Alto Shaam 12.20ES User Manual

PH ONE

U.S.A./C ANAD A

FA X

U.S.A. O NLY

D UE TO ON G O IN G P R OD U C T IM P RO V EM E NT , S P EC I FI C AT I ON S A RE SU BJ E CT TO CH AN G E WI T H OU T N O TI C E .P RI N TE D I N U. S .A .

ITEM NO. _______________________

capacity of twenty-four (24) full-size or gn 1/1 pans,

model 12•20es touch

twelve (12) full-size sheet or gn 2/1 pans

12•20es series

l

EcoSmart design uses less electricity and water than

competitive models. Reduced energy setting further minimizes

electricity use.

l

Exclusive Gold-n-Brown™ features gives the operator the ability to

achieve the ideal cooking environment for the ideal finish.

l

Expandable system to meet your specific requirements.

l

Cook with the included product temperature probe (not included as

standard on S-control models) or by time.

l

Cooks with variable steam, convection heat, or a combination of both

to roast, steam, bake, or oven-fry. Cooking speeds are increased by as

much as 70% compared to conventional cooking methods.

l

CombiClean® feature uses jets of water for fully automated cleaning.

Use either commercial-strength CombiClean Tablets or Combitherm

Cleaning Liquid Spray.

l

CombiTouch®

— Intuitive CombiTouch control is fully operable from the touch screen.

— Store up to 250 recipes, each with up to 9 steps. CombiTouch comes

standard with more than 100 preprogrammed recipes and photos.

— Six precise and consistent Gold-n-Brown™ browning levels.

— Multi-shelf Timers track cooking time of ten different food items in

the same oven.

— Advance reversing fan design provides excellent baking results and

prevents excessive water and power consumption.

ANSI/NSF 4

Provide Alto-Shaam Combitherm® floor-standing Model 12•20e s electric CombiOven designed with EcoSmart® technology for reduced

energy and water usage and include operational modes for steam, convection, and a combination of steam and convection heat. Standard

features to include patented automatic steam venting; Gold-n-Brown™ browning function and a self-adjusting, flush-mounted rotary

door handle. Oven is to be constructed of 18 gauge stainless steel, include an attached spray hose with backflow preventer, cool-down

function, automatic cleaning function, and four (4) adjustable legs. Each oven is to accommodate up to twelve (12) full-size sheet pans

or twenty-four (24) full-size hotel pans, include standard right-hand door hinging, and Roll-in pan cart with twelve (12) non-tilt support

rails (21-1/16" (535mm) horizontal width between rails, and 2-5/8" (65mm) vertical spacing between rails), six (6) stainless steel shelves,

removable drip tray and cart handle.

CombiTouch® Control: includes six different browning levels; two-speed reversing fan with coordinated enting system, USB port for data

access, quick-connect single-point internal product temperature probe in the oven interior.

Deluxe Control: includes a quick-connect single-point internal product temperature probe in the oven interior and programming

capability with Rapid-Touch™ operational quick-keys.

Standard Control: includes a quick-connect single-point internal product temperature probe in the oven interior.

S-Control: with quick-connect single-point internal product temperature probe in the oven interior as an option.

• Electrical Choices

➥Specify voltage:

208-240 3ph

380-415 3ph

440-480 3ph

FACTORY INSTALLED

• Door Options

➥Specify choice

Right-hand Door Hinging,

standard

Recessed Door, optional

increases oven width by

4" (102mm)

• Probe

➥Specify choice

Multi-point, hard-wired

temperature probe

[5005678] - not available on

ovens with S-Control

• Single-point, removable

temperature probe included on Touch, Deluxe

and Standard controls

S-Control oven [5005679]

• Security Devices for

correctional facility use.

Base package: excludes

temperature probe

➥Specify additional choices

Anti Entrapment Device

[5011081]

Control Panel Security Cover

[5012224]

Hasp Door Lock (padlock

not included) [5011079]

Tamper-Proof Screw Package

for oven [5013925]

Seismic Feet Package

[5015198]

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 • U.S.A.

www.alto-shaam.com

: 262.251.3800 800.558.8744

: 262.251.7067 800.329.8744

#44 5 - 11 /1 3

WATER REQUIREMENTS WATER QUALITY MINIMUM STANDARDS

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE (1) TREATED WATER INLET: 3/4" NPT*

ONE (1) UNTREATED WATER INLET: 3/4" NPT*

LINE PRESSURE: 30 to 90 psi 2.8 to 6.2 bar

WATER DRAIN:

1-1 /2"

CONNE CTION WITH A

2"

MINIM UM AIR GAP INSTALLE D AS CLOSE

TO THE OVEN AS POSSI BLE. MATERIAL S MUST WITHS TA ND TEMPE RATURES UP TO

200°F (93°C).

It is the sole responsibility of the owner/operator/purchaser of this

equipment to verify that the incoming water supply is comprehensively

tested and if required, a means of “water treatment” provided that would

meet compliance requirements with the published water quality standards

published below. Non-compliance with these minimum standards will

potentially damage this equipment and/or components and VOID the

original equipment manufacturer’s warranty. Alto-Shaam recommends

using OptiPure

®

[www.optipurewater.com] products to properly treat your

water.

CLEARANCE REQUIREMENTS

Contaminant

Free Chlorine

Hardness

Chloride

pH

Silica

Total Dissolved Solids (tds)

Inlet Water Requirements

Less than 0.1 ppm (mg/L)

30-70 ppm

Less than 30 ppm (mg/L)

7.0 to 8.5

Less than 12 ppm (mg/L)

50-125 ppm

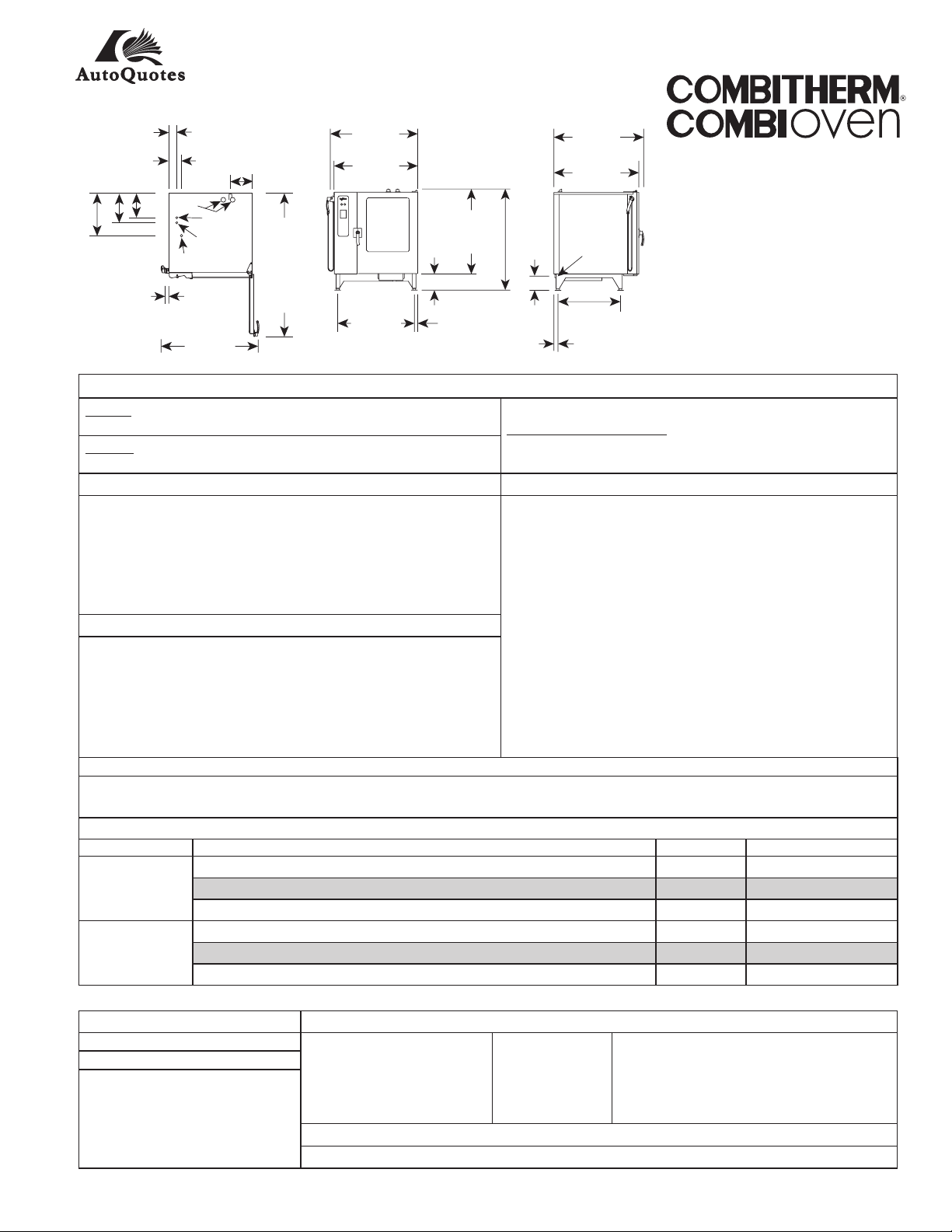

LEFT 6" (152mm) RECOMMENDED SERVICE ACCESS: 18" (457mm)

20" (508mm) FROM HEAT PRODUCING EQUIPMENT

RIGHT* 4" (102mm) TOP: 20" (508mm) FOR AIR MOVEMENT

BACK* 4" (102mm) BOTTOM: 5-1/8" (130mm) FOR LEGS

TOP 20" (508mm)

FOR AIR MOVE MENT

BOTTOM 5-1/8" (130mm)

FOR LEGS

*6" (152mm) from grease producing equipment

* Can manifold off of

one 3/4" line.

Untreated Water

Intake (Bottom)

Treated Water

Intake (Bottom)

Electrical Connection

(Bottom)

46-3/4"

(1186mm)

44-3/4"

(1136mm)

48"

(1218mm)

45-5/16"

(1151mm)

33-1/2"

(851mm)

2-1/16" (52mm)

Water Drain

(Bottom)

51-15/16"

(1319mm)

2" (50mm)

76-15/16" (1954mm)

7-11/16" (195mm)

54-3/8" (1381mm)

13-1/16" (331mm)

15-13/16" (401mm)

22-11/16"

(576mm)

11-7/8"

(302mm)

Water Drain

(Back)

4-1/4"

(106mm)

6-11/16"

(169mm)

Steam Vents

(Top)

46-1/2"

(1155mm)

8-15/16"

(226mm)

1-13/16"

(46mm)

40-15/16"

(1039mm)

WEIGHT CAPACITY

NET 750 lb (340 kg) FULL-SIZE PANS: 20" x 12" x 2-1/2" Twenty-four (24)

SHIP 891 lb (404 kg) GN 1/1: 530 x 325 x 65mm Twenty-four (24)

CRATE DIMENSIONS: (L x W x H)

GN 2/1: 650 x 530 x 65mm Twelve (12)

53" x 53" x 87" FULL-SIZE SHEET PANS:* 18" x 26" x 1" Twelve (12)

(1346 x 1346 x 2210mm)

ON WIRE SHELVES ONLY

288 lb (131 kg) MAXIMUM

VOLUME MAXIMUM: 180 quarts (128 liters)

*ADDITIONAL WIRE SHELVES REQUIRED FOR MAXIMUM CAPACITY

INSTALLATION REQUIREMENTS

• Oven must be installed level. • Hood installation is required.

• Water supply shut-off valve and back-flow preventer when required by local code.

ELECTRICAL

(DEDICATED CIRCUIT REQUIRED) - DO NOT CONNECT TO A G.F.I. OUTLET

MODEL

VOLTAGE PH HZ AMPS kW AWG CORD & PLUG

12•20ES Touch

208 – 240 3 60 75.6 - 87.0/ph 27.7 - 36.6 AWG 2 no cord or plug

380 – 415 3 50/60 41.4 - 36.1/ph 27.8 - 36.7 AWG 6 no cord or plug

440 – 480 3* 60 36.0 - 43.5/ph 27.8 - 36.7 AWG 6 no cord or plug

12•20ES

208 – 240 3 60 75.6 - 87.0/ph 27.2 - 36.1 AWG 2 no cord or plug

380 – 415 3 50/60 41.4 - 36.1/ph 27.2 - 36.1 AWG 6 no cord or plug

440 – 480 3* 60 36.0 - 43.5/ph 27.2 - 36.1 AWG 6 no cord or plug

*ELECTRICAL SERVICE CHARGE APPLIES

DIMENSIONS: h x w x d

exterior

54-3/8" X 46-3/4" X 48" (1381 X 1186 X 1218mm)

interior:

38-11/16" x 26-1/4" x 32-11/16" (983 x 667 x 830mm)

12•20es series

exterior with recessed door:

54-3/8" x 50-3/4" x 48" (1381 x 1288 x 1218mm)

#44 5 - 11 /1 3 d ue t o on g oi ng pr od u ct im pr o ve m en t, sp e ci f ic a ti o ns a re su b je c t to ch an g e wi t ho u t no t ic e . w ww .a l to - sh aa m .c om

Loading...

Loading...