Page 1

^ ■ \

9441A

Anniversary Series Power Amplifier

O pe r at i ng an d S e rv i ce In s tr u ct i on s

ALTEC LANSING® CORPORATION

n MARK IV coiiipiiiiy

P. O. Box 26105 © Oklahoma City, OK • 73126-0105 USA © Tel: (405) 324-5311 © FAX: (405) 324-89b1

Page 2

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Table of Contents

1 ELECTRICAL

1.1 120 V ac, 50/60 Hz Power Connection.«;........................................................................................... 1

1.2 220/240 V ac, 50/60 Hz Power Connections....................................................................................... 1

2 INSTALLATION.................................................................................................................................... 1

2.1 Eack Mounting .................................................................................................................................. 1

2.2 Ventilation ............................................................................................................................ . 1

3 SIGNAL CONNECTIONS...................................................................................................................... 2

3.1 Input Connections ............................................................................................................................. 2

3.2 Line Output Connections.................................................................................................................... 2

3.3 Output Connections........................................................................................................................... 2

3.4 Output Cable Selection....................................................................................................................... 2

3.4.1 Calculating Power Los.ses with 8 ohm Loads

3.4.2 Calculating Power Losses with 4 ohm Loads................................................................................. 2

3.5 Damping Factor.......................................................................................................................... . 2

3.5.1 Calculating the Maximum Length of Cable for a Specified Damping Factor

3.C Speaker Protection Fuse Selection ...................................................................................................... 5

3.7 Compros.sion Driver Protection Capacitors ........................................................................................... 5

4 OCTAL ACCESSORY SOCKETS

5 PROTECTION SYSTEMS .............................................................................................................. . . 5

5.1 Load Protection Circuitry..................................................................................................................... 5

5.2 Amplifier Protection Circuitry ............................................................................................................... 5

5.3 Protect Indicator........................................................................................................................ . . 6

......................................................................... ...........................................................

..................................................................................

...............................

. 3

‘ 1

2

G OPERATION......................................................................................................................................... 6

G.l Dual Mode of Operation............................................................................................................... . . 6

G.2 Bridge Mode of Operation ................................................................................................................... 6

7 IN CASE OF PROBLEMS

8 SPECIFICATION

9 SERVICE INFORMATION.................................................................................................................. 10

9.1 Equipment Needed......................................................................................................................... 11

9.2 Adjusting SVRl and SVR2, the BIAS Trimpots

9.3 Ordering Replacement Parts ..............................

9.4 Factory Service

9.5 Technical Assistance .........................................

...................

................................................

6

7

11

11

11

11

ALTEC JJCStSING^ CORPORATION o a Mar-k W Company

Page 3

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

1 ELECTRICAL

Two amplifier models are

available. One model has a 50/60

Hz power transformer with two

120 V ac primary windings. These

windings may be wired in parallel

or series for operation at either

120 V ac or 220/240 V ac. The

other amplifier model is for export

into countries where tlie ac line

voltage is 100 volts, 50/60 Hz. The

next two sections refer to the first

model witli the dual 120 V ac pri

mary windings.

1.1 120 V ac, 50/60 Hz

Power Coimections

'rhe amplifier is provided

with the primary of the power

transformer slrappcil for 120 V ac

operation from the factory. Refer

to Figure 2 for the wirijjg deUiils.

WARNING: Verify that the power

transformer’s priinaiy circuit con

figuration is correct for the in

tended ac line voltage BEFORE

applying power to the amplifier.

1.2 220/240 V ac, 50/60 Hz

Power Connections

The power transformer

has two 120 volt primary windings

which can be connected in parallel

for 120 V ac line voltages, or in

series to meet 220/240 V ac re

quirements. Use the following

procetlures to re-strap the primary

of the power transformer for

220/240 V ac applications.

1. Malce sure the amplifier is

not connected to any

power source.

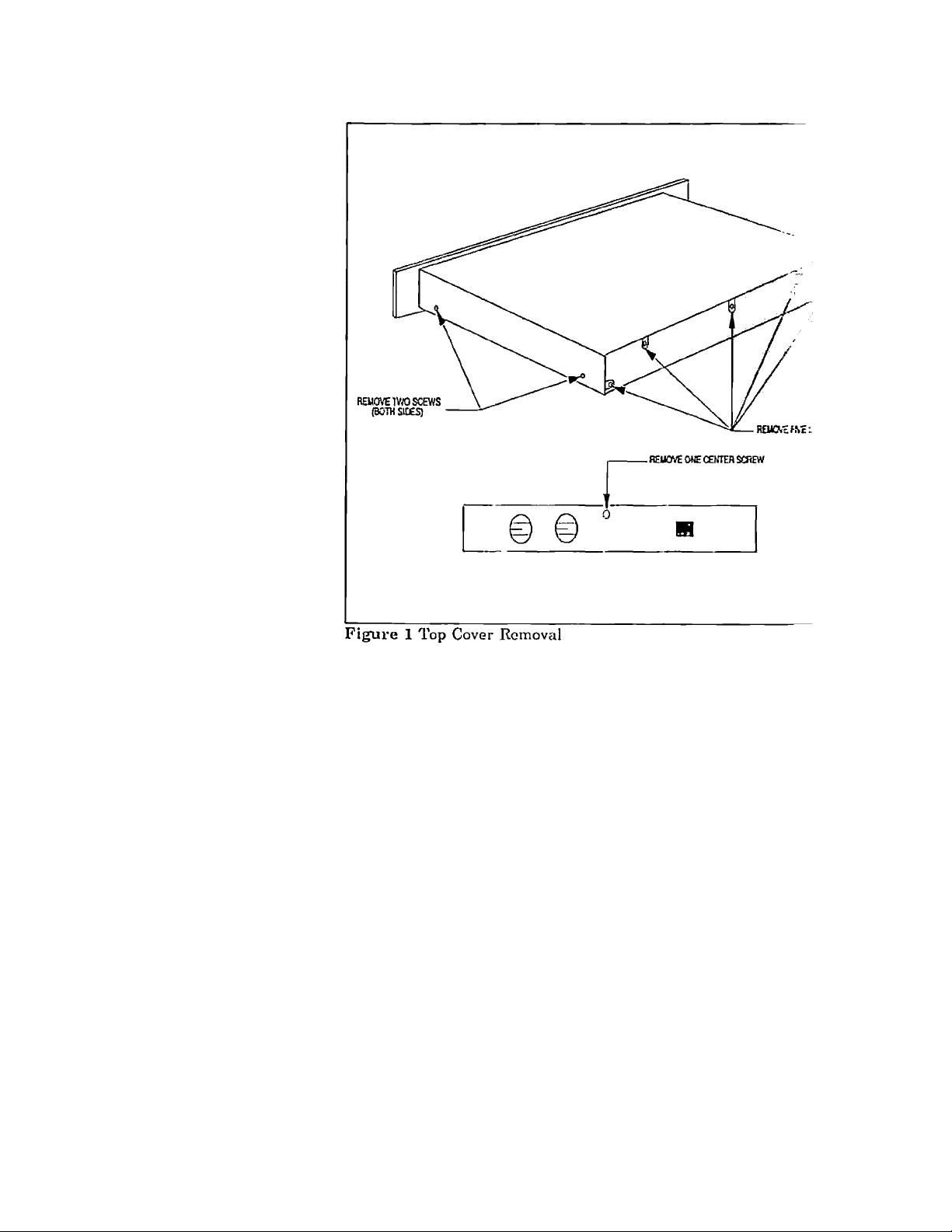

2. Remove and save the ten

screws securing the top

cover. Refer to Figure 1

for the exact screw loca

tions.

3. Locate terminal block TBl

located behind the AC

main power switch. Re

connect the leads as

shown in Figure 2.

4.

Install the top cover with

the ten screws previously

romovetl.

5.

Install the 2.0 A fuse,

T2.0A /250V slo-blo or

equivalent.

6.

Install the 230 Vac 50/-

60Hz and the T2.0A/250V

decals in the proper

positions.

INSTALLATION

2.1

Rack Mounting

The amplifier may be in

stalled in a standard 19 inch

equipment rack. It requires 1.75

inches of vortical rack space and

secures to the rack cabinet with

the-four rack mount screws and

cup washers provided in the hard

ware kit.

2.2 Ventilation

The amplifier m.;;;t be

adequately vontil.ntod tn ir.'oid ex

cessive temjjerature rise, i si;ould

not be used in areas where the

ambient temperature exceeds SO'C

(122°F). To determine i .imbient air temperature, opemte the

system in the rack until the tem

perature stabilizes. Mea'"ro the

ambient air with a bulb-type ther

mometer held at the botloin of the

uppermost amplifier. Dc tmt let

the thermometer touch the netal

chassis because the chassis will be

hotter than the ambient a:.-. If the

air temperature exceerls 50°C

(122°F), the equipment siiould be

spaced at least 1.75 inches apart

or a blower installed to provide

sufficient air movement within

the cabinet.

WARNING: Do not operate the

amplifier within a completely

closed unventilated housing.

ALTEC LANSING* CORPORATION • a Mark IV Company

Page 4

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

For example, suppose an installer

uses 160 feet of 10 GA 2-wire

cable with an 8 H speaker system.

WHITE (A.a HECEPTAia^

The total po%ver loss in .U. cable

is;

A. 120 V ac Primary Wiring

X I ^

WHITE (A.C RECEPTACLE)

BIACK BUWHT BLUE

BLACK BLIWirr BLUE

_______________

nV/HT BROWN

8.240 V ac Primary Wiring

BRIWHT BROWN

Figure 2 Primaiy Wiring Configuration for 120 V ac and 220/240 V ac

SIGNAL CONNEC

TIONS

3.1

Input Connection.s

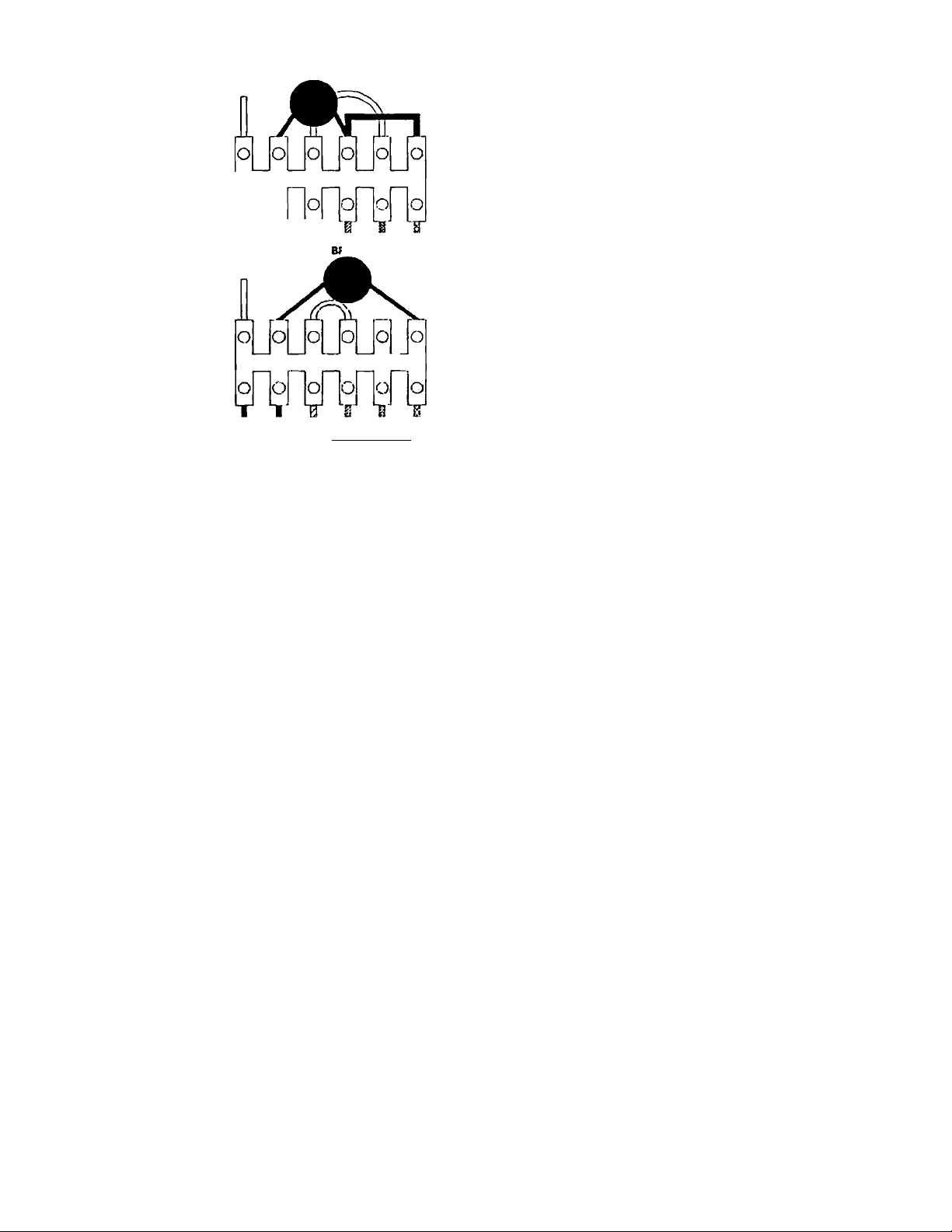

Balanced input connec

tions may be made to either the

Va phono (TRS) or the female

XLR connectors. For single-ended

inputs, strap the low (—) input to

ment. Refer to Figure 3 for po.ssi-

ble applications.

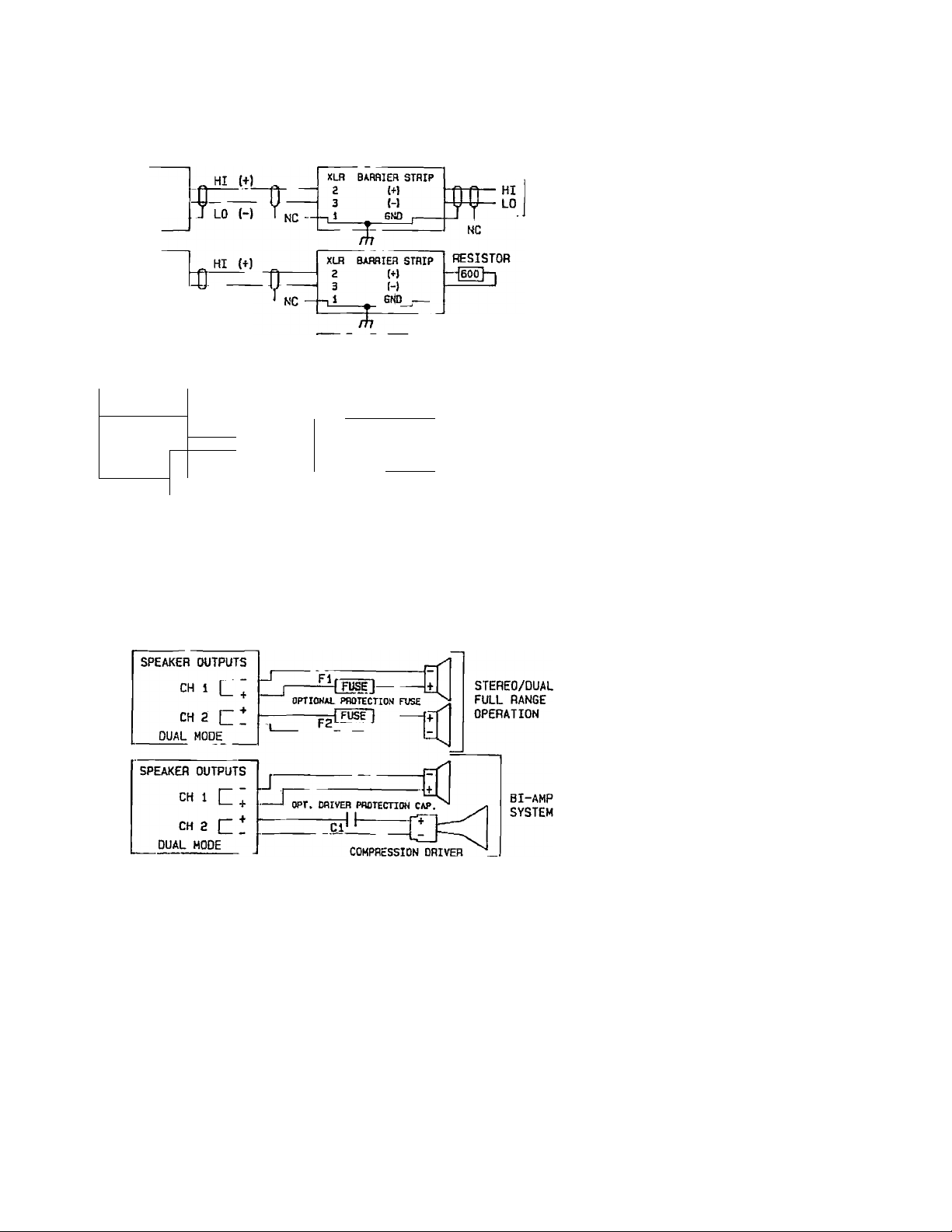

3.3 Output Connections

Output connections are

made to the four terminal barrier

strip connector located on the rear

of the unit. Refer to Figure 4 for

tj'pical output connections.

ground (pin 3 on XLR or Ring on

Va" phone). Otherwise, the elect

ronically-balanced input stage will

see 6 dB loss input signal level

than with a balanced input. Refer

to Figure 3 for typical input con

nections.

3.4 Output Cable Selection

Speaker wire size plays an

important part in quality sound

systems. Small wire gauges can

waste power and reduce the

damjiing factor at the speaker

terminals. This can add coloration

3.2 Line Output Connec

tions

TliD XLR and Vi" phone

connectors are wired in parallel.

Pin 2 of the XLR is the Tip of the

and muddincss to the sound. To

help offset this problem. Table I

has been assembled to enable you

to calculate the power losses in

the speaker cable.

Va" phono comiector, and pin 3 is

the Ring. Since the input imped

ance of the electronically-balanced

input stage is high (15 kohms),

there is minimal loading on the

signal source, Wien the input

connections are made to one con

nector, the other may be used as

an auxiliary line output to feed

other high input impedance equip

3.4.1 Calculating Power

Losses with 8 ohm

Loads

To calculate the total

power loss in the spealcer cable,

multiply the power loss per foot

(or meter) of the 2-wire cable sel

ected from Table 1 by the length

of the cable in feet (or meters).

Total Power Loss in cable

= 0.0191 watts/foot X lOr feet

= 3.0 watts

Does this mean that whena er the

amplifier produces 75 walls of

output power, 72.0 watts (75 watts

minus 3.0 watts) will be delivered

to the 8 ohm load? N'^d The

actual load impedance is ohms

plus the resistance of Iht cable

(0.00204 ohms/foot times L'"' feet)

for a total load imped.nice of

8.3264 ohms. At the 8 lated

output power, the output, /oltage

is 24.4 V rms. Therefore, I t ■ amp

lifier produces 71.5 wati - with

this load instead of 75 wa.‘ . This

was calculated by squaring the

voltage and dividing by I load

impedance (24.4* divid. i by

8.3264 ohms). As a result, ue act

ual power delivered to thf !-ad is

68.5 watts (71.5 watts minus 3.0

watts).

Had 18 GA wire been used hi the

above example, the lass in the

cable would have been Ifl.r ivatts.

Tliis example lllustrale.s I im

portance of using the pro; . wire

size.

3.4.2 Calculating <wer

Losses with 4 ohm

Loads

To calculate the- i sses

when using a 4 ohm speak .-; os

tein, multiply the loss at hms

by 3. In the above exampk-. the 10

GA wire would consume 9,'' watts

of power while the 18 GA '.■.•ire

would waste 58.5 watts more

than half of the amplifier’’^ ohm

power rating.

3.5 Damping Factor

The higher the da aping

factor rating of an amplill'-!' the

greater the ability of the am; lifier

A1.TEC lANSING' CORPORATION * a Mark T\' Company

Page 5

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

inward but its niomontum cmises

it to overshoot its resting point.

SOURCE AMPLIFIER'S INPUTS

BALANCED

SOURCE

BALANCH3

SOURCE

H/600 OHM

TERMINATION

UNBALANCED

SOURCE

------------

UNBALANCED

SOURCE

/, 1

LO (-)

HOT

HOT

J COM

'G j

r

NC

Figure 3 Topical Input Connections

SINGLE-ENDEO AUX OUTPUT

XLn BAFIflIEH STRIP

2 (+)

3 (-)

6Ю ¡-

7lr ^

ЯЛ

ВАИЙ1ЕП STHIP

2

Э

—t i

(t)

H

E.ND ,

%

Ж.

-----

AUX OUTPUTS

(USER OPTIONS)

BAL

OUTPUT

HOT

KEEP

COM

CABLE

RUNS

UNDER

6 ft

HOT

OR 2 m

COM

NC

This overshoot will dampen itself

out eventually but the unwanted

movements can add consitlerable

distortion products to tlu touiul.

In the process of moving hv.vard

through the magnetic fieUh the

voice coil assembly generatos a

current of opposite polarity tn the

original signal. This current in

duces a voltage or "back EMF”

which travels through the speaker

wire to the amplifier's '.utput.

The lower the amplifier’i. output

impedance, the faster tl.o overslioot of the voice coil will dampen

out. The output impedii'io; of an

amplifier can be calculated by

dividing the rated output linped-

ancG, typically 8 ohms, uy the

damping factor. The 944 i A has a

damping factor rating ; 100

which corresponds to an 4Utput

impedance of 0.08 ohni.s.

AMPLIFIER'S OUTPUTS

SPEAKER OUTPUTS

CH 1 L‘

eniOGE OUTPUT Q I I

CH г

BRIDGE MODE

Figure 4 'Topical Output Connections

to control unwanted speiiker cone

movements. When a signal drives

a woofer, current flowing through

the voice coil creates a magnetic

field. This field interacts with the

LOUDSPEAKER LOADS

HIGH POWER

FULL RANGE/

=0]

SUBWOOFER

permanent magnetic field in the

gap and forces tlie combination

cone and voice coil assembly to

move outward. When the signal is

removed, the assembly moves

3.5.1 Calculating the

Maximum Length of

Cable for a Spenified

Damping Factor Spec

ification at the Load

Tlie damping factor rating

is typically never realiz-т-: at the

load because of the rosisLunce of

the cable (and other facLnia such

as the contact resistance of an

output relay or the resistance of

an output fuse). Tlie damping fac

tor at the load should be 30 for

general paging systems ami 50 for

high fidelity music systcm.s. Econ

omics usually dictate, however,

that these numbers are cut-in

half. The resulting dampiiig factor

at the load should be based on ex

perience and customer satis

faction. Once a minimum; c ciiiping

factor is determined for => partic

ular type of installation, the fol

lowing equation can calculate the

maximum length of 2-wire cable

which can be used to achieve the

minimum damping factor .s^x cified

at the load:

ALTEC LANSING* CORPORATION • a Mark TV Company

Page 6

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Max. Length of 2-wire cable in

feet

ZL — Zo

= DF

DCR/ft

where

ZL is thé load impedance

to comiect to the amp

lifier;

Zo is the amplifier’s out

put impedance (0.08 ohms

for the 944lA);

DF is the minimum permi.ssible damping factor at

tlie load; and

DCR/ft i.s the DC resis

tance of the 2-wire cable

per foot from Table I.

The same equation can be used to

calculate the maximum cable

length in meters by substituting

the DCR per meter value from

Table I.

Let’s use the equation. Suppose

ZL equals 8 ohms, Zo = 0.08

ohms, and the minimum damping

factor at tlic load is 25. In addi

tion, IS GA cable is preferred.

Then, the maxiinxim length of 18

GA cable which can be used to

achieve a damping factor of 25 fit

the load is;

8

25

(0.08)

IS.4 feet

0.01302 n/ft

Table I 9441A Power Losses in 2-wire Speaker Cable

Power

AWC, nc:n/fi I.ciss/n Socllonal UCR/iTicler I^ishKlcr

(0Л) (îVil) (willt.s/(1)

G 0.Ü0Û8I

8 0.00121 0.0i:)4 8.30 0.0042I 0.0394

10

12

И

IG

18 0.01302 0.1218 0.82

20 0.02070 0.1935

22

0.0020'!

0.00324

O.OO.'il.'i 0.0482

0.0081!)

0.03202 0.:t073

0.0075

0.0191

0.0303 3.31

0.0767

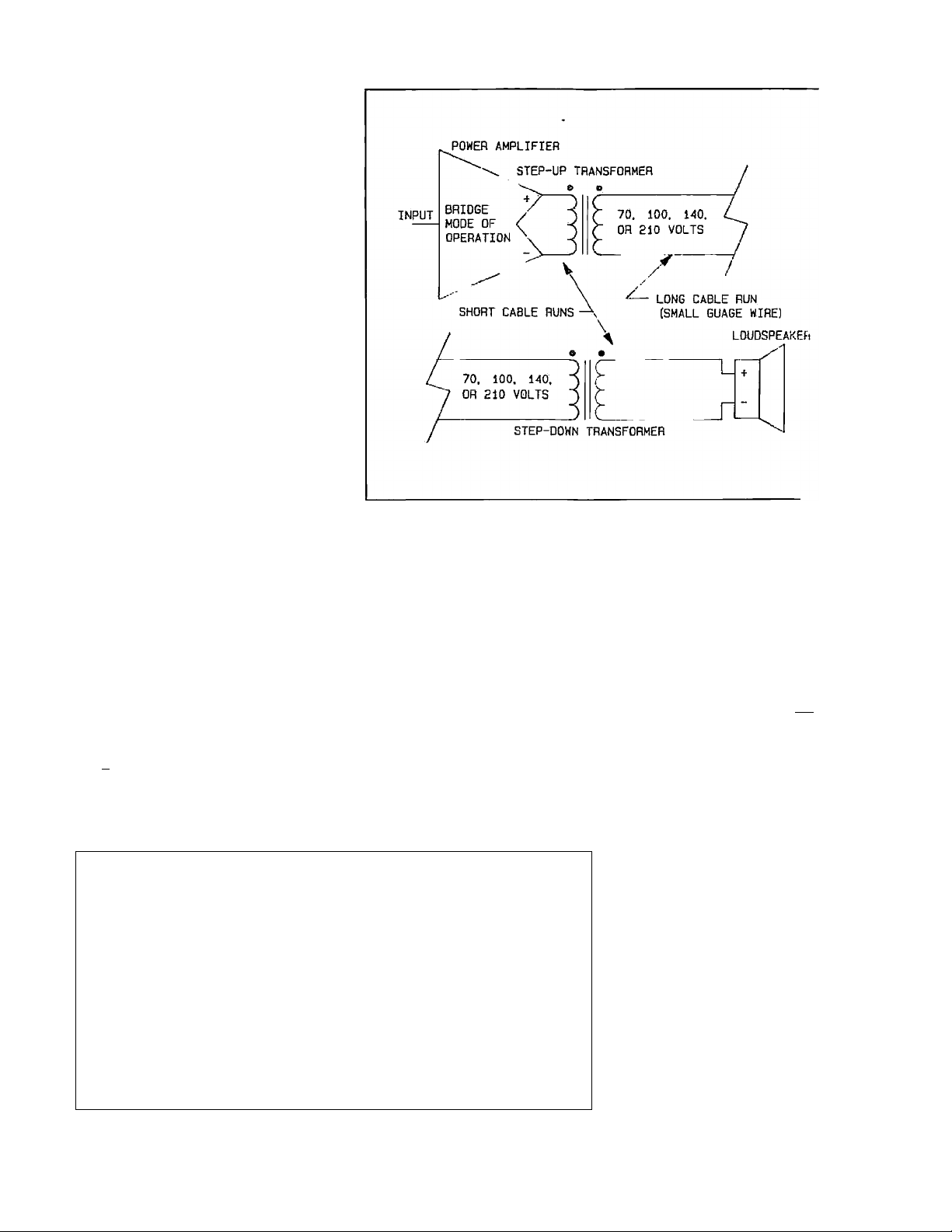

Figure 5 High-voltage Distribution System

Sometimes it may be necessarj' to

locate the speaker 100 feet or

more away from the amplifier. In

this situation, a much larger

gauge cable is required. However,

this may not be jiractical or eco

nomical. The size of the 2-wire

cable can be greatly reduced by

stepping up the output voltage of

tlie amplifier to 70, 100, 140, or

210 volt, using an output trans

former, then stepping down the

voltage at the load. Such a system

is shown in Figure 5.

Cable Crossarea (iiim*) (U/m)

13.30 0.00204

5.26 0.00669

2.08 0.01691

I.3I 0.02085 0.2508

0.52

0.33 0.10658

0.01063 0.0052

0.042S9 0.39Î16

0.06764 0.6288

Power

(woUs,/m)

0.0247

0.0626

0.1581

0.9860

I'he maximum

cable in this situation can be

approximated from the following

equation:

Max. Length of 2-wire o;

feet

(Pout)(DCR./ft)

where

V is the stejipod-up

voltage of the system;

Pout is the rated output

power of the amidifier;

Zo is the output imfiedance of the amplifier (0.08

ohms for the 9441A r,

ZL is the load impeo.mce;

DCR/ft is tb. DC

resistance of th: 2-wire

cable per foot from Table

I; and

DF is the minimum

permissible damping fac

tor at the load.

length of v-v/ire

ie in

Zo

J_

ZJ.

DF

ALTEC LANSING* CORPORATION © a Mark IV Company

Page 7

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Suppose a 210 volt system were

used at a 200 watt power level to

drive an 8 ohm load with a mini

mum damping factor of 25. Using

the same 18 GA cable as before,

the maximum length can now be

508 feet. Power companies use

this technique to transfer large

amounts of power over great dis

tances.

3.6 Speaker Protection

Fuse Selection

Sometimes it may be de

sirable to use in-line fuses (fuses

in series with the output) to pro

tect loud-sixjakor s3 'stems (or the

ampIirieiO- It is difficult, however,

todotermino the proper fuse value

with the correct lime lag and

overload cliaracteristics to match

the limitations of a speaker sj’stem. The values shown in Table II

should serve only as a guide. To

use, determine the power rating

and load value. Then, select a

standard value fuse of the next

smaller value to the one listed in

tlie table.

The values are calculated for fastblow fuses which carry 135% of

their current rating for an liour

but will blow within 1 second at

200%. Other fuse values may be

calculated for different power

levels from the following equation:

Fuse value =

(Pout X ZL)^ amps

ZL X 1.35

where

Pout is the output power

rating of the amplifier;

and

ZL is the load impedance.

Use 32 volt fuses if possible; they

typically have the lowest internal

resistance which will help nnnimize deterioration of the damping

factor at the load. Refer to the

example in Figure 4.

Table II Calculated Output Fuse

Values

Power 1 a 8П ion

(4Villl.s)

100 3.70 2.02 1.85

l-TO 3.21 2.27

200 5.2-1 3.70 2.02

3(X1 0.-12

400 7.-11

000

bond

0.07

LoafI

■-1..5-1 3.21

5.2-1

0.42

l.o.-)(l

3.70

4.5-1

3.7 Compression Driver

Protection Capacitors

Compression drivers, u.sed

for mid to high frequency sound

reproduction, are much more sus

ceptible lo damage from low' fre

quencies than large cone loud

speakers. Even though an elec

tronic crossover may be cmploj’od,

problems may arise in the cables

between the cros.sover and the

power amplifier, or from misadjustment of the cros.sover.

Either of those situations could

apply low frequency signals or

hum to the driver and cause

damage. To prevent a potential

mishap, Altec Lansing recom

mends using a capacitor between

the amplifier and the compression

driver to suppre.ss low frequencies

and possible DC. Refer to the

example in Figure 4.

In choosing a value, one must be

careful not lo interfere with the

crossover frequency. As a general

rule, select a capacitor whose

break frequency, with respect to the

load, is 3 dB down at approxi

mately Vu of the high pass comer

frequency.

Table III Compression

Driver

Protection Capacitors

Crossover 3 fl ion

Frequency Driver Driver

500 llz 80 |iF 40 iiF

800 llz 50 цР 25 iiF

1000 Hz 40 III1250 Hz

2000 Hz

3150 Hz 12 tiK

33 >iF 10 pF

20 tiF 10 |aF

20 tiF

6 (iF

Mylar capacitors with ai !st a

100 volt ac rating are -om-

mended. Table III show.: ;e re

commended capacitor val ;; for

use with 8 and 16 olnn dr’ ', rs at

popular crossover frequoucie.';.

4 OCTAL ACCES ORY

SOCKETS

Two octal sockets ¡i' ^rnita

variety of plug-in accessc.rii’n to be

used w'ith the amplifier. Uoi ...ally,

one “U" jumper is ins(-r'- be

tween octal socket pins : ,;d 1,

and another between pins " nid 6.

These jumpers must re;;:. ■; in.

place for the amplifier to .'rate

when not using any . : sorj

modules. To use with an ac .soiy

module, remove (and sr.- -- the

jumpers and install the . ulule

making sure the key on it ■ ■ .'nter

post aligns with the groove- ’ . the

female socket. For operation, refer

to the instructions provide d with

the modulo. Schematically the

module will be inserted '■ r.ween

the input connector and - bal

anced input stage.

Electronic modules are ; ... red

from a bipolar 15 volt su ily in

the amplifier. The sxij-: : is

capable of supplying up to 25 ma

DC of current. Currents ¡¡. i:;;icess

of 25 ma DC may prevent Li; ■ amp

lifier from disengaging :n its

built-in protection mecha:;’ .as.

5 PROTECTION SYS

TEMS

5.1 Load P rote: ’on

Circuiti'y

Each channel ind yend-

ently protects its load from

startup/shutdown transir>n'-DC,

and large subsonic signals.

5.2 Amplifier Protc-otion

Cii'cuitry

A unique current-lL.dling

circuit was designed specifically

for the amplifier. It feat .es a

variable current limit whic! is a

ALTEC LANSING^ CORPORATION * a Mark TV Company

Page 8

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

function of the output signal vol

tage. As a result, the amplifier can

deliver the rated currents into

rated loads but substantially

limits the current into low imped

ance or shorted loads (shorted

output terminals). Once the short

is removed, however, the amplifier

will resume normal operation.

The heatsink is conventionally

cooled. Slioxild the heatsink

temperature of a channel remain

excessively high, both chamiels

will .shut down automatically.

Wien the output devices cool to a

safe operating temperature, the

channels will automatically re

sume normal operation.

5.3 Protect Indicator

I'he “PROTECT” LED

illuminates when either channel

enters thermal protection. If a

shutdown does occur, the chan

nels will resume normal operation

as soon as its devices have cooled

to an acceptable temperature.

If the protection LED illuminates

and there is no indication of ex

cessive temperature, one, or both,

of the channels is in an internal

fault mode. If this occurs, refer to

the service instructions on page

12.

G OPERATION

G.l Dual Mode of

Operation

In the dual mode of opera

tion, the channels may be

operated independently. After in

stallation and hookup, verify that

the mode switch, located on the

rear panel, is in the “DUAL” posi

tion and rotate the level controls

fully counterclockwise (full atten

uation). Input a 0 dBu (0.775 V

rms) nominal signal level and

apply power. Slowly increase the

level controls until the desired

output power is obtained. If either

“CLIP” LED illuminates, reduce

the outjnit with the channel level

control or reduce the input signal

level at its source.

WARNING: Never attempt to con

nect the outputs of the two chan

nels in parallel.

6.2 Bridge Mode of

Operation

After installation and

hookup, verify that the mode

switch, located on the rear panel,

is in the “BRIDGE” position.

Rotate both levels controls fully

counterclockwise (full attenua

tion). Input a 0 dBu (0.775 V rms)

nominal signal level into channel

1 only and apply power. Slowly in

crease the level control of channel

1 until the desired output power

is obtained. If either “CLIP” LED

illuminates, reduce the output

level with the level control or re

duce the input signal level at its

soiirce.

CAUTION: Be sure that no input

connections are made to channel 2

and that its level control is fully

counterclockwise (OFF).

WARNING: The bridged output

mode provides a true halariced-to-

ground output. Do not use any test

equipment to test or evaluate tins

amplifier which does not have

floating grounds.

In Case of Problems

Please check the following

items:

1.

Verify that tlie amplifier

is properly coimected to

an ac power source and

that the source is active.

2.

Verify that the input

connections are properly

made. Refer to Figure 3.

3.

Verify that the output

comiections are properly

made. Refer to Figure 4.

4.

Check the input and out

put cables for proper

‘ wiring and continuity,

5. Check the signal source

and the load.

6. Ensure that the two

jumpers for each octal

socket are properly in

stalled (if not using op

tional plug-in modides).

7. Ensure that any aece.ssory

modules installed do not

draw more than i'u ma

DC of current.

8. Check that the mode

switch is in tin; •' :ured

position.

NOTICE: Repairs performed, by

other than authorized wananiy

stations (Dealers) or q: 'ified

personnel shall void the ivm—anty

period of this unit. To avoid loss

of warranty, see your neare;-; Altec

Lansing authorized dealer, or call

Altec Lansing Customer e-ervice

directly at (405) 324-531' Fc\X

(405) 324-8981, or write:

Altcc Lansing Customei

Sciwice/Repair

10500 W. Reno

Oklahoma City, OK 73128

U.S.A.

AIAEC LANSING^ CORPORATION o o Mark T\^ Company

Page 9

operating and Service Instructions for the Altec Lansing 944lA Power Amplifier

8

Conditions:

1. 0 dBu = 0.775 volts rins.

2. Dual mode ratings are for each channel.

3. Both channels operating at rated output power

4. 120 volt ac line input voltage maintained for all

Continuous Rated Output Power:

(20 IIz - 20 kHz at less than 0.1% THD)

Dual mode, 4 fi; 100 watts/ch

Bridge mode, 8 fl: 200 watts

Dual mode, 8 fl; 75 watt..s/ch

Bridge mode, 16 Cl: 150 watts

Continuous Rated Output Pow'er to Subwoofer:

(20 llz - 1 kHz at less than 0.1% TIID)

Dual mode, 4 0: 130 watts/ch

Bridge mode, 8 O: 260 watts

Dual mode, 8 O: 95 watts/ch

Bridge mode, 16 O: 180 watts

Miiximum Midband Output Power:

(Ref. 1 kllz, 1% TIID, @120 volts ac line voltage)

Dual mode, 4 O:

Bridge mode, 8 O:

Dual mode, 8 O:

Bridge mode, 16 0:

(Ref. 1 kHz, 1% THD, @108 volts ac (10% sag))

Dual mode, 4 O:

Bridge mode, 8 O:

Dual mode, 8 O:

Bridge mode, 16 O:

SPECIFICATIONS

unless noted.

tests unless noted.

>145 watts/ch

>270 watts

>100 watts/ch

>200 watts

>115 watl.s/ch

>220 watts

> 80 watts/ch

>155 watts

Voltage Gain:

(Ref. 1 kHz)

Dual mode, 4 fl: 28 dB

Dual mode, 8 Cl: 30 dB

Bridge mode, 8 fl: 34 dB

Bridge mode, 16 fl: 36 dB

Input Sensitivity for Rated Output Powci-

(Ref. 1 kllz, ±0.5 dB)

Dual mode, 4 fl:

Bridge mode, 8 fl:

Dual mode, 8 fl:

Bridge mode, 16 ft:

Miiximum Input Level:

(Ref. 1 kHz)

Input Impedance:

(Ref. 1 kHz)

Balanced:

Unbalanced:

Polarity:

Phase Response:

(Any mode)

20 Hz:

20 kHz:

THD: <0.1% aVp. <0.05%)

(Any mode, 30 kHz measurement bandwidth i

OdBu (0.774 V - ' s)

-0.25 dBu (0.752 v rms)

+1.0 dBu (0.869 V .rms)

+ 1.0 dBu (0.869 ” rms)

+20 dBu (7.75 V . ms)

30 kfl

15 kfl

Positive-going signal

applied to pin 2 of TvLR

or (+) of */«" phone (tip)

produces positive-going

signal at (+) output

terminal.

<+25°

>—25°

(Ref. 1 kHz, 1% THD, @100 volts ac (17% sag))

Dual mode, 4 Cl:

Bridge mode, 8 fl;.

Dual mode, 8 fl:

Bridge mode, 16 fl:

Headroom (Before clip): >1 dB

(Ref. 1 kHz, 1% TIID, single channel mode)

Frequency Response: 10 Hz - 50 kHz

(Ref. 1 kHz, 1 watt output, +0/—3 dB)

Power Bandwidth; 20 Hz - 20 kHz

(Ref. 1 kHz, +0/—1 dBr where 0 dBr = rated output

power in any mode)

> 95 watts/ch

>185 watts

> 70 watts/ch

>135 watts

ALTEC LANSING'^ CORPORATION » « Mark IV Company

IMD (SMPTE 4:1);

(Any mode)

Slew Rate:

Dual mode, 4 or 8 il:

Bridge mode, 8 or 16 fl:

Damping Factor:

(Dual mode, 8 fl)

1 kHz:

(Ref. 1 kHz, 0 dBr = rated output power into 8

ohms, single channel operating)

Noise; > 100 dB

(Below rated output power, A-weighting filter, 8 fl

dual mode, 50/60 Hz ac line frequency)

<0.1%

>19 V/psec

>37 V/psec

>100

<55 dBrCrosstalk:

Page 10

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Amplifier Protection;

Load Protection:

Cooling:

Hea(.sink:

Output Topology:

Output TVp®'

Dual mode:

Bridge mode:

Output Devices:

Total number:

Pdmax rating:

Vceo:

Ic:

Tjmax:

Controls and Switches:

Front:

Rear:

Front Panel Indicators:

Shorted output term

inals, Over-temperature,

RF interference

Startup/shutdown trans

ients, DC faults. Sub

sonic signals

Conventional heatsink

True complementary

symmetry

Unbalanced, each chan

nel

Balanced

4 devices

130 watts

180 volts DC

15 amps DC

150 “C

Two input level controls.

Power switch

Mode switch

Power LED, Clip LED (x

2), Protect LED

Operating ac Voltage

Range: Operates from line

voltages as low as 90

volts (at reduced output

power) assuminf; = 120 V

ac nominal line.

Power Consumption/

Heat Produced:

(Both channels operating in dual mode wit!- i kHz

sinewave input signal at slated output power into 4

Cl loads)

idle:

30 watts/0.102 kBTU/h

l/8lh max

midband power:

270 watts/0.833 kBTU/h

l/3rd max

midband power:

390 watts/1.099 kliTU/h

Rated output power: 600 walts/1.360 kBTU/h

Max midband power: 730 watts/1.490 kB'f'UAi

Opei'ating Temperature

Range;

Up to бО^С 122“F)

ambient

Dimensions (Rear of rack cars to max depth):

1.75 in II X 19 in W X

12.8 in D

(4.44 cm II X 48.26 cm W

X 32.51 cm D)

Connections;

Input:

Output:

Power:

Fuse Tjpe:

Power Requirements:

'// phone (x 2),

Female XLR (x 2),

Octal accessory socket (x

2), powered with ±15

volts DC at 25 ma.

Barrier strip

6 ft (1.83 m), 3-wire, 18

GA power cord with

NEMA 5-15 plug/IEC

T 4 A/250 V Slo-Blo or

equivalent (for 120 Vac

use)

120 Vac, 50/60HZ, 300

watts (configurable to

220/240 Vac). 100 Vac.

50/60 Hz model avail

able.

Shipping Weight:

Net Weight:

Color:

Enclosure;

Standard Accessories:

22 lbs (9.97 kg)

18 lbs (8.16 kg)

Black

Rack mount chassis, 16

GA steel, 3/16 i:; 5052

aluminum alloy front

panel

4 - “U” jumper idugs for

octal sockets '3 per

socket, installetl'

1 - Operating instruct

ions mid Service Manual

1 - 1'2 A/250 V ni.se (for

220/240 V ac '

ALTEC LANSING^ CORPORATION o a Mark TV Company

Page 11

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Optional Accessories:

1^9 )V

Power Limiter

put Bridging

mer

15515A Input Bridging

Transformer with Pad

15170 100 watt Auto

former

* 15581A 24 dB/oct

Li nkwitz-Riley Crossover

15594A-XXX 18 dB/oct

Low Pass Filters

15595A-XXX 18 dB/oct

High Pass Filters

15509A Bass Boost

module

The “-xxx” represents various corner frequencies

available for the corresponding filter.

* Note: Tlie 14712A, and the 15581A will

extend above and below the back panel

0.625 inches (1.58 cm).

ALTEC LANSING CORPORATION continually

strives to improve products and performance.

Tlierefore, the specifications are subject to ch.mge

witliout notice.

V

ALTEC LANSING* CORPORATION • a Mark IV Company

Page 12

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

off

9441A Power Amplifier

SERVICE INSTRUCTIONS

* * * CAUTION * * *

NO USER SERVICEABLE PARTS INSIDE. EXTREMELY ILAZARDOUS VOLTAGES AND CURRENTS MAY BE ENCOUNTERED

WITHIN THE CHASSIS. THE SERVICING INFORMATION CON

TAINED \VITHIN THIS DOCUMENT IS ONLY FOR USE BY ALTEC

LANSING AUTHORIZED WARRANTY REPAIR STATIONS AND

QUALIFIED SERVICE PERSONNEL. TO AVOID ELECTRIC

SHOCK, DO NOT PERFORM ANY SERVICING OTHER THAN THAT

CONTAINED IN THE OPERATING INSTRUCTIONS UNLESS YOU

ARE QUALIFIED TO DO SO. OTHERWISE, REFER ALL SER

VICING TO QUALIFIED SERVICE PERSONNEL.

10

ALTEC LANSING* CORPORATION o a Mark IV Company

Page 13

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

9 SERVICE INFORM

ATION

WARNING; No user serviceable

parts inside. Extremely hazardous

voltages and currents may be en

countered within the chassis. The

servicing information contained

within this document is only for

use by Altec iMusing authorized

warranty repair stations and

qualiped service personnel. To

avoid electric shock DO NOT per

form any servicing other than that

contained in the Operating Instr

uctions unless you are qualified to

do so. Otherwise, refer all servi

cing to qualified senice personnel.

NOTICE: Modifications to Altec

Lansing products are not recom

mended. Such modifications shall

be at the sole expense of the

pcrson(s) or company responsible,

and any damage resulting there

from shall not be covered under

warranty or otherwise.

9.2 Equipment Needocl

To precisely adjust the

trimpots, you must have tlie fol

lowing equipment:

1 — Digital DC volt meter

2 — 4 Cl load rated at 200

watts

1 — Small non-conducting

flat-blade screwdriver or

set of plastic TV

alignment tools

Miscellaireous handtools

(to remove the top cover)

NOTE; If you need to verify the

amplifier's performance against

the rated specipcations, you must

be able to maintain the ac line

voltage constant at 120 V ac (or

240 V ac if wired according to

Figure 2). Therefore, we recom

mend a suitably rated variac (50

ampere rating at 120 V ac).

9.2 Adjusting VR02 and

VR102, the BIAS

Trimpot

To adjust VR02 and VR102 for

the proper bias, follow the pro

cedures below:

1. Turn power off and dis

connect the unit from its

power source. Make sure

the unit is in the Dual

mode with 4 D loads con

nected to each channel.

2. Remove the ten screws se

curing the top cover.

Refer to Figure 1 for the

.screw locations.

3. Channel 1: Locate the

junction of Ql2’s emitter

and R37. Connect the pos

itive side of the digital DC

volt meter to the junction

of QI2’s emitter and R37.

Then locate the junction

of Ql4’s emitter and R38.

Connect the negative side

of the digital DC volt

meter to the junction of

Ql4’s emitter and R38.

Connect the unit to its

power source and turn the

power on. Adjust VR02 so

that the digital DC volt

meter reads 7 milli volts

DC (± .2 mVdc). Turn

power off and disconnect

the unit from its power

source.

Note; Adjust Bias im

mediately after turning

power on.

4. Channel 2: Locate the

junction of Qll2’s emitter

and R137. Connect the

positive side of the digital

DC volt meter to the

junction of Q112’s emitter

and R137. Tlien locate

the junction of Qll4’s

emitter and R138.

Connect the negative side

of the digital DC volt

meter to the junction of

Qll4’s emitter and R138.

Connect the unit to its

power source and turn the

power on. Adjust VR102

so that the digiUiI DC volt

meter reads 7 milli volts

DC (± .2 mVdc). furn

power off and disc'.'iinect

the unit from its pow'er

source.

Note: Adjust r.ias im

mediately after Lii ruing

power on.

0

Re-install the lop cover

.

with the ten screws pre

viously removed.

9.7

Oi'ilex'ing Replacement

Parts

To order replacvinent

parts, look up the <r.lering

number from the componen, parts

listing and call (405) 32-5-531L,

FAX (405) 324-8981, or wrih-:

Altec I.ansing

Replacement Parts Sales

P.O. Box 26105

Oldahoma City, OK 73120-0105

9.8 Factory Service

If factory ser\ ice is

required, ship the unit ;;i its

original packing prepaid tv

Altec Lansing Customer

Service/Repair

10500 W. Reno

Oklalioma City, OK 73128

Enclose a note describing the pro

blem in as much detail as possible.

Include any additional helpful in

formation such as test conditions,

where used, how used, etc,

9.9 Technical Assisi anee

For applications assistance

or other technical information,

contact the Technical Services

Manager. You can call (405) 3245311, FAX (405) 324-8981, or

write:

Altec Lansing

Technical Services Manager

P.O. Box 26105

Oklalioma City, OK 73126-0105

ALTEC LANSING'^ CORPORATION • a Mark IV Company

11

Page 14

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

r

J02p4-(i> ^

JOI

JD2r

‘ I» .

Jtot

V'-

Ao

f«s 3’

<?>X JKJ3 0>

^ <*)

y IV.

S’-

IV,

r^IV.

•['«') —I

I C I0> nPCCE M'Xir

m

SW7

prtS—

5JJt%

tS^II

M-ThV

A c<ut top| .

0Ù? a>.'>

A'»TOW •?

«• ‘'■4 -■{

:^>\d

lip ^

KJO I

1

I ip

«£««1

Ziri"

I C*) *

«K1V. ^r,..., ,,

-1 - . I

Bi* 2i/n

-Wi?5}—

8?0* IV.

Sag ¿Y"-;

rt u *

CM?

11 i

II

¡■il

25

ite

----

12

!.v

-<^Y\

CK*I

H \—

tt*0*

♦ DV

<

(I')

<

Figure 6 Schematic of 9441A, Sheet 1 of 2

ALTEC LANSING* CORPORATION ® a Mark IV Company

jW

w

©

©

l3V/\

itr iV.

1 • -5K

OMT

■ _ } r T ^

"*3,0 '

gT77.'

•a

■o^N

A8MT I

iVM

fl!

to:

Page 15

operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

__

Figure 7 Schematic of 9441A, Sheet 2 of 2

ALTEC LANSING* CORPORATION • a Mark IV Company

13

Page 16

operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Component Parts Listing for the 9441A

Reference Ordering

Designator Number

Name and Description

(

ROl, R02, RlOl, R102 47-03-121532

R03, R103 47-03-122803

R04-07, R104-107 47-03-028238

R08, R108 47-03-037660

R09, R109 47-01-028011

RIO, RllO, 47-01-028530

Rll, R25, Rll, R125 47-01-102072

R12, R44, R45, R47, R51, 47-01-102106

R112, R144, R145, R147, R151,

R203

R13, R113 47-03-028274

R14, R30, R114, R130 47-01-102112

R15, R18, R115. R118 47-01-102080

R16, R19, R116, R119 47-01-102054

R17, R28, R32, R117, R128, 47-03-038030

R132

R20, R33, R120, R133 47-03-028694

R21, R121, 47-03-038031

R22, R122, 47-03-122953

R23, R123,— 47-03-038032

R24, R124 47-01-102085

R26 47-01-102111

R27, R127, R202, R206, R207 47-01-102102

R29, R129 47-01-102110

R31, R131 47-01-102129

R34, R134 47-01-038033

R35, R36, R135, R136 47-01-038034

R37, R38, R137, R138 47-01-037992

R39, R43, R139, R143, 47-01-038035

R40, R140 47-01-038030

R41, R141 47-01-102098

R42, R142 47-01-102094

R46, R56, R146, R152 47-01-102119

R48, R58, R14S 47-01-102114

R49, R50-53, R59, R149, R150 47-01-102121

R54 47-01-107013

R55 47-01-102109

R57 47-01-102108

R63 47-01-038038

R126, R154 47-01-102082

R153, R201 47-01-102127

R204, R205 47-01-124444

R208, R208 47-01-102066

R210, R211 47-01-102046

R212, R213 47-01-113781

COI, C04, C19, GIOÌ, C104, 15-06-037215

C119

C02, C03, C102, C103 15-02-038039

C05, C105 15-01-038040

Resistor, 1.0 Kii, 0.25 watt, 1%, metal film

Resistor, 10 n, 0.25 watt, 1%, metal film

Resistor, 15.0 Kil, 0.25 watt, 1%, metal film

Resistor, 3.32 kil, 0.25 w'att, 1%, metal film

Resistor, 240 kfl, 0.25 watt, 5%, metal film

Resistor, 30 kfì, 0.25 watt, 5%, metal film

Resistor, 560 fl, 0.25 watt, 5%, metal film

Resistor, 15 Kfl, 0.25 watt, 5%, metal film

Resistor. 39.2 Kfl, 0.25 watt, 17c, metal film

Re.sistor, 27 Kfl, 0.25 watt, 5%, metal film

Resistor, 1.2 Kfl, 0.25 watt, 5%, metal film

Resistor, 100 fl 0.25 watt, 5%, metal film

Resistor, 91 fl, 0.25 watt, 1%, metal film

Resistor, 150 Í1, 0.25 watt, 1%, metal film

Resistor, 47 Kfl, 0.25 watt, 1%, metal film

Resistor, 22.1 Kfl, 0.25 watt, 1%, metal film

Resistor, 820 fl, 0.25 watt, 1%, metal film

Resistor, 2 Kfl, 0.25 watt, 5%, meUd film

Resistor, 24 kfl, 0.25 watt, 5%, metal film

Resistor, 10 Kfl, 0.25 watt, 5%, metal film

Resistor, 22 kfl, 0.25 watt,

Resistor, 120 Kfl, 0.25 watt, 57c, metal film

Resistor, 300 fl, 2 watt, 5%, metal oxide

Resistor, 68 fl, 2 watt, 5%, metal oxide

Resistor, 0.330 fl, 5 watt, 5%, cement

Resistor, 10 fl, 2 watt, 5%, metal oxide

Resistor, 80 Kfl, 0.25 watt, 57c, metal film

Resistor, 6.8 Kfl, 0.25 watt, 57c, metal film

Resistor, 4.7 Kfl, 0.25watt, 5%, metal film

Resistor, 47 Iffl, 0.25 watt, 5%, metal film

Resistor, 33 KD, 0.25 watt, 5%, metal film

Resistor, 56 Kfl, 0.25 watt, 5%, metal film

Resistor, 220 Kfl, 0.25 watt, 50c, metal film

Resistor, 20 Kfl, 0.25 watt, 5%, metal film

Resistor, IS Iffl, 0.25 watt, 57c, metal film

Resistor, 1.5 Kfl, 0.25 watt, 57c, metal oxide

Resistor, 1.5 Kfl, 0.25 watt, 5%, metal film

Resistor, 100 Kfl, 0.25 watt, 5%, metal film

Resistor, 4.7 Kfl, 2 watt, 5%, metal oxide

Resistor, 330 fl, 0.25 w'att, 5%, metal film

Resistor, 47 fl, 0.25 watt, 57c, metal film

Resistor, 330 fl, 2 watt, 5%, metal oxide

Capacitor, 0.1 pF, 100 volt, 5%, mylar

Capacitor, 100 pF, 100 volt, 57c ceramic

Capacitor, 0.1 pF, 50 VDC. electrolytic

5%, metal film

14

ALTEC LANSING^ CORPORATION ® a Mark W Company

Page 17

operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Reference Ordering

Designator Number

Name and Description

C06, C106 15-06-038041

C07, C17, C18, C107, C117, 15-06-038042

Capacitor, 680 pF, 100 volt, 5%, polypropylene

Capacitor, 200 pF, 100 volt, 5%, polypx-opylene

C118

C08, C09, C108. C109 15-02-038043

CIO, C13, Clio, C113 15-01-038002

Cll, cm 15-01-038044

C12, Cl 12 15-02-038006

C14, Cl5, C21, Cl 14, C115, 15-01-037907

Capacitor, 10 pF, 200 volt, 5%, ceramic

Capacitor, 47 pF, 63 VDC, electrolytic

Capacitor, 22 pF, 25 VDC, electrolytic (B.P.)

Capacitor, 30 pF, 200 volt, 6%, ceramic

Capacitor, 4.7 pF, 50 VDC, electrolytic

C121

C16, C116 15-01-038045

C20 C22, C120, C122 15-01-038046

C23, C24, C123, C124 15-01-038047

C25, C125 15-01-038048

C26 15-01-038049

C27, C28 15-01-038050

C201, C202 15-01-038005

C203, C204 15-01-038001

C205, C206 15-01-038000

C207 15-01-038051

LOl, LlOl 56-01-038052

DOl, D05, D06, DlOl, D105, 48-01-038053

Capacitor, 4.7 pF, 50 VDC, electrolytic (B.P.)

Capacitor, 100 pF, 100 VDC, electrolytic

Capacitor, 0.22 pF, 100 VDC, electrolytic

Capacitor, .47 pF, 50 VDC, electrolytic

Capacitor, 22 pF, 50 VDC, electrolytic

Capacitor, 47 pF, 50 VDC, electrolytic

Capacitor, 1000 pF, 63 VDC, electrolytic

Capacitor, 47 pF, 16 VDC, electrolytic

Capacitor, 22 pF, 16 VDC, electrolytic

Capacitor, 1 pF, 50 VDC, electrolytic

Inductor, 0.7 pF, coil

Diode, 1S155, switching

D106

D02, D04, D102, D104, D107,

48-02-042787 Diode, 1N4004, rectifier

D202, D203

D03, D103

D201

D204, D205

TCOl, ICIOI

IC02

QOl-03, Q17, QlOl-103, Q117

Q04, Q05, Q08, Q16, Q104,

48-01-122601

48-02-037985

48-01-037984

17-01-124804

48-03-026634

48-03-124824

Diode, 1N4148, switching

Diode, KBPC15-04, bridge

Zener Diode, 15 v(dt, 0.5 watt

1C, NJM 5532S ( ^. Г, рЛ

IC, ТЛ 7317P

Transistor, 2SA 970 GR, PNP

Transistor, 2SC 2240 GR, NPN

Q105, Q108, Q116, Q118

Q06, Q09, Q106, Q109 48-03-038054

Q07, QlO, Q107, QUO 48-03-037237

Qll, Qlll 48-03-038055

Q12, Q112 48-03-038056

Q03, Q04, Q103, Q104 48-03-026634

Q13, Q113 48-03-038057

Q14, Q114 48-03-038058

Q15, Q115 48-03-037983

Q201 48-03-124822

Q202 48-03-037236

53-02-038017

TSl, TS2 53-01-038061

56-08-038059

FI 51-04-038060

SWl 51-02-038066

у

SW2 53-01-038061

VROl, VRIOI 47-01-038063

Transistor, 2SC 2235 Y, NPN

Transistor, 2SA 965 Y, PNP

Transistor, 2SC 4381 Y, NPN

Transistor, 2SC 3519 Y, NPN

Transistor, 2SA 970 GR, PNP

Transistor, 2SA 1667 Y, PNP

Transistor, 2SA 1386 Y, PNP

Transistor, 2SC 2229 Y, NPN

Transistor, KTC 223SA Y, NPN

Transistor, KTA 968 Y, PNP

Thermister, NTC B57364-S209-M

Thermal switch, 115N

Transformer, 9441A (UB)

Fuse, T4 amp, 250 volt, SB-UL-GLS

Switch, power, H 8650 VB (250V lOA)

Switch, bridge, SS22F22-G9

Potentiometer, volume, 18PN01 C41 15SKA5K

ALTEC LANSING^ CORPORATION • a Mark IV Company

15

Page 18

operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

Reference

Designator

VR02, VR102

LED 01, 101, 102, 201

Ordering

Number

47- 06-038064

45-01-038065

48- 04-038018

21-03-038019

28-13-026422

Neime and Description

Potentiometer, bias, 422Z BlK

Relay, AW 8812

L.E.D., KLR-124 3 mm

Dual Binding Post, TB-301D RED/Black

Hardware, rack mount

21-01-013567 Jumper, Octal Socket, gold flash

r

l

16

ALTEC LANSING* CORPORATION o o Mark IV Company

Page 19

Operating and Service Instructions for the Altec Lansing 9441A Power Amplifiei

ADDENDUM

TO THE ALTEC LANSING 9441A

OPERATING AND SERVICE INSTRUCTIONS

The following is a change to the Electrical Instructions of the Altec Lansing 944lA Power Amplifier found on pages

1 and 2 of the Operating and Service Instructions (Part Number 42-02-037980).

1.2 220/240 V ac, 60/60 Hz Power' Connections

The power transformer has two 120 volt primary windings which can be connected in parallel for 120 V ac line

voltages, or in series to meet 220/240 V ac requirements. Use the following procedures to re-strap the i-i-imary of

the power transformer for 220/240 V ac applications.

1. Make sure the amplifier is not connected to any power source.

2. Remove and save the ten screws securing the top cover. Refer to Figure 1 for the exact screw locations.

3. Locate terminal block TBl located behind the AC main power switch. Reconnect the leads as showr- in Figure

2.

4. Install the top cover with the ton screws previously removed.

5. Install the 2.0A fuse, T2.0A /250V slo-blo or equivalent.

6. Install the 230 Vac 50/60Hz and the '1'2.0A/250V decals in the proper positions.

Figure 2 Primary wiring Configuration for 120 V ac and 220 V uc

Printed in U.S.A. 7/92

Revision 1 42-02-038412

Page 20

operating and Service Instructions for the Altec Lansing 9441A Power Amplifier

P.O. Box 26105 * Oklahoma City, OK • 73120-0105 • USA * Tol; (405) 324-5311 • FAX; (405] 324-8961

Printed in U.S.A. 04/92

a Maik IV 05tn|)an/

© 1992 by Altee Lansing Corporation. Ail liglils reserved worldwide.

42-02-037980

Loading...

Loading...