SERIES 3500

TRACE OXYGEN TRANSMITTER

Alpha Omega Instruments Corp.

40 Albion Road, Suite 100

Lincoln, RI 02865

Phone: 401-333-8580

Fax: 401-333-5550

Website: www.aoi-corp.com

Email: salescontact@aoi-corp.com

VERSION 4.0 COPYRIGHT 06/18

ALPHA OMEGA INSTRUMENTS CORP. ALL

RIGHTS RESERVED INCLUDING THE RIGHT TO

REPRODUCE THIS MANUAL, OR ANY PORTION

THEREOF, IN ANY FORM.

ALPHA OMEGA INSTRUMENTS CORP.

______________________________________________________________________

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

WARRANTY

Alpha Omega Instruments Corp. warrants the products delivered to be free from defects in

material and workmanship at the time of delivery to the FOB point specified in the purchase

order, its liability under this warranty being limited to repairing or replacing, at Alpha Omega

Instruments' option, items (excluding the oxygen sensor) which are returned to it prepaid within

two (2) years from the date of shipment and found to Seller’s satisfaction to be defective.

Alpha Omega Instrument's one (1) year sensor warranty offers protection for one full year from

the date of shipment of the Series 3500 Trace Oxygen Transmitter. Any sensor from a Series

3500 Trace Oxygen Transmitter that fails under normal use must be returned to Seller prepaid

and, if such sensor is determined by Seller to be defective, Seller shall provide Buyer a

replacement sensor. Buyer must provide the serial number of the transmitter from which the

sensor has been removed. If a sensor is found to be defective and a new one issued, the

warranty of the replacement sensor (s) is for a period of one year from the date of shipment. At

times, it may be necessary to ship a replacement sensor in advance of receiving one returned

for warranty claim. In such cases, if the returned sensor is not covered under warranty, the user

will be charged the full price of a replacement sensor. In no event shall Alpha Omega

Instruments Corp. be liable for consequential damages. NO PRODUCT IS WARRANTED

AS BEING FIT FOR A PARTICULAR PURPOSE AND THERE IS NO WARRANTY OF

MERCHANTABILITY.

This warranty applies only if:

(i) the items are used solely under the operating conditions and manner

recommended in this manual, specifications, or other literature;

(ii) the items have not been misused or abused in any manner or repairs attempted

thereon;

(iii) written notice of the failure within the warranty period is forwarded to Alpha

Omega Instruments Corp. and, the directions received for properly identifying

items returned under warranty are followed;

(iv) the return notice authorizes Alpha Omega Instruments Corp. to examine and

disassemble returned products to the extent the Company deems necessary to

ascertain the cause of failure.

The warranties stated herein are exclusive. THERE ARE NO OTHER WARRANTIES, EITHER

EXPRESSED OR IMPLIED, BEYOND THOSE SET FORTH HEREIN, and Alpha Omega

Instruments Corp. does not assume any other obligation or liability in connection with the sale or

use of said products.

Disclaimer of Warranty

Alpha Omega Instruments Corp. makes no representation or warranties, either expressed or implied, by or with respect to anything in this

manual, including, but not limited to, implied warranties of merchantability or fitness for a particular purpose. In no event will Alpha Omega

Instruments Corp. be liable for any damages, whether direct or indirect, special, consequential, or incidental arising from the use of this

manual. Some states in the USA do not allow the exclusion of incidental or consequential damages. Alpha Omega Instruments Corp. also

reserves the right to make any changes to improve the performance of its products at any time and without notice.

ALPHA OMEGA INSTRUMENTS CORP.

______________________________________________________________________

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

TABLE OF CONTENTS

PAGE

WARRANTY

SECTION 1.0 SPECIFICATIONS 1

SECTION 2.0 SYSTEM DESCRIPTION 3

SECTION 3.0 INSTALLATION PROCEDURES 4

SECTION 4.0 OPERATING PROCEDURES 5

SECTION 5.0 CALIBRATION PROCEDURES 6

SECTION 6.0 REPLACEMENT OF THE OXYGEN SENSOR 8

FIGURE 1.0 SERIES 3500 TRANSMITTER BOARD 10

FIGURE 2.0 WIRING DETAILS FOR THE 4-20 mADC Output 11

FIGURE 3.0 OPTIONAL NEMA 7 EXPLOSION PROOF VERSION 12

APPENDIX A MSDS FOR THE 3SEN OXYGEN SENSOR 13

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

SECTION 1.0

SPECIFICATIONS

PERFORMANCE

Measurement Ranges (parts per million)

0-10, 0-50, 0-100, 0-500, 0-1,000, 0-5,000, 0-10,000, and 0-20,000.

Accuracy 1 + 1% of full scale.

Linearity + 1% of full scale.

Response Time 90% of full scale in less than 10 seconds (typical). The response time for

ranges of 0-50 PPM or less depend to a great extent on the design of

the sample delivery system including the materials used.

Sensor Type Electrochemical Sensor. (Optional CO2 Resistant Sensor Available).

Temperature Standard.

Compensation

Operating Temp. 40° to 105°F (5° to 40°C).

Range <40° F (<5º C ) use heated sensor enclosure

>104ºF (>40º C ) cooling of sample gas/sensor required

Warranty Two years electronics one year sensor.

ELECTRICAL

Electrical Input 14-32 VDC @ 4-20

Analog Output 4-20 mADC with a maximum loop resistance of 600 ohms.

SAMPLE GAS

CHARACTERISTICS

Sample Flow Rate 1.0 to 2.0 standard cubic feet per hour (SCFH).

0.5 to 1.0 liters/ minute (LPM).

Sample Gas 0.1 to 1.5 psig (0.007 to 0.1 kg/cm2).

Pressure Limits.

Entrained Solids <3 mg/ft3 no in-line filter required

>3 mg/ft3 in-line filter required

1

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

Hydrocarbon Mist <0.7 mg/ft3 no in-line filter required

>0.7 mg/ft3 in-line filter required

CONSTRUCTION

Enclosure Polycarbonate, rated NEMA 4X (IP66) without optional equipment

Optional NEMA 7 Explosion Proof

Gas Connections: 1/4" compression fittings with manual isolation valves.

Dimensions 5.5 in (139.9 mm) length.

8.8 in (223.5 mm) width.

3.4 in (86.4 mm) deep.

Note: All dimensions are without optional equipment

1

Stated at constant temperature and pressure

2

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

SECTION 2.0

SYSTEM DESCRIPTION

General Description

The Series 3500 Trace Oxygen Transmitter is a DC powered trace oxygen transmitter designed to

provide accurate and dependable trace oxygen measurements in a variety of gases. The transmitter

enclosure is made from durable polycarbonate, and is rated for NEMA 4 (IP 66) service.

The instrument is powered from 14 - 32 Volts DC and provides a 4-20 mADC output that can be sent

to a datalogger, recorder, PLC, DCS, etc. Options include a pressure regulator, flow meter, an in-line

filter for sample gases that contain particulate matter, and explosion proof (NEMA 7) housing.

Ambient Temperature Electrochemical Sensor

The Series 3500 Trace Oxygen Transmitter features an advanced trace oxygen sensor. The sensor is

a lead-oxygen battery comprised of a lead anode, a gold plated cathode, and an electrolyte consisting

of potassium hydroxide. All types of electrochemical transducers have three primary components; a

cathode, anode, and electrolyte. In the Alpha Omega Instruments advanced oxygen sensor, the

cathode is the sensing electrode or the site where chemical reduction of the oxygen takes place.

The chemical reactions are as follows:

Cathode Reaction 4e- + O2 + 2H2O 4OH- (1)

In the above reaction, four electrons combine with one oxygen molecule to produce four hydroxyl ions.

This cathodic half-reaction occurs simultaneously with the following anodic half-reaction:

Anode Reaction Pb + 2OH- PbO + H2O + 2e- (2)

The anode (lead) is oxidized (in a basic media) to lead oxide and in the process, two electrons are

transferred for each atom of lead that is oxidized. The sum of the half-reactions (1) and (2) results in

the overall reaction (3):

Overall Reaction O2 + 2Pb 2PbO (3)

From this reaction it can be seen that the sensor is very specific for oxygen providing there are no

gaseous components in the sample stream capable of oxidizing lead. The only likely compounds that

meet this requirement are the halogens (iodine, bromine, chlorine, and fluorine).

In reaction (1), four electrons are transferred for each oxygen molecule undergoing reaction. In order

to be reacted, and oxygen molecule must diffuse through both the sensing membrane and the thin film

of electrolyte maintained between the sensing membrane and the upper surface of the cathode. The

rate at which oxygen molecules reach the surface of the cathode determines the electrical output.

This rate is directly proportional to the concentration of oxygen in the gaseous mixture surrounding the

sensor cell.

3

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

SECTION 3.0

INSTALLATION PROCEDURES

Unpacking the Instrument

Upon opening the shipping container, carefully unpack the transmitter to check if the outer surfaces

have been damaged. If so, report the findings immediately to Alpha Omega Instruments who will

provide further instructions. If there is no apparent damage, check the contents to ensure all items

were shipped. In some cases, items may be backordered.

ALL DAMAGE AND SHORTAGE CLAIMS MUST BE MADE

KNOWN TO ALPHA OMEGA INSTRUMENTS WITHIN 10

DAYS AFTER RECEIPT OF SHIPMENT.

There are four screws securing the cover of the Series 3500 Trace Oxygen Transmitter. Removing

these screws allows access to the inside of the enclosure. The cover should be removed and the

interior of the enclosure checked to ensure that no components have been loosened or dislodged. If

there are loose or dislodged components, notify the factory for further instructions. If all is

found to be satisfactory, the installation procedure can begin.

For a Series 3500 instrument supplied with an explosion proof NEMA 7 enclosure, access to the inside

of the instrument is gained by removing the cast aluminum cover from the base by turning the cover in

a counterclockwise fashion. If there are loose or dislodged components, notify the factory for

further instructions. If all is found to be satisfactory, the installation procedure can begin.

Electrical Installation

The Series 3500 Trace Oxygen Transmitter is powered by a user supplied power supply, and as such,

there is no AC power cord. Power to the Series 3500 should be 14 - 32 VDC @ 4-20 mADC.

Consideration should be given to the loop resistance of the cable in relation to the DC power used.

The following formula should be used to determine the maximum loop resistance allowed for your

power supply:

RL (K ohms max>) = Input VDC - 12

20

Wiring to the Analog Output

The Series 3500 Trace Oxygen Transmitter is a true blind transmitter, that is, it has no power source of

its own and operates from loop power supplied by an external power supply. The Series 3500 will

adjust the load current on the external power supply in such a manner that the loop current that flows

will reflect the level of oxygen being measured over the milliamp current range of 4-20 mADC. To

wire to the 4-20 mADC output, connect the external power supply to terminals J8(+) and J9(-) Please

refer to figure 2, Wiring Details for the 4-20 mADC Output.

Plumbing Installation

The Series 3500 Trace Oxygen Transmitter is equipped with 1/4” compression fittings for both

gas inlet and outlet. CAUTION: WHENEVER TIGHTENING GAS CONNECTIONS, IT IS

IMPERATIVE THAT THE MANUAL VALVES NOT BE TWISTED OR TURNED. A CRITICAL GAS

SEAL MAY BE DISRUPTED, LEADING TO AIR LEAKAGE! THIS WILL VOID ANY WARRANTY .

4

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

SECTION 4.0

OPERATING PROCEDURES

Gas System Pressure Limits

For sample gases and/or calibration gases that are under pressure, it is imperative that the sample

gas pressure to the sensor be kept to under 1.5 pounds per square inch. If it is expected to be in

excess of 1.5 psig (0.1 kg/cm2) a pressure regulator should be used.

Range Identification

The Series 3500 Trace Oxygen Transmitter is available in eight (8) different ranges. To identify the

specific range of the transmitter in question, please refer to the original purchase order document or

invoice from Alpha Omega Instruments. In it, you will find a model number starting with the number

3500. The letter immediately following "3500" is the range identifier. The various ranges, with their

associated identifier, are as follows:

Range Identifier

0-10 ppm A

0-50 ppm B

0-100 ppm C

0-500 ppm D

0-1,000 ppm E

0-5,000 ppm F

0-10,000 ppm G

0- 20,000 ppm H

Over Range

It is quite important that the sensor not be exposed to high levels of oxygen for prolonged periods of

time. Should this happen, response time will be adversely effected. To help eliminate this problem,

the Series 3500 Trace Oxygen Transmitter is equipped with valves that are used to isolate the sensor

during times when the instrument it is in storage, in transit, or off line. When not in use, it is highly

recommended that the sensor housing be purged with an inert gas to ensure an "on scale" oxygen

reading is obtained. Once accomplished, the sensor should be isolated by closing both valves. It is

recommended that the inlet valve be closed first, followed immediately by the outlet valve (optional AC

or DC powered solenoid valves are available from the factory). Alpha Omega Instruments sensor

housing has been helium leak tested and shown to provide exceptional protection from ingression of

oxygen from sources outside the housing.

Sample Connections

The sample flow connections to the Series 3500 Trace Oxygen Transmitter are 1/4 inch stainless steel

compression fittings.

Electrical Output

The standard Series 3500 provides 4-20 mADC output over the range of instrument. A signal of 4

mADC is equivalent to 0 ppm oxygen with 20 mADC equivalent to the full scale value.

5

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

SECTION 5.0

CALIBRATION PROCEDURES

Routine Span Gas Calibration Checks

The Series 3500 Trace Oxygen Transmitter has been calibrated at the factory prior to shipment.

However, with the potential hazards associated with shipping instrumentation, it is advisable that the

transmitter be given a system calibration check prior to start-up. Alpha Omega Instruments trace

oxygen sensors feature high accuracy and excellent long term stability characteristics. As a result,

routine maintenance is kept to a minimum. As is the case with all gas analyzers and transmitters, it is

advisable to periodically check the overall system calibration. The frequency of these checks is often

determined by in-house calibration protocols. If none exists, Alpha Omega Instruments Corp.

recommends a calibration check be made once every 2-3 months.

Calibration Gas

The oxygen sensor used in the Series 3500 Trace Oxygen Transmitter has a linear output. As a

result, it can be calibrated using a single calibration gas as long as the test is performed accurately.

The calibration gas should contain a defined concentration of oxygen with a balance of nitrogen (N2).

The actual concentration of oxygen should be chosen based on the range of the transmitter. Alpha

Omega Instrument's recommendation is to obtain a calibration gas that has a concentration of oxygen

somewhere between 40-60% of full scale. For instance, if a transmitter has a measuring range of 0-10

ppm, a calibration gas containing 4-6 ppm oxygen/balance nitrogen should be used.

Procedure for Checking Calibration

1) Select a cylinder of calibration gas as described above.

2) When selecting a pressure regulator to use with the cylinder gas, it is advisable to use a two-stage

regulator with the second stage capable of delivering a gas sample at a pressure of 1.0 psig.

Also, be sure to choose a regulator with a metal diaphragm, preferably stainless steel.

3) In addition to the selection of the pressure regulator, care must be taken to choose the correct

sample tubing materials. For trace oxygen measurements, stainless steel or copper tubing is the

material of choice.

4) Begin flowing the calibration gas to the transmitter by connecting the gas to the inlet valve. The

flow of calibration gas should be set to 0.5 liter per minute. If the optional flow meter was not

purchased with the Series 3500, it is advisable to secure one for use during calibration. Begin

monitoring the 4-20 mADC output waiting until a stable reading has been established.

5) Once the oxygen reading has stabilized, check the system for gas leaks. This is best done when

step 4 has been completed. An easy method of determining the leak integrity of the system is to

vary the flow rate of the calibration gas. If increasing the flow rate from 0.5 liter per minute to 1

liter per minute causes a drop in the reading, there is a good chance that somewhere between the

gas source and inlet to the sensor there is a leak. Check all gas fittings, connections, etc. If the

integrity of the sample delivery system appears to be good, move on to step 6.

6

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

6) The milliamp current output controlled by the transmitter should reflect the oxygen concentration of

the calibration gas. As an example, if a 0-10 ppm range transmitter is being calibrated with a 5

ppm calibration gas, an output of 12 mADC should be obtained. The general form of the equation

for determining the oxygen concentration reading “PPM” from the 4-20 mADC reading in

milliamps “mADC” is:

where “FSV” is the Full Scale Value for the oxygen range selected. In the example given above,

10/16=5

x

ppm.

PPM=(12−4

7) If the oxygen value obtained from the analog output differs from that which is expected from the

calibration gas, a span adjustment should be made. (BE SURE TO ALLOW THE READING TO

COME INTO EQUILIBRIUM BEFORE MAKING ANY ADJUSTMENTS. OXYGEN ADSORBED ON

INPUT LINES, VALVES, REGULATORS AND FILTERS MAY TAKE SOME TIME TO

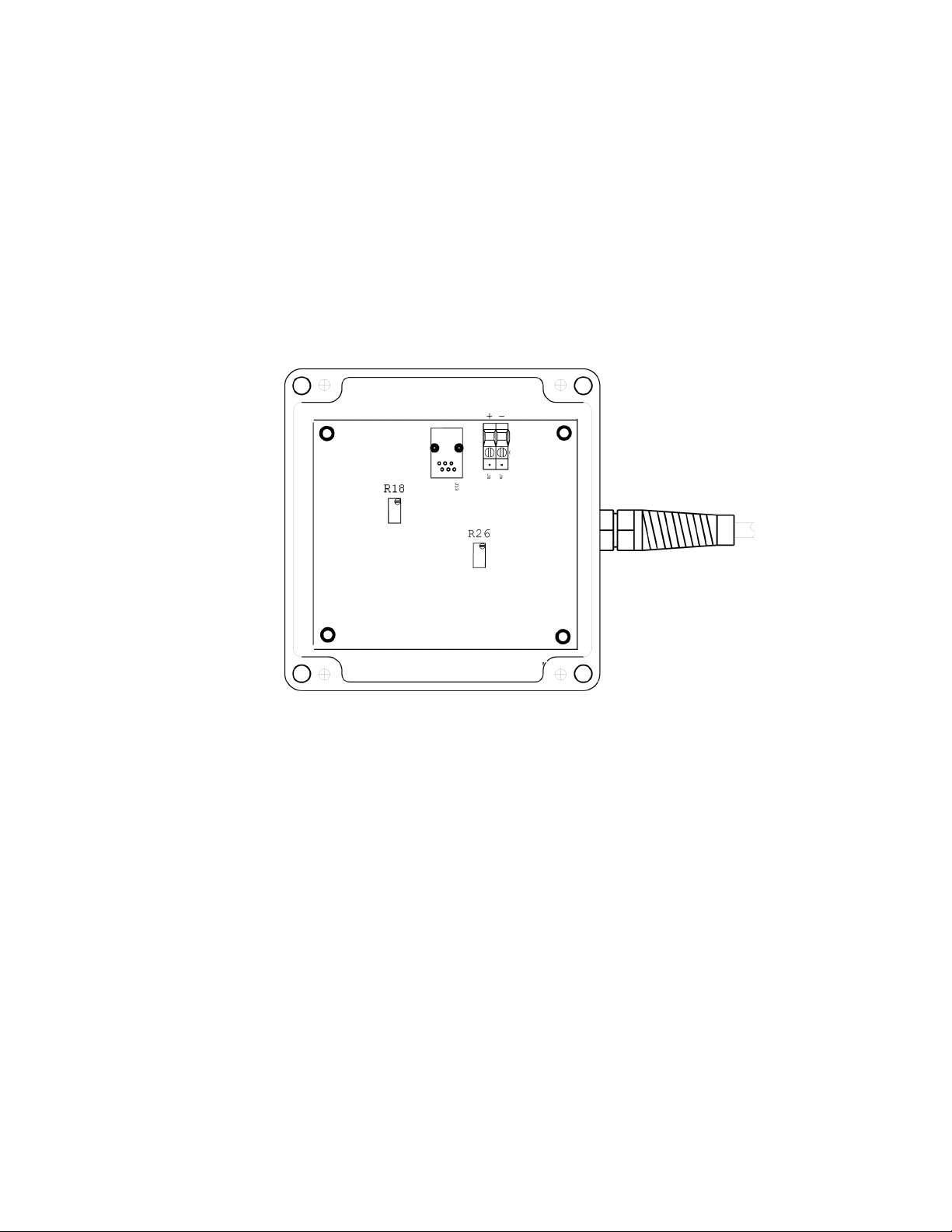

COMPLETELY DESORB) To accomplish this, refer to Figure 1.0 and locate the gain adjustment

(R26). Adjust this potentiometer so the oxygen value reflected in the analog output is equal to the

oxygen value represented by the calibration gas.

Once step 7 has been completed, resume normal operation.

Zero Adjustment

During factory calibration, the zero adjustment is made to compensate for parts per billion

concentrations of oxygen that enter the sensor housing and plumbing system through leakage. In

addition, there is a small error produced by oxygen dissolved in the electrolyte of the sensor. The

amounts vary from system to system, but it is not uncommon to have an oxygen readings in the range

of 0.1 ppm. Alpha Omega Instruments does not recommend the user make any zero adjustments

unless a new sensor has been installed. To make a zero gas adjustment, the steps outlined in the

aforementioned section should be followed with some important distinctions.

)

PPM=(mADC−4

) x

FSV/16

The sample gas used for zeroing the transmitter should be catalytically scrubbed in order to remove

residual oxygen. After treatment, the zero gas should contain < 50 ppb of oxygen. Do not attempt to

make any adjustments to the zero setting unless the quality of the zero gas sample can be assured to

be as described above.

Once the transmitter is placed on zero gas, enough time should be given for the reading to stabilize.

This length of time will be predicated on factors such as length of tubing, tubing material, flow rate, etc.

Once the zero reading has stabilized, if the oxygen value obtained from the 4-20 mADC output is not

equivalent to zero (4 mADC) an offset adjustment should be made. To do this, locate the zero

adjustment R18 (Figure 1.0). Adjust this potentiometer so the oxygen value reflected in the 4-20

mADC output is at 4 mADC. Once accomplished, the transmitter can now be placed back in service.

7

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

SECTION 6.0

REPLACEMENT OF THE OXYGEN SENSOR

Procedure for Replacing the Oxygen Sensor

The Alpha Omega Instruments oxygen sensor is designed to operate for prolonged periods of time

without replacement. However, in time the sensor's performance will dictate that a replacement be

made. One indicator is a decrease in time intervals for routine calibrations. When this happens, a

replacement sensor should be ordered directly from the factory.

To install a new sensor follow the directions below:

1. Remove power from the instrument.

IT IS ADVISABLE TO KEEP A LOW PPM GAS FLOWING THROUGH THE SENSOR

HOUSING WHILE THE SENSOR IS BEING REPLACED. IT IS IMPORTANT THAT WHEN A

NEW SENSOR IS INSTALLED, THE TIME BETWEEN WHEN IT WAS UNPACKED AND

FIRST EXPOSED TO CALIBRATION GAS SHOULD BE KEPT TO AN ABSOLUTE MINIMUM.

THE AMOUNT OF TIME TAKEN TO ACHIEVE THE GAS CALIBRATION LEVEL IS A

FUNCTION OF HOW LONG THE SENSOR WAS EXPOSED TO AIR DURING

REPLACEMENT. WHEN A NEW SENSOR IS INSTALLED, IT MAY TAKE APPROXIMATELY

ONE HOUR TO REACH EQUILIBRIUM ON A CALIBRATION GAS.

2. Locate the sensor housing (metal enclosure mounted below the polycarbonate enclosure).

If the enclosure to which the sensor housing is attached is permanently mounted and the gas lines are

rigidly installed, it will be necessary to disconnect both gas inlet and outlet lines.

3. With one hand supporting the sensor housing, loosen (do not remove) the four servo clamp screws

that hold the metal ring to the enclosure. The sensor housing will drop from the enclosure.

4. Disconnect the modular connector at the top of the sensor housing.

5. Remove the socket head screws that hold the two halves of the sensor housing together. Once

these screws have been removed, the two halves should easily separate.

WHEN SEPARATING THE TOP HALF OF THE SENSOR HOUSING FROM

THE BOTTOM HALF, NEVER TWIST THE TWO AS THIS WILL CAUSE

DAMAGE TO THE SPRING LOADED PINS THAT ARE USED TO MAKE

ELECTRICAL CONNECTION TO THE SENSOR. ALSO, BE CAREFUL NOT

TO BEND THESE PINS WHEN THE SENSOR HALVES ARE APART.

6. Remove the old sensor from the bottom half of the sensor housing.

8

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

THE SENSOR CONTAINS A SMALL AMOUNT OF CAUSTIC

ELECTROLYTE, WHEN DISCARDING SPENT SENSORS, CARE SHOULD

BE GIVEN NOT TO PUNCTURE THE SENSOR OR TO TAKE IT APART.

DISPOSE OF THE SPENT SENSOR ACCORDING TO LOCAL, COUNTY, OR

STATE GUIDELINES.

7. Remove the existing O ring and examine the grooves in the upper and lower halves of the sensor

housing to be sure they are clean. Replace the O ring with the new one supplied with the sensor.

Apply a light coating of silicon grease to the O ring prior to reinstalling the O ring.

8. Remove the new sensor from its package. Before installing it in the lower half of the sensor

housing, REMOVE THE CAP and then install the sensor with the two gold rings facing outward from

housing.

9. Take the two halves of the sensor housing and align them so the socket head screws can be

reinstalled. Hand tighten the socket head screws being careful to do so evenly. If any resistance is

experienced when starting any of these three socket head screws, do not force the screws into the

threads. Instead, if resistance is felt, simply rotate the screw CCW while pushing down on it until you

feel the threads snap to a new starting location and again try to install the screw in the CW direction. If

there is still a resistance to installing the screw, repeat the above procedure until the screw can be

started without any difficulty.

10. Reconnect the cable and install the sensor back on the case with the servo clamp.

11. Reconnect the gas lines and begin processing gas through the sensor housing. Apply power and

calibrate according to previous instructions.

9

ALPHA OMEGA INSTRUMENTS CORP.

Figure 1.0

Series 3500 Transmitter Board

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

10

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

Figure 2.0

Wiring Details for the 4-20 mADC Output

11

ALPHA OMEGA INSTRUMENTS CORP.

Figure 3.0

Series 3500 with NEMA 7 Enclosure

SERIES 3500 TRACE OXYGEN TRANSMITTER Instruction Manual

_____________________________________________________________________

12

APPENDIX A

Material Safety Data Sheet for the 3SEN Oxygen Sensor

10.1 Product Identification

Product Name

Synonyms Electrochemical Sensor, Galvanic Fuel Cell

Manufacturer Alpha Omega Instruments Corp.

Emergency Phone Number

Preparation / Revision Date

Notes

10.2 Specific Generic Ingredients

Carcinogens at levels > 0.1%

Others at levels > 1.0%

CAS Number

Oxygen Sensor Model Prefix 3SEN

40 Albion Road, Suite 100

Lincoln, RI 02865

401.333.8580

January 1, 1995

Oxygen sensors are sealed, contain

protective coverings and in normal

conditions do not present a health

hazard.

Information applies to electrolyte unless

otherwise noted.

None

Potassium Hydroxide, Lead

Potassium Hydroxide = KOH 1310-

58-3, Lead = Pb 7439-92-1

Chemical (Synonym) and

Family

Potassium Hydroxide (KOH) – Base,

Lead (Pb) – Metal

10.3 General Requirements

Use Potassium Hydroxide - electrolyte, Lead - anode

Handling Rubber or latex gloves, safety glasses

Storage

10.4 Physical Properties

Boiling Point Range

Melting Point Range

Freezing Point

Molecular Weight

Specific Gravity

Vapor Pressure

Vapor Density

pH

Solubility in H2O

Indefinitely

100 to 115° C

KOH -10 to 0° C, Lead 327° C

-40 to 0° C

KOH = 56, Lead = 207

1.09 @ 20° C

Not applicable

Not applicable

> 14

Complete

13

APPENDIX A

Material Safety Data Sheet for the 3SEN Oxygen Sensor

% Volatiles by Volume

Evaporation Rate

Appearance and Odor

10.5 Fire and Explosion Data

Flash and Fire Points

Flammable Limits

Extinguishing Method

Special Fire Fighting Procedures

Unusual Fire and Explosion Hazards

10.6 Reactivity Data

Stability

Conditions Contributing to Instability

Incompatibility

Hazardous Decomposition Products

Conditions to Avoid

None

Similar to water

Colorless, odorless aqueous solution

Not applicable

Not flammable

Not applicable

Not applicable

Not applicable

Stable

None

Avoid contact with strong acids

None

None

10.7 Spill or Leak

Steps if material is released

Waste Disposal Method

Sensor is packaged in a sealed plastic bag,

check the sensor inside for electrolyte

leakage.

If the sensor leaks inside the plastic bag or

inside an analyzer sensor housing do not

remove it without rubber or latex gloves and

safety glasses and a source of water.

Flush or wipe all surfaces repeatedly with water or

wet paper towel (fresh each time).

In accordance with federal, state and

local regulations

10.8 Health Hazard Information

Primary Route(s) of Entry

Exposure Limits

Ingestion, eye and skin contact

Potassium Hydroxide - ACGIH TLV 2

mg/cubic meter; Lead - OSHA PEL .05

mg/cubic meter

Ingestion Electrolyte could be harmful or fatal if swallowed.

Oral LD50 (RAT) = 2433 mg/kg

Eye Electrolyte is corrosive and eye contact could result

in permanent loss of vision.

Skin Electrolyte is corrosive and skin contact could result

in a chemical burn.

Inhalation Liquid inhalation is unlikely.

14

APPENDIX A

Material Safety Data Sheet for the 3SEN Oxygen Sensor

Symptoms

Medical Conditions

Aggravated

Carcinogenic Reference

Data

Other

Eye contact - burning sensation.

Skin contact - soapy slick feeling.

None

NTP Annual Report on Carcinogens - not listed

LARC Monographs - not listed

OSHA - not listed

Lead is listed by some states as a chemical

known to cause birth defects or other

reproductive harm.

15

Loading...

Loading...