Alto Shaam 1200-UP-SR Operators Manual

W164 N9221 Water Street • P.O. Bo x 450 • M en om on ee Fa ll s, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744

US A/CA NA DA FAX: 262.251.7067 • 800.329.8744 U.S .A . ONLY

www.alto-shaam.com

Holding Cabinet

Electronic or Manual Control

200-U P

1

Models:

1200-S

1200-UP

1200- S

P RI N TE D IN U .S .A .

• INSTALLATION

• OPERATION

• MAINTENANCE

MN-28680 • 09/09

Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Procedures and Precautions . . . . . . . . . . . . . . . . . 2

Sanitation

Sanitation/Food Safety . . . . . . . . . . . . . . . . . . . . . . . 18

Internal Food Product Temperatures . . . . . . . . . . . . . 18

Installation

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . 3

Clearance Requirements. . . . . . . . . . . . . . . . . . . . . . . 3

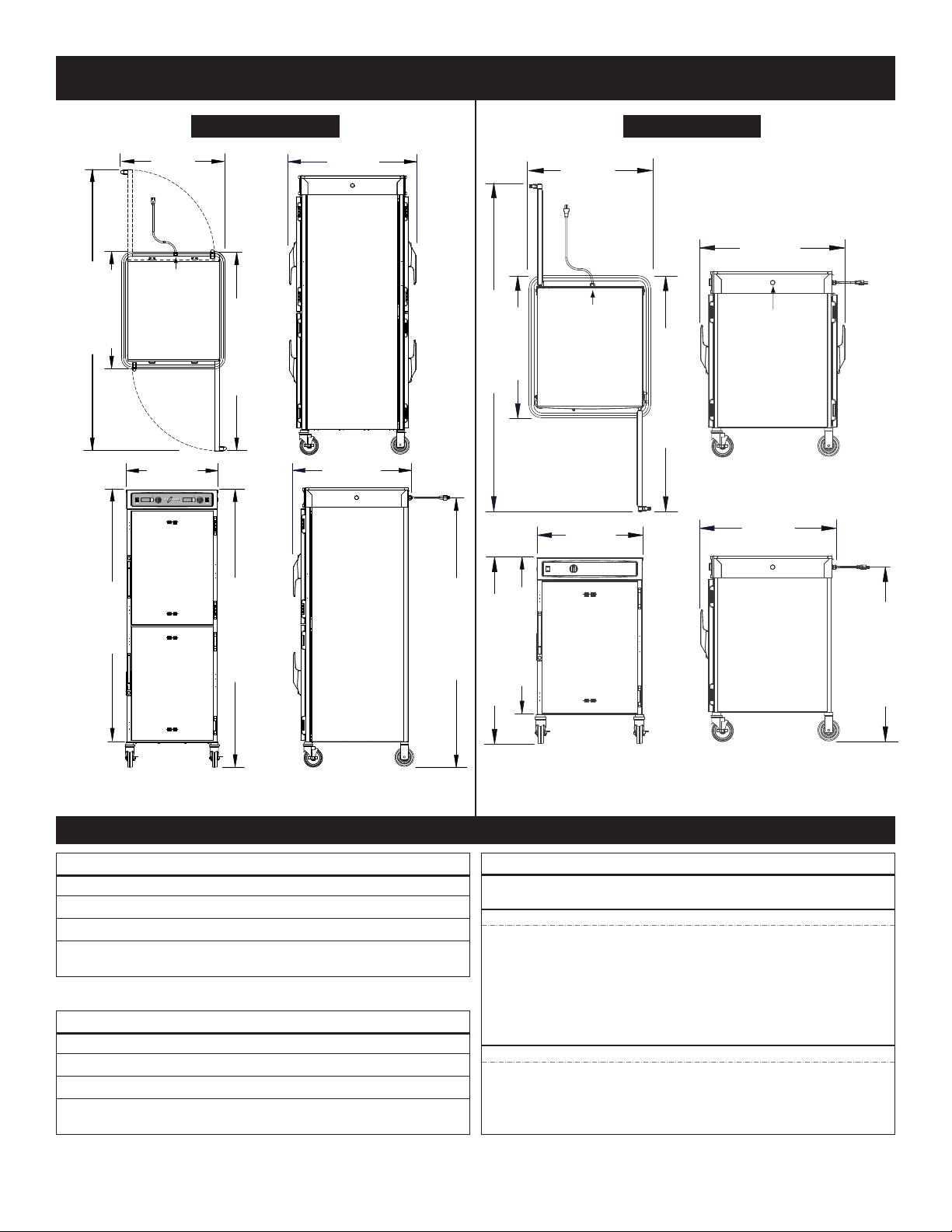

Dimension Drawings, weights & capacities . . . . . . . . . 4

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . 5

Universal Pan Slides/Side Racks and Shelves . . . . . . 6

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Restraint Requirements - Mobile Equipment . . . . . . . . 7

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . 8

User Safety Information . . . . . . . . . . . . . . . . . . . . . . . 9

Before Initial Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Heating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Instructions

Manual Control Operation . . . . . . . . . . . . . . . . . . . . . 10

Electronic Control Identification . . . . . . . . . . . . . . . . . 11

Electronic Control Set-Up . . . . . . . . . . . . . . . . . . . . . 12

Electronic Control Operation . . . . . . . . . . . . . . . . . . . 12

Electronic Holding Cabinet Special Features . . . . . . . 13

Heat Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HACCP Documentation . . . . . . . . . . . . . . . . . . . . . . . 13

HACCP Documentation w/ Kitchen Management . . . . 13

Dough Proofing Instructions . . . . . . . . . . . . . . . . . . . 13

Electronic Control Timer Programming . . . . . . . . . . . 14

General Holding Guidelines. . . . . . . . . . . . . . . . . . . . 15

Care and Cleaning

Cleaning and Preventative Maintenance . . . . . . . . . . 16

Protecting Stainless Steel Surfaces. . . . . . . . . . . . . . 16

Cleaning Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning Materials . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Clean Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Service

Thermostat Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . 19

Trouble Shooting Trouble Shooting -

ANUAL CONTROL

M

ELECTRONIC CONTROL . . . . . . . . . . . 21

. . . . . . . . . . . . . . 20

Exterior Service View - 1200-S . . . . . . . . . . . . . . . . 22

Exterior Service View - 1200-UP . . . . . . . . . . . . . . . . 23

Exterior Service Parts List. . . . . . . . . . . . . . . . . . . . . 24

Cable Heating Kits . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Bonnet Assembly View - Manual Control . . . . . . . 25-26

Bonnet Assembly Parts List - Manual Control . . . . . . 27

Bonnet Assembly View - Electronic Control . . . . . . . . 28

Bonnet Assembly Parts List - Electronic Control . . . . 29

Wire Diagrams

1200-S, 120V 1200-S, 208-240V 1200-S, 230V 1200-S, 120V 1200-S, 208-240V 1200-S, 230V 1200-UP, 120V 1200-UP, 208-240V 1200-UP, 230V 1200-UP, 120V 1200-UP, 208-240V 1200-UP, 230V -

MANUAL . . . . . . . . . . . . . . . . . . . . . . . 30

MANUAL . . . . . . . . . . . . . . . . . . . . 31

MANUAL . . . . . . . . . . . . . . . . . . . . . . . 32

ELECTRONIC . . . . . . . . . . . . . . . . . . . . 33

ELECTRONIC . . . . . . . . . . . . . . . . . 34

ELECTRONIC . . . . . . . . . . . . . . . . . . . . 35

MANUAL . . . . . . . . . . . . . . . . . . . . . . 36

MANUAL . . . . . . . . . . . . . . . . . . . 37

MANUAL . . . . . . . . . . . . . . . . . . . . . . 38

ELECTRONIC . . . . . . . . . . . . . . . . . . . 39

ELECTRONIC . . . . . . . . . . . . . . . . 40

ELECTRONIC . . . . . . . . . . . . . . . . . . . 41

Warranty

Transportation Damage and Claims . . . . . . Back Cover

Limited Warranty . . . . . . . . . . . . . . . . . . . . . Back Cover

D E L I V E R Y

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and report

it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

N O T E: All claims for warranty must include the

full model number and serial number of

the unit.

U N PA C K I N G

1. Carefully remove the

appliance from the

carton or crate.

N O T E: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner or

manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 1

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

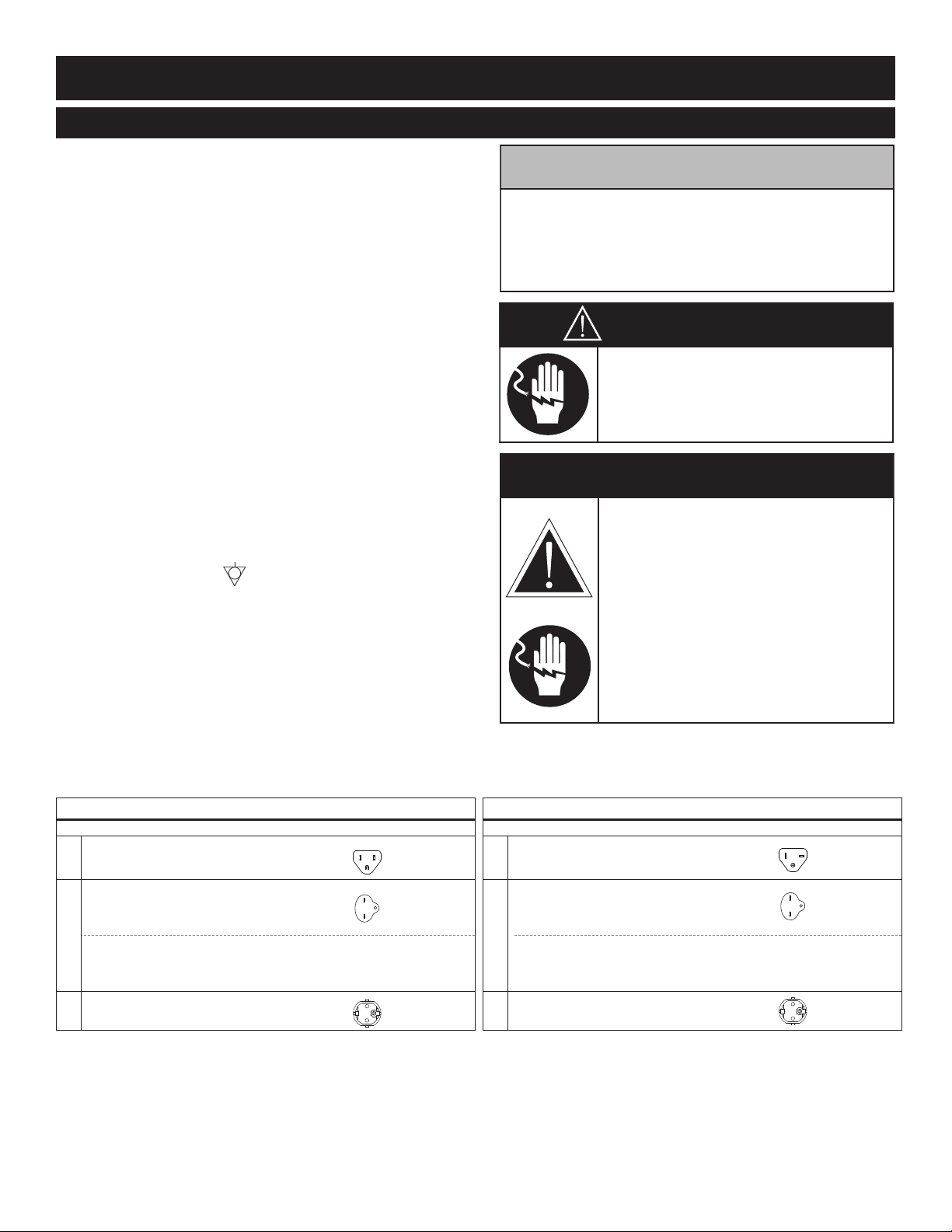

N O T E : Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

C A U T I O N

Used to indicate the presence of a hazard that can

or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

C A U T I O N

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

D A N G E R

Used to indicate the presence of a

hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

W A R N I N G

Used to indicate the presence of a

hazard that CAN cause personal injury,

possible death, or major property

damage if the warning included with

this symbol is ignored.

SAF E TY PR O CEDU R ES

AND P RECA U TION S

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

N O T E

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 2

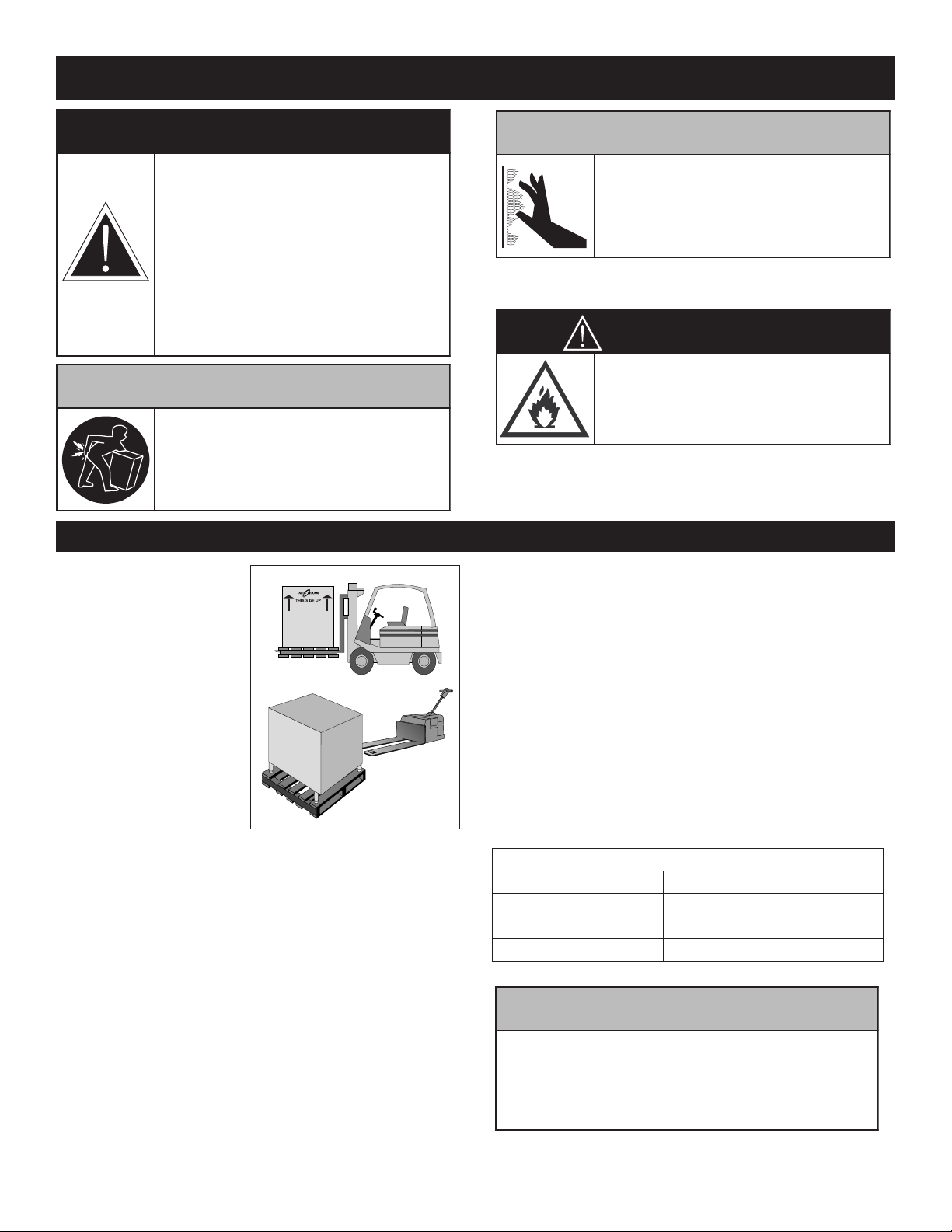

I N S T A L L A T I O N

®

D A N G E R

I

MPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

D A N G E R

DO NOT store or use gasoline or other

flammable vapors or liquids in the

vicinity of this or any other appliance.

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

O

PERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

N O T E

If the appliance has been unplugged for an

extended period of time , the Real Time

Clock may require recharging. Plug the

unit into the proper receptacle for a

minimum of 24 hours.

The Alto-Shaam cook

and hold oven must be

installed in a location

that will permit the

oven to function for its

intended purpose and

to allow adequate

clearance for

ventilation, proper

cleaning, and

maintenance access.

1. The oven must be installed on a stable and

level surface.

2. DO NOT install this appliance in any area

where it may be affected by any adverse

conditions such as steam, grease, dripping

water, high temperatures, or any other severely

adverse conditions.

3. DO NOT store or use any flammable liquids or

allow flammable vapors in the vicinity of this

oven or any other appliance.

4. This appliance must be kept free and clear of

any combustible materials.

5. This appliance must be kept free and clear of

any obstructions blocking access for

maintenance or service.

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 3

S I T E I N S T A L L AT I O N

Emissions testing conducted by Underwriters

Laboratories, Inc.® was found to be in

compliance with the applicable requirements of

NFPA96: 2004 Edition, Par. 4.1.1.2. U.L

emissions sampling of grease laden vapor

resulted in a total of 0.55 milligrams per cubic

meter with no visible smoke and is considered

representative of all oven models in the line.

Based on these results, hood installation and/or

outside venting should not be a requirement in

most areas. Verify local codes for locations

where more restrictive codes are applicable.

MINIMUM CLEARANCE REQUIREMENTS

BAC K

LE FT SIDE

RI GH T S ID E

TOP

3" (76mm)

1" (25mm)

1" (25mm)

2" (51mm)

71-15/16" (1827mm)

Electrical

Connection

R

each-In

Shown with

o

ptional bumper

*73-7/16" (1864mm) - with optional 3" (76mm) casters

*75-3/4" (1924mm) - with optional 6" (152mm) legs

24-9/16"

(624mm)

68" (1727mm)

74-13/16" (1900mm)*

with 5" (127mm) casters

31-1/2"

(799mm)

32-15/16" (837mm)

54-11/16" (1388mm)

28-3/16"

(716mm)

C

L

33-13/16"

(859mm)

76-3/8" (1939mm)

IoI

o

IoI

o

LOWER CAVITY

UPPER CAVITY

I N S T A L L A T I O N

33" (837mm)

54-11/16" (1388mm)

28-3/16"

(716mm)

76-3/8" (1939mm)

Electrical

C

onnection

Shown with

optional bumper

C

L

Reach-In

33-13/16"

(859mm)

43-3/16" (1097mm)*

with 5" (127mm) casters

36-7/16" (926mm)

24-9/16"

(624mm)

31-1/2"

(799mm)

40-3/8" (1025mm)

Electrical

C

onnection

Pass-Through

O

ption

*41-1/16" (1043mm) - with optional 3" (76mm) casters

*43-5/16" (1099mm) - with optional 6" (152mm) legs

odel 120 0-U P

M

odel 120 0-S

M

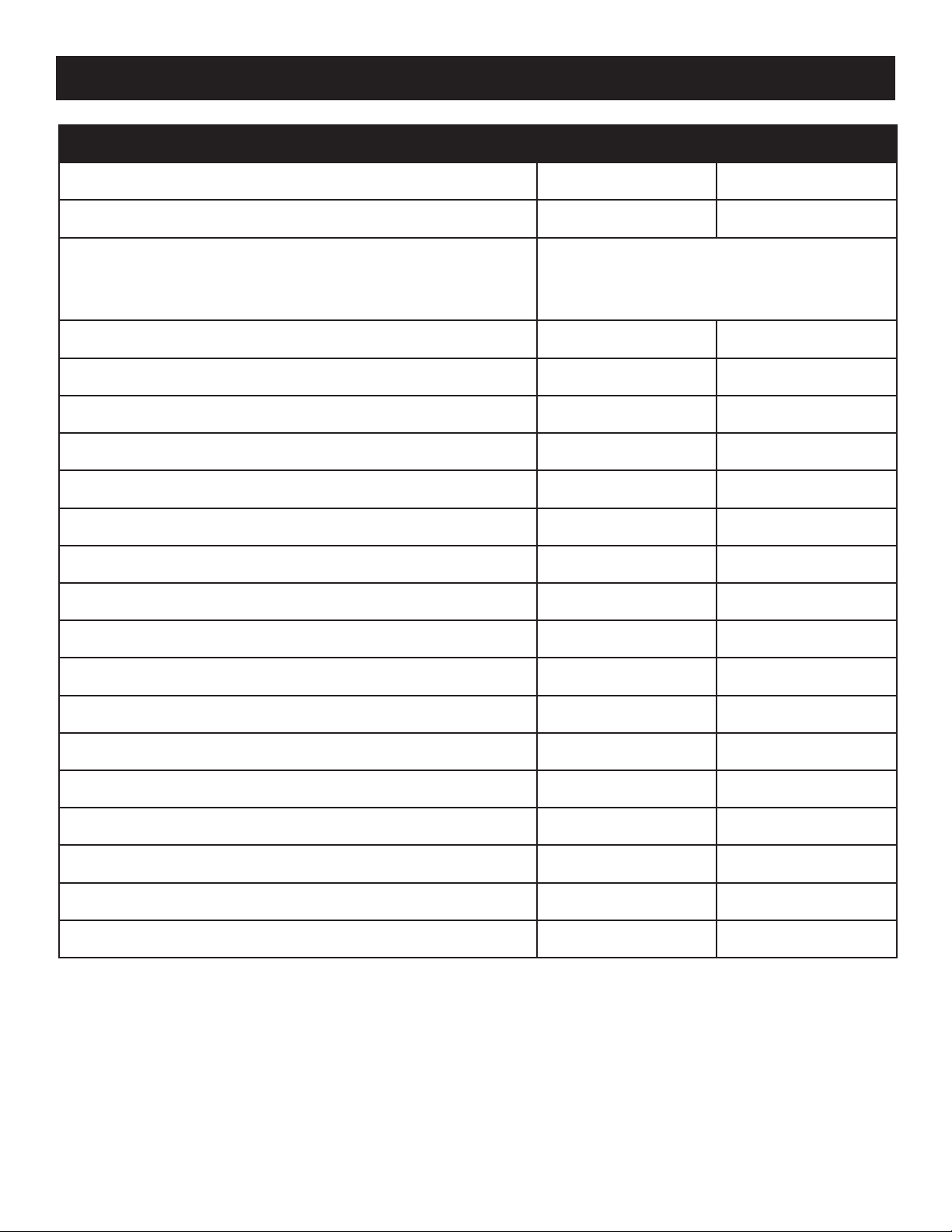

W E I G H T S A N D C A PA C I T I E S

WE IGHT - 1200- S

NE T 165 lb (75kg) 180 lb (82kg)

SH IP 205 lb (93kg) 225 lb (102kg)

CA RT ON D IM EN SI ON S: (HXWXD)

50" X 35" X 35" (1270mm x 889mm x 889mm)

12 00-S/ STD 120 0-S /H D

WE IGHT - 1200- UP

12 00-UP /STD 12 00-UP /HD

NE T 276 lb (125kg) 301 lb (137kg)

SH IP 315 lb (142kg) 350 lb (159kg)

CA RT ON D IM EN SI ON S: (HXWXD)

82" X 35" X 35" (2083mm x 889mm x 889mm)

PR ODUCT \PAN CA PACITY (PER COMPARTMENT)

192 lbs (87kg) MAXIMUM

VOLUME MAXIMUM: 120 QUARTS (152 LITERS)

—WITH PAN SLIDES PROVIDED: —WITH ADDT'L PAN SLIDES:

FULL -SIZE PANS: GASTRONORM 1/ 1:

Eight (8) 20" x 12" x 2-1/2" (530 x 325 x 65mm) up to 16 Pans

Eight (8) 20" x 12" x 4" (530 x 325 x 100mm) up to 10 Pans

Eight (8) 20" x 12" x 6" (530 x 325 x 150mm)

FULL -SIZE SHEE T PANS:

Four (4) 18" x 26" x 1" up to 16 Pans

UNIV ERSAL PAN SLI DES - 1 -3/4" (44mm) CE NTERS

—WITH OPTIONAL SIDE RACKS FOR SHELVES

FULL -SIZE PANS: GASTRONORM 1/ 1:

Sixteen (16) 20" x 12" x 2-1/2" (530 x 325 x 65mm)

Ten (10) 20" x 12" x 4" (530 x 325 x 100mm)

Eight (8) 20" x 12" x 6" (530 x 325 x 150mm)

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 4

I N S T A L L A T I O N

O P T I O N S a n d A C C E S S O R I E S

1200-S 1200-UP

Electronic Control (FACTORY IN STALLATION ONLY) AVAILABLE AVAILABLE

Computer Software (ELECTRONIC CO NT RO L ONLY)

HA CC P DOCUMENTATION

HA CC P

& K IT CH EN MANAGEMENT NETWORKING

REFER TO SPECIFICATION #9015,

FOR APPLICABLE PART NUMBERS

Bumper, Full Perimeter 5010295 5010295

Caster Package, 3" (76mm) 5010293 5010293

Door Assembly, Window (FACTORY IN STA LL ATI ON ONLY) 5005142 5005142

Door Lock with Key LK-22567 LK-22567

Handle Kit, Push/Pull (SET OF FOUR) 55662 55662

Legs, 6" (152mm) 5010294 5010294

Pan Grid, Wire 18" x 26" (457mm x 660mm) PN-2115 PN-2115

Pass-Through Design AVAILABLE AVAILABLE

Probe, internal product temperature (ELECTRONIC CONTROL) AVAILABLE AVAILABLE

Shelf, Chrome Plated Wire, for side racks SH-2733 SH-2733

Shelf, Stainless Steel Wire, for side racks SH-23738 SH-23738

Side Rack Model AVAILABLE AVAILABLE

Stacking Hardware 5010295 N/A

Universal Angle Pan Slides, Chrome SR-24447 SR-24447

Universal Angle Pan Slides, Stainless Steel SR-24762 SR-24762

Water Reservoir, Pan 1775 1775

Water Reservoir, Cover 1774 1774

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 5

I N S T A L L A T I O N

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

D A N G E R

DIS C ONNE C T UNI T FROM

POW E R SOU R CE B E FORE

CLE A NING O R SER VICI N G.

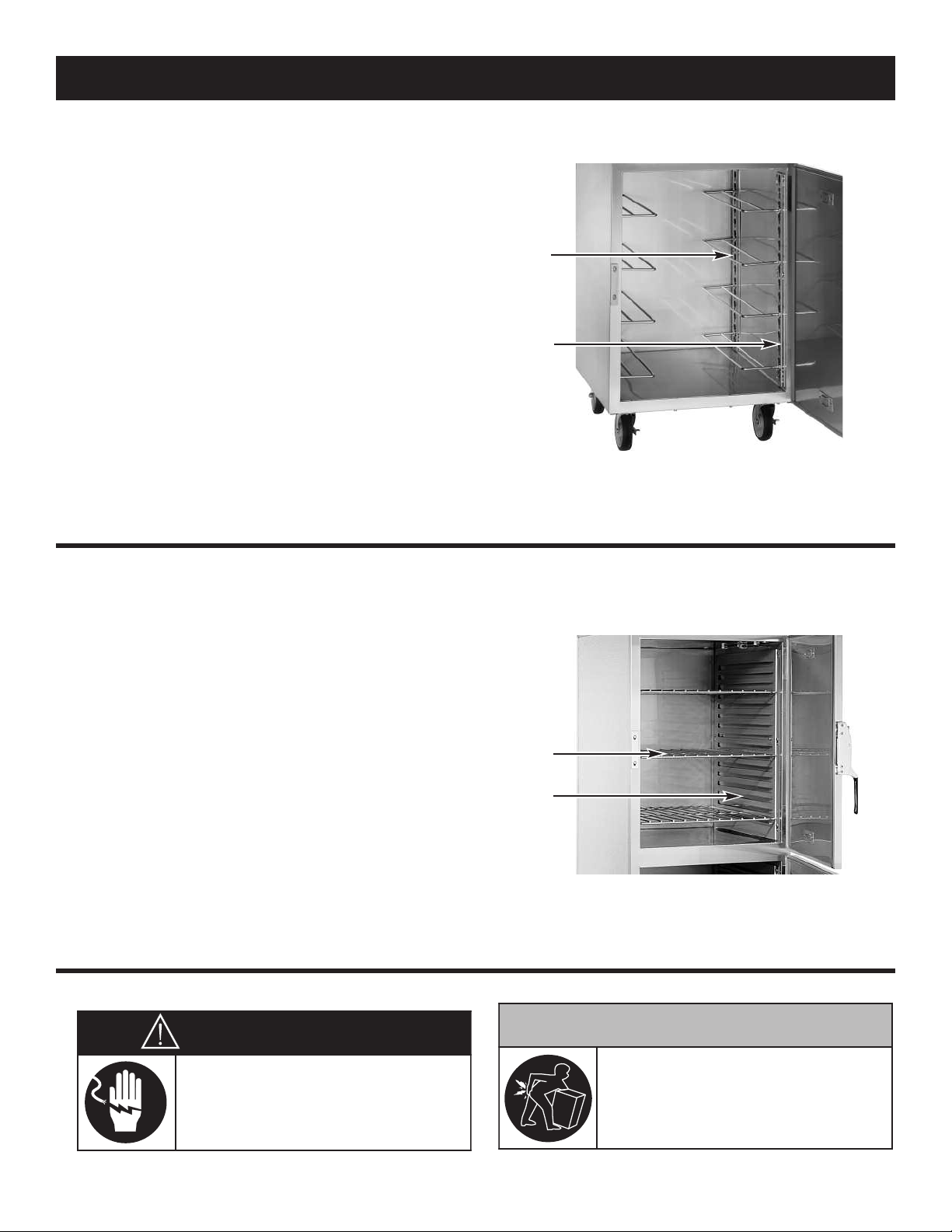

UNI VERSA L PAN SLIDES

As an alternative to universal pan

slides, the 1200-UP model can be

ordered as a “side rack” model which

is equipped with two (2) side racks and

three (3) chrome plated wire shelves

per compartment.

Univers al Pan Slid es,

chrom e pl ate

SR-2444 7

Side Rail

16046

SID E R ACKS AND SHELVES

Model 1200-UP that has been converted

with side racks to accommodate full and

half size U.S. Hotel and European

Gastronorm pans or sheet pans on the

side racks.

SH-2373 8, s ta inless stee l

Shelf

or S H-2733, chrome plat e

Side Rack

SR-2527 1

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 6

S I T E I N S T A L L A T I O N

W A R N I N G

RISK OF E LECTRIC SHOCK.

Appliance must be secured

to building structure.

I N S T A L L A T I O N

A number of adjustments are associated with

initial installation and start-up. It is important

hat these adjustments be conducted by a qualified

t

service technician. Installation and start-up

adjustments are the responsibility of the dealer or

user. These adjustments include but are not

limited to thermostat calibration, door adjustment,

leveling, electrical hook-up and installation of

optional casters or legs.

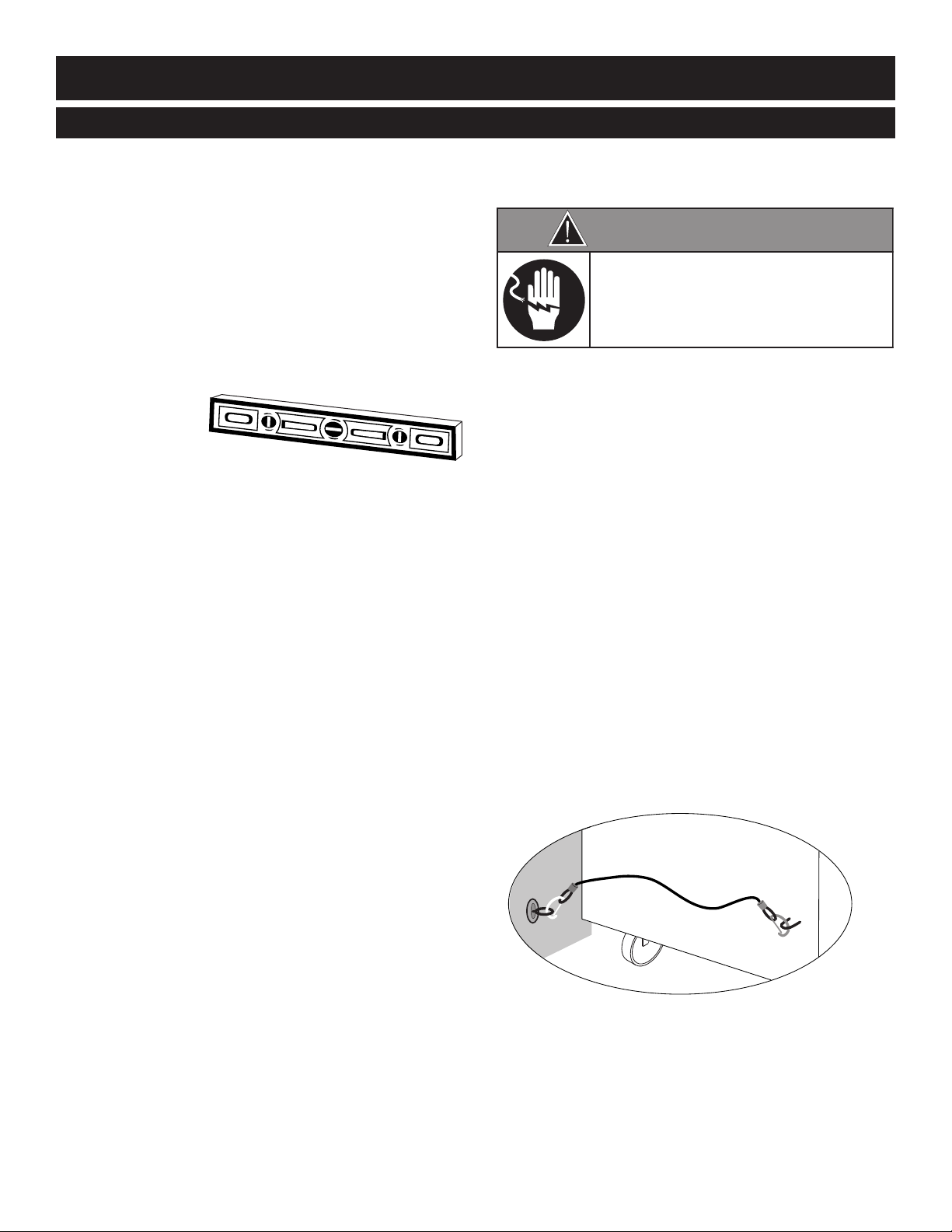

LEV ELING

Level the oven

from side-to-side and front-toback with the use of a spirit level. For ovens

installed with casters, it is important that the

installation surface be level due to the probability

of frequent oven repositioning.

We recommend checking the level of the oven

periodically to make certain the floor has not

shifted nor the oven moved.

NOTE: Failure to properly level this oven can

cause improper function and will result

in the uneven baking with products

consisting of semi-liquid batter.

RES TRAIN T R EQUIR EMENT S

—MO BILE EQU IPMEN T

Any appliance that is not furnished with a power

supply cord but that includes a set of casters must

be installed with a tether. Adequate means must

be provided to limit the movement of this

appliance without depending on or transmitting

stress to the electrical conduit. The following

requirements apply:

1. Maximum height of casters is 6" (152mm).

2. Two of the casters must of be the locking type.

Such mobile appliances or appliances on mobile

3.

stands must be installed with the use of a flexible

connector secured to the building structure.

A mounting connector for a restraining device is

located on the lower back flange of the appliance

chassis or on an oven stand, approximately 18"

(457mm) from the floor. A flexible connector is not

supplied by nor is it available from the factory.

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 7

I N S T A L L A T I O N

D A N G E R

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON APPLIANCE NAMEPLATE.

D A N G E R

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in according with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

C A U T I O N

THIS SECTION IS PROVIDED FOR THE ASSISTANCE

OF QUALIFIED SERVICE TECHNICIANS ONLY AND

IS NOT INTENDED FOR USE BY UNTRAINED OR

UNAUTHORIZED SERVICE PERSONNEL.

E L E C T R I C A L

1. An identification tag is permanently mounted on

the cabinet.

2. Plug cabinet into a properly grounded receptacle

ONLY, positioning the unit so the power supply cord

is easily accessible in case of an emergency.

Arcing will occur when connecting or disconnecting

the unit unless all controls are in the “OFF” position.

3. If necessary, a proper receptacle or outlet

configuration as required for this unit, must be

installed by a licensed electrician in accordance with

applicable, local electrical codes.

For 2 30V:

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in

close vicinity, an equalization-bonding stud is

provided. An equalization bonding lead must be

connected to this stud and the other appliances /

metal parts to provide sufficient protection against

potential difference. The terminal is marked with the

following symbol.

NOTE:

The appliance must be connected to an electrical

circuit that is protected by an external GFCI outlet.

E L E C TR I C A L- 1 2 0 0 -S

VOLTAGE PHASE CY CLE/HZ A MPS K

at 120 1 60 8.3 1.0 NE MA 5-15P,

120

208-240 (AGCY) 1 60 4.2 1.0 NE MA 6-15P,

at 208 1 60 3.6 .75

at 240 1 60 4.2 1.0 (U SA ON LY)

100 0W

208-240 (AGCY) 1 60 8.4 2.0

208 - 2 40

at 208 1 60 7.2 1.5

at 240 1 60 8.4 2.0

200 0W

230

1000W

at 230 1 50 3.9 .90

2000W

at 230 1 50 7.8 1.8 220-230V PLUG

W

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 8

15A-125V PLUG

15A-250V PLUG

NO CO RD

NO PL UG

CE E 7/7,

E L E C TR I C A L - 1 20 0 - U P

VOLTAGE PHASE CY CLE/HZ A MPS K

at 120 1 60 16.0 1.92 NE MA 5-20P,

120

208-240 (AGCY) 1 60 9.6 2.0 NEMA 6-15P ,

at 208 1 60 7.2 1.5

at 240 1 60 9.6 2.0 (U SA ON LY)

200 0W

208-240 (AGCY) 1 60 16.7 4.0

208 - 2 40

at 208 1 60 14.4 3.0

at 240 1 60 16.7 4.0

400 0W

2000W

at 230 1 50 8.0 1.85

230

4000W

at 230 1 50 16.0 3.67 220-230V PLUG

W

20A-125V PLUG

15A-250V PLUG

CORD&PLUG

NO CO RD

NO PL UG

CE E 7/7,

I N S T A L L A T I O N

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

U S E R S A F E T Y I N F O R M A T I O N

This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated hazards

of this appliance. Operating instructions and

warnings must be read and understood by all

operators and users.

1. Unit must be connected to the appropriate

power source.

2. Use hand protection when handling hot items.

3. Preheat the unit for 30 minutes before use.

4. Be certain only hot foods are placed into the unit.

BEFORE I NIT IAL U SE:

1. Clean both the interior and exterior of the unit

with a damp, clean cloth and mild soap solution.

Rinse carefully.

2. Clean and install the cabinet side racks. Shelves

should be positioned with the curved end up and

toward the back of the unit (reach-in models).

HEATING C HAR ACT ERI STI CS

The cabinet is equipped with a special heating cable.

Through this Halo Heat concept, the heating cable is

mounted against the walls of the unit to provide an

evenly applied heat source controlled by a thermostat.

The design and operational characteristics of the unit

eliminate the need for a moisture pan or a heat

circulating fan. Through even heat application,

the quality of food products is maintained up to

several hours or more.

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 9

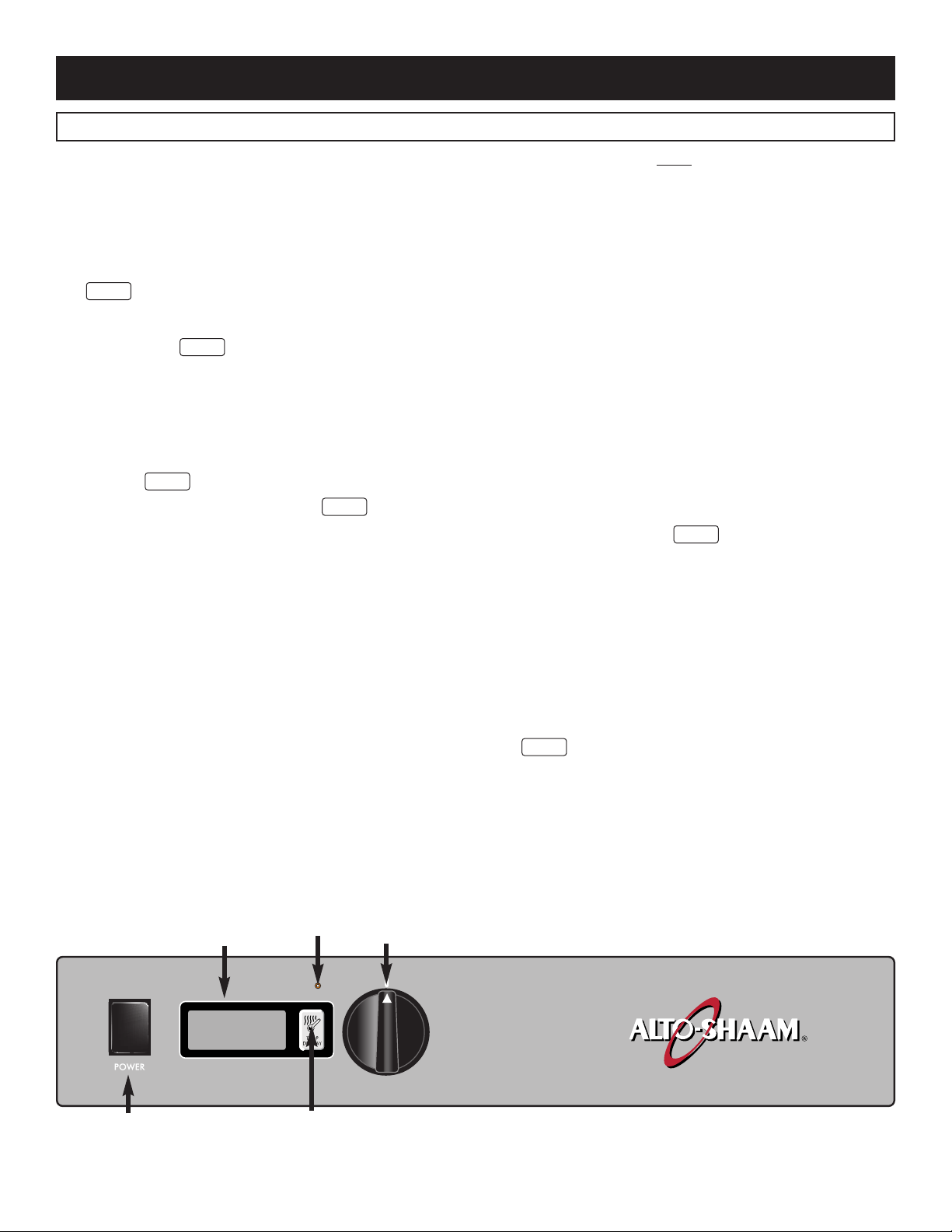

IoI

o

O P E R A T I O N

M A N U A L C O N T R O L

1. PREHEAT AT 200°F (93°C) FOR 30 MINUTES

EFORE LOADING FOOD.

B

ush power switch to “ON” position. The power

P

button will illuminate.

2. Rotate the control knob to 200°F (93°C). The Set

temperature will appear in the Digital Display

and the temperature display light will

S2 00

illuminate. Press the Temperature Display Button

at any time to display the A ctual inside air

temperature .

A1 90

To toggle between Set and Actual:

Factory default is to display Set temperature in the

Digital Display. To display Actual temperature:

With the control ON press and hold the

Temperature Button for 5 seconds. The control will

show , then show the Actual temperature.

Repeate to toggle to Set point .

AC T

SE T

Press the Temperature Display Button at any time

to display the alternate temperature.

3. When the inside air temperature reaches the desired

holding temperature, the temperature display light

will turn off.

4. Load the cabinet with hot food only.

The purpose of the holding cabinet is to maintain

hot food at proper serving temperatures. Only hot

food should be placed into the cabinet. Before

loading the unit with food, use a food thermometer

to make certain all food products are at an internal

temperature range of 140° to 160°F (60° to 71°C).

All food not within the proper temperature

range should be heated before loading into the

holding cabinet.

5. Check to make certain the cabinet door is securely

closed, and rotate the control knob to 160°F (71°C).

THIS WILL NOT

E THE FINAL SETTING.

B

NECESSARILY

The proper temperature range for the food being

held will depend on the type and quantity of

product. Whether or not the door vents should be

open or closed will also depend on the type of food

being held. When holding food for prolonged

periods, it is advisable to periodically check the

internal temperature of each item to assure

maintenance of the proper temperature range.

Reset the holding temperature accordingly.

TO TO GGL E BET WEE N FA HRE NHE IT

AND C ELS IUS

The factory default is Fahrenheit. To change to Celsius:

1. With the control OFF (i.e. temperature setting in the

OFF position), press and hold the Temperature

Display button for 5 seconds.

2. The control will show for 3 seconds to verify

DE GC

selection and then show the temperature. (Set Point

or Actual, whichever the user has selected) in ºC.

3. Repeat to toggle to Fahrenheit.

Note : With a p ow e r f ailure, facto ry te st, e tc., the control

w ill re tain th e ºC o r ºF se tting sele cte d b y th e user w h e n

p o w er is re sto re d.

PO WER FAI LUR E

When power is lost, then resumes, the display will

flash for 4 seconds, then display the set holding

-A C-

temperature for 4 seconds and will alternate until

acknowledged. To acknowledge, press any key.

This feature will alert you when there is a power failure,

indicating that food safety may be compromised.

On/Off Power

Switch

Digital

Display

Temperature

Display Light

Temperature

Display Button

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 10

Temperature

Control Knob

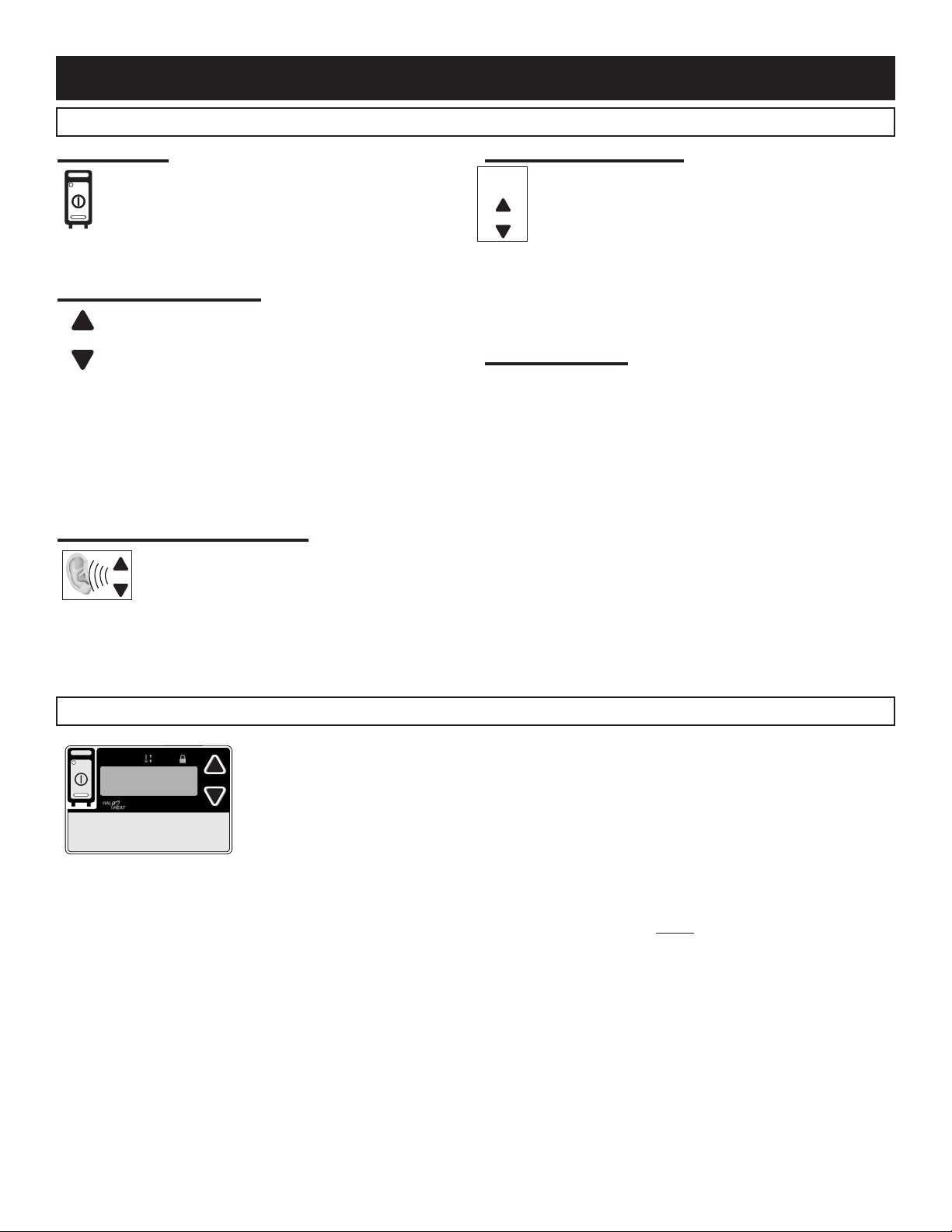

O P E R A T I O N

1

23456

E L E C T R O N I C C O N T R O L O P T I O N

POWER ON INDICATOR LIGHT

ON/OFF KEY

HEAT INDICATOR

LED DISPLAY

OCK INDICATOR

L

P/DOWN

U

RROW KEYS

A

POWER ON INDICATOR LIGHT

ON/OFF KEY

EAT INDICATOR

H

SHELF TIMER KEYS

LED DISPLAY

OCK INDICATOR

L

P/DOWN

U

RROW KEYS

A

1200-S, 1200-UP • IN STA LL ATI ON /O PE RAT IO N/ SE RV IC E M AN UA L - PG . 11

O P E R A T I O N

123456

E L E C T R O N I C C O N T R O L S E T- U P

N/ OFF KEY

O

Press the ON/OFF key once and the power

ndicator light will illuminate. Press and hold

i

the ON/OFF key until the LED display turns

off (at least three seconds) and power

indicator light goes out.

UP/DOWN ARROW KEY

The UP and DOWN arrow keys are used for a

variety of settings when selecting the holding

temperature. If an arrow key is pressed and

released the display will show the current set

temperature for two seconds. If an arrow key

is held (at least eight seconds), the value will

change at a rapid rate. If the arrow key is

pressed and released in rapid succession, the

set temperature will change by increments of

one degree.

ENABLE / DISABLE BEEPER

A beeper sounds when an error code is

displayed. To choose between beeper on

and beeper off mode, the control must be

off, then press and hold the DOWN arrow

key until either "ON" or "OFF" is shown

in the LED display. Release arrow key

when desired mode is displayed.

AHRENHEIT/CELS IUS

F

°F/ °C

CONTROL LOCK

The warmer controls can be locked so that no

changes can be made to the set temperature.

With the control off, to choose between

ahrenheit and Celsius, press and hold the UP

F

arrow key until either °F or °C is shown in

LED display. Release key when desired

setting is displayed.

The control has a four-digit LED display. When

the display is on, it will show current holding

temperature, as well as diagnostic information.

To lock the display, press and hold the

ON/OFF key and the Up Arrow key at the

same time. The lock LED will illuminate.

When the lock LED is illuminated, additional

programming will not be functional other than

the key sequence required to unlock the panel.

To unlock the display, press and hold the

ON/OFF key and the Down Arrow key at the

same time. The lock LED will extinguish. The

panel keys will resume normal function.

E L E C T R O N I C C O N T R O L O P E R AT I O N

1. Preheat at 200°F (93°C)

for 30 minutes.

Press the ON key, and set

the temperature to 200°F

(93°) by using the

UP/DOWN arrow keys.

Allow a minimum of 30

minutes preheating time before loading the

holding cabinet with food. Closing the vents on

the inside of the door will speed the preheating

process. The LED heat indicator light will go

“Out” after approximately 30 minutes preheat

time, or when the air temperature inside the unit

reaches the temperature set by the operator. The

Set indicator will light up anytime the temperature

is set or reset.

2. L oad wit h ho t food o nly.

The purpose of the holding cabinet is to maintain

hot food at proper serving temperature. Only hot

food should be placed into the cabinet. Before

loading the cabinet with food, use a food

thermometer to make certain all products are at

an internal temperature range of 140° to 160°F

(60° to 71°C). Any food product not within the

proper temperature range should be heated before

loading into the holding cabinet.

3. R ese t th e co ntrol t o 16 0°F (71 °C) .

Check to make certain the cabinet door is securely

closed, and reset to 160°F (71°C) by using the

UP/DOWN keys

TH IS W ILL NOT NECESSARILY

BE THE F INAL SETTING.

The proper temperature range and OPEN or CLOSED

door vent position will depend on the type and

quantity of product. When holding food for

prolonged periods, it is advisable to periodically

check the internal temperature of each item with a

food thermometer to assure maintenance of the

proper temperature range of 140° to 160°F

(60° to 71°C).

1200-S, 1200-UP • I NS TAL LAT IO N/OP ER ATI ON /S ERVICE MA NU AL - PG. 12

Loading...

Loading...