Page 1

PH ONE

U.S.A./C ANAD A

FA X

U.S.A. O NLY

D UE TO ON G O IN G P R OD U C T IM P RO V EM E NT , S P EC I FI C AT I ON S A RE SU BJ E CT TO CH AN G E WI T H OU T N O TI C E .P RI N TE D I N U. S .A .

ITEM NO. _______________________

model 20•20esG with CombitouCh Control

roll-in pan Cart inCluded

capacity of forty (40) full-size or gn 1/1 pans,

twenty (20) full-size sheet or gn 2/1 pans

ANSI/NSF 4

20•20esG series

l

EcoSmart design uses less electricity and water than competitive models.

Reduced energy setting further minimizes electricity use.

l

Exclusive Gold-n-Brown™ features gives the operator the ability to

achieve the ideal cooking environment for the ideal finish.

l

Expandable system to meet your specific requirements.

l

Cook with the included product temperature probe (not included as standard on

S-control models) or by time.

l

Cooks with variable steam, convection heat, or a combination of both to roast,

steam, bake, or oven-fry. Cooking speeds are increased by as much as 70%

compared to conventional cooking methods.

l

CombiClean® feature uses jets of water for fully automated cleaning. Use either

commercial-strength CombiClean Tablets or Combitherm Cleaning Liquid Spray.

l

Boiler-free flash-steam generation increases reliability by eliminating boiler

maintenance and boiler heating element burnout. Steam levels are maintained

without a water reservoir.

l

Optional, CombiSmoker® oven with smoking technology smokes any product,

hot or cold.

l

CombiTouch®

— Intuitive CombiTouch control is fully operable from the touch screen.

— Store up to 250 recipes, each with up to 9 steps. CombiTouch comes standard

with more than 100 preprogrammed recipes and photos.

— Six precise and consistent Gold-n-Brown™ browning levels.

— Multi-shelf Timers track cooking time of ten different food items in the

same oven.

— Advance reversing fan design provides excellent baking results and

prevents excessive water and power consumption.

Provide Alto-Shaam Combitherm® floor-standing Model 20•20es G flash-steam gas CombiOven designed with EcoSmart® technology for

reduced energy and water usage and include operational modes for steam, convection, and a combination of steam and convection heat.

Standard features to include patented automatic steam venting; Gold-n-Brown™ browning function and a self-adjusting, flush-mounted

rotary door handle. Oven is to be constructed of 18 gauge stainless steel, include an attached spray hose with backflow preventer, cooldown function, automatic cleaning function, and four (4) adjustable legs. Each oven is to accommodate up to twenty (20) full-size sheet

pans or forty (40) full-size hotel pans, include standard right-hand door hinging, and Roll-in pan cart with twenty (20) non-tilt support

rails (21-1/16" (535mm) horizontal width between rails, and 2-5/8" (65mm) vertical spacing between rails), ten (10) stainless steel shelves,

removable drip tray and cart handle.

CombiTouch® Control: includes six different browning levels; two-speed reversing fan with coordinated venting system, USB port for data

access, quick-connect single-point internal product temperature probe in the oven interior.

Deluxe Control: includes a quick-connect single-point internal product temperature probe in the oven interior and programming

capability with Rapid-Touch™ operational quick-keys.

Standard Control: includes a quick-connect single-point internal product temperature probe in the oven interior.

S-Control: with quick-connect single-point internal product temperature probe in the oven interior as an option.

• Electrical Choices

➥Specify voltage:

120 1ph

208-240 1ph*

208-240 3ph

380-415 3ph*

* Touch only

• Gas Type

➥Specify choice:

Natural

Propane

FACTORY INSTALLED

• Door Swing

➥Specify choice

Right-hand Door Hinging,

standard

Recessed Door, optional

increases oven width by

4" (102mm)

Alternate Burner Orifice -

specify elevation for elevations

higher than 2,000 feet (610m)

above sea level

Smoking Function, optional

(not available on 120V units)

• Probe

➥Specify choice

Multi-point, hard-wired

temperature probe

[5005678] - not available

on ovens with S-Control

• Single-point, removable

temperature probe -

included on Touch, Deluxe

and Standard controls

S-Control oven without

smoker [5011570]

S-Control oven with

smoker [5011571]

• Security Devices for

correctional facility use.

Base package: excludes

temperature probe

➥Specify additional choices

Anti Entrapment Device

[5011081]

Control Panel Security Cover

[5012224]

Hasp Door Lock (padlocks

not included) [5011079]

Tamper-Proof Screw Package

for oven [5013923]

Seismic Feet Package

[5015198]

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 • U.S.A.

www.alto-shaam.com

: 262.251.3800 800.558.8744

: 262.251.7067 800.329.8744

#47 5 - 12 /1 3

Page 2

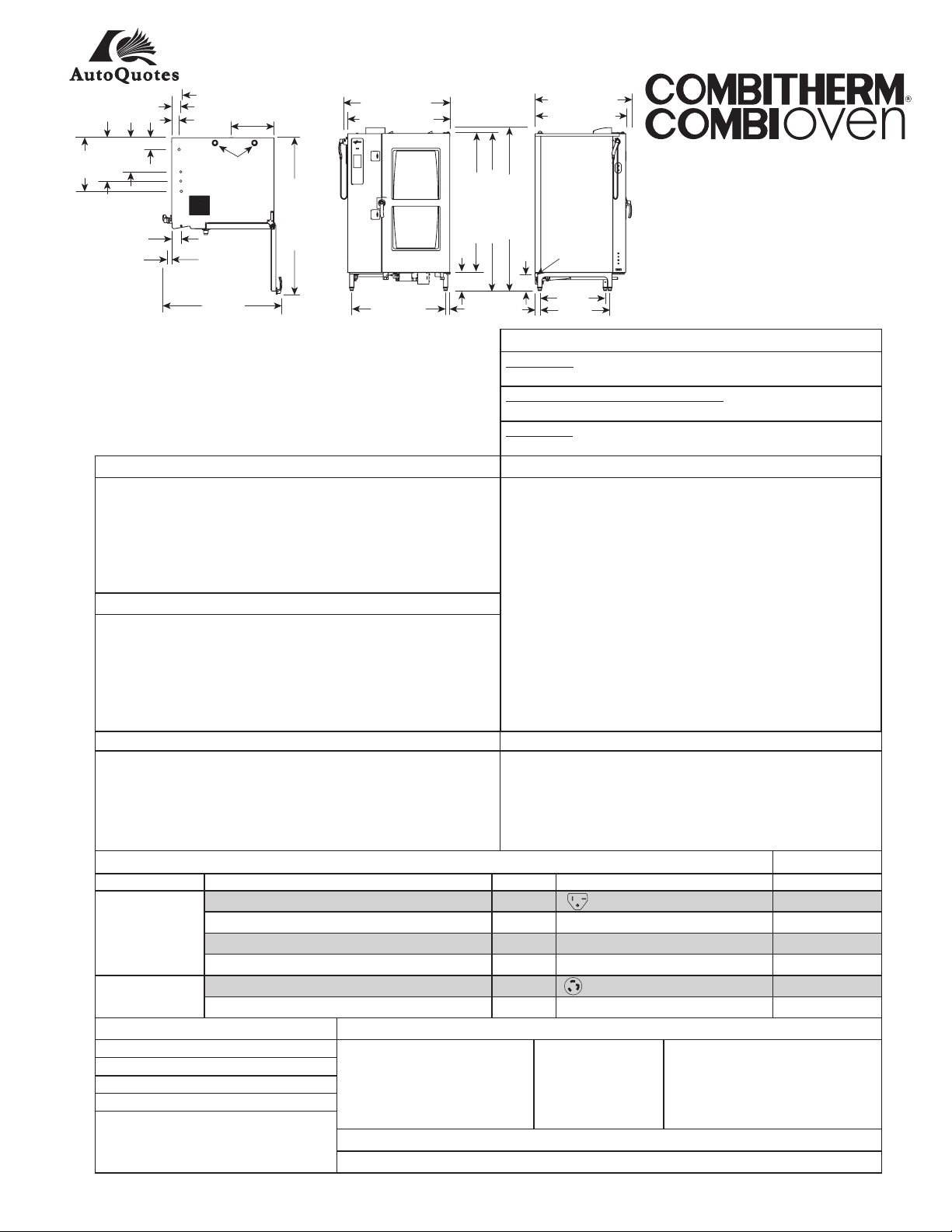

[A,B] 4-3/8" (110mm)

[D] 4-9/16" (116mm)

[C] 3-9/16"

(89mm)

Water Drain

(Side Back)

[D] 4-5/8" (116mm)

2" (50mm)

55-7/16"

(1407mm)

73-13/16" (1875mm)

5-7/8"

(148mm)

17-1/4"

(438mm)

19-11/16"

(500mm)

26-9/16"

(675mm)

19-15/16"

(506mm)

D

A = UNTREATED WATER

B = TREATED WATER

C = ELECTRICAL

D = GAS

C

B

A

49-13/16" (1264mm)

47-13/16" (1214mm)

44" (1118mm)

2"

(49mm)

8-15/16" (226mm)

76-5/8" (1946mm)

74-9/16" (1893mm)

65-5/8" (1667mm)

30-5/8"

(778mm)

32-13/16"

(833mm)

2-3/16"

(56mm)

Water Drain

(Bottom)

7-11/16" (195mm)

45-3/16" (1148mm)

42-9/16" (1080mm)

Steam

Vents

(Top)

WEIGHT CAPACITY

OVEN NET 720 lb est (327 kg) FULL-SIZE PANS: 20" x 12" x 2-1/2" Forty (40)

OVEN SHIP 1047 lb (475 kg) GN 1/1: 530 x 325 x 65mm Forty (40)

TROLLEY NET 180 lb (82 kg) GN 2/1: 650 x 530 x 65mm Twenty (20)

TROLLEY SHIP 245 lb (111 kg) FULL-SIZE SHEET PANS:* 18" x 26" x 1" Twenty (20)

CRATE DIMENSIONS: (L x W x H)

ON WIRE SHELVES ONLY

OVEN:

54" x 49" x 85" (1374 x 1245 x 2159mm)

480 lb (218 kg) MAXIMUM

TROLLEY:

35" x 35" x 82" (889 x 889 x 2083mm)

VOLUME MAXIMUM: 300 quarts (380 liters)

*ADDITIONAL WIRE SHELVES REQUIRED FOR MAXIMUM CAPACITY

GAS REQUIREMENTS (TYPE MUST BE SPECIFIED ON ORDER)

INSTALLATION REQUIREMENTS

CONNECTED ENERGY LOAD:

160,000 Btu / hr (Natural Gas)

• Oven must be installed level.

• Hood installation is required.

• Water supply shut-off valve and back-flow preventer when

required by local code.

• Alternate burner orifice is required for installation sites at

elevations of 2,000 feet (610m) above sea level.

150,000 Btu / hr (Propane)

HOOK-UP:

3/4"

NPT

MINIMUM CONNECTED PRESSURE:

5.5" W.C. (Natural Gas)

9" W.C. (Propane)

MAXIMUM CONNECTED PRESSURE:

14" W.C.

ELECTRICAL (DEDICATED CIRCUIT REQUIRED) - DO NOT CONNECT TO A G.F.I. OUTLET

CombiSmoker

®

MODEL

VOLTAGE PH HZ AMPS kW AW G CORD & PLUG Additional kW

20•20ESG Touch

120 1 60 9.0 1.04 AWG 12 NEMA 5-20P, 20A, 125V Plug

SK NOT AVAILABLE

208 – 240 1 50/60 5.0 1.04 AWG 12 no cord or plug + .7 kw

208 – 240 3 50/60 5.0/ph 1.04 AWG 12 no cord or plug + .7 kw

380 – 415 3 50/60 2.0/ph 1.44 AWG 12 Bare End, 3 Wire + ground +.7 kw

20•20ESG

120 1 60 22.0 2.6 AWG 10 NEMA L6-30P, 30A, 125V Plug

SK NOT AVAILABLE

208 – 240 3 50/60 4.27/ph 1.54 AWG 12 Bare End, 3 Wire + ground + .7 kw

WATER REQUIREMENTS WATER QUALITY MINIMUM STANDARDS

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE (1) TREATED WATER INLET: 3/4" NPT*

ONE (1) UNTREATED WATER INLET: 3/4" NPT*

LINE PRESSURE: 30 to 90 psi 2.8 to 6.2 bar

WATER DRAIN:

1-1/2"

CONNE CTION WITH A

2"

MINIM UM AIR GAP INSTALLE D AS CLOSE

TO THE OVEN AS POSSI BLE. MATERIAL S MUST WITHS TAND TEMPE RATURES UP TO

200°F (93°C).

It is the sole responsibility of the owner/operator/purchaser of this

equipment to verify that the incoming water supply is comprehensively

tested and if required, a means of “water treatment” provided that would

meet compliance requirements with the published water quality standards

published below. Non-compliance with these minimum standards will

potentially damage this equipment and/or components and VOID the

original equipment manufacturer’s warranty. Alto-Shaam recommends

using OptiPure

®

[www.optipurewater.com] products to properly treat your

water.

CLEARANCE REQUIREMENTS

Contaminant

Free Chlorine

Hardness

Chloride

pH

Silica

Total Dissolved Solids (tds)

Inlet Water Requirements

Less than 0.1 ppm (mg/L)

30-70 ppm

Less than 30 ppm (mg/L)

7.0 to 8.5

Less than 12 ppm (mg/L)

50-125 ppm

LEFT 6" (152mm) RECOMMENDED SERVICE ACCESS: 18" (457mm)

20" (508mm) FROM HEAT PRODUCING EQUIPMENT

RIGHT* 4" (102mm) TOP: 20" (508mm) FOR AIR MOVEMENT

BACK* 4" (102mm) BOTTOM: 5-1/8" (130mm) FOR LEGS

TOP 20" (508mm)

FOR AIR MOVE MENT

BOTTOM 5-1/8" (130mm)

FOR LEGS

*6" (152mm) from grease producing equipment

* Can manifold off of

one 3/4" line.

DIMENSIONS: H x W x D

EXTERIOR:

76-5/8" x 49-13/16" x 45-3/16" (1946mm x 1264mm x 1148mm)

EXTERIOR WITH RECESSED DOOR:

76-5/8" x 53-13/16" x 45-3/16" (1946mm x 1366mm x 1148mm)

INTERIOR:

54-15/16" x 25-1/4" x 33-7/8" (1395mm x 640mm x 860mm)

20•20esG series

#47 5 - 12 /1 3 d ue t o on g oi ng pr od u ct im pr o ve m en t, sp e ci f ic a ti o ns a re su b je c t to ch an g e wi t ho u t no t ic e . w ww . al to -sh a am . co m

Page 3

CombiTouch Deluxe Standard S-Control

Steam Mode

• Automatic steaming at 212°F (100°C).

• Quick steaming.

Touch — 213°F to 250°F (101°C to 121°C).

Deluxe, Standard, S-Control — 213°F to 248°F (101°C to 120°C).

• Low temperature steaming for poaching or proofing.

Touch — 85°F and 211°F (29°C and 99°C).

Deluxe, Standard, S-Control — 86°F and 211°F (30°C and 99°C).

20•20esG series

Combination Mode

• Combines steam and convection modes for faster production and better

moisture retention.

• Improves yield, quality and shelf life.

• Automatic humidity control.

Touch — 212°F to 485°F (100°C to 252°C).

Deluxe, Standard, S-Control — 212°F to 482°F (100°C to 250°C).

Convection Mode

• Cooking, roasting, baking and finishing applications.

Touch — 85°F to 485°F (29°C to 252°C).

Deluxe, Standard, S-Control — 86°F to 482°F (30°C to 250°C).

Retherm Mode

• Bulk food or plated meal reheating with automatic steam injection.

Touch — 245°F to 320°F (118°C to 160°C).

Deluxe, Standard, S-Control — 248°F to 320°F (120°C to 160°C).

• Automatic humidity control.

Gold-n-Brown™

• Gold-n-Brown vents just the right amount of humidity in the oven cavity

for perfect browning.

Touch — Six levels of Gold-n-Brown are featured.

Moisture Injection

• A quick burst of moisture can be added with a touch of a button at any

time when cooking in the convection mode.

HACCP Data Access (CombiTouch only)

• Records cooking mode, time and temperature completed within a two

week time period. The information is captured in a text format and can be

downloaded to a USB device.

CombiSmoker® (option)

• Smoke any product, hot or cold, utilizing real wood chips.

• Functions in both combination and convection mode.

• Function can be programmed into operating procedure.

• Sample bag of wood chips included.

#47 5 - 12 /1 3 d ue t o on g oi ng pr od u ct im pr o ve m en t, sp e ci f ic a ti o ns a re su b je c t to ch an g e wi t ho u t no t ic e . www.alto-shaam.com

Page 4

20•20esG series

OPTIONS & ACCESSORIES

COMBITHERM CLEANING LIQUID — spe ci al ly fo rmulate d f or co mb itherm ove ns

➥ t we lv e (12) c ontai ne rs /case , 1 quar t (c. 1 lit er ) e ac h [sp ecial hand li ng re qu ired] CE-24750

COMBICLEAN® TABLETS — s pe ci ally formu la te d f or co mb ither m ove ns

➥ 90 (0.5 o un ce ) p ac kets eac h con ta in er CE-28892

EXTENDED ONE-YEAR WARRANTY CONTACT FACTORY

FRY BASKET, 12" x 20" (325mm x 530mm) BS-26730

GAS LINE QUICK DISCONNECT KIT CR-33543

GRILLING GRATE, 12" x 20" (325mm x 530mm) SH-26731

HEAT SHIELD 5009492

POULTRY GREASE TRAY wi th dr ain: 1-1/ 2" (38mm) dee p 4758

POULTRY ROASTING RACKS:

6 ch ic ke n c ap acity , sel f-tr ussin g — fits in si de ra ck s: 12 ra ck s p er ov en 501443 8

6 ch ic ken c apaci ty — fit s f ul l-size pan : 10 r ac ks pe r o ve n sh-230 00

8 ch ic ken c apaci ty — fit s f ul l-size pan : 12 r ac ks pe r o ve n sh-236 19

10 c hi ck en ca pacit y — fits in si de ra ck s: 12 ra cks p er ov en sh-226 34

PREHEAT SEALING STRIP (to pr eh eat r ight ha nd un its w ithou t rol l-in tr ol ley) 1010739

PREHEAT SEALING STRIP (to pr eh eat r ecessed do or un it s w it ho ut ro ll-in tr ol le y) 1010752

PROBE, SOUS VIDE PR-34747

ROLL-IN PAN CART (h x w x d): UN-27970

66-1/1 6" x 28-15/16" x 35-3/16" (1678mm x 734mm x 892mm)

in te rch an ge abl e w it h 20•20 co mb i ma te ho ld in g c abi ne t a nd Qc2- 100Qu ic kc hi l le r

ROLL-IN PAN CART — CORRECTIONAL INSTITUTION (h x w x d ): 5010642

66-1/1 6" x 28-15/16" x 35-3/16" (1678mm x 734mm x 892mm)

in cl udes tampe r-pr oof s crews an d wel de d h an dle

in te rch an ge abl e w it h 20•20 co mb i ma te ho ld in g c abi ne t a nd Qc2- 100Qu ic kc hi l le r

ROLL-IN PLATE CART (h x w x d) in te rc ha n ge ab le wi th 20 •20co mb im ate h old in g c ab in e t:

108 p la te ca pa city – 65- 7/8" x 28-15/16 " x 39-7/8" (1674mm x 734mm x 1012mm)

2-11/1 6" (69mm) sp acing un-279 71

108 p la te ca pa city – 65- 7/8" x 28-15/16 " x 39-7/8" (1674mm x 734mm x 1012mm)

2-11/1 6" (69mm) sp acing – co rre ct io na l i ns tit ut io n 500989 9

78 pl at e c ap acity – 65 -7/8" x 28-15/1 6" x 39-7/8" (1674mm x 734mm x 1012mm)

3-1/2" (89mm) sp ac ing un-283 11

SCALE FREE™ (cit ru s b as ed, n on-corr os iv e d el iming prod uc t) CE-27889

SERVICE START-UP CHECK a vail abl e th roug h a n a lto- sh aam f aste am ce nt er SPECIFY AS REQUIRED

SHELF, STAINLESS STEEL WIRE SH-22473

THERMOBAG (co ve r f or ro ll -in t rolley) BL-29128

WOOD CHIPS — bu lk pa ck 20 lb (9 kg)

➥ Apple ...... wc-22543 ➥ Cherry ...... wc- 22541 ➥ Hickory ......wc-2829 ➥ Maple ..... wc-22545

#47 5 - 12 /1 3 d ue to o n go i ng pr od u ct i mp ro v em e nt , s pe ci f ic a ti o ns a re s ub je c t to ch an g e wi t ho u t no t ic e . www.alto-shaam.com

Loading...

Loading...