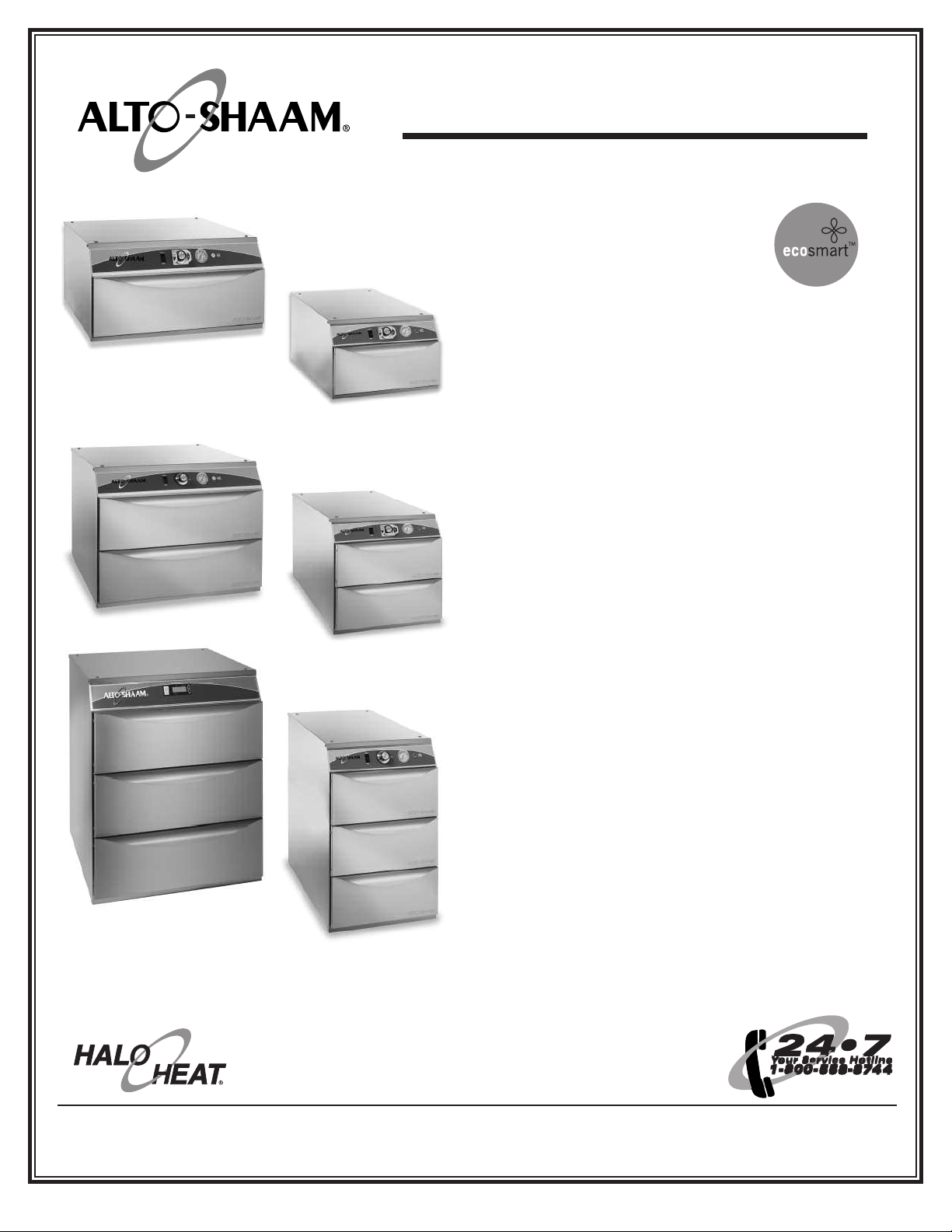

Alto-Shaam 500-2D User Manual

D r a w e r W a r m e r s

W164 N9221 Water Street • P.O. Bo x 450 • M enomo nee F alls, Wi scons in 53 052-0450 USA

PHON E: 262.251.3800 • 800.558.8744

US A/ CAN AD A FAX: 262.251.7067 • 800.32 9.8744 U.S.A . ON LY

www.alto-shaam.com

E l e c t r i c

MAN UAL or

ELECT RON I C CONTROL

Models:

500-1D, 1DN

500-2D, 2DN

500-3D, 3DN

P R I N T E D I N U .S .A .

• INSTALLATION

• OPERATION

• MAINTENANCE

MN-28645 • 02/10

Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Procedures and Precautions . . . . . . . . . . . . . . . . . 2

Sanitation

Sanitation/Food Safety . . . . . . . . . . . . . . . . . . . . . . . 13

Internal Food Product Temperatures . . . . . . . . . . . . . 13

Installation

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . 3

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . 3

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

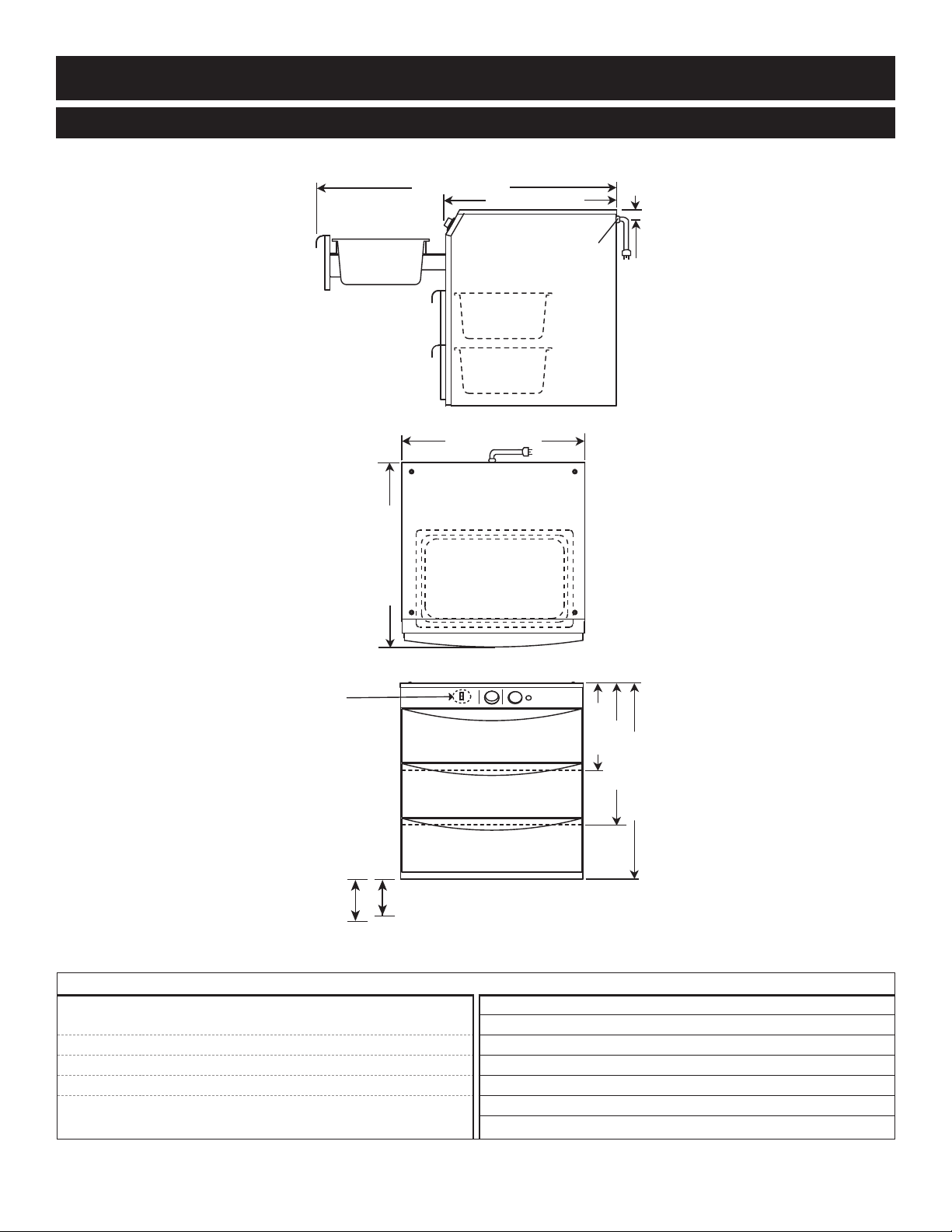

Dimension Drawing - 500-1D, 2D, 3D . . . . . . . . . . . . . 4

Options and Accessories - 500-1D, 2D, 3D . . . . . . . . . 4

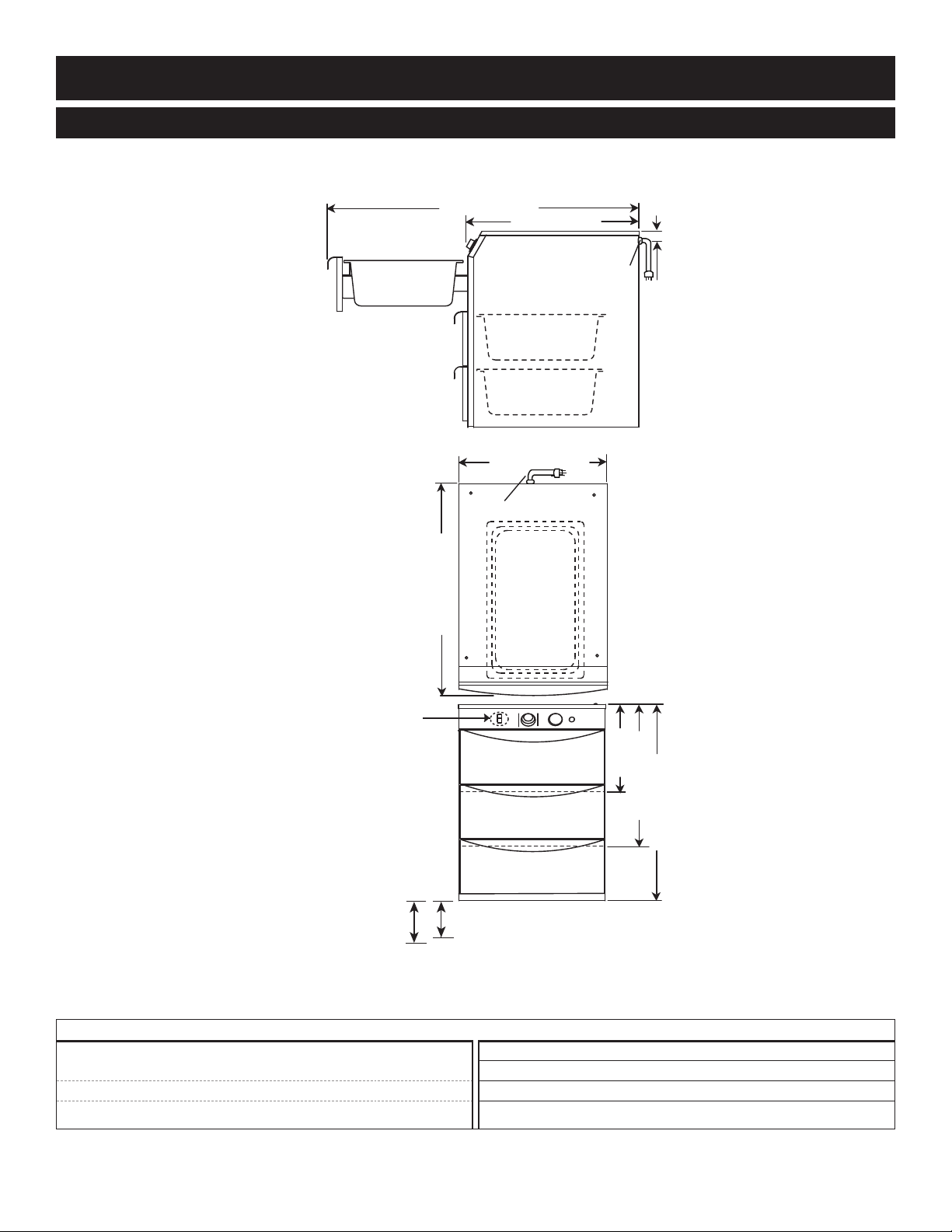

Dimension Drawing - 500-1DN, 2DN, 3DN . . . . . . . . . 5

Options and Accessories - 500-1DN, 2DN, 3DN . . . . . 5

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions

User Safety Information. . . . . . . . . . . . . . . . . . . . . . . . 7

Before Initial Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Heating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 7

Food Product Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation - Manual Control . . . . . . . . . . . . . . . . . . . . . 8

Operation - Electronic Control . . . . . . . . . . . . . . . . . . . 9

General Holding Guidelines . . . . . . . . . . . . . . . . . . . . 10

Care and Cleaning

Cleaning and Preventative Maintenance . . . . . . . . . . 11

Protecting Stainless Steel Surfaces . . . . . . . . . . . . . . 11

Cleaning Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Service

Manual Control

Thermostat and Heat Light Sequence . . . . . . . . . . 14

Thermostat Calibration . . . . . . . . . . . . . . . . . . . . . 14

Electronic Control

Trouble Shooting Checklist . . . . . . . . . . . . . . . . . . 14

Trouble Shooting - Error Codes . . . . . . . . . . . . . . . 15

Exterior Service Parts - 500-1D, 2D, 3D . . . . . . . . 16

Exterior Service Parts - 500-1DN, 2DN, 3DN. . . . . 17

Service Views. . . . . . . . . . . . . . . . . . . . . . . . . . 18-20

Wire Diagrams

Manual Control

500-1DN, 2DN - 120V . . . . . . . . . . . . . . . . . . . . . . 21

500-1DN, 2DN, 3DN - 208-240V . . . . . . . . . . . . . . 22

500-1D, 2D, 3D, 1DN, 2DN, 3DN - 230V . . . . . . . . 23

500-#DN - 120V . . . . . . . . . . . . . . . . . . . . . . . . . . 24

500-1D, 2D - 120V . . . . . . . . . . . . . . . . . . . . . . . . 25

500-3D - 120V . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

500-1D, 2D, 3D - 208-240V . . . . . . . . . . . . . . . . . . 27

Electronic Control

500-1D, 2D, 3D, 1DN, 2DN, 3DN - 120V . . . . . . . . 28

500-1D, 2D, 3D, 1DN, 2DN, 3DN - 230V . . . . . . . . 29

500-1D, 2D, 3D, 1DN, 2DN, 3DN - 208-240V . . . . 30

Warranty

Transportation Damage and Claims. . . . . . . Back Cover

Limited Warranty . . . . . . . . . . . . . . . . . . . . . Back Cover

D E L I V E R Y

This Alto-Shaam appliance has been

thoroughly tested and inspected to ensure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and report

it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to ensure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

N O T E : All claims for warranty must include the

full model number and serial number of

the unit.

U N P A C K I N G

1. Carefully remove the

appliance from the

carton or crate.

N O T E : Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner or

manager of the business or to the person

responsible for training operators. Addi tional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

Draw er Warmer I nstal lation/Opera tion/Service Manual • 1.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

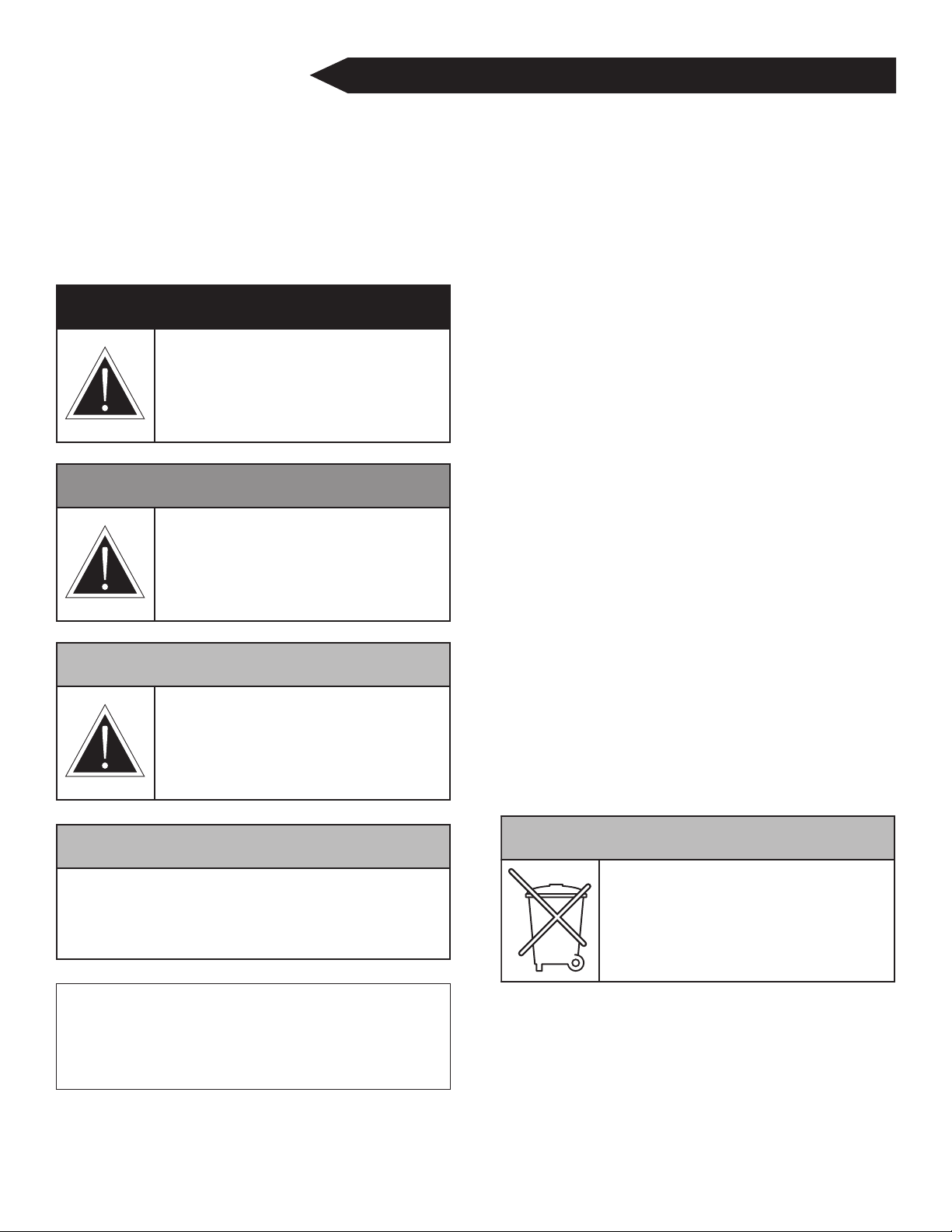

N O T E : Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

C A U T I O N

Used to indicate the presence of a hazard that can

or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

C A U T I O N

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

D A N G E R

Used to indicate the presence of a

hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

W A R N I N G

Used to indicate the presence of a

hazard that CAN cause personal injury,

possible death, or major property

damage if the warning included with

this symbol is ignored.

SAFE T Y PROCE D U R E S

AND PRECA U T I O N S

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

N O T E

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

Draw er Warmer I nstal lation/Opera tion/Service Manual • 2.

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

D A N G E R

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH,

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

S I T E I N S TA L L A T I O N

I N S T A L L A T I O N

1. The cabinet, complete with unattached items and

accessories, may be delivered in one or more

ackages. Check to ensure all accessories ordered

p

have been received.

2. This appliance is designed for the purpose of

maintaining hot food at a temperature for safe

consumption. The unit must be installed on a

level surface in a location that will permit the

equipment to function for its intended purpose

and allow adequate access for proper cleaning

and maintenance.

3. The appliance must not be installed in any area

where it will be affected by steam, grease,

dripping water, high temperatures, or any other

severely adverse conditions.

C L E A R A N C E R E Q U I R E M E N T S

3-inches (76mm) at the back

2-inches (51mm) at the top

1-inch (25mm) at both sides

5. In order to maintain standards established by the

National Sanitation Foundation, all equipment

ust be equipped with casters or 4" (102mm)

m

legs to provide minimum unobstructed space

beneath the unit; or secured flush at the bottom

and the entire base sealed with NSF approved

sealant. Warranty will become null and void if

these directions are not followed.

WE IGHT

500-1D 500-2D 500-3D

ET

N

SH IP 90 lb (41 kg) 125 lb (57 kg) 165 lb (75 kg)

80 lb (36 kg) 115 lb (52 kg) 150 lb (68 kg)

On site venting for proper airflow must also be

provided for built-in counter installations.

4. Level the appliance from side-to-side and

front-to-back with the use of a spirit level.

Draw er Warmer I nstal lation/Opera tion/Service Manual • 3.

WE IGHT

500-1DN 500-2DN 500-3DN

NE T 67 lb (30 kg) 100 lb (45 kg) E ST. 130 lb (59 kg) ES T.

SH IP 75 lb (34 kg) 112 lb (51 kg) 145 lb (66 kg)

500-1D

500-2D

500-3D

1-11/16" (42mm)

C

L

24-3/8" (618mm)

4

0-1/16" (1018mm)

22-13/16" (579mm)

11-3/4"

(298mm)

19" (482mm)

26-1/8" (663mm)

ELECTRICAL CONNECTION

ELECTRICAL CONNECTION

HI-LO Switch available only on 500 -1D and 5

00 -2D.

6-3/4" (171mm) FOR

LEG STAND OR 5" (127mm)

CASTER STAND ASSEMBLY

24-5/8" (625mm)

HANDLE

4-7/8" (121mm)

FOR CASTER STAND ASSEMBLY

WITH 3" (76mm) CASTERS

S I T E I N S TA L L A T I O N

500-1D, 500-2D, 500-3D

I N S T A L L A T I O N

OPTIONS & ACCESSORIES

Built-in Trim Kit

500-1D 44224

500-2D 44226

500-2D FOR BU2-48, BU2-72 55532

500-2D FOR BU2-96 44231

500-3D 44228

Caster Stand Assembly with 5" (127mm) casters 15379

Caster Package, 3" (76mm) casters (must order 15379) 14227

Drawer Assembly with vents 55536

Leg Stand Assembly 15380

Pan, oversize, 15" x 20" x 5" (381 x 508 x 127 mm) PN-2123

Perforated pan grid, 15" x 20" (381 x 508 mm) 1231

Perforated pan grid,

12" x 20" (305 x 508 mm) 16642

Draw er Warmer I nstal lation/Opera tion/Service Manual • 4.

500-1DN

500-2DN

500-3DN

1-11/16" (42mm)

C

L

16-7/16"(418mm)

5

0-7/8" (1291mm)

2

8-1/8" (714mm)

E

LECTRICAL CONNECTION

ELECTRIC CONNECTION

HANDLE

6-3/4" (171mm) FOR

LEG STAND OR 5" (127mm)

CASTER STAND ASSEMBLY

4-7/8" (121mm) FOR 3" (76mm)

CASTER STAND ASSEMBLY

H

I-L

O

Sw

i

t

ch

av

ai

l

ab

l

e o

n

l

y

o

n

5

0

0

-1

D

N

an

d

5

0

0

-2

D

N

.

29-15/16" (761mm)

26-3/16" (663mm)

11-11/16"

(296mm)

18-7/8" (479mm)

S I T E I N S TA L L A T I O N

500-1DN, 500-2DN, 500-3DN

I N S T A L L A T I O N

O P T I O N S & A C C E S S O R I E S

Built-in Trim Kit

500-1DN 44225

500-2DN 44227

500-3DN 44229

Caster Stand Assembly 55534

Drawer Assembly with vents 55537

Leg Stand Assembly 55535

Perforated pan grid,

12" x 20" (305mm x 508mm) 16642

Draw er Warmer I nstal lation/Opera tion/Service Manual • 5.

D A N G E R

ELECTRICAL CONNECTIONS MUST

BE MADE BY A QUALIFIED SERVICE

TECHNICIAN IN ACCORDANCE WITH

APPLICABLE ELECTRICAL CODES.

D A N G E R

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON APPLIANCE NAMEPLATE.

D A N G E R

T

o avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in accordance with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

D A N G E R

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH,

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

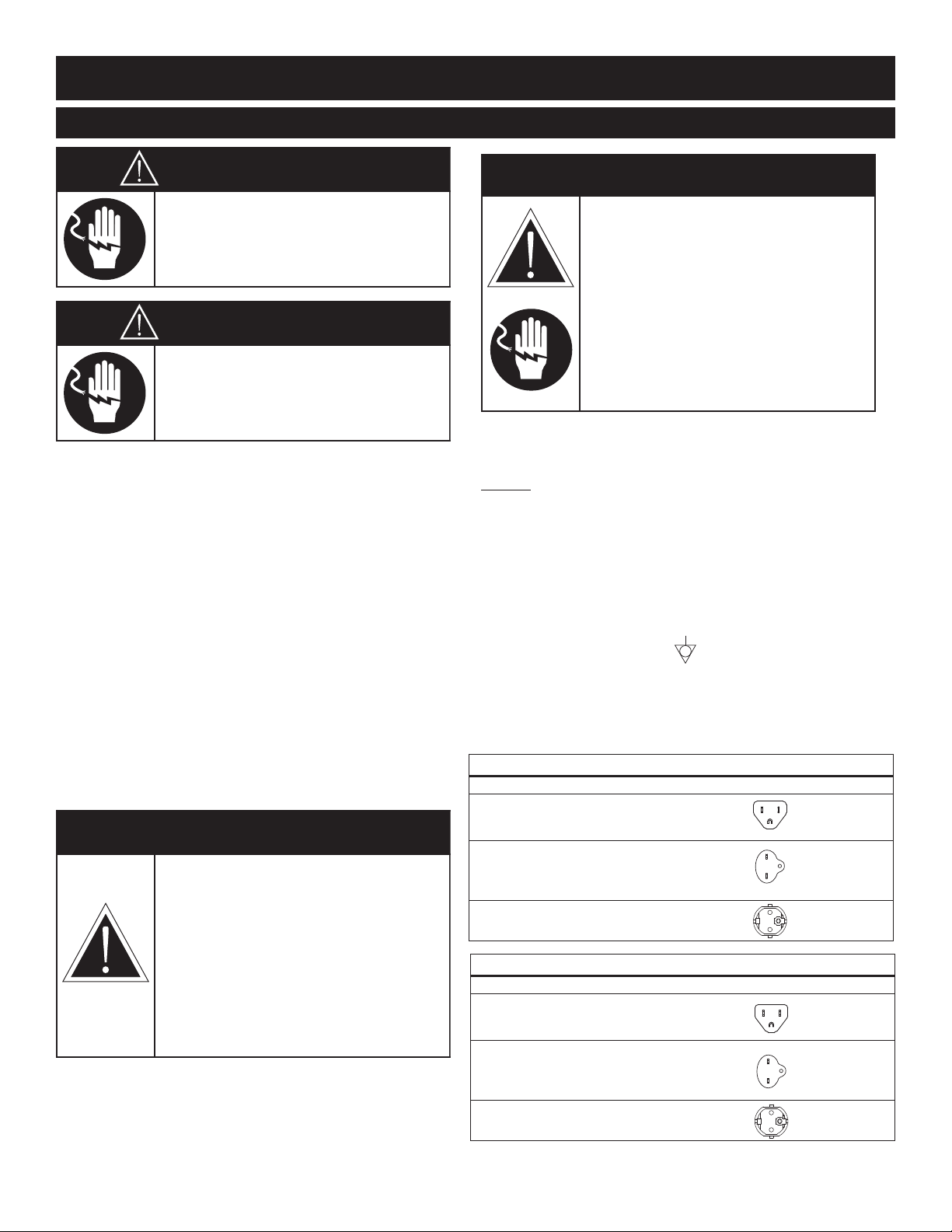

E L E C T R I C A L

I N S T A L L A T I O N

1. An identification tag is permanently mounted on

the cabinet.

2. Plug cabinet into a properly grounded receptacle

ONLY, positioning the unit so the power supply

cord is easily accessible in case of an emergency.

Arcing will occur when connecting or

disconnecting the unit unless all controls are in

the “OFF” position.

3. If necessary, a proper receptacle or outlet configuration as required for this unit, must be

installed by a licensed electrician in accordance

with applicable, local electrical codes.

23 0V:

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in

close vicinity, an equalization-bonding stud is

provided. An equalization bonding lead must be

connected to this stud and the other appliances /

metal parts to provide sufficient protection against

potential difference. The terminal is marked with

the following symbol.

NOT E: The appliance must be connected to an

electrical circuit that is protected by an external

GFCI outlet.

EL ECTR ICA L - 500- 1D; 500 -2D; 500 -3D

VOLTAGE PHASE CYCLE/HZ AMPS kW

120 1 60 LOW 4.0 0.5 NEMA 5-15P

HI GH 8.5 1.05 15A, 125V PLUG

at 208 1 50/60 3.8 0.8

at 240 1 50/60 4.4 1.05

230 1 50/60 4.2 0.97

NEMA 6-15P

15A, 250V PLUG

FOR USA ONLY

CEE 7/7,

220-230V PLUG

Draw er Warmer I nstal lation/Opera tion/Service Manual • 6.

EL ECTR ICA L - 500- 1DN; 50 0-2D N; 500- 3DN

VOLTAGE PHASE CYCLE/HZ AMPS kW

120 1 60 LOW 4.0 0.5 NEMA 5-15P

HI GH 8.5 1.05 15A, 125V PLUG

at 208 1 50/60 3.8 0.8

at 240 1 50/60 4.4 1.05

230 1 50/60 4.2 0.97

Wire di agrams a re l oc ated i nside the bonnet of th e unit.

NEMA 6-15P

15A, 250V PLUG

FOR USA ONLY

CEE 7/7,

220-230V PLUG

I N S T A L L A T I O N

U S E R S A F E T Y I N F O R M A T I O N

his appliance is intended for use in commercial

T

stablishments where all operators are familiar with

e

he purpose, limitations, and associated hazards of

t

his appliance. Operating instructions and warnings

t

must be read and understood by all operators

and users.

1. Make sure the unit is connected to the

appropriate power source.

2. Use hand protection when handling

hot items.

3. Preheat the unit for 30 minutes before use.

4. Be certain only hot foods are placed into

the unit.

BEFOR E INITIAL U SE:

Before operating the unit, clean both the interior

and exterior of the unit with a clean, damp cloth

and mild soap solution. Rinse carefully. Clean and

install the drawer warmer pan(s). The drawer

assembly is completely removable. Clean as a

sanitation measure.

HEATIN G CHARACTERISTIC S

OOD P RODUC T T IPS

F

Br ead and Rol ls

Breads and rolls are traditionally difficult to hold

for prolonged periods due to the very low

moisture content of these products. For best

results and longest possible holding life, it is

recommended these products be placed in a

plastic bag while in the warming drawer. Breads

and rolls should be held at a temperature no

higher than 120° to 140°F (49° to 60°C).

Po t atoe s

— for the best results when holding potatoes:

1. D o n ot overcook .

Regardless of the temperature at which potatoes

are cooked or what type of oven is used, it is

important that this product does not achieve a

final internal product temperature in excess of

195°F (91°C). Over-cooking will further reduce

the moisture content and consequently, reduce

the holding life. Potatoes should be removed

from the oven when they reach an internal

temperature of approximately 190°F (88°C).

After they are removed from the oven, the

internal temperature will continue to increase.

The drawer warmer is equipped with a special

heating cable. Through this Halo Heat concept, the

heating cable is mounted against the walls of the

unit to provide an evenly applied heat source

controlled by a thermostat. The design and

operational characteristics of the unit eliminate the

need for a moisture pan or a heat circulating fan.

Through even heat application, the quality of food

products is maintained up to several hours or more.

P R O D U C T C A PA C I T Y

36 lbs (16 kg)

(34 BAK ED POTATO ES, 50 DI NNE R ROL LS)

Draw er Warmer I nstal lation/Opera tion/Service Manual • 7.

2. A llow pot atoe s t o s tabil ize bef o re

pl a cing in dra wer war mer.

When potatoes are removed from a conventional

high-temperature oven, they have an extremely

high surface temperature. If they are placed in

the drawer warmer while they are this hot on the

outside, moisture will be pulled from the inside

of the potato and condensation will form on the

outside. Holding results under these conditions

will not be totally satisfactory. Remove potatoes

from the oven and allow the surface temperature

to stabilize before placing them in the controlled

holding atmosphere of the drawer warmer.

MA XIM UM • E AC H DRAW ER

O P E R A T I O N

M A N U A L C O N T R O L

. Dual wat tage con trol .

1

The one and two drawer, 120V warmers are

provided with a HIGH/LOW power switch.

Use the HIGH position at 1000 watts for meats,

potatoes, and vegetables — use the LOW

position at 500 watts for breads and rolls.

thermometer to make certain all food products

are at an internal temperature range of

140° to 160°F (60° to 71°C). All food not within

the proper temperature range should be heated

before putting into the drawer warmer.

2. Preheat a t 2 00°F (93 °C) for 30 min utes.

When the thermostat is turned clockwise to an

“ON” position, the indicator light will illuminate

and will remain lit as long as the unit is calling

for heat. Allow a minimum of 30 minutes of

preheating before loading the warmer with food.

The indicator light will go “OUT” after

approximately 30 minutes, or when the air

temperature inside the unit reaches the

temperature set by the operator.

3. Loa d t he draw er warme r w ith pan s o f

ho t f ood only.

The purpose of the unit is to maintain hot food

at proper serving temperatures. Only hot food

should be placed into the warmer. Before

loading the unit with food, use a food

4. Reset the t hermo stat to 16 0 °F (71° C).

Check to make certain the drawer is securely

closed, and reset the thermostat to 160°F (71°C).

THIS WILL NOT NECESSARILY BE TH E

FINAL SETTING.

The proper temperature range for the food being

held will depend on the type and quantity of

product. When holding food for prolonged

periods, it is advisable to periodically check the

internal temperature of each item to assure

maintenance of the proper temperature range.

High Limit Switch

(120V Only)

Draw er Warmer I nstal lation/Opera tion/Service Manual • 8.

Thermostat Knob

Temperature

Gauge

Heat

Indicator

Light

Loading...

Loading...