Page 1

A

LANSING®

1590E

Power Amplifier

SPECIFICATIONS

KEY FEATURES

★ DC Voltage Backup Ensures

Uninterrupted Operation

★ Switchable High-Pass Filter

Gain:

Input Sensitivity;

Power Output:

Frequency Response;

Input Impedance;

Load Impedance:

Load Voltage:

Output Impedance:

67 dB.

0.8 Vrms for rated output.

200 watts at less than 1% THD

from 50 Hz to 12 kHz.

±1 dB, 20 Hz to 20 kHz at 1 watt

output.

±1 dB, 50 Hz to 12 kHz at rated

output.

15 kohms.

15 kohms balanced with 15335A

Line Transformer.

150/600 ohms balanced with

15095A Line Transformer.

25, 50,100, and 200 ohms.

70.7,100,140 and 200 volts.

Less than 25% of nominal load

impedance.

DESCRIPTION

The Altec Lansing

designed for applications where uninterrupted operation

is a priority. The

1590E

less than 1% total harmonic distortion (THD) from 50 Hz

to 12 kHz, and has a frequency response of -1 dB from

20 Hz to 20 kHz at one watt output. Output transformer

taps provide connections for 70.7, 100, 140 and 200

volt line distribution systems.

The

1590E

features silicon solid-state circuitry, a

switchable high-pass filter for use in speech systems,

input connections for high impedance devices and for

150/600 ohm or 15,000 ohm balanced inputs, fail-safe

protection for output transistors, and a hinged front

panel for rapid access to the chassis interior.

The

1590E

is capable of operation from a negative

grounded 24/28 V DC source. The

for use in commercial audio systems and fire protective

signaling systems.

Designed for rack-mounted use, the

six units of vertical space. 10.5 inches (26.7 cm).

1590E

Power Amplifier is

provides 200 watts of power at

1590E

is UL listed

1590E

occupies

Noise Level:

Operating

Temperature Range:

Controls:

Power Required:

Special Features:

Output noise 85 dB below rated

output.

Upto55°C(131°F).

1 VOLUME control, continuously

variable.

1 power OFF-ON switch.

1 high-pass filter switch.

100/120/220/240 AC, 50/60 Hz,

25 Wat zero signal,

420Wat 200Woutput,

24/28 V DC (battery (-) is ground),

0.2 A at zero signal,

14 A at 200 W output.

Automatic transfer from AC to DC

power in the event of AC power

failure.

Dissipation sensing circuit for

protection of output transistors.

High-pass filters.

-or-

Page 2

CONDUIT

. KNOCKOUTS

FOR SPEAKER

WIRING

TRANSFORMER

ACCESSORY

RECEPTACLE

The input leads are connected to terminals

3 and 4 of the INPUT terminal board (see

Figure 4).

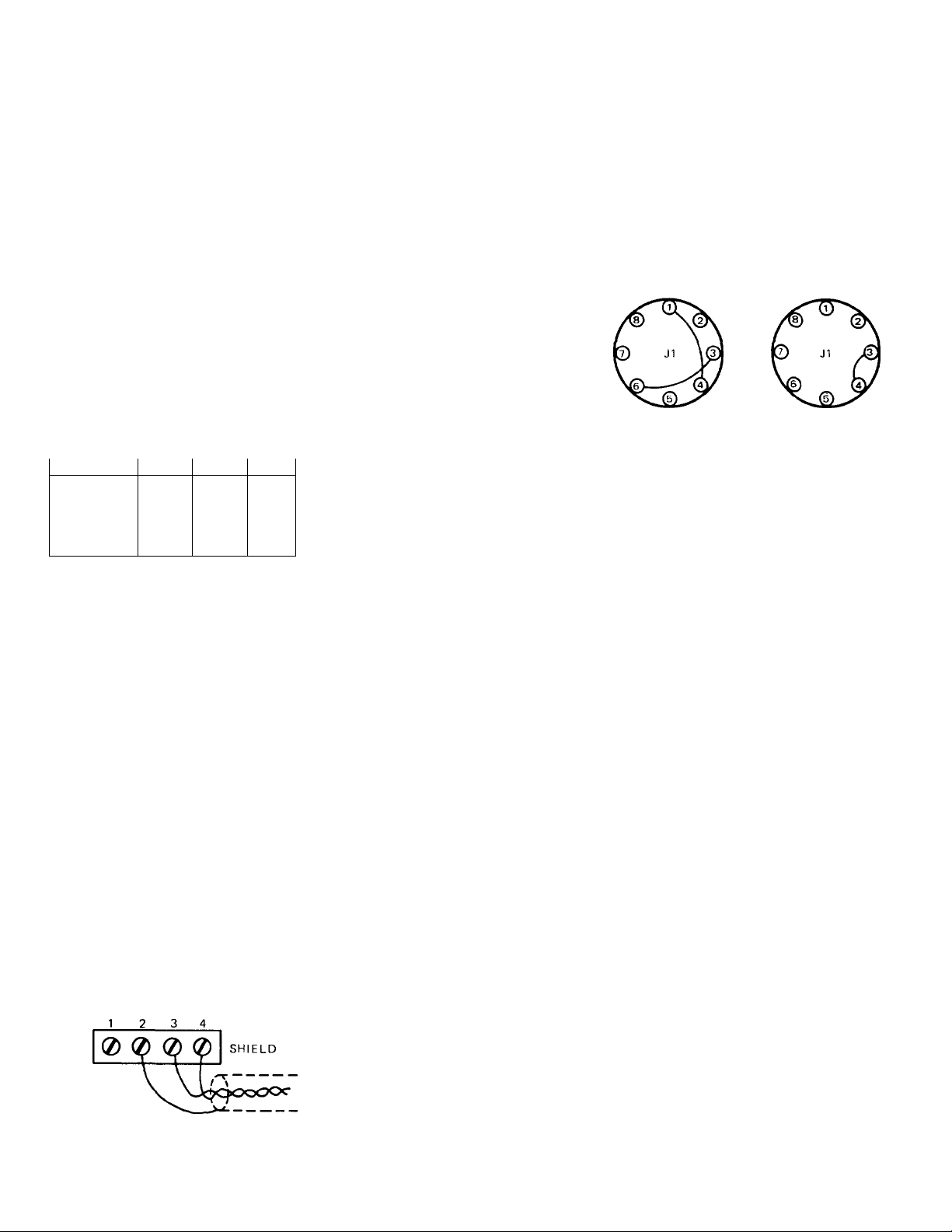

When shipped from the factory, pins 3 and 4

of J1 are strapped together to provide a

600-ohm Input. A 150-ohm Input may be

obtained by removing the strap from pins 3

and 4 and then strapping pin 1 to 4, and

strapping pin 3 to 6 (see Figure 5).

Both the direct and transformer Isolated

inputs may be used simultaneously If Isola

tion resistors are Installed In either or both

input lines, to prevent one Input source

from short circuiting to the other.

I I

VOLTAGE ' _

RATING BATTERY

NAMEPLATE TERMINAL

BOARD

BATTERY

FUSE

HEAT SINK

SHROUD

Figure 2. Rear View of 1590 Power Amplifier

Terminal Block TB8/TB9 Connections

Transformer T1

Wire Color 100 V 120 V

Brown TB9-4 TB8-4 TB8-4

White

Black TB9-7 TB9-7

White-Brown

White-Black

Permanent AC Power Connections*

Pilot Light S2-4

AC Cord (black)

AC Cord (white)

Switch SW2-3

Fuse FI-2

Capacitor C7

Capacitor C6

*Do not make any wiring changes of

these wire connections when altering

the amplifier for different primary

power operating voltage.

TB8-4 TB9-4

TB9-1 TB8-3 TB9-4

TB9-8

TB9-8 TB9-8

TB9-6

TB8-9

TB9-9

TB8-5

TB8-8

TB9-10

TB8-10

240V

TB9-2

TB9-5

Figure 3. Primary Power Conversion Chart

for 100V, 120V, and 240V 50/60 Hz Operation

4. Select the appropriate voltage rating

label from the rating label strip supplied

with the amplifier. Affix label over pre

vious voltage rating designation on

chassis. See Figure 2.

INPUT

INPUT

0 0

SHIELD

Figure 4. Input Connections

INPUT

TERMINAL

FILTER

SWITCH

5. When 1590 is strapped for 200V or 240V

line power, replace front panel fuse (FI)

with 2A, 250V, slo-blo type fuse.

6. Close front panel and secure with four

screws previously removed.

BOARD

Battery Connections

If desired, the 1590 may be connected to an

external 24/28 volt battery with minus (-)

as ground. Terminals for the dc power con

nections are on TB4 (see Figure 2). If ac

power fails, transfer to dc power Is instan

taneous, autoamtic and silent. The battery

ower supply Is not operated by the primary

power ON-OFF switch on the front panel. If

switching of battery power Is desired, an

external relay or switch should be provided

by the user.

Input Connections

Input connections may be either direct or

transformer-isolated at the INPUT terminal

board (TB1) (see Figure 2). Direct coupling

Is accomplished by connecting the Input

leads (shielded conductor recommended)

to terminals 1 and 2. Terminal 2 Is ground

(see Figure 4).

For transformer-isolated input, a plug-in

15095A or 15335A Line Transformer must be

plugged into receptacle J1 (see Figure 2).

DIRECT CONNECTION

1. For unbalanced high-impedance sources.

2. For bridging unbalanced low-impedance

lines having signal voltages of 0.8V rms

or higher.

TRANSFORMER ISOLATED CONNECTION

1. For balanced or unbalanced lines of 150

or 600 ohms* up to level of + 15 dBm

(with 15095A Line Transformer),

2. For low-impedance line bridging input or

15,000 ohm line-matching input (with

15335A Line Transformer),

'Factory wiring at receptacle J1 Is for 600

ohms (see Figure 5).

150 ÍÍ WIRING

600Í2 WIRING

Figure 5. Wiring of Transformer Accessory

Receptacle for Input Impedance of 150 or

600 Ohms. Factory Wiring Is for 600 Ohms

Output Connections

Output transformer taps provide connec

tions tor 25V (140 watts), 30V, 70.7V, 100V,

140V and 200V distribution systems. Class I

wiring must be used for 100V, 140V and

200V systems. Class II wiring may be used

only for the 30V and 70V systems. Connec

tions are made at terminal board TB2

located within the chassis (see Figure 6).

Wiring from the speaker system feeds

through the chassis to TB2; Vi" conduit

knockouts In the chassis provide access to

output terminals of TB2 and permit termina

tion as required for Class I wiring (see Fig

ure 2).

Recommended wire size for 200V operation

is 18 gauge (solid or stranded), for which

power loss Is V2 dB per 1900 feet of paired

wire. When rigid conduit is not used clamptype cable connectors must be Installed in

the conduit knockouts to secure the cable

and provide strain relief.

NOTE-

Typical clamp-type cable connectors

are the Appleton CG-1850 (for Class I

flexible cord such as type SV or SVT),

and the Appleton CG-1250 (for Class

II audio cable usch as Alpha Wire

Corp. No. 1897 [stranded] or No. 1797

[solid]).

After speaker distribution wires are passed

to the site of TB2, quick-connect terminal

clips (T&B type RA257) must be installed.

Be sure that output wiring between knock

outs and TB2 does not exceed 9 Inches In

length. Strip '/*" Insulation from the wire

ends and install the terminal clips. Twist

stranded wire to assure that all strands

properly enter the sleeve of the terminal

clip. Use an appropriate crimping tool (such

as M. Klein & Sons #1002) to crimp the

terminal clips to the wire ends.

Connect terminal clips to the terminals of

TB2 which have the desired Impedance. If

total speaker system Impedance falls be

tween two rated output values of the 1590,

-2-

Loading...

Loading...