Alto Shaam 1200-UP User Manual

®

F o o d H o l d i n g C a b i n e t

E l e c t r i c

Models:

1000-UP

1200-UP

Manual Control

1000-UP/HD

• I N STALLATION

• OPERATION

• MAINTENANCE

1200-UP/HD

PHONE: 262.251.3800 • 800.558.8744

P R I N T E D I N U .S .A .

W 1 6 4 N 9 2 2 1 Wa t e r St r e et • P.O. Bo x 4 5 0 • Meno m o nee Falls, Wisconsin 53052 - 0 4 5 0 USA

USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

WEBSITE: www.alto-shaam.com

#838 • 8/07

DELIVERY

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and

report it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

UNPACKING

1. Carefully remove the

appliance from the

carton or crate.

NOTE: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

®

# 8 3 8 • I N S TA L L A T I O N / O P E R A T I O N / S E RV I C E MA NUA L • 1.

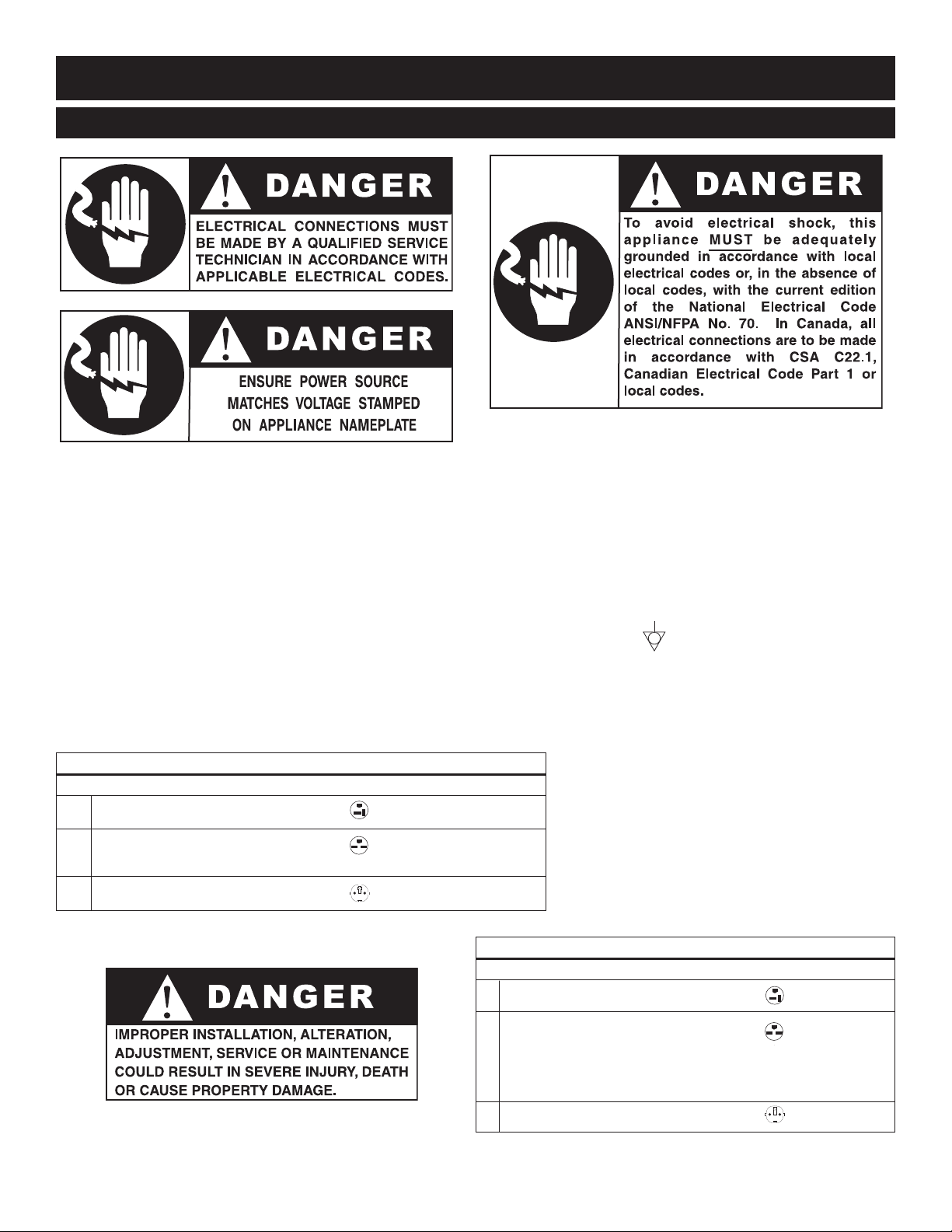

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

Used to indicate the

presence of a hazard that

will

cause severe personal

injury, death, or substantial

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can

cause personal injury,

possible death, or major

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor or

moderate personal injury

or property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor

personal injury, property

damage, or a potential

unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this

appliance is authorized or recommended.

2. This appliance is intended for use in

commercial establishments where all

operators are familiar with the purpose,

limitations, and associated hazards of this

appliance. Operating instructions and

warnings must be read and understood by

all operators and users.

3. Any troubleshooting guides, component

views, and parts lists included in this manual

are for general reference only and are intended

for use by qualified technical personnel.

4. This manual should be considered a

permanent part of this appliance. This

manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and

labels must remain with the appliance if the

item is sold or moved to another location.

NOTE:

# 8 3 8 • I N S TA L L A T I O N / O P E R A T I O N / S E RV I C E MA NUA L • 2.

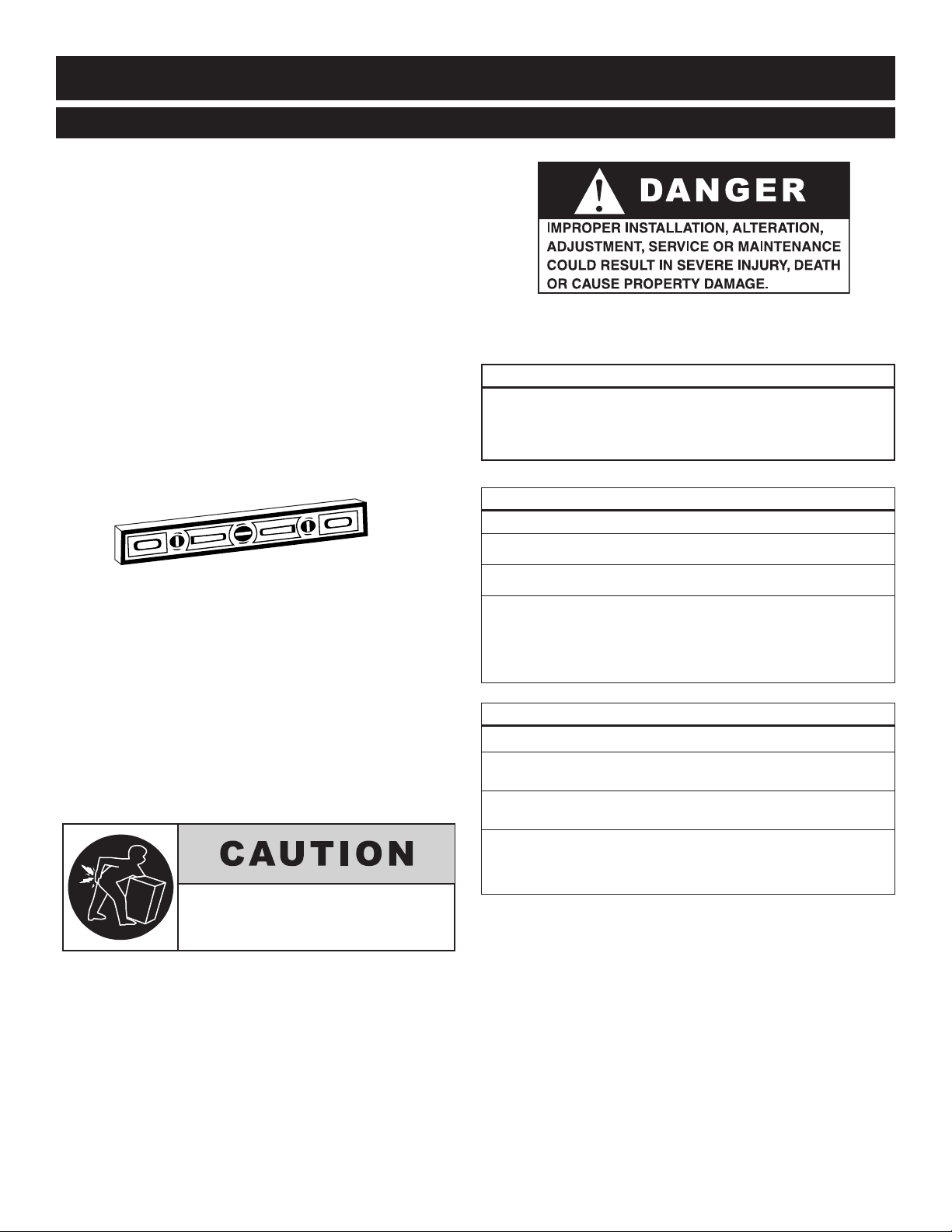

I N S T A L L A T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

S I T E I N S T A L L A T I O N

1. This appliance is designed for the purpose of

maintaining hot food at a temperature for

safe consumption. The unit must be

installed on a level surface in a location that

will permit the equipment to function for its

intended purpose and allow adequate access

for proper cleaning and maintenance.

2. The appliance must not be installed in any

area where it will be affected by steam,

grease, dripping water, high temperatures, or

any other severely adverse conditions.

3. Level the appliance from side-to-side and

front-to-back using a spirit level.

C L EA R AN C E R E Q U I R E M EN T S

3-inches (76mm) at the back, 2-inches (51mm) at the top,

1-inch (25mm) at both sides

W E IG H T

1000-UP/STD 1000-UP/HD

4. In order to maintain standards established

by the National Sanitation Foundation, all

equipment must be equipped with casters or

6" (152mm) legs to provide minimum

unobstructed space beneath the unit; or

secured flush at the bottom and the entire

base sealed with NSF approved sealant.

Warranty will become null and void if these

directions are

not followed.

NET 241 lb (109 kg) 270 lb (122kg)

SHIP 275 lb (125kg) 303 lb (137kg)

CARTON

DIMENSIONS

W E IG H T

NET 276 lb (125kg) 301 lb (137kg)

SHIP 315 lb (142kg) 350 lb (159kg)

CARTON

DIMENSIONS

:

:

(2032mm x 762mm x 940mm)

(2159mm x 762mm x 940mm)

80" x 30" x 37"

H x W x D ( ES T.)

1200-UP/STD 1200-UP/HD

85" x 30" x 37"

H x W x D ( ES T.)

# 8 3 8 • I N S TA L L A T I O N / O P E R A T I O N / S E RV I C E MA NUA L • 3.

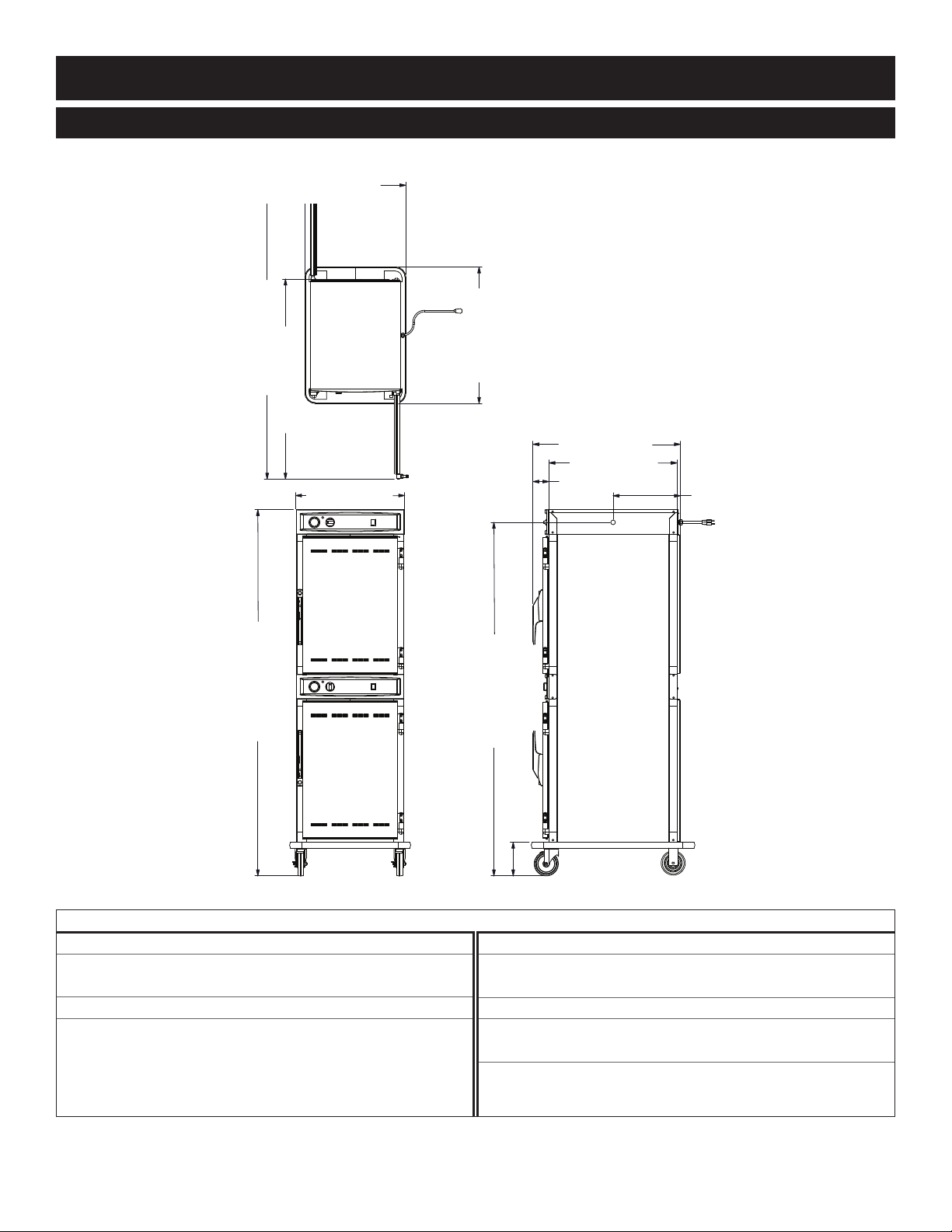

I N S T A L L A T I O N

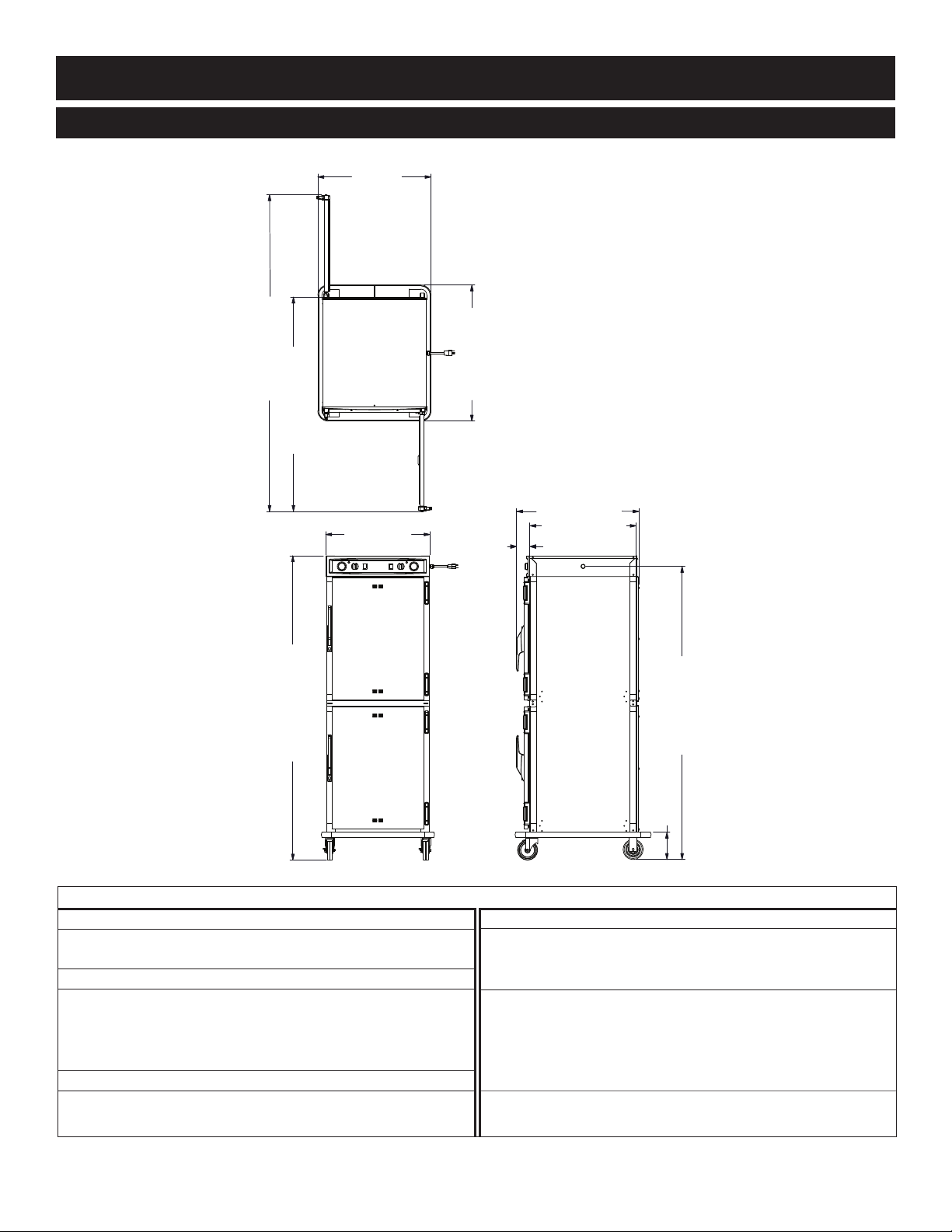

75-11/16" (1922mm)

73-1/16" (1855mm)

7" (177mm)

30-1/2" (774mm)

26-1/2" (673mm)

3-5/16"

(84mm)

13-15/16"

(353mm)

71-7/16" (1813mm)

49-5/8" (1260mm)

33-7/8" (860mm)

with bumper

22-5/8" (573mm)

25-1/16"

(636mm)

with bumper

electrical

pass-thru

E X T E R I O R D I M E N S I O N S

1000-UP

O P TI O NS & A C C E S S O R I E S

Bumper, FU LL PE RI METER 5005103

Casters, 3-1/2" (89mm)

2 RI GID , CS-25674

Casters, 3-1/2" (89mm) 2 SW IV EL W/BR AKE CS-25675

Door Lock with Key LK-22567

HACCP Network Options (

REF ER TO SPECIFIC ATION #9015 FOR APPLICABLE PART NUMBERS

➥ HACCP Documentation

➥ HACCP with Kitchen Management

EL EC TR ON IC C ONTROL O NLY)

Legs, 6" (152mm) Flanged (SET OF FOU R) 5004863

Pan Grid, Wire, chrome plated PN-2115

➥ PAN IN SE RT 18" x 26" (457mm x 660mm x 25mm)

Probe, Internal Temperature (E LE CT RO NI C C ON TROL) AVAILABLE

Shelf, Stainless Steel, REACH-IN SH-2325

Shelf, Stainless Steel, PASS -T HR OUGH SH-2346

Water Reservoir Pan

(I NCLUDED WI TH PR OOFING CAB IN ET ) 1775

Water Reservoir Pan Cover* 1774

# 8 3 8 • I N S TA L L A T I O N / O P E R A T I O N / S E RV I C E MA NUA L • 4.

75-11/16" (1922mm)

72-7/8" (1851mm)

6-13/16" (172mm)

78-3/4" (2000mm)

26" (659mm)

30-1/2" (773mm)

26-1/2" (672mm)

3-5/16" (83mm)

53-5/16" (1353mm)

33-7/8" (860mm)

with bumper

electrical

pass-thru

28-3/16"

(716mm)

with bumper

E X T E R I O R D I M E N S I O N S

1200-UP

I N S T A L L A T I O N

O P TI O NS & A C C E S S O R I E S

Bumper, FU LL PE RI METER 5004861

Casters, 3-1/2" (89mm)

2 RI GID , CS-25674

Casters, 3-1/2" (89mm) 2 SW IV EL W/BR AKE CS-25675

Door Lock with Key LK-22567

HACCP Network Options (

REF ER TO SPECIFIC ATION #9015 FOR APPLICABLE PART NUMBERS

EL EC TR ON IC C ONTROL O NLY)

➥ HACCP Documentation

➥ HACCP with Kitchen Management

Legs, 6" (152mm) Flanged (SET OF FOU R) 5004863

Pan Grid, chrome plated, wire PN-2115

➥

PAN IN SE RT 18" x 26" (457mm x 660mm x 25mm)

Probe, Internal Temperature (E LE CT RO NI C C ON TROL) AVAILABLE

Universal Angle Configuration

➥ Pan Slides, Chrome Plated SR-24447

➥ Pan Slides, Stainless Steel SR-24762

Side Rack Configuration

➥ Side Rack, Chrome Plated SR-22445

➥ Side Rack, Stainless Steel SR-23739

➥ Shelf, Stainless Steel SH-23738

➥ Shelf, Chrome Plated SH-2733

Water Reservoir Pan 1775

Water Reservoir Pan Cover 1774

# 8 3 8 • I N S TA L L A T I O N / O P E R A T I O N / S E RV I C E MA NUA L • 5.

I N S T A L L A T I O N

E L E C T R I C A L I N S T A L L A T I O N

1. An identification tag is permanently mounted on

the cabinet.

2. Plug cabinet into a properly grounded receptacle

ONLY, positioning the unit so the power supply

cord is easily accessible in case of an emergency.

Arcing will occur when connecting or disconnecting

the unit unless all controls are in the “OFF” position.

3. If necessary, a proper receptacle or outlet

configuration as required for this unit, must be

installed by a licensed electrician in accordance with

applicable, local electrical codes.

EL ECTR ICA L • 10 00-U P

VOLTAGE PHASE CYCLE/HZ AMPS

at 120 1 60 16.0 2.0 NE MA

120

at 208 1 50/60 7.2 1.5

208

240

at 240 1 50/60 8.3 2.0

at 230 1 50 7.8 1.8

230

kW

5-20P, 20A-125

NE MA

6-15P, 15A-250

USA ONLY)

(

CE E 7/7, 220-23 0V PL UG

Fo r 230V:

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in

close vicinity, an equalization-bonding stud is

provided. An equalization bonding lead must be

connected to this stud and the other appliances /

metal parts to provide sufficient protection against

potential difference. The terminal is marked with the

following symbol.

NO TE:

The appliance must be connected to an electrical

circuit that is protected by an external GFCI outlet.

V P LUG

V P LUG

EL ECTR ICA L • 12 00-U P

VOLTAGE PHASE CYCLE/HZ AMPS

at 120 1 60 16.0 2.0

120

at 208 1 50/60 7.2 1.5

at 240 1 50/60 8.3 2.0

at 208 1 50/60 14.4 3.0

208 - 240

at 240 1 50/60 16.0 4.0

at 230 1 50 7.8 1.8

230

# 8 3 8 • I N S TA L L A T I O N / O P E R A T I O N / S E RV I C E MA NUA L • 6.

kW

NE MA 5-15P,

20A-125V PLU G

NE MA

6-15P,

15A-250

220-230

V P LUG

(USA ONLY)

NO COR D

NO PLU G

7/7,

CE E

V P LUG

Loading...

Loading...