Alto Shaam 12.20-RTM-e Installation Manual

®

2800-RTM

ANUAL CONTROL

M

R e t h e r m & Fo o d H o l d i n g O ve n

Elect ronic or Manual Contro l

Models:

Manual Control

12•20-RT M WI T H RO LL-I N CA R T

2800-RT M

2800/S-R TM

2800/s-RTM

MANUAL CONTROL

OPTIONAL CASTERS

12•20-RTM/e

ELECTRONIC

CONTROL

Electronic Control

12•20-RT M/e WI T H ROLL-I N CART

2800-RT M/e

2800/

S-R TM /e

• INSTALLATION

• OPERATION

• MAI NTENANCE

W 1 6 4 N 9 2 2 1 W a t e r S t r e e t • P. O . B o x 45 0 • M e n o m o n e e F a l ls , W i s c o n s i n 5 3 0 52 - 0 4 5 0 U S A

PHONE: 262.251.3800 • 800.558.8744

P R I N T E D IN U .S .A .

USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

WEBSITE: www.alto-shaam.com

#887 • 03/07

SECTION 1 - INSTALLATION

Delivery / Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Procedures & Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Site Installation / User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Stacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5, 6

Product/Pan Capacity –– Options & Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SECTION 2 - OPERATION

Manual Control

Identification and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Electronic Control

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Program Preset Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Setting the Internal Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Fail Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Operational Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Beeper Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Fahrenheit or Celsius Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Preset Keys Lock & Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Control Panel Lock & Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Audible Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Operating Features & Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Product Reheating Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

General Holding Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

I N D E X

SECTION 3 - CARE AND CLEANING

Cleaning and Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Clean the Oven Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Roll-in Cart/Food Trolley Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Daily Gasket Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Sanitation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SECTION 4 - SERVICE

Service Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 thru 22

Service Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 thru 28

Cable Replacement Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30, 31

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 thru 39

Transportation Damage & Claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

DELIVERY

T

his Alto-Shaam appliance has been

t

horoughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and

report it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

UNPACKING

1. Carefully remove the

appliance from the

carton or crate.

NOTE: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

®

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 1

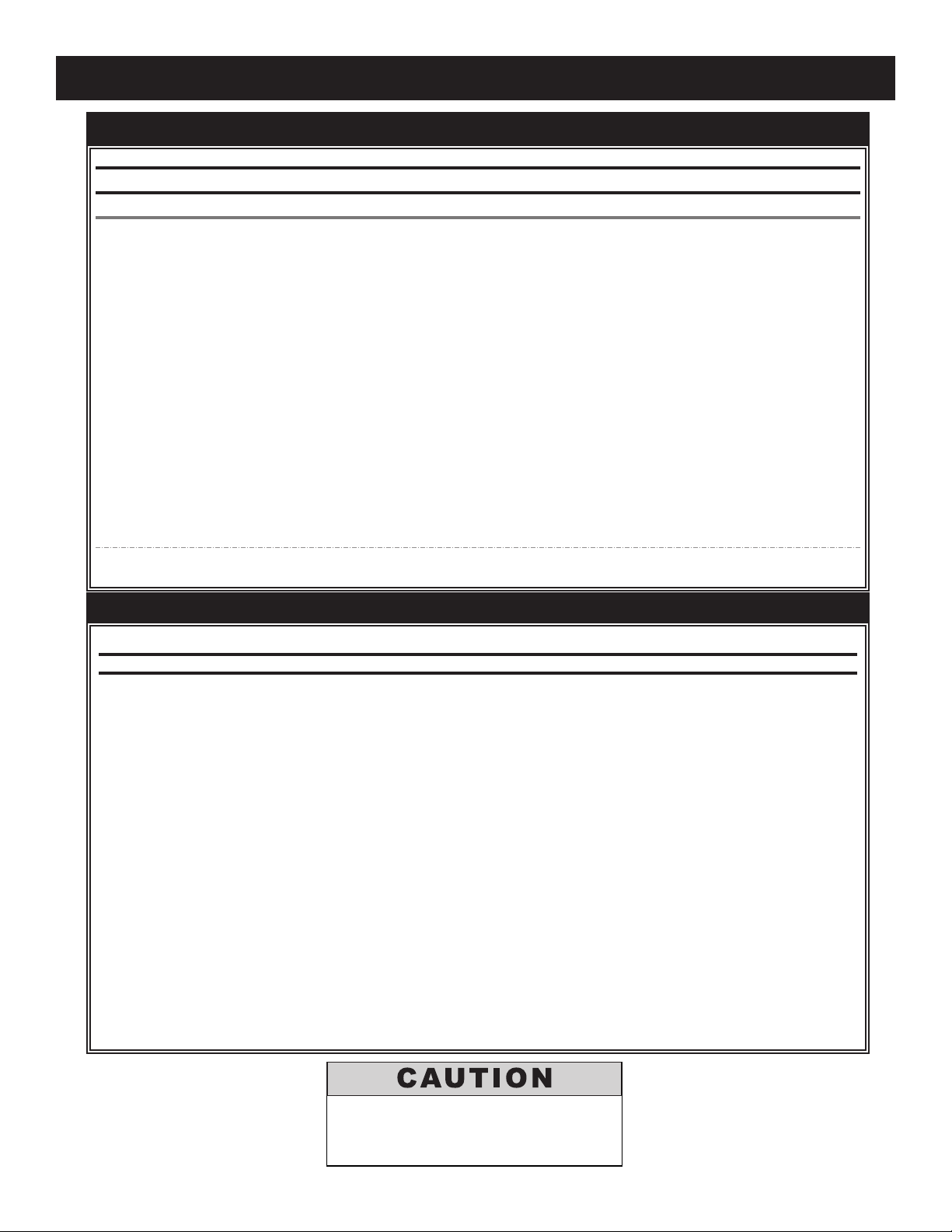

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

Used to indicate the

presence of a hazard that

will

cause severe personal

injury, death, or substantial

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can

cause personal injury,

possible death, or major

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor or

moderate personal injury

or property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor

personal injury, property

damage, or a potential

unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this

appliance is authorized or recommended.

2. This appliance is intended for use in

commercial establishments where all

operators are familiar with the purpose,

limitations, and associated hazards of this

appliance. Operating instructions and

warnings must be read and understood by

all operators and users.

3. Any troubleshooting guides, component

views, and parts lists included in this manual

are for general reference only and are intended

for use by qualified technical personnel.

4. This manual should be considered a

permanent part of this appliance. This

manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and

labels must remain with the appliance if the

item is sold or moved to another location.

NOTE:

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 2

I N S T A L L A T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

TO MAINTAIN SAFE TEMPERATURE LEVELS,

COLD FOOD FOR RETHERMALIZATION OR

REHEATING MUST NEVER BE ADDED TO THE

OVEN WHILE HOT FOODS ARE BEING HELD.

S I T E I N S T A L L A T I O N U S E R I N F O R M A T I O N

The oven, complete with unattached items and

accessories, may be delivered in one or more packages.

Check to ensure that all the accessories ordered have

been received with the oven.

This retherm and food holding oven is designed for the

purpose of heating food to its proper temperature and

maintaining the hot food at a temperature for safe

consumption. It must be installed in a location that will

permit it to function for its intended purpose and allow

adequate access for proper cleaning and maintenance.

C L EA R A N C E RE Q U I R E M EN T S

6-inches (152mm) at the back, top, and both sides

1. The oven should be installed on a stable and level

surface. Level the appliance from side-to-side and

back-to-back with the use of a spirit level.

2. DO NOT install the oven in any area where it may be

affected by any adverse conditions like steam, grease,

dripping water, high temperatures, etc.

3. DO NOT install adjacent to flammable surfaces.

W E IG H T

2800/s-

2800-

RTM 270 lbs (122 kg)

RTM 384 lbs (174kg)

BE FORE INIT IAL USE:

Clean both the interior and exterior of the cabinet with

a damp cloth and mild soap solution. Rinse carefully.

Become familiar with the operation of the controls.

Read this manual carefully and retain it for future

reference. Alto-Shaam Retherm and Food Holding ovens

have undergone extensive tests reheating individual

meals, bulk convenience entrées, pre-cooked frozen items,

and cooking a variety of raw foods at temperatures up to

400°F (204°C).

The design elements of this oven incorporate a series of

fans to evenly distribute heat and reach temperature

requirements quickly. This oven is best suited for school

food service, healthcare satellite kitchens, catering, or

any kitchen that is reheating individual meals or bulk

food from a commissary. These meals usually consist of

a casserole item such as lasagna, or a meat and starch

item such as turkey with stuffing, and vegetables. Since

these ovens are fully functioning ovens with high

temperatures, a variety of items, such as cookies, chicken

breasts, and frozen vegetables can also be cooked.

While Retherm and Food Holding ovens have both

cooking and holding capabilities, using these ovens for

roasting large cuts of meat is not recommended. The fans

operate continuously during the retherm cycle. It is

recommended to cover food to retain moisture and to

maximize the holding times.

HE ATING CHAR ACTE RIST ICS

The oven is equipped with a special, low heat density,

heating cable. Through the Halo Heat concept, the

heating cable is mounted against the walls of the oven

compartment to provide an evenly applied heat source

controlled by an electronic thermostat. Through even

heat application, products are reheated to serving

temperature from either a chilled or frozen state and the

quality of a food product is maintained at a holding

temper a ture up to as m uch as sev e ral hours .

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 3

This retherm and holding oven has a distinct advantage

over a convection oven. While each oven takes

approximately the same time to cook or reheat, this

oven automatically converts to a holding cabinet where

an entire oven load can remain until serving time. (The

unit must remain connected to a electrical power source

when in this holding stage.) Since individual and bulk

meals are reheated in covered containers, maximum

holding life is achieved when operating these ovens

with the type of precooked products suggested.

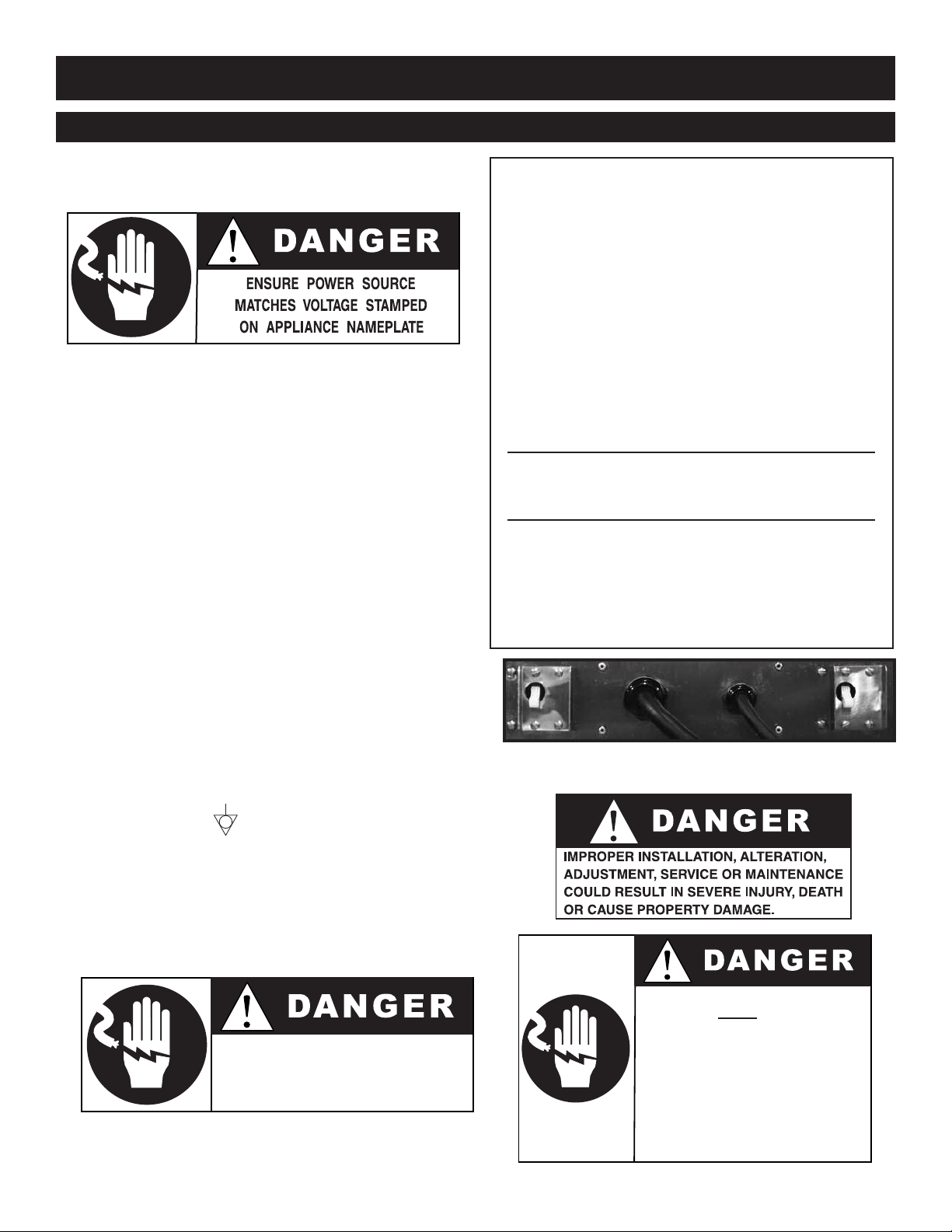

E L E C T R I C A L

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be made

in accordance with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

ELECTRICAL CONNECTIONS MUST

BE MADE BY A QUALIFIED SERVICE

TECHNICIAN IN ACCORDANCE WITH

APPLICABLE ELECTRICAL CODES.

I N S T A L L A T I O N

1. An identification tag is permanently mounted on the

exterior of the oven.

2. A proper receptacle or outlet configuration, as

required for the oven, must be installed by a licensed

electrician. The unit must be grounded in accordance

with applicable local electric codes. In the U.S.A. the

oven must be grounded in accordance with the

National Electrical Code.

3. Means for disconnection must be incorporated in the

fixed wiring in accordance with wiring rules.

4. Plug the unit into a properly grounded receptacle

only, positioning the oven so that the supply cord is

easily accessible in case of an emergency. Arcing will

occur when connecting or disconnecting the unit

unless all controls are in the “OFF” position.

NOT E:

380V 3 phase units are furnished with two

electrical cords. The larger cord is used when

a 380V 3 phase power source is available

during rethermalization or holding functions.

The smaller power cord is used after moving

the oven to a holding area where a lower

voltage receptacle is available for hot food

hold ing only.

Each cord is furnished with an individual

ON/OFF circuit breaker switch located at the

back next to the cord. Remember to turn ON

the power for the appropriate electrical cord.

Never plug in both cords at the

same time.

Electr i c al damage could occur.

This feature is provided as a customer

convenience when the oven is to be moved to a

separate hol d ing area (following product

rethermalization) where a 380V 3 phase power

source is usually not available.

23 0V u nits : To prevent an electrical shock hazard

between the appliance and other appliances or metal

parts in close vicinity, an equalization-bonding stud

is provided. An equalization bonding lead must be

connected to this stud and the other appliances /

metal parts to provide sufficient protection against

potential difference. The terminal is marked with the

following symbol.

NO TE: The appliance must be connected to an

electrical circuit that is protected by an

external GFCI outlet.

#887 • Re therm and Food Hold O v en • Opera tion and Ca r e Man ual • 4

Retherm

Switch

Retherm

Cord

Holding

Cord

Holding

Switch

I N S T A L L A T I O N

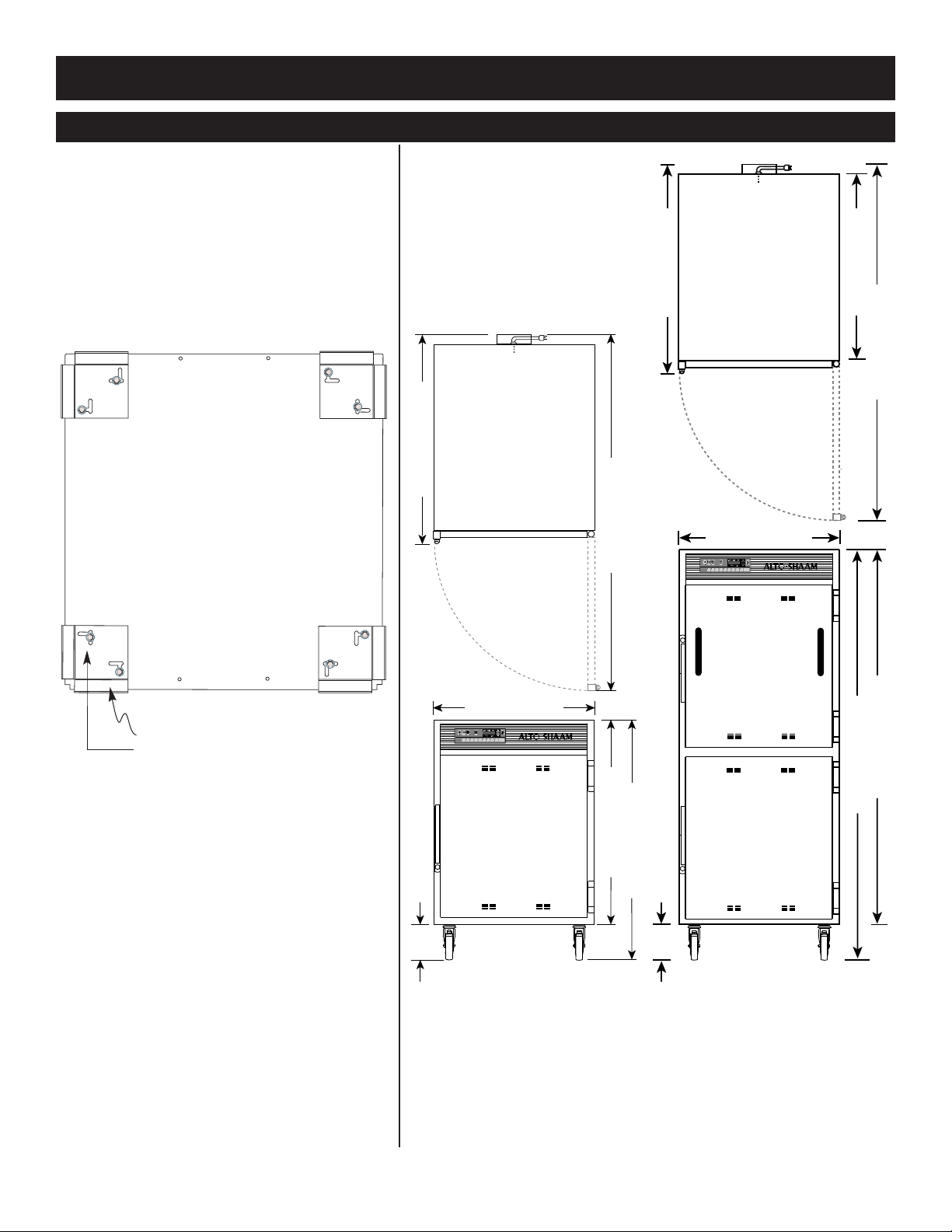

64-7/8" (1647mm)

30-3/4" (781mm)

32-1/8" (816mm)

37-3/8" (949mm)

65-3/8" (1659mm)

71-1/2" (1816mm)

6-1/16" (154mm)

E

lectrical

C

onnection

2-3/4" (71mm)

from top

C

L

P

RESETS

ABCDEFGHI CANCEL

64-7/8" (1648mm)

30-3/4" (782mm)

37-5/16" (947mm)

35-5/16" (897mm)

41-9/16" (1056mm)

6-1/4" (159mm)

OPTIONAL CASTERS

Electrical Connection

2-3/4" (71mm) from top

C

L

PRESETS

A

BCDEFGH

I C

ANCEL

BOTTOM VIEW

OF TOP OVEN

S T A C K I N G I N S T R U C T I O N S D I M E N S I O N S

Model 2800/S-RTM MANUAL CONTROL

Model 2800/S-RTM/e ELECTRONIC CONTROL

OVEN STACKING KIT 5001115

(OPTION)

FRONT OF OVEN

4: Stacking Hardware Corners

8: Serr. Hex Head Screws SC-2351

Fasten stacking corners to bottom of oven

using 2: 5/16-189 serr. hex hd screws on

each corner.

Mo del 280 0/S -RT M

MA N UA L CO N TR O L

Mo del 280 0/S -RT M/e

EL E CT R ON I C CO NT R OL

Mo del 280 0-R TM

MA N UA L CO N TR O L

Mo del 280 0-R TM/ e

EL E CT R ON I C CO NT R OL

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 5

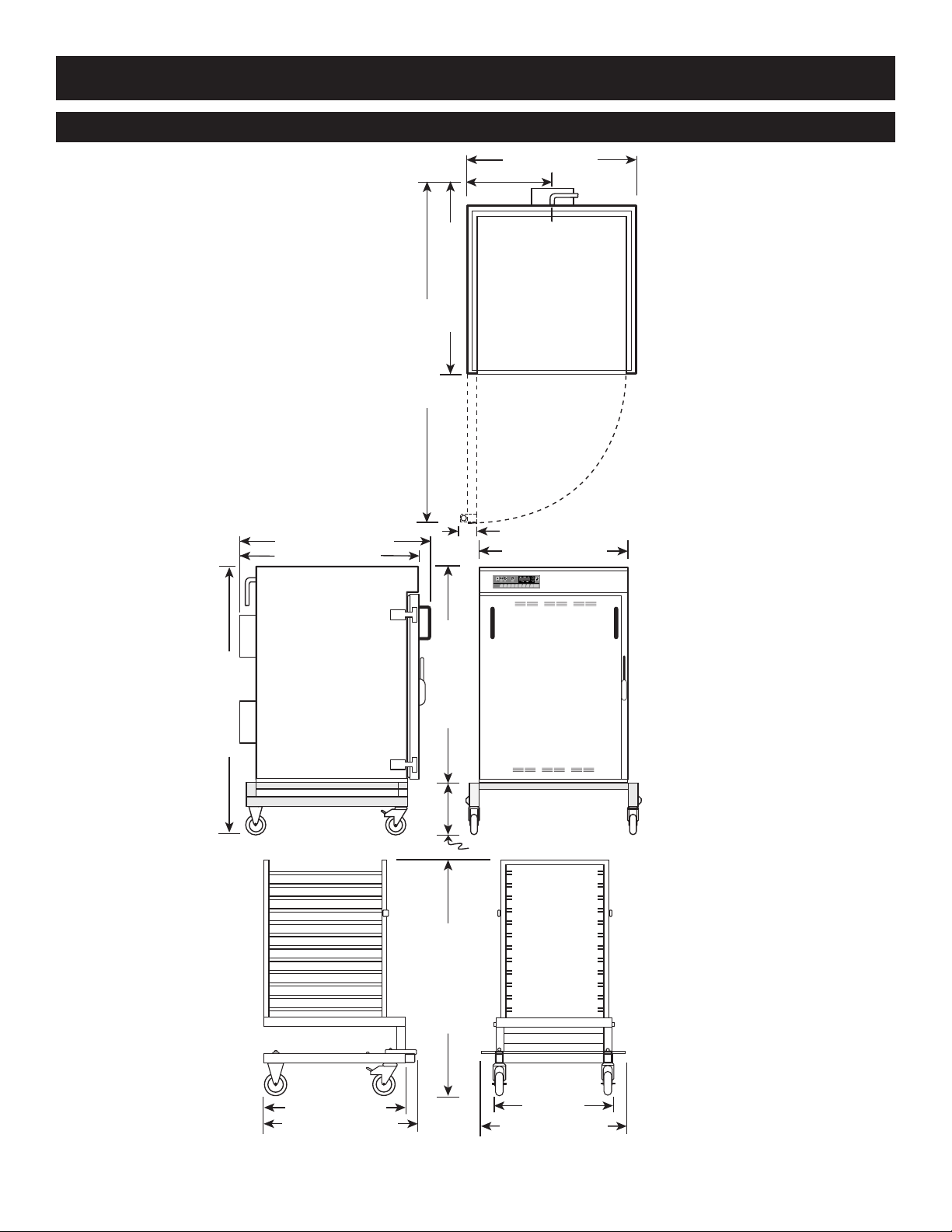

36-3/4" (933mm)

7

2

-

3

/

8

"

(

1

8

3

8

m

m

)

ELECTRICAL

CONNECTION

3-1/2" (89mm)

From Top

3-1/2" (89mm)

32-7/8" (832mm)

4

8

-

1

/

8

"

(

1

2

2

2

m

m

)

5

0

-

1

/

2

"

(

1

2

8

2

m

m

)

30-5/16" (770mm)

24-1/8"

(617mm)

31-15/16" (811mm)

29-1/2" (749mm)

C

L

4

1

-

1

/

2

"

(

1

0

5

4

m

m

)

10-1/2" (267mm)

ALTO-SHAAM

58-3/4" (1492mm)

10-3/4"

(273mm)

4

1

-

1

/

2

"

(

1

0

5

4

m

m

)

4

3

-

1

1

/

1

6

"

(

1

1

0

9

m

m

)

PRESETS

A

BCDEFGH

I C

ANCEL

Mo del 12• 20- RTM

AN U AL C ON T RO L

M

IT H RO L L

W

N CA RT

-I

Mo del 12• 20- RTM/e

EL E CT R ON I C CO NT R OL

WI T H RO LL

-I N CA RT

I N S T A L L A T I O N

D I M E N S I O N S

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 6

I N S T A L L A T I O N

TO MAINTAIN SAFE TEMPERATURE LEVELS,

COLD FOOD FOR RETHERMALIZATION OR

REHEATING MUST NEVER BE ADDED TO THE

OVEN WHILE HOT FOODS ARE BEING HELD.

P R O D U C T / P A N C A P A C I T Y

1 2 •2 0 -R T M 2 8 00 - RT M 2 8 00 / S- R TM

MA X I M UM 28 8 lb s ( 131 kg) 38 4 lb s ( 174 kg) 19 2 lb s ( 87 kg)

VOLU ME MAXI MUM 18 0 QT S (22 8 L ) 24 0 QT S (30 4 L ) 1 20 Q T S (152 L)

FULL-SIZE PANS

20" x 12" x 2-1/2" (GN 1/ 1) 24 32 16

FULL-SIZE SHEET PANS

18" x 26" x 1" 12* 16 8

WIRE ENTRÉE BASKETS #47

13"x26" (330mm x 660mm) -- 32 16

ENTRÉE PANS PER BASKET 10 10

ENTREE PER UNIT -- 320 160

WIRE ENTREE BASKETS #53

13"x20" (330mm x 508mm) 26 32 16

ENTRÉE PANS PER BASKET 88 8

ENTREE PER UNIT -- 256 128

ENTRÉE PANS PER CART 208 -- --

NT RÉ E PAN SIZE

E

: 6-1/2" X 5" (165mm X 127mm) *w it h o ptio n al s h e l v e s

O P T I O N S & A C C E S S O R I E S

12•20 2800-RTM 2800/S-RTM

DESCRIPTION SERIES SERIES SERIES

HACCP Network Options (ELECTRONIC CONTROL ONLY)

REFER TO SPECIFICATION #9015, DATED 10/05 OR AFTER FOR APPLICABLE PART NUMBERS

HACCP Documentation

HACCP with Kitchen Management

Baskets, s/s wire entree #53 - 13" x 20" (330mm x 508mm) BS-25591 BS-25591 BS-25591

#47 - 13" x 26" (330mm x 660mm) -- BS-25592 BS-25592

#47C - 18" x 26" (457mm x 660mm) -- BS-27765 BS-27765

Bumper, full perimeter assembly with 5" (127mm) casters -- 5001159 5001159

Cart, roll-in (trolley) with removable pan rail supports 5000723 -- -Cart, roll-in (trolley) included as standard 5814 -- -Casters, 5" (127mm)

Probe, internal product temp.,

ELECTRONIC CONTROL ONLY AVAILABLE AVAILABLE AVAILABLE

Legs, 6" (152mm) -- 5205 5205

Preheat Sealing Strip 1000664 -- -Shelves, stainless steel wire SH-22473 -- -Stacking Hardware -- -- 5001115

INCLUDED INCLUDED 4007

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 7

M A N U A L C O N T R O L • O P E R A T I O N

햷

햶

햸

햴

햵

햳

햲

햹

Make sure the proper electrical cord is connected to the appropriate power source, and the circuit breaker is on.

C O N T R O L I D E N T I F I C A T I O N M A N U A L C O N T R O L O P E R A T I O N

햲 ON/ OFF PO WER SWI TCH

ON/OFF power switch provides access to operation

The

of the control system.

➜ The power ON indicator light 햳 will illuminate and

will remain lit as long as the power switch is

To disengage power, press the power switch to the

OFF O position and the ON/OFF indicator light will

go out.

햴 HOL D THER MOS TAT

The HOLD THERMOSTAT has a temperature range of

60° to 240°F (16° to 116°C).

➜ The holding indicator light

the hold thermostat is turned clockwise from the

OFF position to an operator set temperature. The

holding indicator light will cycle

hold thermostat calls for heat. This process will

continue as long as the hold thermostat is engaged.

햵 will illuminate when

ON and OFF as the

햶 RET HERM T HER M OSTAT

The RETHERM THERMOSTAT has a temperature

range of 100° to 400°F (38° to 204°C).

➜ The retherm indicator light

the timer

indicator light will cycle

thermostat calls for heat.

햸 is advanced clockwise. The retherm

햷 will illuminate when

ON and OFF as the retherm

햸 RET HERM T IME R (4 hour maximum)

When advanced clockwise, the RETHERM TIMER

will engage the retherm thermostat which will remain

active until the timer is rotated or cycles to the

OFF position.

ON I .

1. Press the ON/OF F power key 쐃 to the ON position.

The power

disengage power, press the power switch to the

position and the ON/O FF indicator light will go out.

ON indicator light 쐇 will illuminate. To

2. Turn the RETHERM THERMOSTAT 쐄 clockwise to

the reheating temperature desired.

3. Turn the HOLD THERMOSTAT 쐋 clockwise to the

holding temperature desired for the reheated product.

4. Preheat the oven by advancing the TIMER knob 쐆

clockwise to activate the Retherm Thermostat. Allow

the oven to preheat until the “RETHERM” indicator

light goes out.

5. Load product.

6. RES E T TIME R TO THE C ORRE C T PERI OD

OF RETHE RM TIM E . (4 hour maximum)

A. To set time, turn the timer knob past the

required time period then immediately bring it

back to the correct setting.

B. Refer to individual cooking instructions for

length of time necessary to retherm.

C. When timer cycles to the “OFF” position, the

oven temperature automatically lowers to the

selected “HOLD” temperature.

D. The internal temperature of the product will

continue to increase as the oven temperature

lowers to the selected holding temperature.

햹 HOL DING T EMP E RATU RE GAU GE

The HOLDING TEMPERATURE GAUGE reflects the

air temperature inside the cabinet.

OFF

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 8

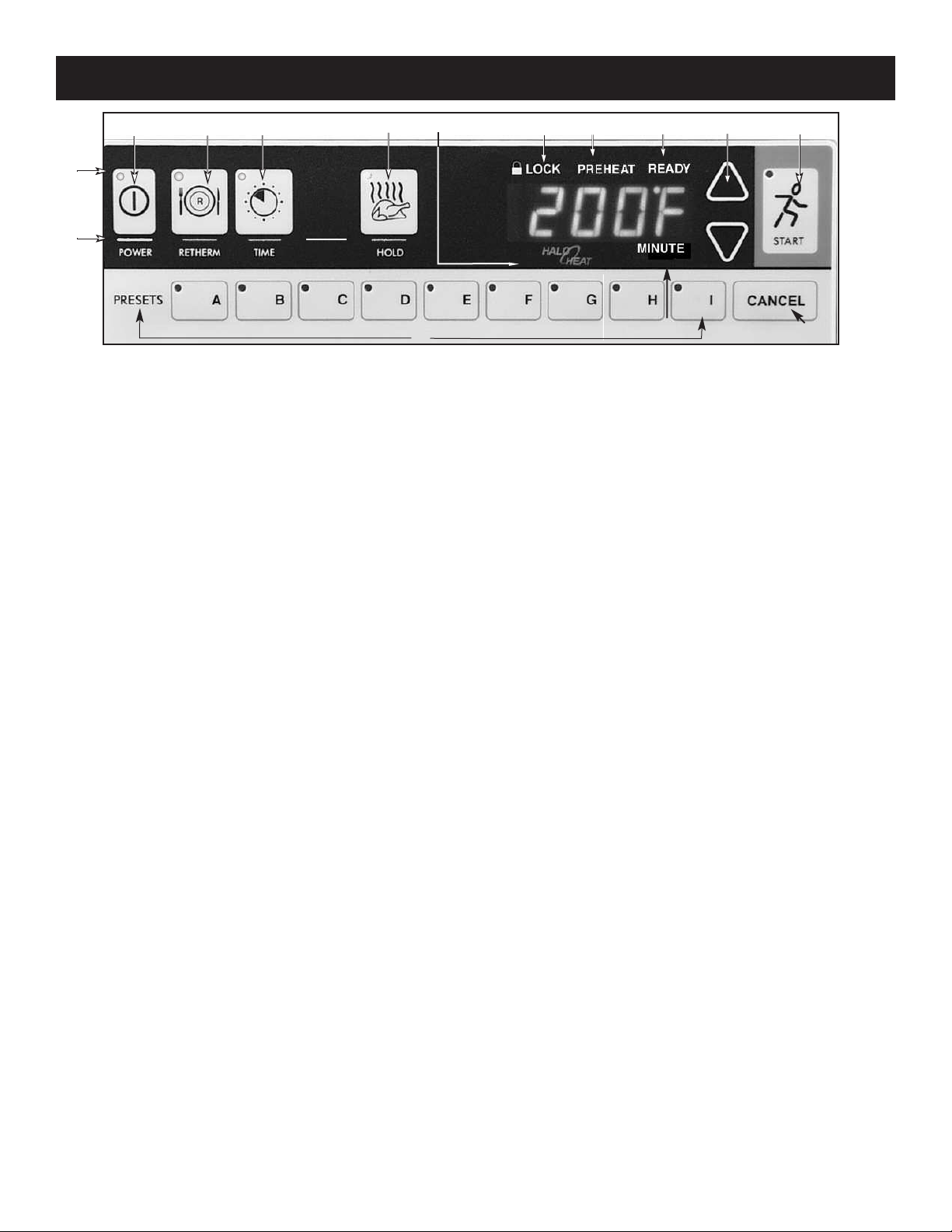

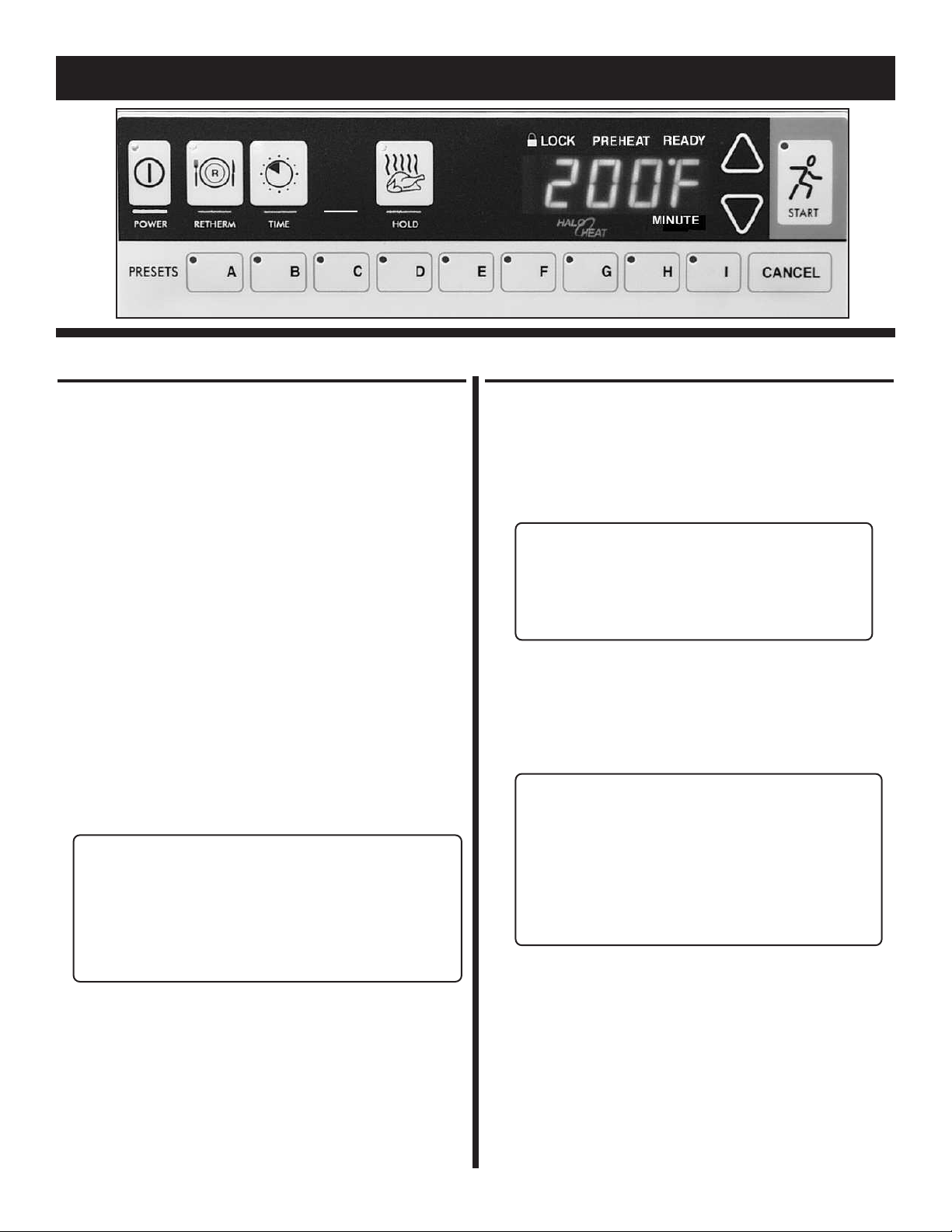

E L E C T R O N I C C O N T R O L • O P E R A T I O N

햵

햻

햽

햲

햳

햴

헂

RO B E

P

햲 O N / O F F P O W E R K E Y

ON/OFF power key provides access to operation of

The

the control system. Press the

energize the control. The power

illuminate. To disengage power, press and hold the

ON/OFF key for four seconds. An audible signal will

sound and the

If there is a power loss during operation, the

key light will flash. To clear a flashing ON/OF F key

indicator, press and release the power key. (See Power

Fail Detect paragraph for additional information).

ON/OFF indicator light will go out.

ON/OFF power key to

ON indicator light will

ON/OFF

햳 R E T H E R M K E Y

The retherm or regeneration key provides the operator

with a temperature range setting of 100°F to 400°F

(38°C to 204°C).

햴 T I M E K E Y

Used to select retherm time up to a maximum of 24

hours and to review operator set time.

햵 H O L D K E Y

Provides the operator with the a hot food holding

temperature range of 60°F to 205°F (16°C to 96°C). Press

the hold key and use the up and down arrow keys to

adjust the holding temperature. Press and hold this key

to review the operator set holding temperature.

햶 H A L O H E AT I ND I CAT O R

The Halo Heat indicator light will illuminate during the

preheating cycle and will remain lit until the oven

reaches the operator set retherm temperature. Once the

set temperature has been reached, the Halo Heat

indicator will illuminate periodically as the unit calls

for heat.

햷 P R E H E AT I N D I C AT O R

The preheat indicator will illuminate until the retherm

oven reaches the operator set temperature.

햸 R E A D Y I N D I C AT O R

The ready indicator will illuminate when the preheat

temperature has been reached and the retherm oven is

ready for product loading.

The ready indicator will illuminate again when the

retherm time has expired and the temperature decreases

from the retherm temperature to the holding

temperature.

햹 U P / D O W N A R R O W KE Y S

The arrow keys function to adjust the set temperature of

the retherm mode and the hold mode. With the oven

햾

햶

헁

햷햸햹

햿

power

up or down arrow key to adjust the temperature in

increments of 1-degree. Press and hold the mode key

while pressing the up or down arrow key to adjust the

temperature in increments of 10-degrees.

The arrow keys also function to adjust the set time.

With the oven power

by the up or down arrow key to adjust the time in

increments of 1-minute. Press and hold the time key

and the up or down arrow key to adjust the time in

increments of 10 minutes.

ON, press the required mode key followed by the

ON, press time time key followed

햺

헀

햺 S T A R T KE Y

The start key is used to start or stop a retherm

operation. Press and release the start key to initiate a

selected mode sequence. Press and hold the start key to

stop a selected mode sequence. Release the key when

an audible signal is heard.

햻 G R E E N I N D I C AT O R LI G HT S

Located within each function key, the green indicators

identify the current mode of operation. These indicators

also function as an operator prompt to initiate

additional action on the part of the operator.

햽 A M B E R I N D I C AT O R LI G HT S

Located below each function key, the amber indicators

identify the current mode of operation. These indicators

also allow the operator to identify the current LED

display information.

햾 P R E S E T P R O G R AM K E Y S

Keys A through H provides memory storage and

operating function for up to eight individual operator

set retherm programs. The I key enables the program

key locking function.

햿 O V E N D I S P L AY

Indicates set preheat temperature, retherm time, holding

temperature, and a countdown of remaining time.

헀 C A N C E L K E Y

The cancel key erases a program from stored memory.

헁 L O C K K E Y

Indicates settings used in retherm are locked.

헂 P R O B E K E Y (o p t i on al )

Used to select and review internal product probe

temperature setting.

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 9

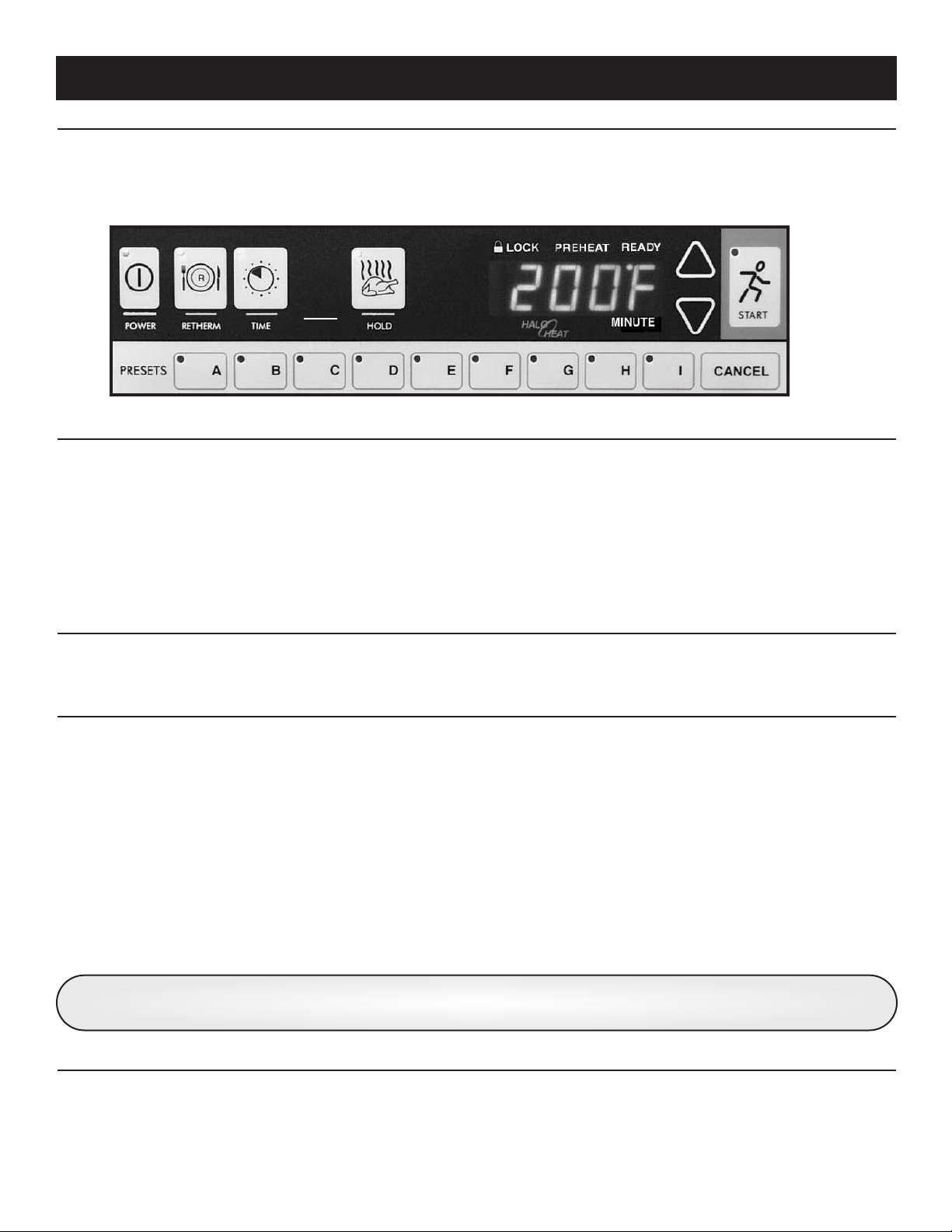

E L E C T R O N I C • B A S I C O P E R A T I O N

RO B E

P

Make sure the proper electrical cord is connected to the appropriate power source, and the circuit breaker is switched on.

RETHER M BY T IME

(or PROBE if equipped):

1.

Press the Control Powe r key O

N

.

2. Press the Retherm key. The last operator set

retherm temperature will appear in the display.

To change the retherm temperature, press the Up

or Down arrow keys.

3. Press Time key (or optional Probe key ) . The last

operator set time will appear in the display. To

change the retherm (or probe) time, press the Up

or Down arrow keys.

4. Press Hold key. The last operator set holding

temperature will appear in the display. To

change the holding temperature, press the Up or

Down arrow keys.

5. Wait for the Ready indicator to illuminate.

The Retherm oven is automatically

programmed to preheat to the retherm

temperature. When the unit has finished

preheating, a triple beep will sound every

30 seconds. Both the Ready and Start

indicator lights will flash.

RETHERM WITH PRESET MENU KEYS:

1.

Press the Control Powe r key ON.

2. Press the selected Preset program key.

A green Preset Program key indicator

light will illuminate in the upper left-hand

corner of a lettered key when the key has

been programmed.

SEE FOLLO WING PAGE F O R

PRO GRAM M ING I NSTRU CTION S.

3. Wait for the Ready indicator to illuminate.

The Retherm oven will automatically

preheat to the programmed retherm

temperature. When the unit has finished

preheating, a triple beep will sound every

30 seconds. Both the Ready and Start

indicator lights will flash.

4. Load food products inside the retherm oven and

6. Load food products inside the retherm oven and

securely close the oven door.

7. Press the Start Key.

To vi ew th e t e mperat ure in s ide the

oven co mpartm ent, press an d hold

the H old ke y.

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 10

securely close the oven door.

5. Press the Start Key.

To vi ew the tem peratu r e ins ide th e

oven comp artmen t, pres s and hold

the H old ke y.

E L E C T R O N I C • P R O G R A M P R E S E T K E Y S

PRESET MENU KEYS

This Alto-Shaam Retherm oven allows the operator to set up to eight retherm programs. Each program can be preset

in any program mode to retherm by time or by internal temperature. Programs are recalled and stored using the Preset

keys labeled “A through H”. These keys, along with the key labeled “I”, share additional functions described in the

operation section of this manual.

PR O BE

PROGRAMMING A RETHERM PROGRAM

Prior to this procedure make sure the oven is “OFF”. Select the food product to be programmed. Press and release

control On/ Off key. The oven will beep for one second and power to the unit will be indicated by an illuminated green

indicator light located in the upper left corner of the On/ Off key. The oven will begin operating in the hold mode. The

amber Hold indicator will be illuminated and the last set hold temperature will be displayed.

Press Hold key. To change the hold temperature, press the Up or Down arrow key.

Press Retherm key. Oven preheat indicator will illuminate and the last set retherm temperature is displayed. To

change the Retherm temperature, press the Up or Down arrow key.

TO RETHERM BY TIME

Press the Time key. Last set time is displayed. To change the set time, press the UP or Down arrow key. The green

Time indicator will illuminate.

TO RETHERM BY PROBE (if oven is equipped with a probe)

Press the Probe key. Last set internal product temperature is displayed. To change the set temperature, press the

Up or Down arrow keys. The green Probe indicator will illuminate.

The oven preheat indicator will illuminate. Oven is now in the preheat mode

and is automatically programmed to preheat to the retherm temperature.

Select a letter code for the product programmed by the previous steps. Press and hold the selected Preset key until

you hear a brief, four second beep. The letter key program indicator light will illuminate and the product programmed

is now stored in memory for the specific letter key pressed. Additional programs can be stored in the remaining Preset

keys if not previously programmed.

Note: The last Preset key used will be the oven retherm run sequence for the next products to be programmed.

Setting can be manually changed for the next product and an alternate pre-programmed letter key selected.

After programming a specific product into memory for a Preset key,

it is important to make a written permanent record of the product and the program letter assigned.

ERASING A RETHERM PROGRAM

To erase a program, the oven must be in either the power-up mode or in the preheat mode. The oven cannot be

running a Preset Menu program.

When the oven is in the power-up mode or in the preheat mode, press and hold both the Cancel key and the

appropriate letter Preset key to be erased. The oven will beep in approximately four seconds, and the program’s

indicator light will go out to indicate the program has been erased.

#887 • Re therm and Food Hold Oven • Opera tion and Care Man ual • 11

Loading...

Loading...