Alto Shaam 1000-TH-I-HD Service Manual

#837A • 3/2005

PRINTED IN U. S .A .

INSTALLATION

OPERATION

AND

MAINTENANCE

MANUAL

LOW TEMPERATURE

OVEN

COOK

HOLD

MODEL:

1000-TH-I/HD

1000-TH-I/HD/D

1000-TH-I/HD/PT

1000-TH-I/STD

1000-TH-I/STD/D

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558-8744 USA/CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

#837A O&C MANUAL•1000-TH-I FAMILY

PG. 1

Unpacking and Setup

The Alto-Shaam Cooking and Holding

Oven has been thoroughly tested, checked for

calibration, and inspected to ensure only the

highest quality oven is provided. When you

receive your oven, check for any possible

shipping damage and report it at once to the

delivering carrier.

(See Transportation Damage

and Claims section of this manual.)

The oven, complete with unattached items

and accessories, may be delivered in one or more packages.

Check to insure that all the following items have been

received with each standard unit:

2 Ea. Drip Pans 1 Ea. External Drip Tray

4 Ea. Oven Side Racks 4 Ea. Casters

6 Ea. Wire Shelves 16 Ea. Caster Mtg. Screws

The heavy duty models have the full perimeter bumper

and casters installed at the factory.

Save all the information and instructions packed inside

the oven. Complete and return the warranty card to the

factory as soon as possible to insure prompt service in the

event of a warranty parts and labor claim.

Note: Any and all claims for warranty must include the

full model and serial number of the unit.

This cook and hold oven is designed for the purpose of

heating food to its proper temperature and maintaining the

hot food at a temperature for safe consumption. It must be

installed in a location that will permit it to function for its

intended purpose and allow adequate access for proper

cleaning and maintenance.

Oven Characteristics

The oven is equipped with a special, high-heat-density,

heating cable. Through the Halo Heat concept, the heating

cable is mounted against the walls of the cooking cavity to

provide an evenly applied heat source controlled by a

thermostat. The design and operational characteristics of

the oven eliminates the need for a moisture pan or a heat

circulating fan. Through even heat application, the quality

of a food product is maintained up to several hours.

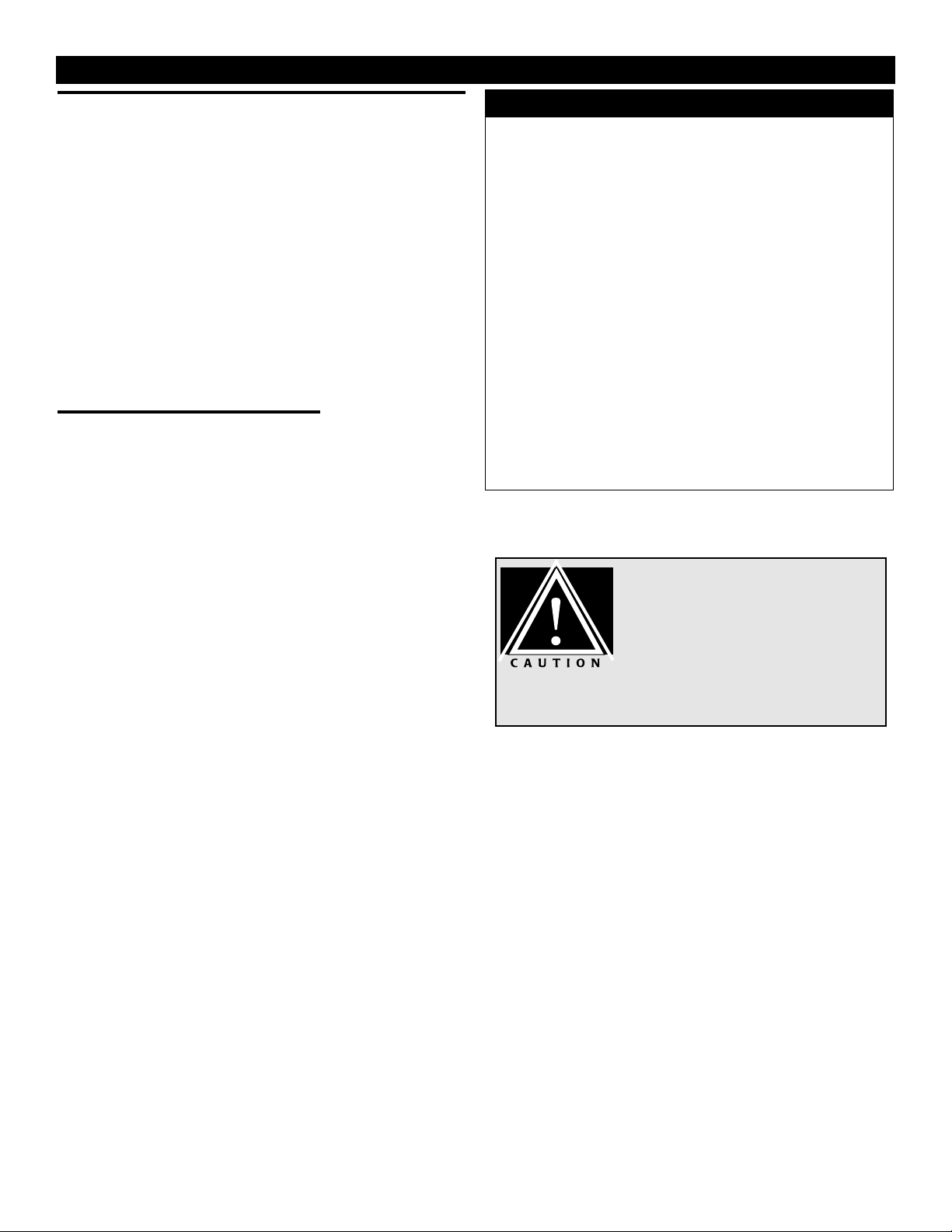

Electrical Installation

1.An identification tag is permanently mounted on

the oven.

SAMPLE

2.All models at 208/240 volts are dual rated units with a

conversion switch mounted under an access cover on the

rear of the oven, near the power cord.

With the voltage conversion switch in the 200 volt

through 208 volt (

UPPER) position, the oven will

function properly with a source voltage of between 200

volts and 208 volts.

With the voltage conversion switch in the 220-240 volt

(

LOWER) position, the unit will function properly with a

source voltage of between 220 volts and 240 volts.

NOTE: All 208/240 volt units are shipped from the

factory with the voltage conversion switch in the

220-240 volt position. Again, ensure that the

voltage conversion switch position and the

available power source match.

3. If necessary, a proper receptacle or outlet must be

installed by a licensed electrician in accordance with

applicable local electrical codes. This oven must be

grounded in accordance with the requirements of

the National Electrical Code or applicable local

country codes.

Ensure power source matches voltage

stamped on oven nameplate.

At no time should the oven be steamed cleaned,

washed down, or flooded with water or liquid

solution. Do not use water jet to clean. Severe

damage or electrical hazard could result.

Disconnect oven from power source before

cleaning or servicing.

Cold food for rethermalization or reheating

must never be added to the oven while hot

food is being held.

®

®

INSTALLATION

Start-Up

For the best service, the oven should be installed level. The oven should NOT be installed in any area where it may be

affected by steam, grease, dripping water, high temperatures or any other severely adverse conditions.

1. Before operating the oven, clean both the interior and exterior of the unit with a damp cloth and mild soap solution.

Rinse carefully.

2. Install the external drip tray on the lower front of the oven. See installation instructions located in this manual.

3. Clean and install the oven side racks and oven shelves. Shelves should be positioned with the curved end up and

toward the back of the oven. Insert the drip pan on the interior bottom surface of the oven.

4. Before operating the unit with product, become familiar with the operation of the controls. Read the following

“

General Operation” section of this manual and operate the various control functions.

PATENT NOS.

3521030

4595247

®

PH

#837A O&C MANUAL• 1000-TH-I FAMILY

PG. 2

INSTALLATION

Thermostat/Indicator Light Sequence

Whenever the start-up procedure has been

completed, the indicator light will indicate the power

ON/OFF condition of the heating cable and

consequently, the cycling of the oven as it maintains

the dialed cavity temperature. If the light does not

indicate after normal start-up, the main power source,

the main power breaker, and/or the oven control

circuitry must be checked. If a oven compartment does

not hold the temperature as dialed, the calibration of

the thermostat must be checked. (SEE THE PARAGRAPH

ON THERMOSTAT CALIBRATION

.) If a cooking

compartment fails to heat or heats continuously with

the thermostat off, the thermostat must be initially

checked for proper operation. If all is in order, a

continuity and resistance check of the heating cable

should be made. (SEE THE CIRCUIT DIAGRAM.)

Thermostat Calibration

At 250° F (121° C) COOK

and 140° F (60° C) HOLD

The thermostat is precision calibrated at the

factory. Normally, no adjustment or recalibration is

necessary unless the thermostat has been mishandled in

transit or changed or damaged while in service. A

thermostat with a sensing bulb operates on hydraulic

pressure. Consequently, any bending of the bulb

results in a change in its volume and displaces the

accuracy of the thermostat calibration.

A thermostat should be checked or recalibrated by

placing a quality temperature indicator at the center of

an empty oven cavity. DO NOT CALIBRATE WITH

FOOD PRODUCT IN THE OVEN. The temperature

must be allowed to stabilize at one particular setting for

at least two hours. Following temperature stabilization,

the center of the thermal swing of the cavity

temperature should approximately coincide with the

thermostat dial setting.

The calibration screw of the thermostat is located

in the dial shaft. With the shaft held stationary, a

minute clockwise motion of the calibration screw

appreciably lowers the thermostat setting while a

reverse motion results in the opposite condition. After

achieving the desired cycling of the thermostat, the

calibration screw must be sealed in place with a few

drops of sealant.

[RED NAIL POLISH OR EQUIVALENT IS ACCEPTABLE.]

Bumpers

➥ Corner Guards. . . . . . . . . . . . . . . . . . . . . . . . . . 5221

➥ Full Perimeter . . . . . . . . . . . . . . . . . . . . . . . . . . 4994

Carving Holder

➥ Prime Rib . . . . . . . . . . . . . . . . . . . . . . . . . . HL-2635

➥ Ship Round . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4459

Door Lock with Key . . . . . . . . . . . . . . . . . . . . LK-22567

Drip Pan

➥ Standard with Drain . . . . . . . . . . . . . . . . . . . . . 14824

➥ Extra Deep . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1115

Legs, 6" (152mm) . . . . . . . . . . . . . . . . . . . . . . . . . 5205

Pan Grid, Wire

➥ 18" x 26" Pan Insert . . . . . . . . . . . . . . . . . . . PN-2115

Security Panel with Key Locking Handle

➥ Upper Control . . . . . . . . . . . . . . . . . . . . . . . . . . 4372

➥ Center Control. . . . . . . . . . . . . . . . . . . . . . . . . . 4368

Shelves

➥ S/S Flat Wire . . . . . . . . . . . . . . . . . . . . . . . . SH-2325

➥ S/S Rib Rack . . . . . . . . . . . . . . . . . . . . . . . . SH-2773

Thermostat, Cooking

➥ 250°F Limit. . . . . . . . . . . . . . . . . TT-3978/KN-3491

OPTIONS AND ACCESSORIES

At no time should the oven

interior or exterior be steam

cleaned, hosed down, or flooded

with water or liquid solution. Do

not use water jet to clean. Severe

damage or electrical hazard could

result voiding the warranty.

#837A O&C MANUAL•1000-TH-I FAMILY

PG. 3

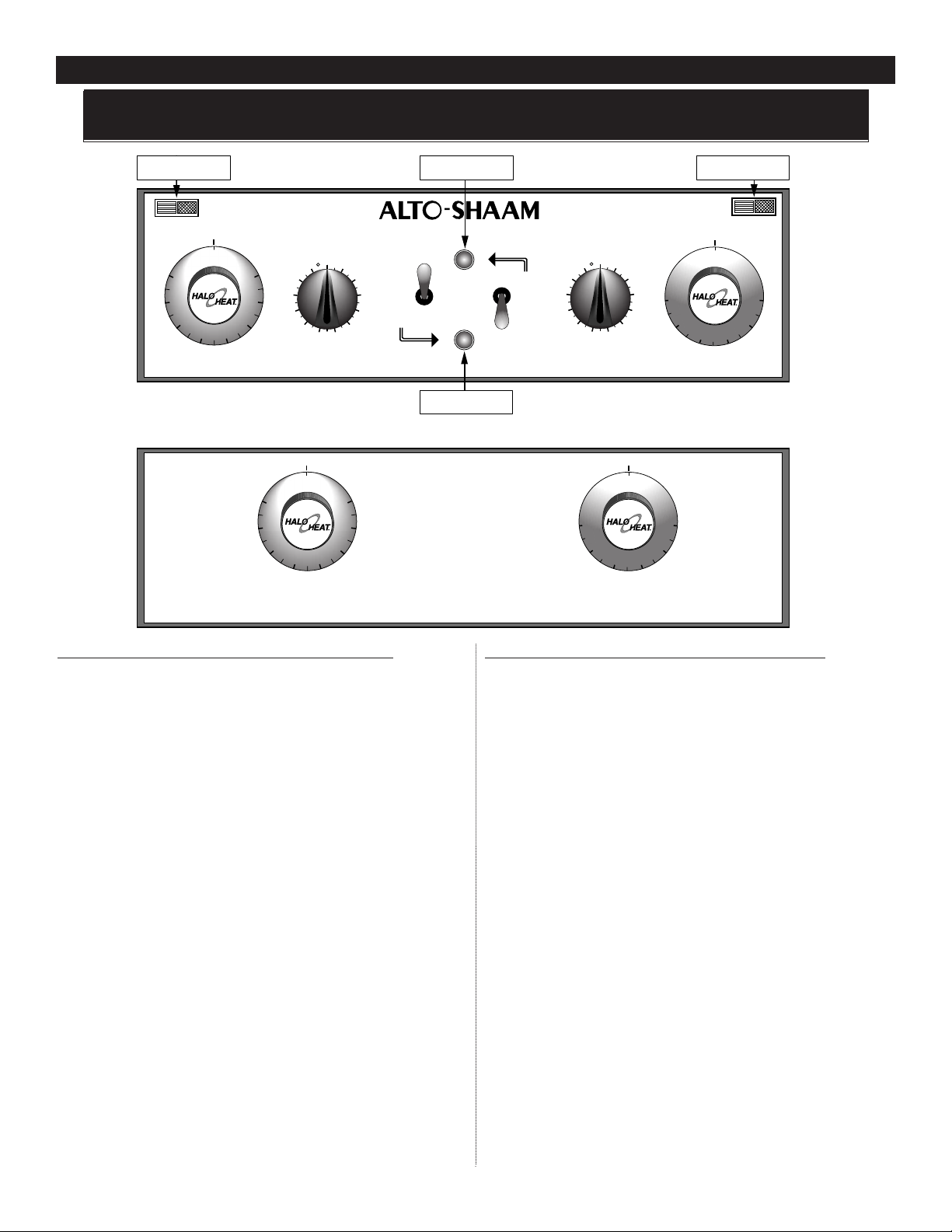

OPERATION

UPPER COOKING COMPARTMENT

1. Turn upper oven POWER SWITCH “ON.”

— Upper oven POWER “ON” INDICATOR LIGHT

will illuminate and will remain lit as long as the

upper oven Power Switch is in the “ON” position.

2. Set the upper oven HOLD THERMOSTAT to the

required holding temperature.

— Upper oven HOLDING INDICATOR LIGHT will

illuminate as the Hold Thermostat calls for heat.

This process will continue as long as the upper

oven Power Switch and Hold Thermostat are in

the “ON” position.

3.Set upper oven COOK THERMOSTAT to the

required cooking temperature

4.To preheat the upper oven, activate the Cook

Thermostat by turning the upper oven COOKING

TIMER clockwise.

— Upper oven COOKING INDICATOR LIGHT and

HOLDING INDICATOR LIGHT will illuminate as

the Cook Thermostat calls for heat. This process

will continue until the upper oven Cooking Timer

cycles or is turned to the “OFF” position.

LOWER COOKING COMPARTMENT

1. Turn lower oven POWER SWITCH “ON.”

— Lower oven POWER “ON” INDICATOR LIGHT

will illuminate and will remain lit as long as the

lower oven Power Switch is in the “ON” position.

2. The lower oven HOLD THERMOSTAT is located on

the lower control panel. Set the lower oven HOLD

THERMOSTAT to the required holding temperature.

— Lower oven HOLDING INDICATOR LIGHT will

illuminate as the Hold Thermostat calls for heat.

This process will continue as long as the lower

oven Power Switch and Hold Thermostat are in

the “ON” position.

3. The lower oven COOK THERMOSTAT is located on

the lower control panel. Set the lower oven COOK

THERMOSTAT to the required cooking temperature.

4. To preheat the lower oven, activate the Cook

Thermostat by turning the lower oven COOKING

TIMER clockwise.

— Lower oven COOKING INDICATOR LIGHT and

HOLDING INDICATOR LIGHT will illuminate as

the lower oven Cook Thermostat calls for heat.

This process will continue until the lower oven

Cooking Timer cycles or is turned to the “

OFF”

position.

These instructions are basic operational guidelines only. For complete instructions, see the

Cooking Guidelines Booklet packed with the oven.

INDICATOR LIGHTS

LOWER OVEN

HOLD COOK

LOWER OVEN

ELEMENT

OFF

60 F

0

8

100

120

HOLD TEMP

UPPER OVEN

POWER ON LIGHT

UPPER OVEN

®

COOK TIMER

LOWER OVEN

OFF

1

200

180

160

1

4

0

12

11

10

9

8

67

TURN PAST TIME DESIRED

THEN SET TIME

OFF

60 F

0

8

100

HOLD TEMP

LOWER OVEN

200

180

160

1

4

0

120

5

2

3

4

ON

OFF

LOWER OVEN

UPPER OVEN

POWER ON LIGHT

LOWER OVEN

ON

OFF

COOK TIMER

UPPER OVEN

OFF

1

12

11

10

9

8

TURN PAST TIME DESIRED

THEN SET TIME

5

67

OFF

100 F

150

0

0

2

COOK TEMP

LOWER OVEN

2

4

3

2

5

0

100 F

150

COOK TEMP

UPPER OVEN

350

300

INDICATOR LIGHTS

UPPER OVEN

HOLD COOK

UPPER OVEN

ELEMENT

OFF

350

3

00

2

5

0

0

0

2

Loading...

Loading...