Page 1

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

International

Bottom Mount

Refrigerators

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Amana

AB1924PEK*

AB2026PEK*

AB2225PEK*

AB2226PEK*

AB2526PEK*

G32026PEK*

G32526PEK*

GB1924PEK*

GB2225PEK*

GB2526PEK*

16023324

July 2004

Page 2

!

!

!

!

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however, that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts,

testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

WARNING

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.AMANA.COM ............................................... 1-800-843-0304

WWW.JENNAIR.COM ............................................ 1-800-536-6247

WWW.MAYTAG.COM ............................................. 1-800-688-9900

CAIR Center in Canada .......................................... 1-800-688-2002

Amana Canada Product .......................................... 1-866-587-2002

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16023324 Rev. 0 ©2004 Maytag Services

Page 3

Table of Contents

Important Information .................................................... 2

Product Design ............................................................. 4

Component Testing ....................................................... 5

Service Procedures ......................................................10

Service Equipment .......................................................10

Drier Replacement ....................................................... 10

Refrigerant Precautions ................................................ 11

Line Piercing Valves ..................................................... 11

Open Lines .................................................................. 11

Compressor Operational Test ....................................... 11

Dehydrating Sealed Refrigeration System .................... 12

Leak Testing .................................................................12

Testing Systems Containing a

Refrigerant Charge ................................................. 12

Testing Systems Containing

No Refrigerant Charge ............................................12

Restrictions .................................................................. 13

Symptoms .............................................................13

Testing for Restrictions .......................................... 13

Evacuation and Charging .............................................. 14

Evacuation .............................................................14

Charging ................................................................ 15

Refrigerant Charge ................................................. 15

HFC134a Service Information ....................................... 16

Health, Safety, and Handling ..................................16

Comparison of CFC12 and HFC134a Properties .....16

Replacement Service Compressor ................................17

Compressor Testing Procedures ............................ 17

Brazing ........................................................................ 17

Refrigerant Flow ...........................................................18

Cabinet Air Flow ...........................................................19

Two Way Machine Compartment Air Flow Diagram ...... 20

One Way Machine Compartment

Air Flow Diagram .........................................................21

Typical External Sweat Pattern...................................22

Troubleshooting Chart................................................23

System Diagnosis ........................................................26

Disassembly Procedures

Fresh Food Door ....................................................29

Freezer Door ..........................................................29

Freezer Drawer ......................................................29

Refrigerator Compartment

Light Bulb ..............................................................29

Light Bulb Assembly .............................................. 29

Light Bulb Sockets ................................................ 30

PC Control Board ...................................................30

Light Switch ...........................................................30

Temp- Assure™ Damper control ............................30

Fresh Food Thermistor ...........................................30

Water Tank ............................................................30

Water Dispenser ....................................................31

Freezer Compartment

Freezer Thermistor ................................................. 31

Light Socket .......................................................... 31

Light Switch ...........................................................31

Freezer Back Panel ............................................... 31

Evaporator Fan and Evaporator Motor ................... 31

Defrost Terminator (thermostat) ..............................32

Defrost Heater ....................................................... 32

Evaporator Removal ...............................................32

Drawer Assembly ................................................... 33

Drawer Rails ..........................................................33

Rack and Pinion Gear ............................................ 33

Bottom of Cabinet

Front roller assembly ............................................. 33

Rear roller assembly............................................33

Machine Compartment

Condenser Fan and Fan motor ............................... 33

Compressor ........................................................... 33

Overload/Relay/Capacitor ....................................... 34

Condensate Drain Pan ........................................... 34

Condensate Drain Tube ..........................................34

Condenser Removal ............................................... 34

Control Board ( Mid Level)

Programming Mode ............................................... 35

Defrost Operation ...................................................35

Forced Defrost Mode ............................................. 35

Service Test Mode .................................................36

Service Test 1-Defrost Thermostat & Defrost Circuit

Test ....................................................................... 37

Service Test 2-Compressor/Condenser Fan Test ....37

Service Test 3-Evaporator/Freezer Fan Test ........... 37

Service Test 4-Fresh Food Thermistor Test ............ 38

Service Test 5-Freezer Thermistor Test .................. 38

Service Test 6-Open Damper Test ..........................39

Service Test 7-FF Performance Adjustment ............ 39

Service Test 8-FZ Performance Adjustment ............39

©2004 Maytag Services 16023324 Rev. 0 3

Page 4

Product Design

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Refrigeration System

Compressor forces high temperature vapor into fan

cooled tube and wire condenser where vapor is cooled

and condensed into high pressure liquid by circulation

of air across condenser coil. (See Refrigerant Flow

Diagram, page 18)

High pressure liquid passes into post-condenser loop

which helps to prevent condensation around freezer

compartment opening and through molecular sieve drier

and into capillary tube. Small inside diameter of

capillary offers resistance, decreasing pressure, and

temperature of liquid discharged into evaporator.

Capillary diameter and length is carefully sized for each

system.

Capillary enters evaporator at top front. Combined liquid

and saturated gas flows through front to bottom of coil

and into suction line. Aluminum tube evaporator coil is

located in freezer compartment where circulating

evaporator fan moves air through coil and into fresh food

compartment.

Large surface of evaporator allows heat to be absorbed

from both fresh food and freezer compartments by

airflow over evaporator coil causing some of the liquid to

evaporate. Temperature of evaporator tubing near end of

running cycle may vary from -25°C to -32°C.

Saturated gas is drawn off through suction line where

superheated gas enters compressor. To raise

temperature of gas, suction line is placed in heat

exchange with capillary.

Defrost System

Mid Level Electronic Defrost

The Control Board adapts the compressor run time

between defrosts to achieve optimum defrost intervals

by monitoring the length of time the defrost heater is

on.

After initial power up, defrost interval is 4 hours

compressor run time. Defrost occurs immediately after

the 4 hours.

Note: Once unit is ready to defrost there is a 4 minute

wait time prior to the beginning of the defrost

cycle.

Optimum defrost is 15 minutes. Each additional minute

the defrost thermostat remains closed, 1 hr. is

subtracted from the previous defrost interval. Each

minute the thermostat opens prior to optimum defrost,

it extends the next defrost interval 1 hr. When defrost

thermostat opens there is a 4-6 minute drip time before

compressor restarts or Control Board will terminate

defrost at 25 minutes if defrost thermostat has not

opened and will reset the defrost interval to the 8 hr.

minimum setting.

4 hours of continuous compressor run resets the next

defrost interval to 8 hours and will initiate a defrost, if 8

hours of compressor run time has also occurred.

Temperature Controls

Freezer compartment temperature is regulated by air

sensing thermostat at top front of freezer compartment

which actuates compressor. Control should be set to

maintain freezer temperature between -17.8°C to -

18.9°C.

Fresh food compartment temperature is regulated by an

air damper control governing amount of refrigerated air

entering fresh food compartment from freezer. Fresh

food compartment temperature should be between

3.3°C and 4.4°C.

4 16023324 Rev. 0 ©2004 Maytag Services

Page 5

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Compressor

When compressor electrical circuit is

energized, the start winding current

causes relay to heat. After an amount of

starting time, the start winding circuit

turns off. The relay will switch off the start

winding circuit even though compressor

has not started (for example, when

attempting to restart after momentary

power interruption).

With “open” relay, compressor will not

start because there is little or no current

to start windings. Overload protection will

open due to high locked rotor run winding

current.

With “shorted” relay or capacitor,

compressor will start and overload

protector will quickly open due to high

current of combined run and start

windings.

With open or weak capacitor, compressor

will start and run as normal but will

consume more energy.

Resistance test

1. Disconnect power to unit.

2. Discharge capacitor by shorting across terminals with a resistor for 1 minute.

NOTE: (Some compressors do not have a run capacitor.)

3. Remove leads from compressor terminals.

4. Set ohmmeter to lowest scale.

5. Check for resistance between

Terminals “S” and “C”, start winding

Terminals “R” and “C”, run winding

If either compressor winding reads open (infinite or very high resistance) or

dead short (0 ohms), replace compressor.

Ground test

1. Disconnect power to refrigerator.

2. Discharge capacitor, if present, by shorting terminals through a resistor.

3. Remove compressor leads and use an ohmmeter set on highest scale.

4. Touch one lead to compressor body (clean point of contact) and other probe

to each compressor terminal.

• If reading is obtained, compressor is grounded and must be replaced.

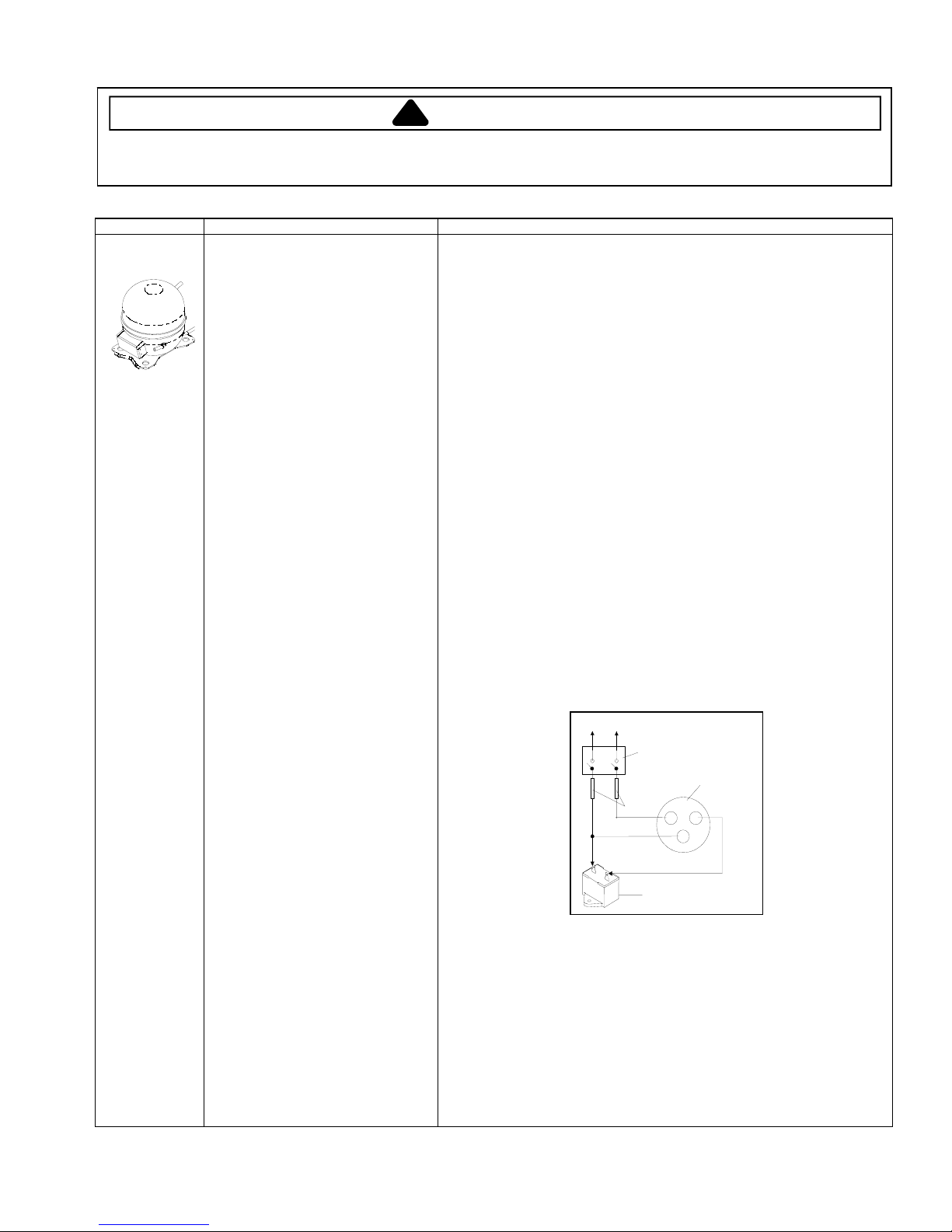

Operation test

If voltage, capacitor, overload, and motor winding tests do not show cause for

failure, perform the following test:

1. Disconnect power to refrigerator.

2. Discharge capacitor by shorting capacitor terminals through a resistor.

3. Remove leads from compressor terminals.

4. Wire a test cord to power switch.

5. Place time delayed fuse with UL rating equal to amp rating of motor in test

cord socket. (Refer to Technical Data Sheet)

6. Remove overload and relay.

7. Connect start, common and run leads of test cord on appropriate terminals of

compressor.

8. Attach capacitor leads of test cord together. If capacitor is used, attach

capacitor lead to a known good capacitor of same capacity.

To AC supply

©2004 Maytag Services

Switch

Compressor

Fuses

CRS

Capacitor

Test configuration

9. Plug test cord into multimeter to determine start and run wattage and to check

for low voltage, which can also be a source of trouble indications.

10. With power to multimeter, press start cord switch and release.

• If compressor motor starts and draws normal wattage, compressor is okay

and trouble is in capacitor, relay/overload, freezer temperature control, or

elsewhere in system.

• If compressor does not start when direct wired, recover refrigerant at high

side. After refrigerant is recovered, repeat compressor direct wire test. If

compressor runs after recovery but would not run when direct wired before

recover, a restriction in sealed system is indicated.

• If compressor does not run when wired direct after recovery, replace faulty

compressor.

16023324 Rev. 0 5

Page 6

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Capacitor

Condenser Condenser is a tube and wire

Run capacitor connects to relay terminal

3 and L side of line.

Some compressors do not require a run

capacitor; refer to the Technical Data

Sheet for the unit being serviced.

construction located in machine

compartment.

Condenser is on high pressure discharge

side of compressor. Condenser function

is to transfer heat absorbed by refrigerant

to ambient.

Higher pressure gas is routed to

condenser where, as gas temperature is

reduced, gas condenses into a high

pressure liquid state. Heat transfer takes

place because discharged gas is at a

higher temperature than air that is

passing over condenser. It is very

important that adequate air flow over

condenser is maintained.

Condenser is air cooled by condenser fan

motor. If efficiency of heat transfer from

condenser to surrounding air is impaired,

condensing temperature becomes higher.

High liquid temperature means liquid will

not remove as much heat during boiling

in evaporator as under normal conditions.

This would be indicated by high than

normal head pressures, long run time,

and high wattage. Remove any lint or

other accumulation, that would restrict

normal air movement through condenser.

From condenser the refrigerant flows into

a post condenser loop which helps

control exterior condensation on flange,

center mullion, and around freezer door.

Refrigerant the flows through the drier to

evaporator and into compressor through

suction line.

To avoid electrical shock which can cause severe personal injury or death,

discharge capacitor through a resistor before handling.

1. Disconnect power to refrigerator.

2. Remove capacitor cover and disconnect capacitor wires.

3. Discharge capacitor by shorting across terminals with a resistor for 1 minute.

4. Check resistance across capacitor terminals with ohmmeter set on “X1K”

scale.

• Good—needle swings to 0 ohms and slowly moves back to infinity.

• Open—needle does not move. Replace capacitor.

• Shorted—needle moves to zero and stays. Replace capacitor.

• High resistance leak—needle jumps toward 0 and then moves back to

constant high resistance (not infinity).

Leaks in condenser can usually be detected by using an electronic leak detector

or soap solution. Look for signs of compressor oil when checking for leaks. A

certain amount of compressor oil is circulated with refrigerant.

Leaks in post condenser loop are rare because loop is a one-piece copper tube.

For minute leaks:

1. Separate condenser from rest of refrigeration system and pressurize

condenser up to a maximum of 16.20 Bar with a refrigerant and dry nitrogen

combination.

2. Recheck for leaks.

To avoid severe personal injury or death from sudden eruption of high

pressures gases, observe the following:

Protect against a sudden eruption if high pressures are required for leak

checking.

Do not use high pressure compressed gases in refrigeration systems

without a reliable pressure regulator and pressure relief valve in the

lines.

WARNING

!

WARNING

!

6 16023324 Rev. 0

©2004 Maytag Services

Page 7

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Overload / Relay

Control board

Ice maker Optional on some models.

Evaporator fan

motor

Electric damper

control

When voltage is connected and relay is

cool, current passes through relay to start

winding.

After a short time, current heats the

resistor in relay and resistance will rise

blocking current flow through relay.

Start winding remains in the circuit through

run capacitor.

Solid state relay plugs directly on

compressor start and run terminals. Relay

terminals 2 and 3 are connected within

relay. Run capacitor is connected to relay

terminal 3. L2 side of 120 VAC power is

connected to relay terminal 2.

On some models.

See “Control Board” section for

troubleshooting information.

See “Ice Maker” section for service

information.

Evaporator fan moves air across

evaporator coil and throughout refrigerator

cabinet.

Damper control balances the air delivery

between refrigerator and freezer

compartments providing temperature

control for refrigerator.

Electrical voltage activates damper control

and door closes restricting flow of air from

freezer compartment to refrigerator

compartment.

1. Disconnect power to the refrigerator.

2. Remove relay cover and disconnect leads.

3. Check resistance across terminals 2 and 3 with an ohmmeter:

Normal = 3 to 12 ohms

Shorted = 0 ohms

Open = infinite ohms

1. Disconnect power to unit.

2. Disconnect fan motor leads.

3. Check resistance from ground connection solder. Trace to motor frame must

not exceed .05 ohms.

4. Check for voltage at connector to motor with unit in refrigeration mode and

compressor operating.

Check resistance across terminals.

If no resistance across terminals replace damper control.

©2004 Maytag Services

16023324 Rev. 0 7

Page 8

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Switch, refrigerator

light,

Switch, freezer

light

Switch, water

dispenser

Drier

Single pole, single throw switch

completes circuit for light when door is

open.

Single pole, double throw switch

completes circuit for light when door is

open. Opens circuit to icemaker when

door is open.

Single pole, single throw switch

completes circuit for water solenoid when

button is depressed.

Drier is placed at post condenser loop

outlet and passes liquefied refrigerant to

capillary.

Desiccant (20) 8 x 12 4AXH - 7 M>S> Grams

Check resistant across terminals.

Switch arm depressed

“NO” terminals Open

Switch arm up

“NO” terminals Closed

Check resistant across terminals.

Switch arm depressed

“NO” terminals Open

”NC” terminals Closed

Switch arm up

“NO” terminals Closed

“NC” terminals Open

Check resistant across terminals.

Water button not depressed

“NO” terminals Open

Water button depressed

“NO” terminals Closed

Drier must be changed every time the system is opened for testing or

compressor replacement.

NOTE: Drier used in R12 sealed system is not interchangeable with

drier used in R134a sealed system. Always replace drier in R134a

system with Amana part number B2150504.

Before opening refrigeration system, recover HFC134a refrigerant for safe

disposal.

1. Cut drier out of system using the following procedure. Do not unbraze drier.

2. Applying heat to remove drier will drive moisture into the system.

3. Score capillary tube close to drier and break.

4. Reform inlet tube to drier allowing enough space for large tube cutter.

5. Cut circumference of drier 31.75 mm below condenser inlet tube joint to drier.

6. Remove drier.

7. Apply heat trap paste on post condenser tubes to protect grommets from high

heat.

8. Unbraze remaining part of drier. Remove drier from system.

9. Discard drier in safe place. Do not leave drier with customer. If refrigerator is

under warranty, old drier must accompany warranty claim.

To avoid death or severe personal injury, cut drier at correct location.

Cutting drier at incorrect location will allow desiccant beads to scatter. If

spilled, completely clean area of beads.

WARNING

!

8 16023324 Rev. 0

©2004 Maytag Services

Page 9

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Evaporator Inner volume of evaporator allows liquid

Evaporator heater

(defrost)

Thermostat

(defrost)

Thermistor

Condenser motor

ECM condenser

motor

refrigerant discharged from capillary to

expand into refrigerant gas.

Expansion cools evaporator tube and fin

temperature to approximately -20°F

transferring heat from freezer section to

refrigerant.

Passing through suction line to

compressor, the refrigerant picks up

superheat (a relationship between

pressure and temperature that assures

complete vaporization of liquid

refrigerant) as the result of capillary tube

soldered to suction line.

Refrigerant gas is pulled through suction

line by compressor, completing

refrigeration cycle.

Activated when defrost thermostat,

defrost timer, and freezer control

complete circuit through heater.

Thermostat is in a series circuit with

terminal 2 of defrost timer, and defrost

heater. Circuit is complete if evaporator

fan motor operates when cold.

Controls the circuit from freezer

thermostat through defrost terminator to

defrost heater. Opens and breaks circuit

when thermostat senses preset high

temperature.

Temperature sensing device Check resistance across leads.

Condenser fan moves cooling air across

condenser coil and compressor body.

Condenser fan motor is in parallel circuit

with compressor.

Condenser fan moves cooling air across

condenser coil and compressor body.

Condenser fan motor is in parallel circuit

with compressor.

Test for leaks in evaporator with electronic leak detector or with soap solution.

Compressor oil is circulated with refrigerant; check for oil when checking for

leaks.

For minute leaks:

1. Separate evaporator from rest of refrigeration system and pressurize

evaporator up to a maximum of 9.65 Bar with a refrigerant and dry nitrogen

combination.

2. Recheck for leaks.

WARNING

!

To avoid severe personal injury or death from sudden eruption of high

pressures gases, observe the following:

Protect against a sudden eruption if high pressures are required for leak

checking.

Do not use high pressure compressed gases in refrigeration systems

without a reliable pressure regulator and pressure relief valve in the

lines.

Check resistance across heater.

To check defrost system:

1. Thermocouple defrost thermostat and plug refrigerator into wattmeter.

2. Turn into defrost mode. Wattmeter should read specified watts (according to

Technical Data Sheet).

3. When defrost thermostat reaches specified temperature ±15°C (see

Technical Data Sheet), thermostat should interrupt power to heater.

Test continuity across terminals.

With power off and evaporator coil below freezing, thermostat should show

continuity when checked with ohmmeter. See “Heater, evaporator (defrost)”

section for additional tests.

After defrost thermostat opens, thermostat remains open until end of defrost cycle

and refrigerator starts cooling again. Defrost thermostat senses a preset low

temperature and resets (closes).

Temperature Resistance

25°C 10,000 ohms

2.2°C 29,500 ohms

-17.7°C 86,300 ohms

Check resistance across coil.

Check resistance across coil.

©2004 Maytag Services

16023324 Rev. 0 9

Page 10

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Service Equipment

Listed below is equipment needed for proper servicing

of HFC134a systems. Verify equipment is confirmed

by manufacturer as being compatible with HFC134a

and ester oil system.

Equipment must be exclusively used for HFC134a.

Exclusive use of equipment only applies to italic items.

• Evacuation pump

Check with vacuum pump supplier to verify equipment

is compatible for HFC134a. Robinair, Model 15600

2 stage, 6 cubic feet per minute pump is

recommended.

• Four-way manifold gauge set, with low loss hoses

• Leak detector

•

Charging cylinder

• Line piercing saddle valve

(Schroeder valves). Seals must be HFC134a and

ester oil compatible. Line piercing valves may be used

for diagnosis but are not suitable for evacuation or

charging, due to minute holes pierced in tubing. Do

not leave mechanical access valves on system.

Valves eventually will leak. Molecules of HFC134a are

smaller than other refrigerants and will leak where

other refrigerants would not.

• Swagging tools

•

Flaring tools

• Tubing cutter

• Flux

• Sil-Fos

• Silver solder

• Oil for swagging and flaring

Use only part # R0157532

• Copper tubing

Use only part # R0174075 and # R0174076

• Dry nitrogen

99.5% minimum purity, with -40°C or lower dew point

• Crimp tool

• Tube bender

• Micron vacuum gauge

• Process tube adaptor kit

• Heat trap paste

• ICI appliance grade HFC134a

Drier Replacement

Before opening refrigeration system, recover

HFC134a refrigerant for safe disposal.

Every time sealed HFC134a system is repaired, drier

filter must be replaced with, part # B2150504.

Cut drier out of system by completing the following

steps. Do not unbraze drier filter. Applying heat to

remove drier will drive moisture into system.

WARNING

!

To avoid risk of severe personal injury or death, cut

drier at correct location. Cutting drier at incorrect

location will allow desiccant beads to scatter.

Completely clean area of beads, if spilled.

1. Score capillary tube close to drier and break.

2. Reform inlet tube to drier allowing enough space

for large tube cutter.

3. Cut circumference of drier at 31.75 millimeters,

below condenser inlet tube joint to drier.

4. Remove drier.

5. Apply heat trap paste on post condenser tubes to

protect grommets from high heat.

6. Unbraze remaining part of drier. Remove drier

from system.

7. Discard drier in safe place. Do not leave drier with

customer. If refrigerator is under warranty, old

drier must accompany warranty claim.

10 16023324 Rev. 0 ©2004 Maytag Services

Page 11

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Refrigerant Precautions

WARNING

!

To avoid risk of personal injury, do not allow

refrigerant to contact eyes or skin.

CAUTION

!

To avoid risk of property damage, do not use

refrigerant other than that shown on unit serial

number identification plate.

NOTE: All precautionary measures recommended by

refrigerant manufacturers and suppliers apply

and should be observed.

Line Piercing Valves

Line piercing valves can be used for diagnosis, but

are not suitable for evacuating or charging due to

holes pierced in tubing by valves.

NOTE: Do not leave line piercing valves on system.

Connection between valve and tubing is not

hermetically sealed. Leaks will occur.

Open Lines

During any processing of refrigeration system, never

leave lines open to atmosphere. Open lines allow water

vapor to enter system, making proper evacuation more

difficult.

Compressor Operational Test

(short term testing only)

If compressor voltage, capacitor, overload, and motor

winding tests are successful (do not indicate a fault),

perform the following test:

1.Disconnect power to unit.

2.Discharge capacitor by shorting capacitor

terminals through a resistor.

NOTE: Not all units have run capacitor.

3.Remove leads from compressor terminals.

4.Attach test cord to compressor windings.

• Common lead on test cord attaches to C terminal

on compressor.

• Start lead on test cord attaches to S terminal on

compressor.

• Run lead on test cord attaches to M terminal on

compressor.

To AC supply

Switch

Compressor

Fuses

Attaching Capacitor for Compressor Test

5. Connect a known good capacitor into circuit as shown

above. For proper capacitor size and rating, see

technical data sheet for unit under test.

NOTE: Ensure test cord cables and fuses meet

specifications for unit under test (see Technical

Sheet for unit under test).

6. Replace compressor protector cover securely.

7. Plug test cord into outlet, then press and release start

cord switch.

CAUTION

!

To avoid risk of damage to compressor windings,

immediately disconnect (unplug) test cord from power

source if compressor does not start. Damage to

compressor windings occurs if windings remain

energized when compressor is not running.

If compressor runs when direct wired, it is working

properly. Malfunction is elsewhere in system.

If compressor does not start when direct wired, recover

system at high side. After the system is recovered,

repeat compressor direct wire test.

If compressor runs after system is recovered (but

would not operate when wired direct before recovery) a

restriction in sealed system is indicated.

If motor does not run when wired direct after recovery,

replace faulty compressor.

CRS

Capacitor

©2004 Maytag Services 16023324 Rev. 0 11

Page 12

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Dehydrating Sealed Refrigeration System

Moisture in a refrigerator sealed system exposed to

heat generated by the compressor and motor reacts

chemically with refrigerant and oil in the system and

forms corrosive hydrochloric and hydrofluoric acids.

These acids contribute to breakdown of motor winding

insulation and corrosion of compressor working parts,

causing compressor failure.

In addition, sludge, a residue of the chemical reaction,

coats all surfaces of sealed system, and will eventually

restrict refrigerant flow through capillary tube.

To dehydrate sealed system, evacuate system (see

paragraph

Evacuation

).

Leak Testing

DANGER

!

To avoid risk of serious injury or death from violent

explosions, NEVER use oxygen or acetylene for

pressure testing or clean out of refrigeration

systems. Free oxygen will explode on contact with

oil. Acetylene will explode spontaneously when put

under pressure.

Testing Systems Containing No Refrigerant Charge

1. Connect cylinder of nitrogen, through gauge

manifold, to process tube of compressor and liquid

line strainer.

2. Open valves on nitrogen cylinder and gauge manifold.

Allow pressure to build within sealed system.

3. Check for leaks using soap suds.

If a leak is detected in a joint, do not to attempt to repair

by applying additional brazing material. Joint must be

disassembled, cleaned and rebrazed. Capture refrigerant

charge (if system is charged), unbraze joint, clean all

parts, then rebraze.

If leak is detected in tubing, replace tubing. If leak is

detected in either coil, replace faulty coil.

It is important to check sealed system for refrigerant

leaks. Undetected leaks can lead to repeated service

calls and eventually result in system contamination,

restrictions, and premature compressor failure.

Refrigerant leaks are best detected with halide or

electronic leak detectors.

Testing Systems Containing a Refrigerant Charge

1. Stop unit operation (turn refrigerator off).

2. Holding leak detector exploring tube as close to

system tubing as possible, check all piping, joints,

and fittings.

NOTE: Use soap suds on areas leak detector cannot

reach or reliably test.

12 16023324 Rev. 0 ©2004 Maytag Services

Page 13

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Restrictions

Symptoms

Restrictions in sealed system most often occur at

capillary tube or filter drier, but can exist anywhere on

liquid side of system.

Restrictions reduce refrigerant flow rate and heat

removal rate. Wattage drops because compressor is

not circulating normal amount of refrigerants.

Common causes of total restrictions are moisture,

poorly soldered joints, or solid contaminants. Moisture

freezes at evaporator inlet end of capillary tube. Solid

contaminants collect in filter drier.

If restriction is on low side, suction pressure will be in a

vacuum and head pressure will be near normal.

If restriction is on high side, suction pressure will be in

a vacuum and head pressure will be higher than

normal during pump out cycle.

Refrigeration occurs on low pressure side of partial

restriction. There will be a temperature difference at

the point of restriction. Frost and/or condensation will

be present in most case at the point of restriction.

Also, system requires longer to equalize.

Slight or partial restriction can give the same

symptoms as refrigerant shortage including lower than

normal back pressure, head pressure, wattage, and

warmer temperatures.

Total restriction on the discharge side of compressor,

when restriction is between compressor and first half

of condenser, results in higher than normal head

pressure and wattage while low side is being pumped

out.

Testing for Restrictions

To determine if a restriction exists:

1. Attach gauge and manifold between suction and

discharge sides of sealed system.

2. Turn unit on and allow pressure on each side to

stabilize. Inspect condenser side of system. Tubing

on condenser should be warm and temperature

should be equal throughout (no sudden drops at any

point along tubing).

• If temperature of condenser tubing is consistent

throughout, go to step 4.

• If temperature of condenser tubing drops suddenly

at any point, tubing is restricted at point of

temperature drop (if restriction is severe, frost may

form at point of restriction and extend down in

direction of refrigerant flow in system). Go to step 5.

3. Visually check system for kinks in refrigeration line

which is causing restriction. Correct kink and repeat

step 2.

4. Turn unit off and time how long it takes high and low

pressure gauges to equalize:

• If pressure equalization takes longer than 10

minutes, a restriction exists in the capillary tube or

drier filter. Go to step 5.

• If pressure equalization takes less than 10 minutes,

system is not restricted. Check for other possible

causes of malfunction.

5. Recover refrigerant in sealed system.

NOTE: Before opening any refrigeration system,

capture refrigerant in system for safe disposal.

6. Remove power from unit.

CAUTION

!

To avoid risk of personal injury or property damage,

take necessary precautions against high

temperatures required for brazing.

7. Remove and replace restricted device.

8. Evacuate sealed system.

9. Charge system to specification.

NOTE: Do not use captured or recycled refrigerant in

units. Captured or recycled refrigerant voids any

compressor manufacturer's warranty.

NOTE: Charge system with exact amount of refrigerant.

Refer to unit nameplate for correct refrigerant

charge. Inaccurately charged system will cause

future problems.

©2004 Maytag Services 16023324 Rev. 0 13

Page 14

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Evacuation and Charging

CAUTION

!

To avoid risk of fire, sealed refrigeration system

must be air free. To avoid risk of air contamination,

follow evacuation procedures exactly.

NOTE: Before opening any refrigeration system, EPA

regulations require refrigerant in system to be

captured for safe disposal.

Proper evacuation of sealed refrigeration system is an

important service procedure. Usable life and

operational efficiency greatly depends upon how

completely air, moisture and other non-condensables

are evacuated from sealed system.

Air in sealed system causes high condensing

temperature and pressure, resulting in increased

power requirements and reduced performance.

Moisture in sealed system chemically reacts with

refrigerant and oil to form corrosive hydrofluoric and

hydrochloric acids. These acids attack motor windings

and parts, causing premature breakdown.

Before opening system, evaporator coil must be at

ambient temperature to minimize moisture infiltration

into system.

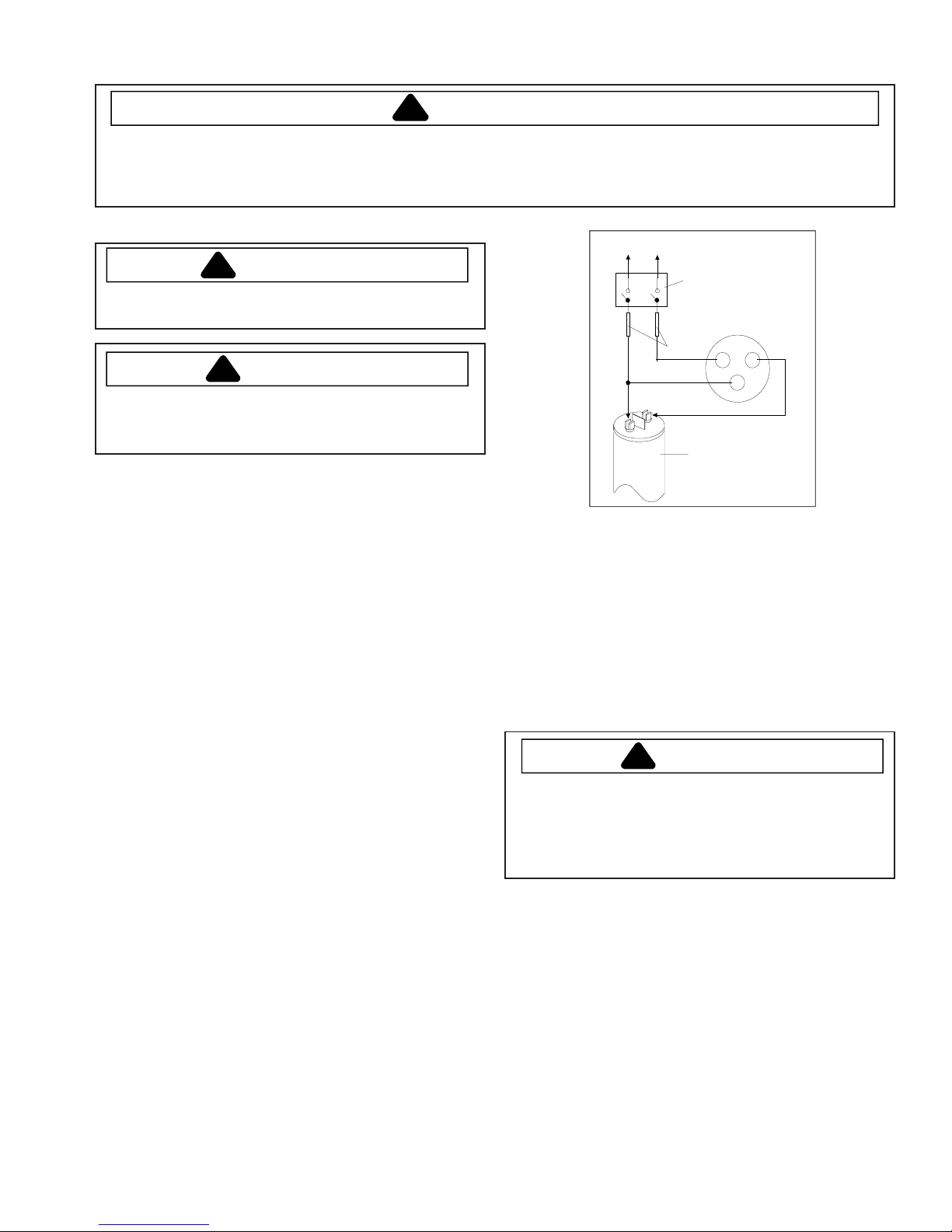

Evacuation

To evacuate sealed refrigeration system:

1. Connect vacuum pump, vacuum tight manifold set

with high vacuum hoses, thermocouple vacuum

gauge and charging cylinder as shown in illustration.

Evacuation should be done through I.D. opening of

tubes not through line piercing valve.

2. Connect low side line to compressor process tube.

3. Connect high side line to drier/process tube.

4. Evacuate both simultaneously. With valve “C” and “F”

closed, open all other valves and start vacuum pump.

Thermistor

Vacuum Gauge

Compressor

Low Side Gauge

Charging Hose

Compressor

Process

Tube

.6 cm Copper

Tubing

Valve

Vacuum Pump

Equipment Setup For Evacuation And Charging

5. After compound gauge (low side) drops to

approximately .98 Bar, open valve “C” to vacuum

thermocouple gauge and take micron reading.

NOTE: A high vacuum pump can only produce a good

vacuum if oil in pump is not contaminated.

6. Continue evacuating system until vacuum gauge

registers 600 microns.

7. At 600 microns, close valve “A” to vacuum pump and

allow micron reading in system to balance. Micron

level will rise.

• If in 2 minutes, micron level stabilizes at 1000

microns or below, system is ready to be charged.

• If micron level rises above 1000 microns and

stabilizes, open valve “A” and continue evacuating.

• If micron reading rises rapidly and does not

stabilize, a leak still exists in system.

Close valve “A” to vacuum pump and valve “C” to

vacuum gauge. Invert charging cylinder and open

charging cylinder valve “F” to add partial charge for

leak checking. With leak detector, check manifold

connections and system for leaks. After locating

leak, capture refrigerant, repair leak, and begin at

step 1.

E

High Side Gauge

D

Valve

Charging Hose

C

B

A

Drier/Process Tu be

Charging

Cylinder

F

Valve

14 16023324 Rev. 0 ©2004 Maytag Services

Page 15

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Charging

NOTE: Do not use captured or recycled refrigerant in

units. Captured or recycled refrigerant voids any

warranty.

NOTE: Charge system with exact amount of refrigerant.

Refer to unit serial plate for correct refrigerant

charge. Inaccurately charged system will cause

future problems.

To charge system:

1. Close valves “A” to vacuum pump and “C” to vacuum

gauge and “E” to low side manifold gauge.

2. Set scale on dial-a-charge cylinder for corresponding

HFC134a pressure reading.

3. Open valve “F” to charging cylinder and let exact

amount of refrigerant flow from cylinder into system.

Close valve.

Low side gauge pressure should rise shortly after

opening charging cylinder valve as system pressure

equalizes through capillary tube.

If pressure does not equalize, a restriction typically

exists at capillary/drier braze joint.

4. If pressure equalizes, open valve “E” to low side

manifold gauge and pinch off high side drier process

tube.

5. Start compressor and draw remaining refrigerant from

charging hoses and manifold into compressor

through compressor process tube.

6. To check high side pinch-off drier process tube. Close

valve “D” to high side gauge. If high side pressure

rises, repeat high side pinch-off and open valve “D”.

Repeat until high side pinch-off does not leak.

7. Pinch-off compressor process tube and remove

charging hose. Braze stub closed while compressor is

operating.

8. Disconnect power. Remove charging hose and braze

high side drier process tube closed.

9. Recheck for refrigerant leaks.

Refrigerant Charge

Refrigerant charge in all capillary tube systems is

critical and exact amount is required for proper

performance. Factory charges are shown on serial

plate.

NOTE: Do not use refrigerant other than shown on

serial plate.

©2004 Maytag Services 16023324 Rev. 0 15

Page 16

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

HFC134a Service Information

CAUTION

HFC134a is alternative refrigerant for CFC12.

HFC134a has an ozone depletion potential (ODP)

factor of 0.0 and a global warming potential (GWP)

To minimize contamination, exercise extreme care

when servicing HFC134A sealed systems.

factor of 0.27. HFC134a is not flammable and has

acceptable toxicity levels. HFC134a is not

interchangeable with CFC12. There are significant

differences between HFC134a and CFC12 which must

be considered when handling and processing

refrigeration system.

Health, Safety, and Handling

Health, safety and handling considerations for

HFC134A are virtually no different than those for

CFC12.

Health, Safety, and

Handling

Allowable overall

exposure limit

Vapor exposure to skin No effect Same

Liquid exposure to skin Can cause frostbite Same

Vapor exposure to eye Very slight eye irritant Same

Liquid exposure to eye Can cause frostbite Same

Above minimum exposure

limit

Safety and handling Wear appropriate skin

Spill management Remove or extinguish

Fire explosion hazards May decompose if

Disposal procedures Recycle or reclaim. Same

1,000 ppm Same

Can cause Asphyxiation,

Tachycardia, and Cardia

Arrhythmias

and eye protection. Use

with adequate

ventilation.

ignition or combustion

sources. Evacuate or

ventilate area.

contact with flames and

heating elements.

Container may explode

if heated due to resulting

pressure rise.

Combustion products

are toxic.

CFC12 HFC134a

Same

Same

Same

Same

• No trace of other refrigerants is allowed in HFC134a

systems. Chlorinated molecules in other refrigerants

such as CFC12, etc. will lead to capillary tube

plugging.

• Ester oil is used in HFC134a systems. Do not use

mineral oil. HFC134a and mineral oils cannot be

mixed. If mineral oils were used in HFC134a systems,

lubricant would not return to compressor and would

cause early compressor failure. If significant amount of

oil has been lost from compressor, replace oil rather

than adding oil.

• Ester oils used in HFC134a systems are so

hydroscopic that by the time an inadequate system

performance is detected, oil will be saturated with

moisture.

• CFC12 has much higher tolerance to system

processing materials, such as drawing compounds,

rust inhibitors, and cleaning compounds, than

HFC134a. Such materials are not soluble in HFC134a

systems. If materials were to be washed from system

surfaces by ester oils, they could accumulate and

eventually plug capillary tube.

• Care must be taken to minimize moisture entering

HFC134a system. Do not leave compressor or system

open to atmosphere for more than 10 minutes.

Excessive moisture in HFC134a system will react with

compressor oil and generate acid.

• Compressor must be replaced when performing low

side leak repair.

• Drier filter must always be replaced with service drier

filter, part #B2150504.

Important: Unbrazing drier filter from tubing will drive

Comparison of CFC12 and HFC134a Properties

Properties/Characteristics CFC12 HFC134a

Ozone Depletion Potential

(ODP)

Global Warming Potential

(GPW)

Molecular weight 121 102

Boiling point at 1 atmosphere -22°F (-30°C) -15°F (-

Vapor pressure at 77°F

(25°C)

Liquid density at 77°F (25°C) 82 lb/ft

Flammability No No

High-side system operating

Pressure at 65°F (18°C)

Low-side system operating

Pressure at 65°F (18°C)

1.0* 0.0*

3.2* 0.27*

80 psig 82 psig

3

HFC134a approximately 3 psig

higher than CFC12

HFC134a approximately 2 psig

lower than CFC12

126°C)

75 lb/ft

3

moisture from desiccant and into system, causing

acids to form. Do not unbraze filter drier from tubing. If

CFC12 service drier was installed in HFC134A system,

drier could overload due to excessive moisture.

• HFC134a compatible copper tubing, part #R0174075

.635 millimeter x 457.2 millimeter length and part

#R0174076 7.93 millimeter x 609.6 millimeter must be

used when replacing tubing.

• Avoid system contamination by using Towerdraw E610

evaporating oil, part # R0157532, when flaring,

swagging, or cutting refrigeration tubing.

16 16023324 Rev. 0 ©2004 Maytag Services

!

Page 17

Service Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Replacement Service Compressor

HFC134a service compressors will be charged with

ester oil and pressurized with dry nitrogen. Before

replacement compressor is installed, pull out 1 rubber

plug. A

a

Positive pressure in compressor is vital to keep

moisture out of ester oil. Do not leave compressor

open to atmosphere for more than 10 minutes.

Compressor Testing Procedures

Refer to Technical Data Sheet “Temperature

Relationship Chart” for operating watts, test points,

and temperature relationship test for unit being tested.

• Temperature testing is accomplished by using 3 lead

• Thermocouple tips should be attached securely to

• Do not test during initial

• Refrigerator must operate minimum of 20 minutes

• Turn control to colder to obtain required on time.

• Wattage reading must be recorded in conjunction with

• Suction and head pressures are listed on

pop

from pressure release should be heard. If

pop

sound is not heard, do not use compressor.

WARNING

!

To avoid death or severe personal injury, never use

oxygen, air or acetylene for pressure testing or

clean out of refrigeration system. Use of oxygen,

air, or acetylene may result in violent explosion.

Oxygen may explode on contact with oil and

acetylene will spontaneously explode when under

pressure.

thermocouple temperature tester in specific locations.

Test point T-1 is outlet on evaporator coil and T-2 is

inlet. Test point T-3 is suction tube temperature

midway between where armaflex ends and suction

port of compressor (approximately 304.8 millimeters

from compressor).

specified locations.

pull down

or balanced temperature condition to occur before

proceeding with testing.

after thermocouples are installed.

temperature test to confirm proper operation.

“Temperature and Relationship Chart”. Normally these

are not required for diagnosis but used for confirmation

on systems which have been opened.

. Allow one off cycle

Brazing

CAUTION

!

To avoid risk of personal injury or property damage,

take necessary precautions against high

temperatures required for brazing.

Satisfactory results require cleanliness, experience,

and use of proper materials and equipment.

Connections to be brazed must be properly sized, free

of rough edges, and clean.

Generally accepted brazing materials are:

• Copper to copper joints: SIL-FOS (alloy of 15

percent silver, 80 percent copper, and 5 percent

phosphorous). Use without flux. Recommended

brazing temperature is approximately 760°C. Do not

use for copper to steel connection.

• Copper to steel joints: SILVER SOLDER (alloy of 30

percent silver, 38 percent copper, 32 percent zinc).

Use with fluoride based flux. Recommended brazing

temperature is approximately 649°C.

• Steel to steel joints: SILVER SOLDER (see copper

to steel joints).

• Brass to copper joints: SILVER SOLDER (see

copper to steel joints).

• Brass to steel joints: SILVER SOLDER (see copper

to steel joints).

©2004 Maytag Services 16023324 Rev. 0 17

Page 18

Refrigerant Flow

R

CAPILLARY

TUBE

Note: Capillary Tube and

Suction Tube are

located under Fresh

SUCTION

Food floor.

TUBE

EVAPORATOR

COMPRESSOR

DISCHARGE

TUBE

CONDENSER

POST CONDENSE

TUBE

DRYER

PROCESS

TUBE

18 16023324 Rev. 0 ©2004 Maytag Services

Bottom Mount

Refrigerant Flow Diagram

Page 19

Cabinet Air Flow

REFRIGERATOR

RETURN AIR

TUNNELS

REFRIGERATOR AIR

SUPPLY TUNNEL TO

FRESH FOOD COMPARTMENT

CONTROL DAMPER

CRISPER AIR

SUPPLY PORT

EVAPORATOR FAN

ASSEMBLY

FREEZER AIR

SUPPLY GRILLE

EVAPORATOR

EVAPORATOR

COVER

FREEZER RETURN AIR

THOUGH LOUVERS AT

BOTTOM OF EVAPORATOR

COVER

Bottom Mount

Cabinet Air Flow Diagram

©2004 Maytag Services 16023324 Rev. 0 19

Page 20

Machine Compartment Air Flow

Compressor

Condenser

Condenser Fan

Assembly

Two Way Bottom Mount

Machine Compartment Air Flow Diagram

20 16023324 Rev. 0 ©2004 Maytag Services

Page 21

Machine Compartment Air Flow

©2004 Maytag Services 16023324 Rev. 0 21

One Way Bottom Mount

Machine Compartment Air Flow Diagram

Page 22

Typical External Sweat Pattern

g

CLASSIFICATION OF

CONDENSATION

1 = Haze or fog

2 = Beading

3 = Beads or small drops

4 = Drops runnin

Conditions after 4 hour

Laboratory Sweat Test.

Ambient: 90 dF

Relative humidity 84%

Refrigerator Temp. 40 dF

Freezer Temp. 0 dF

together

# 1

Refrigerator

door bottom

Center

mullion

Freezer

door top

Freezer

door bottom

# 1

# 2

# 1

No sweat on side

when compressor

is running

# 2

22 16023324 Rev. 0 ©2004 Maytag Services

Page 23

Troubleshooting Chart

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Troubleshooting chart on following pages contains symptoms that may be seen in malfunctioning units. Each

symptom is accompanied by one or more possible causes and by a possible remedy or test to determine if

components are working properly.

Symptom Possible Causes Corrective Action

Unit does not run

Refrigerator section too warm

No power to unit Check for power at outlet. Check

fuse box/circuit breaker for blown

fuse or tripped breaker. Replace or

reset.

Faulty power cord Check with test light at unit; if no

circuit and current is indicated at

outlet, replace or repair.

Low voltage Check input voltage for proper

voltage. Take appropriate action to

correct voltage supply problem.

Faulty motor Check all connections are tight and

secure.

Jumper across terminals of control. If

unit runs, replace control.

Faulty relay Check relay. Replace if necessary.

Faulty compressor Check compressor motor windings

for opens/shorts.

Perform compressor direct wiring

test.

Replace if necessary.

Faulty overload Check overload for continuity.

NOTE: Ensure

compressor/overload are below

trip temperature before testing.

Replace if necessary.

Excessive door opening Consumer education

Overloading of shelves Consumer education

Warm or hot foods placed in cabinet Consumer education

Cold control set too warm Set control to colder setting.

Poor door seal Level cabinet. Adjust hinges.

Replace gasket.

Refrigerator airflow Check damper is opening by

removing grille. With door open,

damper should open. Replace if

faulty.

Turn control knob to colder position.

Interior light remains on Check switch. Replace if necessary.

Faulty condenser fan or evaporator

fan

Faulty compressor Replace compressor.

Check fan and wiring. Replace if

necessary.

©2004 Maytag Services 16023324 Rev. 0 23

Page 24

Troubleshooting Chart

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Symptom Possible Causes Corrective Action

Refrigerator section too cold

Freezer and refrigerator sections too

warm

Unit runs continuously

Unit runs continuously. Temperature

normal.

Unit runs continuously. Temperature

too cold.

Noisy operation

Refrigerator temperature control set

too cold

Refrigerator airflow not properly

adjusted

Temperature controls set too warm Reset temperature controls.

Poor door seal Level cabinet. Adjust hinges.

Dirty condenser or obstructed grille Check condenser and grille. Clean.

Faulty control Test control. Replace if failed.

Refrigerant shortage or restriction Check for leak or restriction. Repair,

Freezer temp control set too cold Adjust freezer temperature control. Freezer section too cold

Faulty control Test control. Replace if failed.

Temperature control set too cold Adjust temperature control.

Dirty condenser or obstructed grille Check condenser and grille. Clean.

Poor door seal Level cabinet. Adjust hinges.

Interior light remains on Check switch. Replace if necessary.

Faulty condenser fan or evaporator

fan

Faulty control Test control. Replace if failed.

Refrigerant shortage or restriction Check for leak or restriction. Repair,

Refrigerant overcharge Check for overcharge. Evacuate and

Air in system Check for low side leak. Repair,

Ice on evaporator See “Ice on evaporator”.

Faulty defrost thermostat Check thermostat. Replace if

Loose flooring or floor not firm Repair floor or brace floor.

Cabinet not level Level cabinet.

Tubing in contact with cabinet, other

tubing, or other metal

Drip pan vibrating Adjust drain pan.

Fan hitting another part Ensure fan properly aligned and all

Worn fan motor bearings Check motor for loss of lubricant or

Compressor mounting grommets

worn or missing. Mounting hardware

loose or missing

Free or loose parts causing or

allowing noise during operation

24 16023324 Rev. 0 ©2004 Maytag Services

Adjust refrigerator temperature

control.

Check air flow.

Replace gasket.

evacuate and recharge system.

Replace gasket.

Check fan and wiring. Replace if

necessary.

evacuate and recharge system.

recharge system.

evacuate and recharge system.

necessary.

Adjust tubing.

attaching hardware and brackets are

tight and not worn. Tighten or

replace.

worn bearings. Replace if necessary.

Tighten hardware. Replace

grommets if necessary.

Inspect unit for parts that may have

worked free or loose or missing

screws. Repair as required.

Page 25

Troubleshooting Chart

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all earthing wires are connected before certifying unit as repaired and/or operational.

Symptom Possible Causes Corrective Action

Frost or ice on evaporator

Unit starts and stops frequently

(cycles on and off)

Defrost thermostat faulty Check defrost thermostat. Replace if

failed.

Evaporator fan faulty Check fan motor. Replace if failed.

Defrost heater remains open Check defrost heater continuity.

Replace if failed.

Open wire or connector Check wiring and connections.

Repair as necessary.

Refrigerant shortage or restriction Check for leak or restriction. Repair,

evacuate and recharge system.

Loose wire or thermostat

connections

Supply voltage out of specification Check input voltage. Correct any

Overload protector open Check overload protector for

Faulty compressor motor capacitor

(some compressors do not require

motor capacitor)

Faulty fan motor Check fan motor. Replace if failed.

Restricted air flow Check condenser and grille for dirt.

Refrigerant shortage or restriction Check for leak or restriction. Repair,

Check wiring and connections.

Repair as necessary.

supply problems.

continuity. If open, replace overload.

NOTE: Ensure

overload/compressor are below

trip temperature before testing.

Check capacitor for open/short.

Replace if necessary.

NOTE: Discharge capacitor

before testing.

Clean.

evacuate and recharge system.

©2004 Maytag Services 16023324 Rev. 0 25

Page 26

System Diagnosis

SUCTION

PRESSURE

CONDITION

Refrigerant

Overcharge

Shortage of

Refrigerant

Partial

Restriction

Air in System Near Normal Increase Warmer Warmer Warmer Increase

Low Ambient

Installations

(High

Ambients the

Reverse)

Additional

Heat Load

VARIATION

FROM

NORMAL

Increase Increase Warmer Warmer Colder Increase

Decrease

Decrease

Decrease Decrease Colder Warmer Warmer Decrease

Increase Increase Warmer Warmer Warmer Increase

HEAD

PRESSURE

VARIATION

FROM

NORMAL

Decrease or

Increase

See Text

Decrease or

Increase

See Text

Note 2

T1 INLET

TEMPERATURE

VARIATION

FROM NORMAL

Colder Warmer Warmer Decrease

Colder Warmer Warmer Decrease

T2 OUTLET

TEMPERATURE

VARIATION

FROM NORMAL

T3 SUCTION

TEMPERATURE

VARIATION

FROM NORMAL

WATTAGE

VARIATION

FROM

NORMAL

Inefficient

Compressor

Increase

Normal or

Decrease

Warmer or

Colder

Symptoms of an Overcharge

• Above normal freezer temperatures.

• Longer than normal or continuous run.

• Freezing in refrigerator.

• Higher than normal suction and head pressure.

• Higher than normal wattage.

• Evaporator inlet and outlet temperatures warmer than

normal.

• Suction tube temperature below ambient. Always

check for separated heat exchanger when suction

temperature is colder than ambient.

Various conditons could indicate an overcharge. For

example, if the cooling coil is not defrosted at regular

intervals, due to a failure of the defrost system, the

refrigerant will "flood out" and cause the suction line to

frost or sweat. The cause of this problem should be

corrected rather than to purge refrigerant from the

sytem. Running the freezer section colder than

necessary (-18.9 to -18.3 °C is considered normal

package temperatures) or continuous running of the

compressor for a variety of reasons, or the freezer fan

motor not running, may give the indication of an

overcharge.

Warmer Warmer Decrease

Symptoms of Refrigeration Shortage

• Rise in food product temperature in both

compartments. (See Note 1 below.)

• Long or continuous run time.

• Look for obvious traces of oil that would occur due to a

leak or cracked refrigerant line.

• Lower than normal wattage.

• Compressor will be hot to touch because of the heat

generated by the motor windings from long continuous

running. It will not be as hot as it would be with a full

charge and long run times for some other reason such

as a dirty condenser.

• Depending on the amount of the shortage, the

condenser will not be hot, but closer to room

temperature. The capillary tube will be warmer than

normal from a slight shortage.

• If the leak is on the high side of the system, both

gauges will show lower than normal readings and will

show progressively lower readings as this charge

becomes less. The suction pressure guage will

probably indicate a vacuum.

• If the leak is on the low side of the system the suction

pressure guage will be lower than normal - probably in

a vacuum - and the head pressure gauge will be

higher than normal. It will probably continue to

become higher because air drawn in through the leak

is compressed by the compressor and accumulates in

26 16023324 Rev. 0 ©2004 Maytag Services

Page 27

System Diagnosis

the high side (condenser) of the system.

• Only partial frosting of evaporator instead of even

frosting of entire coil.

NOTE 1: Usually the first thing that is noticed by the

user is a rise in temperature foods. Although

temperatures will rise in both the freezer section

and the food compartment, the frozen meats

and vegetables will not thaw immediately. The

customer doesn't associate the problem with

the freezer section and will first notice that milk

and other food beverages are not cold enough.

Under some circumstances, such as in the case of

forced air meatkeeper model with a slight shortage of

refrigerant, freezing in the food compartment may be

experienced due to the additional running time. With a

refrigerant leak, however, it always gets worse and as

the refrigerant charge decreases the temperature will

continue to rise.

With a shortage of refrigerant the capillary line will not

have a full column of liquid. As a result, there is a

noticeable hissing sound in the evaporator. This should

not be mistaken for the regular refrigerant boiling

sounds that would be considered normal.

Symptoms of a Restriction

Always remember refrigeration (cooling) occurs on the

low pressure side of a partial restriction (obviously a

total restriction will completely stop the circulation of

refrigerant and no cooling will take place).

Physically feel the refrigeration lines when a restriction

is suspected. The most common place for a restriction

is at the drier-filter or at the capillary tube inlet or outlet.

If the restriction is not total there will be a temperature

difference at the point of restriction, the area on the

evaporator side will be cooler. In many cases frost and/

or condensation will be present. A longer time is

required for the system to equalize.

Any kinked line will cause a restriction so the entire

system should be visually checked.

A slight restriction will give the same indications as a

refrigerant shortage with lower than normal back

pressure, head pressure, and wattage, warmer product

temperatures.

NOTE 2: If a total restriction is on the discharge side of

the compressor, higher than normal head

pressures and wattages would result. This is

true only while the low side is being pumped out

and if the restriction was between the

compressor and the first half of the condenser.

©2004 Maytag Services 16023324 Rev. 0 27

To diagnose for a restriction versus a refrigerant

shortage, discharge the system, replace the drier-filter,

evacuate and recharge with the specified refrigerant

charge. If the unit performs normally three possibilities

exist: 1) refrigerant loss, 2) partially restricted drierfilter, and 3) moisture in system.

If the unit performs as it previously did you may have a

restricted capillary line or condenser or kinked line.

Find the point of restriction and correct it.

A restriction reduces the flow rate of the refrigerant and

consequently reduces the rate of heat removal.

Complete restriction may be caused by moisture, solid

contaminants in the system, or a poorly soldered joint.

Moisture freezes at the evaporator inlet end of the

capillary tube or solid contaminants collect in the drierfilter. The wattage drops because the compressor is not

circulating the usual amount of refrigerant.

As far as pressure readings are concerned, if the

restriction, such as a kinked line or a joint soldered shut

is anywhere on the low side, the suction pressure would

probably be in a vacuum while the head pressure will be

near normal. If the restriction is on the high side, the

suction pressure, again, will probably be in a vacuum

while the head pressure will be higher than normal

during the pump out period described earlier. In either

case, it will take longer than the normal ten minutes or

so for the head pressure to equalize with the low side

after the compressor stops.

Symptoms of Air in System

This can result from a low side leak or improper

servicing. If a leak should occur on the low side, the

temperature control would not be satisfied; thus,

continuous running of the compressor would result. The

compressor would eventually pump the low side into a

vacuum drawing air and moisture into the system. Air

and R134A do not mix so the air pressure would be

added to the normal head pressure, resulting in higher

than normal head pressures.

One way to determine if air is in the system is to read

the head pressure gauge with the product off and

evaporator and condenser at the same temperature and

then take the temperature on the condenser outlet tube.

This temperature should be within 3° or 4° F. of what the

Pressure-Temperature Relation chart shows for the

given idle head pressure. If the temperature of the

condenser outlet is considerably lower than the idle

head pressure of the gauge this would indicate there is

air in the system.

Thorough leak checking is necessary. Correct the

source of the leak. Do not attempt to purge off the air

because this could result in the system being

undercharged. It is best to discharge, replace drier,

evacuate and recharge with the specified refrigerant

charge.

Page 28

System Diagnosis

Symptoms of Low or High Ambient

Temperature Installation

Lower ambient air temperature reduces the condensing

temperature and therefore reduces the temperature of

the liquid entering the evaporator. The increase in

refrigeration effect due to operation in a lower ambient

results in a decrease in power consumption and run

time. At lower ambients there is a reduction in cabinet

heat leak which is partially responsibile for lower power

consumption and run time.

An increase in refrigeration effect cannot be expected