Page 1

Stratix II GX Device Handbook, Volume 1

101 Innovation Drive

San Jose, CA 95134

www.altera.com

SIIGX5V1-4.4

Page 2

Copyright © 2009 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific device designations, and all other words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the trademarks and

service marks of Altera Corporation in the U.S. and other countries. All other product or service names are the property of their respective holders. Altera products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights, and copyrights. Altera warrants

performance of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make

changes to any products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information, product, or service described herein except as

expressly agreed to in writing by Altera Corporation. Altera customers are advised to obtain the latest version of device specifications before relying on any published information and before placing orders for

products or services.

ii Altera Corporation

Page 3

Contents

Section I. Stratix II GX Device Data Sheet

Chapter 1. Introduction

Features ................................................................................................................................................... 1–1

Referenced Document ........................................................................................................................... 1–5

Document Revision History ................................................................................................................. 1–5

Chapter 2. Stratix II GX Architecture

Transceivers ............................................................................................................................................ 2–1

Transmitter Path ............................................................................................................................... 2–4

Receiver Path ................................................................................................................................... 2–14

Loopback Modes ............................................................................................................................ 2–30

Transceiver Clocking ..................................................................................................................... 2–35

Other Transceiver Features ........................................................................................................... 2–41

Logic Array Blocks .............................................................................................................................. 2–44

LAB Interconnects .......................................................................................................................... 2–45

LAB Control Signals ....................................................................................................................... 2–46

Adaptive Logic Modules .................................................................................................................... 2–48

ALM Operating Modes ................................................................................................................. 2–50

Arithmetic Mode ............................................................................................................................ 2–55

Shared Arithmetic Mode ............................................................................................................... 2–58

Shared Arithmetic Chain ............................................................................................................... 2–60

Register Chain ................................................................................................................................. 2–61

Clear and Preset Logic Control .................................................................................................... 2–63

MultiTrack Interconnect ..................................................................................................................... 2–63

TriMatrix Memory ............................................................................................................................... 2–69

M512 RAM Block ............................................................................................................................ 2–70

M4K RAM Blocks ........................................................................................................................... 2–73

M-RAM Block ................................................................................................................................. 2–75

Digital Signal Processing (DSP) Block .............................................................................................. 2–81

Modes of Operation ....................................................................................................................... 2–85

DSP Block Interface ........................................................................................................................ 2–85

PLLs and Clock Networks .................................................................................................................. 2–89

Global and Hierarchical Clocking ................................................................................................2–89

Enhanced and Fast PLLs ............................................................................................................... 2–97

Enhanced PLLs ............................................................................................................................. 2–109

Fast PLLs ........................................................................................................................................ 2–109

I/O Structure ...................................................................................................................................... 2–110

Double Data Rate I/O Pins ......................................................................................................... 2–118

External RAM Interfacing ........................................................................................................... 2–122

Altera Corporation iii

Page 4

Contents Stratix II GX Device Handbook, Volume 1

Programmable Drive Strength ................................................................................................... 2–124

Open-Drain Output ...................................................................................................................... 2–125

Bus Hold ........................................................................................................................................ 2–125

Programmable Pull-Up Resistor ................................................................................................ 2–126

Advanced I/O Standard Support .............................................................................................. 2–126

On-Chip Termination .................................................................................................................. 2–130

MultiVolt I/O Interface ............................................................................................................... 2–133

High-Speed Differential I/O with DPA Support .......................................................................... 2–136

Dedicated Circuitry with DPA Support .................................................................................... 2–138

Fast PLL and Channel Layout .................................................................................................... 2–141

Referenced Documents ..................................................................................................................... 2–142

Document Revision History ............................................................................................................. 2–143

Chapter 3. Configuration & Testing

IEEE Std. 1149.1 JTAG Boundary-Scan Support ............................................................................... 3–1

SignalTap II Embedded Logic Analyzer ............................................................................................ 3–3

Configuration ......................................................................................................................................... 3–3

Operating Modes .............................................................................................................................. 3–4

Configuration Schemes ................................................................................................................... 3–6

Device Security Using Configuration Bitstream Encryption ..................................................... 3–7

Device Configuration Data Decompression ................................................................................. 3–7

Remote System Upgrades ............................................................................................................... 3–8

Configuring Stratix II GX FPGAs with JRunner .......................................................................... 3–8

Programming Serial Configuration Devices with SRunner ....................................................... 3–9

Configuring Stratix II FPGAs with the MicroBlaster Driver ..................................................... 3–9

PLL Reconfiguration ........................................................................................................................ 3–9

Temperature Sensing Diode (TSD) ................................................................................................... 3–10

Automated Single Event Upset (SEU) Detection ............................................................................ 3–12

Custom-Built Circuitry .................................................................................................................. 3–12

Software Interface ........................................................................................................................... 3–12

Referenced Documents ....................................................................................................................... 3–13

Document Revision History ............................................................................................................... 3–13

Chapter 4. DC and Switching Characteristics

Operating Conditions ........................................................................................................................... 4–1

Absolute Maximum Ratings ........................................................................................................... 4–1

Recommended Operating Conditions .......................................................................................... 4–2

Transceiver Block Characteristics .................................................................................................. 4–3

DC Electrical Characteristics ........................................................................................................ 4–42

I/O Standard Specifications ......................................................................................................... 4–43

Bus Hold Specifications ................................................................................................................. 4–56

On-Chip Termination Specifications ........................................................................................... 4–56

Pin Capacitance .............................................................................................................................. 4–58

Power Consumption ........................................................................................................................... 4–59

Timing Model ....................................................................................................................................... 4–59

Preliminary and Final Timing ...................................................................................................... 4–59

I/O Timing Measurement Methodology .................................................................................... 4–60

iv Altera Corporation

Page 5

Stratix II GX Device Handbook, Volume 1 Contents

Internal Timing Parameters .......................................................................................................... 4–69

Stratix II GX Clock Timing Parameters ....................................................................................... 4–76

Clock Network Skew Adders .......................................................................................................4–81

IOE Programmable Delay ............................................................................................................. 4–82

Default Capacitive Loading of Different I/O Standards .......................................................... 4–83

I/O Delays ....................................................................................................................................... 4–84

Maximum Input and Output Clock Toggle Rate ....................................................................... 4–98

Duty Cycle Distortion ....................................................................................................................... 4–118

DCD Measurement Techniques ................................................................................................. 4–118

High-Speed I/O Specifications ........................................................................................................ 4–126

PLL Timing Specifications ................................................................................................................ 4–130

External Memory Interface Specifications ..................................................................................... 4–132

JTAG Timing Specifications ............................................................................................................. 4–134

Referenced Documents ..................................................................................................................... 4–136

Document Revision History ............................................................................................................. 4–137

Chapter 5. Reference and Ordering Information

Device Pin-Outs ..................................................................................................................................... 5–1

Ordering Information ........................................................................................................................... 5–1

Referenced Documents ......................................................................................................................... 5–2

Document Revision History ................................................................................................................. 5–2

Altera Corporation v

Page 6

Contents Stratix II GX Device Handbook, Volume 1

vi Altera Corporation

Page 7

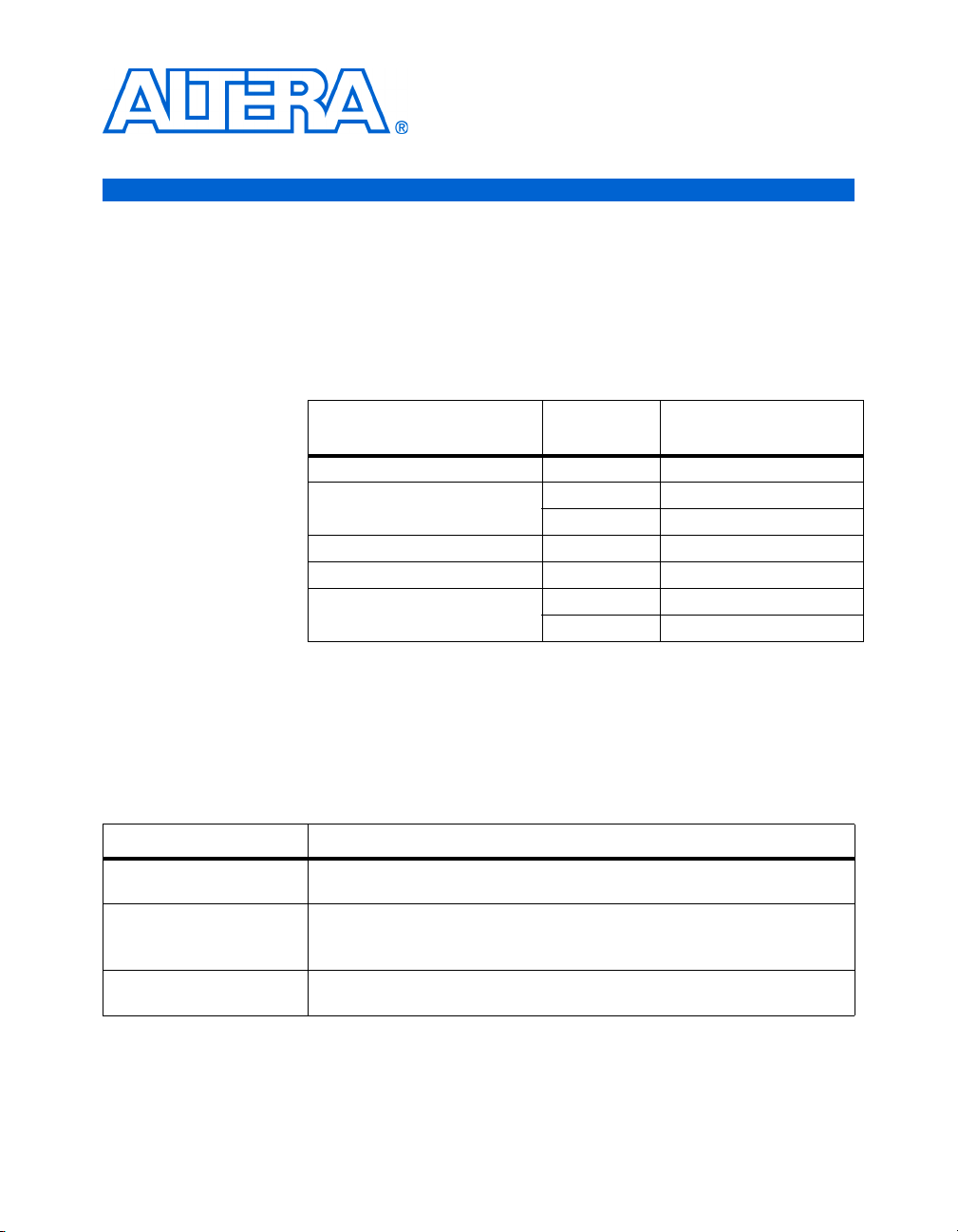

Chapter Revision Dates

The chapters in this book, Stratix II GX Device Handbook, Volume 1, were revised on the following

dates. Where chapters or groups of chapters are available separately, part numbers are listed.

Chapter 1. Introduction

Revised: October 2007

Part number: SIIGX51001-1.6

Chapter 2. Stratix II GX Architecture

Revised: October 2007

Part number: SIIGX51003-2.2

Chapter 3. Configuration & Testing

Revised: October 2007

Part number: SIIGX51005-1.4

Chapter 4. DC and Switching Characteristics

Revised: June 2009

Part number: SIIGX51006-4.6

Chapter 5. Reference and Ordering Information

Revised: August 2007

Part number: SIIGX51007-1.3

Altera Corporation vii

Page 8

Chapter Revision Dates Stratix II GX Device Handbook, Volume 1

viii Altera Corporation

Page 9

About this Handbook

This handbook provides comprehensive information about the Altera®

Stratix II GX family of devices.

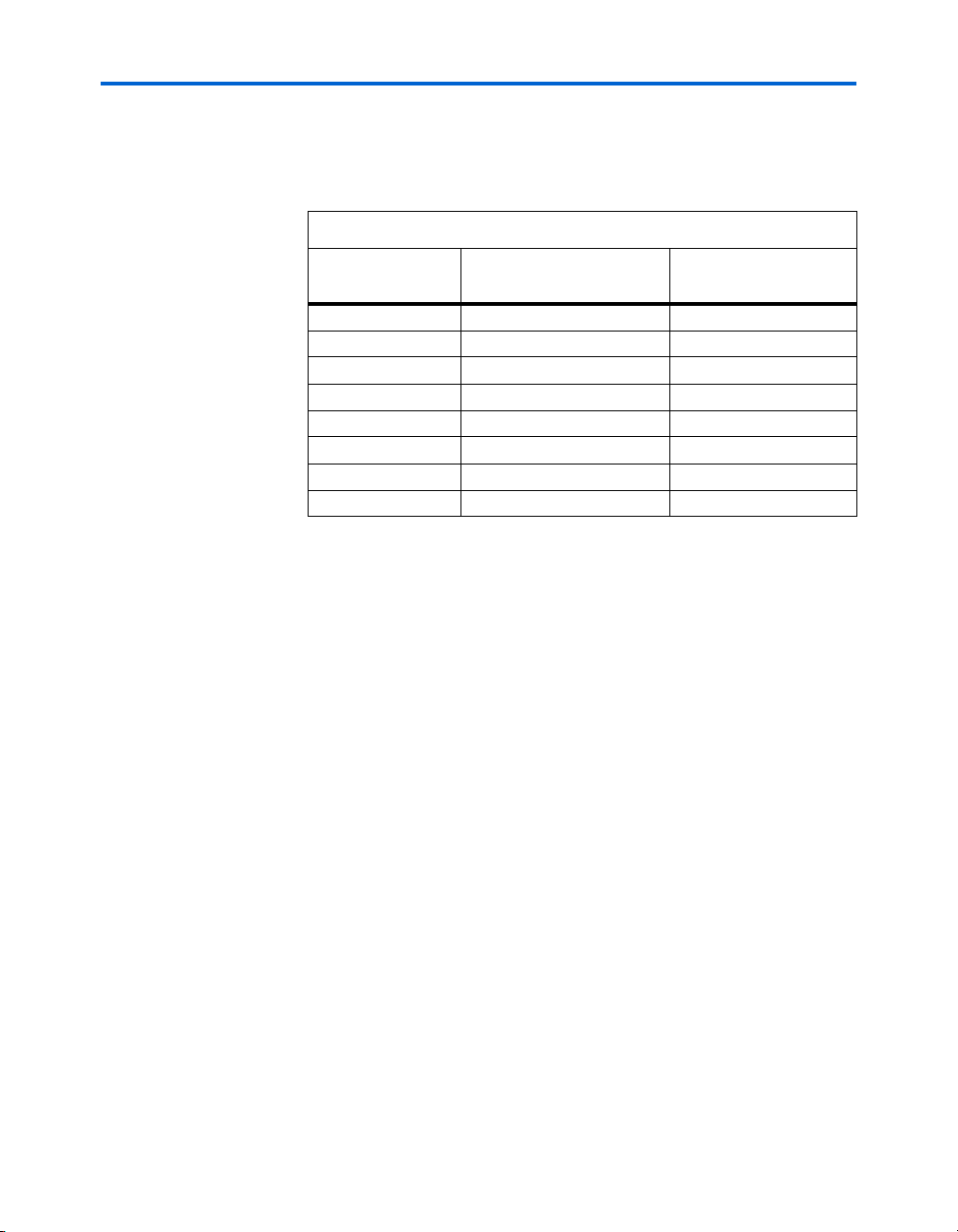

How to Contact

For the most up-to-date information about Altera products, refer to the

following table.

Altera

Contact

Method

Email custrain@altera.com

Email nacomp@altera.com

Email authorization@altera.com

Address

Typographic

Contact (1)

Technical support Website www.altera.com/support

Technical training Website www.altera.com/training

Product literature Email www.altera.com/literature

Altera literature services Website literature@altera.com

Non-technical support (General)

(Software Licensing)

Note to table:

(1) You can also contact your local Altera sales office or sales representative.

This document uses the typographic conventions shown below.

Conventions

Visual Cue Meaning

Bold Type with Initial

Capital Letters

bold type External timing parameters, directory names, project names, disk drive names,

Italic Type with Initial Capital

Letters

Command names, dialog box titles, checkbox options, and dialog box options are

shown in bold, initial capital letters. Example: Save As dialog box.

filenames, filename extensions, and software utility names are shown in bold

type. Examples: f

Document titles are shown in italic type with initial capital letters. Example: AN 75:

High-Speed Board Design.

, \qdesigns directory, d: drive, chiptrip.gdf file.

MAX

Altera Corporation ix

Preliminary

Page 10

Typographic Conventions Stratix II GX Device Handbook, Volume 1

Visual Cue Meaning

Italic type Internal timing parameters and variables are shown in italic type.

Examples: t

Variable names are enclosed in angle brackets (< >) and shown in italic type.

Example: <file name>, <project name>.pof file.

Initial Capital Letters Keyboard keys and menu names are shown with initial capital letters. Examples:

Delete key, the Options menu.

“Subheading Title” References to sections within a document and titles of on-line help topics are

shown in quotation marks. Example: “Typographic Conventions.”

PIA

, n + 1.

Courier type Signal and port names are shown in lowercase Courier type. Examples: data1,

tdi, input. Active-low signals are denoted by suffix n, e.g., resetn.

Anything that must be typed exactly as it appears is shown in Courier type. For

example:

actual file, such as a Report File, references to parts of files (e.g., the AHDL

keyword

Courier.

1., 2., 3., and

a., b., c., etc.

● • Bullets are used in a list of items when the sequence of the items is not important.

■

v The checkmark indicates a procedure that consists of one step only.

1 The hand points to information that requires special attention.

c

w

r The angled arrow indicates you should press the Enter key.

f The feet direct you to more information on a particular topic.

Numbered steps are used in a list of items when the sequence of the items is

important, such as the steps listed in a procedure.

A caution calls attention to a condition or possible situation that can damage or

destroy the product or the user’s work.

A warning calls attention to a condition or possible situation that can cause injury

to the user.

c:\qdesigns\tutorial\chiptrip.gdf. Also, sections of an

SUBDESIGN), as well as logic function names (e.g., TRI) are shown in

x Altera Corporation

Preliminary

Page 11

Section I. Stratix II GX

Device Data Sheet

This section provides designers with the data sheet specifications for

Stratix® II GX devices. They contain feature definitions of the

transceivers, internal architecture, configuration, and JTAG

boundary-scan testing information, DC operating conditions, AC timing

parameters, a reference to power consumption, and ordering information

for Stratix II GX devices.

This section includes the following chapters:

■ Chapter 1, Introduction

■ Chapter 2, Stratix II GX Architecture

■ Chapter 3, Configuration & Testing

■ Chapter 4, DC and Switching Characteristics

■ Chapter 5, Reference and Ordering Information

Revision History

Altera Corporation Section I–1

Refer to each chapter for its own specific revision history. For information

on when each chapter was updated, refer to the Chapter Revision Dates

section, which appears in the full handbook.

Page 12

Stratix II GX Device Data Sheet Stratix II GX Device Handbook, Volume 1

Section I–2 Altera Corporation

Page 13

SIIGX51001-1.6

1. Introduction

The Stratix® II GX family of devices is Altera’s third generation of FPGAs

to combine high-speed serial transceivers with a scalable,

high-performance logic array. Stratix II GX devices include 4 to 20

high-speed transceiver channels, each incorporating clock and data

recovery unit (CRU) technology and embedded SERDES capability at

data rates of up to 6.375 gigabits per second (Gbps). The transceivers are

grouped into four-channel transceiver blocks and are designed for low

power consumption and small die size. The Stratix II GX FPGA

technology is built upon the Stratix II architecture and offers a 1.2-V logic

array with unmatched performance, flexibility, and time-to-market

capabilities. This scalable, high-performance architecture makes

Stratix II GX devices ideal for high-speed backplane interface,

chip-to-chip, and communications protocol-bridging applications.

Features

This section lists the Stratix II GX device features.

■ Main device features:

● TriMatrix memory consisting of three RAM block sizes to

implement true dual-port memory and first-in first-out (FIFO)

buffers with performance up to 550 MHz

● Up to 16 global clock networks with up to 32 regional clock

networks per device region

● High-speed DSP blocks provide dedicated implementation of

multipliers (at up to 450 MHz), multiply-accumulate functions,

and finite impulse response (FIR) filters

● Up to four enhanced PLLs per device provide spread spectrum,

programmable bandwidth, clock switch-over, real-time PLL

reconfiguration, and advanced multiplication and phase

shifting

● Support for numerous single-ended and differential I/O

standards

● High-speed source-synchronous differential I/O support on up

to 71 channels

● Support for source-synchronous bus standards, including SPI-4

Phase 2 (POS-PHY Level 4), SFI-4.1, XSBI, UTOPIA IV, NPSI,

and CSIX-L1

● Support for high-speed external memory, including quad data

rate (QDR and QDRII) SRAM, double data rate (DDR and

DDR2) SDRAM, and single data rate (SDR) SDRAM

Altera Corporation 1–1

October 2007

Page 14

Features

● Support for multiple intellectual property megafunctions from

®

MegaCore® functions and Altera Megafunction Partners

Altera

Program (AMPPSM) megafunctions

● Support for design security using configuration bitstream

encryption

● Support for remote configuration updates

■ Transceiver block features:

● High-speed serial transceiver channels with clock data recovery

(CDR) provide 600-megabits per second (Mbps) to 6.375-Gbps

full-duplex transceiver operation per channel

● Devices available with 4, 8, 12, 16, or 20 high-speed serial

transceiver channels providing up to 255 Gbps of serial

bandwidth (full duplex)

● Dynamically programmable voltage output differential (V

and pre-emphasis settings for improved signal integrity

● Support for CDR-based serial protocols, including PCI Express,

Gigabit Ethernet, SDI, Altera’s SerialLite II, XAUI, CEI-6G,

CPRI, Serial RapidIO, SONET/SDH

● Dynamic reconfiguration of transceiver channels to switch

between multiple protocols and data rates

● Individual transmitter and receiver channel power-down

capability for reduced power consumption during

non-operation

● Adaptive equalization (AEQ) capability at the receiver to

compensate for changing link characteristics

● Selectable on-chip termination resistors (100, 120, or 150 Ω) for

improved signal integrity on a variety of transmission media

● Programmable transceiver-to-FPGA interface with support for

8-, 10-, 16-, 20-, 32-, and 40-bit wide data transfer

● 1.2- and 1.5-V pseudo current mode logic (PCML) for 600 Mbps

to 6.375 Gbps (AC coupling)

● Receiver indicator for loss of signal (available only in PIPE

mode)

● Built-in self test (BIST)

● Hot socketing for hot plug-in or hot swap and power

sequencing support without the use of external devices

● Rate matcher, byte-reordering, bit-reordering, pattern detector,

and word aligner support programmable patterns

● Dedicated circuitry that is compliant with PIPE, XAUI, and

GIGE

● Built-in byte ordering so that a frame or packet always starts in

a known byte lane

● Transmitters with two PLL inputs for each transceiver block

with independent clock dividers to provide varying clock rates

on each of its transmitters

OD

)

1–2 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 15

● 8B/10B encoder and decoder perform 8-bit to 10-bit encoding

and 10-bit to 8-bit decoding

● Phase compensation FIFO buffer performs clock domain

translation between the transceiver block and the logic array

● Receiver FIFO resynchronizes the received data with the local

reference clock

● Channel aligner compliant with XAUI

f Certain transceiver blocks can be bypassed. Refer to the Stratix II GX

Architecture chapter in volume 1 of the Stratix II GX Device Handbook for

more details.

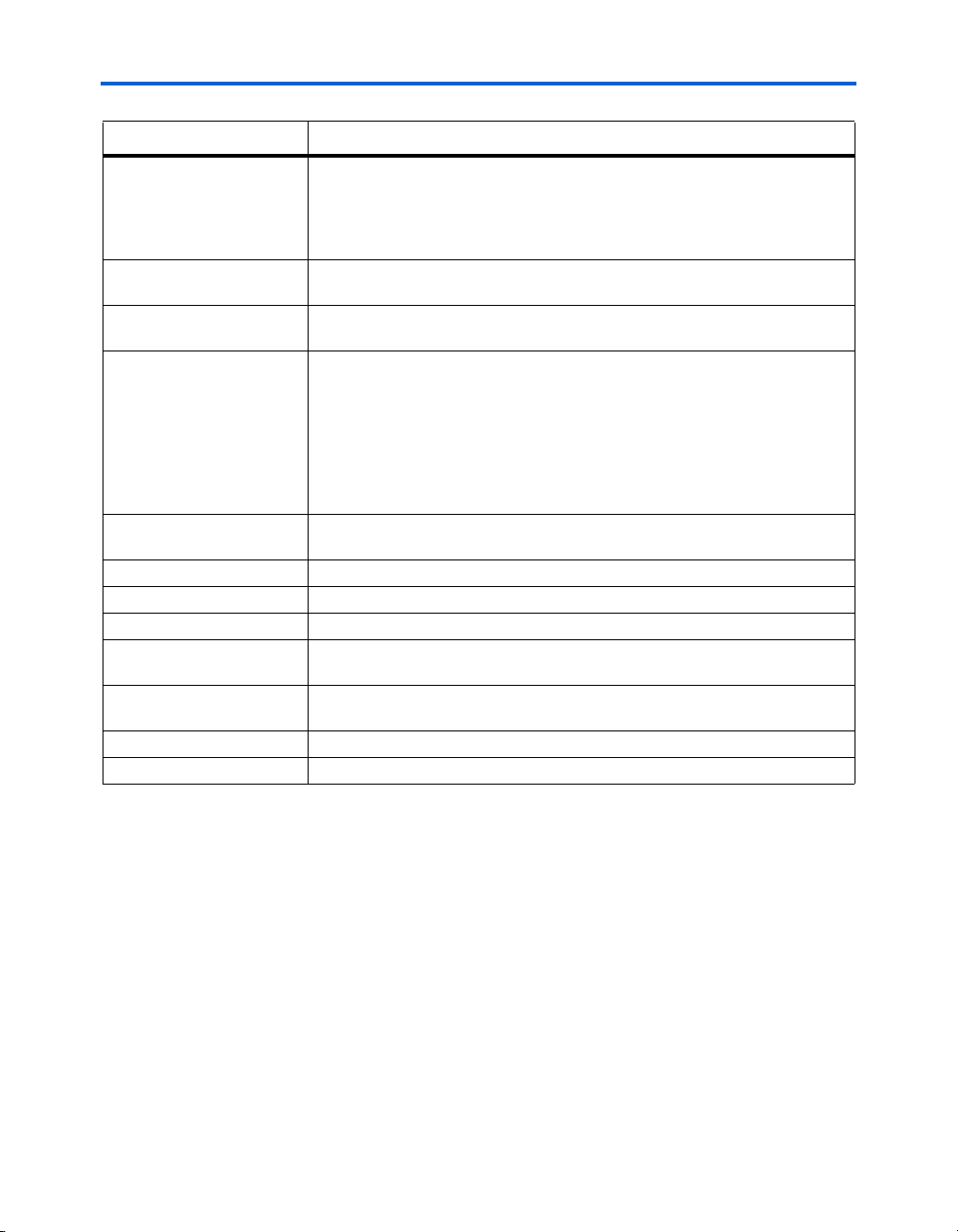

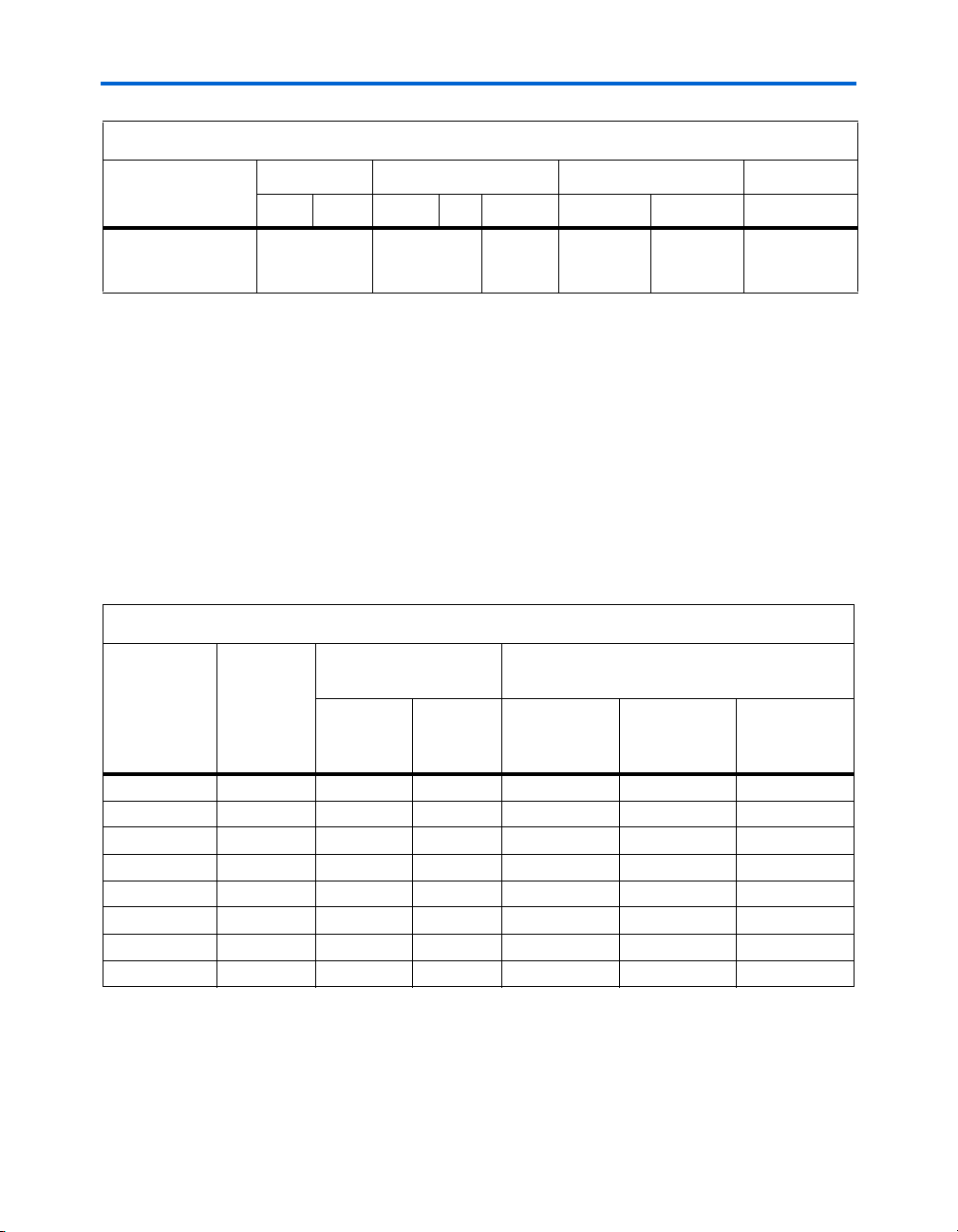

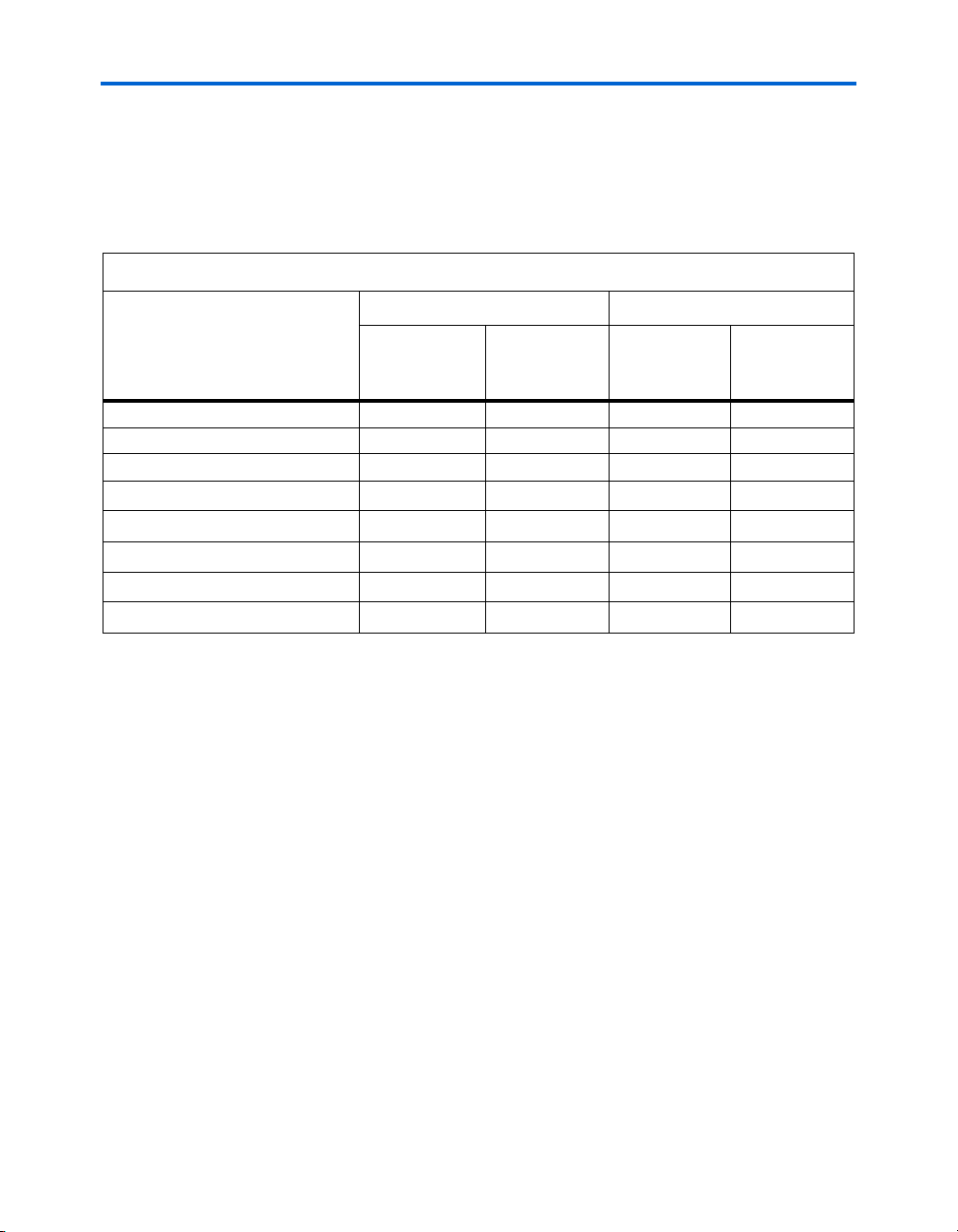

Table 1–1 lists the Stratix II GX device features.

Table 1–1. Stratix II GX Device Features (Part 1 of 2)

Introduction

Feature

EP2SGX30C/D EP2SGX60C/D/E EP2SGX90E/F EP2SGX130/G

CD CD E E F G

ALMs 13,552 24,176 36,384 53,016

Equivalent LEs 33,880 60,440 90,960 132,540

Transceiver

channels

Transceiver data rate 600 Mbps to

Source-synchronous

receive channels (1)

Source-synchronous

transmit channels

M512 RAM blocks

(32 × 18 bits)

M4K RAM blocks

(128 × 36 bits)

M-RAM blocks

(4K × 144 bits)

Total RAM bits 1,369,728 2,544,192 4,520,448 6,747,840

Embedded

multipliers (18 × 18)

DSP blocks 16 36 48 63

PLLs 4 4 4 8 8 8

Maximum user I/O

pins

48 4 812 12 16 20

6.375 Gbps

31 31 31 42 47 59 73

29 29 29 42 45 59 71

202 329 488 699

144 255 408 609

12 46

64 144 192 252

361 364 364 534 558 650 734

600 Mbps to 6.375 Gbps 600 Mbps to

6.375 Gbps

600 Mbps to

6.375 Gbps

Altera Corporation 1–3

October 2007 Stratix II GX Device Handbook, Volume 1

Page 16

Features

Table 1–1. Stratix II GX Device Features (Part 2 of 2)

Feature

EP2SGX30C/D EP2SGX60C/D/E EP2SGX90E/F EP2SGX130/G

CD CD E E F G

Package 780-pin

FineLine BGA

Note to Ta b le 1 – 1 :

(1) Includes two sets of dual-purpose differential pins that can be used as two additional channels for the differential

receiver or differential clock inputs.

780-pin

FineLine BGA

1,152-pin

FineLine

BGA

1,152-pin

FineLine

BGA

1,508-pin

FineLine

BGA

1,508-pin

FineLine BGA

Stratix II GX devices are available in space-saving FineLine BGA

packages (refer to Table 1–2). All Stratix II GX devices support vertical

migration within the same package. Vertical migration means that you

can migrate to devices whose dedicated pins, configuration pins, and

power pins are the same for a given package across device densities. For

I/O pin migration across densities, you must cross-reference the available

I/O pins using the device pin-outs for all planned densities of a given

package type to identify which I/O pins are migratable. Table 1–3 lists the

Stratix II GX device package sizes.

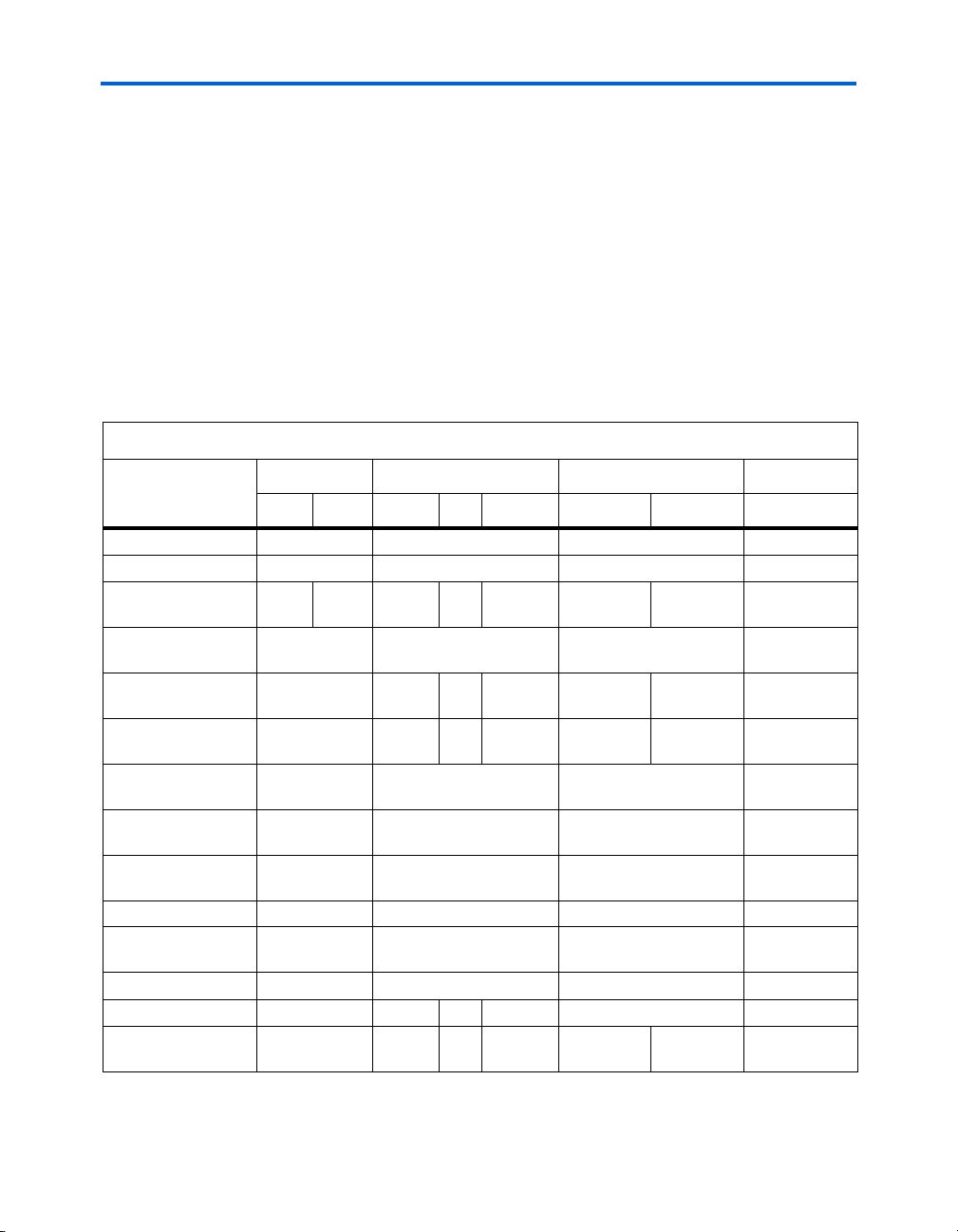

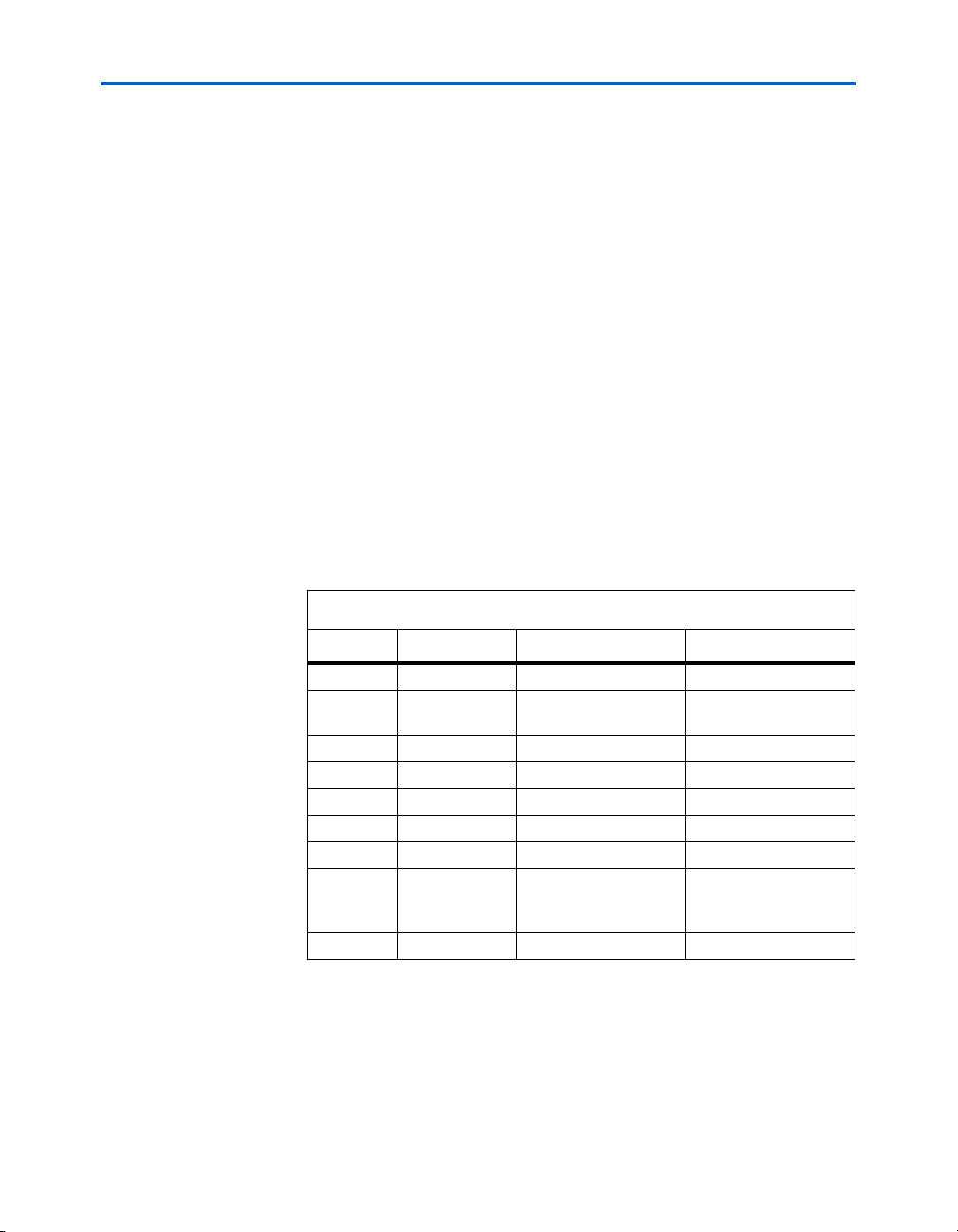

Table 1–2. Stratix II GX Package Options (Pin Counts and Transceiver Channels)

Source-Synchronous

Channels

Device

EP2SGX30C 4 31 29 361 — —

EP2SGX60C 4 31 29 364 — —

EP2SGX30D 8 31 29 361 — —

EP2SGX60D 8 31 29 364 — —

EP2SGX60E 12 42 42 — 534 —

EP2SGX90E 12 47 45 — 558 —

EP2SGX90F 16 59 59 — — 650

EP2SGX130G 20 73 71 — — 734

Note to Ta b le 1 – 2 :

(1) Includes two differential clock inputs that can also be used as two additional channels for the differential receiver.

Transceiver

Channels

Receive (1) Transmit

FineLine BGA

Maximum User I/O Pin Count

780-Pin

1,152-Pin

FineLine BGA

(29 mm)

(35 mm)

1,508-Pin

FineLine BGA

(40 mm)

1–4 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 17

Introduction

Table 1–3. Stratix II GX FineLine BGA Package Sizes

Dimension 780 Pins 1,152 Pins 1,508 Pins

Pitch (mm) 1.00 1.00 1.00

Area (mm

Length width (mm × mm) 29 × 29 35 × 35 40 × 40

2

)

841 1,225 1,600

Referenced Document

This chapter references the following document:

■ Stratix II GX Architecture chapter in volume 1 of the Stratix II GX

Device Handbook

Document

Table 1–4 shows the revision history for this chapter.

Revision History

Table 1–4. Document Revision History

Date and Document

Version

October 2007, v1.6 Updated “Features” section.

Minor text edits.

August 2007, v1.5 Added “Referenced Documents” section.

Minor text edits.

February 2007, v1.4

June 2006, v1.3

April 2006, v1.2

February 2006, v1.1

October 2005

v1.0

● Changed 622 Mbps to 600 Mbps on

page 1-2 and Table 1–1.

● Deleted “DC coupling” from the

Transceiver Block Features list.

● Changed 4 to 6 in the PLLs row

(columns 3 and 4) of Table 1–1.

Added the “Document Revision History”

section to this chapter.

● Updated Table 1–2.

● Updated Table 1–1.

● Updated Table 1–2.

● Updated Table 1–1.

Added chapter to the Stratix II GX Device

Handbook.

Changes Made Summary of Changes

Added support information for the

Stratix II GX device.

Updated numbers for receiver channels and

user I/O pin counts in Table 1–2.

Altera Corporation 1–5

October 2007 Stratix II GX Device Handbook, Volume 1

Page 18

Document Revision History

1–6 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 19

Deserializer

Serializer

Word

Aligner

8B/10B

Decoder

XAUI

Lane

Deskew

Byte

Deserializer

8B/10B

Encoder

Phase

Compensation

FIFO Buffer

Reference

Clock

Reference

Clock

Byte

Serializer

Phase

Compensation

FIFO Buffer

Rate

Matcher

PCS Digital Section

FPGA Fabric

PMA Analog Section

Byte

Ordering

Receiver

PLL

Transmitter

PLL

Clock

Recovery

Unit

m

n

n

m

(1)

(2)

(2)

(1)

SIIGX51003-2.2

2. Stratix II GX Architecture

Transceivers

Stratix®II GX devices incorporate dedicated embedded circuitry on the

right side of the device, which contains up to 20 high-speed 6.375-Gbps

serial transceiver channels. Each Stratix II GX transceiver block contains

four full-duplex channels and supporting logic to transmit and receive

high-speed serial data streams. The transceivers deliver bidirectional

point-to-point data transmissions, with up to 51 Gbps (6.375 Gbps per

channel) of full-duplex data transmission per transceiver block.

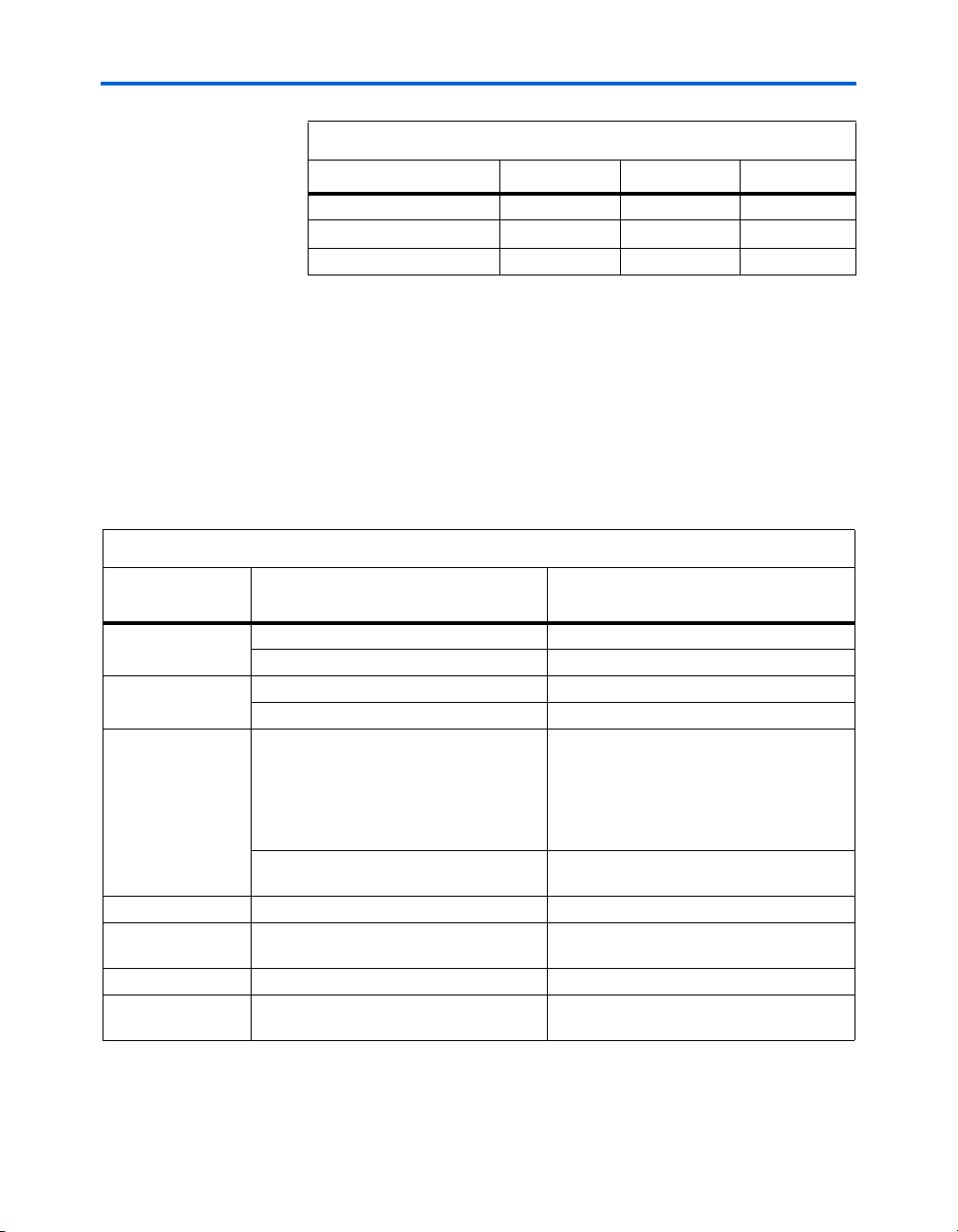

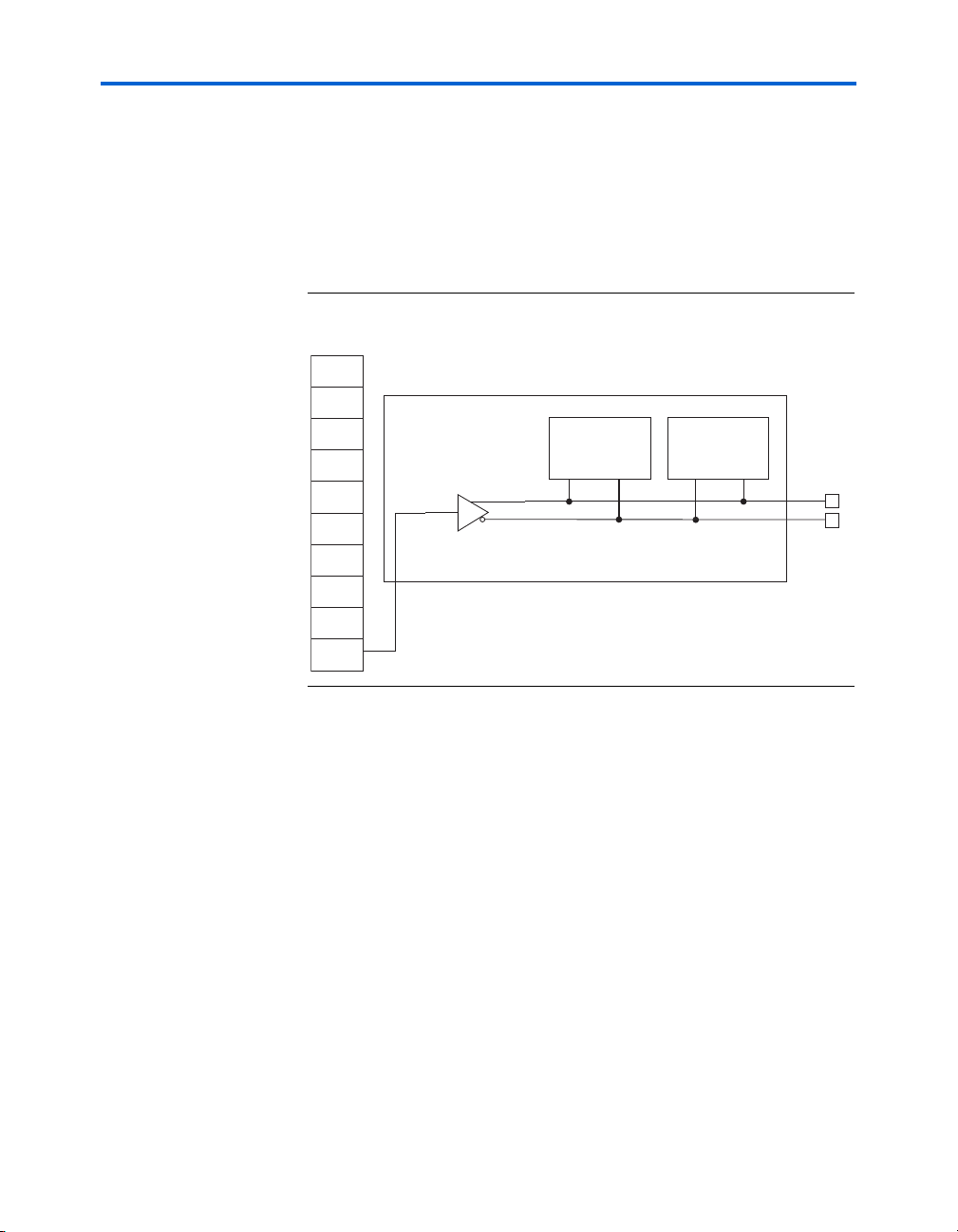

Figure 2–1 shows the function blocks that make up a transceiver channel

within the Stratix II GX device.

Figure 2–1. Stratix II GX Transceiver Block Diagram

Notes to Figure 2–1:

(1) n represents the number of bits in each word that need to be serialized by the transmitter portion of the PMA or have

been deserialized by the receiver portion of the PMA. n = 8, 10, 16, or 20.

(2) m represents the number of bits in the word that pass between the FPGA logic and the PCS portion of the transceiver.

m = 8, 10, 16, 20, 32, or 40.

Transceivers within each block are independent and have their own set of

dividers. Therefore, each transceiver can operate at different frequencies.

Altera Corporation 2–1

October 2007

Each block can select from two reference clocks to provide two clock

domains that each transceiver can select from.

Page 20

Transceivers

There are up to 20 transceiver channels available on a single Stratix II GX

device. Table 2–1 shows the number of transceiver channels and their

serial bandwidth for each Stratix II GX device.

Table 2–1. Stratix II GX Transceiver Channels

Device

EP2SGX30C 4 51 Gbps

EP2SGX60C 4 51 Gbps

EP2SGX30D 8 102 Gbps

EP2SGX60D 8 102 Gbps

EP2SGX60E 12 153 Gbps

EP2SGX90E 12 153 Gbps

EP2SGX90F 16 204 Gbps

EP2SGX130G 20 255 Gbps

Number of Transceiver

Channels

Serial Bandwidth

(Full Duplex)

Figure 2–2 shows the elements of the transceiver block, including the four

transceiver channels, supporting logic, and I/O buffers. Each transceiver

channel consists of a receiver and transmitter. The supporting logic

contains two transmitter PLLs to generate the high-speed clock(s) used by

the four transmitters within that block. Each of the four transmitter

channels has its own individual clock divider. The four receiver PLLs

within each transceiver block generate four recovered clocks. The

transceiver channels can be configured in one of the following functional

modes:

■ PCI Express (PIPE)

■ OIF CEI PHY Interface

■ SONET/SDH

■ Gigabit Ethernet (GIGE)

■ XAUI

■ Basic (600 Mbps to 3.125 Gbps single-width mode and 1 Gbps to

6.375 Gbps double-width mode)

■ SDI (HD, 3G)

■ CPRI (614 Mbps, 1228 Mbps, 2456 Mbps)

■ Serial RapidIO (1.25 Gbps, 2.5 Gbps, 3.125 Gbps)

2–2 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 21

Stratix II GX Architecture

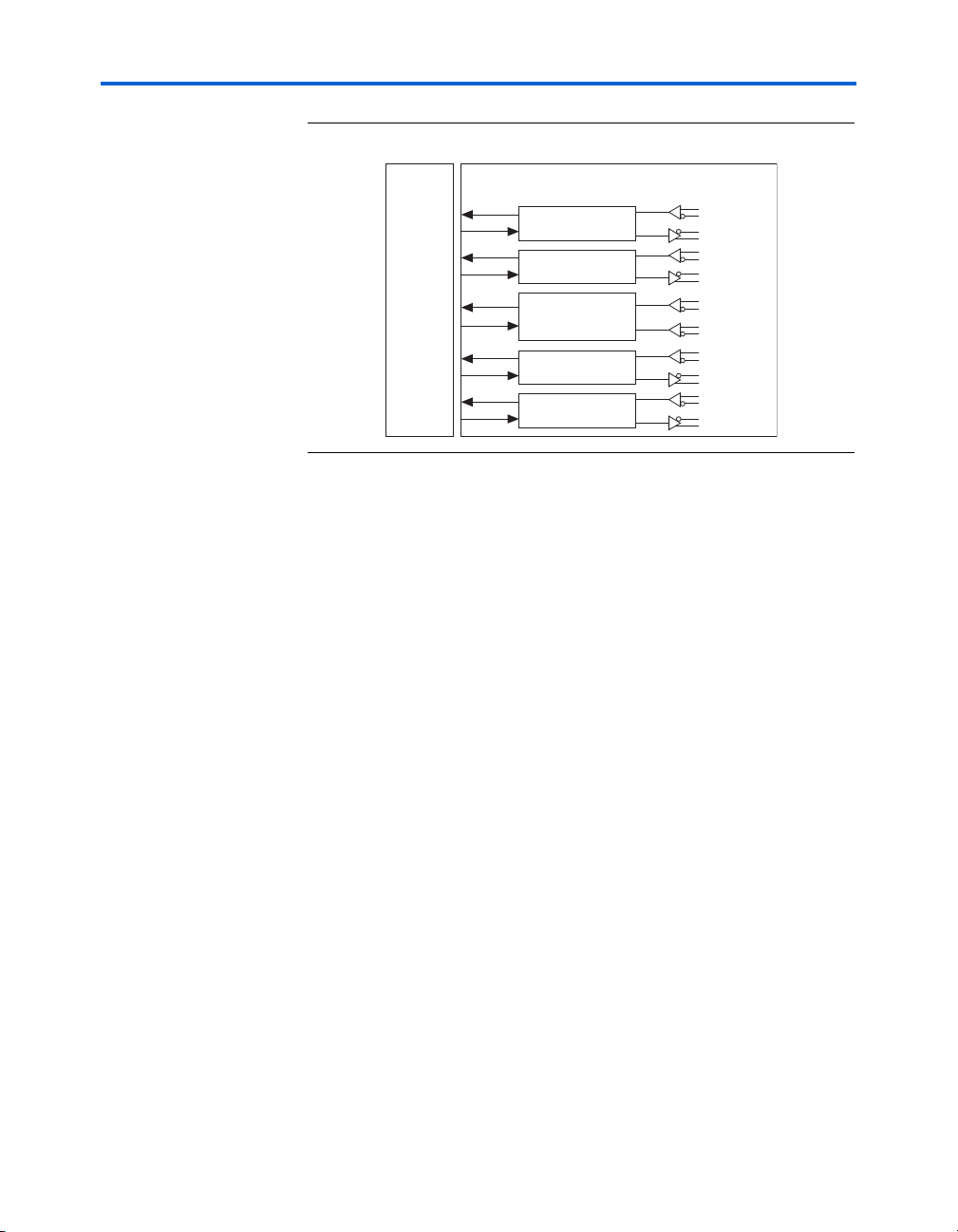

Channel 1

Channel 0

Channel 2

Supporting Blocks

(PLLs, State Machines,

Programming)

Channel 3

RX1

TX1

RX0

TX0

RX2

TX2

RX3

TX3

REFCLK_1

REFCLK_0

Transceiver BlockStratix II GX

Logic Array

Figure 2–2. Elements of the Transceiver Block

Each Stratix II GX transceiver channel consists of a transmitter and

receiver. The transceivers are grouped in four and share PLL resources.

Each transmitter has access to one of two PLLs. The transmitter contains

the following:

■ Transmitter phase compensation first-in first-out (FIFO) buffer

■ Byte serializer (optional)

■ 8B/10B encoder (optional)

■ Serializer (parallel-to-serial converter)

■ Transmitter differential output buffer

The receiver contains the following:

■ Receiver differential input buffer

■ Receiver lock detector and run length checker

■ Clock recovery unit (CRU)

■ Deserializer

■ Pattern detector

■ Word aligner

■ Lane deskew

■ Rate matcher (optional)

■ 8B/10B decoder (optional)

Altera Corporation 2–3

October 2007 Stratix II GX Device Handbook, Volume 1

■ Byte deserializer (optional)

■ Byte ordering

■ Receiver phase compensation FIFO buffer

Designers can preset Stratix II GX transceiver functions using the

®

Quartus

differential output voltage (V

Stratix II GX transceiver channel supports various loopback modes and is

II software. In addition, pre-emphasis, equalization, and

) are dynamically programmable. Each

OD

Page 22

Transceivers

capable of built-in self test (BIST) generation and verification. The

ALT2GXB megafunction in the Quartus II software provides a

step-by-step menu selection to configure the transceiver.

Figure 2–1 shows the block diagram for the Stratix II GX transceiver

channel. Stratix II GX transceivers provide PCS and PMA

implementations for all supported protocols. The PCS portion of the

transceiver consists of the word aligner, lane deskew FIFO buffer, rate

matcher FIFO buffer, 8B/10B encoder and decoder, byte serializer and

deserializer, byte ordering, and phase compensation FIFO buffers.

Each Stratix II GX transceiver channel is also capable of BIST generation

and verification in addition to various loopback modes. The PMA portion

of the transceiver consists of the serializer and deserializer, the CRU, and

the high-speed differential transceiver buffers that contain pre-emphasis,

programmable on-chip termination (OCT), programmable voltage

output differential (V

), and equalization.

OD

Transmitter Path

This section describes the data path through the Stratix II GX transmitter.

The Stratix II GX transmitter contains the following modules:

■ Transmitter PLLs

■ Access to one of two PLLs

■ Transmitter logic array interface

■ Transmitter phase compensation FIFO buffer

■ Byte serializer

■ 8B/10B encoder

■ Serializer (parallel-to-serial converter)

■ Transmitter differential output buffer

Transmitter PLLs

Each transceiver block has two transmitter PLLs which receive two

reference clocks to generate timing and the following clocks:

■ High-speed clock used by the serializer to transmit the high-speed

differential transmitter data

■ Low-speed clock to load the parallel transmitter data of the serializer

The serializer uses high-speed clocks to transmit data. The serializer is

also referred to as parallel in serial out (PISO). The high-speed clock is fed

to the local clock generation buffer. The local clock generation buffers

divide the high-speed clock on the transmitter to a desired frequency on

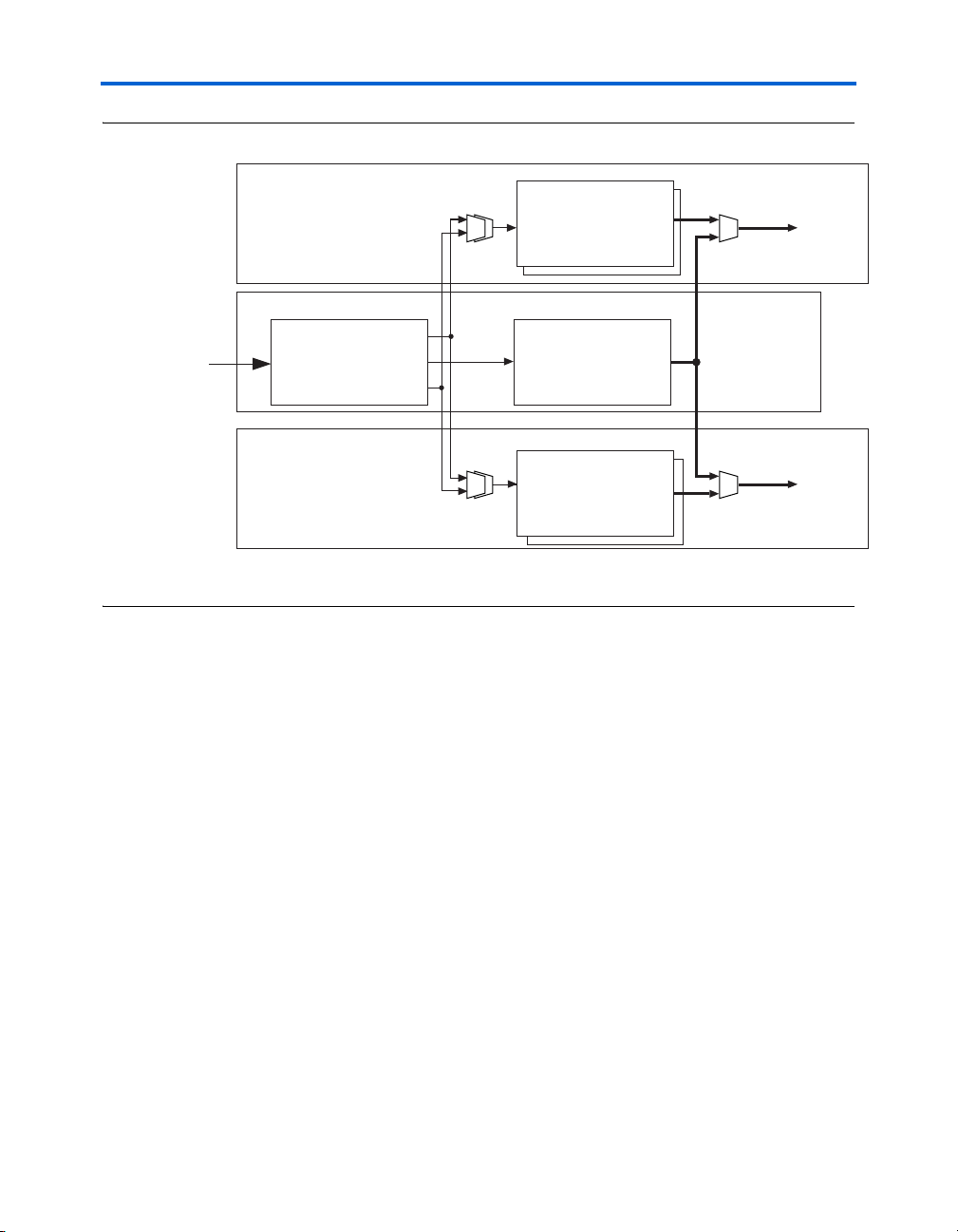

a per-channel basis. Figure 2–3 is a block diagram of the transmitter

clocks.

2–4 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 23

Figure 2–3. Clock Distribution for the Transmitters Note (1)

Transmitter PLL Block

Central Clock

Divider Block

TX Clock

Gen Block

TX Clock

Gen Block

Transmitter Channel [3..2]

Transmitter Channel [1..0]

Transmitter High-Speed &

Low-Speed Clocks

Transmitter High-Speed &

Low-Speed Clocks

Transmitter Local

Clock Divider Block

Transmitter Local

Clock Divider Block

Reference Clocks

(refclks,

Global Clock

(1)

,

Inter-Transceiver

Lines)

Central Block

Note to Figure 2–3:

(1) The global clock line must be driven by an input pin.

Stratix II GX Architecture

The transmitter PLLs in each transceiver block clock the PMA and PCS

circuitry in the transmit path. The Quartus II software automatically

powers down the transmitter PLLs that are not used in the design.

Figure 2–4 is a block diagram of the transmitter PLL.

The transmitter phase/frequency detector references the clock from one

of the following sources:

■ Reference clocks

■ Reference clock from the adjacent transceiver block

■ Inter-transceiver block clock lines

■ Global clock line driven by input pin

Two reference clocks, REFCLK0 and REFCLK1, are available per

transceiver block. The inter-transceiver block bus allows multiple

transceivers to use the same reference clocks. Each transceiver block has

Altera Corporation 2–5

October 2007 Stratix II GX Device Handbook, Volume 1

one outgoing reference clock which connects to one inter-transceiver

block line. The incoming reference clock can be selected from five

inter-transceiver block lines IQ[4..0] or from the global clock line that

is driven by an input pin.

Page 24

Transceivers

k

Figure 2–4. Transmitter PLL Block Note (1)

Transmitter PLL 0

÷

m

Inter-Transceiver Block

Routing (IQ[4:0])

Dedicated Local

REFCLK 0

Inter-Transceiver Block

Routing (IQ[4:0])

Dedicated Local

REFCLK 1

From PLD

÷

To Inter-Transceiver

Block Line

From PLD

÷

/22

2

INCLK

INCLK

PFD

PFD

Note to Figure 2–4:

(1) The global clock line must be driven by an input pin.

The transmitter PLLs support data rates up to 6.375 Gbps. The input clock

frequency is limited to 622.08 MHz. An optional pll_locked port is

available to indicate whether the transmitter PLL is locked to the

reference clock. Both transmitter PLLs have a programmable loop

bandwidth parameter that can be set to low, medium, or high. The loop

bandwidth parameter can be statically set in the Quartus II software.

up

CP+LF

dn

÷

m

up

CP+LF

dn

VCO

VCO

÷

L

Transmitter PLL 1

÷

L

High-Speed

Transmitter PLL0 Clock

High-Speed

Transmitter PLL Cloc

High-Speed

Transmitter PLL1 Clock

Table 2–2 lists the adjustable parameters in the transmitter PLL.

Table 2–2. Transmitter PLL Specifications

Parameter Specifications

Input reference frequency range 50 MHz to 622.08 MHz

Data rate support 600 Mbps to 6.375 Gbps

Multiplication factor (W) 1, 4, 5, 8, 10, 16, 20, 25

Bandwidth Low, medium, or high

2–6 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 25

Stratix II GX Architecture

Transmitter Phase Compensation FIFO Buffer

The transmitter phase compensation FIFO buffer resides in the

transceiver block at the PCS/FPGA boundary and cannot be bypassed.

This FIFO buffer compensates for phase differences between the

transmitter PLL clock and the clock from the PLD. After the transmitter

PLL has locked to the frequency and phase of the reference clock, the

transmitter FIFO buffer must be reset to initialize the read and write

pointers. After FIFO pointer initialization, the PLL must remain phase

locked to the reference clock.

Byte Serializer

The FPGA and transceiver block must maintain the same throughput. If

the FPGA interface cannot meet the timing margin to support the

throughput of the transceiver, the byte serializer is used on the

transmitter and the byte deserializer is used on the receiver.

The byte serializer takes words from the FPGA interface and converts

them into smaller words for use in the transceiver. The transmit data path

after the byte serializer is 8, 10, 16, or 20 bits. Refer to Table 2–3 for the

transmitter data with the byte serializer enabled. The byte serializer can

be bypassed when the data width is 8, 10, 16, or 20 bits at the FPGA

interface.

Table 2–3. Transmitter Data with the Byte Serializer Enabled

Input Data Width Output Data Width

16 bits 8 bits

20 bits 10 bits

32 bits 16 bits

40 bits 20 bits

If the byte serializer is disabled, the FPGA transmit data is passed without

data width conversion.

Altera Corporation 2–7

October 2007 Stratix II GX Device Handbook, Volume 1

Page 26

Transceivers

Table 2–4 shows the data path configurations for the Stratix II GX device

in single-width and double-width modes.

1 Refer to the section “8B/10B Encoder” on page 2–8 for a

description of the single- and double-width modes.

Table 2–4. Data Path Configurations Note (1)

Single-Width Mode Double-Width Mode

Parameter

Without Byte

Serialization/

Deserialization

Fabric to PCS data path width (bits) 8 or 10 16 or 20 16 or 20 32 or 40

Data rate range (Gbps) 0.6 to 2.5 0.6 to 3.125 1 to 5.0 1 to 6.375

PCS to PMA data path width (bits) 8 or 10 8 or 10 16 or 20 16 or 20

Byte ordering (1)

Data symbol A (MSB)

Data symbol B

Data symbol C

Data symbol D (LSB)

Note to Ta bl e 2 – 4 :

(1) Designs can use byte ordering when byte serialization and deserialization are used.

vvvv

With Byte

Serialization/

Deserialization

Without Byte

Serialization/

Deserialization

With Byte

Serialization/

Deserialization

vv

v

vv

vv

8B/10B Encoder

There are two different modes of operation for 8B/10B encoding.

Single-width (8-bit) mode supports natural data rates from 622 Mbps to

3.125 Gbps. Double-width (16-bit cascaded) mode supports data rates

above 3.125 Gbps. The encoded data has a maximum run length of five.

The 8B/10B encoder can be bypassed. Figure 2–5 diagrams the 10-bit

encoding process.

2–8 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 27

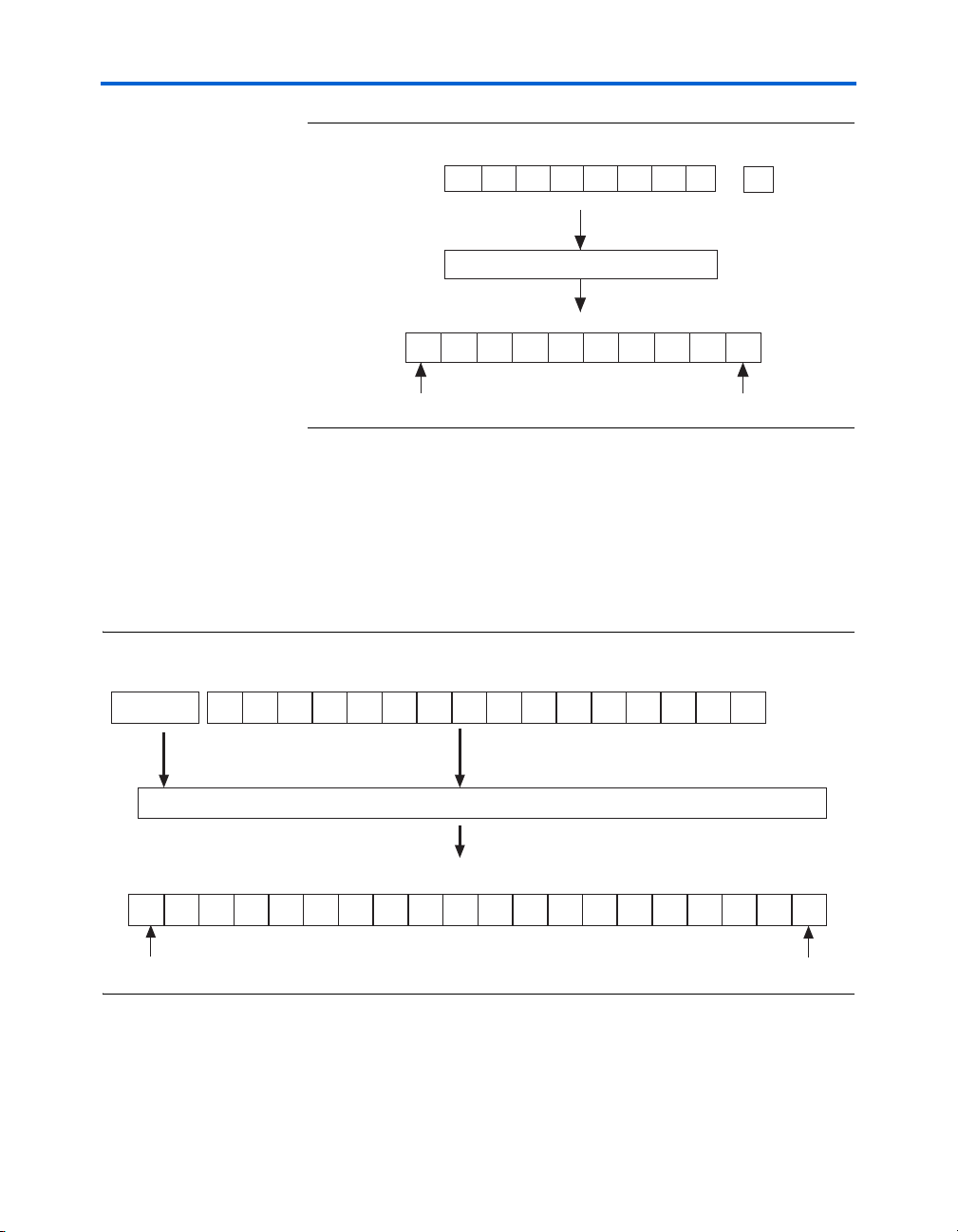

Figure 2–5. 8B/10B Encoding Process

t

Cascaded 8B/10B Conversion

G' F' E' D' C' B' A'H' G F E D C B AH

Parallel Data

CTRL[1..0] 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

LSB

MSB

g' f' i' e' d'

c'

b' a'

j'

h' g f iedc bajh

19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

76543210

HGFED CB A

8B/10B Conversion

jhgfiedcba

9876543210

Stratix II GX Architecture

+

ctrl

MSB sent last

In single-width mode, the 8B/10B encoder generates a 10-bit code group

from the 8-bit data and 1-bit control identifier. In double-width mode,

there are two 8B/10B encoders that are cascaded together and generate a

20-bit (2 × 10-bit) code group from the 16-bit (2 × 8-bit) data + 2-bit

(2 × 1-bit) control identifier. Figure 2–6 shows the 20-bit encoding

process. The 8B/10B encoder conforms to the IEEE 802.3 1998 edition

standards.

Figure 2–6. 16-Bit to 20-Bit Encoding Process

LSB sent firs

Upon power on or reset, the 8B/10B encoder has a negative disparity

which chooses the 10-bit code from the RD-column. However, the

running disparity can be changed via the tx_forcedisp and

tx_dispval ports.

Altera Corporation 2–9

October 2007 Stratix II GX Device Handbook, Volume 1

Page 28

Transceivers

Transmit State Machine

The transmit state machine operates in either PCI Express mode, XAUI

mode, or GIGE mode, depending on the protocol used. The state machine

is not utilized for certain protocols, such as SONET.

GIGE Mode

In GIGE mode, the transmit state machine converts all idle ordered sets

(/K28.5/, /Dx.y/) to either /I1/ or /I2/ ordered sets. /I1/ consists of a

negative-ending disparity /K28.5/ (denoted by /K28.5/-) followed by a

neutral /D5.6/. /I2/ consists of a positive-ending disparity /K28.5/

(denoted by /K28.5/+) and a negative-ending disparity /D16.2/

(denoted by /D16.2/-). The transmit state machines do not convert any of

the ordered sets to match /C1/ or /C2/, which are the configuration

ordered sets. (/C1/ and /C2/ are defined by [/K28.5/, /D21.5/] and

[/K28.5/, /D2.2/], respectively). Both the /I1/ and /I2/ ordered sets

guarantee a negative-ending disparity after each ordered set.

XAUI Mode

The transmit state machine translates the XAUI XGMII code group to the

XAUI PCS code group. Table 2–5 shows the code conversion.

Table 2–5. Code Conversion

XGMII TXC XGMII TXD PCS Code-Group Description

0 00 through FF Dxx.y Normal data

1 07 K28.0 or K28.3 or

1 07 K28.5 Idle in ||T||

1 9C K28.4 Sequence

1 FB K27.7 Start

1 FD K29.7 Terminate

1 FE K30.7 Error

1 See IEEE 802.3

reserved code

groups

1 Other value K30.7 Invalid XGMII character

K28.5

See IEEE 802.3

reserved code groups

Idle in ||I||

Reserved code groups

The XAUI PCS idle code groups, /K28.0/ (/R/) and /K28.5/ (/K/), are

7

automatically randomized based on a PRBS7 pattern with an x

+ x6 + 1

polynomial. The /K28.3/ (/A/) code group is automatically generated

between 16 and 31 idle code groups. The idle randomization on the /A/,

/K/, and /R/ code groups is done automatically by the transmit state

machine.

2–10 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 29

Stratix II GX Architecture

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

Low-speed

parallel clock

High-speed

serial clock

Serial data

out (to output

buffer)

D8

D9

D8

D9

10

Serializer (Parallel-to-Serial Converter)

The serializer converts the parallel 8, 10, 16, or 20-bit data into a serial data

bit stream, transmitting the least significant bit (LSB) first. The serialized

data stream is then fed to the high-speed differential transmit buffer.

Figure 2–7 is a diagram of the serializer.

Figure 2–7. Serializer Note (1)

Note to Figure 2–7:

(1) This is a 10-bit serializer. The serializer can also convert 8, 16, and 20 bits of data.

Transmit Buffer

The Stratix II GX transceiver buffers support the 1.2- and 1.5-V PCML

I/O standard at rates up to 6.375 Gbps. The common mode voltage (V

of the output driver is programmable. The following V

available when the buffer is in 1.2- and 1.5-V PCML.

■ V

■ V

= 0.6 V

CM

= 0.7 V

CM

values are

CM

CM

Altera Corporation 2–11

October 2007 Stratix II GX Device Handbook, Volume 1

)

Page 30

Transceivers

Serializer

Programmable

Termination

Programmable

Pre-Emphasis

Output Buffer

Output

Pins

Programmable

Output

Driver

f Refer to the Stratix II GX Transceiver Architecture Overview chapter in

volume 2 of the Stratix II GX Handbook.

The output buffer, as shown in Figure 2–8, is directly driven by the

high-speed data serializer and consists of a programmable output driver,

a programmable pre-emphasis circuit, a programmable termination, and

a programmable V

Figure 2–8. Output Buffer

CM

.

Programmable Output Driver

The programmable output driver can be set to drive out differentially

200 to 1,400 mV. The differential output voltage (V

) can be changed

OD

dynamically, or statically set by using the ALT2GXB megafunction or

through I/O pins.

The output driver may be programmed with four different differential

termination values:

■ 100 Ω

2–12 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

■ 120 Ω

■ 150 Ω

■ External termination

Page 31

Stratix II GX Architecture

V

MAX

V

MAX

V

MIN

V

MIN

Pre-Emphasis % = (

− 1) × 100

Differential signaling conventions are shown in Figure 2–9. The

differential amplitude represents the value of the voltage between the

true and complement signals. Peak-to-peak differential voltage is defined

as 2 × (V

HIGH

– V

mode voltage is the average of V

) = 2 × single-ended voltage swing. The common

LOW

high

and V

low

.

Figure 2–9. Differential Signaling

Single-Ended Waveform

True

Complement

V

high

+V

OD

-

V

low

V

= V

OD

high

(Differential)

−

V

low

Differential Waveform

+V

OD

2 * V

OD

+400

0-V Differential

-V

OD

−400

Programmable Pre-Emphasis

The programmable pre-emphasis module controls the output driver to

boost the high frequency components, and compensate for losses in the

transmission medium, as shown in Figure 2–10. The pre-emphasis is set

statically using the ALT2GXB megafunction or dynamically through the

dynamic reconfiguration controller.

Figure 2–10. Pre-Emphasis Signaling

Altera Corporation 2–13

October 2007 Stratix II GX Device Handbook, Volume 1

Page 32

Transceivers

Programmable

Output

Driver

50, 60, or 75

9

V

CM

Pre-emphasis percentage is defined as (V

is the differential emphasized voltage (peak-to-peak) and V

V

MAX

MAX/VMIN

– 1) × 100, where

MIN

is

the differential steady-state voltage (peak-to-peak).

Programmable Termination

The programmable termination can be statically set in the Quartus II

software. The values are 100 Ω, 120 Ω , 150 Ω , and external termination.

Figure 2–11 shows the setup for programmable termination.

Figure 2–11. Programmable Transmitter Terminations

PCI Express Receiver Detect

The Stratix II GX transmitter buffer has a built-in receiver detection circuit

for use in PIPE mode. This circuit provides the ability to detect if there is

a receiver downstream by sending out a pulse on the channel and

monitoring the reflection. This mode requires the transmitter buffer to be

tri-stated (in electrical idle mode).

PCI Express Electric Idles (or Individual Transmitter Tri-State)

The Stratix II GX transmitter buffer supports PCI Express electrical idles.

This feature is only active in PIPE mode. The tx_forceelecidle port

puts the transmitter buffer in electrical idle mode. This port is available in

all PCI Express power-down modes and has specific usage in each mode.

Receiver Path

This section describes the data path through the Stratix II GX receiver. The

Stratix II GX receiver consists of the following blocks:

■ Receiver differential input buffer

■ Receiver PLL lock detector, signal detector, and run length checker

■ Clock/data recovery (CRU) unit

■ Deserializer

■ Pattern detector

■ Word aligner

2–14 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 33

Stratix II GX Architecture

■ Lane deskew

■ Rate matcher

■ 8B/10B decoder

■ Byte deserializer

■ Byte ordering

■ Receiver phase compensation FIFO buffer

Receiver Input Buffer

The Stratix II GX receiver input buffer supports the 1.2-V and 1.5-V

PCML I/O standard at rates up to 6.375 Gbps. The common mode voltage

of the receiver input buffer is programmable between 0.85 V and 1.2 V.

You must select the 0.85 V common mode voltage for AC- and

DC-coupled PCML links and the 1.2 V common mode voltage for

DC-coupled LVDS links.

The receiver has programmable on-chip 100-, 120-, or 150-Ω differential

termination for different protocols, as shown in Figure 2–12. The

receiver’s internal termination can be disabled if external terminations

and biasing are provided. The receiver and transmitter differential

termination resistances can be set independently of each other.

Figure 2–12. Receiver Input Buffer

Programmable

Termination

Input

Pins

Programmable

Equalizer

Differential

Input

Buffer

Programmable Termination

The programmable termination can be statically set in the Quartus II

software. Figure 2–13 shows the setup for programmable receiver

termination. The termination can be disabled if external termination is

provided.

Altera Corporation 2–15

October 2007 Stratix II GX Device Handbook, Volume 1

Page 34

Transceivers

Transmission

Line

C1

R1/R2 = 1K

V

DD

× {R2/(R1 + R 2)} = 0.85/1.2 V

50/60/75-

Ω

Termination

Resistance

R1

R2

V

DD

Receiver External Termination

and Biasing

Stratix II GX Device

Receiver External Termination

and Biasing

RXIP

RXIN

Receiver

Figure 2–13. Programmable Receiver Termination

Differential

50, 60, or 75 Ω

50, 60, or 75 Ω

V

CM

Input

Buffer

If a design uses external termination, the receiver must be externally

terminated and biased to 0.85 V or 1.2 V. Figure 2–14 shows an example

of an external termination and biasing circuit.

Figure 2–14. External Termination and Biasing Circuit

2–16 Altera Corporation

Programmable Equalizer

The Stratix II GX receivers provide a programmable receive equalization

feature to compensate the effects of channel attenuation for high-speed

signaling. PCB traces carrying these high-speed signals have low-pass

filter characteristics. The impedance mismatch boundaries can also cause

signal degradation. The equalization in the receiver diminishes the lossy

attenuation effects of the PCB at high frequencies.

Stratix II GX Device Handbook, Volume 1 October 2007

Page 35

Stratix II GX Architecture

1 The Stratix II GX receivers also have adaptive equalization

capability that adjusts the equalization levels to compensate for

changing link characteristics. The adaptive equalization can be

powered down dynamically after it selects the appropriate

equalization levels.

The receiver equalization circuit is comprised of a programmable

amplifier. Each stage is a peaking equalizer with a different center

frequency and programmable gain. This allows varying amounts of gain

to be applied, depending on the overall frequency response of the channel

loss. Channel loss is defined as the summation of all losses through the

PCB traces, vias, connectors, and cables present in the physical link.

Figure 2–15 shows the frequency response for the 16 programmable

settings allowed by the Quartus II software for Stratix II GX devices.

Figure 2–15. Frequency Response

High

Medium

Low

Bypass EQ

Receiver PLL and CRU

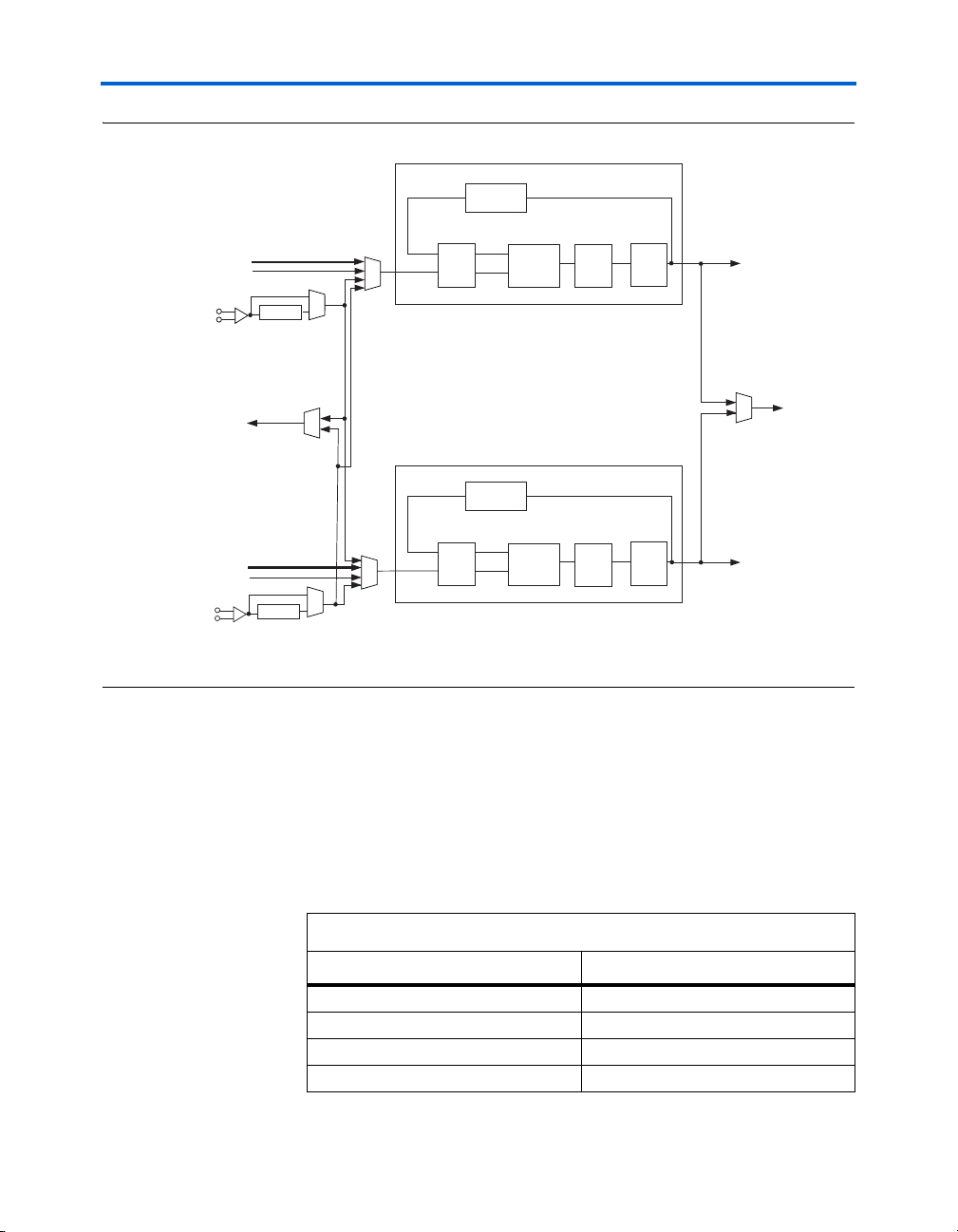

Each transceiver block has four receiver PLLs, lock detectors, signal

detectors, run length checkers, and CRU units, each of which is dedicated

to a receive channel. If the receive channel associated with a particular

receiver PLL or CRU is not used, the receiver PLL and CRU are powered

down for the channel. Figure 2–16 shows the receiver PLL and CRU

circuits.

Altera Corporation 2–17

October 2007 Stratix II GX Device Handbook, Volume 1

Page 36

Transceivers

rx_cruclk

CP+LF

Up

Down

VCO

÷m

÷1, 4, 5, 8, 10, 16, 20, or 25

rx_datain

High Speed RCVD_CLK

Low Speed RCVD_CLK

Down

Up

rx_locktorefclk

rx_rlv[ ]

rx_locktodata

rx_freqlocked

Clock Recovery Unit (CRU)

PFD

÷L

÷2÷N

÷1, 2, 4

÷1, 2, 4

rx_pll_locked

Figure 2–16. Receiver PLL and CRU

The receiver PLLs and CRUs can support frequencies up to 6.375 Gbps.

The input clock frequency is limited to the full clock range of 50 to

622 MHz but only when using REFCLK0 or REFCLK1. An optional

RX_PLL_LOCKED port is available to indicate whether the PLL is locked

to the reference clock. The receiver PLL has a programmable loop

bandwidth which can be set to low, medium, or high. The Quartus II

software can statically set the loop bandwidth parameter.

All the parameters listed are programmable in the Quartus II software.

The receiver PLL has the following features:

■ Operates from 600 Mbps to 6.375 Gbps.

■ Uses a reference clock between 50 MHz and 622.08 MHz.

■ Programmable bandwidth settings: low, medium, and high.

■ Programmable rx_locktorefclk (forces the receiver PLL to lock

to the reference clock) and rx_locktodata (forces the receiver PLL

to lock to the data).

■ The voltage-controlled oscillator (VCO) operates at half rate and has

two modes. These modes are for low or high frequency operation

and provide optimized phase-noise performance.

■ Programmable frequency multiplication W of 1, 4, 5, 8, 10, 16, 20, and

25. Not all settings are supported for any particular frequency.

■ Two lock indication signals are provided. They are found in PFD

mode (lock-to-reference clock), and PD (lock-to-data).

2–18 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 37

Stratix II GX Architecture

The CRU has a built-in switchover circuit to select whether the PLL VCO

is aligned by the reference clock or the data. The optional port

rx_freqlocked monitors when the CRU is in locked-to-data mode.

In the automatic mode, the CRU PLL must be within the prescribed PPM

frequency threshold setting of the CRU reference clock for the CRU to

switch from locked-to-reference to locked-to-data mode.

The automatic switchover circuit can be overridden by using the optional

ports rx_locktorefclk and rx_locktodata. Table 2–6 shows the

possible combinations of these two signals.

Table 2–6. Receiver Lock Combinations

rx_locktodata rx_locktorefclk VCO (Lock to Mode)

00 Auto

0 1 Reference clock

1x Data

If the rx_locktorefclk and rx_locktodata ports are not used, the

default is auto mode.

Deserializer (Serial-to-Parallel Converter)

The deserializer converts a serial bitstream into 8, 10, 16, or 20 bits of

parallel data. The deserializer receives the LSB first. Figure 2–17 shows

the deserializer.

Altera Corporation 2–19

October 2007 Stratix II GX Device Handbook, Volume 1

Page 38

Transceivers

High-speed

serial clock

D7

D6

D5

D4

D3

D2

D1

D0

D8

D9

Low-speed

parallel clock

D7

D6

D5

D4

D3

D2

D1

D0

D8

D9

10

Figure 2–17. Deserializer Note (1)

Note to Figure 2–17:

(1) This is a 10-bit deserializer. The deserializer can also convert 8, 16, or 20 bits of data.

Word Aligner

The deserializer block creates 8-, 10-, 16-, or 20-bit parallel data. The

deserializer ignores protocol symbol boundaries when converting this

data. Therefore, the boundaries of the transferred words are arbitrary. The

word aligner aligns the incoming data based on specific byte or word

boundaries. The word alignment module is clocked by the local receiver

2–20 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

recovered clock during normal operation. All the data and programmed

patterns are defined as big-endian (most significant word followed by

least significant word). Most-significant-bit-first protocols such as

SONET/SDH should reverse the bit order of word align patterns

programmed.

Page 39

Stratix II GX Architecture

Word

Aligner

datain dataout

bitslip

enapatternalign

syncstatus

patterndetect

clock

This module detects word boundaries for the 8B/10B-based protocols,

SONET, 16-bit, and 20-bit proprietary protocols. This module is also used

to align to specific programmable patterns in PRBS7/23 test mode.

Pattern Detection

The programmable pattern detection logic can be programmed to align

word boundaries using a single 7-, 8-, 10-, 16-, 20, or 32-bit pattern. The

pattern detector can either do an exact match, or match the exact pattern

and the complement of a given pattern. Once the programmed pattern is

found, the data stream is aligned to have the pattern on the LSB portion

of the data output bus.

XAUI, GIGE, PCI Express, and Serial RapidIO standards have embedded

state machines for symbol boundary synchronization. These standards

use K28.5 as their 10-bit programmed comma pattern. Each of these

standards uses different algorithms before signaling symbol boundary

acquisition to the FPGA.

The pattern detection logic searches from the LSB to the most significant

bit (MSB). If multiple patterns are found within the search window, the

pattern in the lower portion of the data stream (corresponding to the

pattern received earlier) is aligned and the rest of the matching patterns

are ignored.

Once a pattern is detected and the data bus is aligned, the word boundary

is locked. The two detection status signals (rx_syncstatus and

rx_patterndetect) indicate that an alignment is complete.

Figure 2–18 is a block diagram of the word aligner.

Figure 2–18. Word Aligner

Altera Corporation 2–21

October 2007 Stratix II GX Device Handbook, Volume 1

Page 40

Transceivers

Control and Status Signals

The rx_enapatternalign signal is the FPGA control signal that

enables word alignment in non-automatic modes. The

rx_enapatternalign signal is not used in automatic modes (PCI

Express, XAUI, GIGE, CPRI, and Serial RapidIO).

In manual alignment mode, after the rx_enapatternalign signal is

activated, the rx_syncstatus signal goes high for one parallel clock

cycle to indicate that the alignment pattern has been detected and the

word boundary has been locked. If the rx_enapatternalign is

deactivated, the rx_syncstatus signal acts as a re-synchronization

signal to signify that the alignment pattern has been detected but not

locked on a different word boundary.

When using the synchronization state machine, the rx_syncstatus

signal indicates the link status. If the rx_syncstatus signal is high, link

synchronization is achieved. If the rx_syncstatus signal is low,

synchronization has not yet been achieved, or there were enough code

group errors to lose synchronization.

In some modes, the rx_enapatternalign signal can be configured to

operate as a rising edge signal.

f For more information on manual alignment modes, refer to the

Stratix II GX Device Handbook, volume 2.

When the rx_enapatternalign signal is sensitive to the rising edge,

each rising edge triggers a new boundary alignment search, clearing the

rx_syncstatus signal.

The rx_patterndetect signal pulses high during a new alignment,

and also whenever the alignment pattern occurs on the current word

boundary.

SONET/SDH

In all the SONET/SDH modes, you can configure the word aligner to

either align to A1A2 or A1A1A2A2 patterns. Once the pattern is found,

the word boundary is aligned and the word aligner asserts the

rx_patterndetect signal for one clock cycle.

2–22 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 41

Stratix II GX Architecture

Programmable Run Length Violation

The word aligner supports a programmable run length violation counter.

Whenever the number of the continuous ‘0’ (or ‘1’) exceeds a user

programmable value, the rx_rlv signal goes high for a minimum pulse

width of two recovered clock cycles. The maximum run values supported

are shown in Table 2–7.

Table 2–7. Maximum Run Length (UI)

Mode

PMA Serialization

8 Bit 10 Bit 16 Bit 20 Bit

Single-Width 128 160 — —

Double-Width — — 512 640

Running Disparity Check

The running disparity error rx_disperr and running disparity value

rx_runningdisp are sent along with aligned data from the 8B/10B

decoder to the FPGA. You can ignore or act on the reported running

disparity value and running disparity error signals.

Bit-Slip Mode

The word aligner can operate in either pattern detection mode or in

bit-slip mode.

The bit-slip mode provides the option to manually shift the word

boundary through the FPGA. This feature is useful for:

■ Longer synchronization patterns than the pattern detector can

accommodate

■ Scrambled data stream

■ Input stream consisting of over-sampled data

This feature can be applied at 10-bit and 16-bit data widths.

The word aligner outputs a word boundary as it is received from the

analog receiver after reset. You can examine the word and search its

boundary in the FPGA. To do so, assert the rx_bitslip signal. The

rx_bitslip signal should be toggled and held constant for at least two

FPGA clock cycles.

For every rising edge of the rx_bitslip signal, the current word

boundary is slipped by one bit. Every time a bit is slipped, the bit received

earliest is lost. If bit slipping shifts a complete round of bus width, the

word boundary is back to the original boundary.

Altera Corporation 2–23

October 2007 Stratix II GX Device Handbook, Volume 1

Page 42

Transceivers

KRKKKRRRKKRA

Lane 3

KRKKKRRRKKRA

Lane 2

KRKKKRRRKKRA

Lane 1

KRKKKRRRKKRA

Lane 0

KRKKKRRRKKRA

Lane 3

KRKKKRRRKKRA

Lane 2

KRKKKRRRKKRA

Lane 1

KRKKKRRRKKRA

Lane 0

Before

After

The rx_syncstatus signal is not available in bit-slipping mode.

Channel Aligner

The channel aligner is available only in XAUI mode and aligns the signals

of all four channels within a transceiver. The channel aligner follows the

IEEE 802.3ae, clause 48 specification for channel bonding.

The channel aligner is a 16-word FIFO buffer with a state machine

controlling the channel bonding process. The state machine looks for an

/A/ (/K28.3/) in each channel, and aligns all the /A/ code groups in the

transceiver. When four columns of /A/ (denoted by //A//) are

detected, the rx_channelaligned signal goes high, signifying that all

the channels in the transceiver have been aligned. The reception of four

consecutive misaligned /A/ code groups restarts the channel alignment

sequence and sends the rx_channelaligned signal low.

Figure 2–19 shows misaligned channels before the channel aligner and

the aligned channels after the channel aligner.

Figure 2–19. Before and After the Channel Aligner

2–24 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 43

Stratix II GX Architecture

Rate Matcher

Rate matcher is available in Basic, PCI Express, XAUI, and GIGE modes

and consists of a 20-word deep FIFO buffer and a FIFO controller.

Figure 2–20 shows the implementation of the rate matcher in the

Stratix II GX device.

Figure 2–20. Rate Matcher

dataoutdatain

Rate

Matcher

wrclock

rdclock

In a multi-crystal environment, the rate matcher compensates for up to a

± 300-PPM difference between the source and receiver clocks. Table 2–8

shows the standards supported and the PPM for the rate matcher

tolerance.

Table 2–8. Rate Matcher PPM Support Note (1)

Standard PPM

XAUI ± 100

PCI Express (PIPE) ± 300

GIGE ± 100

Basic Double-Width ± 300

Note to Table 2–8:

(1) Refer to the Stratix II GX Transceiver User Guide for the Altera®-defined scheme.

Basic Mode

In Basic mode, you can program the skip and control pattern for rate

matching. In single-width Basic mode, there is no restriction on the

deletion of a skip character in a cluster. The rate matcher deletes the skip

characters as long as they are available. For insertion, the rate matcher

inserts skip characters such that the number of skip characters at the

output of rate matcher does not exceed five. In double-width mode, the

rate matcher deletes skip character when they appear as pairs in the

upper and lower bytes. There are no restrictions on the number of skip

characters that are deleted. The rate matcher inserts skip characters as

pairs.

Altera Corporation 2–25

October 2007 Stratix II GX Device Handbook, Volume 1

Page 44

Transceivers

GIGE Mode

In GIGE mode, the rate matcher adheres to the specifications in clause 36

of the IEEE 802.3 documentation for idle additions or removals. The rate

matcher performs clock compensation only on /I2/ ordered sets,

composed of a /K28.5/+ followed by a /D16.2/-. The rate matcher does

not perform clock compensation on any other ordered set combinations.

An /I2/ is added or deleted automatically based on the number of words

in the FIFO buffer. A K28.4 is given at the control and data ports when the

FIFO buffer is in an overflow or underflow condition.

XAUI Mode

In XAUI mode, the rate matcher adheres to clause 48 of the IEEE 802.3ae

specification for clock rate compensation. The rate matcher performs

clock compensation on columns of /R/ (/K28.0/), denoted by //R//.

An //R// is added or deleted automatically based on the number of

words in the FIFO buffer.

PCI Express Mode

PCI Express mode operates at a data rate of 2.5 Gbps, and supports lane

widths of ×1, ×2, ×4, and ×8. The rate matcher can support up to

± 300-PPM differences between the upstream transmitter and the

receiver. The rate matcher looks for the skip ordered sets (SOS), which

usually consist of a /K28.5/ comma followed by three /K28.0/ skip

characters. The rate matcher deletes or inserts skip characters when

necessary to prevent the rate matching FIFO buffer from overflowing or

underflowing.

The Stratix II GX rate matcher in PCI Express mode has FIFO overflow

and underflow protection. In the event of a FIFO overflow, the rate

matcher deletes any data after the overflow condition to prevent FIFO

pointer corruption until the rate matcher is not full. In an underflow

condition, the rate matcher inserts 9'h1FE (/K30.7/) until the FIFO is not

empty. These measures ensure that the FIFO can gracefully exit the

overflow and underflow condition without requiring a FIFO reset.

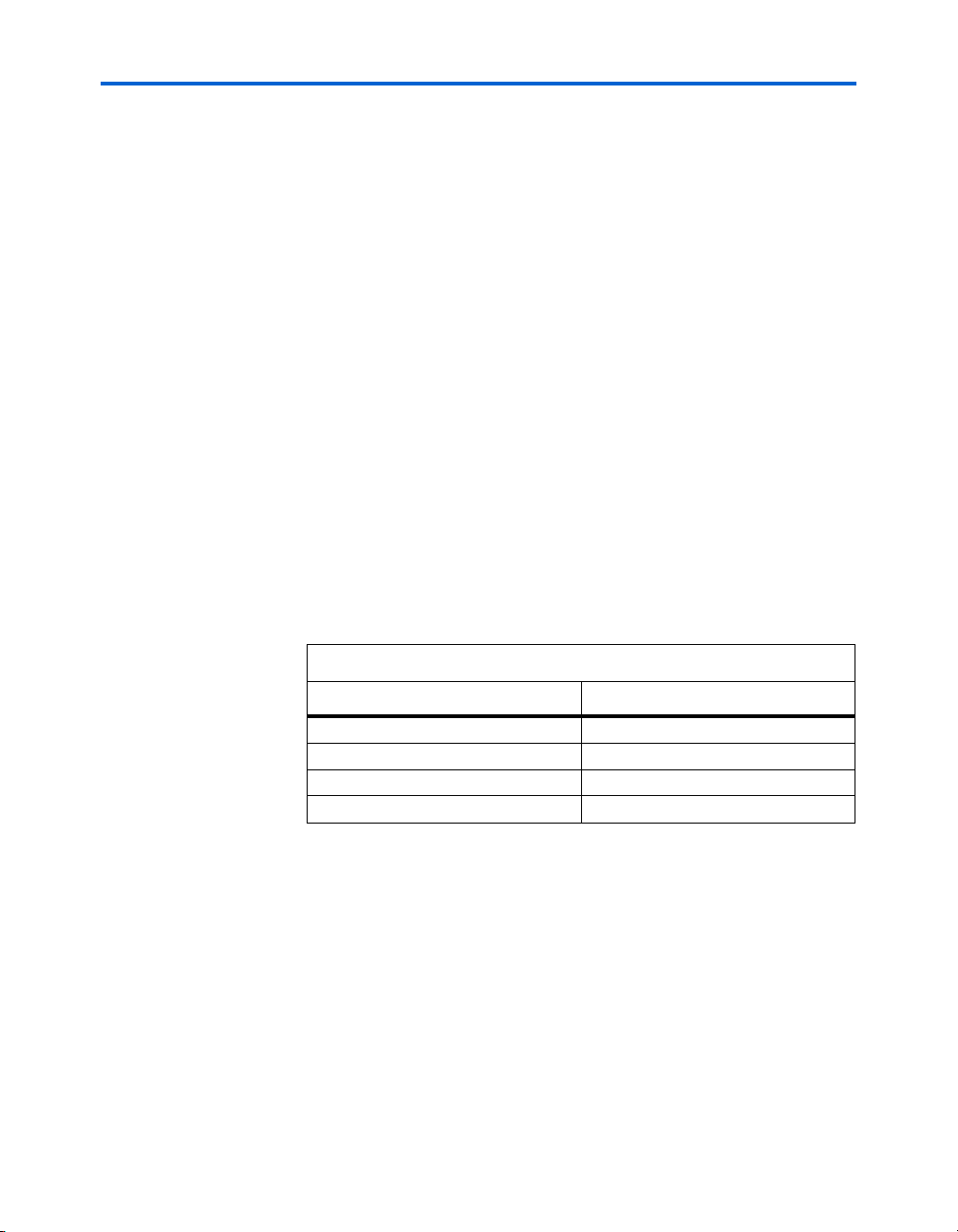

8B/10B Decoder

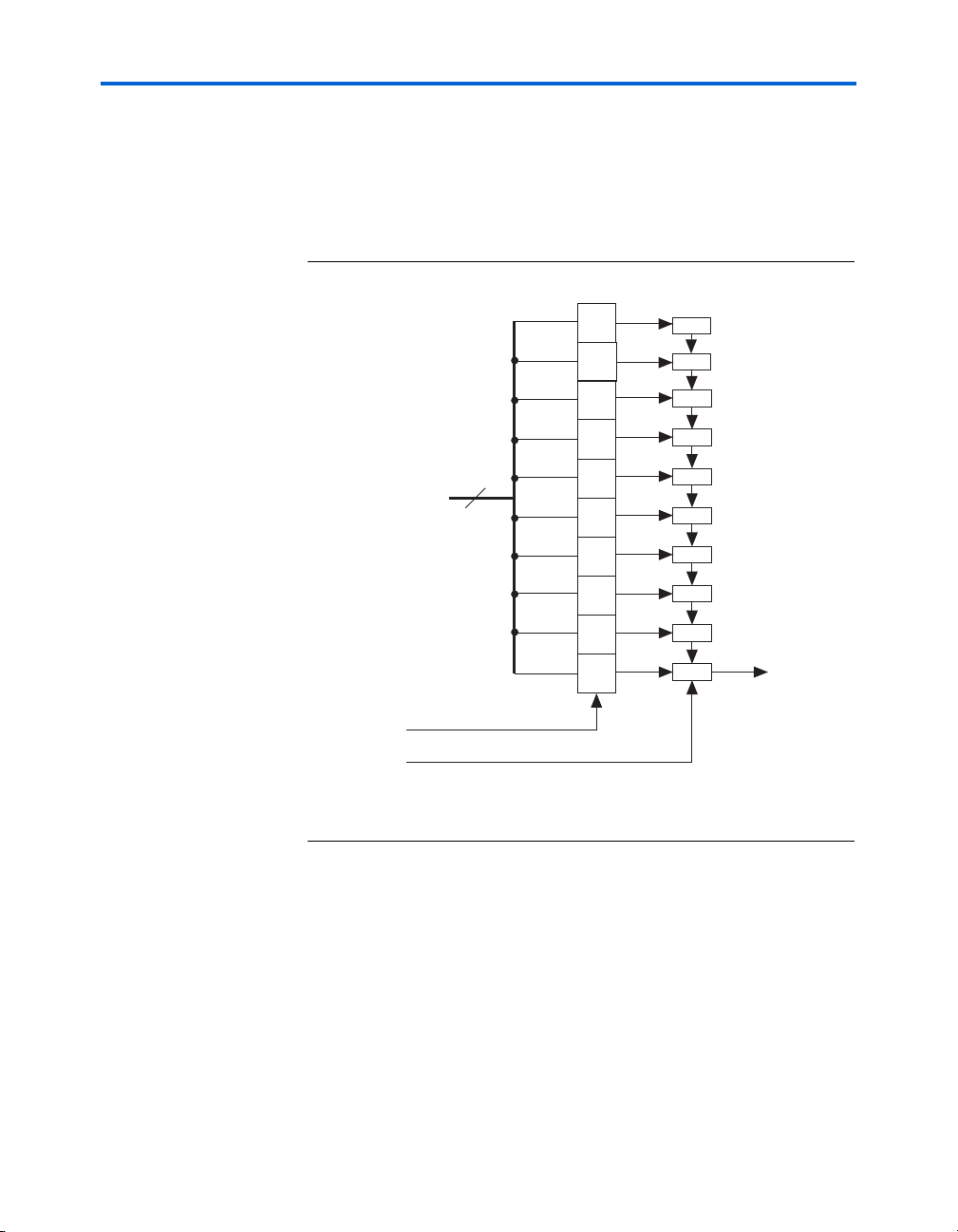

The 8B/10B decoder (Figure 2–21) is part of the Stratix II GX transceiver

digital blocks (PCS) and lies in the receiver path between the rate matcher

and the byte deserializer blocks. The 8B/10B decoder operates in

single-width and double-width modes, and can be bypassed if the

8B/10B decoding is not necessary. In single-width mode, the 8B/10B

decoder restores the 8-bit data + 1-bit control identifier from the 10-bit

code. In double-width mode, there are two 8B/10B decoders in parallel,

which restores the 16-bit (2 × 8-bit) data + 2-bit (2 × 1-bit) control identifier

from the 20-bit (2 × 10-bit) code. This 8B/10B decoder conforms to the

IEEE 802.3 1998 edition standards.

2–26 Altera Corporation

Stratix II GX Device Handbook, Volume 1 October 2007

Page 45

Stratix II GX Architecture

8B/10B

Decoder

MSByte

datain[19..10]

To Byte

Deserializer

dataout[15..8]

Status Signals[1] (1)

8B/10B

Decoder

LSByte

datain[9..0]

dataout[7..0]

Status Signals[0]

From Rate

Matcher

(1)

Figure 2–21. 8B/10B Decoder

The 8B/10B decoder in single-width mode translates the 10-bit encoded

data into the 8-bit equivalent data or control code. The 10-bit code

received must be from the supported Dx.y or Kx.y list with the proper

disparity or error flags asserted. All 8B/10B control signals, such as

disparity error or control detect, are pipelined with the data and