniere requiert un circuit alternatif monophase

trifilaire de 120/240 V ou 120/208 Vet 60 Hz. Les codes

exigent que la cuisiniere soit dotee d'un circuit separe

partant du panneau de distribution electrique et que

celui-ci soit protege par un sectionneur et des fusibles, au

niveau du panneau de distribution electrique ou dans un

coffret electrique separ& Dans certaines municipalites,

une gaine blindee flexible ou rigide dolt 6tre utilisee entre

le panneau de distribution electrique et le boftier de

raccordement se trouvant a I'arriere de la cuisiniere.

D'autres municipalites autorisent le branchement de la

cuisiniere sur une prise murale polarisee a trois ou quatre

ills placee dans un endroit pratique pres de I'arriere de la

cuisiniere. La cuisiniere est branchee sur cette prise

I'aide d'une fiche a trois ou quatre broches avec cordon

d'alimentation (spirale) homologue pour cuisiniere

solidement fixe au bornier de la cuisiniere par une retenue

mecanique appropriee.

region oe les codes Iocaux interdisent la mise a la terre

par le neutre. Dans ce cas, une installation a 4 ills est

OBLIGATOIRE. Une installation a 3 ills peut 6tre utilisee

si les codes Iocaux le permettent. UTILtSER DES

CONDUCTEURS EN CUIVRE OU EN ALUMINIUM. Le

bornier est prevu pour des conducteurs en cuivre ou en

aluminium. Si un cordon d'alimentation flexible est exig&

il est recommande de ne pas utiliser de cordon d'une

Iongueur superieure a 4 pi. Si un cordon d'alimentation

flexible est exig& il est recommande de ne pas utiliser de

cordon d'une Iongueur superieure a 4 pi. Realiser les

connexions tel qu'indique ci-dessous en se referant aux

illustrations appropriees (voir les figures 6 et 7). Une fois

I'installation effectuee, verifier que toutes les connexions

n'ont pas de jeu et remettre tousles couvercles.

Enlever le couvercle d'acces au bornier a I'arriere de la

cuisiniere (voir figure 5).

CONNEXIONS DE LA CUISINII_RE (Canada)

Ce modele est dote d'un cordon d'alimentation (spirale)

installe en usine. Aucune connexion n'est necessaire. II

suffit de la brancher. Voir la figure 2, page 16, pour

I'emplacement des prises.

REMARQUE : Pour remplacer le cordon d'alimentation,

utiliser UNIQUEMENT un cordon d'alimentation pour

cuisiniere calibre a 240 volts minimum et 40 ou 50

amperes prevue pour une utilisation avec une ouverture

pour raccordement nominale de 1 3/8 po (35 mm) de

diametre et muni de serre-fils.

/

,I

I

|

CONNEXIONS DE LA CUISINII_RE

Certains modeles ont un cordon d'alimentation (spirale)

installe en usine. Dans ce cas, il n'y a aucune connexion

realiser au niveau de la cuisiniere. 11suffit de brancher la

fiche dans la prise murale. D'autres modeles ne sont pas

munis d'un cordon d'alimentation et dans ce cas, le

raccordement a I'alimentation electrique de la maison est

necessaire. NE PAS OUBLIER - seul des cordons

quatre ills peuvent 6tre utilises avec les circuits de

derivation nouvellement installes (NEC 1996), les

maisons mobiles, les vehicules de Ioisir ou dans toute

FIGURE 5

-19-

Page 20

RACCORDEMENT DE LA CUISINI#RE

FIGURE 6

INSTALLATION D'UN CORDON D'ALIMENTATION OU D'UNE GAINE .,&.3 FILS

Verifier que la barrette de mise a la terre en cuivre

EST CONNECTIVE entre la borne du milieu du bornier

et le chassis de la cuisiniere.

.

Si du c_blage nu en aluminium ou en cuivre est utilise,

attacher les cosses d'adaptation tel qu'indique a la

figure 6. (Voir Connexion a ills nus). Les couples sont

indiques ci-dessous.

Le fil du milieu du cordon d'alimentation ou le fil de

masse de la gaine a trois ills DOlT 6tre connecte a la

INSTALLATION ACCEPTABLE - FICHE .&.TROIS FILS

borne neutre (celle du milieu) du bornier. Les deux

autres ills du cordon ou de la gaine sont connectes

aux bornes des deux extremites du bornier. La polarite

n'a pas a 6tre respectee. Pour une connexion avec du

fil nu, attacher le fil a la cosse correspondante tel

qu'indiqu& Les couples sont indiques ci-dessous.

4. Placer la retenue mecanique a bride sur le dessus de

la plaque support de gaine tel qu'indique et serrer la

bride sur le cordon d'alimentation ou la gaine.

CONNEXION A_FILS NUS

_ROUGE

DU CORDON OU

DE LA GAINE

BARRETTE DE MISE ,&,LA

TERRE RACCORDEE EN

PLAQUE DE MECANIQUE

RETENUE

SUPPORT DE _ C,_BLE AWG

GAINE

USlNE

Cv°ScS[_ DD_Du#M_TIINoN_- NOIR

SPECIFICATIONSDE COUPLE POUR FIL8NU8

'SE gECL E"

L'PRIS E ENCASTREE

DANS LE MUR

N'EST PAS ENCASTREE

COSSEAU BORN_ER- 20 PO-LB

10-14

8

4-6

INSTALLATION

v "'"---BLANC

COUPLEDE

20 PO-LB

25 PO-LB

35 PO-LB

ALTERNATIVE

FIGURE 6

-20-

Page 21

FIGURE 7

INSTALLATION D'UN CORDON

D'ALIMENTATION OU D'UNE GAINE A 4

FILS

(MAISONS MOBILES OU SI LES CODES L'EXIGENT)

1. La barrette de mise a la terre en cuivre reliant la borne

neutre (celle du milieu) du bornier et le chassis DOlT

_tre enlevee tel qu'indique a la figure 7. Garder la vis

de mise a la terre verte pour fixer le fil de terre du

cordon a 4 ills. Utiliser uniquement un cordon

d'alimentation ou une gaine a 4 ills.

2. Si du c_blage nu en aluminium ou en cuivre est utilise,

attacher les cosses d'adaptation tel qu'indique a la

figure 6. (Voir Connexion a ills nus). Les couples sont

indiques ci-dessous.

3. Le fil de terre du cordon d'alimentation ou de la gaine

dolt 6tre relie au chassis de la cuisiniere en utilisant la

vis de mise a la terre verte.

4. Le fil blanc du cordon d'alimentation ou de la gaine doit

6tre connecte a la borne neutre (celle du milieu) du

bornier. Les deux autres fils du cordon sont connectes

aux bornes de m6me couleur (rouge et noire) du

bornier. Pour une connexion avec du fil nu, attacher le

fil a la cosse correspondante tel qu'indiqu& Les

couples sont indiques ci-dessous.

5. Placer la retenue mecanique a bride sur le dessus de

la plaque support de gaine tel qu'indique et la serrer

sur le cordon d'alimentation ou la gaine.

CONVERSION D'UNE INSTALLATION 3

FILS A UNE INSTALLATION 4 FILS

(Modeles amovibles avec cordon d'alimentation en

place)

Debrancher la cuisiniere du secteur. Enlever le couvercle

du bornier se trouvant a I'arriere de la cuisiniere et

deconnecter le cordon d'alimentation a 3 ills du bornier.

Suivre les instructions donnees a la figure 7 pour

connecter le cordon a 4 fils.

REMARQUE : Pour remplacer le cordon d'alimentation,

utiliser UNIQUEMENT un cordon d'alimentation pour

cuisiniere calibre a 240 volts minimum et 40 ou 50

amperes prevu pour une utilisation avec une ouverture

pour raccordement nominale de 1 3/8 po (35 mm) de

diametre et muni de serre-fils.

BLANC

NOIR

MISE A LA

MASSE AU

CH,_SSlS

RETENUE MECANIQUE

1 1/2 PO

INSTALLATION ACCEPTABLE - FICHE A QUATRE FILS

/,,,, t, -_ CONNEXIONA

1,./ _\/ \

PLAQUE DE i,-__ \\ _ -," j

SUPPORT D _1_"_'_ "._X \\! _.

Cette partiede la\_)_" _ "_'_. _."_'_. ,'_

barrette de mise & _-_.'_ _ v._

la terre dolt @tre "'"_"*_' _ .... _'_" AVE,ACOEScsEsD'oAc_uAPMTATIOTANON_ BLANC

CM) MINIMUM

/ \

DU CORDON COSSE AU BORNIER - 20 PO-LB

OU DE LA

GAINE CABLE AWG COUPLE DE

INSTALLATION ALTERNATIVE

10-14 20 PO-LB

ILISER AVEC UNE

GAINE. ENLEVER LE (_,

SUPPO,RT, RETOURNER ET

FIXER A NOUVEAU AVEC

LE PETIT TROU VISIBLE.

8 25 PO-LB

4-6 I 35 PO-LB

,If

ENCASTREE

DANS LE MUR.

TOURNER LA PRISE DANS

L'AUTRE SENS TEL \_

QU'INDIQUE SI ELLE /_,._

N'EST PAS ENCASTREE-- Z/

FIGURE 7

-21-

-z..

Loading...

Loading...