Alto Shaam 500-S-HD Service Manual

#823/32/36 • 7/2004

PRINTED IN U. S .A .

INSTALLATION

OPERATION

AND

MAINTENANCE

MANUAL

FOOD

HOLDING

CABINET

Manual or Electronic

Control

MODELS:

500-S

750-S

1000-S

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558-8744 USA/CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

Manual Control

Electronic Control

500-S

750-S

1000-S

with Manual Control

and casters

The Alto-Shaam Holding Cabinet has

been thoroughly tested, checked for

calibration, and inspected to insure only the

highest quality cabinet is provided. When you

receive your cabinet, check for any possible

shipping damage and report it at once to the

delivering carrier.

See Transportation

Damage and Claims section located in this manual.

The cabinet, complete with unattached items and

accessories, may be delivered in one or more packages. Check

to ensure that the following items have been received as

standard with each unit.

500-S 2: SIDE RACKS 2: WIRE SHELVES

750-S 2: SIDE RACKS 3: WIRE SHELVES

1000-S 2: SIDE RACKS 4: CASTERS

Save all the information and instructions packed inside the

cabinet. Complete and return the warranty card to the factory

as soon as possible to assure prompt service in the event of a

warranty parts and labor claim.

NOTE: All claims for warranty must include the

full model number and serial number of the

cabinet.

The cabinet is equipped with a special heating cable.

Through this Halo Heat concept, the heating cable is

mounted against the walls of the unit to provide an

evenly applied heat source controlled by a thermostat.

The design and operational characteristics of the unit

eliminate the need for a moisture pan or a heat

circulating fan. Through even heat application,

the quality of food products is maintained up to several

hours or more.

1. An identification tag is permanently mounted on

the cabinet.

2. Plug cabinet into a properly grounded receptacle

ONLY, positioning the unit so the power supply

cord is easily accessible in case of an emergency.

3. If necessary, a proper receptacle or

outlet configuration as required for this unit,

must be installed by a licensed electrician

in accordance with applicable, local electrical codes.

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 1.

HOLDING CABINETS

®

UNPACKING and SET-UP ELECTRICAL INSTALLATION

®

®

PATENT NOS.

3521030

4595247

®

PH

ENSURE POWER SOURCE

MATCHES VOLTAGE STA M PED

ON NAMEPLATE OF UNIT

START-UP

HEATING CHARACTERISTICS

Disconnect unit from power

source before cleaning

or servicing.

At no time should the inside or

outside of the cabinet be washed

down, flooded with water or

liquid solution

. Do not clean

with water jet. NEVER STEAM

CLEAN. Severe damage or

electrical hazard could result.

Warranty becomes void

if unit is flooded.

1. The unit should be installed level and should NOT be installed in any area where it may be affected by steam,

grease, dripping water, high temperatures or any other severely adverse conditions.

2. Before operating the cabinet, clean both the interior and exterior of the unit with a damp, clean cloth and

mild soap solution. Rinse carefully.

3. Clean and install the cabinet side racks. Shelves should be positioned with the curved end up and toward the

back of the unit.

4. Before operating the unit, become familiar with the operation of the controls. Read this manual and keep it

in a secure location.

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 2.

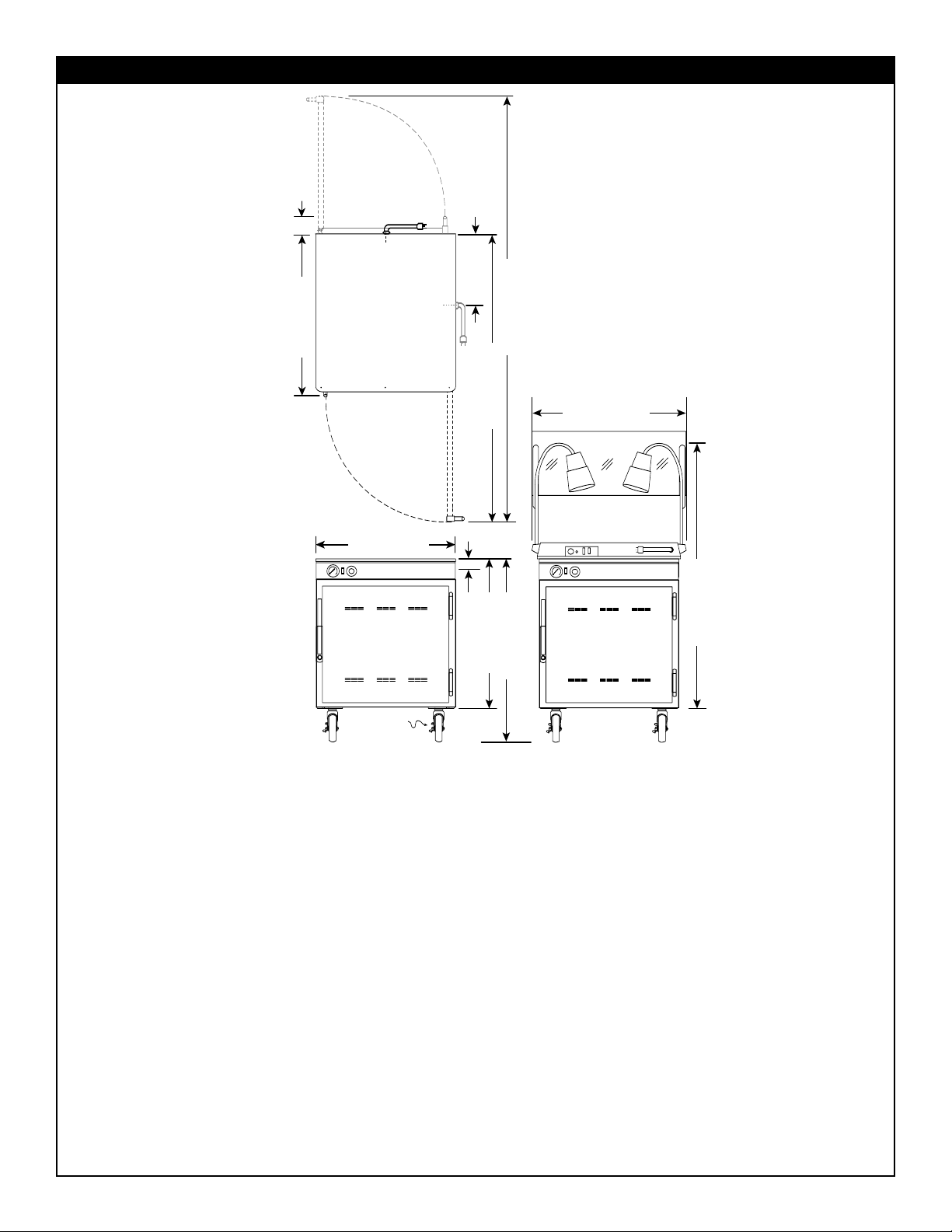

INSTALLATION

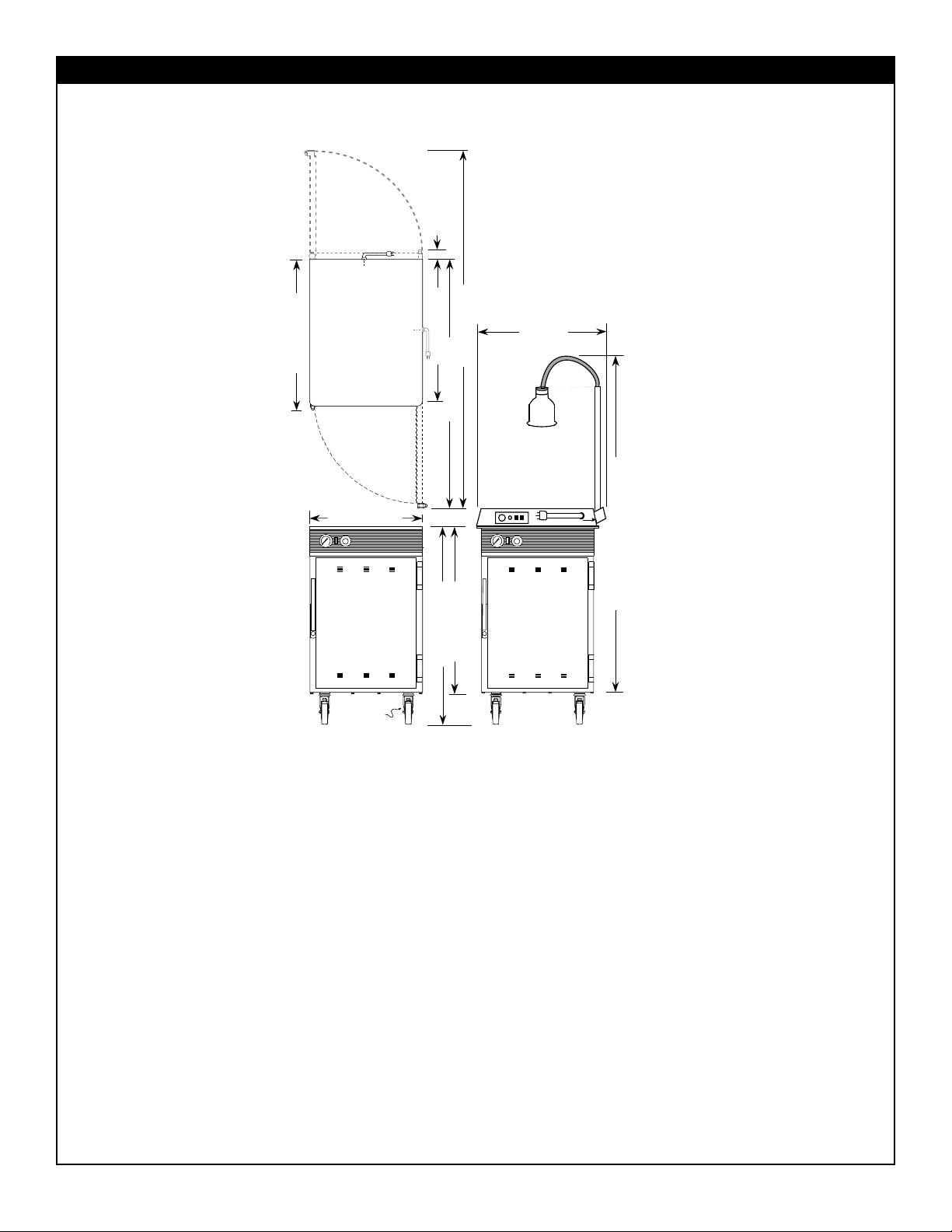

39-7/8" (1013mm)

17-5/8" (447mm)

25-7/16" (646mm)

500-S

500-S/PT

500-S/TM

57-1/2" (1461mm)

27-9/16" (700mm)

33-11/16" (855mm)

22-1/4" (565mm)

3-3/8" (86mm)

6-1/32" (153mm)

for 5" casters or

6" legs

65-3/4" (1670mm) MAXIMUM

19-5/16"

(491mm)

C

L

REACH-IN

Electrical

Connection

1-7/8" (48mm)

from top

C

L

PASS-THROUGH

Bumper, Full-perimeter Rubber Assembly with Stem Casters . . . . . . . . . . .44094

Carrying Handle Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55662

Carving Holder

➥ Prime Rib Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HL-2635

Casters, 3" (76mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14227

Casters, 5" (127mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4007

Drip Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PN-2122

Drip Tray - External . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4018

Legs, 6" (152mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5205

Security Panel Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5002181

Shelf

➥ Chrome Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SH-2107

➥ Stainless Steel Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SH-2326

Stacking Kit

500-S on top of 500-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

500-S on top of 500-TH/II . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

500-S on top of 500-TH/III . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

500-TH/II on top of 500-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

500-TH/III on top of 500-S . . . . . . . . . . . . . . . . . . . . . . . . . . . .5000811

TMS Carvery on top of 500-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16222

Electronic Control . . . . . . . . . . . . . . . . .Specify on order as required

Electronic Control with multiple timers . .Specify on order as required

HACCP/Kitchen Management Software . . . . . . . . . . . .Contact factory

Options & Accessories

500-S

Outside

Dimensions

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 3.

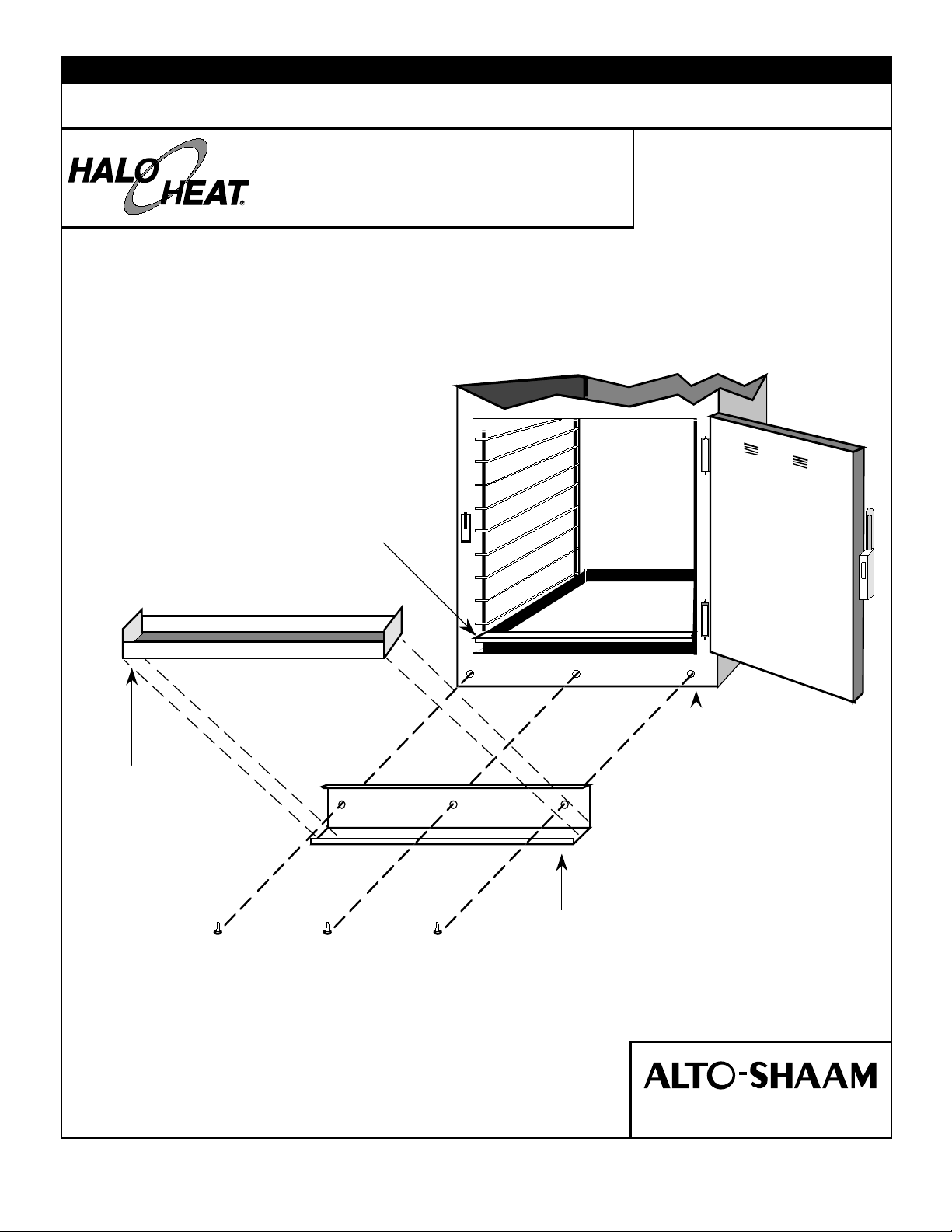

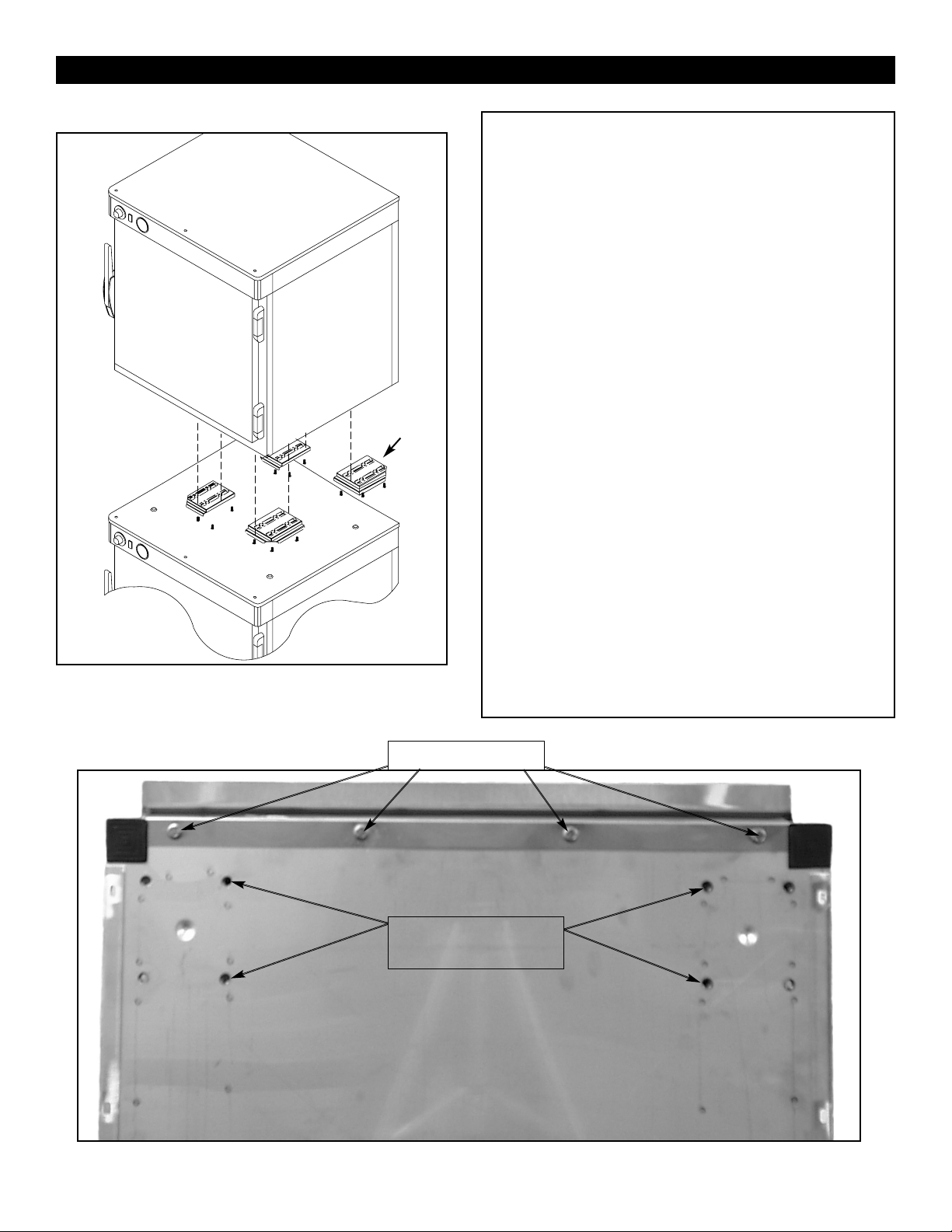

WHEN MOUNTING DRIP TRAY,

SEAL DRIP TRAY HOLDER TO

UNIT WITH AN R.T.V. SEALANT

DRIP TRAY

DRIP TRAY HOLDER

OPTIONAL DRIP TRAY MOUNTING INSTRUCTIONS

MODELS:

W164 N9221 Water Street • P. O. Box 450

Menomonee Falls, Wisconsin 53052-0450

EXTERNAL DRIP TRAY PACKAGE: #4018

500-S OPTIONAL

For on-site installation of the external drip tray, it is

necessary to drill and tap 3 holes in the cabinet as

shown on the above drawing. Use a 8 — 32 tap, 1/8" drill bit or #30 bit.

[Bottom of oven interior • Below side-racks]

OPTIONAL DRIP PAN

®

3: 8 — 32 x 1/2" SCREWS

[A/S PN: SC-2425]

INSTALLATION

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 4.

INSTALLATION

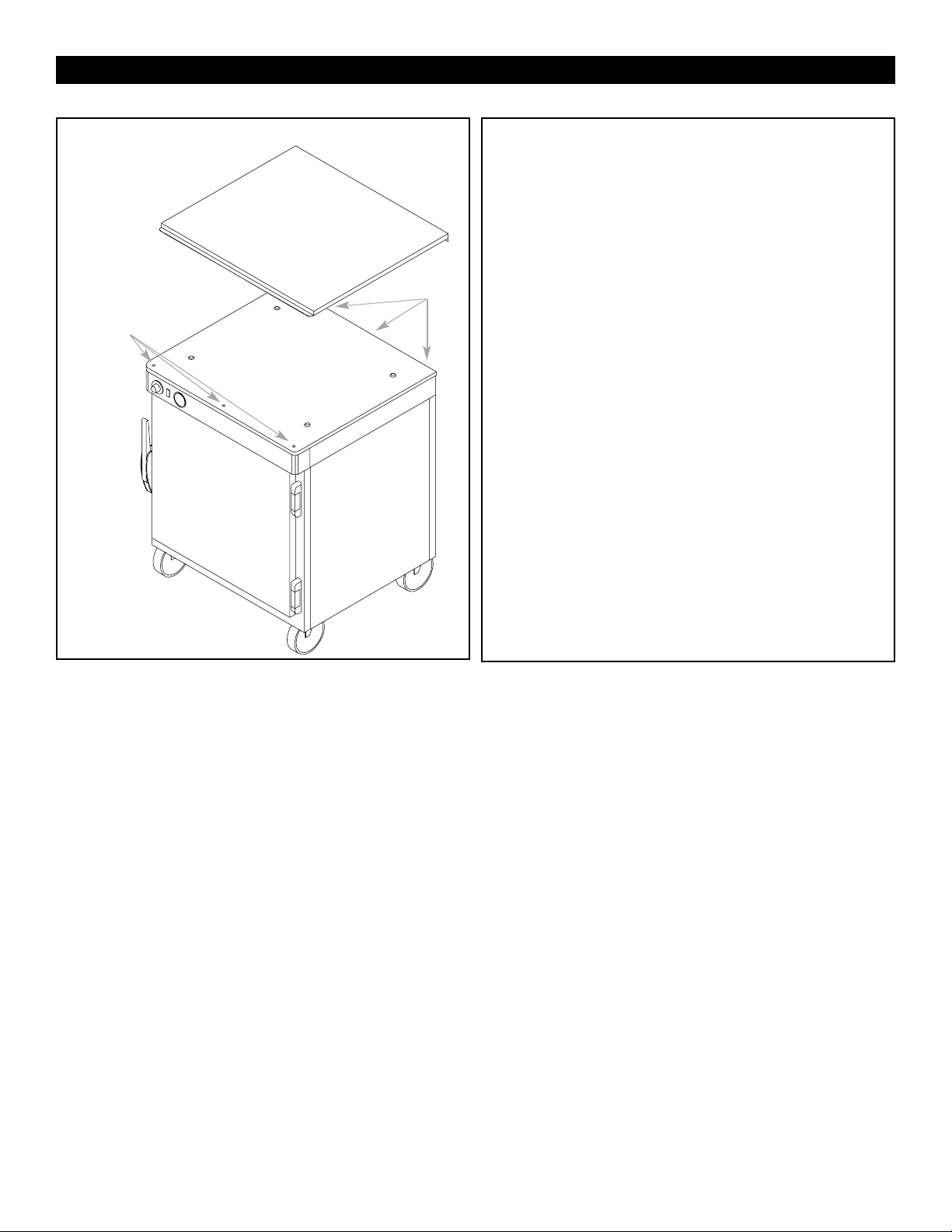

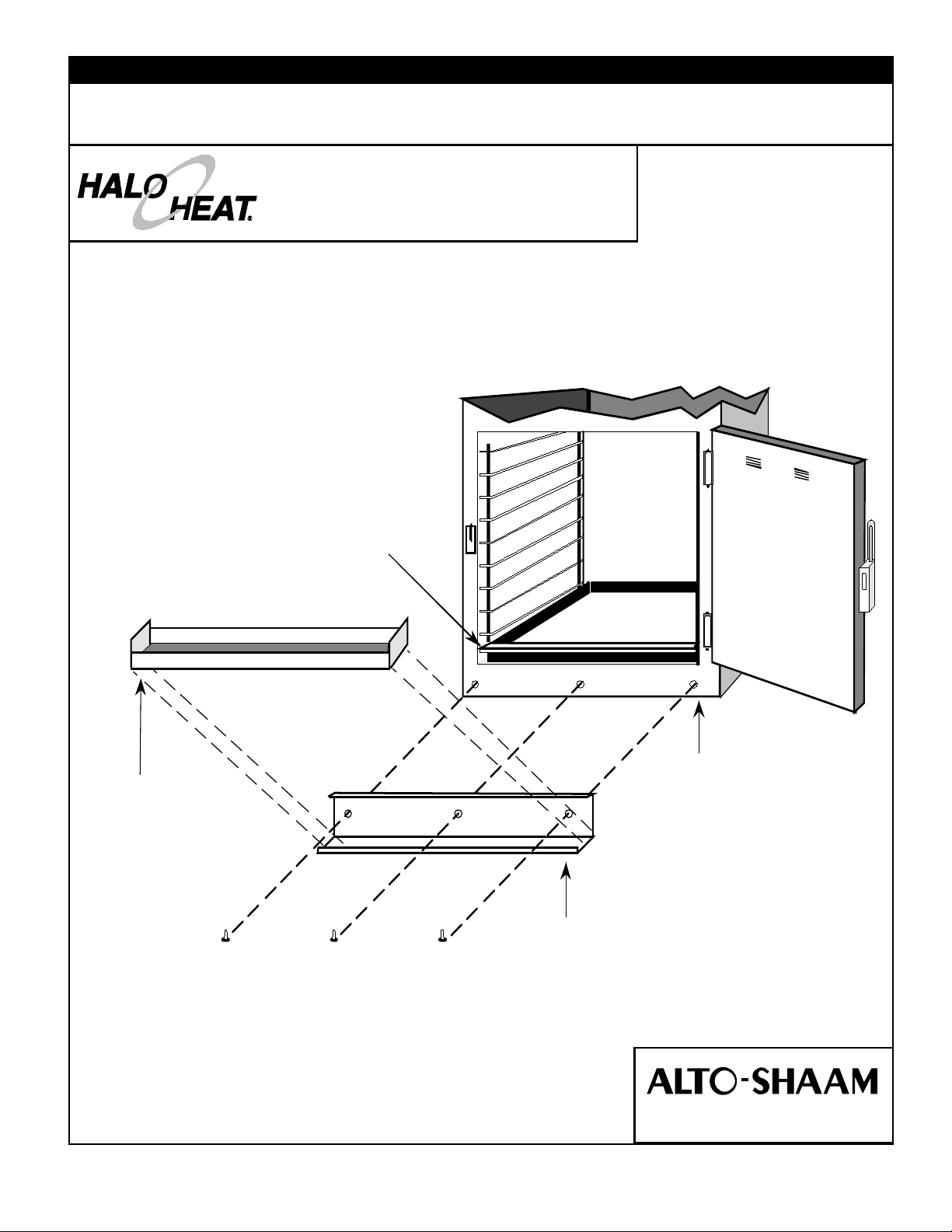

Stacking Instructions

No. 16222 or 16237 kit for

750-S

Using Stacking Platform from

kits 16222 or 16237

to provide carving shelf:

1. Remove the three screws in the top plate at the

front of the cabinet.

2. Remove the three screws in the back plate near the

top of the cabinet.

2. Position the stacking platform on top of the unit

with the flange in front, aligning the holes in the

platform over the holes in the cabinet.

3. Reinstall the cabinet screws removed in steps 1 and 2

through the platform holes to attach it to the cabinet,

front and back.

4. Place the carvery shelf on the stacking platform.

500-S or

stacking carving shelf

Step 1

Step 2

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 5.

INSTALLATION

Stacking Instructions

STACKING PLATE INSTALLATION

Kit #5001359

1. Measure the length and width of the top surface of the

cabinet to be positioned at the bottom of the stacking

equipment combination. Add 1/8-inch to both the length

and the width dimension.

2. Turn the cabinet to be placed at the top of the stacking

combination upside down so that the top surface is on the

floor. Remove the eight (8) bolts located at the front (door

side) and at the rear of the cabinet. Replace the bolts with

the eight (8) nylon plugs provided in the stacking kit (RI-

26196).

3. Place the four (4) stacking plates at each corner of the

cabinet. Position the plates with the upright flange

pointing up and to the outside of the cabinet. Align the

holes in the stacking plates with the predrilled holes in the

bottom of the cabinet using both the length and width

dimensions obtained in step 1.

4. When the correct alignment has been achieved, loosely

fasten each stacking plate with four (4) screws provided in

the stacking kit. DO NOT TIGHTEN SECURELY since

minor adjustments may be necessary.

5. Stack the cabinets and make any necessary minor

adjustments to the stacking plates. When properly aligned,

the door on the top cabinet should be flush with the door

on the bottom cabinet.

6. When proper alignment has been made, remove the top

cabinet from the stacking combination. Firmly secure all

four stacking plates by individually removing each screw

and reattaching it in combination with one of the square

washers provided in the stacking kit.

Step 2 above.

Steps 3 and 4

above.

Depth

Width

Stacking

Plate

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 6.

Bumper, Full-perimeter Rubber Assembly with Stem Casters . . . . . . . . . . .44107

Door with window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55609

Drip Tray - External . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4020

Carrying Handle Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55662

Carving Holder

➥ Prime Rib Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HL-2635

➥ Ship Round Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4459

Casters, 3" (76mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14227

Casters, 5" (127mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4007

Drip Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1062

Drip Tray - External . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4020

Legs, 6" (152mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5205

Security Panel Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5002180

Shelf

➥ Chrome Plated Wire, Flat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SH-2105

➥ Chrome Plated Wire, Lip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SH-2327

➥ Stainless Steel Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SH-2324

Transport Handle Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55575

Stacking Kit

750-S on top of 750-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

750-S on top of 750-TH/II . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

750-S on top of 750-TH/III . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

750-TH/II on top of 750-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

750-TH/III on top of 750-S . . . . . . . . . . . . . . . . . . . . . . . . . . . .5000811

BCS carvery on top of 750-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16237

Electronic Control . . . . . . . . . . . . . . . . .Specify on order as required

Electronic Control with multiple timers . .Specify on order as required

HACCP/Kitchen Management Software . . . . . . . . . . . .Contact factory

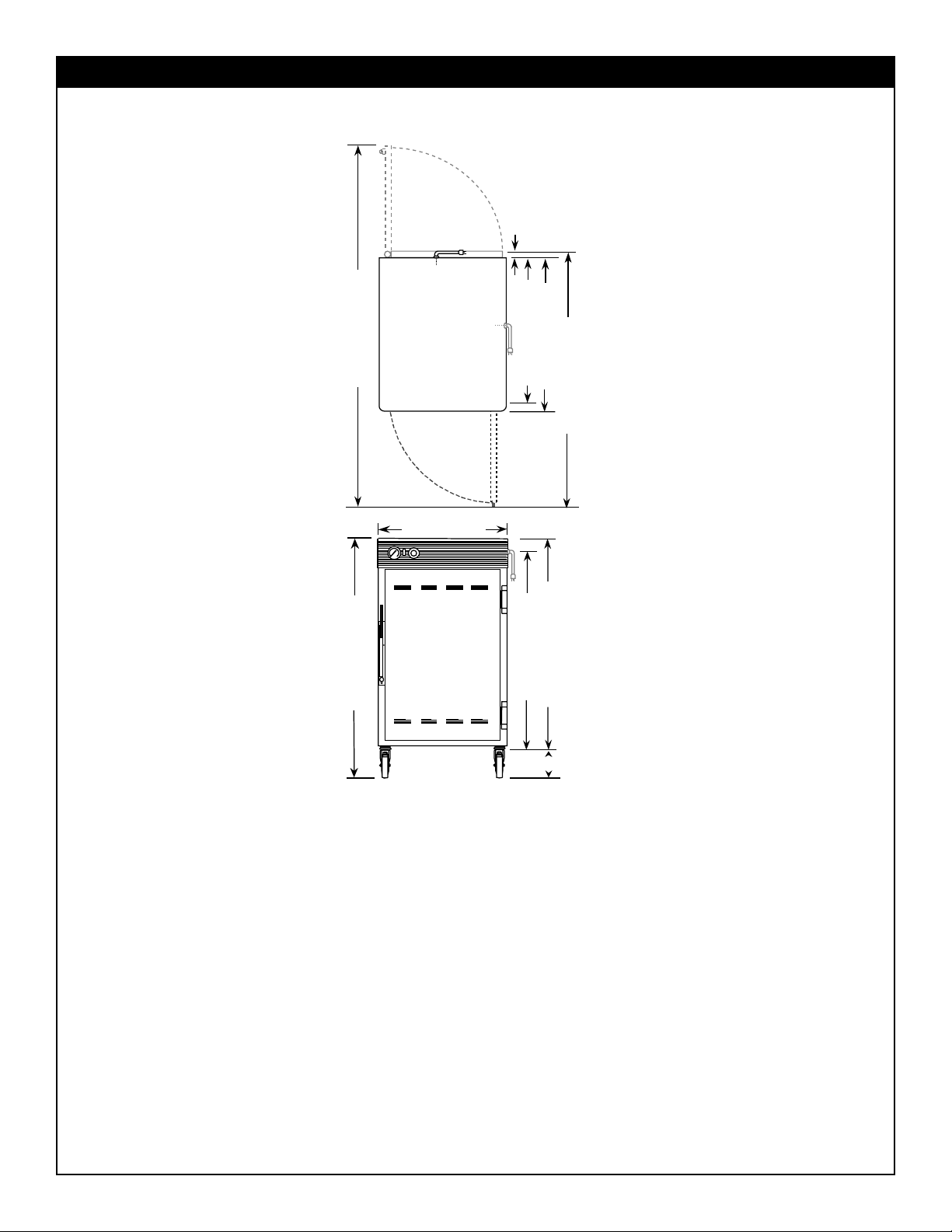

INSTALLATION

27-1/8" (689mm)

30-1/2" (775mm)

25-1/2" (648mm)

32-7/16" (849mm)

65-3/8" (1661mm)

52-1/2" (1334mm)

77-11/16" (1973mm)

1-15/16" (49mm)

28-1/8" (714mm)

6-3/16" (157mm)

for 5" casters or

6" legs

C

L

REACH-IN

Electrical

Connection

1-15/16" (49mm)

from top

PASS-THROUGH

CORD LOCATION

13" (330mm)

3-3/8" (86mm)

Options & Accessories

750-S

Outside

Dimensions

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 7.

WHEN MOUNTING DRIP TRAY,

SEAL DRIP TRAY HOLDER TO

UNIT WITH AN R.T.V. SEALANT

DRIP TRAY

DRIP TRAY HOLDER

DRIP TRAY MOUNTING INSTRUCTIONS

MODEL:

W164 N9221 Water Street • P. O. Box 450

Menomonee Falls, Wisconsin 53052-0450

EXTERNAL DRIP TRAY PACKAGE: #4020

750-S OPTIONAL

For on-site installation of the external drip tray, it is

necessary to drill and tap 3 holes in the cabinet as

shown on the above drawing. Use an 8 – 32 tap, 1/8" bit drill or #30 bit.

[Bottom of oven interior • Below side-racks]

OPTIONAL DRIP PAN

®

3: 8 — 32 x 1/2" SCREWS

[A/S PN: SC-2425]

INSTALLATION

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 8.

INSTALLATION

Bumper, Full-perimeter Rubber Assembly with Stem Casters . . . . . . . . . . .44119

Carrying Handle Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55662

Casters, 3" (76mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14227

Door, Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15148

Legs, 6" (152mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5205

Pan Grid, Chrome, Wire

➥ 18" x 26" Pan Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PN-2115

Security Panel Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5002182

Shelf, Stainless Steel Wire

➥ Reach-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SH-2325

➥ Pass-Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SH-2346

Stacking Kit, cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001359

• Outside Dimensions •

1000-S • Options & Accessories

49-1/2" (1258mm)

1000-S

71-3/4" (1823mm)

36-1/8" (918mm)

29-1/4" (743mm)

1-3/4" (44mm)

22" (559mm)

C

L

REACH-IN

Electrical

Connection

2-7/8" (73mm)

from top

C

L

PASS-THROUGH

5-5/8" (143mm)

PASS-THROUGH ELECTRICAL CONNECTION

33-1/4" (845mm)

41-3/4" (1060mm)

30-5/8" (778mm)

(PASS- THROUGH)

Electronic Control . . . . . . . . . . . . . . . . . Specify on order as required

Electronic Control with multiple timers . . Specify on order as required

HACCP/Kitchen Management Software . . . . . . . . . . . . Contact factory

1000-S

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 9.

OPERATION - MANUAL CONTROL

1. Preheat at 200°F (93°C) for 30 minutes.

When the thermostat is turned clockwise to the ON

position, the indicator light will illuminate and will

remain lit as long as the unit is calling for heat.

Allow a minimum of 30 minutes of preheating before

loading the holding cabinet with food. Closing the

vents on the inside of the door will speed up the

process. The indicator light will go OUT after

approximately 30 minutes, or when the air

temperature inside the unit reaches the temperature

set by the operator.

2. Load the cabinet with hot food only.

The purpose of the holding cabinet is to maintain

hot food at proper serving temperatures. Only hot

food should be placed into the cabinet. Before

loading the unit with food, use a food thermometer

to make certain all food products are at an internal

temperature range of 140° to 160°F (60° to 71° C).

All food not within the proper temperature range

should be heated before loading into the holding

cabinet.

3. Reset the thermostat to 160°F (71°C).

Check to make certain the cabinet door is securely

closed, and reset the thermostat to 160°F (71°C).

THIS WILL NOT NECESSARILY BE THE FINAL

SETTING.

The proper temperature range for the food being

held will depend on the type and quantity of

product. Whether or not the door vents should be

open or closed will also depend on the type of food

being held. When holding food for prolonged

periods, it is advisable to periodically check the

internal temperature of each item to assure

maintenance of the proper temperature range.

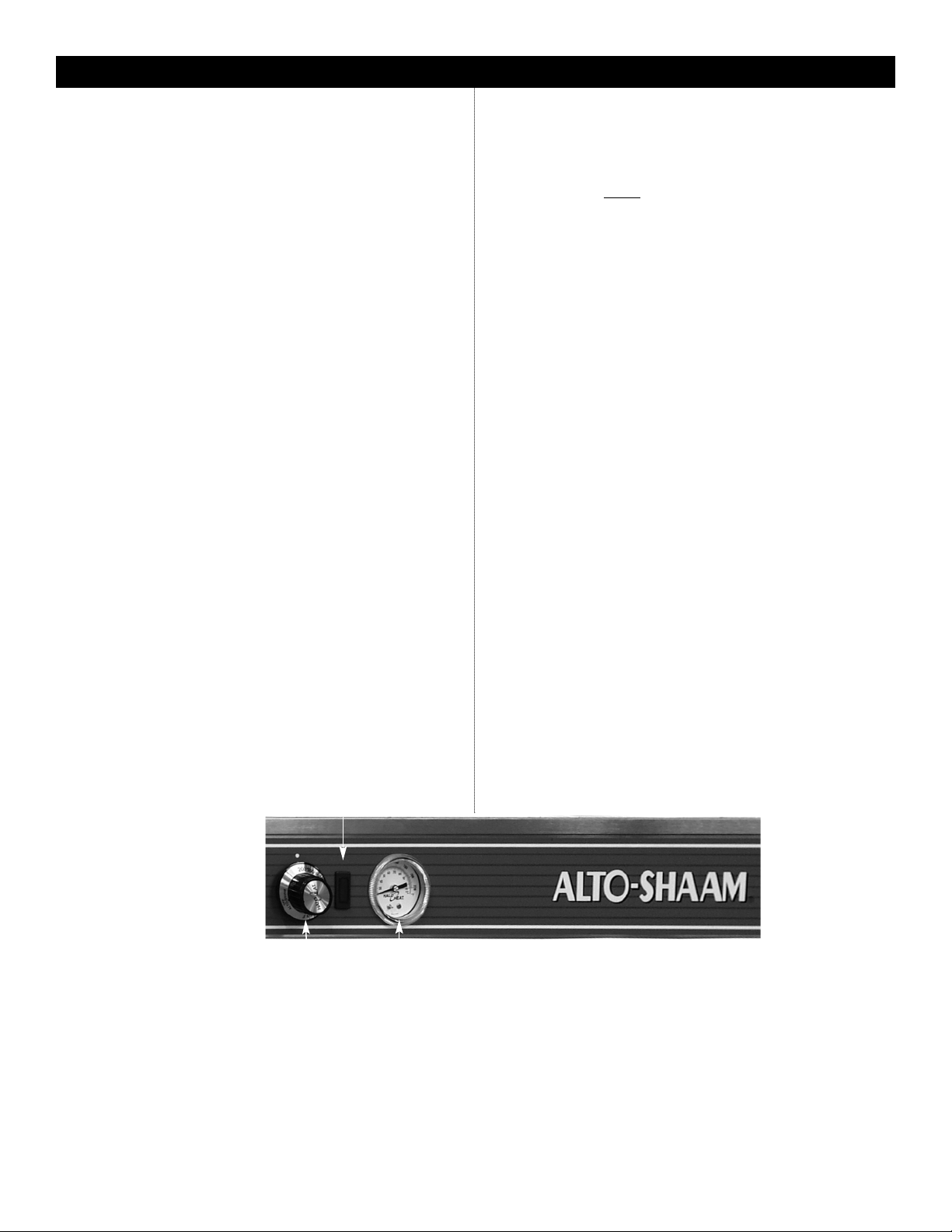

Heat

Indicator

Light

Thermostat Temperature Gauge

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 10.

OPERATION - ELECTRONIC CONTROL

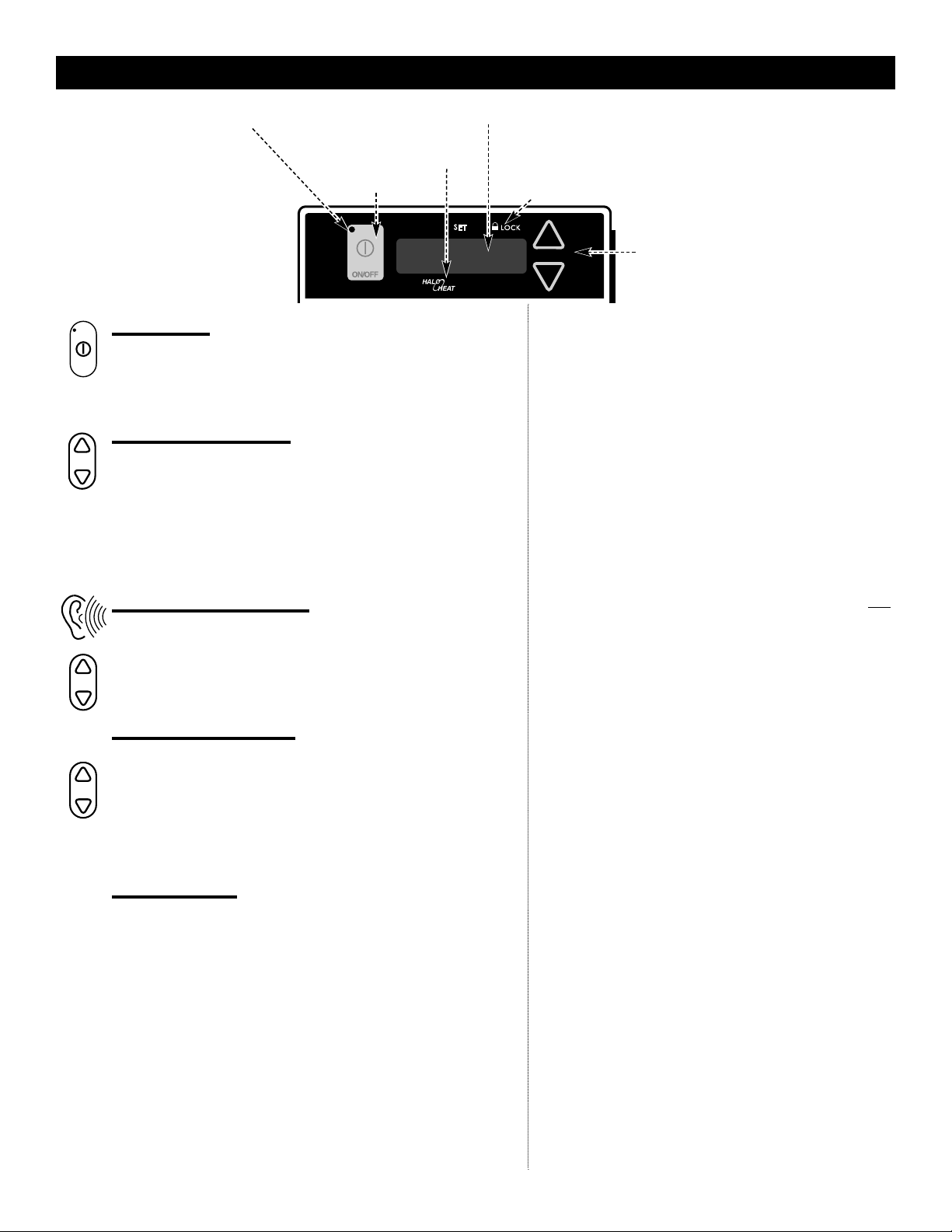

POWER INDICATOR LIGHT

UP/DOWN

ARROWS

ON/OFF POWER KEY

LOCK INDICATOR

LED DISPLAY

HEAT INDICATOR

LIGHT

ON/OFF KEY

Press the on/off key once and the power indicator light will

illuminate. Press and hold the on/off key until the LED

display turns off (at least three seconds) and on/off indicator

goes out.

UP/DOWN ARROW KEY

The up and down arrow keys are used for a variety of settings

when selecting the holding temperature. If an arrow key is pressed

and released the display will show the current set temperature for

two seconds. If an arrow key is held (at least eight seconds), the

value will change at a rapid rate. If the arrow key is pressed and

released in rapid succession, the set temperature will change by

increments of one degree.

ENABLE/DISABLE BEEPER

A beeper sounds when an error code is displayed.

To choose between beeper on and beeper off mode, the

control must be OFF, then press and hold the down arrow

key until either "ON" or "OFF" is shown in the LED display.

Release arrow key when desired mode is displayed.

FAHRENHEIT / CELSIUS

With the control OFF, to choose between Fahrenheit and Celsius,

press and hold the up arrow key until either °F or °C is shown

in the LED display. Release key when desired setting is displayed.

The control has a four-digit LED display. When the display

is ON, it will show current holding temperature, as well as

diagnostic information.

CONTROL LOCK

The warmer controls can be locked so that no changes can

be made to the set temperature.

To

lock the display, press and hold the ON/OFF key and

the Up Arrow key at the same time. The lock indicator will

illuminate. When the lock indicator is illuminated, additional

programming will not be functional other than the key

sequence required to unlock the panel.

To

unlock the display, press and hold the ON/OFF key and

the Down Arrow key at the same time. The lock indicator

will extinguish. The panel keys will resume normal function.

1. Preheat at 200°F (93°C) for 30 minutes.

Press the ON key, and set the temperature to

200°F (93C°) by using the UP/DOWN arrow

keys. Allow a minimum of 30 minutes

preheating time before loading the drawer

warmer with food. The LED heat indicator

light will go “OUT” after approximately 30

minutes preheat time, or when the air

temperature inside the unit reaches the

temperature set by the operator.

2. Load with pans of hot food only.

The purpose of the warmer is to maintain hot

food at proper serving temperature. Only hot

food should be placed into the unit. Before

loading with food, use a food thermometer to

make certain all products are at an internal

temperature range of 140° to 160°F (60° to

71°C). Any food product not within the

proper temperature range should be heated

before loading into the unit.

3. Reset the control to 160°F (71°C).

Check to make certain the drawer is securely

closed, and reset to 160°F (71°C) by using

the UP/DOWN keys.

THIS WILL NOT NECESSARILY BE THE

FINAL SETTING.

The proper temperature range will depend on

the type and quantity of product. When

holding food for prolonged periods, it is

advisable to periodically check the internal

temperature of each item with a food

thermometer to assure maintenance of the

proper temperature range of

140° to 160°F (60° to 71° C).

°F / °C

EXCLUSIVE FEATURES

HEAT RECOVERY

The patented SureTemp™ heat recovery system in this unit will immediately compensate for any loss of heat when

the door is opened. In order to maintain a more consistent cavity temperature, the control will automatically

apply heat to the unit's interior while the door is open and for a short time after the door is closed. If the door

remains open for more than three minutes, the solid state electronic control will sound three rapid beeps every

ten seconds until the door is closed.

HACCP & KITCHEN MANAGEMENT SOFTWARE

These holding units can be ordered equipped with the HACCP/Kitchen Management option for connection

to a PC. The units also have the capability of being connected to the internet via a Gateway device. This

can provide temperature recording data as well as setup and diagnostic information which can be used for

HACCP documentation.

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 11.

OPERATION - ELECTRONIC CONTROL

#823/32/36 INSTALLATION/OPERATION/SERVICE MANUAL • 12.

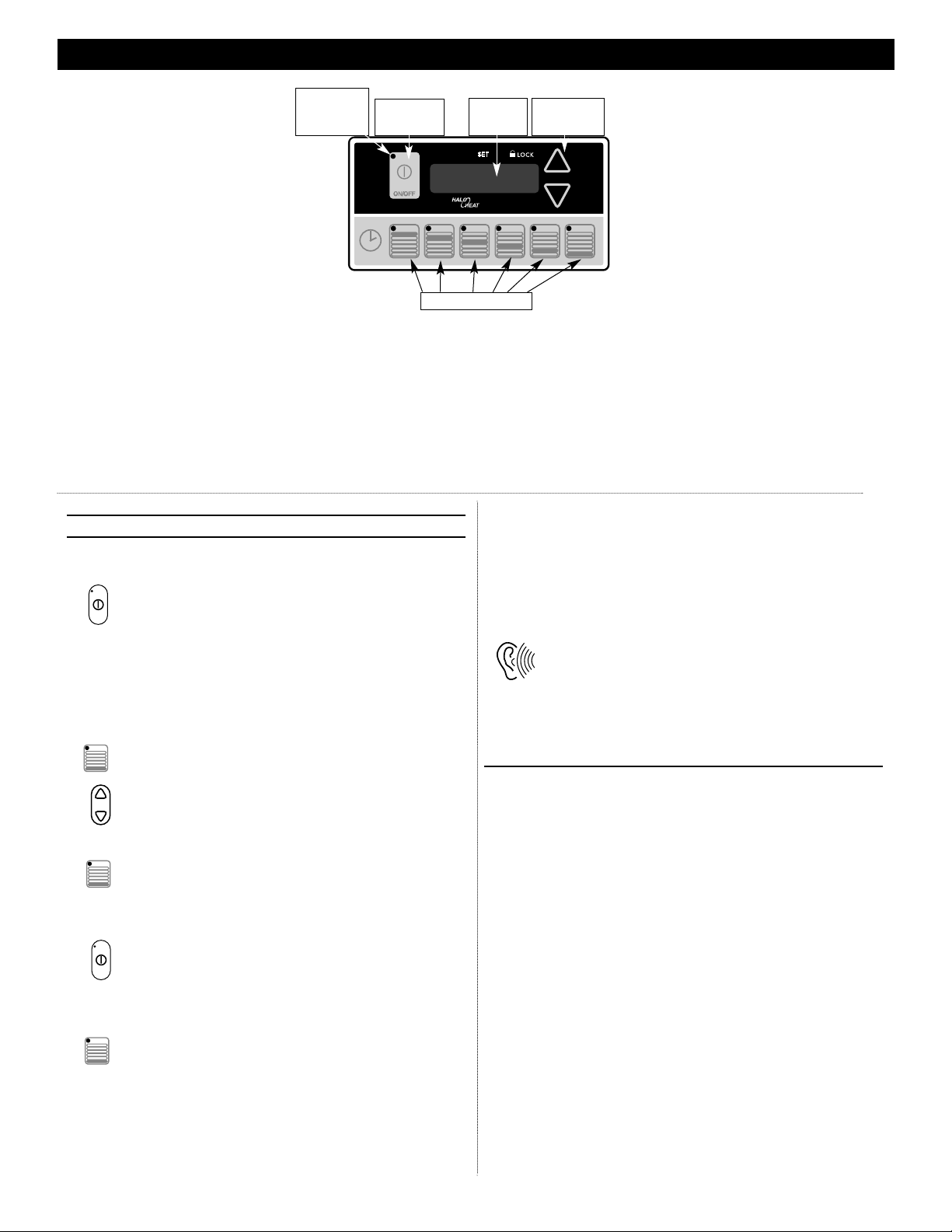

Timer Programming Information

1. Turn On/Off Power Key OFF.

Press the On/Off Key until the display turns OFF

(at least 3 seconds) and On/Off Key's Power

Indicator Light goes out.

Note: The following steps can only be done

when the On/Off Power Key is OFF.

2. Set Shelf Timer Keys.

Press and hold a Shelf Timer Key (at least 3

seconds) until a value is shown in the LED display.

Use the Up or Down Arrow Key to change the

time desired.

3. Set Additional Timer Keys.

Repeat step 2 for each Shelf Timer Key to be

programmed.

4. Turn On/Off Power Key ON.

When selected timers have been programmed,

press the On/Off key to turn ON unit. Power

Indicator Light will illuminate.

5. Press Shelf Timer Key.

Press selected Shelf Timer Keys to activate. Shelf

LED display will illuminate and the count down will

begin.

The Shelf Timer Key LED with the least amount

of time remaining will flash slowly and the LED

display will alternate between hold temperature

and time remaining.

6. Turn OFF alarm.

Listen for beeping alarm. Press flashing shelf

timer key to turn OFF alarm.

Reprogram Shelf Timer Keys

If you wish to reprogram holding times, turn OFF power.

Press the desired Timer Shelf Key and input new time

using Up or Down Arrow Key. Turn unit ON and press

each Shelf Timer Key to start the count downs.

Important Note: Timer Station Key retains

initial time settings in

memory. Count down times

are cancelled when On/Off Key

is turned OFF. It may help to

note any remaining count

down times before

reprogramming.

Power Failure: The Power Indicator Light by

On/Off Power Key

will blink to

indicate a power failure. To stop

the blinking, simply depress On/Off

Key. The memory will not be

impaired.

1234 56

OPERATION - ELECTRONIC CONTROL - OPTION

Up/Down

Arrows

LED

Display

On/Off

Key

Shelf Timer Keys

The Multiple Shelf Timer Key option is available for hot food holding units with the electronic control.

These keys monitor food safety by using a timer-based "First-In, First-Out" product management

system. Products should be cooked to HACCP recommended internal temperature and then held in

the unit. The Timer system allows operator to select holding times when the unit is loaded.

Multiple timer keys correspond to various pan locations in the holding unit.

As the timers expire, alarms notify the operator.

Power

Indicator

Light

Loading...

Loading...