Page 1

20•20 COMBINATION

OVEN/STEAMER

COMBITHERM®

EELLEECCTTRRIICC

MMLL SSEERRIIEESS

INSTALLATION

AND

MAINTENANCE

®

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 ●U.S.A.

PHONE: (262)251-3800 (800)558-8744

U.S.A./CANADA FAX: (262)251-7067 (800)329-8744 U.S.A. (262)251-1907 INTERNATIONAL

www.alto-shaam.com

PRINTED IN USA

20•20ML ELECTRIC MARINE 05/03

Page 2

COMBITHERM®INSTALLATION

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 1

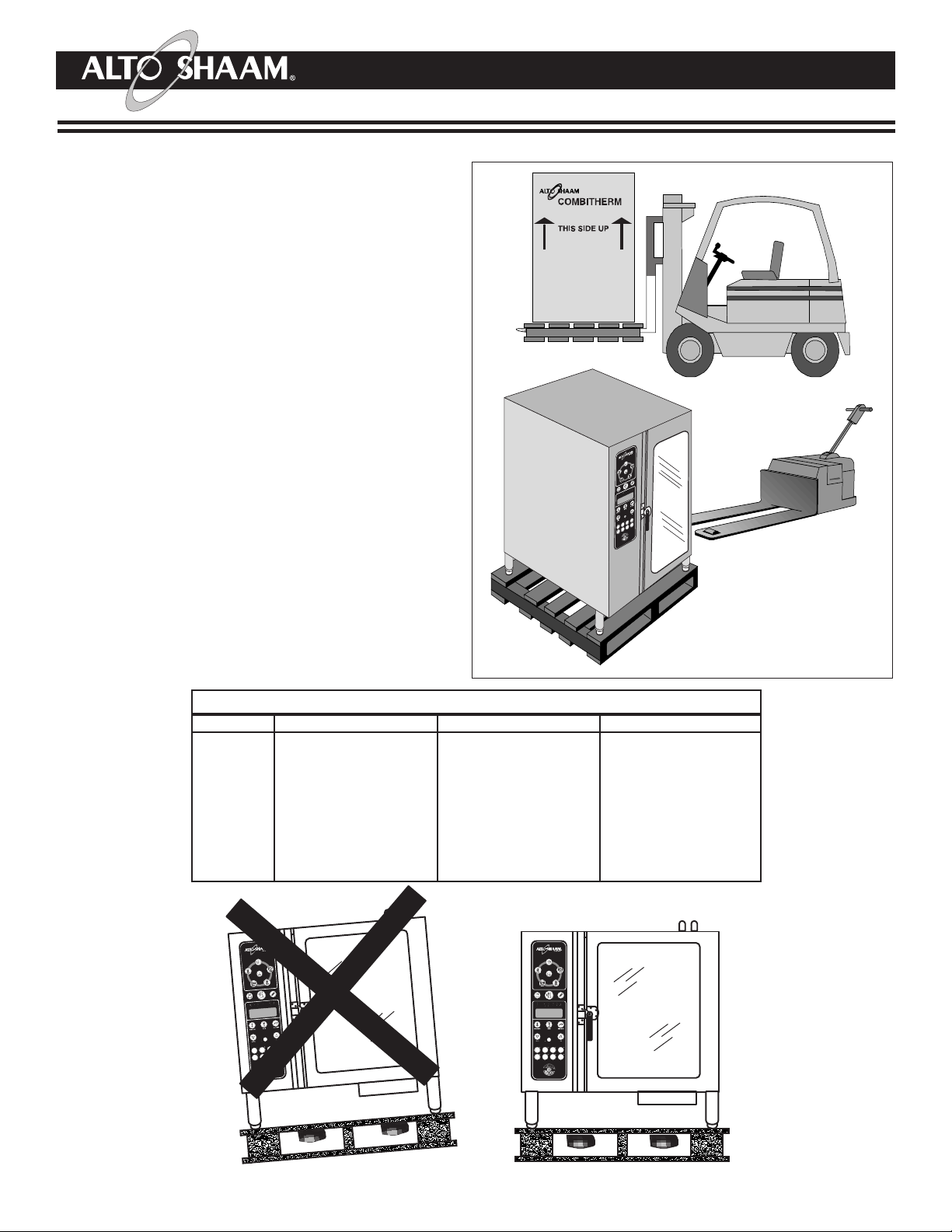

RECEIVING & TRANSPORTATION

Upon receipt of the Combitherm combination

oven/steamer, check the exterior of the shipping

carton for any physical damage that could result in

damage to the contents. If the oven was not

received from the carrier in an upright position,

there is a stronger possibility of concealed damage.

Remove the carton or uncrate the unit carefully

and inspect for any transit damage. Immediately

report any damage to the delivering freight carrier.

The oven must remain on the pallet

while being moved to the installation site

by fork lift or pallet lift truck.

Note the dimensions required for doorways and

aisles for access of the oven and pallet to the

installation site. Transport the oven in an upright

and level position only. Do not tilt the oven.

With the oven on the original pallet, remove the

carton and all packaging materials. Open the oven

door and remove all documents and other

materials from the oven interior. Remove the

roll-in cart if so equipped.

®

MODEL

20•20

WIDTH

48-1/4" (1226mm)

DEPTH

50-1/2" (1283mm)

HEIGHT W/PALLET

82-3/8" (2092mm)

PALLETIZED DIMENSIONS

Page 3

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 2

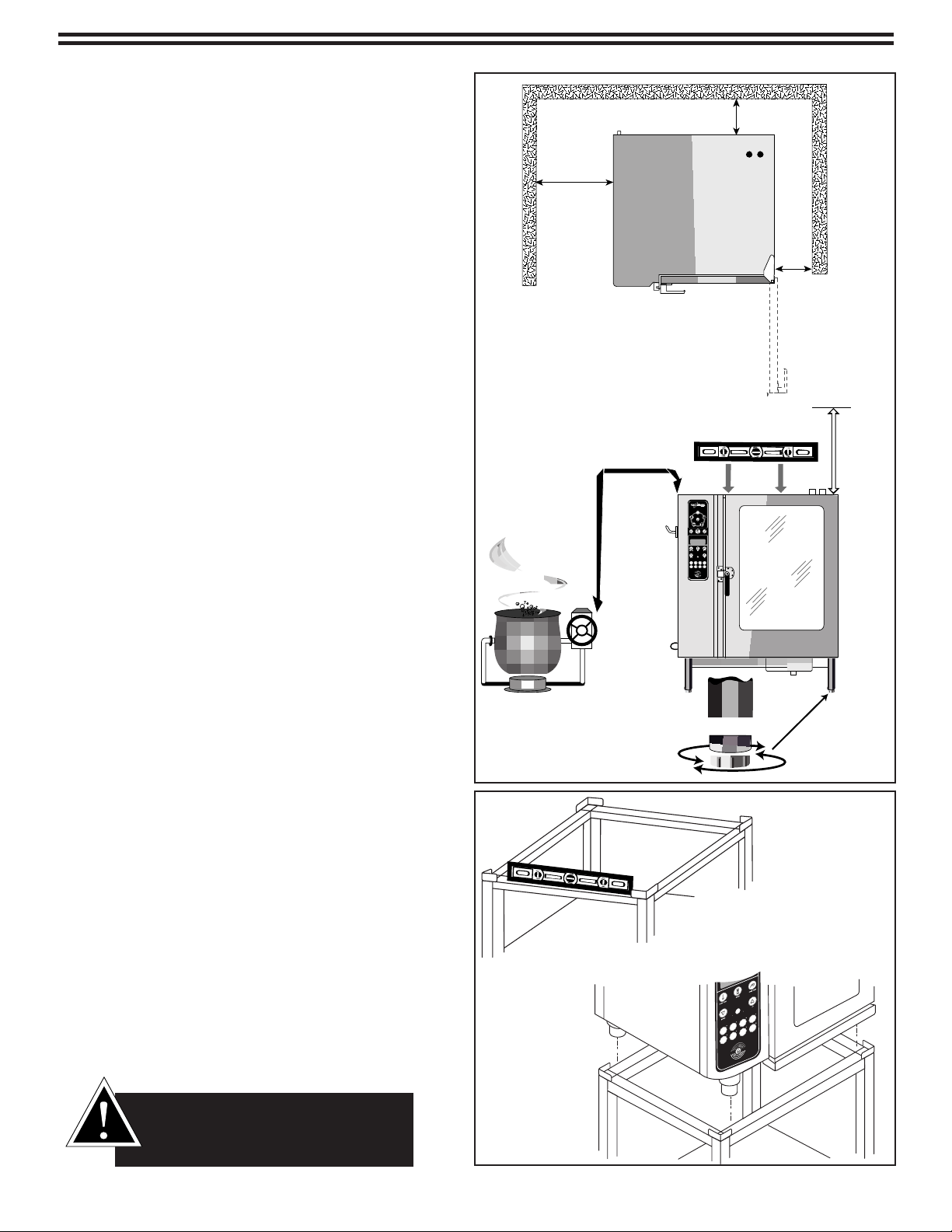

BASIC INSTALLATION SITE REQUIREMENTS

HOOD INSTALLATION IS REQUIRED

• Installation surface must be level.

• Do not install adjacent to flammable surfaces.

• Deep fat fryers or similar heat producing equipment must not be installed in

the immediate vicinity of the hand shower.

The oven must remain on the pallet while being moved

to the installation site with fork lift or pallet lift truck.

Do not tilt the oven.

VENTILATION

A steam ventilation hood is mandatory for the operation of the oven. The ventilation hood must be installed

in accordance with local building codes for steam exhaust and must protrude 12-inches to 20-inches

(300mm to 500mm) over the front side of the oven. A grease filter must be located in the protruding area of

the hood. Grease filters should be thoroughly cleaned on a regular basis following manufacturer's

instructions. Ventilation hoods must ensure an adequate amount of incoming air during operation and must

be operated whenever the combination oven/steamer is used in order to avoid the accumulation of

condensation in the hood area.

COMBITHERM®INSTALLATION

Page 4

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 3

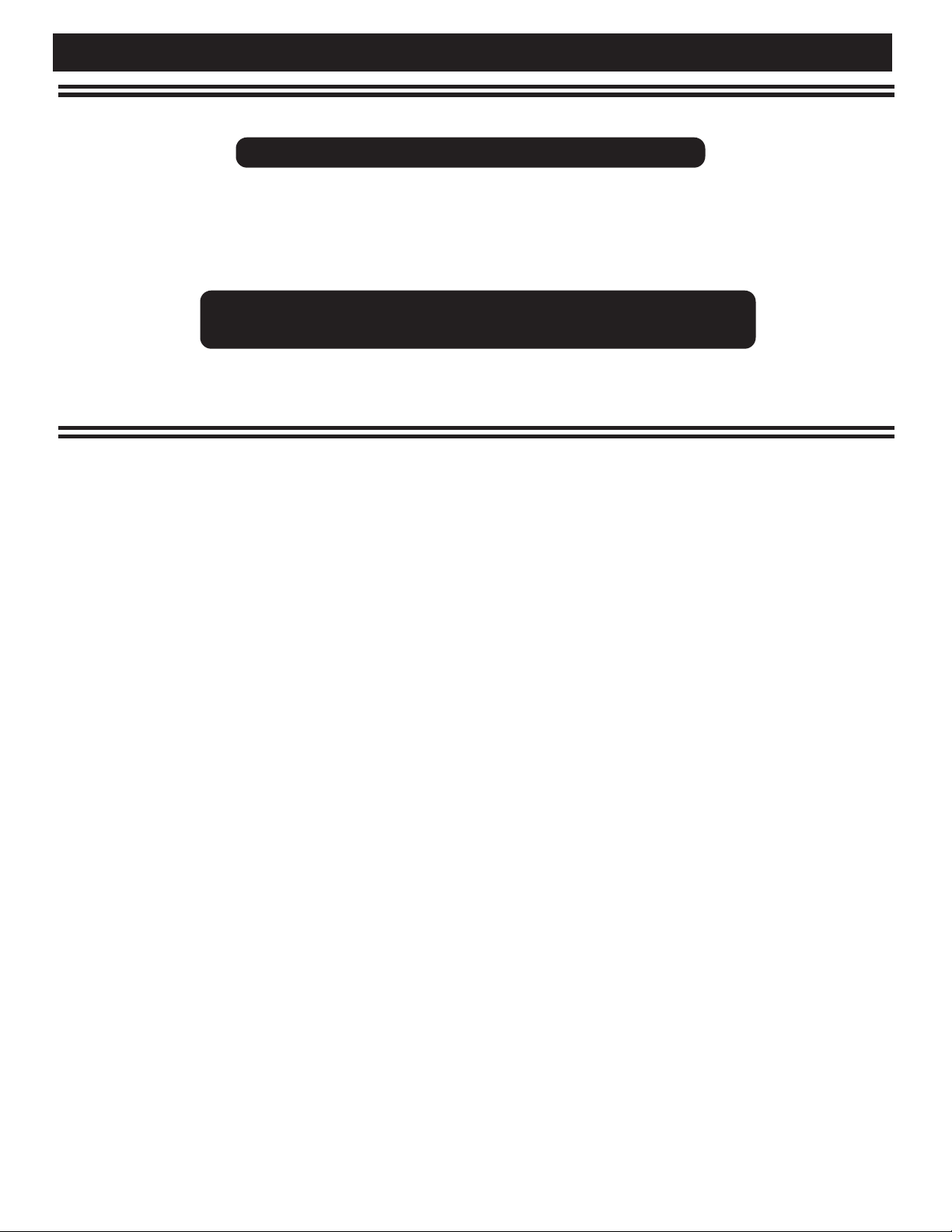

POSITIONING ON SITE

Lift the oven from the pallet with a fork lift or pallet lift truck positioned at the front of the oven.

To avoid damage, position the lift forks to the left of the condenser as indicated in one of the two

diagrams shown below. For additional damage protection, the use of two wooden boards, placed

between the bottom of the oven and the lifting forks, is strongly recommended.

MODEL

20•20

NET WEIGHT

958 lb (435 kg)

10"

(254mm)

3"

(76mm)

8"

(203mm)

CONDENSER

MODEL

20•20

COMBITHERM®INSTALLATION

Page 5

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 4

INSTALLATION REQUIREMENTS

■■

■■

Do not install oven adjacent to flammable

surfaces. Strictly observe all local fire

safety regulations.

■■

■■

In order to ensure proper ventilation, a

minimum distance of at least 6-inches

(152mm) must be kept from the control

panel side [LEFT] of the oven and any

adjoining surfaces.

NOTE: In addition to ventilation

requirements, additional clearance

is needed for service access. A

minimum distance of 18-inches

(457mm) is strongly recommended.

■■

■■

Allow a minimum of 4-inches (102mm) from

the right side of the oven to allow the door

to open to at least a 90° angle. Fully opened,

the door will extend up to a 225° angle. If

the oven is furnished with the retractable

door option, allow a minimum clearance of

6-1/2-inches (16cm).

■■

■■

Allow a minimum clearance of 4-inches

(102mm) from the back of the oven for

plumbing connections.

■■

■■

Allow a 20-inch (50cm) clearance at the top of

the oven for free air movement and for the

steam vent(s) located at the top [RIGHT-REAR].

■■

■■

Do not install the oven adjacent to heat

producing equipment such as fryers,

broilers, etc. Minimum clearance

recommended: 20-inches (50cm).

Place the Combitherm oven on a stable, LEVEL

horizontal surface. For counter-top models, the

oven stand must be level. In addition, the overall

height of the oven should be positioned so the

operating controls and shelves may be

conveniently reached from the front.

ALL INSTALLATION INSTRUCTIONS

AND REQUIREMENTS MUST BE

STRICTLY OBSERVED.

IMPROPER CONNECTION

OF THIS APPLIANCE

NULLIFIES ALL WARRANTIES.

18"

(46cm)

4"

(102mm)

4" (102mm)

RETRACTABLE

DOOR OPTION:

6-1/2" (165mm)

20"

(50cm)

MINIMUM

20"

(50cm)

Page 6

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 5

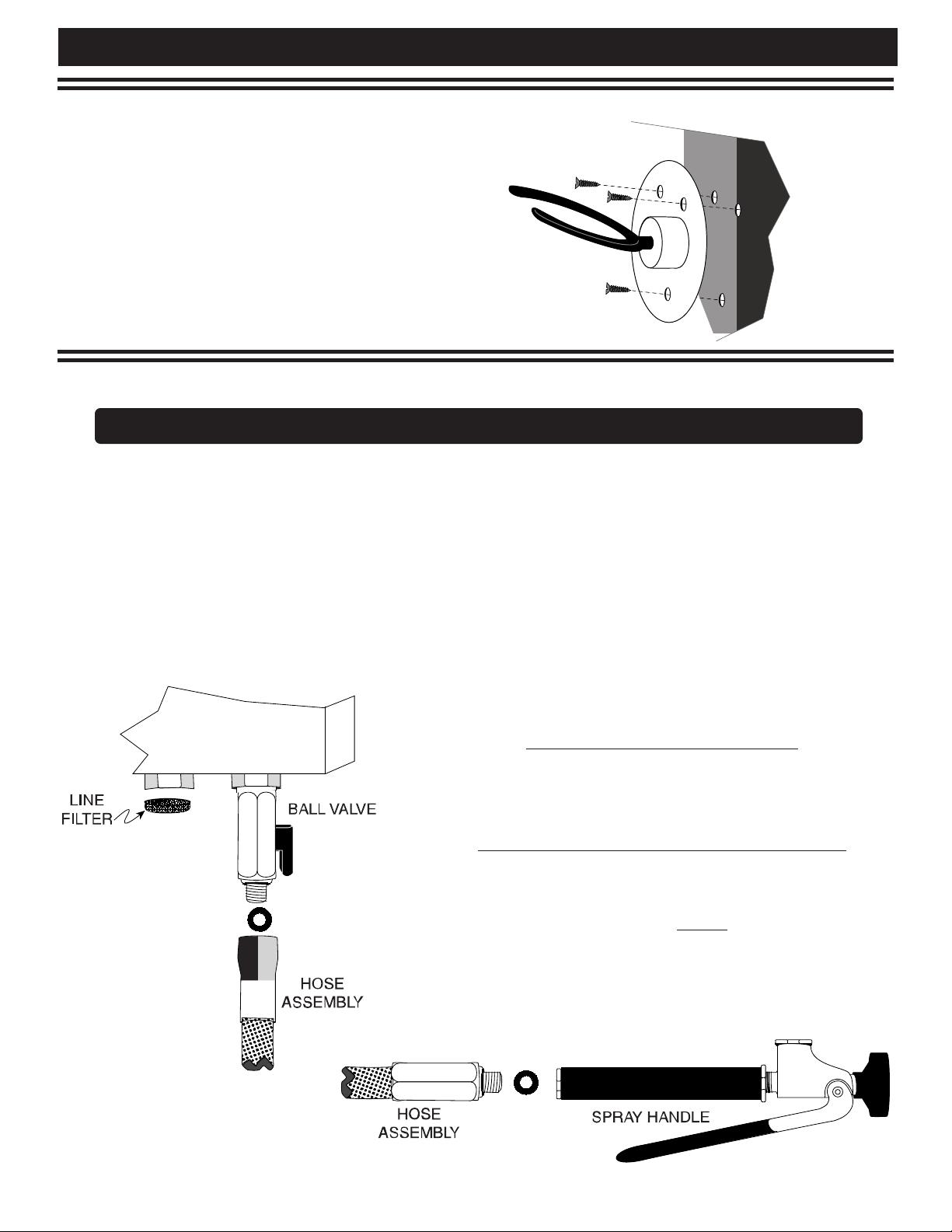

WATER SUPPLY

CONNECT TO POTABLE (DRINKABLE) COLD WATER ONLY

WATER PRESSURE REQUIREMENTS: MINIMUM 30 PSI (2 BAR)

MAXIMUM 90 PSI (6 BAR)

Flush the water line at the installation site before connecting the oven to the water supply. A shut-off valve

and approved back-flow preventer must be installed when connecting the oven to the cold water intake.

The water supply line must be a minimum of 3/4-inch (19mm). A water filtration system is recommended if

the water supply is between 7 and 9 grains of hardness. If water tests over 14 grains of hardness, the

installation of a water softener is strongly recommended. Install the line filter at the cold water intake

connection point.

PIPE SEALING TAPE (TEFLON®) MUST BE USED

AT ALL CONNECTION POINTS.

The use of a pipe sealing compound is not recommended.

THE SHUT-OFF VALVE MUST BE IN THE OPEN

POSITION WHEN THE OVEN IS BEING USED.

The hand shower spray hose is installed adjacent to the cold

water intake connection. A ball valve is installed on the

oven for hose connection to the COLD water source.

Assemble the washer and the flexible hose on the ball valve

and hang the spray handle on the holder previously

installed on the oven.

COMBITHERM®INSTALLATION

ASSEMBLY REQUIREMENTS

HAND SHOWER HOLDER

Fasten the hand shower holder in the holes

provided on the oven using the three (3)

screws packaged with the holder.

Page 7

COMBITHERM®INSTALLATION

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 6

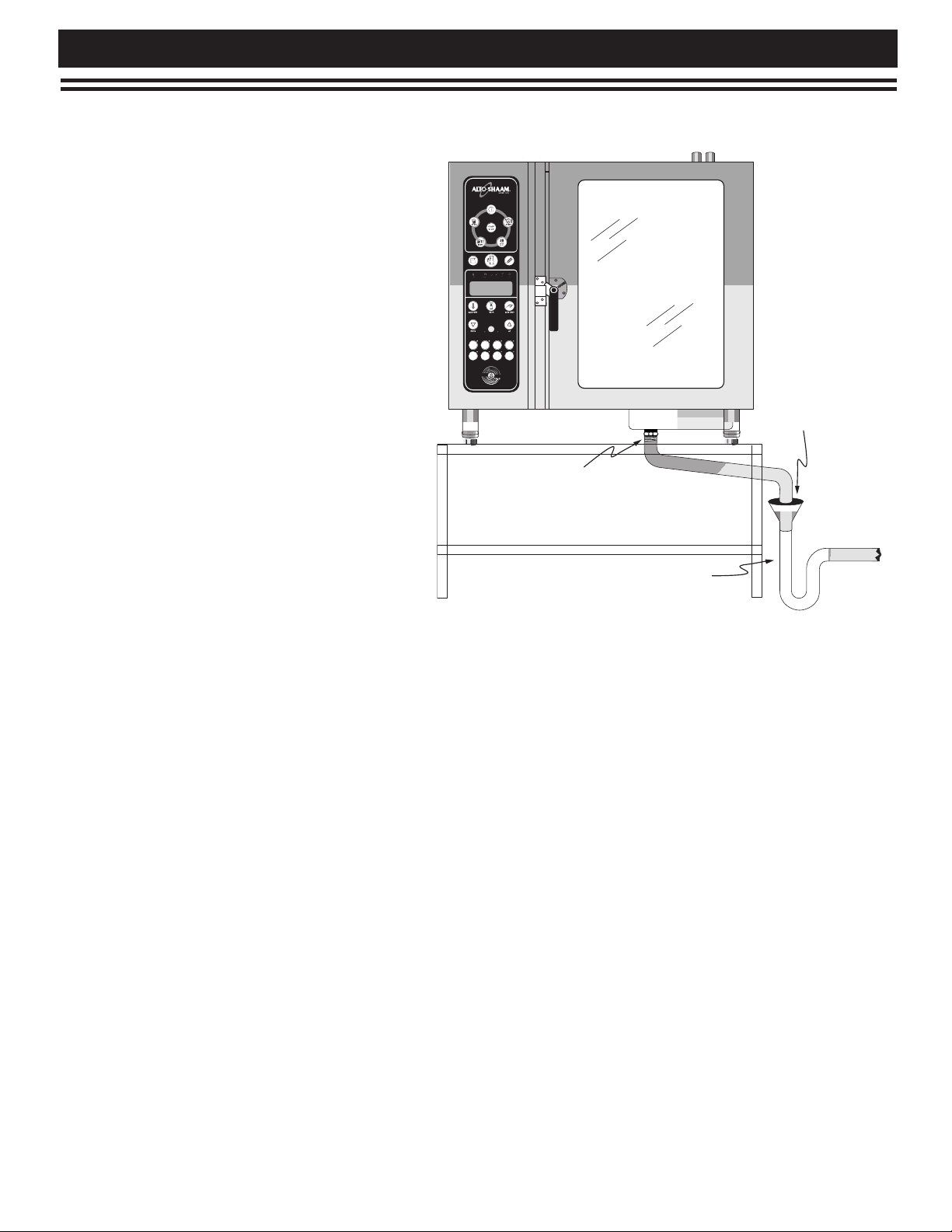

WATER DRAINAGE

The oven must discharge through an indirect

waste pipe by means of an air gap. The drain

thread is 1-1/4-inch (32mm) NPT.

A union is required. Install a 1-1/4-inch

(32mm) diameter drain line. The drain line

must always be a positive gradient away from

the Combitherm oven and not more than 12inches (305mm) before an air gap.

NOTE: In the U.S.A., this equipment is to be

installed to comply with the Basic

Plumbing Code of the Building

Officials and Code Administrators

International, Inc. [BOCA], and the

Food Service Sanitation Manual of the

Food & Drug Administration [FDA].

If several units are to be connected to one

drain pipe, the dimensions of the pipe must

be sufficient to allow an unobstructed water

drain system.

AVERAGE DRAIN WATER TEMPERATURE

149°F (65°C)

1-1/4" (32mm) diameter NPT

WASTE PIPE

1-1/2" to 2" minimum diameter

(c. 38mm to 51mm)

2" (51mm)

Air Gap

Page 8

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 7

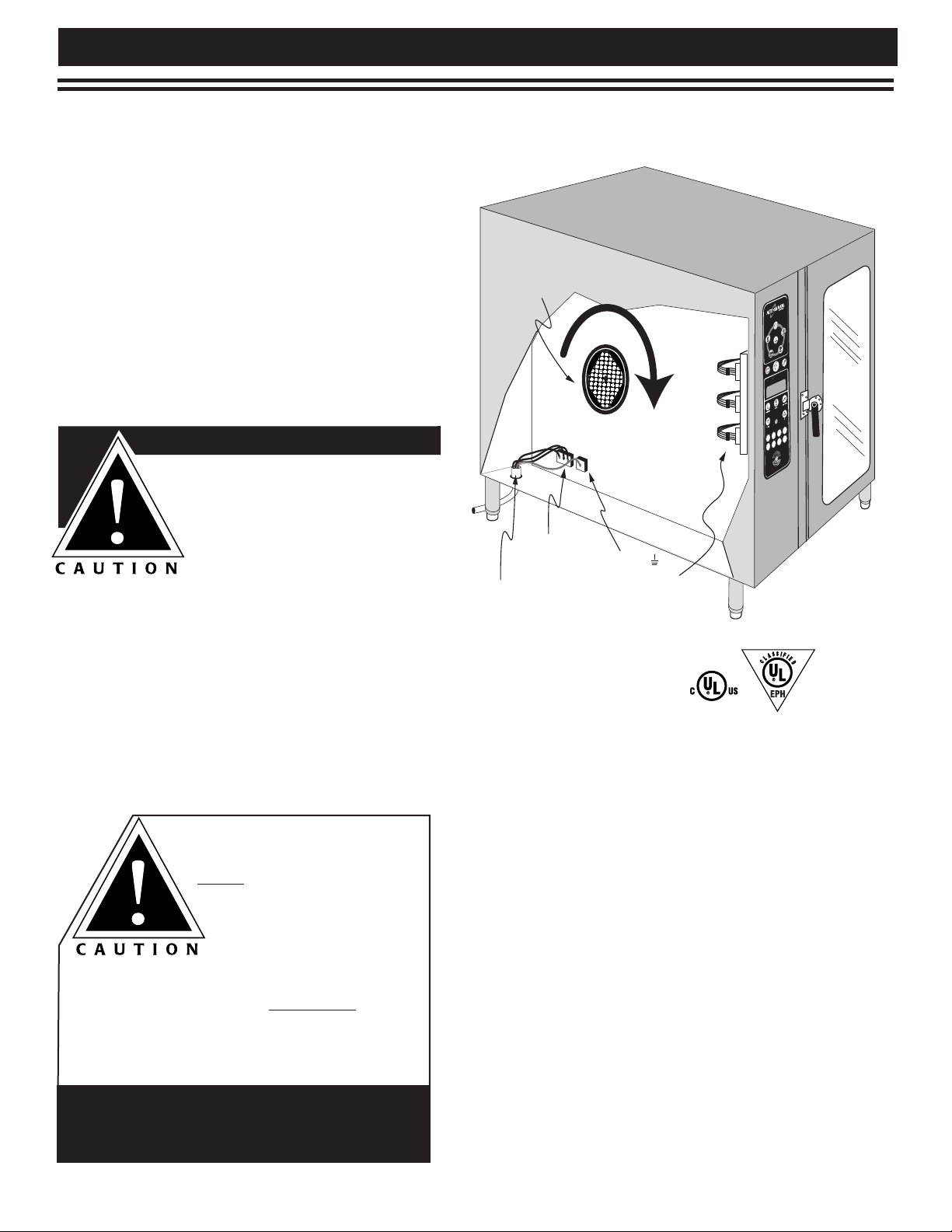

ELECTRICAL INSTALLATION

ELECTRICAL CONNECTIONS MUST BE

MADE BY A QUALIFIED ELECTRICIAN IN

ACCORDANCE WITH APPLICABLE

ELECTRICAL CODES.

An electrical wiring diagram is located behind

the control panel on the left side of the oven.

The oven must be installed by a qualified

electrician. This appliance must be branch

circuit protected with proper ampacities, in

accordance with the wiring diagram located in

the electrical compartment of the oven. The

oven must be properly grounded in accordance

with the National Electrical Code and applicable

local codes.

CAUTION

ENSURE THE AVAILABLE POWER

SOURCE MATCHES THE

VOLTAGE STAMPED ON THE

NAMEPLATE OF THE OVEN.

Wire size for the main incoming power to the

unit must match the minimum size listed in the

specifications applicable to the specific oven

model. For supply connections, locate the wire

size posted on the label located on the electrical

control box cover, behind the service panel or

elsewhere listed in this manual.

When connecting to a Delta-B (wild leg) on a 3-phase system, the wild leg must be connected to line 3.

Before operating the oven, check all cable

connections in the electrical connection area

for tightness since connections can loosen

during transport.

NOTE: After both water and electrical

connections have been completed,

operate the oven in any cooking

mode for a period of 15 minutes and

recheck the main power connections

at the terminal block to make

certain they remain tight.

FOLLOWING ELECTRICAL

CONNECTION, THE FAN

MUST ROTATE IN THE

SAME DIRECTION AS

THE ARROW

LOCATED ON THE

OVEN FAN MOTOR.

THIS APPLIANCE WILL NO

T

FUNCTION PROPERLY AND DAMAGE

CAN OCCUR IF THE MOTOR

ROTATION IS NOT CORRECT.

Electrical

Panel

Terminal

Block

Electrical

Connection

MOTOR

with

Rotation Direction

Ground

TO CHANGE MOTOR DIRECTION,

EXCHANGE TWO OF THE

INCOMING PHASES.

ANSI/NSF4

COMBITHERM®INSTALLATION

Page 9

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 8

Type of Oven floor

w/roll-in cart

Pan INCHES 40: 12" x 20"

Capacity 20: 18" x 26"

GASTRONORM 40: GN 1/1

20: GN 2/1

Side Rack INCHES 2-5/8

Spacing (MILLIMETERS) (65mm)

Interior INCHES 26-1/4

Width (MILLIMETERS) (667)

Interior INCHES 32-11/16

Depth (MILLIMETERS) (830)

Interior INCHES 60-1/4

Height (MILLIMETERS) (1530)

Noise

Level

Spray Hose 102-inches

Length (2600mm)

Water Consumption 21-26.5 gal/hr

(

APPROX.) (80-100 l/hr)

Steam Generator

Water Consumption

0.21 gal/min

(

APPROX.) (0.8 l/min)

Steam Generator 111.1 lb/hr

Rating (APPROX.) (50.4 kg/hr)

Steam

Generator

GALLONS 5.3

Volume (LITERS) (20)

Radiated

Heat

BTU/HR 15729

Loss (K J/H) (16608)

Latent

Heat

BTU/HR 11783

Loss (kJ/h) (12442)

Total

Heat

BTU/HR 27513

Loss (kJ/h) (29050)

Air Circulation

(WITH/WITHOUT HOOD)

cubic feet/hr 67804/54031

▲▲T=8K (m

3

/h) (1920/1530)

Air Circulation

(WITH/WITHOUT HOOD)

cubic feet/hr 25426/18363

▲▲x=5g/kg (m

3

/h) (720/520)

ADDITIONAL TECHNICAL DATA

20•20ML

MODEL ➜➜

The noise emission level related to the workplace is lower than: 70 dBA

Page 10

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 9

POST-INSTALLATION CHECK LIST

In order for this oven to operate properly, installation must conform with the instructions provided in this

manual. Following full installation the following list is provided as a final check to help assure conformance.

INSTALLER REQUIREMENTS INITIALS/DATE

■■

■■ Bottom of oven has been checked for damage due to improper positioning on site.

■■

■■ Proper clearances have been allowed at the top of the oven and from all adjacent surfaces

with allowance of free air access to all vents.

■■

■■ Clearance has been provided at the left of the oven for service access.

■■

■■ A minimum distance of 20-inches (1/2 meter) has been provided between the oven and any

heat producing equipment such as fryers, broilers, etc.

■■

■■ The oven has been leveled on a stable surface.

■■

■■ The oven has been connected to COLD water on a single water connection.

■■

■■ Incoming water pressure is between a minimum of 30 PSI and a maximum of 90 PSI.

■■

■■ Water testing over 14 grains of hardness includes either the installation of a water softener

or the verbal recommendation to the owner/operator for water softener installation.

■■

■■ Installation of drain is at a minimum of 1-1/4" (32mm) with a positive descending slope.

■■

■■ 2" (51mm) air gap at drain is free of obstructions.

■■

■■ Motor direction correctly corresponds with the direction of the arrow on the motor.

■■

■■ Electrical safety devices and phase rotation have been checked.

INSTRUCTIONS TO OWNER/OPERATOR INITIALS/DATE

■■

■■ Owner/operator has been instructed on proper method of flushing the steam generator

and safe procedures for handling the steam generator drain cap.

■■

■■

Owner/operator has been instructed on the importance of cleaning the oven along with

proper cleaning procedures including automatic steam generator flush, daily cleaning of

the interior, and monthly decalcification.

■■

■■ Owner/operator has been advised to use authorized Combitherm oven cleaner only.

■■

■■

Owner/operator has been informed of the safety warnings located in the operation guide

including the warning not to handle pans containing liquid or semi liquid products

positioned above eye level of the operator.

Damage directly attributed to improper set up, installation, or cleaning can invalidate warranty claims.

COMBITHERM® INSTALLATION

Page 11

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 10

POWER ON/OFF KEY

STEAM MODE KEY

PROGRAMMED MENU KEY

COOKING TEMPERATURE KEY

DOWN ARROW KEY

MOISTURE VENT KEY

START / STOP KEY

CHEF FUNCTION KEY

TIME KEY

SUPERHEATED STEAM AND

RETHERM MODE KEY

CONVECTION MODE KEY

PROGRAM INSTALL/EDIT KEY

FUNCTION & OPERATING

CONTROL PANEL DISPLAY

CORE TEMPERATURE KEY

UP ARROW KEY

QUICK PROGRAM KEYS

CONVECTION MODE KEY

INDICATORS

DELUXE MODELS ONLY

DELUXE MODELS ONLY

DELUXE MODELS ONLY

ELECTRIC MODELS ONLY

CONTROL PANEL IDENTIFICATION

ADJUSTMENT KNOB

N/A THIS UNIT

N/A THIS UNIT

Page 12

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 11

POWER ON/OFF KEY

Activates power to the oven and

automatically fills the steam generator with

water which will heat to a stand-by mode

temperature of 150°F (65°C). The steam

generator flush is also activated by pressing

this key.

STEAM MODE KEY

The oven will operate in the steam mode at

a temperature range of 86°F to 248°F

(30°C to 120°C).

• Automatic steaming at 212°F (100°C)

FACTORY-SET DEFAULT

.

• Quick steaming between 213°F and 248°F

(101°C and 120°C).

• Low Temperature Steaming between

86°F and 211°F (30°C and 99°C).

START/STOP KEY

Initiates all cooking mode functions and

programmed procedures stored in memory.

Stops an activated cooking mode or

programmed procedure currently in

progress, and exits Chef function key.

SUPERHEATED STEAM AND

CONVECTION MODE KEY

Selection key for the combination steam

and convection cooking mode which can be

set within a temperature range of

212°F to 482°F (100°C and 250°C).

PROGRAMMED MENU KEY

Shows a list menu in display of all stored

cooking programs and is also used to exit

the list menu display. DELUXE MODELS ONLY.

CHEF FUNCTION KEY

Used to select programmed menu

functions, various auxiliary functions, and

several chef help instructions.

COOKING TEMPERATURE KEY

Used to set the required cooking

temperature, to recall the set cooking

temperature, or to check the actual oven

temperature in conjunction with the down

arrow key

, the up arrow key or the

adjustment knob .

TIME KEY

Used to set the required cooking time or

recall the set cooking time in conjunction

with the down arrow key , the up arrow

key or the adjustment knob .

DOWN ARROW KEY

Used to decrease displayed cook temperature

, time , or core temperature and as a

scrolling key for programming functions.

ADJUSTMENT KNOB

Serves the same function as the up and

down arrow keys to increase or decrease

the displayed cook temperature , time ,

or core temperature .

MOISTURE VENT KEY

Immediately vents steam and condensate

from the oven compartment while cooking in

the Convection mode or in the

Superheated Steam and Convection mode .

RETHERM MODE KEY

Food rethermalization or reheating mode

will operate with automatic steam injection

at a temperature range of 248°F and 320°F

(120°C and 160°C).

CONVECTION MODE KEY

Selection key for convection cooking

without steam at a temperature range of

86°F to 482°F (30°C and 250°C).

PROGRAM INSTALL AND EDIT KEY

Used to create, change, duplicate, and delete

programmed menus. DELUXE MODELS ONLY.

FUNCTION & OPERATING INDICATORS

CONTROL PANEL DISPLAY

CORE TEMPERATURE KEY

Used to set the required internal product

temperature, to recall the internal product

temperature set by the operator, or to display

the current internal temperature of the

product in conjunction with the down arrow

key , the up arrow key or the adjustment

knob .

UP ARROW KEY

Used to increase displayed cook temperature ,

time , or core temperature and as a

scrolling key for programming functions.

QUICK PROGRAM KEYS

Immediate access to frequently used

operator set programs including cooking

modes, cleaning, and other oven functions.

DELUXE MODELS ONLY.

CONTROL PANEL IDENTIFICATION

Reduced Power

Reduced Fan Speed

Confirmation of

Oven Operation

Key Lock

Moisture Vent

Peak Power Use

Energy Protection

ELECTRIC MODELS ONLY

N/A THIS UNIT

N/A THIS UNIT

Page 13

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 12

IMPORTANT SAFETY PRECAUTIONS

For safe release of the cooking

compartment steam, initially

open the door approximately

2" (50mm) only. Stand

behind the door as the hot

steam is released.

STEAM

DO NOT USE THE ATTACHED HAND-HELD HOSE TO SPRAY ANYTHING OTHER

THAN THE INTERIOR OF THE COMBITHERM OVEN COMPARTMENT.

AT NO TIME SHOULD THE EXTERIOR OF THE OVEN BE STEAM

CLEANED, HOSED-DOWN WITH THE HAND-SPRAYER, FLOODED WITH

WATER, OR FLOODED WITH LIQUID SOLUTION OF ANY KIND.

DO NOT USE THE SPRAY HOSE IN A HOT COOKING COMPARTMENT. ALLOW

THE OVEN TO COOL TO A MINIMUM OF 150°F (66°C).

DO NOT USE HIGH PRESSURE WATER CLEANING METHODS ON THE INTERIOR

OR EXTERIOR OF THE COMBITHERM OVEN.

DO NOT HANDLE PANS CONTAINING LIQUID OR SEMI LIQUID PRODUCTS

POSITIONED ABOVE EYE LEVEL OF THE OPERATOR. SUCH PRODUCTS

CAN SCALD AND CAUSE SERIOUS INJURY.

USE AUTHORIZED COMBITHERM LIQUID OVEN CLEANER ONLY.

UNAUTHORIZED CLEANING AGENTS MAY DISCOLOR OR HARM INTERIOR SURFACES OF THE

OVEN. READ AND UNDERSTAND LABEL AND MATERIAL SAFETY DATA SHEET BEFORE

USING THE OVEN CLEANER.

FOR OPERATOR SAFETY

NOTE AND OBSERVE ALL SAFETY PRECAUTIONS LOCATED THROUGHOUT THIS MANUAL.

Page 14

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 13

Preventive Maintenance

In addition to the routine cleaning and maintenance procedures, there are several additional steps to be

taken for both sanitation purposes and to keep the oven running at top operating efficiency. These

additional safeguards will help prevent inconvenient down time and costly repairs.

●

DO NOT DISPOSE OF GREASE, FAT, OR SOLID WASTE DOWN THE OVEN DRAIN. Fats and solids

will eventually coagulate in the drain system, causing blockage. Consequently, water will back-up

into the condenser and interior oven compartment, resulting in an oven that is inoperable.

●

MAKE CERTAIN THE DRAIN SCREEN IS ALWAYS IN PLACE. REMOVE ANY SOLID WASTE

MATERIAL FROM THE DRAIN SCREEN BEFORE IT ENTERS THE DRAIN SYSTEM. The routine

removal of solids from the drain screen will help prevent blockage.

●

USE THE AUTHORIZED COMBITHERM OVEN CLEANER ONLY. The use of unauthorized

cleaning agents may discolor or harm the interior surfaces of the oven.

●

TO PROLONG THE LIFE OF THE DOOR GASKET, REMOVE AND CLEAN THIS ITEM DAILY. The

acids and related compounds found in fat, particularly chicken fat, will weaken the composition

of the gasket unless cleaned on a daily basis.

●

TO ADDITIONALLY PROTECT GASKET LIFE, ALLOW OVEN DOOR TO REMAIN SLIGHTLY

OPEN AT THE END OF THE PRODUCTION DAY. An open door will relieve the pressure on the

door gasket.

●

ROUTINELY CLEAN DOOR HINGES. Open oven door to relieve tension. Clean all parts of the hinge.

Routine Cleaning Requirements

DAILY OVEN CLEANING

To be performed at the end of each production day or between production shifts.

DAILY STEAM GENERATOR FLUSH

When operating the oven on a regular basis, the steam generator must be flushed once a day. This

procedure will prevent lime deposits and scale build-up from forming in the steam generator.

MONTHLY DECALCIFICATION

It is VERY important to decalcify the steam generator, particularly in areas with extremely hard water. This

procedure should be performed once a month, in addition to the daily steam generator flush.

COMBITHERM®CLEANING & MAINTENANCE

Page 15

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 14

Flushing the electric Combitherm steam generator on a daily basis helps to prolong the life of the steam generator

heating elements and helps prevent the necessity of service requirements. The control provides this feature as an

automatic function when the oven

ON/OFF power key is pressed to the ON position at the start of each working day.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION AT THE START OF THE DAY.

YES

PRESS THE START KEY OR CHEF FUNCTION

KEY TO BEGIN THE STEAM GENERATOR FLUSH.

The steam generator is automatically drained,

flushed, and refilled with water within 5 minutes

or less. Following this time period, the

Combitherm is ready for operation.

NO

TO CANCEL THE STEAM GENERATOR FLUSH, ROTATE

THE ADJUSTMENT KNOB ONE TURN TO THE RIGHT

UNTIL "NO" IS HIGHLIGHTED IN THE DISPLAY.

PRESS THE START KEY OR CHEF FUNCTION

KEY TO CONFIRM CANCELLATION.

If steam generator flush cancellation is not initiated within 10 seconds of the appearance of the display

message, the flushing function will automatically start. Following cancellation, the Combitherm is ready

for operation. The flushing process

must be initiated manually at a later time during the working day if

not conducted at startup.

MANUAL STEAM GENERATOR FLUSH

PERFORM DAILY WHEN THE STEAM GENERATOR FLUSH IS NOT PERFORMED AT THE START OF THE WORKING DAY.

WITH THE OVEN AT ROOM TEMPERATURE

1.

Press the Power Switch to the OFF position, rotate the Steam Generator Drain Cap located at the back of

the oven until water begins to flow from the four holes in the cap. In approximately 20 to 60 seconds, a

sufficient quantity of water will have drained from the steam generator so that the drain cap can be

completely removed.

2.

As the water continues to flow from the generator, it will have a milky or cloudy appearance, which

indicates deposits in the generator are beginning to flush through the system. Let the water continue to

drain until the flow begins to subside.

3.

When the flow begins to subside, remove the hand-held hose from the side of the oven and direct a

stream of fresh water directly into the steam generator drain opening located directly behind Steam

Generator Drain Cap. Repeat this procedure several times until the water begins to run clear.

4.

Press the oven Power Switch to the ON position. When the audible signal is heard, press the Steam

Mode Key. A new supply of fresh, cold water will begin to flow through the steam generator. Repeat

this procedure several times until the water runs completely clear.

5.

Once the water is completely clear, replace the Steam Generator Drain Cap over the steam generator

drain by turning it clockwise, by hand, until there is a slight resistance.

AT THE START OF EACH WORK DAY

DO NOT OVER-TIGHTEN STEAM GENERATOR DRAIN CAP.

Flush steam generator?

AUTOMATIC STEAM GENERATOR FLUSH

DISPLAY MESSAGE INDICATES:

Page 16

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 15

DAILY OVEN CLEANING

DO NOT SPRAY CLEANER INTO A HOT OVEN.

ALLOW THE OVEN TO COOL TO 150° F (60° C).

The temperature in the display indicates the air temperature inside the oven compartment and

not the interior walls of the oven. Always make certain to allow the oven walls to cool to a

minimum of 150°F (60°C) before spraying the compartment with oven cleaner.

1. Remove all food scraps and residue

from the oven drain .

2. Wearing safety glasses and rubber

gloves, remove the drain screen

and spray Combitherm liquid

oven cleaner directly into the drain

pipe . Replace the drain screen.

3. Generously spray the interior oven

surfaces with an even coat of

Combitherm Liquid Oven Cleaner.

Spray all built-in components,

shelves, side racks, and pans.

4. Once a week, loosen the thumb

screw(s) and swing Fan Guard Cover

Plate toward the back of the oven.

Spray the back of the Fan Guard

Cover Plate, the oven fan, and the left-hand side of the oven. Close the swing out Cover Plate . Lock

the cover into place and tighten thumb screw(s).

5. Insert the Combitherm Liquid Oven Cleaner spray nozzle directly into the Steam By-Pass Port and

spray several times.

6. Securely close the oven door.

RUBBER GLOVES AND PROTECTIVE EYE WEAR

MUST BE WORN WHEN USING THE OVEN CLEANER.

USE AUTHORIZED COMBITHERM

LIQUID OVEN CLEANER ONLY.

Unauthorized cleaning agents may discolor or harm interior surfaces of the oven. Read and understand

label and material safety data sheet before using the oven cleaner.

Causes severe burns. Do not get in eyes, on skin, or on clothing. Do not wear contacts. Harmful or

fatal if swallowed. Do not breathe mist. Use in well ventilated area. Keep out of reach of children.

Do not use on aluminum. Do not mix with anything but water.

THOROUGHLY RINSE EMPTY CONTAINER WITH WATER AND SAFELY DISCARD.

COMBITHERM®CLEANING & MAINTENANCE

Page 17

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 16

AUTOMATIC CLEANING PROGRAM

The Combitherm automatic cleaning function selects the proper temperature

for each step of the cleaning process.

With the oven power on:

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the clean symbol is highlighted in the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate

the adjustment knob to select YES for the automatic

cleaning function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING AND START THE CLEANING PROGRAM.

THE OVEN WILL BEGIN A 20 MINUTE, 2-STEP CLEANING CYCLE.

• 10 minutes at 86°F (30°C) to allow the cleaning agent to work

• 10 minutes at full steam temperature of 212°F (100°C) to clean the oven

FOR DELUXE OVENS WITH A PROGRAMMED MENU KEY

FOLLOW STEPS 1 THROUGH 6 ON THE PRECEDING PAGE.

With the oven power on:

PRESS THE PROGRAMMED MENU KEY.

Rotate the adjustment knob to program 250 = CLEAN.

PRESS THE START KEY.

DELUXE MODELS CAN ALSO BE CLEANED AS SHOWN IN THE PREVIOUS INSTRUCTIONS.

7. When the buzzer signals the end of the cleaning process, press the start/stop key to

deactivate the audible signal or open the oven door.

8. With the door open, use the hand held hose and direct a stream of water into the Steam By-Pass Port

to rinse away oven cleaner residue.

9. Rinse the interior and all sprayed components with the hand-held hose. Make certain to thoroughly

rinse all surfaces to remove any cleaning solution residue. Use a non-abrasive cleaning pad for any

problem areas.

10. Loosen the thumb screw(s) and swing Fan Guard Cover Plate toward the back of the oven.

Thoroughly rinse the back of the Fan Guard Cover Plate, the oven fan, and the left-hand side of the

oven. Close the swing out Cover Plate . Lock the cover into place and tighten thumb screw(s).

LEAVE DOOR SLIGHTLY OPEN AFTER CLEANING

Clean

➡

➡

➡

COMBITHERM®CLEANING & MAINTENANCE

Page 18

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 17

COMBITHERM®CLEANING & MAINTENANCE

ELECTRIC COMBITHERM DECALCIFICATION

Decalcification — ELECTRIC

It is VERY important to decalcify the oven, particularly in areas with extremely hard water.

PERFORM ONCE A MONTH in addition to the daily steam generator flush.

WITH THE OVEN AT ROOM TEMPERATURE

1. Begin decalcification with the power switch in the OFF position.

2. Rotate the Steam Generator Drain Cap until water begins to flow from the four holes in the cap. In

approximately 20 to 60 seconds, a sufficient quantity of water will have drained from the steam generator so

that the drain cap can be completely removed.

3. As the water continues to flow

from the generator, it will have

a milky or cloudy appearance,

which indicates deposits in the

generator system are beginning

to flush out. Let the water

continue to drain until the flow

completely subsides. Replace

the Steam Generator Drain Cap

by turning it clockwise until

there is a slight resistance.

4. Unscrew the cap from the

Decalcification Port . With

the use of a funnel, pour

one-half gallon (c. 2 liters) of

distilled white vinegar into the

Decalcification Port.

5. Replace the cap on the

Decalcification Port

and tighten securely.

Scalding water will erupt from the Decalcification Port when

the oven is operating unless the cap is replaced and tightened.

Page 19

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 18

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

THE WATER IN THE STEAM GENERATOR WILL BEGIN TO HEAT. ALLOW THE

OVEN TO REMAIN IN THIS POSITION FOR A MINIMUM PERIOD OF

10 MINUTES TO DECALCIFY THE STEAM GENERATOR.

In the case of extreme calcification build-up such as in areas with very hard water, ovens can be left in

this condition overnight. Follow the remaining instructions at the start of the next production day.

This procedure will help keep the oven operating at peak efficiency.

After a period of 10 minutes or longer —

PRESS THE ON/OFF POWER KEY TO THE OFF POSITION.

6. USING HAND PROTECTION, rotate the Steam Generator Drain Cap until water begins to flow from the

four holes in the cap. In approximately 20 to 60 seconds, a sufficient quantity of water will have drained

from the steam generator so that the drain cap can be completely removed. Let the water continue to drain

until the flow completely subsides.

7. Open the oven door. Loosen the thumb screw(s) and swing Fan Guard Cover Plate toward the back of

the oven. Using the hand-held hose, direct a stream of water directly into the Steam Exit Port several

times. Close the swing-out Cover Plate . Lock the cover into place and tighten thumb screw(s). Close

the oven door.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

PRESS THE STEAM MODE KEY.

A new supply of fresh water will begin to fill the steam generator and will flush out all remaining

vinegar from the steam generator.

AFTER APPROXIMATELY 5 MINUTES OF OPERATION IN THE STEAM MODE, PRESS THE START/STOP KEY.

PRESS THE ON/OFF POWER KEY TO THE OFF POSITION AND OPEN THE OVEN DOOR.

8. USING HAND PROTECTION, replace the Steam Generator Drain Cap by turning it clockwise until there

is a slight resistance. At the end of the production day, leave the door slightly ajar.

DO NOT COOK IN ANY PROGRAM MODE

WITH VINEGAR IN THE STEAM GENERATOR SYSTEM.

DURING DECALCIFICATION THE WATER FLOWING FROM THE DRAIN CAP IS

EXTREMELY HOT! USE HAND PROTECTION WHEN TOUCHING THE STEAM

GENERATOR DRAIN CAP. DO NOT TOUCH THE WATER FLOWING OUT OF THE

STEAM GENERATOR DRAIN CAP OR STEAM GENERATOR DRAIN.

COMBITHERM®CLEANING & MAINTENANCE

ELECTRIC COMBITHERM DECALCIFICATION

Page 20

COMBITHERM®CLEANING & MAINTENANCE

ROLL-IN CART/FOOD TROLLEY CLEANING

1. Remove food trolley to a cart wash area. Trolleys may be cleaned

using any mild cleaning detergent and warm water.

2. Hand wipe all framing, slides, drip pan, and base. Thoroughly

clean debris from the casters. A spray hose can be used for

easier cart cleaning.

3. Remove detergent solution with warm water.

4. Wipe or spray with a sanitizing solution designed for use on metal

and vinyl food contact surfaces.

5. Allow trolley to air dry.

As an alternative, trolleys can be sprayed with Combitherm

liquid oven cleaner while inside the oven. Allow the trolley to

remain in the oven through the normal cleaning cycle,

followed by steps 2 through 5 above.

DAILY GASKET CLEANING

It is important to prolong the life of the oven gasket by cleaning this

item on a daily basis. Routine cleaning will help protect the

composition of the gasket from deterioration caused by acidic foods.

After allowing the oven to cool, remove pull-out gasket and wash in

hot, soapy water. Do not place in the dishwasher.

Always replace the gasket before cleaning the

oven interior or operating the oven.

COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 19

Page 21

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 20

EMERGENCY OPERATION

In the event of an error code, operation of the Combitherm can be continued on a limited basis for a short

duration. Cooking times may be longer than normal operation and close monitoring of the cooking

process is recommended. Contact an authorized service agency immediately if the problem cannot be

rectified with simple steps in the troubleshooting guidelines located in this manual. Error conditions

under which continued operation can be conducted are indicated by

YES in the chart shown below.

When the oven malfunctions, an error code will appear in the display.

PRESS THE START/STOP KEY TO ACKNOWLEDGE THE ERROR.

The keys for the usable operational modes will begin to flash and can be operated normally.

SELECT AND PRESS ONE OF THE COOKING MODES INDICATED.

The oven control will only respond to the oven mode keys flashing.

SET THE OVEN CONTROLS AS IF OPERATING UNDER NORMAL CIRCUMSTANCES.

Depending on the error code involved, oven function, such as temperature range, may be limited.

PRESS THE START/STOP KEY TO BEGIN THE COOKING PROCESS.

PRESS THE START/STOP KEY WHEN THE TIMER EXPIRES.

WHEN THE OVEN FAULT IS CORRECTED, THE COMBITHERM WILL RETURN TO NORMAL OPERATION.

1

Cooking time increases significantly. Food on the upper shelves is finished first.

2

Water injection into the condenser is activated for the entire cooking mode (high water consumption).

3

When error codes E23 and E26 appear simultaneously, steam generator does not preheat.

ERROR DISPLAY MESSAGE GAS ELECTRIC STEAM

1

SUPERHEATED CONVECTION RETHERM DELTA-T

CODE MODE STEAM MODE MODE MODE MODE

E01 Low water level YES YES NO NO up to 356°F NO YES

(180°C)

E02 EL-temperature too high YES YES YES Up to 284°F Up to 284°F Up to 284°F Up to 284°F

CONTROL COMPARTMENT TEMP (140°C) (140°C) (140°C) (140°C)

E03 Fan Fault NO YES Up to 212°FNO NONONO

BLOWER FAN (100°C)

E04 EL-fan fault NO YES YES Up to 284°F Up to 284°F Up to 284°F Up to 284°F

CONTROL COOLING FAN (140°C) (140°C) (140°C) (140°C)

E05 Gas fault YES NO YES YES YES YES YES

E15 Condenser oven temperature YES YES NO NO Up to 356°F NO YES

HIGH CONDENSATE TANK TEMP (180°C)

E21 Oven probe error NO YES 212°F only NO NO NO NO

TEMPERATURE PROBE (100° C)

E22 CTC error TEMPERATURE PROBE YES YES YES YES YES YES YES

E23 SG-probe error YES YES YES YES YES YES YES

STEAM GENERATOR PROBE B4

E24 Bypass probe error NO YES Up to 210°F NO YES NO YES

(99°C)

E25 Condenser probe error NO YES YES

2

Up to 356°F2Up to 356°F2Up to 356°F

2

YES

2

B3 PROBE (180°C) (180°C) (180°C)

E26 SG probe error NO YES YES YES YES YES YES

STEAM GENERATOR PROBE

E23 & SG probe error

3

NO YES YES

3

YES

3

YES

3

NO YES

3

E26 STEAM GENERATOR PROBE B4

E33 SG heat error NO YES YES YES YES YES YES

STEAM GENERATOR ELEMENT

E34 Steam Generator pump error NO YES YES YES YES YES YES

E81 Program memory error YES YES YES YES YES YES YES

E83 Algorithm error YES YES YES YES YES YES YES

E89 12C error YES YES YES YES YES YES YES

Page 22

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 21

TROUBLESHOOTING

In the event of a Combitherm malfunction during operation, an error code and message will appear in the

display to assist in finding a rapid solution to the problem. The following is a list of all error codes including

the possible cause along with a solution.

ERROR

CODE

E01

E01

E02

E03

E03

E04

E11

E13

E15

DESCRIPTION OF ERROR

Low water level: Sufficient water level in steam generator

has not been reached with 3 minutes.

Low water level: Water pressure is under 11 PSI (0.7 bar)

after the solenoid valve is opened for 5 seconds.

Excessive temperature in service area: An additional fan

will engage at a temperature of 113°F (45°C) and the

error message will occur at a service area temperature of

176°F (80° C).

Fan motor shuts down from a tripped internal PTC.

Motor shuts down fan.

Auxiliary 120 fan motor not running.

Oven probe (N6 thermocouple) measures a temperature in

excess of 572°F (300°C).

Steam generator probe (B4 thermocouple) measures a

temperature in excess of 248°F (120°C).

Condenser probe (B3 thermocouple) measures a temperature

in excess of 212°F (100°C).

POSSIBLE CAUSE/REMEDY

Water tap is closed.

Filter in solenoid valve or water connection is clogged.

Water level probe is calcified or defective.

Solenoid valve Y1 is defective.

Pressure loop is calcified.

Steam generator drain cap is not water tight.

Water tap is closed.

Filter in solenoid valve or water connection is clogged.

Solenoid valve Y1 is defective.

Auxiliary 12 V fan does not turn on due to defective

thermostat or contactor.

Ventilation vents are blocked due to inefficient distance from

wall at installation site.

Minimum distance to equipment such as fryers, grills,

kettles, etc. has not been maintained.

A phase from the main power supply is missing.

The fan motor is defective.

Power phase reversed causing fan to run in reverse.

A fuse is tripped.

Trip circuit has been set too low.

Direction of motor rotation is wrong.

A phase is missing from the main power supply.

The motor protection switch is defective.

Power phase reversed causing fan to run in reverse.

The fan motor is defective.

Auxiliary fan is defective.

Defective wiring or loose connection to auxiliary fan.

Convection contactors are burned and no longer disengage.

Motor not operating due to two defective F10 fuses.

Calcification in steam generator.

Water level probe is grounded causing immersion elements

to energize.

Water tap is closed.

Oven is connected to warm water supply.

Inlet filter on solenoid valve is dirty.

Condenser cooling solenoid valve or solenoid valve coil is

defective.

Page 23

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 22

TROUBLESHOOTING

Alto-Shaam has established a twenty-four hour emergency service

call center to offer immediate customer access to a local authorized

service agency outside of standard business hours. The

emergency service access is provided exclusively for

Alto-Shaam equipment and is available throughout

the United States through the use of Alto-Shaam's

toll-free number. Emergency service access is available

seven days a week including holidays

.

ERROR

CODE

E23

E25

E26

E27

E33

E34

E80

E95

DESCRIPTION OF ERROR

Steam generator probe (B4 thermocouple) is interrupted.

Condenser probe (B3 thermocouple) is interrupted.

Safety temperature probe (N8 thermocouple) is interrupted.

STB (N8 thermocouple) measures a temperature in excess of

266°F (130°C).

Steam generator probe (B3) fails to measure increase in

temperature to 41°F (5°C) within a 3 minute period of time.

Steam generator pump malfunction.

ID (identity) error.

Software error.

POSSIBLE CAUSE/REMEDY

Probe connection is bad at X6 on the control module.

Steam generator probe (B4) is defective.

Bad probe connection.

Probe connection is bad at X6 on the control module.

Condenser probe (B3) is interrupted or defective.

Bad probe connection.

Probe connection is bad at X6 on the control module.

STB steam generator probe (N8) is interrupted or defective.

Bad probe connection.

Calcification in steam generator

Water level probe is grounded causing immersion elements

to energize.

Immersion heater defective.

Heater contactors defective.

B3 probe calcified.

Pump (M4) defective.

Pump blocked or dirty.

Ground short on water level probe due to calcification.

Fill opening in water settling area of level probe is calcified.

The electronic control cannot differentiate between gas or

electric operation and disconnects all circuit connections.

Contact problem on X3 connection.

Communication problem between software and hardware.

Incompatibility between software and hardware.

Page 24

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 23

DOOR PARTS:

DOOR, ARM (MARINE MODELS ONLY) CT-22887

DOOR, ARM PLATE (

MARINE MODELS ONLY) CT-22885

DOOR BUSHING, ARM (MARINE MODELS ONLY) CT-22886

DOOR, HANDLE INSERT HD-23084

DOOR HANDLE, RIGHT HAND HD-2934

DOOR LATCH, RIGHT HAND LT-25058

DOOR LATCH INSET, RIGHT HAND LT-25836

DOOR, LATCH MAGNET SWITCH LT-3738

DOOR LATCH MOUNTING HARDWARE SC-22768

DOOR, INNER BUMPER BM-25072

DOOR, INNER BUMPER STOP BM-25089

DOOR, OS CPL RIGHT HAND CT-2510037

DRIP TRAY 14475

GASKET, DOOR GS-2954

HINGE, INNER DOOR PART PI-25339

HINGE, INNER DOOR PART PI-25340

HINGE, LOWER BRACKET HG-25159

HINGE, LOWER PLATE HG-25100

HINGE, LOWER DOOR RATCHET HG-25101

HINGE, UPPER BRACKET HG-25160

HINGE, UPPER DOOR RATCHET HG-25079

HINGE, UPPER PLATE MOUNTING HARDWARE:

— SCREW, AXIS SC-25102

— WASHER, COVERING WS-25127

— WASHER, ECCENTRIC BLOCK WS-25124

— WASHER, SCHMORR STYLE WS-25478

— HINGE, TOP STOP HG-25077

INNER DOOR, RH, FOR RETRACTABLE DOOR DR-25146

ELECTRICAL/ELECTRONIC PARTS:

ADJUSTING ROCKER (COMPLETE) KN-33734

ADJUSTING ROCKER KNOB KN-33735

BOARD, LED CLOSED SYSTEM BA-33732

BOARD, COMMUNICATION 5000KM BA-33738

BOARD, DISPLAY CONTROL BA-33732

BOARD, POWER SUPPLY BA-33737

BOARD, PROGRAM MODULE (

DELUXE MODELS) BA-33742

—CONNECTOR, X11/X12 CR-33743

BOARD, RELAY CONTROL BA-33736

BUSHING, DISTANCE BU-25094

PART DESCRIPTION 20• 20

Parts List • Combitherm ML Electric

Page 25

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 24

ELECTRICAL/ELECTRONIC PARTS ( CONTD.):

TERMINAL BLOCK X7 (CONNECTOR, 9 POLES) TM-33774

TERMINAL BLOCK X6 (CONNECTOR, 16 POLES) TM-33773

CONTACTORS, 20A, TYPE # DL4K-01 CN-3652

CONTACTORS, 25A, TYPE # DL7K-4H CN-3654

CONTACTORS, 50A, TYPE # DL15K-00 CN-3731

ELEMENT, HEATING, FLANGED IMMERSION 6kW EL-33412

ELEMENT, HEATING, FLANGED IMMERSION 9kW EL-33411

ELEMENT, HEATING, O-RING SA-23932

ELEMENT, HEATING, CONVECTION (440-480V, 3PH) EL-3853

ELEMENT, HEATING, CONVECTION MNTG HARDWARE

— WASHERS, FLAT WS-22294

— WASHERS, SPLIT LOCK WS-22300

— HEX NUTS NU-22286

—O-RING SA-23932

—WASHER, CONICAL 13607

FAN, INTAKE, AUXILIARY DC4112NX FA-3568

FAN, WHEEL WH-3734

FUSE, SLOW-BLO 2AMP, 250V FU-33184

FUSE, SC-5 FU-33581

FUSE, NEOZED 6.3AMP FU-33452

FUSE HOLDER, DIN RAIL MOUNT WITH DISCONNECT FU-33756

FUSE HOLDER, 15AMP, 3POL, CLASS G FU-3842

FUSE HOLDER, 60AMP, 3POL, CLASS G FU-33039

FUSE, 45AMP, MP, CLASS G 10•18 (208-240V, 3PH) FU-33040

MOTOR, SUB ASSEMBLY (208-240V, 1PH/3 PH 5000602

NUT, KNURLED M3 NU-25095

PANEL, CONTROL OVERLAY (DELUXE MODELS) PE-25345

PANEL, CONTROL OVERLAY (

DELUXE PROGRAM OPTIONS) PE-25048

PANEL LOCK-DOWN SCREW CL-24089

LOCK CLIP WS-24090

PROBE, MULTI-POINT CTC PR-33746

PROBE, TEMPERATURE PR-33759

PROBE, THERMOCOUPLE (1650mm WIRE LENGTH) PR-33784

PROBE, STEAM BYPASS & WATER COOLING,

(THERMOCOUPLE, 3050mm WIRE LENGTH) PR-33751

PROBE SEAL, THERMOCOUPLE SA-25061

PROBE, WATER LEVEL PR-3706

PROBE, WATER LEVEL TIP CONNECTORS CR-3851

PART DESCRIPTION 20• 20

Parts List • Combitherm ML Electric

Page 26

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 25

ELECTRICAL/ELECTRONIC PARTS ( CONTD.):

SWITCH, MOTOR PROTECTION (3PH ONLY) SW-33378

TERMINAL, PLUG TM-3926

TERMINAL BLOCK X1 TM-33747

TERMINAL BLOCK X2 TM-33748

TERMINAL BLOCK X3 TM-33749

TERMINAL, GROUND TM-3781

TERMINAL GROUND X10 TM-3782

TERMINAL PARTITION TM-3786

TERMINAL BLOCK X10 TM-3780

TERMINAL BLOCK X10 & X11 TM-3778

TERMINAL JUMPER BAR (2 POLE) TM-33674

TERMINAL JUMPER BAR (3 POLE) TM-33106

TERMINAL JUMPER BAR (2 POLE) TM-33064

TERMINAL JUMPER BAR (4 POLE) TM-3787

TRANSFORMER TN-33344

THERMOSTAT, SAFETY TT-3750

VALVE, TRIPLE SOLENOID VA-25481

MECHANICAL PARTS:

BUSHING, MOTOR ASSEMBLY BU-23894

BUSHING, SOCKET MEMBRANE, VENT BU-22204

CLEAR FLEX HOSE HO-22255

DRAIN SCREEN DA-2943

LIGHT BULB LP-3686

LIGHT, GLASS COVER LP-33413

LIGHT SEAL SA-23934

LIGHT, SOCKET RECEPTACLE RP-3986

PROBE PLUG ADAPTOR PG-3826

PROBE PLUG PG-3827

PROBE PLUG SEAL SA-22199

PROBE SEAL, INSERT SA-22322

PROBE SEAL, CONE SA-22321

PROBE SEAL, TOP SA-22320

SCREW COVER, M6 NATURAL SC-23936

STEAM GENERATOR OUTLET CAP CP-22758

STEAM GENERATOR OUTLET CAP WASHER, SILICONE WS-22751

TROLLEY BRIDGE, LOWER FRONT 12773

TROLLEY GASKET, BOTTOM GS-22576

PART DESCRIPTION 20• 20

Parts List • Combitherm ML Electric

Page 27

20•20ML COMBITHERM ELECTRIC INSTALLATION AND MAINTENANCE MANUAL

PG. 26

PLUMBING PARTS:

BACK FLOW PREVENTER VA-2457

CONDENSATE TANK COVER NUT SC-24070

CONDENSATE TANK COVER SCREW SC-23936

CONDENSER, INJECTION NOZZLE 5000284

CONDENSER, O-RING SA-22212

CONDENSER, O-RING 8x2.5 EPDM SA-23109

DRAIN, STEAM GENERATOR PUMP DA-24973

PUMP MOUNTING HARDWARE 1000719

PIPE, DRAIN EXTENSION PP-25137

HAND SHOWER ASSEMBLY:

— HAND SHOWER (FULL ASSEMBLY) 14577

— HOSE, BALL VALVE VA-22684

— HOSE, SPRAY HANDLE PB-23920

— HOSE ASSEMBLY PB-24066

— HOSE, SPRAY NOZZLE PB-23919

— HOSE WASHERS, FLAT SEAL - 3/4" (19mm) WS-22207

HOSE, CONNECTOR ELBOW

WITH SEAL HO-22116

HOSE, CONNECTOR ELBOW SEAL WS-22208

HOSE, PUMP HO-25070

HOSE, RADIATOR HO-22254

HOSE, STEAM BYPASS HO-2957

PROBE, MEASURE WELD 5000283

STEAM GENERATOR DRAIN ELBOW EB-25106

STEAM GENERATOR INJECTION NOZZLE 5000292

SCREEN FILTER FI-2946

WATER CONDITIONER KIT FI-23014

INCLUDES: WATER CONDITIONER CARTRIDGE FI-12017

TROLLEY PARTS: PART NUMBER 5815

TROLLEY CASTERS, 5" (127mm) RIGID CS-23578

TROLLEY CASTERS, 5" (127mm) SWIVEL WITH BRAKE CS-23579

TROLLEY DRIP PAN 14475

TROLLEY HANDLE FR-22715

TROLLEY GUIDE BLOCK, TEFLON® BK-22100

TROLLEY SHELF SH-22473

TROLLEY SHELF LOCK LK-22556

PART DESCRIPTION 20• 20

Parts List • Combitherm ML Electric

Page 28

TRANSPORTATION

DAMAGE and CLAIMS

All Alto-Shaam

equipment is sold F.O.B.

shipping point, and

when accepted by the

carrier, such shipments

become the property of

the consignee.

Should damage occur in shipment, it is a matter between

the carrier and the consignee. In such cases, the carrier is

assumed to be responsible for the safe delivery of the

merchandise, unless negligence can be established on the

part of the shipper.

1. Make an immediate inspection while the equipment is

still in the truck or immediately after it is moved to the

receiving area. Do not wait until after the material is

moved to a storage area.

2. Do not sign a delivery receipt or a freight bill until you

have made a proper count and inspection of all

merchandise received.

3. Note all damage to packages directly on the carrier ’s

delivery receipt.

4. Make certain the driver signs this receipt. If he refuses

to sign, make a notation of this refusal on the receipt.

5. If the driver refuses to allow inspection, write the

following on the delivery receipt:

Driver refuses to allow inspection

of containers for visible damage.

6. Telephone the carrier’s office immediately upon finding

damage and request an inspection. Mail a written

confirmation of the time, date, and the person called.

7. Save any packages and packing material for further

inspection by the carrier.

8. Promptly file a written claim with the carrier and

attach copies of all supporting paperwork.

We will continue our policy of assisting our customers in

collecting claims which have been properly filed and

actively pursued. We cannot, however, file any damage

claims for you, assume the responsibility of any claims,

nor accept deductions in payment for such claims.

LIMITED

WARRANTY

Alto-Shaam, Inc. warrants to the original purchaser that

any original part that is found to be defective in material

or workmanship will, at our option, subject to provisions

hereinafter stated, be replaced with a new or rebuilt part.

The labor warranty remains in effect one (1) year from

installation or fifteen (15) months from the shipping date,

whichever occurs first.

The parts warranty remains in effect one (1) year from

installation or fifteen (15) months from the shipping date,

whichever occurs first.

Exceptions to the one year part warranty period are as listed:

A. Halo Heat cook/hold ovens include a five (5) year

parts warranty on the heating element. Labor will be

covered under the terms of the standard warranty

period of one (1) year or fifteen (15) months.

B. Alto-Shaam Quickchillers include a five (5) year parts

warranty on the refrigeration compressor. Labor will

be covered under the terms of the standard warranty

period of one (1) year or fifteen (15) months.

This warranty does not apply to:

1. Calibration.

2. Replacement of light bulbs and/or the replacement of

display case glass due to damage of any kind.

3. Equipment damage caused by accident, shipping,

improper installation or alteration.

4. Equipment used under conditions of abuse, misuse,

carelessness or abnormal conditions.

5. Any losses or damage resulting from malfunction,

including loss of product or consequential or

incidental damages of any kind.

6. Equipment modified in any manner from original model,

substitution of parts other than factory authorized parts,

removal of any parts including legs, or addition of any parts.

This warranty is exclusive and is in lieu of all other warranties,

expressed or implied, including the implied warranties of

merchantability and fitness for purpose. In no event shall the

Company be liable for loss of use, loss of revenue, or loss of

product or profit, or for indirect or consequential damages.

This warranty is in lieu of all other warranties expressed or

implied and Alto-Shaam, Inc. neither assumes or authorizes

any persons to assume for it any other obligation or liability in

connection with Alto-Shaam equipment.

ALTO-SHAAM, INC.

Warranty effective January 1, 2000

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 ●U.S.A.

PHONE: 262.251.3800 FAX : 262.251.7067

●

800.329.8744 U.S.A./CANADA

WEBSITE

:

800.558.8744 U.S.A./CANADA 262.251.1907 INTERNATIONAL

WWW.alto-shaam.com

PRINTED IN U.S .A .

RECORD THE MODEL AND SERIAL NUMBER OF THE OVEN FOR EASY REFERENCE. ALWAYS REFER TO

BOTH MODEL AND SERIAL NUMBER IN ANY CONTACT WITH ALTO-SHAAM REGARDING THE OVEN.

Model Number: _____________________________________ Date Installed: _____________________________________

Voltage: ____________________________________________ Purchased From: ____________________________________

Serial Number: ______________________________________ ____________________________________________________

Loading...

Loading...