Page 1

MANUAL

®

Alpha

Wet Blade

Cutting Kit

Instruction Manual

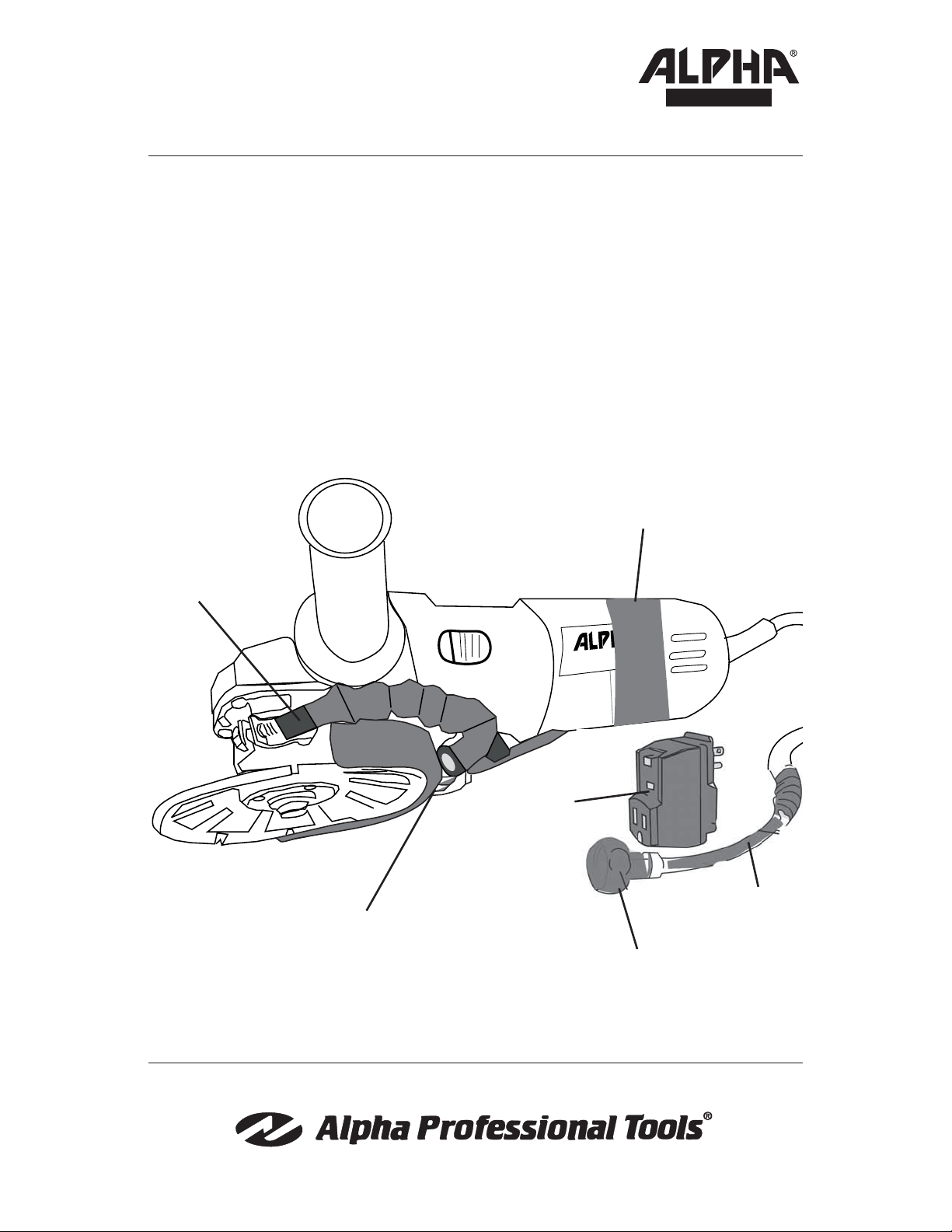

Hook & Loop Strap

Coolant Tube

Blade Guard

*Tool and Blade sold separately

®

HSG-125

GFCI

Water Line

Garden Hose Adapter

Part No: WBCKIT

103 Bauer Drive, Oakland, NJ 07436 • 800-648-7229 • Fax: 800-286-0114

www.alpha-tools.com

Page 2

TABLE OF CONTENTS

CONTENTS

Parts List .............................................................................................. 3

Instructions ........................................................................................... 3

Creating Thread Holes for the Protective Guard .................................. 4

Assembly of WBCKIT Guard ................................................................ 4

Installation of WBCKIT Guard .............................................................. 5

Garden Hose Adapter Installation ........................................................ 6

Installation of Plastic Wire Wrap ........................................................... 7

Installation of GFCI ............................................................................... 7

Completed Assembly ............................................................................ 7

SERVICE

Use only Alpha Professional Tools® accessories and spare parts. Should

components which have been described need to be exchanged, please contact

your dealer or Alpha Professional Tools®.

CAUTION!

• Attach the Wet Blade Cutting Kit correctly by following the procedure in this

instructional manual.

• During operation, be sure to wear personal safety equipment.

NEED MORE INFORMATION

For information on Alpha Professional Tools® complete product line, visit us on the

web at www.alpha-tools.com.

2

Page 3

PARTS LIST

4

9

1

2

3

6

5

7

8

No. Item Description Part Number

1. Protective Guard for HSG-125

The WBCKIT can also be attached to

other grinders with minimal alteration

to their safety guards

2. Water Line (10’) 3m*

3. Garden Hose Adapter*

4. Ground Fault Circuit Interrupter GFCI-1

5. Hook & Loop Strap 140003

6. Coolant Tube 140004

7. 90 degree Swivel Fitting 140005

8. Plastic Ties PDH-CABLETIES

9. Plastic Wire Wrap 140002

* Not sold separately.

INSTRUCTIONS

140007

133287

Alpha Professional Tools® provides the highest quality parts and manufacturing techniques

in the manufacture of this product. In order to obtain the maximum effectiveness and

provide the highest degree of safety, it is necessary to review and follow these instructions

carefully before using the tool.

3

Page 4

CREATING THREAD HOLES FOR THE PROTECTIVE GUARD

Hole Size:

5mm or #8 Drill Bit

Illustration of

Protection Guard

10mm (3/8”)

25mm (1”)

ASSEMBLY OF WBCKIT GUARD

STEP 1

1. Thread plastic cable tie through

holes in the guard. (If using another

grinder the safety guard must be

altered to accomodate cable ties

as shown above).

STEP 3

STEP 2

2. Place coolant tube between holes

on Guard and tighten in place with

plastic tie.

STEP 4

3. Repeat steps 1 and 2 to completely secure the coolant tube to

the guard.

WBCKIT Guard Assembly

4

4. Trim plastic ties with pliers as shown

above.

Page 5

INSTALLATION OF WBCKIT GUARD

Note: It is important to securely attach the

WBCKIT to the tool.

1. Before tightening, slide the protective cover

onto clamping collar so that the lip on the

protective cover fi ts into the groove on the

tool.

2. Position the protective cover with the

shield facing backwards. Push down

until the protective cover is fi rmly seated

on the clamping collar.

3. Tighten the clamping screw to a snug fi t.

The protective cover should not be able

to move.

Groove

4. Take one end of the water line and insert

into the “push to connect” side of the 90

degree swivel fi tting.

5. Push tubing until it contacts the bottom of

the fi tting. Pull back slightly on the tubing

to ensure correct engagement.

Note: Tubing should not pull out from

fi tting.

6. To release tubing from fitting, push

tubing inward, push down on the release

collar and then pull tubing free from

connection.

Release

Collar

5

Page 6

GARDEN HOSE

ADAPTER INSTALLATION

1. Take the open end of the

water line and place the

compression fitting nut on

the tube as shown. Push

the tube into the connector

base.

2. Tighten the compression nut with a

14mm wrench to a secure condition.

Compression Nut

Base

Push Tube

Water Line

Note: Do not overtighten connection.

If leakage occurs during startup,

tighten in small increments until a

leak tight connection is made.

3. Position hook & loop strap

around the waterline and grinder body.

Note: Position the strap away

from the vent ports of

grinder.

4. The 90 degree swivel fi tting

can be moved to give a tight

installation to the grinder

body.

14mm Wrench

5. Adjust the strap to a tight position.

6

Vent ports

Page 7

INSTALLATION OF

PLASTIC WIRE WRAP

1. Install the plastic wire wrap

around both power cord and

water-line as shown.

2. Finish the wrapping procedure until secure.

INSTALLATION OF GFCI

1. Install the GFCI to the grinder

power cord as shown. Connect to power and check the

GFCI for proper function by

pressing the test and reset

buttons.

Caution: Do not operate a

grinder with a water-feed system, without a GFCI installed

and in proper working condition.

COMPLETED ASSEMBLY

7

Page 8

103 Bauer Drive, Oakland, NJ 07436 • 800-648-7229 • Fax: 800-286-0114

www.alpha-tools.com

Copyright © 2009 Alpha Professional Tools. All rights reserved.

Loading...

Loading...