Page 1

ELECTRIC DRYER

INSTALLATION INSTRUCTIONS

INSTRUCTIONS POUR UINSTALLATION DU

SECHE-LINGE ELECTRIQUE

INSTRUCCIONES DE INSTALACION DE LA

SECADORA ELECTRICA

Table of Contents

DRYER SAFETY ......................................................................... 2

iNSTALLATiON REQUIREMENTS ............................................. 3

Tools and Parts ...................................................................... 3

Location Requirements ......................................................... 4

Electrical Requirements ........................................................ 6

Install Leveling Legs .............................................................. 6

VENTING REQUIREMENTS ...................................................... 7

Plan Vent System ................................................................... 8

install Vent System ................................................................ 9

Connect Vent .......................................................................... 9

LEVEL DRYER .......................................................................... 10

COMPLETE INSTALLATION CHECKLIST .............................. 10

REVERSE DOOR SWING (OPTIONAL} ................................... 11

TROUBLESHOOTING .............................................................. 12

Table des mati_res

SECURITE DU SECHE-LINGE ................................................ 13

EXIGENCES D'INSTALLATION ............................................... 14

Outillage et pi_ces ............................................................... 14

E×igences d'emplacement .................................................. 15

Specifications 61ectriques ................................................... 17

Installation des pieds de nivellement ................................. 18

SEGURIDAD DE LA SECADORA ............................................ 25

REQUISITOS DE INSTALACION ............................................. 26

Herramientas y piezas ......................................................... 26

Requisitos de ubicacibn ...................................................... 27

Requisitos el_ctricos ........................................................... 29

InstalaciSn de las patas niveladoras .................................. 30

EXIGENCES CONCCERNANT L'EVACUATION ..................... 18

Planification du syst_me d'_vacuation .............................. 19

Installation du circuit d'_vacuation .................................... 20

Raccordment du conduit d'_vacuation ............................. 21

REGLAGE DE L'APLOMB DU SECHE-LINGE ........................ 21

ACHEVER UINSTALLATION - LISTE DE VERiFiCATiON ...... 22

iNVERSiON DE LA PORTE (FACULTATIF) .............................. 22

DEPANNAGE ............................................................................ 24

REQUISITOS DE VENTILACION ............................................. 30

PlanificaciSn del sistema de ventilaciSn ........................... 31

InstalaciSn del sistema de ventilaciSn ............................... 32

ConexiSn del conducto de escape ..................................... 33

NIVELACION DE LA SECADORA ............................................ 33

LISTA DE CONTROL DE LA INSTALACION TERMINADA .... 34

CAMBIO DEL SENTIDO DE ABERTURA DE LA

PUERTA (OPCIONAL} .............................................................. 34

SOLUCION DE PROBLEMAS .................................................. 36

W10629448A

4KWED4750

4KWED4900

4KMEDCl00

4KMEDC300

4KNED4400

4KNED4600

4KAED4900

Page 2

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING - ...i.kofFi,o..

- Clothes dryer installation must be performed by a qualified installer.

- install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with flexible plastic venting materials or flexible metal

(foil type) duct. if flexible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers, Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire,

= To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

FOR YOUR SAFETY

1. Do not use or store gasoline or other flammable materials in this appliance or near this appliance.

2. Do not spray aerosols in the vicinity of this appliance while it is in operation.

3. Do not modify this appliance.

2

Page 3

IM PORTANT SAFETY INSTRUCTIONS

WARNING." To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic

precautions, including the following:

[] Read all instructions before using the dryer. _J_

[] Keep a minimum clearance of 100 mm (4 in.) between the

rear of the dryer and any wall.

[] The operation of this appliance may affect the operation of

other types of appliances which take their air supply for safe

combustion from the same room. There has to be adequate

ventilation to replace exhausted air and thus avoid the

back-flow of gases into the room from appliances burning

other fuels, including open fires, when operating the tumble

dryer. If in doubt, consult the appliance manufacturers.

[] Do not obstruct the air supply to the dryer (see Installation

Instructions for minimum clearances).

[] Do not place items exposed to cooking oils inyour dryer.

Oil-affected items can ignite spontaneously, especially when

exposed to heat sources such as in a tumble dryer. The

items become warm causing an oxidation reaction in the oil.

Oxidation creates heat. If the heat cannot escape, the items

can become hot enough to catch fire. Piling, stacking or

storing oil-affected items can prevent heat from escaping

and so create a fire hazard.

[] If it is unavoidable to dry inthe dryer items that have been

soiled with substances such as cooking oil, acetone, alcohol,

petrol, kerosene, spot removers, turpentine, waxes and wax

removers, or that have been contaminated by hair care

products, should be washed in hot water with an extra

amount of detergent before being dried in the dryer. These

items may give off vapours that could ignite or explode. Such

washing will reduce, but not eliminate, the hazard.

[] This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instructions concerning

use of the appliance by persons responsible for their safety.

[] Children should be supervised to ensure that they do not

play with the appliance.

[] The dryer should not be used if industrial chemicals have

been used for cleaning.

[] Before the dryer is removed from service or discarded,

remove the doors to the drying compartment.

[] Do not reach into the dryer if the drum is moving. A door

switch is fitted for your safety.

[] Do not install or store the dryer where it will be exposed

to the weather.

[] Do not tamper with controls.

[] Do not continue to use this appliance if it appears to be

faulty.

[] Do not repair or replace any part of the dryer or attempt

any maintenance unless specifically recommended in this

Use and Care Guide. Repairs and servicing should only

be carried out by competent service personnel.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product. Follow their instructions.

[] Clean dryer lint screen before or after each load. Do not

operate dryer without lint screen in place.

[] Keep area around the exhaust and inlet openings and

adjacent surrounding areas free from the accumulation of

lint, dust, and dirt.

[] The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

[] See Installation Instructions for earthing instructions.

[] Do not dry unwashed items in this dryer.

[] The final part of a tumble dryer cycle occurs without heat

(cool down cycle) to ensure that the items are left at a

temperature that ensures the items will not be damaged.

[] kems such as foam rubber (latex foam), shower caps,

waterproof textiles, rubber backed articles and clothes or

pillows fitted with foam rubber pads must only be dried

on a clothesline.

[] If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualified

person in order to avoid a hazard.

WARNING: Never stop a tumble dryer cycle before the

end of the drying cycle unless all items are quickly removed

and spread out so that the heat is dissipated.

SAVE THESE INSTRUCTIONS

INSTALLATIONREQUIREMENTS

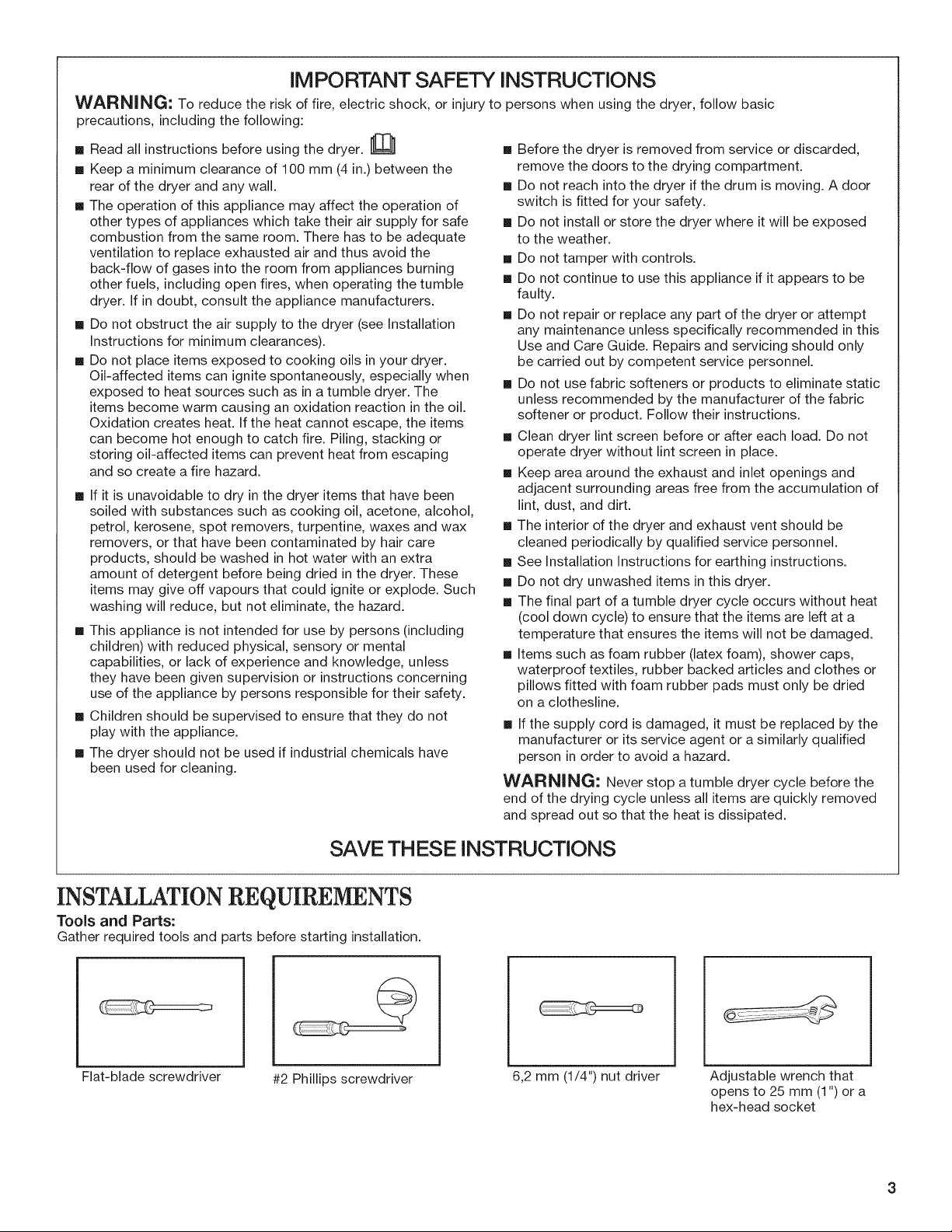

Tools and Parts:

Gather required tools and parts before starting installation.

@

Flat-blade screwdriver

#2 Phillips screwdriver

6,2 mm (1/4") nut driver Adjustable wrench that

opens to 25 mm (1") or a

hex-head socket

Page 4

Utilityknife Tapemeasure

Pliers

Level

Caulkinggunandcompound

forinstallingnewexhaustvent

Wirestripper

(directwireinstallations)

Parts supplied (all models):

Leveling legs (4)

Parts package is located in dryer drum. Check that all parts

are included.

Parts needed: (not supplied with dryer)

[] Electric Cord and Plug

[] Vent clamps

[] Vent elbows and ductwork

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with dryers.

The kit should contain:

[] A UL listed 30-amp power supply cord, rated 240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

[] A UL listed strain relief.

Additional parts may be required, depending on your installation.

Check local codes. Check existing electrical supply and venting.

Read "Electrical Requirements" and "Venting Requirements"

before purchasing parts.

Tinsnips

(newventinstallations)

LOCATION REQUIREMENTS

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 460 mm (18 inches) above the floor

for a garage installation.

Failure to do so can result in death, explosion,

or fire.

Select proper location for your dryer to improve performance

and minimize noise. Check code requirements. Some codes limit,

or do not permit, installation of the dryer in garages, closets,

mobile homes, or sleeping quarters. Contact your local building

inspector.

You will need:

[] A location that allows for proper exhaust installation. The

dryer must be exhausted to the outdoors. See "Venting

Requirements."

[] A floor that will support the dryer and a total weight (dryer

and load) of 90,7 kg (200 Ibs). The combined weight of a

companion appliance should also be considered.

[] A level floor with maximum slope of 25 mm (1") under entire

dryer. If slope is greater than 25 mm (1"), install Extended

Dryer Feet Kit. Clothes may not tumble properly and models

with automatic sensor cycles may not operate correctly if

dryer is not level.

[] It is important to make sure the room has an adequate air

supply for drying operation. The operation of this appliance

may affect the operation of other appliances which take their

air supply for safe combustion from the same room.

[] Adequate ventilation must be provided to avoid a backflow

of gases into the room from appliances burning other

fuels, including open fires. If in doubt consult the appliance

manufacturers.

iMPORTANT: The dryer must not be installed or stored in an

area where it will be exposed to water and/or weather. Do not

operate your dryer at temperatures below 7°C (45°F). At lower

temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended. Check code

requirements. Some codes limit, or do not permit, installation of

the dryer in garages, closets, or sleeping quarters. Contact your

local building inspector.

Proper installation is your responsibility.

4

Page 5

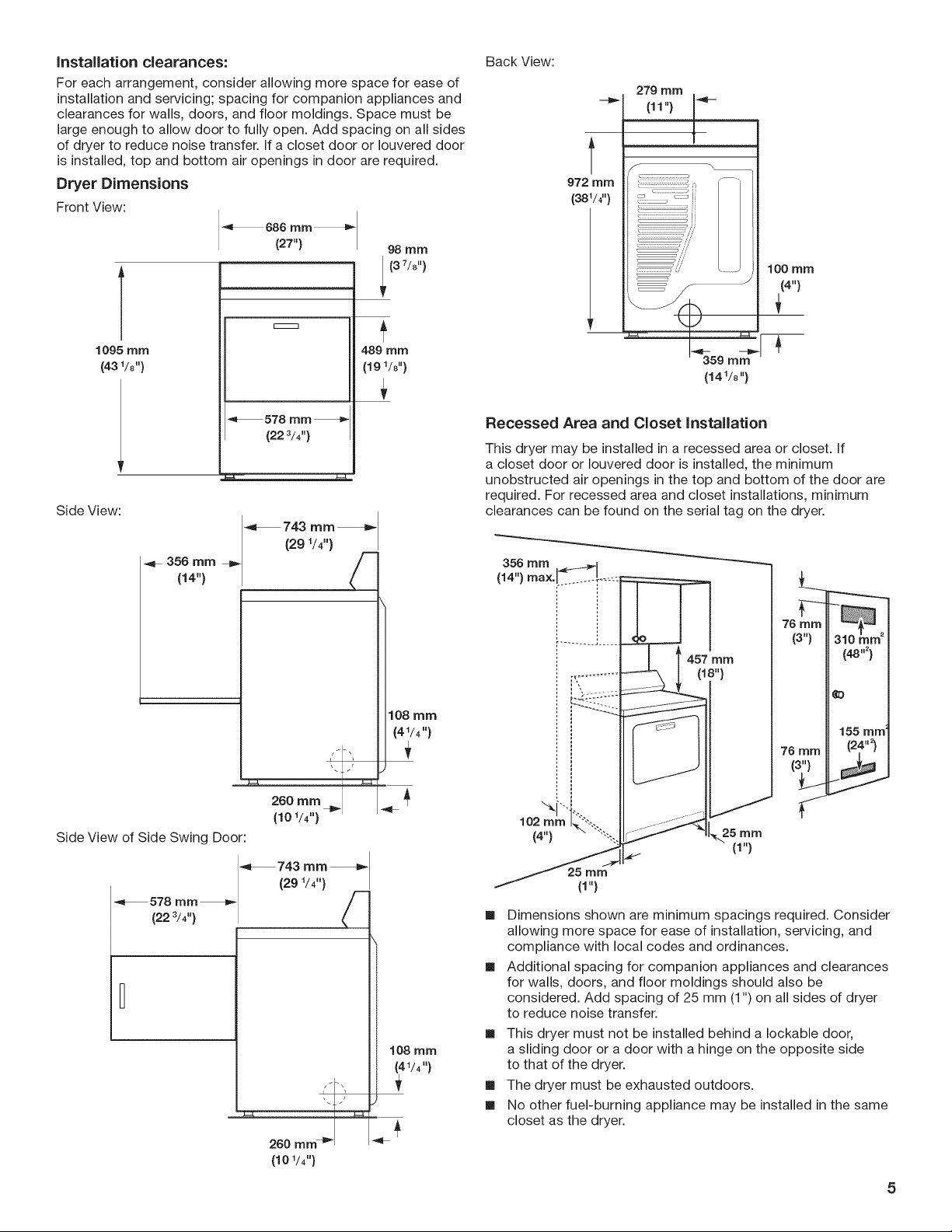

Installation clearances:

For each arrangement, consider allowing more space for ease of

installation and servicing; spacing for companion appliances and

clearances for walls, doors, and floor moldings. Space must be

large enough to allow door to fully open. Add spacing on all sides

of dryer to reduce noise transfer. If a closet door or Iouvered door

is installed, top and bottom air openings in door are required.

Dryer Dimensions

Front View:

_686 mm_

(27)

Back View:

279 mm

,", IT

t

t

972 mm

{381/4'')

i

100 mm

(4"}

1095 mm

(431/8"}

Side View:

_578 mm_

(22 3/4"}

m

_743 rnm_

356 mm _- (29 1/4 ) r

(14")

489 mm

(191/o"}

108 mm

(41/4'')

359 mm

(141/8"}

Recessed Area and Closet Installation

This dryer may be installed in a recessed area or closet. If

a closet door or Iouvered door is installed, the minimum

unobstructed air openings in the top and bottom of the door are

required. For recessed area and closet installations, minimum

clearances can be found on the serial tag on the dryer.

356 mm _----_1

(14"} max [........ !.....

76

r- ........ j .....

mm

"}

(:

5 ram1

76

Side View of Side Swing Door:

_578 mm_

(22 3/4")

{101/4")

_743 mm_

(29 1/4")

260 mm4_

(101/4")

?-

108 mm

(41/4 ")

102mm I_%'.....

(4"} \ ""%.

f (1")

[] Dimensions shown are minimum spacings required. Consider

allowing more space for ease of installation, servicing, and

compliance with local codes and ordinances.

[] Additional spacing for companion appliances and clearances

for walls, doors, and floor moldings should also be

considered. Add spacing of 25 mm (1") on all sides of dryer

to reduce noise transfer.

[] This dryer must not be installed behind a Iockable door,

a sliding door or a door with a hinge on the opposite side

to that of the dryer.

[] The dryer must be exhausted outdoors.

[] No other fuel-burning appliance may be installed in the same

closet as the dryer.

J

,..25mm

(1"}

Page 6

ELECTRICAL REQUIREMENTS

ENectricaNShock Hazard

ENectrically ground this appliance.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

This dryer is supplied without an electric cord and plug.

It is your responsibility:

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate and in

conformance with all local codes and ordinances.

[] To supply the required single phase, 240 volt, 60 Hz, AC

only electrical supply on a separate 30-amp circuit fused on

both sides of the line. A time-delay fuse or circuit breaker is

recommended. Connect to an individual branch circuit. Do

not have a fuse in the neutral or grounding circuit.

[] Do not use an extension cord.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly installyour dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

if using a power supply cord:

[] If the supply cord is damaged, it must be replaced by the

manufacturer, a qualified service agent, or other qualified

person to avoid a hazard.

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

[] A UL listed 30-amp power supply cord, rated 240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

[] A UL listed strain relief.

Connecting by direct wire:

Power supply cable must match power supply and be:

[] Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), covered with flexible metallic conduit. All

current-carrying wires must be insulated.

[] 10-gauge solid copper wire (do not use aluminum).

[] At least 5 ft (1.52 m) long.

[] Disconnection must be incorporated in the fixed wiring in

accordance to the wiring rules for your region.

Recommended Grounding Method

[] It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

GROUNDING INSTRUCTIONS

m=For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

INSTALL LEVELING LEGS

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Prepare dryer for leveling legs

To avoid damaging floor, use a large flat piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

6

Page 7

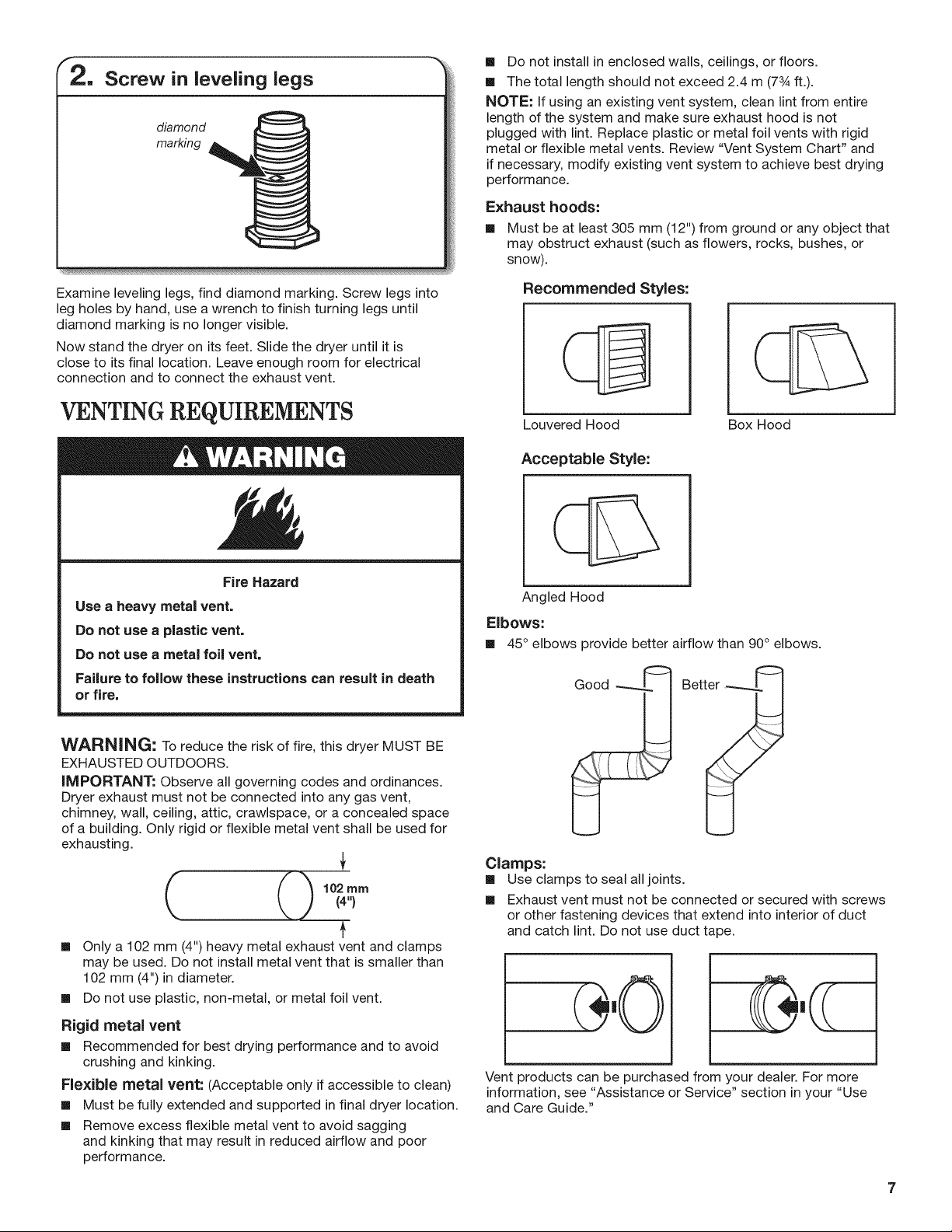

2, Screw in leveling legs

diamond

marking

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 2.4 m (73Aft.).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not

plugged with lint. Replace plastic or metal foil vents with rigid

metal or flexible metal vents. Review "Vent System Chart" and

if necessary, modify existing vent system to achieve best drying

performance.

Exhaust hoods:

[] Must be at least 305 mm (12")from ground or any object that

may obstruct exhaust (such asflowers, rocks, bushes, or

snow).

Examine leveling legs, find diamond marking. Screw legs into

leg holes by hand, use a wrench to finish turning legs until

diamond marking is no longer visible.

Now stand the dryer on its feet. Slide the dryer until it is

close to its final location. Leave enough room for electrical

connection and to connect the exhaust vent.

VENTING REQUIREMENTS

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent,

Failure to follow these instructions can result in death

or fire,

Recommended Styles:

Louvered Hood

Box Hood

Acceptable Style:

Angled Hood

Elbows:

[] 45° elbows provide better airflow than 90° elbows.

Bet

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

(4")

[] Only a 102 mm (4") heavy metal exhaust vent and clamps

may be used. Do not install metal vent that is smaller than

102 mm (4")in diameter.

[] Do not use plastic, non-metal, or metal foil vent.

Rigid metal vent

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[] Must be fully extended and supported in final dryer location.

[] Remove excess flexible metal vent to avoid sagging

and kinking that may result in reduced airflow and poor

performance.

Clamps:

[] Use clamps to seal all joints.

[] Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

Vent products can be purchased from your dealer. For more

information, see "Assistance or Service" section in your "Use

and Care Guide."

Page 8

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

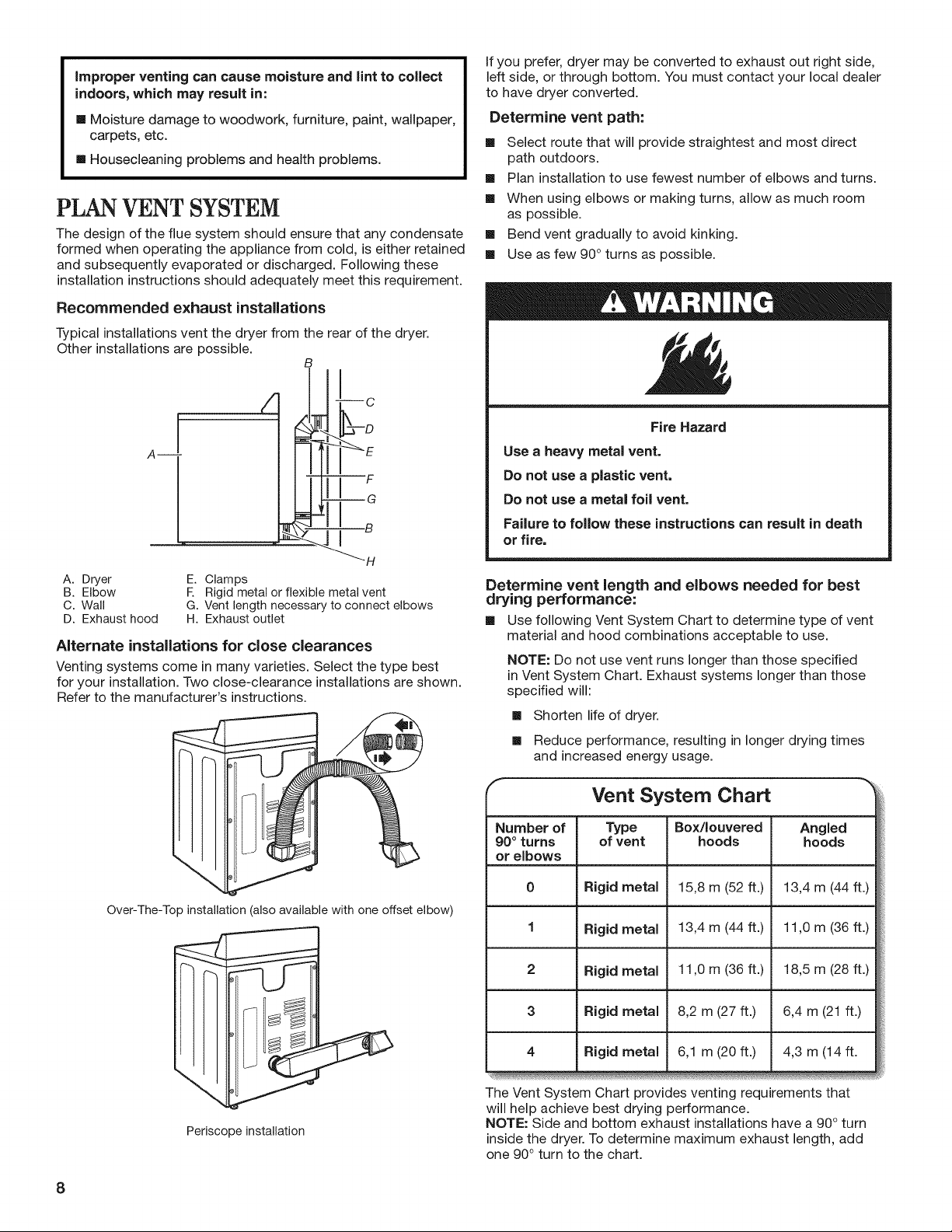

PLAN VENT SYSTEM

The design of the flue system should ensure that any condensate

formed when operating the appliance from cold, is either retained

and subsequently evaporated or discharged. Following these

installation instructions should adequately meet this requirement.

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

A--

G

If you prefer, dryer may be converted to exhaust out right side,

left side, or through bottom. You must contact your local dealer

to have dryer converted.

Determine vent path:

[] Select route that will provide straightest and most direct

path outdoors.

[] Plan installation to use fewest number of elbows and turns.

[] When using elbows or making turns, allow as much room

as possible.

[] Bend vent gradually to avoid kinking.

[] Use as few 90° turns as possible.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer's instructions.

Over-The-Top installation (also available with one offset elbow)

E. Clamps

E Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Determine vent length and elbows needed for best

drying performance:

[] Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified

in Vent System Chart. Exhaust systems longer than those

specified will:

[] Shorten life of dryer.

[]

Reduce performance, resulting in longer drying times

and increased energy usage.

f

Vent System Chart

Number of

90 ° turns

or elbows

2

3

Type

of vent

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Box/Iouvered Angled

hoods hoods

15,8 m (52 ft.) 13,4 m (44 ft.)

13,4 m (44 ft.) 11,0 m (36 ft.)

11,0 m (36 ft.) 18,5 m (28 ft.)

8,2 m (27 ft.) 6,4 m (21 ft.)

Periscope installation

4

The Vent System Chart provides venting requirements that

will help achieve best drying performance.

NOTE: Side and bottom exhaust installations have a 90° turn

inside the dryer. To determine maximum exhaust length, add

one 90° turn to the chart.

Rigid metal

6,1 m (20 ft.) 4,3 m (14 ft.

8

Page 9

The maximum length using a 51 mm x 152 mm (2"x 6")

rectangular vent with 2 elbows and a 64 mm (2-1/2") exhaust

hood is 2,4 m (8 ft).

For exhaust systems not covered by the Vent System Chart (such

as multiple unit hookups, plenums, and power-assist fans), see

Service Manual. (To purchase the Service Manual, contact your

local authorized service dealer.)

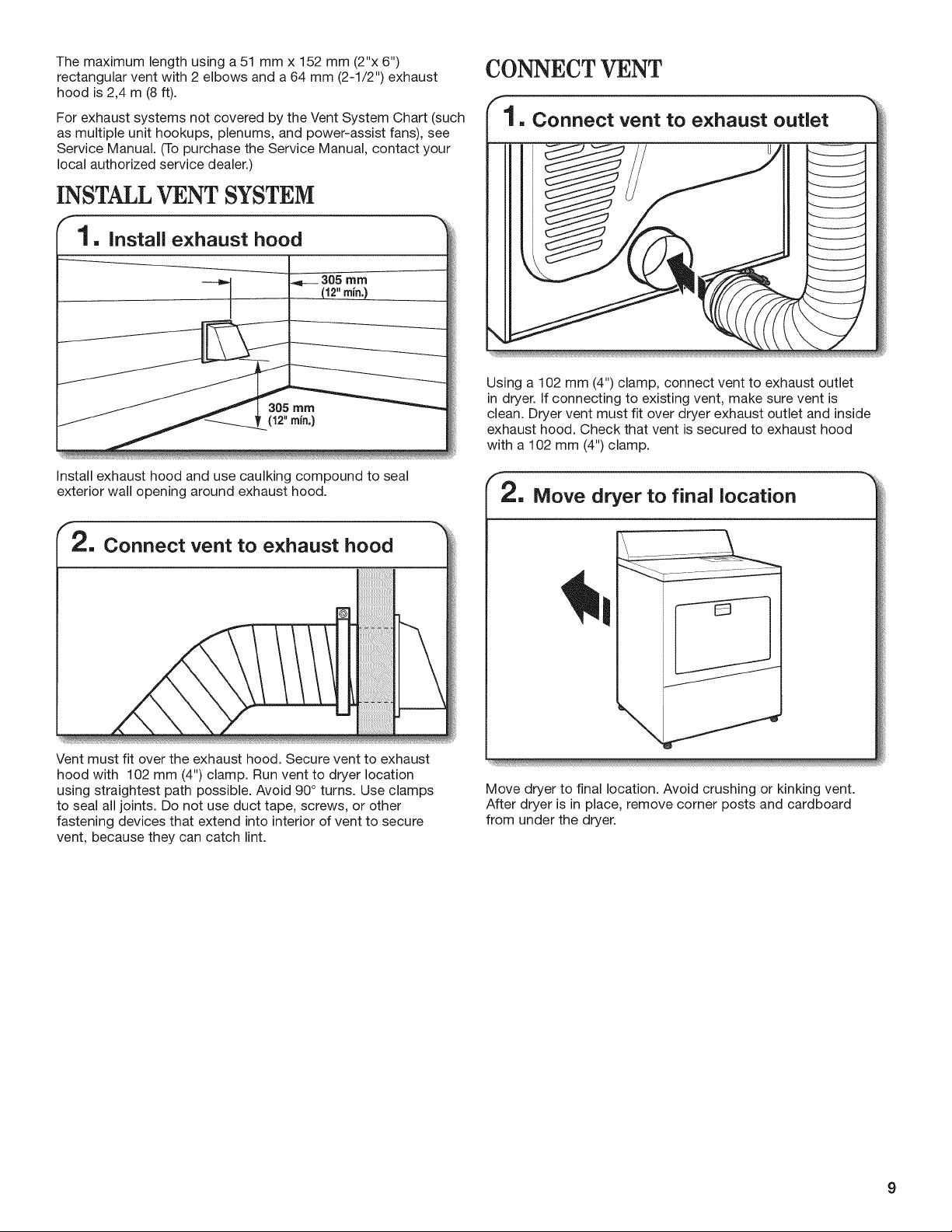

INSTALLVENT SYSTEM

1, Install exhaust hood

305 rnm

(12"rain,)

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

CONNECT VENT

Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must fit over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 102 mm (4") clamp.

2, Move dryer to final location

, Connect vent to exhaust hood

I

Vent must fit over the exhaust hood. Secure vent to exhaust

hood with 102 mm (4") clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

Move dryer to final location. Avoid crushing or kinking vent.

After dryer is in place, remove corner posts and cardboard

from under the dryer.

Page 10

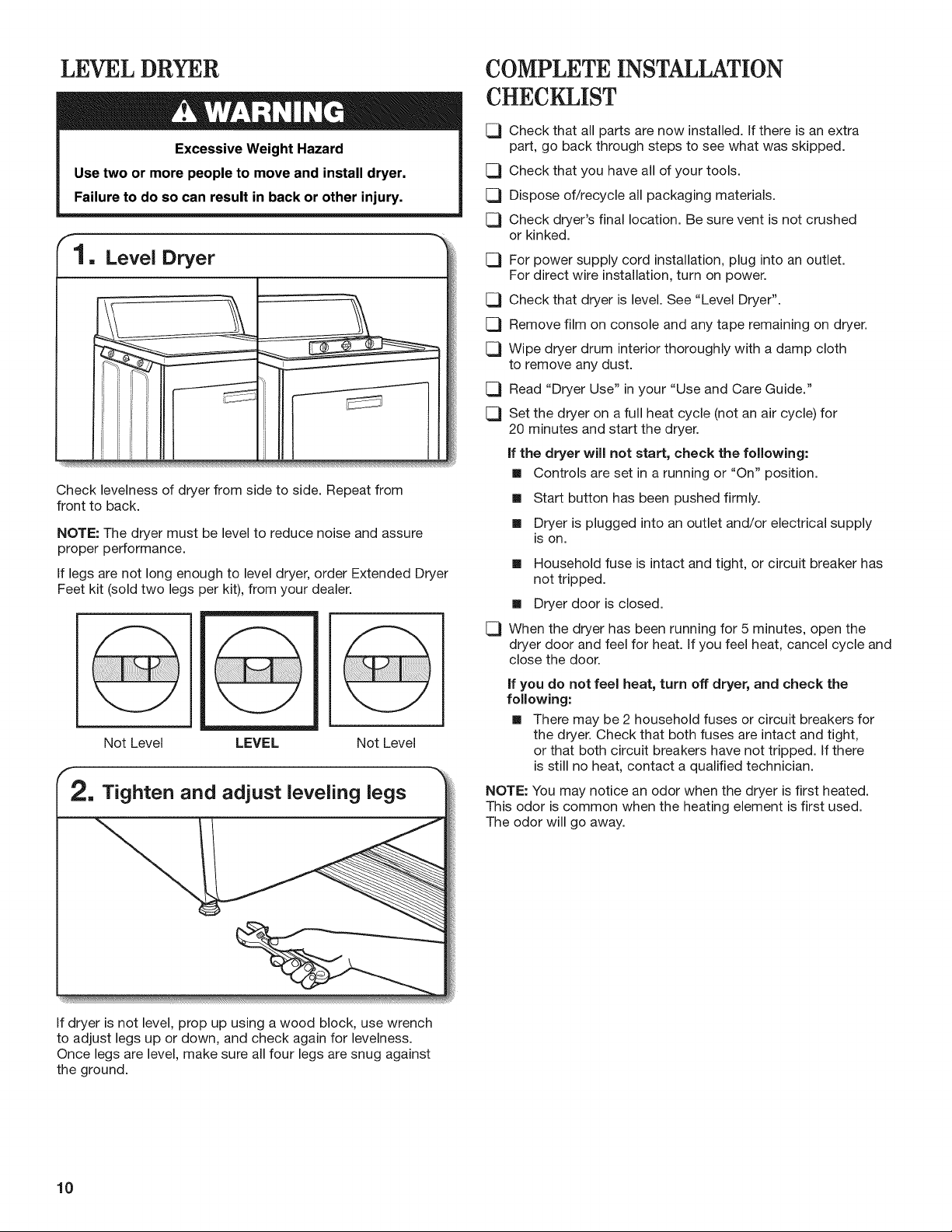

LEVEL DRYER

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1, Level Dryer

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level to reduce noise and assure

proper performance.

If legs are not long enough to level dryer, order Extended Dryer

Feet kit (sold two legs per kit), from your dealer.

Not Level LEVEL Not Level

2, Tighten and adjust leveling legs

COMPLETE INSTALLATION

CHECKLIST

[_ Check that all parts are now installed. If there is an extra

part, go back through steps to see what was skipped.

[_ Check that you have all of your tools.

[_ Dispose of/recycle all packaging materials.

[_ Check dryer's final location. Be sure vent is not crushed

or kinked.

[_ For power supply cord installation, plug into an outlet.

For direct wire installation, turn on power.

[_ Check that dryer is level. See "Level Dryer".

[_ Remove film on console and any tape remaining on dryer.

[_ Wipe dryer drum interior thoroughly with a damp cloth

to remove any dust.

[_ Read "Dryer Use" in your "Use and Care Guide."

[_ Set the dryer on a full heat cycle (not an air cycle) for

20 minutes and start the dryer.

If the dryer will not start, check the following:

[] Controls are set in a running or "On" position.

[] Start button has been pushed firmly.

[] Dryer is plugged into an outlet and/or electrical supply

is on.

[] Household fuse is intact and tight, or circuit breaker has

not tripped.

[] Dryer door is closed.

[_ When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you feel heat, cancel cycle and

close the door.

If you do not feel heat, turn off dryer, and check the

following:

[] There may be 2 household fuses or circuit breakers for

the dryer. Check that both fuses are intact and tight,

or that both circuit breakers have not tripped. If there

is still no heat, contact a qualified technician.

NOTE: You may notice an odor when the dryer is first heated.

This odor is common when the heating element is first used.

The odor will go away.

If dryer is not level, prop up using a wood block, use wrench

to adjust legs up or down, and check again for levelness.

Once legs are level, make sure all four legs are snug against

the ground.

10

Page 11

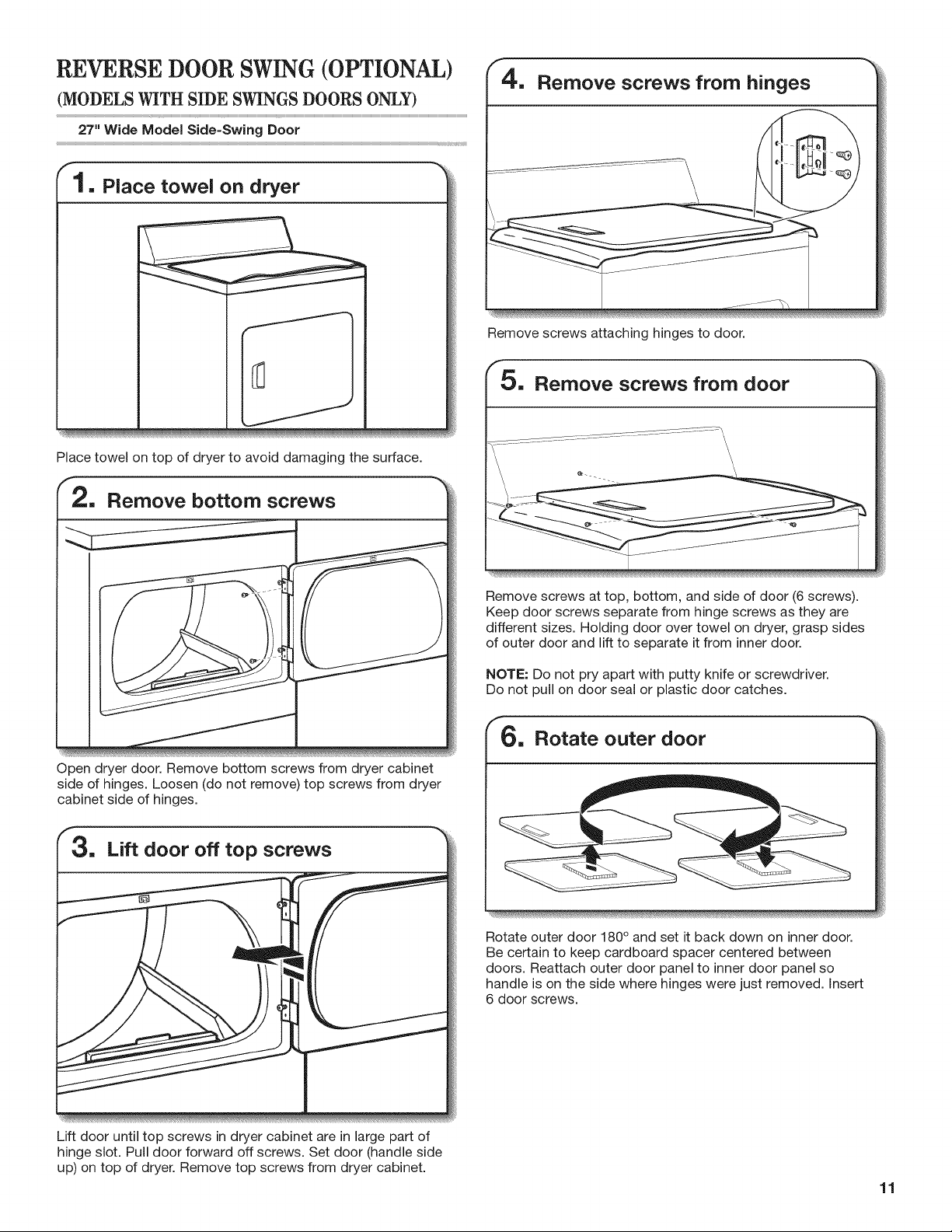

REVERSE DOOR SWING (OPTIONAL)

(MODELS WITH SIDE SWINGS DOORS ONLY)

27" Wide Model Side-Swing Door

1, Place towel on dryer

Place towel on top of dryer to avoid damaging the surface.

Remove bottom screws

4, Remove screws from hinges

Remove screws attaching hinges to door.

5. Remove screws from door

\

\

\

\

Open dryer door. Remove bottom screws from dryer cabinet

side of hinges. Loosen (do not remove) top screws from dryer

cabinet side of hinges.

Lift door off top screws

Remove screws at top, bottom, and side of door (6 screws).

Keep door screws separate from hinge screws as they are

different sizes. Holding door over towel on dryer, grasp sides

of outer door and lift to separate it from inner door.

NOTE: Do not pry apart with putty knife or screwdriver.

Do not pull on door seal or plastic door catches.

6, Rotate outer door

Rotate outer door 180° and set it back down on inner door.

Be certain to keep cardboard spacer centered between

doors. Reattach outer door panel to inner door panel so

handle is on the side where hinges were just removed. Insert

6 door screws.

Lift door until top screws in dryer cabinet are in large part of

hinge slot. Pull door forward off screws. Set door (handle side

up) on top of dryer. Remove top screws from dryer cabinet.

11

Page 12

7, Flip door over

Flip door over so handle side is down.

8, Attach door hinges

dryer cabinet

NOTE: 2 people may be needed to reinstall door.

Insert screws into the bottom holes on left side of dryer

cabinet. Tighten screws halfway. Position door so large end of

door hinge slot is over screws. Slide door up so screws are in

bottom of slots. Tighten screws. Insert and tighten top screws

in hinges.

fll, Check door strike alignment

Reattach door hinges to dryer door so that the larger hole is

at the bottom of the hinge.

Remove the 4 screws that attach 2 plugs on the left side.

Transfer plugs to opposite side using the same 4 screws.

12

Close door and check that door strike aligns with door catch.

If it is needed, slide door catch left or right within slot to

adjust alignment.

TROUBLESHOOTING

See the "Use and Care Guide" to possibly avoid the cost of a

service call.

Page 13

SECURITE DU SECHE-LINGE

Votre s_curit_ et celle des autres est tr_s importante.

Nous donnons de nombreux messages de securite importants dans ce manuel et sur votre appareil m6nager. Assurez-vous de

toujours life tousles messages de s6curit6 et de vous y conformer.

Voici le symbole d'alerte de securit&

Ce symbole d'alerte de s6curit6 vous signale les dangers potentiels de d6c_s et de blessures graves h vous

et h d'autres.

Tousles messages de s6curit6 suivront le symbole d'alerte de securit6 et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient :

Risque possible de d_c_s ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_c_s ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s6curit6 vous diront quel est le danger potentiel et vous disent comment r6duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT -"Risque d'incendie"

- L'installation du s_che-linge doit _tre effectu_e par un installateur qualifi_.

- installer le s_che-linge conforrn_rnent aux instructions du fabricant et aux codes Iocaux.

- Ne pas installer de s_che-linge avec des mat_riaux d'6vacuation en plastique

souple. Si un conduit m_tallique souple {de type papier d'aluminium) est installS,

celui-ci doit 6tre d'un type sp_cifique identifi_ par le fabricant de I'appareil et

convenir h une utilisation avec les s_che-linge. Les mat_riaux d'_vacuation

souples sont connus pour s'affaisser, 6tre facilement _cras6s et bloquer les peluches.

Ces situations obstrueront le d6bit d'air du s_che-linge et augmenteront le

risque d'incendie.

- Pour r_duire le risque de blessure grave ou de d(_c_s, suivre routes

les instructions d'installation.

- Conserver ces instructions.

POUR VOTRE SECURITE

1. Ne pas utiliser ni entreposer d'essence ou d'autres materiaux inflammables 9, I'int6rieur ou h proximit6 de cet appareil.

2. Ne pas vaporiser d'a6rosols h proximit6 de cet appareil durant son fonctionnement.

3. Ne pas modifier cet appareil.

13

Page 14

IMPORTANTES INSTRUCTIONS DE SECURITE

AVERTISSEMENT : Afin de r6duire le risque d'incendie, de choc 61ectrique ou de blessures corporelles Iors de

I'utilisation du seche-linge, il convient d'observer certaines pr6cautions fondamentales, notamment :

[] Lire toutes les instructions avant d'utiliser le seche-linge. _ I Retirer les portes du compartiment de s6chage avant de

[] Laisser un d6gagement minimal de 100 mm (4") entre I'arriere

du seche-linge et les 6ventuelles parois environnantes.

[] Le fonctionnement de cet appareil peut affecter celui d'autres

appareils dont la source d'approvisionnement en air se fait

dans la m6me piece pour une combustion sans danger.

Lorsqu'on utilise le seche-linge, une a6ration ad6quate est

n6cessaire pour renouveler Fair rejet6 et ainsi 6viter le retour

dans la piece de gaz en provenance d'appareils m6nagers

utilisant d'autres carburants comme combustible, y compris

les feux ouverts. En cas de doute, consulter le fabricant de

I'appareil.

[] Ne pas obstruer I'alimentation en air du seche-linge (voir les

instructions d'installation pour les d6gagements minimaux).

[] Ne pas placer d'articles t&ch6s d'huile de cuisson dans le

seche-linge. Des articles ayant 6t6 au contact d'huile peuvent

s'enflammer spontan6ment, surtout s'ils sont expos6s h des

sources de chaleur, telles un seche-linge. Les articles

peuvent chauffer, entrainant une r6action d'oxydation de

I'huile. Le ph6nomene d'oxydation cr6e de la chaleur. Si la

chaleur ne peut pas s'6chapper, les articles peuvent devenir

suffisamment chauds pour prendre feu. Le fait d'empiler,

d'entasser ou d'entreposer des articles ayant 6t6 au contact

d'huile peut emp6cher la chaleur de s'6chapper et cr6er un

risque d'incendie.

[] Si I'on doit faire s6cher dans le seche-linge des articles ayant

6t6 souill6s par des substances telles que de I'huile de

cuisson, ac6tone, alcool, p6trole, k6rosene, produit

d6tachant, t6r6benthine, cire, d6capant pour cire ou produits

de coiffure, ils doivent 6tre lav6s a I'eau chaude avec un

suppl6ment de d6tergent avant d'6tre s6ch6s dans le

seche-linge. Ces articles sont susceptibles de d6gager des

vapeurs qui pourraient s'enflammer ou exploser. Les laver

ainsi au pr6alable permet de r6duire mais non de supprimer

ce risque.

[] Cet appareil ne convient pas a une utilisation par des

personnes (y compris des enfants) a capacit6s physiques,

sensorielles ou mentales r6duites, ou d6pourvues

d'exp6rience et de connaissances, a moins qu'elles ne soient

plac6es sous supervision ou qu'elles aient regu des

instructions concernant I'utilisation de I'appareil par une

personne responsable de leur s6curit&

[] II convient de surveiller les enfants pour qu'ils ne jouent pas

avec I'appareil.

[] Ne pas utiliser le seche-linge si I'on a utilis6 des produits

chimiques industriels pour le nettoyage.

retirer le seche-linge pour un entretien ou de le mettre

au rebut.

[] Ne pas acc6der a I'int6rieur du seche-linge pendant le

fonctionnement du tambour. Pour votre s6curit6,

I'appareil est pourvu d'un contacteur de porte.

[] Ne pas installer ou entreposer le seche-linge dans un

endroit oQ il serait expos6 aux intemp6ries.

[] Ne pas effectuer d'intervention non autoris6e sur les

commandes.

[] Ne pas utiliser ce seche-linge s'il semble d6fectueux.

[] Ne pas proc6der a I'entretien, a la r6paration ou au

remplacement de n'importe quelle piece du seche-linge,

moins que ceci ne soit sp6cifiquement recommand6

dans le guide d'utilisation et d'entretien. Seul un

d6panneur comp6tent est habilit_ a effectuer une

intervention de r_paration ou d'entretien sur cet appareil.

[] Ne pas utiliser d'assouplissants pour tissu ou de produits

pour 61iminer 1'61ectricit6 statique a moins que cela ne

soit recommand_ par le fabricant d'assouplissants pour

tissu ou du produit. Suivre leurs instructions.

[] Nettoyer le filtre a peluches du seche-linge avant ou

apres chaque charge. Ne pas utiliser le seche-linge si

le filtre a peluches n'est pas install&

[] La zone situ6e autour des ouvertures de prise ou

d'6vacuation d'air et les zones adjacentes doivent 6tre

exemptes de peluches et poussieres.

[] L'int_rieur du seche-linge et le conduit d'_vacuation

doivent 6tre nettoy_s r_gulierement par un personnel

d'entretien qualifi&

[] Voir les instructions d'installation pour les instructions

de mise h la terre.

[] Ne pas faire s_cher d'articles non laves dans ce

seche-linge.

[] La partie finale du programme de s_chage par culbutage

a lieu sans chaleur (programme de refroidissement) pour

que les articles soient laiss_s h une temperature qui ne

risque pas de les endommager.

[] Les articles tels que le caoutchouc mousse (mousse de

latex), les bonnets de douche, les textiles imperm6abilis6s,

les articles avec endos de caoutchouc et les v6tements

ou oreillers rembourr_s avec matelassage en mousse

doivent _tre s_ch_s uniquement sur une corde h linge.

[] Si le cordon d'alimentation est endommag6, il doit 6tre

remplac6 par le fabricant, son agent de service ou toute

autre personne qualifi_e afin d'_viter tout danger.

AVERTISSEMENT : Ne jamais arr6ter un seche-linge

en phase de culbutage avant la fin du programme de

s_chage &moins de retirer les articles rapidement et de les

_tendre afin de dissiper la chaleur.

CONSERVER CES INSTRUCTIONS

EXIGENCES D'INSTALLATION

Outillage et Pi_ces

Rassembler les outils et pi_ces n_cessaires avant de commencer

I'installation.

14

Tournevis & lame plate Tournevis Phillips n° 2

Page 15

Cl6&douilleoutourne-

6croude6,2mm(1/4")

Cl6_.moletteavecouverture

jusqu'a25mm(1")oucl6

douillehexagonale

Couteauuniversel Metre&ruban

Pince Niveau

Pi_ces n_cessaires : (non fournies avec le s_che-linge)

[] Cordon d'alimentation

[] Clapets d'6vacuation

[] Coudes et les conduits de ventilation

En cas d'utilisation d'un c_ble d'alirnentation

_lectrique :

Utiliser un ensemble de c&ble d'alimentation 61ectrique

homologu6 UL marqu6 pour utilisation avec les seche-linge.

Uensemble dolt contenir :

[] Un c&ble d'alimentation 61ectrique homologu6 UL de

30 amperes, 240 volts minimum. Le c&ble dolt _tre de type

SRD ou SRDT et mesurer au moins 4 pi (1,22 m) de long.

Les ills raccord6s au seche-linge doivent se terminer par des

cosses rondes ou & fourche & pointes relev6es.

[] Un serre-c&ble (homologation UL).

Des pieces suppl6mentaires seront peut-_tre n6cessaires,

selon I'installation. Consulter les codes Iocaux. V@ifier

I'alimentation 61ectrique et le circuit d'6vacuation existants.

Consulter "Sp6cifications 61ectriques" et "Exigences concernant

1'6vacuation" avant d'acheter les pieces.

EXIGENCES D'EMPLACEMENT

Pistoletacalfeutrageet

compos6decalfeutrage(pour

I'installationd'unnouveau

conduitd'6vacuation)

Pincead6nuder

(installationsavec

raccordementparc&blage

direct)

Pi_ces fournies (pour tous les modules) :

Pieds de nivellement (4)

Retirer le sac de pieces du tambour du seche-linge. V@ifier

la pr6sence de toutes les pieces.

Cisailledeferblantier

(pourI'installation

d'unnouveauconduit

d'6vacuation)

Risque d'explosion

Garder les raati_res et les vapeurs inflammables, telle

que ressence, loin de la s_cheuse.

Placer la s_cheuse au moins 460 ram (18 po) au-dessus

du plancher pour une installation darts un garage.

Le non-respect de ces instructions peut causer

un d_c_s, une explosion ou un incendie.

Choisir un emplacement appropri6 pour le seche-linge afin

d'en am61iorer la performance et de r6duire au maximum le

bruit qu'il produit. V6rifier les sp6cifications des codes. Certains

codes limitent ou interdisent I'installation des seche-linge dans

un garage, un placard, une maison mobile ou une chambre

coucher. Contacter I'inspecteur en b&timents local.

II vous faudra :

[] Un emplacement permettant une 6vacuation appropri6e.

U6vacuation du seche-linge dolt se faire a I'ext@ieur. Voir

"Exigences concernant 1'6vacuation".

[] Le plancher dolt pouvoir soutenir le poids du seche-linge

de 90,7 kg (200 Ib). Tenir 6galement compte du poids des

appareils voisins.

[] Un plancher de niveau avec une pente maximale de

25 mm (1") sous I'ensemble du seche-linge. Si I'inclinaison

est sup@ieure a 25 mm (1"), installer I'ensemble de pieds

d'extension. Si le seche-linge n'est pas d'aplomb, il est

possible que le lingene culbute pas convenablement et que

les programmes command6s par d6tecteurs automatiques ne

fonctionnent pas correctement.

[] II est important de s'assurer que la piece dans laquelle se

trouve I'appareil possede un approvisionnement d'air suffisant

pour permettre son bon fonctionnement. Uutilisation de cet

appareil peut affecter celle d'autres appareils dont la source

d'approvisionnement en air se fait dans la m6me piece pour

une combustion sans danger.

15

Page 16

[] Unea6rationad6quateestn6cessairepour6viterleretour

danslapiecedegazenprovenanced'appareilsm6nagers

utilisantd'autrescarburantscommecombustible,ycompris

lesfeuxouverts.Encasdedoute,consulterlefabricantde

I'appareil.

IMPORTANT:Leseche-lingenedoltpas6treinstall6ouremis6

dansunendroitoQilseraexpos6&I'eauet/ouauxintemp6ries.

Nepasfairefonctionnerleseche-linge_,destemp6ratures

inf6rieures&7°C(45°F).Destemp6raturesinf6rieurespourraient

emp_cherI'arr_tduseche-linge&lafindesprogrammes

automatiquescommand6spard6tecteur,etcauserdesdur6es

prolong6esdes6chage.V6rifierlessp6cificationsdescodes.

CertainscodeslimitentouinterdisentI'installationdelas6cheuse

dansungarage,unplacardouunechambre&coucher.

ContacterI'inspecteurenb&timentslocal.

C'est&I'utilisateurqu'incombelaresponsabilit6der6aliserune

installationcorrecte.

D_gagements de s6paration :

Pour chaque type de configuration, pr6voir davantage de

d6gagement pour faciliter I'installation et I'entretien : laisser

suffisamment de d6gagement pour les appareils m6nagers

voisins et pour les tours, les portes et les plinthes. L'espacement

dolt 6tre assez grand pour permettre d'ouvrir completement la

porte. Ajouter un espace suppl6mentaire tout autour du seche-

linge pour r6duire le transfert de bruit. Si I'on installe une porte de

placard ou une porte & persiennes, des ouvertures d'a6ration au

sommet et au bas de la porte sont n6cessaires.

Dimensions du produit

Vue de face " _686 rnm_

(27 }

Vue lat6rale de la porte &ouverture lat6rale "

_743 mm_

(29 V4")

_578 mm_

(22 3/4")

260 m

(10V4")

Vue arriere "

279 mm

(11") J'_--

L

F

t

972 mm

(38V4"}

_ j/'/'

• )

J

i[

E

108 mm

(41/4 ")

100 mm

(4"}

1095 mm

(431/8"")

Vue lat6rale "

_578 mm_

(22 3/4")

_743 mm_

356 mm _ (29 1/4 ) F

(14")

489 mm

(191/o"}

108 mm

(41/4'')

359 mm

(141/8")

Espacement pour une installation darts

un encastrement ou darts un placard

Ce seche-linge peut 6tre install6 dans un encastrement ou un

placard. Pour installation dans un placard avec porte, on dolt

pr6voir des ouvertures minimums d'entr6e d'air en haut et en bas

de la porte. Pour les installations dans un encastrement ou un

placard, les dimensions minimales sont indiqu6es sur 1'6tiquette

du num6ro de s6rie du seche-linge.

16

260 mm

(101/4")

Page 17

356 rnrn _j

(14") max.[........ !.....

76

.......... j .....

457mm

1'(..........

102mm I_"-'.....

(4") "" ""%..

/

f (1")

[] Les dimensions indiqu6es correspondent aux d6gagements

minimaux n6cessaires. Un espace suppl6mentaire peut @re

n6cessaire pour faciliter I'installation et I'entretien, et pour

respecter les codes et reglements Iocaux.

[] Un espace suppl6mentaire peut @re requis pour les moulures

de porte et de plancher et pour les plinthes. Un espace

suppl6mentaire de 25 mm (1") doit 6tre envisag6 de tousles

c6t6s du seche-linge afin de r6duire le transfert de bruit.

[] Ne pas installer ce seche-linge derriere une porte pouvant

6tre ferm6e fl cl6, une porte coulissante ou une porte avec

charniere situ6e du c6t6 oppos6 a celui du seche-linge.

[] Le seche-linge doit 6vacuer a I'ext@ieur.

[] Aucun autre appareil consommant un combustible ne doit

6tre install6 dans le m6me placard que le seche-linge.

/

mm

(1")

(:

76

(:

SPECIFICATIONS ELECTRIQUES

[] Ne pas utiliser de c&ble de rallonge.

[] Si les codes le permettent et si I'on utilise un conducteur

distinct de liaison & la terre, il est recommand6 qu'un

61ectricien qualifi6 v@ifie la qualit6 de la liaison a la terre.

Raccordement 61ectrique

Pour installer correctement le seche-linge, d6terminer le type

de raccordement 61ectrique &utiliser et suivre les instructions

ci-dessous.

En cas d'utilisation d'un c_ble d'alimentation 61ectrique :

[] Si le cordon d'alimentation est endommag6, il doit 6tre

remplac6 par lefabricant, un agent de service qualifi6 ou

toute autre personne qualifi6e afin d'6viter tout danger.

Utiliser un ensemble de c&ble d'alimentation 61ectrique

homologu6 UL et marqu6 pour utilisation avec les seche-linge.

L'ensemble doit contenir :

[] Un c&ble d'alimentation 61ectrique homologu6 UL de 30

amperes, 240 volts minimum. Le c&ble dolt 6tre de type SRD

ou SRDT et mesurer au moins 4 pi (1,22 m) de long. Les fils

raccord6s au seche-linge doivent se terminer par des cosses

rondes ou & fourche & pointes relev6es.

[] Un serre-c&ble (homologation UL).

Raccordement direct :

Le c&ble d'alimentation 61ectrique doit correspondre &

I'alimentation 61ectrique et r6pondre aux crit@es suivants :

[] Un c&ble en cuivre & gaine non m6tallique ou blind6 souple

(avec fil de liaison a la terre), avec conduit m6tallique souple.

Tous les ills sous tension doivent 6tre isol6s.

[] Fil en cuivre plein de calibre AWG 10 (ne pas utiliser

d'aluminium).

[] Longueur d'au moins 5 pi (1,52 m) de long.

[] Le dispositif de d6connexion dolt 6tre incorpor6 clans le

c&blage fixe, conform6ment aux reglements Iocaux en matiere

de raccordement en vigueur dans la r6gion de I'utilisateur.

M6thode recomrnand6e de liaison a la terre

[] II incombe & I'utilisateur de contacter un 61ectricien qualifi6

afin de veiller & ce que I'installation 61ectrique soit r6alis6e de

fagon ad6quate et en conformit6 avec les exigences de tous

les codes et reglements Iocaux.

Risque de choc 61ectrique

Relier cet appareil fl la terre.

Ne pas utiliser de cordon de rallonge.

Le non=respect de ces instructions peut causer un

deces, un incendie ou un choc 61ectrique.

Ce sech.e-linge est livr6 sans c&ble d'alimentation 61ectrique et

sans prise.

II incombe & I'utilisateur de respecter les points suivants :

[] Contacter un 61ectricien qualifi&

[] Veiller & ce que I'installation 61ectrique soit correctement

effectu6e et soit conforme aux prescriptions de tousles

codes Iocaux et nationaux en vigueur.

[] Uappareil doit 6tre aliment6 par un circuit monophas6 de

240 V, 60 Hz, CA uniquement sur un circuit s6par6 de

30 amperes, prot6g6 par fusible aux deux extr6mit6s de la

ligne. On recommande d'utiliser un fusible ou un disjoncteur

temporis& On recommande 6galement que cet appareil soit

aliment6 par un circuit ind6pendant. Le circuit du neutre ou

de liaison a la terre ne doit pas contenir de fusible.

iNSTRUCTIONS DE LIAISON A LA TERRE

I Pour un s_che-linge reli6 & la terre et connect6 par un

cordon :

Ce s_che-linge doit 6tre reli6 & la terre. En cas d'anomalie

de fonctionnement ou de panne, la liaison & la terre r6duira

le risque de choc 61ectrique en offrant au courant 61ectrique

un itin6raire d'6vacuation de moindre r6sistance.

La fiche doit 6tre branch6e sur une prise de courant

appropri6e qui est bien install6e et reli6e & la terre

conform6ment & tousles codes et r_glements Iocaux.

AVERTISSElVlENT " Un raccordement inappropri6

du conducteur de liaison & la terre peut causer un risque de

choc 61ectrique. En cas de doute concemant la liaison & la

terre du seche-linge, consulter un 61ectricien qualifi6, un

agent ou personnel d'entretien. Ne pas modifier la fiche

fournie avec le s_che-linge; si elle ne s'adapte pas a la

prise, faire installer une prise appropri6e par un 61ectricien

qualifi&

CONSERVEZ CES INSTRUCTIONS

17

Page 18

INSTALLATIONDES PIEDS DE

EXIGENCES CONCERNANT

NIVELLEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour d_placer et

installer le s_che-linge,

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

1, Preparer le s che-linge pour

ies pieds de nivellernent

Afin d'6viter d'endommager le plancher, utiliser un grand

morceau de carton plat extrait de la bofte d'emballage

du s_che-linge et le placer entierement sous le s_che-linge.

Saisir fermement le corps du s_che-linge (et non pas

le panneau de la console) puis reposer le s_che-linge sur

le carton avec precaution.

2. Visser les pieds de nivellement

symboleen I_

forme de l_

I°sangel_

Examiner les pieds de nivellement pour trouver le rep_re

en forme de Iosange. Visser manuellement les pieds dans

les trous pour pieds de nivellement et utiliser une cl6 pour

terminer le vissage, jusqu'a ce que le rep_re en forme de

Iosange ne soit plus visible.

A present, redresser le s_che-linge et le placer sur ses

pieds. Faire glisser le s_che-linge jusqu'a ce qu'il se trouve

proximit6 de son emplacement final. Laisser suffisamment

d'espace pour pouvoir r6aliser le raccordement 61ectrique

et raccorder le conduit d'6vacuation.

UEVACUATION

Risque d'incendie

Utiliser un conduit d'_vacuation en m_tal Iourd,

Ne pas utiliser un conduit d'_vacuation en plastique,

Ne pas utiliser un conduit d'_vacuation en feuille

de m_tal.

Le non-respect de ces instructions peut causer

un d_c_s ou un incendie.

AVERTISSEMENT : Pour r6duire le risque d'incendie,

ce s_che-linge dolt EVACUER UAIR A UEXTERIEUR.

IMPORTANT : Observer les dispositions de tousles codes

et r_glements en vigueur. Le conduit d'6vacuation du seche-

lingene dolt pas _tre raccord6 h une 6vacuation de gaz, une

chemin_e, un mur, un plafond, un grenier, un vide sanitaire ou

un vide de construction. Seul un conduit d'6vacuation m6tallique

rigide ou souple doit etre utilis6 pour le systeme d'6vacuation.

i

0 102ram

[] Utiliser uniquement un conduit d'6vacuation en metal Iourd

de 102 mm (4") et des brides de serrage. Ne pas installer

un conduit d'6vacuation m6tallique de diam_tre inf6rieur

102 mm (4").

[] Ne pas utiliser de conduit de plastique ou de m6tal tr_s

mince.

Conduit rn6tallique rigide :

[] Recommand6 pour une performance de s6chage id6ale afin

d'6viter tout 6crasement ou deformation.

Conduit rn6tallique flexible : (Acceptable uniquement

si son acc_s restefacile pour lenettoyage)

[] Doit _tre entierement d6ploy6 et soutenu h I'emplacement

d'installation final du s_che-linge.

[] Enlever tout exces de conduit flexible pour 6viter tout

affaissement et d6formation susceptible de r6duire la

capacit6 d'6vacuation et le rendement.

[] Ne pas installer le conduit m6tallique flexible darts des cavit6s

ferm6es de mur, plafonds ou planchers.

[] La Iongueur totale ne doit pas d6passer 2,4 m (73/4pi.).

REMARQUE : Lors de I'utilisation d'un systeme d'evacuation

existant, nettoyer et _liminer la charpie sur toute la Iongueur du

syst_me, et veiller h ce que le clapet d'evacuation ne soit pas

obstru_ par de la charpie. Remplacer tout conduit de plastique

ou en aluminium par un conduit metallique rigide ou souple.

Consulter h nouveau le tableau des systemes d'_vacuations

et modifier le systeme d'_vacuation existant au besoin pour

obtenir un meilleur s_chage.

(4")

18

Page 19

Clapets d'_vacuation :

[] Dolt se trouver a au moins 305 mm (12") du plancher ou

de tout objet susceptible d'obstruer I'ouverture d'6vacuation

(tels des fleurs, des pierres, des buissons ou de la neige).

Styles recommand_s

Clapet & persiennes Clapet de type boite

Style acceptable :

Clapet inclin6

Coudes :

[] Les coudes & 45° permettent une meilleure circulation

de I'air que les coudes & 90 °.

Mie

PLANIFICATION DU SYSTEME

D'EVACUATION

La conception du systeme d'6vacuation dolt permettre & toute

condensation form6e pendant le fonctionnement de I'appareil

d'6tre retenue ou 6vapor6e ou encore 6vacu6e. En suivant ces

instructions d'installation, ces exigences sent convenablement

respect6es.

Instalations d'_vacuation recommand_es

Les installations typiques consistent & acheminer le conduit

d'6vacuation & I'arriere du seche-linge. D'autres installations

sent possibles.

B

A. S_che-linge

B. Raccord coud6

C. Mur

D. Clapet

d'6vacuation

E. Brides

ZCJ. s

E Conduit d'6vacuation m6tallique rigide

ou souple

G. Longueur de conduit d'6vacuation

n6cessaire pour le raccordement des

coudes

H. Bouche de d6charge

H

Brides de serrage :

[]

Utiliser des brides pour sceller tousles joints.

[]

Le conduit d'6vacuation ne dolt pas 6tre raccord6 ou fix6

avec des vis ou tout autre dispositif de serrage qui se

prolongerait & I'int@ieur du conduit et retiendrait la charpie.

Ne _as utiliser de ruban adh6sif pour conduit.

(,),0 n%,c

Le mat@iel d'6vacuation peut 6tre achet6 aupres de votre

revendeur. Pour plus d'informations, voir la section "Assistance

ou service" du "Guide d'utilisation et d'entretien".

Une mauvaise _vacuation de I'air peut causer de

I'humidit_ et une accumulation de charpie _ I'int_rieur de

la maison, ce qui peut provoquer :

[] Dommages par I'humidit6 aux boiseries, meubles, peinture,

papier-peint, tapis, etc.

[] Problemes de nettoyage dans la maison et problemes

de sant&

Autres installations avec d6gagement r6duit

II existe de nombreux systemes d'6vacuation. Choisir le systeme

qui convient le mieux a votre installation. Deux installations

& d6gagement r6duit sent illustr6es. Voir les instructions du

fabricant.

Installation au-dessus du s_che-linge @galement

disponible avec un coude d6cal6)

\

Installation de p@iscope

19

Page 20

Si vous pr6f6rez, le s_che-linge peut etre converti pour

6vacuer par le bas. Contactez votre revendeur local pour

convertir le s_che-linge.

D_terminer I'itin_raire d'acheminement du conduit :

[] Choisir I'itineraire d'acheminement vers I'ext6rieur qui sera

le plus direct et le plus rectiligne.

[] Planifier I'installation de fagon h introduire un nombre minimal

de coudes et de changements de direction.

[] Si des coudes ou changements de direction sont utilis6s,

pr6voir autant d'espace que possible.

[] Plier le conduit graduellement pour 6viter de le d6former.

[] Utiliser le moins possible de changements de direction a 90°.

Risque d'incendie

Utiliser un conduit d'_vacuation en rn_tal Iourd,

Ne pas utiliser un conduit d'_vacuation en plastique.

Ne pas utiliser un conduit d'_vacuation en feuille

de m_tal.

Le non-respect de ces instructions peut causer

un d_c_s ou un incendie.

Le tableau des systemes d'6vacuation indique les criteres

d'6vacuation qui vous aideront a obtenir une performance

de s6chage id6ale.

REMARQUE : Les installations d'6vacuation par le bas

comportent un changement de direction a 90° a I'int6rieur

du s_che-linge. Pour 6tablir la Iongueur maximale du conduit

d'6vacuation, ajouter un changement de direction a 90 ° au

tableau.

Pour une installation faite avec des conduits rectangulaires de

51 mm x 152 mm (2 pox 6 po) et comportant 2 coudes et un

clapet de d6charge de 64 mm (2-1/2 po), la Iongueur maximale

de conduit est 2,4 m (8 pi).

Pour les systemes d'6vacuation non illustr6s dans le tableau

de sp6cifications des conduits (notamment les raccordements

multiples, les pl6nums, et les ventilateurs motoris6s), voir dans

le Manuel d'entretien Whirlpool la section "Evacuation des

s_che-linge Whirlpool", disponible chez votre revendeur de

pieces Whirlpool.

INSTALLATIONDU CIRCUIT

D'EVACUATION

"1, Installer ie clapet d' vacuation

mm

D_terminer la Iongueur du conduit et le hombre

de coudes n_cessaires pour une performance

optimale de s_chage:

[] Utiliser le tableau des systemes d'6vacuation suivant

pour d6terminer le type de mat6riel d'6vacuation et

les combinaisons de hotte acceptables.

REMARQUE : Ne pas utiliser de conduits de Iongueur sup6rieure

la valeur sp6cifi6e dans le tableau des systemes d'6vacuation.

Si la Iongueur du circuit est sup6rieure a la valeur sp6cifi6e dans

le tableau, on observera :

[] Un cycle de vie r6duit du s_che-linge.

[] Une r6duction du rendement, avec temps de s6chage plus

longs et une plus grande consommation d'6nergie.

Tableau des syst rnes d' vacuation

Nombre Type de Clapets Hottes

de coudes conduit d'_vacuation d'_vacuation

90° d'_vacuation de type inclines

0 rigide 15,8 m (52 pi.) 13,4 m (44 pi.)

1 M_tallique

2 M_tallique

3 M_tallique

4 M_tallique

M_tallique

rigide 13,4 m (44 pi.) 11,0 m (36 pi.)

rigide 11,0 m (36 pi.) 18,5 m (28 pi.)

rigide 8,2 m (27 pi.) 6,4 m (21 pi.)

rigide 6,1 m (20 pi.) 4,3 m (14 pi.)

boite ou

persiennes

305 rnrn

(12"rain.)

Installer le clapet d'6vacuation et utiliser un compos6 de

calfeutrage pour calfeutrer le c6t6 ext6rieur de I'ouverture

murale autour du clapet d'_vacuation.

f

2, Raccordement du conduit

d'_vacuation au clapet

Le conduit dolt _tre plac_ par dessus le clapet d'_vacuation.

Fixer ensemble le conduit et le clapet avec une bride de

102 mm (4"). Acheminer le conduit jusqu'h I'emplacement

du seche-linge en utilisant le chemin le plus rectiligne

possible. Eviter les changements de direction h 90°. Utiliser

des brides pour sceller tous les joints. Ne pas utiliser de

ruban adh_sif pour conduit, de vis ou autres dispositifs de

fixation qui se prolongeraient a I'int_rieur du conduit pour

fixer le conduit d'_vacuation; ceux-ci pourraient retenir

la charpie.

2O

Page 21

RACCORDEMENT DU CONDUIT

REGLAGE DE L'APLOMB DU

D'EVACUATION

au clapet d'_vacuation Risque du poids excessif

A I'aide d'une bride de serrage de 102 mm (4"), relier le

conduit d'evacuation h la bouche d'evacuation du sechelinge.

Si on utilise le conduit d'evacuation existant, s'assurer qu'il

est propre. Le conduit d'evacuation du seche-linge doit _tre

fix6 par-dessus la bouche d'evacuation du seche-linge, et

I'interieur du clapet d'evacuation. Verifier que le conduit

d'evacuation est fix6 au clapet d'evacuation & I'aide d'une

bride de serrage de 102 mm (4").

:2. Placer ie s_che-linge

son emplacement final

SECHE-LINGE

Utiliser deux ou plus de personnes pour ddpiacer et

installer la s_cheuse,

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

Verifier I'aplomb du seche-linge dans le sens transversal.

Repeter I'operation dans le sens avant-arriere.

REMARQUE : Le seche-linge dolt _tre d'aplomb pour que

le systeme de detection d'humidite fonctionne correctement.

Si les pieds ne sont pas assez longs pour obtenir un aplomb

correct du seche-linge, commander un Ensemble de pieds

d'extension pour seche-linge, piece n° 279810 (deux pieds par

ensemble), chez un revendeur.

Placer le seche-linge a son emplacement final. Eviter

d'ecraser ou de deformer le conduit d'evacuation. Une fois

le seche-linge en place, retirer le carton sous le seche-linge.

Pas d'aplomb D'APLOMB Pas d'aplomb

:2. R_glage des pieds de niveilement

Si le seche-linge n'est pas d'aplomb, le soulever & I'aide d'une

cale en bois, regler les pieds vers le haut ou vers le bas

I'aide d'une cle et contr61er de nouveau I'aplomb. Une fois

que les pieds de nivellement sont d'aplomb, s'assurer que les

quatre pieds sont en contact ferme avec le plancher.

21

Page 22

ACHEVER L'INSTALLATION.

LISTE DE VERIFICATION

[_ V6rifier que toutes les pieces sont maintenant install6es. S'il

reste une piece, passer en revue les diff6rentes 6tapes pour

d6couvrir laquelle aurait 6t6 oubli6e.

[_ V6rifier la pr6sence de tousles outils.

[_ Jeter/recycler tous les mat6riaux d'emballage.

[_ V6rifier I'emplacement d6finitif du s_che-linge. S'assurer

que le conduit d'6vacuation n'est pas 6cras6 ou d6form6.

[_ Pour une installation avec cordon d'alimentation 6(ectrique,

brancher dans une prise reli6e h la terre. Pour une installation

raccordement direct, mettre I'appareil sous tension.

[_ V6rifier que le s_che-linge est d'aplomb. Voir "R6glage de

I'aplomb du s_che-linge".

[_ Oter la pellicule protectrice de la console et tout ruban

adh6sif rest6 sur le s_che-linge.

[_ Essuyer soigneusement I'int6rieur du tambour

du s_che-linge avec un chiffon humide pour 61iminer

toute trace de poussiere.

[_ Life la section "Utilisation du s_che-linge" dans le "Guide

d'utilisation et d'entretien".

[_ R6gler le s_che-linge pour un programme de s6chage

complet (pas le programme de s6chage a I'air) de 20 minutes

et mettre le s_che-linge en marche.

Si le s_che=linge ne d_rnarre pas, v_rifier ce qui suit :

[] Les commandes sont r6gl6es a la position de marche

ou sur "ON" (marche)

[] Le bouton Start (mise en marche) a 6t6 enfonc6

fermement.

[] Le s_che-linge est branch_ dans une prise reli6e a la terre

et/ou I'alimentation 6(ectrique est connect6e.

[] Le fusible du domicile est intact et serf6; le disjoncteur

n'est pas d6clench6.

[] La porte du s_che-linge est ferm6e.

[_ Apr_s 5 minutes de fonctionnement, ouvrir la porte du s_che-

linge et d6terminer si I'on d6tecte de la chaleur. Si de la

chaleur est d6tect6e, annulet le programme et fermer la porte.

Si le s_che=linge n'est pas chaud & I'int_rieur, _teindre (e

s_che=linge et v_rifier ce qui suit :

[] II peut y avoir 2 fusibles ou disjoncteurs domestiques

distincts pour le s_che-linge. Wrifier que les deux fusibles

sont intacts et bien en place ou que les deux disjoncteurs

ne se sont pas d6clench6s. S'il n'y a toujours pas de

chaleur, contacter un technicien qualifi6.

REMARQU I= : II est possible que le s_che-linge d6gage une

certaine odeur Iorsqu'il chauffe pour la premiere fois. Cette odeur

est normale Iorsque 1'616ment chauffant est utilis6 pour

la premiere fois. Uodeur disparaYtra.

INVERSION DE LA PORTE

(FACULTATIF)

(MODELES AVEC PORTES ._ O[WERTURE

LATERALE UNIQUEMENT)

ModUle large avec porte & ouverture lat_rale de 27"

1, Placer une serviette sur

ie s che-linge

Placer la serviette sur le dessus du s_che-linge pour _viter

d'endommager la surface.

Ouvrir la porte du s_che-linge. Oter les vis inf_rieures de la

portion des charnieres attach_e a la caisse du s_che-linge.

Desserrer (ne pas retirer) les vis sup_rieures de la portion des

charnieres attach_e a la caisse du seche-linge.

des vis sup rieures

22

Soulever la porte jusqu'a ce que les vis sup_rieures situ_es

dans la caisse du s_chedinge se trouvent dans la pattie

_vas_e de I'encoche de charniere. Tirer la porte vers I'avant

pour la d_gager des vis. Placer la porte (c6t_ poign_e vers

le haut) sur le s_che-linge. Retirer les vis sup_rieures de la

caisse du s_che-linge.

Page 23

Retirerlesvisfixantlescharnieresalaporte.

Retourner la porte de fa(;on ace que la poign6e soit orient6e

vers le bas.

5, ()ter ies vis du panneau de porte

Retirer les vis du sommet, du bas et du c6t6 de la porte

(6 vis). Conserver s6par6ment les vis de porte et les vis

de charniere, car elles sont de tallies diff6rentes. Tout en

maintenant la porte sur la serviette et sur le s_che-linge,

saisir les c6t6s de la porte externe et la soulever pour la

s6parer de la porte interne.

REMARQUE : Ne pas utiliser de couteau a mastic ou de

tournevis pour s6parer les portes. Ne pas tirer sur le joint

ou les pitons de retenue en plastique de la porte.

6, Faire pivoter ia porte externe

8, Fixer les charni_res de porte

Faire pivoter de 180° puis la replacer sur la porte interne.

Veiller a maintenir la cale d'espacement en carton centr6e

entre les portes. Fixer a nouveau le panneau de porte externe

sur le panneau de porte interne de fagon ace que la poign6e

se trouve du c6t6 oQ les charnieres viennent d'etre retir6es.

Ins6rer les 6 vis de porte.

R6installer les charnieres de porte sur la porte du s_che-linge

de fagon ace que letrou le plus gros se trouve dans la pattie

inf6rieure de la charniere.

23

Page 24

9, Retirer les bouchons d'obturation

et les transf6rer

I

Oter les 4 vis fixant les 2 bouchons d'obturation du c6t6

gauche. Transf6rer les bouchons d'obturation au c6t6 oppos6

I'aide des m_mes 4 vis.

1 1, ¢ontrSier I'alignement du piton

de la porte

Fermer la porte et v6rifier que le piton de la porte est align6

avec la g&che de la porte. Au besoin, faire glisser la g&che

de la porte vers la gauche ou vers la droite a I'int6rieur de

I'encoche pour r6gler I'alignement.

de charni_re de ia caisse du

s_che-linge

REIVlARQUE : II faudra peut-_tre deux personnes pour

r6installer la porte.

Ins6rer les vis dans les trous inf6rieurs du c6t6 gauche de

la caisse du seche-linge. Serrer les visa moiti6. Positionner

la porte de fagon ace que le c6t6 large de I'encoche de la

charniere de porte se trouve au-dessus des vis. Faire glisser la

porte vers le haut de fagon ace que les vis se trouvent au fond

des encoches. Resserrer les vis. Ins6rer les vis sup6rieures

dans les charnieres et les setter.

DEPANNAGE

Pour 6ventuellement 6viter le coot d'une visite de service,

consulter le "Guide d'utilisation et d'entretien".

24

Page 25

SEGURIDAD DE LA SECADORA

Su seguridad y la seguridad de los demos es rnuy irnportante.

Hemos incluido muchos mensajes importantes de seguridad en este manual yen su electrodom6stico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el simbolo de advertencia de seguridad.

Este simbolo le llama la atenciSn sobre peligros potenciales que pueden ocasionar la muerte o una lesi6n a

usted y a los demas.

Todos los mensajes de seguridad irhn a continuaci6n del simbolo de advertencia de seguridad y de la palabra

"PELIGRO" o "ADVERTENCIA". Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted puede

rnorir o sufrir una lesi6n grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesibn grave.

Todos los mensajes de seguridad le diran el peligro potencial, le dirhn c6mo reducir las posibilidades de sufrir una lesi6n y Io que

puede suceder si no se siguen las instrucciones.

ADVERTENC|A - ...io.godoi°oo°dio..

m

La instalaci6n de la secadora de ropa debe estar a cargo de un instalador cornpetente.

m

Instale la secadora de ropa segdn las instrucciones del fabricante y los c6digos locales.

m

No instale una secadora de ropa con rnateriales de ventiiaci6n de pl_stico flexible o un

conducto de metal flexible (de hoja de metal). Si se usa un conducto de metal flexible,

6ste deber_ set de un tipo especifico, que est6 identificado pot el fabricante de

electrodorn_sticos corno apto para ser usado con secadoras de ropa. Es sabido que

los rnateriales de ventilaci6n flexible se derrurnban, se aplastan con facilidad y atrapan

pelusa. Estas condiciones obstruir&n el flujo de aire de la secadora de ropa y

aurnentar_n el riesgo de incendio.

Para reducir el riesgo de lesiones severas o la rnuerte, siga todas ias instrucciones

de instalaciSn.

Guarde estas instrucciones.

PARA SU SEGURiDAD

1. No use ni guarde gasolina ni otros materiales inflamables dentro de este aparato ni cerca del mismo.

2. No rocie con aerosoles en la proximidad de este aparato mientras este en funcionamiento.

3. No modifique este aparato.

25

Page 26

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA: A fin de reducir el riesgo de incendio, choque el6ctrico o de daSo alas personas que usen la secadora,

deben seguirse las precauciones bhsicas, incluidas las siguientes:

[] Lea todas las instrucciones antes de usar la secadora.

[] Mantenga un espacio minimo de pot Io menos 100 mm

(4 pulg) entre la parte posterior de la secadora y cualquier

pared.

[] El funcionamiento de este aparato puede afectar el

funcionamiento de otros tipos de aparatos que obtienen

el suministro de aire para la combusti6n segura desde

la misma habitaci6n. Debe haber una ventilaci6n adecuada

para reemplazar el aire de salida y de esta manera evitar

el contraflujo de gases en la habitaci6n proveniente de

aparatos que quemen otros combustibles, incluyendo

fuegos abiertos, cuando haga funcionar la secadora con

rotaci6n. Si tiene dudas, consulte a los fabricantes de

electrodom6sticos.

[] No obstruya el suministro de aire a la secadora (vea las

Instrucciones de instalaci6n para los espacios minimos).

[] No coloque los objetos expuestos a aceite para cocinar en

su secadora. Los articulos impregnados con aceite pueden

incendiarse esponthneamente, especialmente cuando se los

expone a fuentes de calor, como una secadora que gira. Los

articulos pueden calentarse, Io que causa una reacci6n de

oxidaci6n en el aceite. La oxidaci6n produce calor. Si el calor

no puede escapar, los articulos pueden ponerse Io

suficientemente calientes como para prenderse fuego. Si se

hacen pilas, se amontonan o se guardan articulos manchados

con aceite, esto impedirh que el calor se escape y ocasionarh

un peligro de incendio.

[] Si no puede evitarse el secar articulos que se hayan

ensuciado con substancias tales como aceite de cocina,

acetona, alcohol, gasolina, queroseno, quitamanchas,

aguarrhs, ceras y quitaceras, o que hayan sido contaminados

por productos para el cuidado del cabello, 6stos deberhn

lavarse en agua caliente con una cantidad adicional de

detergente antes de secarse en la secadora. Estos articulos

pueden despedir vapores que pueden encenderse o causar

una explosi6n. Este lavado reducirh pero no eliminarh

el riesgo.

[] Este aparato no ha sido dise_ado para set usado por

personas (incluidos ni_os) con capacidad fisica, sensorial

o mental reducida, o falta de experiencia y conocimiento,

a menos que Io hagan bajo supervisi6n o siguiendo las

instrucciones relativas al uso del aparato, a cargo de

personas responsables por su seguridad.

[] Los ni_os peque_os deberhn estar bajo supervisi6n para

asegurarse de que no jueguen con el electrodom6stico.

[] No deberh usarse la secadora si se han usado productos

quimicos industriales para la limpieza.

[] Quite la puerta de la secadora al compartimiento de

secado antes de ponerla fuera de funcionamiento o de

descartarla.

[] No introduzca las manos en la secadora cuando el tambor

esth en movimiento. Para su seguridad se ha incluido un

interruptor de puerta.

[] No instale o almacene esta secadora donde estarh

expuesta a la intemperie.

[] No trate de forzar los controles.

[] No continQe usando este aparato si parece estar

defectuoso.

[] No repare o reemplace ninguna pieza de la secadora ni

trate de repararla a menos que esto se recomiende

especificamente en este Manual uso y cuidado. La

reparaci6n y el servicio deben ser hechos solamente por

un personal de servicio competente.

[] No utilice suavizantes de telas o productos para eliminar

la esthtica de prendas a menos que Io recomiende el

fabricante del suavizante de telas o del producto en uso.

Siga sus instrucciones.

[] Limpie el filtro de pelusa antes o despu6s de cada carga.

No ponga a funcionar la secadora sin el filtro de pelusa

en su lugar.

[] Mantenga el Area alrededor de la abertura de ventilaci6n

y entrada y las Areas adyacentes a esta abertura sin

pelusa, polvo o tierra.

[] La parte interior de la secadora y el ducto de escape se

deben limpiar peri6dicamente. Esta limpieza la debe Ilevar

a cabo un personal de servicio calificado.

[] Vea las instrucciones de instalaci6n para las instrucciones

de conexi6n a tierra.

[] No seque en esta secadora articulos que no hayan sido

lavados.