Page 1

mb1_serv.ing

Alsatom MB1A/MC MB1/MC

INDEX

EQUIPMENT REQUIRED................................................................................... 2

A) PRELIMINARY PROCEDURE......................................................................... 2

B) LOW VOLTAGE POWER SUPPLY (board 801260-801260/a) ............................ 2

1) Testing power supply voltage +5V and +15V (TP1, TP2). .......................... 2

C) MICROCONTROLLER (board 801261-801262) ............................................... 2

1) Testing once equipment is turned on ......................................................... 2

3) Calibrating Vref voltage........................................................................... 3

4) Testing RF modulation signal.................................................................... 3

4) ONE SHOT timing test (single pulse) ......................................................... 4

5) superpulsed timing test ........................................................................... 4

E) POWER SUPPLY (board 801260-801260/a) ................................................... 5

1) Calibrating reference voltage Vrefa ........................................................... 5

2) Testing power supply driving PWM signal .................................................. 5

3) Calibrating minimum voltage .................................................................... 5

4) Calibrating maximum voltage ................................................................... 5

F) RADIOFREQUENCY (board 801260-801260/a) ............................................... 5

1) Testing neutral plate circuit...................................................................... 5

2) Testing working frequency....................................................................... 6

3)Calibrating the sloped signal (saw-tooth signal) ............................................ 6

4) Calibrating dead time .............................................................................. 6

5) testing the RF power amplifier.................................................................. 7

6) Calibrating current limiter ........................................................................ 7

7) Testing output power.............................................................................. 7

8) Calibrating maximum RF leakage current.................................................... 7

9) Bipolar coagulation test ........................................................................... 7

G) CALIBRATING RF PROTECTION SYSTEMS .................................................... 8

1) Protection from malfunction caused by modulation signal ............................. 8

2) Protection from malfunction caused by power supply................................... 8

H) CHECKING THE AUDIO SIGNAL LEVEL ......................................................... 8

I) CHECKING RF CURRENT LEAKAGE................................................................ 8

CURVES OF POWER CHANGES BY CHANGING THE LOADS

(FROM 50 TO 2000 OHMS) ............................................................................ 9

CURVES OF POWER INCREMENT (WITH NOMINAL LOAD) .................................. 9

Schematic blocks ........................................................................................... a

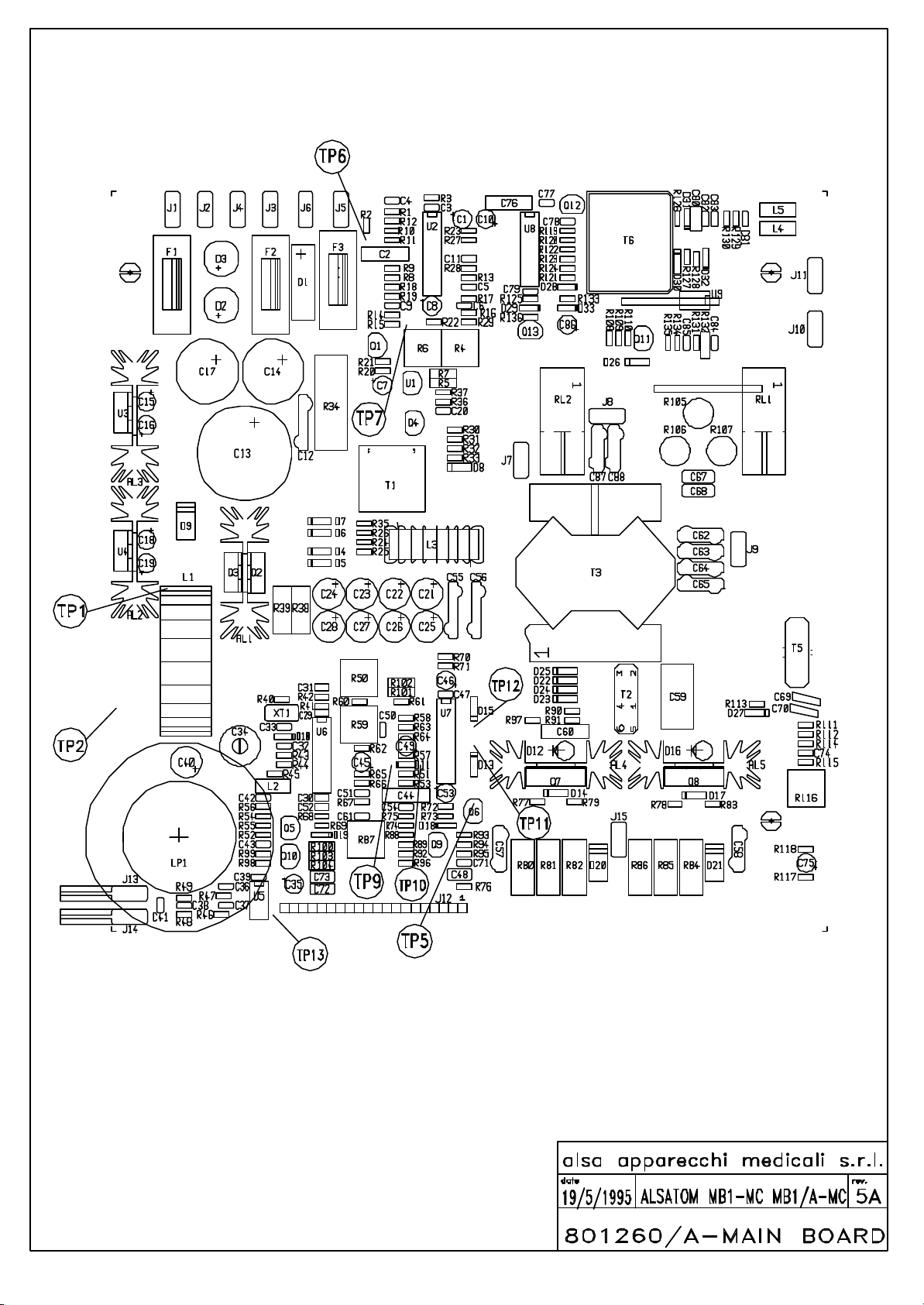

801260/a main board ..................................................................................... b

801261 MB1/A-MC microprocessor board ......................................................... c

801262 MB1-MC microprocessor board............................................................. d

.................................................................................. rev. september ’95

1

Page 2

SERVICE MANUAL

EQUIPMENT REQUIRED

DESCRIPTION FEATURES EXAMPLE

Double tracking Passband: Tektronix

oscilloscope DC - 100 MHz mod. 2235A

digital multimeter Accuracy: Hewlett Packard

DC = 1%, AC = 2% mod. E2373A

Thermoelement Passband: YOKOGAWA

10 Hz - 5 MHz mod. 2016

Digital Passband: Hewlett Packard

frequency meter 10 Hz - 100 MHz mod. HP 5384A

Voltage probe Passband: Tektronix

x 10 DC - 200 MHz mod. P6063B

Voltage probe Passband: Tektronix

x 1000 DC - 10 MHz mod. P6015

Current probe Passband: Tektronix

DC - 50 MHz mod. A6302/AM 503

A) PRELIMINARY PROCEDURE

a) remove the fuse F3 from the MAIN BOARD (board 801260-801260/a).

b) insert plug from pedal control into input port PEDAL.

c) insert neutral plate plug in its appropriate outlet MONOPOLAR.

d) insert power supply cable in current outlet.

B) LOW VOLTAGE POWER SUPPLY (board 801260-801260/a)

1) T

ESTING POWER SUPPLY VOLTAGE

+5V

AND

+15V (TP1, TP2).

a) short the R33 resistor (board 801260-801260/a). This prevents activation of the RF power generator, thus

preventing possible damage to electronic circuits that have not been tested yet.

b) set oscilloscope vertical sensivity at 1V/div. (in DC mode).

c) connect the oscilloscope probe to test point TP1.

d) turn on electrosurgical unit and make sure voltage is between 4.7V e 5.3V.

e) with oscilloscope in AC mode and sensivity set at 0.1V/div verify that ripple voltage is not over 10mVpp.

f) move oscilloscope probe on test point TP2 (Vert: 1V/div; DC) and make sure voltage is between 14.3V and

15.7V.

C) MICROCONTROLLER (board 801261-801262)

ESTING ONCE EQUIPMENT IS TURNED ON

1) T

When the electrosurgical unit is turned on, the microcontroller does automatically a selftest (about 15 seconds) to

verify anomalies of working (if present). If everything is all right, you’ll have in sequence:

- lighting of 5 green LEDs of working mode;

- lighting of power display;

- lighting of timer display (only in MB1/A-MC model);

- lighting of red LED (neutral plate alarm), yellow LED (CUT/BLEND activation) and blue LED (FORCED

COAG/SOFT COAG/BIPOLAR activation) with short acoustic signals.

After the selftest procedure, the unit shows what version of the software is being used (with a short acoustic

signal) and the display pertaining to output power shows the number '0'.

After turning on the unit, during the selftest or any other condition, the system controls and prevents possible

abnormalities shutting down output power and displaying error type with its specific code:

2

Page 3

KIND OF PROBLEM ACOUSTIC DISPLAY

SIGNAL CODE

RAM memory

(during the selftest)

1kHz 70ms ON 130ms OFF

EPROM memory

(during the selftest)

1kHz 70ms ON 130ms OFF

Supply voltage

(during the selftest)

1kHz 70ms ON 130ms OFF

RF signal modulation

(during the selftest)

1kHz 70ms ON 130ms OFF

Supply voltage

(during activation)

1kHz 70ms ON 130ms OFF

RF signal modulation

(during activation)

1kHz 70ms ON 130ms OFF

Internal variables check failure

1kHz 70ms ON 130ms OFF

Foot pedal failure

1kHz 70ms ON 130ms OFF

Neutral plate alarm

1kHz 190ms ON 190ms OFF

-

WARNING!!! AFTER TURNING ON THE ELECTROSURGICAL UNIT, IF NO LED LIGHTS, DON’T USE THE UNIT AND

CALL THE TECHNICAL SERVICE.

ALIBRATING

3) C

REF

V

VOLTAGE

a) connect the voltmeter to test point TP3 (board 801261-801262).

b) turn trimmers R57 and R61 fully clockwise (board 801261-801262).

c) set trimmer R2 (board 801261-801262) so that voltage is exactly at 4.94V.

4) T

ESTING

MODULATION SIGNAL

RF

a) connect oscilloscope probe to test point TP4 (board 801261-801262).

b) set 10W as power index in BLEND function.

c) with the electrosurgical unit turned on, test the modulation signal taking as reference the following wave-form:

Vert.: (DC) 1V/div

Hor.: 20 µs/div

e) set 10W as power index in the FORCED COAG function.

f) with the electrosurgical unit turned on, test the modulation signal, taking as reference the following wave-forms:

3

Page 4

Vert.: (DC) 1V/div

Hor.: 10 µs/div

Vert.: (DC) 1V/div

Hor.: 2 µs/div

g) set 10W as power index in the SOFT COAG function.

h) with the electrosurgical unit turned on, test the modulation signal, taking as reference the following wave-form:

Vert.: (DC) 1V/div

Hor.: 20 µs/div

4) ONE SHOT

TIMING TEST (SINGLE PULSE

)

(only for MB1/A-MC model).

a) always with oscilloscope probe on test point TP4 (board 801261-801262), set 10W as power index in the CUT

function.

b) push one time only the push-button "T" of the TIMER section. Now the timer display must show "1".

c) with the electrosurgical unit turned on, test the modulation signal, taking as reference the following wave-form:

Vert.: (DC) 1V/div

Hor.: 5 ms/div

e) verify the timing accuracy programming timer digits from 1÷99 (10ms÷0.99s).

SUPERPULSED TIMING TEST

5)

a) always with oscilloscope probe on test point TP4 (board 801261-801262) and 10W as power index in the CUT

function; push several times the push-button "T" until the digit '1' of TIMER display begins to flash.

b) verify the timing, taking as reference the following wave-form:

4

Page 5

Vert.: (DC) 1V/div

Hor.: 5 ms/div

Verify the duty-cycle is 50%.

c) push again the push-button "T" to leave the TIMER function.

d) turn off the electrosurgical unit.

e) remove jumper shorting the R33 resistor (board 801260-801260/a).

E) POWER SUPPLY (board 801260-801260/a)

ALIBRATING REFERENCE VOLTAGE VREFA

1) C

a) connect TP5 to ground. This prevents activation of the RF power generator, thus preventing possible damage to

electronic circuits that have not been tested yet.

b) insert F3 fuse.

c) set trimmer R4 at center position (board 801260-801260/a).

d) turn on electrosurgical unit and wait for the display to show '0'.

e) calibrate trimmer R6 (board 801260-801260/a) so that voltage at test point TP6 is exactly 8.0V.

ESTING POWER SUPPLY DRIVING

2) T

PWM

SIGNAL

a) connect oscilloscope probe to test point TP7 (board 801260-801260/a).

b) set 100W as power index in the CUT function.

c) activate and make sure the following wave-form appears:

Vert.: (DC) 2V/div

Hor.: 20 µs/div

ALIBRATING MINIMUM VOLTAGE

3) C

a) set 2W as power index in the CUT function.

b) make sure that, when the electrosurgical unit is not activated, voltage is lower than 3V in test point

TP8 (board 801260-801260/a).

c) press the activation pedal and bring voltage to 7V on TP8, by using trimmer R4 (board 801260-801260/a).

ALIBRATING MAXIMUM VOLTAGE

4) C

a) set 70W as power index in the FORCED COAG function.

b) press activation pedal and bring voltage to 134V on TP8, by using trimmer R6 (board 801260-801260/a).

Calibration of the two voltages, the maximum and the minimum, are interactive; thus, it is necessary to repeat

calibrations until the values that have been indicated are reached.

d) remove the jumper used to create electrical bonding on TP5 (mosfet drain Q6 board 801260-801260/a).

F) RADIOFREQUENCY (board 801260-801260/a)

a) short R33 resistor (board 801260-801260/a).

This prevents activation of the RF power generator, thus preventing possible damage to electronic circuits that

have not been tested yet.

ESTING NEUTRAL PLATE CIRCUIT

1) T

a) select CUT function.

5

Page 6

b) disconnect the two end conductors in the plate and then insert a 1000 ohm resistor in series.

c) check that red LED ALARM is turned on, at the same time that the LED turns on, a repetitive acoustic signal will

give warning of an error in the neutral plate.

d) once again, short the end conductors on the neutral plate.

ESTING WORKING FREQUENCY

2) T

a) set 10W as power index in the CUT function.

b) connect frequency meter to test point TP9 (board 801260-801260/a).

c) with the electrosurgical unit turned on, make sure that working frequency is 950 kHz (± 10kHz).

d) calibrate the trimming capacitor C24 (board 801260-801260/a) in such a way that the wave-form is the

following:

Vert.: (DC) 1V/div

Hor.: 50 ns/div

ALIBRATING THE SLOPED SIGNAL (SAW-TOOTH SIGNAL

3)C

)

a) always with the CUT function activated, regulate the R50 trimmer (board 801260-801260/a) in such a way that

the wave-form on test point TP10 will be the following:

Vert.: (DC) 1V/div

Hor.: 200 ns/div

b) turn the electrosurgical unit off.

c) remove jumper shorting the R33 resistor (board 801260-801260/a) and insert fuse F3.

ALIBRATING DEAD TIME

4) C

a) connect a load of 500 ohm to the MONOPOLAR output hook up.

b) set 10W as power index in the CUT function.

c) turn the R59 trimmer fully counterclockwise (board 801260-801260/a).

d) using both inlets of the oscilloscope, connect probe “1” to test point TP11, and probe “2” on test point TP12.

e) with the electrosurgical unit turned on, turn the R50 trimmer so that dead time (i.e. the time at which both

signals are at zero level) is equal to 250ns (board 801260-801260/a).

TP11 ADD-TP12 INVERT

Vert.: (DC) 5V/div

Hor.: 500 ns/div

6

Page 7

g) increase dead time by another 25ns by using trimmer R59 (board 801260-801260/a).

TESTING THE

5)

POWER AMPLIFIER

RF

a) set 100W as power index in the CUT function.

b) insert the RF current probe in series in the output.

c) activate the electrosurgical unit and make sure it has the following wave-form:

Vert.: (AC) 0.2A/div

Hor.: 500 ns/div

ALIBRATING CURRENT LIMITER

6) C

a) bring output load to 200 ohm.

b) set 70W as power index in the FORCED COAG function.

c) calibrate the R87 trimmer (board 801260-801260/a) in such a way that the current flowing through the output

load is 580mA.

ESTING OUTPUT POWER

7) T

a) bring the output load to 500 ohm.

b) with power set at 70W in FORCED COAG, make sure that effective current in the load is equal to 380mA

(± 5%). If necessary, it is possible to adjust the maximum output power by adjusting the R6 trimmer (board

801260-801260/a). Calibrating the R6 trimmer is allowed only if the voltage that is supplying the final stage

does not exceed 135V.

c) set 10W as power index in the CUT function.

d) make sure that the effective current in the load is equal to 140mA (± 5%). If necessary, it is possible to adjust

the maximum output power by adjusting the R4 trimmer (board 801260-801260/a).

e) set 140W as power index in the BLEND function.

f) make sure that affective current in the load is equal to 520mA (±5%).

NOTE: This manual contains a chapter (page 9) with output power curves for the electrosurgical unit; for a

complete test of the device, refer to these curves.

8) C

ALIBRATING MAXIMUM

LEAKAGE CURRENT

RF

a) bring load resistor to 1500 ohm.

b) set 150W as power index in the CUT function.

c) connect the oscilloscope probe on test point TP8.

d) by calibrating the R116 trimmer (board 801260-801260/a), find the point in which the tension displayed in the

oscilloscope decreases abruptly from 52V to 42V (± 20%).

IPOLAR COAGULATION TEST

9) B

a) connect the load in the BIPOLAR outlets.

b) bring load resistor to 100 ohm.

b) set 60W as power index in the BIPOLAR function.

c) turn on the electrosurgical unit and make sure that the effective current in the load is equal to 780mA (± 5%).

Vert.: (AC) 0.5A/div

Hor.: 500 ns/div

7

Page 8

G) CALIBRATING RF PROTECTION SYSTEMS

ROTECTION FROM MALFUNCTION CAUSED BY MODULATION SIGNAL

1) P

a) bring load resistor to 1000 ohm.

b) set 40W as power index in the FORCED COAG function.

c) with the electrosurgical unit activated, turn the R61 trimmer (board 801261-801262) slowly counterclockwise,

until the audio signal becomes intermittent and, at the same time, the RF output signal stops.

d) now turn the R61 trimmer (board 801261-801262) clockwise 15 degrees.

e) always keeping the power index at 40W, make sure that all functions are properly activated.

f) in order to simulate a malfunction condition, short the R52 resistor (board 801260-801260/a) and activate in

FORCED COAG; The audio signal must warn of a malfunction condition.

g) remove jumper shorting the R52 resistor.

2) P

ROTECTION FROM MALFUNCTION CAUSED BY POWER SUPPLY

a) bring load resistor to 500 ohm.

b) set 40W as power index in the FORCED COAG function.

c) with the electrosurgical unit activated, turn slowly the R57 trimmer counterclockwise (board 801261-801262)

until the audio sound becomes intermittent.

d) now, turn the R57 trimmer (board 801261-801262) clockwise 15 degrees.

e) always keeping the power index at 40W, make sure that all functions are properly activated.

H) CHECKING THE AUDIO SIGNAL LEVEL

The audio level has no control. The frequency and amplitude of the signal require no calibrating and are generated

directly by the microprocessor. To check, proceed as follows:

a) set 2W as power index of the CUT function.

b) connect the oscilloscope probe to test point TP13.

c) activate and make sure that the wave-form is the following:

Vert.: (AC) 2V/div

Hor.: 0.5 ms/div

I) CHECKING RF CURRENT LEAKAGE

High frequency current leakage, for insulated equipment, must never exceed 150mA RMS, as required by the CEI

EN 60601-2-2 REGULATIONS (IEC 601-2-2). The microprocessor for the electrosurgical unit MB1/A-MC has

controls allowing it to keep well below such limit. To test the efficiency of these controls, it is indispensable to

duplicate the most extreme test conditions, which in the case of the electrosurgical unit MB1/A-MC are obtained

with the CUT, BLEND, FORCED COAG and SOFT COAG at their highest power setting.

The average figures for leakage current are 110mA.

Measurement must be made as indicated by the CEI EN 60601-2-2 REGULATIONS (with insulated equipment).

8

Page 9

CURVES OF POWER CHANGES BY CHANGING THE LOADS (FROM 50 TO 2000 OHMS)

CURVES OF POWER INCREMENT (WITH NOMINAL LOAD)

9

Page 10

10

Page 11

Page 12

Page 13

Page 14

Page 15

ELECTROSURGICAL UNIT MB1A/MC - MB1/MC Revised: May 19,1995

801260/a MAIN BOARD Revision: 5A

Bill Of Materials September 25, 1995 11:38:34

Reference Part Description Cod. alsa

________________________________________________________________________

R1 330 Resistenza Strato 1/4 W 5% 430171

R2 330 Resistenza Strato 1/4 W 5% 430171

R3 3K9 Resistenza Strato 1/4 W 5% 430350

R4 10KT Trimmer Cermet 403066

R5 8K/1% Resistenza di precisione 1% 0.5W 430469

R6 2KT Trimmer Cermet 403092

R7 3K/1% Resistenza di precisione 1% 0.5W 430459

R8 10 Resistenza Strato 1/4 W 5% 430180

R9 12K Resistenza Strato 1/4 W 5% 430351

R10 330K Resistenza Strato 1/4 W 5% 430173

R11 10K Resistenza Strato 1/4 W 5% 430339

R12 150K Resistenza Strato 1/4 W 5% 430360

R13 220K Resistenza Strato 1/4 W 5% 430352

R14 100K Resistenza Strato 1/4 W 5% 430177

R15 1K Resistenza Strato 1/4 W 5% 430170

R16 27K Resistenza Strato 1/4 W 5% 430340

R17 10K Resistenza Strato 1/4 W 5% 430339

R18 100K Resistenza Strato 1/4 W 5% 430177

R19 1K Resistenza Strato 1/4 W 5% 430170

R20 100 Resistenza Strato 1/4 W 5% 430336

R21 1K Resistenza Strato 1/4 W 5% 430170

R22 47K Resistenza Strato 1/4 W 5% 430218

R23 10 Resistenza Strato 1/4 W 5% 430180

R24 56 Resistenza Strato 1/4 W 5% 430444

R25 1K Resistenza Strato 1/4 W 5% 430170

R26 56 Resistenza Strato 1/4 W 5% 430444

R27 10 Resistenza Strato 1/4 W 5% 430180

R28 10K Resistenza Strato 1/4 W 5% 430339

R29 10K Resistenza Strato 1/4 W 5% 430339

R30 22K Resistenza Strato 1/4 W 5% 430179

R31 47K Resistenza Strato 1/4 W 5% 430218

R32 4K7 Resistenza Strato 1/4 W 5% 430167

R33 10K Resistenza Strato 1/4 W 5% 430339

R34 33K/6W/F Res. 33 Kohm 6W a filo assiale 430463

R35 1K Resistenza Strato 1/4 W 5% 430170

R36 100K Resistenza Strato 1/4 W 5% 430177

R37 5K6 Resistenza Strato 1/4 W 5% 430344

R38 10K/1W Resistenza Strato 1 W 430320

R39 10K/1W Resistenza Strato 1 W 430320

R40 1K8 Resistenza Strato 1/4 W 5% 430198

R41 100 Resistenza Strato 1/4 W 5% 430336

R42 1K8 Resistenza Strato 1/4 W 5% 430198

R43 1K8 Resistenza Strato 1/4 W 5% 430198

R44 220 Resistenza Strato 1/4 W 5% 430358

R45 1K8 Resistenza Strato 1/4 W 5% 430198

R46 22K Resistenza Strato 1/4 W 5% 430179

R47 15K Resistenza Strato 1/4 W 5% 430345

R48 10K Resistenza Strato 1/4 W 5% 430339

R49 10 Resistenza Strato 1/4 W 5% 430180

R50 10KT Trimmer Cermet 403066

R51 10K Resistenza Strato 1/4 W 5% 430339

R52 4K7 Resistenza Strato 1/4 W 5% 430167

R53 47 Resistenza Strato 1/4 W 5% 430334

R54 220 Resistenza Strato 1/4 W 5% 430358

R55 10K Resistenza Strato 1/4 W 5% 430339

R56 100 Resistenza Strato 1/4 W 5% 430336

R57 1K8 Resistenza Strato 1/4 W 5% 430198

R58 220K Resistenza Strato 1/4 W 5% 430352

R59 200KT Trimmer Cermet 403104

R60 33K Resistenza Strato 1/4 W 5% 430172

R61 27K Resistenza Strato 1/4 W 5% 430340

R62 1K Resistenza Strato 1/4 W 5% 430170

R63 560 Resistenza Strato 1/4 W 5% 430178

R64 56K Resistenza Strato 1/4 W 5% 430176

R65 27K Resistenza Strato 1/4 W 5% 430340

R66 560 Resistenza Strato 1/4 W 5% 430178

R67 27K Resistenza Strato 1/4 W 5% 430340

R68 27K Resistenza Strato 1/4 W 5% 430340

R69 10K Resistenza Strato 1/4 W 5% 430339

R70 22 Resistenza Strato 1/4 W 5% 430447

R71 22 Resistenza Strato 1/4 W 5% 430447

R72 10 Resistenza Strato 1/4 W 5% 430180

R73 100K Resistenza Strato 1/4 W 5% 430177

R74 10K Resistenza Strato 1/4 W 5% 430339

R75 1K Resistenza Strato 1/4 W 5% 430170

R76 2K2 Resistenza Strato 1/4 W 5% 430343

R77 12 Resistenza Strato 1/4 W 5% 430415

R78 12 Resistenza Strato 1/4 W 5% 430415

R79 1K Resistenza Strato 1/4 W 5% 430170

R80 1K/3W/A Res. Antinduttiva 3W assiale 430450

R81 1K/3W/A Res. Antinduttiva 3W assiale 430450

R82 1K/3W/A Res. Antinduttiva 3W assiale 430450

R83 1K Resistenza Strato 1/4 W 5% 430170

R84 1K/3W/A Res. Antinduttiva 3W assiale 430450

R85 1K/3W/A Res. Antinduttiva 3W assiale 430450

R86 1K/3W/A Res. Antinduttiva 3W assiale 430450

R87 5KT Trimmer Cermet 403052

Page 16

ELECTROSURGICAL UNIT MB1A/MC - MB1/MC Revised: May 19,1995

801260/a MAIN BOARD Revision: 5A

Bill Of Materials September 25, 1995 11:38:34

Reference Part Description Cod. alsa

________________________________________________________________________

R88 1K Resistenza Strato 1/4 W 5% 430170

R89 100 Resistenza Strato 1/4 W 5% 430336

R90 470 Resistenza Strato 1/4 W 5% 430169

R91 470 Resistenza Strato 1/4 W 5% 430169

R92 4K7 Resistenza Strato 1/4 W 5% 430167

R93 47K Resistenza Strato 1/4 W 5% 430218

R94 10K Resistenza Strato 1/4 W 5% 430339

R95 10K Resistenza Strato 1/4 W 5% 430339

R96 100 Resistenza Strato 1/4 W 5% 430336

R97 2K2 Resistenza Strato 1/4 W 5% 430343

R98 470 Resistenza Strato 1/4 W 5% 430169

R99 22K Resistenza Strato 1/4 W 5% 430179

R100 2K/1% Resistenza di precisione 1% 0.5W 430461

R101 11K/1% Resistenza di precisione 1% 0.5W 430467

R102 11K/1% Resistenza di precisione 1% 0.5W 430467

R103 11K/1% Resistenza di precisione 1% 0.5W 430467

R104 33K2/1% Resistenza di precisione 1% 0.5W 430472

R105 10K/5W Resistenza Antind. 5 W 430471

R106 10K/5W Resistenza Antind. 5 W 430471

R107 10K/5W Resistenza Antind. 5 W 430471

R108 47 Resistenza Strato 1/4 W 5% 430334

R109 4K7 Resistenza Strato 1/4 W 5% 430167

R110 10K Resistenza Strato 1/4 W 5% 430339

R111 2K2 Resistenza Strato 1/4 W 5% 430343

R112 2K2 Resistenza Strato 1/4 W 5% 430343

R113 12 Resistenza Strato 1/4 W 5% 430415

R114 4K7 Resistenza Strato 1/4 W 5% 430167

R115 470 Resistenza Strato 1/4 W 5% 430169

R116 5KT Trimmer Cermet 403052

R117 100 Resistenza Strato 1/4 W 5% 430336

R118 1K Resistenza Strato 1/4 W 5% 430170

R119 220 Resistenza Strato 1/4 W 5% 430358

R120 220 Resistenza Strato 1/4 W 5% 430358

R121 22K Resistenza Strato 1/4 W 5% 430179

R122 33K Resistenza Strato 1/4 W 5% 430172

R123 100 Resistenza Strato 1/4 W 5% 430336

R124 680 Resistenza Strato 1/4 W 5% 430194

R125 180 Resistenza Strato 1/4 W 5% 430342

R126 10 Resistenza Strato 1/4 W 5% 430180

R127 470 Resistenza Strato 1/4 W 5% 430169

R128 1K5 Resistenza Strato 1/4 W 5% 430199

R129 560 Resistenza Strato 1/4 W 5% 430178

R130 820 Resistenza Strato 1/4 W 5% 430200

R131 18K Resistenza Strato 1/4 W 5% 430346

R132 10M Resistenza Strato 1/4 W 5% 430431

R133 100K Resistenza Strato 1/4 W 5% 430177

R134 2K2 Resistenza Strato 1/4 W 5% 430343

R135 1M Resistenza Strato 1/4 W 5% 430331

R136 100 Resistenza Strato 1/4 W 5% 430336

C1 10u/T/35V Cond.Tantalio 400134

C2 1n/P Cond.Poliestere 400278

C3 100n Cond.Ceramico multistrato 400139

C4 100n Cond.Ceramico multistrato 400139

C5 100p/NPO Cond.Ceramico NPO 400260

C6 220P/C Cond.Ceramico disco 400240

C7 10u/T/35V Cond.Tantalio 400134

C8 1u/T/35V Cond.Tantalio 400173

C9 22p/C Cond.Ceramico disco 400290

C10 10u/T/35V Cond.Tantalio 400134

C11 100n Cond.Ceramico multistrato 400139

C12 10n/C/1KV Cond.Ceramico disco 400133

C13 470u/E/250V Cond. Elettrolitico Verticale 400304

C14 1000u/E/35V Cond.Elettrolitico 400256

C15 10u/T/35V Cond.Tantalio 400134

C16 10u/T/35V Cond.Tantalio 400134

C17 1000u/E/35V Cond.Elettrolitico 400256

C18 10u/T/35V Cond.Tantalio 400134

C19 10u/T/35V Cond.Tantalio 400134

C20 680p/C/500V Cond.Ceramico 400292

C21 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C22 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C23 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C24 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C25 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C26 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C27 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C28 22u/E/100V/V Cond. Elett. verticale SMPS 400286

C29 100n Cond.Ceramico multistrato 400139

C30 470p/C Cond.Ceramico disco 400242

C31 100p/NPO Cond.Ceramico NPO 400260

C32 220P/C Cond.Ceramico disco 400240

C33 12p/C Cond.Ceramico disco 400269

C34 7_100p Compensatore 7/100p 400289

C35 10u/T/35V Cond.Tantalio 400134

C36 100p/NPO Cond.Ceramico NPO 400260

C37 100n Cond.Ceramico multistrato 400139

C38 68n Cond.Ceramico multistrato 400273

C39 10n Cond.Ceramico multistrato 400251

Page 17

ELECTROSURGICAL UNIT MB1A/MC - MB1/MC Revised: May 19,1995

801260/a MAIN BOARD Revision: 5A

Bill Of Materials September 25, 1995 11:38:34

Reference Part Description Cod. alsa

________________________________________________________________________

C40 22u/E/35V Cond. Elettrolitico verticale 400237

C41 100n Cond.Ceramico multistrato 400139

C42 47p/NPO Cond.Ceramico NPO 400255

C43 100p/NPO Cond.Ceramico NPO 400260

C44 220p/PP/400V/A Cond.Polipropilene assiale 400280

C45 10u/T/35V Cond.Tantalio 400134

C46 10u/T/35V Cond.Tantalio 400134

C47 100n Cond.Ceramico multistrato 400139

C48 220n/P Cond.Poliestere metallizzato 400271

C49 10u/T/35V Cond.Tantalio 400134

C50 100n Cond.Ceramico multistrato 400139

C51 100n Cond.Ceramico multistrato 400139

C52 10n Cond.Ceramico multistrato 400251

C53 1u/T/35V Cond.Tantalio 400173

C54 100n Cond.Ceramico multistrato 400139

C55 10n/C/1KV Cond.Ceramico disco 400133

C56 10n/C/1KV Cond.Ceramico disco 400133

C57 2n2/C/3KV Cond.Ceramico disco 400223

C58 2n2/C/3KV Cond.Ceramico disco 400223

C59 220n/PP/400V Cond. Polipropilene Siemens 400297

C60 1n/P Cond.Poliestere 400278

C61 10n Cond.Ceramico multistrato 400251

C62 1n/C/3KV Cond.Ceramico disco 400224

C63 1n/C/3KV Cond.Ceramico disco 400224

C64 1n/C/3KV Cond.Ceramico disco 400224

C65 1n/C/3KV Cond.Ceramico disco 400224

C67 47p/C/6KV Cond. Ceramico disco HT 400301

C68 47p/C/6KV Cond. Ceramico disco HT 400301

C69 680p/C/500V Cond.Ceramico 400292

C70 680p/C/500V Cond.Ceramico 400292

C71 100n Cond.Ceramico multistrato 400139

C72 220n/P Cond.Poliestere metallizzato 400271

C73 220n/P Cond.Poliestere metallizzato 400271

C74 10n Cond.Ceramico multistrato 400251

C75 1u/T/35V Cond.Tantalio 400173

C76 1n/P Cond.Poliestere 400278

C77 100n Cond.Ceramico multistrato 400139

C78 100n Cond.Ceramico multistrato 400139

C79 2n2/C Cond.Ceramico disco 400261

C80 220n/P Cond.Poliestere metallizzato 400271

C81 100n Cond.Ceramico multistrato 400139

C82 100n Cond.Ceramico multistrato 400139

C83 100n Cond.Ceramico multistrato 400139

C84 100n Cond.Ceramico multistrato 400139

C85 100n Cond.Ceramico multistrato 400139

C86 10u/T/35V Cond.Tantalio 400134

C87 2n2/C/3KV Cond.Ceramico disco 400223

C88 2n2/C/3KV Cond.Ceramico disco 400223

D1 KBL06 Ponte Raddrizzatore 4A/600V 420069

D2 WL04 Ponte Raddrizzatore 1A 420013

D3 WL04 Ponte Raddrizzatore 1A 420013

D4 12V/1W Diodo Zener 12V/1W 420019

D5 12V/1W Diodo Zener 12V/1W 420019

D6 12V/1W Diodo Zener 12V/1W 420019

D7 12V/1W Diodo Zener 12V/1W 420019

D8 2V7/0.5W Diodo Zener 2V7-1/2W 420067

D9 BYT03/400 Diodo Ultra Fast 3A/400V 420071

D10 BAT83 Diodo Schottky 420070

D11 1N4148 Diodo 420010

D12 150V/5W Diodo Zener 150V/5W 420091

D13 11DQ06 Diodo Schottky 420054

D14 12V/1W Diodo Zener 12V/1W 420019

D15 11DQ06 Diodo Schottky 420054

D16 150V/5W Diodo Zener 150V/5W 420091

D17 12V/1W Diodo Zener 12V/1W 420019

D18 BAT83 Diodo Schottky 420070

D19 10V/0.5W Diodo Zener 10V-1/2W 420068

D20 BYT03/400 Diodo Ultra Fast 3A/400V 420071

D21 BYT03/400 Diodo Ultra Fast 3A/400V 420071

D22 11DQ06 Diodo Schottky 420054

D23 11DQ06 Diodo Schottky 420054

D24 11DQ06 Diodo Schottky 420054

D25 11DQ06 Diodo Schottky 420054

D26 1N4007 Diodo 420001

D27 11DQ06 Diodo Schottky 420054

D28 1N4148 Diodo 420010

D29 1N4148 Diodo 420010

D30 11DQ06 Diodo Schottky 420054

D31 10V/0.5W Diodo Zener 10V-1/2W 420068

D32 2V7/0.5W Diodo Zener 2V7-1/2W 420067

D33 1N4148 Diodo 420010

Q1 VN10KM Mosfet N 427054

Q2 IRF740 Mosfet N 427076

Q3 IRF740 Mosfet N 427076

Q4 BC237B Transistor NPN 427057

Q5 BC237B Transistor NPN 427057

Q6 VN10KM Mosfet N 427054

Q7 IRF740 Mosfet N 427076

Page 18

ELECTROSURGICAL UNIT MB1A/MC - MB1/MC Revised: May 19,1995

801260/a MAIN BOARD Revision: 5A

Bill Of Materials September 25, 1995 11:38:34

Reference Part Description Cod. alsa

________________________________________________________________________

Q8 IRF740 Mosfet N 427076

Q9 BC237B Transistor NPN 427057

Q10 VN10KM Mosfet N 427054

Q11 BC237B Transistor NPN 427057

Q12 VN10KM Mosfet N 427054

Q13 VN10KM Mosfet N 427054

L1 520uH Induttanza toroidale cod. 700 713623

L2 150uH/175mA Induttanza 422008

L3 713621 Ind. AMIDON T94-2 713621

L4 1mH/100mA Induttanza 422005

L5 1mH/100mA Induttanza 422005

U1 LM431 Regolatore 482078

U2 UC3525 PWM UC3525 482060

U3 LM78S15 Regolatore di tensione POS. +15V 482086

U4 LM7805 Regolatore LM7805 482003

U5 LM386 Amplificatore BF LM386 482056

U6 74HCT00 HCT 7400 482049

U7 UC3825 PWM UC3825 482064

U8 4093 CMOS CD4093 482025

U9 SFH600-2 Fotoaccoppiatore SFH600-2 482022

XT1 1MHZ/C Risuonatore ceramico 252002

RL1 40.52-12VDC Rele' OMRON 404040

RL2 40.52-12VDC Rele' OMRON 404040

T1 421026 Trasf. di impulsi (2 secondari) SIRIO 421026

T2 713337 Trasformatore di corrente A.F. 713337

T3 801263/A Trasf. uscita MB1/MC MB1A/MC 801263/A

T5 713708 Lettore di corrente (T68-2) 713708

T6 421025 Trasf. isolatore 10KV SIRIO 421025

F1 1A/T Fusibile 1 A T 5x20 mm 433009

F2 1A/T Fusibile 1 A T 5x20 mm 433009

F3 2A/T Fusibile 2 A T 5x20 mm 433001

J1 399028 Conn. Faston C.S. Dritto 399028

J2 399028 Conn. Faston C.S. Dritto 399028

J3 399028 Conn. Faston C.S. Dritto 399028

J4 399028 Conn. Faston C.S. Dritto 399028

J5 399028 Conn. Faston C.S. Dritto 399028

J6 399028 Conn. Faston C.S. Dritto 399028

J7 399028 Conn. Faston C.S. Dritto 399028

J8 399028 Conn. Faston C.S. Dritto 399028

J9 399028 Conn. Faston C.S. Dritto 399028

J10 399028 Conn. Faston C.S. Dritto 399028

J11 399028 Conn. Faston C.S. Dritto 399028

J12 strip_10p Strip 10 pin 446015/10

Ja12 strip_10p Strip 10 pin 446015/10

J13 399029 Conn. Faston C.S. 90 gradi 399029

J14 399029 Conn. Faston C.S. 90 gradi 399029

J15 399028 Conn. Faston C.S. Dritto 399028

LP1 449125 Altoparlante 8 ohm 0.25 W 449125

AL1 ML73_2 Dissipatore in alluminio 713249

AL2 ML73_2 Dissipatore in alluminio 713249

AL3 ML73_2 Dissipatore in alluminio 713249

AL4 ML73_2 Dissipatore in alluminio 713249

AL5 ML73_2 Dissipatore in alluminio 713249

Page 19

Page 20

Page 21

ELECTROSURGICAL UNIT MB1A/MC Revised: September 19, 1995

801261 MICROCONTROLLER SECTION Revision: 4A

Bill Of Materials September 25, 1995 14:45:56

Reference Part Description Cod. alsa

________________________________________________________________________

R1 560 Resistenza Strato 1/4 W 5% 430178

R2 5KT Trimmer Cermet 403052

R3 1K/1% Resistenza di precisione 1% 0.5W 430458

R4 3K/1% Resistenza di precisione 1% 0.5W 430459

R5 100 Resistenza Strato 1/4 W 5% 430336

R6 1K Resistenza Strato 1/4 W 5% 430170

R7 10K Resistenza Strato 1/4 W 5% 430339

R8 1K8 Resistenza Strato 1/4 W 5% 430198

R9 22K Resistenza Strato 1/4 W 5% 430179

R10 560 Resistenza Strato 1/4 W 5% 430178

R11 10K Resistenza Strato 1/4 W 5% 430339

R12 10K Resistenza Strato 1/4 W 5% 430339

R13 10K Resistenza Strato 1/4 W 5% 430339

R14 100 Resistenza Strato 1/4 W 5% 430336

R15 100 Resistenza Strato 1/4 W 5% 430336

R16 100 Resistenza Strato 1/4 W 5% 430336

R17 100 Resistenza Strato 1/4 W 5% 430336

R18 10K Resistenza Strato 1/4 W 5% 430339

R19 10K Resistenza Strato 1/4 W 5% 430339

R20 1K Resistenza Strato 1/4 W 5% 430170

R21 1K Resistenza Strato 1/4 W 5% 430170

R22 100 Resistenza Strato 1/4 W 5% 430336

R23 100 Resistenza Strato 1/4 W 5% 430336

R24 1K Resistenza Strato 1/4 W 5% 430170

R25 100 Resistenza Strato 1/4 W 5% 430336

R26 10K Resistenza Strato 1/4 W 5% 430339

R27 10K Resistenza Strato 1/4 W 5% 430339

R28 10K Resistenza Strato 1/4 W 5% 430339

R29 1K Resistenza Strato 1/4 W 5% 430170

R30 1K Resistenza Strato 1/4 W 5% 430170

R31 100 Resistenza Strato 1/4 W 5% 430336

R32 100 Resistenza Strato 1/4 W 5% 430336

R33 80/1% Resistenza di precisione 1% 0.5W 430460

R34 3K/1% Resistenza di precisione 1% 0.5W 430459

R35 80/1% Resistenza di precisione 1% 0.5W 430460

R36 10K Resistenza Strato 1/4 W 5% 430339

R37 560 Resistenza Strato 1/4 W 5% 430178

R38 22K Resistenza Strato 1/4 W 5% 430179

R39 22K Resistenza Strato 1/4 W 5% 430179

R40 22K Resistenza Strato 1/4 W 5% 430179

R41 22K Resistenza Strato 1/4 W 5% 430179

R42 22K Resistenza Strato 1/4 W 5% 430179

R43 10K Resistenza Strato 1/4 W 5% 430339

R44 1K Resistenza Strato 1/4 W 5% 430170

R46 10K Resistenza Strato 1/4 W 5% 430339

R47 10K Resistenza Strato 1/4 W 5% 430339

R48 10K Resistenza Strato 1/4 W 5% 430339

R50 10K Resistenza Strato 1/4 W 5% 430339

R51 10K Resistenza Strato 1/4 W 5% 430339

R52 1K Resistenza Strato 1/4 W 5% 430170

R53 100 Resistenza Strato 1/4 W 5% 430336

R54 10K Resistenza Strato 1/4 W 5% 430339

R55 100 Resistenza Strato 1/4 W 5% 430336

R56 1K/1% Resistenza di precisione 1% 0.5W 430458

R57 5KT Trimmer Cermet 403052

R58 1K Resistenza Strato 1/4 W 5% 430170

R59 10K Resistenza Strato 1/4 W 5% 430339

R60 1K/1% Resistenza di precisione 1% 0.5W 430458

R61 20KT Trimmer Cermet 403050

R63 1K/1% Resistenza di precisione 1% 0.5W 430458

R64 1K Resistenza Strato 1/4 W 5% 430170

R65 NU NOT USED ----- R66 22K Resistenza Strato 1/4 W 5% 430179

R67 470 Resistenza Strato 1/4 W 5% 430169

R68 470 Resistenza Strato 1/4 W 5% 430169

R69 47 Resistenza Strato 1/4 W 5% 430334

R70 47 Resistenza Strato 1/4 W 5% 430334

R72 10K Resistenza Strato 1/4 W 5% 430339

R73 10K Resistenza Strato 1/4 W 5% 430339

R74 10K Resistenza Strato 1/4 W 5% 430339

R75 10K Resistenza Strato 1/4 W 5% 430339

C1 10n Cond.Ceramico multistrato 400251

C2 47p/NPO Cond.Ceramico NPO 400255

C3 10u/T/35V Cond.Tantalio 400134

C4 100n Cond.Ceramico multistrato 400139

C5 100n Cond.Ceramico multistrato 400139

C6 100n Cond.Ceramico multistrato 400139

C7 100n Cond.Ceramico multistrato 400139

C8 100n Cond.Ceramico multistrato 400139

C9 100n Cond.Ceramico multistrato 400139

C10 10u/T/35V Cond.Tantalio 400134

C11 22p/C Cond.Ceramico disco 400290

C12 22p/C Cond.Ceramico disco 400290

C13 10u/T/35V Cond.Tantalio 400134

C14 100n Cond.Ceramico multistrato 400139

C15 10u/T/35V Cond.Tantalio 400134

C16 1N/C Cond.Ceramico disco 400252

C17 100n Cond.Ceramico multistrato 400139

Page 22

ELECTROSURGICAL UNIT MB1A/MC Revised: September 19, 1995

801261 MICROCONTROLLER SECTION Revision: 4A

Bill Of Materials September 25, 1995 14:45:56

Reference Part Description Cod. alsa

________________________________________________________________________

C18 2n2/C Cond.Ceramico disco 400261

C19 10u/T/35V Cond.Tantalio 400134

C20 100n Cond.Ceramico multistrato 400139

C21 100n Cond.Ceramico multistrato 400139

C22 100n Cond.Ceramico multistrato 400139

C23 100n Cond.Ceramico multistrato 400139

C24 47u/E/50V Cond.Elettrolitico 400296

C25 100n Cond.Ceramico multistrato 400139

C26 100n Cond.Ceramico multistrato 400139

C27 10n Cond.Ceramico multistrato 400251

C28 1u/T/35V Cond.Tantalio 400173

C29 10n Cond.Ceramico multistrato 400251

C30 100n Cond.Ceramico multistrato 400139

D1 GL5HR8 Diodo Led Rosso 5 mm 420025

D2 5V6/0.5W Diodo Zener 5V6/0.5W 420018

D3 LED_Y3 Led giallo 3mm 420079

D4 LED_Y3 Led giallo 3mm 420079

D5 LED_Y3 Led giallo 3mm 420079

D6 LED_Y3 Led giallo 3mm 420079

D7 LED_Y3 Led giallo 3mm 420079

D8 MAN6760C Display 7 Segmenti anodo comune 420060

D9 MAN6760C Display 7 Segmenti anodo comune 420060

D10 MAN6760C Display 7 Segmenti anodo comune 420060

D11 MAN6760C Display 7 Segmenti anodo comune 420060

D12 MAN6760C Display 7 Segmenti anodo comune 420060

D14 GL5HY8 Diodo Led Giallo 5 mm 420036

D15 GL5HB8 Diodo Led Blu 5 mm 420092

D16 NU NOT USED ----- D17 1N4148 Diodo 420010

D18 1N4148 Diodo 420010

Q1 BC237B Transistor NPN 427057

Q2 BC237B Transistor NPN 427057

Q3 BC237B Transistor NPN 427057

Q4 BC237B Transistor NPN 427057

Q5 BC237B Transistor NPN 427057

Q6 BC237B Transistor NPN 427057

Q7 BC307B Transistor PNP 427058

Q8 BC237B Transistor NPN 427057

Q9 BC237B Transistor NPN 427057

L1 100uH/275mA Induttanza 422006

L2 6uH8/800mA Induttanza 422007

U1 LM431 Regolatore 482078

U2 80C552 Microprocessore 482077

U3 74HC373 74HC373 482066

U4 27256 EPROM 256K 482067

U5 SAA1064 Display decoder 482080

XT1 12Mhz/HC18 Quarzo 12 Mhz 252005

SW1 MTG_1241 Pulsante da C.S. SCHURTER 416094

SW2 MTG_1241 Pulsante da C.S. SCHURTER 416094

SW3 MTG_1241 Pulsante da C.S. SCHURTER 416094

SW4 MTG_1241 Pulsante da C.S. SCHURTER 416094

SW5 MTG_1241 Pulsante da C.S. SCHURTER 416094

SW6 MTG_1241 Pulsante da C.S. SCHURTER 416094

J1 PAD_CI Capocorda realizzato su C.S. ----- J2 PAD_CI Capocorda realizzato su C.S. ----- J3 JUMP_20P Jumper 20 poli 384035+384027

J4 PAD_CI Capocorda realizzato su C.S. ----- J5 PAD_CI Capocorda realizzato su C.S. ----- J6 399028 Conn. Faston C.S. Dritto 399028

Page 23

Page 24

Page 25

ELECTROSURGICAL UNIT MB1/MC Revised: September 19,1995

801262 MICROCONTROLLER SECTION Revision: 4A

Bill Of Materials September 25, 1995 14:46:55

Reference Part Description Cod. alsa

_________________________________________________________________________

R1 560 Resistenza Strato 1/4 W 5% 430178

R2 5KT Trimmer Cermet 403052

R3 1K/1% Resistenza di precisione 1% 0.5W 430458

R4 3K/1% Resistenza di precisione 1% 0.5W 430459

R5 100 Resistenza Strato 1/4 W 5% 430336

R6 1K Resistenza Strato 1/4 W 5% 430170

R7 10K Resistenza Strato 1/4 W 5% 430339

R8 1K8 Resistenza Strato 1/4 W 5% 430198

R9 22K Resistenza Strato 1/4 W 5% 430179

R10 560 Resistenza Strato 1/4 W 5% 430178

R11 10K Resistenza Strato 1/4 W 5% 430339

R12 10K Resistenza Strato 1/4 W 5% 430339

R13 10K Resistenza Strato 1/4 W 5% 430339

R14 100 Resistenza Strato 1/4 W 5% 430336

R15 100 Resistenza Strato 1/4 W 5% 430336

R16 100 Resistenza Strato 1/4 W 5% 430336

R17 100 Resistenza Strato 1/4 W 5% 430336

R18 10K Resistenza Strato 1/4 W 5% 430339

R19 10K Resistenza Strato 1/4 W 5% 430339

R20 1K Resistenza Strato 1/4 W 5% 430170

R21 1K Resistenza Strato 1/4 W 5% 430170

R22 100 Resistenza Strato 1/4 W 5% 430336

R23 100 Resistenza Strato 1/4 W 5% 430336

R24 1K Resistenza Strato 1/4 W 5% 430170

R25 100 Resistenza Strato 1/4 W 5% 430336

R26 10K Resistenza Strato 1/4 W 5% 430339

R27 10K Resistenza Strato 1/4 W 5% 430339

R28 10K Resistenza Strato 1/4 W 5% 430339

R29 1K Resistenza Strato 1/4 W 5% 430170

R30 1K Resistenza Strato 1/4 W 5% 430170

R31 100 Resistenza Strato 1/4 W 5% 430336

R32 100 Resistenza Strato 1/4 W 5% 430336

R33 80/1% Resistenza di precisione 1% 0.5W 430460

R34 3K/1% Resistenza di precisione 1% 0.5W 430459

R35 80/1% Resistenza di precisione 1% 0.5W 430460

R36 10K Resistenza Strato 1/4 W 5% 430339

R37 560 Resistenza Strato 1/4 W 5% 430178

R38 22K Resistenza Strato 1/4 W 5% 430179

R39 22K Resistenza Strato 1/4 W 5% 430179

R40 22K Resistenza Strato 1/4 W 5% 430179

R41 22K Resistenza Strato 1/4 W 5% 430179

R42 22K Resistenza Strato 1/4 W 5% 430179

R43 10K Resistenza Strato 1/4 W 5% 430339

R44 1K Resistenza Strato 1/4 W 5% 430170

R46 10K Resistenza Strato 1/4 W 5% 430339

R47 10K Resistenza Strato 1/4 W 5% 430339

R48 10K Resistenza Strato 1/4 W 5% 430339

R50 10K Resistenza Strato 1/4 W 5% 430339

R51 10K Resistenza Strato 1/4 W 5% 430339

R52 1K Resistenza Strato 1/4 W 5% 430170

R53 100 Resistenza Strato 1/4 W 5% 430336

R54 10K Resistenza Strato 1/4 W 5% 430339

R55 100 Resistenza Strato 1/4 W 5% 430336

R56 1K/1% Resistenza di precisione 1% 0.5W 430458

R57 5KT Trimmer Cermet 403052

R58 1K Resistenza Strato 1/4 W 5% 430170

R59 10K Resistenza Strato 1/4 W 5% 430339

R60 1K/1% Resistenza di precisione 1% 0.5W 430458

R61 20KT Trimmer Cermet 403050

R63 1K/1% Resistenza di precisione 1% 0.5W 430458

R64 1K Resistenza Strato 1/4 W 5% 430170

R65 NU NOT USED ----- R66 22K Resistenza Strato 1/4 W 5% 430179

R67 470 Resistenza Strato 1/4 W 5% 430169

R68 470 Resistenza Strato 1/4 W 5% 430169

R69 47 Resistenza Strato 1/4 W 5% 430334

R70 47 Resistenza Strato 1/4 W 5% 430334

R72 10K Resistenza Strato 1/4 W 5% 430339

R73 10K Resistenza Strato 1/4 W 5% 430339

R74 10K Resistenza Strato 1/4 W 5% 430339

R75 10K Resistenza Strato 1/4 W 5% 430339

C1 10n Cond.Ceramico multistrato 400251

C2 47p/NPO Cond.Ceramico NPO 400255

C3 10u/T/35V Cond.Tantalio 400134

C4 100n Cond.Ceramico multistrato 400139

C5 100n Cond.Ceramico multistrato 400139

C6 100n Cond.Ceramico multistrato 400139

C7 100n Cond.Ceramico multistrato 400139

C8 100n Cond.Ceramico multistrato 400139

C9 100n Cond.Ceramico multistrato 400139

C10 10u/T/35V Cond.Tantalio 400134

C11 22p/C Cond.Ceramico disco 400290

C12 22p/C Cond.Ceramico disco 400290

C13 10u/T/35V Cond.Tantalio 400134

C14 100n Cond.Ceramico multistrato 400139

C15 10u/T/35V Cond.Tantalio 400134

C16 1N/C Cond.Ceramico disco 400252

C17 100n Cond.Ceramico multistrato 400139

Page 26

ELECTROSURGICAL UNIT MB1/MC Revised: September 19,1995

801262 MICROCONTROLLER SECTION Revision: 4A

Bill Of Materials September 25, 1995 14:46:55

Reference Part Description Cod. alsa

_________________________________________________________________________

C18 2n2/C Cond.Ceramico disco 400261

C19 10u/T/35V Cond.Tantalio 400134

C20 100n Cond.Ceramico multistrato 400139

C21 100n Cond.Ceramico multistrato 400139

C22 100n Cond.Ceramico multistrato 400139

C23 100n Cond.Ceramico multistrato 400139

C24 47u/E/50V Cond.Elettrolitico 400296

C25 100n Cond.Ceramico multistrato 400139

C26 100n Cond.Ceramico multistrato 400139

C27 10n Cond.Ceramico multistrato 400251

C28 1u/T/35V Cond.Tantalio 400173

C29 10n Cond.Ceramico multistrato 400251

C30 100n Cond.Ceramico multistrato 400139

D1 GL5HR8 Diodo Led Rosso 5 mm 420025

D2 5V6/0.5W Diodo Zener 5V6/0.5W 420018

D3 LED_Y3 Led giallo 3mm 420079

D4 LED_Y3 Led giallo 3mm 420079

D5 LED_Y3 Led giallo 3mm 420079

D6 LED_Y3 Led giallo 3mm 420079

D7 LED_Y3 Led giallo 3mm 420079

D8 MAN6760C Display 7 Segmenti anodo comune 420060

D9 MAN6760C Display 7 Segmenti anodo comune 420060

D10 MAN6760C Display 7 Segmenti anodo comune 420060

D14 GL5HY8 Diodo Led Giallo 5 mm 420036

D15 GL5HB8 Diodo Led Blu 5 mm 420092

Q1 BC237B Transistor NPN 427057

Q2 BC237B Transistor NPN 427057

Q3 BC237B Transistor NPN 427057

Q4 BC237B Transistor NPN 427057

Q5 BC237B Transistor NPN 427057

Q6 BC237B Transistor NPN 427057

Q7 BC307B Transistor PNP 427058

Q8 BC237B Transistor NPN 427057

Q9 BC237B Transistor NPN 427057

L1 100uH/275mA Induttanza 422006

L2 6uH8/800mA Induttanza 422007

U1 LM431 Regolatore 482078

U2 80C552 Microprocessore 482077

U3 74HC373 74HC373 482066

U4 27256 EPROM 256K 482067

U5 SAA1064 Display decoder 482080

XT1 12Mhz/HC18 Quarzo 12 Mhz 252005

SW1 MTG_1241 Pulsante da C.S. SCHURTER 416094

SW2 MTG_1241 Pulsante da C.S. SCHURTER 416094

SW3 MTG_1241 Pulsante da C.S. SCHURTER 416094

J1 PAD_CI Capocorda realizzato su C.S. ----- J2 PAD_CI Capocorda realizzato su C.S. ----- J3 JUMP_20P Jumper 20 poli 384035+384027

J4 PAD_CI Capocorda realizzato su C.S. ----- J5 PAD_CI Capocorda realizzato su C.S. ----- J6 399028 Conn. Faston C.S. Dritto 399028

Loading...

Loading...