Page 1

ITEM NO. _______________________

ANSI/NSF 4

COMBITHERM®

MODEL 20•20ESG DELUXE

CAPACITY OF FORTY (40) FULL-SIZE OR GN 1/1 PANS,

TWENTY (20) FULL-SIZE SHEET OR GN 2/1 PANS

20

20ESG

G A S C O M B I NAT I O N OV E N / S TE AM E R

• Flash-steam generation makes

conventional steam generator obsolete:

— Eliminates steam generating boiler maintenance

— Ends boiler heating element burn-out

— Maintains steam levels without a water reservoir

• Cook by internal product temperature or time with temperature

ariable steam, convection heat, or a combination of both to roast,

v

steam, bake, or oven-fry in a single piece of equipment.

• Provides increased food quality and expands menu options

while increasing production efficiency and speed by as much

as 70-percent compared to conventional cooking methods.

• EcoSmart

electricity and water during both normal operation and the

cleaning function.

• Gold-n-Brown™ feature provides the operator with the ability to

add additional product color.

• AutoClean™ feature simplifies the cleaning process to a single

oven function.

• Standard and Deluxe control offers a 2-speed fan, cool-down

feature, additional moisture injection, Delta-T cooking,

multiple language display, and other control features.

• Enhanced safety feature includes automatic steam venting

immediately before cooking time expires.

technology reduces energy cost by using less

™

PATEN T #7, 282,6 74

SHORT FORM SPECIFICATIONS:

Provide Alto-Shaam Combitherm®floor standing Model 20•20ES G flash-steam combi oven/steamer designed with EcoSmart™

technology for reduced energy and water usage and include operational modes for steam, convection, and a combination of steam and

convection heat. Standard features to include energy efficient forced-air power burner, patented heat exchange system, electronic

ignition, patented automatic steam venting; Gold-n-Brown™ browning function; and a self-adjusting, flush-mounted rotary door handle

with a steam venting safety stop. Control to include 2-speed fan and cool-down function. Oven is to be constructed of 18 gauge stainless

steel, include an attached spray hose with backflow preventer, and automatic cleaning function. The oven is to accommodate up to

20 full-size sheet pans or 40 full-size hotel pans, include a removable door gasket for easy replacement, and standard right-hand door

hinging. Includes roll-in pan cart with removable drip tray and cart handle.

STANDARD C ONTROL: To include removable quick-connect internal product temperature probe in the oven interior.

DELUXE C ON TROL: To include removab le quick-conn ect internal product temperatu re p robe in the oven interior

and programming capability with Rapid-Touch™ operational quick-keys.

S-CONTROL: To include removable quic k-connect internal product tem perature probe in the oven interior as an option.

MODELS:

20•20ES G: STA ND ARD

■■

■■

20•20ES G: DE LUXE

■■

20•20ES G: S-CON TR OL

W164 N9221 Water Street • P.O. Box 450 • Menomonee Fall s, Wisconsin 53052-0 45 0 • U.S.A .

PH ON E: 262.2 51 .3800 800.558.87 44 U.S .A ./CA NADA FAX : 262. 251.7067 800.329.8744 U. S.A . ON LY

D UE TO O NG O IN G PR O DU C T I MP RO V EM E NT , S PE C IF IC AT I ON S A RE S UB J EC T T O C HA N GE W IT H OU T N O TI CE .P RI NT E D I N U .S .A . #475 - 1 / 08

STANDARD FEATU RES AND A CCESSORIES

• Roll-in pan cart completely interchangeable with QC-100 QuickChiller™

and 20•20 Combimate® companion holding cabinet with:

Twenty (20) non-tilt pan support rails

21-1/16" (535mm) horizontal width between rails

2-5/8" (65mm) vertical spacing between rails

Ten (10) stainless steel shelves

Removable drip tray and cart handle

• Four (4) adjustable legs

• One (1) hand-held shower with backflow preventer

• One (1) flush-mounted rotary door latch with steam venting position

• Single-point detachable temperature probe (

www.alto-s haam.com

OP TI ONAL ON S-CONTR OL MOD ELS)

PATEN T PEN DING

Page 2

G A S C O M B I N AT I O N OV E N/ ST EA M E R 20

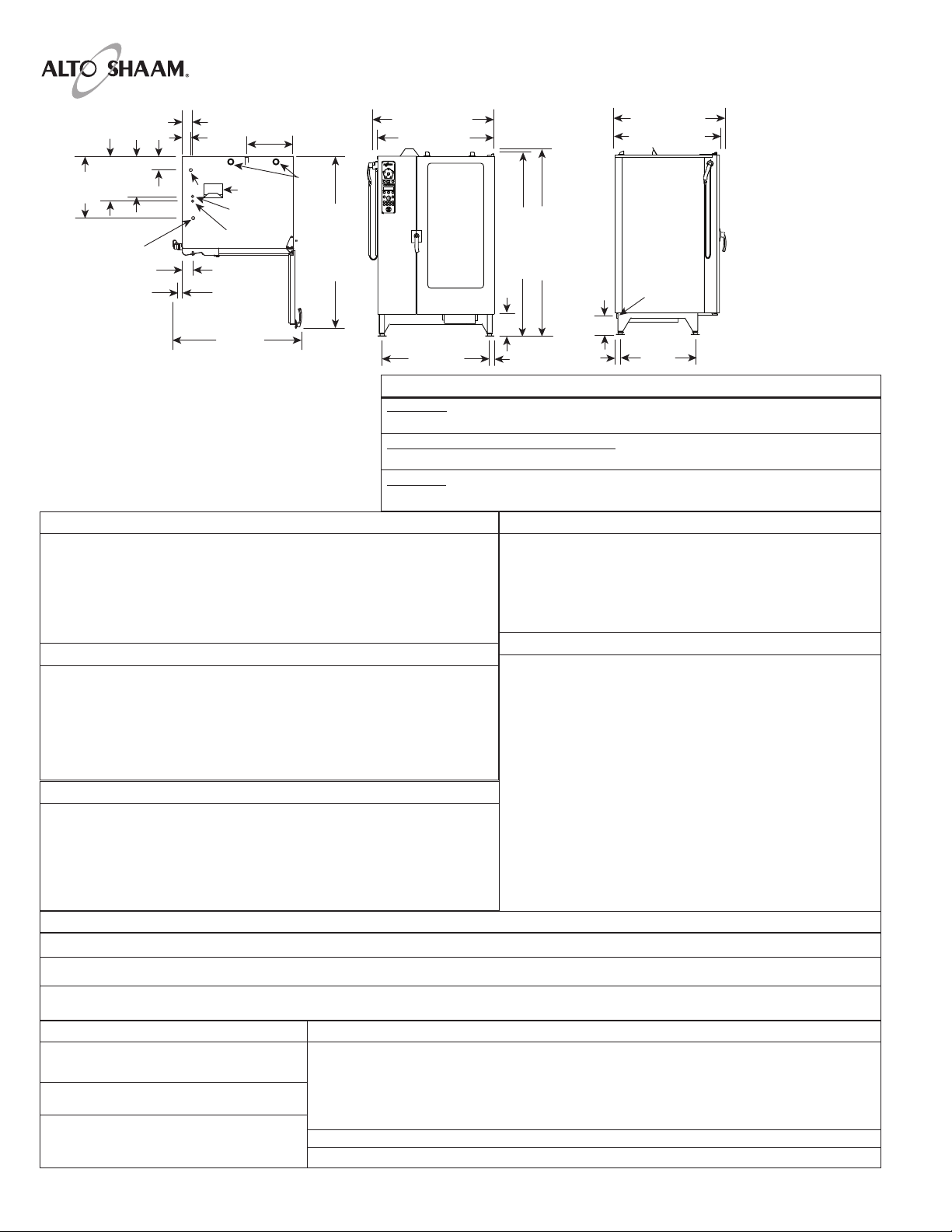

49-13/16" (1264mm)

47-13/16" (1214mm)

45-3/16" (1148mm)

4

2-9/16" (1080mm)

30-1/2"

(775mm)

44" (1118mm)

2

" (49mm)

2-3/16"

(56mm)

8-15/16" (226mm)

76-5/8" (1946mm)

75-1/4" (1911mm)

Water Drain

(Bottom)

7-11/16" (195mm)

4

-3/8" (110mm)

3

-9/16"

(89mm)

Water Drain

(Side Back)

Gas Exhaust (Top)

Electrical Connection

(Bottom)

Treated Water

Intake (Bottom)

Untreated Water

Intake (Bottom)

Gas Connection

(Bottom)

4-5/8" (116mm)

2" (50mm)

5

5-7/16"

(1407mm)

73-13/16" (1874mm)

6" (151mm)

17-3/8"

(441mm)

19-3/8"

(491mm)

26-3/4"

(678mm)

2

0-1/4"

(514mm)

Steam

V

ents

(Top)

D I ME NS I O N S: H x W x D

EX TE RIOR:

76-5/8" x 49-13/16" x 45-3/16" (1946mm x 1264mm x 1148mm)

EX TE RIOR WIT H R ET RACTABLE DO OR :

76-5/8" x 53-13/16" x 45-3/16" (1337mm x 1366mm x 1148mm)

NT ER IOR

I

:

54-15/16" x 25-1/4" x 33-7/8" (1395mm x 640mm x 860mm)

20ESG

C L EA RA N C E R E Q UI R E M EN T S

LE FT : 6" (152 mm) PL US SE RVIC E AC CESS : 18 " (4 57 mm ) R ECOM MEN DE D

20 " (508mm ) F RO M H EA T P RO DU CI N G E QU IP M E N T

: 4" (10 2mm) TO P : 20" (508mm) FOR AIR MOVEMENT

RI GH T

: 4" (10 2mm) BO TT OM: 5-1/8" (130m m) FOR LEGS

BA CK

WAT E R R E Q UI R E M EN T S

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE (1) TREATED WATER INLET: 3/4" NPT

ONE (1) UNTREATED WATER INLET: 3/4" NPT

LINE PRESSURE: 30 to 90 psi 2.8 to 6.2 bar

WATER DRAIN: 1-1/2"

FERNCO CONNECTION WITH AIR GAP

I N STA L L AT I O N R E Q UI R E M EN TS

Oven must be installed level. Hood installation. Water supply

shut-off valve and back-flow preventer. Alternate burner orifice

is required for installation sites at elevations of 3,000 feet (914m)

above sea level.

E L EC TR I C A L

VOLTAGE PHASE CYCLE/HZ AWG AMPS kW

110 - 120 1 50/60 2 Wire plus ground, AWG 10 22.0 2.64

W E IG HT

NE T 838 lb E ST. (380 kg) ES T.

SH IP 1325 lb EST . (601 kg) E ST.

CR ATE 82" X 56" X 50" ES T.

DI ME NSION S: (2083 x 1422 x 1270mm)

OT HE R V OLTAG ES AVAILA BL E: Range 200 — 415V — 1 or 3 ph, 50 or 60 Hz

C A PA CI T Y

FULL-SIZE PANS: 20" x 12" x 2-1/2" Forty (40)

FULL-SIZE SHEET PANS:* 18" x 26" x 1" Twenty (20)

ON WIRE SHELVES ONLY

GN 1/1: 530 x 325 x 65mm Forty (40)

GN 2/1: 650 x 530 x 65mm Twenty (20)

VO LUM E M AXI MUM

G A S R E QU I R E M E NT S

ON NE CTED E NERGY LOA D

C

HO OK -UP: 3/4" NPT

MI NI MUM CON NE CTE D PR ESSUR E: 5.5" W.C. (Natural Gas)

: 190,000 Btu/hr

9" W.C. (P ropane)

MA XI MUM CON NE CTE D PR ESSUR E: 14" W.C.

GA S T YPE MU ST BE SP ECIF IED ON O RDER .

WAT E R Q U A LI T Y M I N I MU M STA N D AR DS

USING A WATER SUPPLY NOT MEETING ALTO-SHAAM'S

MINIMUM WATER QUALITY STANDARDS WILL VOID THIS

WARRANTY. It is the responsibility of the purchaser to ensure

that incoming water supply is compliant with the specifications

listed through adequate treatment measures. Installation of the

CombiGuard™ Water Filtration System is recommended, but this

system may not address all water quality issues present.

Contaminant Inlet Water Requirements (untreated water)

Free Chlorine Less than 0.1 ppm (mg/L)

Hardness Less than 3 gpg (52 ppm)

Chloride Less than 30 ppm (mg/L)

pH 7.0 to 8.5

Alkalinity Less than 50 ppm (mg/L)

Silica Less than 12 ppm (mg/L)

Total Dissolved

Solids (tds) Less than 60 ppm

480 lb (218 kg) M AXI MUM

: 300 QU ARTS (380 L ITE RS)

*A DDI TIO NAL W IRE SHE LVES RE QUI RED FO R MA XIM UM CAPA CIT Y

#475 - 1/08 D UE T O ON G OI N G P RO D UC T I M PR OV E ME N T, SP EC I FI CA TI O NS A RE S UB J EC T T O C HA N GE W IT H OU T N O TI CE . www.a lto-s haam. com

Page 3

D e l u x e C o n t r o l

(P IC T UR ED )

he Combitherm deluxe control

T

includes all the operational functions

of the standard control and adds a

programming function. Program

memory can accept up to 250

procedures, each with up to 20 steps

in any combination of cooking

modes. The deluxe control also

features a set of 8 Rapid-Touch™

keys to assign frequently used

programs to cook at the touch of a

single button.

S t a n d a r d C o n t ro l

The Combitherm standard control

includes all operational functions

shown to steam, bake, and roast by

time or internal product temperature.

The control features the Gold-nBrown™automatic browning

function, a Retherm Mode for plate

regeneration, plus a wide variety of

auxiliary functions and operational

settings. This control is offered for

operators that do not require

programming capability.

S - C o n t r o l

The Combitherm S-Control

includes all basic combination

oven operational modes with the

use of rotary dials. The S-Control

also features the Gold-n-Brown

automatic browning function, an

automatic cleaning setting, an

oven cool-down function, and a

half-speed fan position. S-Control

models can also be furnished with

Core Temperature option package.

™

20

20ESG

G A S C O M B I N AT I O N OV E N/ ST EA M E R

team Mode

S

A

utomatic steaming at 212°F (100°C)

Quick steaming between 213°F and

48°F (101°C and 120°C)

2

Low temp steaming between 86°F and

211°F (30°C and 99°C)

Combination Mode

Steam and convection cooking with a

temperature range of 212°F to 482°F

(100°C to 250°C)

Convection Mode

Cooking without steam at a

temperature range of 86°F to 482°F

(30°C to 250°C)

Retherm Mode

Food or plated meal reheating with

automatic steam injection at a

temperature range of 248°F to 320°F

(120°C to 160°C)

Core Temperature Mode

Cooking by sensing internal

product temperature in any

selected cooking mode

Gold-n-Brown

An automatic browning function

to be set or programmed as needed

to add additional product color in

the combination or convection mode

of operation.

™

#475 - 1/08 D UE T O ON G OI N G P RO D UC T I M PR OV E ME N T, SP EC I FI CA TI O NS A RE S UB J EC T T O C HA N GE W IT H OU T N O TI CE . www.a lto-s haam. com

Page 4

G A S C O M B I N AT I O N OV E N/ ST EA M E R

FA CT O RY IN S TA L LE D O P T I O N S

(M AY REQ UI RE ADDIT IONAL LEAD TI ME )

Gas Type

NATUR AL

■■

PR OPANE

■■

■■

Al t ernat e B urner O r ific e

RE QU IRED F OR INS TAL LATION SIT ES AT EL EVATIONS

3,000 F EET (914m) ABO VE SE A L EV EL

OF

■■

Re c esse d D oor [5006522]

IN CR EASES OVE N WI DTH BY 4" (102mm)

Single-point removable temperature probe (

NC LU DED ON S TAN DARD AND D EL UXE OVENS

I

OP TI ONAL ON S -CONT RO L O VENS [5005679]

■■

■■

Mu l ti-p o int, h a rd- w ire d i nter n a l pro d uct tempe r atur e pro b e [5005678]

NO T AVAILA BL E ON O VE NS WIT H S-CO NTROL

Se c urit y D evic e s [5006528]

■■

FO R CO RRECT IONAL FAC ILITY USE

IN CL UDES C ONTROL S EC URITY PAN EL

FL AN GED LE GS F OR F LOOR O R COUN TER BOLT IN G (PADLOC KS NOT I NC LUDED )

■■

Co m pute r S oftw a re Optio n s [5005676]

N ot av ailabl e on S-C o n trol Mod els .

RE FE R TO HACCP SPE CIFIC ATI ON S HE ET #9015

FO R A PP LICAB LE PART NUMBE RS

■■

HA C CP D o cume n tati o n

, DOO R LO CK, TA MP ER-PR OO F SC RE W PACKAGE ,

PATENT PEN DI NG)

20

20ESG

■■

HA C CP D o cume n tati o n with K i tche n M anage ment

■■

Wi rele s s HACC P Doc u ment a tion w i th Kit c hen Man ageme nt

IEEE 802.11 b STANDA RD S

#475 - 1/08 D UE T O ON G OI N G P RO D UC T I M PR OV E ME N T, SP EC I FI CA TI O NS A RE S UB J EC T T O C HA N GE W IT H OU T N O TI CE . www.a lto-s haam. com

Page 5

20

G A S C O M B I N AT I O N OV E N/ ST EA M E R

20ESG

Ten (10) Chicken Roasting Rack

SH-22634

Fry Basket BS-26730 Grilling Grate SH-26731

Six (6) Chicken Roasting Rack

AN NO T INC LUDE D

(P

) SH-23000

Roll-in Pan Rack

UN-27970

#475 - 1/08 D UE T O ON G OI N G P RO D UC T I M PR OV E ME N T, SP EC I FI CA TI O NS A RE S UB J EC T T O C HA N GE W IT H OU T N O TI CE . www.a lto-s haam. com

Roll-in Plate Rack

UN-27971

Page 6

20

20ESG

G A S C O M B I N AT I O N OV E N/ ST EA M E R

OPTIONS & ACCESSORIES

CHICKEN GREASE TRAY WI TH D RAIN: 1-1/2" (38mm) D EEP 4758

■■

CHICKEN ROASTING RACKS:

■■

HI CK EN C APA CI TY

6 C

■■

8 CH IC KEN CAPACITY — FI TS F ULL-SIZ E PAN : 12 RACK S PER OVE N SH-23619

10 C HI CKEN C APACI TY — FITS I N SI DE R ACKS: 12 RA CKS PER OVE N SH-22634

■■

■■

COMBIGUARD™ TRIPLE-GUARD WATER FILTRATION SYSTEM (I NCLUDES 1 CART RIDGE) FI-23014

COMBIGUARD™ REPLACEMENT FILTER FI-26356

■■

FRY BASKET, 12" X 20" (325mm x 530mm) BS-26730

■■

■■

GRILLING GRATE, 12" X 20" (325mm x 530mm) SH-26731

IT S FU LL-SIZ E PAN

— F

AC KS P ER O VE N

: 10 R

SH-23000

PREHEAT SEALING STRIP (TO P REHEAT WIT HO UT R OL L-IN T ROLLEY) 5007924

■■

■■

OVEN CLEANER — SPEC IALLY FOR MULATE D FO R COMB ITHERM OV EN S

➥ TWELVE (12) C ONTAINER S/CAS E, 1 QUART (C . 1 LI TER) EAC H CE-24750

■■

QUICK DISCONNECT KIT CR-33543

ROLL-IN PAN CART (HXWXD): UN-27970

■■

65-1/8"

IN TE RCHANGE ABLE WI TH 20•20 C OMBIMATE H OL DING CA BI NET AN D QC-100 Q UICKC HILLER

ROLL-IN PLATE CART (HXWXD) I NT ERCHANG ABLE W ITH 20•20 COMBI MATE HOL DI NG CAB INET:

■■

■■

■■

SCALE FREE™(C IT RUS BA SED, NON -C ORROS IV E DELI MING P RODUC T) CE-27889

SERVICE START-UP CHECK AVAILABLE T HROUG H AN ALT O-SHA AM FAS TE AM CE NTER SPECI FY AS R EQUIRED

■■

■■

SHELF, STAI NLESS STEEL WIRE SH-22473

X 30-5/16" X 33-13/16" (1653mm x 770mm x 858mm)

65-1/2" X 30-5/16" X 39-9/16" (1663mm x 770mm x 1004mm) 2-11/16" (69mm) SPA CI NG UN-27971

65-1/2" X 30-5/16" X 39-9/16" (1663mm x 770mm x 1004mm) 3-1/2" (89mm) SPACI NG UN-28311

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wiscons in 5305 2- 0450 • U. S.A.

PH ON E: 262.2 51 .3800 800.558.87 44 U.S. A. /CA NA DA FAX : 262.25 1. 7067 800 .329.8744 U.S.A. ONLY

D UE TO O NG O IN G P R OD U CT I MP RO V EM E NT , SP E CI F IC AT IO N S A RE S U BJ E CT T O C HA NG E W I TH O UT N OT I CE .PR I NT ED I N U .S . A. # 47 5 - 1/ 08

www.alto-s haam.com

Loading...

Loading...