Page 1

AMERICAN-LINCOLN

TECHNOLOGY

772

Operator's

Alto

Manual

American-Lincoln

Beginning with

Serial No. 102569

READ THIS BOOK!

This book has important information for the use and safe operation of this machine. Failure

to read this book prior to operating or attempting any service or maintenance procedure to

your machine could result in injury to you or to other personnel; damage to the machine or to

other property could occur as well. you must have training in the operation of this machine

before using it. If you or your operator (s) cannot read English, have this manual explained

fully before attempting to operate this machine.

Si Ud. o sis operadores no pueden leer el Inglés, se hagen explicar este manual

completamente antes de tratar el manejo o servicio de esta máquina.

772

Scrubmobile

ISO 9001

U

®

L

#

FILE A2287

All directions given in this book are as seen from the operator's position at the rear of the machine.

For new books, write to: Alto U.S., Inc., 1100 Haskins Road, Bowling Green, Ohio 43402

Part No. 2-86-00173 1994 American-Lincoln Technology®

931030

Printed in the USA

Page 2

TABLE OF CONTENTS

MACHINE SPECIFICATIONS ........................................................................................................................... 1-5

MODEL H772 DIMENSIONS ............................................................................................................................. 1-10

SAFETY PRECAUTIONS .................................................................................................................................. 1-11

SAFETY DECALS ............................................................................................................................................. 1-12

MACHINE PREPARATION................................................................................................................................ 1-14

MACHINE SYSTEMS & CONTROLS ............................................................................................................... 1-15

FORD 3930 TRACTOR POWER UNIT..................................................................................................... 1-15

BRAKE CONTROLS ................................................................................................................................. 1-16

BRAKE PEDAL LOCK .............................................................................................................................. 1-16

PARKING BRAKE ..................................................................................................................................... 1-16

FOOT THROTTLE .................................................................................................................................... 1-16

DIFFERENTIAL LOCK .............................................................................................................................. 1-16

INDEPENDENT PTO CONTROL LEVER ................................................................................................. 1-16

8X2 TRANSMISSION GEARSHIFT LEVERS ........................................................................................... 1-17

CLUTCH.................................................................................................................................................... 1-17

BRUSH DRIVE AND CONTROL HYDRAULICS ....................................................................................... 1-17

SOLUTION TANKS ................................................................................................................................... 1-18

RECOVERY TANKS ................................................................................................................................. 1-18

VACUUM TURBINE .................................................................................................................................. 1-18

SOLUTION METERING SYSTEM ............................................................................................................ 1-18

SPLASH CONTROL SYSTEM .................................................................................................................. 1-18

SQUEEGEE CONTROL............................................................................................................................ 1-18

BRUSH DRIVE CONTROL ....................................................................................................................... 1-18

BRUSH DRIVE LOCK-UP......................................................................................................................... 1-18

RECOVERY SOLUTION LEVEL WARNING ............................................................................................ 1-18

TRACTOR CONTROLS AND INSTRUMENTS ................................................................................................. 1-19

LIGHT SWITCH ........................................................................................................................................ 1-19

KEY STARTER SWITCH .......................................................................................................................... 1-19

DIESEL ENGINE STOP CONTROL .......................................................................................................... 1-19

HAND THROTTLE .................................................................................................................................... 1-19

FUEL GAUGE ........................................................................................................................................... 1-19

TEMPERATURE GAUGE ......................................................................................................................... 1-19

WARNING LIGHTS................................................................................................................................... 1-19

HOUR METER .......................................................................................................................................... 1-19

TACHOMETER ......................................................................................................................................... 1-19

HORN BUTTON ........................................................................................................................................ 1-19

CAMEL RECYCLING SYSTEM CONTROL PANEL ......................................................................................... 1-20

CAMEL RECYCLING SYSTEM ON/OFF SWITCH .................................................................................. 1-20

SOLUTION HIGH WARNING LIGHT ........................................................................................................ 1-20

DETERGENT LOW WARNING LIGHT ..................................................................................................... 1-20

DETERGENT FLOW KNOB ..................................................................................................................... 1-20

THE SCRUBBING SYSTEM ............................................................................................................................ 1-21

THE BASIC SCRUBBING SYSTEM COMPONENTS .............................................................................. 1-21

THE STANDARD SCRUBBING SYSTEM - HOW IT WORKS ................................................................. 1-22

THE CAMEL SCRUBBING SYSTEM - HOW IT WORKS ......................................................................... 1-23

OPERATING INSTRUCTIONS .......................................................................................................................... 1-24

PRE-START CHECK-LIST ........................................................................................................................ 1-24

STARTING PROCEDURE-GASOLINE & LP ENGINES ......................................................................... 1-24

WARM WEATHER STARTING ................................................................................................................. 1-24

COLD WEATHER STARTING ................................................................................................................ 1-24

STARTING PROCEDURE-DIESEL ENGINES ......................................................................................... 1-25

WARM WEATHER STARTING ................................................................................................................. 1-25

COLD WEATHER STARTING ................................................................................................................ 1-25

COLD WEATHER STARTING AIDS ......................................................................................................... 1-25

THERMOSTAT .......................................................................................................................................... 1-25

COOLANT IMMERSION HEATER ............................................................................................................ 1-26

STARTING THE TRACTOR WITH JUMPER CABLES............................................................................. 1-25

STOPPING THE ENGINE ......................................................................................................................... 1-26

GASOLINE / LP ENGINES ....................................................................................................................... 1-26

DIESEL ENGINES .................................................................................................................................... 1-26

TO OPERATE THE TRANSMISSION ....................................................................................................... 1-27

TO DRIVE THE MACHINE........................................................................................................................ 1-27

TO OPERATE THE SCRUBBING EQUIPMENT....................................................................................... 1-27

American-Lincoln Technology 1-2

772 Operator’s Manual

Page 3

TABLE OF CONTENTS

TO OPERATE WHILE DOUBLE SCRUBBING ........................................................................................ 1-28

TO END THE SCRUBBING OPERATION ................................................................................................ 1-28

TO STOP THE ENGINE............................................................................................................................ 1-28

POST OPERATION INSTRUCTIONS - ENGINE STOPPED.................................................................... 1-29

TO CLEAN THE SOLUTION TANKS ...................................................................................................... 1-29

TO CLEAN THE RECOVERY TANK......................................................................................................... 1-29

TO OPERATE THE VACUUM WAND ...................................................................................................... 1-29

PUSHING OR TOWING ......................................................................................................................... 1-30

OPERATION ON GRADES ....................................................................................................................... 1-30

SERVICE INSTRUCTIONS ............................................................................................................................... 1-31

SERVICE CHART ..................................................................................................................................... 1-31

HELPFUL HINTS FOR CLEANING OPERATION .................................................................................... 1-33

BRUSH LOAD AND WEAR ...................................................................................................................... 1-34

SQUEEGEE TOOL FLOOR HEIGHT ADJUSTMENT ............................................................................... 1-34

SQUEEGEE TOOL LEVEL ADJUSTMENT .............................................................................................. 1-35

AUTOMATIC SQUEEGEE LIFT ADJUSTMENT ....................................................................................... 1-35

SQUEEGEE LIFT HEIGHT ADJUSTMENT .............................................................................................. 1-36

TURBINE BELT ADJUSTMENT ................................................................................................................ 1-36

SPLASH SKIRT ADJUSTMENT ................................................................................................................ 1-37

SERVICING THE RECOVERY TANK ....................................................................................................... 1-37

SERVICING THE SOLUTION TANK ........................................................................................................ 1-38

VACUUM RELIEF VALVE ......................................................................................................................... 1-38

CHECKING THE ENGINE OIL LEVEL ..................................................................................................... 1-39

CHANGING THE ENGINE OIL & FILTER ................................................................................................. 1-39

CHECKING THE ENGINE COOLING SYSTEM ....................................................................................... 1-40

CHECKING THE FUEL FILTER / SEDIMENT .......................................................................................... 1-40

SEPARATOR............................................................................................................................................. 1-40

SEDIMENT SEPARATOR ......................................................................................................................... 1-40

BLEEDING THE DIESEL FUEL SYSTEM ................................................................................................ 1-41

AIR CLEANER .......................................................................................................................................... 1-42

TRANSMISSION ....................................................................................................................................... 1-43

POWER STEERING HYDRAULICS ......................................................................................................... 1-44

HYDRAULIC LIFT SYSTEM (REAR AXLE) .............................................................................................. 1-45

HYDRAULIC OIL FILTER .......................................................................................................................... 1-45

LUBRICATION FITTINGS ......................................................................................................................... 1-45

ENGINE COOLING SYSTEM ................................................................................................................... 1-46

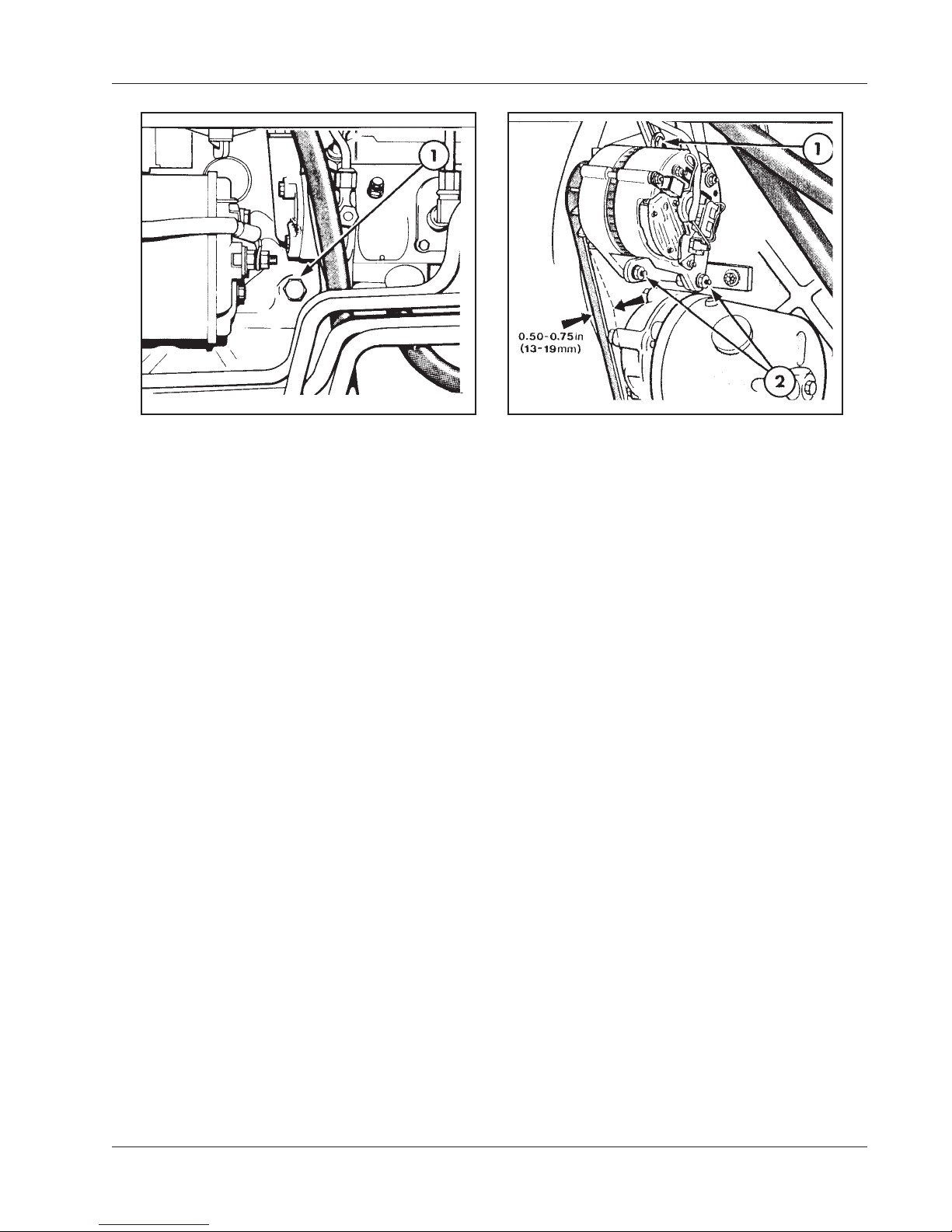

FAN BELT ADJUSTMENT ........................................................................................................................ 1-47

ALTERNATOR........................................................................................................................................... 1-47

REGULATOR (VOLTAGE) ........................................................................................................................ 1-47

BATTERY .................................................................................................................................................. 1-48

TIRES ..................................................................................................................................................... 1-48

FUEL INJECTION PUMP .......................................................................................................................... 1-48

BRAKE ADJUSTMENT ............................................................................................................................. 1-49

CLUTCH PEDAL ADJUSTMENT .............................................................................................................. 1-49

SPARK PLUGS ......................................................................................................................................... 1-50

DISTRIBUTOR POINTS............................................................................................................................ 1-50

VALVE CLEARANCES ............................................................................................................................. 1-50

FUEL INJECTORS .................................................................................................................................... 1-50

ENGINE SPEED ADJUSTMENT .............................................................................................................. 1-50

FRONT WHEEL BEARINGS .................................................................................................................... 1-50

STANDARD HARDWARE TORQUE VALUES ............................................................................................... 1-51

HYDRAULIC FITTING TORQUE CHART ....................................................................................................... 1-52

DECIMAL METRIC CONVERSION CHART ..................................................................................................... 1-53

TROUBLESHOOTING GUIDE - SCRUBBER SYSTEMS ............................................................................... 1-54

TROUBLESHOOTING GUIDE - HYDRAULIC SYSTEM ................................................................................. 1-55

TROUBLESHOOTING GUIDE - POWER STEERING SYSTEM ..................................................................... 1-56

TROUBLESHOOTING GUIDE - GASOLINE/DIESEL ENGINE SYSTEMS .................................................. 1-57

TROUBLESHOOTING GUIDE - LP ENGINES ............................................................................................... 1-58

TROUBLESHOOTING GUIDE - GENERAL ENGINE SYSTEM ...................................................................... 1-60

TROUBLESHOOTING GUIDE - CAMEL RECYCLING PUMP ........................................................................ 1-62

TROUBLESHOOTING GUIDE - CAMEL DETERGENT PUMP ........................................................................ 1-63

ELECTRICAL SCHEMATIC DIAGRAM .......................................................................................................... 1-64

ELECTRICAL CONNECTION DIAGRAM ......................................................................................................... 1-65

1-3 American-Lincoln Technology

772 Operator’s Manual

Page 4

TABLE OF CONTENTS

HYDRAULIC SCHEMATIC DIAGRAM - STANDARD MACHINE ..................................................................... 1-66

HYDRAULIC SCHEMATIC DIAGRAM -CAMEL MACHINE ............................................................................ 1-67

HARDWARE ABBREVIATIONS ........................................................................................................................ 1-68

ORDERING PARTS ........................................................................................................................................... 1-69

TABLE OF CONTENTS – CHAPTER 2 ............................................................................................................ 2-1

FRAME, BRACKETS & BUMPER ............................................................................................................ 2-2

BRUSH DRIVE ......................................................................................................................................... 2-4

BRUSH LIFT & SOLUTION CONTROL .................................................................................................... 2-6

TURBINE .................................................................................................................................................. 2-8

SQUEEGEE LIFT ...................................................................................................................................... 2-10

SQUEEGEE TOOL ................................................................................................................................... 2-12

SOLUTION TANK ..................................................................................................................................... 2-14

CAMEL SOLUTION TANK COMPONENTS ........................................................................................... 2-16

RECOVERY TANK.................................................................................................................................... 2-18

CAMEL RECOVERY TANK .................................................................................................................... 2-20

LIQUID PROPANE .................................................................................................................................... 2-22

EXHAUST SYSTEM .................................................................................................................................. 2-24

CAMEL RECYCLING SYSTEM ................................................................................................................ 2-26

HYDRAULICS (SCRUBBING SYSTEM) .................................................................................................. 2-28

CAMEL HYDRAULICS (SCRUBBING SYSTEM) ................................................................................... 2-30

ELECTRICAL ASSEMBLY ...................................................................................................................... 2-32

DECALS .................................................................................................................................................... 2-34

TABLE OF CONTENTS – CHAPTER 3 ............................................................................................................ 3-1

BRUSH OPTIONS .................................................................................................................................... 3-2

FOAM FILLED TIRES ............................................................................................................................... 3-3

FRONT BUMPER ..................................................................................................................................... 3-4

OVERHEAD GUARD ................................................................................................................................ 3-5

TURN SIGNAL OPTION ........................................................................................................................... 3-6

WARNING LIGHT OPTION ...................................................................................................................... 3-7

BRAKE LIGHT OPTION ............................................................................................................................ 3-8

CATALYTIC MUFFLER OPTION FOR GAS AND LP .............................................................................. 3-10

TRANSMISSION LOCK OUT ................................................................................................................... 3-11

VACUUM WAND ...................................................................................................................................... 3-12

INDEX ..................................................................................................................................................... 3-14

WARRANTY ..................................................................................................................................................... 3-17

American-Lincoln Technology 1-4

772 Operator’s Manual

Page 5

MACHINE SPECIFICATIONS

CLEANING PATH 72 inches

TRAVEL SPEED 1.3 - 14 MPH

TURNING RADIUS 117 inches

AISLE WIDTH FOR U-TURNS 20 Feet

DIMENSIONS

Length 138.50 inches

Width 93.3 inches

Height 66.5 Inches without Guard

WEIGHT 5800 lbs. Net

FRAME

Main frame assembly utilizes Ford 3930 Series industrial tractor as base component. All heavy-duty steel

construction.

POWER SOURCE

Available in gasoline, liquid propane (LP) or diesel power 45 P.T.O.-HP, 3-cylinder, liquid cooled, Ford 201

cu. in. industrial engine, electric start, Engine air filter, 17.3 gal. Fuel tank, LP model includes a 33 lb. tank

(ICC) and fittings, catalytic exhaust muffler to reduce emissions (Diesel model).

TRANSMISSION

8-speed forward, 2-speed reverse, manual high-low gear shift with foot operated clutch.

ELECTRICAL SYSTEM

12 volt, automotive type, with maintenance free battery.

HYDRAULIC SYSTEM

Heavy-duty Ford Tractor gear pump provides power to individually mounted brush drive motors. 2500 PSI

high pressure relief valve for squeegee and brush lift mechanisms.

SOLUTION TANKS

Two (2) 100 gallon capacity each, steel construction, one on each side, crossover allows filling from either

side, clean-out doors and oversize fill openings are standard.

RECOVERY TANK

One (1) 210 gallon capacity, steel construction, equipped with vacuum shut-off float activated when tank

reaches capacity. Clean-out doors anddump valves for easy draining.

VACUUM SYSTEM

Power provided by a regenerative air turbine, V-belt driven from the tractor PTO to 5,000 RPM.

SCRUBBING BRUSHES

Four (4) 18 inches diameter, disc type

Brushes are mounted to a 3/8" steel frame and are readily accessible. Hydraulic cylinder raises and lowers

brush assembly off ground level for travel and storage. Scrub brush discs are gimbals mounted to follow

irregular floor contours. One-piece or sectional brushes are available.

1-5 American-Lincoln Technology

772 Operator’s Manual

Page 6

MACHINE SPECIFICATIONS

OPTIONAL BRUSHES

Bassine

Straight wire

Nylon

Amerfil (.025)

Amerfil (.040)

Amerfil and wire (One-piece only)

Amergrit

Supergrit

Soft Nylon

Crimped wire scarifier (sectional only)

SQUEEGEE ASSEMBLY

Two (2) overlapping, independently suspended double-bladed, gum rubber. Swivel caster allows adjustment

up and down for optimum pick-up pressure. Provides maximum recovery from cracks and porous surfaces.

Squeegees lift automatically when unit goes into reverse direction.

STEERING

Hydrostatic power steering.

BRAKES

Mechanical wet discs on individual rear wheels, separate parking brakecontrol.

CONTROLS

Key start ignition Tachometer,

Alternator warning light Recovery tank level warning light

Headlights Horn button

Rear reflectors Brush and squeegee raise/lower levers

Engine hour meter, PTO lever

Brush drive control Solution metering control.

BEARINGS & LUBRICATION

All ball bearings on rotating shafts are lubricated for long life and sealed against dust and foreign material.

Grease fittings are provided to allow for proper lubrication at all necessary points.

TIRES

Front (2) 7.50 - 18 pneumatic rubber

Rear (2) 13.6 - 28 pneumatic rubber

FILTERS

One (1) engine and one (1) hydraulic oil filter trap particles down to 10 microns in size.

American-Lincoln Technology 1-6

772 Operator’s Manual

Page 7

MACHINE SPECIFICATIONS

FORD 3930 TRACTOR SPECIFICATIONS

CAPACITIES

Fuel Tank 17.3 US gals.

Cooling System 11.2 US qt.

Power Steering System 2.3 US qt.

Engine Crankcase

With Filter Change 7 US qt.

Without Filter Change 6 US qt.

Hydraulic Lift System

(Rear Axle)

With Ind. P.T.O. 12.0 US gal.

Transmission

8 x 2 3.2 US gal.

ENGINE

Bore 4.4 in.

Stroke 4.4 in.

Displacement 201 cu. in.

Compression Ratio

Diesel/Gasoline 16.3:1 / 7.75:1

Firing Order 1 - 2 - 3

Idle Speed(rpm) 600-850

Maximum Speed: No Load (rpm)2175

Rated (rpm) 2000

Low Idle 600-850

Valve Clearance

(Lash) Warm

Engine

Intake 0.014 in. - 0.016 in.

Exhaust 0.017 in. - 0.019 in.

LUBRICANTS

All Ford Tractor lubricants are specially blended from select base stocks and premium additives for long life

and trouble-free service. The use of these lubrications is recommended as follows:

Oils:

Transmission/Rear Axle/hydraulic Sump Ford M2C134-D/C

Power Steering Pump Ford M2C134-D/C

Engine Crankcase Ford M2C121-E

(see note below)

Grease:

Front Wheel Bearings and all Grease Fittings-M1C75-A/B or M1C137-B

NOTE: Engine Crankcase Oils

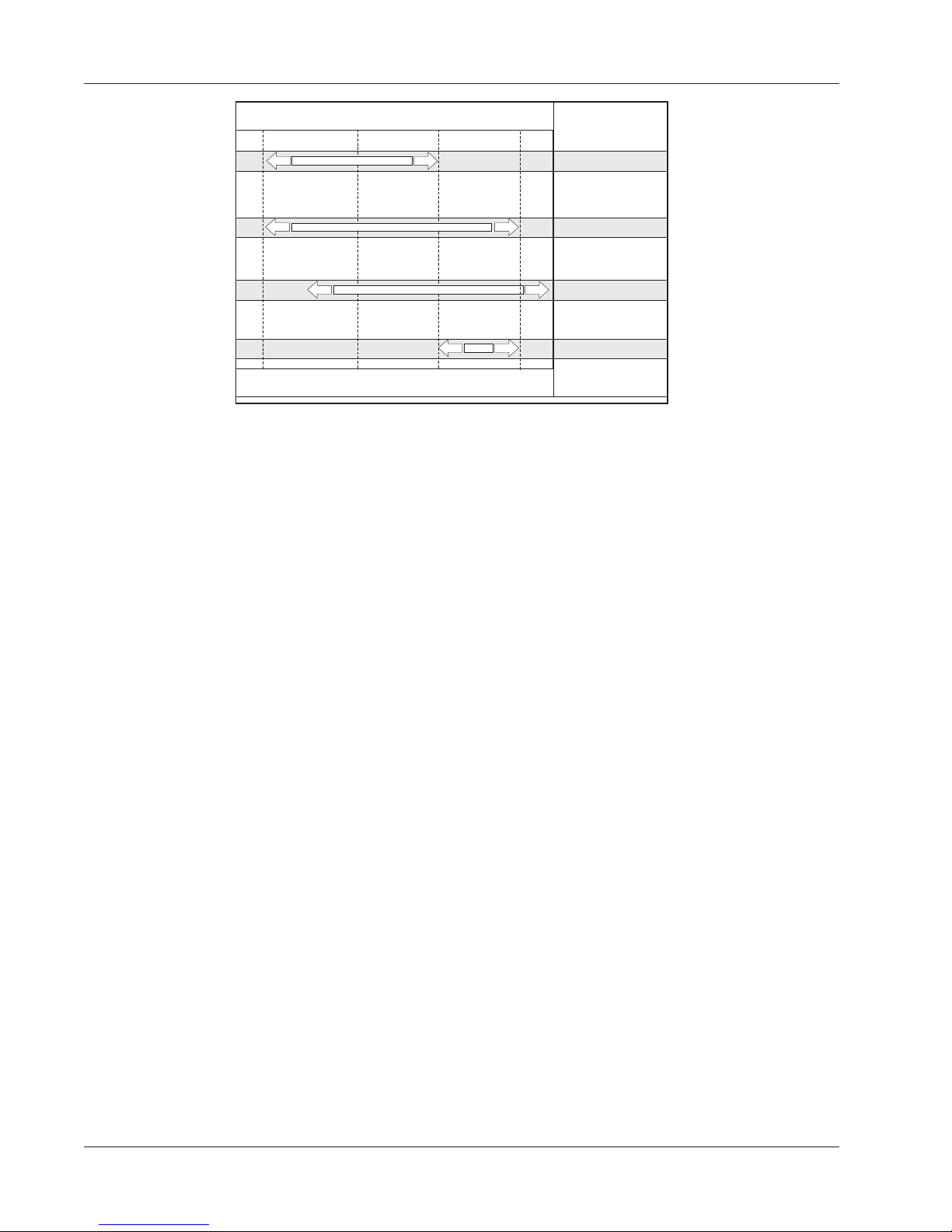

1) Viscosity grade selection for your climate:(see Figure 2)

1-7 American-Lincoln Technology

772 Operator’s Manual

Page 8

MACHINE SPECIFICATIONS

-25ºC

-10ºC

0ºC +32ºC

SAE 10W

SAE 10W-30

SAE 15W-40

SAE 30

-13ºF

P4840

OUTDOOR TEMPERATURES AND RANGES OF APPLICATION

In areas where prolonged periods of extreme temperatures are encountered, local lubricant practices are

acceptable, such as the use of SAE 5W, SAE 40 or SAE 50 grades of oil. These oils much be of API CD or

SF/CD Quality.

Engine crankcase oil drain intervals should be adjusted downward when diesel fuel sulfur content is above

0.5%. Consult your dealer for details of Engine Crankcase Oil Usage.

+14ºF +32ºF

+90ºF

COOLING SYSTEM

Type Pressurized liquid, re-circulating bypass

Water Pump

Type Centrifugal

Drive V-belt

Fan

Diameter 16 in.

Fan belt deflection 1/4 to 1/2 in. with 25 lbs. force applied midway between alternator and

crankshaft pulleys

Thermostat:

Starts to Open180° F

Fully Open203° F

Radiator Cap10 psi

ELECTRICAL SYSTEM

Alternator 12-volt

Output 55 amp. (STD)

Voltage Regulator Integral

Battery

Diesel Engine 107 amp. hour rating

Ground negative

Starting Motor positive engagement

Headlamp Sealed Beam Unit

(Std. Fenders) No. 4419

Headlamp (Opt. Flat Top Fenders)

Dual Beam (inner) Lamps No. 4460

Tail Lamp Bulb No. 1155

Flasher Warning Lamp Bulb No. 1156

Instruments and Warning

Light Bulb No. 1895

American-Lincoln Technology 1-8

772 Operator’s Manual

Page 9

MACHINE SPECIFICATIONS

IGNITION SYSTEM

Diesel

Type compression

Gasoline

Type spark

Method coil and distributor

Distributor Point Gap-Breaker 0.022-0.025 in.

Dwell Angle 35-38

Timing (at 600-700 rpm with vacuum line disconnected)

5 Deg. BTDC

Spark Plugs

Type Autolite AG5

Gap 0.023-0.027 in.

CLUTCH

w/Independent P.T.O. 13 in. single dry plate

Pedal Free Travel 1.1-1.6 In.

BRAKES

Type Mechanical, wet disc

Disc Diameter 8.0 in. O.D.,6.8 in. I.D.

No. Of Discs 3 Per Side

STEERING

Type Hydrostatic Power

Steering

Turns Lock-to-Lock 3.4

Pump

Type gear

FUEL SYSTEM

Carburetor (Gasoline):

Type Zenith

Injection Pump (Diesel)

Type Distributor

8 x 2 TRANSMISSION

ROAD SPEED IN MILES PER HOUR AND KILOMETERS PER HOUR

Gear 1450 RPM

1 1.2 MPH

2 1.51 MPH

3 2.65 MPH

4 3.60 MPH

5 4.31 MPH

6 5.38 MPH

7 4.46 MPH

8 12.85 MPH

R1 1.77 MPH

R2 6.20 MPH

Tire Size 13.6 x 28

Engine Speed

1-9 American-Lincoln Technology

772 Operator’s Manual

Page 10

55.00

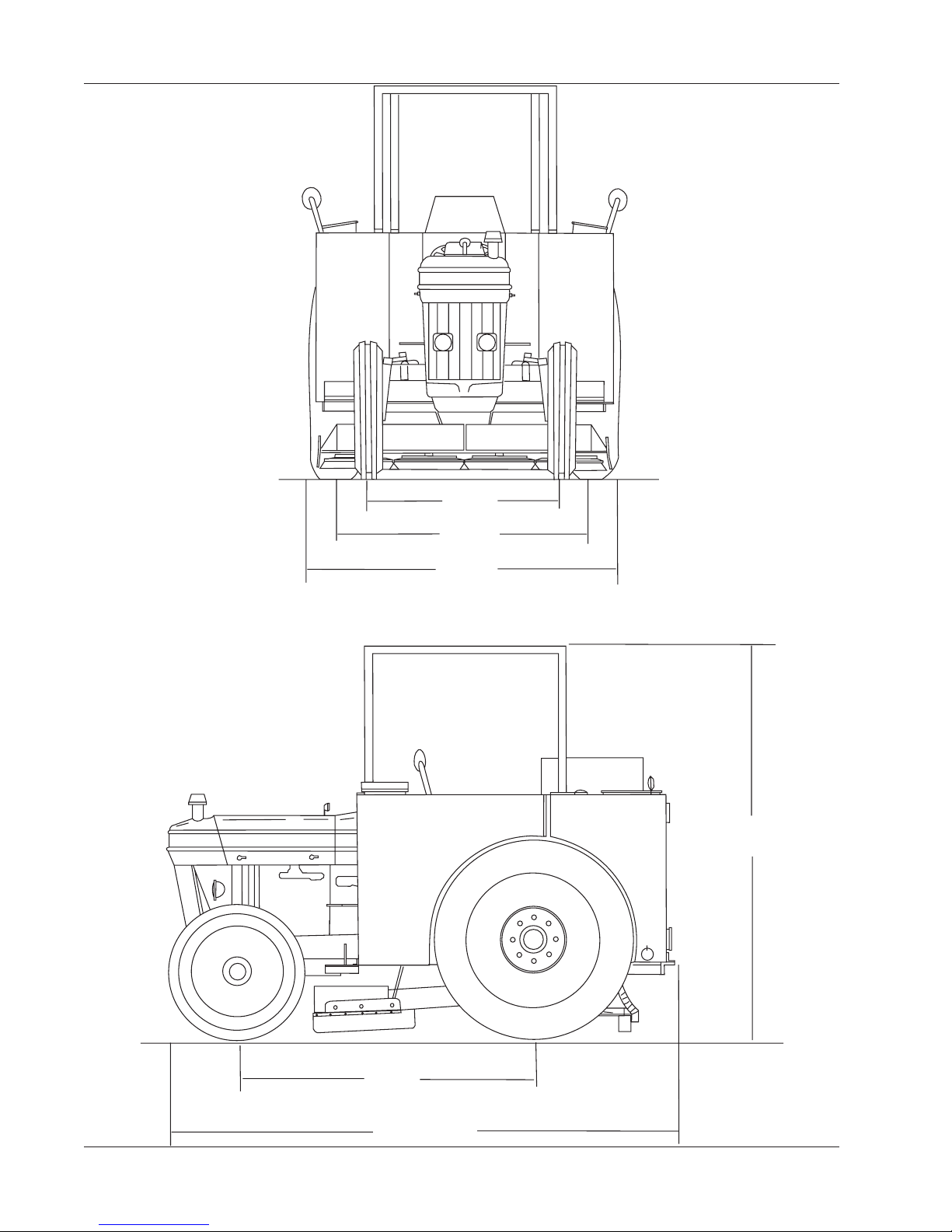

MACHINE DIMENSIONS

67.25

81.75

90.40

American-Lincoln Technology 1-10

772 Operator’s Manual

84.50

138.50

Page 11

SAFETY PRECAUTIONS

THE FOLLOWING STATEMENTS ARE USED THROUGHOUT THIS MANUAL AS INDICATED IN THEIR

DESCRIPTIONS:

DANGER

To warn of immediate hazards which will result in severe personal injury or death.

WARNING

To warn of hazards or unsafe practices which could result in severe personal injury or death.

CAUTION

To warn of hazards or unsafe practices which could result in minor personal injury.

ATTENTION

To warn of unsafe practices which could result in extensive equipment damage.

NOTE

To give important information or to warn of unsafe practices which could result in equipment damage.

The following information signals potentially dangerous conditions to the operator or equipment. Read this

manual carefully. Know when these conditions can exist. Then, take necessary steps to train machine operating personnel.

WARNING

Only enter and leave the machine from the right (curb) side using steps and handlebar provided.

Do not fill fuel tank with engine running. Do not smoke or use open flame near the fuel tank. Do not overfill LP

tank. Make sure fuel container and machine are electrically connected when refueling.

Lead acid batteries emit a highly explosive hydrogen gas that can be ignited by electrical arcing or by smoking.

Provide adequate ventilation system to properly expel discharged gases. Check exhaust system regularly for

leaks. Ensure that exhaust manifolds are secure and not warped.

Keep away from powerful vacuum fan suction at fan intake. Do not remove hose on fan intake housing while

running.

CAUTION

Avoid moving parts of the unit. Loose jackets, shirts or sleeves should not be permitted when working on

machine because of the danger of becoming caught in moving parts. Make sure all nuts and bolts are secure.

Keep shields and guards in position. If adjustments must be made while the unit is running, use extreme caution

around hot manifolds, moving parts, V-belts, etc. Disconnect positive battery terminal before removing instru-

ment panel.

Do not start machine unless you are in driver’s seat, with foot on brake pedal, or hand brake engaged, and

transmission in neutral position.

1-11 American-Lincoln Technology

772 Operator’s Manual

Page 12

SAFETY DECALS

THE FOLLOWING SAFETY DECALS ARE MOUNTED ON THE MACHINE. FIND AND NOTE THEIR LOCATION. REPLACE ALL SAFETY DECALS THAT ARE LOST OR ILLEGIBLE

CAUTION

FOR SAFETY, OBSERVE THE FOLLOWING WARNINGS. FAILURE TO COMPLY MAY CREATE A SERIOUS RISK OF

INJURY TO YOURSELF AND OTHERS. THIS MACHINE SHOULD NOT BE USED IN HAZARDOUS LOCATIONS

INCLUDING AREAS OF VOLATILE DUST OR VAPOR CONCENTRATIONS

1. Operators must be trained, Qualified and Understand the Operator’s Manual Before Starting.

2. Use caution when mounting and dismounting the machine particularly on wet surfaces.

3. Operate only from the designated operator’s position. Keep inside the body of the machine. Keep hands

and feet on the designated controls. Always operate in well Lighted areas.

4. Do not dump Hopper over an open pit or dock. Do not dump hopper when positioned on grade (Ramp).

Machine must be level (Horizontal).

5. The operator must exhibit extreme caution when negotiating, turning and traveling across grades or

ramps.

6. Start, stop, change directions, travel and brake smoothly. Slow down when turning. Avoid uneven surfaces

and loose materials.

7. Watch out for obstructions, especially overhead.

8. Carry no passengers on machine.

9. Set parking brake when leaving the machine. Chock (block) the wheels if the machine is to be parked on a

grade or ramp, or is to be worked on.

10. Never leave the operator’s seat with the engine running.

11. Report damage or faulty operation immediately. Do not operate the machine until repairs have been

WARNING

NO GASOLINE, COMBUSTIBLE OR FLAMMABLE MATERIAL IN THIS TANK USE DIESEL FUEL ONLY.

WARNING

1. NEVER FILL FUEL TANK WHILE ENGINE IS RUNNING

2. TO AVOID STATIC DISCHARGE, BE SURE FUEL CONTAINER AND MACHINE ARE GROUNDED

BEFORE POURING FUEL.

DO NOT FILL - LIQUID PROPANE ONLY

WARNING

ALWAYS SET PARKING BRAKE AND SHUT OFF ENGINE BEFORE LEAVING SEAT OF MACHINE.

WARNING

DO NOT REMOVE RADIATOR CAP WHILE ENGINE IS HOT. RADIATOR CORE MUST BE KEPT CLEAN TO PRE-

VENT OVERHEATING.

WARNING

KEEP HANDS AND CLOTHING AWAY FROM ROTATING FAN AND BELTS TO PREVENT SERIOUS INJURY

WARNING

START ENGINE ONLY FROM OPERATORS SEAT, IF SAFETY START SWITCH IS BY-PASSED, ENGINE CAN START

WITH TRANSMISSION IN GEAR.

DO NOT CONNECT OR SHORT ACROSS TERMINALS ON STARTER SOLENOID.

ATTACH BOOSTER CABLES AS SHOWN ON BATTERY DECAL.

STARTING IN GEAR CAUSING RUNAWAY, CAN RESULT IN SERIOUS INJURY.

American-Lincoln Technology 1-12

772 Operator’s Manual

Page 13

SAFETY DECALS

WARNING

BEFORE STARTING AND OPERATING:

-KNOW THE OPERATION AND SAFETY INSTRUCTIONS IN THE OPERATORS MANUAL,

AND ON THE TRACTOR.

-CLEAR THE AREA OF BYSTANDERS.

-LOCATE AND KNOW THE OPERATION OF ALL CONTROLS.

-FASTEN YOUR SEAT BELT.

START ENGINE ONLY FROM OPERATORS SEAT WITH TRANSMISSION IN NEUTRAL, P.T.O.DISENGAGED AND

HYDRAULIC CONTROLS IN LOWERED POSITION.

AVOID ACCIDENTAL CONTACT WITH THE GEARSHIFT LEVER WHILE THE ENGINE IS RUNNING. UNEXPECTED

TRACTOR MOVEMENT CAN RESULT.

SLOW DOWN ON TURNS, ROUGH GROUND AND SLOPES TO AVOID UPSET.

DO NOT PERMIT ANYONE BUT THE OPERATOR TO RIDE ON THE TRACTOR. THERE IS NO SAFE PLACE FOR

RIDERS.

LOCK BRAKES TOGETHER, USE WARNING LIGHT AND SMV EMBLEM WHILE DRIVING ON ROADS.

LOWER EQUIPMENT, PLACE GEAR SHIFT LEVERS IN NEUTRAL, STOP ENGINE AND APPLY PARKING BRAKE

BEFORE LEAVING TRACTOR SEAT.

FAILURE TO FOLLOW ANY OF THE INSTRUCTIONS ABOVE CAN CAUSE SERIOUS INJURY TO THE OPERATOR

OR OTHER PERSONS.

Replacement Materials Are Available From Your Local FORD New Holland Dealer or From:

FORD New Holland Service Publications - 500 Diller Ave. New Holland, Pa. 17557

WARNING

TO JUMP START

(Negative Grounded Battery)

1. SHEILD EYES.

2. CONNECT ONE END OF ONE CABLE TO POSITIVE [+] TERMINALS OF EACH BATTERY.

3. CONNECT ONE END OF OTHER CABLE TO NEGATIVE [ - ] TERMINAL OF GOOD BATTERY.

4. CONNECT OTHER END TO ENGINE BLOCK OF VEHICLE BEING STARTED. TO PREVENT

DAMAGE TO OTHER ELECTRICAL COMPONENTS ON VEHICLE BEING STARTED, MAKE

CERTAIN THAT ENGINE IS AT IDLE SPEED BEFORE DISCONNECTING JUMPER CABLES.

1-13 American-Lincoln Technology

772 Operator’s Manual

Page 14

Alto

MACHINE PREPARATION

772

American-Lincoln

P4330 FIGURE 3

MACHINE PREPARATION

YOUR AMER-CAN-LINCOLN 772 SCRUBMOBILE HAS BEEN SHIPPED COMPLETE, BUT DO NOT ATTEMPT TO OPERATE WITHOUT READING THE FOLLOWING INSTRUCTIONS.

1. Connect the squeegees.

2. Connect and tighten battery cables

3. Fill tank with appropriate fuel

WARNING

Never fill fuel tank while the engine is running. Always be sure the fuel dispenser and machine are electrically

connected before fueling. This can be easily done by providing an insulated wire (permanently attached to the

container) with battery clip on the other end.

4. Check engine crankcase oil level. Although properly lubricated at factory, check before starting engine.

No special break-in oil is used and recommended number of operating hours before the initial oil change is

50 hours. See lubrication and maintenance section of the Ford tractor manual.

5. Check radiator coolant level. Permanent type antifreeze is added at the factory to provide protection to

approximately -35ºF. To retain this protection level, always add ½ part water to ½ part anti-freeze.

6. In addition to regular service operations listed, the following items should be checked every 10 hours or

daily during the first 50 hours of operation.

-Transmission Oil Level

-Rear Axle Oil Level

-Rear Wheel Nuts for Tightness

American-Lincoln Technology 1-14

772 Operator’s Manual

Page 15

BRAKE PEDALS

MACHINE SYSTEMS & CONTROLS

RECOVERY SOLUTION

LEVEL WARNING

LIGHT

FORD TRACTOR

SQUEEGEE CONTROL

SOLUTION TANK

8 SPEED TRANSMISSION

SOLUTION TANK

BRUSH CONTROL

BRUSH DRIVE

CONTROL VALVE

RECOVERY

TANK

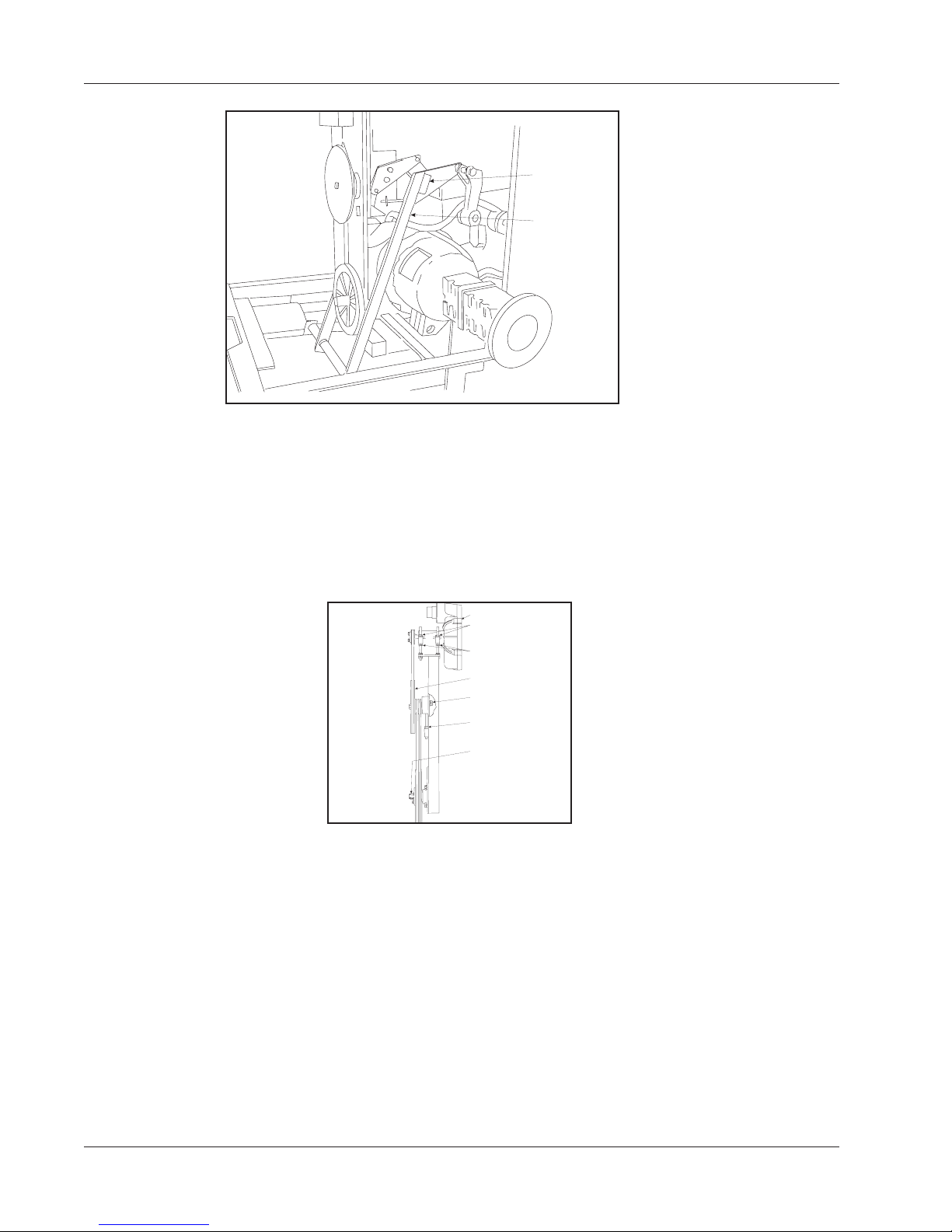

FORD 3930 TRACTOR POWER UNIT - Figure 4

The American-Lincoln H772 Scrubber utilizes a Ford Tractor Model 3930 as the power unit. The power unit

provides hydraulic power for the brush drive, squeegee and brush position functions. The independent Power

take off is used to drive the vacuum turbines.

This manual includes some pertinent Ford Tractor Operator’s Manual information for the 3930. Consult the

Ford 3930 Operator’s Manual for all other tractor related information. Parts for the 3930 power unit are

available from your local Ford New Holland Dealer.

Standard Features:

Tires:

SOLUTION CONTROL

SPLASH CONTROL

BRUSH DRIVE

PTO TURBINE DRIVE

CLUTCH

SQUEEGEE

TOOLS

P3982 FIGURE 4

-The Ford Tractor is equipped with an 8 x 2 speed mechanical foot clutch controlled transmission.

-The engine is governed at 1450-1500 RPM. Power take off is 435.

-Mechanical wet disc independently controlled brakes are provided for each rear wheel.

-Ford power steering is provided.

-Headlights and rear work light are provided.

-Differential lock for added traction (not used while scrubbing)

Pneumatic Type

Front 7.50 18 rim size

Rear 13.6 28 rim size

1-15 American-Lincoln Technology

772 Operator’s Manual

Page 16

MACHINE SYSTEMS & CONTROLS

P.T.O. CONTROL LEVER

PARKING BRAKE

BRAKE PEDAL HANDLE

BRAKE PEDAL LOCK

FOOT THROTTLE

P4232 FIGURE 5

BRAKE CONTROLS - Figure 5

The right brake pedal is used to brake the right rear wheel. The left pedal is used to brake the left rear wheel.

Depress both pedals simultaneously to stop the tractor.

BRAKE PEDAL LOCK - Figure 5

The brake pedal lock is used to lock the brake pedals together. Always lock the pedals together when the

tractor is operated at road speeds.

PARKING BRAKE - Figure 5

The parking brake handle is used to lock the brakes. Always apply the parking brake when the tractor is

parked.

To apply the brake:

1. Lock the parking brakes together with the brake pedal lock.

2. Pull up on the parking brake handle and turn it ¼ turn.

3. Depress both brake pedals.

To release the parking brake:

1. Turn the handle ¼ turn so the tabs will enter the slot in the handle guide.

2. Depress the brake pedals to release the ratchet.

3. Release he brake pedals.

FOOT THROTTLE - Figure 5

The foot throttle is used independently of the hand throttle to control the speed of the tractor. It is recommended that you use the foot throttle when driving on the highway.

IMPORTANT

When it is necessary to use the foot throttle, set the hand throttle to the idle position (fully forward).

DIFFERNTIAL LOCK - Figure 5 (not used for scrubbing)

The differential lock is used to lock the rear axle shafts together, providing additional traction in wet or loose

soil.

INDEPENDENT P.T.O. CONTROL LEVER - Figure 5

The P.T.O is “independent”, which means that is can be engaged or disengaged while the tractor is either

moving or stopped. To engage, move lever forward. Moving the lever fully in reverse will disengage the P.T.O.

and apply a P.T.O. brake. The brake will remain applied as long as the engine is running and the control lever

is rearward. When the engine is shut off, the brake will release so that the shaft can be turned by hand when

attaching equipment. On the H772 the P.T.O. is used to drive the vacuum turbine.

American-Lincoln Technology 1-16

772 Operator’s Manual

Page 17

MACHINE SYSTEMS & CONTROLS

8x2 SHIFT PATTERN

12 4

3

5

7R2

L

N

RI

8

N

6

N

H

CLUTCH PEDAL

HIGH-LOW SHIFT LEVER

P4234 FIGURE 6

8x2 TRANSMISSION GEARSHIFT LEVERS - Figure 6

The 8-speed transmission levers are used to select the appropriate gear for driving the machine. The transmission gear shift lever is the longer of the two levers and is used to select one of four forward speeds. The

High-Low shift lever is used to select either the High or Low range of forward and reverse gears. Placing the

lever in the forward position selects the low range. Always depress the clutch pedal before moving either of

the two levers.

A diagram of the shift pattern is provided directly below the Proof-Meter on the tractor.

See the chart on page 10 for gear and speed information.

CLUTCH - Figure 6

The foot-operated clutch pedal is used to engage/disengage the engine from the transmission while changing

gears and stopping. The pedal must be completely depressed, to stop forward travel of the tractor, or while

shifting gears.

BRUSH DRIVE & CONTROL HYDRAULICS

The transmission driven hydraulic pump, located in the differential housing, delivers 5.61 GPM at 1450 engine

RPM. Relief valve pressure is 2500 psi.

The rear axle differential and axle housings are used as the hydraulic reservoir. System capacity is 12 gal.

Pump pressure drives the four scrubbing brushes at 180 RPM at loads to 100 lbs. A directional spool valve

(see Figure 4) allows brush rotation in either direction.

The Ford Tractor hydraulic position control is used to raise and lower the squeegee independent of the

brushes.

The four 18" diameter disc brushes are raised and lowered independently with a separate directional valve

spool. A knob actuated lock-off valve is also provided to prevent leakdown when transporting long distances.

1-17 American-Lincoln Technology

772 Operator’s Manual

Page 18

MACHINE SYSTEMS & CONTROLS

SOLUTION TANKS

The machine is equipped with two, .125" thick tanks saddle mounted and interconnected. They may be filled

from wither side of the machine.

Each tank has an inlet filter screen to prevent contaminants from entering the metering valves.

Liquid cleaning compounds are added to the solution water in the tanks.

RECOVERY TANKS

The 210 gallon, .125" thick steel recovery tank is fitting with two pick up tubes and an air/water separation

system. Tank is fitted with clean out doors and drain valves.

P.T.O VACUUM TURBINE

One PTO belt driven turbine, at 5000 RPM, provides the air movement and water lift through the float manifold

system. The control lever is located below the brush drive valves and behind the solution control. To engage

the vacuum turbine move the lever forward.

SOLUTION METERING SYSTEM

The scrubbing solution is metered from the solution tanks by the “L” shaped lever control located in the left

side of the transmission housing above the clutch pedal (see Figure 4). Lift and position to start solution flow.

The solution is gravity fed to the center of the 4 scrubbing disc brushes. The maximum flow is 5gpm.

With brushes down solution lowering the lever stops flow. Solution flow also stop when brushes are raised

“full” up.

SPLASH CONTROL SYSTEM

The splash control system (see Figure 4) consists of flexible adjustable skirts as part of the brush drive

system. They provide containment of the shower few solution to a 72" path.

SQUEEGEE CONTROL

The squeegee control levels (see Figure 4) which are located at the driver’s right hand position, control the

squeegee position. The draft control lever is locked in one position at the factory near setting “2”. The other

lever is used to raise and lower the squeegees. Always position lever full “up” or full “down”.

With the squeegee is the full “down” position the squeegee will raise automatically when the manual transmission shift lever is moved to reverse gear position.

BRUSH DRIVE CONTROL

The two spool valve assembly at the operator’s left hand controls position and brush rotation. The handle

nearest to the operator controls the rotation of the brushes. Push forward or pull back to detented positions.

The other handle is pushed forward to lower the brushes to the floor and pull back to raise the brushes.

Always lower the brushes completely.

BRUSH DRIVE LOCK-UP

With brushes up for transporting or storage the small know controlled valve behind the brush raise-lower

handle can be closed by turning the knob clockwise until seated tightly.

RECOVERY SOLUTION LEVER WARNING

The red lens lamp (see Figure 4) flashes when the float controlled limit switch on the top of the recovery tank

is actuated by a water level 9" from the top of the tank. This indicates that the recovery tank needs to be

emptied.

American-Lincoln Technology 1-18

772 Operator’s Manual

Page 19

TRACTOR CONTROLS & INSTRUMENTS

- +

X100

15

10

25

20

5

0

ENGINE COOLANT

TEMPERATURE GAUGE

ENGINE OIL PRESSURE

WARNING LIGHT

HAND THROTTLE

FUEL GAUGE

ALTERNATOR

HOUR METER &

TACHOMETER

-+

WARNING LIGHT

AIR CLEANER

RESTRICTION

LIGHT SWITCH

WARNING LIGHT

HORN BUTTON

KEY STARTER SWITCH

DIESEL STOP CONTROL

P4230 FIGURE 7

LIGHT SWITCH - Figure 7

The light switch is a rocker ON/OFF switch. Depressing the rocker switch turns lights on or off.

KEY STARTER SWITCH - Figure 7

The key starter switch actuates the starter motor and the thermostat.

DIESEL ENGINE STOP CONTROL - Figure 7

Pull the stop control fully out to cut off the fuel supply to the injectors and stop the engine. The knob must be pushed fully in before

restarting the engine.

HAND THROTTLE - Figure 7

Pull the throttle down to increase engine rpm. Push the throttle up to decrease engine rpm.

FUEL GAUGE - Figure 7

The needle indicated the amount of fuel remaining in the tank.

TEMPERATURE GAUGE - Figure 7

The engine coolant temperature gauge indicates the temperature of the engine coolant. If the needle enters the red area of the gauge

while the engine is running, stop the engine and investigate the cause.

WARNING LIGHTS - Figure 7

When the key starter switch is turned “ON” the warning lights will come on. When the engine is running, the lights will go out as the

engine rpm is increased. If they do not go out:

Engine Oil Pressure Warning Light: Stop the engine immediately and investigate the cause. This indicates oil pressure only. The

operator must still check the crankcase from proper oil level.

Alternator Warning Light: It is an indication that the battery is not being charged. Investigate the cause as soon as possible, otherwise

the battery will become discharged.

Air Cleaner Restrict Warning Light: Illuminates when the air cleaner requires service and the engine is running. If the light illuminates

while the engine is running, stop the engine and service the air cleaner as described in the Ford Tractor maintenance section of this

manual.

HOUR METER - Figure 7

The hour meter indicated the time that the tractor has been operated, based on as average engine speed of 2055 rpm. Engine speeds

below 2055 rpm accumulate hours at a slower rate than clock hours. Engine speed above 2055 rpm build up hours faster than clock

hours. Use the hour meter as a guide to determine hourly service and maintenance intervals.

TACHOMETER - Figure 7

The tachometer indicates the engine rpm. Scrubber is operated at the full throttle (1450-1500rpm).

HORN BUTTON - Figure 7

The horn button is a momentary push button control located above the key switch.

1-19 American-Lincoln Technology

772 Operator’s Manual

Page 20

THE CAMEL RECYCLING SYSTEM CONTROL PANEL

DETERGENT FLOW

MIN

CB-1

RECYCLING

SYSTEM

OFF

ON

HIGH

SOLUTION

LOW

SOLUTION

C0431 FIGURE 8

THE CAMEL RECYCLING SYSTEM ON/OFF SWITCH - Figure 8

The Camel ON/OFF switch is used to turn the Camel Recycling System on and off.

SOLUTION HIGHT WARNING LIGHT - Figure 8

The solution high warning light will illuminate if the solution tank is too full of solution from the recycling system.

RECYCLING

LOW

DETERGENT

OFF

MAX

DETERGENT LOW WARNING LIGHT - Figure 8

The detergent low warning light will illuminate when the detergent tank is low, warning the operator to add

detergent.

DETERGENT FLOW KNOB - Figure 8

The detergent flow knob is a rotary control that regulates the detergent flow into the scrubbing solution. The

operator may choose from any detergent setting for light to heavy cleaning applications. The detergent light

will illuminate when the detergent tank is low, warning the operator to add detergent.

LOW SOLUTION WARNING LIGHT - Figure 8

The low solution warning light will illuminate when the solution tanks are low on solution. When this occurs

the recycling system switch should be turned on to begin recycling, which will fill the solution tanks.

RECYCLING LIGHT - Figure 8

The recycling light illuminates to indicate that the recycling system in on.

American-Lincoln Technology 1-20

772 Operator’s Manual

Page 21

THE BASIC SCRUBBING SYSTEM

D

C

A

B

B

HG

P3983 FIGURE 9

BASIC SCRUBBING SYSTEM COMPONENTS

A. Solution Feed Tubes D. Squeegee Tools G. Metering Valves

B. Solution Tubes E. Float Cage H. Scrub Brushes

C.Vacuum Tubes F. Recovery Tank

D

D

E

F

There are two scrubbing systems available for the 772 scrubmobile:

-Standard Scrubbing System (non-recycling)

-Camel Scrubbing System (with recovery to solution recycling)

Both Scrubbing Systems share the same basic components as shown in Figure 9.

1-21 American-Lincoln Technology

772 Operator’s Manual

Page 22

THE STANDARD SCRUBBING SYSTEM

SOLUTION

TANK

RECOVERY

TANK

FILTER

SCRUB

BRUSH

SQUEEGEE

FLOOR CONTACT

P4759

P4759 FIGURE 10

HOW IT WORKS

During the scrubbing process (Figures 9 &10), a solution of detergent and water from the solution tanks is fed

to the solution lines where it is disbursed to the floor through the four scrubbing brushes that aggressively work

to dislodge soilage.

As the machine moves forward, a high vacuum turbine system lifts dirty water and debris from floor surface,

through the squeegee tools and a recovery tank air/water separation system. A float switch in the tank activates a flashing light on the control panel when the water level in the tank becomes too high. Debris and

sludge settle to the bottom of the recovery tank.

American-Lincoln Technology 1-22

772 Operator’s Manual

Page 23

THE CAMEL SCRUBBING SYSTEM

DETERGENT

TANK

SOLUTION

TANK

SOLUTION

PUMP

RECOVERY

TANK

FILTER

FILTER

FLOW VALVE

ETERGENT

PUMP

SCRUB

SEPARATOR

BRUSH

SQUEEGEE

P4759a

FLOOR CONTACT

P4759a FIGURE 11

HOW IT WORKS

During the scrubbing process (Figures (9 & 11), filtered water from the solution tank is fed to the solution lines

where it combines with the detergent from the metering pumps. This mixture is then fed to the floor where four

disc scrubbing brushes aggressively work to dislodge soilage.

After scrubbing, the used dirty solution is vacuumed from the floor and discharged into the containment

chamber of the recovery tank. Once there a system of baffles helps to clarify the solution on its way to the

pumping chamber of the recovery tank. At intervals, a system of sensors activates the recycling pump which

sends filtered solution from the pumping chamber on its way to the centrifugal separator which aids in further

clarifying of the solution for re-use. In the separator, solids are removed and purged into the containment

chamber. The solids free solution is then fed up through the separator outlet and into the solution tank where it

is ready to be mixed with fresh, metered detergent to be used again as scrubbing solution.

1-23 American-Lincoln Technology

772 Operator’s Manual

Page 24

&

OPERATING INSTRUCTIONS

NOTE

A safety starter permits the starting motor to operate only when the

ELECTRICAL

EQUIPMENT OFF

ACCESSORIES ON

WARNING LIGHTS

INSTRUMENTS ON

THERMOSTAT

HEATER ON

STARTING

MOTOR ON

Always shift both levers to neutral before starting the engine. Never

attempt to start the engine while standing beside the tractor - Always sit

Do not crank the starting motor continuously for more than 30 seconds

P3850 FIGURE 13

PRE-START CHECKLIST

Before starting the machine perform the pre-start checklist:

-Check under the machine for leaks -Check engine coolant level

-Check hydraulic fluid level -Check fuel level gauge or LP tank gauge

-Check engine oil level -Check brake and controls for proper operation

-Check engine air filter -Open fuel shut off valve on fuel tanks.

STARTING PROCEDURE GASOLINE/LP ENGINE

Follow these steps to start the Gasoline/LP Engine:

Warm Weather Starting:

1. Depress the clutch pedal and move the shift levers to the neutral position.

2. Apply the parking brake.

3. Place the hydraulic control lever(s) in the neutral position.

4. Place the P.T.O. control lever in the disengaged position.

5. Open the hand throttle slightly.

6. Turn the key to its start position; when engine starts, release the key.

7. Check to ensure that all the warning lights go out indicating all tractor systems are properly functioning.

If the tractor fails to start, follow the instructions under “COLD WEATHER STARTING”

transmission high-low shift lever is in neutral.

CAUTION

in the seat.

IMPORTANT

to avoid starting motor failure.

Cold Weather Starting (Gasoline Engine):

1. Depress the clutch pedal and move the shift levers to the neutral position.

2. Apply the parking brake.

3. Place the hydraulic control lever(s) in the neutral position.

4. Place the P.T.O. control lever in the disengaged position.

5. Open the hand throttle slightly.

6. Pull the choke all the way out.

7. Turn the key to its start position; when engine starts, release the key.

8. Push the choke all the way in.

9. Check to ensure that all the warning lights go out indicating all tractor systems are properly functioning.

10. Run the engine at 1000rpm for 30 to 60 seconds before driving the tractor.

American-Lincoln Technology 1-24

772 Operator’s Manual

Page 25

OPERATING INSTRUCTIONS

STARTING PROCEDURE GASOLINE/LP ENGINE (cont.)

Cold Weather Starting (L/P Engines):

1. Depress the clutch pedal and move the shift levers to the neutral position.

2. Apply the parking brake.

3. Place the hydraulic control lever(s) in the neutral position.

4. Place the P.T.O. control lever in the disengaged position.

5. Open the hand throttle slightly and do not press the foot pedal.

6. Turn the key to its start position; when engine starts, release the key.

7. Check to ensure that all the warning lights go out indicating all tractor systems are properly functioning.

8. Run the engine at 1000 rpm for 30 to 60 seconds before driving the tractor.

If the engine fails to start, refer to the following instructions:

1. Momentarily depress the foot pedal to the floor.

2. Reposition the hand throttle to the fully closed position and start the engine.

STARTING PROCEDURE FOR THE DIESEL ENGINE

Follow these steps to start the diesel engine.

Warm Weather Starting:

1. Depress the clutch pedal and move the shift levers to the neutral position.

2. Apply the parking brake.

3. Place the hydraulic control lever(s) in the neutral position.

4. Place the P.T.O. control lever in the disengaged position.

5. Open the hand throttle halfway.

6. Turn the key to its start position; when engine starts, release the key.

7. Return the hand throttle to the idle position.

7. Check to ensure that all the warning lights go out indicating all tractor systems are properly functioning.

If the engine fails to start, follow the instructions under “Cold Weather Starting”.

Cold Weather Starting (Diesel Engines):

1. Depress the clutch pedal and move the shift levers to the neutral position.

2. Apply the parking brake.

3. Place the hydraulic control lever(s) in the neutral position.

4. Place the P.T.O. control lever in the disengaged position.

5. Open the hand throttle fully.

6. Turn the key to its start position; when engine starts, release the key.

7. After using the thermostat for 15 seconds turn the key start to the start position.

8. When the engine starts, return the throttle to the idle position and check to ensure all the warning lights

have been extinguished and the gauge readings are normal.

If the engine fails to start, repeat the foregoing procedure. If the engine still fails to start, wat 5 minutes for

battery to recover and repeat the procedure.

COLD WEATHER STARTING AIDS

WARNING

Ether starting aids are available for cold weather starting. Do not use ether in conjunction with thermostart.

Disconnect thermostat before using ether.

THERMOSTART:

The thermostart is available for all diesel tractors. The unit is effective in temperatures down to 0ºF. If colder

temperatures are encountered, a coolant immersion heater, described below, is recommended. The

thermostart element is installed in the air intake manifold. It introduces and ignites fuel in the manifold before it

enters the combustion chamber. The element is operated with the key starter switch. To start a cold engine

with the thermostart, follow the instructions in the diesel engine cold weather starting procedures.

1-25 American-Lincoln Technology

772 Operator’s Manual

Page 26

OPERATING INSTRUCTIONS

COOLANT IMMERSION HEATER (Accessory):

The coolant immersion heater consists of a heating element installed in the right side of the engine block. A

detachable cord is provided for plugging into an electrical outlet. The heater provides for easier starting by

warming the engine coolant and oil and is effective to -20ºF.

To operate the Heater:

1. Plug in the heater to a suitable 115-Volt outlet and leave for two hours before carrying out the cold weather

starting procedures.

2. Disconnect the heater from its power source and install the dust cover in the element.

The heater can be plugged in longer than two hours without damage but its effectiveness will not be increased.

When the heater is not in use, install the dust plug in the element.

STARTING THE TRACTOR WITH JUMPER CABLES:

Follow these instructions to start the engine with jumper cables.

If it is necessary to use jumper cables to start the engine, proceed with the following instructions. Connect one

end of the jumper cable to the tractor battery positive (+) terminal and the other to the auxiliary battery positive

(+) terminal. Connect one end of the other cable first to the auxiliary battery negative (-) terminal and the other

end to the tractor starter negative (-) terminal. Follow the starting procedures after the jumper cables are

connected.

Idle the engine and turn on all electrical equipment (lights, etc.), then disconnect the cables in reverse order of

the connective procedure above. This will help protect the alternator from damage due to extreme load

changes.

NOTE

Reversed battery polarity will damage the voltage regulator and alternator.

WARNING

Batteries contain sulfuric acid and produce explosive gases. Follow the instructions below to prevent personal

injury.

-Wear eye and skin protection

-Keep sparks and flames away

-Always have adequate ventilation while charging or using the battery

-Follow the battery manufacturer’s instruction which are shown on the battery

STOPPING THE ENGINE:

Follow these steps to stop the engine.

1. Reduce the engine speed to idle, then:

Gasoline Engines:

2. Turn the key starter switch, Figure 13, to the “OFF” position.

Diesel Engines:

2. Turn the key starter switch, Figure 13, to the “OFF” position, then pull the diesel stop control out and hold

until the engine stops.

NOTE

Failure to turn the key starter switch to the “OFF” position after the engine stops will result in the warning lights

remaining on, causing the battery to discharge.

American-Lincoln Technology 1-26

772 Operator’s Manual

Page 27

OPERATING INSTRUCTIONS

TO OPERATE THE TRANSMISSION

Follow these steps to operate the transmission.

When the high-low shift lever is in the low range, 1st, 2nd, 3rd, 4th, and (R1) gear ratios can be selected with the

gearshift lever. When the high-low lever is in the high range, 5th, 6th, 7th, 8th, and (R2) gear ratios can be

selected.

IMPORTANT

Avoid using the clutch pedal as a “footrest” (riding the clutch). Prolonged operation in this manner will cause

premature failure of the clutch components.

To change from one gear ratio to another, or to change ranges:

1. Depress the clutch pedal completely.

2. Bring the tractor to a complete stop.

3. Shift to the desired gear and/or range. (Do not attempt to change gears while the tractor is in motion).

WARNING

For your safety, always lock the brake pedals together when traveling at transport speeds. To lock the pedals

together, slide the lock pin across to engage in the hole in the underside of the right hand pedal.

TO DRIVE MACHINE (FOR TRANSPORT)

Follow these steps to drive (transport) the machine to the area to be cleaned.

1. Be sure the brushes and the squeegee are in the “up” position with all the other controls in the “OFF” po

sition. Rotate the knob on the brush drive lock-up valve clockwise to hold the scrub deck in the “up”

position.

2. Release the parking brake.

3. Transport may be done using either the foot throttle or the hand throttle. (For high speed transport, the

foot throttle is recommended).

4. Depress the clutch, select the proper gear for desired transport speed with the transmission lever(s),

slowly release the clutch pedal until the clutch is completely engaged.

5. To stop, depress the brakes, depress the clutch and reduce the throttle speed to idle.

6. Set the parking brake.

TO OPERATE THE SCRUBBING EQUIPMENT

Follow these steps to begin the cleaning operation.

1.Fill the solution tanks.

Standard machine: Mix the detergent and water to the proper ratio for the cleaning task at hand. (Follow

the detergent Mfgr’s recommended mixing ratio). Fill the tanks through the one or both of the fill doors

on top of the solution tanks.

Camel machine: Fill the detergent tank with straight detergent. Fill the solution tanks with straight water.

If there is no static water already on the area to be cleaned; the recovery tank can be filled also. This

will provide additional “scrub” time. When filling the Camel recovery tanks, take care not to fill the

center section of the tank. The left and right sides of the recovery tank can be filled to a maximum

of 2/3 full. Do not fill the center section of the recovery tank.

2. Transport the machine to the area to be scrubbed.

3. Release the brush deck by turning the “brush deck lock-up valve” counterclockwise. Lower the brush deck

by pushing the brush deck lift handle forward. The lever is located on the outbound side of the “brush

deck control valve” assembly (see Figure 4).

4. Increase tractor engine speed to full governed speed: 1450-1500 rpm.

5. Lower the squeegees to the floor by positioning the quadrant lever to the pulled back position. (The

squeegee will not lower until the transmission is placed in either 1st or 2nd gear).

6. Turn on the vacuum turbine by engaging the P.T.O. lever. Moving the lever to the forward position (see

Figure 5) does this. Once the P.T.O. lever is engaged, the vac turbine will come on when the squeegees

are lowered.

7. Check the squeegees for proper deflection of the squeegee rubber.

1-27 American-Lincoln Technology

772 Operator’s Manual

Page 28

OPERATING INSTRUCTIONS

TO OPERATE THE SCUBBING EQUIPMENT (cont.)

Follow these steps to operate the scrubbing equipment.

1. Engage the solution flow

Standard Machine: Lift the solution control lever located near the operator’s left foot (see Figure 4).

Camel Machine: Turn on the “Recycling System” switch and dial in the desired detergent flow (see Figure

8).

2. Engage brush rotation by moving the inboard lever on the brush control valve (see Figure 4). Placingthe

lever forward is for scrubbing while moving forward, and placing the lever backwards is for scrubbing while

moving in reverse (see double scrubbing operation)

3. Begin scrubbing

NOTE

To avoid leaving solution on the floor, stop solution flow 20' before turning or stopping.

TO OPERATE WHILE DOUBLE SCRUBBING

Follow these instructions to operate while double scrubbing.

When heavy soil build-up is present, additional chemical solution time and extra scrubbing may be desirable.

NOTE

This procedure can only be used if safety conditions are controlled for wet flooring.

-Do not lower the squeegee, and scrub in forward direction.

-Reverse the brush rotation and scrub backward over the area just scrubbed.

-Reverse the brush rotation, lower the squeegees and scrub entire are again. This time the squeegees will

remove all the dirty solution.

TO END THE SCRUBBING OPERATION

Follow these steps to stop the scrubbing operation.

Discontinue scrubbing whenever a “solution low”, “detergent low’, “high solution”, or “high recovery” light is

illuminated.

1. Shift transmission levers into neutral.

2. Reduce engine rpm to idle.

3. Apply parking brake.

4. Stop the solution flow

Standard & Camel Machine: Lift the “solution control lever” located near the operator’s

left foot (see Figure 4).

Camel Machine: Turn on the “Recycling System” switch and dial in desired detergent

flow (see Figure 8).

5. Stop the brush rotation by placing the “brush rotation control” lever in the center position.

6. Raise the brush deck by pulling the “brush deck lift control” lever backwards.

7. Raise the squeegee tools by pushing the “quadrant lever” all the way forward and down.

8. Stop the vacuum turbine by pulling the P.T.O. lever all the way back.

9. Transport the machine to appropriate are for Post Operation cleaning and service.

10. Shut down engine.

TO STOP THE ENGINE

Follow these steps to stop the engine.

1. Reduce the engine speed to idle, then:

Gasoline Engines:

2. Turn the key starter switch to the “OFF” position (see Figure 13).

Diesel Engines:

2. Turn the key starter switch to the “OFF” position (see Figure 13), then pull the diesel stop control out and

hold until the engine stops.

American-Lincoln Technology 1-28

772 Operator’s Manual

Page 29

OPERATING INSTRUCTIONS

POST-OPERATION INSTRUCTIONS - ENGINE STOPPED

Perform these steps after the machine has been shut down.

-Close the LPG fuel valve as required.

-Check for string or wire tangled on scrub brushes.

-Check scrub brushes for wear or damage.

-Check squeegees for wear, damage, or adjustment.

-Drain and clean recovery tanks.

-Clean the recovery tank’s screen and float.

-Check vacuum pipes and hoses for obstructions.

-Check the slash skirt for wear, damage, or adjustment.

-Check the outlet strainers in the solution tanks for contamination.

-Fill fuel tank

-Check for leaks

TO CLEAN THE SOLUTION TANKS

Follow these instructions to clean the solution tanks after every scrubbing cycle.

Standard Machine:

-Inspect, remove, and clean the solution inlet filter on the bottom of the LH & RH tanks.

-Flush the sediment accumulations from the floor of the tanks.

Camel Machine:

-Inspect, remove, and clean the solution inlet filter on the bottom of the LH & RH tanks.

-Dirt and sludge build-up can be flushed out the pipe plugs located at the rear of the tanks.

-Disconnect and clean the crossover hoses periodically or as often as needed depending on service

conditions.

TO CLEAN THE RECOVERY TANK

Follow these instructions to clean the recovery tank after every scrubbing cycle.

Standard & Camel Machines:

-Position a corner of the machine near a floor drain.

-Standard Machine - open a drain valve.

-Camel Machine - Release the drain hose, lower it to the drain and open the hose end plug

-Open all clean out doors. Use a hose and squeegee to remove the dirt and sludge from to bottom of

the tank.

-Remove the clean out caps located on top of the recovery tank. Inspect and flush the pickup tubes

and squeegee hoses.

TO OPERATE THE VACUUM WAND (Option)

The vacuum wand gives the machine the added flexibility of picking up spills not accessible by the machine. A

15' hose utilizes the machine vacuum system.

WARNING

Use the vacuum wand option only if the machine can be locates on level surface

TO OPERATE THE VACUUM WAND

1. Stop the engine and engage the machine parking brake

WARNING

Always engage the parking brake before operating the vacuum wand.

1-29 American-Lincoln Technology

772 Operator’s Manual

Page 30

OPERATING INSTRUCTIONS

TO OPERATE VACUUM WAND (cont.)

2. Remove wand and hose assembly from mounting clips on top of the tanks.

3. Push hose end unto 1.50" fitting located on the left hand squeegee assembly.

4. Position the LH squeegee valve to connect the pick up hose to the vacuum wand hose by moving flat lever

to the left to stop position.

5. Position the right hand squeegee valve lever to the left to close off the right hand pickup hose.

6. Start the engine.

7. Place throttle in the “full” rpm position.

8. When finished, shut off the engine.

9. Remove and store vacuum wand and hose.

10. Reposition squeegee hoses by moving both levers full right.

IMPORTANT

The pickup hose assembly can also be used as a sumping system. When the pickup hose is submerged continu-

ously the engine rpm must be reduces to 1000-rpm max. to prevent overload of the vacuum system drive belts.

PUSHING OR TOWING

The machine may be pushed or towed with transmission shift levers in neutral at speeds appropriate for safety.

OPERATION ON GRADES

The machine may be operated on grades up to 12º if the surface provides adequate traction.

WARNING

Always test wet surface traction part way up or part way down sloped area so that if slipping does occur, control

can be regained before reaching the bottom of the slope.

American-Lincoln Technology 1-30

772 Operator’s Manual

Page 31

SERVICE CHART

11

3,22

19 13

1

4

18

18

2,32

14

10

16

8

8

9

2,19,23

21

30

24,26,27

25,28,29

20

31

6,7 17 16

5

9

15

1-31 American-Lincoln Technology

FIGURE 15

772 Operator’s Manual

Page 32

SERVICE CHART

SERVICE CHART FOR 772 SCRUBMOBILE GAS/LP/ AND DIESEL

For service assistance, consult your factory authorized American-Lincoln dealer. For best performance,

replaced worn parts with genuine American-Lincoln parts.

EVERY 8 HOURS or DAILY operation check and clean/adjust if necessary:

1. Fuel level

2. Engine oil level