Page 1

SIGNALING

Access & Power Integration

Combine Altronix Power and Accessories with

Access Controllers from the Industry’s Leading Manufacturers

Installation Guide

All registered trademarks are property of their respective owners. More than just power.™

Rev. 101817

Installing Company: _____________________ Service Rep. Name: __________________________________________

Address: ________________________________________________________ Phone #: _________________________

Page 2

Overview:

Trove accommodates various combinations of access controllers and accessories from the industry’s leading manufacturers with or without

Altronix power supplies and accessories for access systems. A variety of backplanes offer a wide range of scalable access and power configurations. Trove simplifies board layout and wire management, while reducing installation and labor costs.

Trove Model Identification:

Series

Trove

Enclosure Size

(Access Controller Manufacturer)

Backplane Model

Backplane Size

C = CDVI

1

18” x 14.5” x 4.625”

(457mm x 368mm x 118mm)

BL = Universal Blank Backplane*

Trove

2

27.25” x 21.75” x 6.5”

(692.2mm x 552.5mm x 165.1mm)

3

36.12” x 30.125” x 7.06”

(917.5mm x 768.1mm x 179.3mm)

HW = Honeywell ProWatch/WinPak*

BL = Universal Blank Backplane*

HW = Honeywell ProWatch/WinPak*

*Not evaluated by UL.

Also Available:

TMV2 - Trove2 door backplane, compatible with Mercury or HID/VertX boards and Altronix sub-assemblies (Fig. 11, pg. 13).

DM = DMP*

M = Mercury

PD = ProdataKey*

V = HID/VertX

AM = AMAG

BH = Bosch*

CV = CDVI

DM = DMP*

HN = Honeywell NetAXS*

KA = Keyscan

KH = Kantech*

M = Mercury

PX = Paxton*

SH = Software House

SL = Sielox*

V = HID/VertX

Z = ZKTeco*

CV = CDVI*

M = Mercury*

SH = Software House*

V = HID/VertX*

16.625” x 12.5” x 0.06”

(422.3mm x 317.5mm x 1.5mm)

1

16.625” x 12.5” x 0.3125”

(422.3mm x 317.5mm x 7.9mm)

2

25.375” x 19.375” x 0.3125”

(644.5mm x 492.1mm x 7.9mm)

3

34.0” x 28.0” x 0.3125”

(863.6mm x 711.2mm x 7.9mm)

1

Specifications:

Agency Listings:

• UL 294 - 6th edition. Trove1 and Trove2 Power Controllers: Line Security I, Destructive Attack I, Endurance IV, Stand-by Power II.

• This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme á la norme NMB-003 du Canada.

Environmental:

• Humidity and Temperature conditions as tested by UL (85%, +/-5% @ 30ºC +/-2ºC), ULC (93%, +/-2% @ 32ºC +/-2ºC).

Battery Backup:

• Trove1 enclosure accommodates up to two (2) 12VDC/7AH batteries.

• Trove2 enclosure accommodates up to four (4) 12VDC/12AH batteries.

• Trove3 enclosure accommodates up to four (4) 12VDC/12AH batteries.

Additional Features:

• 16 Gauge grey enclosure with ample knockouts for convenient access.

- 2 - Trove

Page 3

Installation Instructions:

Edge of

Enclosure

to Access Control Panel

or U.L. Listed

Reporting Device

Enclosure

Honeywell

model # 112

Tamper Switch

or equivalent

(provided)

1. Remove backplane from enclosure. Do not discard hardware.

2. Mark and predrill holes in the wall to line up with the top two/three keyholes in the enclosure. Install

two/three upper fasteners and screws in the wall with the screw heads protruding. Place the enclosure’s

upper keyholes over the two/three upper screws; level and secure. Mark the position of the lower

holes. Remove the enclosure. Drill the lower holes and install the two/three fasteners. Place the

enclosure’s upper keyholes over the two/three upper screws. Install the two/three lower screws

and make sure to tighten all screws (refer to enclosure drawings pages 18-20).

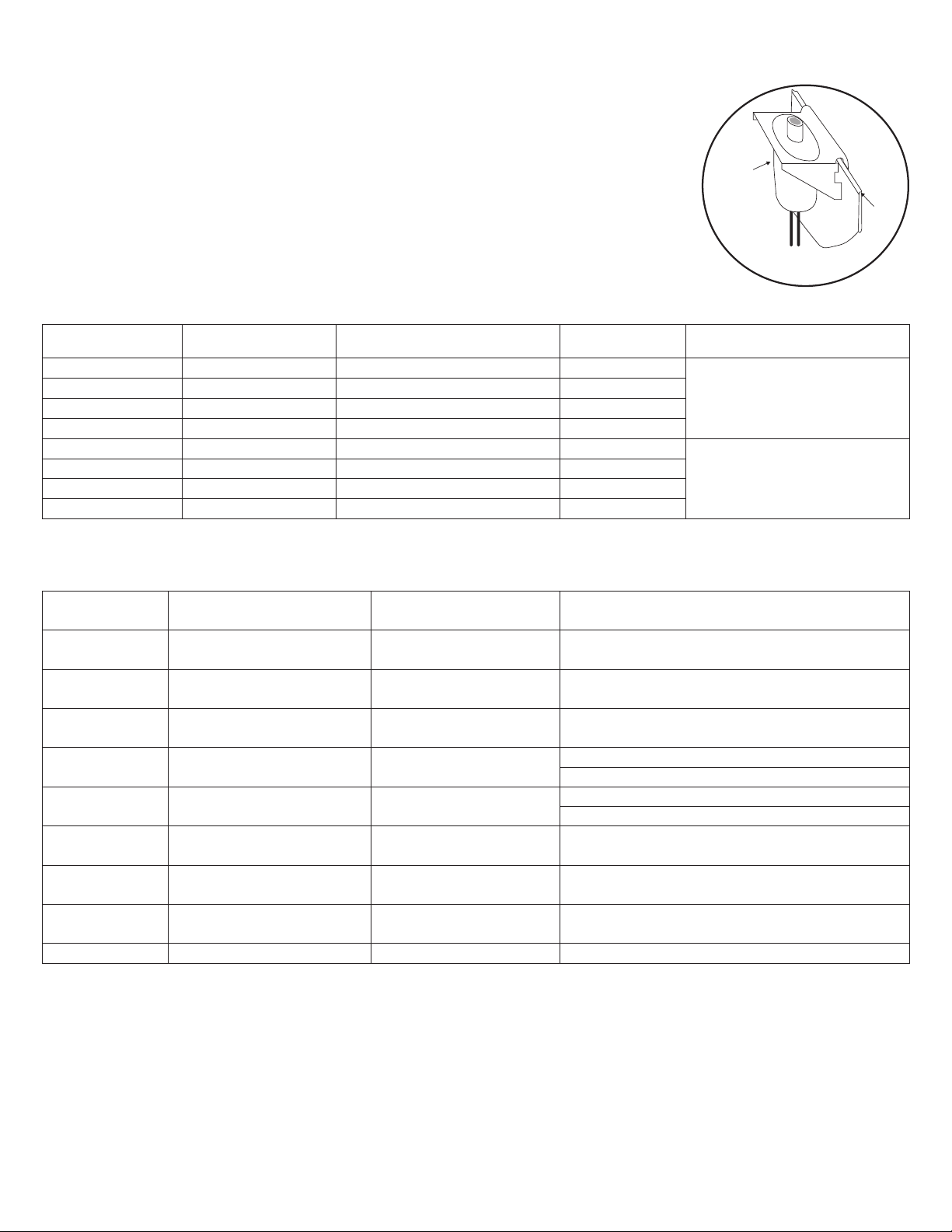

3. Mount included UL Listed tamper switch (Honeywell model 112 or equivalent) in desired

location, opposite hinge. Slide the tamper switch bracket onto the edge of the enclosure

approximately 2” from the right side (Fig. 1, pg. 3). Connect tamper switch wiring to

the Access Control Panel input or the appropriate UL Listed reporting device.

To activate alarm signal open the door of the enclosure.

4. Mount boards to backplane, refer to individual Trove installation instructions.

Power Supply Sub-Assembly Specifications:

Altronix

Power Supply

Input Rating Output Rating

AL400ULXB2 115VAC, 60Hz, 3.5A 12VDC @ 4A or 24VDC @ 3A 4AH

AL600ULXB 115VAC, 60Hz, 3.5A 12VDC or 24VDC @ 6A 7AH

AL1012ULXB 115VAC, 60Hz, 2.6A 12VDC @ 10A 12AH

AL1024ULXB2 115VAC, 60Hz, 4.2A 24VDC @ 10A 12AH

eFlow4NB* 120VAC, 60Hz, 3.5A 12VDC or 24VDC @ 4A 4AH

eFlow6NB* 120VAC, 60Hz, 3.5A 12VDC or 24VDC @ 6A 7AH

eFlow102NB* 120VAC, 60Hz, 3.5A 12VDC @ 10A 12AH

eFlow104NB* 120VAC, 60Hz, 4.5A 24VDC @ 10A 12AH

* LINQ2 can be installed when utilizing eFlow power supply/charger boards.

Battery Size for

30 min. Backup

Refer to

ULXB Installation Instructions

Rev. ULXB-10182016

eFlow Installation Instructions

Rev. EFNB-10182016

Fig. 1

Sub-Assembly Specifications:

Altronix UL Listed

Sub-Assembly

ACM4(CB)

ACM8(CB)

MOM5

PD4UL(CB)

PD8UL(CB)

PD16W(CB)

PDS8(CB)

VR6 Voltage Regulator

LINQ2* Network Communication Module 12-24VDC 100mA max. LINQ2 Installation Instructions Rev. 060514

* LINQ2 can be installed when utilizing eFlow power supply/charger boards.

Description Current Draw Refer to

4 Fused (or PTC) Output

Access Power Controller

4 Fused (or PTC) Output

Access Power Controller

5 PTC Output Power Distribution

Module with Fire Alarm Interface

4 Fused (or PTC) Output

Power Distribution Module

8 Fused (or PTC) Output

Power Distribution Module

16 Fused (or PTC) Output

Power Distribution Module

8 Fused (or PTC) Dual Input

Power Distribution Module

12VDC @ 0.4A max. or

24VDC @ 0.2A max.

12VDC @ 0.5A max. or

24VDC @ 0.3A max.

ACM4/ACM4CB Installation Instructions Rev. 051311

ACM8/ACM8CB Installation Instructions Rev. 042811

12-24VDC 55mA max. MOM5 Installation Instructions Rev. 042811

N/A

N/A

N/A

PD4UL Installation Instructions IIPD4UL Rev. 051311

PD4ULCB Installation Instructions IIPD4ULCB Rev. 051311

PD8UL Installation Instructions IIPD8UL Rev. 051311

PD8ULCB Installation Instructions IIPD8ULCB Rev. 051311

PD16W/PD16WCB Installation Instructions

IIPD16W Rev. 051311

N/A PDS8/PDS8CB Installation Instructions Rev. 070116

24VDC @ 1.75A or 3.5A

Output: 5VDC or 12VDC @ 6A

VR6 Installation Instructions Rev. 050517

Trove - 3 -

Page 4

Installation Instructions:

Wiring methods shall be in accordance with the National Electrical Code/NFPA 70/ANSI, CSA C22.1, Canadian Electrical Code, Part I,

Safety Standard for Electrical Installations, Part I, and with all local codes and authorities having jurisdiction.

Product is intended for indoor use only, within the protected or restricted area.

1. The power supply is pre-wired to the ground (chassis). Connect main incoming ground to the provided green grounding conductor lead.

Connect unswitched AC power (115VAC/120VAC 60Hz) to the terminals marked [L, N] on a single or both power supply boards.

Use 14 AWG or larger for all power connections.

Keep power-limited wiring separate from non power-limited wiring.

Minimum 0.25” spacing must be provided (Figs. 5-12, pgs. 7-14).

CAUTION: Do not touch exposed metal parts. Shut branch circuit power before installing or servicing equipment.

There are no user serviceable parts inside. Refer installation and servicing to qualified service personnel.

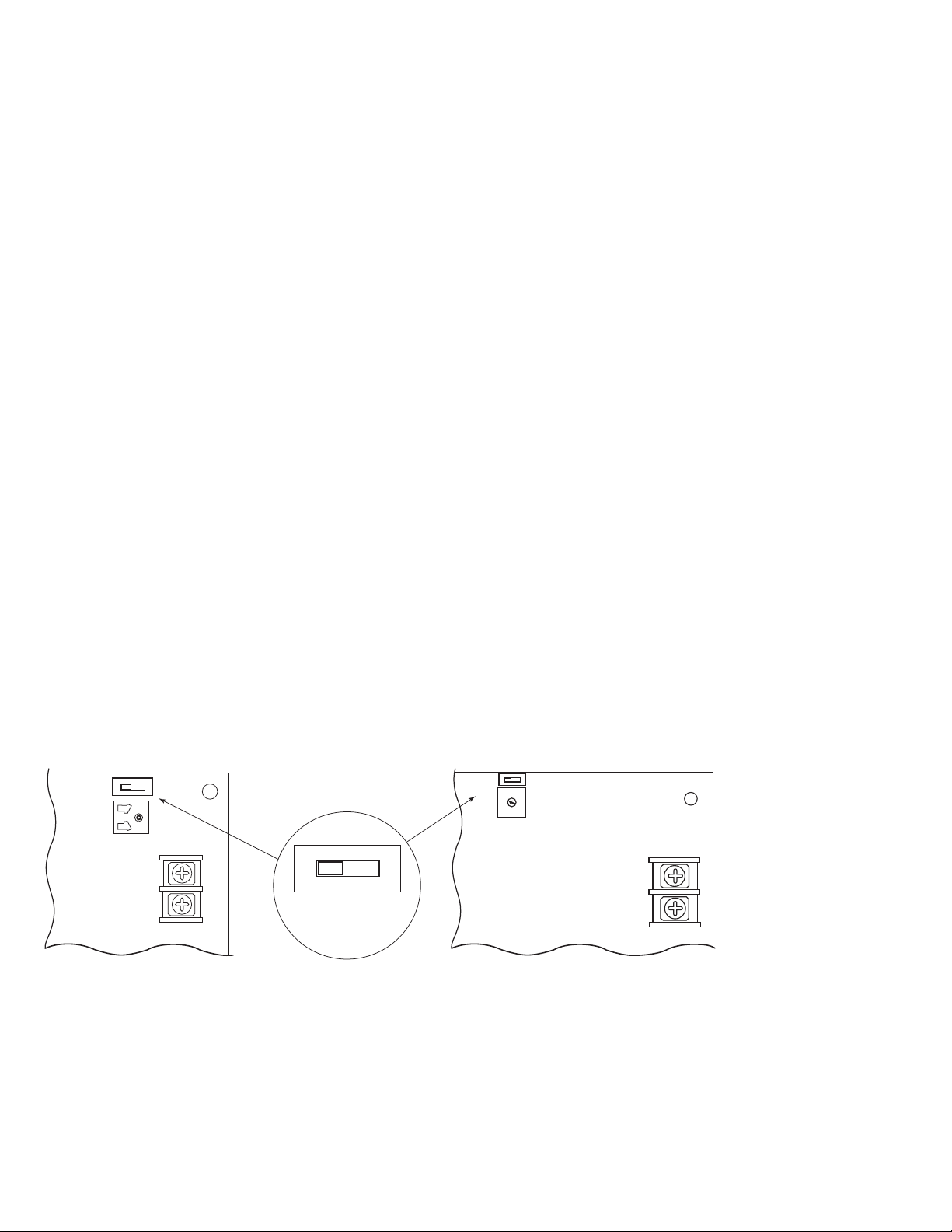

2. Select desired DC output voltage by setting SW1 to the appropriate position on the AL400ULXB2, AL600ULXB, eFlow4NB, and

eFlow6NB power supply (Fig. 2, pg. 4). AL1012ULXB and eFlow102NB power supplies are factory set at 12VDC and

AL1024ULXB2 and eFlow104NB power supplies are factory set at 24VDC.

3. Measure the output voltage of the unit before connecting any devices to ensure proper operation.

Improper or high voltage will damage these devices (Figs. 3d, 4h, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

4. Connect devices or Altronix sub-assembly modules to be powered to the terminals marked [– DC +]

(Figs. 3d, 4h, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

eFlow Power Supply: For auxiliary device connection, this output will not be affected by Low Power Disconnect or Fire

Alarm Interface. Connect device to the terminals marked [+ AUX –] (Fig. 3f, pg. 6, Figs. 5-12, pgs. 7-14).

5. For Access Control applications batteries are optional. Batteries are not optional for ULC-S319. Capacity capable of providing

30 minutes of stand-by is required (See Power Supply Specifications, Pg. 3). When batteries are not used, a loss of AC will result in

the loss of output voltage. When the use of stand-by batteries is desired, they must be lead acid. Connect battery to the terminals

marked [– BAT +]. Use two (2) 12VDC batteries connected in series for 24VDC operation (battery leads included)

(Figs. 3c, 4g, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14). Use batteries - Casil CL1270 (12V/7AH), CL12120 (12V/12AH) batteries

or UL recognized BAZR2 batteries of an appropriate rating.

6. Connect appropriate signaling notification devices to AC FAIL & BAT FAIL supervisory relay outputs

(Figs. 3b, 4b, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

For eFlow Power Supply/Chargers (steps 7-10):

7. To delay AC reporting for 2 hrs., set dip switch [AC Delay] to OFF position (Fig. 4c, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

To delay AC reporting for 1 min., set dip switch [AC Delay] to ON position (Fig. 4c, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

Note: Must be set to ON position for Burglar Alarm Applications.

8. To enable Fire Alarm Disconnect set dip switch [Shutdown] to ON position (Fig. 4c, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

To disable Fire Alarm Disconnect set dip switch [Shutdown] to OFF position (Fig. 4c, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

9. Trigger terminals are end of a line resistor supervised (10k ohms). Opening or shorting trigger

terminals will cause [DC] output to shutdown (Fig. 4d, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

10. Place a jumper for non-latching FACP. A momentary short on these terminals resets FACP latching

[Trigger EOL Shutdown] (Fig. 4d, pg. 6, Figs. 5-10, pgs. 7-12, Fig. 12, pg. 14).

11. Please ensure that the cover is secured with the provided key lock.

Power Supply Board Output Voltage Settings:

Fig. 2

OFF - 24V

ON - 12V

ON

SW1

ON

+ DC ---

OFF - 24V

OFF - 24V

ON - 12V

ON

--- DC +

ON - 12V

AL400ULXB2/AL600ULXB

Power Supply Board

- 4 - Trove

eFlow4NB/eFlow6NB

Power Supply Board

Page 5

Terminal Legend Function/Description

L, G, N

– DC +

Trigger EOL Supervised

(eFlow only)

NO, GND RESET

(eFlow only)

+ AUX –

(eFlow only)

AC Fail

NC, C, NO

Bat Fail

NC, C, NO

Connect 115VAC/120VAC 60Hz to these terminals: L to hot, N to neutral, G to ground (non power-limited)

(ULXB - Fig. 3a, pg. 6, eFlow - Fig. 4a, pg. 6).

AL300ULXB2 - 12VDC or 24VDC @ 2.5A continuous output (power-limited output) (Fig. 3d, pg. 6).

AL400ULXB2 - 12VDC @ 4A or 24VDC @ 3A continuous output (power-limited output) (Fig. 3d, pg. 6).

AL600ULXB - 12VDC or 24VDC @ 6A continuous output (non power-limited output) (Fig. 3d, pg. 6).

AL1012ULXB - 12VDC @ 10A continuous output (non power-limited output) (Fig. 3d, pg. 6).

AL1024ULXB2 - 24VDC @ 10A continuous output (non power-limited output) (Fig. 3d, pg. 6).

eFlow3NB - 12VDC or 24VDC @ 2A continuous output (power-limited output) (Fig. 4h, pg. 6).

eFlow4NB - 12VDC or 24VDC @ 4A continuous output (power-limited output) (Fig. 4h, pg. 6).

eFlow6NB - 12VDC or 24VDC @ 6A continuous output (non power-limited output) (Fig. 4h, pg. 6).

eFlow102NB - 12VDC @ 10A continuous output (non power-limited output) (Fig. 4h, pg. 6).

eFlow104NB - 24VDC @ 10A continuous output (non power-limited output) (Fig. 4h, pg. 6).

Fire Alarm Interface trigger input from a short or FACP. Trigger inputs can be normally open,

normally closed from an FACP output circuit (Power-Limited input) (Fig. 4d, pg. 6).

FACP interface latching or non-latching (Power-Limited) (Fig. 4c, pg. 6).

Auxiliary Power-Limited output rated @ 1A (unswitched) (Power-Limited output) (Fig. 4f, pg. 6).

Indicates loss of AC power, e.g. connect to audible device or alarm panel. Relay normally energized

when AC power is present. Contact rating 1A @ 30VDC (Power-Limited) (Figs. 3b, 4b, pg. 6).

Indicates low battery condition, e.g. connect to alarm panel. Relay normally energized when DC power

is present. Contact rating 1A @ 30VDC. A removed battery is reported within 5 minutes.

Battery reconnection is reported within 1 minute (Power-Limited) (Figs. 3b, 4b, pg. 6).

Terminal Identification:

Stand-by battery connections (non power-limited) (Figs. 3c, 4g, pg. 6).

AL300ULXB2, AL400ULXB2, AL600ULXB and AL1012ULXB - maximum charge current 0.7A.

– BAT +

AL1024ULXB2 - maximum charge current 3.6A.

eFlow - maximum charge current 1.54A.

Note: Expected battery life is 5 years; however, it is recommended changing batteries in 4 years or

less if needed.

Maintenance:

Unit should be tested at least once a year for the proper operation as follows:

Output Voltage Test: Under normal load conditions, the DC output voltage should be checked for proper voltage level.

Battery Test: Under normal load conditions check that the battery is fully charged, check specified voltage

(12VDC @ 13.2 or 24VDC @ 26.4) both at the battery terminal and at the board terminals marked [– BAT +] to ensure

that there is no break in the battery connection wires.

Replacing Batteries: Disconnect existing batteries. Connect battery to the terminals marked [– BAT +].

Use two (2) 12VDC batteries connected in series for 24VDC operation.

Trove - 5 -

Page 6

Fig. 3 - ULXB configuration

3a 3b

3e

5A 250V

LG N

DCAC BAT

BAT FAIL

OFF --- 24V

ON --- 12V

NC C NO NC C NO

AC FAIL

ON

3d

+ DC ---

3c

+ BAT ---

Fig. 4 - eFlowNB configuration

5A 250V

5A 250V

LG N

AC FAIL

AC1

NC C NO NC C NO

BAT FAIL

OFF --- 24V

ON --- 12V

AC

ON

DC

4i

AC DELAY SHUTDOWN

O

N

enable

1 min.

disable

2 hr.

3A

3A 32V

TRIGGER EOL

SUPERVISED

NO GND

RESET

+ AUX –

4h

--- DC +

4g

--- BAT +

4a 4b

- 6 - Trove

4e 4f4d4c

Page 7

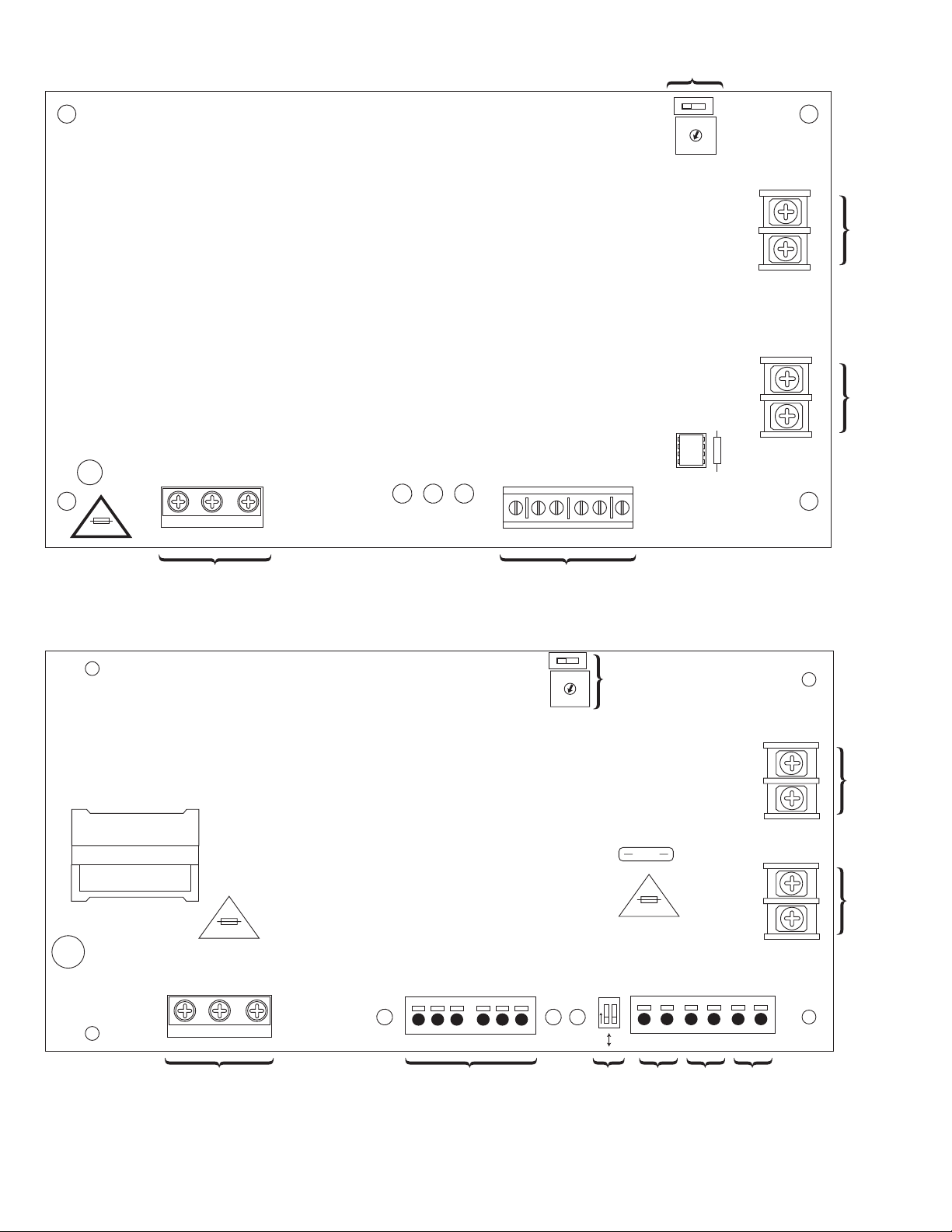

Fig. 5

115VAC Input, 60Hz

(non power-limited)

Trove1 Power Distribution Modules Configuration:

Supervisory Connections

(power-limited)

Power Supply/Charger

PD Outputs

to Devices

(non power-

limited)

PD4UL/CB

PD8UL/CB

Battery Connections

(non power-limited)

DC Output

(non power-

limited)

Trove - 7 -

Page 8

Fig. 6

115VAC Input, 60Hz

(non power-limited)

Trove1 MOM5 Configuration:

Supervisory Connections,

DC Outputs to Devices

and Fire Alarm Interface

(power-limited)

Power Supply/Charger

MOM5

DC Output

(powerlimited)

Battery Connections

(non power-limited)

- 8 - Trove

Page 9

Fig. 7

115VAC Input, 60Hz

(non power-limited)

Trove1 ACM4(CB) Configuration:

ACM Outputs to Devices and

Supervisory Connections

(power-limited)

Power Supply/Charger

DC Output

(powerlimited)

ACM4/CB

Battery Connections

(non power-limited)

Trove - 9 -

Page 10

Fig. 8

115VAC Input, 60Hz

(non power-limited)

Trove2 Power Distribution Modules Configuration:

DC Output

(power-limited)

Power Supply/Charger

Battery Connections

(non power-limited)

Supervisory Connections

(power-limited)

DC Output

(non power-limited)

Power Supply/Charger

PD16W/CB

PD8UL/CB

PD4UL/CB

PD Outputs to Devices

PD Outputs to Devices

Battery Connections

(non power-limited)

BAT DC

Supervisory Connections

(power-limited)

Battery Connections

(non power-limited)

- 10 - Trove

Page 11

Fig. 9

115VAC Input, 60Hz

(non power-limited)

Power Supply/Charger

Power Supply/Charger

Trove2 MOM5 Configuration:

DC Output

(power-limited)

Battery Connections

(non power-limited)

Supervisory Connections

(power-limited)

DC Output

(non power-limited)

MOM5

Battery Connections

(non power-limited)

BAT DC

Supervisory Connections

(power-limited)

Fire Alarm Interface

DC Outputs to Devices

(power-limited)

(power-limited)

Battery Connections

(non power-limited)

Trove - 11 -

Page 12

Fig. 10

115VAC Input, 60Hz

(non power-limited)

Power Supply/Charger

Power Supply/Charger

Trove2 ACM Configuration:

DC Output

(power-limited)

Battery Connections

(non power-limited)

Supervisory Connections

(power-limited)

DC Output

(non power-limited)

ACM8/CB

Supervisory Connections

(power-limited)

Supervisory Connections

(power-limited)

ACM Outputs to Devices

ACM4/CB

ACM Outputs to Devices

Battery Connections

(non power-limited)

Supervisory Connections

(power-limited)

BAT DC

Supervisory Connections

(power-limited)

Supervisory Connections

(power-limited)

Battery Connections

(non power-limited)

- 12 - Trove

Page 13

Fig. 11

TMV2 Sub-Assembly Configuration:

PD4UL/CB

PD8UL/CB

ACM4/CB

MOM5

GB1 Mounting Bracket

PD4UL/CB

PD8UL/CB

ACM4/CB

MOM5

GB1 Mounting Bracket

PD4UL/CB

PD8UL/CB

ACM4/CB

MOM5

GB1 Mounting Bracket

Trove - 13 -

Page 14

Fig. 12

115VAC Input, 60Hz

(non power-limited)

Power Supply/Charger

Power Supply/Charger

Trove3 ACM/PD Configuration:

DC Output

(power-limited)

Battery Connections

(non power-limited)

Supervisory Connections

(power-limited)

DC Output

(non power-limited)

Battery Connections

(non power-limited)

BAT DC

Supervisory Connections

(power-limited)

ACM8/CB

ACM8/CB

PD8UL/CB

PD4UL/CB

PD8UL/CB

PD4UL/CB

Supervisory Connections

(power-limited)

ACM Outputs to Devices

Supervisory Connections

(power-limited)

ACM Outputs to Devices

PD Outputs to Devices

PD Outputs to Devices

Supervisory Connections

(power-limited)

Supervisory Connections

(power-limited)

Battery Connections

(non power-limited)

Trove - 14 -

Page 15

eFlow Power Supply/Chargers can be Controlled and Monitored while

Reporting Power/Diagnostics from Anywhere over the Network...

LINQ2 - Network Communication Module

LINQ2 provides remote IP access to real-time data from eFlow power supply/chargers to help keep

systems up and running at optimal levels. It facilitates fast and easy installation and set-up, minimizes system downtime, and eliminates unnecessary service calls, which helps reduce Total Cost

of Ownership (TCO) - as well as creating a new source of Recurring Monthly Revenue (RMR).

LINQ2

Features:

- UL Listed in the U.S. and Canada.

- Local or remote control of up to (2) two Altronix eFlow power output(s) via LAN and/or WAN.

- Monitor real time diagnostics: DC output voltage, output current, AC & battery status/service, input trigger state change,

output state change and unit temperature.

- Access control and user managment: Restrict read/write, Restrict users to specific resources

- Two (2) integral network controlled Form “C” Relays.

- Three (3) programmable input triggers: Control relays and power supplies via external hardware sources.

- Email and Windows Dashboard notifications

- Event log tracks history.

- Secure Socket Layer (SSL).

- Programmable via USB or web browser - includes operating software and 6 ft. USB cable.

LINQ2 Mounts Inside any Trove Enclosure

LINQ2 Module

Network Connection:

Installation, Programming

and Monitoring

Altronix eFlow

Power Supply

- 15 - Trove

Page 16

Notes:

- 16 - Trove

Page 17

Notes:

Trove - 17 -

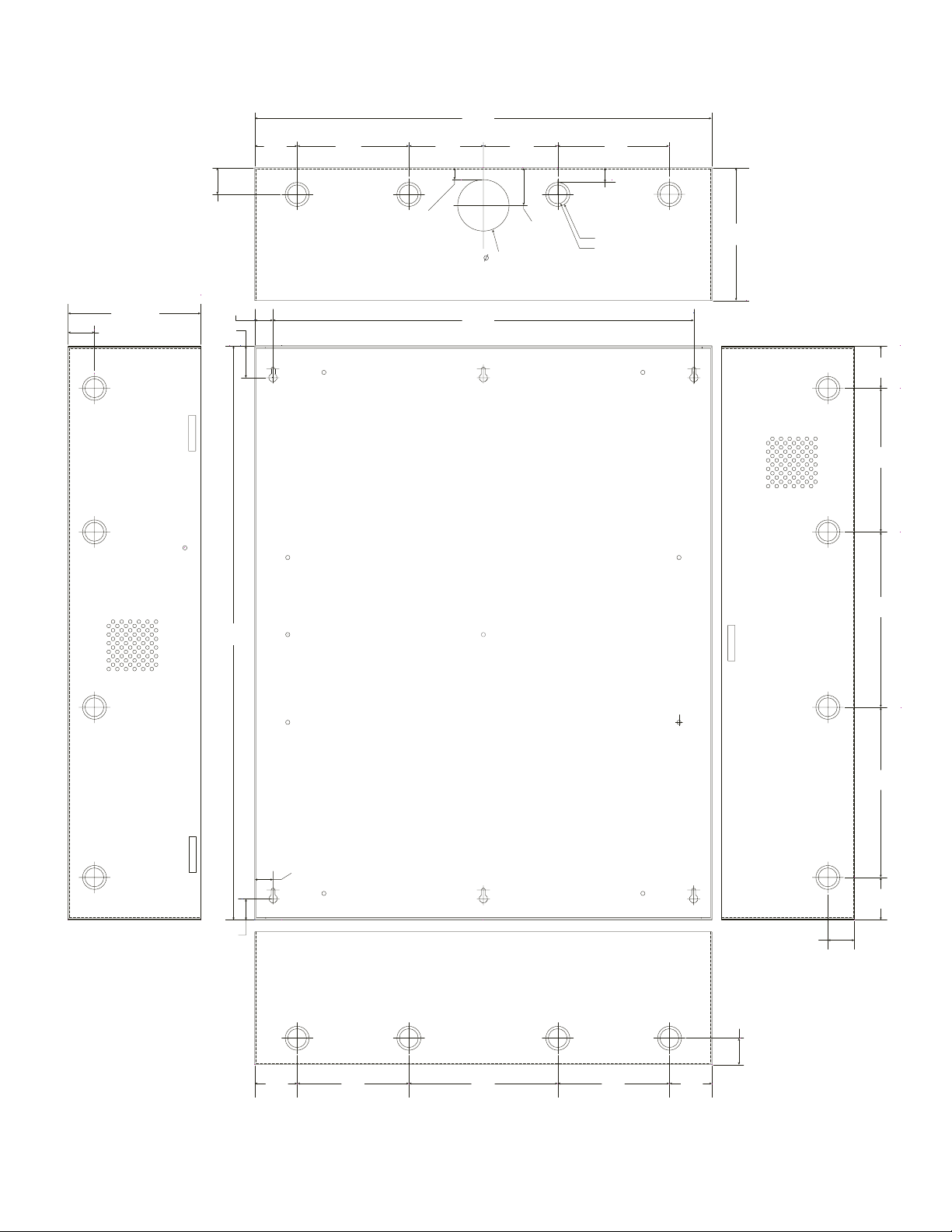

Page 18

1.25”

(31.75mm)

1.5”

(38.09mm)

(114.3mm)

0.569”

(14.52mm)

4.5”

Trove1 Enclosure Dimensions:

18” x 14.5” x 4.625” (457.2mm x 368.3mm x 117.47mm)

14.5”

13.0”

(330.2mm)

(368mm)

(49.483mm)

1.948”

(184.15mm)

0.5897”

(14.98mm)

7.25”

1.45”

(36.83mm)

1.25”

(31.75mm)

1.5”

(38.09mm)

8.5”

(215.9mm)

6.5”

(165.1mm)

18.0”

(457.2mm)

0.6012”

(15.27mm)

1.0958”

(27.83mm)

4.5”

(114.3mm)

4.5”

(114.3mm)

2.75”

(69.85mm)

8.5”

(215.9mm)

6.5”

(165.1mm)

1.115”

(28.32mm)

1.362”

(34.59mm)

1.25”

(31.75mm)

- 18 - Trove

Page 19

1.25”

(

)

(

)

(

)

(

)

(

)

(31.75mm)

Trove2 Enclosure Dimensions:

27.25” x 21.75” x 6.5” (692.15mm x 552.5mm x 165.1mm)

21.50”

(546.1mm)

2.00”

(50.8mm)

5.25”

(133.35mm)

3.50”

(88.9mm)

0.5625”

(14.29mm)

3.50”

(88.9mm)

(44.96mm)

2.415”

(61.34mm)

1.77”

5.25”

(133.35mm)

0.685”

(17.399mm)

Knockouts

1.125” (28.32mm)

0.885” (22.479mm)

6.25”

(158.75mm)

6.25”

(158.75mm)

1.25”

(31.75mm)

G

0.85”

(21.59mm)

1.5”

(38.1mm)

27.00”

(685.8mm)

19.80”

(502.92mm)

2.00”

(50.8mm)

6.75”

(171.45mm)

8.25”

(209.54mm)

8.00”

(203.2mm)

0.85”

(21.59mm)

2.00”

(50.8mm)

1.00”

(25.4mm)

1.25”

(31.75mm)

2.00”

50.8mm

Trove - 19 -

5.25”

133.35mm

7.00”

177.79mm

5.25”

133.35mm

2.00”

50.8mm

1.25”

(31.75mm)

Page 20

Trove3 Enclosure Dimensions:

(50.8mm)

(222.3mm)

(222.3mm)

(219mm)

2.00”

7.12”

9.5”

9.5”

(273.1mm)

(273.1mm)

(269.8mm)

(917.5mm)

36.12” x 30.125” x 7.06” (917.5mm x 768.1mm x 179.3mm)

2.00”

(50.8mm)

10.75”

10.62”

1.25”

(31.8mm)

G

G

1.25”

(31.75mm)

1.10”

(27.9mm)

(50.8mm)

1.07”

(27.2mm)

33.63”

(854.20mm)

(222.25mm)

14.01”

(355.9mm)

(241.3mm)

30.12”

(768.1mm)

(241.3mm)

(45.21mm)

14.01”

(355.9mm)

1.78”

1.55”

(39.37mm)

2.00”

(50.8mm)

10.75”

(273.1mm)

10.62”

(269.8mm)

36.12”

10.75”

1.25”

(31.8mm)

2.00”

8.75”

8.62”

8.75”

7.06”

(179.3mm)

10.75”

(273.1mm)

1.25”

(31.8mm)

Altronix is not responsible for any typographical errors. Product specifications are subject to change without notice.

140 58th Street, Brooklyn New York 11220 USA | phone: 718-567-8181 | fax: 718-567-9056

website: www.altronix.com | e-mail: info@altronix.com | Made in USA.

IITrove - Rev. 101817 I10R

MEMBER

- 20 - Trove

Loading...

Loading...