Page 1

WPTV248UL Series

CCTV Outdoor Power Supplies

Installation Guide

Models Include:

• WPTV248UL • WPTV248ULCB

- 24VAC @ 3.5A (85VA) - 24VAC @ 3.5A (85VA).

or 28VAC @ 3A (85VA). or 28VAC @ 3A (85VA).

- Eight (8) Fuse Protected Outputs. - Eight (8) PTC Protected Outputs.

• WPTV248175UL • WPTV248175ULCB

- 24VAC @ 7A (175VA) - 24VAC @ 7A (175VA)

or 28VAC @ 6.25A (175VA). or 28VAC @ 6.25A (175VA).

- Eight (8) Fuse Protected Outputs. - Eight (8) PTC Protected Outputs.

• WPTV248300UL • WPTV248300ULCB

- 24VAC @ 12.5A (300VA) - 24VAC @ 12.5A (300VA)

or 28VAC @ 10A (280VA). or 28VAC @ 10A (280VA).

- Eight (8) Fuse Protected Outputs. - Eight (8) PTC Protected Outputs.

Rev. 040506

Page 2

Overview:

WPTV248UL Series outdoor CCTV Power Supplies provide power via eight (8) fused or PTC protected outputs for CCTV

Cameras, heaters, and other video accessories. Units are UL Listed UL 2044 “U.S. and Canada for CCTV Equipment.”

Eight (8) Output WPTV Reference Chart:

Altronix

Model Number

WPTV248UL

WPTV248ULCB

WPTV248175UL

WPTV248175ULCB

WPTV248300UL

WPTV248300ULCB

Output Voltage (VAC)

24VAC 3.5A

28VAC 3A

24VAC 3.5A

28VAC 3A

24VAC 7A

28VAC 6.25A

24VAC 7A

28VAC 6.25A

24VAC 12.5A

28VAC 10A

24VAC 12.5A

28VAC 10A

Total Output Current

(Power)

Number of Outputs

PTC Protected Outputs

(Class 2 power-limited

for Dry locations,

Class 3 for Wet

locations).

8 ----

8

8 ----

8

8 ----

8

P

P

P

Fuse Protected Outputs

Individual Output

Current (max per

output - not to exceed

total output current)

3.5A 3.5A

P

---- 2.5A ----

3.5A 3.5A

P

---- 2.5A ----

3.5A 3.5A

P

---- 2.5A ----

Fuse Ratings

Main Fuse Ratings

5A/

250V

5A/

250V

10A/

250V

10A/

250V

15A/

32V

15A/

32V

Primary In-line Fuse

Ratings

115VAC 50/60Hz Input

Current

3.5A/

250V

3.5A/

250V

0.9A

0.9A

---- 1.76A

---- 1.76A

---- 2.7A

---- 2.7A

Agency Listings

Specifications:

Input:

• 115VAC, 50/60Hz.

Output:

• Eight (8) fuse or PTC protected outputs.

• 24VAC or 28VAC.

• Outputs are rated @ 3.5A (fused) or 2.5A (PTC).

• Surge suppression.

Features:

• Secondary fuse rated @ 5A/250V.

• AC power LED.

Features (cont’d):

• Unit maintains camera synchronization.

• Ease of installation saves time & eliminates costly labor.

• Spare fuses provided.

(all models w/primary and/or secondary fuses).

• NEMA 4 Rated enclosure for outdoor use.

Enclosure Dimensions (H x W x D approx.):

12” x 8” x 6” (304.8mm x 203.2mm x 152.4mm).

Installation Instructions:

Unit should be installed in accordance with The National Electrical Code and all applicable Local Regulations.

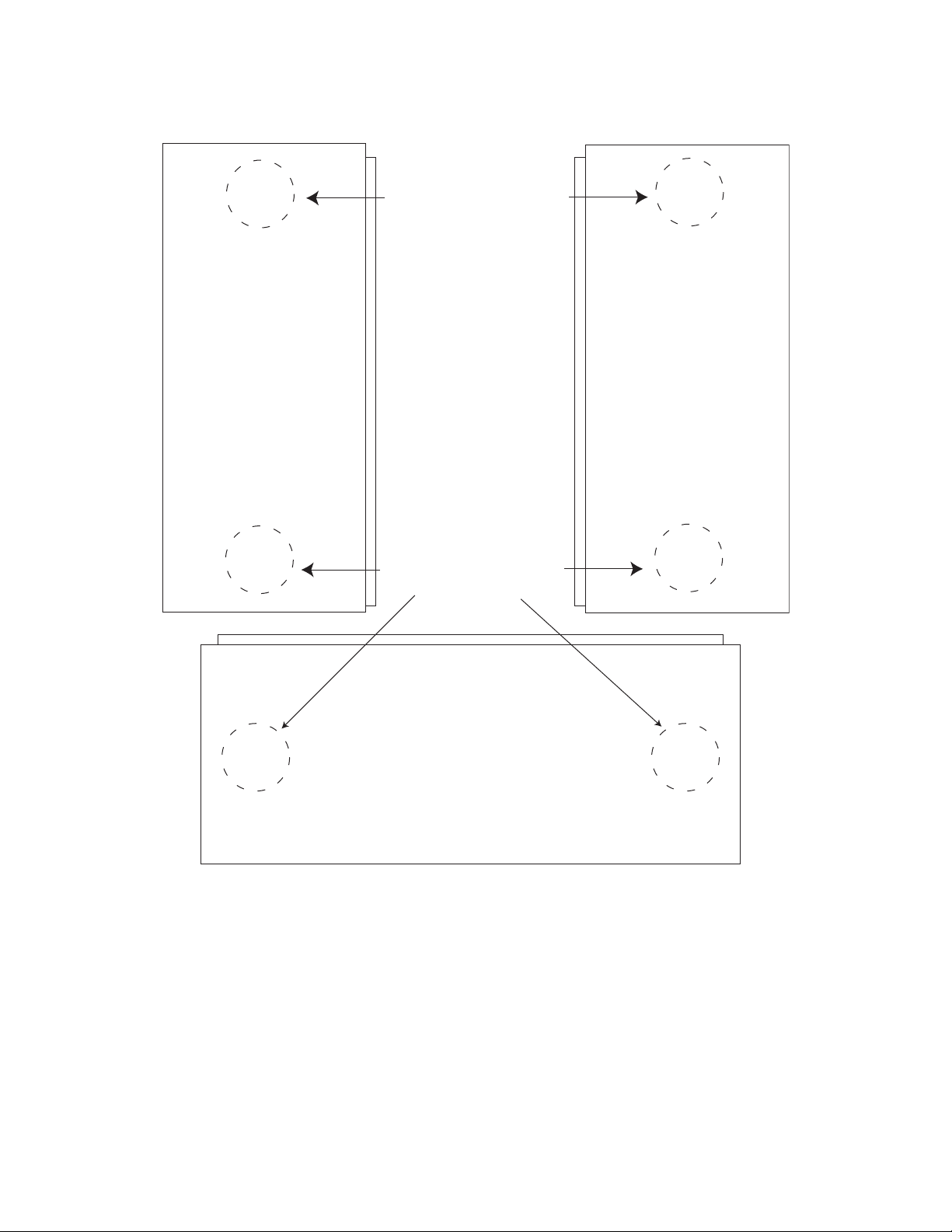

1. Remove back plate inside the enclosure by removing four (4) mounting screws (Figs. 2a-7a, pgs. 5-10 ).

2. Mark and drill desired knockouts on the enclosure to facilitate wiring. For suggested wire entry locations refer to

(Fig. 1, pg. 4). Use weather tight NEMA 4 rated connectors, bushings, and cables

3. Unit can be wall or pole mounted.

Wall Mount:

- Mark and drill holes to line up with the top and bottom holes of the enclosure flange.

- Secure enclosure with appropriate fasteners (Fig. 9 and Fig. 9a, pg. 11).

Pole Mount:

- Refer to the detailed pole mount instructions (pg. 11).

Secure enclosure to earth ground.

4. Set power switch on power distribution board marked [PD] to OFF position for models WPTV248UL or

WPTV248ULCB (Figs. 2b, 3b, pgs. 5, 6). Set power disconnect circuit breaker to OFF position for all other models

(Figs. 4b-7b, pgs. 7-10).

- 2 - WPTV248ULseries

Page 3

5. All units are factory set for 24VAC operation.

For 28VAC operation adjust unit prior to mounting and applying power as follows:

Change the wire position so that the black wire [28V] is connected to the terminal marked [P] and the yellow wire

[24V] is connected to the terminal marked [S].

Note: WPTV248ULCB set for 28VAC operation is not Class 2, not power-limited.

6. Place back plate with all internal parts, using four (4) screws, back into WP enclosure (Figs. 2a-7a, pgs. 5-10).

7. Connect AC power to the black and white flying leads of the transformer(s) (Figs. 2-7, pgs. 5-10),

secure green lead to earth ground. Use 18 AWG or larger for all power connections.

Keep power-limited (PTC protected outputs only) wiring separate from non power-limited wiring.

Minimum 0.25” spacing must be provided. Use separate entries.

8. Set power switch on power distribution board marked [PD] to ON position for models WPTV248UL or

WPTV248ULCB (Figs. 2b, 3b, pgs. 5, 6). Set power disconnect circuit breaker to ON position for all

other models (Figs. 4b-7b, pgs. 7-10).

9. Measure output voltage before connecting devices. This helps avoiding potential damage.

Terminals marked [1P - 8P] are of the same polarity.

CAUTION: Determine the maximum operating voltage of the equipment being powered before adjusting

the output voltage.

10. Set power switch on power distribution board marked [PD] to OFF position for models WPTV248UL or

WPTV248ULCB (Figs. 2b, 3b, pgs. 5, 6). Set power disconnect circuit breaker to OFF position for all

other models (Figs. 4b-7b, pgs. 7-10).

11. Connect devices to terminals marked [1P - 1N] through [8P - 8N] on PD8/PD8CB board (Figs. 2-7, pgs. 5-10),

carefully observing polarity.

12. Set power switch on power distribution board marked [PD] to ON position for models WPTV248UL or

WPTV248ULCB (Figs. 2b, 3b, pgs. 5, 6). Set power disconnect circuit breaker to ON position for all

other models (Figs. 4b-7b, pgs. 7-10).

13. Green LED will illuminate when power is present.

14. Upon completion of wiring, secure enclosure door with the cam lock (supplied).

Caution: Equipment to be installed/serviced by authorized/trained personnel only.

Shut branch circuit power before installing/servicing equipment.

WARNING: This installation should be made by qualified service personnel. Unit should be installed in accordance with the National Electrical Codes and all local codes. For continued protection against risk of fire replace

all fuses only with the same type and rating (3.5A/250VAC).

Terminal Identification:

PD8 - Power Distribution Module

Terminal Legend Function/Description

1P - 8P AC output.

1N - 8N AC output.

The lightning flash with arrow head symbol within an equilateral triangle is intended to alert the user to the

presence of an insulated DANGEROUS VOLTAGE within the product’s enclosure that may be of sufficient

magnitude to constitute an electric shock.

The exclamation point within an equilateral triangle is intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the literature accompanying the appliance.

CAUTION: To reduce the risk of electric shock do not open enclosure. There are

no user serviceable parts inside. Refer servicing to qualified service personnel.

WPTV248ULseries - 3 -

Page 4

Fig. 1

Right PanelLeft Panel

Suggested Locations

for Wire Entries

Suggested Locations

for Wire Entries

Bottom Panel

- 4 - WPTV248ULseries

Page 5

Fig. 2

WPTV248UL

Fig. 2a

Fig. 2b

24VAC or 28VAC

output 1 (Follow

same procedure

using terminals

2P & N through

8P & N

outputs 2 through 8)

Primary

In-line

Fuse

1 2 3 4 5 6 7 8

P

FUSED POWER OUTPUTS

N

COMMON POWER OUTPUTS

Class 1 Outputs

non power-

limited

XFMR

D1

R1

NPS

White

Lead

LED

INPUT

non power-

limited

MAIN FUSE

OFF

ON

Black

Lead

115VAC

Input

50/60 Hz.

Green

Lead

(Ground)

Black

Lead

ON OFF

Terminal Blocks for Fig. 2

24VAC or 28VAC

fused or PTC protected outputs

WPTV248ULseries - 5 -

1 through 8.

Page 6

Fig. 3

WPTV248ULCB

24VAC or 28VAC

output 1 (Follow

same procedure

using terminals

2P & N through

8P & N

outputs 2 through 8)

F1 F2 F3 F4 F5 F6 F7 F8

P

FUSED POWER OUTPUTS

N

COMMON POWER OUTPUTS

D1

R1

NPS

LED

MAIN FUSE

ON OFF

INPUT

Fig. 3a

Fig. 3a

ON OFF

24VAC configuration: Class 2 Not Wet/Class 3 Wet

28VAC configuration: Class 1

Primary

In-line Fuse

non power-

limited

XFMR

White

Lead

non power-

limited

Black

Lead

Green

Lead

(Ground)

Black

Lead

115VAC

Input

50/60 Hz.

Terminal Blocks for Fig. 3

24VAC or 28VAC

fused or PTC protected outputs

1 through 8.

- 6 - WPTV248ULseries

Page 7

Fig. 4

WPTV248175UL

Fig. 4a

XFMR

non power-

limited

Black

Lead

White

Lead

Green

Lead

(Ground)

MAIN FUSE

115VAC

Input

50/60 Hz.

Fig. 4b

Illuminated Power Disconnect

Circuit Breaker with manual reset

Terminal Blocks for Fig. 4

24VAC or 28VAC

fused or PTC protected outputs

WPTV248ULseries - 7 -

1 through 8.

Page 8

Fig. 5

WPTV248175ULCB

Fig. 5a

F1 F2 F3 F4 F5 F6 F7 F8

P

FUSED POWER OUTPUTS

N

COMMON POWER OUTPUTS

non power-

limited

XFMR

D1

R1

NPS

Black

Lead

White

Lead

LED

INPUT

Green

Lead

(Ground)

MAIN FUSE

115VAC

Input

50/60 Hz.

Fig. 5b

Illuminated Power Disconnect

Circuit Breaker with manual reset

Terminal Blocks for Fig. 5

24VAC or 28VAC

fused or PTC protected outputs

- 8 - WPTV248ULseries

1 through 8.

Page 9

Fig. 6

WPTV248300UL

24VAC or 28VAC

output 1 (Follow

same procedure using

terminals 2P & N

through 8P & N

outputs 2 through 8)

Fig. 6a

MAIN FUSE

Fig. 6b

Class 1 Outputs

XFMR*

non power-

limited

Black

Lead

White

Lead

Green

Lead

(Ground)

115VAC

Input

50/60 Hz

Illuminated Power Disconnect

Circuit Breaker with manual reset

Terminal Blocks for Fig. 6

24VAC or 28VAC

fused or PTC protected outputs

1 through 8.

WPTV248ULseries - 9 -

Page 10

Fig. 7

WPTV248300ULCB

Fig. 7a

F1 F2 F3 F4 F5 F6 F7 F8

MAIN FUSE

24VAC or 28VAC

output 1 (Follow

same procedure using

terminals 2P & N

through 8P & N

outputs 2 through 8)

P

FUSED POWER OUTPUTS

N

COMMON POWER OUTPUTS

24VAC configuration

Class 2 Not Wet/Class 3 Wet

XFMR*

D1

R1

NPS

LED

INPUT

non power-

limited

Green

(Ground)

Black

Lead

White

Lead

Lead

115VAC

Input

50/60 Hz

Fig. 7b

Illuminated Power Disconnect

Circuit Breaker with manual reset

Terminal Blocks for Fig. 7

24VAC or 28VAC

fused or PTC protected outputs

- 10 - WPTV248ULseries

1 through 8.

Page 11

Wall Mount Installation

1- Place unit at desired location and secure with mounting

screws (not included) (Fig. 8, pg. 7).

Fig. 8

Pole Installation Using Optional Pole Mount Kit PMK1 (not included):

This installation should be made by qualified service personnel. This product contains no serviceable parts. PMK1 is intended for use with Altronix outdoor rated power supplies or accessories housed in WP1, WP2, WP3 and WP4 enclosures.

Brackets are designed for use with the Wormgear Quick Release Straps (two included).

1. Thread one (1) wormgear quick release strap through the slots on the back of a mounting bracket (Fig. 9, pg. 7).

2. Once the desired height of the top Pole Mount bracket is achieved, tighten the straps down by sliding open end

of the strap through the locking mechanism on the strap, then tighten the screw with

flat head screwdriver or 5/16” hex socket driver (Fig. 10, pg. 7).

Fig. 9

Fig. 10

Fig. 11

3. Attach the bottom bracket to the enclosure by inserting bolts through the

flange of the enclosure and into the bracket, tightening bolts with a

7/16” hex socket (Fig. 12, pg. 7).

4. Thread the second wormgear quick release strap through the slots on the

back of the bottom mounting bracket (Fig. 9, pg. 7).

5. Mount enclosure onto the top bracket by inserting bolts through

flange of the enclosure and into the bracket,

tightening bolts with a 7/16” hex socket (Fig. 11, pg. 7).

6. Tighten the straps of the bottom bracket down by sliding the open end of

the strap through the locking mechanism on the strap, then tighten screw

with flat head screwdriver or 5/16” hex socket driver (Fig. 13/13a, pg. 7).

7. Clip excess straps.

Fig. 13 - 2” to 8”(50.8mm to 203.2mm) Fig. 13a - 5” (127mm) square pole

diameter round pole

Fig. 12

WPTV248ULseries - 11 -

Page 12

6”

152.4mm

Enclosure Dimensions (H x W x D approximate):

12” x 8” x 6” (304.8mm x 203.2mm x 152.4mm)

8”

203.2mm

14”

355.6mm

13”

330mm

4.05”

103mm

MOUNTING PANEL

GALVANIZED

12”

305mm

6.7”

170mm

CARBON STEEL SHEET

9.84”

250mm

0.08”

2mm

4.21”

107mm

Altronix is not responsible for any typographical errors.

140 58th Street, Brooklyn, New York 11220 USA, 718-567-8181, fax: 718-567-9056

web site: www.altronix.com, e-mail: info@altronix.com. Lifetime Warranty, Made in U.S.A.

- 12 - WPTV248ULseries

II1WPTV248UL Series E23P

MEMBER

Loading...

Loading...