Page 1

SII51002-4.3

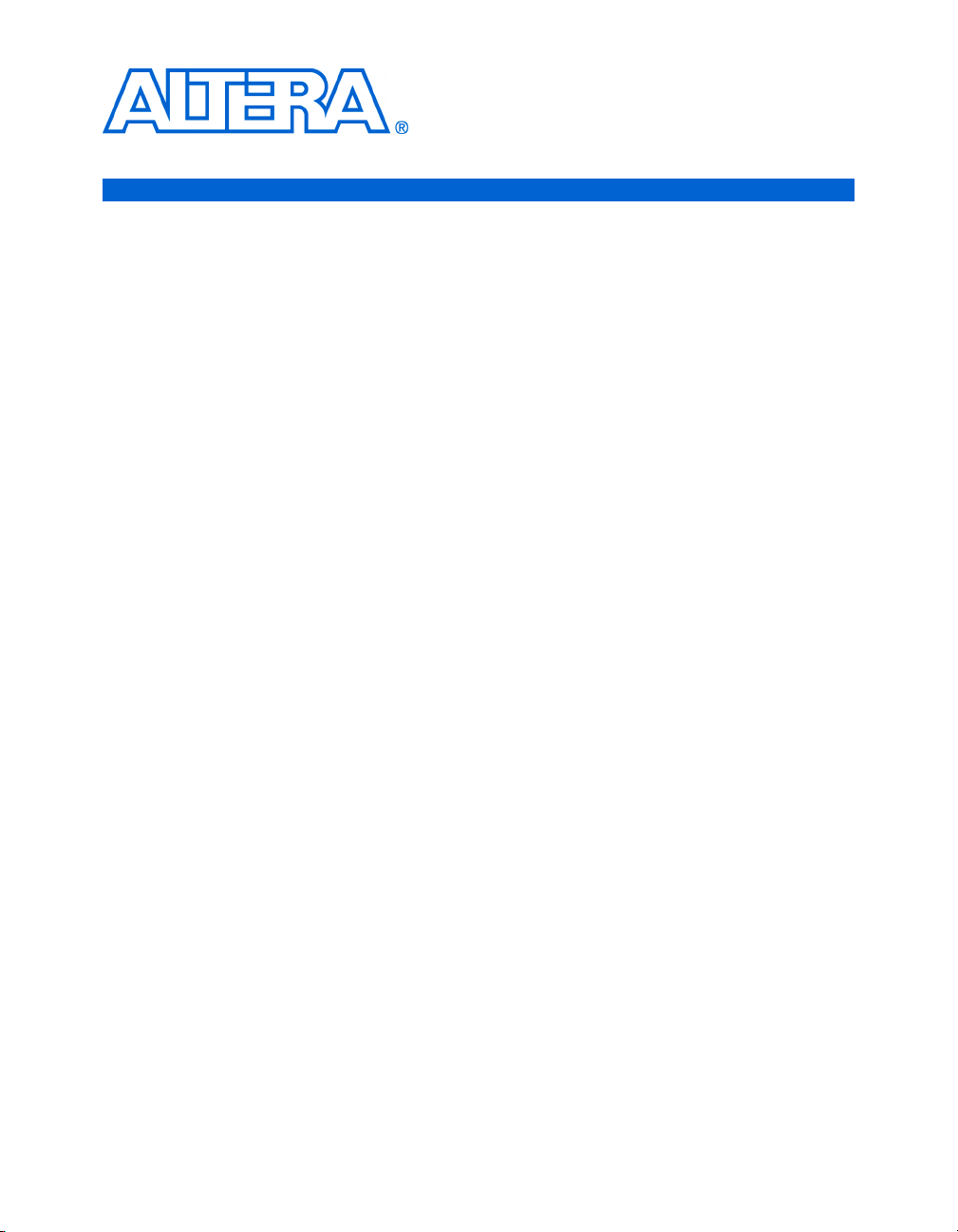

2. Stratix II Architecture

Functional Description

Stratix®II devices contain a two-dimensional row- and column-based

architecture to implement custom logic. A series of column and row

interconnects of varying length and speed provides signal interconnects

between logic array blocks (LABs), memory block structures (M512 RAM,

M4K RAM, and M-RAM blocks), and digital signal processing (DSP)

blocks.

Each LAB consists of eight adaptive logic modules (ALMs). An ALM is

the Stratix II device family’s basic building block of logic providing

efficient implementation of user logic functions. LABs are grouped into

rows and columns across the device.

M512 RAM blocks are simple dual-port memory blocks with 512 bits plus

parity (576 bits). These blocks provide dedicated simple dual-port or

single-port memory up to 18-bits wide at up to 500 MHz. M512 blocks are

grouped into columns across the device in between certain LABs.

M4K RAM blocks are true dual-port memory blocks with 4K bits plus

parity (4,608 bits). These blocks provide dedicated true dual-port, simple

dual-port, or single-port memory up to 36-bits wide at up to 550 MHz.

These blocks are grouped into columns across the device in between

certain LABs.

M-RAM blocks are true dual-port memory blocks with 512K bits plus

parity (589,824 bits). These blocks provide dedicated true dual-port,

simple dual-port, or single-port memory up to 144-bits wide at up to

420 MHz. Several M-RAM blocks are located individually in the device's

logic array.

DSP blocks can implement up to either eight full-precision 9 × 9-bit

multipliers, four full-precision 18 × 18-bit multipliers, or one

full-precision 36 × 36-bit multiplier with add or subtract features. The

DSP blocks support Q1.15 format rounding and saturation in the

multiplier and accumulator stages. These blocks also contain shift

registers for digital signal processing applications, including finite

impulse response (FIR) and infinite impulse response (IIR) filters. DSP

blocks are grouped into columns across the device and operate at up to

450 MHz.

Altera Corporation 2–1

May 2007

Page 2

Functional Description

Each Stratix II device I/O pin is fed by an I/O element (IOE) located at

the end of LAB rows and columns around the periphery of the device.

I/O pins support numerous single-ended and differential I/O standards.

Each IOE contains a bidirectional I/O buffer and six registers for

registering input, output, and output-enable signals. When used with

dedicated clocks, these registers provide exceptional performance and

interface support with external memory devices such as DDR and DDR2

SDRAM, RLDRAM II, and QDR II SRAM devices. High-speed serial

interface channels with dynamic phase alignment (DPA) support data

transfer at up to 1 Gbps using LVDS or HyperTransport

standards.

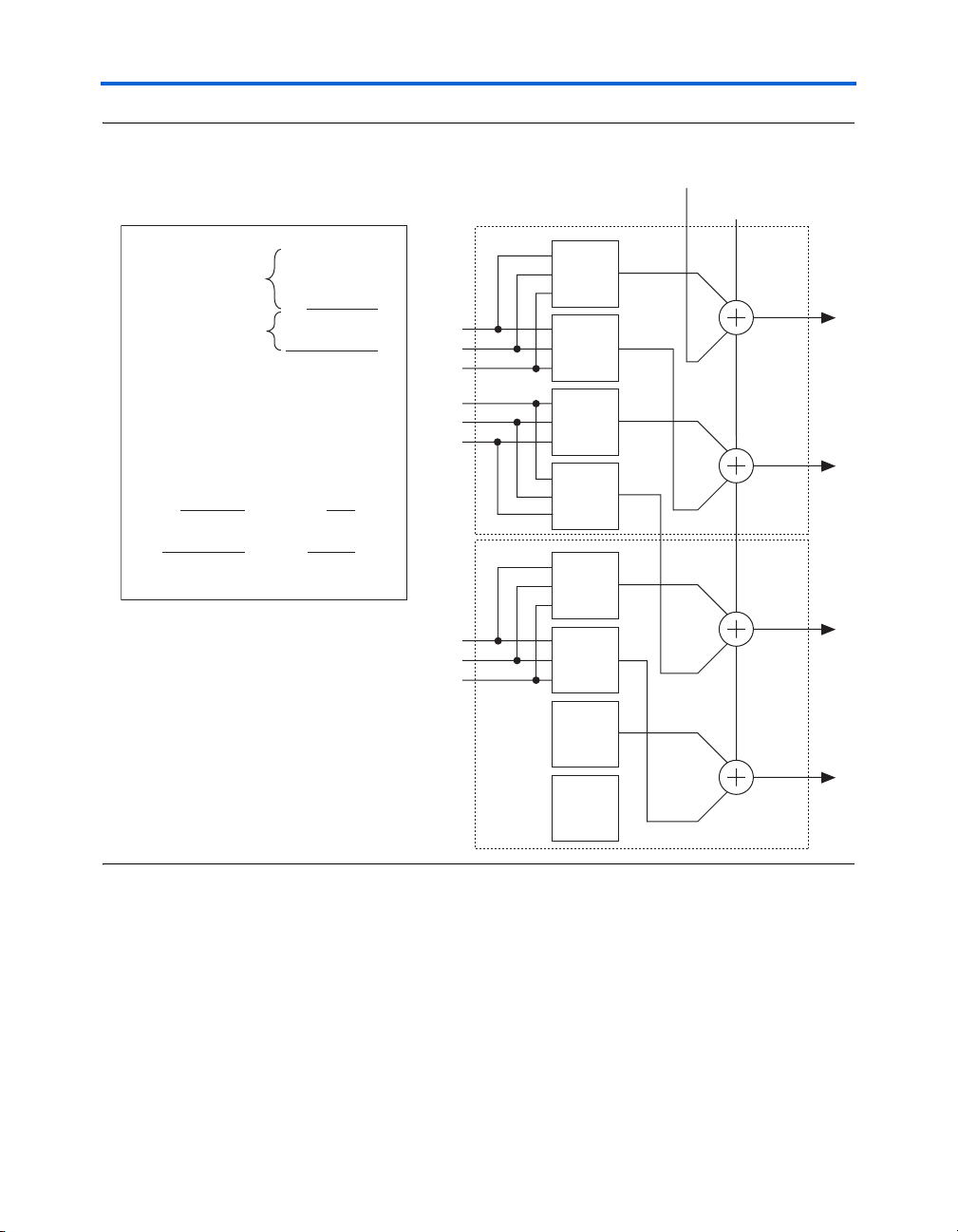

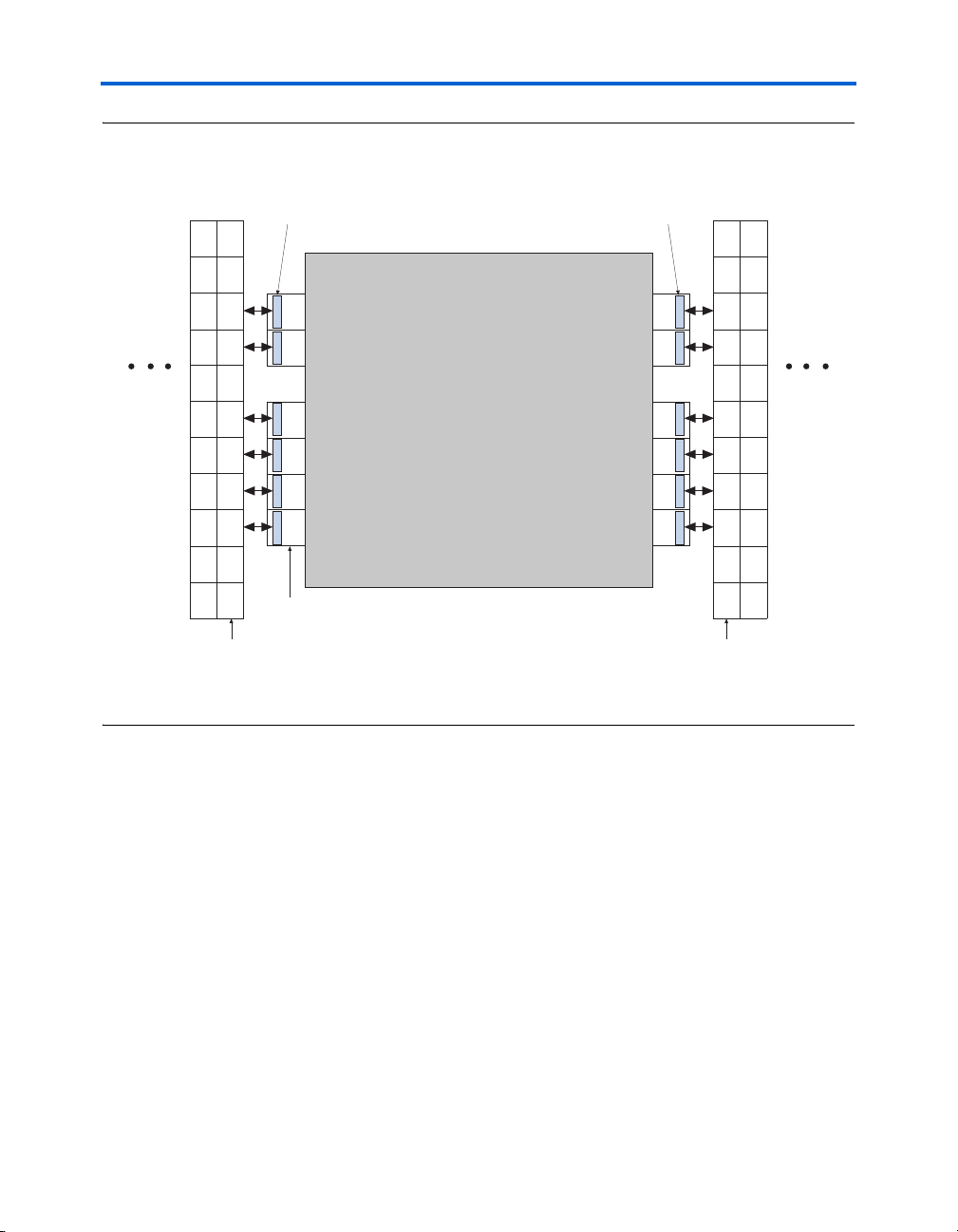

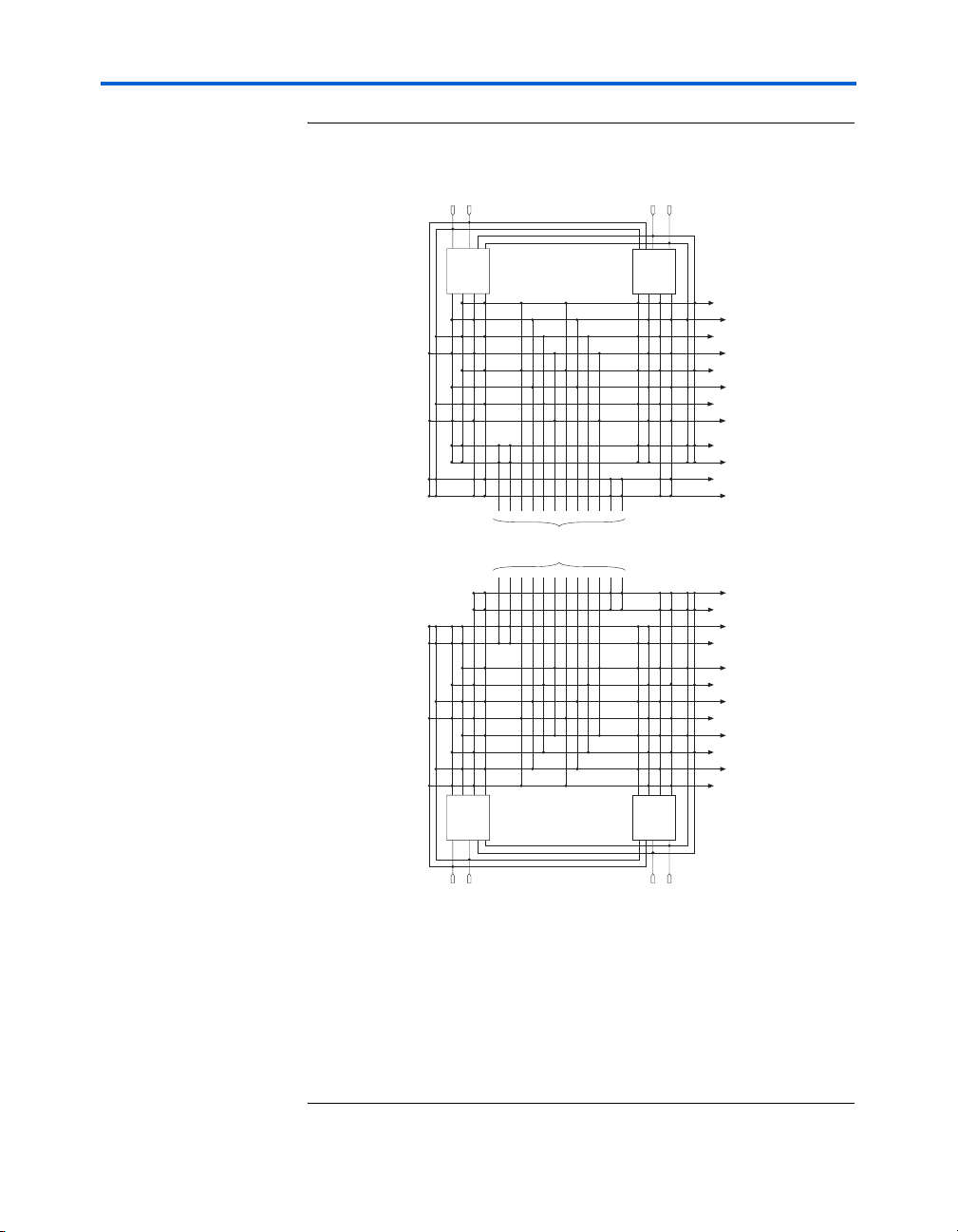

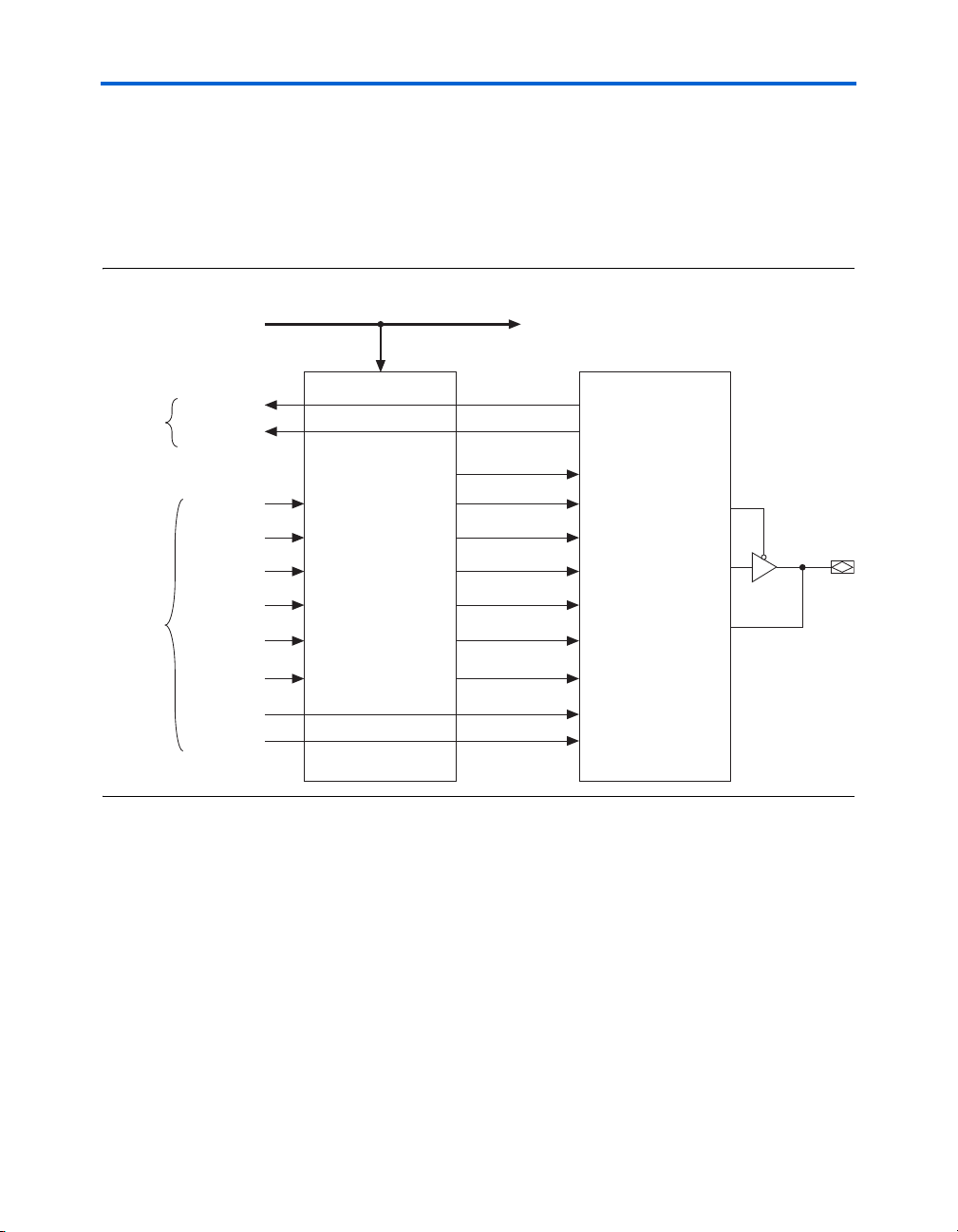

Figure 2–1 shows an overview of the Stratix II device.

Figure 2–1. Stratix II Block Diagram

M512 RAM Blocks for

Dual-Port Memory, Shift

Registers, & FIFO Buffers

DSP Blocks for

Multiplication and Full

Implementation of FIR Filters

M4K RAM Blocks

for True Dual-Port

Memory & Other Embedded

Memory Functions

IOEs Support DDR, PCI, PCI-X,

SSTL-3, SSTL-2, HSTL-1, HSTL-2,

LVDS, HyperTransport & other

I/O Standards

TM

technology I/O

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

DSP

Block

IOEs IOEs

LABs LABs

LABs

LABs LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABsLABs

M-RAM Block

LABsLABs

LABsLABs

2–2 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 3

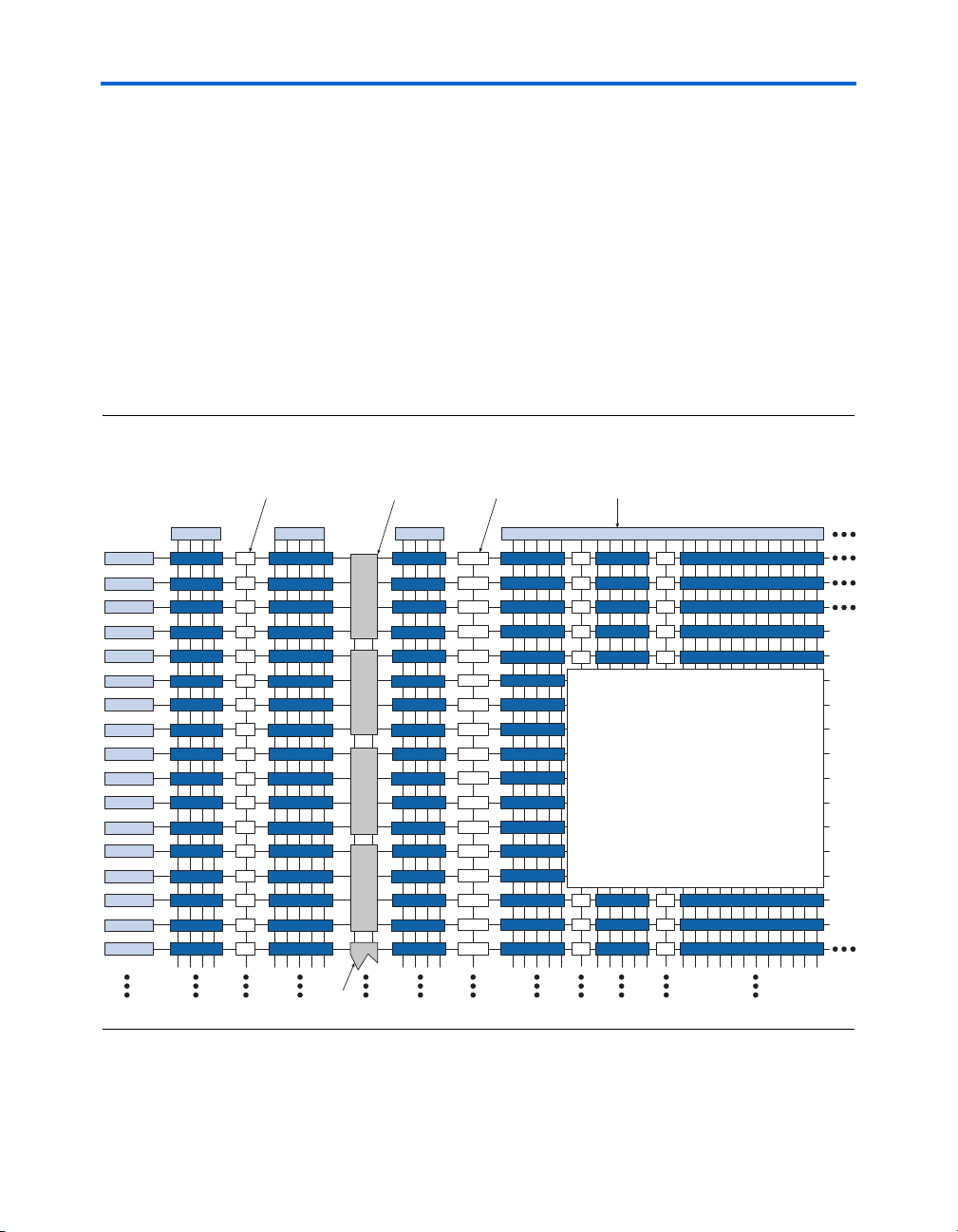

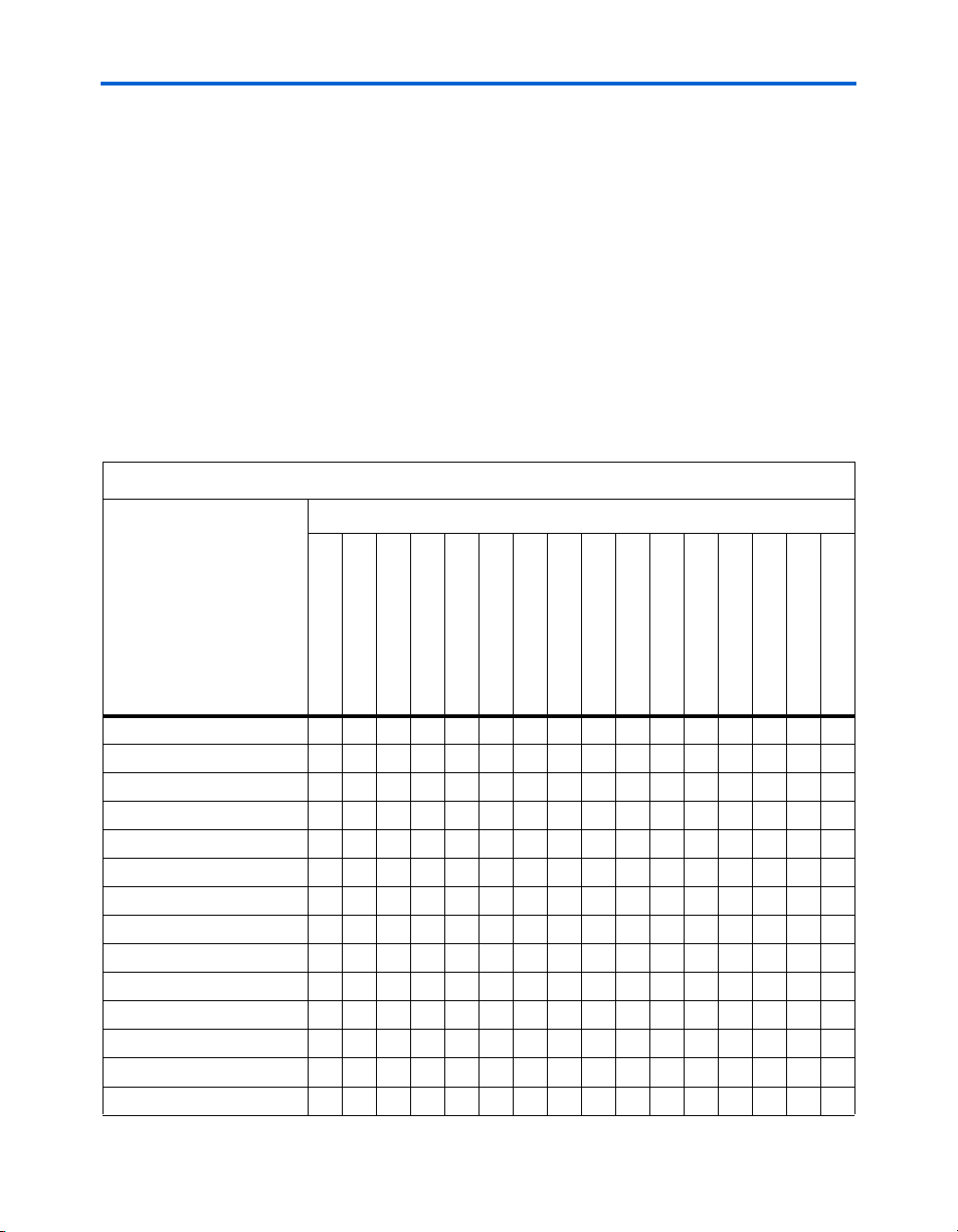

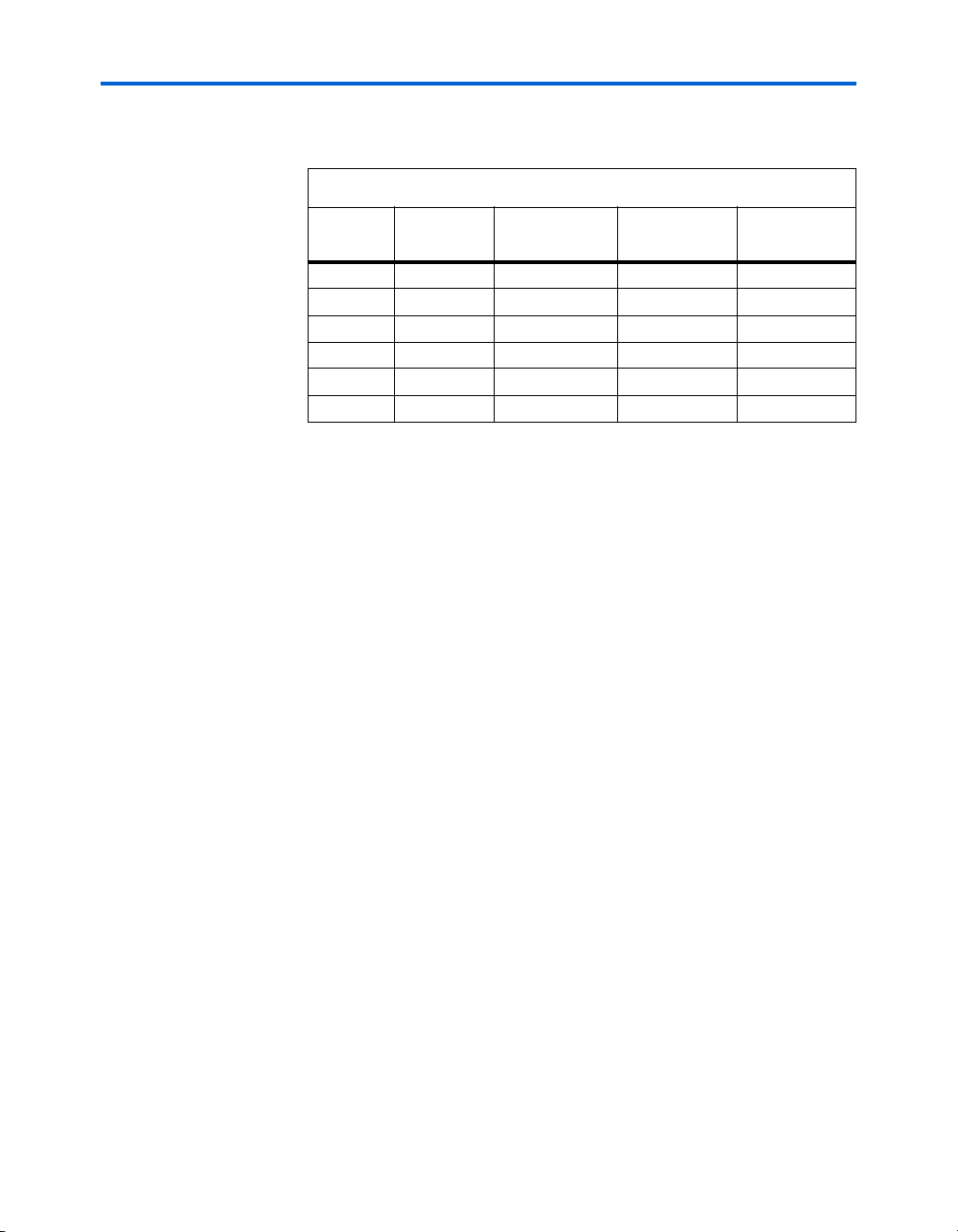

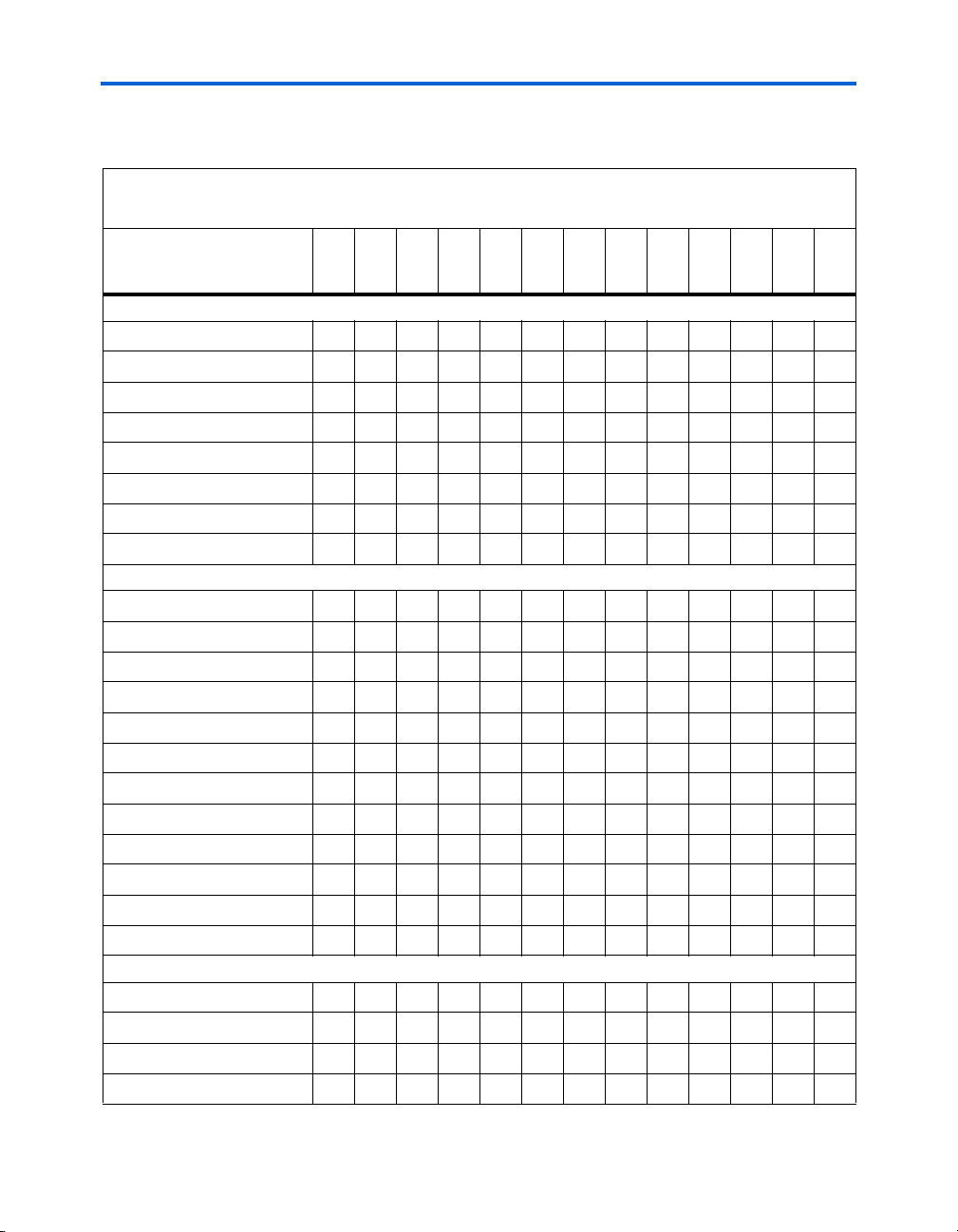

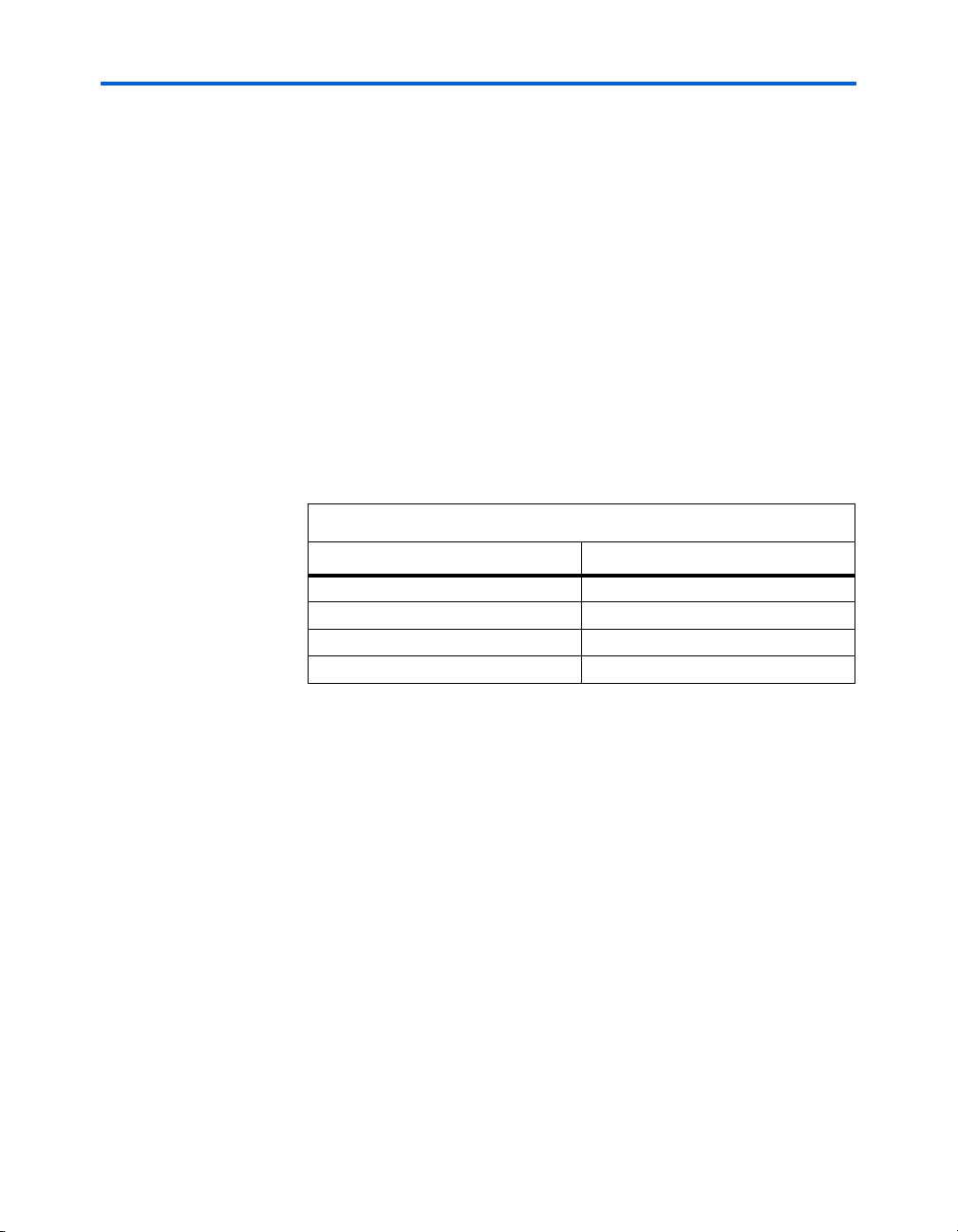

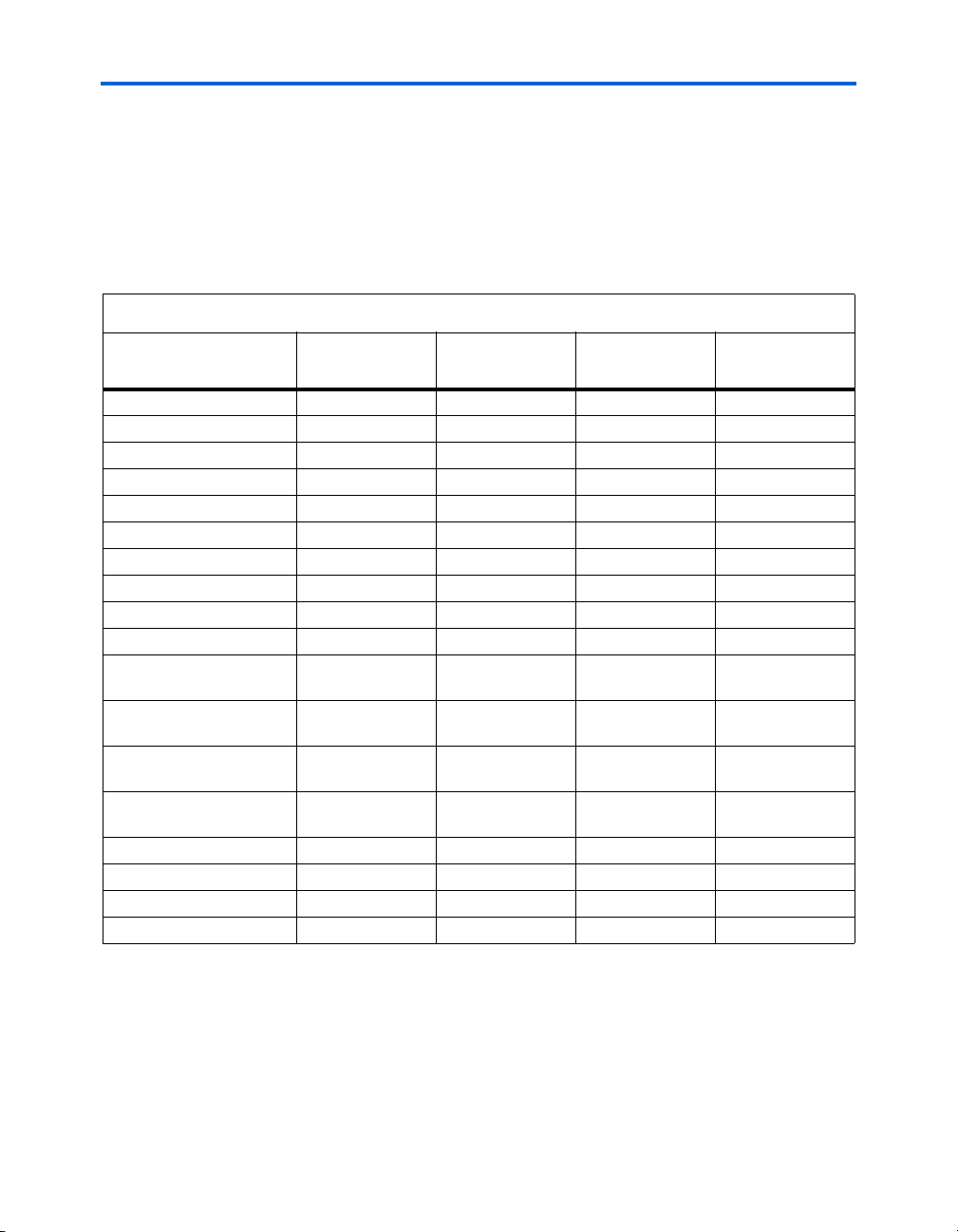

The number of M512 RAM, M4K RAM, and DSP blocks varies by device

along with row and column numbers and M-RAM blocks. Table 2–1 lists

the resources available in Stratix II devices.

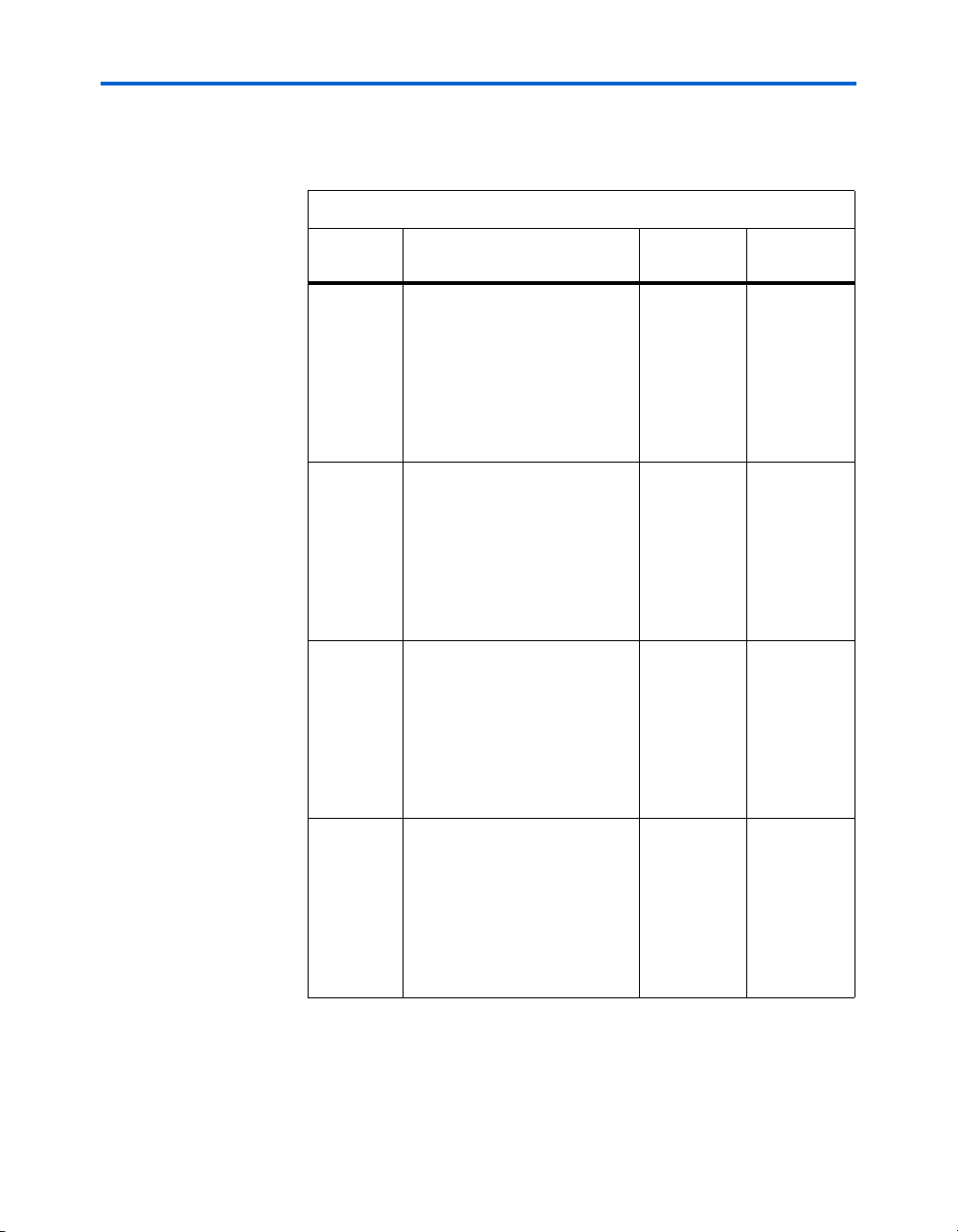

Table 2–1. Stratix II Device Resources

Stratix II Architecture

Device

EP2S15 4 / 104 3 / 78 0 2 / 12 30 26

EP2S30 6 / 202 4 / 144 1 2 / 16 49 36

EP2S60 7 / 329 5 / 255 2 3 / 36 62 51

EP2S90 8 / 488 6 / 408 4 3 / 48 71 68

EP2S130 9 / 699 7 / 609 6 3 / 63 81 87

EP2S180 11 / 930 8 / 768 9 4 / 96 100 96

Logic Array Blocks

M512 RAM

Columns/Blocks

Each LAB consists of eight ALMs, carry chains, shared arithmetic chains,

LAB control signals, local interconnect, and register chain connection

lines. The local interconnect transfers signals between ALMs in the same

M4K RAM

Columns/Blocks

M-RAM

Blocks

DSP Block

Columns/Blocks

LAB

Columns

LAB Rows

LAB. Register chain connections transfer the output of an ALM register to

®

the adjacent ALM register in an LAB. The Quartus

II Compiler places

associated logic in an LAB or adjacent LABs, allowing the use of local,

shared arithmetic chain, and register chain connections for performance

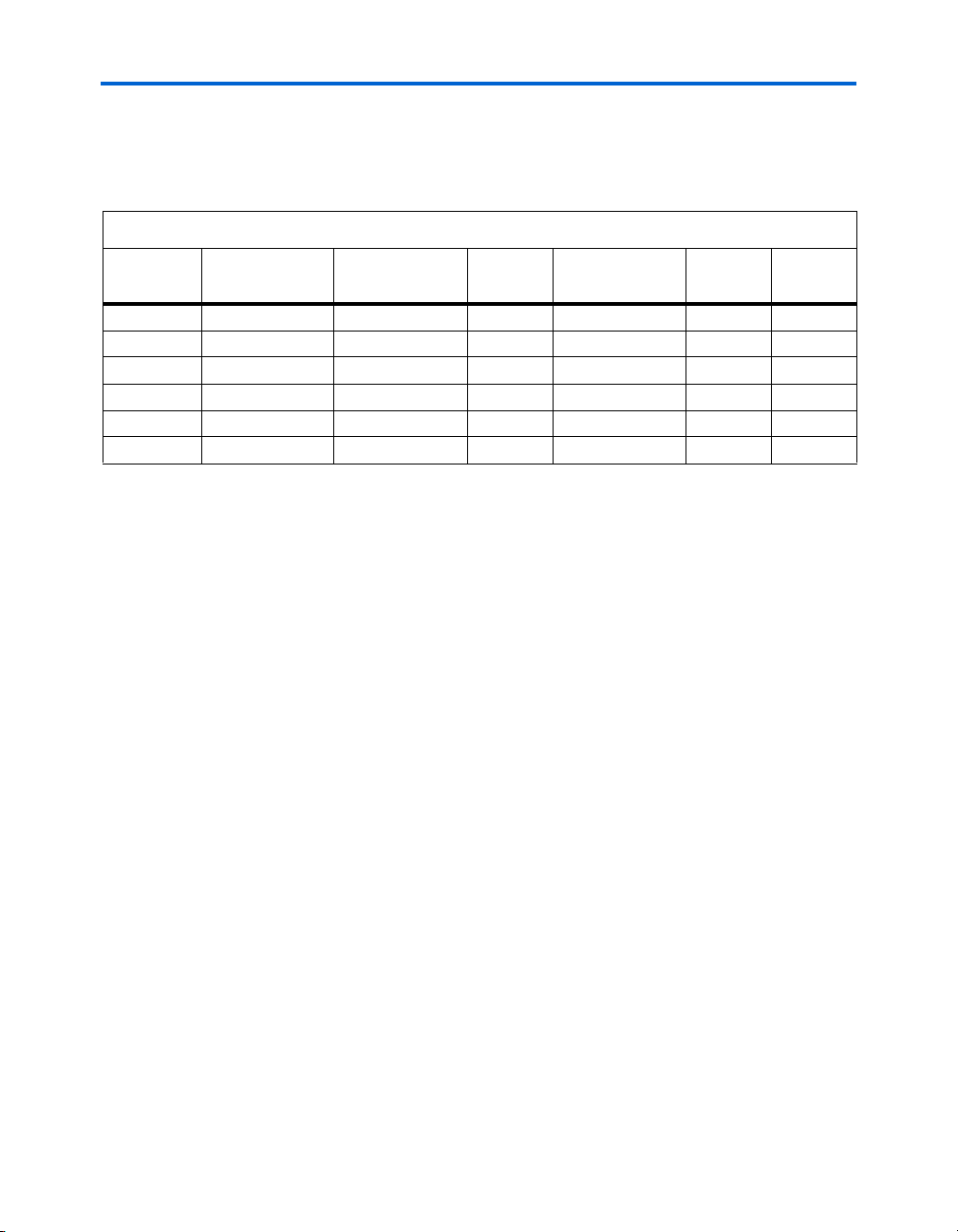

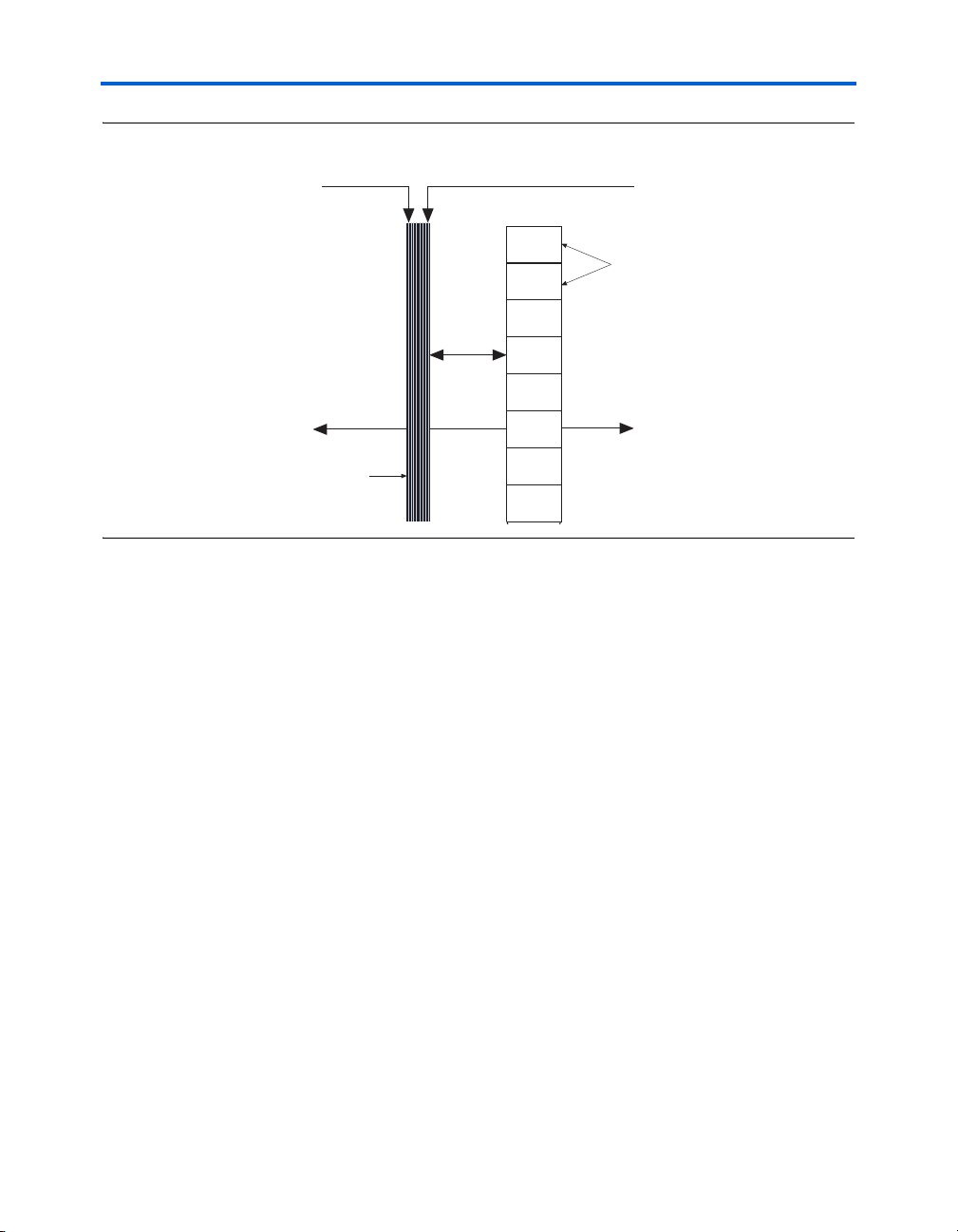

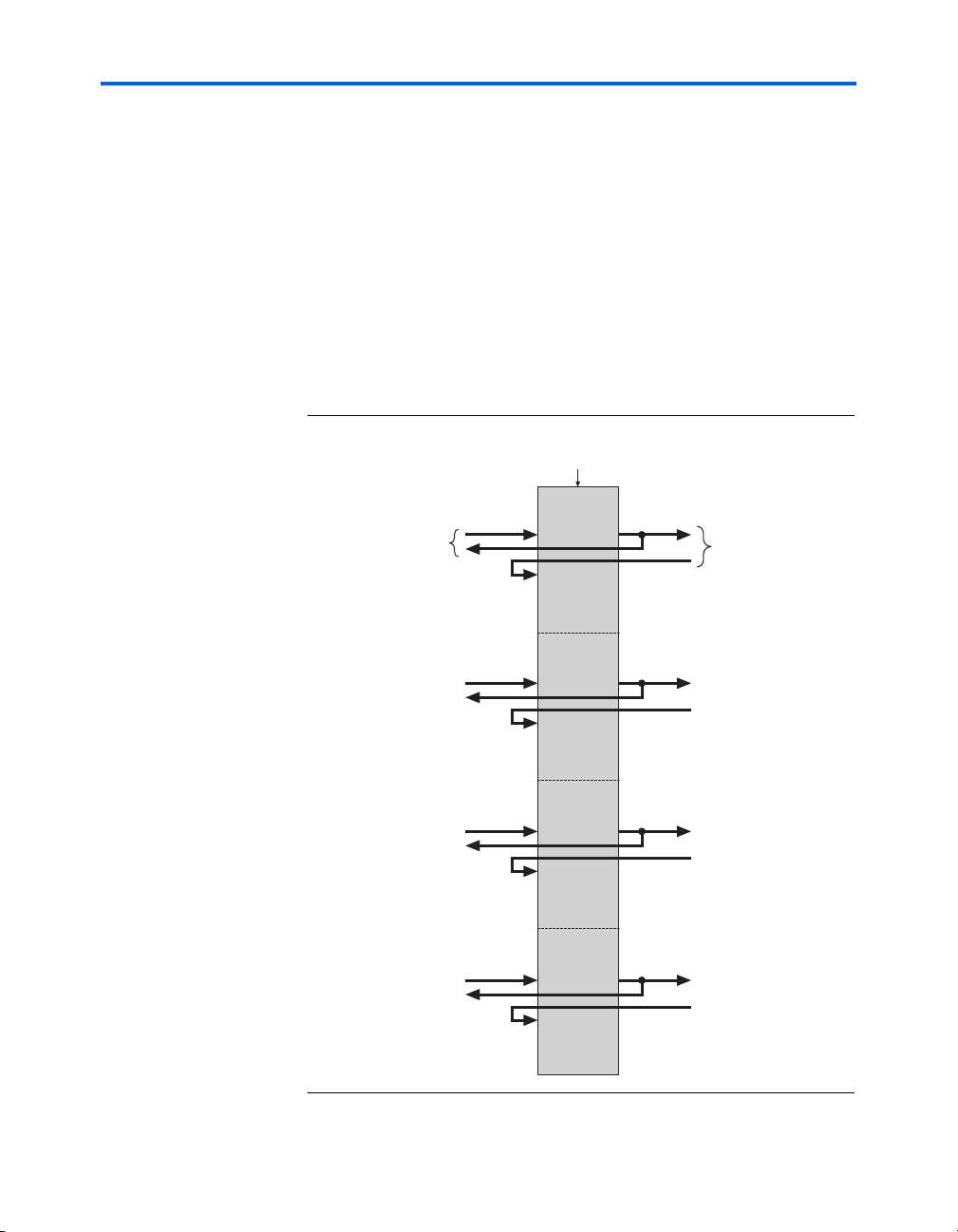

and area efficiency. Figure 2–2 shows the Stratix II LAB structure.

Altera Corporation 2–3

May 2007 Stratix II Device Handbook, Volume 1

Page 4

Logic Array Blocks

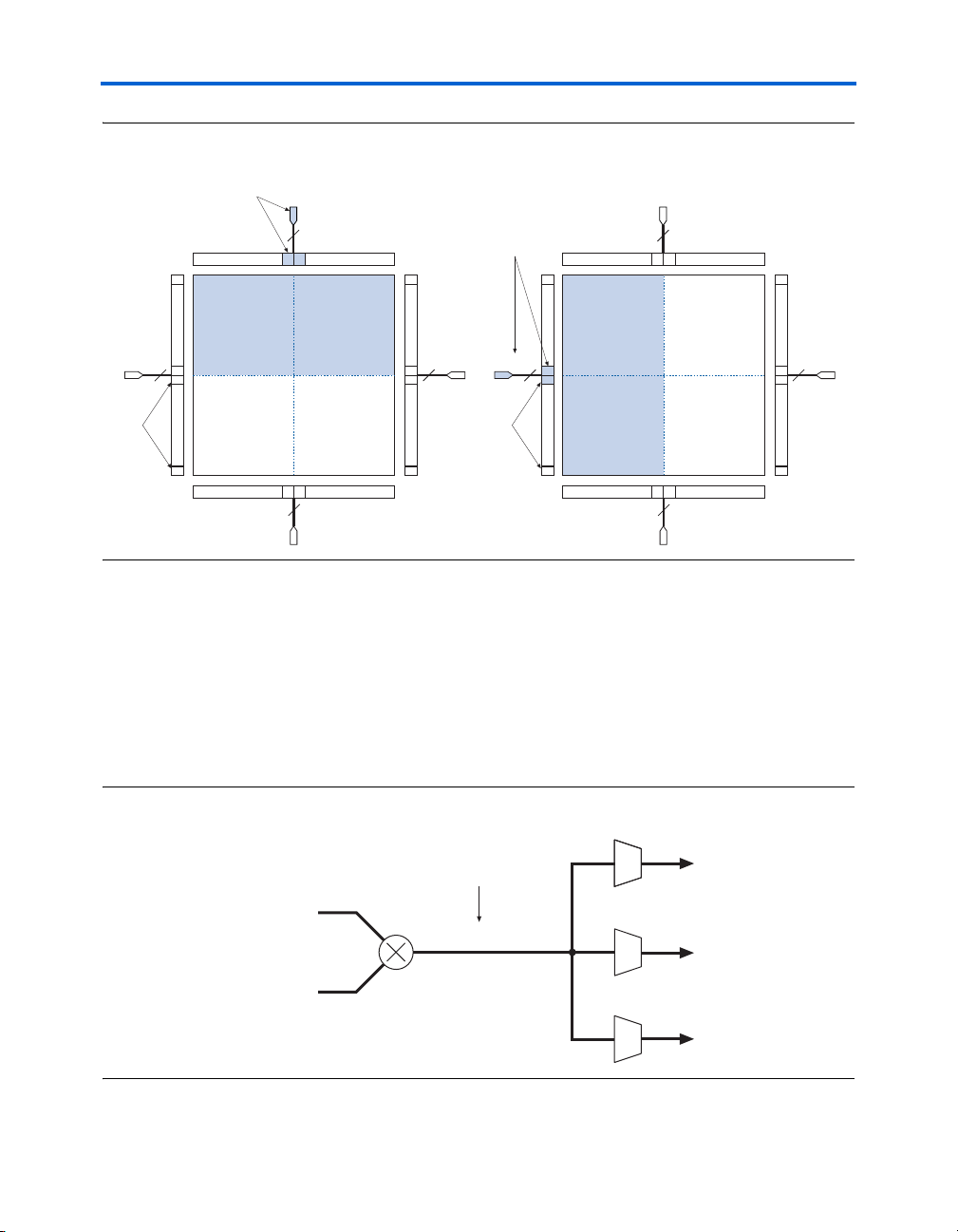

Figure 2–2. Stratix II LAB Structure

Direct link

interconnect from

adjacent block

Row Interconnects of

Variable Speed & Length

ALMs

Direct link

interconnect from

adjacent block

Direct link

interconnect to

adjacent block

Direct link

interconnect to

adjacent block

Local Interconnect

LAB

Local Interconnect is Driven

from Either Side by Columns & LABs,

& from Above by Rows

Column Interconnects of

Variable Speed & Length

LAB Interconnects

The LAB local interconnect can drive ALMs in the same LAB. It is driven

by column and row interconnects and ALM outputs in the same LAB.

Neighboring LABs, M512 RAM blocks, M4K RAM blocks, M-RAM

blocks, or DSP blocks from the left and right can also drive an LAB's local

interconnect through the direct link connection. The direct link

connection feature minimizes the use of row and column interconnects,

providing higher performance and flexibility. Each ALM can drive

24 ALMs through fast local and direct link interconnects. Figure 2–3

shows the direct link connection.

2–4 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 5

Figure 2–3. Direct Link Connection

Direct link interconnect from

left LAB, TriMatrix memory

block, DSP block, or IOE output

Stratix II Architecture

Direct link interconnect from

right LAB, TriMatrix memory

block, DSP block, or IOE output

ALMs

Direct link

interconnect

to left

Direct link

interconnect

to right

Local

Interconnect

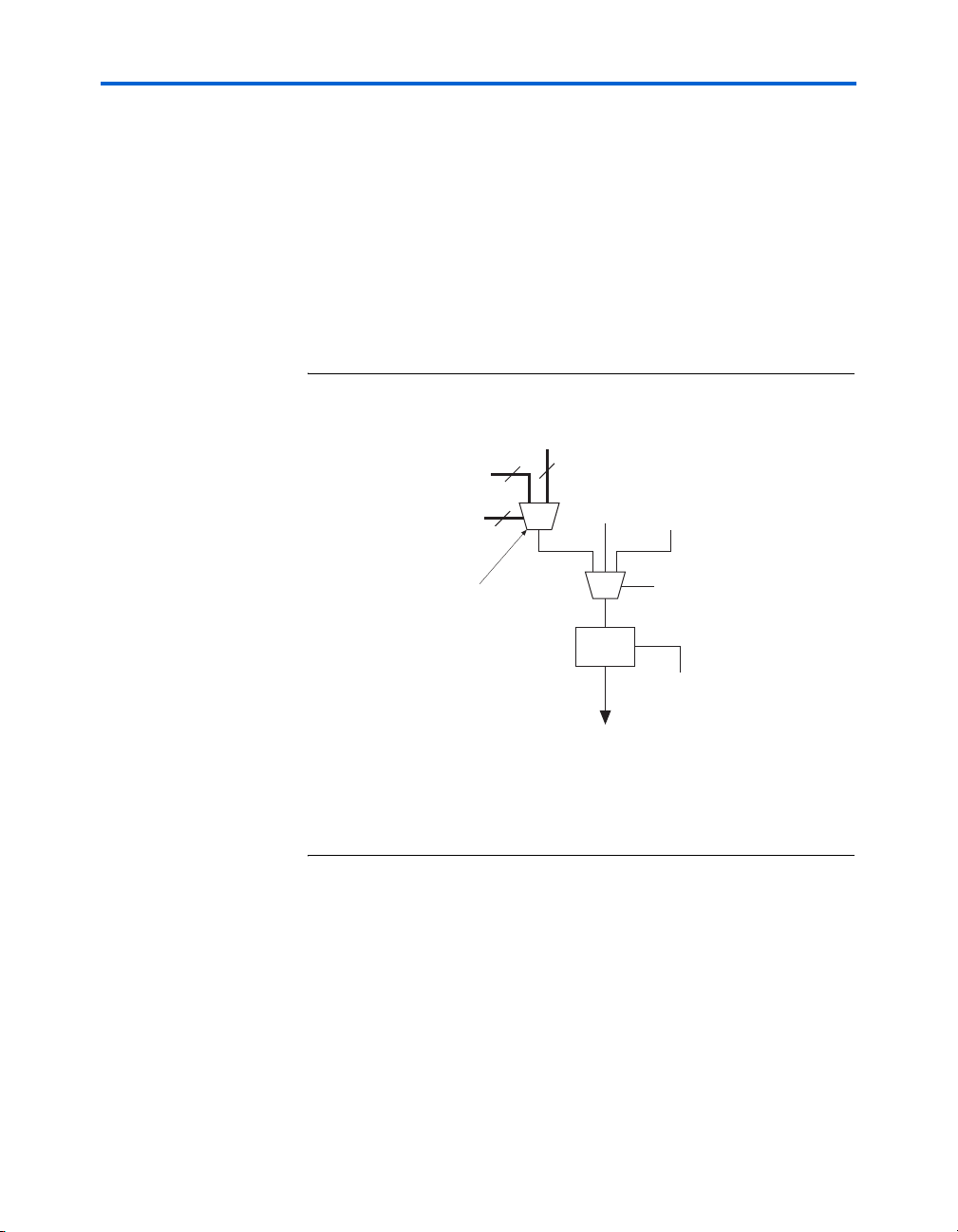

LAB Control Signals

Each LAB contains dedicated logic for driving control signals to its ALMs.

The control signals include three clocks, three clock enables, two

asynchronous clears, synchronous clear, asynchronous preset/load, and

synchronous load control signals. This gives a maximum of 11 control

signals at a time. Although synchronous load and clear signals are

generally used when implementing counters, they can also be used with

other functions.

Each LAB can use three clocks and three clock enable signals. However,

there can only be up to two unique clocks per LAB, as shown in the LAB

control signal generation circuit in Figure 2–4. Each LAB's clock and clock

enable signals are linked. For example, any ALM in a particular LAB

using the labclk1 signal also uses labclkena1. If the LAB uses both

the rising and falling edges of a clock, it also uses two LAB-wide clock

signals. De-asserting the clock enable signal turns off the corresponding

LAB-wide clock.

Each LAB can use two asynchronous clear signals and an asynchronous

load/preset signal. By default, the Quartus II software uses a NOT gate

push-back technique to achieve preset. If you disable the NOT gate

push-up option or assign a given register to power up high using the

Quartus II software, the preset is achieved using the asynchronous load

Altera Corporation 2–5

May 2007 Stratix II Device Handbook, Volume 1

Page 6

Adaptive Logic Modules

signal with asynchronous load data input tied high. When the

asynchronous load/preset signal is used, the labclkena0 signal is no

longer available.

The LAB row clocks [5..0] and LAB local interconnect generate the

LAB-wide control signals. The MultiTrack

skew allows clock and control signal distribution in addition to data.

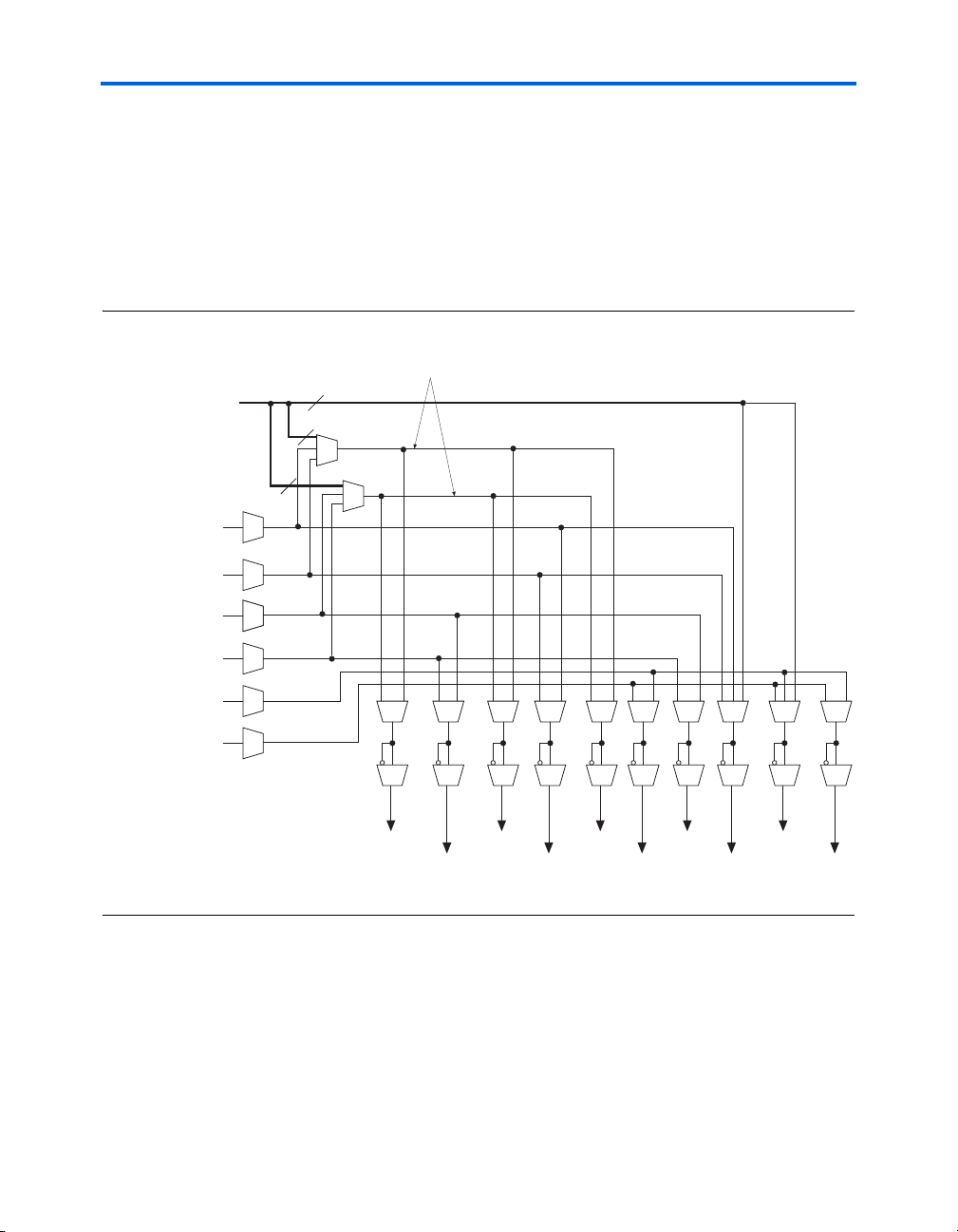

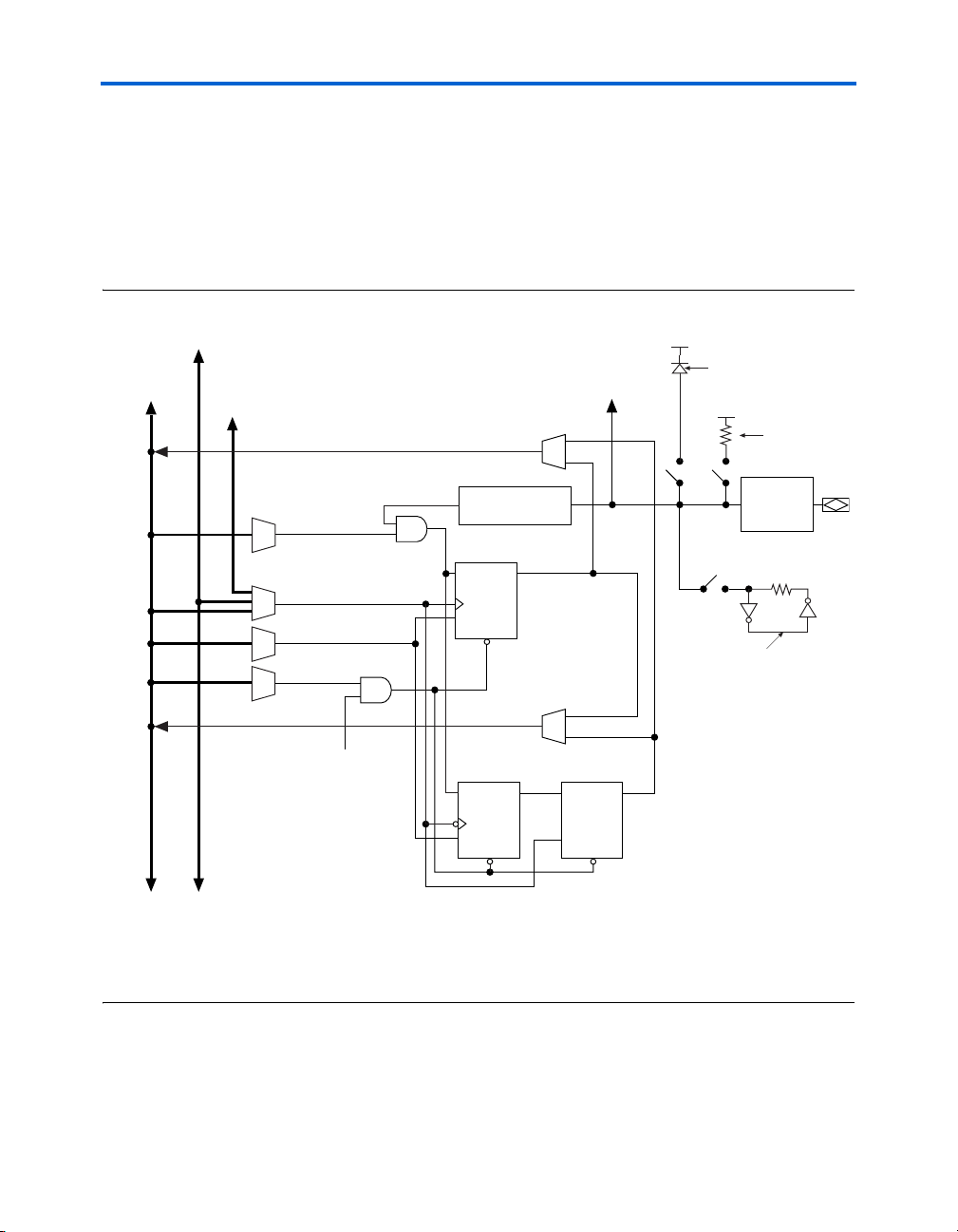

Figure 2–4 shows the LAB control signal generation circuit.

Figure 2–4. LAB-Wide Control Signals

Dedicated Row LAB Clocks

Local Interconnect

Local Interconnect

Local Interconnect

Local Interconnect

Local Interconnect

Local Interconnect

6

6

6

There are two unique

clock signals per LAB.

TM

interconnect's inherent low

labclr1

Adaptive Logic

Modules

labclk0

labclkena0

or asyncload

or labpreset

labclk1

labclkena1 labclkena2 labclr0 synclr

labclk2

syncload

The basic building block of logic in the Stratix II architecture, the adaptive

logic module (ALM), provides advanced features with efficient logic

utilization. Each ALM contains a variety of look-up table (LUT)-based

resources that can be divided between two adaptive LUTs (ALUTs). With

up to eight inputs to the two ALUTs, one ALM can implement various

combinations of two functions. This adaptability allows the ALM to be

2–6 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 7

completely backward-compatible with four-input LUT architectures. One

r

r

r

r

ALM can also implement any function of up to six inputs and certain

seven-input functions.

In addition to the adaptive LUT-based resources, each ALM contains two

programmable registers, two dedicated full adders, a carry chain, a

shared arithmetic chain, and a register chain. Through these dedicated

resources, the ALM can efficiently implement various arithmetic

functions and shift registers. Each ALM drives all types of interconnects:

local, row, column, carry chain, shared arithmetic chain, register chain,

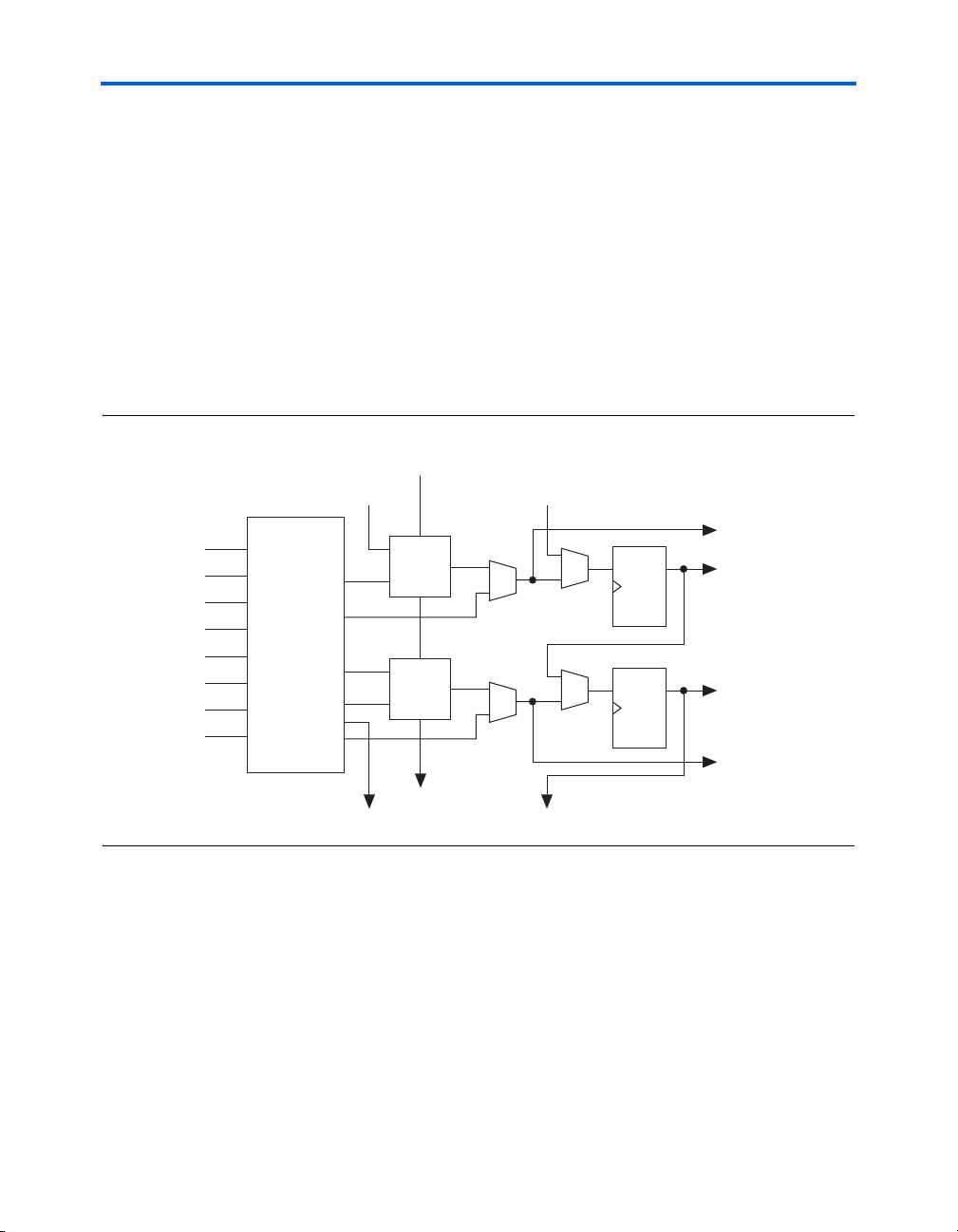

and direct link interconnects. Figure 2–5 shows a high-level block

diagram of the Stratix II ALM while Figure 2–6 shows a detailed view of

all the connections in the ALM.

Figure 2–5. High-Level Block Diagram of the Stratix II ALM

carry_in

shared_arith_in

dataf0

datae0

dataa

datab

datac

datad

datae1

dataf1

Combinational

Logic

shared_arith_out

adder0

adder1

carry_out

reg_chain_in

reg_chain_out

DQ

reg0

DQ

reg1

Stratix II Architecture

To general o

local routing

To general o

local routing

To general o

local routing

To general o

local routing

Altera Corporation 2–7

May 2007 Stratix II Device Handbook, Volume 1

Page 8

Adaptive Logic Modules

Figure 2–6. Stratix II ALM Details

Row, column &

Row, column &

direct link routing

Local

Interconnect

direct link routing

Row, column &

Row, column &

direct link routing

Local

Interconnect

direct link routing

sclr asyncload

syncload ena[2..0]

reg_chain_in

carry_in

shared_arith_in

4-Input

LUT

Q

D

ADATA

PRN/ALD

ENA

3-Input

CLRN

LUT

3-Input

LUT

4-Input

LUT

Q

D

ADATA

PRN/ALD

ENA

3-Input

CLRN

LUT

3-Input

LUT

reg_chain_out

CC

V

carry_out clk[2..0]

shared_arith_out aclr[1..0]

dataf0

Local

Interconnect

datae0

Local

Interconnect

datac

Local

Interconnect

dataa

Local

Interconnect

datab

Local

Interconnect

datad

Interconnect

Local

datae1

Local

Interconnect

dataf1

Local

Interconnect

2–8 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 9

Stratix II Architecture

One ALM contains two programmable registers. Each register has data,

clock, clock enable, synchronous and asynchronous clear, asynchronous

load data, and synchronous and asynchronous load/preset inputs.

Global signals, general-purpose I/O pins, or any internal logic can drive

the register's clock and clear control signals. Either general-purpose I/O

pins or internal logic can drive the clock enable, preset, asynchronous

load, and asynchronous load data. The asynchronous load data input

comes from the datae or dataf input of the ALM, which are the same

inputs that can be used for register packing. For combinational functions,

the register is bypassed and the output of the LUT drives directly to the

outputs of the ALM.

Each ALM has two sets of outputs that drive the local, row, and column

routing resources. The LUT, adder, or register output can drive these

output drivers independently (see Figure 2–6). For each set of output

drivers, two ALM outputs can drive column, row, or direct link routing

connections, and one of these ALM outputs can also drive local

interconnect resources. This allows the LUT or adder to drive one output

while the register drives another output. This feature, called register

packing, improves device utilization because the device can use the

register and the combinational logic for unrelated functions. Another

special packing mode allows the register output to feed back into the LUT

of the same ALM so that the register is packed with its own fan-out LUT.

This provides another mechanism for improved fitting. The ALM can also

drive out registered and unregistered versions of the LUT or adder

output.

f See the Performance & Logic Efficiency Analysis of Stratix II Devices White

Paper for more information on the efficiencies of the Stratix II ALM and

comparisons with previous architectures.

ALM Operating Modes

The Stratix II ALM can operate in one of the following modes:

■ Normal mode

■ Extended LUT mode

■ Arithmetic mode

■ Shared arithmetic mode

Each mode uses ALM resources differently. In each mode, eleven

available inputs to the ALM--the eight data inputs from the LAB local

interconnect; carry-in from the previous ALM or LAB; the shared

arithmetic chain connection from the previous ALM or LAB; and the

register chain connection--are directed to different destinations to

implement the desired logic function. LAB-wide signals provide clock,

asynchronous clear, asynchronous preset/load, synchronous clear,

Altera Corporation 2–9

May 2007 Stratix II Device Handbook, Volume 1

Page 10

Adaptive Logic Modules

synchronous load, and clock enable control for the register. These LABwide signals are available in all ALM modes. See the “LAB Control

Signals” section for more information on the LAB-wide control signals.

The Quartus II software and supported third-party synthesis tools, in

conjunction with parameterized functions such as library of

parameterized modules (LPM) functions, automatically choose the

appropriate mode for common functions such as counters, adders,

subtractors, and arithmetic functions. If required, you can also create

special-purpose functions that specify which ALM operating mode to use

for optimal performance.

Normal Mode

The normal mode is suitable for general logic applications and

combinational functions. In this mode, up to eight data inputs from the

LAB local interconnect are inputs to the combinational logic. The normal

mode allows two functions to be implemented in one Stratix II ALM, or

an ALM to implement a single function of up to six inputs. The ALM can

support certain combinations of completely independent functions and

various combinations of functions which have common inputs.

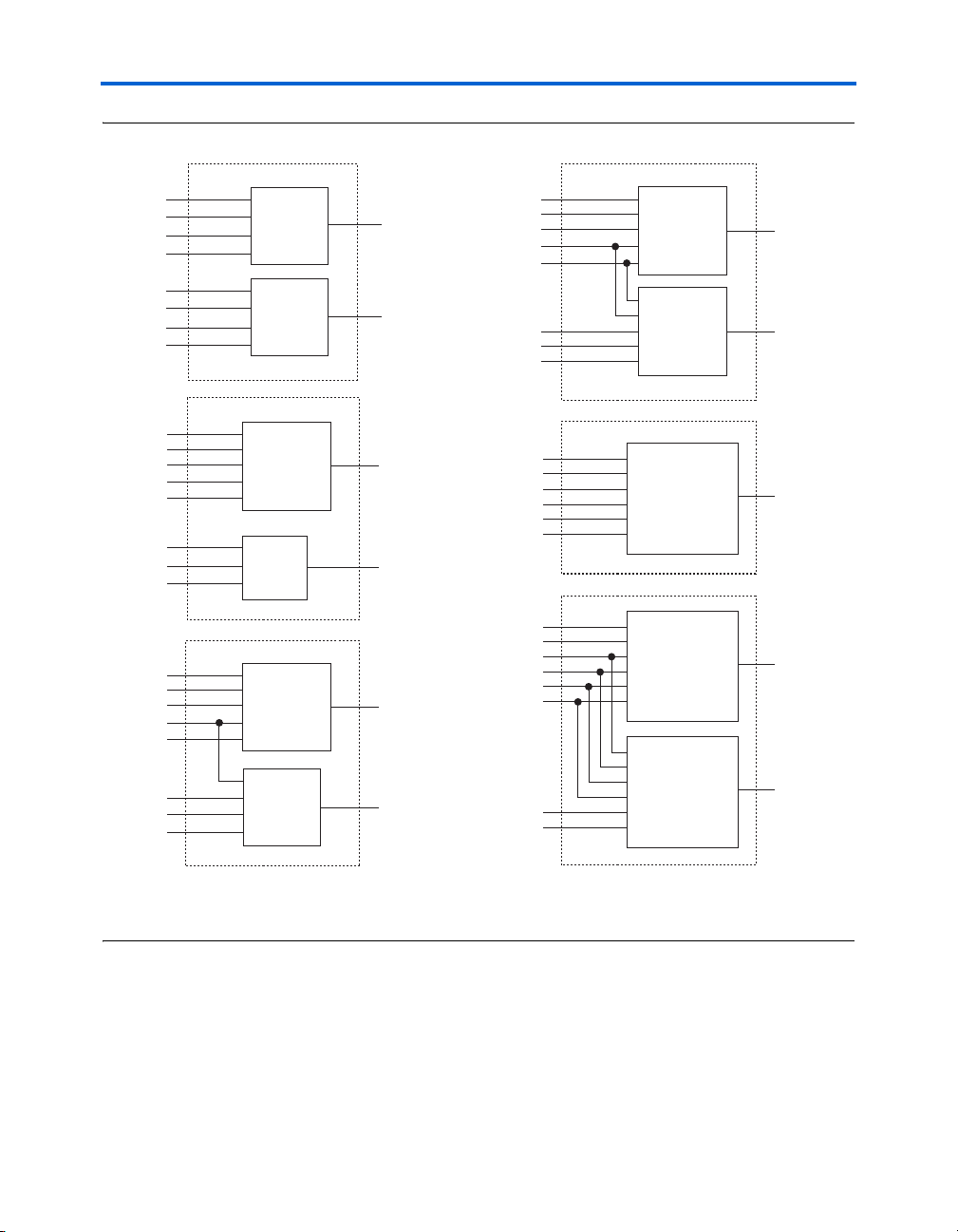

Figure 2–7 shows the supported LUT combinations in normal mode.

2–10 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 11

Figure 2–7. ALM in Normal Mode Note (1)

Stratix II Architecture

dataf0

datae0

datac

dataa

datab

datad

datae1

dataf1

dataf0

datae0

datac

dataa

datab

datad

datae1

dataf1

dataf0

datae0

datac

dataa

datab

4-Input

LUT

4-Input

LUT

5-Input

LUT

3-Input

LUT

5-Input

LUT

combout0

combout1

combout0

combout1

combout0

dataf0

datae0

datac

dataa

datab

datad

datae1

dataf1

dataf0

datae0

dataa

datab

datac

datad

dataf0

datae0

dataa

datab

datac

datad

5-Input

LUT

5-Input

LUT

6-Input

LUT

6-Input

LUT

combout0

combout1

combout0

combout0

datad

datae1

dataf1

4-Input

LUT

combout1

datae1

dataf1

6-Input

LUT

combout1

Note to Figure 2–7:

(1) Combinations of functions with fewer inputs than those shown are also supported. For example, combinations of

functions with the following number of inputs are supported: 4 and 3, 3 and 3, 3 and 2, 5 and 2, etc.

The normal mode provides complete backward compatibility with fourinput LUT architectures. Two independent functions of four inputs or less

can be implemented in one Stratix II ALM. In addition, a five-input

function and an independent three-input function can be implemented

without sharing inputs.

Altera Corporation 2–11

May 2007 Stratix II Device Handbook, Volume 1

Page 12

Adaptive Logic Modules

For the packing of two five-input functions into one ALM, the functions

must have at least two common inputs. The common inputs are dataa

and datab. The combination of a four-input function with a five-input

function requires one common input (either dataa or datab).

In the case of implementing two six-input functions in one ALM, four

inputs must be shared and the combinational function must be the same.

For example, a 4 × 2 crossbar switch (two 4-to-1 multiplexers with

common inputs and unique select lines) can be implemented in one ALM,

as shown in Figure 2–8. The shared inputs are dataa, datab, datac, and

datad, while the unique select lines are datae0 and dataf0 for

function0, and datae1 and dataf1 for function1. This crossbar

switch consumes four LUTs in a four-input LUT-based architecture.

Figure 2–8. 4 × 2 Crossbar Switch Example

4 × 2 Crossbar Switch Implementation in 1 ALM

sel0[1..0]

inputa

inputb

inputc

inputd

out0

out1

dataf0

datae0

dataa

datab

datac

datad

Six-Input

LUT

(Function0)

combout0

sel1[1..0]

datae1

dataf1

Six-Input

LUT

(Function1)

combout1

In a sparsely used device, functions that could be placed into one ALM

may be implemented in separate ALMs. The Quartus II Compiler spreads

a design out to achieve the best possible performance. As a device begins

to fill up, the Quartus II software automatically utilizes the full potential

of the Stratix II ALM. The Quartus II Compiler automatically searches for

functions of common inputs or completely independent functions to be

placed into one ALM and to make efficient use of the device resources. In

addition, you can manually control resource usage by setting location

assignments.

Any six-input function can be implemented utilizing inputs dataa,

datab, datac, datad, and either datae0 and dataf0 or datae1 and

dataf1. If datae0 and dataf0 are utilized, the output is driven to

register0, and/or register0 is bypassed and the data drives out to

the interconnect using the top set of output drivers (see Figure 2–9). If

2–12 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 13

Stratix II Architecture

datae1 and dataf1 are utilized, the output drives to register1

and/or bypasses register1 and drives to the interconnect using the

bottom set of output drivers. The Quartus II Compiler automatically

selects the inputs to the LUT. Asynchronous load data for the register

comes from the datae or dataf input of the ALM. ALMs in normal

mode support register packing.

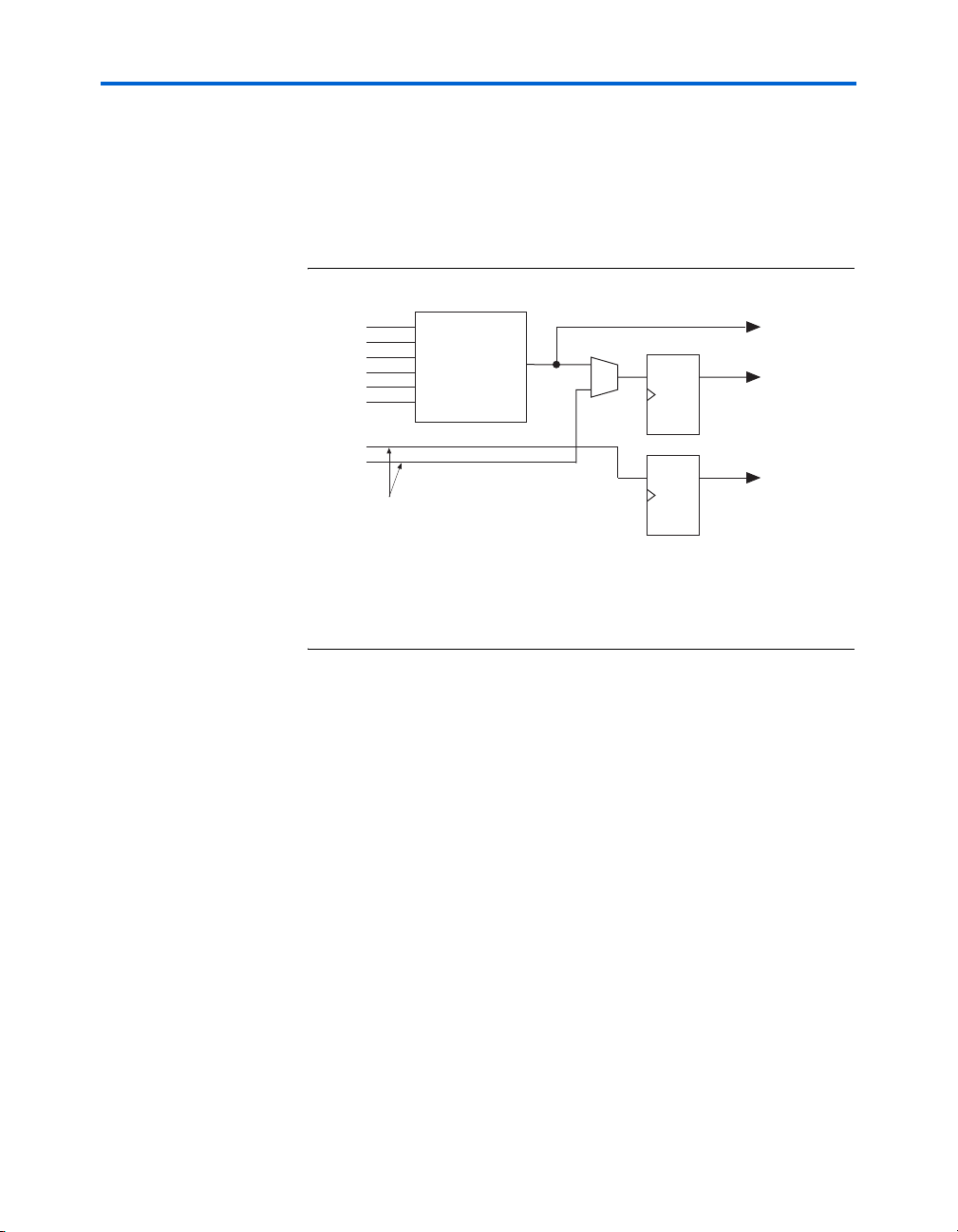

Figure 2–9. 6-Input Function in Normal Mode Notes (1), (2)

dataf0

datae0

dataa

datab

datac

datad

datae1

dataf1

(2)

These inputs are available for register packing.

6-Input

LUT

DQ

reg0

DQ

reg1

To general or

local routing

To general or

local routing

To general or

local routing

Notes to Figure 2–9:

(1) If datae1 and dataf1 are used as inputs to the six-input function, then datae0

and dataf0 are available for register packing.

(2) The dataf1 input is available for register packing only if the six-input function is

un-registered.

Extended LUT Mode

The extended LUT mode is used to implement a specific set of

seven-input functions. The set must be a 2-to-1 multiplexer fed by two

arbitrary five-input functions sharing four inputs. Figure 2–10 shows the

template of supported seven-input functions utilizing extended LUT

mode. In this mode, if the seven-input function is unregistered, the

unused eighth input is available for register packing.

Functions that fit into the template shown in Figure 2–10 occur naturally

in designs. These functions often appear in designs as “if-else” statements

in Verilog HDL or VHDL code.

Altera Corporation 2–13

May 2007 Stratix II Device Handbook, Volume 1

Page 14

Adaptive Logic Modules

r

r

Figure 2–10. Template for Supported Seven-Input Functions in Extended LUT Mode

datae0

datac

dataa

datab

datad

dataf0

datae1

dataf1

(1)

5-Input

LUT

5-Input

LUT

This input is available

for register packing.

combout0

DQ

reg0

To general o

local routing

To general o

local routing

Note to Figure 2–10:

(1) If the seven-input function is unregistered, the unused eighth input is available for register packing. The second

register, reg1, is not available.

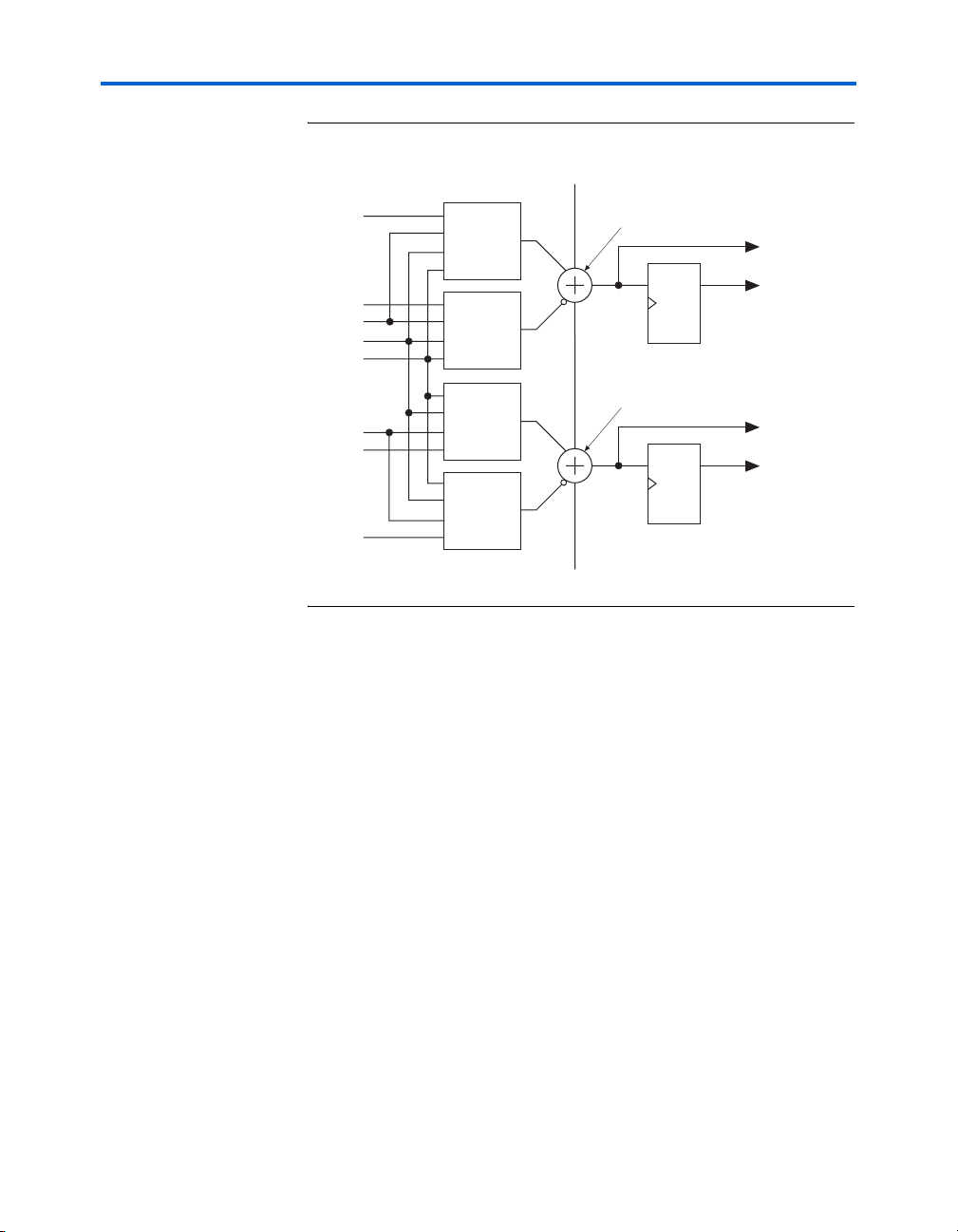

Arithmetic Mode

The arithmetic mode is ideal for implementing adders, counters,

accumulators, wide parity functions, and comparators. An ALM in

arithmetic mode uses two sets of two four-input LUTs along with two

dedicated full adders. The dedicated adders allow the LUTs to be

available to perform pre-adder logic; therefore, each adder can add the

output of two four-input functions. The four LUTs share the dataa and

datab inputs. As shown in Figure 2–11, the carry-in signal feeds to

adder0, and the carry-out from adder0 feeds to carry-in of adder1. The

carry-out from adder1 drives to adder0 of the next ALM in the LAB.

ALMs in arithmetic mode can drive out registered and/or unregistered

versions of the adder outputs.

2–14 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 15

Figure 2–11. ALM in Arithmetic Mode

r

carry_in

Stratix II Architecture

datae0

dataf0

datac

datab

dataa

datad

datae1

dataf1

4-Input

LUT

4-Input

LUT

4-Input

LUT

4-Input

LUT

carry_out

adder0

adder1

DQ

reg0

DQ

reg1

To general or

local routing

To general or

local routing

To general or

local routing

To general o

local routing

While operating in arithmetic mode, the ALM can support simultaneous

use of the adder's carry output along with combinational logic outputs. In

this operation, the adder output is ignored. This usage of the adder with

the combinational logic output provides resource savings of up to 50% for

functions that can use this ability. An example of such functionality is a

conditional operation, such as the one shown in Figure 2–12. The

equation for this example is:

R = (X < Y) ? Y : X

To implement this function, the adder is used to subtract ‘Y’ from ‘X.’ If

‘X’ is less than ‘Y,’ the carry_out signal is ‘1.’ The carry_out signal is

fed to an adder where it drives out to the LAB local interconnect. It then

feeds to the LAB-wide syncload signal. When asserted, syncload

selects the syncdata input. In this case, the data ‘Y’ drives the

syncdata inputs to the registers. If ‘X’ is greater than or equal to ‘Y,’ the

syncload signal is de-asserted and ‘X’ drives the data port of the

registers.

Altera Corporation 2–15

May 2007 Stratix II Device Handbook, Volume 1

Page 16

Adaptive Logic Modules

Figure 2–12. Conditional Operation Example

Adder output

is not used.

ALM 1

X[0]

Y[0]

syncdata

X[1]

Y[1]

Carry Chain

X[2]

Y[2]

ALM 2

Comb &

Adder

Logic

Comb &

Adder

Logic

Comb &

Adder

Logic

Comb &

Adder

Logic

X[0]

X[1]

X[2]

syncload

syncload

syncload

DQ

reg0

DQ

reg1

DQ

reg0

carry_out

R[0]

R[1]

R[2]

To general or

local routing

To general or

local routing

To general or

local routing

To local routing &

then to LAB-wide

syncload

The arithmetic mode also offers clock enable, counter enable,

synchronous up/down control, add/subtract control, synchronous clear,

synchronous load. The LAB local interconnect data inputs generate the

clock enable, counter enable, synchronous up/down and add/subtract

control signals. These control signals are good candidates for the inputs

that are shared between the four LUTs in the ALM. The synchronous clear

and synchronous load options are LAB-wide signals that affect all

registers in the LAB. The Quartus II software automatically places any

registers that are not used by the counter into other LABs.

Carry Chain

The carry chain provides a fast carry function between the dedicated

adders in arithmetic or shared arithmetic mode. Carry chains can begin in

either the first ALM or the fifth ALM in an LAB. The final carry-out signal

is routed t o an ALM , wh ere it i s fe d to loc al, row, or col umn int erc onn ect s.

2–16 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 17

Stratix II Architecture

The Quartus II Compiler automatically creates carry chain logic during

design processing, or you can create it manually during design entry.

Parameterized functions such as LPM functions automatically take

advantage of carry chains for the appropriate functions.

The Quartus II Compiler creates carry chains longer than 16 (8 ALMs in

arithmetic or shared arithmetic mode) by linking LABs together

automatically. For enhanced fitting, a long carry chain runs vertically

allowing fast horizontal connections to TriMatrix memory and DSP

blocks. A carry chain can continue as far as a full column.

To avoid routing congestion in one small area of the device when a high

fan-in arithmetic function is implemented, the LAB can support carry

chains that only utilize either the top half or the bottom half of the LAB

before connecting to the next LAB. This leaves the other half of the ALMs

in the LAB available for implementing narrower fan-in functions in

normal mode. Carry chains that use the top four ALMs in the first LAB

carry into the top half of the ALMs in the next LAB within the column.

Carry chains that use the bottom four ALMs in the first LAB carry into the

bottom half of the ALMs in the next LAB within the column. Every other

column of LABs is top-half bypassable, while the other LAB columns are

bottom-half bypassable.

See the “MultiTrack Interconnect” on page 2–22 section for more

information on carry chain interconnect.

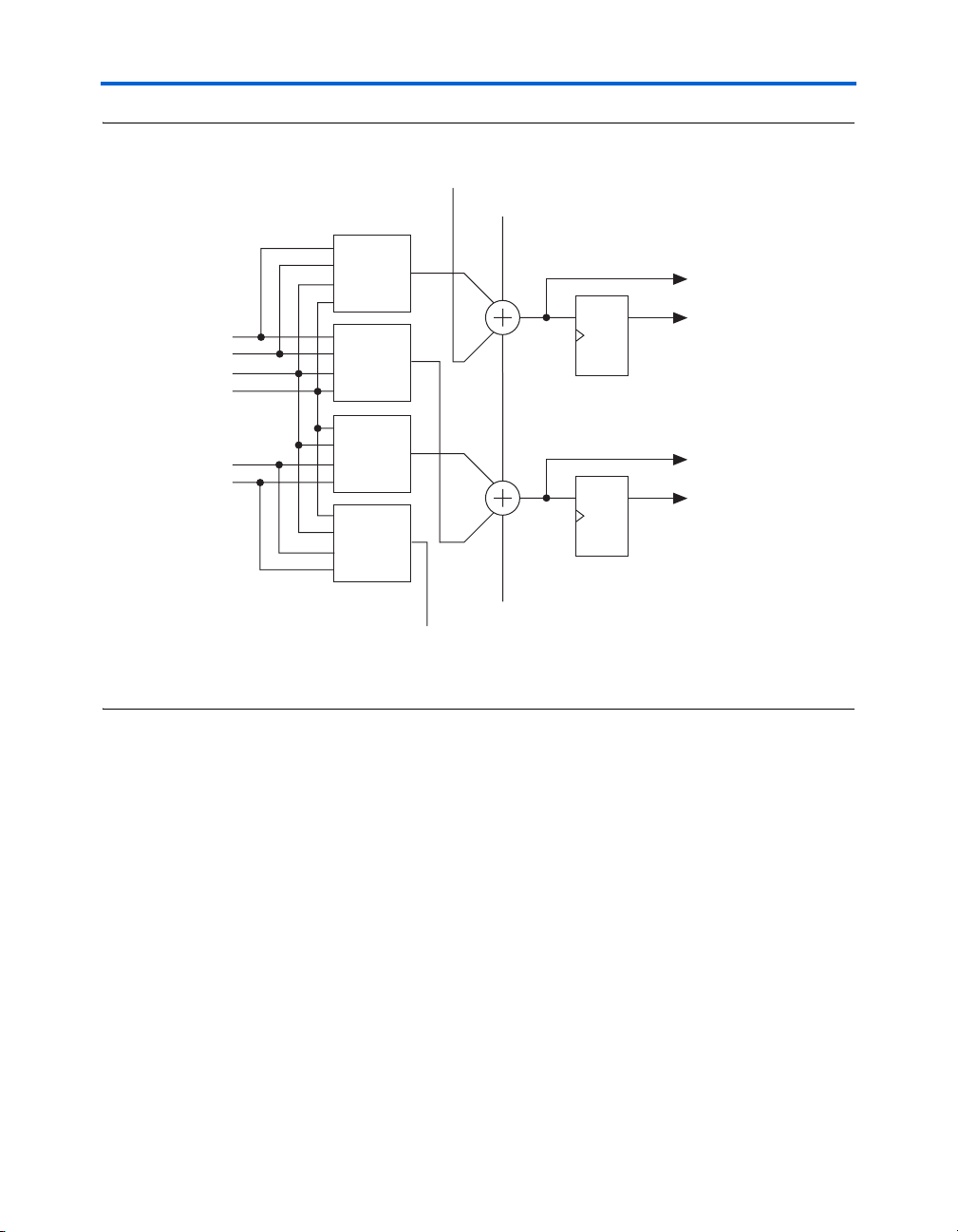

Shared Arithmetic Mode

In shared arithmetic mode, the ALM can implement a three-input add. In

this mode, the ALM is configured with four 4-input LUTs. Each LUT

either computes the sum of three inputs or the carry of three inputs. The

output of the carry computation is fed to the next adder (either to adder1

in the same ALM or to adder0 of the next ALM in the LAB) via a

dedicated connection called the shared arithmetic chain. This shared

arithmetic chain can significantly improve the performance of an adder

tree by reducing the number of summation stages required to implement

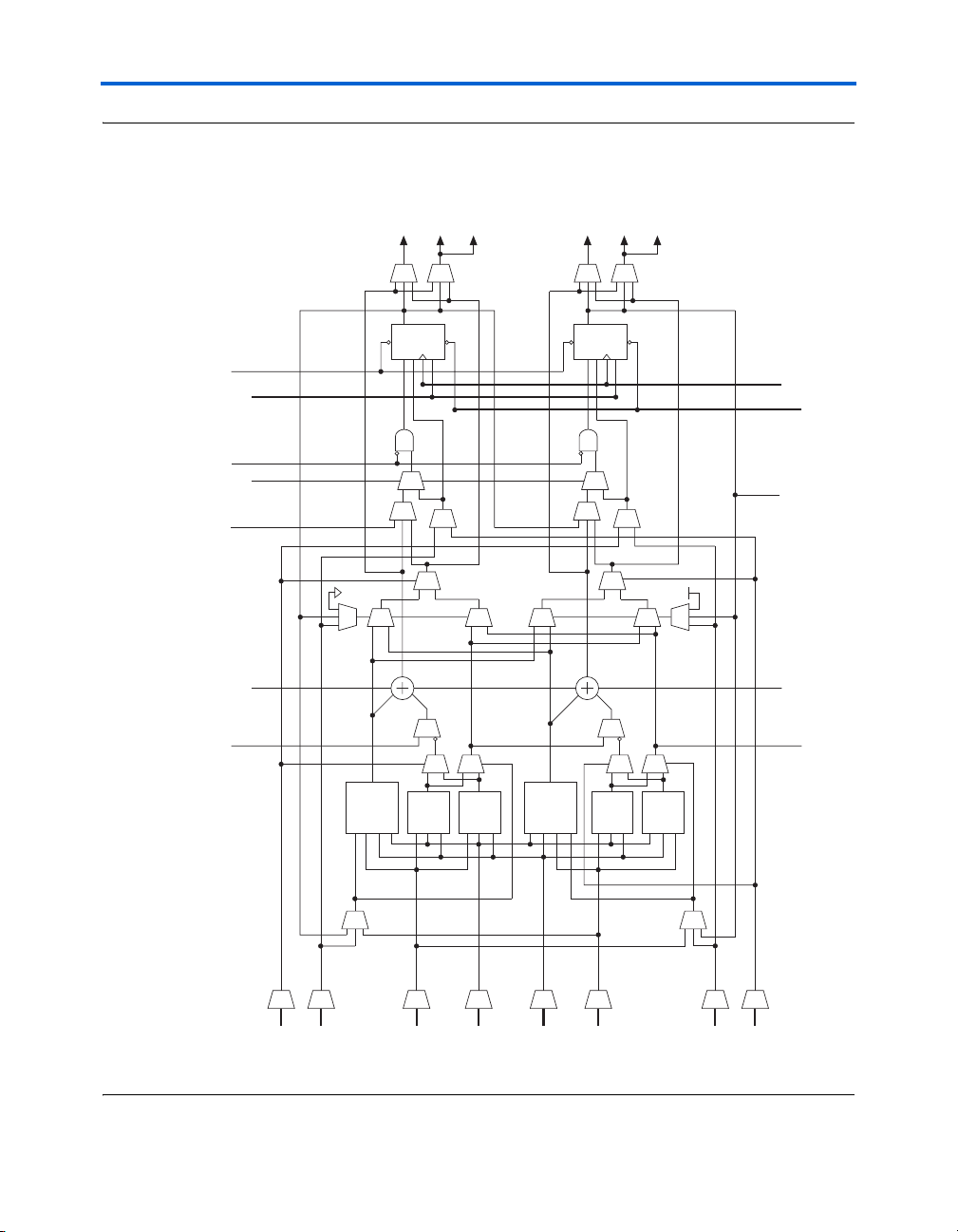

an adder tree. Figure 2–13 shows the ALM in shared arithmetic mode.

Altera Corporation 2–17

May 2007 Stratix II Device Handbook, Volume 1

Page 18

Adaptive Logic Modules

Figure 2–13. ALM in Shared Arithmetic Mode

shared_arith_in

carry_in

4-Input

LUT

DQ

datae0

datac

datab

dataa

datad

datae1

4-Input

LUT

4-Input

LUT

4-Input

LUT

carry_out

shared_arith_out

reg0

DQ

reg1

Note to Figure 2–13:

(1) Inputs dataf0 and dataf1 are available for register packing in shared arithmetic mode.

Adder trees can be found in many different applications. For example, the

summation of the partial products in a logic-based multiplier can be

implemented in a tree structure. Another example is a correlator function

that can use a large adder tree to sum filtered data samples in a given time

frame to recover or to de-spread data which was transmitted utilizing

spread spectrum technology.

To general or

local routing

To general or

local routing

To general or

local routing

To general or

local routing

An example of a three-bit add operation utilizing the shared arithmetic

mode is shown in Figure 2–14. The partial sum (S[2..0]) and the

partial carry (C[2..0]) is obtained using the LUTs, while the result

(R[2..0]) is computed using the dedicated adders.

2–18 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 19

Figure 2–14. Example of a 3-bit Add Utilizing Shared Arithmetic Mode

3-Bit Add Example ALM Implementation

ALM 1

1st stage add is

implemented in LUTs.

2nd stage add is

implemented in adders.

X2 X1 X0

Y2 Y1 Y0

Z2 Z1 Z0

+

S2 S1 S0

+

C2 C1 C0

R3 R2 R1 R0

X0

Y0

Z0

3-Input

LUT

3-Input

LUT

Stratix II Architecture

shared_arith_in = '0'

carry_in = '0'

S0

R0

C0

Binary Add

+

+

1 1 0

1 1 0 1

1 1 0

1 0 1

0 1 0

0 0 1

Decimal

Equivalents

6

5

2

+

1

+

2 x 6

13

X1

Y1

Z1

X2

Y2

Z2

3-Input

3-Input

ALM 2

3-Input

3-Input

3-Input

3-Input

S1

LUT

R1

C1

LUT

S2

LUT

R2

C2

LUT

'0'

LUT

R3

LUT

Shared Arithmetic Chain

In addition to the dedicated carry chain routing, the shared arithmetic

chain available in shared arithmetic mode allows the ALM to implement

a three-input add. This significantly reduces the resources necessary to

implement large adder trees or correlator functions.

The shared arithmetic chains can begin in either the first or fifth ALM in

an LAB. The Quartus II Compiler creates shared arithmetic chains longer

than 16 (8 ALMs in arithmetic or shared arithmetic mode) by linking

LABs together automatically. For enhanced fitting, a long shared

Altera Corporation 2–19

May 2007 Stratix II Device Handbook, Volume 1

Page 20

Adaptive Logic Modules

arithmetic chain runs vertically allowing fast horizontal connections to

TriMatrix memory and DSP blocks. A shared arithmetic chain can

continue as far as a full column.

Similar to the carry chains, the shared arithmetic chains are also top- or

bottom-half bypassable. This capability allows the shared arithmetic

chain to cascade through half of the ALMs in a LAB while leaving the

other half available for narrower fan-in functionality. Every other LAB

column is top-half bypassable, while the other LAB columns are bottomhalf bypassable.

See the “MultiTrack Interconnect” on page 2–22 section for more

information on shared arithmetic chain interconnect.

Register Chain

In addition to the general routing outputs, the ALMs in an LAB have

register chain outputs. The register chain routing allows registers in the

same LAB to be cascaded together. The register chain interconnect allows

an LAB to use LUTs for a single combinational function and the registers

to be used for an unrelated shift register implementation. These resources

speed up connections between ALMs while saving local interconnect

resources (see Figure 2–15). The Quartus II Compiler automatically takes

advantage of these resources to improve utilization and performance.

2–20 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 21

Figure 2–15. Register Chain within an LAB Note (1)

adder0

Combinational

Logic

reg_chain_in

From Previous ALM

Within The LAB

DQ

reg0

Stratix II Architecture

To general or

local routing

To general or

local routing

To general or

local routing

To general or

local routing

To general or

local routing

To general or

local routing

To general or

local routing

To general or

local routing

Combinational

Logic

adder1

adder0

adder1

DQ

reg1

DQ

reg0

DQ

reg1

reg_chain_out

To Next ALM

within the LAB

Note to Figure 2–15:

(1) The combinational or adder logic can be utilized to implement an unrelated, un-registered function.

See the “MultiTrack Interconnect” on page 2–22 section for more

information on register chain interconnect.

Altera Corporation 2–21

May 2007 Stratix II Device Handbook, Volume 1

Page 22

MultiTrack Interconnect

Clear & Preset Logic Control

LAB-wide signals control the logic for the register's clear and load/preset

signals. The ALM directly supports an asynchronous clear and preset

function. The register preset is achieved through the asynchronous load

of a logic high. The direct asynchronous preset does not require a NOTgate push-back technique. Stratix II devices support simultaneous

asynchronous load/preset, and clear signals. An asynchronous clear

signal takes precedence if both signals are asserted simultaneously. Each

LAB supports up to two clears and one load/preset signal.

In addition to the clear and load/preset ports, Stratix II devices provide a

device-wide reset pin (DEV_CLRn) that resets all registers in the device.

An option set before compilation in the Quartus II software controls this

pin. This device-wide reset overrides all other control signals.

MultiTrack

Interconnect

In the Stratix II architecture, connections between ALMs, TriMatrix

memory, DSP blocks, and device I/O pins are provided by the MultiTrack

interconnect structure with DirectDrive

interconnect consists of continuous, performance-optimized routing lines

of different lengths and speeds used for inter- and intra-design block

connectivity. The Quartus II Compiler automatically places critical design

paths on faster interconnects to improve design performance.

DirectDrive technology is a deterministic routing technology that ensures

identical routing resource usage for any function regardless of placement

in the device. The MultiTrack interconnect and DirectDrive technology

simplify the integration stage of block-based designing by eliminating the

re-optimization cycles that typically follow design changes and

additions.

The MultiTrack interconnect consists of row and column interconnects

that span fixed distances. A routing structure with fixed length resources

for all devices allows predictable and repeatable performance when

migrating through different device densities. Dedicated row

interconnects route signals to and from LABs, DSP blocks, and TriMatrix

memory in the same row. These row resources include:

■ Direct link interconnects between LABs and adjacent blocks

■ R4 interconnects traversing four blocks to the right or left

■ R24 row interconnects for high-speed access across the length of the

device

TM

technology. The MultiTrack

2–22 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 23

Stratix II Architecture

The direct link interconnect allows an LAB, DSP block, or TriMatrix

memory block to drive into the local interconnect of its left and right

neighbors and then back into itself. This provides fast communication

between adjacent LABs and/or blocks without using row interconnect

resources.

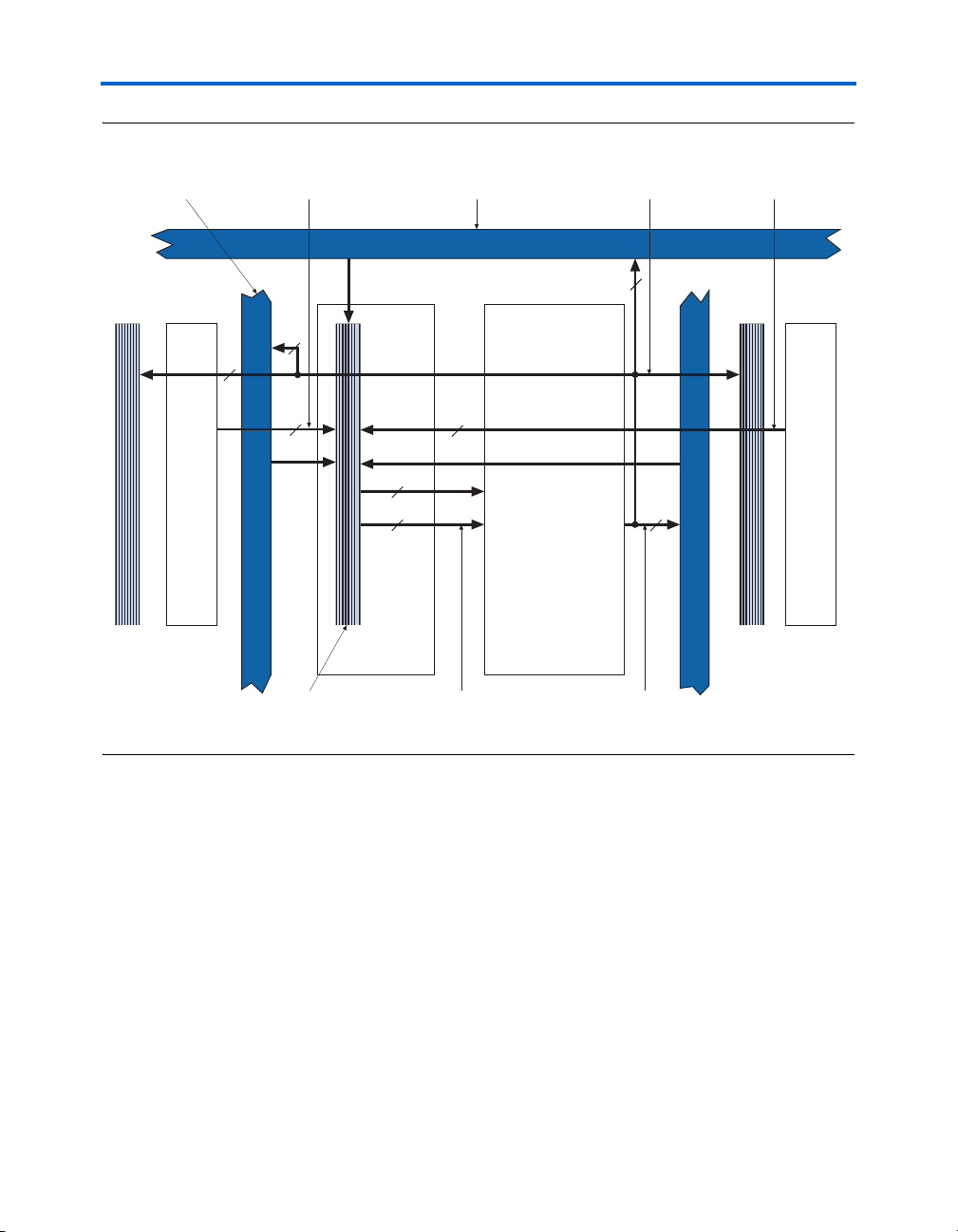

The R4 interconnects span four LABs, three LABs and one M512 RAM

block, two LABs and one M4K RAM block, or two LABs and one DSP

block to the right or left of a source LAB. These resources are used for fast

row connections in a four-LAB region. Every LAB has its own set of R4

interconnects to drive either left or right. Figure 2–16 shows R4

interconnect connections from an LAB. R4 interconnects can drive and be

driven by DSP blocks and RAM blocks and row IOEs. For LAB

interfacing, a primary LAB or LAB neighbor can drive a given R4

interconnect. For R4 interconnects that drive to the right, the primary

LAB and right neighbor can drive on to the interconnect. For R4

interconnects that drive to the left, the primary LAB and its left neighbor

can drive on to the interconnect. R4 interconnects can drive other R4

interconnects to extend the range of LABs they can drive. R4

interconnects can also drive C4 and C16 interconnects for connections

from one row to another. Additionally, R4 interconnects can drive R24

interconnects.

Figure 2–16. R4 Interconnect Connections Notes (1), (2), (3)

Adjacent LAB can

Drive onto Another

LAB's R4 Interconnect

R4 Interconnect

Driving Left

LAB

Neighbor

Primary

LAB (2)

Notes to Figure 2–16:

(1) C4 and C16 interconnects can drive R4 interconnects.

(2) This pattern is repeated for every LAB in the LAB row.

(3) The LABs in Figure 2–16 show the 16 possible logical outputs per LAB.

Altera Corporation 2–23

May 2007 Stratix II Device Handbook, Volume 1

C4 and C16

Column Interconnects (1)

LAB

Neighbor

R4 Interconnect

Driving Right

Page 24

MultiTrack Interconnect

R24 row interconnects span 24 LABs and provide the fastest resource for

long row connections between LABs, TriMatrix memory, DSP blocks, and

Row IOEs. The R24 row interconnects can cross M-RAM blocks. R24 row

interconnects drive to other row or column interconnects at every fourth

LAB and do not drive directly to LAB local interconnects. R24 row

interconnects drive LAB local interconnects via R4 and C4 interconnects.

R24 interconnects can drive R24, R4, C16, and C4 interconnects.

The column interconnect operates similarly to the row interconnect and

vertically routes signals to and from LABs, TriMatrix memory, DSP

blocks, and IOEs. Each column of LABs is served by a dedicated column

interconnect. These column resources include:

■ Shared arithmetic chain interconnects in an LAB

■ Carry chain interconnects in an LAB and from LAB to LAB

■ Register chain interconnects in an LAB

■ C4 interconnects traversing a distance of four block s in up and down

direction

■ C16 column interconnects for high-speed vertical routing through

the device

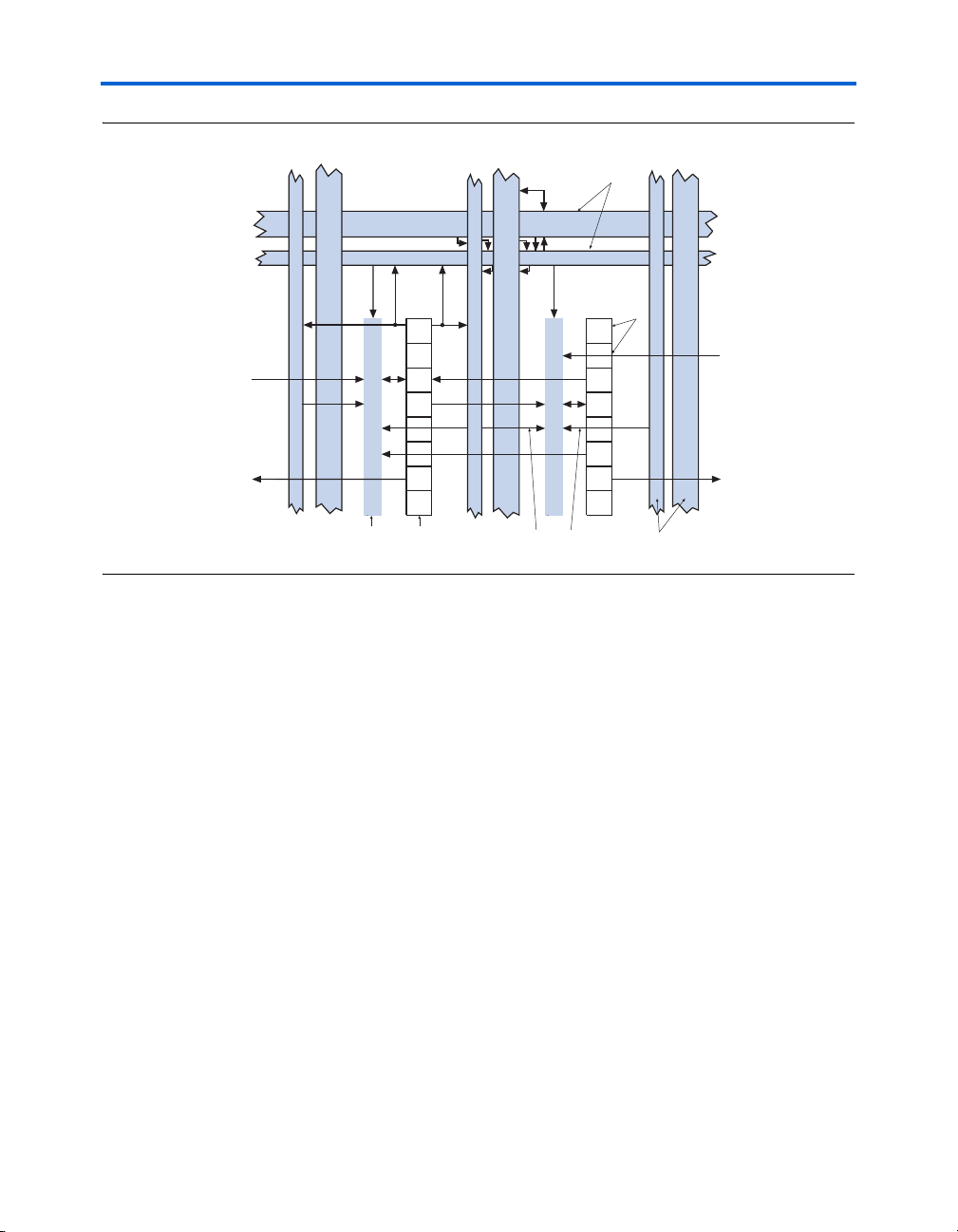

Stratix II devices include an enhanced interconnect structure in LABs for

routing shared arithmetic chains and carry chains for efficient arithmetic

functions. The register chain connection allows the register output of one

ALM to connect directly to the register input of the next ALM in the LAB

for fast shift registers. These ALM to ALM connections bypass the local

interconnect. The Quartus II Compiler automatically takes advantage of

these resources to improve utilization and performance. Figure 2–17

shows the shared arithmetic chain, carry chain and register chain

interconnects.

2–24 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 25

Stratix II Architecture

u

Figure 2–17. Shared Arithmetic Chain, Carry Chain & Register Chain

Interconnects

Local Interconnect

Routing Among ALMs

in the LAB

Carry Chain & Shared

Arithmetic Chain

outing to Adjacent ALM

Local

Interconnect

ALM 1

ALM 2

ALM 3

ALM 4

ALM 5

ALM 6

ALM 7

ALM 8

Register Chain

Routing to Adjacent

ALM's Register Inp

The C4 interconnects span four LABs, M512, or M4K blocks up or down

from a source LAB. Every LAB has its own set of C4 interconnects to drive

either up or down. Figure 2–18 shows the C4 interconnect connections

from an LAB in a column. The C4 interconnects can drive and be driven

by all types of architecture blocks, including DSP blocks, TriMatrix

memory blocks, and column and row IOEs. For LAB interconnection, a

primary LAB or its LAB neighbor can drive a given C4 interconnect. C4

interconnects can drive each other to extend their range as well as drive

row interconnects for column-to-column connections.

Altera Corporation 2–25

May 2007 Stratix II Device Handbook, Volume 1

Page 26

MultiTrack Interconnect

4

Figure 2–18. C4 Interconnect Connections Note (1)

C4 Interconnect

Drives Local and R

Interconnects

up to Four Rows

C4 Interconnect

Driving Up

LAB

Row

Interconnect

Adjacent LAB can

drive onto neighboring

LAB's C4 interconnect

Local

Interconnect

C4 Interconnect

Driving Down

Note to Figure 2–18:

(1) Each C4 interconnect can drive either up or down four rows.

2–26 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 27

C16 column interconnects span a length of 16 LABs and provide the

fastest resource for long column connections between LABs, TriMatrix

memory blocks, DSP blocks, and IOEs. C16 interconnects can cross

M-RAM blocks and also drive to row and column interconnects at every

fourth LAB. C16 interconnects drive LAB local interconnects via C4 and

R4 interconnects and do not drive LAB local interconnects directly.

All embedded blocks communicate with the logic array similar to LABto-LAB interfaces. Each block (that is, TriMatrix memory and DSP blocks)

connects to row and column interconnects and has local interconnect

regions driven by row and column interconnects. These blocks also have

direct link interconnects for fast connections to and from a neighboring

LAB. All blocks are fed by the row LAB clocks, labclk[5..0].

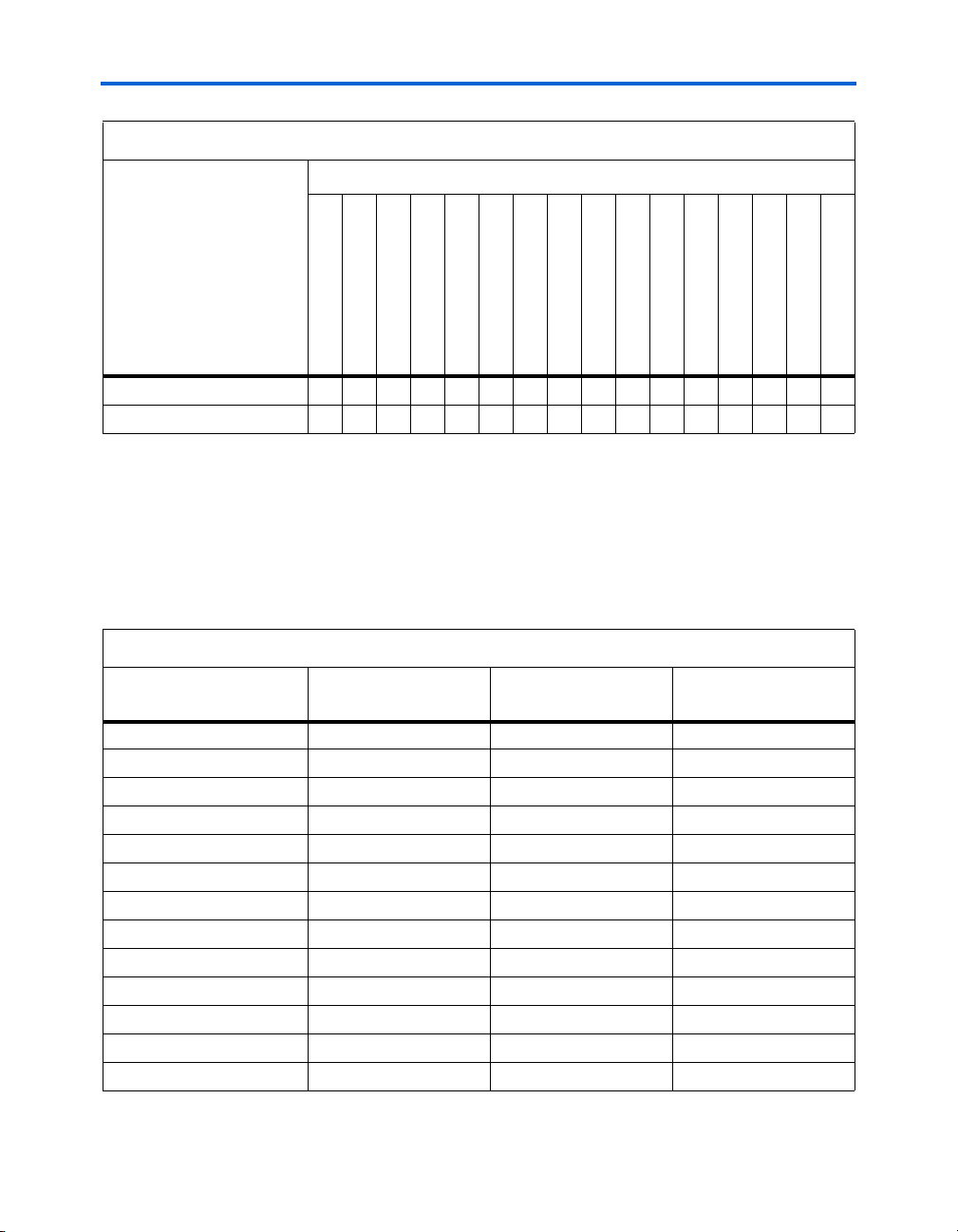

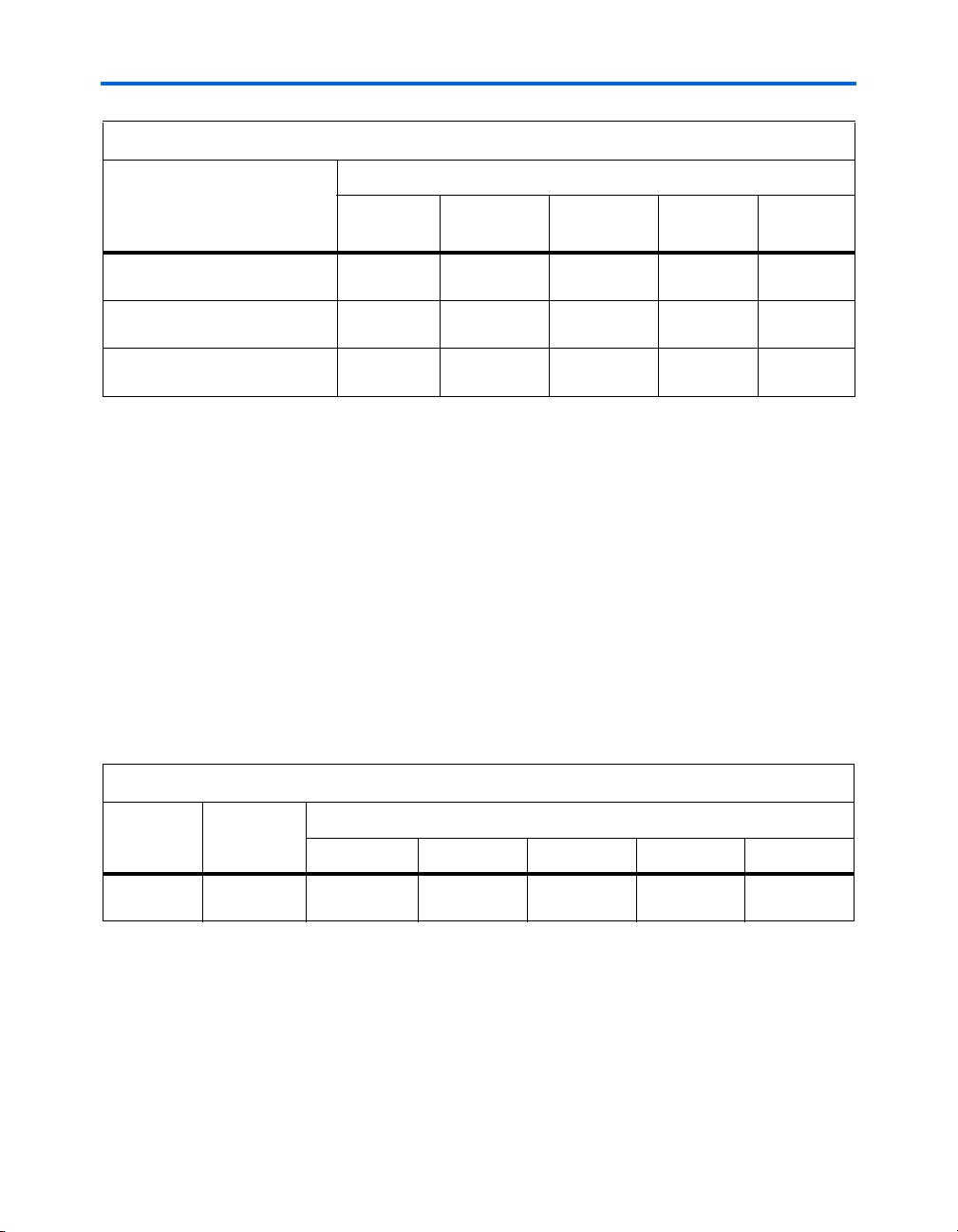

Table 2–2 shows the Stratix II device’s routing scheme.

Table 2–2. Stratix II Device Routing Scheme (Part 1 of 2)

Source

Carry Chain

Register Chain

Local Interconnect

Direct Link Interconnect

v

v vvvv

vvvv

vvv

vvvv

vvv v

vvv v

vvvv

vv v

Shared arithmetic chain

Carry chain

Register chain

Local interconnect

Direct link interconnect

R4 interconnect

R24 interconnect

C4 interconnect

C16 interconnect

ALM

M512 RAM block

M4K RAM block

M-RAM block

DSP blocks

Shared Arithmetic Chain

vvvvvv v

Destination

R24 Interconnect

C4 Interconnect

R4 Interconnect

Stratix II Architecture

ALM

C16 Interconnect

M4K RAM Block

M512 RAM Block

DSP Blocks

M-RAM Block

v

v

v

vvvvvvv

Column IOE

Row IOE

Altera Corporation 2–27

May 2007 Stratix II Device Handbook, Volume 1

Page 28

Tri M a t r ix Memor y

Table 2–2. Stratix II Device Routing Scheme (Part 2 of 2)

Source

Carry Chain

Register Chain

Local Interconnect

Shared Arithmetic Chain

Column IOE

Row IOE

Direct Link Interconnect

vvv

vvvv

R4 Interconnect

Destination

C4 Interconnect

R24 Interconnect

ALM

C16 Interconnect

M512 RAM Block

DSP Blocks

M-RAM Block

M4K RAM Block

Row IOE

Column IOE

TriMatrix

Memory

TriMatrix memory consists of three types of RAM blocks: M512, M4K,

and M-RAM. Although these memory blocks are different, they can all

implement various types of memory with or without parity, including

true dual-port, simple dual-port, and single-port RAM, ROM, and FIFO

buffers. Table 2–3 shows the size and features of the different RAM

blocks.

Table 2–3. TriMatrix Memory Features (Part 1 of 2)

Memory Feature

Maximum performance 500 MHz 550 MHz 420 MHz

True dual-port memory

Simple dual-port memory

Single-port memory

Shift register

ROM

FIFO buffer

Pack mode

Byte enable

Address clock enable

Parity bits

Mixed clock mode

Memory initialization (.mif)

M512 RAM Block

(32 × 18 Bits)

vvv

vvv

vv

vv

vvv

vvv

vvv

vvv

vv

M4K RAM Block

(128 × 36 Bits)

M-RAM Block

(4K × 144 Bits)

vv

(1)

vv

vv

2–28 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 29

Table 2–3. TriMatrix Memory Features (Part 2 of 2)

Stratix II Architecture

Memory Feature

Simple dual-port memory

mixed width support

True dual-port memory

mixed width support

Power-up conditions Outputs cleared Outputs cleared Outputs unknown

Register clears Output registers Output registers Output registers

Mixed-port read-during-write Unknown output/old data Unknown output/old data Unknown output

Configurations 512 × 1

Notes to Ta b l e 2– 3 :

(1) The M-RAM block does not support memory initializations. However, the M-RAM block can emulate a ROM

function using a dual-port RAM bock. The Stratix II device must write to the dual-port memory once and then

disable the write-enable ports afterwards.

M512 RAM Block

(32 × 18 Bits)

vvv

256 × 2

128 × 4

64 × 8

64 × 9

32 × 16

32 × 18

M4K RAM Block

(128 × 36 Bits)

4K × 1

2K × 2

1K × 4

512 × 8

512 × 9

256 × 16

256 × 18

128 × 32

128 × 36

M-RAM Block

(4K × 144 Bits)

vv

64K × 8

64K × 9

32K × 16

32K × 18

16K × 32

16K × 36

8K × 64

8K × 72

4K × 128

4K × 144

Memory Block Size

TriMatrix memory provides three different memory sizes for efficient

application support. The Quartus II software automatically partitions the

user-defined memory into the embedded memory blocks using the most

efficient size combinations. You can also manually assign the memory to

a specific block size or a mixture of block sizes.

When applied to input registers, the asynchronous clear signal for the

TriMatrix embedded memory immediately clears the input registers.

However, the output of the memory block does not show the effects until

the next clock edge. When applied to output registers, the asynchronous

clear signal clears the output registers and the effects are seen

immediately.

Altera Corporation 2–29

May 2007 Stratix II Device Handbook, Volume 1

Page 30

Tri M a t r ix Memor y

M512 RAM Block

The M512 RAM block is a simple dual-port memory block and is useful

for implementing small FIFO buffers, DSP, and clock domain transfer

applications. Each block contains 576 RAM bits (including parity bits).

M512 RAM blocks can be configured in the following modes:

■ Simple dual-port RAM

■ Single-port RAM

■ FIFO

■ ROM

■ Shift register

1 Violating the setup or hold time on the memory block address

registers could corrupt memory contents. This applies to both

read and write operations.

When configured as RAM or ROM, you can use an initialization file to

pre-load the memory contents.

M512 RAM blocks can have different clocks on its inputs and outputs.

The wren, datain, and write address registers are all clocked together

from one of the two clocks feeding the block. The read address, rden, and

output registers can be clocked by either of the two clocks driving the

block. This allows the RAM block to operate in read/write or

input/output clock modes. Only the output register can be bypassed. The

six labclk signals or local interconnect can drive the inclock,

outclock, wren, rden, and outclr signals. Because of the advanced

interconnect between the LAB and M512 RAM blocks, ALMs can also

control the wren and rden signals and the RAM clock, clock enable, and

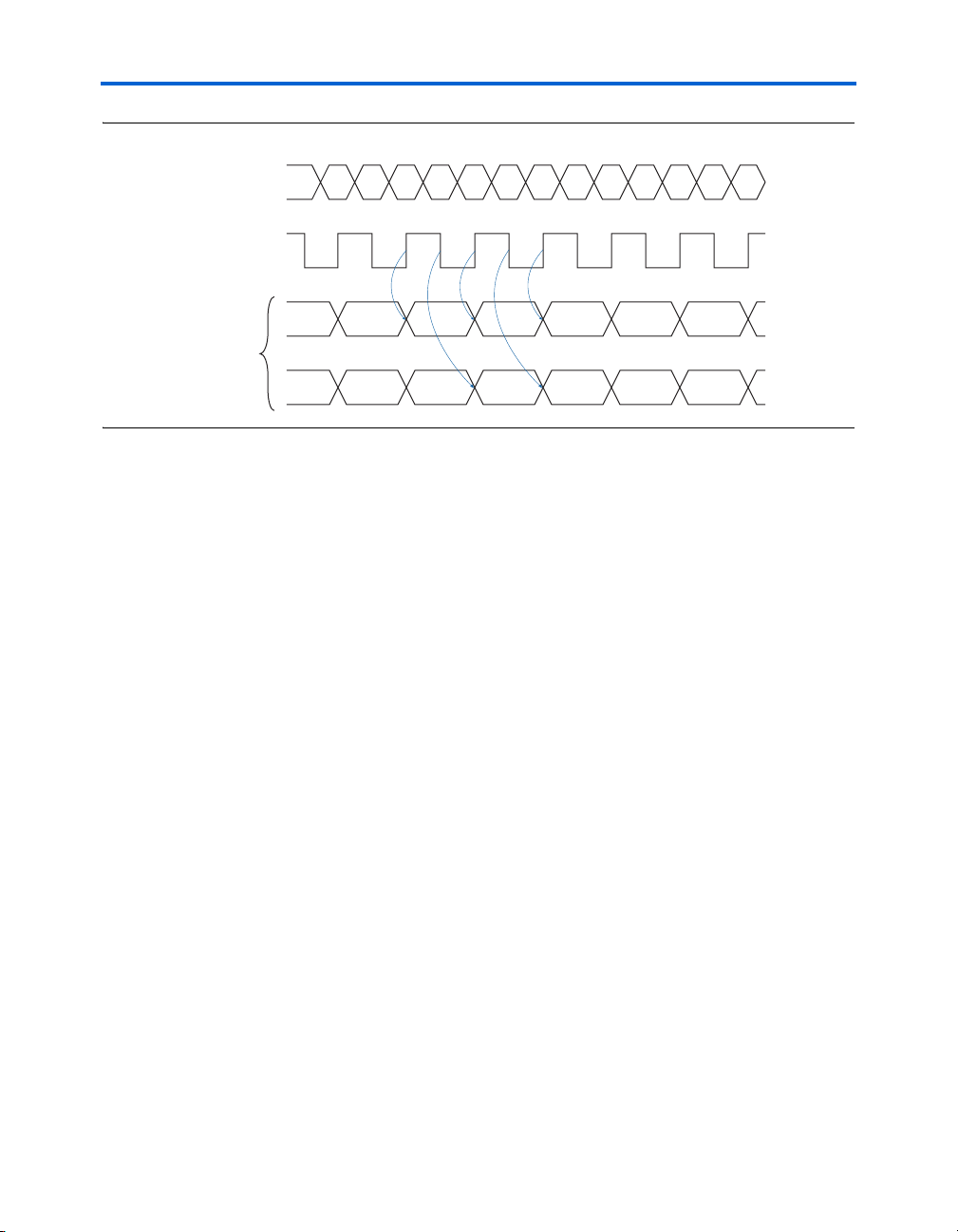

asynchronous clear signals. Figure 2–19 shows the M512 RAM block

control signal generation logic.

The RAM blocks in Stratix II devices have local interconnects to allow

ALMs and interconnects to drive into RAM blocks. The M512 RAM block

local interconnect is driven by the R4, C4, and direct link interconnects

from adjacent LABs. The M512 RAM blocks can communicate with LABs

on either the left or right side through these row interconnects or with

LAB columns on the left or right side with the column interconnects. The

M512 RAM block has up to 16 direct link input connections from the left

adjacent LABs and another 16 from the right adjacent LAB. M512 RAM

outputs can also connect to left and right LABs through direct link

interconnect. The M512 RAM block has equal opportunity for access and

performance to and from LABs on either its left or right side. Figure 2–20

shows the M512 RAM block to logic array interface.

2–30 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 31

Figure 2–19. M512 RAM Block Control Signals

Stratix II Architecture

Dedicated

Row LAB

Clocks

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

6

inclocken

outclocken

outclockinclock

rden

wren

outclr

Altera Corporation 2–31

May 2007 Stratix II Device Handbook, Volume 1

Page 32

Tri M a t r ix Memor y

Figure 2–20. M512 RAM Block LAB Row Interface

C4 Interconnect

R4 Interconnect

Direct link

interconnect

to adjacent LAB

Direct link

interconnect

from adjacent LAB

16

2

6

M512 RAM Block Local

Interconnect Region

clocks

datain

dataout

M512 RAM

Block

control

signals

address

LAB Row Clocks

Direct link

interconnect

to adjacent LAB

Direct link

interconnect

from adjacent LAB

M4K RAM Blocks

The M4K RAM block includes support for true dual-port RAM. The M4K

RAM block is used to implement buffers for a wide variety of applications

such as storing processor code, implementing lookup schemes, and

implementing larger memory applications. Each block contains 4,608

RAM bits (including parity bits). M4K RAM blocks can be configured in

the following modes:

■ True dual-port RAM

■ Simple dual-port RAM

■ Single-port RAM

■ FIFO

■ ROM

■ Shift register

When configured as RAM or ROM, you can use an initialization file to

pre-load the memory contents.

2–32 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 33

The M4K RAM blocks allow for different clocks on their inputs and

outputs. Either of the two clocks feeding the block can clock M4K RAM

block registers (renwe, address, byte enable, datain, and output registers).

Only the output register can be bypassed. The six labclk signals or local

interconnects can drive the control signals for the A and B ports of the

M4K RAM block. ALMs can also control the clock_a, clock_b,

renwe_a, renwe_b, clr_a, clr_b, clocken_a, and clocken_b

signals, as shown in Figure 2–21.

The R4, C4, and direct link interconnects from adjacent LABs drive the

M4K RAM block local interconnect. The M4K RAM blocks can

communicate with LABs on either the left or right side through these row

resources or with LAB columns on either the right or left with the column

resources. Up to 16 direct link input connections to the M4K RAM Block

are possible from the left adjacent LABs and another 16 possible from the

right adjacent LAB. M4K RAM block outputs can also connect to left and

right LABs through direct link interconnect. Figure 2–22 shows the M4K

RAM block to logic array interface.

Figure 2–21. M4K RAM Block Control Signals

Dedicated

Row LAB

Clocks

Local

Interconnect

6

Stratix II Architecture

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

clock_b

clocken_aclock_a

clocken_b

renwe_a

renwe_b

aclr_b

aclr_a

Altera Corporation 2–33

May 2007 Stratix II Device Handbook, Volume 1

Page 34

Tri M a t r ix Memor y

Figure 2–22. M4K RAM Block LAB Row Interface

C4 Interconnect

R4 Interconnect

Direct link

interconnect

to adjacent LAB

Direct link

interconnect

from adjacent LAB

16

M4K RAM Block Local

Interconnect Region

M4K RAM

datain

control

signals

clocks

address

LAB Row Clocks

36

dataout

Block

byte

enable

6

Direct link

interconnect

to adjacent LAB

Direct link

interconnect

from adjacent LAB

M-RAM Block

The largest TriMatrix memory block, the M-RAM block, is useful for

applications where a large volume of data must be stored on-chip. Each

block contains 589,824 RAM bits (including parity bits). The M-RAM

block can be configured in the following modes:

■ True dual-port RAM

■ Simple dual-port RAM

■ Single-port RAM

■ FIFO

You cannot use an initialization file to initialize the contents of an M-RAM

block. All M-RAM block contents power up to an undefined value. Only

synchronous operation is supported in the M-RAM block, so all inputs

are registered. Output registers can be bypassed.

2–34 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 35

Similar to all RAM blocks, M-RAM blocks can have different clocks on

their inputs and outputs. Either of the two clocks feeding the block can

clock M-RAM block registers (renwe, address, byte enable, datain, and

output registers). The output register can be bypassed. The six labclk

signals or local interconnect can drive the control signals for the A and B

ports of the M-RAM block. ALMs can also control the clock_a,

clock_b, renwe_a, renwe_b, clr_a, clr_b, clocken_a, and

clocken_b signals as shown in Figure 2–23.

Figure 2–23. M-RAM Block Control Signals

Dedicated

Row LAB

Clocks

Local

Interconnect

6

Stratix II Architecture

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

clocken_a

clock_a

aclr_a

renwe_a

renwe_b

aclr_b

clocken_b

clock_b

Local

Interconnect

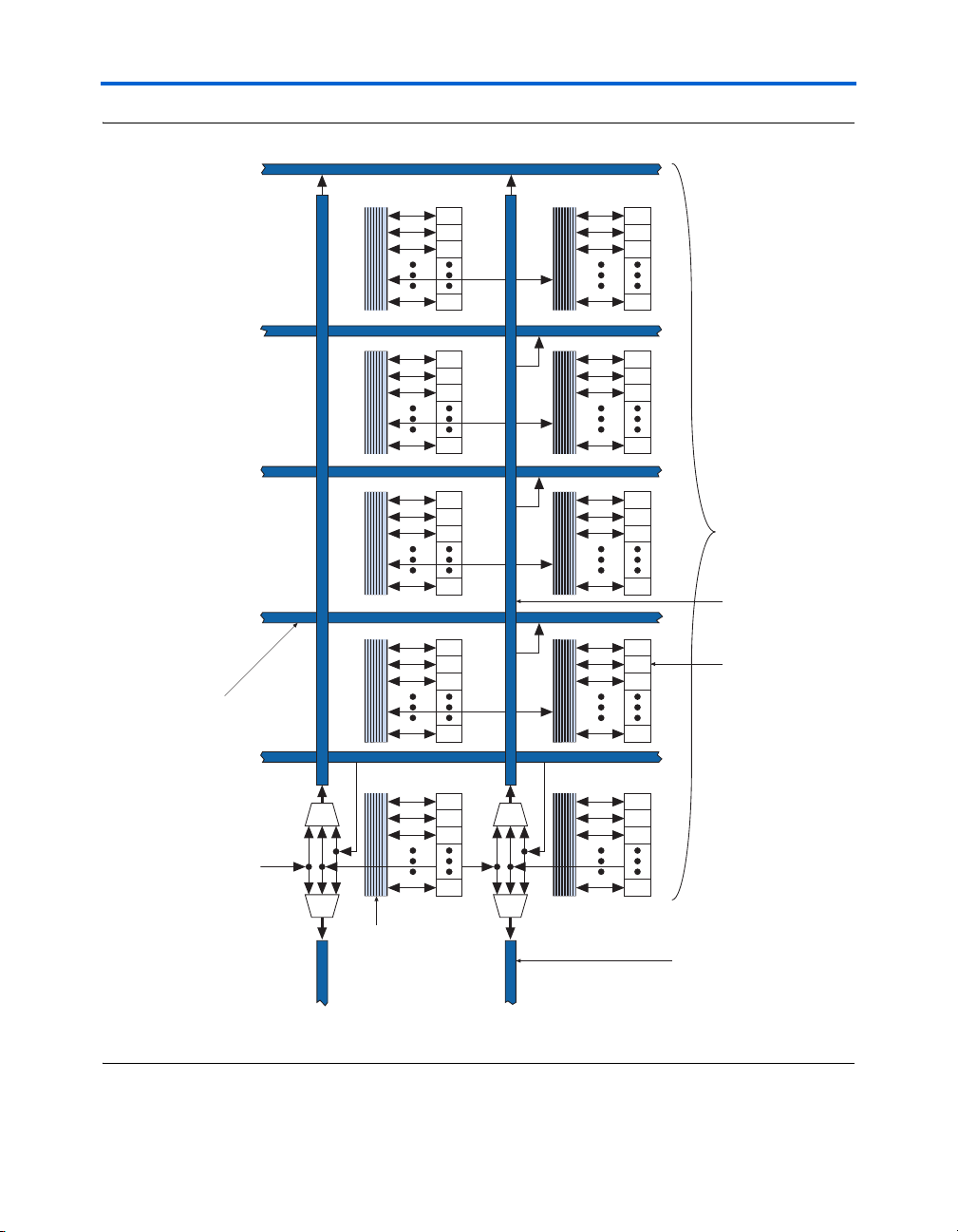

The R4, R24, C4, and direct link interconnects from adjacent LABs on

either the right or left side drive the M-RAM block local interconnect. Up

to 16 direct link input connections to the M-RAM block are possible from

the left adjacent LABs and another 16 possible from the right adjacent

LAB. M-RAM block outputs can also connect to left and right LABs

through direct link interconnect. Figure 2–24 shows an example floorplan

for the EP2S130 device and the location of the M-RAM interfaces.

Figures 2–25 and 2–26 show the interface between the M-RAM block and

the logic array.

Altera Corporation 2–35

May 2007 Stratix II Device Handbook, Volume 1

Page 36

Tri M a t r ix Memor y

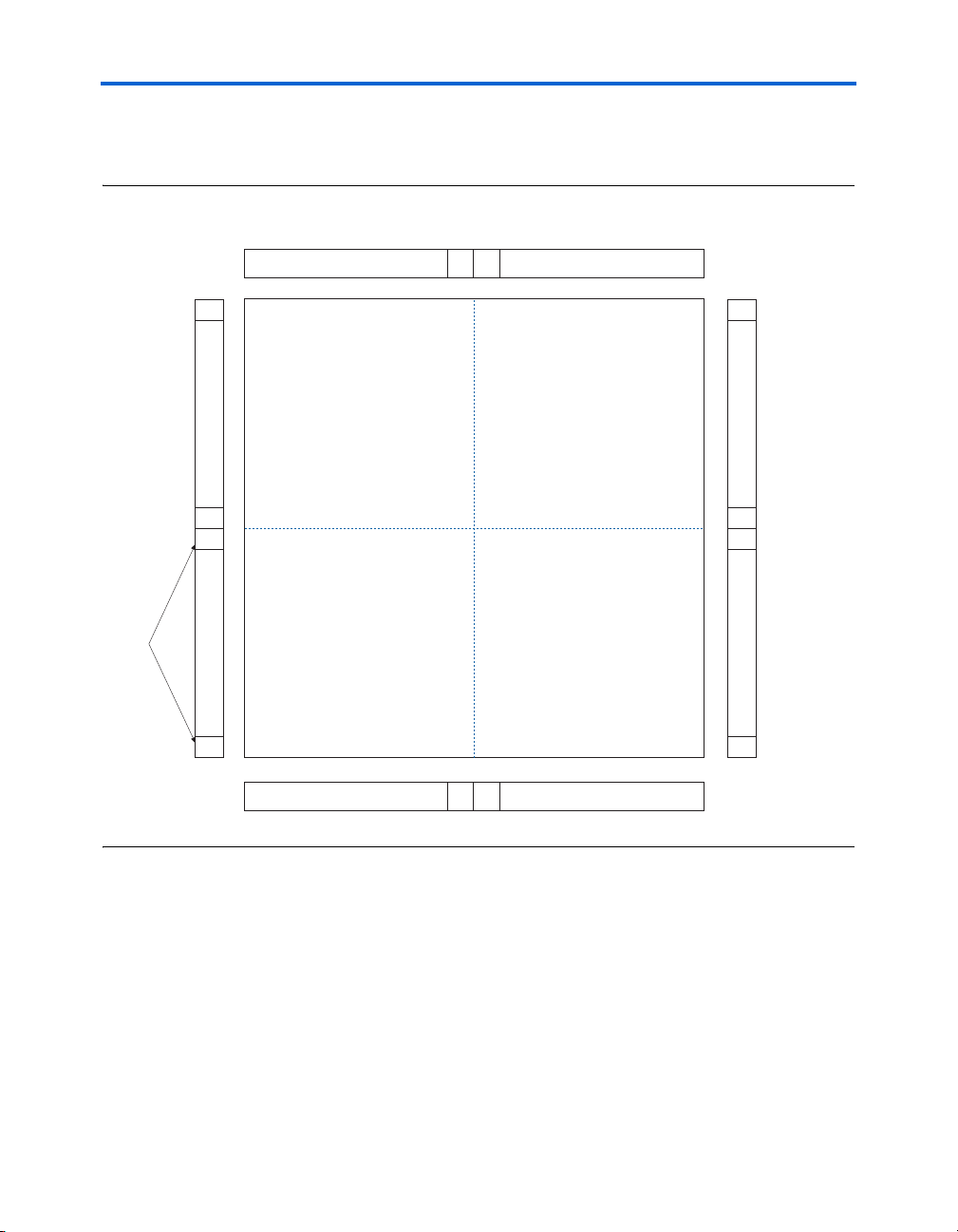

Figure 2–24. EP2S130 Device with M-RAM Interface Locations Note (1)

M-RAM blocks interface to

LABs on right and left sides for

easy access to horizontal I/O pins

M4K

Blocks

M-RAM

Block

M-RAM

Block

M-RAM

Block

M512

Blocks

DSP

Blocks

LABs

M-RAM

Block

M-RAM

Block

M-RAM

Block

DSP

Blocks

Note to Figure 2–24:

(1) The device shown is an EP2S130 device. The number and position of M-RAM blocks varies in other devices.

2–36 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 37

Figure 2–25. M-RAM Block LAB Row Interface Note (1)

Row Unit Interface Allows LAB

Rows to Drive Port A Datain,

Dataout, Address and Control

Signals to and from M-RAM Block

Row Unit Interface Allows LAB

Rows to Drive Port B Datain,

Dataout, Address and Control

Signals to and from M-RAM Block

Stratix II Architecture

L0

L1

M-RAM Block

L2

L3

L4

L5

LAB Interface

Blocks

LABs in Row

M-RAM Boundary

Note to Figure 2–25:

(1) Only R24 and C16 interconnects cross the M-RAM block boundaries.

R0

R1

R2

Port BPort A

R3

R4

R5

LABs in Row

M-RAM Boundary

Altera Corporation 2–37

May 2007 Stratix II Device Handbook, Volume 1

Page 38

Tri M a t r ix Memor y

Figure 2–26. M-RAM Row Unit Interface to Interconnect

R4 and R24 InterconnectsC4 Interconnect

LAB

M-RAM Block

Direct Link

Interconnects

Up to 16

16

Up to 28

Row Interface Block

M-RAM Block to

LAB Row Interface

Block Interconnect Region

dataout_a[ ]

datain_a[ ]

addressa[ ]

addr_ena_a

renwe_a

byteenaA[ ]

clocken_a

clock_a

aclr_a

Table 2–4 shows the input and output data signal connections along with

the address and control signal input connections to the row unit interfaces

(L0 to L5 and R0 to R5).

2–38 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 39

Stratix II Architecture

Table 2–4. M-RAM Row Interface Unit Signals

Unit Interface Block Input Signals Output Signals

L0 datain_a[14..0]

byteena_a[1..0]

L1 datain_a[29..15]

byteena_a[3..2]

L2 datain_a[35..30]

addressa[4..0]

addr_ena_a

clock_a

clocken_a

renwe_a

aclr_a

L3 addressa[15..5]

datain_a[41..36]

L4 datain_a[56..42]

byteena_a[5..4]

L5 datain_a[71..57]

byteena_a[7..6]

R0 datain_b[14..0]

byteena_b[1..0]

R1 datain_b[29..15]

byteena_b[3..2]

R2 datain_b[35..30]

addressb[4..0]

addr_ena_b

clock_b

clocken_b

renwe_b

aclr_b

R3 addressb[15..5]

datain_b[41..36]

R4 datain_b[56..42]

byteena_b[5..4]

R5 datain_b[71..57]

byteena_b[7..6]

dataout_a[11..0]

dataout_a[23..12]

dataout_a[35..24]

dataout_a[47..36]

dataout_a[59..48]

dataout_a[71..60]

dataout_b[11..0]

dataout_b[23..12]

dataout_b[35..24]

dataout_b[47..36]

dataout_b[59..48]

dataout_b[71..60]

f See the TriMatrix Embedded Memory Blocks in Stratix II & Stratix II GX

Devices chapter in volume 2 of the Stratix II Device Handbook or the

Stratix II GX Device Handbook for more information on TriMatrix

memory.

Altera Corporation 2–39

May 2007 Stratix II Device Handbook, Volume 1

Page 40

Digital Signal Processing Block

Digital Signal

Processing

Block

The most commonly used DSP functions are FIR filters, complex FIR

filters, IIR filters, fast Fourier transform (FFT) functions, direct cosine

transform (DCT) functions, and correlators. All of these use the multiplier

as the fundamental building block. Additionally, some applications need

specialized operations such as multiply-add and multiply-accumulate

operations. Stratix II devices provide DSP blocks to meet the arithmetic

requirements of these functions.

Each Stratix II device has from two to four columns of DSP blocks to

efficiently implement DSP functions faster than ALM-based

implementations. Stratix II devices have up to 24 DSP blocks per column

(see Table 2–5). Each DSP block can be configured to support up to:

■ Eight 9 × 9-bit multipliers

■ Four 18 × 18-bit multipliers

■ One 36 × 36-bit multiplier

As indicated, the Stratix II DSP block can support one 36 × 36-bit

multiplier in a single DSP block. This is true for any combination of

signed, unsigned, or mixed sign multiplications.

1 This list only shows functions that can fit into a single DSP block.

Multiple DSP blocks can support larger multiplication

functions.

2–40 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 41

Stratix II Architecture

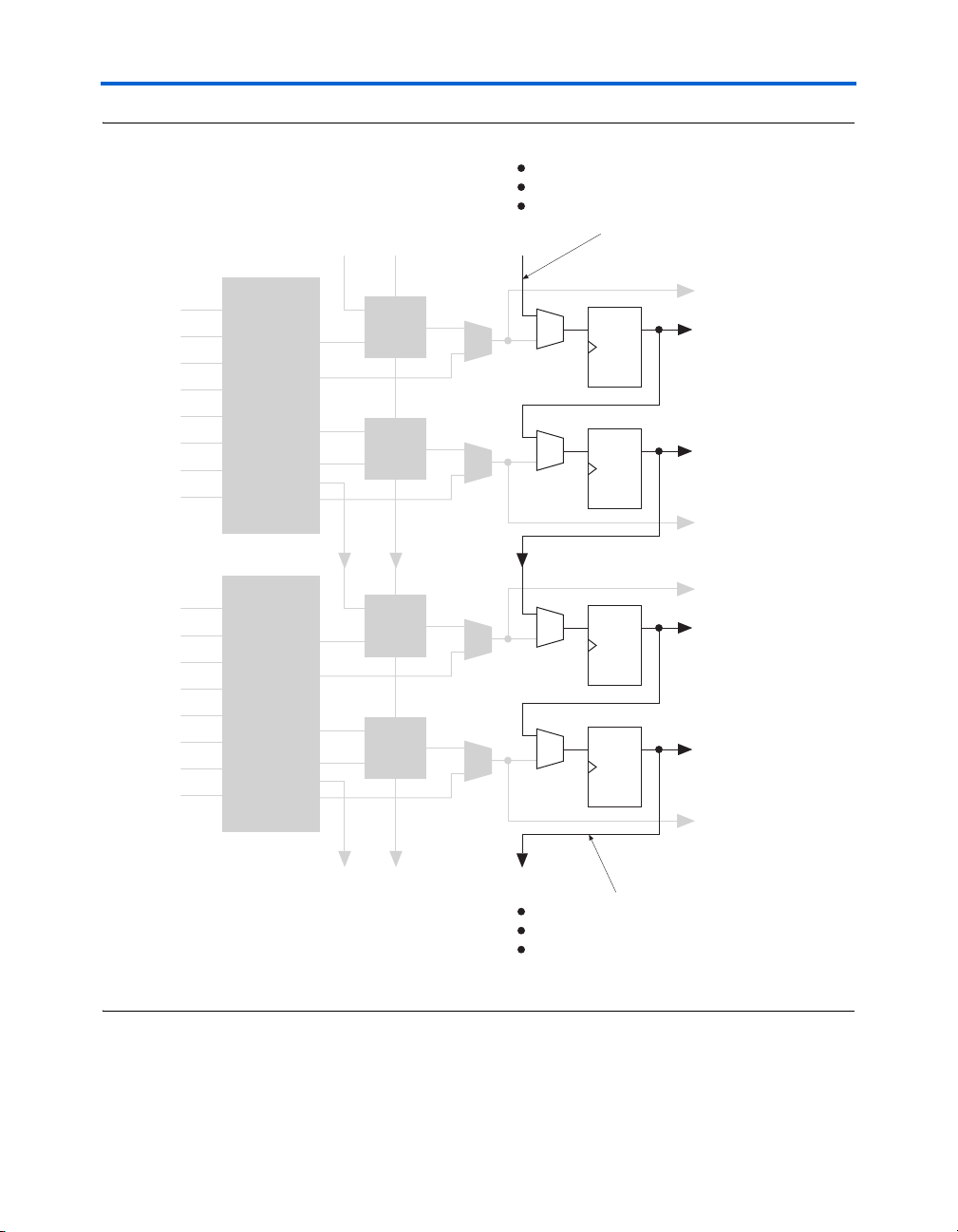

Figure 2–27 shows one of the columns with surrounding LAB rows.

Figure 2–27. DSP Blocks Arranged in Columns

DSP Block

Column

4 LAB

Rows

DSP Block

Altera Corporation 2–41

May 2007 Stratix II Device Handbook, Volume 1

Page 42

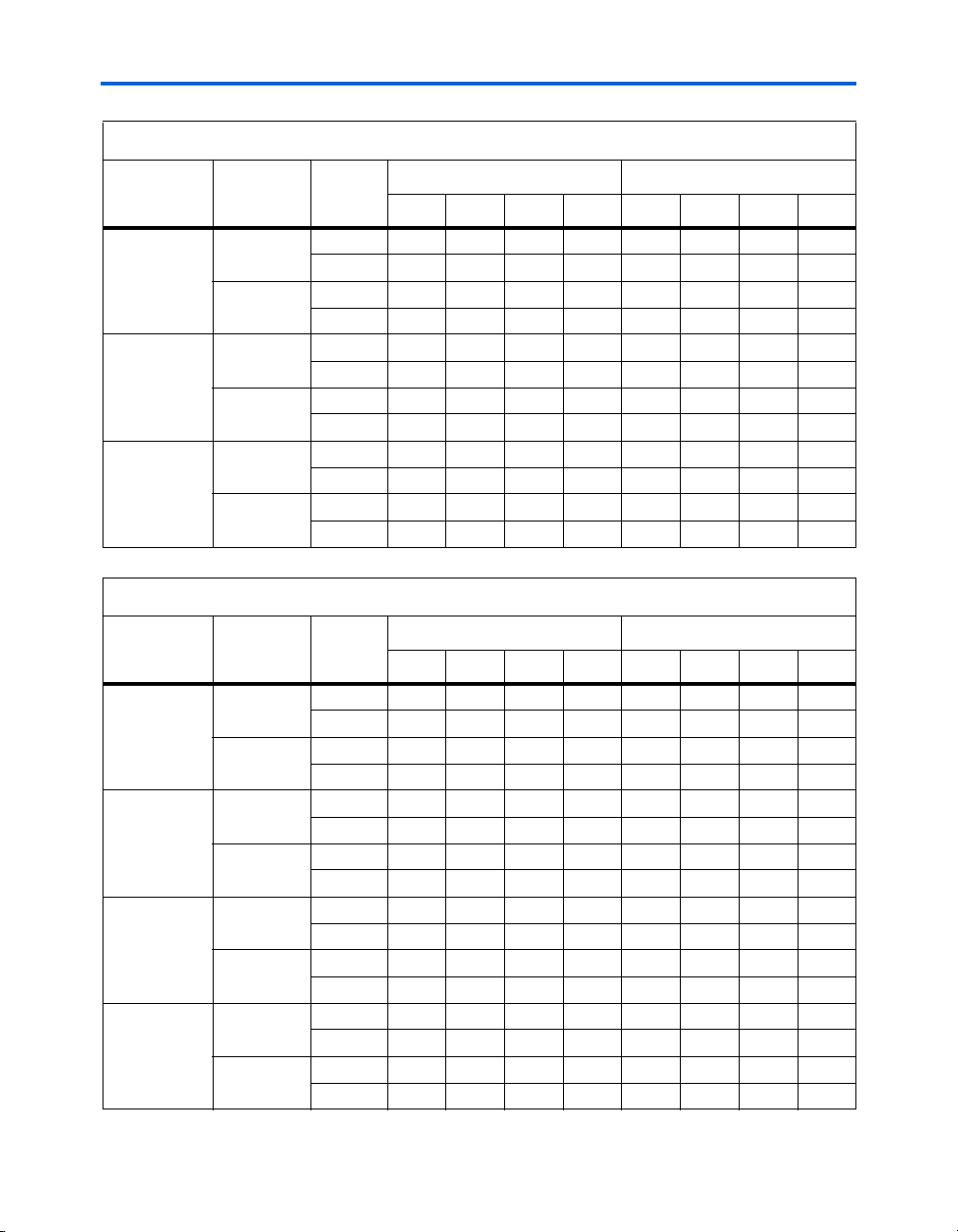

Digital Signal Processing Block

Table 2–5 shows the number of DSP blocks in each Stratix II device.

Table 2–5. DSP Blocks in Stratix II Devices Note (1)

Device DSP Blocks

EP2S15 12 96 48 12

EP2S30 16 128 64 16

EP2S60 36 288 144 36

EP2S90 48 384 192 48

EP2S130 63 504 252 63

EP2S180 96 768 384 96

Note to Ta b l e 2– 5 :

(1) Each device has either the numbers of 9 × 9-, 18 × 18-, or 36 × 36-bit multipliers

shown. The total number of multipliers for each device is not the sum of all the

multipliers.

Total 9 × 9

Multipliers

Total 18 × 18

Multipliers

Total 36 × 36

Multipliers

DSP block multipliers can optionally feed an adder/subtractor or

accumulator in the block depending on the configuration. This makes

routing to ALMs easier, saves ALM routing resources, and increases

performance, because all connections and blocks are in the DSP block.

Additionally, the DSP block input registers can efficiently implement shift

registers for FIR filter applications, and DSP blocks support Q1.15 format

rounding and saturation.

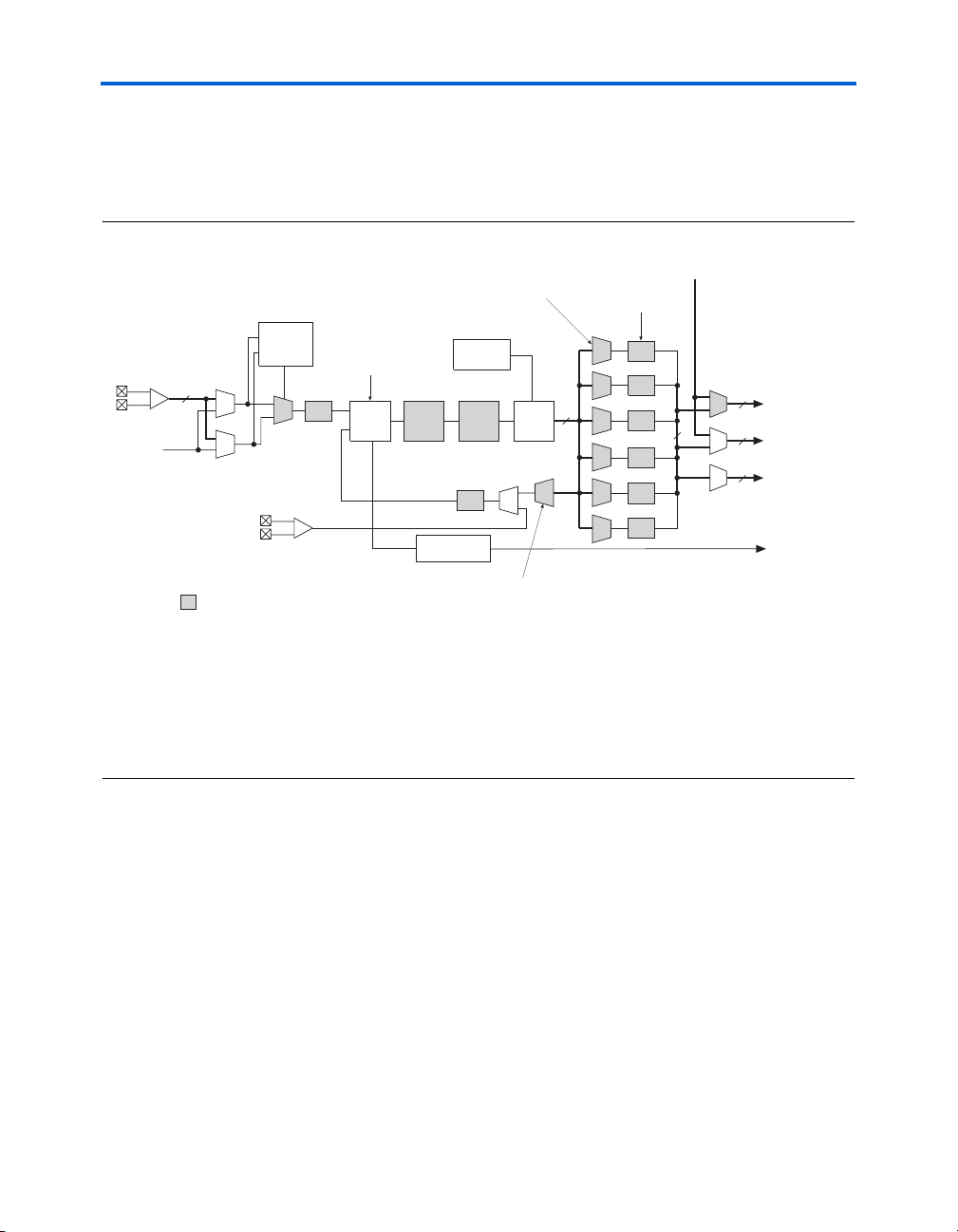

Figure 2–28 shows the top-level diagram of the DSP block configured for

18 × 18-bit multiplier mode.

2–42 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 43

Figure 2–28. DSP Block Diagram for 18 × 18-Bit Configuration

Optional Serial Shift

Register Inputs from

Previous DSP Block

Stratix II Architecture

From the row

interface block

Optional Serial Shift

Register Outputs to

Next DSP Block

in the Column

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

Multiplier Block

Q1.15

Round/

Saturate

Q1.15

Round/

Saturate

Q1.15

Round/

Saturate

Q1.15

Round/

Saturate

Optional Input Register

Stage with Parallel Input or

Shift Register Configuration

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

PRN

DQ

ENA

CLRN

Adder Output Block

Optional Stage Configurable

as Accumulator or Dynamic

Adder/Subtractor

Adder/

Subtractor/

Accumulator

1

Adder/

Subtractor/

Accumulator

2

Optional Pipline

Register Stage

Q1.15

Round/

Saturate

Summation

Block

Adder

Summation Stage

for Adding Four

Multipliers Together

Q1.15

Round/

Saturate

Output

Selection

Multiplexer

to MultiTrack

Interconnect

DQ

ENA

CLRN

Altera Corporation 2–43

May 2007 Stratix II Device Handbook, Volume 1

Page 44

Digital Signal Processing Block

Modes of Operation

The adder, subtractor, and accumulate functions of a DSP block have four

modes of operation:

■ Simple multiplier

■ Multiply-accumulator

■ Two-multipliers adder

■ Four-multipliers adder

Table 2–6 shows the different number of multipliers possible in each DSP

block mode according to size. These modes allow the DSP blocks to

implement numerous applications for DSP including FFTs, complex FIR,

FIR, and 2D FIR filters, equalizers, IIR, correlators, matrix multiplication

and many other functions. The DSP blocks also support mixed modes

and mixed multiplier sizes in the same block. For example, half of one

DSP block can implement one 18 × 18-bit multiplier in multiplyaccumulator mode, while the other half of the DSP block implements four

9 × 9-bit multipliers in simple multiplier mode.

Table 2–6. Multiplier Size & Configurations per DSP Block

DSP Block Mode 9 × 9 18 × 18 36 × 36

Multiplier Eight multipliers with

eight product outputs

Multiply-accumulator - Two 52-bit multiply-

Two-multipliers adder Four two-multiplier adder

(two 9 × 9 complex

multiply)

Four-multipliers adder Two four-multiplier adder One four-multiplier adder -

Four multipliers with four

product outputs

accumulate blocks

Two two-multiplier adder

(one 18 × 18 complex

multiply)

One multiplier with one

product output

-

-

DSP Block Interface

Stratix II device DSP block input registers can generate a shift register that

can cascade down in the same DSP block column. Dedicated connections

between DSP blocks provide fast connections between the shift register

inputs to cascade the shift register chains. You can cascade registers

within multiple DSP blocks for 9 × 9- or 18 × 18-bit FIR filters larger than

four taps, with additional adder stages implemented in ALMs. If the DSP

block is configured as 36 × 36 bits, the adder, subtractor, or accumulator

stages are implemented in ALMs. Each DSP block can route the shift

register chain out of the block to cascade multiple columns of DSP blocks.

2–44 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 45

Stratix II Architecture

s

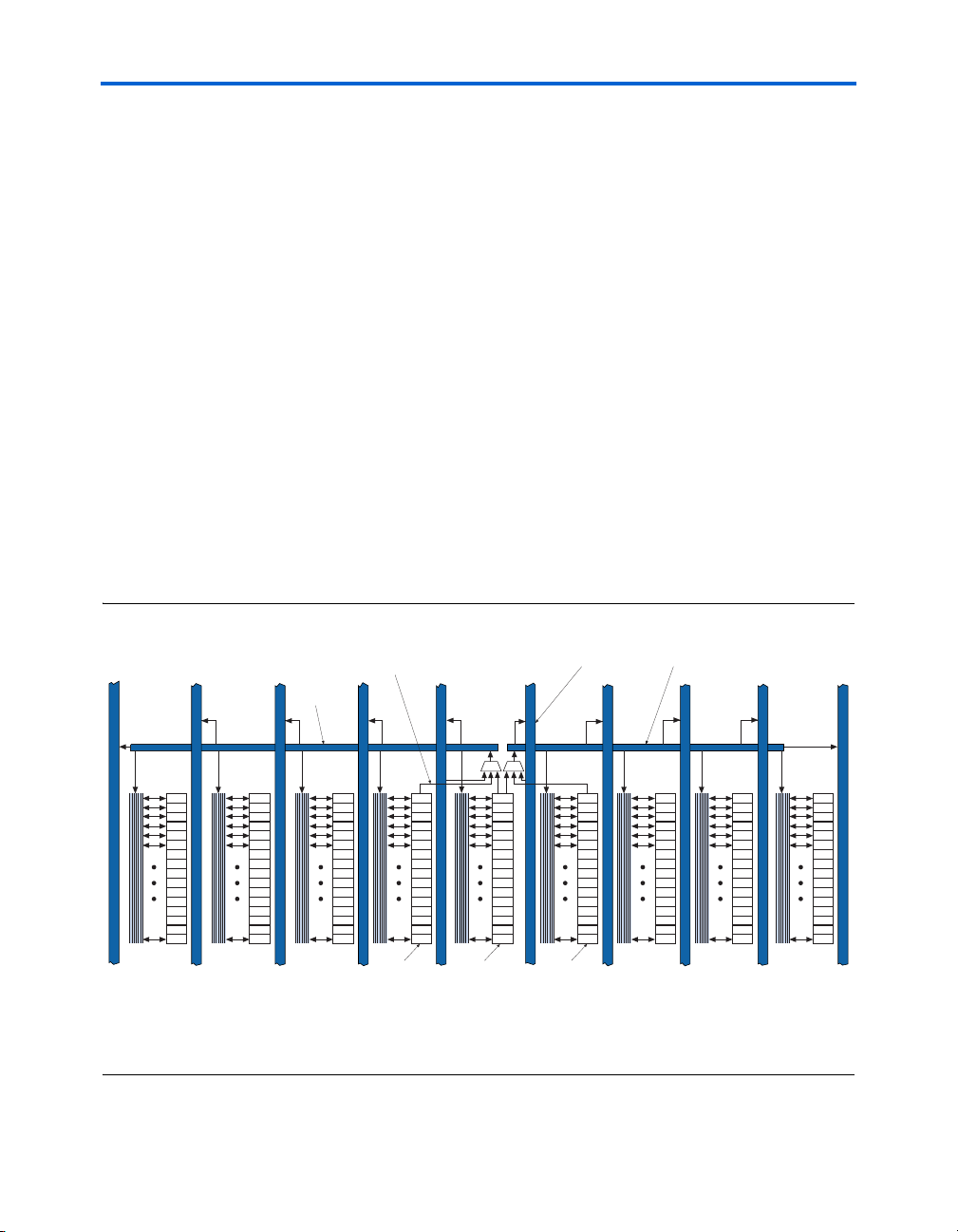

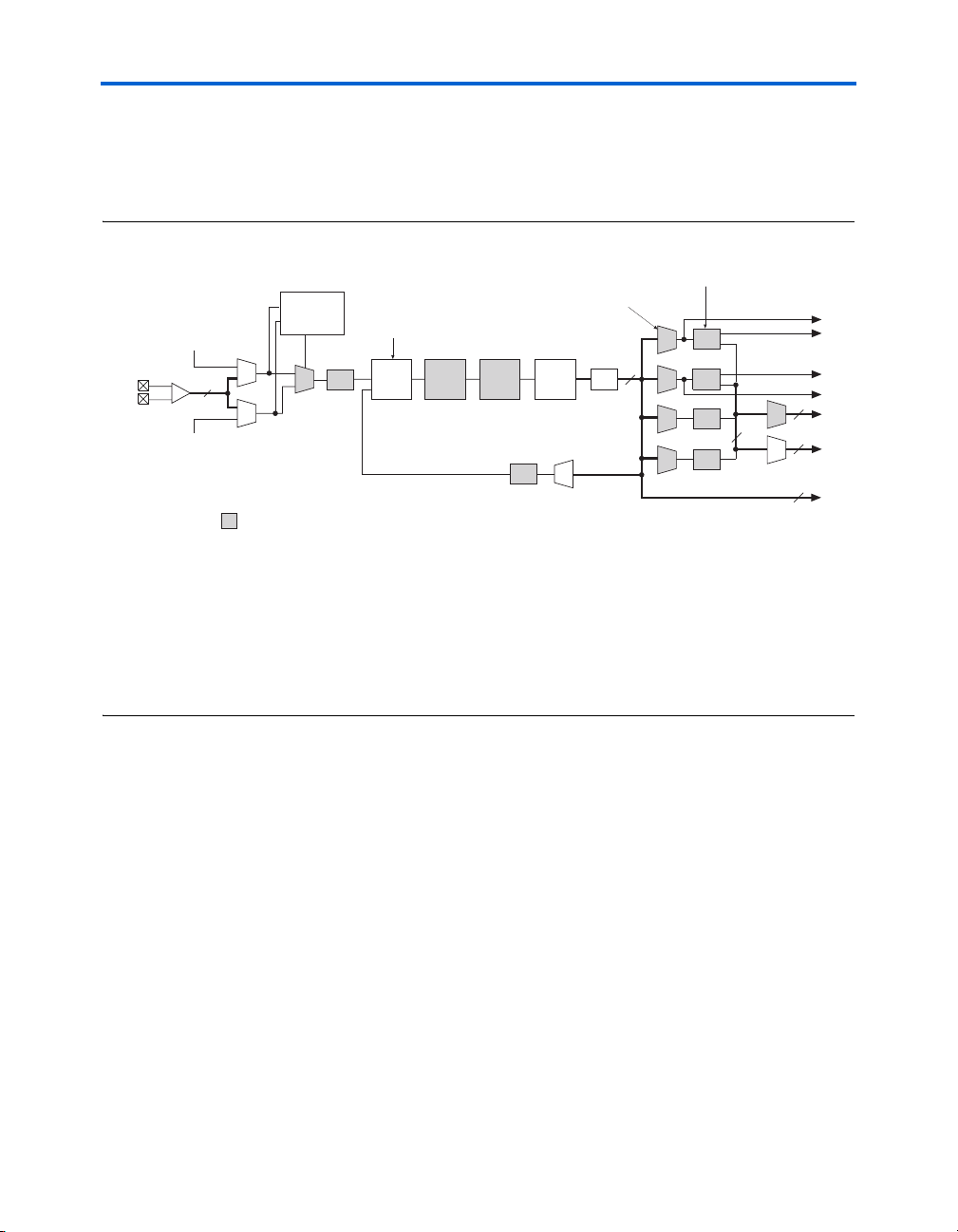

The DSP block is divided into four block units that interface with four

LAB rows on the left and right. Each block unit can be considered one

complete 18 × 18-bit multiplier with 36 inputs and 36 outputs. A local

interconnect region is associated with each DSP block. Like an LAB, this

interconnect region can be fed with 16 direct link interconnects from the

LAB to the left or right of the DSP block in the same row. R4 and C4

routing resources can access the DSP block's local interconnect region.

The outputs also work similarly to LAB outputs as well. Eighteen outputs

from the DSP block can drive to the left LAB through direct link

interconnects and eighteen can drive to the right LAB though direct link

interconnects. All 36 outputs can drive to R4 and C4 routing

interconnects. Outputs can drive right- or left-column routing.

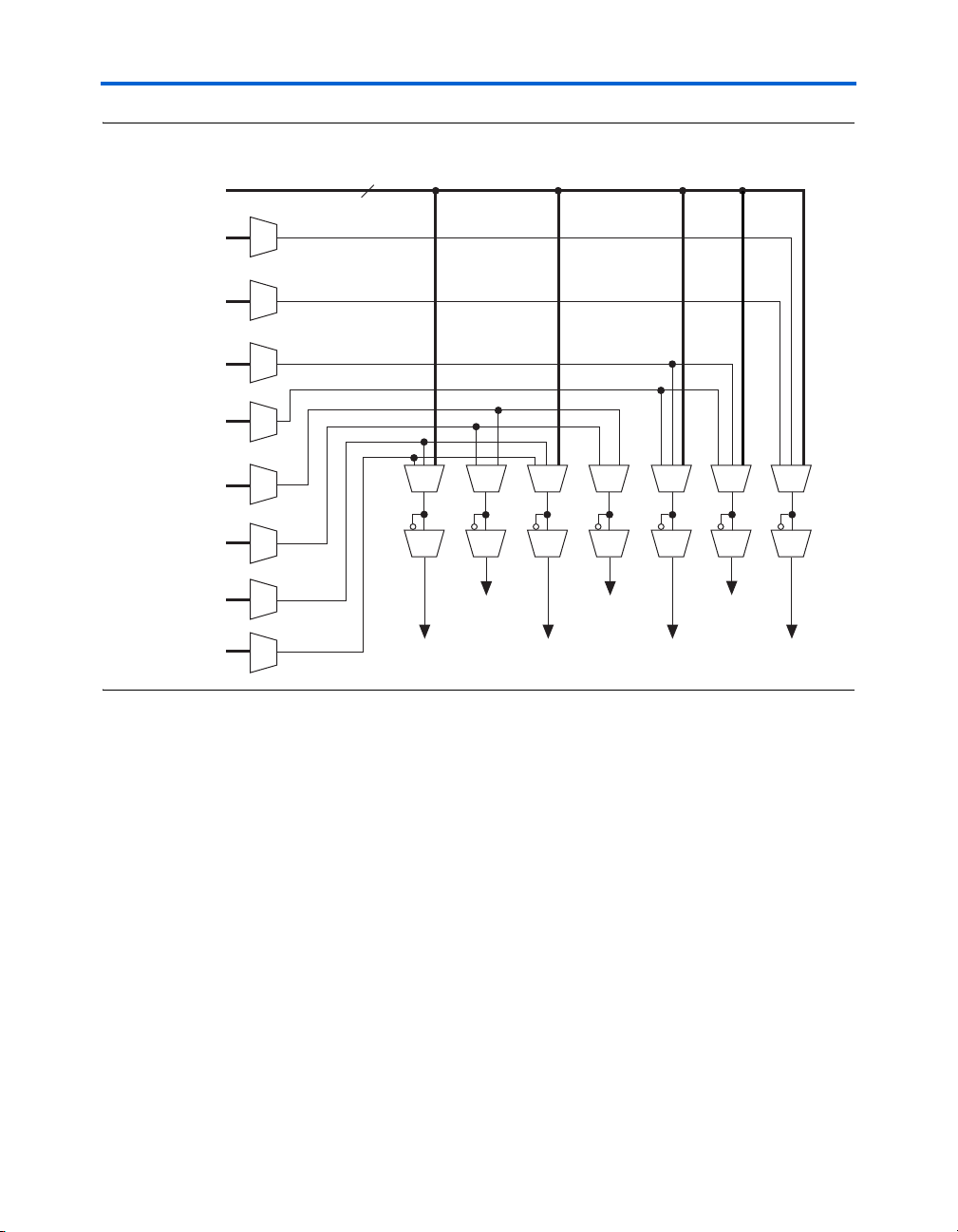

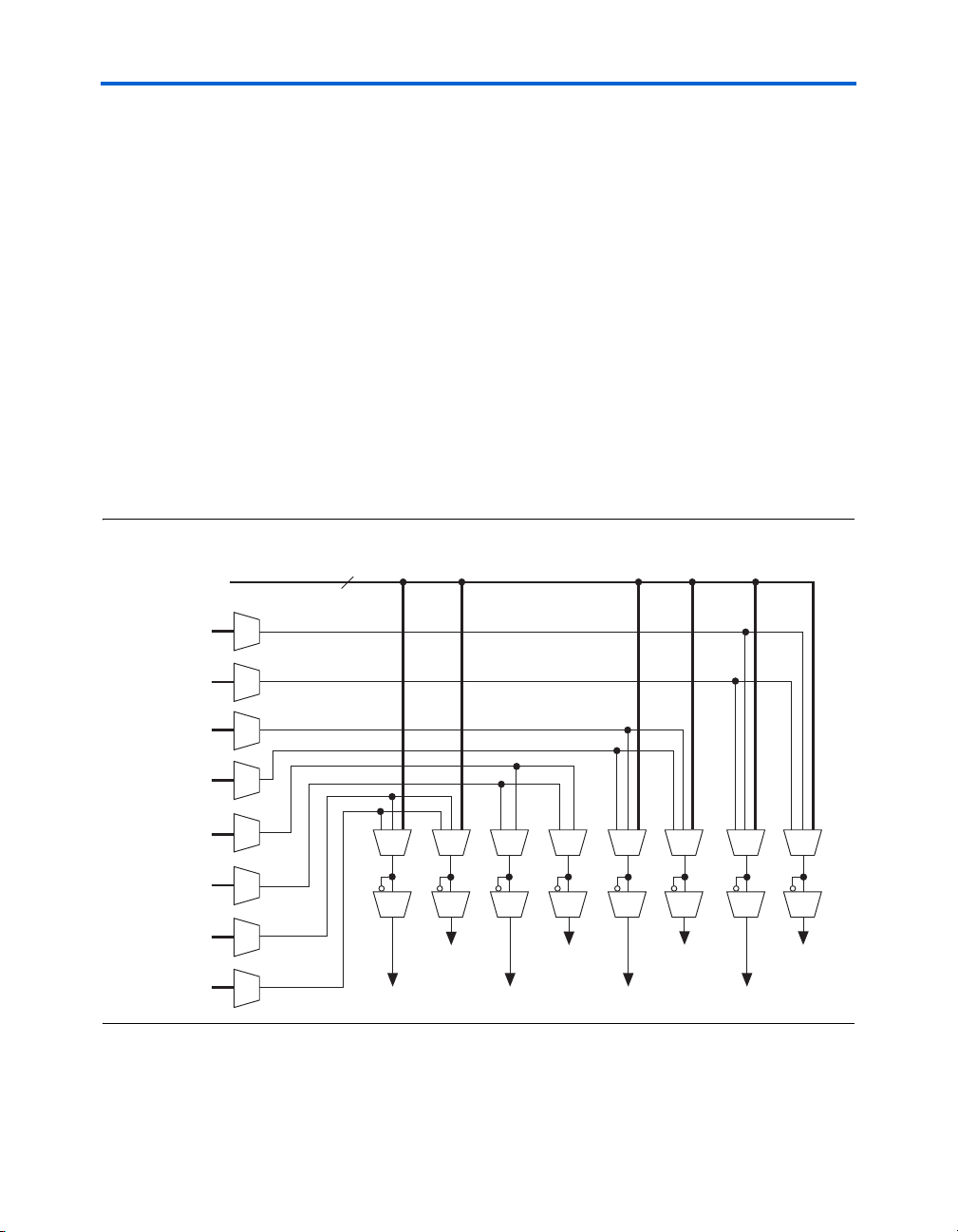

Figures 2–29 and 2–30 show the DSP block interfaces to LAB rows.

Figure 2–29. DSP Block Interconnect Interface

DSP Block

R4, C4 & Direct

Link Interconnects

OA[17..0]

OB[17..0]

A1[17..0]

B1[17..0]

OC[17..0]

OD[17..0]

A2[17..0]

B2[17..0]

OE[17..0]

OF[17..0]

A3[17..0]

B3[17..0]

OG[17..0]

OH[17..0]

A4[17..0]

B4[17..0]

R4, C4 & Direct

Link Interconnect

Altera Corporation 2–45

May 2007 Stratix II Device Handbook, Volume 1

Page 46

Digital Signal Processing Block

Figure 2–30. DSP Block Interface to Interconnect

C4 Interconnect

LAB LAB

Direct Link Interconnect

from Adjacent LAB

18

36

R4 Interconnect

DSP Block

Row Structure

Direct Link Outputs

to Adjacent LABs

36

Direct Link Interconnect

from Adjacent LAB

16

Row Interface

DSP Block to

LAB Row Interface

Block Interconnect Region

12

36

16

Control

A[17..0]

B[17..0]

Block

36 Inputs per Row 36 Outputs per Row

OA[17..0]

OB[17..0]

36

A bus of 44 control signals feeds the entire DSP block. These signals

include clocks, asynchronous clears, clock enables, signed/unsigned

control signals, addition and subtraction control signals, rounding and

saturation control signals, and accumulator synchronous loads. The clock

signals are routed from LAB row clocks and are generated from specific

LAB rows at the DSP block interface.

2–46 Altera Corporation

Stratix II Device Handbook, Volume 1 May 2007

Page 47

Stratix II Architecture

The LAB row source for control signals, data inputs, and outputs is

shown in Ta bl e 2 –7 .

Table 2–7. DSP Block Signal Sources & Destinations

LAB Row at

Interface

0clock0

aclr0

ena0

mult01_saturate

addnsub1_round/ accum_round

addnsub1

signa

sourcea

sourceb

1clock1

aclr1

ena1

accum_saturate

mult01_round

accum_sload

sourcea

sourceb

mode0

2clock2

aclr2

ena2

mult23_saturate

addnsub3_round/ accum_round

addnsub3

sign_b

sourcea

sourceb

3clock3

aclr3

ena3

accum_saturate

mult23_round

accum_sload

sourcea

sourceb

mode1

Control Signals Generated Data Inputs Data Outputs

A1[17..0]

B1[17..0]

A2[17..0]

B2[17..0]

A3[17..0]

B3[17..0]

A4[17..0]

B4[17..0]

OA[17..0]

OB[17..0]

OC[17..0]

OD[17..0]

OE[17..0]

OF[17..0]

OG[17..0]

OH[17..0]

f See the DSP Blocks in Stratix II & Stratix II GX Devices chapter in

volume 2 of the Stratix II Device Handbook or the Stratix II GX Device

Handbook, for more information on DSP blocks.

Altera Corporation 2–47

May 2007 Stratix II Device Handbook, Volume 1

Page 48

PLLs & Clock Networks

PLLs & Clock

Networks

Stratix II devices provide a hierarchical clock structure and multiple PLLs

with advanced features. The large number of clocking resources in

combination with the clock synthesis precision provided by enhanced

and fast PLLs provides a complete clock management solution.

Global & Hierarchical Clocking

Stratix II devices provide 16 dedicated global clock networks and

32 regional clock networks (eight per device quadrant). These clocks are

organized into a hierarchical clock structure that allows for up to

24 clocks per device region with low skew and delay. This hierarchical

clocking scheme provides up to 48 unique clock domains in Stratix II

devices.

There are 16 dedicated clock pins (CLK[15..0]) to drive either the global

or regional clock networks. Four clock pins drive each side of the device,

as shown in Figures 2–31 and 2–32. Internal logic and enhanced and fast

PLL outputs can also drive the global and regional clock networks. Each

global and regional clock has a clock control block, which controls the

selection of the clock source and dynamically enables/disables the clock

to reduce power consumption. Table 2–8 shows global and regional clock

features.

Table 2–8. Global & Regional Clock Features

Feature Global Clocks Regional Clocks

Number per device 16 32

Number available per

quadrant

Sources CLK pins, PLL outputs,

or internal logic

Dynamic clock source

selection

Dynamic enable/disable

16 8

CLK pins, PLL outputs,

or internal logic

v (1)

vv

Note to Ta b l e 2– 8 :

(1) Dynamic source clock selection is supported for selecting between CLKp pins and

PLL outputs only.

Global Clock Network

These clocks drive throughout the entire device, feeding all device