Alto-Shaam 300-HW-D6, 100-HW-D6, 500-HW-D6, 28756 User Manual

W164 N9221 Water Street • P.O. Bo x 450 • M en om on ee Fa ll s, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744

US A/CA NA DA FAX: 262.251.7067 • 800.329.8744 U.S .A . ONLY

www.alto-shaam.com

100-HW

ans not included

p

Hot Food Drop-In Wells

Electric

Models:

100-HW

100-HW/ D6

200-HW

200-HW/ D6

300-HW

300-HW/ D6

400-HW

400-HW/ D6

300-HW

500-HW

500-HW/ D6

• INSTALLATION

• OPERATION

• MAI NTENANCE

P RI N TE D IN U .S .A .

MN-28756 • 05/09

D E L I V E R Y

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and report

it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

N O T E: All claims for warranty must include the

full model number and serial number of

the unit.

U N P A C K I N G

1. Carefully remove the

appliance from the

carton or crate.

N O T E: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner or

manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 1

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

N O T E : Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

C A U T I O N

Used to indicate the presence of a hazard that can

or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

C A U T I O N

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

D A N G E R

Used to indicate the presence of a

hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

W A R N I N G

Used to indicate the presence of a

hazard that CAN cause personal injury,

possible death, or major property

damage if the warning included with

this symbol is ignored.

SAF E TY PROC E DURE S

AND PREC AUTI O NS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

N O T E

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 2

I N S TA L L A T I O N

®

D A N G E R

I

MPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

The Alto-Shaam appliance

must be installed in a

location that will permit the

unit to function for its

intended purpose and

to allow for proper

cleaning, and maintenance.

1. The appliance must be installed on a stable and

level surface. A non-combustible, heat resistant

surface is highly recommended.

2. DO NOT install this appliance in any area where

it may be affected by any adverse conditions such

as steam, grease, dripping water, high

temperatures, etc.

3. The outer walls of the hot well can reach 200°F

(93°C) to 260°F (127°C). Verify countertop material

temperature rating with manufacturer before

installing to ensure counter can withstand heat.

LEV ELING

The heated well should

be leveled before the electrical supply is

connected. Level the appliance from side-to-side

and front-to-back with the use of a spirit level. For

appliances installed on a mobile stand, it is

important that the floor surface be level due to the

probability of frequent repositioning.

NOT E

It is important to apply a food grade silicone

underneath the decor flange to seal flange to the

countertop.

O P T I O N S A N D A C C E S S O R I E S

PAN DIVIDER BARS

• FULL-SIZE 16019

• HALF-SIZE / THIRD-SIZE 11318

R O U G H C U T C O U N T E R T O P O P E N I N G

MO DE L 100-HW and 100-HW/6D ONE PAN: 22-3/8" x 14-1/4" (568mm x 362mm)

MO DE L 200-HW and 200-HW/6D TWO PAN: 22-3/8" x 27-1/8" (568mm x 689mm)

MO DE L 300-HW and 300-HW/6D THREE PAN: 22-3/8" x 40-1/8" (568mm x 1019mm)

MO DE L 400-HW and 400-HW/6D FOUR PAN: 22-3/8" x 53-1/4" (568mm x 1353mm)

MO DE L 500-HW and 500-HW/6D FIVE PAN: 22-3/8" x 66-1/4" (568mm x 1683mm)

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 3

I N S TA L L A T I O N

D A N G E R

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON APPLIANCE NAMEPLATE.

D A N G E R

ELECTRICAL CONNECTIONS MUST

BE MADE BY A QUALIFIED SERVICE

TECHNICIAN IN ACCORDANCE WITH

APPLICABLE ELECTRICAL CODES.

D A N G E R

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in according with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

E L E C T R I C A L C O N N E C T I O N

1. An identification tag is permanently mounted

on the appliance.

2. This appliance is equipped with a three-prong

grounding plug. For your protection against

shock hazard this appliance should be plugged

directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding

prong from this plug. Plug the unit into a

properly grounded receptacle ONLY, positioning

the unit so that the plug is easily accessible in

case of an emergency. Arcing will occur when

connecting or disconnecting the unit unless all

controls are in the “OFF” position.

4. For 230V units:

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in

close vicinity, an equalization-bonding stud is

provided. An equalization bonding lead must be

connected to this stud and the other appliances /

metal parts to provide sufficient protection

against potential difference. The terminal is

marked with the following symbol.

NO TE: The appliance must be connected to an

electrical circuit that is protected by an external

GFCI outlet.

3. Proper receptacle or outlet configuration or

permanent wiring for this unit must be

installed by a licensed electrician in

accordance with applicable local

electrical codes.

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 4

I N S TA L L A T I O N

E L E C T R I C A L S P E C I F I C A T I O N S

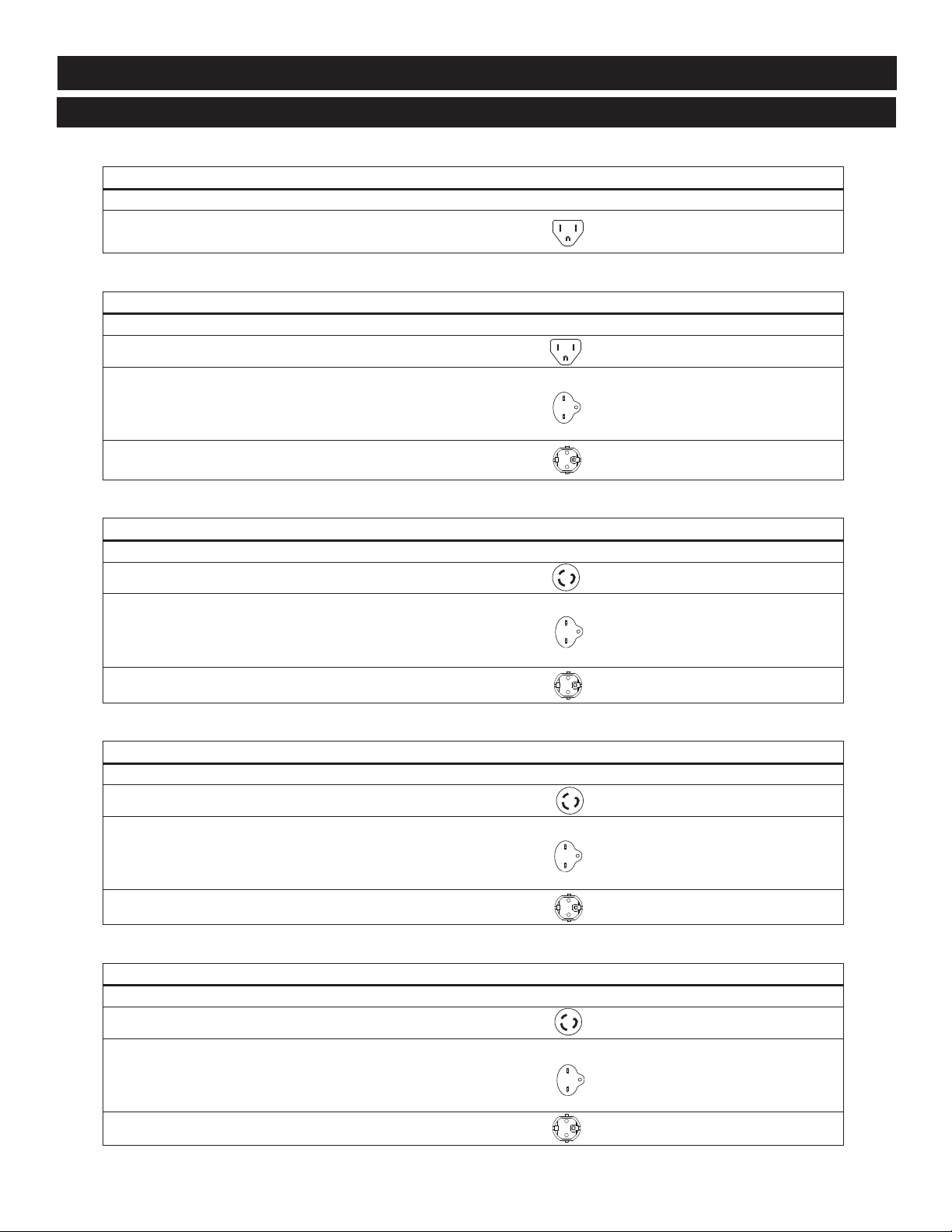

E L E C T R I C A L • 1 0 0 - H W & 1 0 0 - H W / D 6

OLTAGE PHASE CYCL E

V

120 (AGCY)1 60 4.8 0.58 NEMA 5-15P 15A-125V PLUG

E L E C T R I C A L • 2 0 0 - H W & 2 0 0 - H W / D 6

OLTAGE PHASE CYCL E

V

Z AMPS

/ H

Z AMPS

/ H

kW PLUG CONFIGURATION

kW PLUG CONFIGURATION

120 (A

GC Y

)1 60 10.6 1.27 N

EM A

5-15P 15A-125V

PL UG

240 (AGCY)1 60 5.3 1.27

at 208 1 50/60 4.6 0.95

NE MA 6-15P 15A-250V PLU G

at 240 1 50/60 5.3 1.27

AG CY)1 50/60 5.1 1.17 CEE 7/7 220-230V PLUG

230 (

E L E C T R I C A L • 3 0 0 - H W & 3 0 0 - H W / D 6

VOLTAGE PH ASE CYCLE/ H Z A MPS kW PLUG CONFIGURATION

120 (AGCY)1 60 21.4 2.57 NEM A L 5-30P 30A-125V PLUG

240 (AGCY)1 60 10.7 2.57

at 208 1 50/60 9.2 1.93

at 240 1 50/60 10.7 2.57 NEMA 6-15P 15A-250V PLUG

230 (AGCY)1 60 10.3 2.36 CEE 7/7 220-230V PLUG

E L E C T R I C A L • 4 0 0 - H W & 4 0 0 - H W / D 6

VOLTAGE PH ASE CYCLE/ H Z A MPS kW PLUG CONFIGURATION

120 (AGCY)1 60 19.7 2.36 NEM A L 5-30P 30A-125V PLUG

240 (AGCY)1 60 9.9 2.38

at 208 1 60 8.5 1.77

at 240 1 60 9.8 2.36 NEMA 6-15P 15A-250V PLUG

230 (AGCY)1 50/60 9.5 2.19 CEE 7/7 220-230V PLUG

E L E C T R I C A L • 5 0 0 - H W & 5 0 0 - H W / D 6

VOLTAGE PH ASE CYCLE/ H Z A MPS kW PLUG CONFIGURATION

120 1 60 20.0 2.39 NEMA L 5-30P 30A -125V PLUG

240 (AGCY)1 60 10.0 2.39

at 208 1 60 8.6 1.80

NE MA 6-15P 15A-250V PLU G

at 240 1 60 10.0 2.39

230 1 50/60 9.5 2.20

CEE 7/7 220-230V PLUG

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 5

I N S TA L L A T I O N

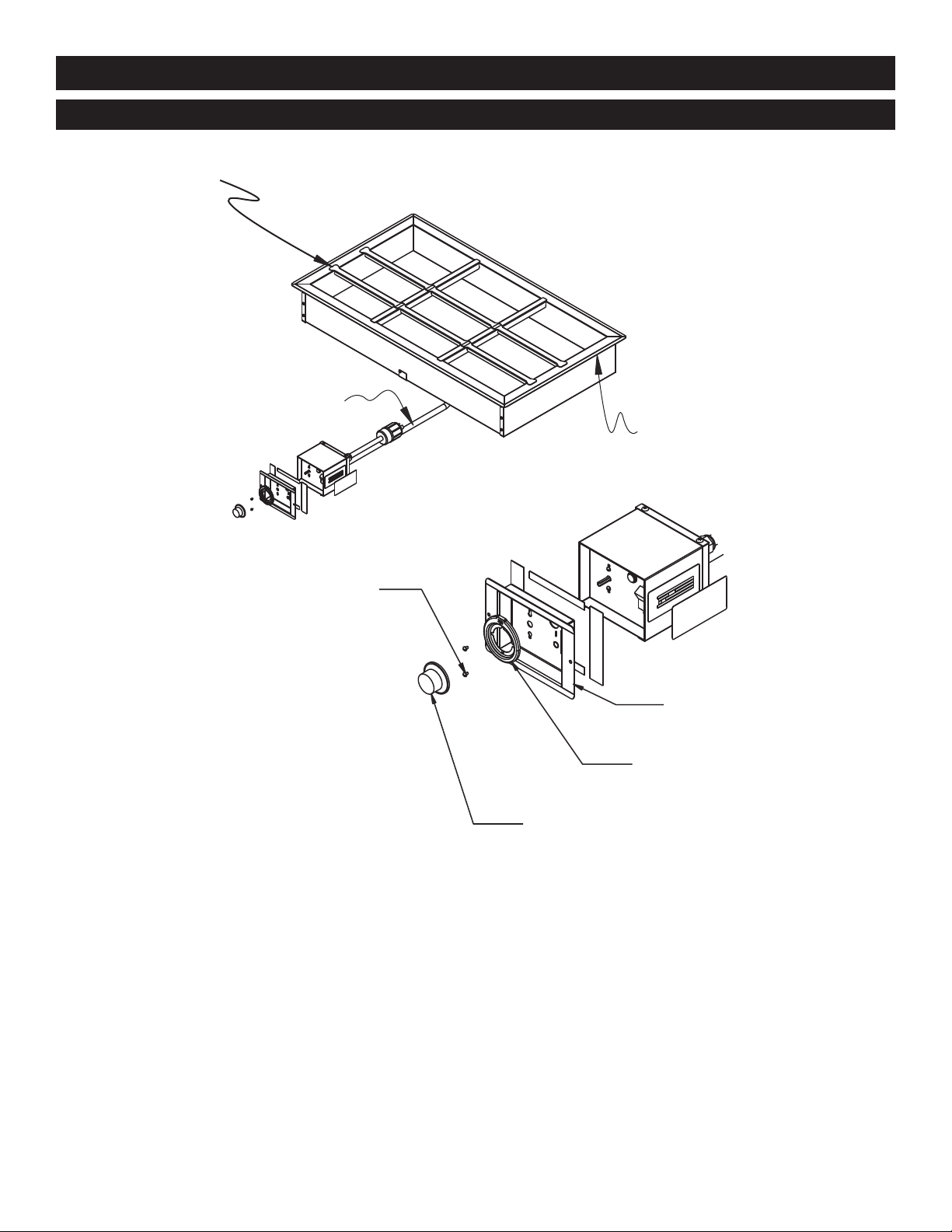

PAN DIVIDER

BARS #16019

FLEXIBLE WATERTIGHT TETHER

Apply a food grade silicone

along the outside edge of

the hot well support flange.

DECOR FACE

BEZEL

THERMOSTAT KNOB

MOUNTING

SCREWS

00-HW, 200-HW & 300-HW REMOTE CONTROL HOUSING MOUNTING INSTRUCTIONS

1

1. Cut a 5-1/4" x 4-1/2" (133.4mm x 114.3mm) opening in the location where the control is to be positioned.

2. Thoroughly clean and dry the mounting surface around the control cut-out opening on which the decor face will be

applied.

NO TE: The control face will not properly adhere to an unclean surface.

3. Remove the protective film from the mounting tape on the inside flanges of the decor face and apply the decor face

to the mounting surface.

4. Position the remote control housing behind the decor face. Use the two (2) mounting screws through the thermostat

bezel of the decor face to fasten the decor face to the control housing.

5. Insert the thermostat knob(s) onto the thermostat shaft(s).

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 6

I N S TA L L A T I O N

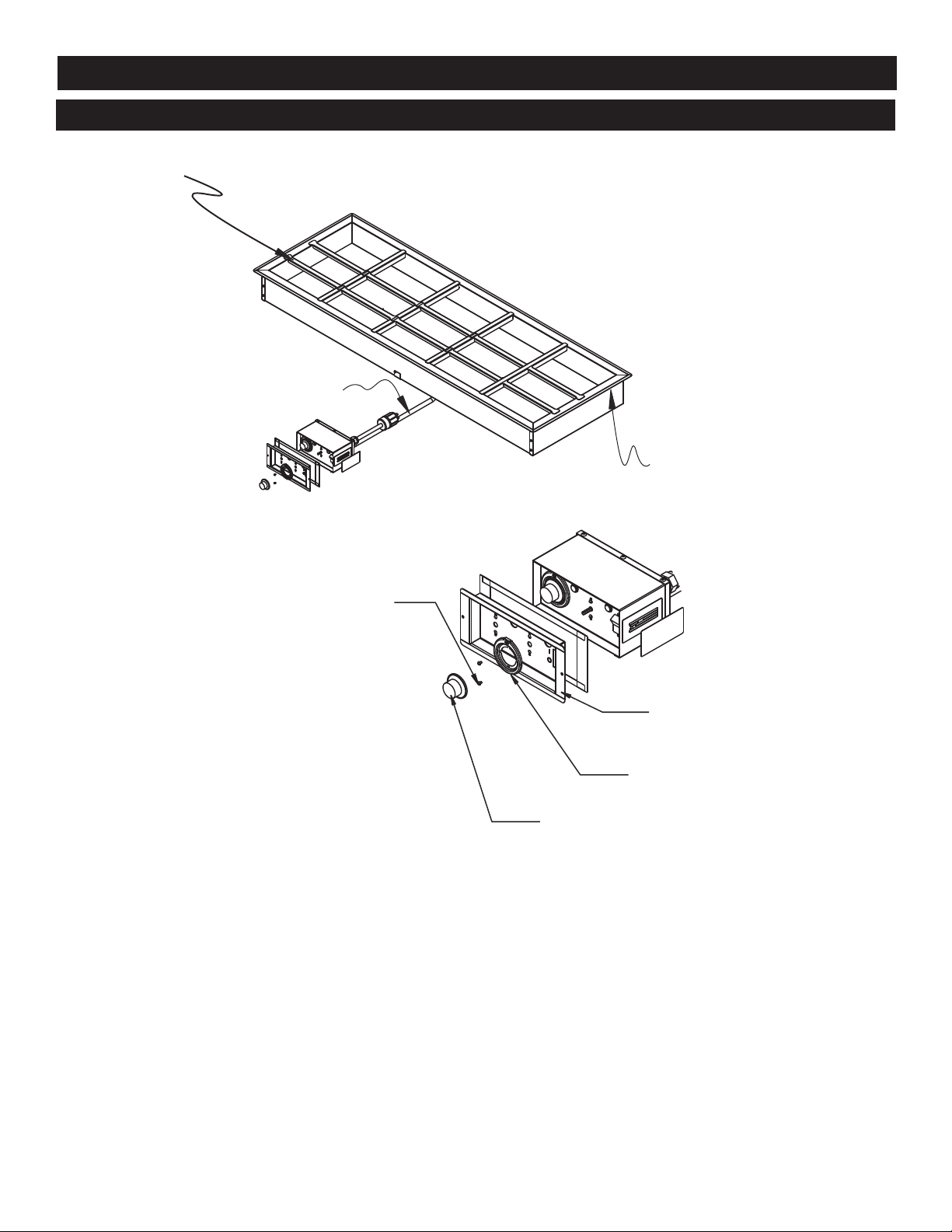

PAN DIVIDER

BARS #16019

FLEXIBLE WATERTIGHT TETHER

MOUNTING

SCREWS

THERMOSTAT KNOB

BEZEL

DECOR FACE

Apply a food grade silicone

along the outside edge of

the hot well support flange.

400-HW & 500-HW REMOTE CONTROL HOUSING MOUNTING INSTRUCTIONS

1. Cut a 9" x 4-1/2" (228.6mm x 114.3mm) opening in the location where the control is to be positioned.

2. Thoroughly clean and dry the mounting surface around the control cut-out opening on which the decor face will be

applied.

NO TE: The control face will not properly adhere to an unclean surface.

3. Remove the protective film from the mounting tape on the inside flanges of the decor face and apply the decor face

to the mounting surface.

4. Position the remote control housing behind the decor face. Use the two (2) mounting screws through the thermostat

bezel of the decor face to fasten the decor face to the control housing.

5. Insert the thermostat knob(s) onto the thermostat shaft(s).

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 7

I N S TA L L A T I O N

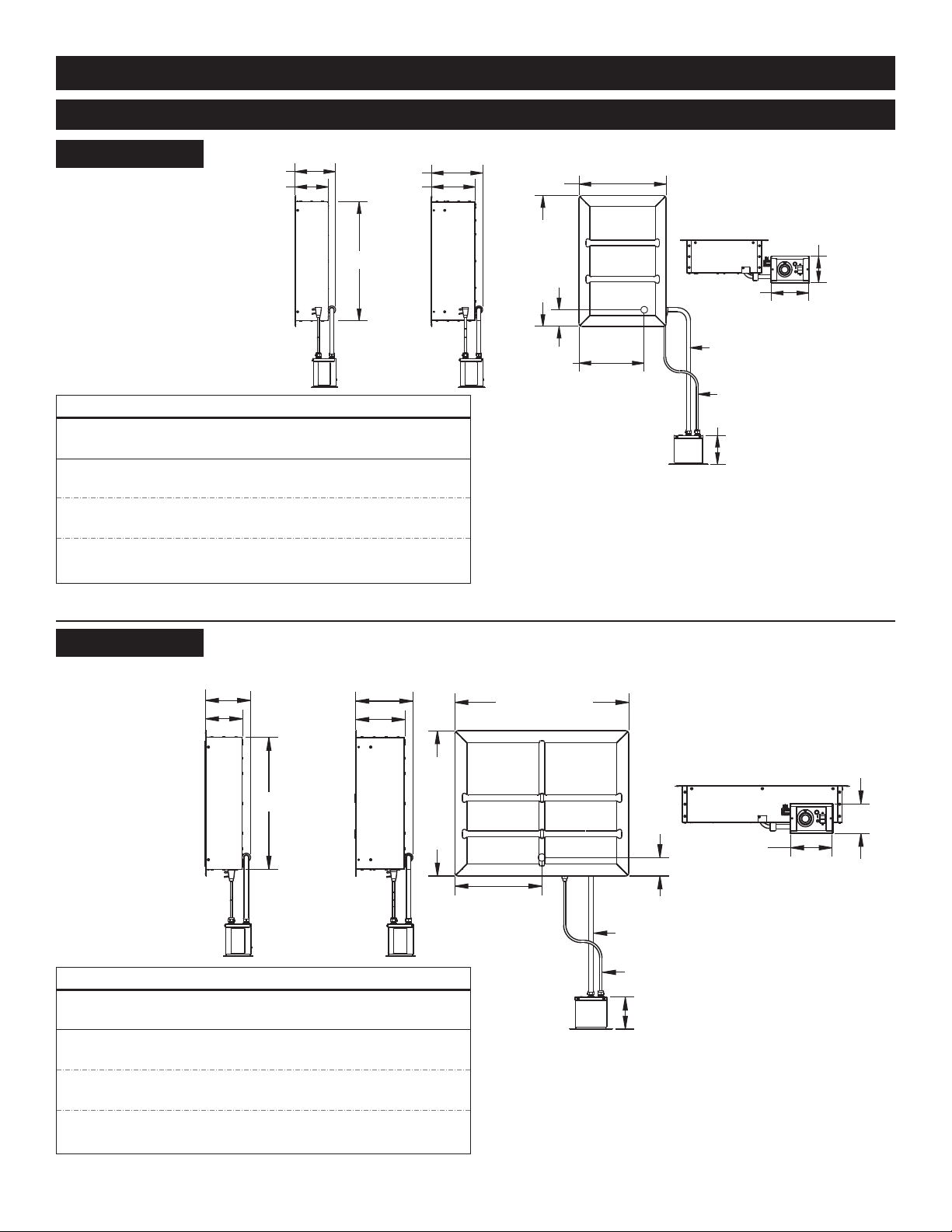

HW DEPTH

HW/D6 D

EPTH

7

-1/2" (190mm)

6-3/16" (157mm)

9

-1/2" (241mm)

8-3/16" (208mm)

7

" (175mm)

5" (125mm)

5-3/8" (136mm)

12-1/16" (306mm)

to electrical cord

3-1/8" (79mm)

to electrical cord

24-3/16" (614mm)

1

6-3/16" (409mm)

22" (558mm)

One (1) flexible

w

ater-tight tether

36" (914mm)

Electrical Cord

60" (1524mm)

HW DEPTH

HW/D6 DEPTH

7-1/2" (190mm)

6-3/16" (157mm)

5-3/8" (136mm)

7" (175mm)

5" (125mm)

9-1/2" (241mm)

8-3/16" (208mm)

22" (558mm)

24-3/16" (614mm)

14-1/2" (367mm)

to electrical cord

3-1/16" (78mm)

to electrical cord

28-15/16" (734mm)

One (1) flexible

water-tight tether

36" (914mm)

Electrical Cord

60" (1524mm)

D I M E N S I O N S • C A P A C I T Y

1 0 0 - H W

PRODUCT\PAN CAPACITY

12 lb (5.4 kg)

FULL-SIZE PANS*: One (1) 12" x 20" x 2-1/2"

HALF-SIZE PANS*: Two (2) 12" x 10" x 2-1/2"

THIRD-SIZE PANS*: Three (3) 12" x 6" x 2-1/2"

*WILL ALSO ACCEPT 4

" (100mm)

MAXIMUM (BASED ON 4" DEEP PANS)

MAX. VOLUME: 7.5 qt. (9.5 L)

GN 1/1 (325mm x 530mm x 65mm)

GN 1/2 (325mm x 265mm x 65mm)

GN 1/3 (325mm x 176mm x 65mm)

DEEP PANS;D6UNITS WILL ACCEPT 6

" (153mm)

DEEP PANS

PRODUCT\PAN CAPACITY

FULL-SIZE PANS*: Two (2) 12" x 20" x 2-1/2"

HALF-SIZE PANS*: Four (4) 12" x 10" x 2-1/2"

THIRD-SIZE PANS*: Six (6) 12" x 6" x 2-1/2"

*WILL ALSO ACCEPT 4" (100mm) DEEP PANS; D6 UNITS WILL ACCEPT 6" (153mm) DEEP PANS

2 0 0 - H W

24 lb (10.8 kg)

MAX. VOLUME: 15 qt (19 L)

MAXIMUM (BASED ON 4" DEEP PANS)

GN 1/1 (325mm x 530mm x 65mm)

GN 1/2 (325mm x 265mm x 65mm)

GN 1/3 (325mm x 176mm x 65mm)

Hot Food Drop-In Wel l Operation & Care Ma n u a l • 8

Loading...

Loading...