Page 1

®

D r a w e r W a r m e r s

E l e c t r i c

MAN UAL or

ELECTRONIC CO NTROL

Models:

500-1D, 1DN

500-2D, 2DN

500-3D, 3DN

• INSTALLATION

• OPERATION

• MAI NTENANCE

W 1 6 4 N 9 2 2 1 W a t e r S t r e e t • P.O . B o x 4 5 0 • M en o m o n e e F a ll s , W i s c on s in 5 3 0 52 - 04 5 0 U S A

PHONE: 262.251.3800 • 800.558.8744 USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

P R I N T E D I N U .S .A .

WEBSITE: www.alto-shaam.com

#818 • 4/07

Page 2

D EL I V E R Y

®

®

®

U NPA C K IN G

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and

report it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

NOT E: All claims for warranty must include the

full model number and serial number of

the unit.

1. Carefully remove the

appliance from the

carton or crate.

NOT E: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DIS CARD THI S MA NUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 1.

Page 3

SAFETY PROCEDURES

A N D P R E C A U T I O N S

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

Used to indicate the

presence of a hazard that

will cause severe personal

injury, death, or substantial

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can cause personal injury,

possible death, or major

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor or

moderate personal injury

or property damage if the

warning included with this

symbol is ignored.

. This appliance is intended to cook, hold or

1

rocess foods for the purpose of human

p

onsumption. No other use for this

c

ppliance is authorized or recommended.

a

2. This appliance is intended for use in

commercial establishments where all

operators are familiar with the purpose,

limitations, and associated hazards of this

appliance. Operating instructions and

warnings must be read and understood by

all operators and users.

3. Any troubleshooting guides, component

views, and parts lists included in this manual

are for general reference only and are

intended for use by qualified technical

personnel.

4. This manual should be considered a

permanent part of this appliance. This

manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and

labels must remain with the appliance if the

item is sold or moved to another location.

NOTE:

Used to indicate the

presence of a hazard that

can or will cause minor

personal injury, property

damage, or a potential

unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 2.

Page 4

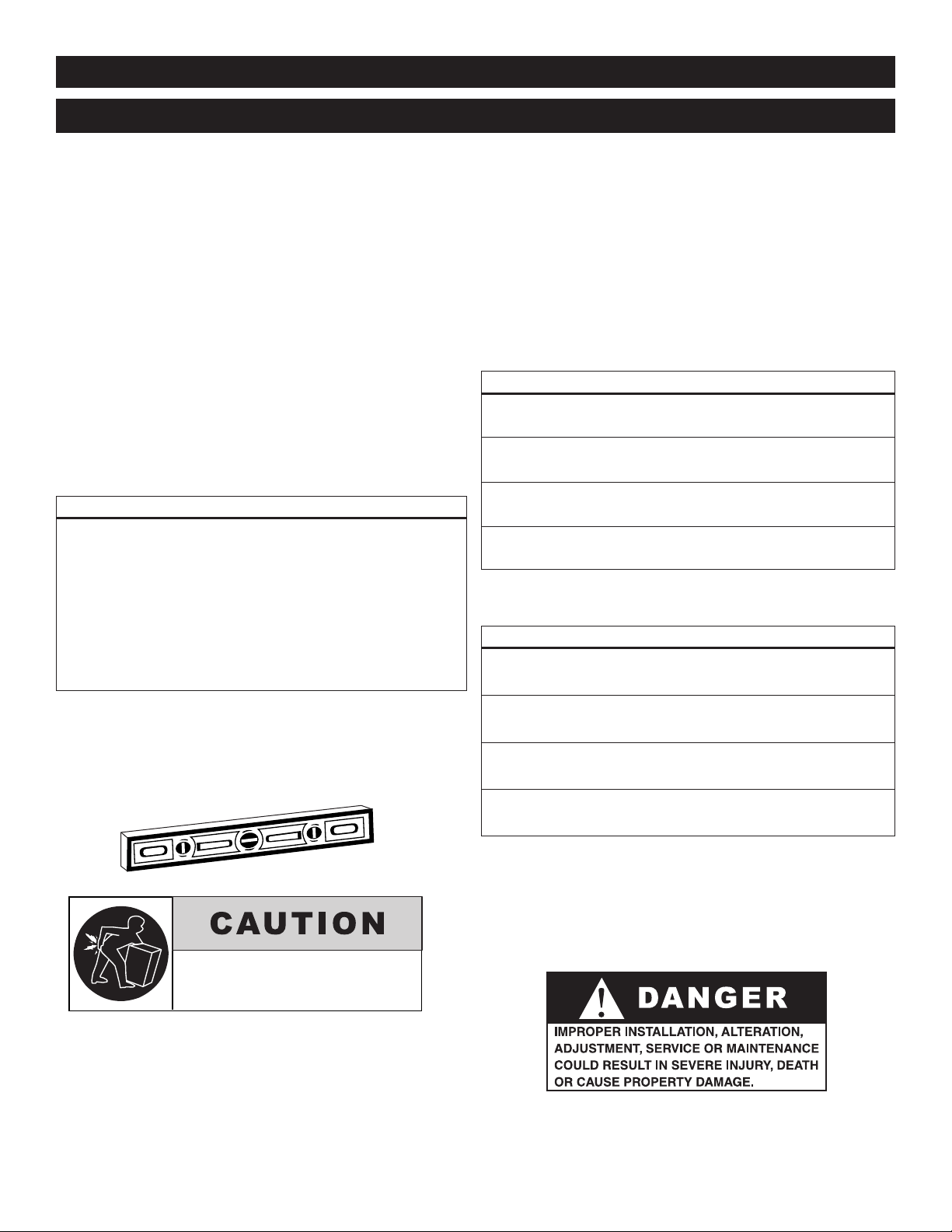

Site In s t allation

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

I N S TA L L AT I O N

1. The cabinet, complete with unattached items and

ccessories, may be delivered in one or more

a

packages. Check to ensure all accessories ordered

have been received.

2. This appliance is designed for the purpose of

maintaining hot food at a temperature for safe

consumption. The unit must be installed on a

level surface in a location that will permit the

equipment to function for its intended purpose

and allow adequate access for proper cleaning

and maintenance.

3. The appliance must not be installed in any area

where it will be affected by steam, grease,

dripping water, high temperatures, or any other

severely adverse conditions.

C L EA R AN C E R E QU I R E M E N TS

3-inches (76mm) at the back

2-inches (51mm) at the top

1-inch (25mm) at both sides

5. In order to maintain standards established

y the National Sanitation Foundation, all

b

equipment must be equipped with casters or

4" (102mm) legs to provide minimum

unobstructed space beneath the unit; or secured

flush at the bottom and the entire base sealed

with NSF approved sealant. Warranty will

become null and void if these directions are

not followed.

WE IGHT

500-1D 500-2D 500-3D

NE T 80 lb (36 kg) 115 lb (52 kg) 150 lb (68 kg)

SHIP 90 lb (41 kg) 125 lb (57 kg) 165 lb (75 kg)

On site venting for pro per airflow must also be

provided for built-in counter install ations.

4. Level the appliance from side-to-side and

front-to-back with the use of a spirit level.

WE IGHT

500-1DN 500-2DN 500-3DN

NE T 67 lb (30 kg) 100 lb (45 kg) ES T. 130 lb (59 kg) E ST.

SHIP 75 lb (34 kg) 112 lb (51 kg) 145 lb (66 kg)

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 3.

Page 5

I N S TA L L AT I O N

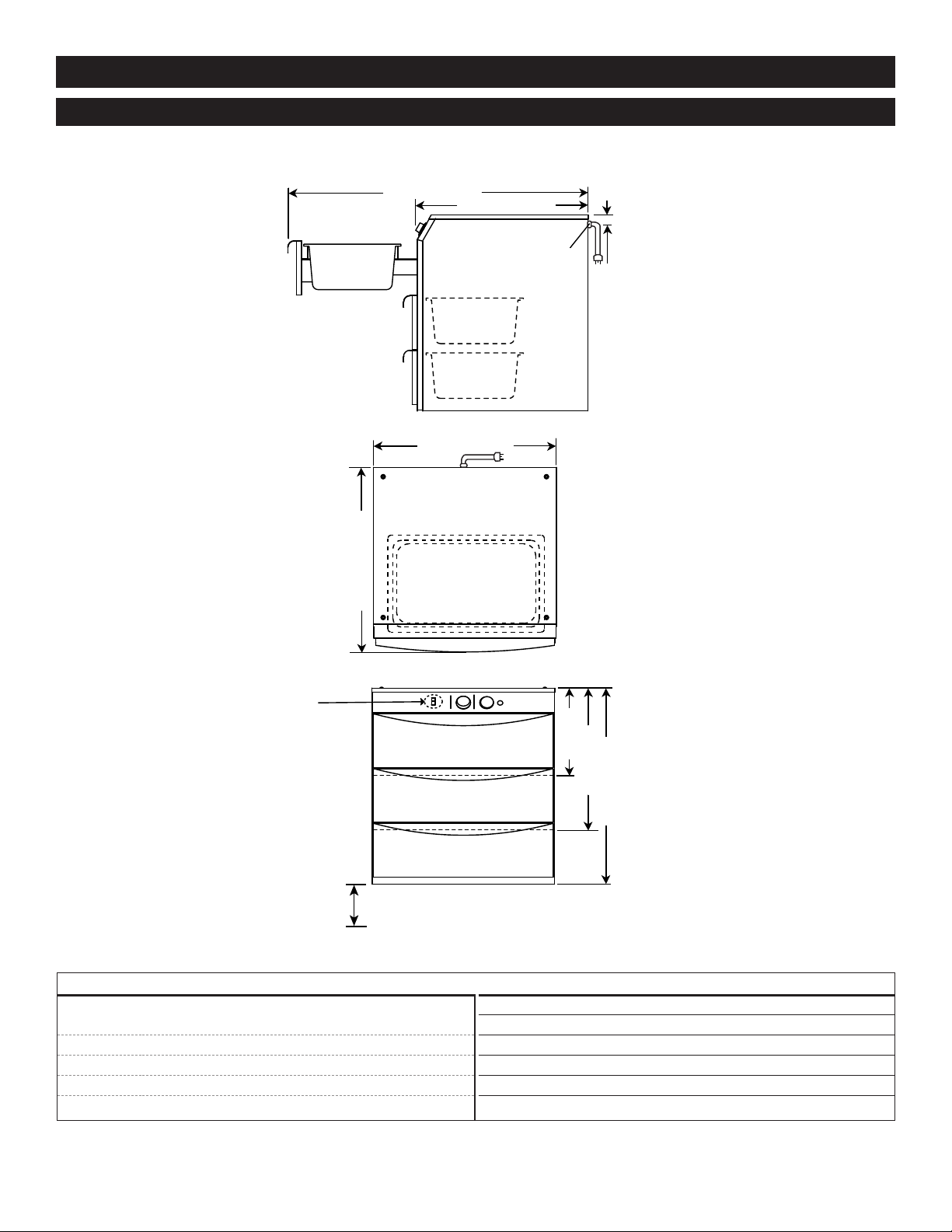

500-1D

500-2D

500-3D

1-11/16" (42mm)

C

L

24-3/8" (618mm)

40-1/16" (1018mm)

2

2-13/16" (579mm)

11-3/4"

(298mm)

19" (482mm)

26-1/8" (663mm)

E

LECTRICAL CONNECTION

ELECTRICAL CONNECTION

H

I-LO

Switch available only on 500 -1D

and 500 -2D.

6-3/4" (171mm)

FOR LEG STAND OR CASTER STAND ASSEMBLY

24-5/8" (625mm)

HANDLE

Exterio r Di m e n sions - 500-1 D , 500-2D, 5 00-3D

O P TI O NS & A C C E S S OR I ES

Built-in Trim Kit

500-1D 44224

500-2D 44226

500-2D FOR BU2-48, BU2-72 55532

500-2D FOR BU2-96 44231

500-3D 44228

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 4.

Caster Stand Assembly 15379

Drawer Assembly with vents 55536

Leg Stand Assembly 15380

Pan, oversize, 15" x 2 0" x 5" (381 x 508 x 127 mm) PN-2123

Perforated pan grid, 15" x 20" (381 x 5 08 mm) 1231

Perforated pan grid,

12" x 20" (305 x 508 mm) 16642

Page 6

I N S TA L L AT I O N

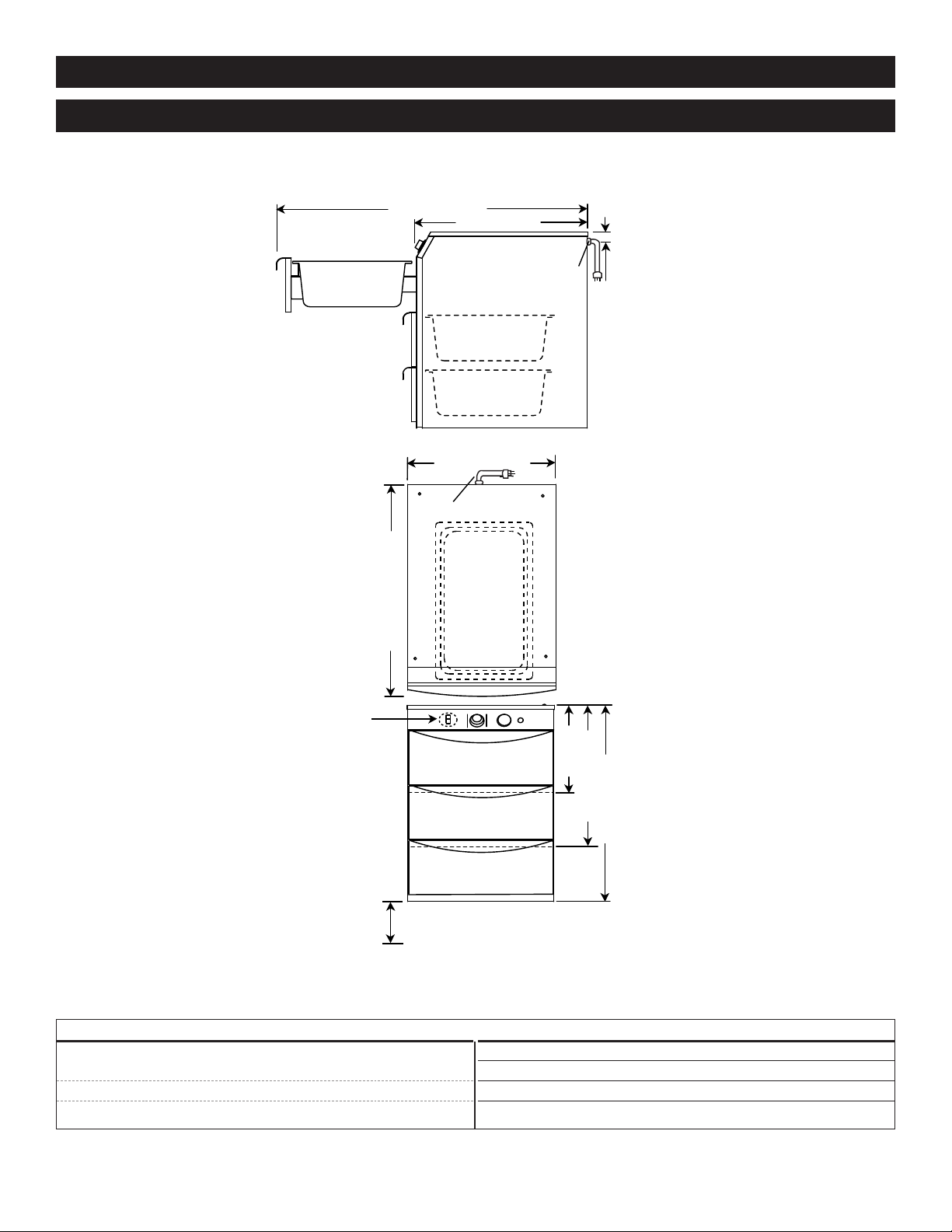

500-1DN

500-2DN

500-3DN

1-11/16" (42mm)

C

L

16-7/16" (418mm)

50-7/8" (1291mm)

28-1/8" (714mm)

11-11/16"

(296mm)

18-7/8" (479mm)

26-3/16" (663mm)

ELECTRICAL CONNECTION

ELECTRICAL CONNECTION

H

I-LO

Switch available

only on 500-1DN

and 500-2DN.

6-3/4" (171mm)

FOR LEG STAND OR CASTER STAND ASSEMBLY

29-15/16" (761mm)

HANDLE

Exterio r Di m e n sions - 500-1 D N , 500-2DN , 5 00-3DN

O P TI O NS & A C C E S S OR I ES

Built-in Trim Kit

500-1DN 44225

500-2DN 44227

500-3DN 44229

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 5.

Caster Stand Assembly 55534

Drawer Assembly with vents 55537

Leg Stand Assembly 55535

Perforated pan grid,

12" x 20" (305mm x 508mm) 16642

Page 7

Panel Overlay

I N S TA L L AT I O N

Manual Control, 120V Unit

Panel Overlay

High Limit Switch

Thermostat Knob

Temperature

Gauge

Manual Control, 208-240V, 230V Units

Drawer Assembly

Heat Indicator

Light

Panel Overlay

Drawer Bearing

Drawer Rail

Stud & Nut

Electronic Control

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 6.

Page 8

E L E C T R I C A L

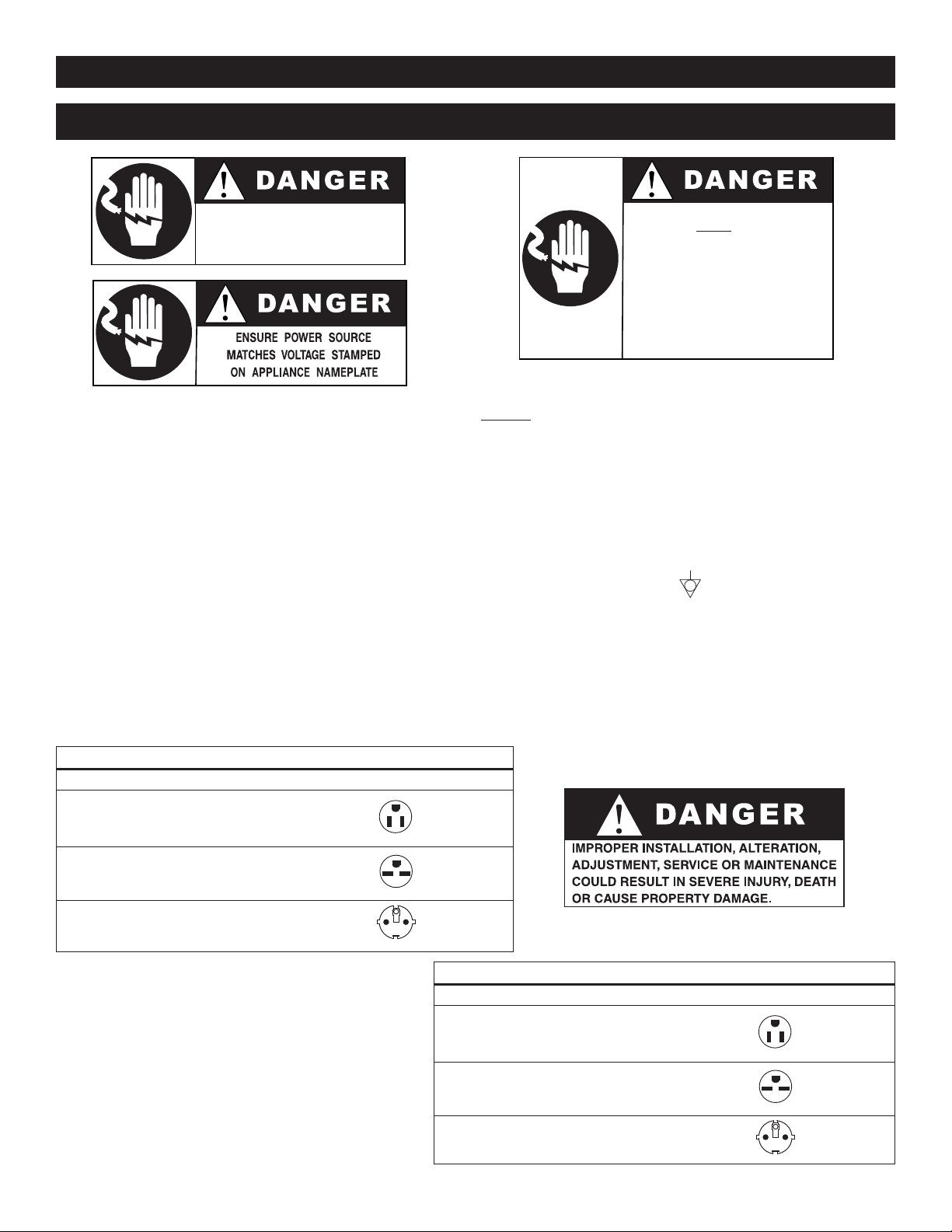

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

l

ocal codes, with the current edition

o

f the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be made

in accordance with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

ELECTRICAL CONNECTIONS MUST

BE MADE BY A QUALIFIED SERVICE

TECHNICIAN IN ACCORDANCE WITH

APPLICABLE ELECTRICAL CODES.

I N S TA L L AT I O N

1. An identification tag is permanently mounted on

the cabinet.

2. Plug cabinet into a properly grounded receptacle

ONLY, positioning the unit so the power supply

cord is easily accessible in case of an emergency.

Arcing will occur when connecting or

disconnecting the unit unless all controls are in

the “OFF” position.

3. If necessary, a proper receptacle or outlet configuration as required for this unit, must be

installed by a licensed electrician in accordance

with applicable, local electrical codes.

EL ECTR ICA L - 50 0-1 D; 50 0-2 D; 50 0-3 D

VOLTAGE PHASE CYCLE/ HZ AMPS kW

120 1 60 LOW 4.0 0.5

HI GH 8.5 1.05

at 208 1 50/60 4.0 0.8

at 240 1 50/60 4.5 1.05

NEMA 5-15P

15A, 125V PLUG

NEMA

15A, 250V PLUG

FOR USA ONLY

230 V:

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in

close vicinity, an equalization-bonding stud is

provided. An equalization bonding lead must be

connected to this stud and the other appliances /

metal parts to provide sufficient protection against

potential difference. The terminal is marked with

the following symbol.

NOT E: The appliance must be connected to an

electrical circuit that is protected by an external

GFCI outlet.

6-15P

230 1 50/60 4.2 0.97

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 7.

7/7,

CEE

220-230V

PLUG

EL ECTR ICA L - 50 0-1 DN; 500- 2DN; 500 -3DN

VOLTAGE PHASE CYCLE/ HZ AMPS kW

120 1 60 LOW 4.0 0.5

HI GH 8.5 1.05

at 208 1 50/60 4.0 0.8

at 240 1 50/60 4.5 1.05

230 1 50/60 4.2 0.97

NEMA 5-15P

15A, 125V PLUG

NEMA

6-15P

15A, 250V PLUG

FOR USA ONLY

7/7,

CEE

220-230V PLUG

Page 9

I N S TA L L AT I O N

U S E R S A F E T Y IN F O R M ATI O N

This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating instructions

and warnings must be read and understood by all

operators and users.

1. Make sure the unit is connected to the

appropriate power source.

2. Use hand protection when handling

hot items.

3. Preheat the unit for 30 minutes before use.

4. Be certain only hot foods are placed

into the unit.

BEFORE INITIAL U SE:

Before operating the unit, cle an both the interior

and exterior of the unit with a clean, da mp cloth

and mild soap solution. Rinse carefully. Clean and

install the drawer warmer pa n(s). The drawer

assembly is completely remova ble. Clean as a

sanitation measure.

HEATIN G CHARACTERISTIC S

FOO D P RODUC T T I PS

Bread and Rol l s

Breads and rol ls are traditionally difficult to hold

for prolonged periods due to th e very low

moisture content of th ese products. Fo r best

results and longest po ssible holding life, it is

recommended these pro ducts be placed in a

plastic bag while in the war m ing drawer. Breads

and rolls should be hel d at a temperature no

higher than 120° to 140°F (49° to 60°C).

Pot atoe s

— for the best results when hold ing potatoes:

1. Do not overcook .

Regardless of the temp erature at which potatoes

are cooked or what type of oven is used, it is

important that this product do es not achieve a

final inter nal prod uct temperature in excess of

195°F (91°C). Over-cooki ng will further reduce

the moisture content and conse quently , reduce

the holding life. Potatoes should be re moved

from the oven when they reach an internal

temperature of approx imately 190°F (88°C).

After they are removed from the oven, the

internal temperature will continue to increase.

The drawer warmer is equippe d with a special

heating cable. Through this Halo Heat concept,

the heating cable is mounted ag ainst th e walls of the

unit to provide an even ly appli ed heat source

controlled by a ther most at. The design an d

operational characteristics of the un it elimi nate the

need for a moisture pan or a heat circulating fan.

Through even heat appl ication , the qua lity of food

products is maintaine d up to se veral ho urs or more.

P R OD U CT C APA C I TY

20 lbs ( 9 kg)

(34 BAK ED P OTATO ES, 50 DI NNE R ROL LS )

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 8.

MA XIM UM • E ACH DRAW ER

2. Allow po t atoe s to sta biliz e b e fore pl acing

in dra wer warm e r.

When potatoes are remo ved from a conventional

high-temperature oven, they have an ex tremely

high surface temperature. If they ar e placed in

the drawer warmer wh ile they are this hot on the

outside, moisture wil l be pull ed from the inside of

the potato and condensation wi ll form on the

outside. Holding results under these conditio ns

will not be totally satisfactory. Remove potatoes

from the oven and allow the surface temperature

to stabilize before pl acing th em in the controlled

holding atmosphere of the draw er warmer.

Page 10

M AN U A L CO N T R O L

1. Dua l w attag e co ntro l.

The one and two drawer, 120V war mers are

provided with a HIGH/LOW power switch.

Use the HIGH position at 1000 wa tts for meats,

potatoes, and vegetables — use the LOW

position at 500 watts for bread s and rolls.

O P E R AT I O N

thermometer to make certain all food products

are at an internal te mperature range of

140° to 160°F (60° to 71 °C). All food not

within the proper temp erature range should be

heated before putting into the drawer warmer.

2. Preheat at 200 °F ( 93°C) fo r 30 min utes.

When the thermostat is turned clockwise to an

“ON” position, the indicator light wil l illumi nate

and will remain lit as long as th e unit is calling

for heat. Allow a minimum of 30 minutes of

preheating before loa ding the warmer with food.

The indicator light will go “OU T” after

approximately 30 minutes, or when the air

temperature inside the unit re aches the

temperature set by the operato r.

3. Loa d t he d rawer war mer with pan s o f

hot fo o d o nly.

The purpose of the unit is to mai ntain ho t food

at proper serving temp erature s. Only hot food

should be placed into the war mer. Bef ore

loading the unit with food, use a food

THERMOSTAT

4. Reset the the rmost at to 1 60°F (71 °C).

Check to make certain the drawer is

securely closed, and reset the ther mostat to

160°F (71°C).

THIS WILL NOT NECESSARILY BE THE

FINAL SETTING.

The proper temperatur e range for the food being

held will depend on the type and quantit y of

product. When holding food for prolong ed

periods, it is advisable to per iodical ly check the

internal temperature of eac h item to assure

maintenance of the pro per temp erature range.

TEMPERATURE

GAUGE

DUAL WATTAGE CONTROL

120V ONLY

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 9.

HEAT INDICATOR LIGHT

Page 11

°F / °C

O P E R AT I O N

POWER INDICATOR LIGHT

ON/OFF POWER KEY

- E L E C T R O N I C C O N T R O L

ED DISPLAY

L

EAT INDICATOR

H

IGHT

L

ON/OFF KEY

Press the on/off key once and the power indicator light will

illuminate. Press and hold the on/off key until the LED

display turns off (at least three seconds) and on/off indicator goes

out.

UP/DOWN ARROW KEY

The up and down arrow keys are used for a variety of settings

when selecting the holding temperature. If an arrow key is pressed

and released the display will show the current set temperature for

two seconds. If an arrow key is held (at least eight seconds), the

value will change at a rapid rate. If the arrow key is pressed and

released in rapid succession, the set temperature will change by

increments of one degree.

ENABLE/DISABLE BEEPER

A beeper sounds when an error code is displayed.

To choose between beeper on and beeper off mode, the

control must be OFF, then press and hold the down arrow

key until either "ON" or "OFF" is shown in the LED display.

Release arrow key when desired mode is displayed.

FAHRENHEIT / CELSIUS

With the control OFF, to choose between Fahrenheit and Celsius,

press and hold the up arrow key until either °F or °C is shown

in the LED display. Release key when desired setting is displayed.

The control has a four-digit LED display. When the display

is ON, it will show current holding temperature, as well as

diagnostic information.

CONTROL LOCK

The war mer controls can be locked so that no changes can

be made to the set temperature.

To lock the display, press and hold the ON/OFF key and

the Up Arrow key at the same time. The lock indicator will

illuminate. When the lock indicator is illuminated, additional

programming will not be functional other than the key

sequence required to unlock the panel.

To unlock the display, press and hold the ON/OFF key and

the Down Arrow key at the same time. The lock indicator

will extinguish. The panel keys will resume normal function.

LOCK INDICATOR

UP/DOWN

RROWS

A

1. Preheat at 200°F (93°C) for

30 minutes.

Press the ON ke y, and set the temperature

to 20 0°F (93C°) by using the UP/DOWN

arrow keys. Allow a minimum of 30

minutes preheating time before loading the

drawe r warmer with food. The L ED heat

indic ato r light will go “OUT” afte r

approxim ate ly 30 minutes preheat time, or

when the air t emperature inside the unit

reaches the temperature set by the operator.

2. Lo ad wit h pans of h ot foo d only.

The purpose of the warmer is to maintain

hot food at prop er serving tempe rat ure .

Only hot

food should be plac ed into th e

unit. Before loading with food, use a food

thermo met er to make certain all products

are at an inter n al temperature rang e of

140° to 160°F (60° to 71°C). Any food

product not within the proper t emp erature

range should be he ated before load ing into

the unit.

3. Re set th e cont rol to 1 60°F ( 71°C ).

Check to make ce rtain the d raw er is

securely closed, and res et to 160° F (71°C)

by us ing the U P/D OWN keys.

THIS WILL NOT NECE SSARILY BE T HE

FINAL SETTING.

The proper temperature range will d epe nd

on th e type a nd quantity of product. When

holdi ng food for prol onged periods, it is

advis abl e to periodic all y check the inter nal

temperat ure of each item with a food

thermo met er to assu re maintenance of the

proper temperature range of

140° to 160°F (60° to 71°C).

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 10.

Page 12

O P E R AT I O N

GENERAL HOLDING GUIDELINES

Chefs , cooks and other specialized food service

perso nne l employ vari ed methods of cooking. Proper

holdi ng temperatures f or a specific food product m ust

be based on the moisture cont ent of the p roduct,

product density, volume, and proper serv ing

tempe rat ure s. Safe hold ing temperatures mu st also

be correlated with pa latability in de termining the length

of ho lding time fo r a specifi c product.

Halo Heat maintains the maximum am ount of product

moist ure content without the addition of water, w ater

vapor, or steam. Ma intaining maxi mum natural product

moist ure preserves the natural flavor of the p rod uct and

provides a more ge nui ne taste. In addition to pr oduct

moist ure retention, the gentle properties of Halo He at

maint ain a consistent temperature thro ugh out the

cabin et without the necessity of a heat di str ibu tion fan,

thereby preventing further moisture loss du e to

evapo rat ion or dehy dra tio n.

When product is re mov ed from a h igh temperature

cooki ng environment for immediate tran sfe r into

equip men t with the lower temperature required for hot

food holding, condensati on can form on the o utside of

the product and o n the inside of plastic containers used

in self-service appli cat ion s. Allowing th e product to

release the initial steam and h eat produced by high

tempe rat ure cooking can alleviate this condition. To

preserve the safety and quality of freshly cooked foods

howev er, a maximum of 1 to 2 minutes must be the

only time period allowed for t he initial he at to be

released from the p rod uct.

Most Halo Heat h olding equipment is provided with

a t hermostat cont rol between 60° and 200°F

(16° to 93°C). If the unit is equipped w ith vents,

close the vents fo r moist holdi ng and open the vents

for crisp holding.

If th e unit i s equipped with a thermos tat indicating

a r ange of be twe en 1 and 10, use a metal-stemmed

indic ati ng ther mometer to measure the internal

tempe rat ure of the pro duct(s) being he ld. Adjust t he

thermo sta t setting t o achieve t he best overa ll setting

based on internal product temperatur e.

H O L D I N G T E M P E R A T U R E R A N G E

ME AT FA H R E N HE I T C E L S IU S

EE F RO AS T — Rare 14 0° F 60 °C

B

BE EF R OA ST — Med/Well Done 16 0° F 71 °C

BE EF B RI SK ET 16 0° — 1 75 °F 7 1° — 7 9° C

OR N BE EF 16 0° — 1 75 °F 7 1° — 7 9° C

C

PAS TR AM I 16 0° — 1 75 °F 7 1° — 7 9° C

PR IM E RI B — Rare 14 0° F 60 °C

TE AK S — Br oi le d/ Fried 14 0° — 1 60 °F 6 0° — 7 1° C

S

RI BS — B ee f or Po rk 16 0° F 71 °C

VE AL 16 0° — 1 75 °F 7 1° — 7 9° C

AM 16 0° — 17 5° F 71° — 79 °C

H

PO RK 16 0° — 1 75 °F 7 1° — 7 9° C

AM B 16 0° — 1 75 °F 7 1° — 7 9° C

L

PO UL TRY

CH IC KE N — Fr ie d/ Baked 16 0° — 1 75 °F 7 1° — 7 9° C

UC K 160 ° — 17 5° F 71 ° — 79°C

D

TU RK EY 16 0° — 1 75 °F 7 1° — 7 9° C

GE NE RA L 16 0° — 1 75 °F 7 1° — 7 9° C

IS H/ S EA FO OD

F

FI SH — B ak ed /F ri ed 16 0° — 1 75 °F 7 1° — 7 9° C

LO BS TE R 1 60 ° — 1 75 °F 71° — 7 9° C

HR IM P — Fr ie d 160° — 1 75 °F 7 1° — 7 9° C

S

BA KE D GO OD S

BR EA DS /R OL LS 12 0° — 1 40°F 49° — 60 °C

MI SC E LL AN EOU S

CA SS ER OL ES 16 0° — 1 75 °F 7 1° — 7 9° C

DO UG H — Pr oo fi ng 80 ° — 10 0° F 2 7° — 3 8° C

EG GS — Fr ie d 15 0° — 1 60 °F 6 6° — 7 1° C

FR OZ EN E NT RE ES 16 0° — 1 75 °F 7 1° — 7 9° C

HO RS D 'O EU VR ES 160° — 18 0° F 71 ° — 82 °C

PAS TA 16 0° — 1 80 °F 7 1° — 8 2° C

PI ZZ A 16 0° — 18 0° F 71 ° — 82 °C

PO TATOE S 180 °F 8 2° C

PL ATED ME AL S 1 80 °F 8 2° C

SA UC ES 1 40 ° — 20 0° F 60 ° — 93°C

SO UP 14 0° — 200° F 60° — 93 °C

VE GE TAB LE S 16 0° — 175° F 71° — 79 °C

Th e ho ld in g te mp erature s li st ed a re s ug ge st ed gu id el in es o nl y.

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 11.

Page 13

C A R E a n d CL E A N I N G

C L E A N I N G A N D P R E V E N T I V E M A I N T E N A N C E

PRO TECT I NG STAIN L ESS STEE L S URFACES

It is important to guard against corrosion in the

care of stainless steel surfaces. Harsh, corrosive,

or inappropriate chemicals can completely destroy

the protective sur face layer of stainless steel.

Abrasive pads, steel wool, or metal implements will

abrade surfaces causing damage to this protective

coating and will eventually result in areas of

corrosion. Even water, particularly hard water that

contains high to moderate concentrations of

chloride, will cause oxidation and pitting that result

in rust and corrosion. In addition, many acidic

foods spilled and left to remain on metal surfaces

are contributing factors that will corrode sur faces.

Proper cleaning agents, mater ials, an d method s

are vital to maintaining the ap pearanc e and life of

this appliance. Spilled foods should be remove d

and the area wiped as so on as pos sible but at the

very least, a minimum of once a day. Always

thoroughly rinse surfaces after using a cleaning

agent and wipe standing water as quickl y as

possible after rinsing.

CLE ANIN G AG ENTS

Use non-abrasive cleaning products designed for use

on stainless steel surfaces. Cleaning agents must be

chloride-free compounds and must not contain

quaternary salts. Never use hydrochloric acid

(muriatic acid) on stainless steel sur faces. Always use

the proper cleaning agent at the manufacturer's

recommended strength. Contact your local cleaning

supplier for product recommendations.

CLE ANIN G MAT ERIAL S

The cleaning function can usua lly be ac complis hed

with the proper cleani ng agent and a soft, clean

cloth. When more aggressive methods mu st be

employed, use a non-abrasive scouring pad on

difficult areas and ma ke certa in to scr ub with the

visible grain of sur face met al to avo id surface

scratches. Never use wire brushes, metal scour ing

pads, or scrapers to re move foo d residue.

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 12.

Page 14

C A R E a n d CL E A N I N G

AT NO TIME SHOULD THE INTERIOR OR

EXTERIOR BE STEAM CLEANED, HOSED

DOWN, OR FLOODED WITH WATER OR

LIQUID SOLUTION OF ANY KIND. DO NOT

USE WATER JET TO CLEAN.

SEVERE DAMAGE OR ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF APPLIANCE IS FLOODED.

The cleanliness and appearance of this unit will contribute considerably

to operating efficiency and savory, appetizing fo od. Good equipment

kept clean works better and lasts longer.

TH OR OU G H LY C LE AN D A ILY

1. Disconnect un it from power source, and l et cool.

2. Remove, co ver or wrap, and refrigerate food.

3. Remove d raw er pans and clean separately. The

drawe r assembly is completely removab le. Remove

from the cabinet an d clean to prevent a bui ld-up of

food residue from i nte r fering with the function of

the drawer assembly. Regular cleanin g will help

prolong the life of these p art s.

4. Clean inte rio r metal sur fac es of the unit with a

damp, clean cloth and any g ood commercial

deter gent or grease solve nt at the r eco mmended

strength . Use a pla stic scouring pa d or oven cleaner

for difficult areas. Rinse carefully t o remove all

residue and wipe dr y.

NO TE: Avoi d the use of abrasive clea ning,

compound s, chloride base d cleaners, or

clean ers containing quat ernary salts. Never

use hydrochloric acid (muriatic acid) on

stainles s steel.

5. Wipe control panel, vents, handles, and gaskets

thorough ly since these areas harbor food debris.

6. Int eri or can b e wiped with a sanitizing solution

after cleaning and rinsing. This solution must

be ap proved for u se on stai nle ss steel food

contact surfaces.

7. To help maintain t he protective fi lm coating on

polis hed stainless st eel , clean the exterior of th e

unit with a c lea ner recommended for stainless s teel

sur fac es. Spray the cleaning agen t on a c lot h and

wipe with the grai n of the stainless steel.

Alway s follow appropriat e state or lo cal health

(hygi ene ) regulations regar din g all applica ble cleaning

and sanitation requiremen ts for foodser vic e equipment.

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 13.

Page 15

S A N I TAT I O N

Food flavor and a roma are usua lly so closely related

that it is diff icu lt, if not impossible, to separate them.

There is also an important, inse par able relationship

betwe en cleanliness and food flavor. Cleanliness, top

opera tin g efficiency, an d appearance o f equipment

contribu te considerably t o savory, a ppe tizing foods.

Good equipment that is kept cl ean, works be tte r and

lasts longer.

Most food imparts i ts own p art icular aroma and many

foods also absorb e xisting odors. Unfortunately, d uri ng

this absorption, there is no disti nct ion between GO OD

and BAD odors. The majority of objectionable f lav ors

and odors troubling food service op erations are c aus ed

by ba cteria growth. Sour ness, ranc idi ty, mustiness,

stale or other OFF flavors ar e usually the result of

ger m activity.

The easiest way to insure f ull , natural f ood flavor is

through comprehensive clean lin ess. This mean s good

control of both vi sib le soil (d irt ) and invisib le soil

(germs ). A thoroug h approach to sa nitation will

provide essential clea nli ness. It wi ll assure an attractive

appea ran ce of equipme nt, along with maximum

effic ien cy and util ity . More importa ntl y, a good

sanit ati on program provides one of th e key element s

in the prevention o f food-bor ne illnesses.

A c ontrolled holding environment for prepared foods

is just one o f the important factors involved in the

preventi on of food-bor ne illnesses. Temperature

monitori ng and cont rol during receiving, storage,

preparat ion , and the service of fo ods are of eq ual

impor tan ce.

The most accurate method of meas uring safe

temperat ure s of both hot and c old foods is by inter nal

product temperature. A quality thermo met er is an

effec tiv e tool for this purpose, and should be routinely

used on all p rod uct s that requ ire holding at a specific

temperat ure .

A c omprehensive sani tat ion program sh oul d focus on

the training of st aff in basi c sanitation p roc edu res .

This includes persona l hygiene, proper handling of ra w

foods, cooking to a safe in ter nal p rod uct temperature,

and the routine mo nit oring of inte r nal temperatures

from rec eiving through se rvice.

Most food-borne i lln esses can b e prevented through

proper temperature control and a co mpr ehe nsive

program of sanitation. Both these fact ors are i mpo rtant

to bu ild quality service as the foundation of customer

satis fac tio n. Safe f ood handling p rac tic es to prevent

food-bor n e illness i s of critical importance to the health

and safety of your customers. HA CCP, an acronym for

Hazard Analysis (at) Critical Control Points, is a quality

control program of op era ting procedures t o assure food

integ rit y, quality, and safety. Taking s tep s necessary to

augme nt food safety practices are b oth cost ef fec tive

and relatively simple. While HACCP guidelines go far

beyond the scope of this manu al, additional info r mation

is available by co ntacting:

Cente r for Food Sa fety and Appl ied Nutrition

Food and Drug Ad min istration

1-888-SA FEF OOD

I N T E RN A L F O OD P R O D U C T TE MP E R A T U RE S

H O T F O O D S

DA N G ER Z O NE 4 0 ° TO 1 40° F ( 4 ° T O 6 0° C )

CR I T ICA L ZO N E 70 ° TO 1 2 0° F (2 1 ° TO 4 9° C )

SA F E ZO N E 1 4 0 ° T O 16 5 ° F ( 6 0° T O 7 4 ° C)

C O L D F O O D S

DA NGE R ZON E ABOV E 4 0° F ( ABO VE 4° C)

SA F E ZO N E 36 °F TO 40 °F ( 2 °C T O 4 °C )

F R O Z E N F O O D S

DA NGE R ZON E ABOV E 3 2° F ( ABO VE 0° C)

CR ITI CA L Z ON E 0 ° T O 3 2° F ( -18 ° TO 0° C )

SA FE ZO NE 0 °F

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 14.

OR BELOW (- 18 °C OR BELOW)

Page 16

S E R V I C E

MANUAL CONTROL

THERMO S TAT and H EAT LIGHT SEQUENCE

Whene ver the thermo sta t is tur ned “ON,” the heat indicator light will i ndicate the powe r ON/OFF condit ion of

the heating cable, and consequent ly, the cycling of the c abi net as it maintains the dialed cavity temperature. If

the light does n ot illuminate af ter normal start-up, the m ain power source, ther most at, and/or light must be

check ed. If the w arming cabinet does not h old the t emp erature as di ale d, the cali bra tion of the thermostat must

be checked. If the warmer fail s to heat or heats cont inuously with th e thermostat “OFF,” the t her mostat m ust

be initially checked for proper o peration. If thes e items ar e checked and found to be in order, a continuity an d

resistan ce check of the heating ca ble should be made. SEE CIRCUIT DIAGR AM.

THERMO S TAT CALIBRATION

The thermostat is precision calibra ted at the factory. Normal ly, no adjustm ent or recalibrat ion is necessa ry

unless the ther most at has been mishandled in transit, changed or abused w hil e in servi ce. A thermo sta t with a

sensi ng bulb operates on hydraulic pressure, consequent ly, any bendi ng of the b ulb results in a change i n its

volum e, and alters the accuracy of the ther mostat c alibration.

A t hermostat shou ld be checked or recalibrated by placing a quality, ther mal i ndi cator at the center of an empty

holdi ng cavity. DO NOT CALIBRATE WITH AN Y FOOD PRODUCT IN THE C ABI NET. Th e thermostat

shoul d be set at 140°F (60°C), and should be allowed to stabilize at that setting for a m ini mum of one hour.

Followin g temperature st abi liz ation, the c enter of the ther mal s win g of the air temperature within the c abinet

shoul d approximately c oin cid e with t he ther mostat d ial setting.

If ca libration is necessary, the calibration screw should be adjusted with g rea t care. The calibration scre w of the

thermo sta t is locat ed in the t hermostat dial shaft. With the shaft held st ationary, a minute, clockwise motion of

the calibration screw appreciably lowe rs the ther m ost at setting. A reverse, or counter-clockwis e motion

apprecia bly raises the thermostat sett ing . After a chi eving the d esi red cycling of the ther m ost at, the calibrat ion

screw must be seal ed. Place a few drops of enamel seal ant directly o n the calibratio n screw.

(RED NAIL POLISH OR EQUIVAL ENT IS ACCE PTABLE.)

T R O U B L E S H O O T I N G C H E C K L I S T • E L E C T R O N I C C O N T R O L

R e p a i r s s h o ul d b e m ad e b y a u t h o r iz e d s e r v i ce a g en t s o n l y.

TROUBLE POSSIBLE CAUSE REMEDY

Unit does not operate. Insufficient power supply. Check power source.

Defective power cord or plug. Check and replace if necessary.

No display in electronic control. Faulty power supply board. Check line voltage for 24V across

pins 7 and 8 on the power supply board and

across terminals J9 and J10 on the electronic

control.

Faulty electronic control. Replace control.

Cannot control temperature but Faulty relay Replace relay.

sensor and electronic control

checks O.K. Heating element grounded. Replace element.

Temperature readout incorrect. Dirty or faulty sensor. Check sensor at 32°F (0°C).

If Ohm reading is 100,

Faulty control. replace display.

If Ohm reading is not 100,

replace sensor.

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 15.

Page 17

S E R V I C E

Error

Code Description/Results

Possible Cause

Service Required

E-10 Air Sensor Fault (shorted)

Inoperative Oven

Air sensor is shorted.

Air sensor is defective.

Air sensor is open or has connection failure.

Need air sensor test. See below.

E

-11

A

ir Sensor Fault (open)

Inoperative Oven

E-30 Under temperature

Oven will not reach set temperature

Oven door closed? Door gasket need replacement? Preheat skipped?

Oven overloaded or has frozen product? Defective air sensor or probe?

Defective solid state relay? Bad wire connections or open heating cable?

Is the high limit switch tripped? If none of the above, call service.

E-31 Over temperature

Oven will shut down

Shorted cable? Defective solid state relay? Defective air sensor?

If none of the above, call service.

E-60 Real time clock error

Inoperative Oven

Appliance has probably been unplugged for more than 30 days. If this is the

case, it should be plugged in with the circuit breaker ON, and the appliance

displaying the E-60 on the front panel for more than 30 minutes. Once this

has been accomplished, the circuit breaker should be turned OFF, or the

appliance unplugged for approximately 10 seconds after which the appliance

should be turned ON again.

E-70 Configuration connector error

Inoperative Oven

Check control connections for loose wires. If none, control must be replaced.

E-78 Voltage low

Inoperative Oven

If 125 VAC unit, voltage is below 90 VAC. Correct.

If 208-240 VAC voltage is below 190 VAC. Correct.

E-79 Voltage high

Inoperative Oven

If 125 VAC unit, voltage is over 130 VAC. Correct.

If 208-240 VAC, voltage is over 250 VAC. Correct.

E-80 EEPROM - Function data error

Inoperative Oven

Replace control.

E-82 EEPROM - Calibration data error

Inoperative Oven

Replace control.

E-84 EEPROM - Unit ID error

Inoperative Oven

Replace control.

E-86 EEPROM - Preset data error

Inoperative Oven

Replace control.

To test air sensor:

Test air sensor by placing sensor in ice water bath and using an ohmmeter set on the ohm scale.

The reading should be 100 ohms resistance. If it is more than 2 ohms higher or lower, sensor needs

to be replaced.

T R O U B L E S H O O T I N G • EL EC T R O N I C CO N T R O L

DRAWER WARMERS - ELECTRON I C CONTROL

#818 I

n s t a lla t i o n

/Opera t i o n / S e r v i c e M a n u a l • 16.

Page 18

Wide Drawer Warmers – Service Parts

Illustrations on following pages.

artDescription

P

Manual or Electronic Control • Wide Drawer Warmers

Air Tunnel 1 1002672 1 1002672 1 1002672

Cable Replacement Kit (CB-3044) 1 4874 1 4874 1 4874

Casing Bottom 1 1002400 1 1002400 1 1002400

Casing Top 1 1002403 1 1002403 1 1002403

Casing 1 1002558 1 1002396 1 1002564

Cordset (120V) 1 CD-3232 1 CD-3232 1 CD-3232

Cordset (208/240) 1 CD-33840 1 CD-33840 1 CD-33840

Cordset (230V) 1 CD-3922 1 CD-3922 1 CD-3922

Drawer Assembly 1 55502 2 55502 3 55502

Drawer front Mounting Stud 4 ST-25019 8 ST-25019 12 ST-25019

Drawer front Mounting Nut 4 NU-2187 8 NU-2187 12 NU-2187

Drawer Bearing 6 BG-24890 12 BG-24890 18 BG-24890

Drawer Pan (

Drawer with vents 1 55536 2 55536 3 55536

Fan, Box (120V) 1 FA-3973 1 FA-3973 1 FA-3973

Fan, Box (208/240V, 230V) 1 FA-3974 1 FA-3974 1 FA-3974

Insulation, Board 3 IN-2003 3 IN-2003 3 IN-2003

Switch (230V), circuit breaker 1 SW-33487 1 SW-33487 1 SW-33487

Switch (120V), wattage 1 SW-3409 1 SW-3409 N/A

Terminal Block 1 BK-3019 1 BK-3019 1 BK-3019

Heat Indicator Light (120V) 1 LI-3027 1 LI-3027 1 LI-3027

Heat Indicator Light (208/240V) 1 LI-3025 1 LI-3025 1 LI-3025

Heat Indicator Light (230V) 1 LI-3951 1 LI-3951 1 LI-3951

Knob, Thermostat (120V, 208/240V) 1 KN-3469 1 KN-3469 1 KN-3469

Knob, Thermostat (230V ONLY)1KN-3474 1 KN-3474 1 KN-3474

Panel Overlay (120V) 1 PE-25068 1 PE-25068 1 PE-25067

Panel Overlay (208/240V, 230V) 1 PE-25067 1 PE-25067 1 PE-25067

Thermostat 1 TT-3057 1 TT-3057 1 TT-3057

Temperature Gauge 1 TH-33713 1 TH-33713 1 TH-33713

Temperature Gauge Lens Cover replacement 1 TH-33956 1 TH-33956 1 TH-33956

Beeper 1 BP-3567 1 BP-3567 1 BP-3567

Block, Sensor 1 BK-33546 1 BK-33546 1 BK-33546

Board, Power Supply 1 BA-33554 1 BA-33554 1 BA-33554

Control, Electronic 1 5000876 1 5000876 1 5000876

Panel Overlay 1 PE-25327 1 PE-25327 1 PE-25327

Relay 1 RL-33558 1 RL-33558 1 RL-33558

Sensor 1 SN-33541 1 SN-33541 1 SN-33541

Thermostat, Electronic, 230V

NOT SHOWN)1PN-25088 2 PN-25088 3 PN-25088

Manual Control Wide • Drawer Warmers

Electronic

ONLY 1 TT-33789 1 TT-33789 1 TT-33789

ty

Q

Control • Wide Drawer Warmers

00-1D

5

ty

Q

00-2D

5

ty

Q

00-3D

5

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 17.

Page 19

Narrow Drawer Warmers – Service Parts

Illustrations on following pages.

artDescription

P

anualorElectronicControl•NarrowDrawerWarmers

M

Air Tunnel 1 1002672 1 1002672 1 1002672

Cable Replacement Kit (CB-3044) 1 4874 1 4874 1 4874

Casing Bottom 1 1002794 1 1002794 1 1002794

Casing Top 1 1002798 1 1002798 1 1002798

Casing 1 1002884 1 1002837 1 1002799

Cordset (120V) 1 CD-3232 1 CD-3232 1 CD-3232

Cordset (208/240) 1 CD-33840 1 CD-33840 1 CD-33840

Cordset (230V) 1 CD-3922 1 CD-3922 1 CD-3922

Drawer Assembly 1 55509 2 55509 3 55509

Drawer front Mounting Stud 4 ST-25019 8 ST-25019 12 ST-25019

Drawer front Mounting Nut 4 NU-2187 8 NU-2187 12 NU-2187

Drawer Bearing 6 BG-24890 12 BG-24890 18 BG-24890

Drawer Pan (NOT SHOWN)1PN-25088 2 PN-25088 3 PN-25088

Drawer with vents 1 55536 2 55536 3 55536

Fan, Box (120V) 1 FA-3973 1 FA-3973 1 FA-3973

Fan, Box (208/240V, 230V) 1 FA-3974 1 FA-3974 1 FA-3974

Insulation, Board 3 IN-2003 3 IN-2003 3 IN-2003

Switch (230V), circuit breaker 1 SW-33487 1 SW-33487 1 SW-33487

Switch (120V) wattage 1 SW-3409 1 SW-3409 N/A

Terminal Block 1 BK-3019 1 BK-3019 1 BK-3019

Manual Control • Narrow Drawer Warmers

Heat Indicator Light (120V) 1 LI-3027 1 LI-3027 1 LI-3027

Heat Indicator Light (208/240V) 1 LI-3025 1 LI-3025 1 LI-3025

Heat Indicator Light (230V) 1 LI-3951 1 LI-3951 1 LI-3951

Knob, Thermostat (120V, 208/240V) 1 KN-3469 1 KN-3469 1 KN-3469

Knob, Thermostat (230V ONLY)1KN-3474 1 KN-3474 1 KN-3474

Panel Overlay (120V) 1 PE-25014 1 PE-25014 1 PE-25013

Panel Overlay (208/240V, 230V) 1 PE-25013 1 PE-25013 1 PE-25013

Thermostat 1 TT-33626 1 TT-33626 1 TT-33626

Temperature Gauge 1 TH-33713 1 TH-33713 1 TH-33713

Temperature Gauge Lens Cover replacement 1 TH-33956 1 TH-33956 1 TH-33956

Electronic

Beeper 1 BP-3567 1 BP-3567 1 BP-3567

Block, Sensor 1 BK-24427 1 BK-24427 1 BK-24427

Board, Power Supply 1 BA-33554 1 BA-33554 1 BA-33554

Control, Electronic 1 5000876 1 5000876 1 5000876

Panel Overlay 1 PE-25326 1 PE-25326 1 PE-25326

Relay 1 RL-33558 1 RL-33558 1 RL-33558

Sensor 1 SN-33541 1 SN-33541 1 SN-33541

Thermostat, Electronic, 230V only 1 TT-33789 1 TT-33789 1 TT-33789

ty

Q

Control • Narrow Drawer Warmers

00-1DN

5

ty

Q

5

00-2DN

ty

Q

00-3DN

5

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 18.

Page 20

S E R V I C E

500-3D • Manual control • top removed

INDICATOR LIGHT

LI-3027

LI-3025

LI-3951

THERMOSTAT

TT-3057

TT-33626

THERMOMETER

TH-33713

INSULATION

IN-2003

WIRING

DIAGRAM

HEATING ELEMENT

CONNECTIONS

TERMINAL BLOCK

BK-3019

ELECTRIC CORD

CD-3232

CD-33840

CD-3922

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 19.

AIR TUNNEL 1002672

(EXHAUST FAN INSIDE)

FA-3973

FA-3974

Page 21

S E R V I C E

500-3D • Electronic control • top removed • 230V

CONTROL #5000876 WITHOUT SCI • CONTROL #5000877 WITH SCI

WIRING

DIAGRAM

HEATING

ELEMENT

CONNECTIONS

SENSOR WIRE

(WHITE)

BEEPER

BP-3567

RELAY

RL-33558

POWER SUPPLY

BA-33554

TERMINAL BLOCK

-3019

BK

AIR TUNNEL

(EXHAUST FAN INSIDE)

FA-3973, FA-3974

INSULATION

IN-2003

1002672

BREAKER SWITCH

SW-33487

THIS PHOTOGRAPH IS AN

ENLARGEMENT OF THE CIRCLED

AREA ABOVE.

ELECTRIC CORD

CD

-3232, CD-33840, CD-3922

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 20.

CORD

BUSHING

BU-3964

Page 22

S E R V I C E

INSULATION

IN-2003

500-3D

Heat Cable Wrap

HEAT ELEMENT

CABLE

CB-3044

500-3D

Interior

THERMOMETER

CAPILLARY

BEARINGS

THERMOSTAT

CAPILLARY

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 21.

Page 23

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 22.

Page 24

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 23.

Page 25

#818 I

n s t a lla t i o n

/Opera t i o n / S e r v i c e M a n u a l • 24.

Page 26

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 25.

Page 27

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 26.

Page 28

#818 I

n s t a lla t i o n

/Opera t i o n / S e r v i c e M a n u a l • 27.

Page 29

#818 I

n s t a lla t i o n

/Opera t i o n / S e r v i c e M a n u a l • 28.

Page 30

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 29.

Page 31

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 30.

Page 32

#818 I n s t a ll a t i o n / Op e r a ti o n / Se r v ic e Ma n u a l• 31.

Page 33

All Alto-Shaam equipment

is sold F.O.B. shipping

point, and when accepted

by the carrier, such

shipments become the

property of the consignee.

Should damage occur in shipment, it is a matter

between the carrier and the consignee. In such cases, the

carrier is assumed to be responsible for the safe delivery

of the merchandise, unless negligence can be established

on the part of the shipper.

1. Make an immediate inspection while the equipment

is still in the truck or immediately after it is moved to

the receiving area. Do not wait until after the

material is moved to a storage area.

2. Do not sign a delivery receipt or a freight bill until

you have made a proper count and inspection of all

merchandise received.

3. Note all damage to packages directly on the carrier’s

delivery receipt.

4. Make certain the driver signs this receipt. If he

refuses to sign, make a notation of this refusal on

the receipt.

5. If the driver refuses to allow inspection, write the

following on the delivery receipt:

Drive r re fus es to allo w ins pe ctio n o f

co ntaine rs fo r v isib le d a ma ge .

6. Telephone the carrier’s office immediately upon

finding damage, and request an inspection. Mail a

written confirmation of the time, date, and the

person called.

7. Save any packages and packing material for further

inspection by the carrier.

8. Promptly file a written claim with the carrier and

attach copies of all supporting paperwork.

We will continue our policy of assisting our

customers in collecting claims which have been properly

filed and actively pursued. We cannot, however, file any

damage claims for you, assume the responsibility of any

claims, or accept deductions in payment for such claims.

Alto-Shaam, Inc. warrants to the original purchaser that any

original part that is found to be defective in material or workmanship

will, at Alto-Shaam's option, subject to provisions hereinafter stated,

be replaced with a new or rebuilt part.

The labor warranty remains in effect one (1) year from installation

o

r fifteen (15) months from the shipping date, whichever occurs first.

Alto-Shaam will bear normal labor charges performed during standard

business hours, and excluding overtime, holiday rates or any

additional fees.

The parts warranty remains in effect for one (1) year from

installation or fifteen (15) months from the shipping date, whichever

o

ccurs first.

However, the heating element on Halo Heat

®

cook/hold ovens

and the refrigeration compressor on Alto-Shaam Quickchillers

™

are

warranted for a period of five (5) years from installation. The labor

warranty is the same as stated above; namely, for one (1) year from

installation or fifteen (15) months from the shipping date, whichever

occurs first.

THIS WARRANTY DOES NOT APP LY TO:

1. Calibration.

2. Replacement of light bulbs and/or the replacement of display

case glass due to damage of any kind.

3. Equipment damage caused by accident, shipping, improper

installation or alteration.

4. Equipment used under conditions of abuse, misuse, carelessness

or abnormal conditions including, but not limited to, equipment

subjected to harsh or inappropriate chemicals including, but not

limited to, compounds containing chloride or quaternary salts, poor

water quality, or equipment with missing or altered serial numbers.

5. Damage incurred as a direct result of poor water quality,

inadequate maintenance of steam generators and/or surfaces

affected by water quality. Water quality and required maintenance

of steam generating equipment is the responsibility of the

owner/operator.

6. Damage caused by use of any cleaning agent other than

Alto-Shaam's Combitherm

®

Cleaner including, but not limited to,

damage due to chlorine or other harmful chemicals. Use of

Alto-Shaam's Combitherm®Cleaner on Combitherm®ovens is

highly recommended.

7. Any losses or damage resulting from malfunction, including loss

of product or consequential or incidental damages of any kind.

8. Equipment modified in any manner from original model,

substitution of parts other than factory authorized parts,

removal of any parts including legs, or addition of any parts.

This warranty is exclusive and is in lieu of all other warranties,

expressed or implied, including the implied warranties of

merchantability and fitness for a particular purpose. In no event

shall Alto-Shaam be liable for loss of use, loss of revenue or profit,

or loss of product, or for any indirect or consequential damages.

No person except an officer of Alto-Shaam, Inc. is authorized to

modify this warranty or to incur on behalf of Alto-Shaam any other

obligation or liability in connection with Alto-Shaam equipment.

ALTO-SHAAM, INC.

TRANSPORTATION

DAMAGE and CLAIMS

®

RECORD THE MODEL AND SERIAL NUMBER OF THE APPLIANCE FOR EASY REFERENCE.

ALWAYS REFER TO BOTH MODEL AND SERIAL NUMBER IN ANY CONTACT WITH ALTO-SHAAM REGARDING THIS APPLIANCE.

Model: _______________________________________________Date Installed: __________________________________________________________

Voltage: ______________________________________________ Purchased From: _______________________________________________

Serial Number: _______________________________________ _______________________________________________________________________

W164 N9221 Water Street●P.O. Box 450●Menomonee Falls, Wisconsin 53052-0450●U.S.A.

PHONE: 262.251.3800 • 800.558-8744 USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

WEBSITE: www.alto-shaam.com

PRINTED IN U. S . A .

LIMITED

WARRANTY

Loading...

Loading...