Page 1

LArslSING

sound

of

3300A

Mixing Consoles

Operating Instructions

ALTEC LANSING CORPORATION

a MAKK IV company

P.O. Box 26105 • Oklahoma City, OK • 73126-0105 USA « Tel: (405) 324-5311 • FAX: (405) 324-5981

Page 2

Operating Instructions for the Altec Ixmsing 3300A Series Mixing Consoles

TABLE OF CONTENTS

1 ELECTRICAL.............................................................................................................................................................. 3

1.1 120 Vac, 50/60 Hz Power Connections.................................................................................................................

1.2 100, 220, 240 Vac, 50/60 Hz Power Connections ................................................................................................. 3

2 INSTALLATION.......................................................................................................................................................... 3

2.1 Rack Mounting................................................................................................................................................... . 3

2.2 Ventilation.................................................................................................................................................... . - 3

3 SIGNAL CONNECTIONS.......................................................................................................................................... 3

3.1 Input Connections ..............................................................................................................................................- 3

3.2 Output Connections .............................................................................................................................................. 4

3.3 Insert Connections............................................................................................................................................... 4

4 OPERATION................................................................................................................................................................ 4

4.1 Input Channel Controls

4.2 Output Section Controls........................................................................................................................................ 3

4.3 Rear Panel Input Connectors .................................................................................................................... * - ■ • 7

4.4 Rear Panel Output Connectors.............................................................................................................................. 9

4.5 Rear Panel Switches............................................................................................................................................ 10

......................................................................

-................................................................ 4

S

5 MOVEABLE REAR PANEL ON THE 3308A MIXER .......................................................................................... 11

6 WRITE-ON LABELS..................

7 SYSTEM SPECIFICATIONS

. 11

. 12

8 SERVICE INFORMATION........................................................................................................................................... 16

8.1 Ordering Replacement Parts............................................................................................................................... 16

8.2 Factory Service .................................................................................................................................................. 16

8.3 Technical Assistance........................................................................................................................................... 16

8.4 Schematics.......................................................................................................................................................... 16

8.5 Component Parts Listing .................................................................................................................................... 24

TABLE OF ILLUSTRATIONS

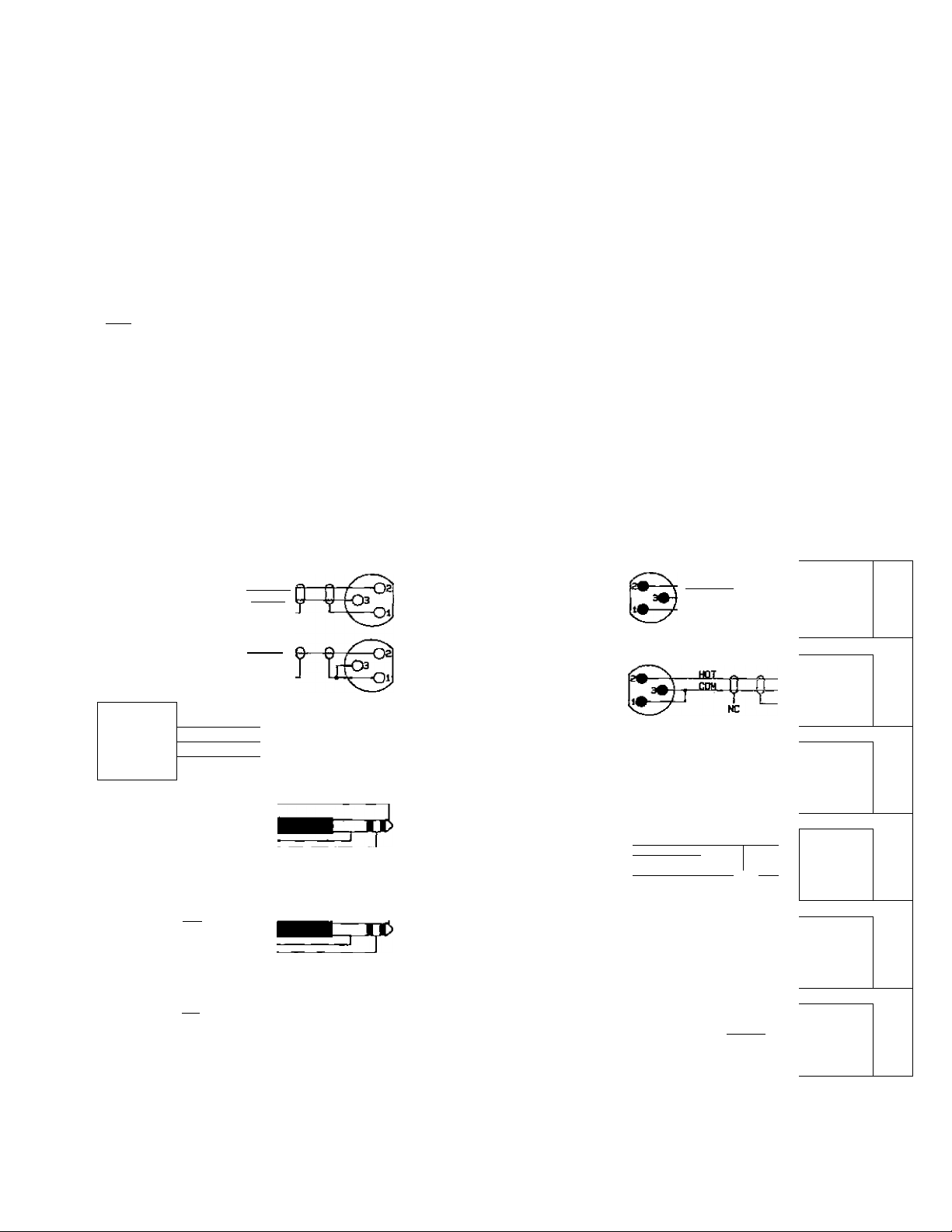

Figure 1. Typical input connections ........................................................................................................................... . , , . 3

Figure 2. Typical output connections .................................................................................................................................. 3

Figure 3. Typical insert connections

.................................................................................................................................. 4

Figure 4, Input channel controls........................................................................................................................................... 4

Figure 5. Output section controls ................................................................................................................................... - 6

Figure 6. Rear panel input connectors ..............................................................................................................................

8

Figure 7. Rear panel output connectors................................................................................................................................ 9

Figure 8, Rear panel switches.......................................................................................................................................... , lO

Figure 9. 8308A moveable rear panel................................................................................................................................ 11

Signal Flow Diagram......................................................................................................................................................... 13

Transformer Primary Wiring Diagram............................................................................................................................. 16

Mixing Console Wiring Diagram.................................................................................................................................. • 17

Input Board Schematic....................................................................................................................................................... 18

Sub Board Schematic......................................................................................................................................................... 19

Main Board Schematic....................................................................................................................................................... 20

Monitor Board Schematic.................................................................................................................................................. 21

Relay Board Schematic...................................................................................................................................................... 22

Power Supply Board Schematic......................................................................................................................................- 22

Display Board Schematic .................................................................................................................................................. 23

ALTEC LANSING^ CORPORATION * a Mark IV Company

Page 3

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

1 ELECTRICAL

1.1 115 Vac 50/60 Hz Operation

Tlie mixing console is provided with

the voltage select switch in the 115

Vac position. Its power supply design

allows it to be powered from 100 Vac

to 120 Vac lines in this switch posi

tion.

1.2 230 Vac 50/60 Hz Operation

The mixing console may be powered

by line volta^s from 220 Vac to 240

Vac by switching the voltage select

switch to tlie 230 Vac position. How

ever, the ac line fuse must be

changed. Refer to Table I for proper

fiise value.

WARNING: Veri^ that the voltage

select switch is in the desired

position, and the proper fuse is in

place for the intended ac line voltage

BEFORE applying power to the

mixing console.

2 INSTALLATION

2.1 Rack Mounting

The 3308A mixer may be placed in a

standard 19 inch equipment rack. It

requires 17,5 inches of vertical speice

(10 standard EIA vertical rack

spaces). For more information on

rack-mount installation, refer to

Section 5 and Figitre 9 of this

manual.

2.2 Ventilation

The 3300A series mixii^ consoles

should not be used in areas where

the ambient temperature exceeds

eO^C (140°F).

Table I. Fuse Selection Chart

I

iOO niA/250 V

300 mA)2M> V

230 niA)250 V

AC LINE

FUSE

AC LINE

VOLTAGE

100 V— 120 V

(8 anii 16 ch only)

100 V — 120 V

eh only)

220 V — 2<I0 V

3 SIGNAL CONN liCTIONS

3.1 Input Connections

Balanced microphc -ne inputs may hi

made to the 3-pin XLR-^jqje con

nector. Balanced line inputs may hi

made to the Vi-inch phone (TRS

connector. For single-ended inputs

strap the low (—) input (pin 3 oi

XLR or Ring on %-inch phone) h

ground. Otherwise;, the electronically

balanced input stage will see 5 dl

less input signal level than with i

balanced input. Refer to Figure 1 fo:

typical input connect ions.

BALANCED

LO-Z

MIC

UNBALANCED

LO-Z

MIC

BAUINCED

LINE

LEVEL

SOURCE

UNeALANCED

LINE

LEVEL

SOURCE

m

UNBALANCED

LINE

LEVEL

SOURCE

UNBALANCED

LINE

LEVEL

SOURCE

M 1*1

J LA

HOT

HI 1+1 p

1

LC H

Y V 1

NC

jjCEL

Not recoABendfid foi* rtm? over 6 feet.

HOT

Not rocoauendeit for runs over B feet.

HPT

-e-r&

J

NC

p---------------—

J

----------------------------

-----------------

^ HI-Z

—UNBALANCED

r^LINE

J INPUT

LO-Z

MIC

INPUT

LO-Z

MIC

INPUT

HI-Z

BALANCED

LINE

INPUT

HI-Z

BALANCED

LINE

INPUT

1 HI-Z

BALANCED

LINE

INPUT

NC

1

1 balanced

Í load

:;);B ALANCEO

__

:.::3AUNCED

__

BALANCED

—1 LOAD

BALANCED

—^ LOAD

UNBALANCED

___

SERVOBALANCED

OUTPUT

SERVOBALANCED

OUTPUT

Mot reconaentfea for runs over 6 feet.

HL-Vl-

^RVO-

BALANCED

OUTPUT

Not recommeniied for runs over ipo feet. BALANCED

UNBALANCED

OUTPUT

Not reconnenoed for runs dver 6 feet.

UN8AU1NCED r

OUTPUT ^

Not recoradended (or runs over 5 feet

UNBALANreO 1

1

--------

____________-

-------

— —

3"

CGH

OUTPUT <dll|^H!i

“i

LOAD

LOAD

^ LOAD

-

Figure 1. Typical input connections.

ALTEC LAVS/VG* CORBORATJOti • a Mark IV Company

Figure 2- Typical output connections.

Page 4

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

3.2 Output Connections

The main outputs of the mixing con

sole are electronically servohalanced. Bzilanced output connec

tions may be made to the male 3-pin

XLR-type connectors. For singleended outputs, strap the low (—)

output (pin 3 on XLR or Ring on ‘/cl

inch phone) to ground. Otherwise,

the electronically servo-balanced

output stage will produce 6 dB less

output signal level than with a

balanced output connection.

Unbalanced connections may be

made to the other Vi-inch phone

(TRS) connectors. Refer to Figure 2

for typical output connections.

3.3 Insert Connections

Signal processing equipment may

easily be inserted in the signal path

by using the Vi-inch phone (TRS) in

sert connectors. The external device

must have line level unbalanced in

puts and outputs. The output signal

from the mixing console is on the

Tip and the input signal is on the

Ring. Tlie Sleeve is ground. Refer to

Figure 3 for a typical insert

connection.

4 OPERATION

4.1 Input Channel Controls

(Refer to Figure 4.)

The input channel is the beginning

of the signal amplification chain of

the mixer. Each input channel will

accept one signal source which may

be equalized, have effects added and

sent to the monitor and main ^stem

for the audience to hear. Each input

hcis a low-impedance microphone in

put (the 8-pin XLR connector) and a

high-impedance microphone or line

input (V«-inch phone jack). The line

input will accept signals from an

instrument, high-impedance micro

phone, tape/CD player, keyboard or

electronic drums or eilmost any other

audio source. Always make sure that

the channel fader (see Figure 4)

I IMUU.ANCCO

j 1 IWVT

1 wjtS/t

EXTEBNiL

EFFECTS

PROCESSOR

^

____

pL.

CHANNEL

“X

h

Y

Aid SUB

•^IS

Figure 3. Typical insert coimection.

and/or master faders (see Figure 5)

are down before plugging or unplug

ging input sources.

1. TRIM Control: This control

adjusts the gain of the input

amplifier to accommoriaie the

wide variation in signal

strength presented to the mixer

by the endless variety of signal

sources.

1110 TRIM control

allows the amplification of each

individual input source to be

optimized. Correct setting of the

TRIM control results in the best

signal-to-noise ratio (no iiiss),

the greatest dynamic range, and

the freedom from overload dis

tortion.

To set the TRIM control

correctly, first set the channel

fader at minimum and depress

the channel PFL switch. Make

sure the source (mic,

instrument) that is plugged into

the channel is used at its

nominal performance level.

Increase the TRIM level until

the level of the PFL meter

reaches 0 VU. Gradually bring

the channel fader up to Uie

desired listening level, 'iliis

insures that nominal level is

maintained throughout the

input channel.

If the level is too low in :e

trim’s gain circuit, hiss . ill

occur. If the level is too high in

the TRIM circuit, overloac' istortion will occur. Keeping ‘-e

channel faders at nominal 1( el

with proper setting of the TT ; ' T

control will keep the sy^’- n

sounding its best and Is

quietest.

ALTEC LANSING^ CORPORATION • a Mark IV Company

Page 5

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

2. EQ Controls: Equalization can

be more simply described as so

phisticated tone control. The

EQ circuits used in the 3300A

series have a substantial

amount of sound shaping

capability.

This wide range ceui be a bonus

when dealing with widelyvarying instrument signals, poor

acoustics or other problems. The

EQ should be used sparingly,

however, for the best results.

Too liberal use of the EQ can

cause phasing problems, add

noise, and use up a lot of ampli

fier power.

2A- HIGH EQ: The high EQ

circuit is a shelving type

filter at 10 kHz with a ±15

dB rzuige. It controls the

treble content of the input

signal Turning the control

counterclockwise decreases

the amount of treble,

clockwise increases it.

2B. MID EQ: The mid EQ cir

cuit is a peaking type filter

with a ±15 dB range. It

controls the midrange con

tent of the input signal.

Turning the control coun

terclockwise decreases the

amount of midrange, clock

wise increases it.

2C. MID Frequency: The mid

frequency circuit controls

the frequency range from

300 Hz to 5 kHz of the

MID EQ control. By vary

ing the FREQUENCY, dif

ferent tonal perspectives

can be created. The sweepable frequency gives much

more control flexibility.

2D. LOWEQ: The low EQ cir

cuit is a shelving type filter

at 100 Hz with a ±15 dB

range. It controls the bass

content of the input signal.

Turning the control coun

terclockwise decreases the

amount of bass, clockwise

increases it.

8. MONITOR Send: The monitor

send control sets the level of

that input signal in the monitor

mix. It is independent of all

input channel controls except

the TRIM control. It is not

affected by the channel EQ

controls or slide fader. Thus, it

is independent of, zmd not

affected by, changes in the main

or house mix.

4. AJJX Sends: Ilie AUX 1 send

control sets the level of that

signal in the AUX 1 mix and is

{x>st-fader, which means that it

is affected by the gain setting of

the fader. The AUX 1 send may

also be used as a mono send for

recording.

The AUX 2 send control sets the

level of that input signal in the

AUX 2 mix and is switchable

PRE or POST fader. In the PRE

position, it serves as another

MONITOR OUT, and in the

POST position, another

EFFECTS OUT.

5. PAN Control: Short for "pan

oramic potentiometer", this con

trol allows the channel’s input

signal to be placed within the

stereo image by assigning more

or less of the signal to the left or

right subgroup controls. Turn

ing the panpot to the left of

center moves the apparent

source toward the left channel.

Turning the panpot to the right

of center moves the apparent

source towzird the right channel.

Centering the control makes the

apparent source centered be

tween the channels. If all inputs

are panned center, the result is

mono.

Some users p>an all the instru

ments to one side and the vocals

to the other and use the sub

group controls to valance them.

6. PFL: PFL(pre-fader listen)

allows the open : to preview

any pre-fader sij, individually

or in combinaLi- through the

headphone out . To activate

the PFL simply ' >press the ap

propriate switcl: The status

indicator will . iit indicating

which pre-fader signals are be

ing monitored. hen the PFL

circuit is engag ' by depressing

a PFL switch, ^ th the right

meter and the headphone circuit

will monitor the audio level of

the selected cha;:ael(s).

In the normal position (all PFL

switches off), tile right meter

monitors the METER switched

bus, and the headphone circuit

monitors the out put of the SUB

L and SUB outputs. The

audio level of ,.he headphone

jack is controlled by the

PHONES conlrri.

7. Channel PEA^ LED: The

channel PEAK IjED monitors

the input channel circuit for

clipping or overload (both before

and after the EQ section). If it

lights, the sign;:, is bordering on

distortion. 'Ihis will be heard in

the output as aarsh, blaring

sound on voiame peaks. This

might be caused by excessive

boost in he channel

equalization controls, or a TRIM

control setting that is too high

for the input signal Generally,

readjusting the TRIM control

will cure '.is undesired

condition.

8. Channel Fader: The slide

fader controls the output level of

the channel as it is fed to the

subgroups. Tl.;: control should

be normally set around the "0"

mark (nomiiia. level). At this

point, the signal level is high

enough to K.eep noise from

creeping in and low enough to

insure plenty of headroom and

ALTEC LANSING* CORPORATION • a Mark IV Company

Page 6

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

4.2 Output Section Controls

1. TO MON Send (AVX 1. AUK

freedom from clipping

distortion. If the fader must run

wide open to get enough, level,

turn up the TRIM control

judiciously or increzise the level

setting of the left and right

subgroup controls. Conversely,

if the fader must be pulled way

back to get the right level, the

TRIM control or ;ereo

subgroup should be adjusted.

Adjust the TRIM control ii’ the

PEAK LED lights, otherwise ad

just the stereo subgroups. For

optimum performance, the

channel FADERS should be run

close to the "0" mark.

(Refer to Figure 5.)

2): The TO MON level control

determines the amount of exter

nally generated effects signals

in the monitor mix. With the

use of this control, the

performers can hear the added

effects in their monitors.

Figure 5. Output section controls.

2. Effects SEND (AUX1,AUX2):

The effects SEND control sets

the level of the signal appearing

at the effects send output

jack(s) going to any type of

outboard effects device(s) such

as a digital reverb. Hanger,

compressor/limiter, etc. The

source of this signal is via the

individual AUX 1 and AUX 2

send level controls on each

input channel.

3. Effects RETURN (AUX 1,

AUX2): The effects RETURN

level control determines the

amount of externally generated

effects signals in the main mix.

This signal is mixed into the

left and right stereo sub

channels via the AUX 1 and

AUX 2 PAN control(s).

4. PAN Control (AUX 1, AUX

2): The effects PAN control

(AUX 1, AUX 2) directs the

signal coming from the effects

ALTEC LANSIN(f CORPORATION • a Mark IV Company

Page 7

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

RETURN level control(s) into

the left Eind/or right sub

chaumels. The control works in

an identical way to the input

channel PAN control.

5. Master Section Controls:

The master section controls

affect the subgroup, main, and

monitor output levels.

The use of subgroups can be

shown by this example: If the

input channel PAN controls are

set fully clockwise for all the vo

cals, then the SUB R fader has

been assigned as a "vocal sub

master”. If the SUB R fader is

raised or lowered, the vocal

level in the mix can be set while

preserving the input channel

balance set among the vocalists.

5A. SUB L (Left Submaster):

Controls the volume of the

left stereo output channel.

It is also used as a

subgroup master.

SB. SU B R (Right

Suomaster): Controls the

vol .ne of the right stereo

01 'ut channel. It is also

1 d as a subgroup master.

5C. MAIN Master: The MAIN

(monaured) output is the

summed mix of the left and

right stereo outputs. The

MAIN master controls the

volume of the output.

5D. MON (Monitor Master):

Controls the volume of the

monitor output signal. The

monitor output is a mix of

the individual channel

monitor sends.

6. TAPE L and TAPE R: These

controls adjust the level of the

tape left and tape right returns.

7. PHONES (Headphone Level):

The PHONES gain control sets

the level at the headphone jack

(front panel on the 3324A and

the 3316A; top panel on the

3308A). Any signal selected by

depressing a PEL switch will be

monitored through the head

phone jack. Without any of the

PFL switches depressed, the

headphone circuit monitors the

left and right subgroup outputs

in stereo.

8. METER Assignment Switch:

A push-push switch is provided

to allow the user to select the

points in the circuit which are

monitored by the VU meters.

When the switch is depressed,

the indication will be the audio

level at the MAIN and MONitor

outputs. In the other (nondepressed) position, signal level

at the SUB Left and SUB Right

outputs win be shown.

9. VU Meters: Two "B" scale ana

log VU meters with integral

peak lights are used to indicate

signal level at selected points in

the circuit (see meter assign

ment switch and PFL switches).

The meter scede indicates a

range from —20 dB to +4 dB

with 0 VU = -1-4 dBu, a stand

ard in the industry. The

integral f>eak light, located in

the upper right-hand corner of

each meter, shows when the

output is above the -1-14 dB

level and the headroom is being

rapidly exhausted and distortion

is imminent. The meters read

either lefl/right stereo, or

main/monitor level. If any of the

PFL switches are depressed, the

right meter will monitor the

PFL bus signal. A PFL LED is

provided on the meter bridge to

acknowledge the condition.

10. LAMP Connector; A BNC-type

socket is provided at the top of

the mixer panel to accommodate

a Littelite* gooseneck lamp to

allow operation of the board in

low-light conditions. These

lamps are available in different

lengths from many professional

sound dealers and attaches

without tools. 'Hie LAMP

connector car. accommodate

either normal or 'gh intensity

lamps.

11. POWER Switch: The power

switch is used to turn the main

ac power on and off.

12. POWER Indicator: This LED

(green) is ilium Ij atcd when the

main ac power is m.

13. PHANTOM Power Indicator:

This LED (red' indicates when

phantom power present at

the microphone inputs.

14. PFL Indicator: This LED

(amber) indicates when the PFL

circuit is activated and shows

that the right meter is reading

the PFL bus sigiial level.

4.3 Rear Panel Input

Connectors

(Refer to Figure 6.)

The 3300A series :.:i;ier can accept

program material covering a dynamic

range of over 100 dB. All of the line

inputs cam safely accept signal levels

up to -f20 dBu. (See specifications

for details.) All lim- inputs are made

through standeiru '/i-inch phone jacks

(except for TAPE inputs). Several of

the inputs that directly access the

mix buses can L.. .ised to stack

mixers together without using up an

input channel. The stacking group

includes the AUX , AUX 2, euid

MONITOR inputs. The AUX return

inputs may also be used as stacking

inputs. For stereo subgroup stacking,

set the AUX 1 PAN control to L, and

the AUX 2 PAN control to R and use

AUX 1 and 2 RETURNS for lefi and

right stacking, respectively.

1. Balanced Low-Z Mic Input:

A female a-pin XLR-type

connector is used for balanced

low-impedam-e microphones.

The MIC .. 'PUT is actively

ALTEC LANSING* CORPORATION • a Mark IV Company

Page 8

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

baleinced; active balancing

allows elimination of the input

transformer (along with its

limitations) while maintaining

the RF auid hum rejection of a

good transformer-coupled input.

It is important during operation

or testing of the mixer that all

faders remain fully down when

ever the mic input is not

perly terminated with a micro

phone or an equivalent 150-ohm

source. An open mic input

invites the introduction of high

noise levels which could produce

lower quality sound or an

incorrect test measurement.

High-Z Line Input; A

standard Vi-inch phone jack is

used for balanced or unbalanced

line level signals. Examples of

these signeds include most

electronic keyboards, drum

machines and synthesizers, tape

pro

decks, CD players, etc. All input

channel controls, including the

variable TRIM control, affect

the LINE input. Maximum

input level before preamp

clipping is -1-24 dBu (12.3

Vrms).

If a sufficient signal level is not

possible with the TRIM control

at its furthest clockwise

position, the input signal must

then be treated as a mic level

signal and connected to the

microphone input. If necessary,

use an appropriate balancing

transformer or a direct box with

the microphone (XLR) input.

AVX RETURN (AUX 1 and

AVX 2): The AUX RETURN

jack(s) feed signals to the

subgroup buses. The signal is

controll^ by the RETURN and

PAN front panel controls.

4. AVX IN (AVX 1 and AVX 2):

The AUX IN jack(s) will put

signals directly into the respec

tive AUX bus. Crosstalk and

buffering protection .re

provided by the input circuit

Eind the signal level is controlled

by the external source.

5. MON IN: The MON IN J^ck

will put signals directly onto the

monitor bus. Crosstalk and

buffering protection are pro

vided by the input circuit and

the signal level is controlled by

the external source.

6. TAPE RETURN: These RCA

jacks Eillow a tape deck or CD

player to be directly connc-cied

to the mixer. The input is fed

into the left and right sub

groups and its level is controlled

by the TAPE L and TAPE R

front panel controls. These jacks

can also be used as other AUX letun s.

ALTEC LANSING* CORPORATION • a Mark IV Company

Page 9

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

figure 7. Rear panel output connectors.

7. INSERT L and R (SUB L

and SUB R): A space-saving

3-conductor (stereo) phone jack

is used for both output from

SUB L and SUB R respectively,

emd for the return to the

mixer’s master section from an

external processing device. Be

sure that the device that is to

be patched in heis line level

unbalanced inputs and outputs.

The signal at the insert jack can

drive loads of 2000 ohms or

greater and the external

processing device should have a

low output internal impedance

(100 ohms or less). Refer to

Section 3.3 of this manual and

Figure 3 for proper connections.

A nominal input signal is a level

of -1-4 dBu; the maximum level

is -(-20 dBu.

(stereo) phone jack is used for

both output from the input

channel and for the return to

the input channel from an

external processing device. Be

sure that the device that is to

be patched in has line level

unbalanced inputs and outputs.

The signal at the insert jack can

drive loads of 2000 ohms or

greater and the external pro

cessing device should have a low

output internal impedance (100

ohms or less). Refer to Section

3.3 of this manual and Figure 3

for proper connections.

A nominal input signal is a level

of -f4 dBu; the maximum level

is -1-20 dBu.

4.4 Rear Panel Output Connec

tions (Refer to Figure 7.)

outputs are servo-balanced and made

through chassis-mount male 3-pin

XLR-tyf>e connectors to a meiximum

level of -1-24 dBu (12.3 Vrms).

All other output connections are line

level, unbalanced, and made through

standard V4-inch phone jacks (except

for RECORD OUT).

1. SUB L Output: This left sub

group output is derived by sum

ming all of the points (channels

and externa'.) assigned to the

left subgroup bus. A PAN con

trol rotated fully counterclock

wise to the ’L” position will

assign that signal only to the

left bus.

2. SUB R Output: This output is

the right subgroup equiveJent of

the SUB L output.

8. Input Channel INSERTs: A

space-saving, 3-conductor

ALTEC LANSING^ CORPORATION • a Mark IV Company

In the 3300A series mixers, the SUB

L, SUB R. MAIN, and MONITOR

3. MAIN Output: The MAIN

output is the summed mix of

Page 10

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

Figure 8. Rear panel switches.

the left and right subgroup

outputs. Since the 3300A series

are true subgroup mixers, all

signals that appear in the main

mix must come through the

subgroup channels.

4. MONITOR Output: The

MONITOR output signal is the

sum of all the input cheuinel

monitor sends and the external

monitor input signal.

5. AUX SEND (AVX 1 and

AVX2): The AUX SEND out

put signal is the sum of all of

the input channel AUX sends

(PRE or POST fader) plus any

signal coming through the AUX

IN input.

6. TAPE RECORD: These

output signals are the sum of all

the input channels and effects

with their position in the L R

stereo mix. The TAPE RECORD

output is via RCA-jacks fixed at

-10 dBV for easy interfacing and

compatibility with semi-pro and

hi-fi tape decks.

4.5 Rear Panel Switches

(Refer to Figure 8.)

1. PHANTOM POWER Switch:

lliis switch turns the phantom

power supply on and off. The

phantom power supply provides

power for condenser-type micro

phones through the microphone

cable. When switched on, it

provides 48 volts dc at pins 2

and 3 on all of the microphone

input connectors. Pin 1 (the

shield conductor) provides the

ground return path. This will

power standard condenser

microphones. When switched on

or off, the voltage will slowly

ramp up or down; it teikes a few

seconds to reach full level. This

prevents unwanted transients

from reaching the microphone

inputs. When the switch is en

gaged, a red LED will light on

the meter bridge to confirm its

operation.

2. VOLTAGE SELECT Switch:

The 3300A series are capable of

operation at 115 or 230 Vac, 50

or 60 Hz. To seifely accomplish

a voltage change, follow tliese

steps:

1. Turn the mixer off and

completely disconr.f;;- the

ac power cord.

2. If the unit is used for 115

Vac (100—120 Vac) opera

tion, be sure a 0.4 amp SloBlo* 3AG fuse is installed

in the fuse holder on the

connector panel. If the unit

is used for 230 Vac (220—

240 Vac) operation, be sure

a 0.25 amp Slo-Blo*

10

ALTEC LANSING^ CORPORATION • a Mark IV Company

Page 11

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

5x20 mm (supplied) fuse is

installed in the fuse holder.

3. Change the chassismounted switch on the

connector panel to the

correct corresponding

voltage.

4. Plug the power cord in the

desired ac line and resume

normal operation.

CAUTION: Before attempting

to move this switch, the mixer

must be turned off and the

power cord disconnected.

Slo-Blo® is a registered trademark of

Littelfuse®, Inc.

5 MOVEABLE REAR PANEL

ON THE 3308A MIXER

One example of the versatility of the

3308A mixer is that it can be either

rack-mounted in a standard 19-inch

equipment rack or mounted in a

table-top. To accommodate a rackmount instaUation, the 3308A is

supplied with its connector panel

placed on its bottom. This prevents

the input/output connectors from

using up valuable vertical rack space.

Figure 9. 3308A moveable rear panel.

The connector panel may be moved <

to the rear of the mixer to

accommodate a table-top installation.

Refer to Figure 9 to move the

connector panel to the rear. When

moving this panel to the rear, care

should be taken not to pinch any

cables between the two panels.

WRITE-ON LABELS

In order to label each channel

without marring the surface of the

mixer, removzible stick-on labels are

available from any office supply

outlet. Labels that are recommended

are Presaply® Removable Labels by

Dennison; part number Den-43-540;

dimensions are %" X 1".

ALTEC LANSING^ CORPORATION • a Mark IV Company

U

Page 12

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

7 SYSTEM SPECIFICATIONS

Tcefing Concfifioru 120 Vrma, 60 Hz line voltogc maintained.

Frequency Response

20 Hi -20 kHz +1, -3 dB, +4 dBu in 600Q

Tolol Harmonic DtslarSon

Less than 0.05%, 20 Hi - 20 kHz, + 4 dBu in 600Q

Less than 0.10%, 20 Hr - 20 kHz, +24 dBu in 6000

Noise

(A-weighled, R, = ISOQ, Q>onnd TRIM minimum)

-131 dBV Equivalent Input Noise.

—87 dBV Rftsiduol Noise.

-81 dBV SUB OUT, MostoT toder nominol, oil Input feders rmnlmum.

-78 dBV SUB OUT, Master ksdor ond all input iodors nominal.

-77 dBV AUX S£ND, Master loder nominol, all AUX sends minimum.

-77 dBV AUX SEND, Master fader ond all AUX sends nominal.

Monmum Voltage Gcdn (+3 dB)

78 dB CH IN to SUB OUT & MON OUT

86 dB CH IN to MAIN OUT

52 dB CH IN to CH INSERT

88 dB CH IN to AUX OUT [post CH fador)

20 dS AUX RETURN to SUB OUT & MON OUT

10 dB AUX IN to AUX OUT

10 dB MON IN to MON OUT

Input Chonnel ^uelizafion

(15 dB rrxxximum boost or cut)

Input Chan noi Control Lo*Z input; 40 dB (12 dB - 52 dB]

Input Terminals

CH Input*

AUX RETURN (U)

INSERT IN

AUX IN, MON IN

TAPE RTN

NOTES: (1) Sensitivity is the lowest level that 4N^II produce о SUB output oi+4 d&u

Lo-Z

Hi-Z

CH{T-")

SUB (l,R}

его in maximum posEfion).

p] XLR'B typo connectors ore balanced. CH Phone Jocks are bolonced

Insert Phone Jocks ore unboionced (T s OUT, R = IN, S s GND).

(3) * 3308A: 8 ch, 33I6A: 16 cb, 3324A; 24 ch.

HIGH: 10 kHz (Shelving)

MID: 300 Hz - S kHz (Peaking)

LOW: 100 Hr (Shelving)

VJ5 7 *>0 .JQ /_1 1 JO _ JDi

Goin

52 dB

27 dB

Actuol Lood

Trim impedance Nominal

60kQ 6000 lin»

SkO

5kQ 6000 line

5kQ

20kQ

5kQ

For Use with

50-ÓO0Q mic3

6000 lines

6000 lines

6000 lines

6000 lines

Crosstalk

Adiocent cbonnd inputs

Input to output

VU Meieni (AD metorx orr Golibroted far 0 VU » + 4 dBu oufaut.}

2 illuminated meters LEFT/MAIN, RIGHT/MONITOR/PFL

dip facBootors

Input Channel:

VU Meters;

Lamp Connector

Pbontom Bower

+ 48 Vdc on electronically balonced microphone inputs (6.8kO source imp^-zance).

Power Requlremonb

Power Соляитрбоп

Console Dimomiona

Console t4o< Woi^Tt

Altee Lonaing continuolly strives to improve produeb ond perfarmoncc. Tberefaro, these

ареегКсаПола ore subject to change without notice.

Input Level

Sensifivity Nominal

-72 dBu (0.20mV) -52 dBu (l,95mV)

-<7 dBu (3.46mV) -27dBu p4.6mV)

-16 dBu (123mV)

-22 dBu (61.6mV) -2 dBu (616mV)

-12 dBu (195mV)

-6 dBu pSBmV)

-20 dBV (TOOmV)

(1.23V), the nominol outpul level when tf)e unit is set to тою mum gain (oil faders emd level controls

(T — +,Rk = GND). Other Phone Jocks and RCA Hn Jocks ore unbolonced.

+ 4 dBu (1.23V)

-2 dBu (616mV)

+4 dBu (1.23V)

-10 dBV (316mV)

-65 dB typieol ot 1 kHz

-60 dB typieol ot 1 kHz

+ 16 dBu (4 dB befare dipping)

+ 14 dBu (10 dB befare dipping)

12 Voc, 375 mA monmum

11S V or 230 V, 50/60 Hz (switch-.l '.

SOW

330&A. 19'x6.63'xl7.5' (483x 168> 445mm)

3316A- 29"x6.25‘x20.75* (737x 159x527mm)

3324A; 39*x6.25‘x20.75’ (991xl59x527mm)

3308Л: 27 Ibe (12.3 kgs)

3316Д; 40 1Ы (18.2 kgs)

3324A; 53 1Ьэ (24 kgs)

Connector

Max. befare Clip

-32 dBu (19.SmV)

-7 dBu p46mV)

—

+20 dBu (7.75V)

—

+26 dBu (15.5V)

-

In MUer

XLR*3 famule

Phono Jack fT85)

Phone jock

Phono Jock fTRS)

Phone .‘oc*

RCA fin Jock

Output Temanola

SUB OUT (l,R)

MAIN OUT

MONITOR OUT

AUX SEND (T,2) lOOO lOkO lines

CH INSERT (T--)

SUB INSERT (L,R) 750 TOkO line» -2 dBu (616mV)

TAPE RECORD (L,R) 7500

PHONES OUT 100O

NOTES: (1) XLR>3 type oannectors ore balanced. CH Phone Jocks are bolanced (T +, R « -, $ — GNO). Other Phone Jocks and RCA Pin Jocks ore unbdonced.

Inserì Phoi»e Jocks ore unbolonced (T a OUT, R « IN, S = GND).

(2) " 3308A: 8 ch, 3316A: 16 ch, 3324A; 24 ch.

12

Actual Source

Impedonce

150Q 6000 lines

T50Q 6000 lines

T50Q 6000 lines

1000

ALTEC LANSING* CORPORATION • a Mark IV Company

For Use with

Nominol

lOkO tines -2 dBu (616mV) +20 dBu (7.75V) Phone Jock (TRS)

lOkO lines -10 dBV pi6mV) + 10 dBV p.lóV)

80 phones

400 phones 3 mW 75 mW

Nominal

+ 4 dBu (T.23V) +24 dBu (12.3V) XlR-3 male

+ 4 dBu (1.23V) +24 dBu (12.3V)

+ 4 dBu (1.23V)

+ 4 dBu (1.23V)

1 mW 25 mW

Output Level

Max. befare Oip

+24 dBu (12.3V)

+20 dBu p.75V) Phono Jock

+20 dBu (7.75V) Phone Jock (TRS]

Connector in Mixer

XLR-3 mole

XLR-3 male

RCA Hn Jock

Stereo

Phones Jock

Page 13

Operating Instructions for the Altec Lansing 3300A Series Mixing Consoles

UIL « bill V CLOl

OHO &I10 tut-«

lua— 3D<i

(CO I I

-----

I «o *

«- Ql-> tt > i-

dlcc 3 ILSte r-9 113 3

tu C OILe Il’3*» A.S9

ocn-u OHO Q.&r>

3ZN UJ3— -«S- 33-<

O—I CO• H—I BO+

NO OH

HH I HP a

E— kl —CLffl

OZ^H Zh-b

— OU.kl QP-<I

Ba:a.a: £0*

XH ^

r»3 i

fic

ALTEC LANSING® CORPORATION • a Mark IV Company

13

Page 14

Qpemitn^ lìti

Loading...

Loading...