Page 1

EXCELL

MCDS

SERVICE MANUAL

- alsa apparecchi medicali s.r.l. -

Page 2

INDEX

INSTRUMENTS REQUIRED

INTRODUCTION

...................................................................................................................................... 2

CONTROL OF SUPPLY SECTION (LOW VOLTAGES)

CONTROL OF SUPPLY SECTION (VARIABLE VOLTAGE)

Ramp signal control.....................................................................................................................................5

Calibration of values of the variable voltage (minimum and maximum)....................................................5

Thermal protection control...........................................................................................................................7

CONTROL OF THE REFERENCE VOLTAGES FOR THE A/D CONVERTERS

CONTROL OF THE LOCAL OSCILLATOR AND OF THE DRIVING SIGNALS

................................................................................................................ 2

............................................................. 5

..................................................... 5

................ 7

.................. 7

ATTENUATION OF PULSE WIDTH (IN THE SPRAY AND FULGURATION

FUNCTIONS)

CALIBRATION OF “POWER READING SECTION”

Analog Multiplier, Calibration of the offset of the "X" inputs.......................................................................9

Analog Multiplier, Calibration of the offset of the "Y" inputs.......................................................................9

PWRFM signal, Calibration of the output offset .......................................................................................10

IRFMB signal, Calibration of the output offset...........................................................................................10

CONTROL OF SIGNALS FOR THE CORRECT OUTPUT POWER

Output signal, control of the average modulation value............................................................................10

Control of the signal proportional to the monopolar output power..........................................................11

Control of the signal proportional to the monopolar and bipolar output current......................................11

Control of monopolar output power..........................................................................................................11

Calibration of the limitation of the maximum output current (only models 400 and 250).........................11

Calibration of the maximum output peak voltage......................................................................................11

Calibration of the maximum monopolar output current ( function per function).......................................12

Control of bipolar output power...............................................................................................................12

Calibration of the maximum bipolar output current ( function per function) .............................................13

Re-enabling of the standard EPROM......................................................................................................13

Control of the neutral plate alarm circuit ( REM type) ..............................................................................13

CONTROL OF HF LEAKAGE CURRENT

WIRING DIAGRAMS, ARRANGEMENT OF COMPONENTS AND LIST OF MATERIALS ......................... a

Block diagram..............................................................................................................................................a

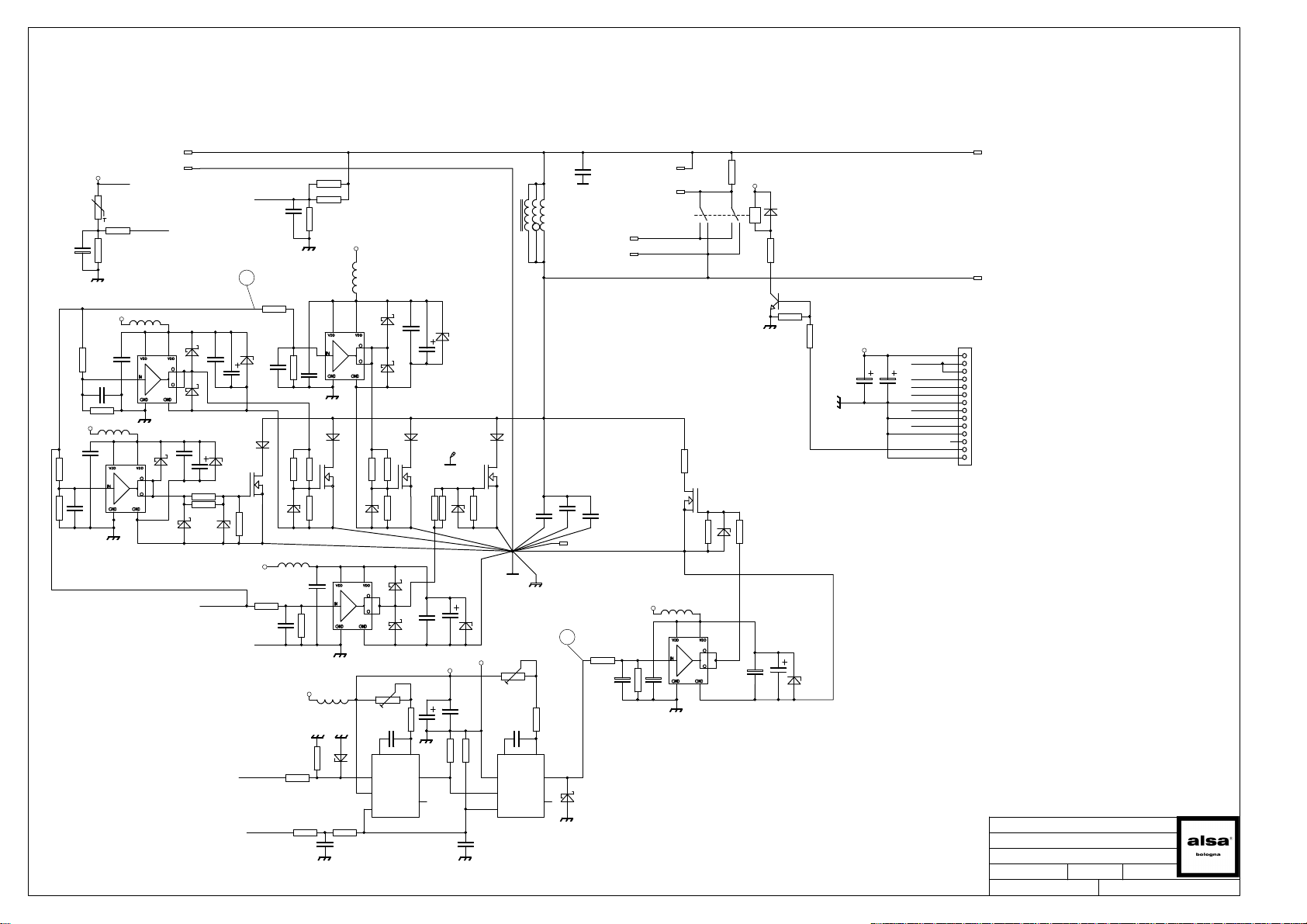

801301 – Power Supply Board. ...................................................................................................................b

801302 – R.F.Main Board ...........................................................................................................................c

801303 – Microcontroller Boar d ..................................................................................................................d

801304 – R.F. Driver Board ........................................................................................................................e

801305 – R.F. Power Board.........................................................................................................................f

801306 – Power Reader Board (1) .............................................................................................................g

801307 – Power Reader Board (2) .............................................................................................................h

801308 – Double Handle & Neutral Plate Control Board.............................................................................i

801309 – Double Switch Handle Board .......................................................................................................j

801310 – Panel Board (400mcds – 250mcds)............................................................................................k

801326 – Panel Board (350mcds – 200mcds)............................................................................................l

UNITS (INTERNAL DETAILS – ELECTRONIC BOARDS, SOCKETS, SWITCHES, ETC.).....................m

WIRINGS CONNECTIONS.........................................................................................................................n

............................................................................................................................................. 8

..................................................................... 9

..................................... 10

...................................................................................... 14

- alsa apparecchi medicali s.r.l. Pag. 1

Page 3

This handbook has been written to provide skilled personnel with a method required to set and

check the characteristics of the device and to assist the user, if necessary, in the identification of the

most frequently encountered faults.

INSTRUMENTS REQUIRED

DESCRIPTION TECHNICAL CHARACTERISTICS EXAMPLE

Oscilloscope Dual channel - Band width: > 40 MHz Tektronix mod. TDS210

Digital Multimeter TRMS reading - Precision: 3% Metrix mod. MX54

Current probe Band width: 200 Hz÷50 MHz Tektronix mod. P6021

Automatic tester as

Dynatech DNY 454A

Tester for H.F. leakage

and output power control

with antinductive loads

from 50 to 1500 ohms

Set of materials needed

for control and calibration

Automatic tester for low

frequency leakage control

(1)

Precision: 5%

Extended wirings,

EPROM memory “calibration and control”

Etc.

Responding to IEC 601-1 International standards

(able to perform tests according to)

Single loads and

thermocouple instruments

0-250 or 500 mA and 0-1,5

Different models of

Company METRON,

Company DYNATECH;

Or

RMS with scale

A

Etc.

INTRODUCTION

The electrosurgical unit EXCELL MCDS is a HF generator, completely controlled by two microcontrollers,

with, as power section, a dumped oscillator (working at a frequency of 475 kHz), able to deliver by output

transformers (for monopolar or bipolar section) a maximum power or of 400 Watt for the monopolar

performances and of 99 Watt for the bipolar performances.

The unit, provided of every possible device needed to select, control and activate different performances and

functions, consists of 4 main sections:

- Power supply section;

- H.F. power section;

- Microcontroller section;

- Output Power reading section.

The power supply section supplies all the continuous voltages required in the device.

These voltages are:

♦ +5V (continuous) for the programmable system;

♦ +15 –15 V (continuous) for driving circuits;

♦ from 0 to 150 V (adjustable) for power supply of H.F. section.

The first three voltages (+5 V and +15 – 15 V) are obtained by means of three linear voltage stabilisers.

The adjustable voltage is obtained using a switching section (configuration FORWARD type), powered by the

mains transformer. The "heart" of this power section consists of a PWM 3525 circuit (working at a frequency

of 115 kHz) driving, by means of a SIRIO transformer (three windings with 1:1:1 transformation ratio),

alternately two MOS-FETs (best choice IRF 740).

The enabling signals and the settings of the power supply of H.F. section, type PWM, are provided directly

by the Microcontroller board.

The microcontroller section controls the correct running of the whole device performing a continuous

autodiagnosis in order to detect any anomalies or damages in the unit or in the accessories connected to it.

For this purpose a main self-test phase runs both every time the unit is turned on and cyclically about every

45 minutes of working. If the system detects a fault the device is stopped until the cause is eliminated

and the display on the front panel shows a error code (see the following table) that provides the operator with

a specific information about the type of fault detected. So some useful information is indirectly achieved

(1) The test of LF leakage current can be performed also by a circuit corresponding to that indicated in the Par. 19.4 of IEC

601-1; using this circuit it is necessary even a rotary transformer (1,5 kV) to adjust the mains supply

- alsa apparecchi medicali s.r.l. -

Pag. 2

Page 4

concerning the part that could be damaged and that needs adjusting in order to restore the complete

efficiency of the unit.

ALARM CODE PROBLEM

blinking displays Device continuously activated for more than 30 seconds

ErrNP

ErrACt

ErrPED

ErrHND

Err21

Err1

ErrIIC

ErrHt1

ErrHt2

ErrUP2

ErrAL5

ErrNPC

ErrAD2

Err9

ErrIO

ErrII

ErrI2

ErrI3

ErrI4

ErrI5

ErrI6

ErrI7

Err2O

Err23

Err25

Err27

Err28

Err30

The H.F. power section consists of an oscillating circuit composed by four MOS-FETS (type IRFPE50)

connected in parallel (in order to obtain the maximum output power), each of which is driven separately by a

MOS-FET driver (type MAX 4420). By means of this oscillating circuit the variable continuous voltage coming

from the power unit section is “transformed” into a sinusoidal wave form with frequency of 475 kHz and the

power is then transferred (from the L7 inductor) to the output transformers (monopolar and bipolar) on the

Mother board. An additional MOS-FET on the same board cuts off the pulses when the unit is activated with

open circuit. The driving signals for this section come from the R.F. driver board, on which a UC 3825 PWM

driver circuit can pick-up (depending on the function settings on the front panel) one of the three ramp

signals used to provide a different pulse width according to the wave form selected (type of performance for

example cut, coag. …). This ramp signal, supplied by the square wave of the local oscillator at 950 kHz , is

sent to the Microcontroller board circuits U5-U6 (74HCT4040 and 16V8 PLD respectively), and it is set using

the R13, R14 and R15 pots in order to obtain the pulse width desired. On the microcontroller board there is

also the acoustic alarm section.

Neutral plate connection problem

Activation error (two activation switches pressed at the same time or wrong activation

compared to the functions selected on the control panel)

Pedal switch pressed when the device was turned on

Hand switch pressed when the device was turned on

Push button on control panel pressed when the device was turned on

General system error

Communication problems between the peripheral units

Over heating in the RF section

Over heating in the power supply section

“Slave” microcontroller trouble

Fault of the +5V power supply of both microcontroller

Fault of neutral plate alarm circuit (inside the unit)

Conversion problems in the digital converter of the “slave” microcontroller

Fault of power supply control in the monopolar RF section

Fault of power supply control in the bipolar RF section

Fault of RF modulation signal control

Fault of reading signal of the monopolar power control

Fault of reading signal of the monopolar power in the “spray” mode control

Fault of reading signal of the bipolar power control

Problems about internal RAM of both microcontrollers

Fault of EPROM CRC control

Fault of EEPROM data integrity control

Fault of master watchdog timer

(available)

System variables complementation error

Problems in reading the effective output current

Output peak voltage reading problems

Problems in the voltage reference of the neutral plate alarm circuit

- alsa apparecchi medicali s.r.l. -

Pag. 3

Page 5

The device consists even of other secondary sections:

a) The Double handle & neutral plate control board contains: the hand activation circuit and the neutral

plate alarm circuit, both with insulation between patient and intermediate circuits granted using

transformers (made with ferrite toroid cores with two insulated windings) capable of withstanding a test

voltage higher than 3000 VAC.

The first one works as follows:

When a push button of the hand switch (connected to the secondary winding of these transformers) is

pressed produces a variation of magnetic flow between the two windings (primary and secondary) and a

reduction of the amplitude of the signal on the primary winding. Therefore this reduction is detected by

the Microcontroller board as the activation of one of the hand switches and consequently it is enable the

H.F. power flowing through the selected output

The second one is realised according to the same principle described above and it is able to control not

only the correct connection of neutral plate (using every kind of neutral plate) but even the contact

neutral plate/tissues (only using split REM neutral plates) and works as follows:

A oscillator composed by U1A 40106)-R1-R61-C1, supplies a current at frequency of 60 kHz ±5 kHz that

drives the T1 transformer. Once the maximum amplitude of the signal is obtained using the R1 pot,

depending on the load connected to the neutral plate, a signal is sent to the window comparator

composed by U2A and U3A op ams (LM324). This comparator provides the microcontroller with the

"information" needed to distinguish the three different levels of contact between neutral plate and tissues

as described below.

Ideal contact: neutral plate/tissues resistance up to about 75 Ω (plate alarm LED off and complete use

of the device)

Poor contact: neutral plate/tissues resistance from about 80 to 150 Ω (plate alarm LED flashing and

maximum output power reduced to max 200W)

Insufficient contact: neutral plate/tissues resistance over than 150 Ω (plate alarm LED always on,

acoustic alarm on, “Err PN” on display and output power stopped).

When the unit is used with standard neutral plates (no split REM) the system works only in

situation of ideal contact (neutral plate cable not broken, well connected to the unit and to the

neutral plate) or insufficient contact (neutral plate cable broken or not connected to the unit or to

the neutral plate).

Power reader board (1) and (2): the circuits on these boards are used for two different purposes:

1) General control of all output powers

2) Dynamic optimisation and stabilisation of the output power (monopolar and bipolar), by means of a

feed back between unit and tissues (electrical load impedances), independently from the variations

of the load impedance.

3) Automatic start/stop of bipolar coagulation (function MPA) according to the variation of load

impedance (tissues).

To obtain these results the circuit supplies the microcontrollers with some signals proportional to the

output power and, according to these signals, the microcontroller “adjusts” the working parameters to

obtain the maximum possible stabilisation of the output power.

The heart of this section is a current and voltage reading transformer that picks up the signals from the

output sending them to some analog multipliers (HA325569 and AD633).

When the automatic bipolar coagulation (MPA) is selected this section evaluates also the impedance

(tissues) connected to the bipolar forceps to obtain the correct start/stop of the output power.

If the impedance is about 30 Ω, the circuit stops the automatic start to avoid a not desired activation

If the impedance is about between 30 and 850 Ω there is the automatic start.

If the impedance is higher than 850 Ω the circuit stops automatically the output power or doesn’t allow

the automatic start.

To avoid instantaneous starting as soon as the forceps touch the tissue, it is possible to adjust the

automatic starting delay (from 1 up to 6 seconds) using the rotary pot on the back of the unit.

a) Double Switch handle board: this board changes (using two relays, which are connected in series for

each monopolar output) the path of H.F. power towards the output selected and activated by the user.

On the same board other two relays are used to check the integrity of the neutral plate circuit and the

bipolar output path during the main self-test routine.

The presence of the self-test system may prevent the repair of the unit as, when a fault is pointed out, stops

the working and many signals required for the communication among the different sections are blocked.

It is therefore necessary to by-pass the self-test routine if the device has to be technically inspected.

For this purpose has been prepared an appropriate EPROM memory (Alsa code 713958) TO BE USED

ONLY AND EXCLUSIVELY DURING THE CALIBRATION PHASE OR FOR TECHNICAL ASSISTANCE.

- alsa apparecchi medicali s.r.l. -

Pag. 4

Page 6

In this memory, useful even for calibration and control procedure, the self-test phase is reduced as possible

The “calibration and control EPROM” must be used as follows:

1) Replace, on the Microcontroller board the standard EPROM with the “calibration and control EPROM”

(paying attention to insert it correctly)

2) Turn on the unit and, to start the “control or calibration procedure”, use on the front panel the push button

M selecting memory II (M_II) and (with push buttons up-down of monopolar CUT or COAGULATION) the

type of control or calibration. The code correspondent to the desired test is shown on the display - monopolar

CUT.

For every test or for every series of tests is below detailed (on the correspondent paragraph) the

selection necessary to start the specific procedure (specific tables of setting)

3) Once performed the starting selection, using push button M, select memory I (M_ I) and perform

calibrations or controls (according to the specific instructions below detailed for every test)

General Warnings about the instructions to perform the controls:

a) To activate the unit you have to use the pedal switch needed for the function selected (for example:

monopolar PC with cut pedal of monopolar double pedal)

b) To select a performance you have to use the correspondent push button S (for example: monopolar

pure cut with push button S “function PC” of cut section area “mono”, bipolar pure cut with push

button S “function PC” of cut section area “bip”)

c) The word “code” is used to identify the value or the code set on the displays

d) When one has to use the current probe to check a wave form or a current on the output circuit

connected to a load, the probe must be connected in series to the load

e) To automatically save the calibrations or settings performed it is necessary to switch the unit off. It is

possible to save every single calibration at a time or all together at the end of the procedure

CONTROL OF SUPPLY SECTION (LOW VOLTAGES)

Turn the device on and check on the Power supply board, using a multimeter, if the stabilised +15V (TP1

“A”), -15V (TP “B”) and +5V (TP “C”) voltages are present and, if necessary, adjust the R105 pot on the

same board to obtain a voltage of +5V (+0.1/-0V).

CONTROL OF SUPPLY SECTION (VARIABLE VOLTAGE)

RAMP SIGNAL CONTROL

Connect the probe of the oscilloscope to TP ”D” (pin 5 of UC 3525) on the Power supply board, turn the

device on and check if the wave form corresponds to the following:

(TP ”D”)

0

CALIBRATION OF VALUES OF THE VARIABLE VOLTAGE (MINIMUM AND MAXIMUM)

To start the following tests perform the selection detailed in the table below

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

00

1)Select M_ I.

2)Connect the multimeter to TP “E” (VREG) on Power supply board, set function “monopolar PC” and code

"FF", activate the device and calibrate the R6 pot on the same board to obtain a continuous voltage of 150V

(± 2 V) on VREG.

3)Connect the probe of the oscilloscope to TP “F” (R22) and the multimeter to TP “E” (VREG), set function

“monopolar PC” and code "FE", activate the device and calibrate the R14 pot to obtain a continuous voltage

of 3V (± 0,1) on VREG and the following wave form on TP “F”:

-

1

TP “A”: Test Point “A”

- alsa apparecchi medicali s.r.l. -

Pag. 5

Page 7

(TP “F”)

0

The settings of the minimum and maximum voltages interact with each other. This check must be repeated

at least three times to check the correctness of the values to be obtained.

4)Activating again the unit with code "AA": a voltage of 100V (± 2V) should be obtained together with the

following wave form on TP “F”:

(TP “F”)

0

5)Set function “bipolar PC” and code "FF", activate the device and calibrate the R4 pot to obtain a

continuous voltage of 150V (± 2V) on VREG.

6)Activate again the device with code "FE" and calibrate the R13 pot to obtain a continuous voltage of 3V

(±0,1V) on VREG and the following wave form on TP “F”:

(TP “F”)

0

The settings of the minimum and maximum voltages interact with each other. This check must be repeated

at least three times to check the correctness of the values to be obtained.

7)Activate again the unit with code "AA": a voltage of 100V (±2V) should be obtained together with the

following wave form on TP “F”:

- alsa apparecchi medicali s.r.l. -

Pag. 6

Page 8

(TP “F”)

0

THERMAL PROTECTION CONTROL

Turn the device on shorting the NTC R79 pins on the Power supply board. The display should show the

alarm code “Err Ht2” with acoustic alarm signal.

Turn the device off and on again to restore normal running conditions.

CONTROL OF THE REFERENCE VOLTAGES FOR THE A/D CONVERTERS

Many of the controls and settings automatically carried out by the unit depend on the calibration of these

voltages. Therefore these values must be particularly precise.

1)On the Microcontroller board, connect the multimeter to TP “G” (R64), calibrate the R70 pot to obtain a

voltage of 4.81V (±0.01 V); connect the multimeter to TP “H” (R66) and calibrate the R68 pot to obtain a

voltage of 110mV (± 0.002 V).

2)On the Panel board, connect the multimeter to TP “I” (LM431) and calibrate the R24 pot to obtain a voltage

of 4.81V (±0.01 V).

CONTROL OF THE LOCAL OSCILLATOR AND OF THE DRIVING SIGNALS

To start the following tests perform the selection detailed on the table below

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

02

1)Select M I

2)Connect the oscilloscope to TP “J” (R.F. driver board)

3)Turn the unit on but not activate it and check the signal: it should correspond to the following wave form (f=

940 kHz ± 5kHz): Turn the unit on but not activate it and

(TP “J”)

The DRVRF2 signal drives the MOS-FETS on the R.F. power board.

2)Disconnect J5 connector of the Power Supply Board, in order to avoid any damages (if the control

circuits for the driving signals of the power section should be faulty).

3)Connect the oscilloscope to TP “K” (D8) of the R.F. driver board, set function monopolar PC, activate the

device and check DRVRF2 signal. It should be as below specified, with a pulse width of 440 ns (±20 ns) (if

necessary calibrate the R13 pot on the same board):

-

0

- alsa apparecchi medicali s.r.l. -

Pag. 7

Page 9

(TP “K”)

e

0

4)Activate again the unit, setting function “monopolar SPR”. You should obtain the following wave form

(pulse width equal to 1 ms (±10 ns), if necessary calibrate the R15 pot:

(TP “K”)

5)Activate again the unit setting on mod. 400 and 250 function “bipolar PC”, or on mod. 350 and 200 function

“bipolar MP”. You should obtain the following wave form (duration equal to 315 ns (± 15ns), if necessary

calibrate the R14 pot):

(TP “K”)

0

0

ATTENUATION OF PULSE WIDTH (IN THE SPRAY AND FULGURATION

FUNCTIONS)

To start the following tests perform the selection detailed in the table below

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

(To perform this test it is necessary a set of cables (wiring for assistance) needed to connect

the R.F. power board placed out of the device so that can be reached easier for any need of

calibration).

1)Disconnect both the standard wiring and the J5 connector on the Power Supply Board and position

the R.F. power board out of the unit. Connect it using the “wiring for assistance” (J5 must be not

connected).

Connect the probe of channel no. 1 of the oscilloscope to TP ”L” (R12) on R.F. power board and the

probe of channel no. 2 to TP “M” (R37) of the same board.

2)Select M I

3)Set the function “monopolar SPR”, activate the device and check the wave form. It should be as

follows:

06

-

- alsa apparecchi medicali s.r.l. -

Pag. 8

Page 10

Ch1

e

Ch2

(TP “L”; TP “M”)

1.4us

1us

Ch1 Ch2

4us

1

2

The width of the "Ch2" pulse must be 4 ms and can be calibrated using the R35 pot on the R.F. power board.

The delay between the two pulses must be equal to 1.4 ms and can be calibrated using the R31 pot of the

same board.

Once this board is calibrated, disconnect the “wiring for assistance” and re-position the board inside the

device re-connecting both the standard wiring and the J5 connector.

CALIBRATION OF “POWER READING SECTION”

To start the following tests perform the selection detailed on the table below

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

The correct running of the whole device depends on the calibration of this section, as the microcontroller

section is mainly based on signals coming from this section to carry out many of the controls and

adjustments needed to grant the efficiency of the unit. It is therefore necessary to perform this calibration

with maximum care.

Before continuing the calibration, turn the R4 pot on the R.F. main board completely anticlockwise in order to release the output current limitation. This current must be limited again

before performing the test “calibration of the limitation of the maximum output current” in order

to avoid damages connecting the output to a load lower than 50 V.

1)Connect the monopolar output to a 400 Ω load and connect the current probe to check the output wave

form and current. Connect the voltage probe to TP “N” on the Power reader board (2, set function

“monopolar PC” and code "56".

2)Activating the unit check the output current, should be equal to 400 mA (the starting code "56" is only a

reference; if necessary adjust until 400 mA are obtained.

Using the R4 pot of the Power reader board (1), calibrate the wave form read by the voltage probe so that it

is without distortions and as equal as possible to the current wave form.

02

(I out; TP “N”)

-

Ch1

Ch2

ANALOG MULTIPLIER, CALIBRATION OF THE OFFSET OF THE "X" INPUTS

1)Connect the R4-R5 resistors on the Power reader board (2) to ground on the opposite side of U2 and

connect the probe of the oscilloscope to TP “O” on the same board.

2)Set function “monopolar PC” and code "10", activate the device and adjust the R3 pot on that board to

obtain the minimum amplitude of signal.

3)Disconnect from ground the R4-R5 resistors.

ANALOG MULTIPLIER, CALIBRATION OF THE OFFSET OF THE "Y" INPUTS

Repeat for the R7-R8 resistors (adjusting pot R6) on the same board the procedure above detailed about

R4-R5 resistors.

- alsa apparecchi medicali s.r.l. -

Pag. 9

1

2

Page 11

PWRFM SIGNAL, CALIBRATION OF THE OUTPUT OFFSET

1)Connect the oscilloscope to TP “P” on Power reader board (2). Set function “monopolar PC” and code 10.

Without activating the device, calibrate the R31 pot on the same board to obtain a voltage of 124 mV .

2)Connect then the probe to TP “Q” (same setting) and, without activating the device, calibrate the R43 pot

to obtain a voltage of 100 mV.

IRFMB SIGNAL, CALIBRATION OF THE OUTPUT OFFSET

1)Connect the oscilloscope to TP “P” on Power reader board (2). Set function “monopolar PC” and code 10.

Without activating the device, calibrate the R75 pot on the same board to obtain a voltage of 133 mV .

2)Connect the oscilloscope to TP “S” (same setting) and, without activating the device, calibrate the R81 pot

to obtain a voltage of 100mV.

Once all these settings have been completed, check the output offsets again with the oscilloscope

connected to TP “N” on Power reader board setting (function “monopolar PC” and codes as detailed

in the following reference table)

Reference table: Use reference values (tol ±5%) if the power reading section needs to be adjusted.

The values for the various test points depend on the H.F. output current specified.

Settino

value

14

2A

3E

53

67

76

90

A5

BA

D2

I OUT

(mA)

100 0.136 0.182 0.050 0.664 0.564 1.220 0.925

200 0.269 0.358 0.174 1.290 1.090 1.700 1.290

300 0.400 0.535 0.382 1.930 1.630 2.080 1.580

400 0.541 0.718 0.685 2.590 2.190 2.410 1.820

500 0.670 0.890 1.050 3.240 2.720 2.690 2.040

600 0.803 1.018 1.390 3.910 3.260 2.950 2.230

700 0.940 1.248 2.060 4.540 3.820 3.190 2.410

800 1.070 1.428 2.700 5.210 4.370 3.410 2.580

900 1.200 1.620 3.400 5.86 4.910 3.620 2.750

1000 1.350 1.793 4.190 6.540 5.400 3.810 2.890

TP “N” TP “N1” TP “N2” TP “P” TP “Q” TP “R” TP “S”

To modify the value on TP “N” on Power reader board (2), set function “monopolar PC”, code as above

detailed, activate the unit and adjust the R5 pot of the Power reader board (1). Doing this calibration also the

value on TP “N2” on Power reader board (2) should be that indicated in the reference table.

The value of TP “N1” on the same board can be calibrated, if necessary, adjusting the R6 pot on the Power

reader board (2).

When you have controlled the voltage on TP “N1” of Power reader board (2), check the corresponding value

on TP “R” of the same board and, if necessary, calibrate R75 on the Power reader board (2) to obtain on TP

“S” of the same board the values of the reference table.

The value on TP “Q” of Power reader board (2) can be calibrated, if necessary, adjusting the R43 pot on the

Power reader board (2).

Additional check:

1)Connect the monopolar output to a load of 400 ohm

2)Select function “monopolar PC”

3)Activate the unit and check the values according to the following table (tol ±10%). For every code selected

is specified the output current, the voltage PWRFM - pin 1 of J3 connector on Power reader board (2), the

voltage IRFMB - pin 3 of the same connector.

Display Iout (mA) PWRFM (V) IRFMB (V)

A9 786.33 4.30 2.57

93 689.67 3.78 2.46

6A 499.67 2.71 2.06

54 395.00 2.15 1.83

3F 297.00 1.61 1.59

13 94.90 0.53 0.89

CONTROL OF SIGNALS FOR THE CORRECT OUTPUT POWER

OUTPUT SIGNAL, CONTROL OF THE AVERAGE MODULATION VALUE

- alsa apparecchi medicali s.r.l. -

Pag. 10

Page 12

To start the test perform the selection detailed on the table below

0

0

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

00 03

Before checking the real output power of the unit, check the setting of the MODMEN parameter as follows:.

1)Connect the monopolar output to a non-inductive load of 400 V.

2)Select M_I.

3)Set function “monopolar PC” and activate the device, the monopolar cut display should show a value of

116 (± 1 digit). If necessary, with the device still activated, calibrate the R34 pot on the Microcontroller board.

CONTROL OF THE SIGNAL PROPORTIONAL TO THE MONOPOLAR OUTPUT POWER

To do this tests perform the selection detailed in the following table:

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

00 02

Selecting M_I and activating the device the monopolar cut display should show a value of the signal

proportional to the output power.

1)Select the function “monopolar PC”, code “AD” and activate the device. The display should show a value of

210 (± 3 digits). If necessary, activating the unit, adjust the R34 pot of the Power Reader board (2)

2)Select the same function but with code “56” and activate the device. The value on the display should be

102 (± 3 digits).

CONTROL OF THE SIGNAL PROPORTIONAL TO THE MONOPOLAR AND BIPOLAR OUTPUT CURRENT

To start this test perform the selection detailed in the table below:

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

02 01

Selecting M_I and activating the device the monopolar cut display should show a value of the signal

proportional to the output current (monopolar and bipolar).

1)Select M_I

2)Set function “monopolar PC” h code “AD” and activate the device. The display should show a value of 122

(± 3 digits). If necessary, activating the unit , adjust the R81 pot of the Power Reader board (2)

2)Select the same function but with code “56” and activate the device. The value on the display should be 84

(± 3 digits).

CONTROL OF MONOPOLAR OUTPUT POWER

1)Connect the monopolar output to a load of 400 V.

2)Set function “monopolar PC” , code “AD” and activate the device. The output current should be equal to

800 mA (± 10%). Setting the power level of “monopolar PC” at “56”, the output current should be equal to

400 mA (± 10%). Check even the wave form of the output current, should be sinusoidal, as shown below:

(I out) (I out)

PC function setting:"AD"

PC function setting: " "

56

CALIBRATION OF THE LIMITATION OF THE MAXIMUM OUTPUT CURRENT (ONLY MODELS 400 AND 250)

1)Connect the bipolar output to a load of 50 V.

2)Set function “bipolar PC” and the maximum power that may be selected. Activate the device and calibrate

the R4 trimmer on the R.F. Main Board adjusting the output current to 1 A (± 10%).

CALIBRATION OF THE MAXIMUM OUTPUT PEAK VOLTAGE

- alsa apparecchi medicali s.r.l. -

Pag. 11

Page 13

To start this test perform the selection as detailed on the table below

p

"

6

"

89

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

The maximum output voltage peak is one of the factors that affect the HF leakage current. The signal

proportional to this voltage peak is VOUTPK.

1)Select M_I

2)Set “monopolar PC”, code “

134 (± 2 digits). If necessary adjust the R9 trimmer on the R.F. Main Board . Check again the VOUTPK value

with setting code “

CALIBRATION OF THE MAXIMUM MONOPOLAR OUTPUT CURRENT

To start this test perform the selection as detailed on the table below

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

This calibration is needed to fix the max imum output curr ent for each f unction. The value es tablished during

the procedure is automatically stored in the EEPROM c ontaining the values of calibration (this EEPROM is

on the Panel board.

Perform this calibration as follows:

1)Connect the monopolar output to an antinductive load of 100 Ω

2)Select M_I

3)Step by step select all the available f unc tions s tar ting f r om “monopolar PC” and, for each function, ac tivate

the unit checking the output current (should be as detailed on the following table 1 for each function).

If the value is differ ent, activating the unit (pressing the pedal switch

down push buttons used on the front panel to set the current for each function.

e

CONTROL OF BIPOLAR OUTPUT POWER

To start this test perform the selection as detailed on the table below

Setting Memory Monopolar Cut Display Monopolar Coag. Display

This setting is used to check the PWRFB parameter.

1)Connect the bipolar output to an antinductive load of 400 Ω

2)Select M_I

3)Set function “bipolar BC” and code “

value of 254 (± 2 digits). If necessary, calibrate the R45 pot on the

4)Activate again the unit setting code “

5)Activate again the unit with the same setting and check the level of the output current .

It should be: 500 mA (±10%) when the display shows the value 254 and 300 mA (±10%) when the display

shows the value 150. The waveforms relative to the two settings are shown below:

(I out) (I out)

M II

50

” (the corresponding value should be 060).

This calibration is possible ONLY pushing the pedal switch corresponding to the function

selected otherwise it is impossible.

PC function setting: "

03

0304

0303

A0

”. Activating the device the monopolar cu t display should show a value of

07

07

0707

mono

Pure Cut (PC) 1.4

Blend I (BC I) 1.3

Blend II (BC II) 1.3

Blend III (BC III) 1.2

monopolar function Iout (A)

PinPoint Contact Soft (PCS) 1.3

Fulguration (F) 1.2

Spray (SPR) 1.2

Auto (A) 1.3

Table 1 – Values detected on load of 100 Ω

02

0206

0202

E6

”. Activating the unit, the monopolar coag. display should show a

89

”, a value of 150 (± 2 digits ) should appear on the display.

E

04

0404

(

FUNCTION PER FUNCTION

-

), adjust the output current by the up-

olar function Iout (A)

06

0606

Microcontroller board

PC function setting: "

)

.

0

- alsa apparecchi medicali s.r.l. Pag. 12

0

Page 14

The models 350 and 200 are without the bipolar cut section. Perform the test as follows:

1)Connect the bipolar output as above specified (point 1), but using a load of 100 V.

2)Set function “bipolar MP” with code “A8”. Activating the unit the monopolar coag. display should show a

value of 165 (± 2 digits) and the output current should be 700 mA (±10%).

3)Activate again the unit setting code “48”. The monopolar coag. display should show a value of 70 (± 2

digits) and the output current should be 300 mA (±10%). The wave forms relative to the two settings are

shown below:

(I out) (I out)

PC function setting: " "A8

0

PC function setting: " "48

device setting: ”A8” device setting: ”48”

CALIBRATION OF THE MAXIMUM BIPOLAR OUTPUT CURRENT ( FUNCTION PER FUNCTION)

To start this test perform the selection as detailed on the table below

Setting Memory Monopolar Cut Display Monopolar Coag. Display

M II

04

-

This calibration is identical to the correspondent one about monopolar functions, and so follow the same

instructions.

The only difference is:

1)The bipolar output must be connected to an antinductive load of 50 ohm

2)The procedure starts from function “bipolar PC” for models 400 and 250 and from function “bipolar MP” for

models 350 and 200

3)The output current of coagulation MPA is equal to that of coagulation MP

4)For values of different functions see the table below

bipolar function I out

(A)

Pure Cut (PC) 1.0

Blend (BC) 1.0

Micro Precise (MP) 0.9

Micro Prec. Auto (MPA) 0.9

Standard Macro (SM) 1.0

Table 2 – Values detected on load of 50 Ω

Once performed all calibrations switch off the unit and switch it on again (so you save all

calibrations and settings)

RE-ENABLING OF THE STANDARD EPROM

Once the maximum bipolar output currents have been calibrated and the unit is turned off, replace the

“calibration and control EPROM” with the standard EPROM, then go on as follows:

1)Turn the device on and wait for the end of the self-test phase (the unit is in standby mode and it is possible

to modify all settings but it is impossible to activate it. The displays may show some strange characters

without meaning.

2)To reset the unit and eliminate the problem simply press one of the two up–down power push buttons of

the section showing the abnormal condition. IF NECESSARY REPEAT THE SAME RESET FOR EACH

AVAILABLE FUNCTION.

CONTROL OF THE NEUTRAL PLATE ALARM CIRCUIT ( REM TYPE)

Perform the control as follows:

1)Connect the probe of the oscilloscope to TP “T” on the Double Handle & Neutral Plate Control Board (Alsa

code 801308).

0

- alsa apparecchi medicali s.r.l. -

Pag. 13

Page 15

2)Turn the unit on and, at the end of the self-test phase, check the presence of the following wave form:

(TP “T”)

0

If the amplitude of signal is different, calibrate the R1 pot on the same board to obtain the maximum

amplitude.

3)Check even if there is a continuous voltage equal to +5.25 V (± 0.05 V) on the TP “U”. If necessary

calibrate the R4 pot on the same board.

Once this calibration has been completed, the functioning range must be as follows:

• With a resistance from 0 to 150 Ω (± 30 Ω) the circuit doesn’t intervene, and the unit wor ks regularly (no

alarm signals or power limitation)

• With a resistance from 150 to 250 Ω (± 30 Ω) the circuit starts intervening. The unit works with the output

power automatically limited (max 200 watt) and the red alarm signal on the front panel flashes

• With a resistance over 250 Ω (± 30 Ω): the circuit works completely. The output power is completely

stopped, and you have all alarm signals (the intermittent acoustic alarm, the red alarm on the front panel

continuously lit up, the code “Err nP”)

The system can be checked using a linear 0-300/500 Ω potentiometer.

CONTROL OF HF LEAKAGE CURRENT

The HF leakage current can be a cause of not desired burning of patients and because of this reason the

Rules state specific requirements and limits (different for units with output circuit completely floating as our

units or circuit reference to earth) to be fulfilled.

These controls can be performed in different ways, all accepted from the Rules.

The first way is with output standard leads, but this system isn’t easy because it is necessary a wide

insulated table able to contain the unit, the instruments needed and the output leads completely laid straight.

In this case the limit accepted is a leakage of 150 mA.

The second one, useable only for the monopolar section of the ESU, is the easiest because is performed

directly at the unit terminals with the output leads as shortest as possible and so the insulated table can be

smaller. In this case the limit accepted is a leakage of 100 mA

In every case this control must be performed according to the following general warnings :

- All different test conditions must strictly respect the specific requirements detailed in the section 19.3.101

(point a) 2, a) 3, b), c)) of the International Standard IEC 60601-2-2

- The testing instruments are extremely important because can produce big errors of reading.

For example many automatic testers require the contemporary connection of all cables needed for the

test (active cable, neutral plate cable and “cable used to do the measure”). This kind of connection

doesn’t allow to respect (performing the test with output leads) the requirement of the distance among

leads (between active and neutral lead 50 cm, between active or neutral lead and lead needed to do the

measurement 25 cm) and produces a not real increasing of the leakage.

Because of this reason it is, at least, necessary to use this kind of instruments checking if the value

detected following the Standard Use manual of instruments corresponds to the value detected fulfilling

the testing requirements of the Rules that state as necessary a distance of 50 cm. between active and

neutral plate cables. Practically that means, using an automatic tester:

“to have a correct reading it is necessary to disconnect from the instrument the cable opposite to that

tested”

- alsa apparecchi medicali s.r.l. -

Pag. 14

Page 16

- When the control is performed using an analogic thermocouple RMS instrument (with reading from 0 to

250 or 500 mA) it is possible to damage it because of a mistake of connection and so it is always

advisable to do first the reading using an instrument with a higher range (for example 0-1,5 A) to do a

first control reading

- the accessories and the connection leads used to perform the measures with output leads must be those

standard supplied with the device

- all measurements must be performed only on insulated tables (distance: 1 mt. from a surface earthed

(the floor)

- during the tests the connection leads, the instruments or the accessories connected to the unit can’t be

touched for any reason in order to avoid every contact towards the earth that would falsify the reliability

of the measurement increasing it.

Measurements of leakage current on monopolar section directly at the HF unit terminals

(maximum limit 100 mA) performed according to requirements of Par. 19.3.101 b) of

International Standard IEC 60601-2-2 III Ed. – 1998 pag. 17

Active electrode (without rated load)

1)Set up the unit, leads and instruments as shown in the figure A (see below) with all the leads as shortest

as possible (active and neutral leads the minimum possible - about 20 cm)

2)Put the unit on the table

- alsa apparecchi medicali s.r.l. -

Pag. 15

Page 17

3)Connect the unit to the mains outlet with the power supply cord (the metallic casing is earthed by means of

the earth connection of the same cord)

4)Lay on the table all different leads (5,6,7) and connect measuring resistance and HF current meter

5)Connect to the earth the cable needed for the measurement (to the mains outlet of point 3)

6)Set the maximum power for every available monopolar function and activate the unit using the foot pedal

checking by the HF current meter the current flowing to earth

Active electrode (with rated load)

Repeat the same measurement with the rated load (antinductive load of 400 ohm) connected between active

and neutral electrodes.

Set up the unit, leads and instruments as shown in the figure A 1 (see below)

Legend: 1)mains outlet perfectly connected to ground

2)perfectly insulated table (with a distance of 1 mt. from the surface connected to ground – wall)

3)power supply cord (folded up to form a bundle having a length not exceeding 40 cm.)

4)HF unit

5)active electrode

6)neutral plate

7)cable needed to do the measurements

8)measuring resistance (antinductive - 200 ohm - at least of 10 Watt)

9)HF current meter (reading instrument)

NEUTRAL PLATE

Repeat for the neutral plate the same procedure above detailed for the active electrode.

Set up the unit , leads and instruments as shown in the figure B (see below)

As for the bipolar functions, the maximum admissible dispersion current must be less than 1% of the

maximum power that may be output by the function in question. For functions which output 99 W, this

current must remain below 70 mA, for functions which output 80 W, the admissible limit is equal to 63 mA

and finally for functions which output 60 W, the limit is 54 mA.

- alsa apparecchi medicali s.r.l. -

Pag. 16

Page 18

Approval:

Drawn by:

+15V

R11

R13

MON

INTIIA

B

-15V

GND

+15V

+5V

R7

MON. MIN.

8

I_ALIM

INTIIA

PWRAUD

SDA

SCL

+15V

-15V

GND

+5V

GND

GND

GND

U1C

R12

1

R14

A

9

6

U1B

4

5

A

R8

R9

R10

-15V

R84

R81

R82

R83

+5V

R1

BIP. B

MIN.

R2

TP1 TP2

R3

R4

BIP

C1

R6

R5

J17

1

2

3

4

To R.F. Main Board

14

13

J18

12

11

10

9

8

7

6

5

4

3

2

1

J19

4

3

2

1

J20

4

3

2

1

b1

To uP1

VDD

+5V

C2

VSS

U1D

11

U1A

13

3

+5V +5V

12

3

2 1

C42

R85

13

15

14

TP3

10

TP4

2

R16 R17

U2

Q1

+5V

R23

Q2

+5V

U5

INT

SDA

SCL

1

A0

2

A1

3

A2

R15

R25 R26

R24

VDC

VSS

P0

P1

P2

P3

P4

P5

P6

P7

C4

F

R19

R86

R87

R88

R89

R91

R90

R92

4

5

6

7

9

10

11

12

R18

R20

C5

PWRAUD

C3

D

C7

R27

R28

C8

R29

R30

R31

C6

R32

C9

R33

C10

R34

R21

R22

PWRBLK PWROFF

ENMON

TERM2

R78

+5V

R80

ENALIM

ENMON

ENARG

PWROFF

ISOCUT

ISOCOG

ISOBCT

ISOBCG

R35

C15

R79

C41

16

5

7

6

3

4

2

1

9

U3

CT

DIS

RT

VREF

SYNC

OSC.OUT

NI INP

INV INP

COMP

C14

R36

ENARG

ISOBCG

ISOBCT

ISOCOG

ISOCUT

15VC13

SS

8

+VIN

D7

C32

A

U11

VO

VO

U12

B

U13

VO

FROM BRIDGE RECTIFIER

(ON THE HEATSINK)

R68

R67

C33

R66

E

L4

R61

C34 C35

R62

C63 C64 C65

VI

GND

GND

VI

C66 C67 C68

VI

GND

C71

R104

R105

J3

C36

Q7

POWER STAGE

D9

D10

R69

F1

VREG

TO RF

GND

J4

R70 R71

C37

J5

-15V

J6

D12

C73

alsa apparecchi medicali s.r.l.

EXCELL 400 MCDS

BIS_O95P Power Supply Board

alsa code: 801301

C38

R72

74

3

+

2

-

R74

TP8

+5V

TP9

TERM2

PWRBLK

+15V

-+

D11

-+

Rev: 4A.2 29/Mar/99

+15V

R73

U4

6

1

5

R75

C39

+5V

GND

+15V

F2

F3

F4

I_ALIM

R76

C40

J8

R77

J9

J10

1

TO uP2 &

2

PANEL BOARD

3

4

5

J11

1

2

3

4

5

From Main

Transformer

+15V

C11

C12

R38

C13

R39

11

1

OUT A

14

OUT B

10

SHUNT

R40 R41

GND

12

ENALIM

R37

Q3

C43

12

6

U6

3

4 5

C46

12

6

U7

3

4 5

C49

12

6

U8

3

4 5

C52

12

6

U9

3

4 5

C55

12

6

U10

3

4 5

T1

6

R46

C17

R94

R93

C44

R96

C47

R95

R98

C50

R97

R100

R99

C53

R102

C56

R101

*

TP5

R55

4

R56

5

2

3

R42

Q4

C16

+5V

R47

Q8

R49

C18

R48

C45

C48

C51

C54

C57

HT

AL1

Q5

R43

R44

ARGIN

PEDBCG

PEDBCT

PEDSCM

PEDCGM

PEDCTM

D1

D2

+15V

R50

C21 C22

TP6

R57

R58

R45

R51

R52

Q9

D8

J12

1

2

3

J13

1

2

3

J14

1

2

3

J1

J2

D5

HT

ARGON

INPUT

BIPOLAR

PEDAL

C58

MONOPOLAR

PEDAL

R63

Q6

D3

L3

D4

R59

C23

D6

R60

+5V

R54

R53

C19 C20

SEC. ISOLATO

-+

D13

R64

R65

C24 C25 C26 C27

C28 C29 C30 C31

+15V

C59 C60

C61 C62

-15V

C

+5V

C69 C70 C72

R103

F5

PER ALIM.

PEDALI

FROM MAIN

TRANSFORMER

J15

J16

Page 19

TO HANDLE & N/P

a

(BIS_O95J)

PEDCGM

PEDSCM

PEDCTM

PEDCGB

PEDSCM

PEDCTB

ARGIN

PEDSCM

N.C.

(BIS_O95D)

SCL

SDA

GND

TERM2

PWRBLK

+15V

(BIS_O95R)

(BIS_O95S)

VREG

GND

(BIS_O95P)

+5V

GND

SCL

SDA

GND

VREG

OUT1

+15V

GND

GND

DRVRF2

+5V

LOAD

GND

TERM1

GND

VREGTS

GND

RLFLTR

RLSLFT

GND

-15V

FROM POWER READ(2)

GND

(BIS_O95Y)

+15V

+5V

PWMAUX

INTIIB

RSTuP2

TERM1

SETIME

N.C.

N.C.

STADBY

PWRBLK

LEDNP

INTAUX

GND

ANAUX

N.C.

FROM HANDLE & N/P

(BIS_O95J)

TO LOUDSPEAKER

GND

PWRAUD

GND

INTIIA

GND

+5V

+5V

GND

-15V

-15V

GND

+15V

+15V

+15V

SCL

SDA

GND

LOUDSP

GND

GND

VOUTPK

WAKBLK

SCL

SDA

FAUDIO

AUDCTR

BIPAUT

AUDMAX

CLKRF

GAL_F6

(BIS_O95H)

SETIME

VREGTS

LEDNP

(BIS_O95G)

IRFLMA

IRFLMB

EPLS

SETIME

I_ALIM

REMLEV

IOVER

MODMEN

BTMHND

VOUTPK

ICLREF

RFENB1

AUDIC3

TERM1

GND

VPKREF

DRVRF2

AUDIC1

AUDIC2

(BIS_O95E)

INTIIA

AUDIC3

GND

-15V

+5V

BIPSET

AUDIC2

AUDIC1

+15V

GND

LOAD

+15V

GND

IRFLMB

PWRAUD

+5V

GND

+5V

DRVRF2

IRFLMA

SDA

SCL

(BIS_O95P)

(BIS_O95J)

CTHND2

CGHND2

INTIIA

RFHND2

+15V

-15V

+5V

GND

BIPAUT

REMLEV

PWRFM

SAMPLE

IRFMB

RDGAIN

PWRFB

GND

LEDNP

BTMHND

RFMON

RFMON2

RFMONB

VO/IO

(BIS_O95W)

-15V

GND

+15V

+5V

CGHND1

CTHND1

RFHND1

BPCON2

RFBIP1

RFBIPB

IRDMBB

IRDMBA

(BIS_O95Y)

SCL

SDA

GND

SCL

SDA

GND

PN_1

PN_2

VRDMBB

VRDMBA

GND

Date:

Drawn by: Approval:

FROM POWER SUPPLY (BIS_O95P)

TO uPII (BIS_O95S)

RFMON

CTHND1

RFHND1

CGHND1

CTHND2

RFHND2

CGHND2

ENHND1

ENHND2

RLSFLT

+15V

GND

PN_1

PN_2

RFBIP1

BPCON2

BPCON2

(BIS_O95T)

PNCON2

BPCON1

PNCON1

CGHND2

CTHND2

Rev.

RFHND2

CGHND1

CTHND1

4B

RFHND1

Page 20

D

AC

B

F

b2

E

Page 21

ELECTROSURGICAL UNIT EXCELL 400 MCDS

POWER SUPPLY BOARD alsa code:

Last revised:

29-mar-99

Date:

801301

Rev.:

4A.2

12-gen-00 13.24

Reference Part Type Description alsa code

R1 150 METAL FILM RESISTOR 1/4 W 5% 430434

R2 150 METAL FILM RESISTOR 1/4 W 5% 430434

R3 8K/1% PRECISION RESISTOR 1% 0.6W 430469

R4 2KT PRESET POTENTIOMETER CERMET 403092

R5 5K/1% PRECISION RESISTOR 1% 0.6W 430490

R6 2KT PRESET POTENTIOMETER CERMET 403092

R7 33K METAL FILM RESISTOR 1/4 W 5% 430172

R8 33K METAL FILM RESISTOR 1/4 W 5% 430172

R9 1K METAL FILM RESISTOR 1/4 W 5% 430170

R10 1K METAL FILM RESISTOR 1/4 W 5% 430170

R11 18K METAL FILM RESISTOR 1/4 W 5% 430346

R12 18K METAL FILM RESISTOR 1/4 W 5% 430346

R13 5KT PRESET POTENTIOMETER CERMET 403052

R14 5KT PRESET POTENTIOMETER CERMET 403052

R15 150K METAL FILM RESISTOR 1/4 W 5% 430360

R16 1K METAL FILM RESISTOR 1/4 W 5% 430170

R17 100K METAL FILM RESISTOR 1/4 W 5% 430177

R18 10K METAL FILM RESISTOR 1/4 W 5% 430339

R19 100K METAL FILM RESISTOR 1/4 W 5% 430177

R20 1K METAL FILM RESISTOR 1/4 W 5% 430170

R21 100 METAL FILM RESISTOR 1/4 W 5% 430336

R22 1K METAL FILM RESISTOR 1/4 W 5% 430170

R23 4K7 METAL FILM RESISTOR 1/4 W 5% 430167

R24 47K METAL FILM RESISTOR 1/4 W 5% 430218

R25 47K METAL FILM RESISTOR 1/4 W 5% 430218

R26 1K METAL FILM RESISTOR 1/4 W 5% 430170

R27 10 METAL FILM RESISTOR 1/4 W 5% 430180

R28 12K METAL FILM RESISTOR 1/4 W 5% 430351

R29 220K METAL FILM RESISTOR 1/4 W 5% 430352

R30 220K METAL FILM RESISTOR 1/4 W 5% 430352

R31 10K METAL FILM RESISTOR 1/4 W 5% 430339

R32 470K METAL FILM RESISTOR 1/4 W 5% 430455

R33 27K METAL FILM RESISTOR 1/4 W 5% 430340

R34 10K METAL FILM RESISTOR 1/4 W 5% 430339

R35 1K METAL FILM RESISTOR 1/4 W 5% 430170

R36 10K METAL FILM RESISTOR 1/4 W 5% 430339

R37 10 METAL FILM RESISTOR 1/4 W 5% 430180

R38 10 METAL FILM RESISTOR 1/4 W 5% 430180

R39 10 METAL FILM RESISTOR 1/4 W 5% 430180

R40 10K METAL FILM RESISTOR 1/4 W 5% 430339

R41 22K METAL FILM RESISTOR 1/4 W 5% 430179

R42 22K METAL FILM RESISTOR 1/4 W 5% 430179

R43 47K METAL FILM RESISTOR 1/4 W 5% 430218

R44 10K METAL FILM RESISTOR 1/4 W 5% 430339

R45 4K7 METAL FILM RESISTOR 1/4 W 5% 430167

R46 100 METAL FILM RESISTOR 1/4 W 5% 430336

R47 1K METAL FILM RESISTOR 1/4 W 5% 430170

R48 100K METAL FILM RESISTOR 1/4 W 5% 430177

R49 10K METAL FILM RESISTOR 1/4 W 5% 430339

R50 220K METAL FILM RESISTOR 1/4 W 5% 430352

R51 220K METAL FILM RESISTOR 1/4 W 5% 430352

R52 10 METAL FILM RESISTOR 1/4 W 5% 430180

R53 2K2 METAL FILM RESISTOR 1/4 W 5% 430343

R54 10K METAL FILM RESISTOR 1/4 W 5% 430339

R55 22 METAL FILM RESISTOR 1/4 W 5% 430447

R56 1K METAL FILM RESISTOR 1/4 W 5% 430170

R57 22 METAL FILM RESISTOR 1/4 W 5% 430447

R58 1K METAL FILM RESISTOR 1/4 W 5% 430170

R59 100K METAL FILM RESISTOR 1/4 W 5% 430177

alsa code:

801301

b3

Page 22

Reference Part Type Description alsa code

R60 3K3 METAL FILM RESISTOR 1/4 W 5% 430197

R61 4K7/3W/F METAL FILM RESISTOR 1 W 430470

R62 4K7/3W/F METAL FILM RESISTOR 1 W 430470

R63 0.22/2W METAL FILM RESISTOR 2 W 430439

R64 0.22/2W METAL FILM RESISTOR 2 W 430439

R65 1K METAL FILM RESISTOR 1/4 W 5% 430170

R66 680 METAL FILM RESISTOR 1/4 W 5% 430194

R67 10K METAL FILM RESISTOR 1/4 W 5% 430339

R68 33K/6W/F WIREWOUND RESISTOR 33 K 6 W 430463

R69 100T PRESET POTENTIOMETER CERMET 403029

R70 3K3 METAL FILM RESISTOR 1/4 W 5% 430197

R71 100 METAL FILM RESISTOR 1/4 W 5% 430336

R72 820 METAL FILM RESISTOR 1/4 W 5% 430200

R73 12 METAL FILM RESISTOR 1/4 W 5% 430415

R74 12 METAL FILM RESISTOR 1/4 W 5% 430415

R75 150K METAL FILM RESISTOR 1/4 W 5% 430360

R76 100 METAL FILM RESISTOR 1/4 W 5% 430336

R77 NU NOT USED -----R78 220 METAL FILM RESISTOR 1/4 W 5% 430358

R79 NTC_V47K NTC THERMISTOR THREADED 47K 5% 430452

R80 11K/1% PRECISION RESISTOR 1% 0.6W 430467

R81 100 METAL FILM RESISTOR 1/4 W 5% 430336

R82 220 METAL FILM RESISTOR 1/4 W 5% 430358

R83 220 METAL FILM RESISTOR 1/4 W 5% 430358

R84 5K6 METAL FILM RESISTOR 1/4 W 5% 430344

R85 5K6 METAL FILM RESISTOR 1/4 W 5% 430344

R86 1K METAL FILM RESISTOR 1/4 W 5% 430170

R87 1K METAL FILM RESISTOR 1/4 W 5% 430170

R88 1K METAL FILM RESISTOR 1/4 W 5% 430170

R89 1K METAL FILM RESISTOR 1/4 W 5% 430170

R90 1K METAL FILM RESISTOR 1/4 W 5% 430170

R91 1K METAL FILM RESISTOR 1/4 W 5% 430170

R92 1K METAL FILM RESISTOR 1/4 W 5% 430170

R93 150 METAL FILM RESISTOR 1/4 W 5% 430434

R94 330 METAL FILM RESISTOR 1/4 W 5% 430171

R95 150 METAL FILM RESISTOR 1/4 W 5% 430434

R96 330 METAL FILM RESISTOR 1/4 W 5% 430171

R97 150 METAL FILM RESISTOR 1/4 W 5% 430434

R98 330 METAL FILM RESISTOR 1/4 W 5% 430171

R99 150 METAL FILM RESISTOR 1/4 W 5% 430434

R100 330 METAL FILM RESISTOR 1/4 W 5% 430171

R101 150 METAL FILM RESISTOR 1/4 W 5% 430434

R102 330 METAL FILM RESISTOR 1/4 W 5% 430171

R103 1K/1% PRECISION RESISTOR 1% 0.6W 430458

R104 27 METAL FILM RESISTOR 1/4 W 5% 430158

R105 100T PRESET POTENTIOMETER CERMET 403029

C1 10u/T/35V TANTALUM ELECTROLYTIC CAPACITOR 400134

C2 100n CERAMIC CAPACITOR 400139

C3 100n CERAMIC CAPACITOR 400139

C4 1u/T/35V TANTALUM ELECTROLYTIC CAPACITOR 400173

C5 22p/C CERAMIC CAPACITOR 400290

C6 100n CERAMIC CAPACITOR 400139

C7 1n/P METALLIZED POLYESTER CAPACITOR 400278

C8 100n CERAMIC CAPACITOR 400139

C9 100p/NPO NPO CERAMIC CAPACITOR 400260

C10 220p/C CERAMIC CAPACITOR 400240

C11 100n CERAMIC CAPACITOR 400139

C12 100n CERAMIC CAPACITOR 400139

C13 10u/T/35V TANTALUM ELECTROLYTIC CAPACITOR 400134

C14 1u/T/35V TANTALUM ELECTROLYTIC CAPACITOR 400173

C15 100n CERAMIC CAPACITOR 400139

C16 100n CERAMIC CAPACITOR 400139

C17 100n CERAMIC CAPACITOR 400139

alsa code:

801301

b4

Page 23

Reference Part Type Description alsa code

C18 470n/P METALLIZED POLYESTER CAPACITOR 400309

C19 100n CERAMIC CAPACITOR 400139

C20 100n CERAMIC CAPACITOR 400139

C21 10n/C/1KV CERAMIC CAPACITOR 400133

C22 10n/C/1KV CERAMIC CAPACITOR 400133

C23 1n/C/3KV HIGH VOLTAGE CERAMIC CAPACITOR 400224

C24 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C25 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C26 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C27 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C28 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C29 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C30 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C31 22u/E/100V/V VERTICAL ELECTROLYTIC CAPACITOR SMPS 400286

C32 2n2/C CERAMIC CAPACITOR 400261

C33 1n/C CERAMIC CAPACITOR 400252

C34 10n/C/1KV CERAMIC CAPACITOR 400133

C35 10n/C/1KV CERAMIC CAPACITOR 400133

C36 470u/E/250V VERTICAL ELECTROLYTIC CAPACITOR 400304

C37 100n CERAMIC CAPACITOR 400139

C38 100n CERAMIC CAPACITOR 400139

C39 100n CERAMIC CAPACITOR 400139

C40 220n/P METALLIZED FILM CAPACITOR 400271

C41 100n CERAMIC CAPACITOR 400139

C42 100n CERAMIC CAPACITOR 400139

C43 100n CERAMIC CAPACITOR 400139

C44 100n CERAMIC CAPACITOR 400139

C45 100n CERAMIC CAPACITOR 400139

C46 100n CERAMIC CAPACITOR 400139

C47 100n CERAMIC CAPACITOR 400139

C48 100n CERAMIC CAPACITOR 400139

C49 100n CERAMIC CAPACITOR 400139

C50 100n CERAMIC CAPACITOR 400139

C51 100n CERAMIC CAPACITOR 400139

C52 100n CERAMIC CAPACITOR 400139

C53 100n CERAMIC CAPACITOR 400139

C54 100n CERAMIC CAPACITOR 400139

C55 100n CERAMIC CAPACITOR 400139

C56 100n CERAMIC CAPACITOR 400139

C57 100n CERAMIC CAPACITOR 400139

C58 220u/E/16V ELECTROLYTIC CAPACITOR 400274

C59 100n CERAMIC CAPACITOR 400139

C60 10u/T/35V TANTALUM ELECTROLYTIC CAPACITOR 400134

C61 100n CERAMIC CAPACITOR 400139

C62 10u/T/35V TANTALUM ELECTROLYTIC CAPACITOR 400134

C63 100n CERAMIC CAPACITOR 400139

C64 1000u/E/35V ELECTROLYTIC CAPACITOR 400256

C65 1000u/E/35V ELECTROLYTIC CAPACITOR 400256

C66 100n CERAMIC CAPACITOR 400139

C67 1000u/E/35V ELECTROLYTIC CAPACITOR 400256

C68 1000u/E/35V ELECTROLYTIC CAPACITOR 400256

C69 100n CERAMIC CAPACITOR 400139

C70 10u/T/35V TANTALUM ELECTROLYTIC CAPACITOR 400134

C71 100n CERAMIC CAPACITOR 400139

C72 1000u/E/35V ELECTROLYTIC CAPACITOR 400256

C73 1000u/E/35V ELECTROLYTIC CAPACITOR 400256

D1 12V/1W ZENER DIODE 12V/1W 420019

D2 12V/1W ZENER DIODE 12V/1W 420019

D3 12V/1W ZENER DIODE 12V/1W 420019

D4 12V/1W ZENER DIODE 12V/1W 420019

D5 2V7/0.5W ZENER DIODE 2V7-1/2W 420067

D6 BYT03/400 ULTRA FAST DIODE 3A/400V 420071

D7 1N4148 DIODE 420010

alsa code:

801301

b5

Page 24

Reference Part Type Description alsa code

D8 12V/0.5W ZENER DIODE 12V-1/2W 420083

D9 1N4148 DIODE 420010

D10 1N4148 DIODE 420010

D11 KBL06 BRIDGE RECTIFIER 4A/600V 420069

D12 KBL06 BRIDGE RECTIFIER 4A/600V 420069

D13 WL04 BRIDGE RECTIFIER 1A 420013

Q1 VN10KM N CHANNEL MOSFET 427054

Q2 BC237B NPN TRANSISTOR 427057

Q3 BC237B NPN TRANSISTOR 427057

Q4 BC237B NPN TRANSISTOR 427057

Q5 IRF740 N CHANNEL MOSFET 427076

Q6 IRF740 N CHANNEL MOSFET 427076

Q7 2N2222A NPN TRANSISTOR 427041

Q8 VN10KM N CHANNEL MOSFET 427054

Q9 BC237B NPN TRANSISTOR 427057

L3 713669 INDUCTOR 1 MH 713669

L4 NU NOT USED -----U1 4066 CMOS CD4066 482017

U2 LM431 VOLTAGE REGULATOR 482078

U3 UC3525 PWM UC3525 482060

U4 TL071 OP.AMP. TL071 482018

U5 PCF8574 II_CBUS I/O EXPANDER 482089

U6 SFH600-2 OPTOCOUPLER SFH600-2 482022

U7 SFH600-2 OPTOCOUPLER SFH600-2 482022

U8 SFH600-2 OPTOCOUPLER SFH600-2 482022

U9 SFH600-2 OPTOCOUPLER SFH600-2 482022

U10 SFH600-2 OPTOCOUPLER SFH600-2 482022

U11 LM78S15 VOLTAGE REGULATOR +15V 482086

U12 LM7915 VOLTAGE REGULATOR -15V 482087

U13 LM78S05 VOLTAGE REGULATOR +5V 482097

T1 421026 PULSE TRANSFORMER (2 SECONDARIES) 421026

F1 5A/T FUSE 5 A T 5X20 MM 433048

F2 2A/T FUSE 2 A T 5X20 MM 433001

F3 2A/T FUSE 2 A T 5X20 MM 433001

F4 2A/T FUSE 2 A T 5X20 MM 433001

F5 100mA/T FUSE 100 MA T 5X20 MM 433046

J1 399028 FASTON CONNECTOR P.C.B. 399028

J2 399028 FASTON CONNECTOR P.C.B. 399028

J3 399028 FASTON CONNECTOR P.C.B. 399028

J4 399028 FASTON CONNECTOR P.C.B. 399028

J5 399028 FASTON CONNECTOR P.C.B. 399028

J6 399028 FASTON CONNECTOR P.C.B. 399028

J8 NU NOT USED ------

J9 NU NOT USED ------

J10 384016 5 POLES PCB CONNECTOR MASCON 384016

J11 384016 5 POLES PCB CONNECTOR MASCON 384016

J12 PAND_3P 3 POLES PCB CONNECTOR PANDUIT MALE 384036

J13 PAND_3P 3 POLES PCB CONNECTOR PANDUIT MALE 384036

J14 PAND_3P 3 POLES PCB CONNECTOR PANDUIT MALE 384036

J15 399028 FASTON CONNECTOR P.C.B. 399028

J16 399028 FASTON CONNECTOR P.C.B. 399028

J17 PICO_4 4 POLES PICOFLEX CONN. MALE P.C.B. 384042

J18 PICO_14 14 POLES PICOFLEX CONN. MALE P.C.B. 384040

J19 PICO_4 4 POLES PICOFLEX CONN. MALE P.C.B. 384042

J20 PICO_4 4 POLES PICOFLEX CONN. MALE P.C.B. 384042

AL1 ART_59_VER ALUMINIUM HEAT SINK 713885

alsa code:

801301

b6

Page 25

Approval:

Drawn by:

+5V

-15V

C6

RFBIP1

R27

1

2

3

RFMON2

3

2

1

BPCON2

3

2

1

1

2

3

2

G1

0

J7

C11

J8

J9

J10

0

G2

SETIME

T1

VREG

J1

1

2 3

C3

C18

R32

13

15

14

R34

1

2

3

R8

R10

U1

INT

SDA

SCL

A0

A1

A2

PCF8574

J3 J4

T3

C4

C5

D5

4

R5

R6

D1 D2

D3 D4

R9

R11

R12

R35

4

P0

5

P1

6

P2

7

P3

9

P4

10

P5

11

P6

12

P7

C27

VDC

R36

R37

R38

+15V

C29

J6J5

R7

2

3

-15V

1

R40R39

C28

C30

Mono/Bip.

675

3

4

2

RL1

1 8

D7

R15

C19

R13

74

U2

1

5

2

C31

C32

+15V

Q1

R16

R17

VOUTPK

C21

R14

6

C20

R41

D6

9876543

10

C35

C33

C34

RF INPUT

OUT1

J2

R2

R4

+5V

+5V

1

2

3

4

5

6

7

8

9

10

11

12

RLFLTR

13

14

TO RF POWER

BOARD

R1

R29

VREGTS

C1

VSS

+15V

GND

DRVRF2

+5V

LOAD

GND

TERM1

RLSLFT

VDC

+15V

R3

C2

SCL

INTIIA

SDA

R31

C23

R33

VDC

VSS

R30

C26

C25

C24

IRFLMA

IRFLMB

J27

c1

C22

RLAUX1

RLSPRY

RLMNBP

RLSLFT

RLBPAB

C36

Taglio/Spray

675

3

1 8

R18

ENHND1

ENHND2

R42

R43

RL2

4

2

D8

Q2

R19

To Double

Handswitch

Control

Board

+15V

RL3

675

3

1 8

D9

R21

R20

5s.

10s.

4

2

8s.

+15V

Q3

R22

10

1

10s.

6

2

5

1

R23

26s.

20

13

2

83

4

26s.

19

18

RFMONB

11

17

C7

9T2

C8

22s.

C9

12

C10

RFBIPB

+5V

R24

R25

R26

1 3

C12

C14

J11

J12

RFMON

C13

PN_1

L1

C15

C16

C17

PN_2

FROM POWER SUPPLY

BOARD

J18

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R28

1 3

2

J13

J14

J15

+15V

I_ALIM

-15V

GND

INTIIA

GND

PWRAUD

GND

AUDIC1

AUDIC2

AUDIC3

+5V

GND

-15V

+5V

GND

+15V

BTMHND

LEDNP

BIPAUT

REMLEV

INTIIA

CGHND1

RFHND1

CTHND1

CGHND2

RFHND2

CTHND2

PN_1

PN_2

HANDLE &

N/P BOARD

L3

SDA

DRVRF2

IRFLMB

LOAD

AUDIC2

INTIIA

GND

VOUTPK

REMLEV

SETIME

LEDNP

J19

J20

J21

J22

J23

BIS_O95E - R.F. Main Board

alsa code: 801302

L4

J16

1

3

5

7

9

11

13

15

17

19

21

23

25

J17

G3

0

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

CTHND1

RFHND1

CGHND1

CTHND2

RFHND2

CGHND2

ENHND1

ENHND2

RLSLFT

+15V

GND

0

G4

TO

DOUBLE

HANDSWITCH

CONTROL

BRD.

alsa apparecchi medicali s.r.l.

EXCELL mod. MCDS

Rev: 4B.2 29/Mar/99

+15V

G5

0

GND

2

4

SCL

6

IRFLMA

8

PWRAUD

10

AUDIC1

12

AUDIC3

14

16

TERM1

18

BTMHND

20

I_ALIM

22

VREGTS

24

BIPAUT

26

0

G6

1

2

3

J24

1

2

3

J25

1

2

3

4

5

J26

L2

GND

Page 26

Può essere anche

BYR29-800

c2

Page 27

ELECTROSURGICAL UNIT EXCELL 400 MCDS

R.F. MAIN BOARD alsa code:

Last revised:

8-Sep-99

Date:

801302

Rev.:

4B.3

12-gen-00 13.25

Reference Part Type Description alsa code

R1 1K METAL FILM RESISTOR 1/4 W 5% 430170

R2 220 METAL FILM RESISTOR 1/4 W 5% 430358

R3 2K2 METAL FILM RESISTOR 1/4 W 5% 430343

R4 2KT PRESET POTENTIOMETER CERMET 403092

R5 560 METAL FILM RESISTOR 1/4 W 5% 430178

R6 560 METAL FILM RESISTOR 1/4 W 5% 430178

R7 100/0.5W METAL FILM RESISTOR 1/2 W 5% 430107

R8 33K METAL FILM RESISTOR 1/4 W 5% 430172

R9 10KT PRESET POTENTIOMETER CERMET 403066

R10 5K6 METAL FILM RESISTOR 1/4 W 5% 430344

R11 100K METAL FILM RESISTOR 1/4 W 5% 430177

R12 47K METAL FILM RESISTOR 1/4 W 5% 430218

R13 100K METAL FILM RESISTOR 1/4 W 5% 430177

R14 560 METAL FILM RESISTOR 1/4 W 5% 430178

R15 47 METAL FILM RESISTOR 1/4 W 5% 430334

R16 100K METAL FILM RESISTOR 1/4 W 5% 430177

R17 10K METAL FILM RESISTOR 1/4 W 5% 430339

R18 47 METAL FILM RESISTOR 1/4 W 5% 430334

R19 100K METAL FILM RESISTOR 1/4 W 5% 430177

R20 10K METAL FILM RESISTOR 1/4 W 5% 430339

R21 47 METAL FILM RESISTOR 1/4 W 5% 430334

R22 100K METAL FILM RESISTOR 1/4 W 5% 430177

R23 10K METAL FILM RESISTOR 1/4 W 5% 430339

R24 1K METAL FILM RESISTOR 1/4 W 5% 430170

R25 NU NOT USED -----R26 1K METAL FILM RESISTOR 1/4 W 5% 430170

R27 10KP/D DUAL POTENTIOMETER 403099

R28 10KP/D DUAL POTENTIOMETER 403099

R29 12 METAL FILM RESISTOR 1/4 W 5% 430415

R30 220 METAL FILM RESISTOR 1/4 W 5% 430358

R31 100 METAL FILM RESISTOR 1/4 W 5% 430336

R32 100 METAL FILM RESISTOR 1/4 W 5% 430336

R33 220 METAL FILM RESISTOR 1/4 W 5% 430358

R34 220 METAL FILM RESISTOR 1/4 W 5% 430358

R35 NU NOT USED -----R36 100 METAL FILM RESISTOR 1/4 W 5% 430336

R37 100 METAL FILM RESISTOR 1/4 W 5% 430336

R38 100 METAL FILM RESISTOR 1/4 W 5% 430336

R39 100 METAL FILM RESISTOR 1/4 W 5% 430336

R40 100 METAL FILM RESISTOR 1/4 W 5% 430336

R41 X_RNET2K2 RESISTOR NETWORK 2K2 430485

R42 10K METAL FILM RESISTOR 1/4 W 5% 430339

R43 10K METAL FILM RESISTOR 1/4 W 5% 430339

C1 1n/C CERAMIC CAPACITOR 400252

C2 100n CERAMIC CAPACITOR 400139

C3 100n CERAMIC CAPACITOR 400139

C4 560p/C/500V CERAMIC CAPACITOR 400294

C5 560p/C/500V CERAMIC CAPACITOR 400294

C6 4N7/PP/2KV POLYPROPYLENE CAPACITOR 400306

C7 3n3/PP/2KV POLYPROPYLENE CAPACITOR 400232

C8 3n3/PP/2KV POLYPROPYLENE CAPACITOR 400232

C9 3n3/PP/2KV POLYPROPYLENE CAPACITOR 400232

C10 3n3/PP/2KV POLYPROPYLENE CAPACITOR 400232

C11 4N7/PP/2KV POLYPROPYLENE CAPACITOR 400306

C12 220n/PP/400V POLYPROPYLENE CAPACITOR (SIEMENS) 400297