Page 1

Refri

Important Safety Instructions ............... 1=2

Installation ............................... 3=9

Temperature Controls .................... 10=11

o

Fresh Food Features ..................... 12-14

Freezer Features ........................... 15

Ice and Water ........................... 16-17

©

m Bottom

Freezer

Foral No. A/01/06 Pa_ No. 12828158

Water Filter ............................. 17-19

0

Food Storage Tips ....................... 20=22

0

Care and Cleaning ...................... 23=26

Operating Sounds .......................... 27

Troubleshooting ........................ 28=30

Warranty & Service ......................... 31

Guide d'utilisation et d'entretien ............. 32

Guia de uso y cuidado ...................... 64

www.amana.col. Lidlo U.S.A.

Page 2

ImportentSefetyinstructions

Installer: Please leave this guide with thB apphance.

Consumer: Please read and keep this Use and

Care Guide for future reference; mtprovides the

proper use and maintenance reformation.

Keep sales receipt and/or canceled check as proof

of purchase.

Call: 1-800-688-9900 U.S.A.

1-800-688-2002 Canada

1-800-688-2080 (U.S. TTY for hearing or

speech impaired)

(Mon.-Fn., 8 am-8 pm Eastern THee)

Have complete model and senal number

identification of your refrngerator. This is located on a

data plate reside the fresh food compartment, on the

upper right s_de. Record these numbers below for

easy access.

Model Number

Serial Number

Date of Purchase

In our continuing effort to improve the quahty and

performance of our apphances, it may be necessary

to make changes to the apphance without rewsmg

this guide.

What You Need to Know About

Safety Instructions

Warning and Important Safety Instructions appearulg ul

this guide are not meant to cover all possible

cond=tions and situations that may occur. Conlmon

sense, caLitlon and care must be exercised when

installing, maintaining or operating apphance.

To reduce risk of injury or death, foflow basic

precautions, including the following:

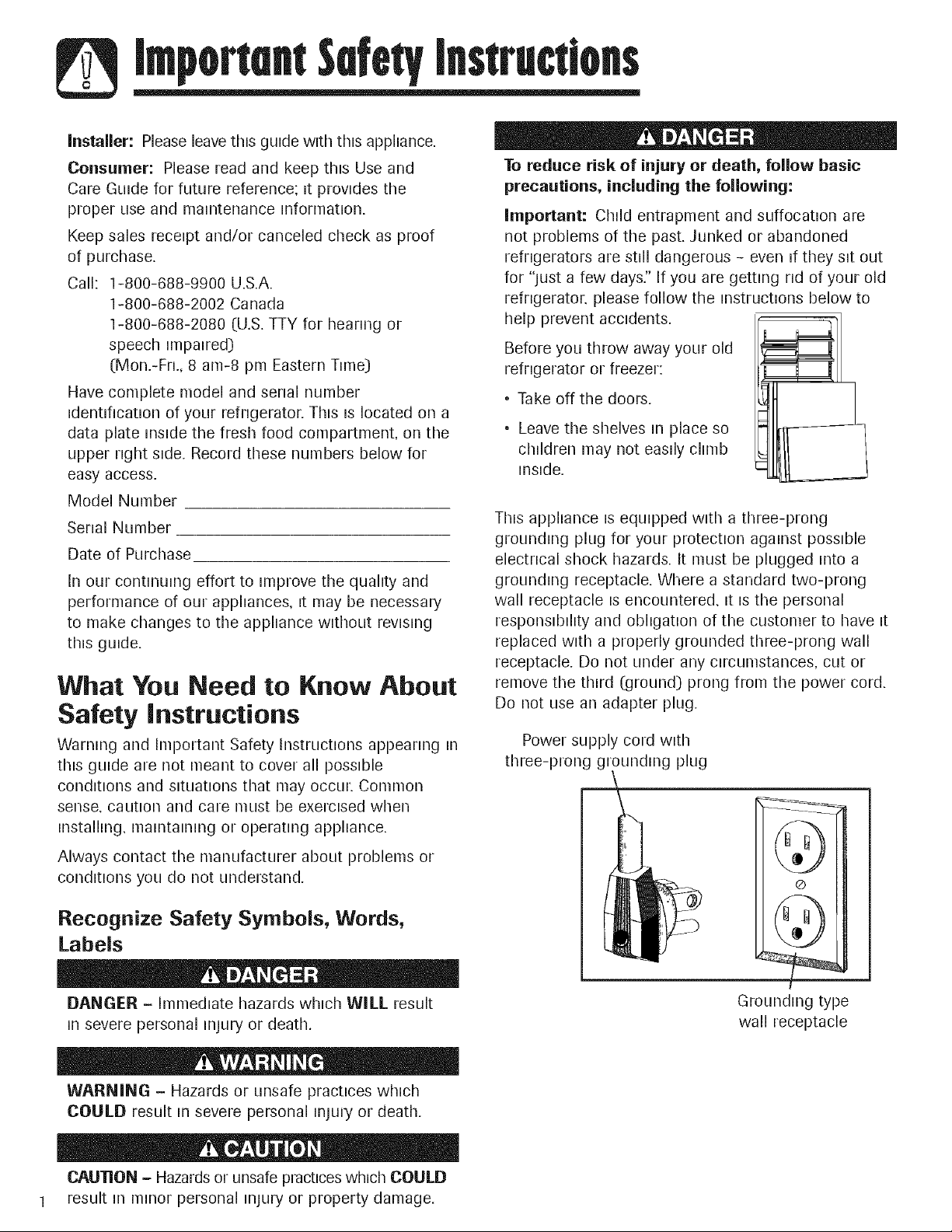

Important: Child entrapment and suffocation are

no_ problems of the past. Junked or abandoned

refrigerators are still dangerous - even mfthey s_t out

for "just a few days." If you are getting nd of your old

refrigerator, please follow the instructions below to

help prevent accidents.

Before you throw away your old

refrigerator or freezer:

, Take off the doors.

• Leave the shelves m place so

children may not easily chmb

reside.

This apphance is eqLnpped with a three-prong

grounding plug for your protection against possible

electncal shock hazards. It must be plugged into a

grounding receptacle. Where a standard two-prong

wall receptacle is encountered, it is the personal

responsibihty and obhgation of the customer to have it

replaced with a properly grounded three-prong wall

receptacle. Do not under any circumstances, cut or

remove the third (ground) prong from the power cord.

Do not use an adapter plug.

Power supply cord with

three-prong grounding plug

Always contact the manufacturer about problems or

conditions you do not understand.

Recognize Safety Symbols, Words,

Labels

DANGER - Immediate hazards which WILL result

in severe personal Injury or death.

WARNING - Hazards or unsafe practices which

COULD result m severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result m minor personal injury or property damage.

Grounding type

wall receptacle

Page 3

ImportentSefetyinstructions

To reduce risk of fire, electric shock, serious injury or 13. Always disconnect refrigerator from electrical

death when using your refrigerator, follow these basic supply before attempting any service. Disconnect

precautions, including tile following: power cord by grasping the plug, not tile cord.

1. Read all instructions before using tile refngerator. 14.

2. Observe all local codes and ordinances.

3. Be sure to follow grounding instructions.

4. Check with a qualified electnclan mfyou are not

sure thB apphance _sproperly grounded. 15.

5. Do not ground to a gas hne.

6. Do not ground to a cold-water p_pe.

7. Refngerator _sdesigned to operate on a separate

115 volt, 15 amp., 60 cycle hne. 16.

8. Do not modify plug on power cord. If plug does 17.

not fit electrical outlet, have proper outlet installed

by a quahfled electrician.

9. Do not use a two-prong adapter, extension cord 18.

or power strip.

10. Do not remove warning tag from power cord. 19.

11. Do not tamper w_th refrigerator controls.

12. Do not serwce or replace any part of refrigerator 20.

unless spec#lcally recommended m Use & Care

Guide or pubhshed user-repmr instructions. Do

not attempt serwce _finstructions are not

understood or _fthey are beyond personal skill

level.

Install refngerator according to Installation

Instruct,ons. All connections for water, electncal

power and grounding must comply with local

codes and be made by hcensed personnel when

requmred.

Keep your refngerator in good condition. Bumping

or dropping refrigerator can damage refngerator

or cause refngerator to malfunctnon or leak. If

damage occurs, have refrigerator checked by

quahfled service techmclan.

Replace worn power cords and/or loose plugs.

Always read and follow manufacturer's storage

and mdealenwronment instructions for _tems being

stored m refrigerator.

Your refrigerator should not be operated In tile

presence of exploswe fumes.

Children should not chmb, hang or stand on any

part of the refrigerator.

Clean up spills or water leakage associated with

water installation.

SAVE THESE INSTRUCTIONS

Page 4

Your refrigerator was packed carefully for shipment.

Remove and discard shelf packaging and tape. Do not

remove the serial plate.

Location

• Do not install refrigerator near oven, radiator or other

heat source. If not possible, shield refrigerator with

cabinet material.

Do not install where temperature falls below 55° F

(13° C) or rises above 110° F (43° C). Malfunction

may occur at this temperature.

• Refrigerator is designed for indoor household

application only.

Measuring the Opening

When installing your refrigerator, measure carefully.

Allow '/2"space at top and '/Z space behind the

machine compartment cover (located in the rea0 for

proper air circulation.

Subflooring or floor coverings (i.e. carpet, tile, wood

floors, rugs) may make your opening smaller than

anticipated.

Some clearance may be gained by using the leveling

procedure under Leveling.

Important: If refrigerator is to be installed into a

recess where the top of the refrigerator is completely

covered, use dimensions from floor to top of hinge cap

to verify proper clearance.

Transporting Your Refrigerator

• NEVER transport refrigerator on its side. If an

upright position is not possible, lay refrigerator on its

back. Allow refrigerator to sit upright for

approximately 30 minutes before plugging it in to

assure oil returns to the compressor. Plugging the

refrigerator in immediately may cause damage to

internal parts.

Use an appliance dolly when moving refrigerator.

ALWAYS truck refrigerator from its side or

back-NEVER from its front.

Leveling

To enhance the appearance and maintain performance,

the refrigerator should be level.

NOte-" Complete any required door reversal, panel

installation and/or a water supply connection, before

leveling.

Materials Needed

• 3/8"hex head driver

• Carpenter's level

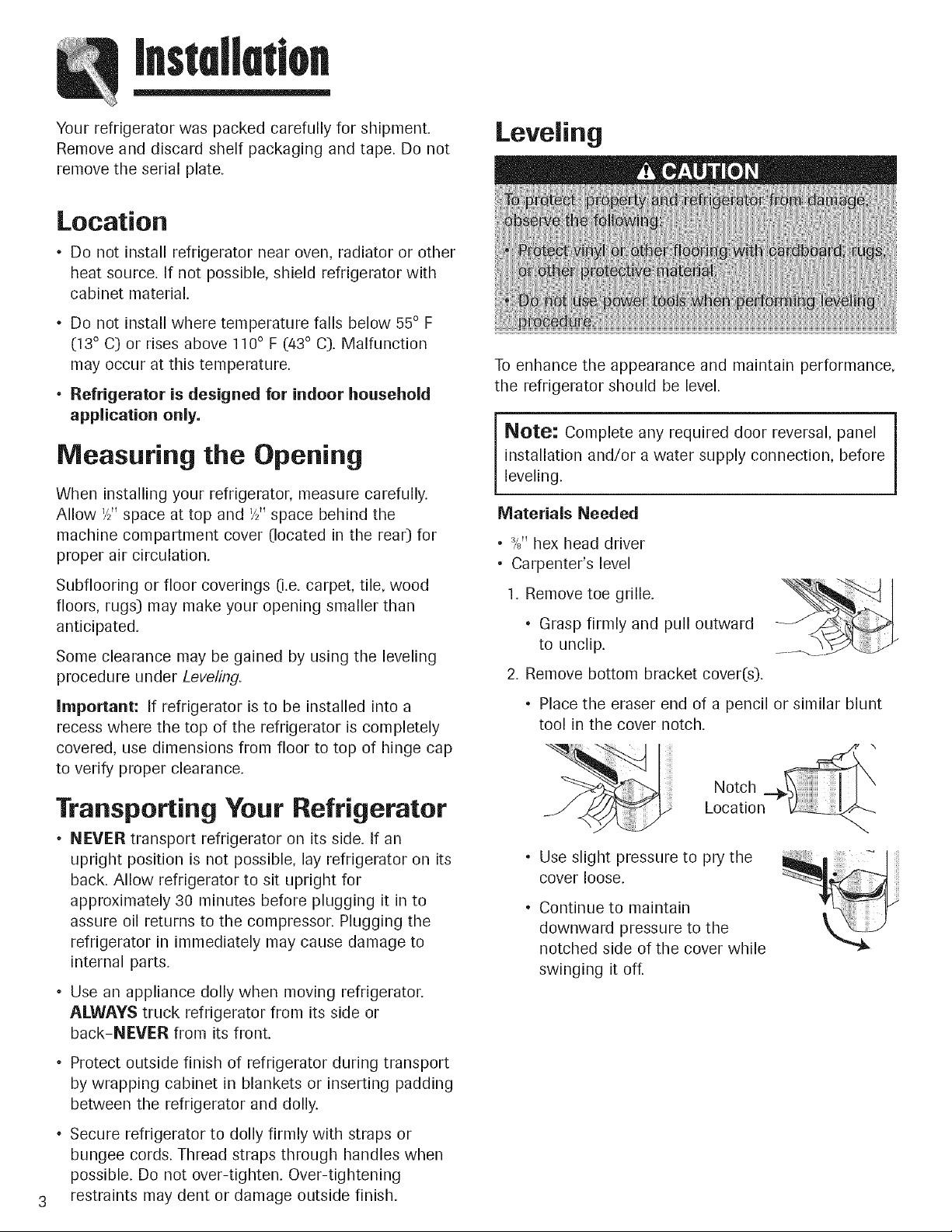

1. Remove toe grille.

• Grasp firmly and pull outward

to unclip.

2. Remove bottom bracket cover(s).

• Place the eraser end of a pencil or similar blunt

tool in the cover notch.

Notch

Location

• Use slight pressure to pry the

cover loose.

Continue to maintain

downward pressure to the

notched side of the cover while

swinging it off.

Protect outside finish of refrigerator during transport

by wrapping cabinet in blankets or inserting padding

between the refrigerator and dolly.

• Secure refrigerator to dolly firmly with straps or

bungee cords. Thread straps through handles when

possible. Do not over-tighten. Over-tightening

restraints may dent or damage outside finish.

Page 5

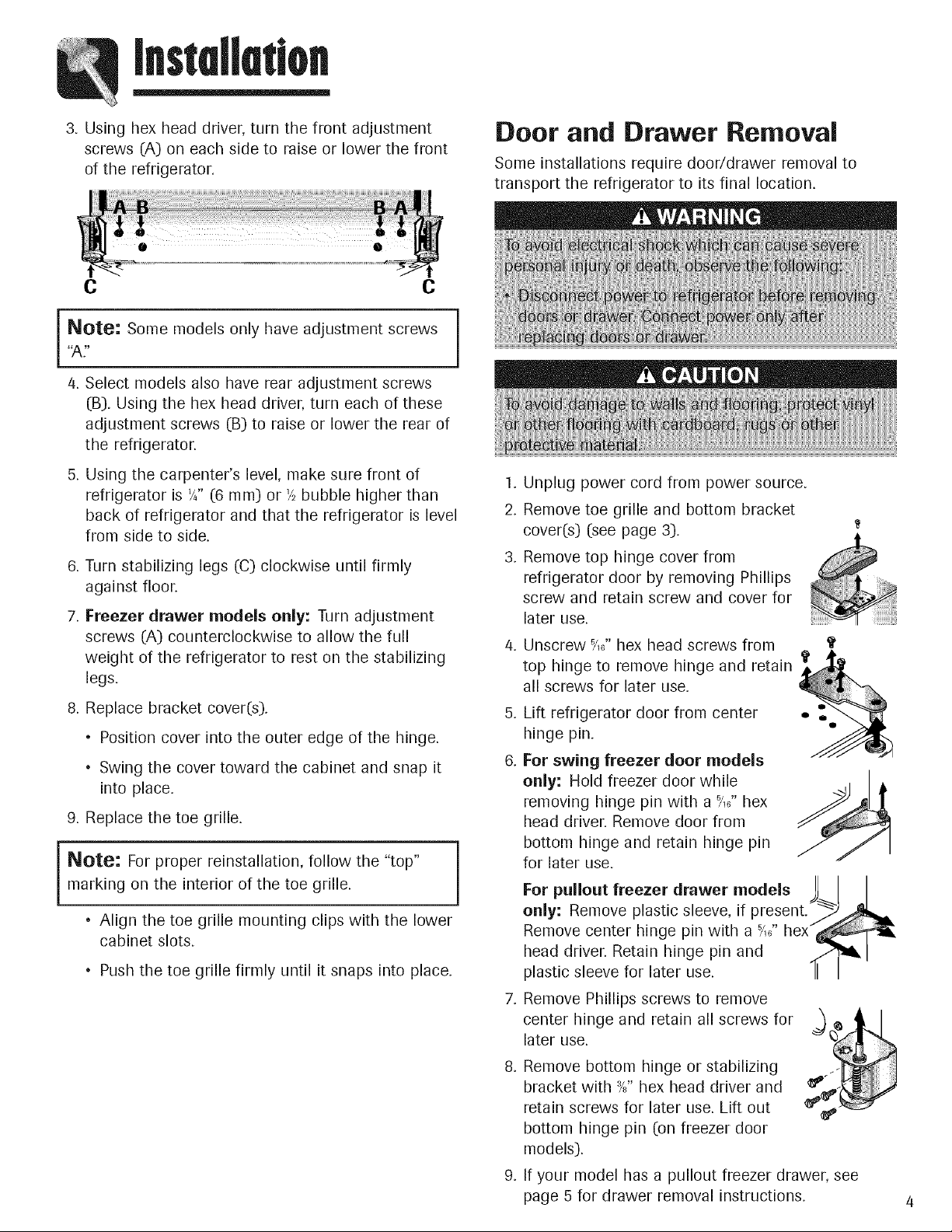

3. Usinghexheaddriver,turnthe frontadjustment

screws(A)oneachsideto raiseor lowerthefront

oftherefrigerator.

C C

i Note-" Some models only have adjustment screws

,:A:,

4. Select models also have rear adjustment screws

(B). Using the hex head driver, turn each of these

adjustment screws (B) to raise or lower the rear of

the refrigerator.

Door and Drawer Removal

Some installations require door/drawer removal to

transport the refrigerator to its final location.

5. Using the carpenter's level, make sure front of

refrigerator is Y4"(6 ram) or '/zbubble higher than

back of refrigerator and that the refrigerator is level

from side to side.

6. Turn stabilizing legs (C) clockwise until firmly

against floor.

7. Freezer drawer models only: Turn adjustment

screws (A) counterclockwise to allow the full

weight of the refrigerator to rest on the stabilizing

legs.

8. Replace bracket cover(s).

• Position cover into the outer edge of the hinge.

• Swing the cover toward the cabinet and snap it

into place.

9. Replace the toe grille.

i Note." For proper reinstallation, follow the "top"marking on the interior of the toe grille.

• Align the toe grille mounting clips with the lower

cabinet slots.

• Push the toe grille firmly until it snaps into place.

1. Unplug power cord from power source.

2. Remove toe grille and bottom bracket

cover(s) (see page 3).

3. Remove top hinge cover from

refrigerator door by removing Phillips

screw and retain screw and cover for

later use.

.

Unscrew -_,6"hex head screws from

top hinge to remove hinge and retain

all screws for later use.

.

Lift refrigerator door from center

hinge pin.

6.

For swing freezer door models

only: Hold freezer door while

removing hinge pin with a t,6" hex

head driver. Remove door from

bottom hinge and retain hinge pin

for later use.

For pullout freezer drawer models

only: Remove plastic sleeve, if l

Remove center hinge pin with a ?,_" hex"

head driver. Retain hinge pin and

plastic sleeve for later use.

Remove Phillips screws to remove

center hinge and retain all screws for

later use.

@

Remove bottom hinge or stabilizing

bracket with -7_"hex head driver and

retain screws for later use. Lift out

bottom hinge pin (on freezer door

models).

.

If your model has a pullout freezer drawer, see

page 5 for drawer removal instructions.

Page 6

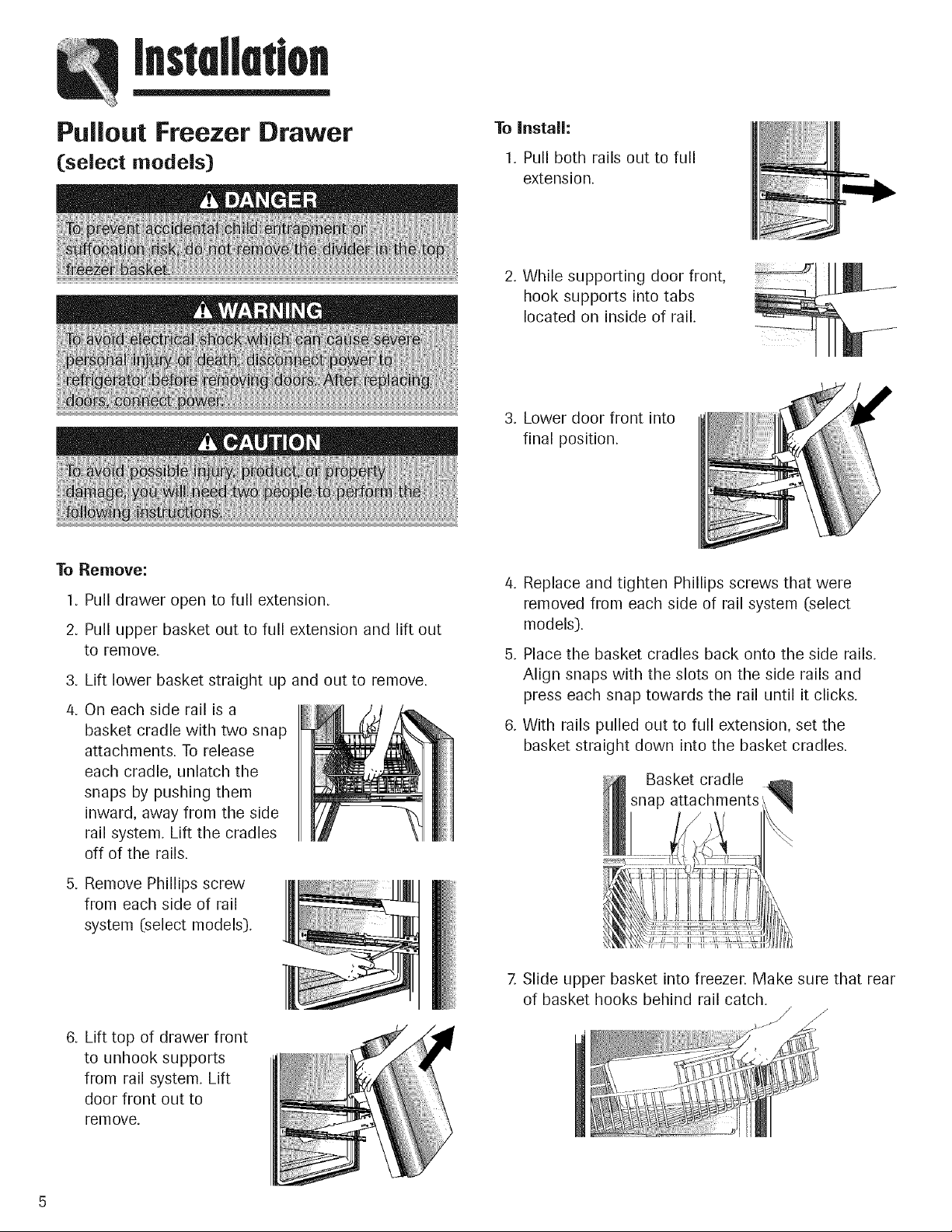

To Install:

1. Pull both rails out to full

extension.

2. While supporting door front,

hook supports into tabs

located on inside of rail.

3. Lower door front into

final position.

To Remove:

1. Pull drawer open to full extension.

2. Pull upper basket out to full extension and lift out

to remove.

.

Lift lower basket straight up and out to remove.

4.

On each side rail is a

basket cradle with two snap

attachments. To release

each cradle, unlatch the

snaps by pushing them

inward, away from the side

rail system. Lift the cradles

off of the rails.

5. Remove Phillips screw

from each side of rail

system (select models).

6. Lift top of drawer front

to unhook supports

from rail system. Lift

door front out to

rein ove.

.

Replace and tighten Phillips screws that were

removed from each side of rail system (select

models:).

Place the basket cradles back onto the side rails.

Align snaps with the slots on the side rails and

press each snap towards the rail until it clicks.

With rails pulled out to full extension, set the

basket straight down into the basket cradles.

Basket cradle

7. Slide upper basket into freezer. Make sure that rear

of basket hooks behind rail catch.

f

Page 7

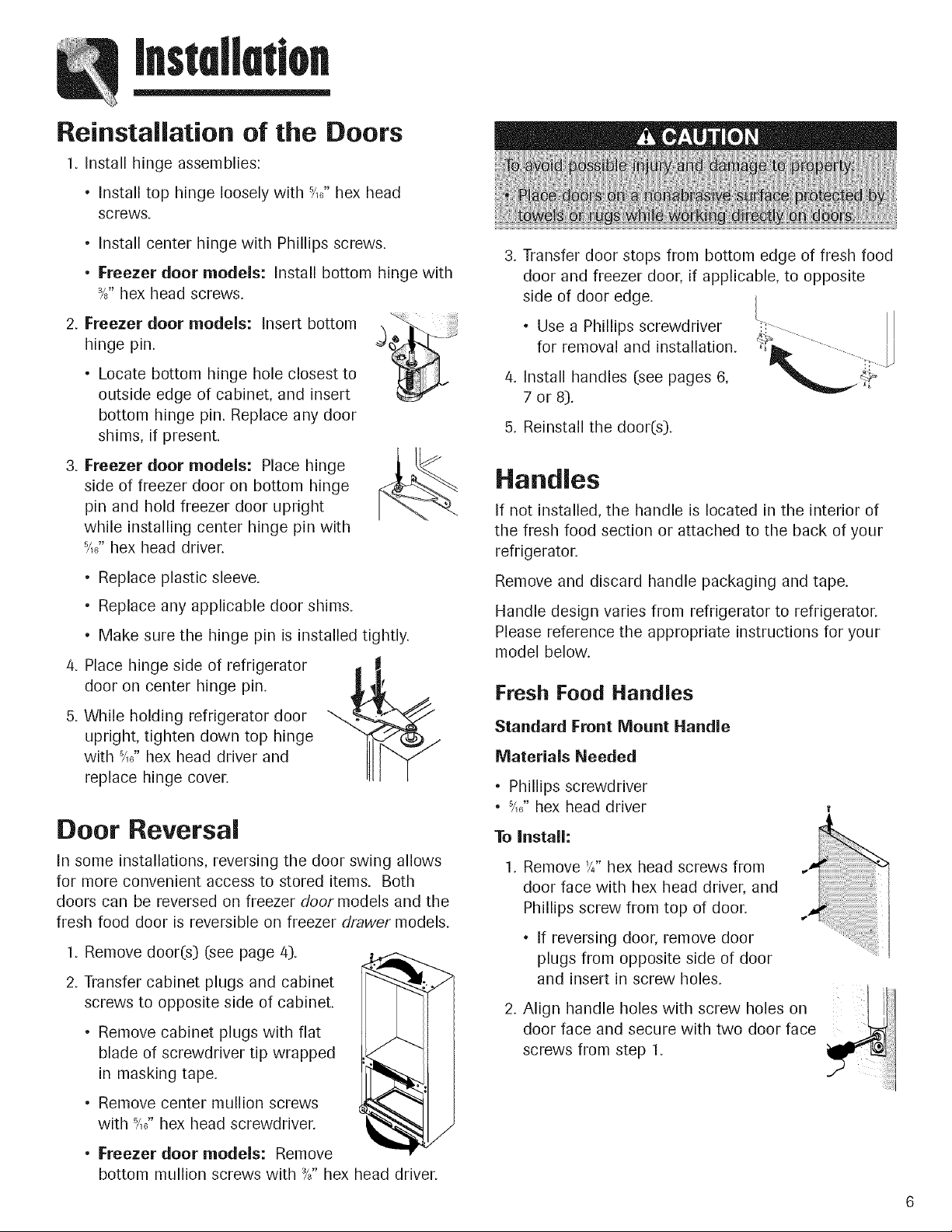

Reinstallation of the Doors

1. install hinge assemblies:

• install top hinge loosely with %" hex head

sorews.

• install center hinge with Phillips screws.

• Freezer door models: install bottom hinge with

3/8"hex head screws.

2. Freezer door models: insert bottom

hinge pin.

• Locate bottom hinge hole closest to

outside edge of cabinet, and insert

bottom hinge pin. Replace any door

shims, if present.

3. Freezer door models: Place hinge

side of freezer door on bottom hinge

pin and hold freezer door upright

while installing center hinge pin with

_/,6"hex head driver.

• Replace plastic sleeve.

• Replace any applicable door shims.

• Make sure the hinge pin is installed tightly.

4. Place hinge side of refrigerator

door on center hinge pin.

5. While holding refrigerator door

upright, tighten down top hinge

with _/,6"hex head driver and

replace hinge cover.

Door Reversal

In some installations, reversing the door swing allows

for more convenient access to stored items. Both

doors can be reversed on freezer door models and the

fresh food door is reversible on freezer drawer models.

1. Remove door(s) (see page 4).

2. Transfer cabinet plugs and cabinet

screws to opposite side of cabinet.

• Remove cabinet plugs with flat

blade of screwdriver tip wrapped

in masking tape.

• Remove center mullion screws

with _/,;' hex head screwdriver.

3. Transfer door stops from bottom edge of fresh food

door and freezer door, if applicable, to opposite

side of door edge.

• Use a Phillips screwdriver

for removal and installation.

4. install handles (see pages 6,

7 or 8).

5. Reinstall the door(s).

I.

'---.....

Handles

If not installed, the handle is located in the interior of

the fresh food section or attached to the back of your

refrigerator.

Remove and discard handle packaging and tape.

Handle design varies from refrigerator to refrigerator.

Please reference the appropriate instructions for your

model below.

Fresh Food Handles

Standard Front Mount Handle

Materials Needed

• Phillips screwdriver

• _/,_"hex head driver

To Install:

1. Remove '/4"hex head screws from

door face with hex head driver, and

Phillips screw from top of door.

• If reversing door, remove door

plugs from opposite side of door

and insert in screw holes.

2. Align handle holes with screw holes on t 1

door face and secure with two door face

screws from step 1.

• Freezer door models: Remove

bottom mullion screws with 3/8"hex head driver.

Page 8

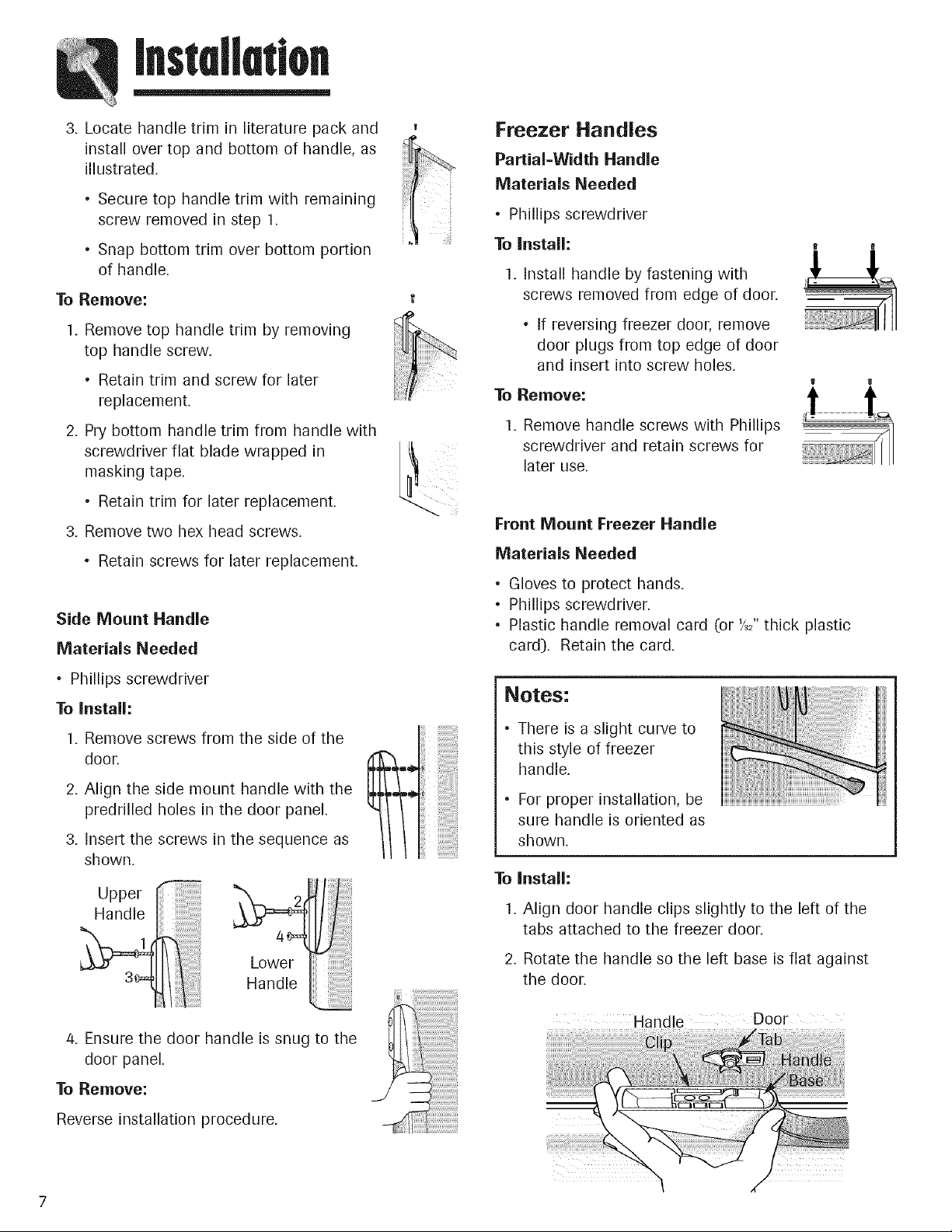

3. Locatehandletrimin literaturepackand

installovertop andbottomof handle,as

illustrated.

* Secure top handle trim with remaining

screw removed in step 1.

Snap bottom trim over bottom portion

of handle.

To Remove:

1. Remove top handle trim by removing

top handle screw.

• Retain trim and screw for later

replacement.

2. Pry bottom handle trim from handle with

screwdriver flat blade wrapped in

masking tape.

• Retain trim for later replacement.

3. Remove two hex head screws.

* Retain screws for later replacement.

Side Mount Handle

Materials Needed

Freezer Handles

Partial-Width Handle

Materials Needed

* Phillips screwdriver

To Install:

1. Install handle by fastening with

screws removed from edge of door.

If reversing freezer door, remove

door plugs from top edge of door

and insert into screw holes.

t II

To Remove:

1. Remove handle screws with Phillips

screwdriver and retain screws for

later use.

Front Mount Freezer Handle

Materials Needed

Gloves to protect hands.

Phillips screwdriver.

• Plastic handle removal card (or '_2"thick plastic

card:). Retain the card.

* Phillips screwdriver

To Install:

1. Remove screws from the side of the

doon

2. Align the side mount handle with the

predrilled holes in the door panel.

3. insert the screws in the sequence as

shown.

4_

Lower

Handle

4. Ensure the door handle is snug to the

door panel.

To Remove:

Reverse installation procedure.

Notes:

There is a slight curve to

this style of freezer

handle.

,, For proper installation, be

sure handle is oriented as

shown.

To install:

1. Align door handle clips slightly to the left of the

tabs attached to the freezer door.

2. Rotate the handle so the left base is flat against

the door.

Handle Door

Page 9

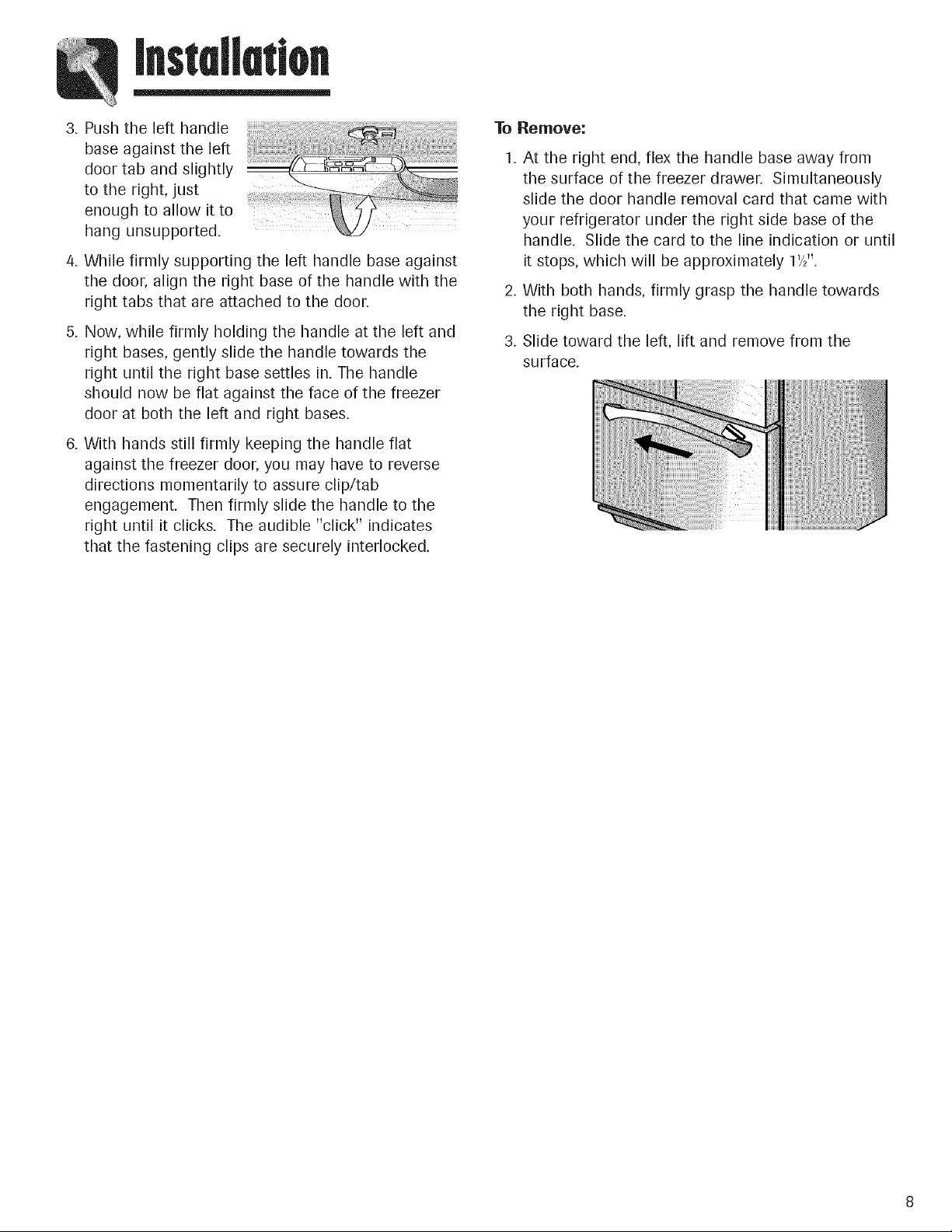

3. Pushtheleft handle

baseagainstthe left

doortabandslightly ......

totheright,just

enoughto allowitto ..................

hangunsupported.

4.Whilefirmlysupportingthelefthandlebaseagainst

thedoor,aligntherightbaseofthe handlewiththe

righttabsthatareattachedtothe door.

5. Now,whilefirmlyholdingthehandleattheleftand

rightbases,gentlyslidethehandletowardsthe

rightuntilthe rightbasesettlesin.Thehandle

shouldnowbeflatagainstthefaceofthe freezer

doorat boththeleftandrightbases.

6.Withhandsstillfirmlykeepingthehandleflat

againstthefreezerdoor,youmayhavetoreverse

directionsmomentarilyto assureclip/tab

engagement.Thenfirmlyslidethehandletothe

rightuntilit clicks.Theaudible"click" indicates

thatthefasteningclipsaresecurelyinterlocked.

To Remove:

1. At the right end, flex the handle base away from

the surface of the freezer drawer. Simultaneously

slide the door handle removal card that came with

your refrigerator under the right side base of the

handle. Slide the card to the line indication or until

it stops, which will be approximately 1'/_".

2. With both hands, firmly grasp the handle towards

the right base.

3. Slide toward the left, lift and remove from the

surface.

Page 10

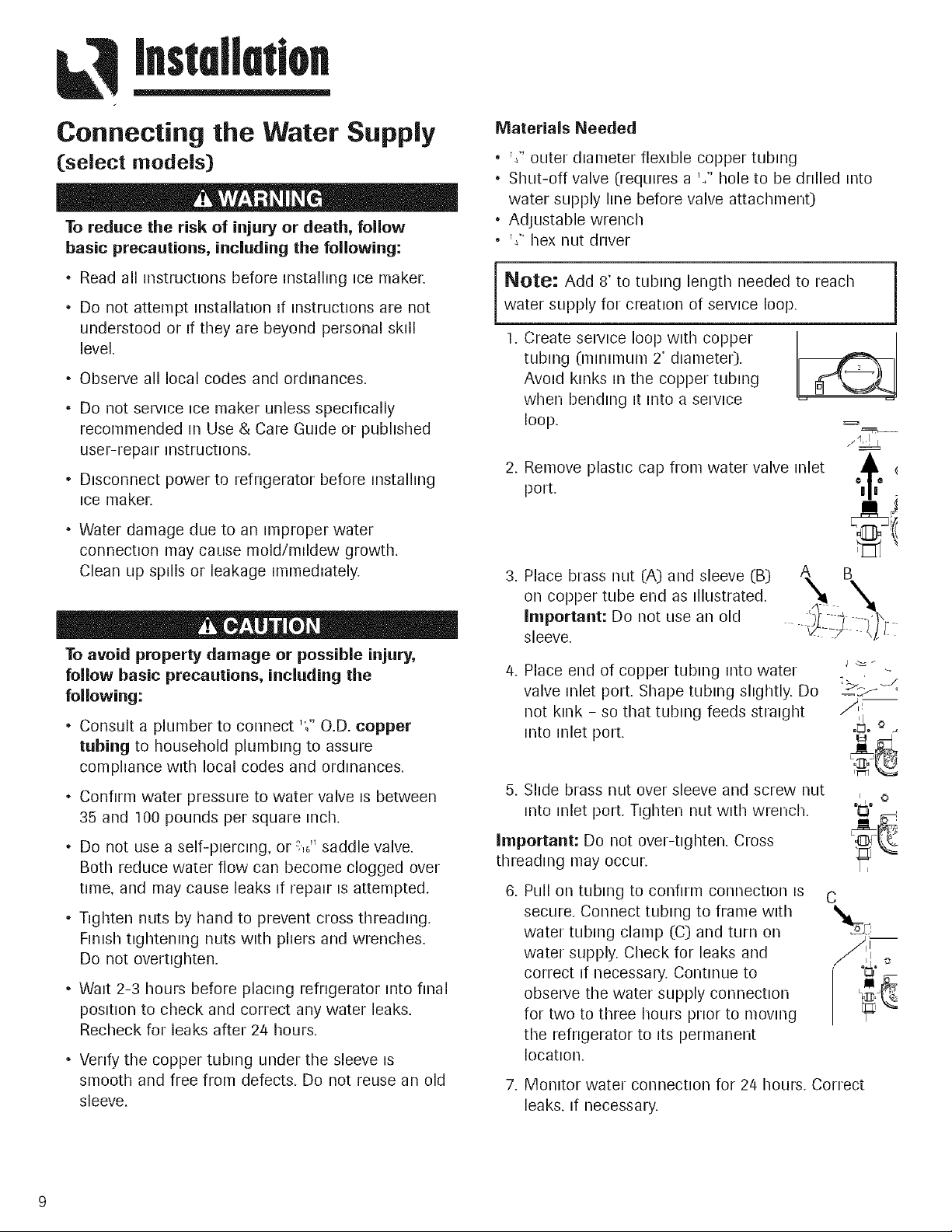

Connecting the Water Supply

Cselect models)

To reduce the risk of injury or death, follow

basic precautions, including the following:

Materials Needed

+ '2' outer diameter flexible copper tubing

+ Shut-off valve (requwes a L" hole to be drilled into

water supply line before valve attachment)

+ Adjustable wrench

+ _" hex nLIt driver

• Read all instructions before installing ice maker.

, Do not attempt installation _f instructions are not

understood or if they are beyond personal skill

level.

° Observe all local codes and ordinances.

Do not service racemaker unless specifically

recommended m Use & Care Grade or pubhslled

user-repaw instructions.

Disconnect power to refrigerator before mstalhng

ice maker.

+ Water damage due to an u_proper water

connecbon may cause mold/mildew growth.

Clean up spills or leakage uamedlately.

To avoid property damage or possible injury,

follow basic precautions, including tile

following:

° Consult a plumber to connect , O.D. copper

tubing to household plumbing to assure

comphance with local codes and ordinances.

+ Confirm water pressure to water valve _sbetween

35 and 100 pounds per square inch.

+ Do not use a self-piercing, or -1,+"saddle valve.

Both reduce water flow can become clogged over

tulle, and may cause leaks if repaw is attempted.

+ Tmghten nuts by hand to prevent cross threading.

FmBh bghtenmg nuts with phers and wrenches.

Do not overt_ghten.

+ Wmt 2-3 hours before placing refrigerator into final

potation to check and correct any water leaks.

Reclleck for leaks after 24 hours.

+ Verify tile copper tubing under the sleeve is

smooth and free from defects. Do not reuse an old

sleeve.

Note: Add 8' to tubing length needed to reach

water supply for creation of service loop.

1. Create service loop with copper

tubing (mulimum 2+diameter).

Avoid kinks m the copper tubing

when bending it into a seMce

loop.

.

Remove plastic cap from water valve inlet _

port. olluo .

3. Place brass nut (A) and sleeve (B) A B

on copper tube end as illustrated.

Important: Do not use an old

sleeve.

4.

Place end of copper tubing into water

valve inlet port. Shape tubing shghtly. Do

not kink - so that tubing feeds straight

into inlet port.

5. Slide brass nut over sleeve and screw nut

into inlet port. Tighten nut with wrench.

Important: Do not over-tighten. Cross

threading may occur.

.

Pull oil tubing to confirm connection is

C

secure. Connect tubing to frame with

water tubing clamp (C) and turn oil

water supply. Check for leaks and

correct if necessary. Continue to

observe the water supply connection

for two to three hours prior to moving

the refrigerator to _ts permanent

location.

7. Monitor water connection for 24 hours. Correct

leaks, if necessary.

&

j,i

_:]]:ou

i ©

_4]y.

Page 11

TemperetureControls

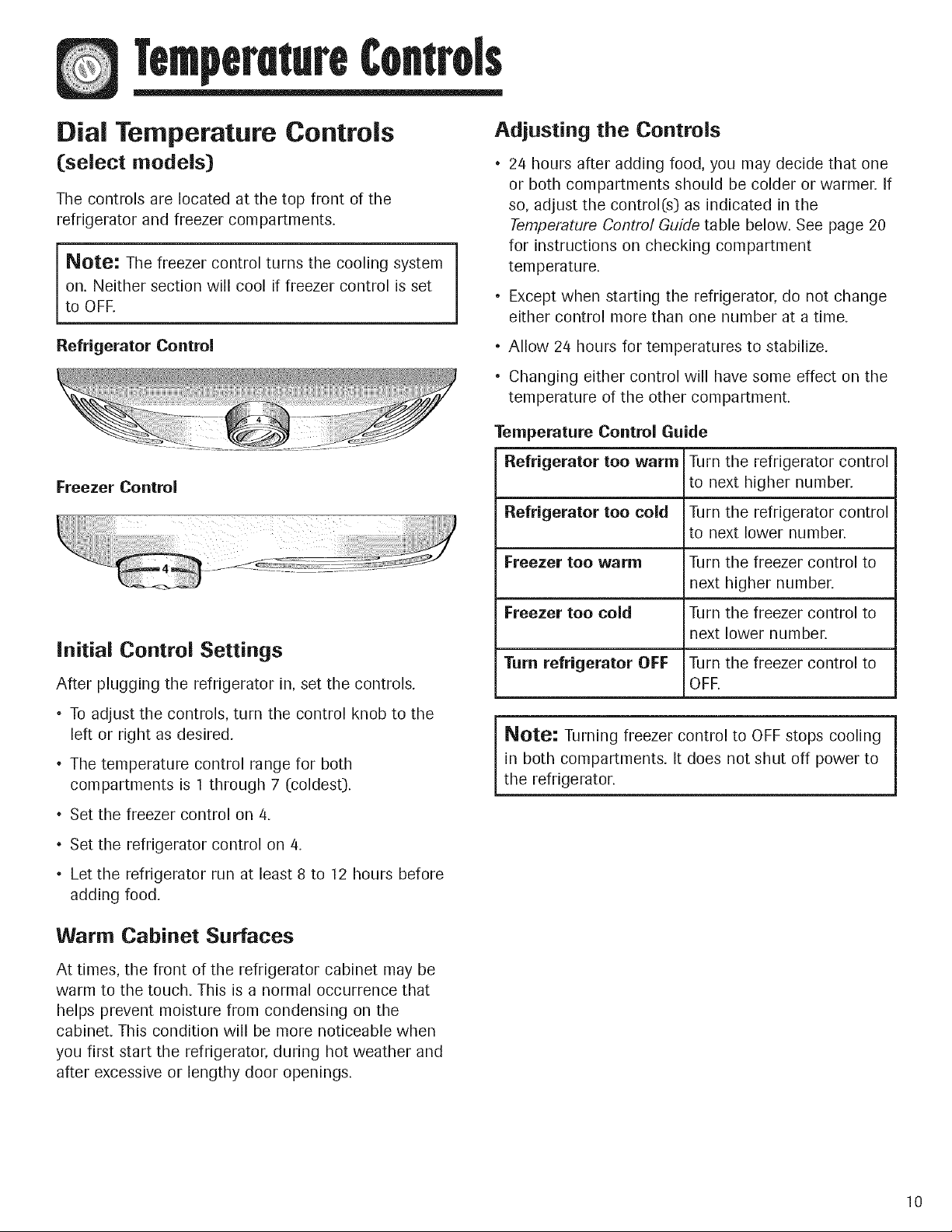

Dial Temperature Controls

[select models]

The controls are located at the top front of the

refrigerator and freezer compartments.

Note: The freezer control turns the cooling system

on. Neither section will cool if freezer control is set

to OFF.

Refrigerator Control

Freezer Control

Initial Control Settings

After plugging the refrigerator in, set the controls.

Adjusting the Controls

24 hours after adding food, you may decide that one

or both compartments should be colder or warmer. If

so, adjust the control(s) as indicated in the

Temperature Control Guide table below. See page 20

for instructions on checking compartment

temperature.

• Except when starting the refrigerator, do not change

either control more than one number at a time.

• Allow 24 hours for temperatures to stabilize.

• Changing either control will have some effect on the

temperature of the other compartment.

Temperature Control Guide

Refrigerator too warm Turn the refrigerator control

to next higher number.

Refrigerator too cold Turn the refrigerator control

to next lower number.

Freezer too warm Turn the freezer control to

next higher number.

Freezer too cold Turn the freezer control to

next lower number.

Turn refrigerator OFF Turn the freezer control to

OFE

• To adjust the controls, turn the control knob to the

left or right as desired.

• The temperature control range for both

compartments is 1 through 7 (coldest).

• Set the freezer control on 4.

• Set the refrigerator control on 4.

• Let the refrigerator run at least 8 to 12 hours before

adding food.

Warm Cabinet Surfaces

At times, the front of the refrigerator cabinet may be

warm to the touch. This is a normal occurrence that

helps prevent moisture from condensing on the

cabinet. This condition will be more noticeable when

you first start the refrigerator, during hot weather and

after excessive or lengthy door openings.

Note: Turning freezer control to OFF stops cooling

in both compartments. It does not shut off power to

the refrigerator.

10

Page 12

TemperetureControls

Touch Temperature Controls

(select models)

The controls are located at the top front of the

refrigerator compartment.

Control

|nitial Control Settings

After plugging the refrigerator in, set the controls.

• Pressing the or pads adjusts the controls

to the desired setting.

• The temperature control range for both

compartments is 1 through 7 (coldest].

• Set the freezer control on 4.

• Set the refrigerator control on 4.

• Let the refrigerator run at least 8 to 12 hours before

adding food.

Warm Cabinet Surfaces

Adjusting the Controls

• 24 hours after adding food, you may decide that one

or both compartments should be colder or warmer. If

so, adjust the control(s) as indicated in the

Temperature Control Guide table below. See page 20

for instructions on checking compartment

temperature.

• Except when starting the refrigerator, do not change

either control more than one number at a time.

• Allow 24 hours for temperatures to stabilize.

Temperature Control Guide

Refrigerator too warm

Refrigerator too cold

Freezer too warm

Freezer too cold

Set the refrigerator control

to next higher number by

pressing the _ pad.

Set the refrigerator control

to next lower number by

pressing the_, pad.

Set the freezer control to

next higher number by

pressing the_ _pad.

Set the freezer control to

next lower number by

pressing the_ pad.

At times, the front of the refrigerator cabinet may be

warm to the touch. This is a normal occurrence that

helps prevent moisture from condensing on the

cabinet. This condition will be more noticeable when

you first start the refrigerator, during hot weather and

after excessive or lengthy door openings.

Turn refrigerator OFF

Press the refrigerator or

freezer _ pad until a dash

(-) appears in the display.

11

Page 13

Shelves

Door Storage

Dairy Center

The Dairy Center provides

convenient door storage for

spreadable items such as butter

and margarine. This compartment can be moved to

different locations to accommodate storage needs. To

use the dairy center, raise the coven

To Remove:

• Raise the cover, pull upward and tilt out.

To install:

Your refrigerator has either Spillsaver TM or non-

sealed shelves. The Spillsaver TM shelves have a spill

retainer edge which allows for easier clean up and

some are equipped with the EasyGlide TM slide out

feature. To slide out (select models), grasp the front of

the shelf and pull forward. Push in the shelf to return

to the original position.

To Remove a Shelf: _tll

• Slightly tilt up the front and lift up

the rear of the shelf, then pull the

shelf straight out.

To Lock the Shelf into Another Position:

* Tilt up the front edge of the shelf.

* Insert the hooks into the desired frame openings and

let the shelf settle into place.

* Be sure the shelf is securely locked at the rear.

The Crisper Top serves as the lower fresh food shelf.

To Remove the Crisper Top:

* Remove drawers as indicated on pages 13 and 14.

• Reverse above procedure.

Door Buckets

Door Buckets can be moved to

meet storage needs.

To Remove:

• Slide bucket up and pull straight out.

To install:

• Slide bucket in and down until firmly seated in the

door linen

Full-width Door Shelf

Full-width Door Shelf removes for easy cleaning.

To Remove:

• Slide shelf up and pull straight out.

To instalh

• Reverse above procedure.

* Place hand under the frame to push up the glass. Lift

glass out.

* Lift frame from refrigerator liner rails.

* To install, repeat above instructions in reverse order.

12

Page 14

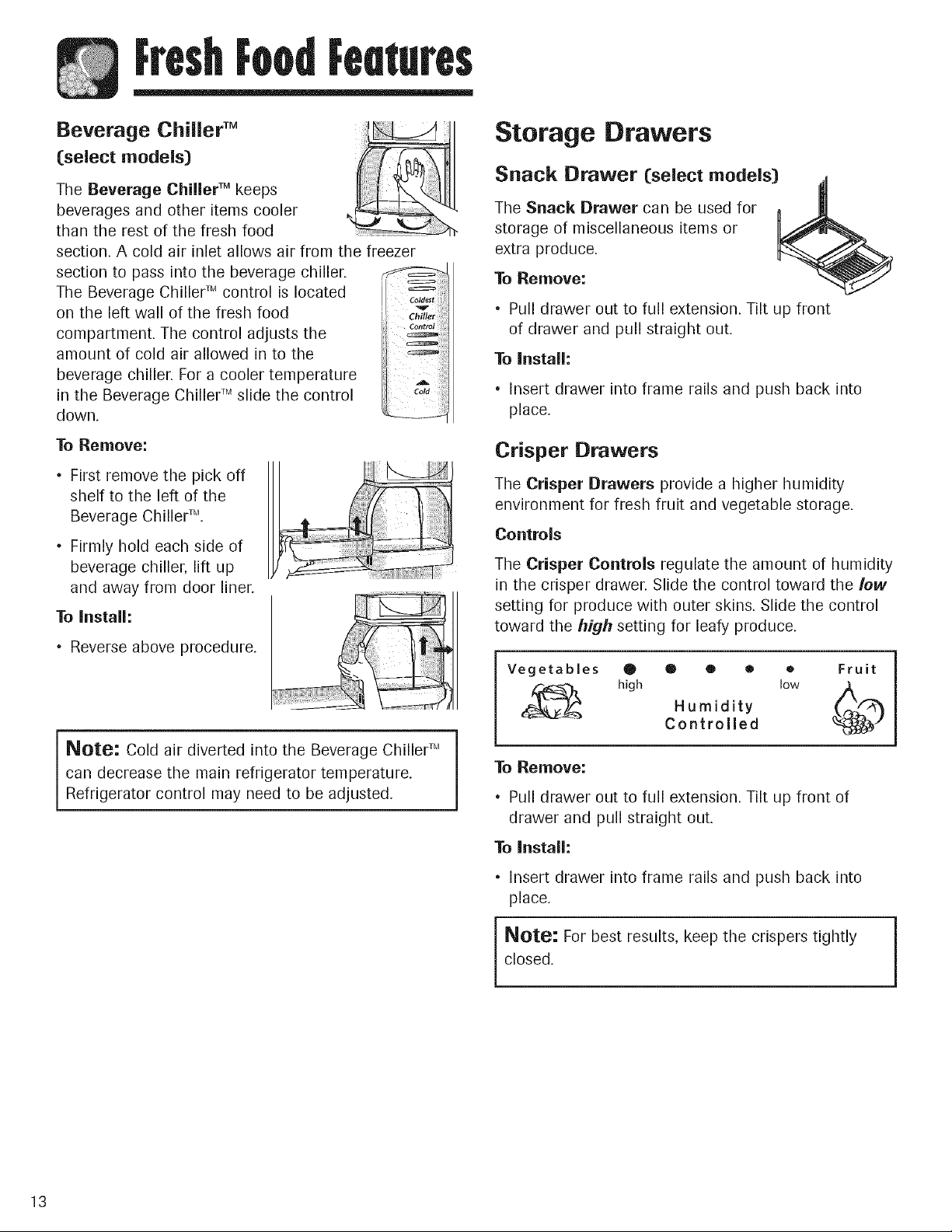

Beverage Chiller TM

[select models]

The Beverage Chiller TM keeps

beverages and other items cooler

than the rest of the fresh food

section. A cold air inlet allows air from the freezer

section to pass into the beverage chiller.

The Beverage Chille¢ Mcontrol is located

on the left wall of the fresh food

compartment. The control adjusts the

amount of cold air allowed in to the

beverage chiller. For a cooler temperature

in the Beverage Chilleff Mslide the control

down.

Storage Drawers

Snack Drawer (select models) ,,M

The Snack Drawer can be used for I _J_

storage of miscellaneous items or I_

extra produce. _ J/Y_.

To Remove:

* Pull drawer out to full extension. Tilt up front

of drawer and pull straight out.

To Install:

• Insert drawer into frame rails and push back into

place.

lift

To Remove:

* First remove the pick off

shelf to the left of the

Beverage Chilleff M.

* Firmly hold each side of

beverage chiller, lift up

and away from door liner.

To install:

* Reverse above procedure.

Note: Cold air diverted into the Beverage Chiller TM

can decrease the main refrigerator temperature.

Refrigerator control may need to be adjusted.

Crisper Drawers

The Crisper Drawers provide a higher humidity

environment for fresh fruit and vegetable storage.

Controls

The Crisper Controls regulate the amount of humidity

in the crisper drawer. Slide the control toward the low

setting for produce with outer skins. Slide the control

toward the high setting for leafy produce.

Vegetables 0 • ® • e Fruit

high low

To Remove:

* Pull drawer out to full extension. Tilt up front of

drawer and pull straight out.

To Install:

,, Insert drawer into frame rails and push back into

place.

Humidity

Controlled

13

Note: For best results, keep the crispers tightly

closed.

1

Page 15

Temperature=Controlled Drawer

Cselect models)

The Chef's Pantry TM drawer is a full-width drawer with

adjustable temperature control. This drawer can be

used for large party trays, dell items, beverages or

miscellaneous items.

There is a temperature control which adjusts the

amount of cold air allowed into the Chef's Pantry TM.

The control is located on the right side of the drawer.

Depending on your model, it is either on the front of

the drawer or under the lid.

Set the control to cold or _ to provide a normal

refrigerator temperature. Set the drawer on the

coldest or _ setting when a temperature colder than

the main refrigerator compartment is desired. Use the

coldest setting when storing meats.

Notes:

• Cold air directed to the Chef's Pantry TM can

decrease refrigerator temperature. Refrigerator

control may need to be adjusted.

* Do not place leafy vegetables in the Chef's

Pantry TM drawer. Colder temperatures could

damage leafy produce.

To Remove:

• Lift lid (select models). Pull drawer out to full

extension. Tilt up front of pantry and pull straight out.

To install:

Beverage Organizer TM (select models)

The Beverage Organizer TM slides out from underneath

the Spillsave¢ _ shelf. The Beverage Organizer TM holds

up to twelve 12-ounce beverage cans.

To Remove:

• Pull out to full extension. Tilt up the front of the

Beverage Organizer TM and pull straight out.

To install:

* Insert Beverage Organizer TM into frame rails and push

back into place.

Accessories

Wine Trivet/Can Rack (select models)

The Wine Trivet/Can Rack

accessory fits in the Chef's PantryTM

or on a shelf.

Bottles or cans can be laid crosswise,

or a single bottle may be laid in the

center depression.

Grip Pads (select models)

The Grip Pads prevent objects from sliding in the door

buckets. Grip Pads are removable

and are top-rack dishwasher safe for

easy cleaning.

Push metal glide rails to the back of the refrigerator

(select models). Place drawer onto rails and slide

drawer back until it falls into place.

Some models feature a divider to organize the Chef's

Pantry TM into sections.

To Remove:

Pull drawer completely out and raise the front of the

divider to unhook it from the rear wall of the pantry

and lift it out.

To install:

• Hook back of divider over rear wall of pantry and

lower into place.

14

Page 16

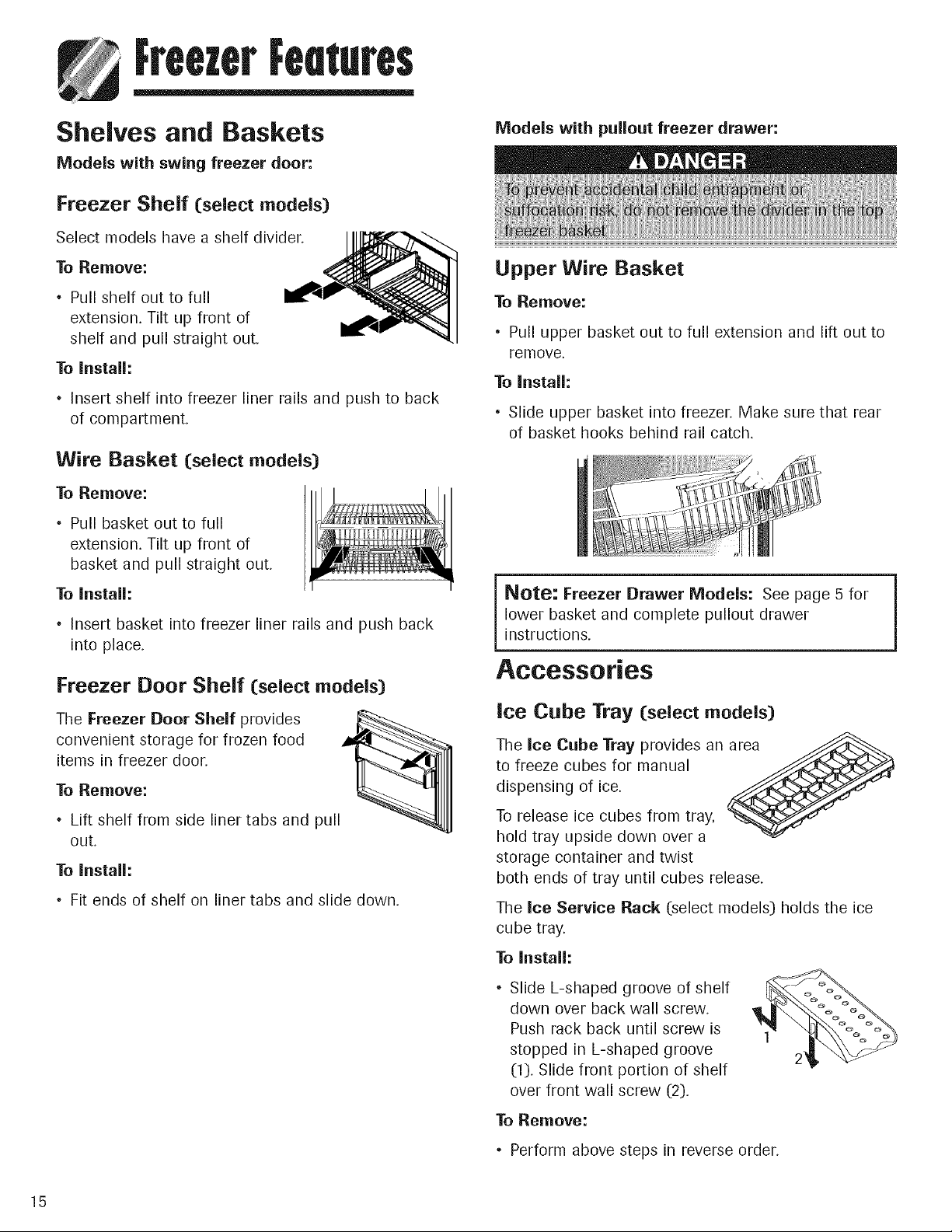

Shelves and Baskets

Models with swing freezer door:

Freezer Shelf [select models]

Select models have a shelf divider.

Models with pullout freezer drawer:

To Remove:

• Pull shelf out to full

extension. Tilt up front of

shelf and pull straight out.

To Install:

• Insert shelf into freezer liner rails and push to back

of compartment.

Wire Basket (select models)

To Remove:

• Pull basket out to full

extension. Tilt up front of

basket and pull straight out.

To install:

• Insert basket into freezer liner rails and push back

into place.

Freezer Door Shelf (select models)

The Freezer Door Shelf provides

convenient storage for frozen food

items in freezer door.

To Remove:

Upper Wire Basket

To Remove:

• Pull upper basket out to full extension and lift out to

remove.

To Install:

• Slide upper basket into freezer. Make sure that rear

of basket hooks behind rail catch.

Note: Freezer Drawer Models: See page 5 for

lower basket and complete pullout drawer

instructions.

Accessories

Ice Cube Tray [select models]

The Ice Cube Tray provides an area

to freeze cubes for manual

dispensing of ice.

• Lift shelf from side liner tabs and pull

out.

To Install:

• Fit ends of shelf on liner tabs and slide down.

15

To release ice cubes from tray,

hold tray upside down over a

storage container and twist

both ends of tray until cubes release.

The Ice Service Rack (select models) holds the ice

cube tray.

To Install:

• Slide L-shaped groove of shelf

down over back wall screw.

Push rack back until screw is

stopped in L-shaped groove

(1). Slide front portion of shelf

over front wall screw (2).

To Remove:

• Perform above steps in reverse order.

Page 17

Automatic ice Maker

(select models)

Note: Energy rating guides that are posted on the

refrigerator at the tmle of purchase do not include

optional ice maker energy usage.

Some models are automatic ice maker ready. The

number of the appropnate ice maker kit is IC1] B. The

k_t contains installation instructions and water

connection instructions.

Other models have a factory installed ice maker.

Connect the ice maker to the water supply as

instructed oil page 9. Proper water flow and a level

refrigerator are essential for optimal ice maker

performance.

Operating instructions

• Conhml ice bm is m place and ice maker arm is

down.

If the ice is not used frequently, the ice cubes will

become cloudy, shnnk, stick together and taste stale.

Empty the ice storage bm penodmally and wash it m

lukewarm water. Be sure to dly the bm thoroughly

before replacing it.

Beverages and foods should not be placed in the ice

storage bin for quick chllhng. These items can block

the sensor aim, causing the ice maker to

malfunction.

• Turn off (arm up) tile ice maker when tile water

supply is to be shut off for several hours.

To Remove the Ice Bin:

• Pull it forward, away from the ice maker. To avoid the

ice maker dumping =cewhile the bm m removed, turn

the ice maker off by raining the sensor arm.

To Install the Ice Bin:

• Reverse the above procedure. Turn the ice maker oil

by lowering the sensor arm.

• After freezer section reaches

approximately 0° F (-18° C), ice

maker fills with water and begins

operating. You will have a complete

harvest of ice approximately every

three hours.

• Allow approximately 24 hoLIrS after installation to

recewe hrst harvest of me.

• Dmcard ice created within first 12 hours of operation

to assure system is flushed of mlpurlties.

• Stop ice production by raining ice maker arm until

click is heard.

• Ice maker will remain m the off position until arm is

pushed down.

• The first one or two batches wHI probably contain

undersEed and HTegular cubes because of all m the

supply hne.

• When the ice cubes are ejected it is nornlal for

several cubes to be joined together at the ends. They

can easily be broken apart. The ice maker will

continue to make ice until the supply of ice cubes

raises the sensor arm, shutting the ice maker off.

• Certain sounds may accompany the various cycles of

the ice maker. The motor may have a shght hun], the

cubes will rattle as they fall into all empty storage

pan and the water valve may click or "'buzz"

occasionally.

'111111111111tll

To avoid personal injury or property damage,

obselve the following:

Do not place fingers or hands on the automatic _ce

making mechanism while tile refngerator is

plugged in. Thin will help protect you from poss=ble

injunj. It will also prevent interference with moving

parts of tile ejector mechamsm and the heating

element that releases tile cubes.

Under certain rare circumstances, ice cubes may

be dBcolored, usually appearing with a green-

bluBh hue. The cause of this unusual dmcoloratlon

can be a combmatmon of factors such as certain

charactermucs of local waters, household

plumbing and the accumulation of copper salts in

an reactive water supply line which feeds the ice

maker. Continued consumption of such discolored

ice cubes may be injurious to health. If such

dmcoloratlon is observed, discard the racecubes

and contact your dealer to purchase and install a

water hne filter.

Water damage due to Haproper water connection

may cause mold/mildew growtll.

Clean up water and ice spills to avoid personal

injury and to prevent mold/mildew growth.

16

Page 18

Water Dispense|" ([select models)

The Water Dispenser ts located on the left stde wall

of the fresh food sectton. ThB destgn ts for cold water

dtspenstng only.

(selectmodels)

To Dispense Water:

• Hold contaner under spout and

press dispenser pad.

Removal and Installation 3

To avoid serious iIJness or death, do not use /4.

refrigerator where water is unsafe or of unknown

quahty without adequate dBmfectlon before or after

use of filter.

After mstalhng a new water filter, always dispense

water for two minutes before remowng the filter for

any reason.

• Tile bypass cap does not filter water. Be sure to

have replacement cartridge available when filter

change is required.

o if water filtration system has been allowed to

freeze, replace filter cartridge.

If system has not been used for a short penod of

trine, and water has an unpleasant taste or odor.

fhsh system by d,spensmg two to three glasses of

water. If unpleasant taste or odor persists, change

filter caltndge. If system has not been used for

three months or more, replace water f_lter

cartridge (:see page 26).

Replacing Water Filter

Important: Air trapped in system [nay cause

water and cartridge to eject. Always dispense

water for two minutes before removing the filter

for any reason. Use caution when removing.

2. Drain water from biter into sink, and dispose in

3. Wipe Lip excess water in filter covet and continue

Rotate gently clockwise until

filter stops. Snap filter cover

closed.

Reduce water spurts by flushing

au from system. Run water

continuously for two minutes through dispenser

until water runs steady. During initial use, allow

about a one- to two-minute delay m water

dispersal to allow internal water tank to fill.

• Additional flushing may be required in some

households where water is of poor quahty.

1. Turn filter counterclockwise until it releases fronl

filter head.

normal household trash.

wtth In/td Installat!on, steps 2 and/4.

Initial Installation

Tile water filter is located in the upper right hand

corner of the fresh food compartnlent.

1. Remove blue bypass cap and

retain for later use.

2. Remove seahng label from end

of filter and insert into filter

head.

17

Tile filter should be changed at least every 12 months.

Important: Condltton of water and amount used

determines hfe span of water filter cartridge. If water

use is high, or if water is of poor quahty, replacement

may need to take place more often.

To purchase a replacement water filter cartridge,

contact your dealer or call 1-877-232-6771 U.S.A. or

1-800-688-8/408 Canada.

Tile dispenser feature may be used without a water

filter cartrtdge. If you choose this optton, replace filter

with blue bypass cap.

Page 19

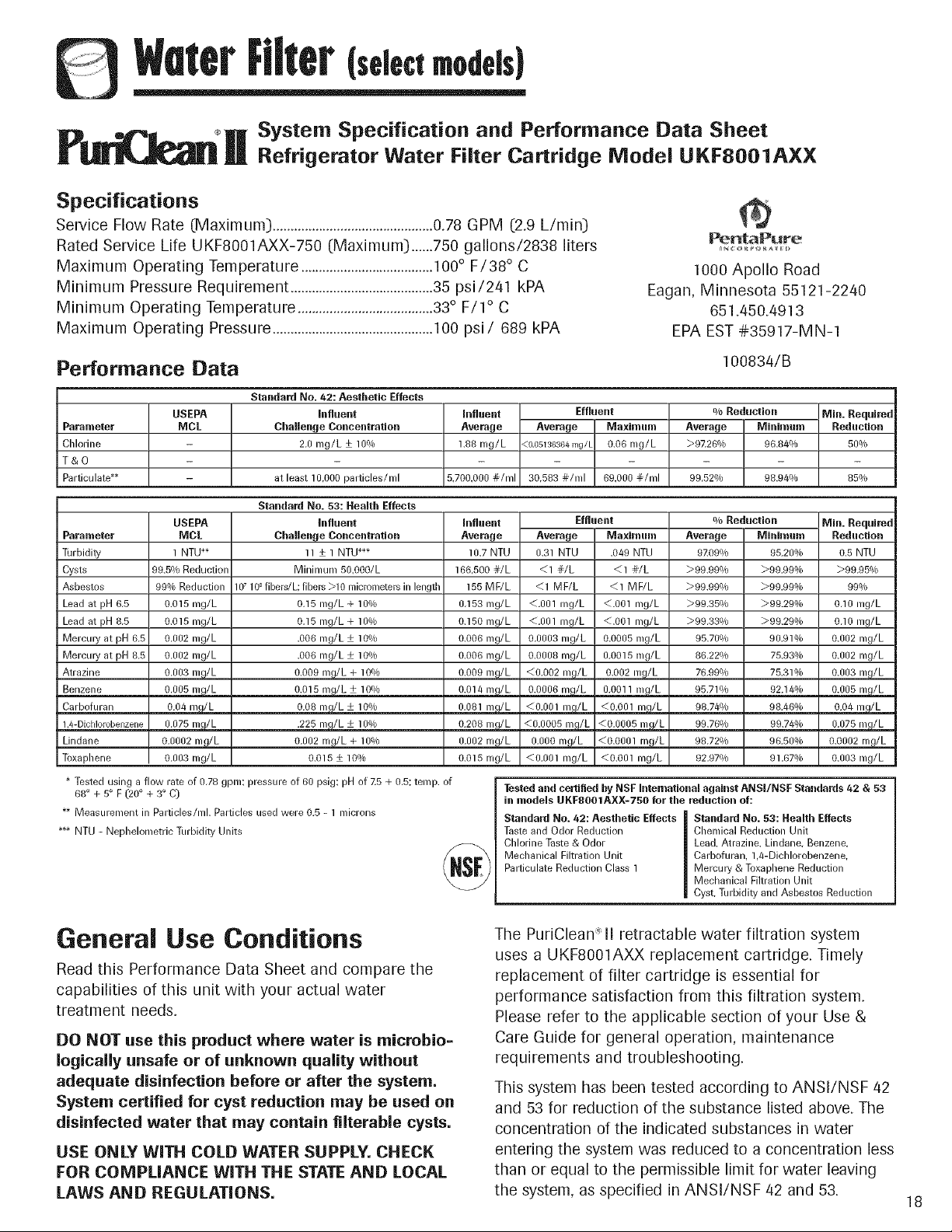

(selectmodels}

System Specification and Performance Data Sheet

Refrigerator Water Filter Cartridge Model UKF8001AXX

Specifications

Service Flow Rate (Maximum) .............................................0.78 GPM (2.9 L/min)

Rated Service Life UKF8001AXX-750 (Maximum) ......750 gallons/2838 liters

Maximum Operating Temperature .....................................100° F/38 ° C

Minimum Pressure Requirement ........................................35 psi/241 kPA

Minimum Operating Temperature ......................................33° F/1 ° C

Maximum Operating Pressure .............................................100 psi/ 689 kPA

PeNtaPu_e

1000 Apollo Road

Eagan, Minnesota 55121-22/40

651./450.4913

EPA EST #35917-MN-1

Performance Data

Standard No. 42: Aesthetic Effects

Parameter

Chlorine

T&O

Particulate**

Paralneter

Turhidity

Cysts

Asbestos

Lead at pH 6,5

Lead at pH 8,5

Mercury at pH 6,5

Mercury at pH 8,5

Atrazine

Benzene

Carbofuran

1,4_Dichlorobenzene

Lindane

Toxaphene

* Tested using a flow rate of 0,78 gpm; pressure of 60 psig; pH of Z5 + 0,5; temp. of

68 ° + 5° F (20 ° + 3° C)

** Measurement in Particles/nil. Particles cised were 0,5 - 1 microns

*** NTU - Nephelometric Turbidity Units

USEPA

MOL

USEPA

iVlCL

1 NTU**

99.5% Reduction

99% Reduction

0.015 mg/L

0.015 mg/L

0,002 mg/L

0,002 mg/L

0,003 mg/L

0,005 in_/L

0.04 In_/L

0,075 mg/L

0,0002 mg/L

0,003 mg/L

Standard No. 53: Health Effects

10_ 10_ fibeB/L; fihers >10 micrometers in length

Infiuent

Challenge Concentration

2.0 mg/L + 10%

at least 10,088 particles/ml 85%

Influent

Challenge Concentration

11 + 1 NTU***

Minimum 50,000/L

0,15 nlg/L + 10%

0.15 mg/L + 10%

.008 nlg/L + 10%

.008 nlg/L + 10%

0.009 mg/L + 10%

0.015 mg/L + 10%

0.08 m_/L + 10%

.225 mq/L + 100/o

0,002 mg/L + 10%

0.015 + 10%

[nguent

Average

1.88 mg/L

5,700,000 @/ml

Infhrant

Average

10.7 NTU

166,500 #/L

155 MF/L

0,153 nlg/L

0.150 mg/L

0.006 mg/L

0.006 mg/L

0.009 In f)/L

0.014 In_/L

0,081 In_/L

0.208 m(_/L

0,002 m{!/L

0.015 mg/L

100834/B

Efguent

Average Maxiraum

c0.05136364 ing/[ 0.98 m,(j/L

30,583 #/ml 69,000 #/ml

Effhlent

Average Maxiraura

0.31 NTU .049 NTU

<1 #/L <1 #/L

<1 MF/L <1 MF/L

<,001 mg/L <.001 mg/L

<,001 mg/L <.001 mg/L

0,0003 mg/L 0.0005 mg/L

0.0008 mg/L 0,0015 mg/L

<0,002 m{)/L 0.002 mg/L

0.0006 mg/L 0.0011 m_/L

<0.001 in_/L <0.001 m g/L

<0.0005 mg/L <0.0005 mg/L

0.000 mf!/L <0.0001 mg/L

<0,001 mg/L <0.001 mg/L

Tested and certified by NSE International against ANSI/NSF Standards 42 & 53

in raodels UKFSOOtAXX-75e for tile reduction of:

Standard No. 42: Aesthetic Effects Standard No. 53: ReaRh Effects

Taste and Odor Reduction Chemical Reduction Unit

Cldorine Taste & Odor Lead, Atrazine, Lindane, Benzene,

Mechanical Filtration Unit Carbofuran, 1A-Dichlorobenzene,

Particulate Reduction Class 1 Mercury & Toxaphene Reduction

% Reduction

Average Miniraura

>9726% 96.84%

99,52% 98.94%

% Reduction

Average JVliiniraum

9Z09% 95,20%

>99.99% >99,99%

>99.99% >99,99%

>99,35% >99.29%

>99,33% >99.29%

95.70% 90,91%

86,22% 75.930/o

76.99% 75,31%

95,71% 92.140/o

98,74% 98,46%

99.76% 99.74%

98,72% 96,50%

92,97% 91,67%

Mechanical Filtration Unit

Cyst, Turbidity and Asbestos Reduction

Min. Required

Reduction

Min. Required

Reduction

>99,95%

0,10 nlg/L

0,10 mg/L

0.002 mg/L

0.002 mg/L

0.003 Ing/L

0.005 in?/L

0.04 Infl/L

0,075 mq/L

0.0002 m{!/L

0.003 mg/L

50%

0.5 NTU

99%

General Use Conditions

Read this Performance Data Sheet and compare the

capabilities of this unit with your actual water

treatment needs.

DO NOT use this product where water is microbic-

logically unsafe or of unknown quality without

adequate disinfection before or after the system.

System certified for cyst reduction may be used on

disinfected water that may contain filterable cysts.

USE ONLY WiTH COLD WATER SUPPLY. CHECK

FOR COMPLIANCE WiTH THE STATE AND LOCAL

LAWS AND REGULATIONS.

The PuriClean :_II retractable water filtration system

uses a UKF8001AXX replacement cartridge. Timely

replacement of filter cartridge is essential for

performance satisfaction from this filtration system.

Please refer to the applicable section of your Use &

Care Guide for general operation, maintenance

requirements and troubleshooting.

This system has been tested according to ANSI/NSF 42

and 53 for reduction of the substance listed above. The

concentration of the indicated substances in water

entering the system was reduced to a concentration less

than or equal to the permissible limit for water leaving

the system, as specified in ANSI/NSF 42 and 53.

18

Page 20

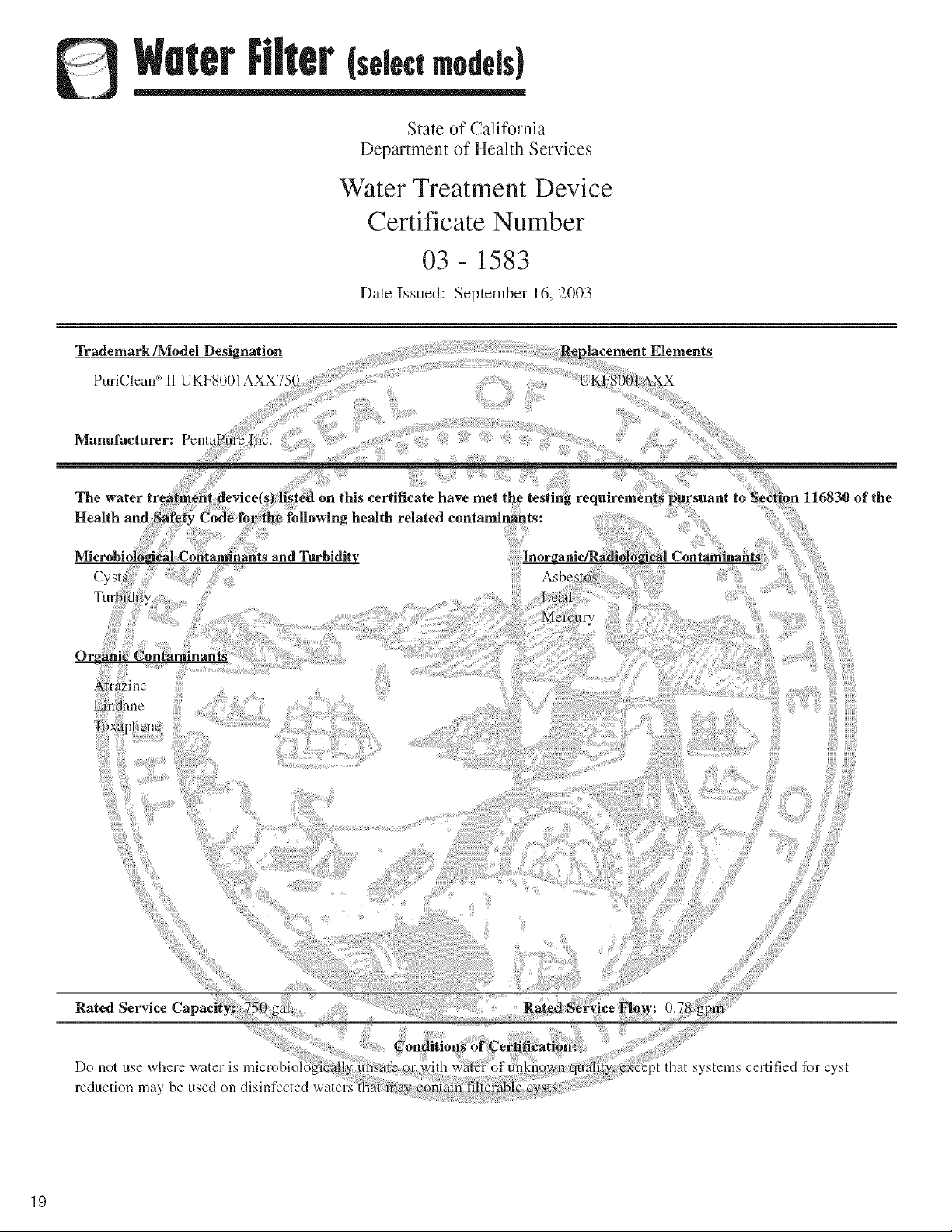

Trademark/Model Designation

PuriClean °'1I

Manufacturer:

(selectmodels}

State of California

Department of Health Services

Water Treatment Device

Certificate Number

03- 1583

Date Issued: September 16, 2003

The water

Cys

Tur

on this certificate have met the

following health related contaminants:

116830 of the

!ii!i i! ....._....

Rated Service CapaCity ; :_;0 g_: Rat_N ice F|_: 0.78 .....

=

Do not use where water is microbiol,

reduction may be used on disinfected

19

that systems certified %r cyst

Page 21

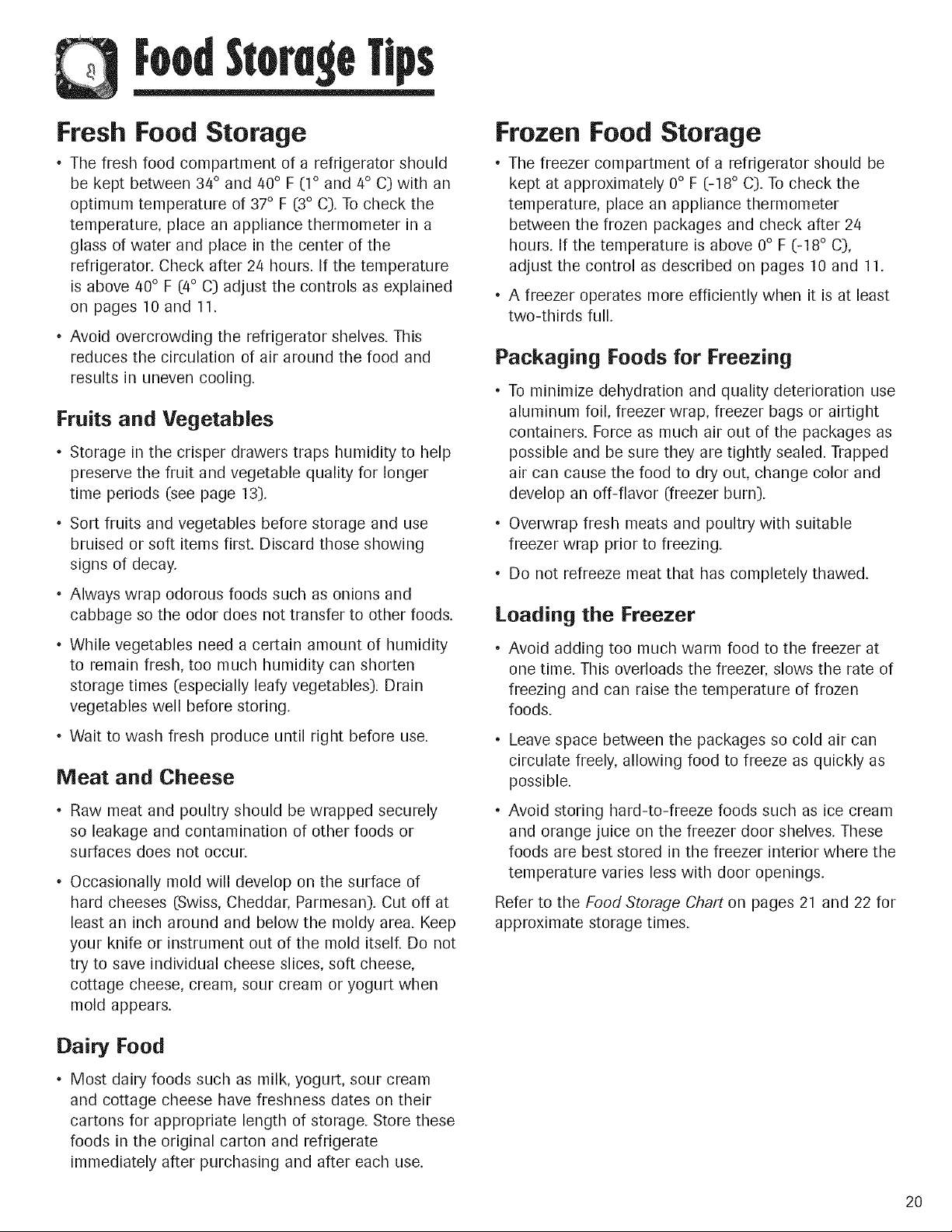

StorageTips

Fresh Food Storage

* The fresh food compartment of a refrigerator should

be kept between 34° and 40° F (1° and 4° C) with an

optimum temperature of 37° F (3° C). To check the

temperature, place an appliance thermometer in a

glass of water and place in the center of the

refrigerator. Check after 24 hours. If the temperature

is above 40° F (4° C) adjust the controls as explained

on pages 10 and 11.

* Avoid overcrowding the refrigerator shelves. This

reduces the circulation of air around the food and

results in uneven cooling.

Fruits and Vegetables

* Storage in the crisper drawers traps humidity to help

preserve the fruit and vegetable quality for longer

time periods (see page 13).

* Sort fruits and vegetables before storage and use

bruised or soft items first. Discard those showing

signs of decay.

• Always wrap odorous foods such as onions and

cabbage so the odor does not transfer to other foods.

Frozen Food Storage

• The freezer compartment of a refrigerator should be

kept at approximately 0° F (-18 ° C). To check the

temperature, place an appliance thermometer

between the frozen packages and check after 24

hours. If the temperature is above 0° F (-18 ° C),

adjust the control as described on pages 10 and 11.

A freezer operates more efficiently when it is at least

two-thirds full.

Packaging Foods for Freezing

To minimize dehydration and quality deterioration use

aluminum foil, freezer wrap, freezer bags or airtight

containers. Force as much air out of the packages as

possible and be sure they are tightly sealed. Trapped

air can cause the food to dry out, change color and

develop an off-flavor (freezer burn).

* Overwrap fresh meats and poultry with suitable

freezer wrap prior to freezing.

* Do not refreeze meat that has completely thawed.

Loading the Freezer

* While vegetables need a certain amount of humidity

to remain fresh, too much humidity can shorten

storage times (especially leafy vegetables). Drain

vegetables well before storing.

* Wait to wash fresh produce until right before use.

Meat and Cheese

* Raw meat and poultry should be wrapped securely

so leakage and contamination of other foods or

surfaces does not occur.

Occasionally mold will develop on the surface of

hard cheeses (Swiss, Cheddar, Parmesan). Cut off at

least an inch around and below the moldy area. Keep

your knife or instrument out of the mold itself. Do not

try to save individual cheese slices, soft cheese,

cottage cheese, cream, sour cream or yogurt when

mold appears.

Dairy Food

* Most dairy foods such as milk, yogurt, sour cream

and cottage cheese have freshness dates on their

cartons for appropriate length of storage. Store these

foods in the original carton and refrigerate

immediately after purchasing and after each use.

Avoid adding too much warm food to the freezer at

one time. This overloads the freezer, slows the rate of

freezing and can raise the temperature of frozen

foods.

* Leave space between the packages so cold air can

circulate freely, allowing food to freeze as quickly as

possible.

Avoid storing hard-to-freeze foods such as ice cream

and orange juice on the freezer door shelves. These

foods are best stored in the freezer interior where the

temperature varies less with door openings.

Refer to the Food Storage Chart on pages 21 and 22 for

approximate storage times.

2O

Page 22

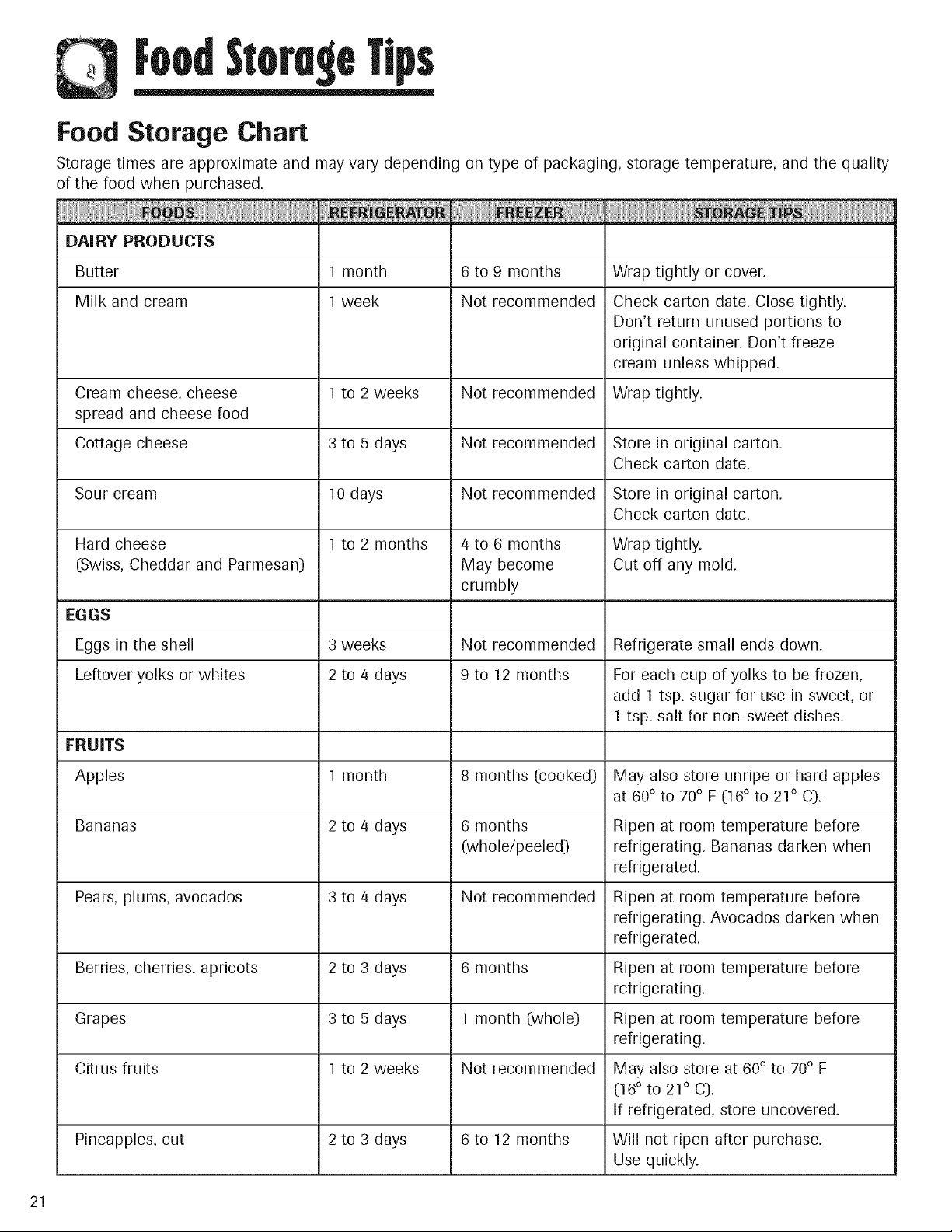

StorageTips

Food Storage Chart

Storage times are approximate and may vary depending on type of packaging, storage temperature, and the quality

of the food when purchased.

DAI RY PRODUCTS

Butter 1 month 6 to 9 months Wrap tightly or cover.

Milk and cream 1 week Not recommended Check carton date. Close tightly.

Don't return unused portions to

original container. Don't freeze

cream unless whipped.

Cream cheese, cheese 1 to 2 weeks Not recommended Wrap tightly.

spread and cheese food

Cottage cheese 3 to 5 days Not recommended Store in original carton.

Check carton date.

Sour cream 10 days Not recommended Store in original carton.

Check carton date.

Hard cheese 1 to 2 months 4 to 6 months Wrap tightly.

(Swiss, Cheddar and Parmesan) May become Cut off any mold.

crumbly

EGGS

Eggs in the shell 3 weeks Not recommended Refrigerate small ends down.

Leftover yolks or whites 2 to 4 days 9 to 12 months For each cup of yolks to be frozen,

add 1 tsp. sugar for use in sweet, or

1 tsp. salt for non-sweet dishes.

FRUITS

Apples 1 month 8 months (cooked) May also store unripe or hard apples

at 60° to 70° F (16° to 21° C).

Bananas 2 to 4 days 6 months Ripen at room temperature before

(whole/peeled) refrigerating. Bananas darken when

refrigerated.

Pears, plums, avocados 3 to 4 days Not recommended Ripen at room temperature before

refrigerating. Avocados darken when

refrigerated.

Berries, cherries, apricots 2 to 3 days 6 months Ripen at room temperature before

refrigerating.

Grapes 3 to 5 days 1 month (whole) Ripen at room temperature before

refrigerating.

Citrus fruits 1 to 2 weeks Not recommended May also store at 60° to 70° F

06 ° to 21° C).

If refrigerated, store uncovered.

Pineapples, cut 2 to 3 days 6 to 12 months Will not ripen after purchase.

Use quickly.

21

Page 23

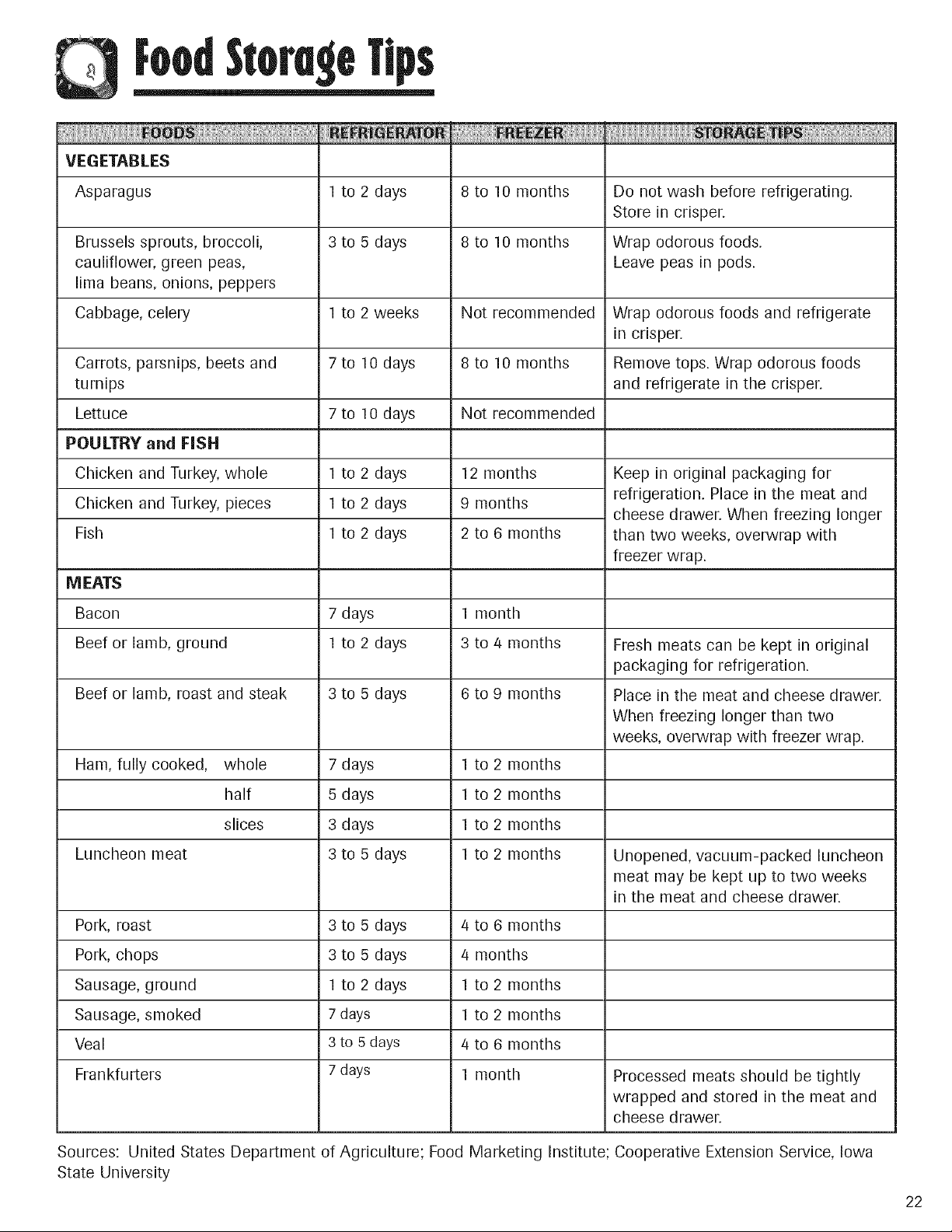

Stora jeTips

VEGETABLES

Asparagus 1 to 2 days 8 to 10 months Do not wash before refrigerating.

Store in crisper.

Brussels sprouts, broccoli, 3 to 5 days 8 to 10 months Wrap odorous foods.

cauliflower, green peas, Leave peas in pods.

lima beans, onions, peppers

Cabbage, celery 1 to 2 weeks Not recommended Wrap odorous foods and refrigerate

in crisper.

Carrots, parsnips, beets and

turnips

Lettuce

POULTRY and FISH

Chicken and Turkey, whole

Chicken and Turkey, pieces

Fish

M EATS

Bacon 7 days 1 month

Beef or lamb, ground 1 to 2 days 3 to 4 months Fresh meats can be kept in original

Beef or lamb, roast and steak 3 to 5 days 6 to 9 months Place in the meat and cheese drawer.

Ham, fully cooked, whole 7 days 1to 2 months

half 5 days 1to 2 months

7 to 10 days 8 to 10 months Remove tops. Wrap odorous foods

and refrigerate in the crisper.

7 to 10 days Not recommended

1 to 2 days

1 to 2 days

1 to 2 days

12 months

9 months

2 to 6 months

Keep in original packaging for

refrigeration. Place in the meat and

cheese drawer. When freezing longer

than two weeks, overwrap with

freezer wrap.

packaging for refrigeration.

When freezing longer than two

weeks, overwrap with freezer wrap.

slices 3 days 1to 2 months

Luncheon meat 3 to 5 days 1to 2 months Unopened, vacuum-packed luncheon

meat may be kept up to two weeks

in the meat and cheese drawer.

Pork, roast 3 to 5 days 4 to 6 months

Pork, chops 3 to 5 days 4 months

Sausage, ground 1 to 2 days 1 to 2 months

Sausage, smoked 7 days 1 to 2 months

Veal 3 to 5 days 4 to 6 months

Frankfurters 7 days 1 month Processed meats should be tightly

wrapped and stored in the meat and

cheese drawer.

Sources: United States Department of Agriculture; Food Marketing Institute; Cooperative Extension Service, Iowa

State University

22

Page 24

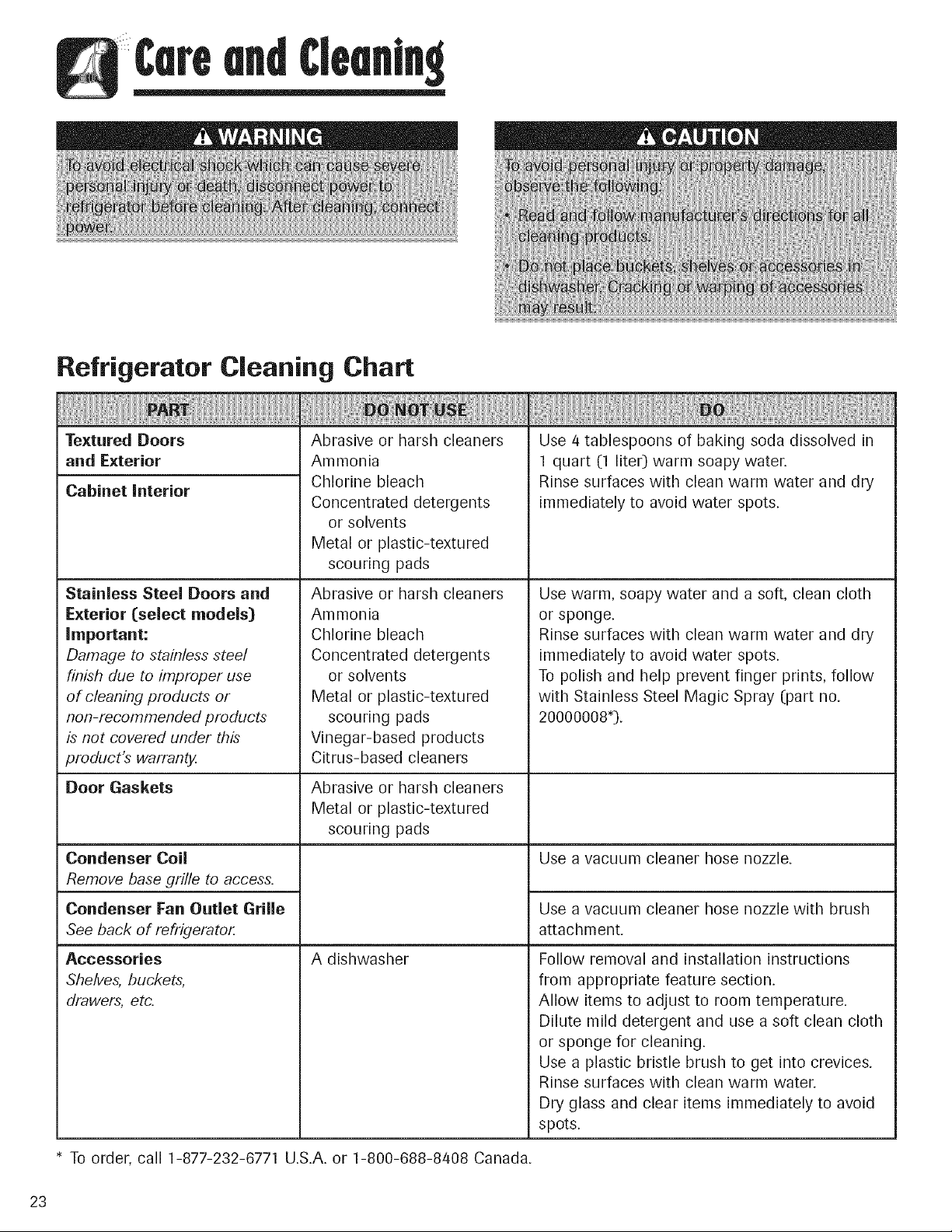

• l:;leanln

Refrigerator Cleaning Chart

Textured Doors

and Exterior

Cabinet interior

Stainless Steel Doors and

Exterior (select models)

important:

Damage to stain/ess stee/

finish due to improper use

of cleaning products or

non-recommended products

is not covered under this

product2 warranty

Door Gaskets

Condenser Coil

Remove base grille to access.

Condenser Fan Outlet Grille

See back of refrigerator

Accessories

She/ves, buckets,

drawers, etc.

Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents

or solvents

Metal or plastic-textured

scouring pads

Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents

or solvents

Metal or plastic-textured

scouring pads

Vinegar-based products

Citrus-based cleaners

Abrasive or harsh cleaners

Metal or plastic-textured

scouring pads

A dishwasher

Use 4 tablespoons of baking soda dissolved in

I quart (1 liter) warm soapy water.

Rinse surfaces with clean warm water and dry

immediately to avoid water spots.

Use warm, soapy water and a soft, clean cloth

or sponge.

Rinse surfaces with clean warm water and dry

immediately to avoid water spots.

To polish and help prevent finger prints, follow

with Stainless Steel Magic Spray (part no.

20000008*).

Use a vacuum cleaner hose nozzle.

Use a vacuum cleaner hose nozzle with brush

attachment.

Follow removal and installation instructions

from appropriate feature section.

Allow items to adjust to room temperature.

Dilute mild detergent and use a soft clean cloth

or sponge for cleaning.

Use a plastic bristle brush to get into crevices.

Rinse surfaces with clean warm water.

Dry glass and clear items immediately to avoid

spots.

* To order, call 1-877-232-6771 U.S.A. or 1-800-688-8408 Canada.

23

Page 25

Cleanln

Removing Odors From

Refrigerator

1. Remove all food and turn the refrigerator OFF.

2. Disconnect power to the refrigerator.

3. Clean the walls, floor, ceiling of cabinet interior,

drawers, shelves and gaskets according to the

instructions on page 23.

4. Dilute mild detergent and brush solution into

crevices using a plastic bristle brush. Let stand for

5 minutes. Rinse surfaces with warm water. Dry

surfaces with a soft, clean cloth.

5. Wash and dry all bottles, containers and jars.

Discard spoiled or expired items.

6. Wrap or store odor-causing foods in tightly sealed

containers to prevent reoccurring odors.

7. Reconnect power to refrigerator and return food to

refrigerator.

8. Allow the refrigerator to cool.

9. After 24 hours, check if odor has been eliminated.

if odor is still present:

1. Remove drawers and place on top shelf of

refrigerator.

Energy Saving Tips

• Avoid overcrowding refrigerator shelves. This reduces

air circulation around food and causes refrigerator to

run longer.

• Avoid adding too much warm food to refrigerator at

one time. This overloads compartments and slows

rate of cooling.

• Do not use aluminum foil, wax paper, or paper

toweling as shelf liners. This decreases air flow and

causes refrigerator to run less efficiently.

• A freezer that is two-thirds full runs most efficiently.

Locate refrigerator in coolest part of room. Avoid

areas of direct sunlight, or near heating ducts,

registers or other heat producing appliances. If this is

not possible, isolate exterior by using a section of

cabinet.

Clean door gaskets every three months according to

cleaning instructions. This will assure that door seals

properly and refrigerator runs efficiently.

Take time to organize items in refrigerator to reduce

time that door is open.

Be sure your doors are closing securely by leveling

refrigerator as instructed in your installation

instructions.

2. Pack refrigerator and freezer sections - including

doors - with crumpled sheets of black and white

newspaper.

3. Place charcoal briquettes randomly on crumpled

newspaper in both freezer and refrigerator

compartments.

4. Close doors and let stand 24 to 48 hours.

• Clean condenser coils as indicated in the cleaning

instructions every three months. This will increase

energy efficiency and cooling performance.

24

Page 26

Cleanln

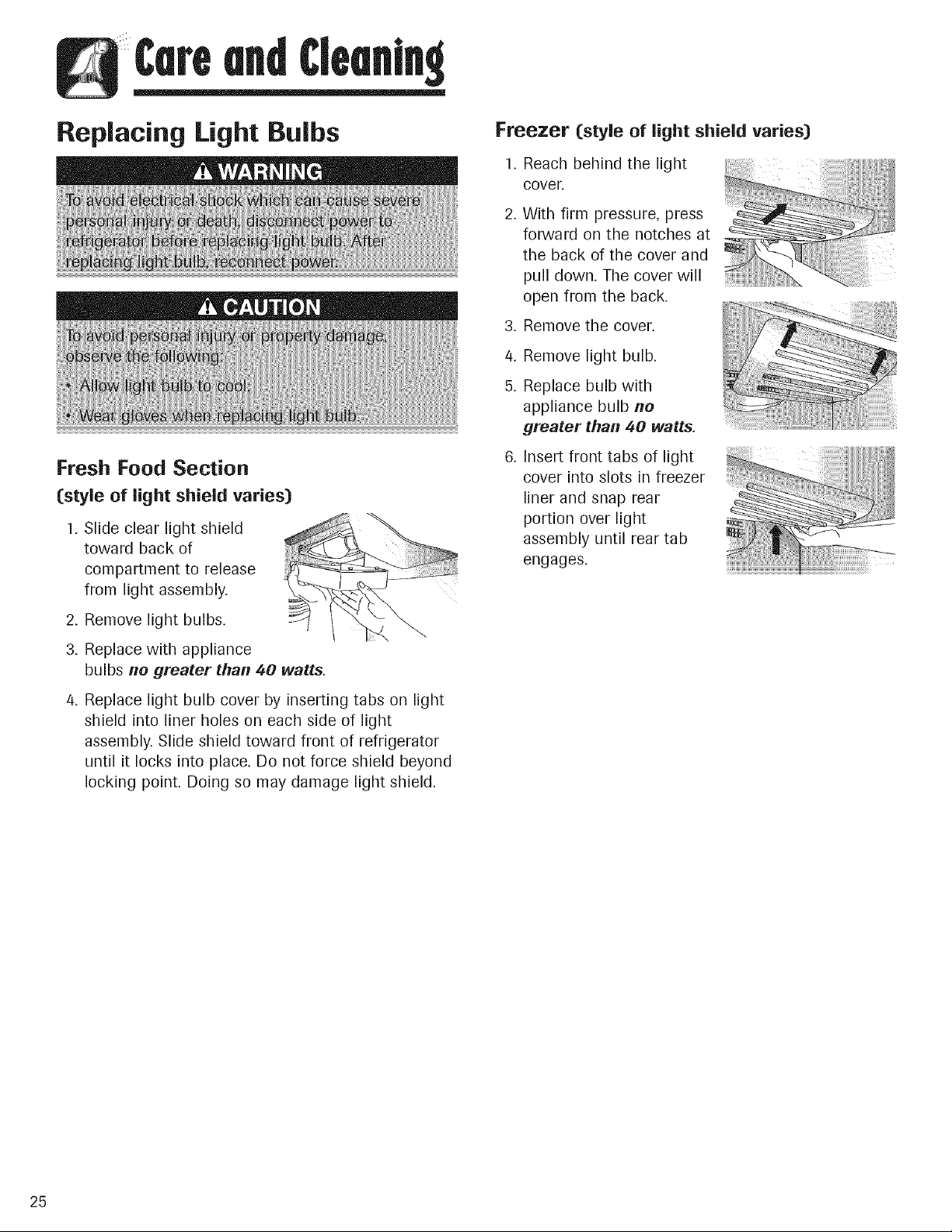

Replacing Light Bulbs

Fresh Food Section

(style of light shield varies)

Slide clear light shield

toward back of

compartment to release

from light assembly.

Freezer (style of light shield varies)

1. Reach behind the light

cover.

2. With firm pressure, press

forward on the notches at

the back of the cover and

pull down. The cover will

open from the back.

3. Remove the cover.

/4. Remove light bulb.

5.

Replace bulb with

appliance bulb ne

greater than 40 watts.

Insert front tabs of light

cover into slots in freezer

liner and snap rear

portion over light

assembly until rear tab

engages.

2. Remove light bulbs.

3. Replace with appliance

bulbs no greater than 40 watts.

4_

Replace light bulb cover by inserting tabs on light

shield into liner holes on each side of light

assembly. Slide shield toward front of refrigerator

until it locks into place. Do not force shield beyond

locking point. Doing so may damage light shield.

25

Page 27

Cleanln

Preparing for Vacation

For short vacations or absences (three months or less):

1. Remove all perishables.

2. If no one will be checking in on the refrigerator

during your absence, remove all frozen items also.

3. If your refrigerator has an automatic ice maker:

• Shut off the water supply to the ice maker at

least one day ahead of time.

• After the last load of ice drops, raise the wire

shut off arm to the OFF position.

• Empty the ice bin

Upon your return:

After a short vacation or absence:

For models with automatic ice makers or dispensers:

• Reconnect the water supply and turn on supply valve

(see page 9).

• Monitor water connection for 24 hours and correct

leaks if necessary.

• Run 10-15 glasses of water from the dispenser to

flush out the system.

• Restart the ice maker.

• Discard at least the first three ice harvests.

After a long vacation or absence:

• If your refrigerator has an automatic ice maker,

reconnect the water supply and turn on supply valve

(see page 9).

• Plug the refrigerator back in and reset controls (see

pages 10 and 11).

4. If the room temperature will drop below 55° F

(13° C), follow the instructions for longer absences.

For long vacations, absences (more than three months)

OR if the room temperature will drop below 55° F

(13° C):

1. Remove food

2. If your refrigerator has an automatic ice maker:

• Shut off the water supply to the ice maker at

least one day ahead of time.

• After the last load of ice drops, raise the wire

shut off arm to the OFF position.

• Empty the ice bin

3. If your refrigerator has a dispenser system with

water filter, remove the water filter cartridge and

install the filter bypass. Dispose of the used

cartridge.

4. Turn the freezer control to OFF with dial controls or

(-) with touch controls (see page 10 or 11).

5. Unplug the refrigerator.

6. Thoroughly clean the interior of both compartments

with a baking soda solution and a clean soft cloth

(four tablespoons of baking soda in one quart of

warm water.).

7. Dry thoroughly.

• Monitor water connection for 24 hours and correct

leaks, if necessary.

For dispenser models, run water through the dispenser

for at least three minutes with the filter bypass in

place, then install water filter (see page 17).

After installing the water filter, run water through the

dispenser continuously for at least two minutes, or

until water runs steady. Initially you may notice a

one-two minute delay in water dispersal as the

internal tanks fills.

• Restart the ice maker.

• Discard ice produced within the first 12 hours (at

least the first three harvests).

Preparing to move:

• Follow the above instructions for long

vacations/absences, through step 7.

• Then secure all loose items such as shelves and

drawers by taping them securely in place to prevent

damage.

• Tape the doors shut

• Use an appliance dolly when moving the refrigerator.

Always truck the refrigerator from its side or back-

never from its front.

8. Leave the doors open to prevent the formation of

mold and mildew.

• Be sure the refrigerator stays in an upright position

during moving.

26

Page 28

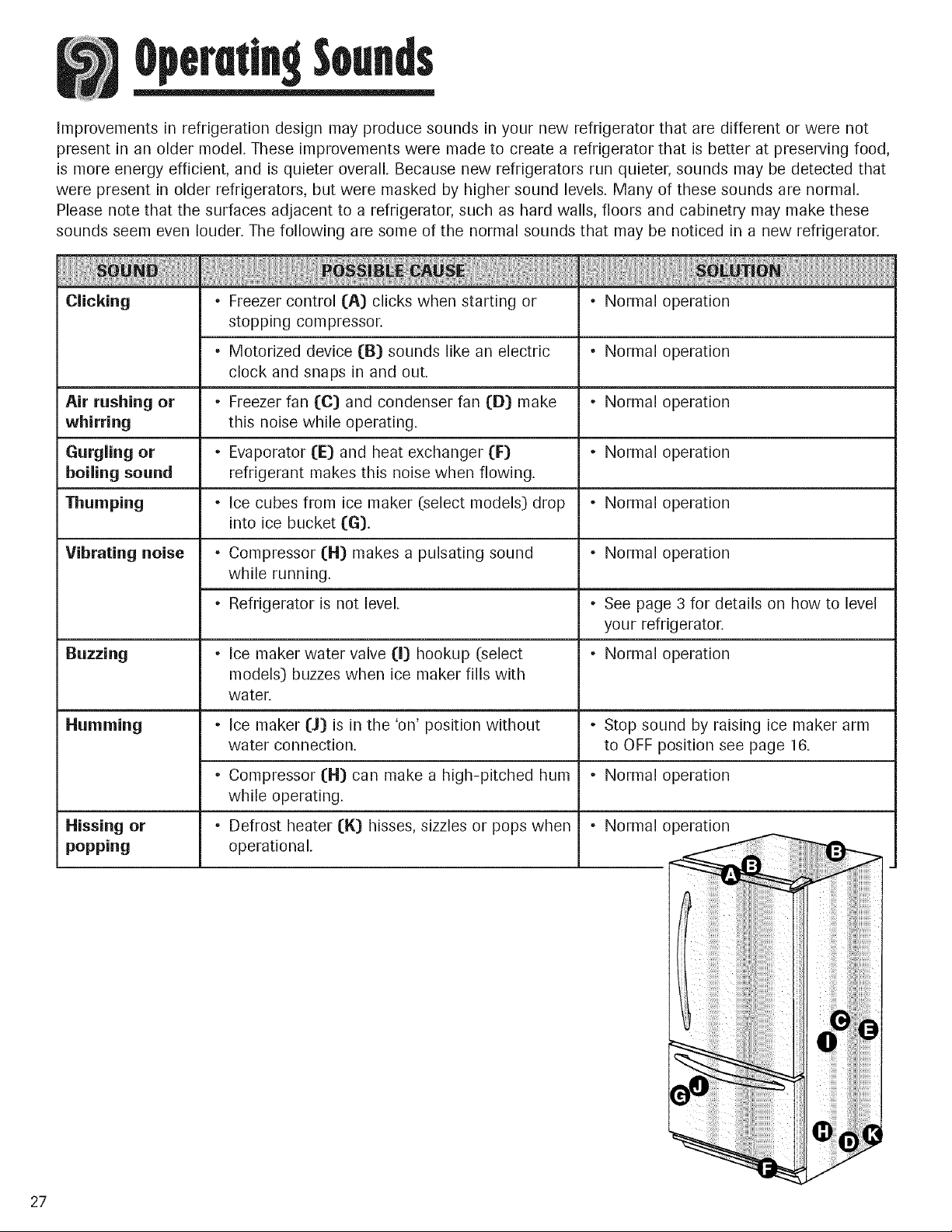

w Operetin9Sounds

Improvements in refrigeration design may produce sounds in your new refrigerator that are different or were not

present in an older model. These improvements were made to create a refrigerator that is better at preserving food,

is more energy efficient, and is quieter overall. Because new refrigerators run quieter, sounds may be detected that

were present in older refrigerators, but were masked by higher sound levels. Many of these sounds are normal.

Please note that the surfaces adjacent to a refrigerator, such as hard walls, floors and cabinetry may make these

sounds seem even louder. The following are some of the normal sounds that may be noticed in a new refrigerator.

Clicking Freezer control (A) clicks when starting or

stopping compressor.

• Motorized device (B) sounds like an electric

clock and snaps in and out.

Air rushing or * Freezer fan (C) and condenser fan (D) make

whirring this noise while operating.

Gurgling or • Evaporator (E) and heat exchanger (F)

boiling sound refrigerant makes this noise when flowing.

Thumping • Ice cubes from ice maker (select models) drop

into ice bucket (G).

Vibrating noise • Compressor (FI) makes a pulsating sound

while running.

• Refrigerator is not level.

Buzzing • ice maker water valve (I) hookup (select

models) buzzes when ice maker fills with

water.

Humming • Ice maker (J) is in the 'on' position without • Stop sound by raising ice maker arm

water connection, to OFF position see page 16.

• Normal operation

Normal operation

Normal operation

• Normal operation

• Normal operation

• Normal operation

See page 3 for details on how to level

your refrigerator.

• Normal operation

• Compressor (H) can make a high-pitched hum • Normal operation

while operating.

poppingHissingor • operationaI.Defr°stheater (K) hisses, sizzles or pops when • Normal

27

Page 29

Troubleshoofln9

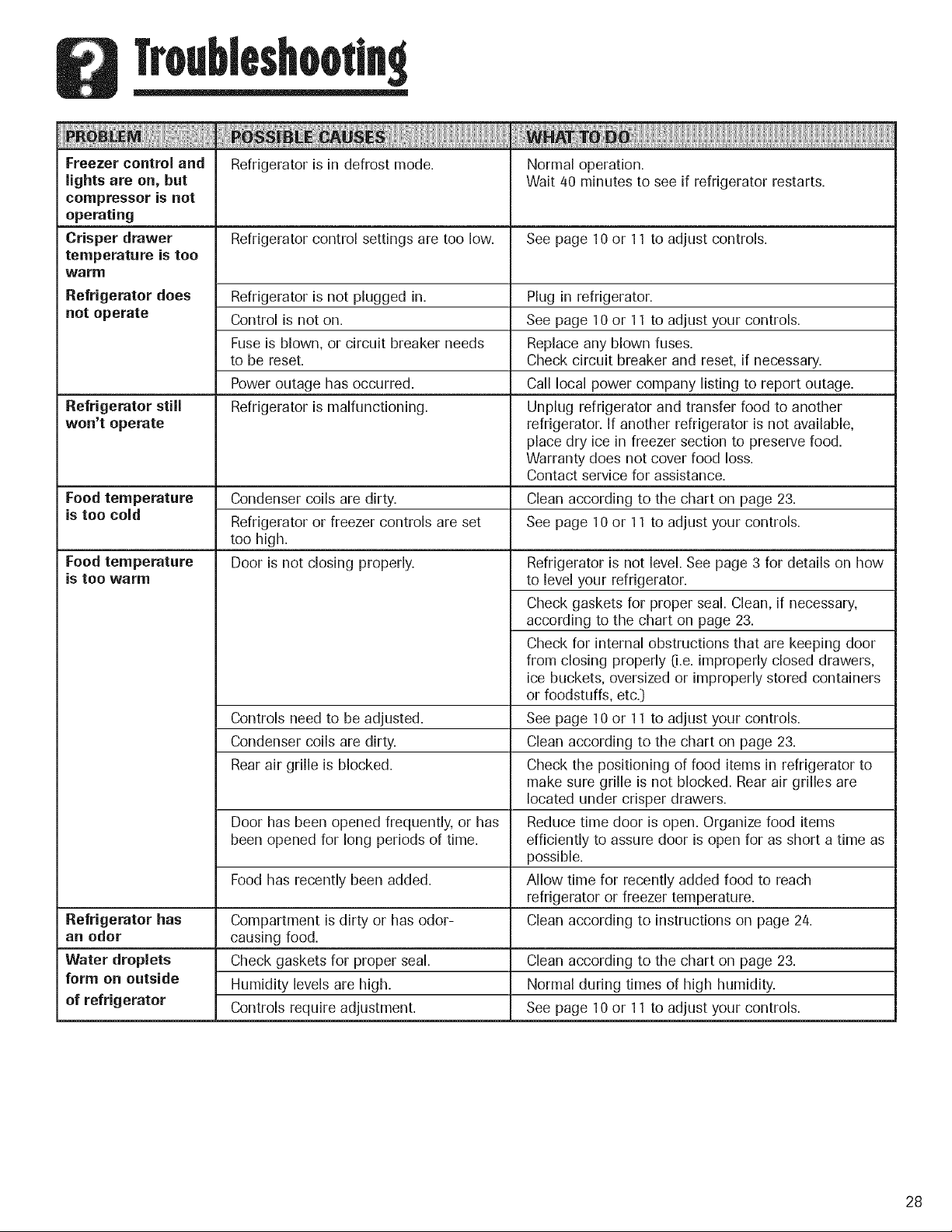

Freezer control and Refrigerator isin defrost mode. Normal operation.

lights are on, but Wait 40 minutes to see if refrigeratorrestarts.

compressor is not

operating

Crisper drawer Refrigerator control settings are too low. See page 10or 11to adjust controls.

temperature is too

warm

Refrigerator does Refrigerator is not plugged in. Plug in refrigerator.

not operate Control is not on. See page 10 or 11to adjust your controls.

Fuse is blown, or circuit breaker needs Replace any blown fuses.

to be reset. Check circuit breaker and reset, if necessary.

Power outage has occurred. Call local power company listing to report outage.

Refrigerator still Refrigerator is malfunctioning. Unplug refrigerator and transfer food to another

won't operate refrigerator. If another refrigerator is not available,

place dry ice in freezer section to preserve food.

Warranty does not cover food loss.

Contact service for assistance.

Food temperature Condenser coils are dirty. Clean according to the chart on page 23.

is too cold Refrigerator or freezer controls are set See page 10 or 11to adjust your controls.

too high.

Food temperature

is too warm

Refrigerator has Compartment is dirty or has odor-

an odor causing food.

Water droplets Check gaskets for proper seal. Clean according to the chart on page 23.

form on outside Humidity levels are high. Normal during times of high humidity.

of refrigerator Controls require adjustment. See page 10 or 11 to adjust your controls.

Door isnot closing properly.

Controls need to be adjusted.

Condenser coils are dirty.

Rear air grille is blocked.

Door has been opened frequently, or has

been opened for long periods of time.

Food has recently been added.

Refrigerator is not level. See page 3 for details on how

to level your refrigerator.

Check gaskets for proper seal. Clean, if necessary,

according to the chart on page 23.

Check for internal obstructions that are keeping door

from closing properly (i.e. improperly closed drawers,

ice buckets, oversized or improperly stored containers

or foodstuffs, etc.)

See page 10 or 11to adjust your controls.

Clean according to the chart on page 23.

Check the positioning of food items in refrigerator to

make sure grille is not blocked. Rearair grilles are

located under crisper drawers.

Reduce time door is open. Organize food items

efficiently to assure door is open for as short a time as

possible.

Allow time for recently added food to reach

refrigerator or freezer temperature.

Clean according to instructions on page 24.

28

Page 30

Troubleshoofln9

Water droplets farm

an inside of

refrigerator

Refrigerator or ice Normal operation.

maker makes

unfamiliar sounds

or seems too loud

Crisper drawers Contents of drawer, or positioning of Reposition food items and containers to avoid

do not close freely items in the surrounding compartment interference with the drawers.

Refrigerator runs

too fraquently

Humidity levels are high or door has

been been opened frequently.

Check gaskets for proper seal.

could be obstructing drawer.

Drawer is not in proper position.

Refrigerator isnot level.

Drawer channels are dirty or need

treatment.

Doors have been opened frequently or

for long periods of time.

Humidity or heat in surrounding area is Normal operation.

high.

Food has recently been added.

Refrigerator is exposed to heat by

environment or by appliances nearby.

Condenser coils are dirty.

Controls need to be adjusted.

Door is not closing properly.

Normal Operation

See page 10 or 11to adjust your controls.

Reduce time door is open.

Organize food items efficiently to assure door is open

for as short a time as possible.

Clean, if necessary, according to the chart on page 23.

See page 27

See page 13 and 14for proper drawer placement.

See page 3 for details on how to level your

refrigerator.

Clean drawer channels with warm, soapy water.

Rinse and dry thoroughly.

Apply a thin layer of petroleum jelly to drawer

channels.

Reduce time door is open.

Organize food items efficiently to assure door is open

for as short a time as possible.

Allow interior environment to adjust for period the

door has been opened.

Allow time for recently added food to reach

refrigerator or freezer temperature.

Evaluate your refrigerator's environment. Refrigerator

may need to be moved to run more efficiently.

Clean, if necessary, according to the chart on page 23.

See page 10 or 11to adjust your controls.

Refrigerator is not level. See page 3 for details on how

to level your refrigerator.

Check gaskets for proper seal.

Clean, if necessary, according to the chart on page 23.

Check for internal obstructions that are keeping door

from closing properly (i.e. improperly closed drawers,

ice buckets, oversized or improperly stored containers

or foodstuffs, etc.)

See Operating Sounds on page 2Z

29

Page 31

ice

Troubleshoofln9

Refrigerator is

leaking water

ice forms in inlet

tube to ice maker

Water flow is

slower than normal

Plastic tubing was used to complete

water connection.

Improper water valve was installed.

Water pressure is low.

Freezer temperature is too high.

Copper tubing has kinks.

Water filter is clogged or needs to be

changed.

Improper water valve was installed.

The manufacturer recommends using copper tubing

for installation. Plastic is less durable and can cause

leakage. The manufacturer is not responsible for

property damage due to improper installation or

water connection.

Check water connection procedure (see page 9:).

Self-piercing and -_,G"saddle valves cause low water

pressure and may clog the line over time. The

manufacturer is not responsible for property

damage due to improper installation or water

connection.

Water pressure must be between 35 to 100 pounds

per square inch to function properly. A minimum

pressure of 35 pounds per square inch is

recommended for refrigerators with water filters.

Adjust freezer control (see page 10 or 11]. Freezer is

recommended to be approximately 0° F (-18° C:).

Turn off water supply and remove kinks. If kinks

cannot be removed, replace tubing.

Change water filter (see page 17_.

Open water valve completely and check for leaks.

3O

Page 32

Warranty

What is Not Covered By These Warranties

1. Conditions and damages resulting from any of the following:

a. Improper installation, delivery, or maintenance.

b. Any repair, modification, alteration, or adjustment not authorized by the

manufacturer or an authorized servicer.

c. Misuse, abuse, accidents, unreasonable use, or acts of God.

d. Incorrect electric current, voltage, electrical and/or gas supply.

e. Improper setting of any control.

2. Warranties are void if the original serial numbers [lave been removed, altered,

or cannot be readily determined.

3. Light bulbs, water filters and air filters.

4. Products purchased for commercial or industrial use.

5. The cost of service or service call to:

a. Correct installation errors. For products requiring ventilation, rigid metal

ducting must be used.

b. Instruct tile user on the proper use of the product.

c. Transport the appliance to and from the servicer.

6. Any food loss due to refrigerator or freezer product failures.

7. Expenses for travel and transportation for product service in remote locations.

8. Outside of the United States and Canada this warranty does not apply.

Contact your dealer to determine if another warranty applies.

CUSTOMER'S SOLEAND EXCLUSIVE

REMEDY UNDER THIS LIMITED

WARRANTY SHALL BEPRODUCT REPAIR

AS PROVIDED HEREIN. IMPLIED

WARRANTIES, INCLUDING WARRANTIES

OF MERCHANTABILITY OR FITNESSFOR

A PARTICULAR PURPOSE,ARE LIMITED

TO ONE YEAR OR THE SHORTEST

PERIOD ALLOWED BY LAW. MAYTAG

CORPORATION SHALL NOT BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES. SOME STATESAND

PROVINCES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL

DAMAGES, OR LIMITATIONS ON THE

DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS,SO

THESE EXCLUSIONS OR LIMITATIONS

MAY NOT APPLY TOYOU. THIS

WARRANTY GIVESYOU SPECIFIC LEGAL

RIGHTS AND YOU MAY ALSO HAVE

OTHER RIGHTS,WHICH VARY STATETO

STATEOR PROVINCE TO PROVINCE.

9. Consequential or incidental damages sustained by any person as a result of

any breach of these warranties. Some states do not allow tile exclusion or

limitation of consequential or incidental damages, so the above exclusion may

not apply.

If You Need Service

First see the Troubleshooting section in your Use and Care Guide or call the