Page 1

us a/Ca na da

u.s.a. O nL Y

Combitherm®

CombiTouch® Gas

TECHNICAL SERVICE

MANUAL

20.20esG CombiTouch 7.14esG CombiTouch

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744

p ri n te d i n u . s. a .

www.alto-shaam.com

FAX: 262.251.7067 • 800.329.8744

M N-2 92 48 • 0 5 /11

Page 2

How to Use this Technical Service Manual

This manual has been compiled as a complete resource for a technician working on Combitherm CombiTouch Gas models.

It includes necessary product information and drawings, along with helpful troubleshooting procedures.

Navigation

On this document, starting with the Main Table of Contents on the following page, you may click on any item that has a

page number and quickly jump to the information you need. Note that you may Return to the Main Table of Contents from

the bottom of any Section Contents page.

Printing

From this document, you may print the Current Page or any range of pages.

Here’s a tip: Because printers vary in their capacity to handle large drawings, make a test print of one of the Wiring

Diagrams before printing the model’s section.

C O MB I T H E RM C O M BI TO U C H G A S TE C Hn I CA l S E Rv IC E M A nU A l • i

Page 3

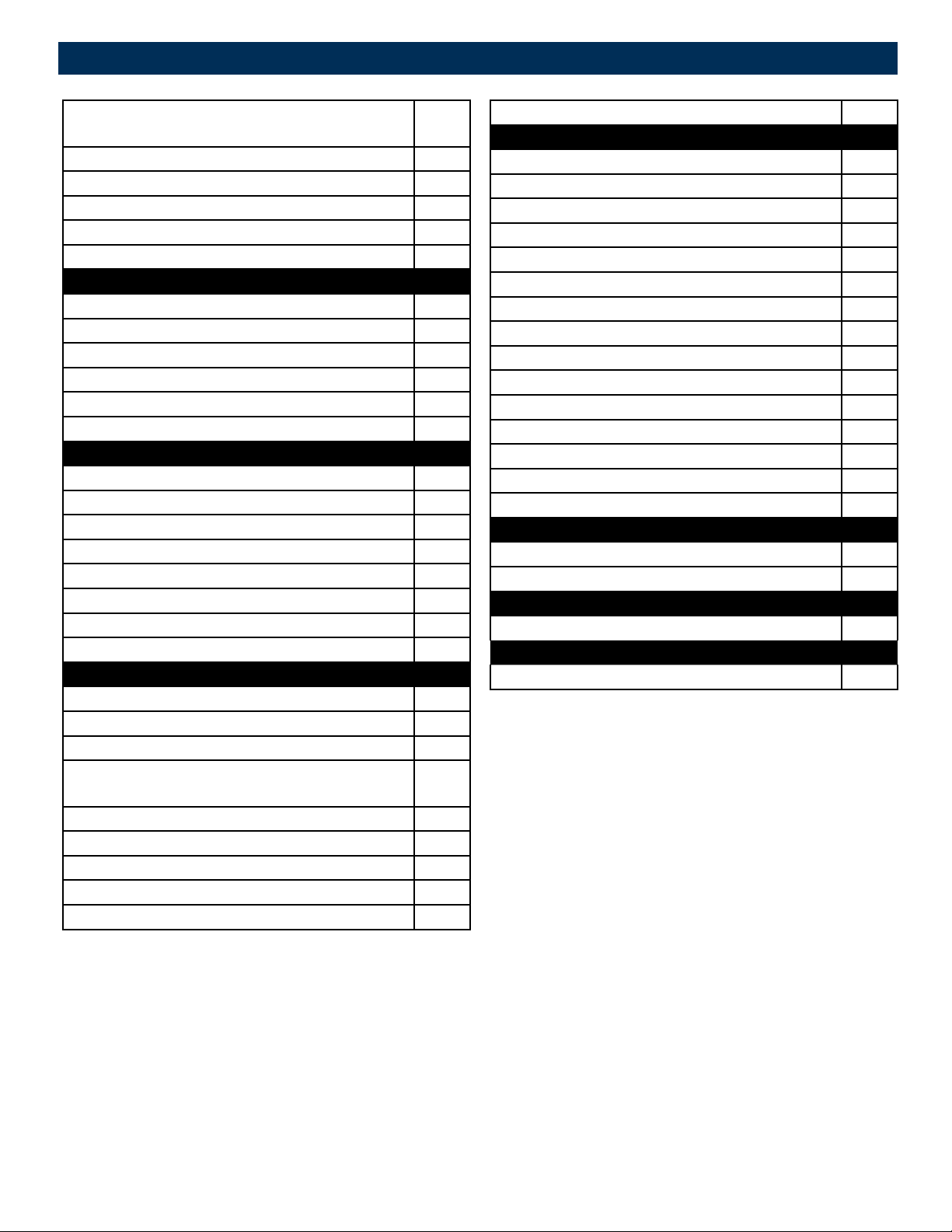

Table of ConTenTs

HOW TO USE THIS TECHNICAL

SERVICE MANUAL

TABLE OF CONTENTS ii

COMBITOUCH CONTROL INTRODUCTION 1

CONTROL PANEL IDENTIFICATION 2

FACTORY DEFAULT SETTINGS 6

SAFETY PRECAUTIONS 7

OPERATION MODES

Steam 8

Combination 10

Convection 12

Retherm 14

Core Temperature Probe 16

Core Temperature - Delta-T 17

AUXILIARY FUNCTIONS

Preheating 18

Gold-n-Brown™ 18

Cool-Down Feature 18

Reduced Fan Speed 19

Reduced Power 19

Multi-shelf Timer 19

Steam Injection 19

CombiSmoker™ Procedures 20

PREPROGRAMMED RECIPES

Using Preprogrammed Recipes 22

Recipe Programming 23

Preprogrammed Bakery Recipes 24

Preprogrammed Convenience

Product Recipes

Preprogrammed Fish & Seafood Recipes 27

Preprogrammed Meat Recipes 28

Preprogrammed Miscellaneous Recipes 30

Preprogrammed Poultry Recipes 31

Preprogrammed Vegetable Recipes 32

i

25

HACCP ACCESS 34

CLEANING & MAINTENANCE

Cleaning Menus 35

Preventive Maintenance 36

Food Trolley Cleaning 36

Protecting Stainless Steel Surfaces 37

Cleaning Agents 37

Cleaning Materials 37

Daily Gasket Cleaning 38

Probe Usage and Cleaning 38

Daily Oven Cleaning 38

Daily Steam Generator Flush 38

Regular Decalcification 38

Monthly Cleaning 38

Combitherm Oven Cleaner Precautions 39

Steam Generator Flush 39

Decalcification 39

TROUBLE SHOOTING

Emergency Operation Mode 40

Error Codes 42

COMBITHERM PARTS

Service Parts 47

COMBITHERM WIRING DIAGRAMS

Index 78

C O MB I T H E RM C O M BI TO U C H G A S TE C Hn I CA l S E Rv IC E M A nU A l • ii

Page 4

INTRODUCTION

COMBITOUCH® CONTROL

The Combitherm CombiTouch control features a simple,

graphics-based control panel that commands all the

oven functions. Access up to 250 of your recipes that

are identied by your own uploaded pictures. Manual

cooking by time and temperature also are easily done with

the CombiTouch control.

Intuitive interface - The Alto-Shaam CombiTouch offers

a simple interface that commands

all of the Combitherm’s cooking

functions. As the name implies, it

is fully operable by touch.

Graphic controls - The highly

visual graphic-based control

overcomes language barriers while

the simple, logical procedures

ensure that correct steps are

followed every time.

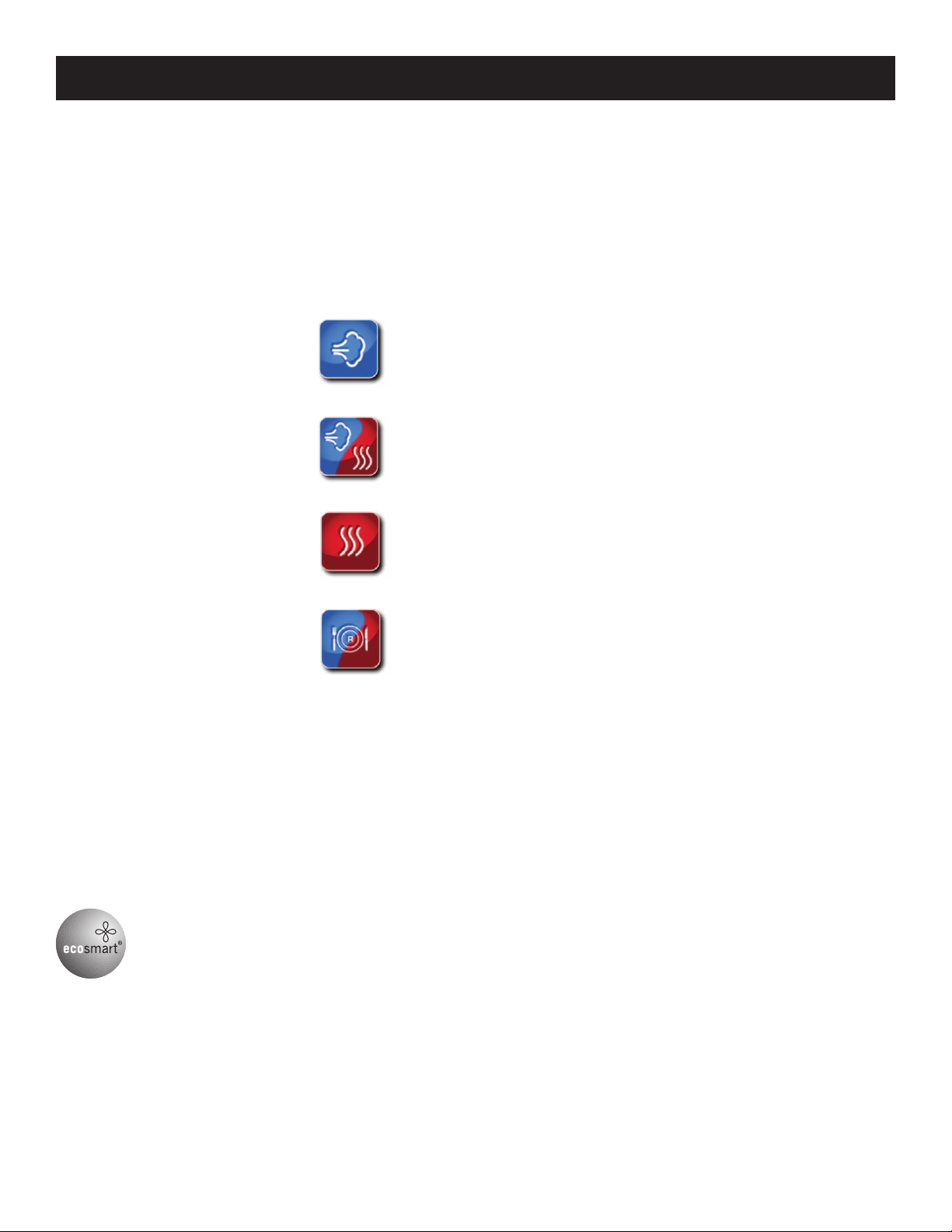

STEAM MODE

COMBINATION MODE

CONVECTION MODE

An excellent memory - Access

up to 250 of your recipes that are

identied by your own uploaded

pictures. The Combitherm

with CombiTouch also comes

standard with more than 100 preprogrammed recipes and photos,

covering most commonly prepared food items.

RETHERM MODE

Standard HACCP - The Combitherm with CombiTouch

includes a standard downloadable HACCP function.

Six levels of Gold-n-Brown™ - Six precise and consistent

browning levels are available with the CombiTouch. The

exclusive Gold-n-Brown feature gives the operator the

ability to achieve the ideal cooking environment for the

ideal nish.

Superior baking - The new two-speed reversing fan

provides excellent and consistent

baking results. A moisture

injection feature provides perfect

sheen and crust on breads and

pastry items.

Multi-shelf timers - Track cooking

time of either seven or 10 different

food items (depending on oven

size) in the same oven with multishelf timers. Time is tracked in

minutes and seconds.

On-board diagnostics - The

CombiTouch system includes

on-board diagnostic functionality

with results displayed right on the

touch screen.

Reduced energy setting - CombiTouch features

an interactive control display with reduced energy setting.

Powerful tool - The CombiTouch control plays an important part in our continuous improvement process. New features

and abilities can be uploaded to your oven as they become available. Simply call our Service Department for assistance.

ECOSMART® TECHNOLOGY

The Alto-Shaam CombiTouch

Combitherm combination oven/steamer

employs Ecosmart operating efficiencies

in the design and application of all

operating and programming functions.

Ecosmart operational characteristics include the use

of a water barrier to close the oven compartment to

the outside air. While maintaining a non-pressurized

atmosphere, the primary purpose of the Ecosmart

system is to prevent the steam and heat generated

within the oven compartment from freely escaping

to the outside.

The Ecosmart design displaces the air within the

cooking compartment and achieves a higher level

of steam saturation that offers quick-steaming at

temperatures above 212°F (100°C).

This guide is provided as an operational aid with

step-by-step instructions of the basic functions of

the Combitherm oven, along with the many other

additional features of the control.

1

Page 5

OPERATING INSTRUCTIONS

CONTROL PANEL IDENTIFICATION

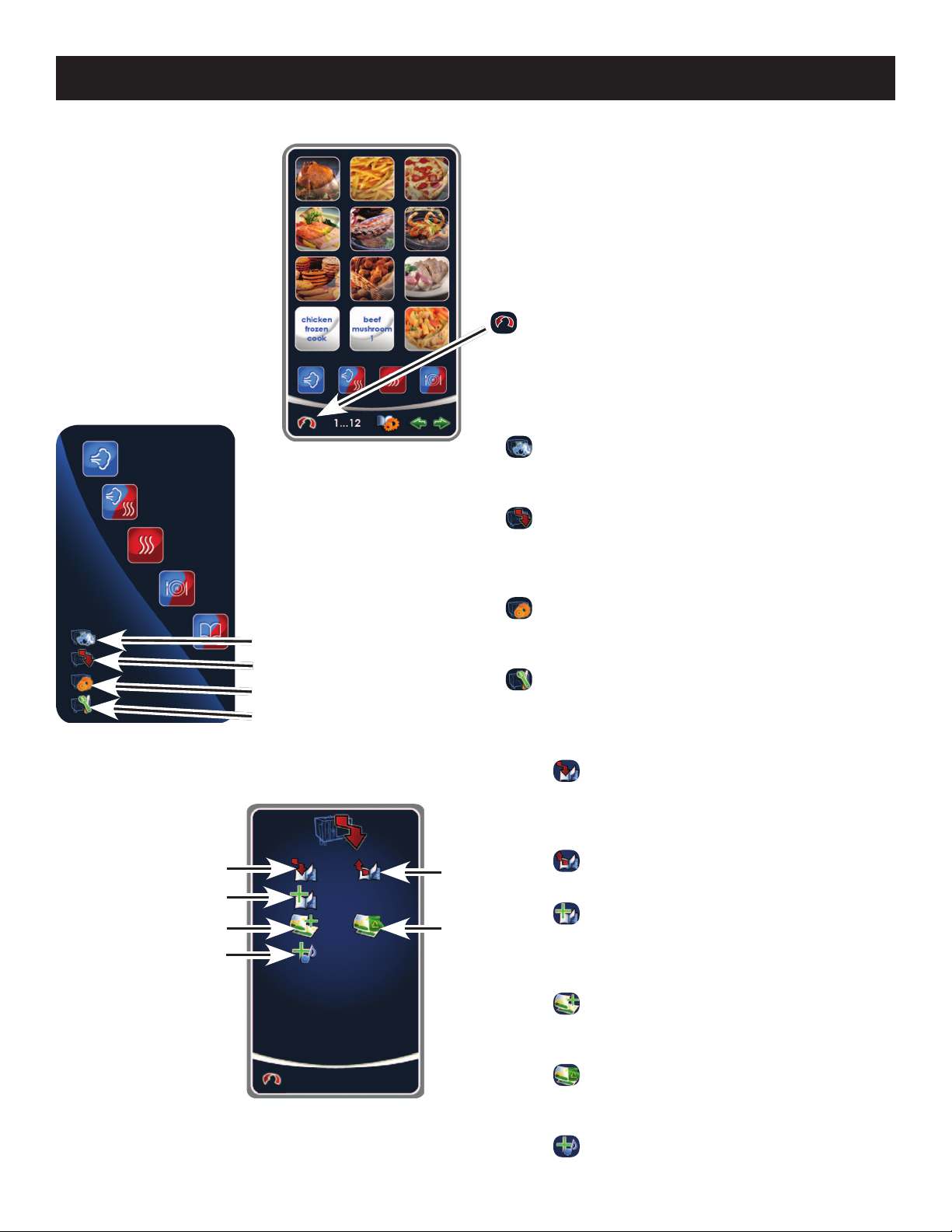

RECIPE MENU

When the oven is powered on, the Recipe Menu is the

rst screen you will see. This allows quick access to

begin the cooking process. As a rst time user, you

may want to personalize your CombiOven to reect the

settings you are most comfortable with.

Return to Previous Screen - Press the red arrow to

access the Main Menu screen.

1. Cleaning Mode

Four (4) cleaning levels are available: rinse, light,

normal, and heavy-duty cleaning.

2. Download/Upload Files

Download all preprogrammed recipes (factory default

MAIN MENU

SCREEN

1 CLEANING MODE

2 DOWNLOAD/UPLOAD FILES

3 SETTINGS

4 SERVICE MODE

(PASSWORD PROTECTED)

and user-programmed) and photos to a USB memory

stick. See below for more information.

3. Settings and HACCP Access

Change factory default settings. See next page for

more information.

4. Service Mode (password protected)

This mode is only available to qualied

service technicians.

UPLOAD/DOWNLOAD SCREEN

1 DOWNLOAD RECIPES

3 ADD ALL RECIPES

4 UPLOAD ALL PHOTOS

6 ADD SOUNDS

2 UPLOAD

RECIPES

5 DELETE

PHOTOS

2

1. Copy Recipes to Oven

Copy all recipes from USB memory stick

to oven. This will replace and overwrite

existing recipes.

2. Copy Recipes from Oven

Copy all recipes from oven to USB memory stick

3. Add Recipes to Oven

Copy all recipes from USB memory stick to the

oven. This will add the recipes to the beginning

of the existing recipe list.

4. Copy Photos to Oven

Upload photo les from a USB memory stick to

oven for user-programmed recipes

5. Delete Photos on Oven

Delete specic photo les used in the

programmed recipes on oven

6. Add Sounds

Page 6

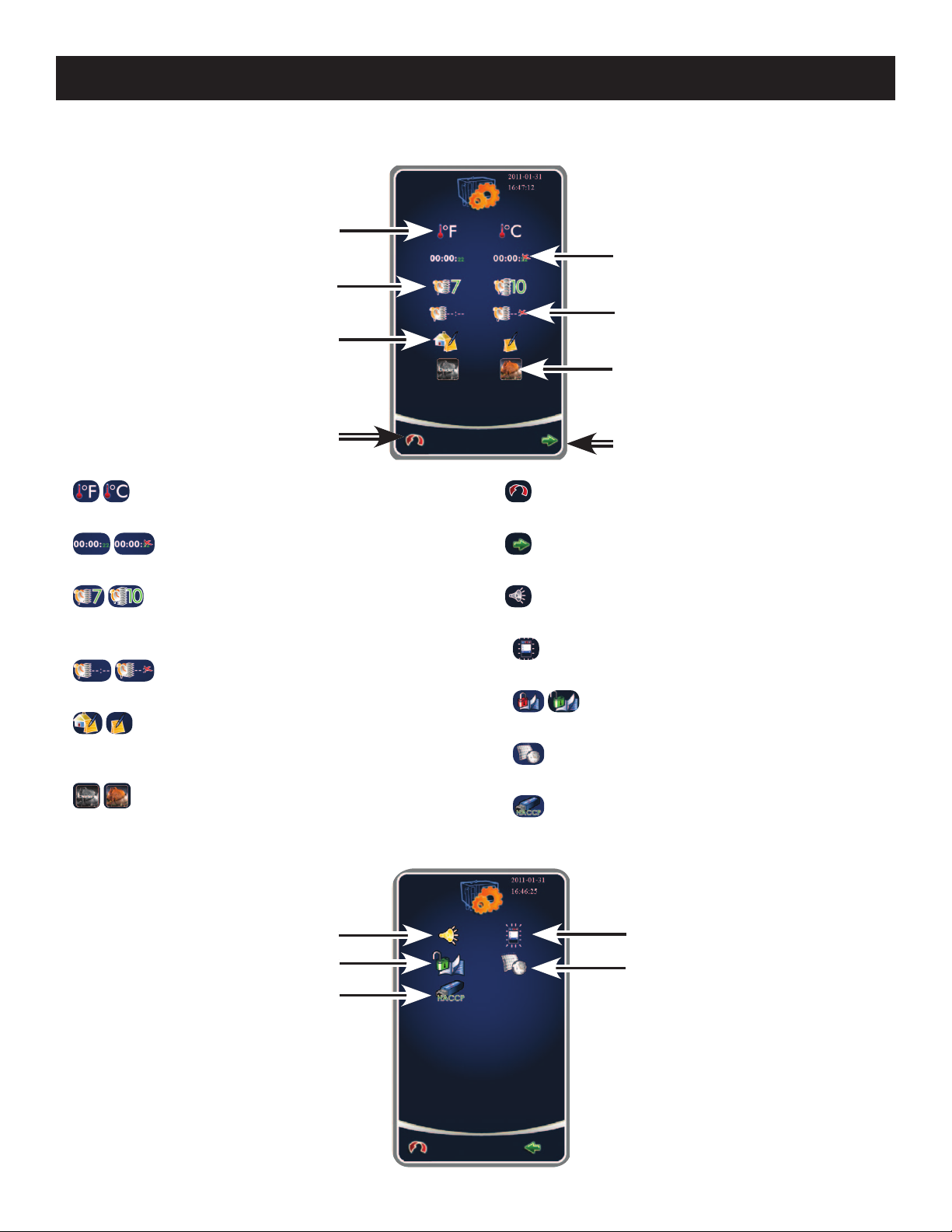

CONTROL PANEL IDENTIFICATION

1 FAHRENHEIT OR CELSIUS

3 NUMBER OF SHELVES FOR

MULTI-SHELF TIMER

5 DEFAULT MEMO

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

SETTINGS SCREEN

2 TIMER FORMAT

4 MULTI-SHELF TIMER FORMAT

6 DISPLAY SETTINGS

7 RETURN TO PREVIOUS SCREEN

1. Fahrenheit or Celsius Function - Choose

temperature format.

2. Timer Format - Display time as

HOURS:MINUTES:SECONDS or HOURS:MINUTES.

3. Multi-shelf Timer Number of Shelves -

Choose the default number shelves in the oven to be

used by the multi-shelf timer.

4. Multi-shelf Timer Format - Display

MINUTES:SECONDS or MINUTES only in timer.

5. Default Memo - Reverts all settings to factory

defaults. Clears all user-input times and temperatures

except those in programmed recipes.

6. Display Settings - Choose to display text or

image assigned to a recipe.

8 FORWARD TO NEXT SCREEN

7. Return to Previous Screen - Return to previous

screen when nished adjusting settings.

8. Forward to Next Screen - Advance to next screen to

review additional settings.

9. Sound/Alarm Settings - Change alarm sounds

and volume.

10. Touchscreen Brightness - Adjust brightness

of Touchscreen.

11. Lock/Unlock Recipes - Password protect

preprogrammed recipes.

12. Set/Change Date & Time - Set or change oven

time and date settings.

13. HACCP Data - Review data collected or

download data to a USB drive.

9 SOUND SETTINGS

11 LOCK/UNLOCK RECIPES

13 HACCP DATA

10 TOUCH SCREEN BRIGHTNESS

12 SET/CHANGE DATE & TIME

3

Page 7

OPERATING INSTRUCTIONS

CONTROL PANEL IDENTIFICATION

1 POWER ON KEY

2 STEAM MODE

3 COMBINATION MODE

6 TEMPERATURE

7 TIME

8 CORE TEMPERATURE

9 PREHEAT

12 REDUCED POWER MODE

22 DELTA-T (ONLY VISIBLE

IN CERTAIN MODES)

1 POWER OFF KEY

4 CONVECTION MODE

5 RETHERM MODE

11 START/STOP ICON

10 COOL DOWN

13 GOLD-N-BROWN MODE

14 SMOKING MODE (OPTIONAL)

15 FAN SPEED

20 MULTI-SHELF TIMER

16 GO TO PREVIOUS SCREEN

17 CLEANING MODE

18 ADD RECIPE

19 FIND RECIPE

4

Page 8

OPERATING INSTRUCTIONS

CONTROL PANEL IDENTIFICATION

MAIN MENU ICONS

1. Power ON key

Activates power to the oven and automatically lls the

steam generator equipped models with water that will

heat to a stand-by mode temperature of 188°F (77°C).

2. Steam Mode

The oven will operate in the steam mode at a

temperature range of 85°F to 250°F (30°C to 121°C).

• Automatic steaming at 212°F (100°C) factory-set

default.

• Quick steaming between 213°F and 250°F (101°C

and 121°C).

• Low temperature steaming between 85°F and 211°F

(29°C and 99°C).

3. Combination Mode

Selection key for cooking with a combination of steam

and convection heat. Can be set between 212°F to 485°F

(100°C and 252°C).

4. Convection Mode

Selection key for convection cooking without steam at a

temperature range of 85°F to 485°F (29°C to 252°C).

5. Retherm Mode

Food rethermalization or reheating mode will operate

with automatic steam injection at a temperature range

of 245°F to 320°F (120°C to 160°C).

6. Temperature

Used to set the required cooking temperature, to recall

the set cooking temperature, or to check the actual oven

temperature.

11. Start/Stop

Initiates all cooking mode functions and programmed

procedures stored in memory. Stops an activated

cooking mode or programmed procedure currently

in progress.

AUXILIARY FUNCTION ICONS

12. Reduced Power Mode

Used to reduce kitchen power peaks and

energy consumption.

13.

Gold-N-Brown Mode

This indicator will illuminate when the browning

function is set by the operator in a timed or

programmed cooking cycle in any mode. Level 1

provides least amount of browning, level 6 the most.

14. Smoking Mode (optional)

This indicator will illuminate when the smoking

function is set by the operator in a timer, probe or

programmed cooking cycle in either convection mode

or combination mode.

15. Fan Speed

This indicator will illuminate whenever the operator

sets a reduced fan speed to protect products affected

by high-velocity air movement.

16. Return to Previous Menu

17. Cleaning Mode

Four (4) cleaning levels are available: rinse, light,

normal, and heavy-duty cleaning.

7. Time

Used to set the required cooking time or recall the set

cooking time.

8. Core Temperature

Used to set the required internal product temperature,

to recall the internal product temperature set by the

operator, or to display the current internal temperature

of the product.

9. Preheat Mode

Preheats the oven cavity to a temperature set by user.

10. Cool Down Mode

Lowers temperature of the oven cavity at an

accelerated pace to temperature set by user.

18. Add Recipe

Used to create, change, duplicate, and delete

programmed menus.

19. Find Recipe

Access a menu list of all stored cooking programs.

20. Multi-shelf Timer

Use separate timers for one or more shelves in the

oven compartment.

21. Steam Injection (not shown on illustration)

Press to add moisture in any cooking mode. Steam will

inject into the cavity as long as the icon is touched.

22. Delta-T Core Temperature (only visible in certain

modes) Cook by probe. Mode automatically adjusts

cooking temperature in proportion to the internal

temperature of the product.

5

Page 9

OPERATING INSTRUCTIONS

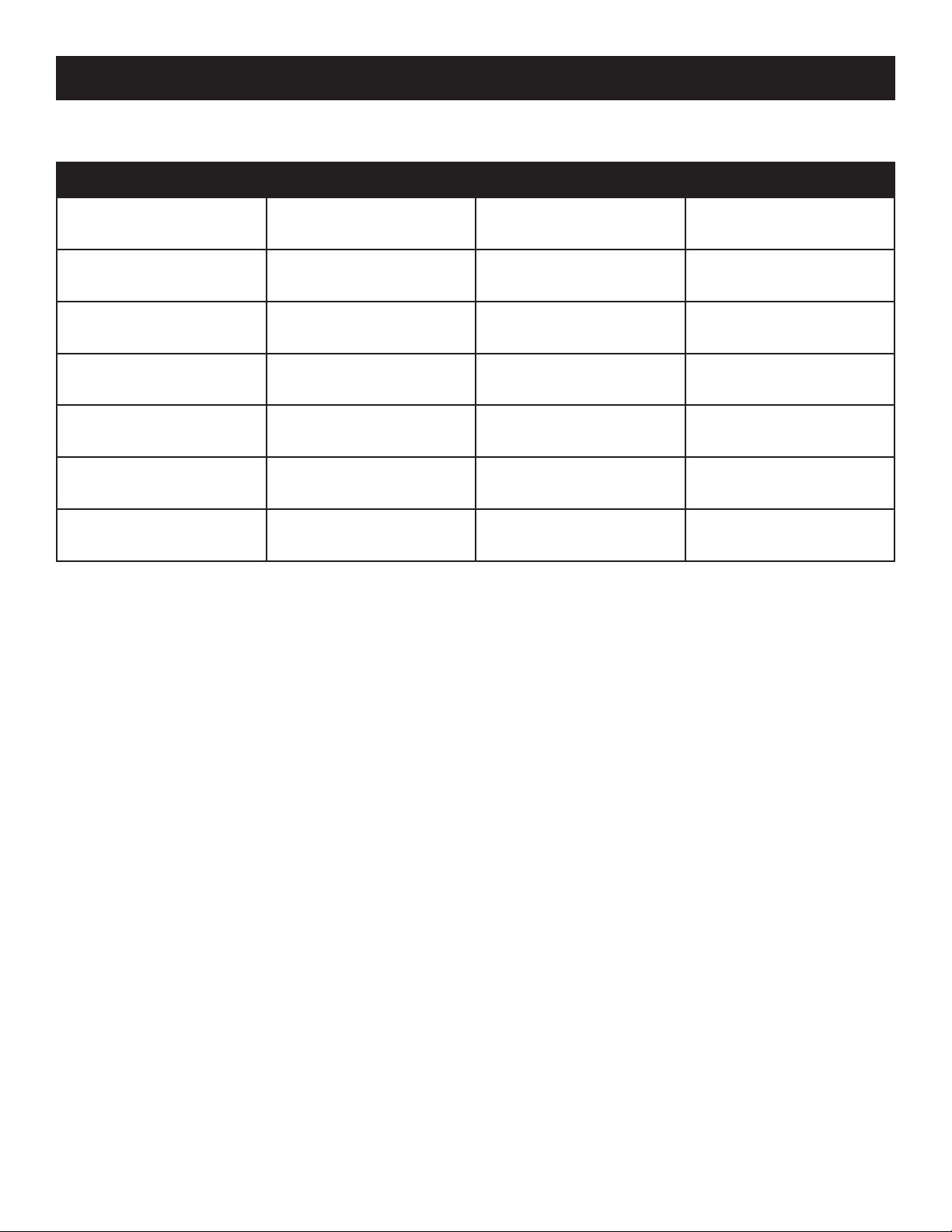

COMBITOUCH FACTORY DEFAULT SETTINGS

COOKING MODE OVEN TEMPERATURE CORE TEMPERATURE COOKING TIME

Steam

Combination Steam

Convection

Retherm

Preheat

Cool Down

Delta T

212°F

(100°C)

350°F

(175C)

350°F

(175°C)

275°F

(135°C)

350°F

(175°C)

212°F

(100°C)

120°F

(50°C)

160°F

(70°C)

160°F

(70°C)

160°F

(70°C)

160°F

(70°C)

N/A N/A

N/A N/A

170°F

(75°C)

25 minutes

60 minutes

30 minutes

5 minutes

N/A

6

Page 10

OPERATING INSTRUCTIONS

IMPORTANT SAFETY PRECAUTIONS

NOTE: Automatic steam venting is a standard safety

feature built into all Combitherm oven models.

This feature vents all steam from the oven

compartment immediately before cooking time

expires or set probe temperature is reached.

This function is provided in all programmed

and timed production when operating in any

Steam, Combination, Convection, and Retherm

cooking mode. Automatic steam venting does

not function if the oven door is opened before

time expires or when the oven has been set to

continuous operation.

DANGER

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

NOTE: Use authorized combitherm oven cleaner only.

unauthorized cleaning agents may discolor or

harm interior surfaces of the oven. Read and

understand label and material safety data sheet

before using the oven cleaner.

FOR OPERATOR SAFETY

NOTE AND OBSERVE ALL SAFETY PRECAUTIONS

LOCATED THROUGHOUT THIS GUIDE

HOT STEAM CAUSES BURNS

ROTATE THE DOOR HANDLE TO THE FIRST OPEN

ROTATION POSITION ONLY. WAIT UNTIL THE

STEAM IS VENTED BEFORE FULLY OPENING THE

DOOR.

CAUTION

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN

IN OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

DO NOT HANDLE PANS CONTAINING LIQUID

OR SEMILIQUID PRODUCTS POSITIONED

ABOVE THE EYE LEVEL OF THE OPERATOR.

SUCH PRODUCTS CAN SCALD AND CAUSE

SERIOUS INJURY.

DO NOT USE THE ATTACHED HAND-HELD

HOSE TO SPRAY ANYTHING OTHER THAN

THE INTERIOR OF THE COMBITHERM OVEN

COMPARTMENT.

DO NOT USE THE SPRAY HOSE ON

THE SURFACE OF A HOT COOKING

COMPARTMENT. ALLOW THE OVEN TO COOL

TO A MINIMUM OF 150°F (66°C).

7

Page 11

OPERATING INSTRUCTIONS

STEAM MODE

The Steam mode provides the operator with the ability

to steam, poach, or blanch. This mode will automatically

steam at the boiling point of water; quick-steam above the

boiling point for faster cooking results; or low temperature

steam, below the boiling point, for more delicate products

such as pâté, mousse, seafood, or custard.

PRESS ON BUTTON TO POWER OVEN ON.

PRESS THE STEAM MODE ICON.

Automatic Steam temperature of 212°F (100°C)

will appear in the display. The last set time or

oven control default setting for time will appear

in the display.

PRESS THE START ICON TO STEAM AT THE

DISPLAYED SETTINGS.

TO CHANGE THE DISPLAYED SETTINGS:

TOUCH THE DISPLAYED TEMPERATURE.

The cooking temperature will appear at the top of

the temperature selection window. Type in desired

temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

• Automatic Steaming 212°F (100°C)

• Quick Steaming 213°F to 250°F (101°C to 121°C)

• Low Temperature Steaming 85°F to 211°F (29°C to 99°C)

TO COOK BY PRODUCT CORE TEMPERATURE:

TOUCH THE PROBE ICON.

The previously set core temperature or oven control

default setting will appear highlighted within the oven

display. Touch the displayed core temperature. The

internal product core temperature will appear at the top

of the temperature selection window. Type in desired

internal product core temperature or use up and down

arrows to adjust temperature. When nished, touch the

green checkmark key to conrm change.

Attach removable probe before activating core

temperature function, and insert into product.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING IN STEAM MODE.

• The temperature and remaining cooking time will

appear in the display.

• If cooking by probe, the actual internal product

temperature will appear next to the icon during

operation. To change the set value for core temperature,

press the temperature next to the icon and make

changes as required.

When the cooking time has expired or the operator set

internal temperature has been reached, an alarm will

sound indicating the end of the operating mode.

• To stop the buzzer, press the red stop key or open

the oven door.

TO COOK BY TIME:

TOUCH THE DISPLAYED TIME.

The cooking time will appear at the top the time selection

window. Type in desired time period or use up and down

arrows to adjust time. When nished, touch the green

checkmark key to conrm change.

Or, to set Continuous Operation mode, type in --:-- and

touch the green checkmark key to conrm.

TO STOP COOKING PROGRAM AT ANY TIME,

PRESS RED STOP BUTTON.

8

Page 12

OPERATING INSTRUCTIONS

STEAM MODE CHEF OPERATING TIPS

This mode will steam a full or partial load of a single

product, or multiple products without transfer of avors.

When steaming multiple products, however, individual

product cooking times must be taken into consideration.

STEAM

Perforated, 2-1/2" deep pans (65mm)

are particularly suitable for use in

this program mode. These pans will

provide a shorter cooking time and

will prevent product over-cooking at

the bottom of the pan.

Separate ice-encrusted vegetables

before steaming to assure

even cooking.

A variety of products can be steamed

at the same time but attention must

be paid to the different cooking times

required for each food product.

HIGH TEMP STEAMING

High temperature steaming is

suitable for hearty, root-type

vegetables such as potatoes, legumes,

and cabbage.

High temperature steaming

provides a cooking time which is

approximately 10-percent shorter

than the regular steam mode

temperature of 212°F (100°C).

Set the steam cooking temperature

between 221°F (105°C) and 230°F

(110°C) for small loads and between

230°F (110°C) and 250°F (121°C) for

full loads.

The non-pressurized atmosphere of the Combitherm

also provides the ability to open the door during the

steam mode in order to monitor products more closely

throughout the steaming process.

LOW TEMP STEAM

The low temperature steam mode

will function whenever the oven

compartment temperature is below

212°F (100°C).

It will take longer to steam products

using the low temperature

steam mode.

Steaming sausages in low

temperature steam prevents cracked

or peeling skins.

Use low temperature steam for

delicate foods such as shrimp, sh,

seafood, and crème caramel.

For best results, low temperature

steam all delicate food items at a

temperature of 210°F (99°C)

or below.

9

Page 13

OPERATING INSTRUCTIONS

COMBINATION MODE

The Combination mode will prove to be the most versatile

and widely used mode the Combitherm oven has to offer.

It will produce the best possible results on the widest

variety of products — all within the shortest period of

time. The unique control function of this mode enables

the operator to roast or bake with a combination of steam

and convection heat. In addition to shorter cooking times,

this combination of steam and heat offers less product

shrinkage and more moisture retention than obtained in a

standard convection oven.

PRESS ON BUTTON TO POWER OVEN ON.

PRESS THE COMBINATION MODE ICON.

The last set values or oven control default setting for

temperature and time will appear in the display.

PRESS THE START ICON TO COOK AT THE

DISPLAYED SETTINGS.

TO CHANGE THE DISPLAYED SETTINGS:

TOUCH THE DISPLAYED TEMPERATURE.

The cooking temperature will appear at the top of

the temperature selection window. Type in desired

temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

• Cooking temperature range: 212 to 485 °F (100 to 252°C)

TO COOK BY TIME:

TOUCH THE DISPLAYED TIME.

TO COOK BY PRODUCT CORE TEMPERATURE:

TOUCH THE PROBE ICON.

The previously set core temperature or oven control

default setting will appear highlighted within the oven

display. Touch the displayed core temperature. The

internal product core temperature will appear at the top

of the temperature selection window. Type in desired

internal product core temperature or use up and down

arrows to adjust temperature. When nished, touch the

green checkmark key to conrm change.

Attach removable probe before activating core

temperature function, and insert into product.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING IN COMBINATION MODE.

• The temperature and remaining cooking time will

appear in the display.

• If cooking by probe, the actual internal product

temperature will appear next to the icon during

operation. To change the set value for core temperature,

press the temperature next to the icon and make

changes as required.

PRESS FOR STEAM INJECTION AT ANY TIME

DURING COOKING. Steam will inject into the

cavity as long as the icon is touched.

When the cooking time has expired or the operator set

internal temperature has been reached, an alarm will

sound indicating the end of the operating mode.

• To stop the buzzer, press the red stop key or open

the oven door.

The cooking time will appear at the top the time selection

window. Type in desired time period or use up and down

arrows to adjust time. When nished, touch the green

checkmark key to conrm change.

Or, to set Continuous Operation mode, type in --:-- and

touch the green checkmark key to conrm.

10

TO STOP COOKING PROGRAM AT ANY TIME,

PRESS RED STOP BUTTON.

Page 14

OPERATING INSTRUCTIONS

COMBINATION MODE CHEF OPERATING TIPS

The Combination mode injects the optimum amount of

steam automatically. There is no need to select moisture

levels. Foods do not dry out. Flavors are retained with no

transfer of avors when mixing product loads.

Due to automatic steam adjustment, the door can be

opened at any time during a cooking operation. Be

certain to observe the safety warning when opening the

oven door.

The Combination mode is particularly efcient when

used for baking, broiling, grilling, stewing, braising,

and roasting.

When using the Combination mode, cooking temperatures

can be reduced 10- to 20-percent below the temperatures

used for conventional cooking methods.

Cooking time will be reduced approximately 40-percent

when cooking at the same temperature used for

convection oven cooking and up to 50- to 60-percent less

time when cooking at the same temperature used for a

conventional oven.

Food browning in the Combitherm begins at a cooking

temperature of approximately 250°F (120°C).

A higher cooking temperature results in heavier browning

but also results in greater product weight loss. To achieve

additional browning use the Moisture Vent Key or set

Gold-n-Brown into the product procedure. Gold-n-Brown

is particularly useful for adding color to high moisture

products such as chicken and other poultry items or

for additional browning of full loads and other

moist products.

The Combination mode provides even browning without

the necessity to turn the pans.

For more even cooking, do not cook in pans deeper than

4" (100mm).

11

Page 15

OPERATING INSTRUCTIONS

CONVECTION MODE

The Convection mode operates with hot circulated air

within a temperature range of 85° to 485°F (29 to 252°C).

For many applications, better results may be

achieved with the Combination mode; therefore, the

operator may want to consider using the Convection

mode on a more limited basis.

PRESS ON BUTTON TO POWER OVEN ON.

PRESS THE CONVECTION MODE ICON.

The last set values or oven control default setting for

temperature and time will appear in the display.

PRESS THE START ICON TO COOK AT THE

DISPLAYED SETTINGS.

TO CHANGE THE DISPLAYED SETTINGS:

TOUCH THE DISPLAYED TEMPERATURE.

The cooking temperature will appear at the top of

the temperature selection window. Type in desired

temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

• Cooking temperature range: 85 to 485 °F (29 to 252°C)

TO COOK BY TIME:

TO COOK BY PRODUCT CORE TEMPERATURE:

TOUCH THE PROBE ICON.

The previously set core temperature or oven control

default setting will appear highlighted within the oven

display. Touch the displayed core temperature. The

internal product core temperature will appear at the top

of the temperature selection window. Type in desired

internal product core temperature or use up and down

arrows to adjust temperature. When nished, touch the

green checkmark key

Attach removable probe before activating core

temperature function, and insert into product.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING IN COMBINATION MODE.

• The temperature and remaining cooking time will

appear in the display.

• If cooking by probe, the actual internal product

temperature will appear next to the icon during

operation. To change the set value for core temperature,

press the temperature next to the icon and make

changes as required.

PRESS FOR STEAM INJECTION AT ANY TIME

DURING COOKING. Steam will inject into the

cavity as long as the icon is touched.

to conrm change.

TOUCH THE DISPLAYED TIME.

The cooking time will appear at the top the time selection

window. Type in desired time period or use up and down

arrows to adjust time. When nished, touch the green

checkmark key to conrm change.

Or, to set Continuous Operation mode, type in --:-- and

touch the green checkmark key to conrm.

When the cooking time has expired or the operator set

internal temperature has been reached, an alarm will

sound indicating the end of the operating mode.

• To stop the buzzer, press the red stop key or open

the oven door.

TO STOP COOKING PROGRAM AT ANY TIME,

PRESS RED STOP BUTTON.

12

Page 16

OPERATING INSTRUCTIONS

CONVECTION MODE CHEF OPERATING TIPS

The Convection Mode can be used to roast or bake

products needing very short cooking times or for high

moisture products such as mufns, cakes, and cookies, or

for browning the surface of the product.

The Convection mode works best with foods containing

little moisture or for very moist food which require a

dryer nished product.

For baking, preheat the Combitherm at a temperature of

325°F to 375°F (163°C to 191°C). Once preheated, reset the

temperature as required.

A higher cooking temperature results in heavier browning

but also results in greater product weight loss. To achieve

additional browning use the Moisture Vent Key or set the

Browning Feature into the product procedure.

13

Page 17

OPERATING INSTRUCTIONS

RETHERM MODE

The Retherm mode operates with hot circulated air within

a temperature range of 245° to 320°F (120° to 160°C).

PRESS ON BUTTON TO POWER OVEN ON.

PRESS THE RETHERM MODE ICON.

The last set values or oven control default setting for

temperature and time will appear in the display.

PRESS THE START ICON TO COOK AT THE

DISPLAYED SETTINGS.

TO CHANGE THE DISPLAYED SETTINGS:

TOUCH THE DISPLAYED TEMPERATURE.

The cooking temperature will appear at the top of

the temperature selection window. Type in desired

temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

• Cooking temperature range: 245 to 320 °F (120 to 160°C)

TO COOK BY TIME:

TO COOK BY PRODUCT CORE TEMPERATURE:

TOUCH THE PROBE ICON.

The previously set core temperature or oven control

default setting will appear highlighted within the oven

display. Touch the displayed core temperature. The

internal product core temperature will appear at the top

of the temperature selection window. Type in desired

internal product core temperature or use up and down

arrows to adjust temperature. When nished, touch the

green checkmark key

Attach removable probe before activating core

temperature function, and insert into product.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING IN COMBINATION MODE.

• The temperature and remaining cooking time will

appear in the display.

• If cooking by probe, the actual internal product

temperature will appear next to the icon during

operation. To change the set value for core temperature,

press the temperature next to the icon and make

changes as required.

to conrm change.

TOUCH THE DISPLAYED TIME.

The cooking time will appear at the top the time selection

window. Type in desired time period or use up and down

arrows to adjust time. When nished, touch the green

checkmark key to conrm change.

Or, to set Continuous Operation mode, type in --:-- and

touch the green checkmark key to conrm.

PRESS FOR STEAM INJECTION AT ANY TIME

DURING COOKING. Steam will inject into the

cavity as long as the icon is touched.

When the cooking time has expired or the operator set

internal temperature has been reached, an alarm will

sound indicating the end of the operating mode.

• To stop the buzzer, press the red stop key or open

the oven door.

TO STOP COOKING PROGRAM AT ANY TIME,

PRESS RED STOP BUTTON.

14

Page 18

OPERATING INSTRUCTIONS

RETHERM MODE CHEF OPERATING TIPS

Since plated meals consist of dissimilar products, there

are several important factors to consider in order to

produce the nest results. Product density (compactness),

thickness, quantity of product on each plate, and quantity

of plates all relate to the length of time necessary to

reheat. Again, experience is the best method to determine

reheating time. Once the time has been determined and

recorded for a specic meal, the results will be consistent

for future reheating times.

HELPFUL HINTS FOR REHEATING ON THE

PLATE

• ALL FOOD COMPONENTS ON THE PLATE SHOULD

BE OF SIMILAR DENSITIES.

• ALL FOOD COMPONENTS ON THE PLATE SHOULD

BE SIMILAR IN THICKNESS.

• ARRANGE ALL FOOD COMPONENTS EVENLY ON

THE PLATE.

• AVOID EXCESSIVE OVERLAPPING OF PRODUCT.

• SAUCES MUST BE HEATED AND ADDED TO

PRODUCT AFTER REHEATING.

• A MIXED VARIETY OF MEALS CAN BE REHEATED

AT THE SAME TIME.

À LA CARTE RETHERMALIZATION

À la carte rethermalization is designed to take a single

plate from a refrigerated temperature to serving

temperature for immediate service. Plates are prepared

in advance, covered, and refrigerated. Preheat the

Combitherm oven. Remove plate from refrigeration and

place in the oven at 275°F (135°C) for an uncovered plate

or 300°F (150°C) for a covered plate. Plates with meat

components will take more time than plates containing

all vegetable components. Follow internal temperature

requirements for reheating and allow for override time.

After reheating, remove the plate from the oven, add any

sauces, garnish, and serve. This process can be repeated

as required.

For the most efcient continuous service, it is suggested

that the Combitherm oven be dedicated to the

rethermalization process during serving hours.

BANQUET RETHERMALIZATION

Banquet rethermalization is designed for high volume, full

or partial load (multiple plate) reheating.

Plates are assembled in advance, covered, and refrigerated

or loaded on the roll-in cart and refrigerated. Preheat

the Combitherm oven at 275°F (135°C) for uncovered

plates or 300°F (150°C) for covered plates. Remove plates

or the roll-in cart from refrigeration, load in the oven

and set timer as required. Follow internal temperature

requirements for reheating and allow for override time.

Remove the plates or roll-in cart from the Combitherm.

Placing our thermal blanket cover over the roll-in cart

keeps food hot for 20 to 40 minutes, depending on the

type of food, retherm temperature, and environmental

factors. For longer holding times, roll the cart into the

CombiMate™ companion holding cabinet.

RETHERMALIZING PREFABRICATED AND

VACUUM-PACKED FROZEN FOODS

For bulk product rethermalization, completely defrost

product bags in walk-in cooler. DO NOT REMOVE

PRODUCT FROM THE BAG. Load thawed bags in

preheated oven and rethermalize in the Low Temperature

Steam mode until the required internal temperature is

reached. Place rethermalized bags in a preheated

holding cabinet set at 140° to 165°F (60° to 74°C) until

ready for service.

For large volume on-the-plate regeneration, defrost

bags in walk-in cooler. Open bags and plate per menu

requirements in a (maximum) 55°F (13°C) refrigerated

room. Place on Alto-Shaam roll-in cart (trolley), and roll

into Combitherm oven preheated at 275°F (135°C).

Regenerate in the Convection mode for 3 to 5 minutes.

Switch to the Retherm mode for an additional 3 minutes

or more if required. Placing our thermal blanket cover

over the roll-in cart keeps food hot for 20 to 40 minutes,

depending on the type of food, retherm temperature, and

environmental factors. For longer holding times, roll the

cart into the CombiMate™ companion holding cabinet.

PLATE COVERS MUST BE USED FOR ON-THE-PLATE REGENERATION.

15

Page 19

OPERATING INSTRUCTIONS

CORE TEMPERATURE PROBE MODE

As an alternative to timer operation, the Core

Temperature Probe mode can be used in conjunction

with any program mode to cook by sensing internal

product temperature using the included probe. For a more

accurate internal temperature, an optional, specialized,

Combitherm product probe senses temperature from four

strategic points and displays a temperature average.

PRESS ON BUTTON TO POWER OVEN ON.

ATTACH REMOVABLE PROBE BEFORE ACTIVATING

CORE TEMPERATURE FUNCTION, AND INSERT

INTO PRODUCT.

The probe must be inserted so that the tip is positioned

in the center of the food mass. For liquid or semi-liquid

foods, suspend the probe in the center of the product and

secure the probe wire to the edge of the container.

PRESS THE REQUIRED COOKING MODE ICON.

The last set values or oven control default setting for

temperature and time will appear in the display.

TOUCH THE PROBE ICON.

The previously set core temperature or default setting

will appear highlighted within the oven display. Touch

the displayed core temperature. The internal product core

temperature will appear at the top of the temperature

selection window. Type in desired internal product

core temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING.

• The actual internal product temperature will appear

next to the icon during operation. To change the set

value for core temperature, press the temperature next

to the icon and make changes as required.

PRESS FOR STEAM INJECTION AT ANY TIME

DURING COOKING. Steam will inject into the

cavity as long as the icon is touched.

PRESS THE START ICON TO COOK AT THE

DISPLAYED SETTINGS, OR

TOUCH THE DISPLAYED TEMPERATURE.

The cooking temperature will appear at the top of

the temperature selection window. Type in desired

temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

When the operator-set internal temperature has been

reached, an alarm will sound indicating the end of the

operating mode.

• To stop the buzzer, press the red stop key or open

the oven door.

TO STOP COOKING PROGRAM AT ANY TIME,

PRESS RED STOP BUTTON.

16

Page 20

OPERATING INSTRUCTIONS

DELTA-T CORE TEMPERATURE COOKING MODE

This special program function cooks by internal product

temperature with the use of the probe. Unlike the

standard core temperature mode however, the Delta-T

oven temperature automatically increases in direct

proportion to the internal temperature of the product. The

Delta-T mode cooks with convection heat but provides a

more gentle method of cooking. Browning occurs toward

the end of the cooking cycle.

PRESS THE ON BUTTON TO POWER OVEN ON.

ATTACH REMOVABLE PROBE BEFORE ACTIVATING

CORE TEMPERATURE FUNCTION, AND INSERT INTO

PRODUCT.

The probe must be inserted so that the tip is positioned

in the center of the food mass. For liquid or semi-liquid

foods, suspend the probe in the center of the product and

secure the probe wire to the edge of the container.

PRESS THE REQUIRED COOKING MODE ICON.

The last set values or oven control default setting for

temperature and time will appear in the display.

PRESS THE DELTA T ICON THAT APPEARS IN

THE LOWER LEFT CORNER OF THE TOUCH

SCREEN.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING.

• The actual internal product temperature will appear

next to the icon during operation. To change the set

value for core temperature, press the temperature next

to the icon and make changes as required.

PRESS FOR STEAM INJECTION AT ANY TIME

DURING COOKING. Each push of the icon will

release one pulse of steam.

When the operator-set internal temperature has been

reached, a buzzer will sound indicating the end of the

operating mode.

• To stop the buzzer, press the red stop key or open

the oven door.

TOUCH THE PROBE ICON.

The previously set core temperature or default setting

will appear highlighted within the oven display. Touch

the displayed core temperature. The internal product core

temperature will appear at the top of the temperature

selection window. Type in desired internal product

core temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

TO STOP COOKING PROGRAM AT ANY TIME,

PRESS RED STOP BUTTON.

17

Page 21

OPERATING INSTRUCTIONS

AUXILIARY FUNCTIONS

All auxiliary functions can be engaged at any time during

any cooking mode and can be programmed into cooking

procedures. At the end of a cooking mode or program, the

oven automatically disengages all auxiliary functions.

PREHEATING FEATURE

SELECT DESIRED COOKING MODE.

PRESS THE GOLD-N-BROWN ICON.

Choose the desired

Gold-n-Brown level. (Level 1 provides least amount

of browning, level 6 the most.) After a level has been

selected, the previous screen will be displayed and the

Gold-n-Brown icon will be highlighted.

PRESS PREHEAT ICON.

The preheat temperature will appear at the top of the

preheat temperature selection window. Type in desired

temperature or use up and down arrows to adjust

temperature. When nished, touch the green checkmark

key to conrm change.

When the preheat temperature has been reached, a

buzzer will sound indicating the end of the preheat

function. To stop the buzzer, press the red stop

icon . The preheat temperature will be maintained

if the stop icon is not pressed.

GOLD-N-BROWN FEATURE

The browning feature is an automatic function designed to

regulate humidity to provide additional color to products

as needed. This feature is particularly useful for adding

color to high moisture products such as chicken and other

poultry items, or for additional browning of full loads

and other moist products. In addition, this feature may

be used to add texture to fried items such as french fries

or breaded chicken. Gold-n-Brown can be used in any

cooking mode and can be programmed into a cooking

procedure.

Browning can be used for any product. Depending on the

type of product and product load, the browning feature

may also slightly increase the set cooking time in order to

fully complete the browning function. This is a standard

operating condition of this feature.

SELECT DESIRED COOKING MODE.

ADJUST TEMPERATURE AND TIME SETTINGS.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING.

The oven will engage the browning feature in the cooking

mode set by the operator. Gold-N-Brown can be used in

steam mode to reduce moisture.

COOL DOWN FEATURE

The cool-down feature provides the operator with the

ability to lower the temperature of the oven compartment

at an accelerated pace. This function is useful when it is

necessary to immediately change from a high temperature

cooking function to a lower temperature function or to the

steam program. This function is also useful to help cool

the oven compartment in preparation for cleaning.

CHEF OPERATING TIP

When using the cool-down feature in preparation

for cleaning, it is important to remember that the

temperature in the display indicates the air temperature

inside the oven compartment and not the interior

walls of the oven. Always allow the oven walls to

cool to a minimum of 140°F (60°C) before spraying the

compartment with oven cleaner.

PRESS COOL DOWN ICON.

The cool down temperature will appear at the top of

the cool down temperature selection window. Type in

desired temperature between 50 and 200°F (10 and 93°C)

or use up and down arrows to adjust temperature. When

nished, touch the green checkmark key to

conrm change.

OPEN OVEN DOOR.

A buzzer will sound indicating the end of the cool down

function. Press the red stop key

to stop the buzzer.

or open the oven door

18

Page 22

OPERATING INSTRUCTIONS

AUXILIARY FUNCTIONS

REDUCED FAN SPEED

The reduced fan speed function is useful for ow-sensitive

products such as soufês and meringues, or any products

affected by a high velocity of air movement.

SELECT DESIRED COOKING MODE AND SET

MODE FUNCTIONS.

PRESS FAN SPEED ICON.

The FAN SPEED icon toggles between 100% and 50%.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING.

REDUCED POWER

The reduced power function can be used to reduce kitchen

power peaks and energy consumption.

SELECT DESIRED COOKING MODE AND SET MODE

FUNCTIONS.

PRESS REDUCED POWER ICON.

MULTI-SHELF TIMER

The multi-shelf timer allows the operator to program

different cook times for individual shelves.

SET COOKING MODE, TEMPERATURE AND TIME.

The time set by the user will be the default time for each

shelf timer.

PRESS THE MULTI-SHELF TIMER ICON.

ADJUST TIME SETTINGS FOR EACH SHELF AND

PRESS GREEN CHECKMARK KEY TO

CONFIRM CHANGE.

PRESS THE GREEN START ARROW ICON FOR

EACH INDIVIDUAL SHELF. The unit will immediately

start running in continuous operation mode.

When time expires for a shelf, the time background will

turn red and an alarm will sound.

OPEN THE DOOR OR PRESS THE RED STOP

BUTTON TO SILENCE ALARM. Remove food

as appropriate.

The REDUCED POWER icon will be highlighted.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING.

The oven will operate with reduced power in whatever

cooking mode is set by the operator.

NOTE: Reduced power will result in

longer cooking times.

STEAM INJECTION

Press to add moisture while in any cooking mode.

Steam will inject into the cavity as long as the icon

is touched.

19

Page 23

OPERATING INSTRUCTIONS

CombiSmoker™ ProCedureS U.S. PAT. 7,157,668; EU PAT. 1659911

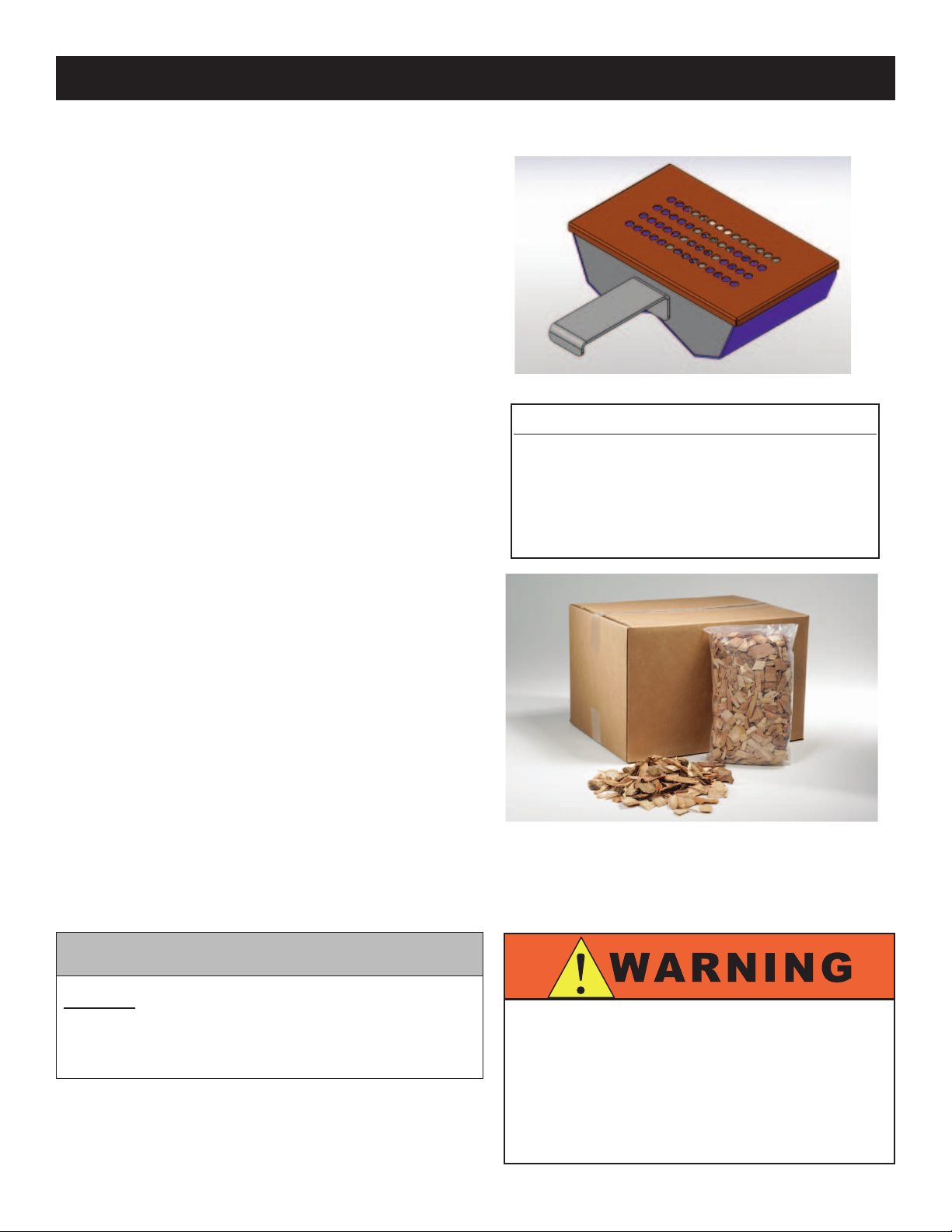

LOAD WOOD CHIPS.

• Measure one container full of dry wood chips.

• Soak dry chips in water for 5 minutes.

• Shake excess water off wood chips.

• Place moistened chips back into the container

and position the container securely on the two prongs

located on the interior back panel of the oven.

A full container of wood chips will produce smoke for an

approximate period of one to two hours depending on the

cooking temperature being used for the selected product.

The preprogrammed CombiTouch recipes have been

tested to ensure complete product smoke penetration and

full smoke avor.

CHEF OPERATING TIP

Products such as ribs that require heavier smoke

penetration to reach full smoke avor should remain in

the oven after cooking has been completed. Do not open

the oven door.

AVAILABLE FROM ALTO-SHAAM

WOOD CHIPS 20 pound bulk packs

THE TOTAL WEIGHT OF

Apple WC-22543

WOOD CHIP BULK PACKS

Hickory WC-2829

MAY VARY DUE TO HIGH

MOISTURE CONTENT

Cherry WC-22541

WHEN PACKAGED.

Sugar Maple WC-22545

Set the oven in the Low Temperature Steam Mode at 140°

to 160°F (60° to 71°C) and allow the product to remain in

the oven for a period of one hour.

If you would like assistance, you are invited to contact

an Alto-Shaam corporate chef for recommendations.

NOTE: Always keep the oven door closed whenever

operating the smoking function.

The CombiTouch CombiSmoker can be operated

without using the smoking function. After using the

oven as a smoker, however, it is necessary to clean the

oven in order to prevent a transfer of smoke avor to

non-smoked products. Cleaning instructions are provided

in this manual.

CAUTION

DO NOT OPEN THE OVEN DOOR DURING THE

SMOKING FUNCTION. The introduction of outside

air in the oven compartment may cause the wood

chips to flame.

THE USE OF IMPROPER MATERIALS FOR

THE SMOKING FUNCTION COULD RESULT IN

DAMAGE, HAZARD, EQUIPMENT FAILURE,

OR COULD REDUCE THE OVERALL LIFE

OF THE OVEN.

20

DO NOT USE SAWDUST FOR SMOKING.

DO NOT USE WOOD CHIPS SMALLER

THAN THUMBNAIL SIZE.

Page 24

OPERATING INSTRUCTIONS

CombiSmoker™ ProCedureS

The ability to smoke product, hot or cold, is offered on

all boiler-free electric models and on all gas models.

The smoking function can be engaged in either the

Combination mode or the Convection mode of operation.

The smoking function cannot be operated when the oven

is operating in the steam mode or the retherm mode.

SELECT CONVECTION OR COMBINATION

COOKING MODE.

TO CHANGE THE TEMPERATURE:

TOUCH THE DISPLAYED TEMPERATURE.

Type desired temperature or use up and down arrows to

adjust temperature then touch the green checkmark key

to conrm.

TO COOK BY TIME:

CAUTION

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN

IN OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

TOUCH THE DISPLAYED TIME.

The cooking time will appear at the top the time selection

window. Type in desired time period or use up and down

arrows to adjust time. When nished, touch the green

checkmark key to conrm change.

Or, to set Continuous Operation mode, type in --:-- and

touch the green checkmark key to conrm.

TO ACTIVATE CombiSmoke:

Press the SMOKING icon. The icon will be

highlighted on the screen.

PRESS THE GREEN START ARROW ICON TO

BEGIN COOKING.

21

Page 25

OPERATING INSTRUCTIONS

PREPROGRAMMED RECIPES

The CombiTouch Combitherm comes preprogrammed

with more than 100 recipes and photo icons, covering

most commonly prepared food items. CombiTouch

also allows you to save up to 250 of your recipes and

uploaded photos.

MAIN MENU COOKING MODE MENU

Select RECIPE MODE from any screen.

Navigate to desired recipe icon using green NEXT and

PREVIOUS SCREEN arrows. Press icon for desired recipe.

Cooking steps will start immediately. (See 24-33 for a list

of all preprogrammed recipes.)

PROGRAMMED

RECIPES

NUMBER OF

RECIPE SCREENS

PREVIOUS

SCREEN

RECIPE MENU

EDIT

RECIPES

PREVIOUS &

NEXT SCREEN

RECIPE

MODE

& NEXT RECIPE

PROGRAM/EDIT RECIPES

EDITABLE

RECIPES

PREVIOUS

DELETE

RECIPE

EDIT

RECIPE

CONFIRM

CHANGES

22

Page 26

OPERATING INSTRUCTIONS

RECIPE PROGRAMMING VIA RECIPE MANAGEMENT SOFTWARE

The recipes can be edited, using the Touchscreen directly

or with the Recipe Management Software. This Windows

based software and step-by-step instructions are available

for download via the Alto-Shaam website.

http://www.alto-shaam.com/combitouch.aspx

RECIPE PROGRAMMING VIA THE TOUCHSCREEN

ADD A RECIPE

The recipe programming function allows the operator

to program a cooking procedure using multiple cooking

modes and any auxiliary functions desired. Recipes

remain programmed until deleted by the operator.

1. Select any cooking mode.

2. Click ADD RECIPE icon.

3. Select rst desired cooking mode. Last input

temperature, time and probe setting will be displayed.

4. Change temperature, time and/or cook by probe as

desired.

5. Change auxilary functions as desired (fan speed,

Gold-N-Brown, etc.)

6. When nished with cooking step, press WRITE

icon. Will display next cooking step programming

screen.

7. Repeat steps 3 through 6 for each cooking step or

proceed to step 8 if only one step in recipe.

8. When nished programming recipe, touch the

CONFIRM CHANGES icon.

9. A keypad will appear. Input name of recipe and assign

a picture. Touch the picture icon to display the picture

instead of text on recipe menu. Press CONFIRM

CHANGES icon.

®

DOWNLOAD

LINK

EDIT A RECIPE

To edit an existing default or user-programmed recipe:

1. Select RECIPE SETTINGS MODE from the Recipe

Menu. The touch screen background will turn red to

indicate that the user is in EDIT MODE.

2. Press the icon of the recipe to be edited. Selected recipe

will be highlighted.

3. Press EDIT RECIPE. The rst cooking step in the

recipe will be displayed.

Or click DELETE RECIPE to remove recipe.

Click CONFIRM CHANGES to conrm deletion.

4. Edit cooking mode, temperature, time, probe

temperature and/or auxilary functions.

5. Press CONFIRM CHANGES. A keyboard will

appear. Edit the title as appropriate. Select a picture

if desired, by pushing the picture icon to view the

picture library.

Press CONFIRM CHANGES at the bottom of

the keyboard.

6. Press CONFIRM CHANGES at the bottom of the

touch screen to exit EDIT RECIPE mode.

10. The saved recipe will appear as the rst recipe in

the list.

11. Touch the newly saved recipe icon. Cooking steps in

recipe will immediately start.

23

Page 27

OPERATING INSTRUCTIONS

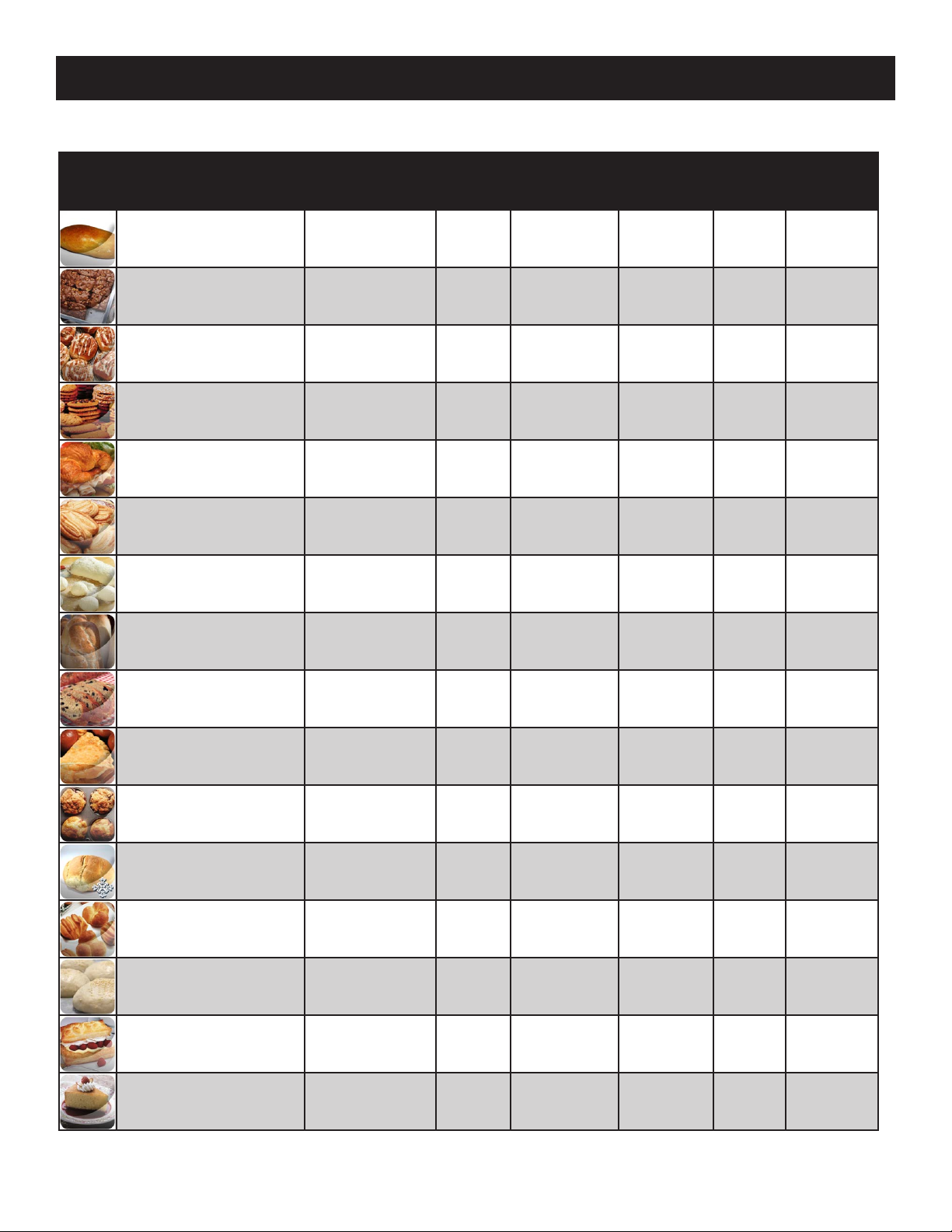

PREPROGRAMMED BAKERY RECIPES

Icon Recipe Oven Mode Temp Time

Fan

Speed Smoker Browning

Bakery retherm Retherm

Brownies Convection

Cinnamon Rolls Combination

Cookies Convection

Croissants Combination

Danish Pastry Combination

Dinner Rolls Combination

French Bread Combination

275°F

(135°C)

325°F

(163°C)

350°F

(177°C)

325°F

(163°C)

325°F

(163°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

4 minutes 100% -- --

25 minutes 100% -- --

20 minutes 100% -- --

12 minutes 50% -- --

15 minutes 50% -- --

15 minutes 100% -- --

10 minutes 100% -- --

20 minutes 100% -- --

Fruit Bread Combination

Fruit Pie Combination

Muffins Convection

Par-baked Bread (frozen) Combination

Par-baked Rolls Combination

Proofing Low Temp Steam

Puff Pastry Combination

Sheet Cake Convection

300°F

(149°C)

340°F

(171°C)

325°F

(163°C)

340°F

(171 °C)

350°F

(177°C)

90°F

(32°C)

350°F

(177°C)

325°F

(163°C)

50 minutes 100% -- --

30 minutes 100% -- --

15 minutes 50% -- --

15 minutes 100% -- --

10 minutes 100% -- --

30 minutes 50% -- --

10 minutes 100% -- --

20 minutes 50% -- --

24

Page 28

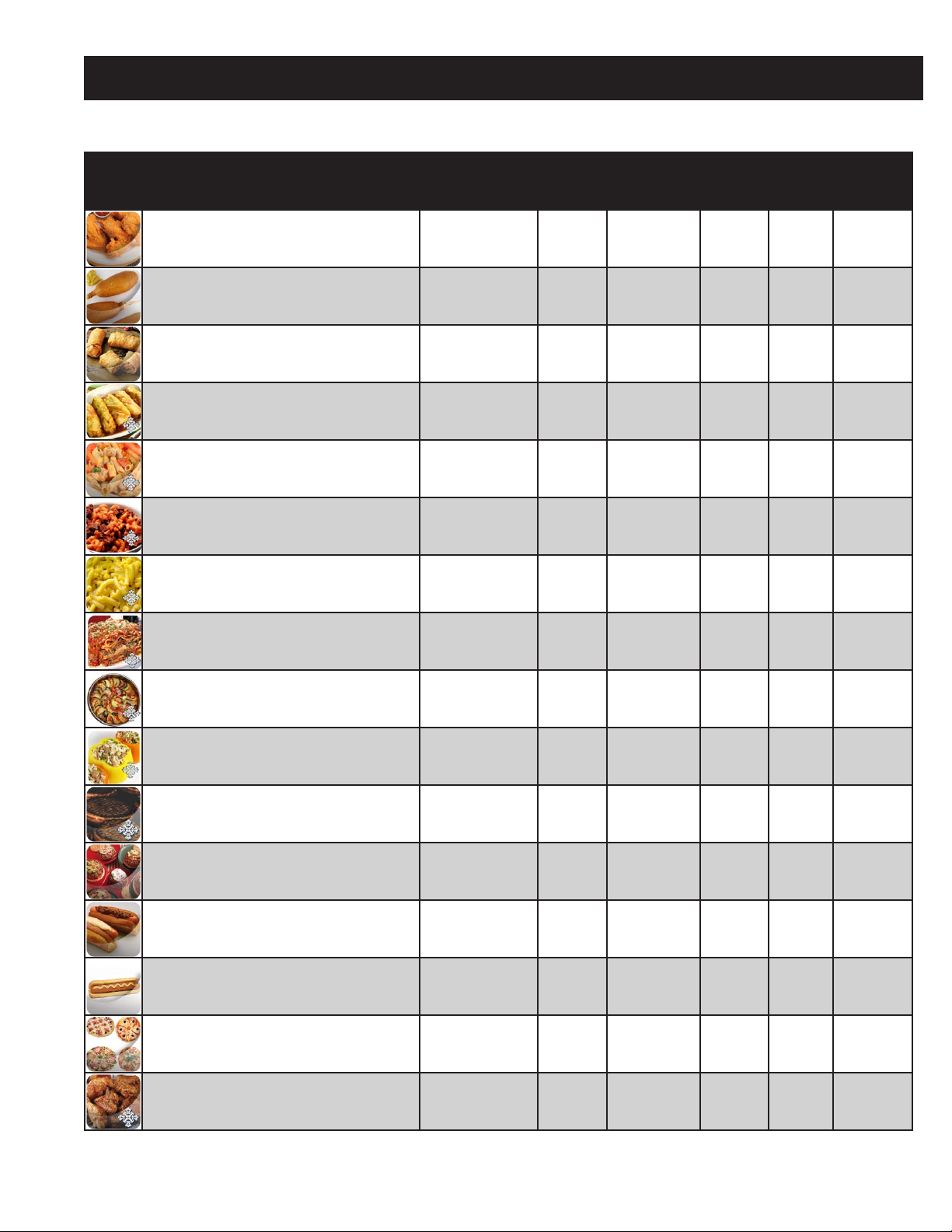

OPERATING INSTRUCTIONS

PREPROGRAMMED CONVENIENCE PRODUCT RECIPES

Icon Recipe Oven Mode Temp Time

Chicken Wings Combination

Corn Dogs Combination

Egg Rolls Combination

Frozen Entrée: Cabbage Rolls

Frozen Entrée: Chicken Primavera

Frozen Entrée: Macaroni & Beef

Frozen Entrée: Macaroni & Cheese

Frozen Entrée: Meat Lasagna

Combination

Combination

Combination

Combination

Combination

400°F

(204°C)

350°F

(177°C)

375°F

(191°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

10 minutes 100% -- 2

18 minutes 100% -- 1

15 minutes 100% -- 3

160°F probe

(71°C)

160 minutes 100% -- --

145 minutes 100% -- --

140 minutes 100% -- --

150 minutes 100% -- --

Fan

Speed Smoker

100% -- --

Browning

Level

Frozen Entrée: Ratatouille

Frozen Entrée: Stuffed Peppers

Hamburger Patties - Frozen Combination

Hamburger Patties - Thawed Combination

Hot Dogs - Low Temp Steam Low Temp Steam

Hot Dogs - Steamed Steam

Mini Pizza Combination

Precooked Chicken Pieces - Frozen (MRB) Convection

Combination

Combination

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

350°F

(177°C)

160°F

(71°C)

212°F

(100°C)

350°F

(177°C)

365°F

(185°C)

35 minutes 100% -- --

150 minutes 100% -- --

12 minutes 100% -- 4

5 minutes 100% -- --

13 minutes 50% -- --

10 minutes 100% -- --

10 minutes 100% -- --

30 minutes 100% -- 3

25

(CONTINUED ON NEXT PAGE)

Page 29

OPERATING INSTRUCTIONS

PREPROGRAMMED CONVENIENCE PRODUCT RECIPES (CONTINUED)

Icon Recipe Oven Mode Temp Time

Precooked Chicken Pieces - Refrigerated Convection

Spring Rolls Combination

Tater Tots Combination

325°F

(163°C)

375°F

(191°C)

375°F

(191°C)

20 minutes 100% -- 1

15 minutes 100% -- --

10 minutes 100% -- 3

Fan

Speed Smoker

Browning

Level

26

Page 30

OPERATING INSTRUCTIONS

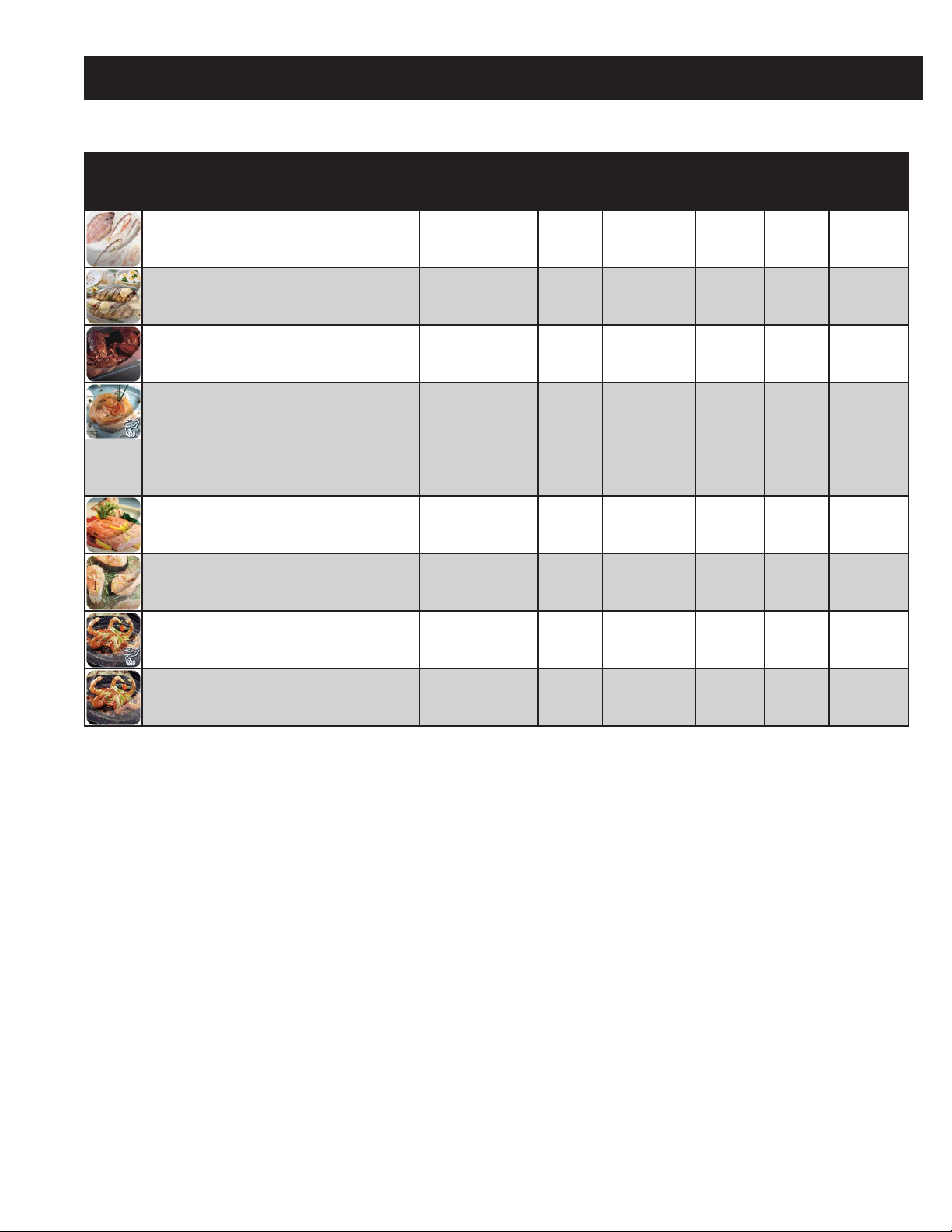

PREPROGRAMMED FISH & SEAFOOD RECIPES

Icon Recipe Oven Mode Temp Time

Baked Fish - Fresh Combination

Grilled Fish Fillets Combination

Lobster - Whole Steam

Salmon - Cold Smoked (1) Convection

(2) Convection

Salmon - Filets Low Steam

Salmon - Steaks Steam

Shrimp - Smoked Convection

400°F

(204°C)

460°F

(238°C)

195°F

(91°C)

34°F

(1°C)

34°F

(1°C)

145°F

(63°C)

145°F

(63°C)

34°F

(1°C)

6 minutes 100% -- 2

4 minutes 100% -- --

13 minutes 50% -- --

15 minutes 50% On --

30 minutes 50% Off --

7 minutes 50% -- --

8 minutes 100% -- --

10 minutes 50% On --

Fan

Speed Smoker

Browning

Level

Shrimp - Steamed Low Steam

160°F

(71°C)

12 minutes 50% -- --

27

Page 31

OPERATING INSTRUCTIONS

PREPROGRAMMED MEAT RECIPES

Icon Recipe Oven Mode Temp Time

Bacon Combination

Beef Brisket - Smoked (1) Combination

(2) Combination

Beef Roast Cook & Hold (1) Delta-T

(2) Steam

Beef Rounds - by Core Temp Delta-T

Beef Rounds - by Time Combination

Beef Short Ribs Combination

375°F

(191°C)

225°F

(107°C)

225°F

(107°C)

125°F

(52°C)

135°F

(57°C)

130°F

(54°C)

250°F

(121°C)

275°F

(135°C)

10 minutes 100% -- --

90 minutes 50% On --

180 minutes 50% -- --

Probe 120°F

(46°C)

Continuous 50% -- 2

Probe 125°F

(52°C)

130 minutes 100% -- --

90 minutes 100% -- --

Fan

Speed Smoker

50% -- --

100% -- 1

Browning

Level

Beef Short Ribs - Smoked (1) Combination

(2) Combination

Beef Tenderloin Combination

Beef Tri-tips Combination

Breakfast Sausage Links Combination

Grilled Pork Chops Combination

Grilled Steaks Combination

275°F

(135°C)

275°F

(135°C)

250°F

(121°C)

250°F

(121°C)

350°F

(177°C)

460°F

(238°C)

460°F

(238°C)

30 minutes 50% On --

60 minutes 100% -- --

Probe 125°F

(52°C)

Probe 125°F

(52°C)

8 minutes 100% -- --

6 minutes 100% -- 1

Probe 130°F

(54°C)

100% -- 2

100% -- 3

100% -- --

(CONTINUED ON NEXT PAGE)

28

Page 32

OPERATING INSTRUCTIONS

PREPROGRAMMED MEAT RECIPES (CONTINUED)

Icon Recipe Oven Mode Temp Time

Ham - by Core Temp Delta-T

Leg of Lamb - by Core Temp Delta-T

Meat Loaf - by Core Temp Combination

Pork - Back Ribs - Raw Combination

Pork - Back Ribs - Smoked (1) Combination

(2) Steam

Pork - Loin Roast - by Core Temp Combination

Pork Ribs Reheat Combination

125°F

(52°C)

125°F

(52°C)

275°F

(135°C)

250°F

(121°C)

250°F

(121°C)

160°F

(71°C)

300°F

(149°C)

400°F

(204°C)

Probe 150°F

(66°C)

Probe 130°F

(54°C)

Probe 155°F

(68°C)

45 minutes 100% -- --

60 minutes 100% On --

Continuous 50% -- --

Probe 150°F

(66°C)

7 minutes 100% -- --

Fan

Speed Smoker

50% -- --

100% -- 2

100% -- 3

100% -- 2

Browning

Level

Pork Shoulder - Smoked (1) Combination

(2) Combination

Rack of Lamb - by Core Temp Delta-T

Sausage - Fresh - by Low Temp Steam Low Temp Steam

225°F

(107°C)

225°F

(107°C)

130°F

(54°C)

160°F

(71°C)

90 minutes 100% On --

Probe 185°F

(85°C)

130 minutes 100% -- 2

15 minutes 50% -- --

-- --

29

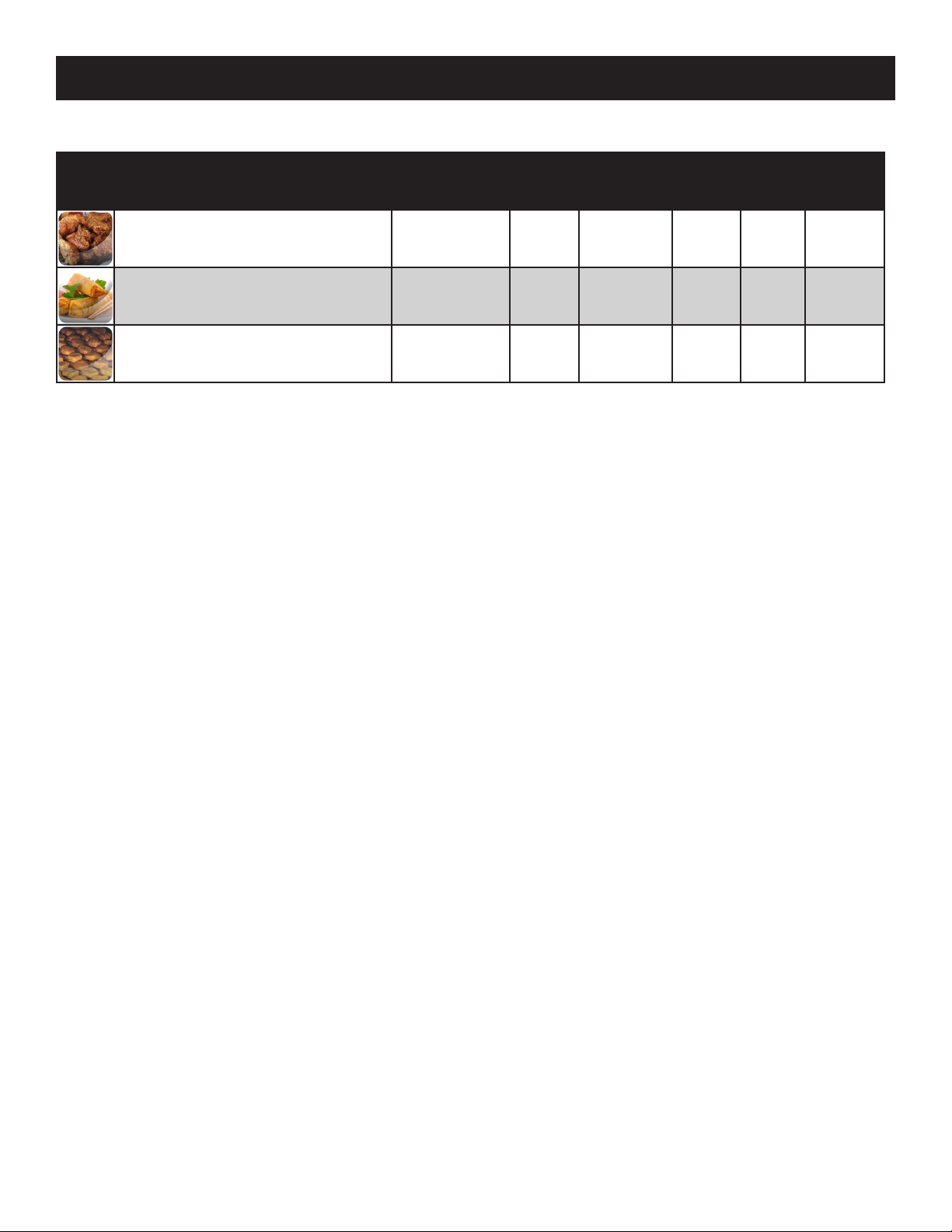

Page 33

OPERATING INSTRUCTIONS

PREPROGRAMMED MISCELLANEOUS RECIPES

Icon Recipe Oven Mode Temp Time

Casseroles - by Core Temp Combination

Casseroles - Time Combination

Custard/Crème Brulee

Eggs - Hardboiled Steam

Eggs - Poached - Low Temp Steam Low Temp Steam

Eggs - Poached - Steamed Steam

Eggs - Scrambled in bag; shake at

18 minutes

Eggs - Scrambled in pan Steam

Low Temp Steam

Steam

350°F

(177°C)

350°F

(177°C)

190°F

(88°C)

212°F

(100°C)

170°F

(77°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

Probe 150°F

(66°C)

30 minutes 100% -- --

45 minutes 50% -- 1

12 minutes 100% -- --

5 minutes 50% -- --

3 minutes 100% -- --

25 minutes 100% -- --

15 minutes 100% -- --

Fan

Speed Smoker

100% -- --

Browning

Level

Eggs - Sous Vide Steam

French Fries - Full Load (1) Convection

(2) Combination

Pasta Steam

Pate en Croute - by Core Temp (1) Convection

(2) Combination

Pizza - Fresh Combination

Rice Steam

Soup in Bag Steam

148°F

(64°C)

400°F

(204°C)

400°F

(204°C)

212°F

(100°C)

350°F

(177°C)

350°F

(177°C)

400°F

(204°C)

212°F

(100°C)

230°F

(110°C)

45 minutes 50% -- --

1 minute 100% -- 4

9 minutes 100% -- 2

20 minutes 100% -- --

10 minutes 100% -- --

Probe 135°F

(57°C)

10 minutes 50% -- 1

20 minutes 100% -- --

50 minutes 100% -- --

100% -- --

Tamales Steam

30

212°F

(100°C)

30 minutes 100% -- --

Page 34

OPERATING INSTRUCTIONS

PREPROGRAMMED POULTRY RECIPES

Icon Recipe Oven Mode Temp Time

Chicken - Frozen Pieces Combination

Chicken - Oven Fried Pieces Combination

Chicken - Thawed Whole Combination

Chicken - Thawed Whole - by Core Temp Combination

Chicken - Whole Smoked (1) Convection

(2) Combination

Chicken baked - Thawed Pieces Combination

Duck Pieces - Raw Combination

350°F

(177°C)

450°F

(232°C)

350°F

(177°C)

350°F

(177°C)

34°F

(1°C)

350°F

(177°C)

375°F

(191°C)

375°F

(191°C)

30 minutes 100% -- 3

18 minutes 100% -- --

35 minutes 100% -- 1

Probe 175°F

(79°C)

15 minutes 50% On --

Probe 175°F

(79°C)

Probe 170°F

(77°C)

25 minutes 100% -- 4

Fan

Speed

100% -- 1

50% -- --

100% -- 2

Smoker

Browning

Level

Duck Whole - by Core Temp (1) Combination

(2) Combination

(3) Combination

Galantine - by Core Temp Low Temp Steam

Grilled Chicken Breasts Combination

Turkey Breast - Precooked - by Time Combination

Turkey Breast - Raw - by Core Temp Combination

Turkey Breast - Smoked (1) Combination

250°F

(121°C)

300°F

(149°C)

400°F

(204°C)

160°F

(71°C)

460°F

(238°C)

275°F

(135°C)

275°F

(135°C)

275°F

(135°C)

15 minutes 100% -- --

10 minutes 100% -- --

Probe 175°F

(79°C)

Probe 135°F

(79°C)

6 minutes 100% -- --

Probe 155°F

(68°C)

Probe 155°F

(68°C)

60 minutes 50% On --

100% -- 3

50% -- --

50% -- --

50% -- 1

(2) Combination

31

275°F

(135°C)

Probe 155°F

(68°C)

100% -- --

Page 35

OPERATING INSTRUCTIONS

PREPROGRAMMED VEGETABLE RECIPES

Icon Recipe Oven Mode Temp Time

Asparagus - Fresh Steam

Asparagus - Frozen Steam

Baked Potatoes Combination

Beets - Fresh Steam

Broccoli - Fresh Steam

Broccoli - Frozen Steam

Brussel Sprouts - Frozen Steam

Cabbage - Fresh Steam

190°F

(88°C)

212°F

(100°C)

350°F

(177°C)

230°F

(110°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

3 minutes 50% -- --

5 minutes 100% -- --

40 minutes 100% -- 1

20 minutes 100% -- --

6 minutes 100% -- --

3 minutes 100% -- --

6 minutes 100% -- --

10 minutes 100% -- --

Fan

Speed Smoker

Browning

Level

Carrots - Fresh Steam

Carrots - Frozen Steam

Cauliflower - Fresh Steam

Cauliflower - Frozen Steam

Corn (Kernels) - Frozen Steam

Corn-on-the-Cob - Fresh Steam

Corn-on-the-Cob - Frozen Steam

225°F

(107°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

10 minutes 100% -- --

6 minutes 100% -- --

5 minutes 100% -- --

4 minutes 100% -- --

4 minutes 100% -- --

14 minutes 100% -- --

10 minutes 100% -- --

(CONTINUED ON NEXT PAGE)

32

Page 36

OPERATING INSTRUCTIONS

PREPROGRAMMED VEGETABLE RECIPES (CONTINUED)

Icon Recipe Oven Mode Temp

Green Beans - Fresh Steam

Green Beans - Frozen Steam

Parsnips - Fresh Steam

Peas - Frozen Steam

Potatoes, Red or Salad Steam

Squash - Fresh Steam

Turnips - Fresh Steam

Zucchini - Fresh Steam

212°F

(100°C)

212°F

(100°C)

230°F

(110°C)

212°F

(100°C)

212°F

(100°C)

212°F

(100°C)

230°F

(110°C)

212°F

(100°C)

Fan

Time

8 minutes

5 minutes

10 minutes

4 minutes

30 minutes

3 minutes

10 minutes

3 minutes 100% -- --

Speed Smoker

100% -- --

100% -- --

100% -- --

100% -- --

100% -- --

100% -- --

100% -- --

Browning

Level

33

Page 37

OPERATING INSTRUCTIONS

HACCP ACCESS

The CombiTouch Combitherm meets the requirements

of established HACCP criteria by providing automated

sampling, record keeping, set-point validation, recipe

used, dates and time. Data is captured when Core

Temperature Probe cooking method is chosen. This data

is retained for the last 30 days. This information can be

viewed on screen or downloaded to a USB drive and then

copied to your computer. The le format is a text (.txt)

le.

NOTE: You access this information from the

Settings Screen. See illustrations on page 2 and 3

for navigation.

1. To download the data collected, remove the cap of a

USB port located on the left side of the oven and insert

the USB ash drive. If the ash drive is not recognized

by the Combitherm, a question mark will appear on

screen. Try again with another ash drive device or

call Alto-Shaam Service.

2.

3.

4. PRESS TO CONFIRM TRANSFER.

5. Remove the USB ash drive and replace the cap on the

USB port located on the left side of the oven.

The download process will automatically create a folder

on the USB ash drive titled “haccp”. Each text le

contains cooking program specics. See illustration below.

PRESS TO DOWNLOAD INFORMATION.

WAIT FOR THE ICON TO CHANGE FROM

LOADING TO COMPLETE.

COOKING

PROGRAM

CHOSEN

DATE

COOKED

TIME

OF DAY

COOKED

PREVIOUS

SCREEN

CORE

TEMPERATURE

RECIPE

USED

HACCP

DOWNLOAD

34

Page 38

CLEANING & MAINTENANCE

The CombiTouch Combitherm offers four (4) cleaning

levels: rinse, light, normal, and heavy-duty cleaning.

CombiClean tablets or Combitherm spray cleaner may be

used. Side racks, shelves and trolleys may remain inside

oven during cleaning.

SELECT CLEANING MODE FROM ANY SCREEN.

NOTE: If oven is too hot to safely clean, an oven with red

interior will appear on the screen and the cool

down function is automatically activated. Allow

oven to cool to 200°F before cleaning.

SELECT RINSE, LIGHT,

NORMAL, OR HEAVY-DUTY CLEANING.

INSERT APPROPRIATE NUMBER OF CombiClean

TABLETS as directed by touchscreen or spray interior of

oven with combi cleaner. User may add one additional

tablet in either normal or heavy duty modes for

particularly dirty ovens.

PRESS THE GREEN START ARROW ICON TO

BEGIN CLEANING.

PRESS GREEN WATER ON ICON TO CONFIRM

THAT WATER SUPPLY IS TURNED ON.

CLEANING MODE MENU

WATER ON

RINSE

LIGHT

CLEANING

CYCLE

PREVIOUS

SCREEN

Leave door slightly ajar when cleaning is nished.

See CLEANING MODE MENU illustration below for

additional cleaning mode information.

COMBI CLEANER REQUIREMENT

The number of required CombiClean

tabs is shown via an animation

WATER OFF

HEAVY-DUTY

CLEANING CYCLE

NORMAL

CLEANING

CYCLE

START/STOP

CLEANING IN PROCESS

OVEN TOO HOT WARNING

Must allow oven to cool down before inserting

CombiClean tabs or spraying with cleaner

35

Page 39

CLEANING & MAINTENANCE

PREVENTATIVE MAINTENANCE

In addition to the routine cleaning and maintenance

procedures, there are several additional steps to be

taken for both sanitation and to keep the oven running

efciently. These additional safeguards will help prevent

down time and costly repairs.

DO NOT DISPOSE OF GREASE, FAT, OR SOLID

WASTE DOWN THE OVEN DRAIN.

Fats and solids will eventually coagulate in the drain

system, causing blockage. Consequently, water

will back-up into the condenser and interior oven

compartment, resulting in an oven that is inoperable.

MAKE CERTAIN THE DRAIN SCREEN IS ALWAYS

IN PLACE. REMOVE ANY SOLID WASTE MATERIAL

FROM THE DRAIN SCREEN BEFORE IT ENTERS THE

DRAIN SYSTEM.

The routine removal of solids from the drain screen will

help prevent blockage.

USE THE AUTHORIZED COMBITHERM OVEN

CLEANER ONLY.

The use of unauthorized cleaning agents may discolor or

harm the interior surfaces of the oven.

TO PROLONG THE LIFE OF THE DOOR GASKET,

CLEAN THIS ITEM DAILY.

The acids and related compounds found in fat,

particularly chicken fat, will weaken the composition of

the gasket unless cleaned on a daily basis. Wipe with a

hot, soapy cloth.

TO ADDITIONALLY PROTECT GASKET LIFE,

ALLOW OVEN DOOR TO REMAIN SLIGHTLY OPEN

AT THE END OF THE PRODUCTION DAY.

An open door will relieve the pressure on the door gasket.

ROUTINELY CLEAN DOOR HINGES.

Open oven door to relieve tension. Clean all parts of

the hinge.

CLEAN PRONGS OF

REMOVABLE PROBE DAILY.

To ensure accurate internal

product temperature readings,

the prongs on the removable

probe must be cleaned daily.

ROLL-IN CART/FOOD TROLLEY CLEANING (ON EQUIPPED MODELS)

1. Remove food trolley to a cart wash area. Trolleys may be cleaned using

any mild cleaning detergent and warm water.

2. Hand wipe all framing, slides, drip pan, and base. Thoroughly clean

debris from the casters. A spray hose can be used for easier cart cleaning.

3. Remove detergent solution with warm water.

4. Wipe or spray with a sanitizing solution designed for use on metal and

vinyl food contact surfaces.

5. Allow trolley to air dry.

As an alternative, trolleys can be cleaned while inside the oven. Allow the

trolley to remain in the oven through the normal cleaning cycle, followed by

steps 2 through 5 above.

36

Page 40

CLEANING & MAINTENANCE

The cleaning function can usually be accomplished

scratches. Never use wire brushes, metal scouring

CLEANING AND PREVENTIVE MAINTENANCE

PROTECTING STAINLESS STEEL SURFACES

It is important to guard against corrosion

in the care of stainless steel

surfaces. Harsh, corrosive,

or inappropriate chemicals

can completely destroy the

protective surface layer

of stainless steel. Abrasive

pads, steel wool, or metal implements will abrade

surfaces causing damage to this protective coating

and will eventually result in areas of corrosion.

Even water, particularly hard water that contains

high to moderate concentrations of chloride, will

cause oxidation and pitting that result in rust

and corrosion. In addition, many acidic foods

spilled and left to remain on metal surfaces are

contributing factors that will corrode surfaces.

Proper cleaning agents, materials, and

methods are vital to maintaining the appearance

and life of this appliance. Spilled foods should be

removed and the area wiped as soon as possible

but at the very least, a minimum of once a day.

Always thoroughly rinse surfaces after using a

cleaning agent and wipe standing water as quickly

CLEANING AGENTS

Use non-abrasive cleaning products designed for

use on stainless steel surfaces. Cleaning agents

must be chloride-free compounds and must not

contain quaternary salts. Never use hydrochloric

acid (muriatic acid) on stainless steel surfaces.

Always use the proper cleaning agent at the

manufacturer's recommended strength.

Contact your local cleaning supplier for

product recommendations.

CLEANING MATERIALS