Alto-Shaam 500 User Manual

LOW TEMPERATURE COOKING

AND HOLDING GUIDELINES

Manually Operated Ovens

LOW TE MPER ATURE C O OKI N G AND HO LDIN G O VEN S

GEN E RA L IN D E X

SECTION 1 • Low Temperature Cooking Introduction

Alto-Shaam Halo Heat . . . . . . . . . . . . . . . . . . . 1

Low Temperature Cooking Facts

Meat and Nutrition . . . . . . . . . . . . . . . . . . . . . 2

Shrinkage Control and Cooking Time . . . . . . . 3

Preventing Bacteria Growth . . . . . . . . . . . . . . 3

Labor and Equipment Cost Reduction . . . . . . 4

Options and Accessories . . . . . . . . . . . . . . . . . 5

SECTION 2 • Low Temperature Coo king Operation

General Operation — Manual Ovens

Oven Characteristics . . . . . . . . . . . . . . . . . . . . 6

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control Panel Identification . . . . . . . . . . . . . . 7

Cooking & Holding Procedures . . . . . . . . . 8-10

Chef Operating Tips . . . . . . . . . . . . . . . . . . . . 11

SECTION 3 • Cleaning and Maintenance . . 12-13

SECTION 5 • Smoker Operation

General Operation — Smokers

Control Panel and Operation . . . . . . . . . . . . . 62

Cooking/Smoking/Holding Procedures . . . . 63

Smoking Times . . . . . . . . . . . . . . . . . . . . . . . . 64

Smoking Procedure Options . . . . . . . . . . . . . 65

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . 65

SECTION 6 • Cooking & Smoking Guidelines

Smoked Beef Brisket . . . . . . . . . . . . . . . . . . . . 66

Smoked Beef Tongue . . . . . . . . . . . . . . . . . . . 66

Smoked Fresh Hams . . . . . . . . . . . . . . . . . . . . 67

Smoked Pork Ribs . . . . . . . . . . . . . . . . . . . . . 67

Smoked Duck . . . . . . . . . . . . . . . . . . . . . . . . . 68

Smoked Turkey . . . . . . . . . . . . . . . . . . . . . . . . 68

Smoked Fish Fillets . . . . . . . . . . . . . . . . . . . . 69

Smoked Salmon, Whole . . . . . . . . . . . . . . . . . 69

Smoked Shrimp . . . . . . . . . . . . . . . . . . . . . . . 70

Cold Smoked Salmon . . . . . . . . . . . . . . . . . . . 71

SECTION 4 • Cooking Guideline

Product Index . . . . . . . . . . . . . . . . . . . . . . . . . 14

Oven Preheating Instructions . . . . . . . . . . . . 14

Beef . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-25

Veal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Lamb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-28

Pork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-34

Processed Meats . . . . . . . . . . . . . . . . . . . . . . . 35

Poultry . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-44

Fish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45-47

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . 48-60

W 1 6 4 N 9 2 2 1 Wa t e r S t r e e t●P. O . B o x 4 5 0●M e n o m o n e e F a l l s , W i s c o n s i n 5 3 0 5 2 - 0 4 5 0●U . S . A .

PHONE: (262)2 51-3800 (800 )558-87 44 U.S. A./C ANAD A●FAX: (262)2 51-7067 (800 )329-87 44 U.S. A.●www.alto-s haam.co m

MN - 2865 5 • 10 /09

SECTION 7 • Food Holding and Sanitation

Food Holding - Function & Value . . . . . . . . . 72

General Holding Guidelines . . . . . . . . . . . . . 72

General Holding Cabinet Operation . . . . . . . 73

Holding Temperature Range . . . . . . . . . . . . . 73

Sanitation and Handling . . . . . . . . . . . . . . . . 74

Food Safety Guidelines . . . . . . . . . . . . . . . . . 75

LOW TEMPERATURE

COOKING INTRODUCTION

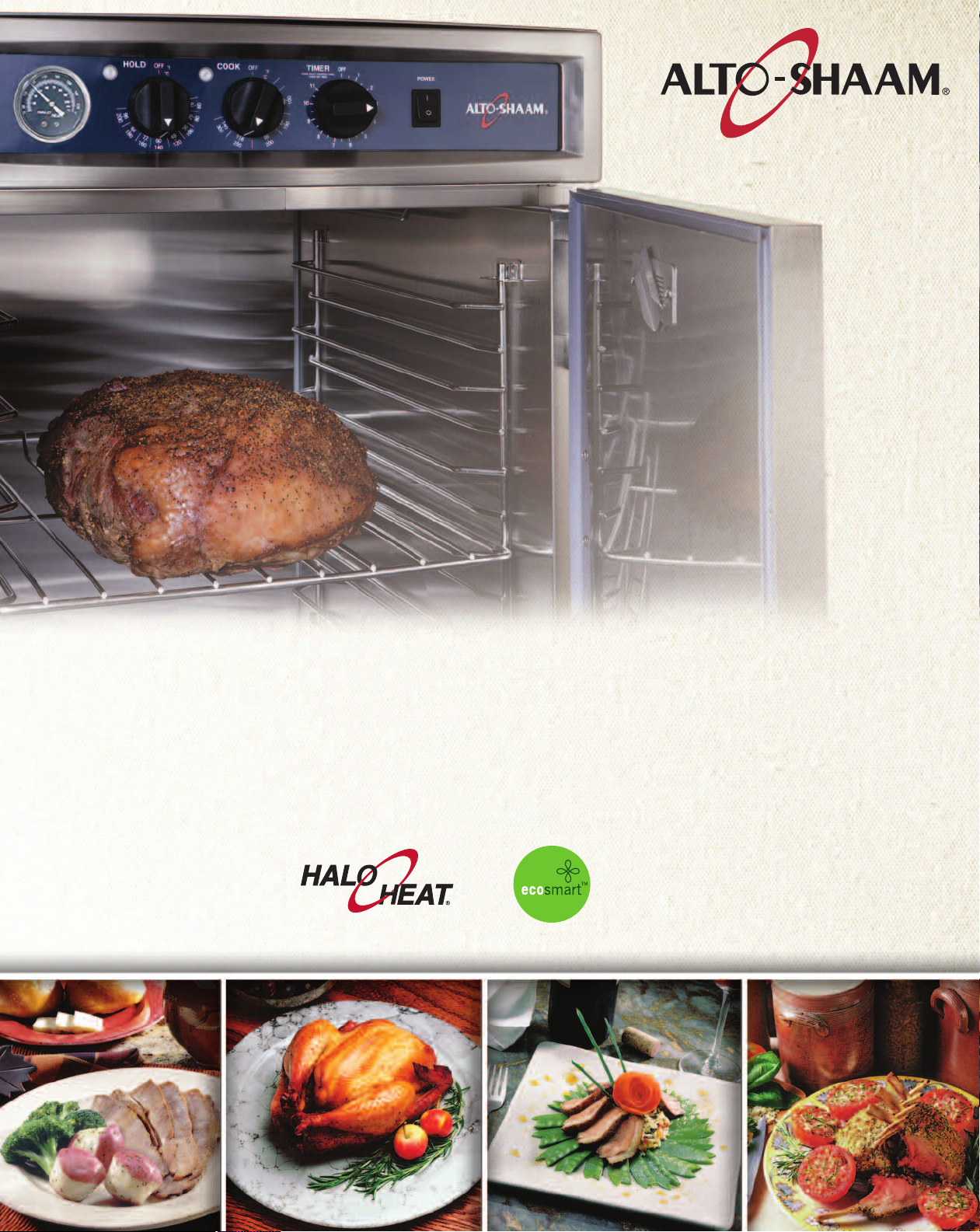

Welcome to the cost saving convenience

of Low Temperature Cooking.

In 1968, Alto-Shaam invented the first

automatic, commercial cook and hold oven

featuring the principle of Halo Heat. The

heating method provided by Halo Heat low

temperature cooking and holding ovens

consists of an electric thermal cable that

encircles the entire cooking and holding

chamber. This creates a gentle blanket or

HALO of radiant heat — surrounding food

with a consistent and uniform temperature

with no air movement inside the oven

compartment. This gentle heating concept

cooks at low temperatures and at a high

level of humidity to preserve product

moisture, flavor, and nutrition. Halo Heat

ovens are designed to convert automatically

from a cooking temperature to a holding

temperature where the product can remain

until it is ready to be served.

Halo Heat is an entirely different system

of cooking. Utilizing this uniform heat

source, Halo Heat dramatically reduces

meat shrinkage; provides natural enzyme

(aging) action for more tender, flavorful

meat; and preserves natural juices along

with nutritional values in all foods. Halo

Heat cooking reduces energy cost, cuts back

on labor and handling, and solves kitchen

space problems. There is no mechanical

ventilation or oven hood necessary in most

areas so the ovens can be moved wherever

they are needed.

Read this booklet carefully. Halo Heat is

a cooking system that requires minimal care

once you have learned the basic principles.

For best results with many products, we

recommend you start your cooking cycle the

evening before — for serving the next day.

In many areas, off-peak power rates are also

lower at night.

If anything you cook in a Halo Heat low

temperature cooking and holding oven

doesn’t meet your highest standards of

quality, please contact one of our food

service professionals for help. Usually, only

a minor change in procedure is required.

SE CTIO N 1 • L OW T EMP ERATU RE COO KIN G I NTRO DUC TION

1.

LOW TEMPERATURE COOKING INTRODUCTION

L OW T E M P E R AT U R E C O O K I N G FAC T S

EAT AND NUTRITION

M

Meat plays a significant role in the diet;

therefore, one of the primary goals in food

preparation is proper nutrition. Meat is one of the

best sources of protein; is a rich source of B

vitamins such as thiamine, riboflavin, and niacin;

and includes fats, carbohydrates, minerals,

pigments, enzymes and water.

All of these elements are affected by cooking,

but over-heating destroys many of them. Low

temperature Halo Heat cooking helps preserve

unstable, heat-sensitive vitamins and nutrients.

A report on the Nutrient Analysis of Roast Beef,

conducted by the University of Wisconsin-Stout

…

in July 1971, concluded, “

Alto-Shaam cooking method results in lower

moisture losses. Even after a 24 hour holding

period, the Alto-Shaam product is nutritionally

equal to, and possibly better than beef roast cooked

in a conventional oven and removed immediately

after cooking.”

Fat contributes greatly to the flavor of meat.

During the cooking process, fat not only melts, but

also changes chemically. With low temperature

cooking there is less chemical change and less fat

melt resulting in a more flavorful finished product.

it is apparent that

Low temperature cooking does not destroy these

enzymes and, particularly in the hold cycle, creates

this natural chemical action to tenderize or age the

meat right in the oven. For this reason, it is

important to use fresh beef and it is essential to

allow the product to remain in the hold cycle for

at least the minimum amount of time suggested

in the individual procedures. The longer meat is

left in the hold cycle the more tender it becomes,

making the purchase of more expensive, aged

meat unnecessary.

Meat is seventy to seventy-five percent water.

High temperatures cause this water to evaporate

during cooking resulting in loss of product

moisture. Cooking at low temperatures in a Halo

Heat oven retains the maximum amount of water

content resulting in a juicier finished product and

an extended holding life.

Along with better nutrition, a more tender

finished product, less shrinkage and higher

moisture content, meat will not require the addition

of as much salt as needed with conventional

cooking methods. Natural flavors are preserved.

This is a significant factor in today’s health

conscious diets.

The enzymes found in meat break down the

tissues and act as natural tenderizing agents. A

premium price is paid for aged meats where this

enzyme action has already started, however;

enzymes are destroyed by high temperatures.

2.

SE CTIO N 1 • L OW T EMP ERATU RE COO KIN G I NTRO DUC TION

LOW TEMPERATURE COOKING INTRODUCTION

L OW T E M P E R AT U R E C O O K I N G FAC T S

SHRINKAGE CONTROL AND COOKING TIME

THERE ARE TWO MAJOR FACTORS CONTROLLING

EAT SHRINKAGE OR COOKING LOSSES.

M

1. Temperature at which meat is cooked:

The higher the temperature at which meat is cooked

the more shrinkage will result. Over-cooked meat

also results in higher losses. Higher temperatures

and over-cooking draws moisture to the surface and

this moisture evaporates or drips out of the meat.

2. Internal temperature of the meat:

Like over-cooking, as meat is brought to a higher

internal temperature shrinkage is increased. For

these two reasons, it is suggested most cuts of red

meat be cooked at 250°F (121°C) and that all cooking

be based on internal product temperature. The use

of a thermometer is encouraged.

THERE ARE FOUR MAJOR FACTORS INVOLVED IN

DETERMINING COOKING TIMES FOR MEAT:

1. The degree of aging on the meat:

Aged meat will cook faster, shrink more, and has a

much shorter holding life than fresh meat.

2. Internal temperature before cooking:

Meat should be placed in a preheated oven directly

from a refrigerated temperature of 38° to 40°F

(3° to 4°C). Meat cooked from a frozen state will

require approximately one and one-half to two times

the normal cooking time. In addition, freezing

ruptures tissue cells creating additional moisture

loss during the cooking process and will result in

more shrinkage.

3. Desired degree of doneness:

The higher the degree of internal temperature

required, the longer the necessary cooking time.

Cooking times in this guideline are based on the

most popular internal product temperatures.

4. Quantity and quality of product.

T O C A L C U L AT E M E A T S H R I N K A G E

STARTING WEIGHT (Weight of Raw Product)

-MIN US: ENDING WEIGHT (Wei ght of Cook ed Product)

E QUA L S: A MO UN T O F SHR IN KAG E

AMO UN T O F S HRI NK AGE ( Tot al W ei g ht L os t i n Coo ki ng)

÷ D I VI DE D B Y: S TA RT IN G WEI GH T ( We igh t o f R aw P rod uc t)

E QUA L S: P ERC EN T O F S HRI NK AGE

E XA MP L E: Raw Beef Roast: 100 l b (45 k g)

Cooked Beef Roast: -95 l b ( -43 k g)

= A MOU NT OF SH RINK AGE: 5. 0 l b (2 k g)

SHRINK AGE D IVID ED BY

STAR TING WEIGH T:

E QUA L S: P ERC ENT OF S HRIN KAGE

PREVENTING BACTERIA GROWTH

The surface of raw meat may become contaminated

in processing, handling by the butcher or chef, or by

other means. Food contamination can also be caused

by unsanitary personal hygiene and work habits,

unclean slicers, knives, and probes, or by faulty

operational procedures. It is important, therefore, that

0.05 = 5 % 0.05 = 5 %

100 5. 0 45 2.0

sanitary procedures be followed at all times during

food preparation and handling. This is your main

protection in guarding against food contamination. For

additional information see the Cle anin g an d

Main ten ance section of this manual.

SE CTIO N 1 • L OW T EMP ERATU RE COO KIN G I NTRO DUC TION

3.

LOW TEMPERATURE COOKING INTRODUCTION

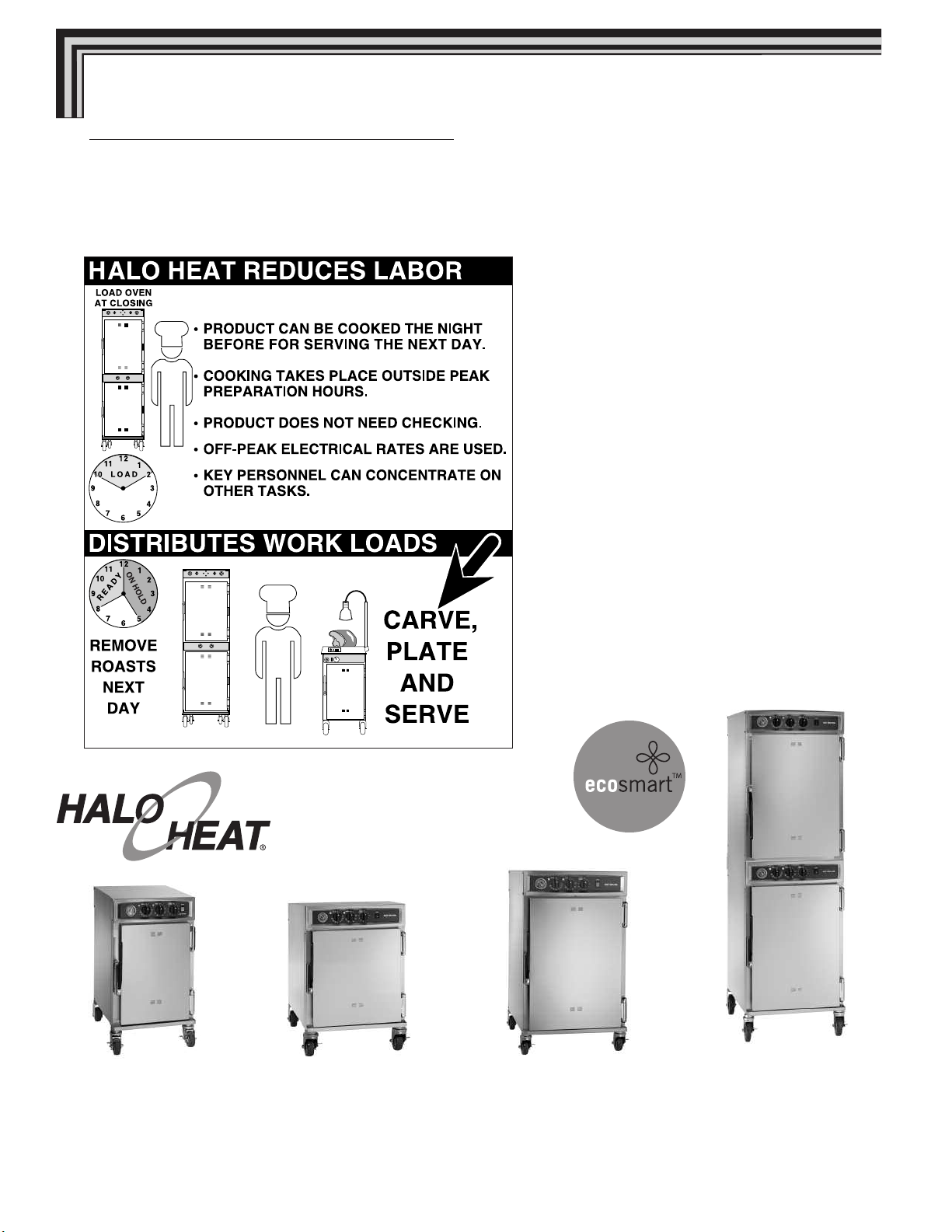

LABOR AND EQUIPMENT COST REDUCTION

Halo Heat ovens are easy to operate and maintain. After the raw product is placed in the oven and the

controls are set, there is no need to check, stir, or adjust the time or the temperature. Minimal time is spent

attending the product during cooking. This advantage, combined with the automatic conversion to the hold

cycle, frees key personnel to concentrate on other tasks including final product and presentation.

When cooking in a Halo Heat oven at a

temperature of 250°F (121°C), outside venting and

expensive exhaust hoods are not necessary in

most areas. Kitchens remain cooler, lowering

energy costs by reducing the exchange of heated

air. Because the ovens do not need outside

venting, they can be put almost anywhere — in

the corner of the kitchen, on a buffet line, or in a

banquet room. The ovens can also be built into a

counter or to save space, can be stacked in

combination with another Halo Heat oven or

holding cabinet of the same or similar

dimensions.

Cooking at low temperatures also reduces

cleaning time. Most food does not normally

carbonize or burn on the interior of the oven.

500-TH SERIES 750-TH SERIES 1000-TH SERIES 1000-TH SERIES

SINGLE COMPARTMENT SINGLE COMPARTMENT SINGLE COMPARTMENT DOUBLE COMPARTMENT

40 lb (18 kg) Capacity 100 lb (45 kg) Capacity 120 lb (54 kg) Capacity 120 lb (54 kg) Capacity

Stackable Design Stackable Design Stackable Design Per Compartment

4.

SE CTIO N 1 • L OW T EMP ERATU RE COO KIN G I NTRO DUC TION

LOW TEMPERATURE COOKING INTRODUCTION

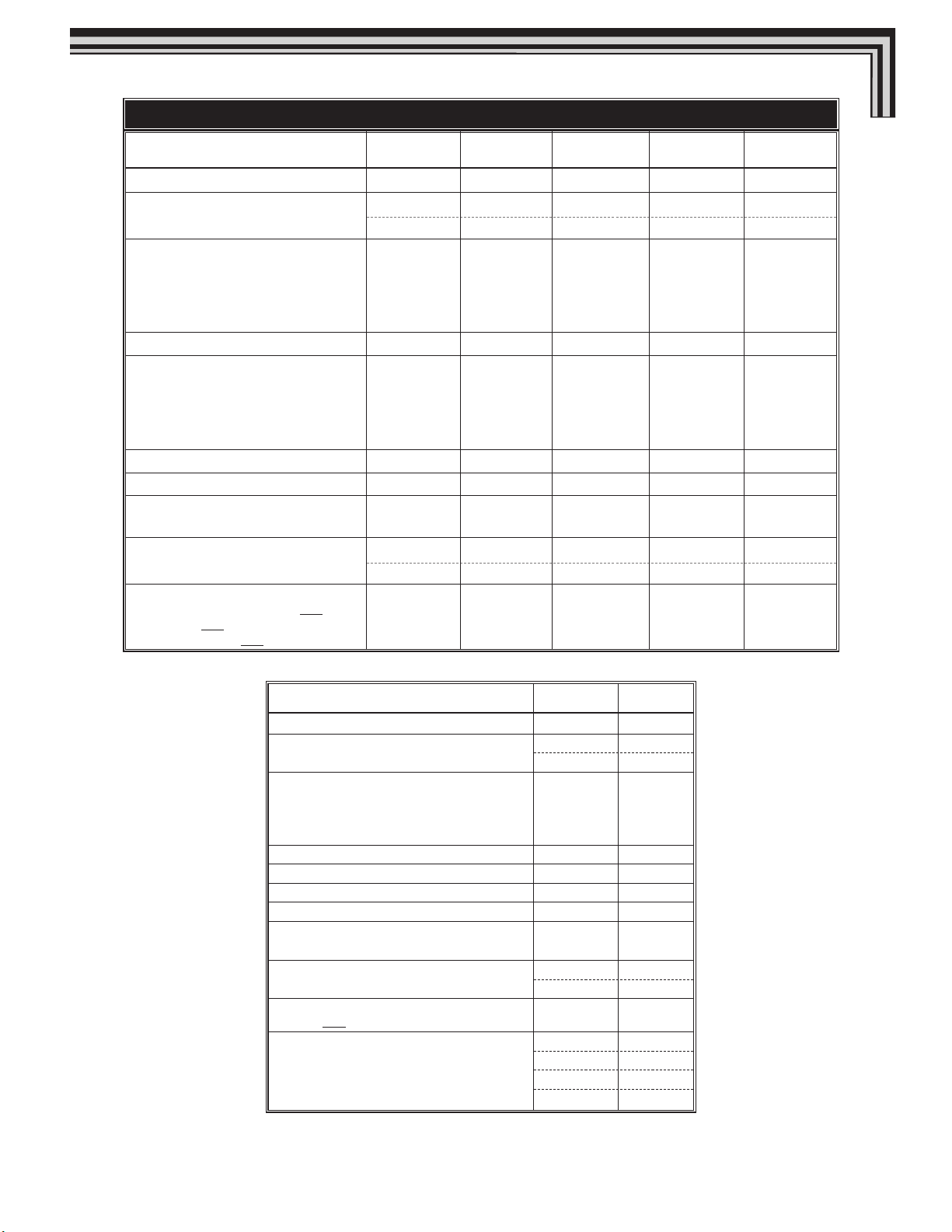

A N U A L C O O K & H O L D O V E N — O P T I O N S & A C C E S SO R I E S

M

DE SCR IPT IO N

10 00- TH- I 10 00- TH- II 1000-TH-II SPLIT 75 0-T H-II 500 -TH-I I

BUMPER FU LL P ERI METER 5009767 5005103 5005103 5004861 5006782

CARVING HOLDER PR IME RI B HL-2635 HL-2635 HL-2635 HL-2635 HL-2635

TE AMSHIP OR CAFET ERI A RO UND

S

WI TH AT TACH ED PAN

4459 4459 4459 4459 4459

CASTER PACKAGE

RI GID, 2 SWIVE L W/BRAKE 5"DI A: STANDAR D STANDAR D 500 4862 5004862 5004862

2

3-1/2" DIA: 5008017 5008017 STA NDA RD STA NDA RD STAND ARD

2-1/2" DIA:— — 5008022 5008022 5008022

DOOR LOCK with KEY E

DRIP PAN

WITH DRAIN

TAND ARD WIT H DR AIN

S

STAN DAR D WI TH D RAIN , 1-11/16":— — — 14831 —

STAN DAR D WI THOU T DR AIN, 1-7/8" 11906 11906 11906 ——

AC H H ANDLE

, 1 -7/16":————14813

LK-22567 LK-22567 LK-22567 LK-22567 LK-22567

LEGS, 6" (O NE SET O F 4) STEMM ED 5011149 5011149 5011149 5004863 5004863

PAN GRID, WIRE 18" X 26" PAN INSERT PN-2115 PN-2115 PN-2115 PN-2115 —

ECU RITY PANE L CONTROL COVER

S

NC LUDES PANEL KE Y L OCK

•I

5005776 5005776 5005776 5004750 5006787

SHELF STA INL ESS ST EEL FL AT W IRE SH-2325 SH-2325 SH-2325 SH-2324 SH-2326

TAINLES S STE EL RIB RACK

S

SH-2773 SH-2773 SH-2773 SH-2743 —

STACKING HARDWARE ——5004864 5004864 5004864

750-TH-II

1000-TH-II

WITH 750-TH-II, 767-SK OR 750-S

500-TH-II

SPLIT WITH 1000-S

WITH 500-TH-II OR 500-S

SM OKE R OPTI ONS A ND MANUAL MAN UAL

ACC ESSOR IES DESC RIP TIO N 7 67- SK 1 76 7-S K

BUMPER FU LL P ERI METER 5004861 5010371

CARVING HOLDER P RIM E R IB HL-2635 HL-2635

4459 4459

CASTER PACKAGE (ONE SET OF 4)

RI GID, 2 SWIVE L W/BRAKE 5" DI A: 5004862 STANDARD

2

3-1/2" DIA: STAN DAR D 5008017

2-1/2" DIA: 5008022 —

DOOR LOCK W ITH KEY EA CH HANDLE LK-2763 LK-2763

DRIP PAN WITH DRAIN 14831 14831

LEGS, 6" (O NE SET O F 4) FL ANGED 5004863 5004863

PAN GRID, WIRE 18 " X 26" PAN I NSE RT PN-2115 PN-2115

SECURITY PANEL CONTROL COVER

IN CLUDES PANEL K EY LOCK 5004750 5004750

SHELVES S TAINLESS S TEE L FLAT WIR E SH-2324 SH-2324

STAINLE SS ST EEL RI B R ACK SH-2743 SH-2743

STACKING HARDWARE

767-SK OVER 767-SK, 750-TH-II, OR 750-S 5004864 —

WOOD CHIPS (20 lb B ULK PAC K) Apple WC-22543 WC-22543

THE TOTAL WEIGHT OF WOOD CHIP BULK

PACKS MAY VARY DUE TO HIGH MOISTURE

CONTENT WHEN PACKAGED

.

Cherry WC-22541 WC-22541

Hickory WC-2829 WC-2829

Sugar Maple WC-22545 WC-22545

SE CTIO N 1 • L OW T EMP ERATU RE COO KIN G I NTRO DUC TION

5.

OPERATION

D A N G E R

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

SEVER E DAMAG E OR

ELECT RICAL H AZA RD

COULD R ESU LT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

OVEN CHARACTERISTICS

The oven is equipped with a special, low-heatdensity, heating cable. Through the Halo Heat

concept, the heating cable is mounted against the

walls of the cooking and holding compartment to

provide an evenly applied heat source, controlled

by an oven sensor. The design and operational

characteristics of the unit eliminates the need for a

moisture pan or a heat circulating fan. Through

even heat application, the food product is cooked

evenly and provides the ability to hold foods for

longer periods of time.

®

START-UP

1. Be fore operating the oven , clean both the

interior and exterior of the unit with a damp

cloth and any good commercial detergent at

the recommended strength. Rinse surfaces by

wiping with a sponge and clean warm water to

remove all detergent residue. Wipe dry with a

clean cloth or air dry.

2. Wipe door gaske ts and control panel dry with

a soft cloth.

3. C lean and in stall the oven side racks, oven

shelves, and external drip tray. Shelves are

installed with curved edge toward the back

of the oven. Insert the drip pan on the interior

bottom surface of the oven.

4. Be fore ope rating the unit with product,

become familiar with the operation of the

controls. Read the following "Control

Description" and "Operation" section of this

cooking guide and begin by operating the

various control functions.

6.

SE CTIO N 2 • O PERAT ION

IoI

o

OPERATION

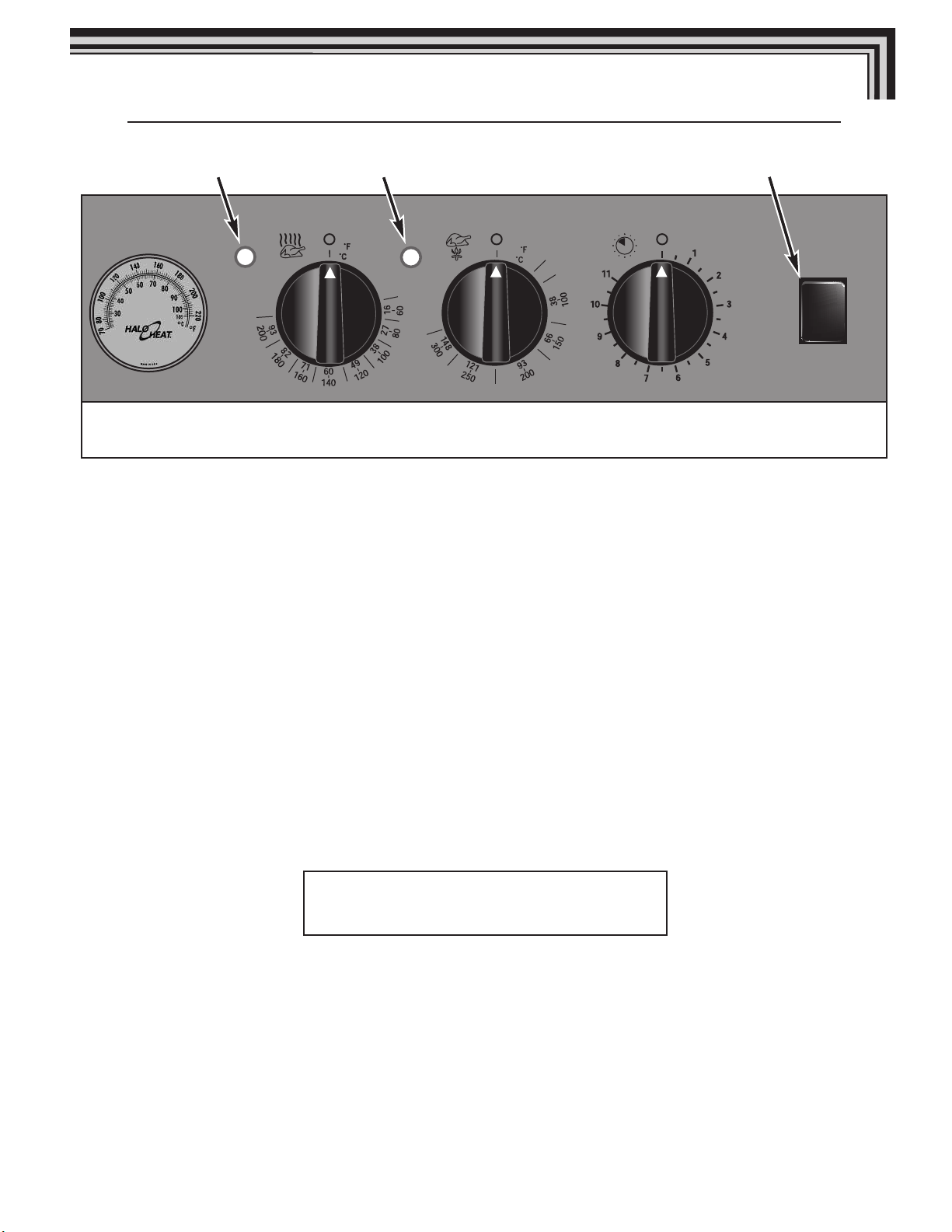

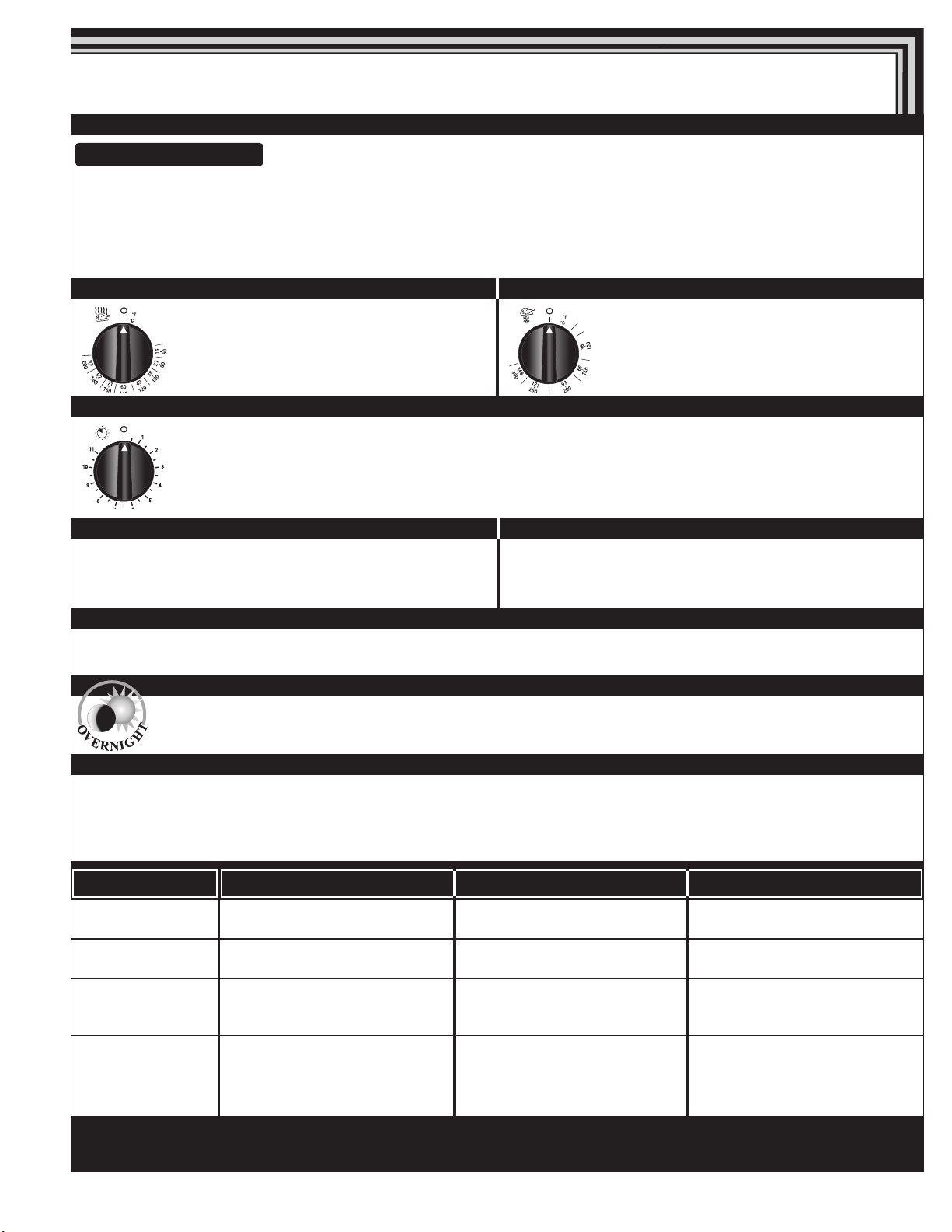

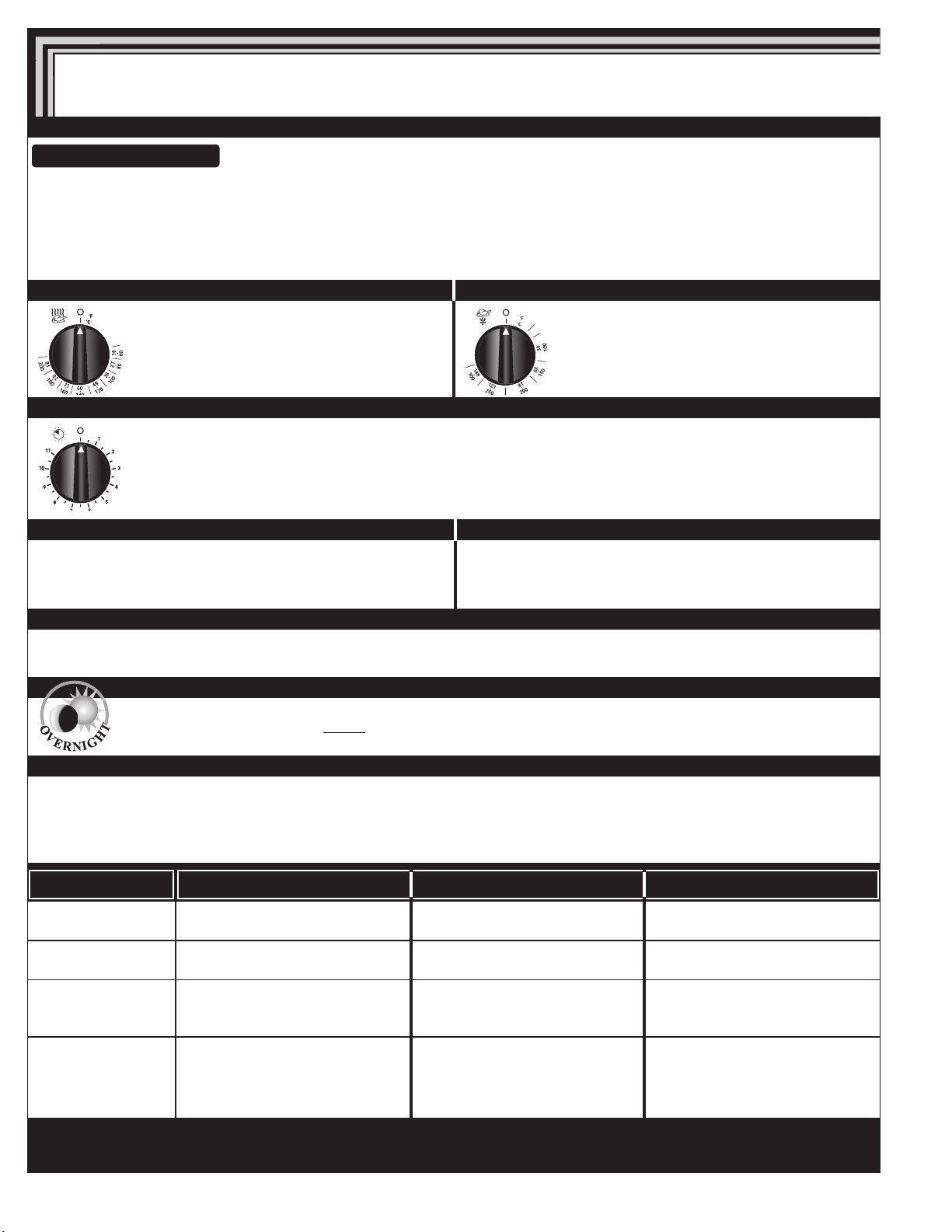

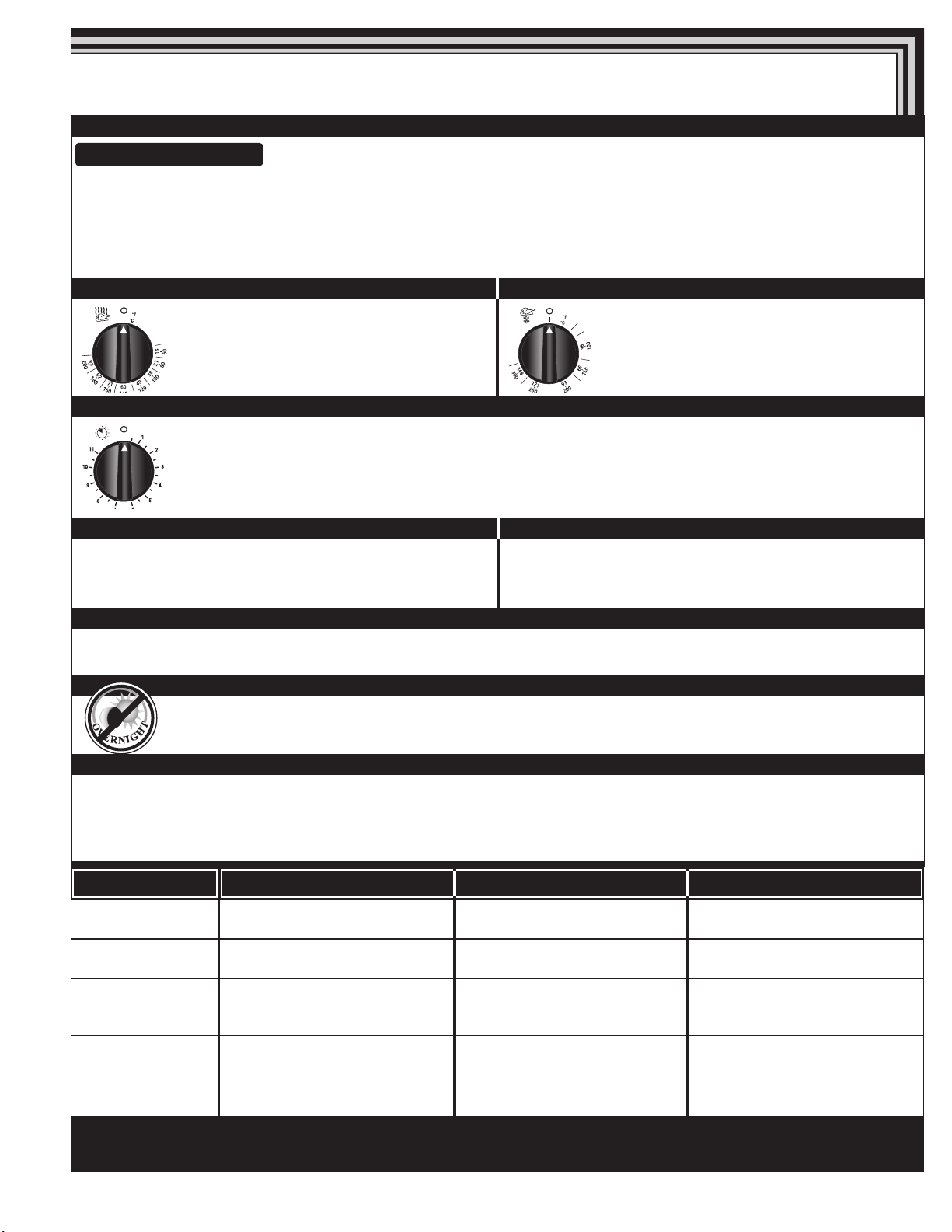

OVEN C O M PA RT M E N T C O N T RO L PANE L I D E N T I F I C ATIO N

HOLDING INDICATOR LIGHT COOKING INDICATOR LIGHT POWER “ON” INDICATOR SWITCH

햲

1. Press oven POWER SWITCH 쐄 “ON.”

• POWER “ ON ” INDICATOR SWITCH will illuminate and will remain lit as long as the power switch

is in the “ON” position.

2. Set “HO LD ” thermostat 쐇 to required holding temperature.

• HOLDING INDICATOR LIGHT will illuminate as the holding thermostat calls for heat.

This process will continue as long as the Power Switch is in the “ON ” position and holding

thermostat is activated.

3. Set “CO OK ” thermostat 쐋 to required cooking temperature.

4. Activate the “ CO OK ” thermostat to preheat the oven by turning the “CO OK IN G” timer 쐏 clockwise.

• COOKING INDICATOR LIGHT and the HOLDING INDICATOR LIGHT will alternately illuminate

as each thermostat calls for heat. This process will continue until the cooking timer cycles or is

turned to the “OFF” position.

햳

HOLD THERMOSTAT

햴

COOK THERMOSTAT

햵

COOKING TIMER

햶

TEMPERATURE GAUGE 쐃 will indicate the

air temperature inside the oven compartment.

SE CTIO N 2 • O PERAT ION

7.

OPERATION

COOKING and HOLDING PROCEDURES — MANUAL OVENS

1. P RE PAR E O VE N FOR CO OK IN G

A. Insert and adjust the required number of

helves inside the cooking compartment.

s

Place the curved edge of the shelf toward

the back of the oven.

B. Adjust the inside door vents as indicated in

the individual cooking procedure selected.

C. Insert drip pan directly on the bottom surface

of the oven compartment.

2. P RE HE AT O VE N

A. Press power switch 쐄 “

ON.”

B. Set the HOLD thermostat 쐇 to the required

holding temperature.

5. C LO SE DOOR

A. Keep door closed during the cooking cycle

6. R ES ET COOKING TIMER

FOR C OR RE CT NUMBER O F H OU RS .

A. To set time, turn the timer knob 쐏 past the

required number of hours then immediately

bring it back to the correct setting.

B. Refer to individual cooking instructions for

length of time necessary to cook.

C. When timer cycles to the “

OFF” position,

the temperature automatically lowers to

the selected HOLD temperature.

D. The product will continue to cook as the oven

C. Set the COOK thermostat 쐋 to the required

cooking temperature.

D. Turn the timer knob 쐏 clockwise to activate

the COOK thermostat.

E. Allow oven to preheat for 45 minutes.

3. P RE PAR E P RO DU CT FO R C OO KI NG

A. Refer to individual cooking instructions.

4. L OA D P RO DU CT ON S HE LVES

A. Refer to individual cooking instructions.

DO

NOT overload the oven.

B. Most meat products are cooked directly on

wire shelves. For many products, the use of

temperature lowers to the selected holding

temperature and must remain in the oven, at

the selected HOLD temperature, for the

minimum number of hours indicated in the

individual cooking instructions.

7. O VE RN IG HT COOK A ND HOLD

A. For maximum product tenderizing and to

reduce labor during peak preparation hours,

overnight cook and hold is highly

recommended for many products.

Refer to individual cooking instructions.

CO NTINUED

pans is not recommended.

8.

SE CTIO N 2 • O PERAT ION

OPERATION

COOKING and HOLDING PROCEDURES — MANUAL OVENS

8. D ET ER MI NI NG I F P RO DU CT

IS SUFFICIENTLY CO OK ED

A. Allow COOK timer to cycle to the

“O FF” position.

B. Before opening the oven door, leave the

product in the HOLD cycle for a minimum of

one hour. This time period will allow the

oven temperature to decrease from the COOK

setting to the selected HOLD temperature.

During this one hour period, the product will

continue to cook.

C. Insert a thermometer into the center of the

product to determine if the correct internal

temperature has been reached.

R E D M E AT:

RARE: 130° to 135°F

(54° to 57°C)

MEDIUM: 140° to 145°F

(60° to 63°C)

WELL: 155° to 160°F

(66° to 71°C)

D. When following the procedures in the

individual product cooking instructions,

additional cooking time should not be

necessary. If, however, the required internal

product temperature has not been reached

after the product has remained in the HOLD

cycle for the one hour minimum time period,

additional cooking time may be added.

Use the same COOK temperature set for the

original cooking cycle until the correct

internal temperature has been reached.

In the United States, FDA food code

requires products such as red meat to

remain in “HOLD” for a specified time

period. This holding time requirement

s based o n t he i nte rna l p ro duct

i

temperature desired for the finished

product and includes the one hour

time period while the oven decreases

from the cooking temperature to the

holding temperature and the product

continues to cook.

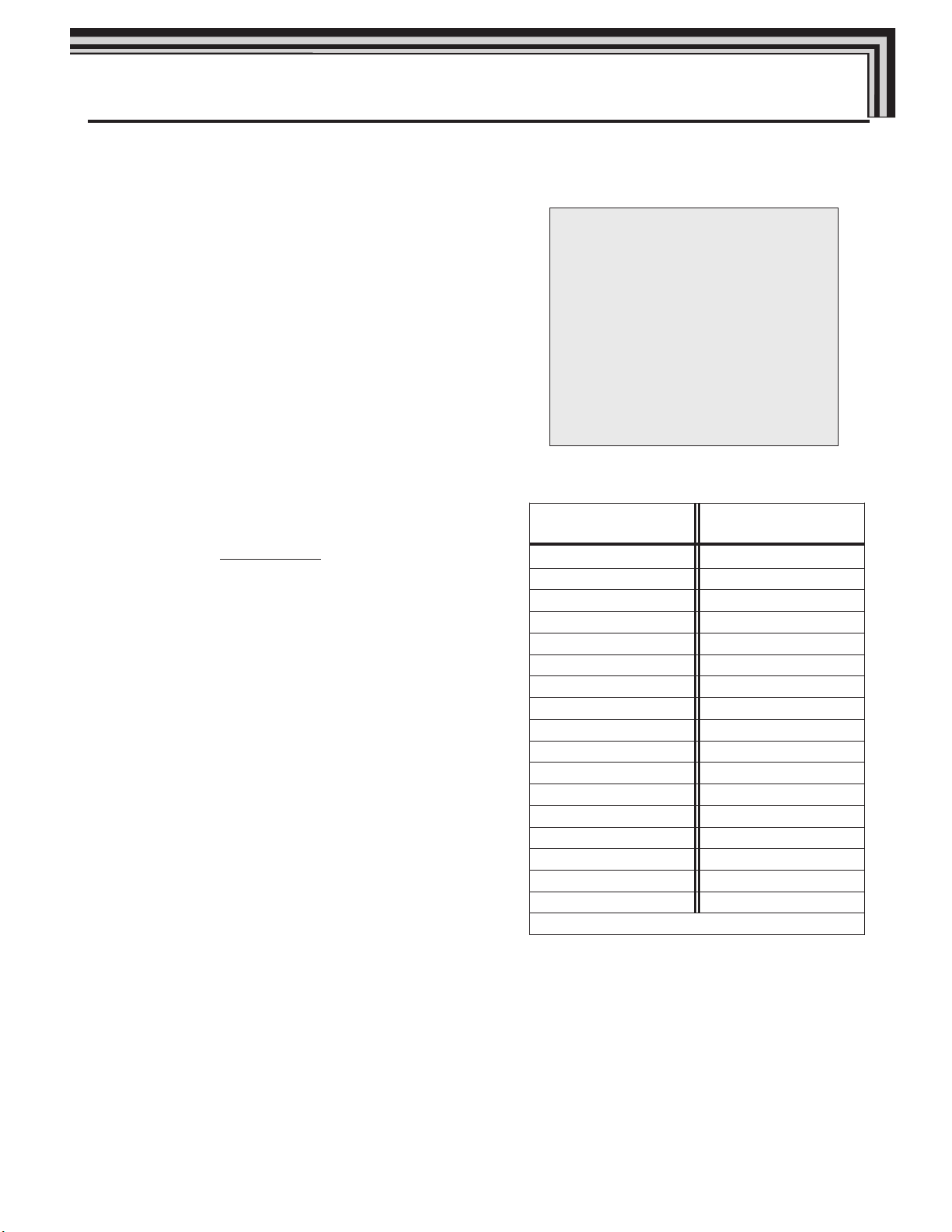

IN TER NAL PR ODU CT

TE MPE RATUR E

130°F (54°C) 1 HOUR, 52 MINUTES

131°F (55°C) 1 HOUR, 29 MINUTES

133°F (56°C) 56 MINUTES

135°F (57°C) 36 MINUTES

136°F (58°C) 28 MINUTES

138°F (59°C) 18 MINUTES

140°F (60°C) 12 MINUTES

142°F (61°C) 8 MINUTES

144°F (62°C) 5 MINUTES

145°F (63°C) 4 MINUTES

147°F (64°C) 2 MINUTES, 14 SECONDS

149°F (65°C) 1 MINUTES, 25 SECONDS

151°F (66°C) 54 SECONDS

153°F (67°C) 34 SECONDS

155°F (68°C) 22 SECONDS

157°F (69°C) 14 SECONDS

158°F (70°C) 0 SECONDS

*HOLDING TIME MAY INCLUDE POST-OVEN HEAT RISE

TI ME * IN H OLD C YCLE

EQ UIR ED B Y FOO D CO DE

R

SE CTIO N 2 • O PERAT ION

9.

OPERATION

COOKING and HOLDING PROCEDURES — MANUAL OVENS

9. R E H E A T I N G

A. Any over production must be removed

from the oven, wrapped, rapidly chilled,

and refrigerated.

B. Product can be removed from refrigerator,

returned to the oven, and reheated the

next day.

C. Products must be reheated at a temperature

range of 250° to 275°F (121° to 135°C). Refer

to individual cooking instructions for the

correct thermostat setting for the product

being reheated.

D. Length of time necessary to reheat a product

depends on the type of product and the

quantity to be reheated. Time should be

based on internal product temperature.

Use a pocket thermometer to determine

the internal product temperature of the

reheated product.

10. C A R E A N D C L E A N I N G

A. Clean interior oven cavity, wire shelves, and

drip pan daily, at the end of each cook and

hold cycle.

B. Refer to Care and

Cleaning

instructions

in Section 3.

United Sates food code requirements

indicate cooked foods that have been

cooled, followed by reheating for hot

food holding, must be reheated to

165°F (74°C). The temperature of

165°F (74°C) must be maintained for

a period 15 seconds.

Always follow federal and local health

(hygiene) codes for the time and internal

temperature required for reheating products.

10 .

SE CTIO N 2 • O PERAT ION

C H E F O P E R ATIN G T I P S

OPERATION

. For cooking specific products, refer to

1

individual cook and hold instructions.

2. To set time, turn the timer knob past the

required number of hours, then immediately

bring it back to the correct setting.

3. When cooking at 250°F (121°C), it takes

approximately one hour for the cooking

temperature to decrease to the selected

holding temperature. During this one hour

time period, the product will continue to cook.

4. The cooking times in this guide are based on

meat taken directly from a refrigerated

temperature of 38° to 40°F (3.3° to 4.4°C), and

placed in a preheated oven. Adjustments must

be made for cooking products at other than

refrigerated temperatures.

5. It is recommended the oven door remain

closed during the cooking cycle. Opening the

door will only increase the length of time

necessary to cook the product.

6. Puncturing an item with any sharp instrument

may introduce bacteria inside the product.

Avoid using a fork to handle products, and

always use standard sanitary methods when

handling any food item.

11. Since there is no air

movement inside the

Halo Heat

®

low

temperature cooking and

holding oven, condensation will

form on the inside of the door during

operation and may leak out of the oven door

vents. This is a normal operating condition,

however; any condensation spilling on the

floor should be periodically wiped as a safety

precaution. There is an External Drip Tray

included as standard with most ovens.

12. Drip pan overflow is a condition caused by

cooking some cuts of beef to an internal

temperature in excess of 130°F (54°C). The

External Drip Tray will help alleviate some of

this overflow problem. There is also an extra

large drip pan available as an option for the

1000-TH series ovens.

13. Overflow may also be caused by overloading

the oven compartment. DO NOT OVERL OAD

TH E OVEN. Follow the recommended load

capacities listed in each individual procedure.

14. For best results, many products should be

cooked on an overnight cook-and-hold basis.

Consult individual procedures for this

recommendation.

7. Use a thermometer to check the internal

temperature of a product. Be certain to

sanitize the thermometer before each use.

8. Aged meat will cook faster, shrink more, and

cannot be held as long as fresh meat. Because

of the tenderizing capabilities of the oven, aged

meat or tenderizing agents such as M.S.G. are

not necessary, and are not recommended.

9. When cooking full loads, never cook below the

second shelf spacing from the bottom of the

oven compartment.

10. Fully clean the oven interior, drip pan, shelves,

and side racks on a daily basis.

SE CTIO N 2 • O PERAT ION

?

P

L

E

H

ME

SO

D

E

E

N

The Alto- Shaa m st aff incl udes cor p orat e

exec utiv e che fs w ho we lcom e que stio n s.

You a re i nvit ed t o c onta ct a nyon e on our

staff by ph one ( 800. 5 58. 8 744 ) or e -mai l

through t he Con tact U s sect ion of o ur

web s ite (www. a lt o-shaa m .co m) f or help

with an y c ook a nd hold procedu re.

11 .

CLEANING & MAINTENANCE

C A U T I O N

TO PROTECT STAINLESS STEEL

SURFACES, COMPLETELY AVOID

THE USE OF ABRASIVE CLEANING

COMPOUNDS, CHLORIDE BASED

CLEANERS, OR CLEANERS

CONTAINING QUATERNARY SALTS.

NEVER USE HYDROCHLORIC ACID

(MURIATIC ACID) ON STAINLESS

STEEL. NEVER USE WIRE

BRUSHES, METAL SCOURING

PADS OR SCRAPERS.

N

O

S

C

R

A

P

E

R

S

N

O

W

I

R

E

B

R

U

S

H

E

S

N

O

S

T

E

E

L

P

A

D

S

PR O T EC TI NG STAINLESS S TE EL SURFACES

It is important to guard against

corrosion in the care of

stainless steel surfaces.

Harsh, corrosive, or

inappropriate chemicals can

completely destroy the

protective surface layer of stainless steel.

Abrasive pads, steel wool, or metal implements

will abrade surfaces causing damage to this

protective coating and will eventually result in

areas of corrosion. Even water, particularly hard

water that contains high to moderate

concentrations of chloride, will cause oxidation

and pitting that result in rust and corrosion. In

addition, many acidic foods spilled and left to

remain on metal surfaces are contributing factors

that will corrode surfaces.

Proper cleaning agents, materials, and

methods are vital to maintaining the appearance

and life of this appliance. Spilled foods should be

removed and the area wiped as soon as possible

but at the very least, a minimum of once a day.

Always thoroughly rinse surfaces after using a

cleaning agent and wipe standing water as quickly

as possible after rinsing.

C L EA NING A GE NT S

Use non-abrasive cleaning products designed for

use on stainless steel surfaces. Cleaning agents

must be chloride-free compounds and must not

contain quaternary salts. Never use hydrochloric

acid (muriatic acid) on stainless steel surfaces.

Always use the proper cleaning agent at the

manufacturer's recommended strength.

Contact your local cleaning supplier for

product recommendations.

C L EA NING M ATE RI AL S

The cleaning function can usually be accomplished

with the proper cleaning agent and a soft, clean

cloth. When more aggressive methods must be

employed, use a non-abrasive scouring pad on

difficult areas and make certain to scrub with the

visible grain of surface metal to avoid surface

scratches. Never use wire brushes, metal scouring

pads, or scrapers to remove food residue.

C L E A N I N G A N D P R E V E N T I V E M A I N T E N A N C E

12 .

SE CTIO N 3 • C LEAN ING & MA INT ENAN CE

CONTINUED

CLEANING & MAINTENANCE

D A N G E R

DISCO NNECT U NIT F RO M

POWER S OURCE B EFO RE

CLEAN ING O R SE RVICI NG.

D A N G E R

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

SEVER E DAMAG E OR

ELECT RICAL H AZA RD

COULD R ESU LT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

The cleanliness and appearance of this equipment will contribute considerably to operating

efficiency and savory, appetizing food. There is an important relationship between

leanliness and food flavor and aroma. Good equipment that is kept clean works

c

better and lasts longer.

Under normal circumstances, this oven should provide you with long and trouble-

free service. There is no preventative maintenance required, however, the following

Equipment Care Guide will maximize the potential life and trouble-free operation of this oven.

2. CLEAN THE EXTERIOR OF THE CABINET

WITH A STAINLESS STEEL POLISH.

To help maintain the protective film coating on

polished stainless steel, clean the exterior of the

cabinet with a cleaner recommended for

stainless steel surfaces. Spray the cleaning

1. CLEAN DAILY

Disconnect the oven from the power source.

Remove all detachable items such as wire

shelves, side racks, and drip pans. Clean these

items separately. Clean the interior metal

surfaces of the oven with a damp, clean cloth

and any good commercial detergent or grease

solvent at the recommended strength. Use a

plastic scouring pad or oven cleaner for

difficult areas. Rinse carefully to remove all

residue and wipe dry.

agent on a clean cloth and wipe with the grain

of the stainless steel.

3. CHECK OVERALL CONDITION

OF THE OVEN ONCE A MONTH.

Check the oven once a month for physical

damage and loose screws. Correct any

problems before they begin to interfere with the

operation of the oven.

4. CHECK THE COOLING FAN

IN THE OVEN CONTROL AREA.

NOTE: Avoid the use of

abrasive cleaning

compounds, chloride

based cleaners, or

cleaners containing

quaternary salts.

Never use hydrochloric acid (muriatic

acid) on stainless steel. Always follow

appropriate state or local health

(hygiene) regulations regarding all

applicable cleaning and sanitation

requirements for equipment.

While the oven is warm, check that the cooling

fan in the oven control area is functioning.

The fan is located on the back of the unit,

toward the top.

SE CTIO N 3 • C LEAN ING & MA INT ENAN CE

13 .

COOKING GUIDELINES

C O O K I N G G U I D E L I N E I N D E X

BE E F

Beef Brisket . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Beef Short Ribs . . . . . . . . . . . . . . . . . . . . . . . .16

Beef Striploin . . . . . . . . . . . . . . . . . . . . . . . . .17

Corned Beef . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Hamburgers . . . . . . . . . . . . . . . . . . . . . . . . . .19

Prime Rib (#109) . . . . . . . . . . . . . . . . . . . . . . .20

Prime Rib, Special . . . . . . . . . . . . . . . . . . . . . .21

Ribeye Roll . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Beef Round . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Beef Round, C

Tenderloin . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Veal Loin . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

AFETERIA/STEAMSHIP

. . . . . . . . . . .24

L A MB

Lamb, Leg . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Lamb Racks (Frenched) . . . . . . . . . . . . . . . . .28

P ORK

Ham, Fresh . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Ham, Cured & Smoked . . . . . . . . . . . . . . . . . .30

Pork Chops . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Pork Loin . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Pork Shoulder . . . . . . . . . . . . . . . . . . . . . . . . .33

Pork Ribs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

P ROCESSED ME AT S

Sausage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

P OU LT RY

Chicken Breasts . . . . . . . . . . . . . . . . . . . . . . . .36

Chicken, Pieces & Halves . . . . . . . . . . . . . . . .37

Chicken, Whole . . . . . . . . . . . . . . . . . . . . . . . .38

Chicken, Fried TWO-STEP M ETHOD . . . . . . . . . . . .39

Cornish Hens . . . . . . . . . . . . . . . . . . . . . . . . .40

Duck, Whole . . . . . . . . . . . . . . . . . . . . . . . . . .41

Turkey, Whole . . . . . . . . . . . . . . . . . . . . . . . . .42

Turkey Breast . . . . . . . . . . . . . . . . . . . . . . . . .43

Turkey Roll . . . . . . . . . . . . . . . . . . . . . . . . . . .44

F ISH

ish, Baked

F

Salmon Steaks . . . . . . . . . . . . . . . . . . . . . . . . .46

Trout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

IL LET S

F

. . . . . . . . . . . . . . . . . . . . .45

.

MI SCELLA N E OUS

Potatoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Quiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Rice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Baked Egg Custard . . . . . . . . . . . . . . . . . . . . .51

Sheet Cake . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Cheese Cake . . . . . . . . . . . . . . . . . . . . . . . . . .53

Frozen Convenience Entrée

Frozen Convenience Entrée PORTIONED . . . . . . . . .55

Frozen Finger Foods . . . . . . . . . . . . . . . . . . . .56

Breakfast Sandwiches . . . . . . . . . . . . . . . . . . .57

Cookies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Doughnuts . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Proofing Dough . . . . . . . . . . . . . . . . . . . . . . . .60

PANS . . . . . . . . . . . . . . . .54

SMOKE D F OODS

Beef Brisket . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Beef Tongue . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Ham, Fresh . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Pork Ribs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Duck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Turkey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Fish Fillets . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Salmon, Whole . . . . . . . . . . . . . . . . . . . . . . . .69

Shrimp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Salmon, Cold Smoked . . . . . . . . . . . . . . . . . . .71

O V E N P R E H E A T I N S T R U C T I O N S

BEFOR E COOKI N G PRO D UCT:

1. Tu rn powe r s witc h “ O N .”

2. S et the H OLD t herm osta t t o t he requ ire d h oldi n g t empe ratu re.

3. S et the C OOK t herm osta t t o t he requ ire d c ooki n g t empe ratu re.

4. Tu rn the t imer kno b c lock wise to a ctiv ate t he COOK the rmos tat.

5. A llow ov en to p reh eat u ntil the CO OK Indic ator Li ght g oes o u t.

14.

SECTIO N 4 • B EEF

COOKING GUIDELINES

BEE F BRI S K E T

P R O DUCT S P E CIFI C A TION S a n d P R E PAR A T ION

P R E HEAT T H E O V E N

Season brisket and wrap individually in clear plastic wrap for cooking. Place wrapped brisket directly on wire shelves.

D O O R V E N T S : O N E - H A L F O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

Beef Brisket, Fresh: 9 to 13 l b (4 to 6 kg)

160°F

(71°C)

250°F

(121°C)

S E T C O OKIN G T I MER

20 minutes per pound for the first roast (44 minutes per kilogram)

plus

add 30 minutes for each additional roast.

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

6 hours

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

24 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

165°F (73°C)

O V E RNIG H T C O O K & H O L D

Highly Recommended

A D D ITIO N A L I N F O R M AT I O N • N O T E S

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

323

1 roast 3 to 4 roasts 2 to 3 roasts

3 roasts

up to 40 lb (18 kg)

6 to 8 roasts

up to 100 lb (45 kg)

none none none

SECTIO N 4 • B EEF

6 to 9 roasts

up to 100 lb (45 kg)

15.

COOKING GUIDELINES

BEE F SHO R T R I B S

R O D UCT S P E C I F I CAT I O N S a n d P R E PAR A T ION

P

P R E HEAT T H E O V E N

eason as desired. Place ribs side-by-side in pans.

S

For an overnight cook and hold, cover pans loosely with clear plastic wrap to retain additional

product moisture.

D O O R V E N T S : O N E - H A L F O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

Short Ribs: 1 0 to 12 oz. pieces

160°F

(71°C)

250°F

(121°C)

S E T C O OKIN G T I MER

3 hours for the first pan

plus

add 30 minutes for each additional pan.

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

6 hours

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

18 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

170° to 190°F (77° to 88°C)

O V E RNIG H T C O O K & H O L D

MUST

do an overnight cook and hold.

A D D ITIO N A L I N F O R M AT I O N • N O T E S

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

16.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

33none

1 half-size sheet pan 1 full-size sheet pan 1 full-size sheet pan

3 half-size sheet pans 3 full-size sheet pans 4 full-size sheet pans

18" x 13" x 1"

1

/1: 530 x 325 x 20mm)

(GN

(N O SHELVES REQUIRED)

18" x 26" x 1"

2

/1: 530 x 650 x 20mm)

(GN

(N O SHELVES REQUIRED)

SECTIO N 4 • B EEF

(GN

18" x 26" x 1"

1

/1: 530 x 325 x 20mm)

(O N WIRE SHELVE S)

COOKING GUIDELINES

BEE F STR I P L O I N

P R O DUCT S P E CIFI C A TION S a n d P R E PAR A T ION

P R E HEAT T H E O V E N

Season as desired. Place roasts directly on the wire shelves with fat side down. Place larger roasts toward the top of the

oven compartment.

D O O R V E N T S : O N E - H A L F O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

Loin, Strip Loin, Short-C ut, Boneless : 8 to 1 2 lb (4 to 5 kg )

140°F

(60°C)

250°F

(121°C)

S E T C O OKIN G T I MER

8 to 10 lb ROA STS (4 t o 4,5 kg):

8 minutes per pound for the first roast

(18 Minutes per kilogram)

plus add 8 minutes for each additional roast

12 lb ROASTS (5 kg ):

10 minutes per pound for the first roast

(22 Minutes per kilogram)

plus add 8 minutes for each additional roast

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

4 hours

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

12 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

130°F (54°C) RARE

O V E RNIG H T C O O K & H O L D

Optional

A D D ITIO N A L I N F O R M AT I O N • N O T E S

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

223

2 roasts 4 roasts 3 roasts

4 roasts

up to 40 lb (18 kg)

8 roasts

up to 100 lb (45 kg)

none none none

SECTIO N 4 • B EEF

9 roasts

up to 100 lb (45 kg)

17.

COOKING GUIDELINES

COR N E D BE E F

R O D UCT S P E C I F I CAT I O N S a n d P R E PAR A T ION

P

P R E HEAT T H E O V E N

Corned Beef: 9 to 12 l b (4 to 5 kg)

Leave the corned beef in the original plastic bag and place the corned beef bag directly on the wire shelf.

D O O R V E N T S : O N E - H A L F O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

160°F

(71°C)

250°F

(121°C)

S E T C O OKIN G T I MER

20 minutes per pound for the first corned beef (44 minutes per kilogram)

plus

add 30 minutes for each additional corned beef.

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

6 or more hours

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

24 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

175°F (79°C)

O V E RNIG H T C O O K & H O L D

MUST

DO AN OVERNIGHT COOK AND HOLD.

A D D ITIO N A L I N F O R M AT I O N • N O T E S

If desired, corn beef can be removed from the bag and wrapped in clear plastic wrap for cooking.

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

18.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

223

2 roasts 3 to 4 roasts 2 to 3 roasts

4 roasts

up to 40 lb (18 kg)

6 to 8 roasts

up to 100 lb (45 kg)

none none none

SECTIO N 4 • B EEF

6 to 9 roasts

up to 100 lb (45 kg)

HAM B U R G E R S

P R O DUCT S P E CIFI C A TION S a n d P R E PAR A T ION

P R E HEAT T H E O V E N

Place hamburger patties side-by-side directly on sheet pans.

D O O R V E N T S : F U L L O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

Ground Beef (fresh, not frozen): 5 oz (142 gr ams) p er patty (M

Ground Beef, frozen: 5 oz (142 g rams) per pa tty (

COOKING GUIDELINES

IN IMUM

)

MI NIMUM )

150°F

(66°C)

250° to 275°F

(121° to 135°C)

S E T C O OKIN G T I MER

FRESH, NOT FROZEN: Approximately 1 hour*

FROZEN: 2-3 hours

Full Load

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

none

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

4 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

165°F (74°C)

O V E RNIG H T C O O K & H O L D

Not Recommended

A D D ITIO N A L I N F O R M AT I O N • N O T E S

*Cooking time depends on the desired degree of doneness. Check internal product temperature before removing the

product from the oven. Always follow local health (hygiene) regulations for all internal temperature requirements.

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

55none

1 half-size sheet pan 1 full-size sheet pan 1 full-size sheet pan

5 half-size sheet pans 5 full-size sheet pans 4 full-size sheet pans

18" x 13" x 1"

1

/1: 530 x 325 x 20mm)

(GN

(N O SHELVES REQUIRED)

(GN2/1: 530 x 650 x 20mm)

SECTIO N 4 • B EEF

18" x 26" x 1"

(N O SHELVES REQUIRED)

18" x 26" x 1"

(GN1/1: 530 x 325 x 20mm)

(O N WIRE SHELVE S)

19.

COOKING GUIDELINES

PRI M E RI B

R O D UCT S P E C I F I CAT I O N S a n d P R E PAR A T ION

P

P R E HEAT T H E O V E N

Season as desired. Place roasts directly on wire shelves with the larger roasts toward the top of the oven compartment.

D O O R V E N T S : O N E - H A L F O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

Beef Rib, Roast Ready, with Fat Cap, #109: 2 0 lb (9kg) Average We ight

140°F

(60°C)

250°F

(121°C)

S E T C O OKIN G T I MER

10 minutes per pound for the first roast (22 minutes per kilogram)

plus

add 30 minutes for each additional roast.

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

4 to 6 hours

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

24 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

130°F (54°C) RARE

O V E RNIG H T C O O K & H O L D

Highly Recommended

A D D ITIO N A L I N F O R M AT I O N • N O T E S

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

20.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

223

1 roast 3 roasts 2 roasts

2 roasts

40 lb (18 kg)

6 roasts

120 lb (54 kg)

none none none

SECTIO N 4 • B EEF

6 roasts

120 lb (54 kg)

COOKING GUIDELINES

PRI M E RI B SPE C I A L

P R O DUCT S P E CIFI C A TION S a n d P R E PAR A T ION

P R E HEAT T H E O V E N

Season as desired. Place roasts directly on wire shelves with the larger roasts toward the top of the oven compartment.

D O O R V E N T S : O N E - H A L F O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

Beef Rib, Roast Ready S pecial, T ied: 14 to 1 8 lb (6 to 8 kg ) Av erage We ight

140°F

(60°C)

250°F

(121°C)

S E T C O OKIN G T I MER

10 minutes per pound for the first roast (22 minutes per kilogram)

plus

add 15 minutes for each additional roast.

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

4 hours

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

24 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

130°F (54°C) RARE

O V E RNIG H T C O O K & H O L D

An overnight cook and hold can be done with this cut.

A D D ITIO N A L I N F O R M AT I O N • N O T E S

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

223

1 roast 3 roasts 2 roasts

2 roasts

36 lb (16 kg)

6 roasts

100 lb (45 kg)

none none none

SECTIO N 4 • B EEF

6 roasts

100 lb (45 kg)

21.

COOKING GUIDELINES

RIB E Y E

R O D UCT S P E C I F I CAT I O N S a n d P R E PAR A T ION

P

P R E HEAT T H E O V E N

Season as desired. Place roasts directly on the wire shelves, fat side down. Place larger roasts toward the top of the

oven compartment.

D O O R V E N T S : O N E - H A L F O P E N

S E T H O LD T H E R M O S TAT S E T C O OK T H E R M O S TAT

Beef Ribeye Roll, Lip On, #112A: 8 to 12 lb (3 to 5 kg)

140°F

(60°C)

250°F

(121°C)

S E T C O OKIN G T I MER

8 to 11 lb (4 to 5 k g) ROASTS: 8 minutes per pound for the first roast (18 minutes per kilogram)

plus add 10 minutes for each additional roast.

12 lb (5 kg) ROAST S: 10 minutes per pound for the first roast (22 minutes per kilogram)

plus add 10 minutes for each additional roast.

M I N I M U M H O L D I N G T I M E R E Q U I R E D M A X I M U M H O L D I N G T I M E

4 hours

TI ME RE QU IRED I N “HOLD” C YC LE B EF ORE S ERV ING.

12 hours

F I N A L I N T E R N A L P R O D U C T T E M P E R A T U R E

130°F (54°C) RARE

O V E RNIG H T C O O K & H O L D

Optional

A D D ITIO N A L I N F O R M AT I O N • N O T E S

M O D E L S

NUMBER OF SHELVES

ITEMS PER SHELF

APPROXIMATE

MAXIMUM CAPACIT Y

PANS

CAPACITIES ARE BASED ON U.S.

PAN SIZES. GASTRONORM PANS

MAY HOLD MORE OR LESS THAN

THE FOOD QUANTITIES INDICATED

The time an d temperature are suggested gui del ine s only. All coo kin g should be b ase d on internal pr odu ct temperatures.

Due to v ari ati ons in pr odu ct quality, w eig ht and desired d egr ee of doneness, the co oki ng timer may nee d to be ad jus ted ac cor din gly.

22.

.

Always follow loc al health (hygiene) re gul ati ons fo r all internal t emp era tur e requirements.

5 0 0 S E R I E S 7 5 0 S E R I E S 1 0 0 0 S E R I E S

223

2 roasts 3 roasts 3 roasts

4 roasts

up to 40 lb (18 kg)

6 roasts

up to 100 lb (45 kg)

none none none

SECTIO N 4 • B EEF

9 roasts

up to 100 lb (45 kg)

Loading...

Loading...