Alto Shaam 1000-UP-STD User Manual

#838/44 • 4/2004

PRINTED IN U. S .A .

OPERATION and CARE MANUAL

®

COOK/HOLD/SERVE SYSTEMS

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558.8744

U.S.A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

FOOD HOLDING CABINET

PASS-THROUGH & REACH-IN

Manual or Electronic Control

MODELS: 1000-UP/HD

1000-UP/P

1000-UP/STD

1000-UPS/HD

1000-UPS/STD

Manual Control

Electronic Control

with optional full

perimeter bumper

assembly

UNPACKING and SET-UP

The Alto-Shaam Holding Cabinet has

been thoroughly tested, checked for calibration,

and inspected to insure only the highest quality

cabinet is provided. When you receive your

cabinet, check for any possible shipping damage

and report it at once to the delivering carrier.

See Transportation Damage

and Claims

section located in this manual.

The cabinet, complete with unattached items and accessories,

may be delivered in one or more packages. Check to ensure that all

accessories that were ordered have been received with each unit.

Save all the information and instructions packed inside the

cabinet. Complete and return the warranty card to the factory as

soon as possible to assure prompt service in the event of a warranty

parts and labor claim.

NOTE: Any claims for warranty must include the full

model number and serial number of the cabinet.

ELECTRICAL INSTALLATION

1. An identification tag is permanently mounted on the cabinet.

2. Plug the cabinet into a properly grounded receptacle ONLY,

positioning the unit so that the power supply cord is easily

accessible in case of an emergency.

3. If necessary, a proper receptacle or outlet configuration,

as required for this unit must be installed by a licensed electrician

in accordance with applicable local electrical codes.

CABINET CHARACTERISTICS

The cabinet is equipped with a special, low-heat-density, heating

cable. Through the Halo Heat concept, the heating cable is mounted

against the walls of the warming compartment to provide an evenly

applied, thermostatically controlled, heat source. The design and

operational characteristics of the cabinet eliminate the need for a

moisture pan or a heat circulating fan. Through even heat

application, the quality of a food product is maintained up to as

much as several hours.

START-UP

1. Before operating the unit, clean both the interior and exterior

of the unit with a clean, damp cloth and mild soap solution.

Rinse carefully.

2. Clean and install the cabinet side racks.

CARE and CLEANING

The cleanliness and appearance of this equipment will

contribute considerably to operating efficiency and

savory, appetizing food. Good equipment that is

kept clean works better and lasts longer.

CLEAN THE UNIT DAILY

1. Disconnect the unit from the power source. Let unit cool.

2. Remove all detachable items such as wire shelves, side racks,

and drip pan. Clean these items separately.

3. Clean the interior metal surfaces of the cabinet with

a clean, damp cloth and any good alkaline or alkaline

chlorinated based commercial detergent or grease

solvent at the recommended strength. Use a plastic

scouring pad or oven cleaner for difficult areas.

Avoid the use of abrasive cleaning compounds,

chloride based cleaners, or cleaners containing

quaternary salts. Rinse carefully to remove all

residue and wipe dry.

NOTE: Never use hydrochloric acid (muriatic acid) on stainless steel.

4. To help maintain the protective film coating on polished

stainless steel, clean the exterior of the cabinet with a

cleaner recommended for stainless steel surfaces. Spray the

cleaning agent on a clean cloth and wipe with the grain of

the stainless steel.

Always follow appropriate state or local health (hygiene) regulations

regarding all applicable cleaning and sanitation requirements.

Disconnect unit from power source before cleaning

or servicing. Never flood the inside or outside

of the unit with water or liquid solution.

Never steam clean. Do not use water jet

to clean. Severe damage or electrical

hazard could result, voiding the warranty.

DOUGH PROOFING

1. Set holding thermostat to 95°F (35°C).

2. Pour approximately 2 quarts (c. 2 liters) of hot water,

140-180°F (60-82°C) into a pan on the bottom surface of the

holding compartment.

3. Preheat cabinet for 45-60 minutes.

4. Remove dough from retarder or refrigerator, and allow covered

product to set up at room temperature.

5. Remove covering and place product in preheated cabinet.

6. Allow dough to remain in the cabinet until it approximately

doubles in size.

7. Remove product from cabinet, brush with egg wash if desired,

and bake according to product manufacturer's directions.

NOTE: The above proofing procedure is suggested as a general

guideline only. Due to variations in product, product

quality, and weight, adherence to the product

manufacturer's instructions are recommended.

#838/44 Operation and Care Manual • 1.

— HOLDING CABINETS

PATENT NOS.

3521030

4595247

®

®

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON UNIT NAMEPLATE

#838/44 Operation and Care Manual • 2.

PROCEDURES

1. Preheat at 200°F (93°C) for 30 minutes.

When the thermostat is turned clockwise to the ON

position, the indicator light will illuminate and will remain lit

as long as the unit is calling for heat. Allow a minimum of

30 minutes of preheating before loading the holding cabinet

with food. Closing the vents on the inside of the door will

speed up the process. The indicator light will go OUT after

approximately 30 minutes, or when the air temperature

inside the unit reaches the temperature set by the operator.

2. Load the cabinet with hot food only.

The purpose of the holding cabinet is to maintain hot food

at proper serving temperatures. Only hot food should be

placed into the cabinet. Before loading the unit with food,

use a food thermometer to make certain all food products

are at an internal temperature range of 140° to 160°F

(60° to 71°C). All food not within the proper temperature

range should be heated before loading into the holding

cabinet.

3. Reset the thermostat to 160°F (71°C).

Check to make certain the cabinet door is securely closed,

and reset the thermostat to 160°F (71°C).

THIS WILL

NOT

NECESSARILY BE THE FINAL SETTING.

The proper temperature range for the food being held will

depend on the type and quantity of product. Whether or

not the door vents should be open or closed will also

depend on the type of food being held. When holding food

for prolonged periods, it is advisable to periodically check

the internal temperature of each item to assure

maintenance of the proper temperature range.

THERMOSTAT

and HEAT LIGHT

SEQUENCE

Whenever the thermostat is turned ON the heat indicator

light will indicate the power ON/OFF condition of the

heating cable, and consequently, the cycling of the cabinet as

it maintains the dialed cavity temperature. If the light does

not illuminate after normal start-up, the main power source,

thermostat, and/or light must be checked. If the warming

cabinet does not hold the temperature as dialed, the

calibration of the thermostat must be checked. If the

warming cabinet fails to heat or heats continuously with the

thermostat OFF, the thermostat must be initially checked for

proper operation. If these items are checked and found to be

in order, a continuity and resistance check of the heating

cable should be made.

SEE CIRCUIT DIAGRAM.

THERMOSTAT CALIBRATION

The thermostat is precision calibrated at the factory.

Normally, no adjustment or recalibration is necessary unless

the thermostat has been mishandled in transit, changed or

abused while in service. A thermostat with a sensing bulb

operates on hydraulic pressure, consequently, any bending of

the bulb results in a change in its volume, and alters the

accuracy of the thermostat calibration.

A thermostat should be checked or recalibrated by placing a

quality, thermal indicator at the center of an empty holding

cavity.

DO NOT CALIBRATE WITH ANY FOOD

PRODUCT IN THE CABINET.

The thermostat should be

set at 140°F (60°C), and should be allowed to stabilize at that

setting for a minimum of one hour. Following temperature

stabilization, the center of the thermal swing of the air

temperature within the cabinet should approximately coincide

with the thermostat dial setting.

If calibration is necessary, the calibration screw should be

adjusted with great care. The calibration screw of the

thermostat is located in the thermostat dial shaft. With the

shaft held stationary, a minute, clockwise motion of the

calibration screw appreciably lowers the thermostat setting.

A reverse, or counter-clockwise motion appreciably raises the

thermostat setting. After achieving the desired cycling of the

thermostat, the calibration screw must be sealed. Place a few

drops of enamel sealant directly on the calibration screw.

(Red nail polish or equivalent is acceptable.)

Manual Control - Standard

Heat

Indicator

Light

Thermostat

Temperature

Gauge

#838/44 Operation and Care Manual • 3.

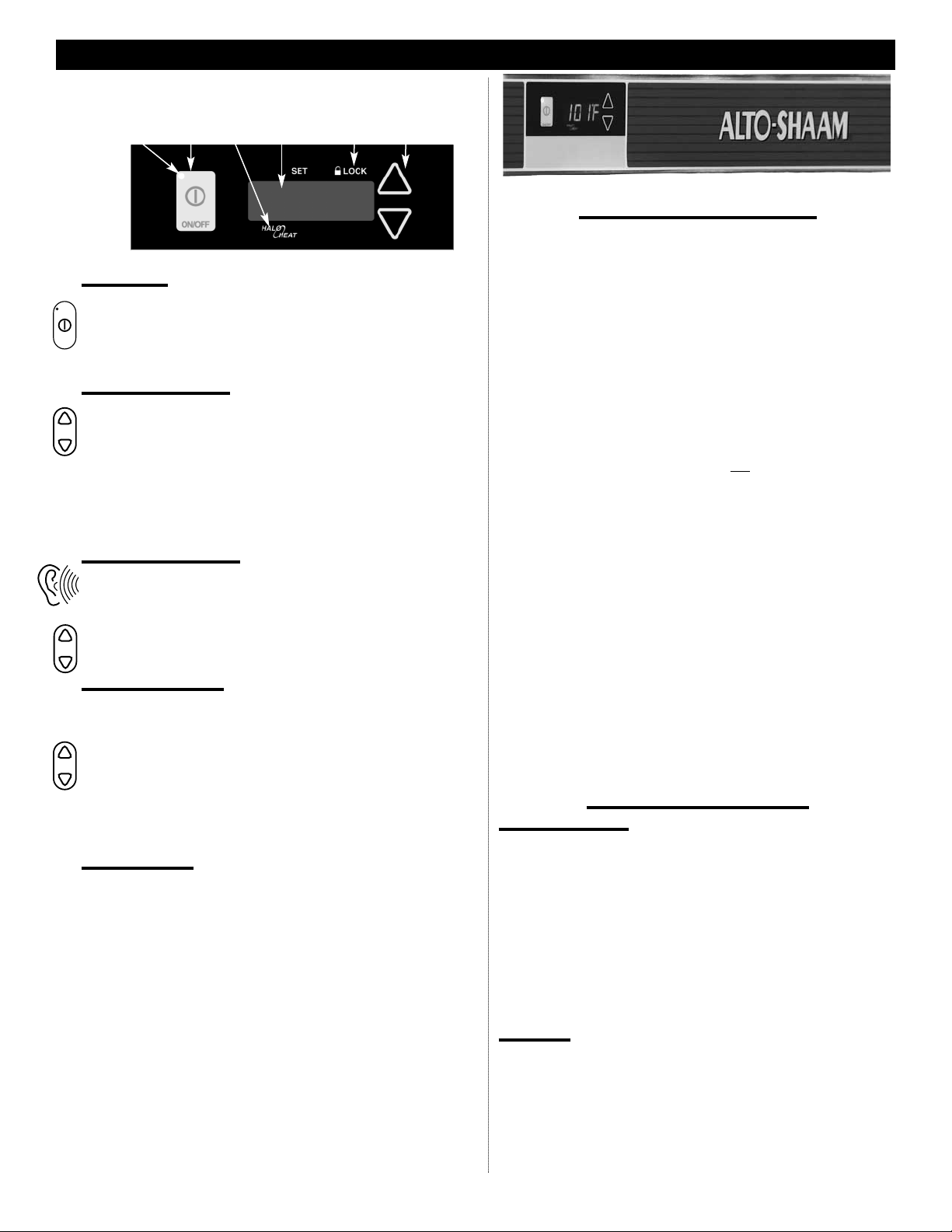

ON/OFF Key

Press the ON/OFF key once and the power indicator light

will illuminate. Press and hold the ON/OFF key until the LED

display turns off (at least three seconds) and power indicator

light goes out.

UP/DOWN Arrow Key

The UP and DOWN arrow keys are used for a variety of settings

when selecting the holding temperature. If an arrow key is

pressed and released the display will show the current set

temperature for two seconds. If an arrow key is held (at least

eight seconds), the value will change at a rapid rate. If the arrow

key is pressed and released in rapid succession, the set

temperature will change by increments of one degree.

Enable/Disable Beeper

A beeper sounds when an error code is displayed.

To choose between beeper on and beeper off mode, the

control must be

off, then press and hold the DOWN arrow

key until either "ON" or "OFF" is shown in the LED display.

Release arrow key when desired mode is displayed.

Fahrenheit / Celsius

With the control off, to choose between Fahrenheit and

Celsius, press and hold the UP arrow key until either

°F or °C is shown in LED display. Release key when

desired setting is displayed.

The control has a four-digit LED display. When the display

is on, it will show current holding temperature, as well as

diagnostic information.

CONTROL LOCK

The warmer controls can be locked so that no changes

can be made to the set temperature.

To

lock the display, press and hold the ON/OFF key

and the Up Arrow key at the same time. The lock LED will

illuminate. When the lock LED is illuminated, additional

programming will not be functional other than the key

sequence required to unlock the panel.

To

unlock the display, press and hold the ON/OFF key

and the Down Arrow key at the same time. The lock

LED will extinguish. The panel keys will resume normal

function.

HEATING PROCEDURE

1. Preheat at 200°F (93°C) for 30 minutes.

Press the ON key, and set the temperature to 200°F (93°C)

by using the UP/DOWN arrow keys. Allow a minimum

of 30 minutes preheating time before loading the holding

cabinet with food. Closing the vents on the inside of the door

will speed the preheating process. The LED heat indicator

light will go OUT after approximately 30 minutes preheat

time, or when the air temperature inside the unit reaches the

temperature set by the operator. The set indicator light will

light up anytime the temperature is set or reset.

2. Load with hot food only.

The purpose of the holding cabinet is to maintain hot food at

proper serving temperature. Only hot

food should be placed

into the cabinet. Before loading the cabinet with food, use a

food thermometer to make certain all products are at an

internal temperature range of 140° to 160°F (60° to 71°C).

Any food product not within the proper temperature range

should be heated before loading into the holding cabinet.

3. Reset the control to 160°F (71°C).

Check to make certain the cabinet door is securely closed,

and reset to 160°F (71°C) by using the UP/DOWN key.

THIS WILL NOT NECESSARILY BE THE FINAL

SETTING.

The proper temperature range--or closing or

opening the door vents--will depend on the type and quantity

of product. When holding food for prolonged periods, it is

advisable to periodically check the internal temperature of each

item with a food thermometer to assure maintenance of the

proper temperature range of 140° to 160°F (60° to 71°C).

EXCLUSIVE FEATURE

HEAT RECOVERY

The patented SureTemp™ heat recovery system

in this unit will immediately compensate for any loss

of heat when the door is opened. In order to maintain a

more consistent cavity temperature, the control will

automatically apply heat to the unit's interior while the

door is open and for a short time after the door is closed.

If the door remains open for more than three minutes, the

solid state electronic control will sound three rapid beeps

every ten seconds until the door is closed.

PRINTING

These holding cabinets can be equipped with an option called

HACCP with Kitchen Management for connection to a PC.

This connects to the internet via a Gateway device, thereby

providing temperature recording data as well as setup and

diagnostic information which can be used for HACCP.

Electronic Control - Option

°F /°C

Power

Indicator

Light

ON/OFF

Power Key

Heat

Indicator

Light

LED

Display

Lock

Indicator

UP/DOWN

Arrows

#838/44 Operation and Care Manual • 4.

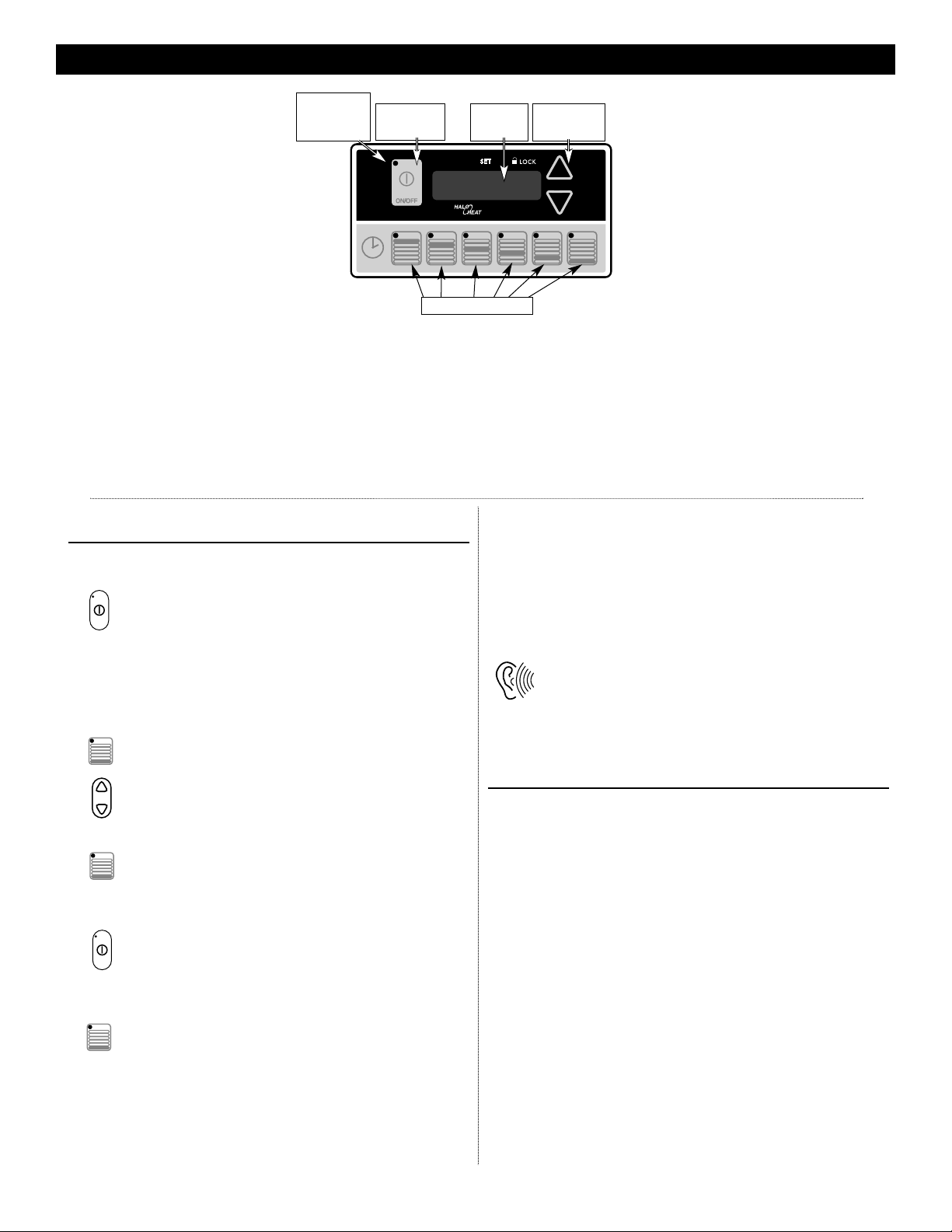

Timer Programming Information

1. Turn On/Off Power Key OFF.

Press the On/Off Key until the display turns OFF

(at least 3 seconds) and On/Off Key's Power

Indicator Light goes out.

Note: The following steps can only be done

when the On/Off Power Key is OFF.

2. Set Shelf Timer Keys.

Press and hold a Shelf Timer Key (at least 3

seconds) until a value is shown in the LED display.

Use the Up or Down Arrow Key to change the

time desired.

3. Set Additional Timer Keys.

Repeat step 2 for each Shelf Timer Key to be

programmed.

4. Turn On/Off Power Key ON.

When selected timers have been programmed,

press the On/Off key to turn ON unit. Power

Indicator Light will illuminate.

5. Press Shelf Timer Key.

Press selected Shelf Timer Keys to activate.

Shelf LED display will illuminate and the count

down will begin.

The Shelf Timer Key LED with the least amount

of time remaining will flash slowly and the LED

display will alternate between hold temperature

and time remaining.

6. Turn OFF alarm.

Listen for beeping alarm. Press flashing shelf timer

key to turn OFF alarm.

Reprogram Shelf Timer Keys

If you wish to reprogram holding times, turn OFF power.

Press the desired Timer Shelf Key and input new time using

Up or Down Arrow Key. Turn unit ON and press each

Shelf Timer Key to start the count downs.

Important Note: Timer Station Key retains

initial

time settings in memory.

Count down times are

cancelled when On/Off Key is

turned OFF. It may help to

note any remaining count down

times before reprogramming.

Power Failure: The Power Indicator Light by

On/Off Power Key

will blink to

indicate a power failure. To stop the

blinking, simply depress On/Off Key.

The memory will not be impaired.

1234 56

Electronic Control - Timer - Option

Up/Down

Arrows

LED

Display

On/Off

Key

Shelf Timer Keys

The Multiple Shelf Timer Key option is available for hot food holding units with the electronic control.

These keys monitor food safety by using a timer-based "First-In, First-Out" product management

system. Products should be cooked to HACCP recommended internal temperature and then held in

the unit. The Timer system allows operator to select holding times when the unit is loaded.

Multiple timer keys correspond to various pan locations in the holding unit.

As the timers expire, alarms notify the operator.

Power

Indicator

Light

#838/44 Operation and Care Manual • 5.

TROUBLE POSSIBLE CAUSE REMEDY

Unit does not operate. Insufficient power supply. Check power source.

Defective power cord or plug. Check and replace if necessary.

No display in electronic control. Faulty power supply board. Check line voltage for 24V across

pins 7 and 8 on the power supply board

and across terminals J9 and J10 on the

electronic control.

Faulty electronic control. Replace control.

Cannot control temperature but Faulty relay Replace relay.

sensor and electronic control

checks O.K. Heating element grounded. Replace element.

Temperature readout incorrect. Dirty or faulty sensor. Check sensor at 32°F (0°C).

Faulty control. If Ohm reading is 100, replace display.

If Ohm reading is not 100, replace sensor.

includes:

CB-3044 Cable Heating Element 108 feet

CR-3226 Ring Connector 4

IN-3488 Insulation Corner 1 foot

BU-3105 Shoulder Bushing 4

BU-3106 Cup Bushing 4

ST-2439 Stud 4

NU-2215 Hex Nut 8

SL-3063 Insulating Sleeve 4

TA-3540 Electrical Tape 1 roll

CABLE HEATING SERVICE

K I T No. 4874

(one kit per compartment)

TROUBLE SHOOTING CHECKLIST • ELECTRONIC CONTROL

Repairs should be made by authorized service agents only.

Remember to

disconnect

the unit from

power source

before

cleaning or

servicing.

OPTIONS & ACCESSORIES

Electronic Control . . . . . . (Factory Installation only)

Electronic Control

➥with multiple timers . . . . (Factory Installation only)

Bumper, full perimeter . . . . . . . . . . . . . . . . . . . .44119

Casters, 3" (76mm) . . . . . . . . . . . . 14227

Casters, 5" (127mm) . . . . . . . . . . . . . . . . . . . . . .4007

HACCP with

Kitchen Management . . . . . . . . . . . . CONTACT FACTORY

Legs, 6" (152mm) . . . . . . . . . . . . . . 5205

Shelves — Stainless Steel Wire

➥Reach-in . . . . . . . . . . . . . . SH-2325

➥Pass-through . . . . . . . . . . . . . SH-2346

Wire Pan Grid

➥18" x 26" Sheet Pan Insert . . . . . . . PN-2115

Window Door . . . . . . . . . . . . . . . 15148

➥(Factory Installation only)

Left hand door swing

➥(Factory Installation only)

Loading...

Loading...