Page 1

Maximal11E

- Power Supply 1:

12VDC @ 4 amp or 24VDC @ 3 amp.

- Power Supply 2:

12VDC @ 4 amp or 24VDC @ 3 amp.

Maximal33E

- Power Supply 1:

12VDC or 24VDC @ 6 amp.

- Power Supply 2:

12VDC or 24VDC @ 6 amp.

Maximal37E

- Power Supply 1:

12VDC or 24VDC @ 6 amp.

- Power Supply 2:

24VDC @ 10 amp.

Maximal75E

- Power Supply 1:

24VDC @ 10 amp.

- Power Supply 2:

12VDC @ 10 amp.

Maximal13E

- Power Supply 1:

12VDC @ 4 amp or 24VDC @ 3 amp.

- Power Supply 2:

12VDC or 24VDC @ 6 amp.

Maximal35E

- Power Supply 1:

12VDC or 24VDC @ 6 amp.

- Power Supply 2:

12VDC @ 10 amp.

Maximal55E

- Power Supply 1:

12VDC @ 10 amp.

- Power Supply 2:

12VDC @ 10 amp.

Maximal77E

- Power Supply 1:

24VDC @ 10 amp.

- Power Supply 2:

24VDC @ 10 amp.

Rev. ME080907

Series

Expandable Power Systems

Installation Guide

Models Include:

More than just power.

TM

Page 2

- 2 - Maximal Expandable Power Systems

Table of Contents:

MaximalE Overview ........................................................................................................ 3

MaximalE Series Configuration Chart ............................................................................ 3

MaximalE Features ....................................................................................................... 3-4

MaximalE Installation Instructions ................................................................................. 4

Maintenance ..................................................................................................................... 4

Power Supply Board Terminal Identification ................................................................. 5

Power Supply Board Stand-by Battery Specifications .................................................... 5

Power Supply Board LED Diagnostics ........................................................................... 6

Power Supply Board Output Voltage Settings ................................................................ 6

MaximalE Battery Hook-up Installation Instructions ..................................................... 7

NEC Power-Limited Wiring Requirements for Maximal11E.......................................... 8

NEC Power-Limited Wiring Requirements for Maximal13E.......................................... 9

NEC Power-Limited Wiring Requirements

for Maximal33E, Maximal35E and Maximal55E .......................................................... 10

NEC Power-Limited Wiring Requirements for Maximal37E and Maximal75E ........... 11

NEC Power-Limited Wiring Requirements for Maximal77E........................................ 12

Enclosure Dimensions .................................................................................................... 13

Page 3

Maximal Expandable Power Systems - 3 -

MaximalE Overview:

Maximal Expandable Power System provide system designers and installers with “maximum” power choices and the

highest levels of versatility. They provide 12VDC, 24VDC, or 12VDC and 24VDC simultaneously via two (2) single

output power supply/chargers. Includes AC fail, low battery and battery presence monitoring. Custom enclosure facilitates

up to four (4) 12VDC/12AH batteries. All interconnecting equipment must be UL Listed.

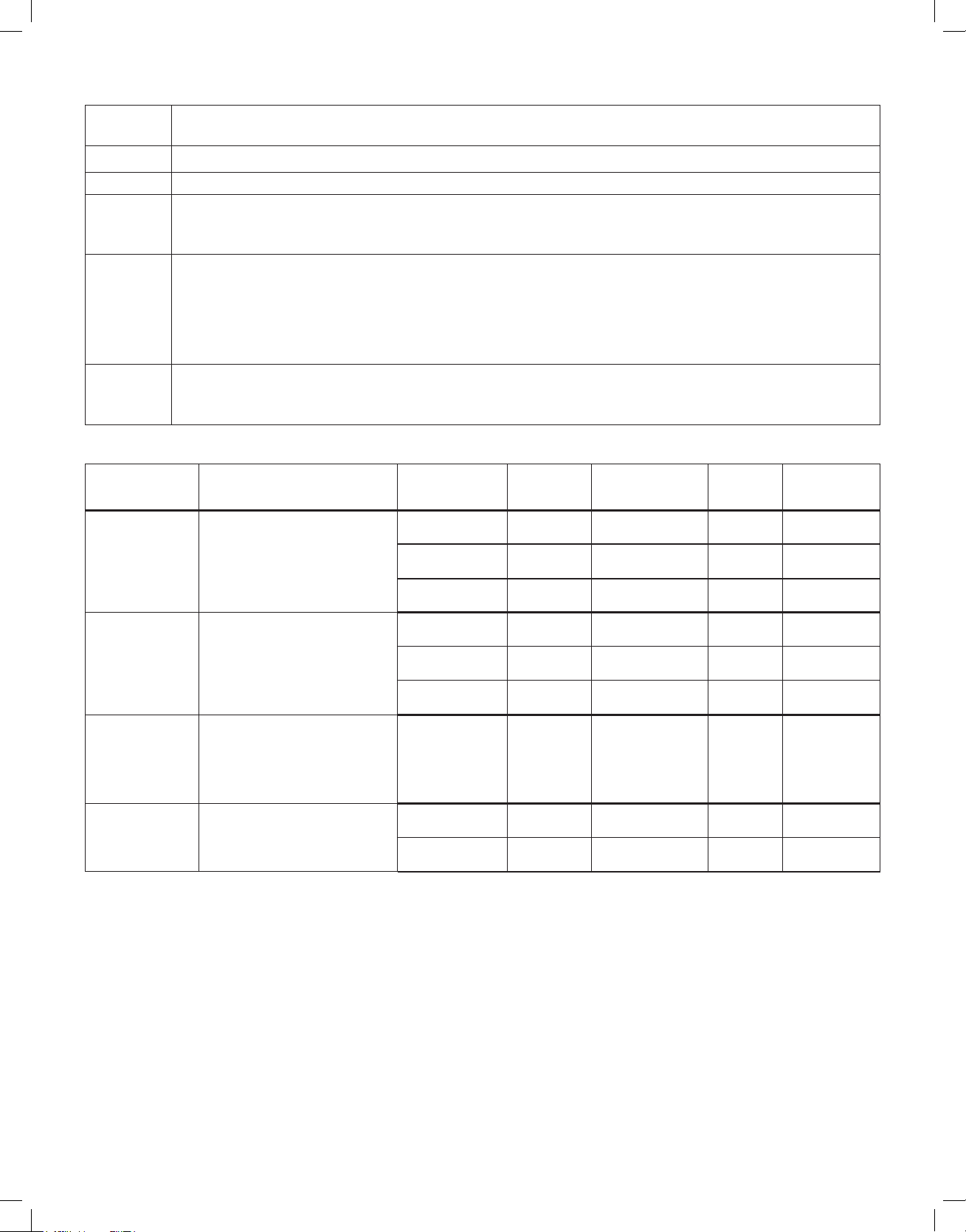

MaximalE Series Configuration Chart:

Altronix

Model Number

Output Voltage Options

Non Power-

Limeted Outputs

Class 2 Rated

Power-Limited

115VAC 60 Hz

Input (current)

Power Supply

Board

Agrncy

Listenings and

File Numbers

Power Supply 1 Power Supply 2

Maximal11E

AL400ULXB AL400ULXB

--- 2 4.5 amp 3.5A/250V

California State Fire

Marshal Approved

UL File # BP6714

UL 294

UL Listed for

Access Control

System Units.

General Signaling

Equipment

Evaluated to

CSA Standard

C22.2 No.205-M1983

12VDC @ 4 amp 12VDC @ 4 amp

12VDC @ 4 amp 24VDC @ 3 amp

24VDC @ 3 amp 24VDC @ 3 amp

Maximal13E

AL400ULXB AL600ULXB

1 1 5 amp 3.5A/250V

12VDC @ 4 amp 12VDC @ 6 amp

12VDC @ 4 amp 24VDC @ 6 amp

24VDC @ 3 amp 12VDC @ 6 amp

24VDC @ 3 amp 24VDC @ 6 amp

Maximal33E

AL600ULXB AL600ULXB

2 --- 7 amp 3.5A/250V

12VDC @ 6 amp 12VDC @ 6 amp

12VDC @ 6 amp 24VDC @ 6 amp

24VDC @ 6 amp 24VDC @ 6 amp

Maximal35E

AL600ULXB AL1012ULXB

2 --- 6 amp 3.5A/250V

12VDC @ 6 amp 12VDC @ 10 amp

24VDC @ 6 amp 12VDC @ 10 amp

Maximal37E

AL600ULXB AL1024ULXB

2 --- 10 amp

3.5A/250V

(AL600ULXB)

10A/250V

(AL1024ULXB)

12VDC @ 6 amp 24VDC @ 10 amp

24VDC @ 6 amp 24VDC @ 10 amp

Maximal55E

AL1012ULXB AL1012ULXB

2 --- 6 amp 3.5A/250V

12VDC @ 10 amp 12VDC @ 10 amp

Maximal75E

AL1012ULXB AL1024ULXB

2 --- 10 amp

3.5A/250V

(AL1012ULXB)

10A/250V

(AL1024ULXB)

12VDC @ 10 amp 24VDC @ 10 amp

Maximal77E

AL1024ULXB AL1024ULXB

2

--- 12.5 amp 10A/250V

24VDC @ 10 amp 24VDC @ 10 amp

MaximalE Features:

• Filteredandelectronicallyregulatedoutputs

(built-in power supply).

• Built-inchargerforsealedleadacidorgeltypebatteries.

• AL400ULXB,AL600ULXBandAL1012ULXB

(Power Supply Board) maximum charge current .7 amp.

AL1024ULXB (Power Supply Board) maximum charge

current 3.6 amp.

• Automaticswitchovertostand-bybatterywhenACfails.

• Zerovoltagedropwhenunitswitchesoverto

battery backup (AC failure condition).

• Lowbatteryandbatterypresencesupervision

(form “C” contact).

Page 4

- 4 - Maximal Expandable Power Systems

MaximalE Features (cont’d):

• Shortcircuitandthermaloverloadprotection

with auto reset.

• ACinputandDCoutputLEDindicators.

• ACfailsupervision(form“C”contact).

• Enclosureaccommodatesuptofour(4)

12VDC/12AH batteries.

Enclosure dimensions: 26”H x 19”W x 6.25”D

MaximalE Installation Instructions:

Wiring methods shall be in accordance with the National Electrical Code/NFPA 70/ANSI, and with all local codes and

authorities having jurisdiction. Product is intended for indoor use only.

Power Supply Board Terminal Identification (pg. 5)

Power Supply Stand-by Battery Specifications (pg. 5)

Power Supply Board LED Diagnostics (pg. 6)

Power Supply Board Output Voltage Settings (pg. 6)

1. Mount unit in desired location. Mark and predrill holes in the wall to line up with the top three keyholes in the

enclosure. Install three upper fasteners and screws in the wall with the screw heads protruding. Place the enclosure’s

upper keyholes over the three upper screws, level and secure. Mark the position of the lower three holes. Remove the

enclosure. Drill the lower holes and install the three fasteners. Place the enclosure’s upper keyholes over the three

upper screws. Install the three lower screws and make sure to tighten all screws (Enclosure Dimensions, pg. 13).

2. The power supply is pre-wired to the ground (chassis). Connect main incoming ground to the provided green

grounding conductor lead. Connect unswitched AC power (115VAC 60Hz) to terminals marked [L, N] on both

power supply boards. Use 14 AWG or larger for all power connections. (Fig. 2, pg. 7).

Keep power limited wiring separate from non-power limited wiring. Minimum .25” spacing must be provided.

3. Select desired DC output voltage by setting SW1 to the appropriate position, (Maximal11E, Maximal13E,

Maximal33E, Maximal35E and Maximal37E) (Fig. 1, pg. 6). Maximal55E power supplies are factory set at 12VDC.

Maximal77E power supplies are factory set at 24VDC. Maximal75E power supplies are factory set at 12VDC and

24VDC, (Power Supply Board Stand-by Battery Specifications, pg. 5).

4. Measure the output voltage of the unit before connecting any devices to ensure proper operation.

Improper or high voltage will damage these devices.

5. Connect devices to be powered to terminals marked [+ DC -] (Fig. 2, pg. 7).

6. For Access Control applications, batteries are optional. When batteries are not used a loss of AC will result in the

loss of output voltage. When the use of stand-by batteries is desired, they must be lead acid or gel type.

Connect battery to terminals marked [+ BAT -- ] (Figs. 2-7, pgs. 7-12).

Use two (2) 12VDC batteries connected in series for 24VDC operation (battery leads included).

7. Battery and AC Supervision outputs: It is required to connect supervisory trouble reporting devices to outputs marked

[AC Fail, BAT FAIL] supervisory relay outputs marked [NC, C, NO] to appropriate visual

notification devices. Use 22 AWG to 18 AWG for AC Fail & Low/No Battery reporting (Fig. 2a, pgs. 7).

8. Mount UL Listed tamper switch (Not Included) (Sentrol model 3012 or equivalent) at the top of the enclosure.

Slide the tamper switch bracket onto the edge of the enclosure approximately 2” from the right side (Fig. 2b, pg. 7).

Connect tamper switch wiring to the Access Control Panel input or the appropriate UL Listed reporting device.

To activate alarm signal open the door of the enclosure.

9. Please insure that the cover is secured with the provided key lock.

Maintenance:

Unit should be tested at least once a year for the proper operation as follows:

Output Voltage Test: Under normal load conditions, the DC output voltage should be checked for proper voltage level

(Power Supply Stand-by Battery Specifications, pg. 5).

Battery Test: Under normal load conditions check that the battery is fully charged, check specified voltage at

the battery terminals and at the board terminals marked [+ BAT -- ] to insure that there is no break in the battery

connection wires.

Note: AL400ULXB, AL600ULXB and AL1012ULXB (Power Supply Board) maximum charge current is .7 amp.

AL1024ULXB (Power Supply Board) maximum charge current is 3.6 amp.

Expected battery life is 5 years, however it is recommended to change batteries within 4 years or less if necessary.

Page 5

Maximal Expandable Power Systems - 5 -

Power Supply Board Terminal Identification:

Terminal

Legend

Function/Description

L. G, N Connect 115VAC 60Hz to these terminals: L to hot, N to neutral, G to ground.

- DC + Refer to Maximal Series Configuration Chart, pg. 3.

AC FAIL

NC, C, NO

Indicates loss of AC power. To meet with UL requirements it is mandatory to connect visual notification

devices, connecting audible notification devices is optional. Relay normally energized when AC power is

present. Contact rating 1 amp @ 28VDC. AC or brownout fail is reported within 1 minute of event.

BAT FAIL

NC, C, NO

Indicates low battery condition, e.g. connect to alarm panel. Relay normally energized when DC

power is present. Contact rating 1 amp @ 28VDC. A removed battery is reported within 5 minutes.

Battery reconnection is reported within 1 minute.

Low battery threshold:

12VDC output threshold set @ approximately 10.5VDC.

24VDC output threshold set @ approximately 21VDC.

+ BAT -

Stand-by battery connections. AL400ULXB, AL600ULXB and AL1012ULXB (Power Supply Board)

maximum charge current is .7 amp. AL1024ULXB (Power Supply Board) maximum charge current is

3.6 amp.

Power Supply Board Stand-by Battery Specifications

Altronix

Model

Power Supply Board Battery

20 min. of

Backup

4 hr. of

Backup

24 hr. of

Backup

60 hr. of

Backup

Maximal11E

Maximal13E

AL400ULXB

(Refer to Fig. 1a, 1b on

pg. 6 for Switch [SW1]

location and position)

12VDC/40AH*

N/A 4 amp 1 amp 300mA

24VDC/12AH

N/A 200mA N/A N/A

24VDC/40AH*

N/A 3 amp 1 amp 300mA

Maximal13E

Maximal33E

Maximal35E

Maximal37E

AL600ULXB

(Refer to Fig. 1b, 1c on

pg. 6 for Switch [SW1]

location and position)

12VDC/40AH*

N/A 6 amp 1 amp 300mA

24VDC/12AH

N/A 200mA N/A N/A

24VDC/40AH*

N/A 6 amp 1 amp 300mA

Maximal35E

Maximal55E

Maximal75E

AL1012ULXB

(Factory set at 12VDC)

12VDC/12AH 10 amp

Battery capacity

for emergency

standby at least

20 min

N/A N/A

Maximal37E

Maximal75E

Maximal77E

AL1024ULXB

(Factory set at 24VDC)

24VDC/12AH

8 amp 1.5 amp 200mA 100mA

24VDC/65AH* N/A

8 amp 1.5 amp 500mA

* Note: Additional battery enclosure required (Figs. 3-5, pgs, 8-10).

Page 6

- 6 - Maximal Expandable Power Systems

NO NC C NO

+ BAT ---

24V - OPEN

12V - CLOSED

AC FAIL

RL3

SW1

AC Delay

BAT FAIL

NC C NO NC C NO

+ BAT ---

DC

AC FAIL

AC

24V - OPEN

12V - CLOSED

SW1

Fig. 1a

AL400ULXB Power Supply Board

Fig. 1c

AL600ULXB Power Supply Board

Fig. 1b

OPEN SWITCH

CLOSED SWITCH

Switch Detail

Power Supply Board LED Diagnostics:

LED

Power Supply Status

Red (DC)

Green (AC)

ON

ON

Normal operating condition.

ON

OFF

Loss of AC, Stand-by battery supplying power

OFF

ON

No DC output. Short circuit or thermal overload condition.

OFF

OFF

No DC output. Loss of AC. Discharged battery

Power Supply Board Output Voltage Settings:

Fig. 1Fig. 1

Page 7

Maximal Expandable Power Systems - 7 -

Ground Lug

--- DC +

BAT FAIL

NO C NC NO C NC

+ BAT ---

AC FAIL

Power Supply Board

L G N

--- DC +

BAT FAIL

NO C NC NO C NC

+ BAT ---

AC FAIL

Power Supply Board

L G N

Ground Lug

Line

Neutral

GroundLine

Neutral

*12VDC operation: For 12VDC operation

only a single battery is needed.

Connect red battery lead

to terminal marked

[+ BAT] and to the

[positive (+)] terminal

of the battery. Connect

black battery lead to

terminal marked [BAT -]

and to the [negative (-)]

terminal of the battery.

Tamper Switch

12VDC Rechargeable

Battery**

(Optional)

12VDC Rechargeable

Battery*

(Optional)

12VDC Rechargeable

Battery**

(Optional)

115VAC

Input

60 Hz.

Ground

+ DC ---

NO C NC NO C NC

+ BAT ---

AC FAIL

**24VDC operation: Connect two (2) 12VDC

batteries in series

Fig. 2

Fig. 2b

Edge of

Enclosure

to Access Control Panel

or U.L. Listed

Reporting Device

Enclosure

Sentrol

model # 3012

Tamper Switch

or equiva lent

(Not Included)

Power Supply Board Terminal

Layout for: AL400ULXB,

AL600ULXB and AL1012ULXB

Fig. 2a

Page 8

- 8 - Maximal Expandable Power Systems

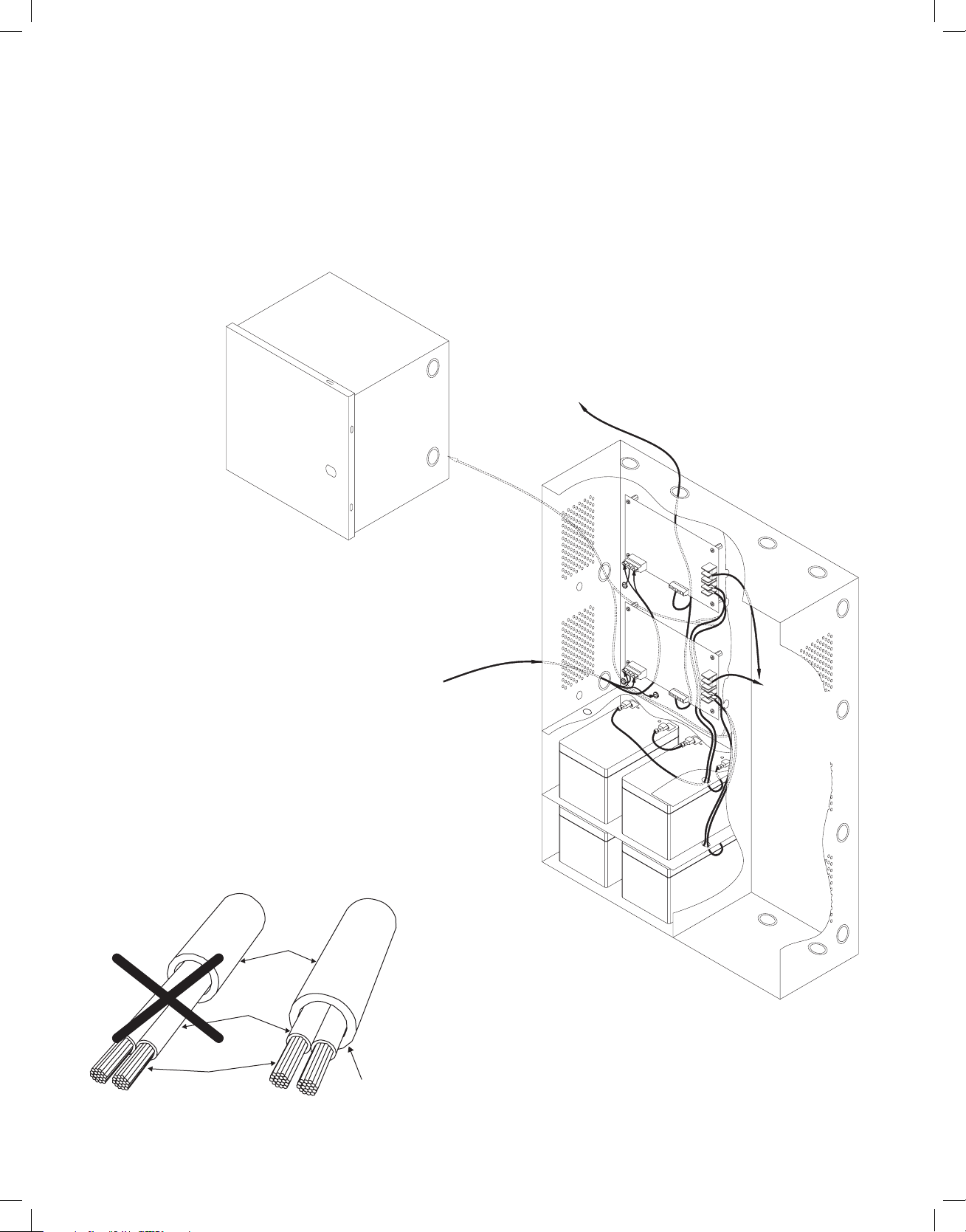

NEC Power-Limited Wiring Requirements for Maximal11E:

Power-limited and non power-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25” away from any non power-limited circuit wiring. Furthermore, all power-limited circuit wiring

and non power-limited circuit wiring must enter and exit the cabinet through different conduits. One such example of this

is shown below. Your specific application may require different conduit knockouts to be used. Any conduit knockouts

may be used. For power- limited applications, use of conduit is optional.

All field wiring connections must be made employing suitable gauge CM or FPL jacketed wire (or equivalent substitute).

Note: Refer to wire handling drawing below for the proper way to install the CM or FPL jacketed wire, (Fig, 3a).

Fig. 3

External

Jacketed

Shield

Incorrect Wire

Handling

Correct Wire

Handling

Pull back external

jacketed shield

approximately 1/2”.

Wi re

Insulation

Solid

Copper

Conductors

Fig. 3a

Supervisory

Connections

(power-limited)

115VAC Input

60Hz

(non power-limited)

Optional Battery

Enclosure

(non power-limited)

DC Output

Wiring

(powerlimited)

Battery

Connections

(non power-limited)

Page 9

Maximal Expandable Power Systems - 9 -

NEC Power-Limited Wiring Requirements for Maximal13E:

Power-limited and non power-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25” away from any non power-limited circuit wiring. Furthermore, all power-limited circuit wiring

and non power-limited circuit wiring must enter and exit the cabinet through different conduits. One such example of this

is shown below. Your specific application may require different conduit knockouts to be used. Any conduit knockouts

may be used. For power- limited applications, use of conduit is optional.

All field wiring connections must be made employing suitable gauge CM or FPL jacketed wire (or equivalent substitute).

Note: Refer to wire handling drawing below for the proper way to install the CM or FPL jacketed wire, (Fig, 4a).

Fig. 4

External

Jacketed

Shield

Incorrect Wire

Handling

Correct Wire

Handling

Pull back external

jacketed shield

approximately 1/2”.

Wi re

Insulation

Solid

Copper

Conductors

Fig. 4a

Supervisory

Connections

(power-limited)

115VAC Input

60Hz

(non power-limited)

Optional Battery

Enclosure

(non power-limited)

DC Output

Wiring

(non

power-

limited)

Battery

Connections

(non power-limited)

DC Output

Wiring

(powerlimited)

Page 10

- 10 - Maximal Expandable Power Systems

NEC Power-Limited Wiring Requirements for Maximal33E, Maximal35E and

Maximal55E:

Power-limited and non power-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25” away from any non power-limited circuit wiring. Furthermore, all power-limited circuit wiring

and non power-limited circuit wiring must enter and exit the cabinet through different conduits. One such example of this

is shown below. Your specific application may require different conduit knockouts to be used. Any conduit knockouts

may be used. For power- limited applications, use of conduit is optional.

All field wiring connections must be made employing suitable gauge CM or FPL jacketed wire (or equivalent substitute).

Note: Refer to wire handling drawing below for the proper way to install the CM or FPL jacketed wire, (Fig, 5a).

Fig. 5

External

Jacketed

Shield

Incorrect Wire

Handling

Correct Wire

Handling

Pull back external

jacketed shield

approximately 1/2”.

Wi re

Insulation

Solid

Copper

Conductors

Fig. 5a

Supervisory

Connections

(power-limited)

115VAC Input

60Hz

(non power-limited)

Optional Battery

Enclosure

(non power-limited)

DC Output

Wiring

(non

power-

limited)

Battery

Connections

(non power-limited)

Page 11

Maximal Expandable Power Systems - 11 -

NEC Power-Limited Wiring Requirements for Maximal37E and Maximal75E:

Power-limited and non power- limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25” away from any non power-limited circuit wiring. Furthermore, all power-limited circuit wiring

and non power-limited circuit wiring must enter and exit the cabinet through different conduits. One such example of this

is shown below. Your specific application may require different conduit knockouts to be used. Any conduit knockouts

may be used. For power-limited applications, use of conduit is optional.

All field wiring connections must be made employing suitable gauge CM or FPL jacketed wire (or equivalent substitute).

Note: Refer to wire handling drawing below for the proper way to install the CM or FPL jacketed wire, (Fig, 6a).

Fig. 6

External

Jacketed

Shield

Incorrect Wire

Handling

Correct Wire

Handling

Pull back external

jacketed shield

approximately 1/2”.

Wi re

Insulation

Solid

Copper

Conductors

Fig. 6a

Supervisory

Connections

(power-limited)

115VAC Input

60Hz

(non power-limited)

Optional Battery

Enclosure

(non power-limited)

DC Output

Wiring

(non

power-

limited)

Battery

Connections

(non power-limited)

Page 12

- 12 - Maximal Expandable Power Systems

NEC Power-Limited Wiring Requirements for Maximal77E:

Power-limited and non power-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25” away from any non power-limited circuit wiring. Furthermore, all power-limited circuit wiring

and non power-limited circuit wiring must enter and exit the cabinet through different conduits. One such example of this

is shown below. Your specific application may require different conduit knockouts to be used. Any conduit knockouts

may be used. For power-limited applications, use of conduit is optional.

All field wiring connections must be made employing suitable gauge CM or FPL jacketed wire (or equivalent substitute).

Note: Refer to wire handling drawing below for the proper way to install the CM or FPL jacketed wire, (Fig, 7a).

Fig. 7

Supervisory

Connections

(power-limited)

115VAC Input

60Hz

(non power-limited)

Optional Battery

Enclosure

(non power-limited)

DC Output

Wiring

(non

power-

limited)

External

Jacketed

Shield

Incorrect Wire

Handling

Correct Wire

Handling

Pull back external

jacketed shield

approximately 1/2”.

Wi re

Insulation

Solid

Copper

Conductors

Fig. 7a

Battery

Connections

(non power-limited)

Page 13

Maximal Expandable Power Systems - 13 -

Enclosure Dimensions:

26”H x 19”W x 6.25”D

Page 14

- 14 - Maximal Expandable Power Systems

Notes:

Page 15

Maximal Expandable Power Systems - 15 -

Notes:

Page 16

- 16 - Maximal Expandable Power Systems

Altronix is not responsible for any typographical errors.

140 58th Street, Brooklyn, New York 11220 USA, 718-567-8181, fax: 718-567-9056

web site: www.altronix.com, e-mail: info@altronix.com, Lifetime Warranty, Made in U.S.A.

IIMaximalE Series L21J

Notes:

MEMBER

Loading...

Loading...