Amana 1CWGD5100VQ, 1CWGD5300VW, 1CWGD5790VQ, 1CWGD5700VW, 1CWGD5200VQ Installation Instructions

Page 1

29" (737 MM) GAS DRYER INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

PARA LA SECADORA A GAS DE 29" (737 MM)

Table of Contents / Índice

DRYER SAFETY....................................... 1

INSTALLATION INSTRUCTIONS ...........4

Tools and Parts...................................... 4

Location Requirements ........................4

Electrical Requirements......................... 5

Gas Supply Requirements..................... 6

Venting Requirements ........................... 7

Plan Vent System .................................. 8

Install Vent System ................................ 9

Install Leveling Legs ..............................9

Make Gas Connection......................... 10

Connect Vent....................................... 10

Level Dryer........................................... 10

Reverse Door Swing (Optional) ........... 11

Complete Installation........................... 12

SEGURIDAD DE LA SECADORA .........13

INSTRUCCIONES DE INSTALACIÓN ..15

Herramientas y piezas .........................15

Requisitos de localización .................. 15

Requisitos eléctricos ...........................17

Requisitos del suministro de gas ........17

Requisitos de ventilación..................... 19

Planificación del sistema de

ventilación............................................ 20

Instalación del sistema de ventilación. 21

Instalación de las patas niveladoras ... 21

Conexión del suministro de gas.......... 22

Conexión del ducto de escape ...........22

Nivelación de la secadora ...................22

Cómo invertir el cierre de la puerta

(opcional)

Complete la instalación .......................23

............................................. 22

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

W10131643A

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When discarding or storing your old clothes dryer, remove the door.

SAVE THESE INSTRUCTIONS

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of re or explosion, or to prevent property damage, personal injury, or death.

– Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the re department.

•

– Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

2

Page 3

In the State of Massachusetts, the following installation instructions apply:

■

Installations and repairs must be performed by a qualied or licensed contractor, plumber, or gastter qualied or licensed by

the State of Massachusetts.

■

If using a ball valve, it shall be a T-handle type.

■

A exible gas connector, when used, must not exceed 3 feet.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

3

Page 4

INSTALLATION INSTRUCTIONS

Tools and Parts

Gather the required tools and parts before starting installation. Read

and follow the instructions provided with any tools listed here.

■ 8" or 10" pipe wrench

■ 8" or 10" adjustable wrench

(for gas connections)

■ Flat-blade screwdriver

■ Adjustable wrench that

opens to 1" (25 mm) or hexhead socket wrench (for

adjusting dryer feet)

■ ¼" nut driver or socket

wrench (recommended)

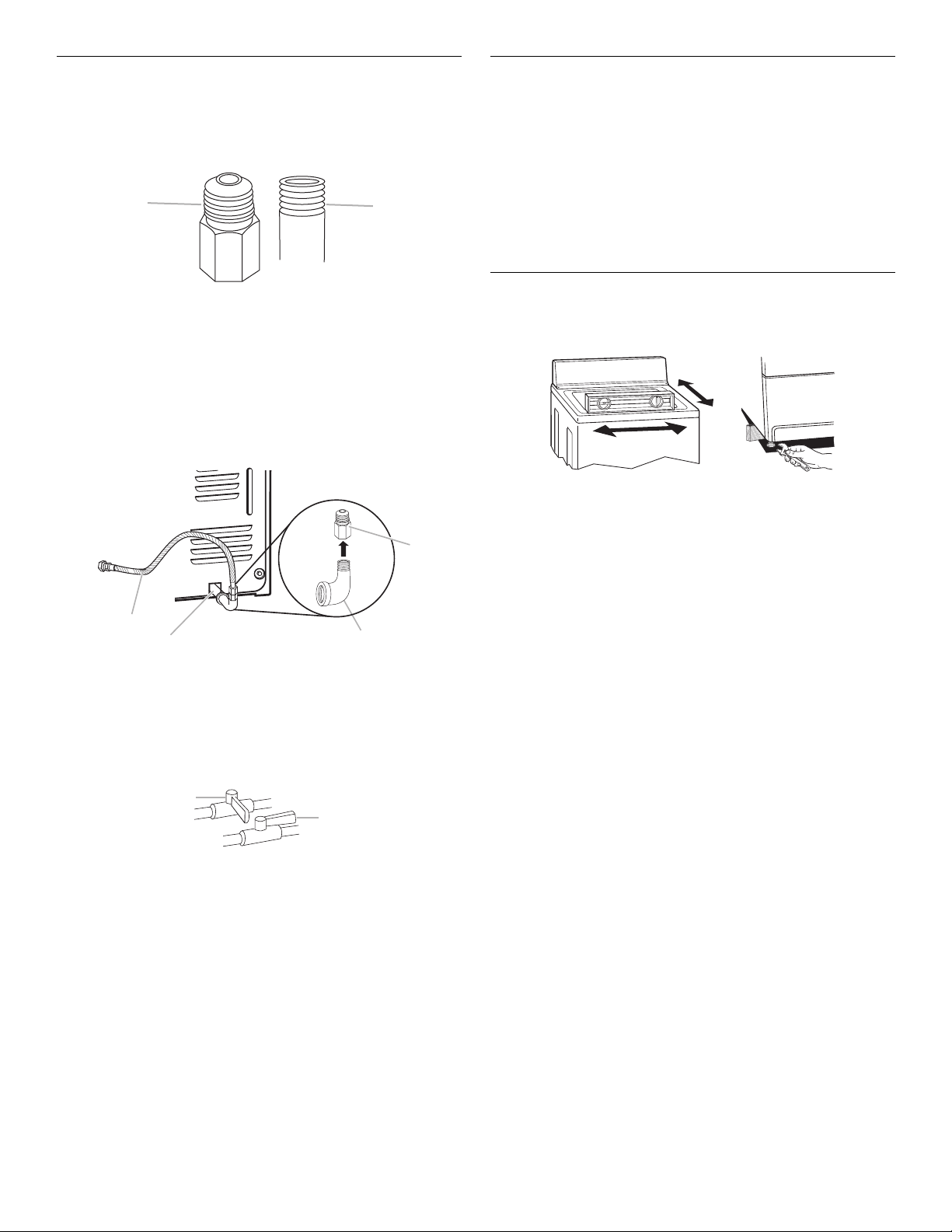

Parts supplied:

Remove parts package from dryer drum. Check that all parts were

included.

Parts needed:

Check local codes and consult gas supplier. Check existing gas

supply, electrical supply and venting, and read “Electrical

Requirements,” “Gas Supply Requirements” and “Venting

Requirements” before purchasing parts.

Mobile home installations require special parts (listed following) that

may be ordered by calling the dealer from whom you purchased

your dryer. For further information, please reference the front page of

the Dryer User Instructions.

■ Mobile Home Installation Kit. Ask for Part Number 346764.

■ Metal exhaust system hardware.

■ Level

■ Knife

■ Vent cla mps

■ Pipe-joint compound

resistant to LP gas

■ Caulking gun and compound

(for installing new exhaust

vent)

■ Pliers

■ Tap e m ea s ure

4 leveling legs

Location Requirements

You will need

■ A location that allows for proper exhaust installation. A gas dryer

must be exhausted to the outdoors. See “Venting

Requirements.”

■ A grounded electrical outlet located within 2 ft (610 mm) of either

side of the dryer. See “Electrical Requirements.”

■ A sturdy floor to support the dryer and a total weight (dryer and

load) of 200 lbs (90.7 kg). The combined weight of a companion

appliance should also be considered.

■ A level floor with a maximum slope of 1" (25 mm) under entire

dryer. (If slope is greater than 1" [25 mm], install Extended Dryer

Feet kit, Part No. 279810.) Clothes may not tumble properly and

models with automatic sensor cycles may not operate correctly

if dryer is not level.

Do not operate your dryer at temperatures below 45ºF (7ºC). At

lower temperatur

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will be

exposed to

Check code requirements. Some codes limit, or do not permit,

stallation of the dryer in garages, closets, mobile homes ,or

in

sleeping quarters. Contact your local building inspector.

NOTE: No

closet as a dryer.

es, the dryer might not shut off at the end of an

water and/or weather.

other fuel-burning appliance can be installed in the same

4

Page 5

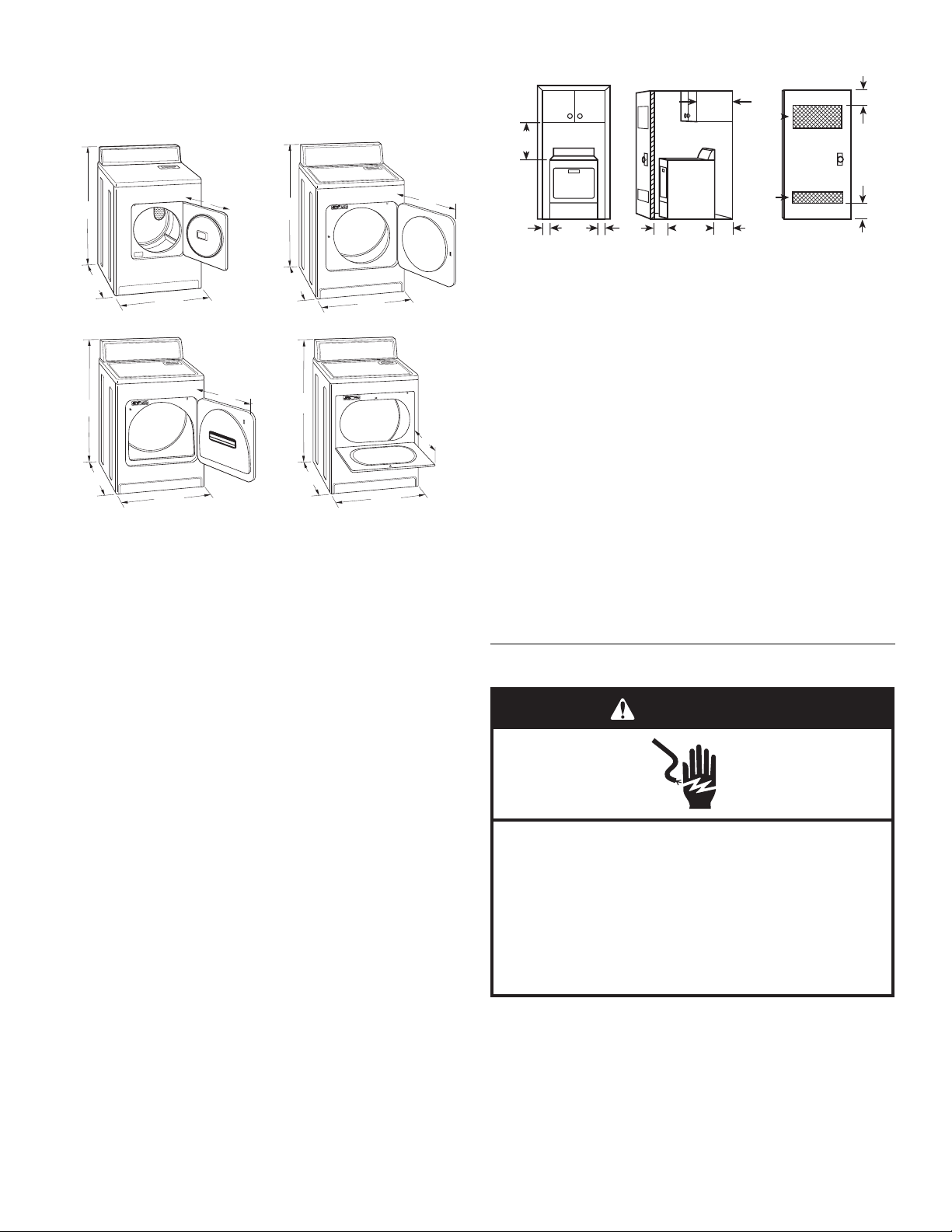

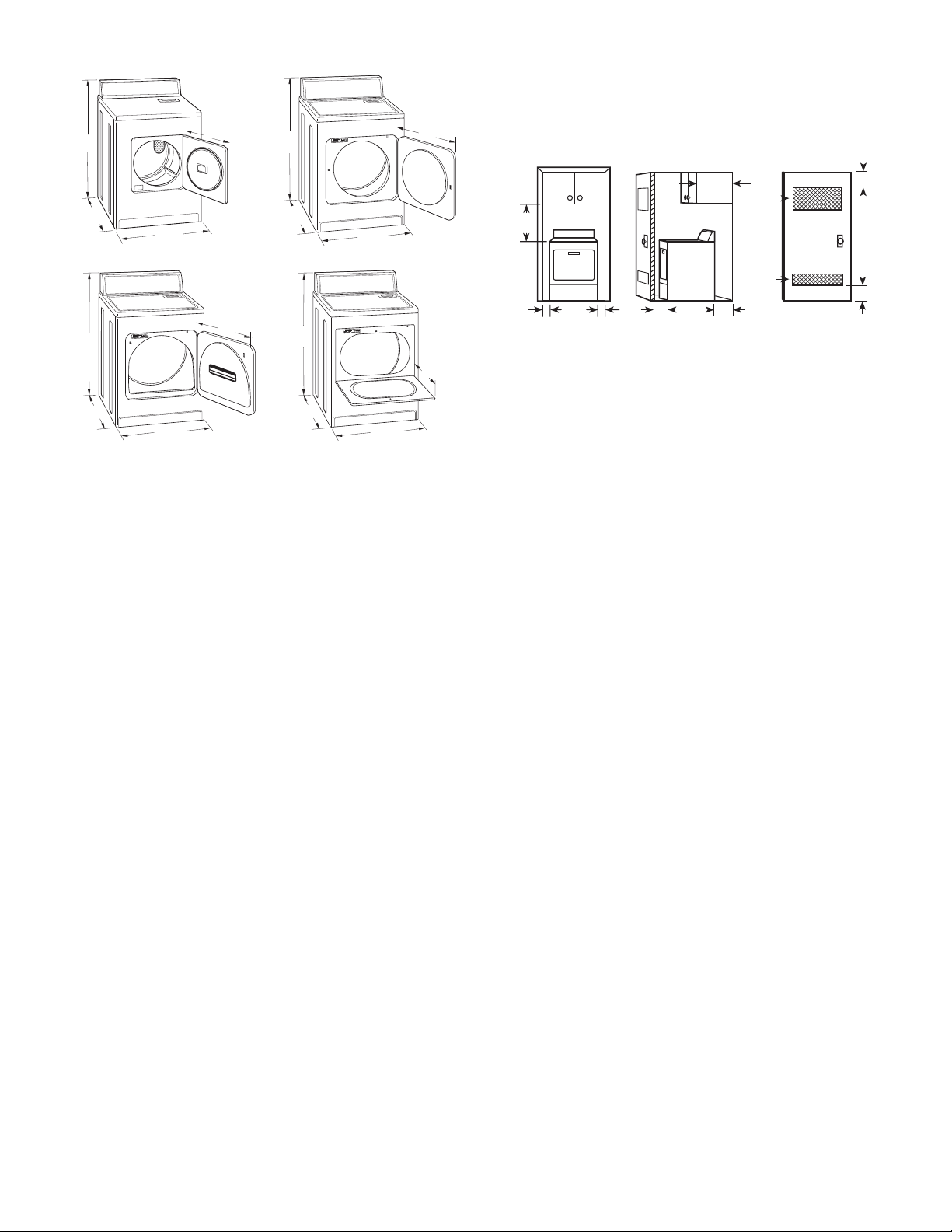

Installation Clearances

(

)

(

)

The location must be large enough to allow the dryer door to

open fully.

Dryer Dimensions

■ Companion appliance spacing should also be considered.

3"*

(76 mm

18"*

(457 mm)

14" max.*

mm)

(356

2

48 in.

*

(310 cm )

2

433/8"

1100mm)

*26"

(660mm)

29"

(737mm)

A

15¼"

(387.4mm)

3

/8"

43

(1100mm)

*27¾"

(705mm)

(737mm)

29"

B

22¾"

(578mm)

1"

(25 mm)

29"

(737 mm)

A

1"*

1"

(25 mm)

(25 mm)

27¾"

(705 mm)

B

5"*

(127 mm)

A. Recessed area

B. Side view - closet or confined area

C. Closet door with vents

2

*

24 in.

(155 cm )

2

3"*

(76 mm)

C

*Required spacing

Mobile Home - Additional Installation Requirements

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Constru

the Federal Standard for Mobile Home Construction and Safety, Title

24, HUD Part 280).

Mobile home installations require:

■ Metal exhaust system hardware, which is available for purchase

■ Mobile Home Installation Kit Part #346764. See “Tools and

■ Special provisions must be made in mobile homes to introduce

ction and Safety Standard, Title 24 CFR, Part 3280 (formerly

from your dealer.

Parts” section for information on ordering.

outside air into the dryer. The opening (such as a nearby

window) should be at least twice as large as the dryer exhaust

opening.

433/8"

1100mm)

27¾"

(705mm)

(737mm)

22¾"

29"

(578mm)

C

3

43

/

"

8

(1100 mm)

*27¾"

(705mm)

(737mm)

(349mm

29"

D

A. Small Opening Side-Swing Door

B. Large Opening Side-Swing Door

C. Wide Opening Side-Swing Door

D. Wide Opening Hamper Door

*Most installations require a minimum 5" (127 mm) clearance

13¾"

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

Installation spacing for recessed area or closet installation

Electrical Requirements

The following spacing dimensions are recommended for this

dryer. This dryer has been tested for spacing of 0" (0 mm)

arance on the sides and rear. Recommended spacing should

cle

WARNING

be considered for the following reasons:

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door, and

floor moldings.

■ Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Electrical Shock Hazard

Failure to follow these instructions can result in death,

re, or electrical shock.

5

Page 6

■ A 120 Volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is recommended that a separate circuit serving

only this dryer be provided.

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the

equipment-grounding conductor can result in a risk of

electric shock. Check with a qualied electrician or service

representative or personnel if you are in doubt as to

whether the dryer is properly grounded. Do not modify the

plug provided with the dryer: if it will not t the outlet, have

a proper outlet installed by a qualied electrician.

SAVE THESE INSTRUCTIONS

Gas Supply Requirements

WARNING

LP gas conversion:

Conversion must be made by a qu

No attempt shall be made to convert

alified technician.

the appliance from the gas

specified on the model/serial rating plate for use with a different gas

without consulting your gas company.

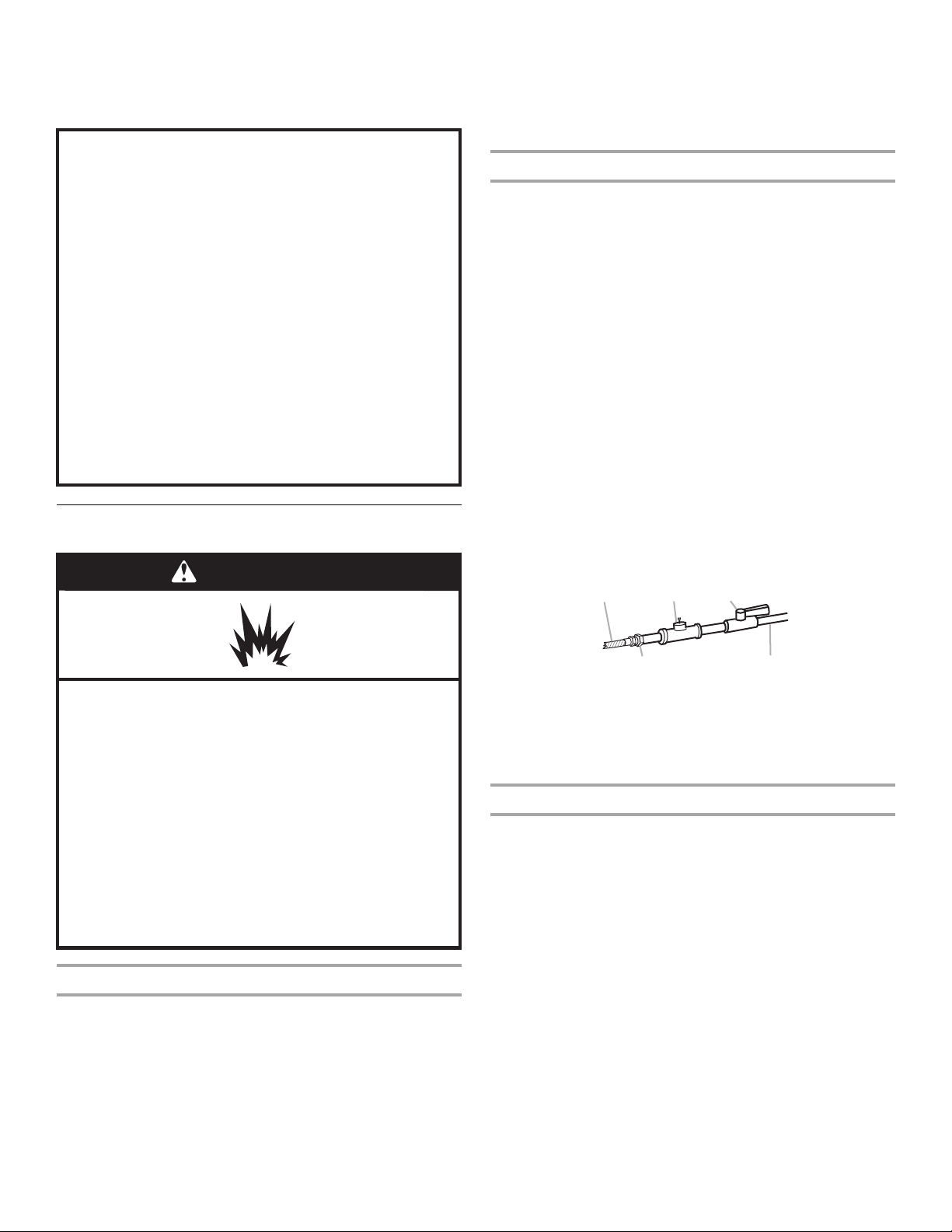

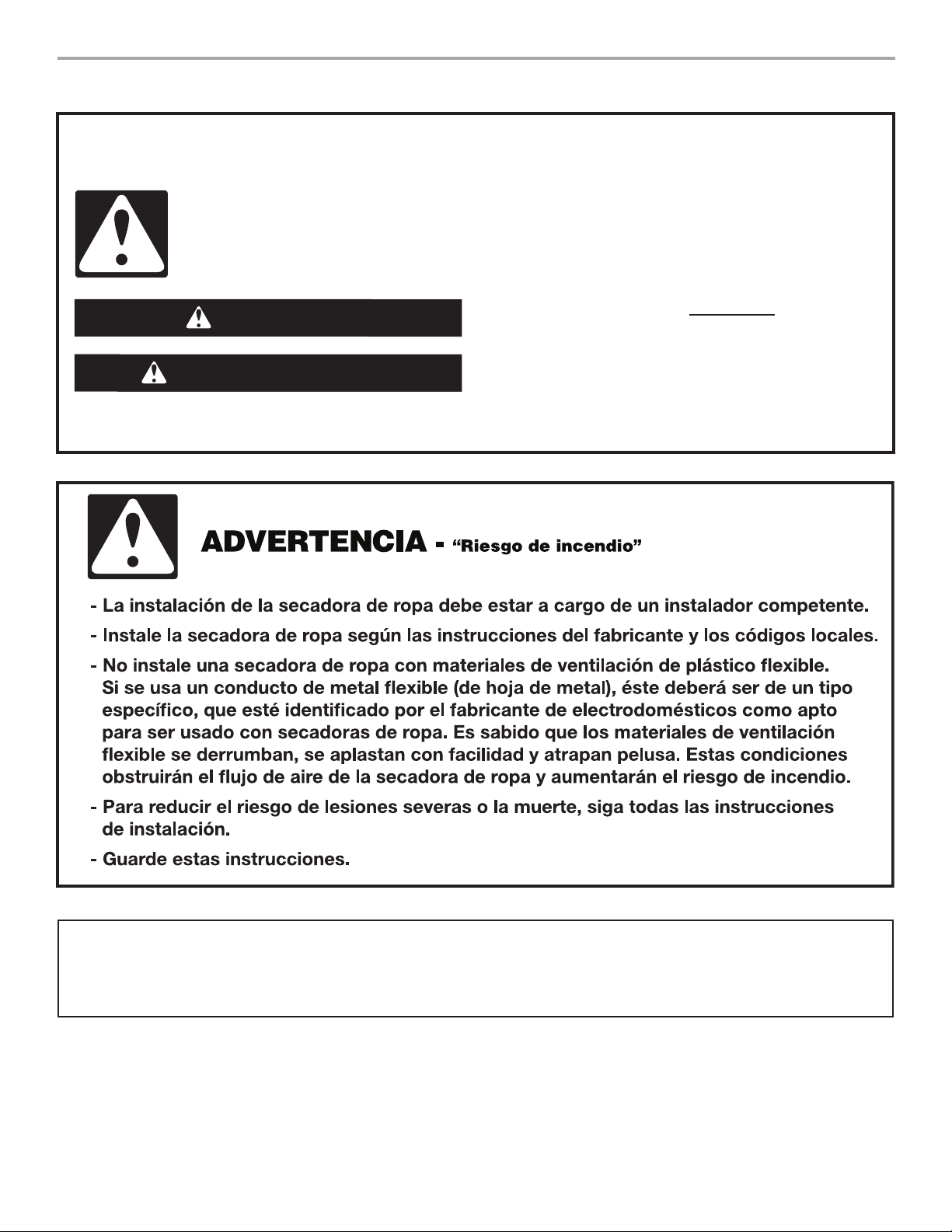

Gas Supply Line

■ Must include

for test gauge connection, immediately upstream of the gas

connection to the dryer. See illustration.

1

■

/2" IPS pipe is recommended.

3

■

/8" approved aluminum or copper tubing is acceptable for

lengths under 20 ft (6.1 m) if local codes and gas supplier

permit.

■ If you are using Natural gas, do not use copper tubing.

■ Lengths over 20 ft (6.1 m) should use larger tubing and a

different size adapter fitting.

■ If your dryer has been converted to use LP gas,

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft (6.1 m), use larger pipe.

NOTE: Pipe-joint

must be used. Do not use TEFLON

■ Must include a shutoff valve:

An individual manual shutoff valve must be installed within

six (6) feet (1.8 m) of the dryer in accordance with the National

Fuel G

The location should be easy to reach for opening and closing.

1

/8" NPT minimum plugged tapping accessible

compounds that resist the action of LP gas

as Code, ANSI Z223.1.

A

C

E

®†

tape.

3

/8" LP

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualied person make sure

gas pressure does not exceed 13" (330 mm) water

column.

Examples of a qualied person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or re.

Gas Type

Natural Gas:

This dryer is equipped for use with Natural gas. It is design-certified

by CSA International for LP (propane or butane) gases with

appropriate conversion.

■ Your dryer must have the correct burner for the type of gas in

your home. Burner information is located on the rating plate in

the door well of your dryer. If this information does not agree

with the type of gas available, contact your dealer or call the

phone numbers referenced on the front page of the Dryer User

Instructions.

B

A.3/8" flexible gas connector

3

/8" pipe to flare adapter fitting

B.

1

/8" NPT minimum plugged tapping

C.

1

D.

/2" NPT gas supply line

E. Gas shutoff valve

D

Gas supply connection requirements

■ Use an elbow and a

between the flexible gas connector and the dryer gas pipe, as

needed to avoid kinking.

■ Use only pipe-joint compound. Do not use TEFLON

■ This dryer must be connected to the gas supply line with a

listed flexible gas connector that complies with the standard

for connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

†

®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

3

/8" flare x 3/8" NPT adapter fitting

®†

tape.

6

Page 7

Burner Input Requirements:

If this is a new vent system

Elevations above 10,000 ft (3,048 m):

■ When installed above 10,000 ft (3,048 m) a 4% reduction of

the burner Btu rating shown on the model/serial number plate

is required for each 1,000 ft (305 m) increase in elevation.

Gas supply pressure testing

■ The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

½ psi.

Dryer Gas Pipe

■ The gas pipe that comes out through the rear of your dryer has a

3

/8" male pipe thread.

1¼"

(32mm)

A

A. 3/8" NPT dryer pipe

9¼"

(235mm)

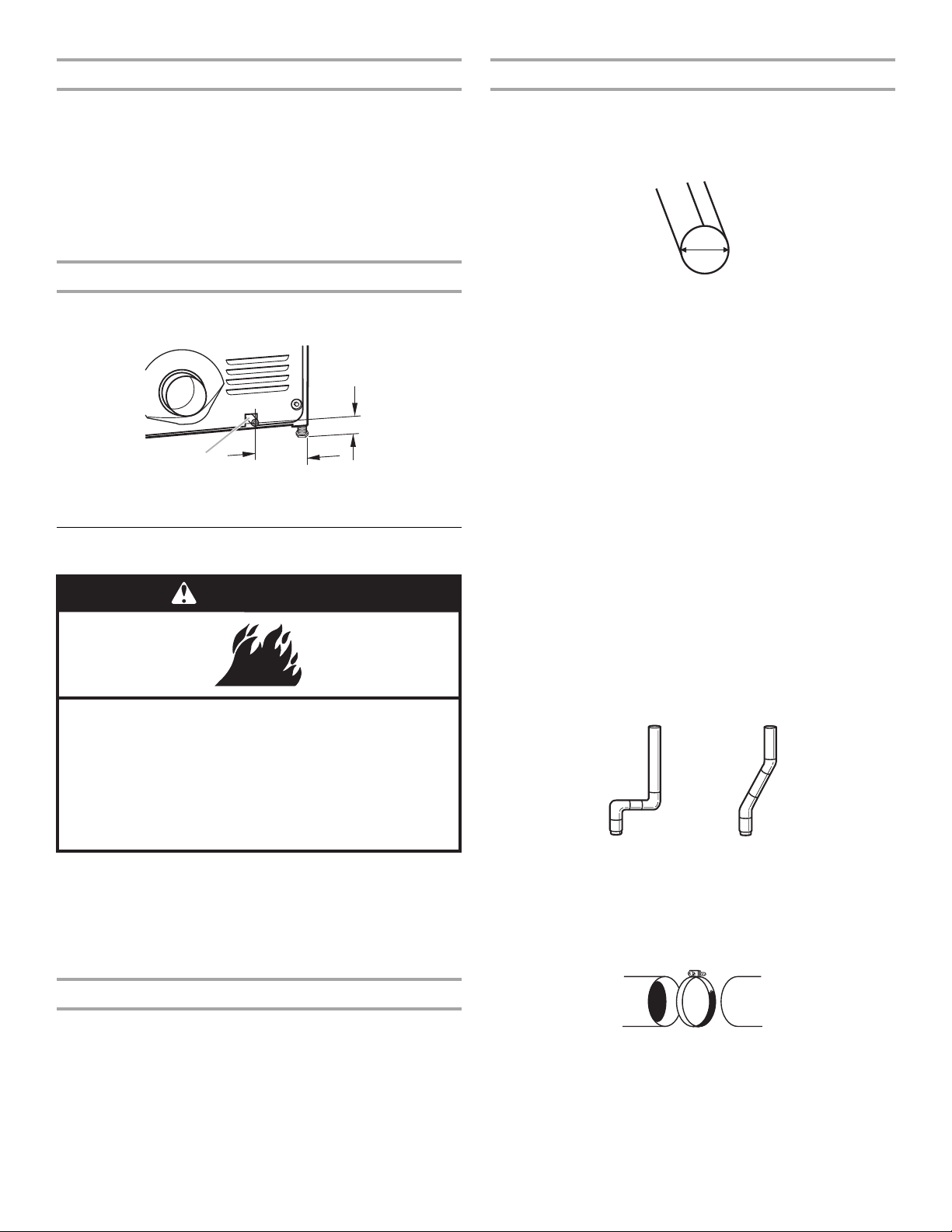

Venting Requirements

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or re.

Vent material

■ Use a heavy metal vent. Do not use plastic or metal foil vent.

■ 4" (102 mm) heavy metal exhaust vent and clamps must be

used. DURASAFE™ venting products are recommended.

4"

102 mm

4" (102 mm) heavy metal exhaust vent

DURASAFE™ vent products can be purchased from your dealer

or the toll-free number listed on the cover of the Dryer User

Instructions. For more information, see the “Assistance or

Service” section of the Dryer User Instructions.

Rigid metal vent

■ For best drying performance, rigid metal vents are

recommended.

■ Rigid metal vent is recommended to avoid crushing and kinking.

Flexible metal

■ Flexible metal vents are acceptable only if accessible for

cleaning.

■ Flexible metal vent must be fully extended and supported when

the dryer is in its final location.

■ Remove excess flexible metal vent to avoid sagging and kinking

that may result in reduced airflow and poor performance.

■ Do not install flexible metal vent in enclosed walls, ceilings or

floors.

■ The total length of flexible metal vent should not exceed

7¾ ft (2.4 m).

Elbows

45° elbows provide better airflow than 90° elbows.

vent

Good Better

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Obse

The dryer exhaust must not be connected into any gas vent,

ch

imney, wall, ceiling, attic, crawlspace, or a concealed space of a

building.

If using an existing vent system

■ Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

■ Replace any plastic or metal foil vent with rigid or flexible heavy

metal vent.

■ Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance. Only rigid or

flexible metal vent shall be used for exhausting.

rve all governing codes and ordinances.

Clamps

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws or

other fastening devices that extend into the interior of the duct

and catch lint. Do not use duct tape.

Clamp

7

Page 8

Exhaust

Recommended hood styles are shown here.

B

A

4"

(102 mm)

4"

(102 mm)

A. Louvered hood style

B. Box hood style

The angled hood style (shown here) is acceptable.

4"

(102 mm)

2½"

(64 mm)

■ An exhaust hood should cap the vent to keep rodents and

insects from entering the home.

■ Exhaust hood must be at least 12" (305 mm) from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks, or bushes, snow line, etc.).

■ Do not use an exhaust hood with a magnetic latch.

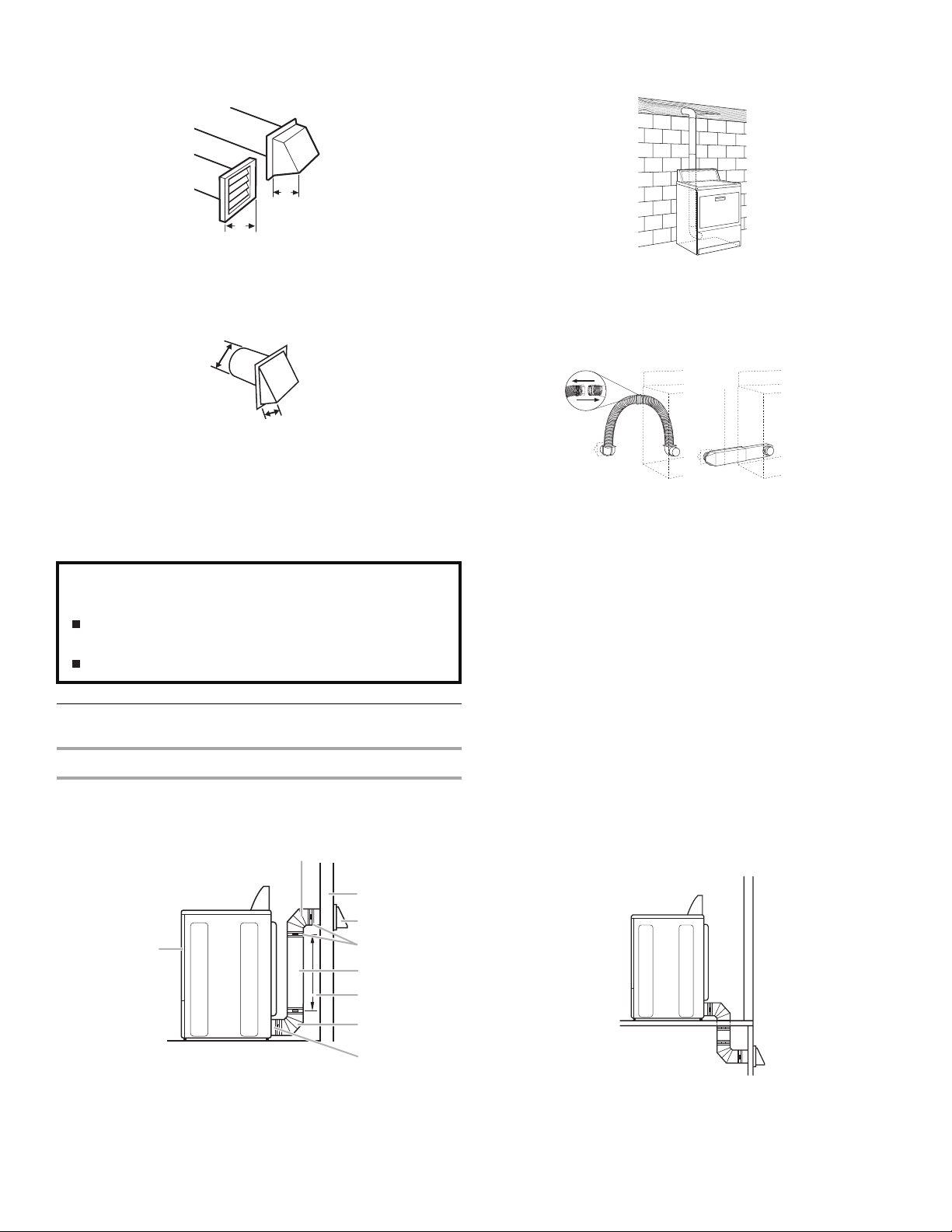

Standard exhaust installation with rigid metal or flexible metal vent

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation. Two close-clearance installations are shown. Refer

to the manufacturer’s instructions.

A

A. Over-the-top installation (also available with

one offset elbow)

B. Periscope installation

B

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Housecleaning problems and health problems.

Plan Vent System

Choose your exhaust installation type

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer. Other

installations are possible.

B

C

D

A

E

F

G

NOTE: The following kits for close clearance alternate installations

are available for purchase. Please see the “Assistance or Service”

section of the Dryer User Instructions.

■ Over-the-Top Installation:

Part Number 4396028

■ Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 4396037 - 0" (0 mm) to 18" (457 mm) mismatch

Part Number 4396011 - 18" (457 mm) to 29" (737 mm)

mismatch

Part Number 4396014 - 29" (737 mm) to 50" (1270 mm)

mismatch

Special provisions for mobil

e home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the m

obile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

8

B

H

E. Clamps

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Page 9

Determine vent path

■ Select the route that will provide the straightest and most direct

path outdoors.

■ Plan the installation to use the fewest number of elbows and

turns.

■ When using elbows or making turns, allow as much room as

possible.

■ Bend vent gradually to avoid kinking.

■ Use the fewest 90° turns possible.

Determine vent length and elbows needed for best drying performance

■ Use the Vent system chart below to determine type of vent

material and hood combinations acceptable to use.

NOTE: D

Vent system chart. Exhaust systems longer than those specified

will:

■ Shorten the life of the dryer.

■ Reduce performance, resulting in longer drying times and

The Vent system chart provides venting r

to achieve the best drying performance.

o not use vent runs longer than those specified in the

increased energy usage.

equirements that will help

Vent system chart

NOTE: Side and bottom exhaust installations have a 90º turn inside

the dryer. To determine maximum exhaust length, add one 90º turn

to the chart.

Number of 90º turns or elbows

0 Rigid met

1 Rigid met

Type of vent

Box or louvered hoods

al 64 ft (20 m) 58 ft (17.7 m)

al 54 ft (16.5 m) 48 ft (14.6 m)

Angled hoods

Install Leveling Legs

WARNING

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. To protect the floor, use a large flat piece of cardboard from the

dryer carton. Place cardboard under the entire back edge of the

dryer. See illustration.

2. Firmly grasp the body of the dryer (not the top or console panel).

Gently lay the dryer on the cardboard.

3. Examine the leveling legs. Find the diamond marking.

4. Screw the legs into the leg holes by hand. Use a wrench to finish

turning the legs until the diamond marking is no longer visible.

5. Place a carton corner post under each of the 2 dryer back

corners. Stand the dryer up. Slide the dryer on the corner posts

until it is close to its final location. Leave enough room to connect

the exhaust vent.

6. Once con

corner posts and cardboard.

nection is made and dryer is in final location, remove

2 Rigid met

3 Rigid met

4 Rigid met

al 44 ft (13.4 m) 38 ft (11.6 m)

al 35 ft (10.7 m) 29 ft (8.8 m)

al 27 ft (8.2 m) 21 ft (6.4 m)

Install Vent System

1. Install exhaust hood. Use caulking compound to seal exterior wall

opening around exhaust hood.

onnect vent to exhaust hood. Vent must fit inside exhaust hood.

2. C

Secure vent to exhaust hood with 4" (102 mm) clamp.

3. Run

vent to dryer location. Use the straightest path possible. See

“Determine vent path” in “Plan Vent System.” Avoid 90º turns.

Use clamps to seal all joints. Do not use duct tape, screws, or

other fastening devices that extend into the interior of the vent to

secure vent, which can catch lint.

For mobile home use

Gas dryers must be securely fastened to the floor.

Mobile home installations require a Mobile Home Installation Kit.

For information on ordering please reference the Dryer User

Instructions.

9

Page 10

Make Gas Connection

A

1. Remove the red cap from the gas pipe.

2. Using a wrench to tighten, connect the gas supply to the dryer.

Use pipe-joint compound on the threads of all non-flared male

fittings. If flexible metal tubing is used, be sure there are no kinks.

B

Connect Vent

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is clean.

The dryer vent must fit over the dryer exhaust outlet and inside the

exhaust hood. Check that the vent is secured to exhaust hood

with a 4" (102 mm) clamp.

ve dryer into its final location. Do not crush or kink vent.

2. Mo

gas models) Check that there are no kinks in the flexible gas

3. (On

line.

4. Once the exha

posts and cardboard.

ust vent connection is made, remove the corner

A. Flared male thread

B. Non-flared male thread

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to the action of LP gas. Do not use

TEFLON®† tape.

A combination of pipe fittings must be used to connect the dryer

to the existing gas line. Shown is a recommended connection.

Your connection may be different, according to the supply line

type, size, and location.

D

A

B

A.3/8" flexible gas connector

3

/8" dryer pipe

B.

3

C.

/8" to 3/8" pipe elbow

3

/8" pipe-to-flare adapter fitting

D.

C

Level Dryer

Check the levelness of the dryer. Check levelness first side to side,

then front to back.

If the dryer is not level, prop up the dryer using a wood block. Use a

wrench to adjust the legs up or down and check again for levelness.

3. Open the shutoff valve in the supply line. The valve is open when

the handle is parallel to the gas pipe.

A

B

A. Closed valve

B. Open valve

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any leak

found.

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

10

Page 11

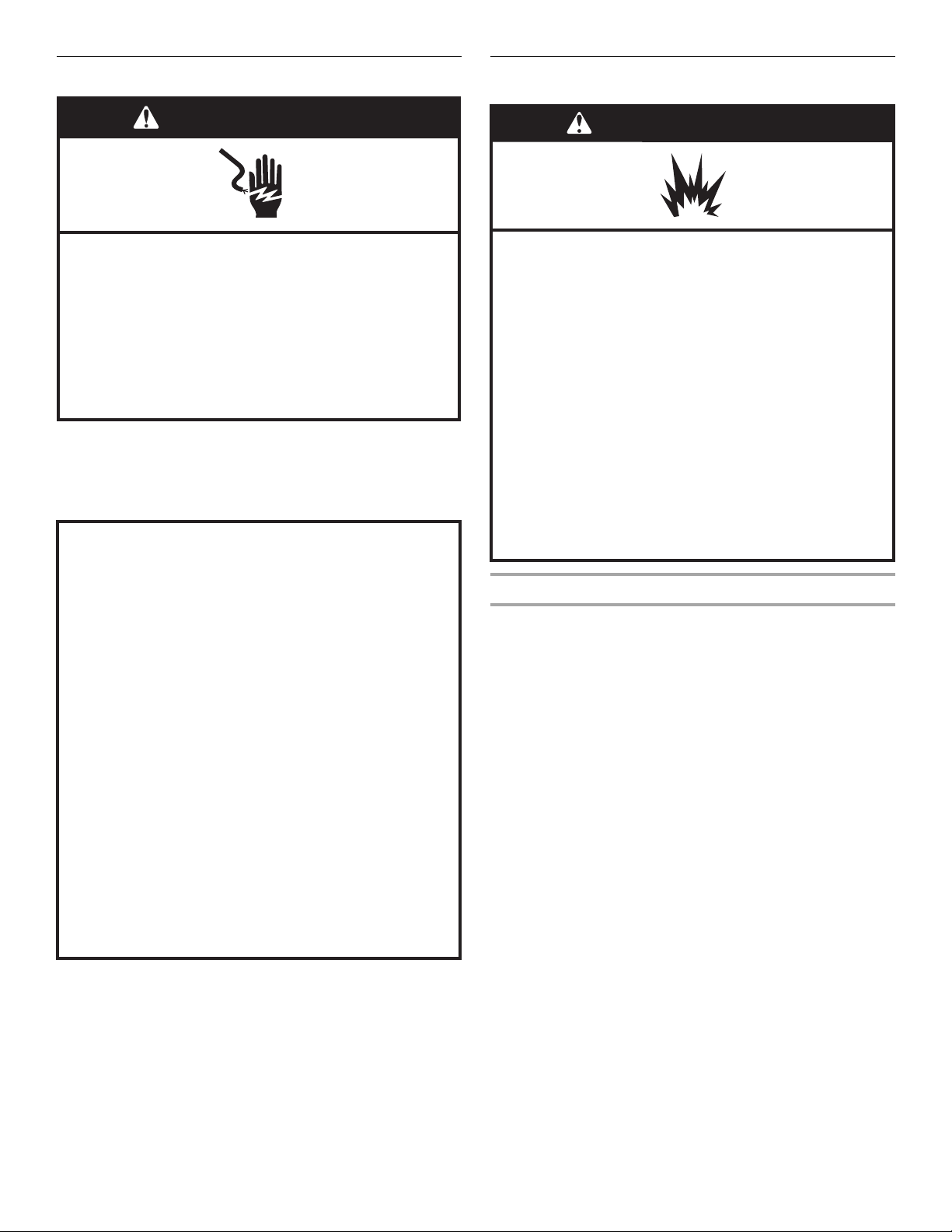

Reverse Door Swing (Optional)

You can change your door swing from a right-side opening to a leftside opening, if desired.

Reversible Large Side-Swing Door

A

B

3. Lif

t door until top screws in cabinet are in large part of hinge slot.

Pull door forward off screws. Set door (handle side up) on top of

dryer. Remove top screws from cabinet.

4. Remove scr

5. Remove screws at top, bottom and side of door (4 screws).

Holding door over towel on dryer, grasp sides of outer door and

gently lift to separate it from inner door. Do not pry apart with putty

knife. Do not pull on door seal or plastic door catches.

6. Be certain to keep cardboard spacer centered between doors.

Reattach outer door panel to inner door panel so handle is on the

side where hinges were just removed.

ews attaching hinges to door.

D

1. Place towel (A) on top of dryer to protect surface.

2. Open d

3. Li

4. Use a small, flat-

5. Insert scr

6. Close door and check that door strike aligns with door catch (B). If

ryer door. Remove bottom screws from cabinet side of

hinges (C). Loosen (do not remove) top screws from cabinet side

of hinges.

ft door until top screws in cabinet are in large part of hinge slot.

Pull door forward off screws. Set door on top of dryer. Remove

top screws from cabinet.

blade screwdriver to gently remove 4 hinge hole

plugs (D) on left side of cabinet. Insert plugs into hinge holes on

right-hand side of cabinet.

ews into bottom holes on left side of cabinet. Tighten

screws halfway. Position door so large end of door hinge slot is

over screws. Slide door up so screws are in bottom of slots.

Tighten screws. Insert and tighten top screws in hinges.

needed, slide door catch left or right within slot to adjust

alignment.

C

Reversible Super Wide Side-Swing Door

A

B

7. Attach door hinges to dryer door so that the larger hole is at the

bottom of the hinge.

8. Remo

9. Inser

10. Remove door strike plug (B). Insert the door strike you removed in

11. Close

ve door strike (E) from cabinet. Use a small, flat-blade

screwdriver to gently remove 4 hinge hole plugs (F) on left side of

cabinet. Insert plugs into hinge holes on right side of cabinet.

t screws into bottom holes on left side of cabinet. Tighten

screws halfway. Position door so large end of door hinge slot is

over screws. Slide door up so screws are in bottom of slots.

Tighten screws. Insert and tighten top screws in hinges.

Step 8 into hole and secure with screw. Insert door strike plug into

original door strike hole and secure with screw.

door and check that door strike aligns with door catch (C). If

it is needed, slide door catch left or right within slot to adjust

alignment.

C

E

F

D

1. Place towel (A) on top of dryer to protect surface.

2. Open d

ryer door. Remove bottom screws from cabinet side of

hinges (D). Loosen (do not remove) top screws from cabinet side

of hinges.

11

Page 12

Complete Installation

1. Check that all parts are now installed. If there is an extra part, go

back through the steps to see which step was skipped.

2. Check that you

3. Check

4. Check that the dryer is level. See “Level Dryer

the dryer’s final location. Be sure the vent is not crushed or

kinked.

have all of your tools.

.”

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

re, or electrical shock.

10. Se

lect a Timed Dry heated cycle, and start the dryer. Do not select

the Air Only Temperature setting.

If the dryer

■ Dryer is plugged into a grounded 3 prong outlet.

■ Electrical supply is connected.

■ Household fuse is intact and tight, or circuit breaker has not

tripped.

■ Dryer door is closed.

11. W

hen the dryer has been running for 5 minutes, open the dryer

door and feel for heat. If you feel heat, cancel cycle and close

door. If you do not feel heat, turn off the dryer and check that the

gas supply line shutoff valve is open.

■ If the gas supply line shutoff valve is closed, open it, then

repeat the 5-minute test as outlined above.

■ If the gas supply line shutoff valve is open, contact a

qualified technician.

will not start, check the following:

5. Plug into a grounded 3 prong outlet. Turn on power.

6. Remo

7. Dispose of/r

8. Read “Dryer Use” in the Dryer User Instructions.

9. Wipe the dry

ve any protective film or tape remaining on the dryer.

ecycle all packaging materials.

er drum interior thoroughly with a damp cloth to

remove any dust.

12

Page 13

SEGURIDAD DE LA SECADORA

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el símbolo de advertencia de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras signican:

PELIGRO

ADVERTENCIA

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Antes de guardar o descartar su vieja secadora, quítele la puerta.

GUARDE ESTAS INSTRUCCIONES

13

Page 14

En el estado de Massachusetts se aplican las siguientes instrucciones de instalación:

■

Las instalaciones y reparaciones se deben efectuar por un contratista, plomero o gasista calicado o licenciado por el estado

de Massachusetts.

■

Si se usa una válvula de bola, debe ser un tipo de manigueta T.

■

Si se usa un conector de gas exible no debe exceder de 3 pies.

14

Page 15

INSTRUCCIONES DE INSTALACIÓN

Herramientas y piezas

Reúna las herramientas y piezas necesarias antes de comenzar la

instalación. Lea y siga las instrucciones provistas con cualquiera

de las herramientas enlistadas aquí.

■ Llave para tubos de 8" ó 10"

■ Llave de tuercas ajustable de

8" ó 10" (para conexiones de

gas)

■ Destornillador de hoja plana

■ Llave de tuercas ajustable

que se abra a 1" (25 mm) o

un

a llave de cubo de cabeza

hexagonal (para regular las

patas de la secadora)

■ Llave para tuercas o llave de

cubo de ¼" (se recomienda)

Piezas suministradas:

Retire el paquete de piezas del tambor de la secadora. Verifique que

estén todas las piezas.

4 patas niveladoras

Piezas para adquirir:

Verifique los códigos locales y con la compañía abastecedora de

gas. Verifique el suministro de gas existente, el suministro eléctrico y

la ventilación y lea “Requisitos eléctricos”, “Requisitos de suministro

de gas” y “Requisitos de ventilación” antes de comprar las piezas.

Las instalaciones en casas rodantes requieren piezas especiales

(enumeradas a continuación) que se pueden ordenar llamando al

distribuidor donde compró la secadora. Para obtener más

información, refiérase a la portada de sus Instrucciones para el

usuario de la secadora.

■ Juego de instalación en casas rodantes. Pida la Pieza Número

346764.

■ Herramientas del sistema de escape de metal.

■ Nivel

■ Abrazaderas para ducto

■ Cuchillo

■ Pegamento para uniones

de tuberías resistente a

gas LP

■ Pistola y masilla para

calafateo (para instalar el

nuevo ducto de escape)

■ Alicates

■ Cinta para medir

Requisitos de localización

ADVERTENCIA

Peligro de Explosión

Mantenga los materiales y vapores inamables, como

la gasolina, lejos de la secadora.

Coloque la secadora a un mínimo de 460 mm sobre

el piso para la instalación en un garaje.

No seguir estas instrucciones puede ocasionar

la muerte, explosión o incendio.

Usted necesitará

■ Una localización que permita una instalación adecuada del

ducto de escape. La secadora a gas debe tener una salida de

ventilación hacia el exterior. Consulte “Requisitos de

ventilación”.

■ Un contacto con conexión a tierra ubicado a unos 2 pies

(610 mm) de cualquiera de los

“Requisitos eléctricos”.

■ Un piso resistente para soportar la secadora con un peso total

(secadora y carga) de 200 lbs (90,7 kg). También se debe

considerar espacio adicional para otro electrodoméstico que le

acompañe.

■ Un piso nivelado con un declive máximo de 1" (25 mm) debajo

de la secadora completa. (Si el declive es mayor que 1" [25

mm], instale el Juego de extensión de patas de la secadora,

Pieza No. 279810.) La ropa quizás no rote adecuadamente y los

modelos con ciclos del sensor automático posiblemente no

funcionen debidamente si la secadora no está nivelada.

No ponga a funcionar su secadora a temperaturas

(7ºC). A temperaturas inferiores, es posible que la secadora no se

apague al final de un ciclo automático. Los tiempos de secado

pueden prolongarse.

No debe instalarse ni guardarse la secadora en un área en donde

pu

eda estar expuesta al agua y/o a la intemperie.

Verifique los requisitos de los códigos

permiten, la instalación de la secadora en garajes, clósets, casas

rodantes o en dormitorios. Póngase en contacto con el inspector de

construcciones de su localidad.

NOTA: No se pu

ede instalar otro electrodoméstico que use

combustible en el mismo clóset en que se encuentra la secadora.

lados de la secadora. Vea

inferiores a 45ºF

. Algunos códigos limitan, o no

Espacios para la instalación

La ubicación debe ser lo suficientemente grande para poder abrir

completamente la puerta de la secadora.

15

Page 16

)

Dimensiones de la secadora

)

433/8"

1100mm)

*26"

(660mm)

433/8"

1100mm)

27¾"

(705mm)

15¼"

29"

(737mm)

(387.4mm)

43

(1100mm)

*27¾"

(705mm)

A

22¾"

(737mm)

29"

(578mm)

C

A. Puerta chica de apertura lateral

B. Puerta grande de apertura lateral

C. Puerta ancha de a

D. Puerta ancha de a

3

/8"

3

43

/

"

8

(1100 mm)

*27¾"

(705mm)

pertura lateral

pertura vertical

(737mm)

(737mm)

29"

B

29"

D

22¾"

(578mm)

13¾"

(349mm

*La mayoría de las instalaciones requieren un espacio mínimo de

5" (127 mm) detrás de la secadora para acomodar el ducto de

pe con codo. Vea “Requisitos de ventilación”.

esca

Espacio para la instalación en un lugar em

potrado o en un clóset

Se recomiendan las siguientes medidas de espacio para esta

secadora. Esta

secadora ha sido puesta a prueba para espacios de

0" (0 mm) en los costados y en la parte posterior. El espacio

recomendado debe ser considerado por los siguientes motivos:

■ Debe considerarse el espacio adicional para facilitar la

instalación y el servicio técnico.

■ Se podrían necesitar espacios libres adicionales para las

molduras de la pared, puerta y piso.

■ Se debe considerar agregar espacio adicional en todos los

lados de la secadora para reducir la transferencia de ruido.

■ Para la instalación en clóset, con una puerta, se requieren

aberturas de ventilación mínimas en la parte superior e inferior

de la puerta. Se aceptan puertas tipo persianas con aberturas

de ventilación equivalentes.

■ También se debe considerar espacio adicional para otro

electrodoméstico que le acompañe.

3"*

(76 mm

3"*

(76 mm)

18"*

(457 mm)

1"

(25 mm)

29"

(737 mm)

A

1"*

1"

(25 mm)

(25 mm)

14" max.*

(356

27¾"

(705 mm)

B

48 in.

mm)

(310 cm )

24 in.

(155 cm )

5"*

(127 mm)

2

*

2

2

*

2

C

A. Lugar empotrado

B. Vista lateral - clóset o lugar confinado

C. Puerta del clóset con orificios de ventilación

*Espacio necesario

Requisitos de instalación adicionales para las casas rodantes

Esta secadora es apropiada para instalaciones en casas rodantes.

instalación debe ajustarse al Estándar de seguridad y

La

construcción de casas fabricadas, Título 24 CFR, Parte 3280

(anteriormente conocido como Estándar federal para la seguridad y

construcción de casas rodantes, Título 24, HUD Parte 280).

Las instalaciones en casas rodantes necesitan:

■ Herramientas del sistema de escape de metal, que se

encuentran disponibles para ser compradas en su

distribuidor.

■ Juego para la Instalación en casas rodantes, Pieza número

346764. Vea la sección “Herramientas y Piezas” para la

información sobre cómo ordenar.

■ Se deben tomar medidas especiales en el caso de casas

rodantes para introducir el aire del exterior en la secadora. La

abertura (como la de una ventana adyacente) deberá ser por lo

menos el doble de tamaño que la abertura de ventilación de la

secadora.

16

Page 17

Requisitos eléctricos

Requisitos del suministro de gas

ADVERTENCIA

Peligro de Choque Eléctrico

Conecte a un contacto de pared de conexión a tierra

de 3 terminales.

No quite la terminal de conexión a tierra.

No use un adaptador.

No use un cable eléctrico de extensión.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque eléctrico.

■ Se necesita un suministro eléctrico de 120 voltios, 60 hertzios,

CA solamente, de 15 ó 20 amperios y protegido con fusible. Se

r

ecomienda el empleo de un fusible retardador o cortacircuitos.

Asimismo se recomienda el uso de un circuito independiente

que preste servicio únicamente a esta secadora.

INSTRUCCIONES PARA LA CONEXIÓN A TIERRA

■

Para la conexión de una secadora mediante cable

eléctrico conectado a tierra:

Esta secadora debe estar conectada a tierra. En el caso de

funcionamiento defectuoso o avería, la conexión a tierra

reducirá el riesgo de choque eléctrico al proporcionar una

vía de menor resistencia para la corriente eléctrica. Esta

secadora está equipada con un cable que cuenta con un

conductor para la conexión a tierra del equipo y un enchufe

de conexión a tierra. El enchufe debe conectarse en un

contacto apropiado, que esté debidamente instalado y

conectado a tierra de acuerdo con todos los códigos y

ordenanzas locales.

ADVERTENCIA: La conexión indebida del

conductor para la conexión a tierra del equipo puede

ocasionar un riesgo de choque eléctrico. Verique con un

electricista, representante o personal de servicio técnico

calicado para asegurarse de que la conexión a tierra de la

secadora sea apropiada. No modique el enchufe

proporcionado con la secadora. Si no encaja en el

contacto, contrate un electricista calicado para que instale

un contacto adecuado.

GUARDE ESTAS INSTRUCCIONES

ADVERTENCIA

Peligro de Explosión

Use una línea de suministro de gas nueva con

aprobación CSA Internacionál.

Instale una válvula de cierre.

Apriete rmemente todas las conexiones de gas.

Si se conecta a un suministro de gas L.P., la presión no

debe exceder una columna de agua de 330 mm

(13 pulg) y debe ser vericada por una persona

calicada.

Ejemplos de una persona calicada incluyen:

personal de servicio del sistema de calefacción con

licencia,

personal autorizado de la compañía de gas, y

personal autorizado para dar servicio.

No seguir estas instrucciones puede ocasionar

la muerte, explosión o incendio.

Tipo de gas

Gas natural:

Esta secadora está equipada par

diseño está certificado por la CSA Internacional para gases LP

(de propano o butano) con la conversión apropiada.

■ Su secadora debe tener el quemador adecuado para el tipo

de gas que tiene en su casa. La información respecto al

quemador está ubicada en la placa de clasificación que está

en la cavidad de la puerta de su secadora. Si esta

información no está de acuerdo con el tipo de gas disponible,

póngase en contacto con el distribuidor o llame a los

números de teléfono mencionados en la portada de las

Instrucciones para el usuario de la secadora.

Conversión de gas

La conversión deberá llevarla a

No se deberá hacer intento alguno p

especificado en la placa de clasificación del modelo/de la serie

de este artefacto por el uso de un gas distinto sin consultar con

el abastecedor de gas.

LP:

a uso con gas natural. Su

cabo un técnico calificado.

ara convertir el uso del gas

17

Page 18

La línea de suministro de gas

A

Requisitos para la conexión del suministro de gas

■ Debe incluir una derivación tapada NPT de por lo menos

1

/8"

accesible para la conexión del manómetro de prueba,

inmediatamente arriba de la conexión de suministro de gas a

la secadora (vea la ilustración).

■ Se recomienda un tubo IPS de

■ Si los códigos locales y el proovedor de gas lo permite, es

aceptable una tubería de aluminio o cobre aprobada de

1

/2".

3

/8"

para longitudes menores de 20 pies (6,1 m).

■ Si usted está usando gas natural, no use tubería de cobre.

■ Las longitudes superiores a los 20 pies (6,1 m) deberán usar

tuberías más largas y un accesorio adaptador de tamaño

distinto.

■ Si su secadora ha sido convertida para usar gas LP, se puede

usar tubería de cobre compatible de LP de

3

/8". Si la longitud

total de la línea de suministro es mayor que 20 pies (6,1 m),

use un tubo más largo.

NOTA: Se deben

que resistan la acción del gas LP. No use cinta de TEFLON

■ Debe incluir una válvula de cierre:

usar pegamentos para uniones de tuberías

®†

Debe instalarse una válvula de cierre individual manual a una

distancia de no más

de 6 pies (1,8 m) de la secadora de

acuerdo con el Código Nacional de Gas combustible

(National Fuel Gas Code), ANSI Z223.1.

La válvula deberá ubicarse en un lugar donde se pueda

alcanzar con facilidad para cerrarla y abrirla.

C

E

■ Use un codo y un accesorio adaptador abocinado NPT de

3

/8" por 3/8" entre el conector de gas flexible y el tubo de gas

de la secadora, para evitar que se doblen.

■ Use solamente compuesto para juntas de tubería. No utilice

cinta TEFLON

■ Esta secadora debe conectarse a la línea de suministro de

®†

.

gas con un conector de gas flexible que cumpla con las

normas para conectores de electrodomésticos a gas, ANSI

Z21.24.

Requisitos de entrada del quemador

Elevaciones superiores a 10.000 pies (3.048 m):

■ Si se instala la secadora a un nivel superior a los 10.000 pies

(3.048 m) de altitud, se requiere una reducción de categoría

de Btu del 4% del quemador, que se muestra en la placa del

número de modelo/serie, por cada incremento de 1.000 pies

.

(305 m) de altitud.

Prueba de presión del suministro de gas

■ Durante pruebas de presión a presiones mayores de

½ lb/pulg², la secadora debe s

er desconectada del sistema

de tubería del suministro de gas.

El tubo de gas de la secadora

■ El tubo de gas que sale por la parte posterior de su secadora

tiene una rosca macho para tubería de

3

/8".

B

A. Conector de gas flexible de

B. Accesorio adaptador

C. Derivación tapada NPT por lo menos de

D. Línea de suministro de gas NPT de

E. Válvula de cierre del gas

3

/8"

abocinado de

D

3

/8"

1

/2"

1¼"

(32mm)

1

/8"

A

A.Tubo NPT de

9¼"

(235mm)

3

/8" de la secadora

†®TEFLON es una marca registrada de E.I. Du Pont De Nemours and Company.

18

Page 19

Requisitos de ventilación

ADVERTENCIA

Peligro de Incendio

Use un ducto de escape de metal pesado.

No use un ducto de escape de plástico.

No use un ducto de escape de aluminio.

No seguir estas instrucciones puede ocasionar

la muerte o incendio.

ADVERTENCIA: Para reducir el riesgo de incendio, esta

secadora DEBE VENTILARSE HACIA EL EXTERIOR.

IMPORTANTE: Observe todas las normas y ordenanzas vigentes.

El ducto de escape de la secadora no debe conectarse a ningún

ducto de escape de gas, chimenea, pared, techo, ático, espacio

angosto o el espacio oculto de un edificio.

Si usa un sistema de ventilación existente

■ Limpie la pelusa que está en toda la longitud del sistema y

asegúrese de que la capota de ventilación no esté obstruida con

pelusa.

■ Reemplace cualquier ducto de escape de plástico o de hoja de

metal por uno de metal pesado rígido o flexible.

■ Vuelva a consultar el cuadro del sistema de ventilación.

Modifique el sistema de ventilación existente si fuera necesario

para lograr el mejor rendimiento de la secadora. Deberá usarse

solamente un ducto de metal rígido o flexible para el escape.

Si este es un nuevo sistema de ventilación

Material de ventilación

■ Use un ducto de escape de metal pesado. No use ducto de

escape de plástico o de hoja de metal.

■ Se debe usar un ducto de escape de metal pesado de

4" (102 mm) y abrazaderas. Los productos de ventilación

DURASAFE™ son recomendables.

Ducto de escape de m

■ Los ductos de escape de metal flexible son aceptables

etal flexible

únicamente si se puede acceder a los mismos para limpiarlos.

■ El ducto de escape de metal flexible debe extenderse y

sostenerse por completo cuando la secadora está en su

ubicación final.

■ Quite el exceso del ducto de metal flexible para evitar que se

doble y se tuerza, lo cual podría dar lugar a una reducción del

flujo de aire y a un rendimiento insuficiente.

■ No instale el ducto de escape de metal flexible en paredes,

techos o pisos encerrados.

■ La longitud total del ducto de metal flexible no deberá exceder

los 7¾ pies (2,4 m).

Codos

Los codos de 45° proveen un mejor flujo de aire que los codos

de 90°.

Bien Mejor

Abrazaderas

■ Utilice abrazaderas para sellar todas las juntas.

■ No debe conectarse ni asegurarse el ducto de escape con

tornillos ni con ningún otro dispositivo de sujeción que se

extienda hacia el interior de dicho ducto y atrape pelusa. No

utilice cinta adhesiva para conductos.

Abrazadera

Respiradero

Los estilos recomendados de capotas de ventilación se ilustr

an

aquí.

B

A

4"

102 mm

Ducto de escape de metal pesado de 4" (102 mm)

Los productos de ventilación DURASAFE™ pueden adquirirse

con su distribuidor o llamando al número gratis que aparece en

la portada de las Instrucciones para el usuario de la secadora.

Para más información, vea la sección “Ayuda o servicio técnico”

de las instrucciones para el usuario de la secadora.

Ducto de escape de metal

■ Para un óptimo rendimiento de secado, se recomiendan ductos

rígido

de escape de metal rígido.

■ Se recomienda el ducto de escape de metal rígido para evitar

que se aplaste o se tuerza.

4"

(102 mm)

4"

(102 mm)

A. Estilo de capota con ventilación tipo persiana

B. Estilo de capota con ventilación tipo caja

El estilo de capota de ventilación angular (que se ilustra aquí) es

aceptable.

4"

(102 mm)

2½"

(64 mm)

19

Page 20

■ Una capota de ventilación debe tapar el ducto de escape para

evitar el ingreso de roedores e insectos a la casa.

■ La capota de ventilación debe estar por lo menos a

12" (305 mm) de distancia del piso o

de cualquier objeto que

pudiese estar en el trayecto del ducto de escape (como flores,

rocas o arbustos, límite de nieve, etc).

■ No use capotas de ventilación con pestillos magnéticos.

La ventilación inadecuada puede ocasionar la

acumulación de humedad y pelusa en la casa, lo cual

puede dar como resultado:

Daños de humedad en la carpintería, muebles, pintura,

empapelado, alfombras, etc.

Problemas en la limpieza de la casa y de salud.

Planificación del sistema de ventilación

Seleccione su tipo de instalación de ventilación

Instalaciones recomendadas de escape

Las instalaciones típicas tienen la ventilación en la parte posterior

de la secadora. Otras instalaciones son posibles.

B

C

D

A

E

F

G

B

A

A. Instalación en la parte superior (también está

disponible con un codo de desviación)

B. Instalación de periscopio

B

NOTA: Se pueden adquirir los siguientes juegos para

instalaciones alternas en espacios limitados. Por favor vea la

sección “Ayuda o servicio técnico” en las Instrucciones para el

usario de la secadora.

■ Instalación en la parte superior:

Pieza número 4396028

■ Instalación de periscopio (Para usar si hay desacoplo entre el

ducto de escape de la pared y el conducto de ventilación de la

secadora):

Pieza número 4396037 - Desacoplo de 0" (0 mm) a

18" (457 mm).

Pieza número 4396011 - Desacoplo de 18" (457 mm) a

29" (737 mm).

Pieza número 4396014 - Desacoplo de 29" (737 mm) a

50" (1270 mm).

Previsiones especiales para las instalaciones en casas rodantes

El ducto de escape deberá sujetarse firmemente en un lugar no

inflamable de la estructura de la casa rodante y no debe terminar

debajo de la casa rodante. El ducto de escape debe terminar en

el exterior.

H

A. Secadora

B. Codo

C. Pared

D. Capota de ventilación

E. Abrazaderas

F. Ducto de metal rígido o de metal flexible

G. Longitud necesaria del ducto de escape

para conectar

H. Salida de ventilación

los codos

Instalación con salida de ventilación estándar con ducto de escape de metal rígido o flexible

Instalaciones alternas para espacios limitados

Los sistemas de ventilación vienen en una amplia gama.

Seleccione el tipo más apropiado para su instalación. A

continuación se ilustran dos tipos de instalación para espacios

limitados. Consulte las instrucciones del fabricante.

Determinación de la vía del ducto de escape

■ Seleccione la vía que proporcione el trayecto más recto y

directo al exterior.

■ Planifique la instalación a fin de usar el menor número posible

de codos y vueltas.

■ Cuando use los codos o haga vueltas, deje todo el espacio

que sea posible.

■ Doble el ducto gradualmente para evitar torceduras.

■ Use la menor cantidad posible de vueltas de 90°.

20

Page 21

Determinación de la longitud del ducto de escape y de los codos necesarios para obtener un óptimo rendimiento de secado

■ Use el cuadro del sistema de ventilación a continuación para

determinar el tipo de material para ducto y la combinación de

capota aceptable a usar.

NOTA:

No use tendidos de ducto de escape más largos que

los especificados en el cuadro del sistema de ventilación. Los

sistemas de ventilación más largos que los especificados:

■ Acortarán la vida de la secadora.

■ Reducirán el rendimiento, dando lugar a tiempos de

secado más largos y un aumento en el consumo de

energía.

El cuadro del sistema de ventilación indica los requisitos de

ventilación que le ayudarán a alcanzar el mejor rendimiento de

secado.

Cuadro del sistema de ventilación

NOTA: Las instalaciones de ventilación laterales e inferiores

tienen una vuelta de 90º dentro de la secadora. Para determinar

la longitud máxima de ventilación, agregue una vuelta de 90º al

cuadro.

Instalación de las patas niveladoras

ADVERTENCIA

Peligro de Peso Excesivo

Use dos o más personas para mover e instalar

la secadora.

No seguir esta instrucción puede ocasionar una

lesión en la espalda u otro tipo de lesiones.

1. Para proteger el piso, use un pedazo de cartón grande y plano del

cartón de la secadora. Coloque el cartón debajo de todo el borde

posterior de la secadora. Vea la ilustración.

2. Sujete con f

o el panel de la consola). Coloque la secadora cuidadosamente

en el cartón.

irmeza el cuerpo de la secadora (no la parte superior

No. de

vu

eltas

de 90º o

codos

0 Metal rígido 64 pies (20 m) 58 pies (17,7 m)

1 Metal rígido 54 pies (16,5 m) 48 pies (14,6 m)

2 Metal rígido 44 pies (13,4 m) 38 pies (11,6 m)

3 Metal rígido 35 pies (10,7 m) 29 pies (8,8 m)

4 Metal rígido 27 pies (8,2 m) 21 pies (6,4 m)

Tipo de ducto Capotas de

ventilación de

caja o tipo

persianas

Capotas angulares

Instalación del sistema de ventilación

1. Instale la capota de ventilación. Emplee una masilla de calafateo

para sellar la abertura de la pared externa alrededor de la capota

de ventilación.

2. Conecte el du

de escape debe encajar dentro de la capota de ventilación.

Asegure el ducto de escape a la capota de ventilación con una

abrazadera de 4" (102 mm).

3. Extienda el ducto

trayectoria más recta posible. Vea “Determinación de la vía del

ducto de escape” en “Planificación del sistema de ventilación”.

Evite giros de 90º. Use abrazaderas para sellar todas las juntas.

No use cinta adhesiva para conductos, tornillos ni otros

dispositivos de fijación que se extiendan dentro del ducto de

escape para fijarlo, los cuales podrían atrapar pelusa.

cto de escape a la capota de ventilación. El ducto

de escape a la ubicación de la secadora. Use la

3. Examine las patas niveladoras. Localice la marca en forma de

diamante.

4. Atornille con la mano las patas en los orificios de las patas. Use

una llave de tuercas para terminar de atornillar las patas hasta

que la marca en forma de diamante no quede visible.

5. Co

loque un poste esquinal de cartón debajo de cada una de

los 2 esquinales posteriores de la secadora. Ponga la

secadora de pie. Deslice la secadora sobre los postes

esquinales hasta que quede cerca de su ubicación final. Deje

suficiente espacio para conectar el ducto de escape.

6. Una ve

z que la conección esté hecha y que la secadora esté

en su ubicación final, quite los postes esquinales y el cartón.

Para uso en casas rodantes

Las secadoras a gas deben ser aseguradas al piso con firmeza.

La instalación en casas rodantes requiere el Juego de Instalación

para casas rodantes. Vea “Instrucciones para el usuario de la

secadora” para información sobre cómo ordenar.

21

Page 22

Conexión del suministro de gas

A

1. Quite la tapa roja del tubo de gas.

2. Utilizando una llave de tuercas para apretar, conecte el suministro

de gas a la secadora. Use sellador compuesto para las roscas de

todos los accesorios macho no abocinados. Si se usa tubería

flexible de metal, asegúrese que no hay partes retorcidas.

B

A. Rosca macho abocinada

B. Rosca macho no abocinada

NOTA: Para las conexiones de gas LP, debe usar un pegamento

de unión de tubos resistente a la acción del gas LP. No use cinta

TEFLON®†.

Se debe usar una combinación de accesorios para tuberías

para conectar la secadora a la línea de suministro de gas

existente. A continuación se ilustra una conexión recomendada.

Su conexión puede ser distinta, de acuerdo con el tipo de línea

de suministro, tamaño y ubicación.

Conexión del ducto de escape

1. Usando una abrazadera de 4" (102 mm), conecte el ducto de

escape a la salida de aire de la secadora. Si se conecta a un

ducto de escape existente, asegúrese de que el mismo esté

limpio. El ducto de escape de la secadora debe encajar sobre la

salida de aire de la secadora y dentro de la capota de ventilación.

Cerciórese de que el ducto de escape esté asegurado a la capota

de ventilación con una abrazadera de 4" (102 mm).

2. Mueva la secadora a su posición

final. No aplaste ni retuerza el

ducto de escape.

3. (En modelos a gas) Asegúrese de que no hayan torceduras en la

línea de gas flexible.

a vez que la conexión del ducto de escape esté lista, quite los

4. Un

esquinales y el cartón.

Nivelación de la secadora

Revise la nivelación de la secadora. Verifique primero de lado a lado

y luego del frente hacia atrás.

Si la secadora no está nivelada, apuntale la secadora, usando un

bloque de madera. Use una llave de tuercas para regular las patas

D

hacia arriba o hacia abajo y verifique nuevamente si la secadora

está nivelada.

Cómo invertir el cierre de la puerta (opcional)

A

B

A. Conector flexible de gas de 3/8"

B. Tubo de la secadora de

C. Codo de tubería de

D. Accesorio adaptador abocinado

3

/8"

3

/8" a 3/8"

C

para tubo de 3/8"

3. Abra la válvula de cierre de la línea de suministro. La válvula está

abierta cuando la manija está paralela al tubo de gas.

A

B

A. Válvula cerrada

B. Válvula abierta

4. Pruebe todas las conexiones aplicando con un cepillo una

solución aprobada para detección de fugas que no sea corrosiva.

Se observarán burbujas si hay fuga. Tape cualquier fuga que

encuentre.

†®TEFLON es una marca registrada de E.I. Du Pont De Nemours and Company.

Si lo desea, puede cambiar la dirección del cierre de la puerta del

lado derecho al lado izquierdo.

Puerta grande de abertura lateral de posición reversible

A

B

D

1. Coloque una toalla (A) encima de la secadora para proteger la

superficie.

2. Abra la pu

erta de la secadora. Extraiga los tornillos inferiores de

las bisagras del lado de la carcasa (C). Afloje (no extraiga) los

tornillos superiores de las bisagras del lado de la carcasa.

3. Levante

la puerta hasta que los tornillos superiores de la carcasa

estén en la parte grande de la ranura de la bisagra. Tire de la

puerta hacia adelante para separarla de los tornillos. Coloque la

puerta encima de la secadora. Extraiga los tornillos superiores de

la carcasa.

4. Use un desto

rnillador pequeño de hoja plana para quitar con

cuidado los cuatro tapones (D) de los orificios de la bisagra que

están en el lado izquierdo de la carcasa. Introduzca los tapones

en los orificios de la bisagra en el lado derecho de la carcasa.

C

22

Page 23

5. Introduzca los tornillos en los agujeros inferiores en el lado

izquierdo de la carcasa. Atorníllelos por la mitad. Coloque la

puerta de tal forma que el extremo grande de la ranura de la

bisagra, esté encima de los tornillos. Deslice la puerta hacia arriba

para que los tornillos estén en la parte inferior de las ranuras.

Apriete los tornillos. Introduzca y apriete los tornillos superiores en

las bisagras.

6. Cierre la puerta y asegúrese de que el tope de la puerta está

alineado con el gancho (B). Si es necesario, deslice el gancho de

la puerta hacia la izquierda o derecha dentro de la ranura para

ajustar la alineación.

Puerta super ancha de abertura lateral de posición reversible

A

B

C

E

7. Fije las bisagras de la puerta a la puerta de la secadora de

manera que el orificio más grande quede en la parte inferior

de la bisagra.

8. Extraiga el tope de la puerta (E) de la carcasa. Use un

destornillador pequeño de hoja plana para quitar

cuidadosamente los 4 tapones para los orificios de la bisagra

(F) que se encuentran al lado izquierdo de la carcasa.

Introduzca los tapones en los orificios de la bisagra en el lado

derecho de la carcasa.

oduzca los tornillos en los orificios inferiores en el lado

9. Intr

izquierdo de la carcasa. Atorníllelos por la mitad. Coloque la

puerta de tal forma que el extremo grande de la ranura de la

bisagra esté sobre los tornillos. Deslice la puerta hacia arriba para

que los tornillos estén en la parte de abajo de las ranuras. Apriete

los tornillos. Introduzca y apriete los tornillos superiores en las

bisagras.

F

D

1. Coloque una toalla (A) encima de la secadora para proteger la

superficie.

2. Abra la puerta de la secadora. Extraiga los tornillos inferiores de

las bisagras del lado de la carcasa (D). Afloje (no extraiga) los

tornillos superiores de las bisagras del lado de la carcasa.

3. Levant

4. Extraiga los tor

5. Extraig

6. T

e la puerta hasta que los tornillos superiores de la carcasa

estén en la parte grande de la ranura de la bisagra. Tire de la

puerta hacia adelante para separarla de los tornillos. Coloque la

puerta (con el lado de la manija hacia arriba) encima de la

secadora. Extraiga los tornillos superiores de la carcasa.

nillos que unen a las bisagras con la puerta.

a los tornillos en la parte superior, inferior y lateral de la

puerta (4 tornillos). Sosteniendo la puerta sobre la toalla en la

secadora, sujete los costados de la parte exterior de la puerta y

levante cuidadosamente para separarla de la parte interior de la

puerta. No los separe utilizando una espátula. No tire del burlete

de la puerta ni de los ganchos plásticos de la misma.

enga cuidado de mantener los espaciadores de cartón

centrados entre las puertas. Vuelva a unir el panel exterior de la

puerta al panel interior de la misma de manera que la manija se

encuentre en el lado de donde se acaban de extraer las bisagras.

10. Extraiga el tapón del tope de la puerta (B). Introduzca el tope

de la puerta que usted quitó en el paso 8 en el orificio, y

asegúrelo con un tornillo. Introduzca el tapón del tope de la

puerta en el orificio original del tope de la puerta y asegúrelo

con un tornillo.

11. Cierr

e la puerta y asegúrese de que el tope de la misma esté

alineado con el gancho de la puerta (C). Si es necesario,

deslice el gancho de la puerta hacia la izquierda o derecha

dentro de la ranura a fin de ajustar la alineación.

Complete la instalación

1. Revise para cerciorarse de que todas las piezas estén instaladas.

Si hay alguna pieza extra, vuelva a revisar todos los pasos para

ver cuál se omitió.

erifique si tiene todas las herramientas.

2. V

3. Revise la ubicación final

ducto de escape no esté aplastado o retorcido.

4. V

erifique si la secadora está nivelada. Vea “Nivelación de la

secadora”

de la secadora. Asegúrese de que el

ADVERTENCIA

Peligro de Choque Eléctrico

Conecte a un contacto de pared de conexión a tierra

de 3 terminales.

No quite la terminal de conexión a tierra.

No use un adaptador.

No use un cable eléctrico de extensión.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque eléctrico.

23

Page 24

5. Conecte a un contacto de pared de conexión a tierra de

3 terminales. Conecte el suministro de energía.

6. Quite la película

protectora o cinta adhesiva que haya quedado

en la secadora.

7. Deshágase de todos los materiales

ea “Uso de la secadora” en las Instrucciones para el usuario

8. L

de embalaje o recíclelos.

de la secadora.

9. Limpie e

l interior del tambor de la secadora meticulosamente con

un paño húmedo para quitar residuos de polvo.

10. Seleccione

un ciclo de secado programado (Timed Dry) con calor

y ponga la secadora en marcha. No seleccione el ajuste de

temperatura de sólo aire (Air Only).Si la secadora no funciona,

revise lo siguiente:

■ Que la secadora esté conectada en un contacto de

3 terminales con conexión a tierra.

■ Que el suministro eléctrico esté conectado.

■ Que el fusible de la casa esté intacto y ajustado, o que no se

haya disparado el cortacircuitos.

■ Que la puerta de la secadora esté cerrada.

11. Despu

és de que la secadora haya estado funcionando durante 5

minutos, abra la puerta y fíjese si está caliente. Si siente calor,

cancele el ciclo y cierre la puerta. Si no siente calor, apague la

secadora y verifique que esté abierta la válvula de cierre de la

línea de suministro de gas.

■ Si está cerrada la válvula de cierre de la línea de suministro

de gas, ábrala y repita la prueba de 5 minutos como se

indicó anteriormente.

■ Si está abierta la válvula de cierre de la línea de suministro

de gas, contacte a un técnico calificado.

W10131643A

© 2008. All rights reserved.

Todos los derechos reservados.

TM DURASAFE is a trademark of Whirlpool, U.S.A.

TM DURASAFE es una marca de comercio de Whirlpool, U.S.A.

Printed in U.S.A.

Impreso en EE.UU.

10/08

Loading...

Loading...