SERIES 2000

PERCENT OXYGEN ANALYZER

Product shown with optional flow meter

Alpha Omega Instruments Corp.

40 Albion Road, Suite 100

Lincoln, RI 02865

Phone: 401-333-8580

Fax: 401-333-5550

Website: www.aoi-corp.com

Email: salescontact@aoi-corp.com

Rev 3.0619.18, June 2018

COPYRIGHT ALPHA OMEGA INSTRUMENTS CORP.

ALL RIGHTS RESERVED INCLUDING THE RIGHT TO

REPRODUCE THIS MANUAL, OR ANY PORTION

THEREOF, IN ANY FORM.

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

WARRANTY

Alpha Omega Instruments Corp. warrants the products delivered to be free from defects in material

and workmanship at the time of delivery to the Fob. point specified in the purchase order, its liability

under this warranty being limited to repairing or replacing, at Alpha Omega Instruments' option, items

which are returned to it prepaid within two years from the date of shipment and found to Seller’s

satisfaction to have been so defective.

Alpha Omega Instrument's two year sensor warranty offers protection for two (2) years from the date

of shipment of the Series 2000 Percent Oxygen Analyzer. Any sensor from a Series 2000 Percent

Oxygen Analyzer that fails under normal use must be returned to Seller prepaid and, if such sensor is

determined by Seller to be defective, Seller shall provide Buyer a replacement sensor. Buyer must

provide the serial number of the analyzer from which the sensor has been removed. If a sensor is

found to be defective and a new one issued, the warranty of the replacement sensor (s) is for a period

of two (2) years from the date of shipment. In no event shall Alpha Omega Instruments Corp. be liable

for consequential damages.

NO PRODUCT IS WARRANTED AS BEING FIT FOR A PARTICULAR

PURPOSE AND THERE IS NO WARRANTY OF MERCHANTABILITY.

This warranty applies only if:

(i) the items are used solely under the operating conditions and manner

recommended in this manual, specifications, or other literature;

(ii) the items have not been misused or abused in any manner or repairs

attempted thereon;

(iii) written notice of the failure within the warranty period is forwarded to

Alpha Omega Instruments Corp. and the directions received for properly

identifying items returned under warranty are followed;

(iv) the return notice authorizes Alpha Omega Instruments Corp. to examine

and disassemble returned products to the extent the Company deems

necessary to ascertain the cause of failure.

The warranties stated herein are exclusive. THERE ARE NO OTHER WARRANTIES, EITHER

EXPRESSED OR IMPLIED, BEYOND THOSE SET FORTH HEREIN, and Alpha Omega Instruments

Corp. does not assume any other obligation or liability in connection with the sale or use of said

products.

Disclaimer of Warranty

Alpha Omega Instruments makes no representation or warranties, either expressed or implied, by or with respect to

anything in this manual, including, but not limited to, implied warranties of merchantability or fitness for a particular

purpose. In no event will Alpha Omega Instruments Corp. be liable for any damages, whether direct or indirect,

special, consequential, or incidental arising from the use of this manual. Some states in the USA do not allow the

exclusion of incidental or consequential damages. Alpha Omega Instruments Corp. also reserves the right to make

any changes to improve the performance of its products at any time and without notice.

i

ALPHA OMEGA INSTRUMENTS CORP.

DO NOT TOUCH!

THIS SYMBOL IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF IMPORTANT OPERATING AND MAINTENANCE

INSTRUCTIONS.

WHEN POWERED, THE PRESENCE OF UN-INSULATED

DANGEROUS VOLTAGES WITHIN THE INSTRUMENT MAY BE

OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRICAL SHOCK RESULTING IN INJURY OR DEATH.

LEAVE ALL SERVICING TO QUALIFIED PERSONNEL.

REMOVE ALL POWER SOURCES WHEN INSTALLING OR

REMOVING AC POWER OR DATA SIGNAL CONNECTIONS

AND WHEN INSTALLING OR REMOVING THE SENSOR, OR

ELECTRONICS.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

WARNINGS

Explanation of graphic symbols

To avoid the risk of fire or electric shock, do not expose the Series 2000 Percent Oxygen Analyzer to

rain or water spray unless the enclosure is rated according to the National Electrical Manufacturer's

Association NEMA 4 (IP66)1 rating.

RF Disclaimer

This instrument generates and uses small amounts of radio frequency energy, and there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

interference to radio or television reception, try to correct the interference by one of more of the

following steps:

1. Reorient the receiving antenna.

2. Relocate the instrument with respect to the receiver.

3. Change the AC outlet of the instrument so the instrument and receiver are on different branch

circuits.

1 NEMA stands for the National Electrical Manufacturers Association and the designation IP"XX" signifies European IEC specifications 144 & 529.

ii

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

TABLE OF CONTENTS

PAGE

WARRANTY i

WARNINGS ii

SECTION 1.0 INTRODUCTION 1

General Description 1

Measurement Ranges 1

Mechanical Configuration 1

Optional Equipment 2

Optional Battery Operation 2

RS-232C Option 2

RS-485 Option 3

Sample Filter Option 3

Filter Element Accessory 3

Flowmeter Option 3

Pressure Regulator Option 3

Sample Pump Option 3

Sensor Heater Option 3

General Specifications 4

SECTION 2.0 INSTALLATION PROCEDURES 6

Unpacking the Instrument 6

Electrical Installation 6

Wiring the AC/DC Power 6

Main Printed Circuit Board (Figure 1) 7

Oxygen Sensor 8

Wiring Alarm Relays 8

Wiring 4-20 mADC and 0-2 VDC Outputs 9

Wiring to the Optional RS-232C or RS-485 Outputs 10

iii

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SECTION 3.0 SYSTEM DESCRIPTION 11

Extended Life Galvanic Sensor 11

Alarms 12

On Board Switch Settings 12

Fail-Safe Operation 13

Alarm Settings 13

SECTION 4.0 DETERMINING SYSTEM CONFIGURATION 14

Model Designation 14

SECTION 5.0 OPERATION 17

Preparation for Operation 17

AC Input Voltage Selection 17

Initial Setup 18

Mounting Configurations 18

Remote Mounted Sensor Enclosures 18

Operating Procedures 19

Power On 19

Front Panel Controls and Indicators 19

Setting the Alarms 20

Alarm Processing 20

Auto-Clear Operation 20

Manual Clear Operation 21

Timing Out 21

Over Range 21

TTL Signals for Analyzers with Autoranging 21

Manual Range Changing 21

Gas System Pressure Limits 22

Sample Connections 22

iv

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SECTION 6.0 CALIBRATION PROCEDURES 23

Initial & Routine Calibration Checks 23

Calibration Gas 23

Procedure for Checking Calibration 23

Zero Adjustment 24

SECTION 7.0 REPLACEMENT OF THE OXYGEN SENSOR 25

Procedure for Replacing the Oxygen Sensor 25

SECTION 8.0 Optional Serial Communications RS232C & RS485 26

SECTION 9.0 Optional RS485 Enhanced Remote Control Commands 31

APPENDICES

Appendix A Bench Top/Portable Design/ Configuration 37

Part Number "BTP"

Appendix B Panel Mount Configurations 38

Part Numbers PNL, PNR, & PTX

Appendix C Remote Sensor Configuration, 42

Part Numbers "BTR & PNR"

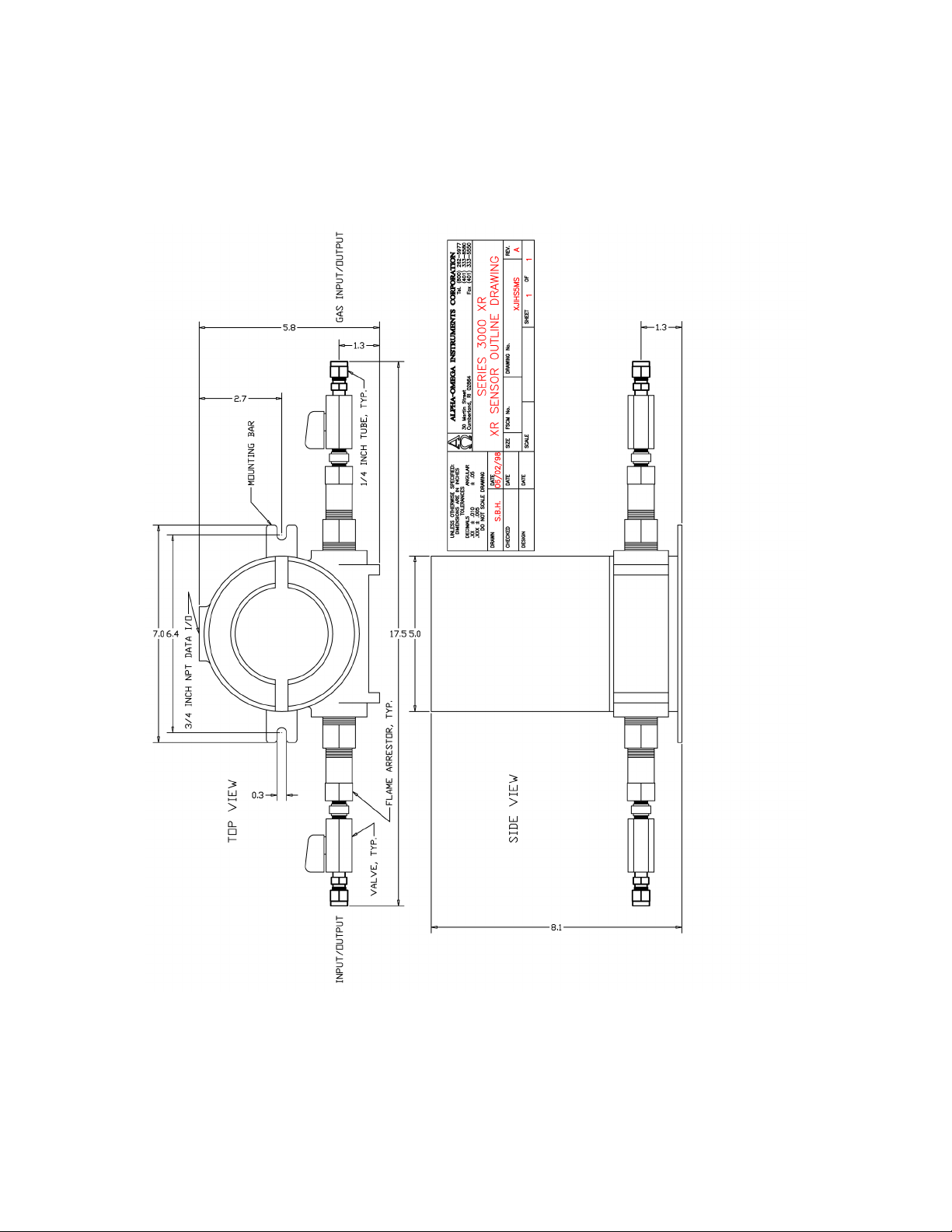

Appendix D Explosion Proof Electronics/Sensor 43

Part Number "EXX".

Appendix E Explosion Proof Sensor Configuration 46

Part Number “BTX & PTX”

Appendix F Explosion Proof Sensor Housing Used with 47

BTX & PTX Configurations.

Appendix G Block Diagram for Remote 2000 PTX (Explosion Proof) 48

Appendix H MSDS for the 2SEN Oxygen Sensor 49

ADDENDA

Addendum 1 Optional Horn/Strobe Alarm 53

Addendum 2 Optional Internal Datalogger 56

Addendum 3 Optional High Volume Pump 58

v

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SECTION 1.0

INTRODUCTION

1.1 General Description

The Series 2000 Percent Oxygen Analyzer is a microprocessor controlled instrument that can be

configured with either one or three percent oxygen ranges. The instrument is powered from either

115/230 VAC, 50-60Hz, or 18-32 VDC input. Battery operation is an option for the bench top/portable

version only. Oxygen values are displayed on a 10.2 mm (0.4") high 4-1/2 digit liquid crystal display

(LCD). The oxygen sensor is mounted in a PVC housing that contains 1/4" gas inlet and outlet

compression fittings. For the bench top/ portable instrument, the sensor housing is located on the rear

panel of the electronics enclosure. For instruments equipped with a remote sensor enclosure, the

sensor housing is either mounted on the enclosure, as is the case with the watertight NEMA 4X (IP 66)

and general purpose NEMA 1 enclosures, or inside the enclosure for the explosion proof, NEMA 7

types.

The front panel of the Series 2000 Percent Oxygen Analyzer contains five switches that provide

access to the analyzer's settings. The instrument is equipped with three oxygen alarm relays and one

status alarm relay. All four relays are Form C (SPDT) types rated at 10 amps at 115/230 VAC and 30

VDC. The relays are user configurable for fail-safe operation. In addition to the four alarm contacts,

the Series 2000 Percent Oxygen Analyzer has a built-in audible alarm and three red LED's for visual

indication of an oxygen alarm condition. The audible alarm may be manually canceled at anytime. If

the audible alarm is canceled, and the alarm event continues, indications of this condition will still be

available through the front panel LED's and relay contact(s).

The Series 2000 Percent Oxygen Analyzer comes equipped with two standard analog outputs, 4-20

mADC and 0-2 VDC. For enhanced communications, the Series 2000 Percent Oxygen Analyzer can

also be equipped with optional RS-232C or RS-485 serial communications. Another standard feature

of the Series 2000 Percent Oxygen Analyzer is autoranging (three range analyzers only). This feature

provides the analyzer with the capability to move either up or down the ranges of measurement

automatically.

1.2 Measurement Ranges with Range Code Designations (codes contained in model number).

Range Code Single Ranges Range Code Multiple Ranges

A 0-100% F 0-10/25/100%

B 0-25% G 0-5/10/25%

C 0-10% H 0-1/10/25%

D 0-5%

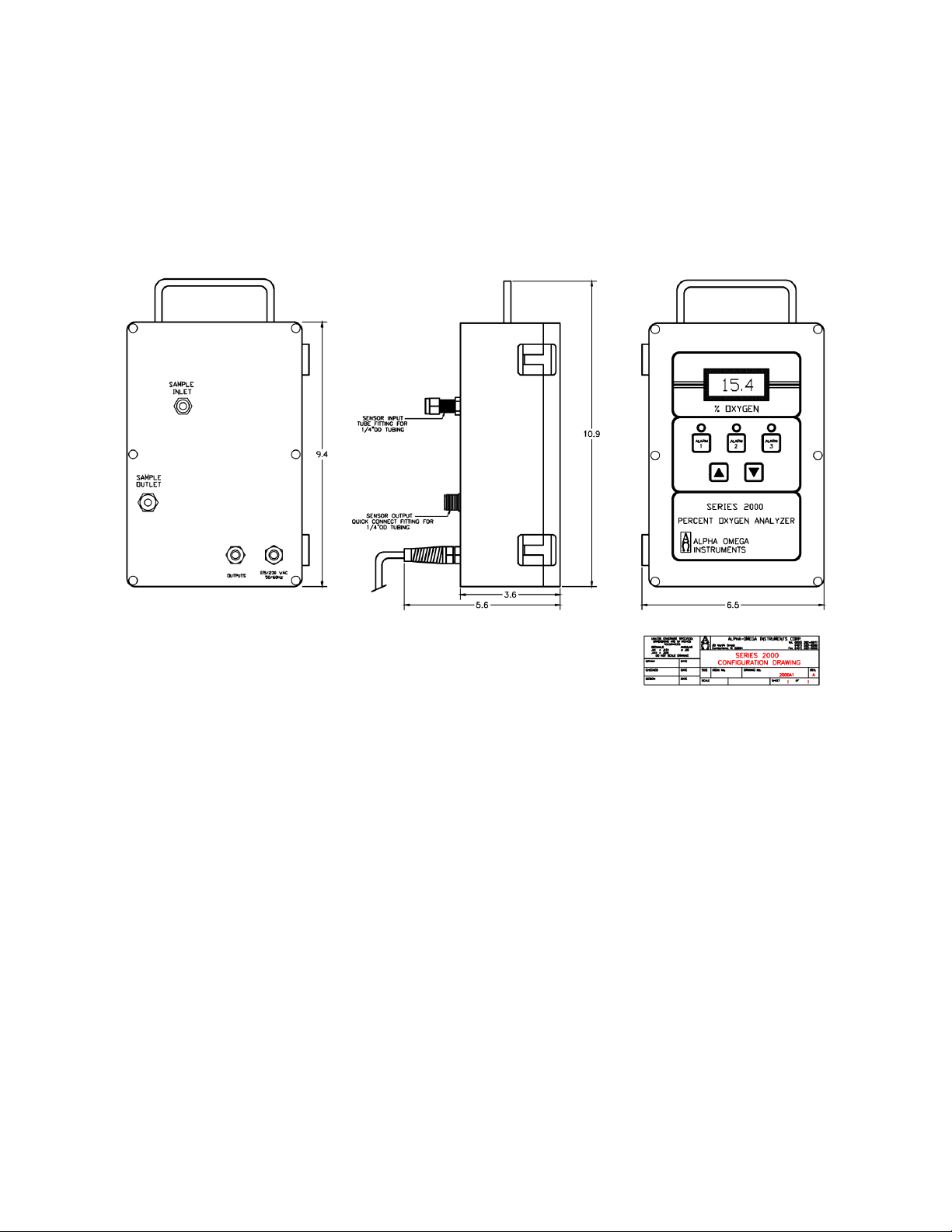

1.3 Mechanical Configurations with Part Number Designations.

Mechanical Code Description

BTP The analyzer enclosure is suitable for bench top or portable use and comes

equipped with a carrying handle. The sensor housing is mounted on the rear of

the enclosure (refer to Appendix A). The enclosure is fabricated from

polycarbonate.

PNL Similar to the BTP configuration with the addition of an aluminum panel frame.

It is not equipped with a carrying handle (refer to Appendix A). The enclosure is

made from polycarbonate with a watertight, NEMA 4X (IP66) rating.

Page 1

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

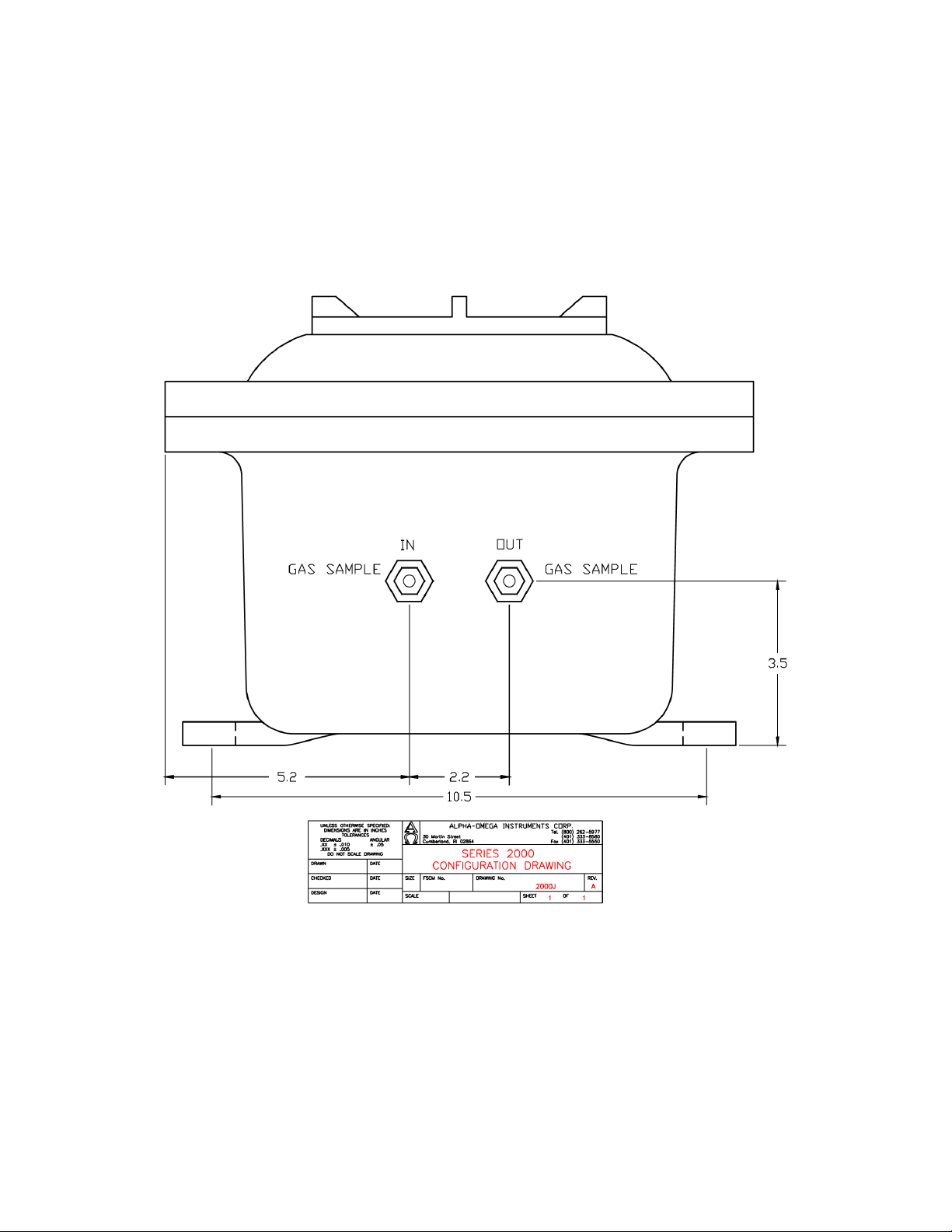

BTR This configuration is comprised of two enclosures (electronics and sensor). The

electronics enclosure is suitable for bench top installations and is made from

polycarbonate with a watertight, NEMA 4X (IP66) rating. The sensor housing is

also made from polycarbonate and carries a NEMA 4X (IP66) rating (refer to

Appendix C). Three feet (1 meter) of interconnecting cable is standard with

additional cabling (up to 4,000 feet) (1,220 meters) available at the time of

order.

PNR Similar to the BTR configuration with the exception of the

electronics enclosure that is equipped with a steel panel frame.

BTX This configuration is comprised of two enclosures (electronics and sensor). The

electronics enclosure is suitable for bench top installations and is made from

polycarbonate with a watertight, NEMA 4X (IP66) rating. The oxygen sensor

housing is mounted inside an aluminum, explosion proof enclosure rated

NEMA 7 for use in areas requiring Class 1, Groups B,C,D, Division 1; Class II,

Groups E,F,G; and Class III protection (refer to Appendix D). Three feet (1

meter) of interconnecting cable is standard with additional cabling (up to 4,000

feet) (1,220 meters) available at the time of order.

PTX Similar to the BTX configuration with the exception of the electronics enclosure

that is equipped with a steel panel frame.

EXX In this configuration both the electronics and sensor are mounted within an

aluminum explosion proof enclosure rated NEMA 7 for use in areas requiring

Class 1, Groups B,C,D, Division 1; Class II, Groups E,F,G; and Class III

protection (refer to Appendix B).

1.4 Optional Equipment

The Series 2000 Percent Oxygen Analyzer Monitor incorporates standard features that make it

suitable for many applications. However, for certain requirements, the user may desire to augment

the capabilities of the instrument by equipping it with one or more options.

1.4.1 Battery Operation Part Number (P/N 2BAT)

The Series 2000 can be equipped so that it may be powered from a normal AC/DC source as well as

an optional built-in NiMH (nickel metal hydride) battery pack. The batteries are installed at the factory

and are designed for applications where the user desires to power the analyzer for short periods using

the batteries. With the battery option, the Series 2000 will operate for a period of at least 8 hours. If

equipped with a sample pump, operating time will be reduced to less than four hours of continuous

use. Other items such as alarms, use of the 4-20 mADC output, etc. could reduce the time intervals

between battery recharging. The Series 2000 is equipped with a “smart charging” capability for the

Nickel Metal Hydride (NiMH) battery pack. Smart charging eliminates the risk of the battery pack

being over-charged (not available with explosion proof systems). To achieve a full-charge after the

batteries have been discharged, allow for approximately 16 hours of charging time.

1.4.2 RS-232C Option (P/N 2RS2)

The RS-232C option is installed at the factory and is designed for applications where enhanced serial

communications is required between the Series 2000 Percent Oxygen Analyzer and a host system.

The maximum distance between monitor and host is 50 feet (15.2 meters).

1.4.3 RS-485 Option (P/N 2RS4)

Page 2

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

The RS-485 option is installed at the factory and is designed for applications where enhanced serial

communications is required between one or several analyzers and a host system over the same

communications channel. The RS-485 format allows both sending and receiving of signals over

greater distances than RS-232C, making it ideal for installations where the analyzer(s) are located at

distances greater than 50 feet (15.2 meters) from the host. The maximum distance recommended

between devices is 4,000 feet (1,220 meters).

1.4.4 Sample Filter Option (P/N 295S)

Miniature T-type 316 stainless steel filter with 1/8" NPT in-line ports. Recommended when particle

loading exceeds 3 mg/ft3 and hydrocarbon mist exceeds 0.7 mg/ft3. Installed at the factory unless

otherwise specified by the customer. Other types of filters are available from Alpha Omega

Instruments. Please consult the factory for specific recommendations.

1.4.5 Filter Element Accessory (P/N 2FBX)

Filter element for the 395S

1.4.6 Flowmeter Option (P/N 2FLM)

Durable one piece clear acrylic flowmeter with easy to read scale in liters per minute.

1.4.7 Pressure Regulator Option (P/N 2PRR)

Stainless steel pressure regulator with a 3,000 psig (211 kg/cm2) inlet capacity and an adjustable

outlet pressure range of 0-5 psig (0 to 0.35 kg/cm2). The regulator does not include a gauge.

1.4.8 Sample Pump Option (P/N 2PMP)

Sample pump designed for applications where the sample pressure is insufficient to transport the

sample through the sensor housing.

1.4.9 Sensor Heater Option (P/N 2HTR)

Sensor heater used for applications where low ambient temperatures are encountered, or where

constant temperature conditions within the enclosure are desired. This option will not operate off

battery power and is only available with the EXX configuration.

Page 3

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

1.4 General Specifications

Measurement Ranges (Percent Oxygen)

Single Range Multiple Range

0-100 0-10/25/100

0-25 0-5/10/25

0-10 0-1/10/25

0-5

Accuracy¹: ±1% of full scale (± 5% for ranges of 0-1%)

Linearity: ±1%

Response Time: 90% of full scale response in less than 20 seconds (typical)

Sensor Type: Ambient Temperature Electrochemical Sensor with EES

Temperature Compensation: Standard

Pressure Compensation: Standard

Operating Temperature: 40° to 104° F (5° to 40°C)

<40°F (<5°C) use heated sensor enclosure

>104°F (>40°C) cooling of sensor required

Warranty: 3 years electronics/ 2 years sensor

ELECTRICAL

Display: 0.4" (10.2 mm) high, 4-1/2digit LCD

Resolution: 0.1 %

Input Power: 115/230 VAC, 50-60Hz or 18-32 VDC, battery backup available

as an option for some models

Outputs: 4-20 mADC and 0-2 VDC standard as is a TTL output for range

identification. RS-232C or RS-485 serial communication optional.

Oxygen Alarm Relays: Three (3) SPDT Form C contacts rated 10A @ 30 VDC/115/230

VAC. User selectable for fail-safe or non fail-safe.

Instrument Status Alarm: Rated identically to the O2 relays

Audible Alarm: Internal buzzer with audible cancel

Page 4

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SAMPLE GAS CHARACTERISTICS

Flow Rate: 1.0 to 2.0 SCFH (0.5 to 1.0 liter/min)

Sample Gas Temperature: 32° to 104° F (0° to 40°C)

Sample Gas Pressure Limits: 0.1 to 1.5 psig (0.007 to 0.1 kg/cm2).

Entrained Solids: <3 mg/ft³: no in-line filter required

>3 mg/ft³: in-line filter is required

Hydrocarbon Mist: <0.7 mg/ft³: no in-line filter required

>0.7 mg/ft³: in-line filter is required

CONSTRUCTION²

Electronics Control Unit: Polycarbonate with a hinged clear front cover, rated NEMA 4X

(IP 66)

Control Unit Dimensions: 9.45 in. (240.5 mm) length

6.50 in. (165.1 mm) width

6.20 in. (157.5 mm) depth

Note: All dimensions are without optional equipment

Gas Connections: Quick connect for 1/4” OD flex tubing or optional 1/4” stainless

steel compression fittings

Sensor Mounting: Local or optional remote mounting

Weight: 11lbs (4.98 kg) (Bench-top Configuration.)

¹ Stated at constant temperature and constant pressure.

² Other mechanical configurations available-consult factory.

Alpha Omega Instruments Corp. reserves the right to change or modify its product specifications without notice.

Page 5

ALPHA OMEGA INSTRUMENTS CORP.

NOTE: IF DAMAGE HAS BEEN FOUND, DO NOT PROCEED

FURTHER, BUT INSTEAD, CONTACT THE FACTORY.

ELECTRICAL INSTALLATION SHOULD BE PERFORMED BY A

CERTIFIED ELECTRICIAN AND SHOULD COMPLY WITH APPLICABLE FEDERAL, STATE, OR LOCAL ELECTRICAL SAFETY

CODES.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SECTION 2.0

Installation procedures

2.1 Unpacking the Instrument

Upon opening the shipping container, carefully unpack the instrument to check if the outer surfaces

have been damaged. If so, report the findings immediately to Alpha Omega Instruments who will, in

turn, provide further instructions.

If there is no apparent damage, check the contents to ensure all items were shipped. In some cases,

items may be back-ordered. All damage and shortage claims must be made known to Alpha

Omega Instruments within 10 days after receipt of shipment.

There are six screws on the Series 2000 Percent Oxygen Analyzer that fasten the clear cover to the

polycarbonate enclosure. Loosen these screws to disengage them from the enclosure, and open the

cover exposing the front panel membrane switches. For the explosion proof version, their are 18

fastening bolts that need to be removed in order to remove the cover from the base. The membrane

panel is installed on a metal backing plate that is hinged and swings out in the same direction as the

cover. Swing out the membrane panel and check inside the control unit to make sure no components

have been loosened or dislodged. If there are loose or dislodged components, notify the factory for

further instructions. If all is found to be satisfactory, the installation procedure can begin.

2.2 Electrical Installation

The Series 2000 Percent Oxygen Analyzer is shipped with a power cord (except for the explosion

proof versions). Some installations may require wiring through conduit into the electrical hub on the

rear panel (where the existing power cord is installed). For such installations, removal of the existing

power cord can be easily accomplished as described in section 2.2.1. The position of jumper S2,

which is located at the lower left quadrant of the printed circuit board determines the line voltage

setting. The default setting is 115 VAC, 50-60Hz. If the AC input voltage is changed in the field,

please refer to Section 5.1.1 for instructions.

2.2.1 Wiring the AC/DC Power in Place of the Existing Power Cord

Referring to the printed circuit board diagram (FIGURE 1.0) on the next page, locate the AC power

terminals 31,32, and 33. Each connector is equipped with a screw terminal wire holder to facilitate

insertion or removal of the wire from the connector. Strip away approximately 6.0 mm (1/4 inch) of

insulation from each of the three conductors and then connect AC line, AC neutral, and chassis

ground to each connector. Tighten down on each screw turning clockwise to securely fasten each

conductor. If the primary power to the instrument is direct current (DC), wire to terminals 29 (BAT+)

and 30 (BAT-). Please refer to the cautionary note on page 17 regarding optional battery operation.

Page 6

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

FIGURE 1.0

Page 7

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

2.2.2 Oxygen Sensor

Wiring of the oxygen sensor has been done at the factory. For information regarding sensor

replacement, please refer to Section 7.0.

2.2.3 Wiring Alarm Relays

In addition to the cable used for the AC/DC power to the Control Unit, access to the control signals

generated from the Series 2000 Percent Oxygen Analyzer is accomplished using signal cabling. This

cable is installed through the output cable gland on the rear of the electronics enclosure. The number

of conductors needed is determined by the number of functions to be controlled.

The Series 2000 Percent Oxygen Analyzer is equipped with four single pole double throw (SPDT)

relays with Form C contacts rated at 10 amperes @ 30 VDC and 115/230 VAC. All alarm relays are

user configurable with the three oxygen alarms defaulting to factory setting of low oxygen alarms. To

configure any of the three oxygen alarm relays to act as high alarms, please refer to Section 5.2.3. As

a reminder, Alarm 4 which is not displayed as a discrete alarm on the front panel, is the instrument

status alarm.

The technique for wiring to the connectors is identical to that discussed in Section 2.2.1. The wiring

configuration is as follows:

Terminal Alarm 1 Relay

26 Common Contact

27 Normally Open Contact

28 Normally Closed Contact

Alarm 2 Relay

23 Common Contact

24 Normally Open Contact

25 Normally Closed Contact

Alarm 3 Relay

20 Common Contact

21 Normally Open Contact

22 Normally Closed Contact

Instrument Status Alarm

17 Common Contact

18 Normally Open Contact

19 Normally Closed Contact

TABLE 1.0 on the next page illustrates the various wiring configurations for the four alarms in the

Series 2000 Percent Oxygen Analyzer based on whether the alarms are going to be configured for

fail-safe or non fail-safe operation.

Page 8

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

Alarm ONContacts

shorted for

Fail-safe OFFFail-safe ON

each Alarm

Relay

High or Low O2

Alarm1 /

Relay 1

High or Low O2

Alarm2 /

Relay 2

High or Low O2

Alarm3 /

Relay 3

Low Battery or

Instrument

Status/ Relay 4

Each of the aforementioned alarm relays can be individually configured for fail-safe operation by

means of a DIP switch located on the main printed circuit board (refer to Section 3.3). If the

instrument is equipped with optional RS-232C or RS-485 communications, the alarms can also be

controlled via these outputs. See the caution note below.

28(NC) to

26(COM)

25(NC) to

23(COM)

22(NC) to

20(COM)

19(NC) to

17(COM)

TABLE 1.0

27(NO) to

26(COM)

24(NO) to

23(COM)

21(NO) to

20(COM)

18(NO) to

17(COM)

IF THE SERIES 2000 PERCENT OXYGEN ANALYZER IS EQUIPPED

WITH EITHER RS-232C OR RS-485 COMMUNICATIONS, PLEASE

REFER TO SECTION 8.0.

2.2.4 Wiring 4-20 mADC and 0-2 VDC Outputs

The Series 2000 Percent Oxygen Analyzer has two standard linear outputs, 4-20 mADC and 0-2 VDC

over the instrument's range(s). These outputs can be measured simultaneously. To wire to the 4-20

mADC output, wire to terminals 12 (4-20) and 13 (AGND). To wire to the 0-2 VDC output, use

terminals 8 (positive {labeled DAC}) and 9 (negative {labeled AGND} ). The terminals can be found on

the right side of the printed circuit board (refer to FIGURE 1.0). Note: If a jumper wire is in place

between terminals 12 and 13, it must be removed prior to using the 4-20 mADC output.

NOTE: IF THE 4-20MA DC OUTPUT IS NOT GOING TO

BE USED, IT SHOULD BE SHORTED TO AVOID AN

OPEN LOOP WARNING VIA TERMINAL 10 (B-LO)

Page 9

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

2.2.5 Wiring to the Optional RS-232C or RS-485 Outputs.

The RS-232C and RS-485 digital communications are options with the Series 2000 Percent Oxygen

Analyzer. Unlike the analog outputs, the Series 2000 Percent Oxygen Analyzer can be ordered with

either option, but not both. To wire for either the RS-232C or RS-485, use terminals 14 (TXD) for

transmit and 15 (RXD) for receive. Note: You must connect the GND terminal for RS-232C and

RS-485 for the instrument to work properly. Further details on these communication channels

are contained in Section 8.0. Section 8.0 is included as part of this manual even if the Series

2000 Percent Oxygen Analyzer has not been equipped with either of the two aforementioned

digital communication loops.

Page 10

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SECTION 3

SYSTEM DESCRIPTION

3.1 Extended Life Galvanic Sensor

The Series 2000 Percent Oxygen Analyzer features an extended life oxygen sensor with a weak acid

electrolyte system. The weak acid electrolyte system retards passivation of the sensor anode by

allowing the products of oxidation to dissolve in the acid electrolyte. In effect, the sensor is renewed

continuously as the weak acid electrolyte tolerates over 20 times the lead oxide (PbO) than potassium

hydroxide (KOH) based sensors. The result is a sensor with a greatly extended useful life.

The extended life sensor is a lead-oxygen battery comprised of a lead anode, and gold cathode, and a

weak acid electrolyte. A gold electrode is bonded onto a non-porous Teflon (FEP) membrane. A small

amount of oxygen permeating through the membrane is reduced electrochemically at the gold

electrode. A resistor and a thermistor (for temperature compensation) are connected between the

cathode and anode. As a result, the lead-oxygen battery is always discharged.

Current flowing through the resistor and thermistor is proportional to the oxygen concentration of the

gas in contact with the Teflon membrane. By measuring the voltage between the resistor and the

thermistor, oxygen concentration can be accurately determined. The two electrode reactions are

depicted below:

Cathode: O2 + 4H+ + 4e 2H2O

Anode: 2Pb + 2H2O 2PbO + 4H+ + 4e

Overall: O2 + 2Pb 2PbO

If PbO generated at the anode remains on the anode, the anode's potential will change and the output

voltage of the sensor would become extremely low. However, in actuality the surface of the lead

anode is continuously renewed because PbO is dissolved back into the electrolyte.

There is a maximum level to the solubility of PbO in the weak acid electrolyte. As a result, when the

electrolyte becomes saturated with PbO, the sensitivity of the sensor will begin to drop signaling time

for replacement of the sensor. When the extended life oxygen sensor is used in ambient air monitoring

applications, carbon dioxide (CO2) that is present will not adversely affect the sensor's performance.

Due to the weak acid electrolyte, CO2 will not react with the electrolyte to form potassium carbonate as

it does with KOH based sensors. As a result, there is no loss in output due to the presence of CO2.

Page 11

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

3.2 Alarms

One of the primary functions of the instrument is to alert the user when alarm conditions have

occurred. To this end, four alarm relays, each capable of switching up to 10 Amperes, are provided.

These isolated relays are single pole double throw (SPDT) relays for maximum user flexibility. These

relay outputs, along with the simultaneous LED and annunciator operation, serve to give maximum

notification to the user of an alarm condition.

An "open collector" output, more appropriately called an "open drain output", in this case, provides an

additional level of operator output for signaling alarm purposes. This "open drain output", from a 50

volt MOSFET transistor, is normally open, but will close or short to ground to indicate an alarm

condition if the 4 to 20 milliamp loop is open.

The front panel display and Relay #4 will indicate a low battery if the instrument is equipped with the

Battery Backup option.

3.3 On Board Switch Settings

Setting the alarms for fail-safe operation and automatic alarm clearing can be accomplished by using

an on board switch bank (SW6) located in the upper right quadrant of the printed circuit board (refer to

FIGURE 1.0). This switch bank has eight (8) individual switches for configuring the Series 2000

Percent Oxygen Analyzer. Refer to FIGURE 3.0 on the next page for a description of the switches.

The Series 2000 Percent Oxygen Analyzer is shipped from the factory with switch #8 in the "OFF"

("switch settings" mode) position. This is the default configuration and will force the Series 2000

Percent Oxygen Analyzer to read the other switches in order to configure the alarms when power is

applied or a warm boot has occurred. If switch #8 is in the "ON" ("user configuration" mode) position,

the Series 2000 Percent Oxygen Analyzer will be configured using battery backed configuration

information. This means the analyzer will ignore the switch settings altogether and "boot" up to user

configured memory. The user configured memory is that which is set up via the front panel or external

communications loop (refer to Section 5.2.2).

Page 12

ALPHA OMEGA INSTRUMENTS CORP.

SW6

O

N

1 2 3 4 5 6 7 8

RELAY 1 - NORMAL

RELAY 2 - NORMAL

RELAY 3 - NORMAL

RELAY 4 - NORMAL

OXYGEN ALARM 3 (LO)

MANUALLY CLEAR ALARMS

SWITCH SETTINGS

RESERVED

RELAY 1 - FAIL-SAFE

RELAY 2 - FAIL-SAFE

RELAY 3 - FAIL-SAFE

RELAY 4 - FAIL-SAFE

OXYGEN ALARM 3 (HI)

AUTO CLEAR ALARMS

USER CONFIGURATION

RESERVED

SW6

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

3.3.1 Fail-Safe Operation

The Series 2000 Percent Oxygen Analyzer will "boot" up based on the settings of oxygen alarm

switches #1 through #4. Switches #1 through #4 control the fail-safe operation for each of the four

alarm relays. Each switch must be turned "ON" to be fail-safe (refer to FIGURE 3.0). In the fail-safe

mode, upon an alarm condition, the corresponding relay will change state (from energized to deenergized) upon loss of AC power. The factory settings for switches #1 through #4 is "OFF" (normal

operation or non fail-safe).

3.3.2 Alarm Settings

With switch #8 in the "OFF" position, the Series 2000 Percent Oxygen Analyzer defaults to configuring

all three Oxygen Alarms as low alarms. With switch #8 in the "ON" position, all user settings will be

retained. Note: to read the switches while operating, just perform a "warm boot". (See Section 5.2.1)

FIGURE 3.0

IF ANY ALARM IS NOT GOING TO BE USED, IT SHOULD

BE DISABLED. TO DO SO, FIRST CONFIGURE EACH

ALARM AS A LOW ALARM, AND THEN SET THE ALARM

TO 0.00

Page 13

ALPHA OMEGA INSTRUMENTS CORP.

P/N KEY:

A

Code Base Model

2000

Series 2000 Percent Oxygen Analyzer with three alarm relays, instrument

status alarm relay, digital display, audible alarm, visual alarm indicators,

NEMA 1 enclosure, 4-20 mADC, and 0-2 VDC analog outputs.

B

Oxygen Ranges

Range Code Range

A 0-100%

B 0-25%

C 0-10%

D 0-5%

E

Left Blank

F 0-10/25/100%

G 0-5/10/25%

H 0-1/10/25%

C

Code Input Power

115 115 VAC

50-60 Hz

230 230 VAC

50 Hz

Input Power Configurations

A

B C

D

Base Model

Code

Range

Code

Input

Code

Mechanical

Configuration Code

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SECTION 4.0

DETERMINING SYSTEM CONFIGURATION

4.1 Model Designation

Before proceeding to the following sections, it is important to determine the system configuration for

the selected analyzer. To best accomplish this, refer to the purchase order to obtain the part number

that was ordered and compare it to the range, input power configuration, and mechanical configuration

shown below.

Page 14

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

Mechanical Configurations

Code Configuration

BTP Benchtop/portable electronics enclosure with carrying handle.

The sensor is mounted on the rear of the electronics enclosure.

PNL Panel mounted electronics enclosure with the sensor mounted

on the rear of the electronics enclosure.

BTR Benchtop electronics enclosure without carrying handle. The sensor

is mounted within a separate NEMA 4X (IP 66) enclosure. Three

D

feet (1 meter) of interconnecting cable is provided to connect the electronics

(1,220 meters), is available.

PNR

within a separate NEMA 4X (IP 66) enclosure. Three feet (1 meter) of

interconnecting cable is provided to connect the electronics

to the sensor. Additional cabling, up to a maximum of 4,000 feet

(1,220 meters), is available.

BTX Benchtop electronics without carrying handle. The sensor is mounted

within a separate explosion proof enclosure rated NEMA 7 for use in

areas requiring Class 1, Groups B,C,D, Division 1; Class II, Groups E,F,G;

and Class III protection. No interconnecting cabling is provided. Cable is

available up to a maximum of 4,000 feet (1,220 meters).

PTX Panel mounted electronics. The sensor is mounted within a

separate explosion proof enclosure rated NEMA 7 for use in

areas requiring Class 1, Groups B,C,D, Division 1; Class II, Groups E,F,G;

and Class III protection. No interconnecting cabling is provided.

Cable is available at up to a maximum of 4,000 feet (1,220 meters).

EXX Electronics and sensor housing are mounted within one explosion

proof enclosure rated NEMA 7 for use in areas requiring Class 1,

Groups B,C,D, Division 1; Class II, Groups E,F,G; and Class III protection.

Panel mounted electronics enclosure. The sensor is mounted

Configuration example : Series 2000 Percent O2 Analyzer with a range of 0-10/25/100%, a selected

power input of 115 VAC 50-60 Hz, with a benchtop/portable mechanical

configuration (p/n 2000-F-115-BTP)

Page 15

ALPHA OMEGA INSTRUMENTS CORP.

OPTIONS/ACCESSORIES

Item Description P/N

RS-232C Serial Communications

-Maximum distance between host and analyzer is 50 feet. (15 meters).

2RS2

RS-485 Serial Communications-

Provides capability to communicate with several analyzers

2RS4

High Capacity Sample Filter -

316 stainless steel (SS) body with 316 SS filter element. Filters

295S

particle sizes > 5 microns. The filter housing is equipped with 1/4” compression gas fittings.

Spare Filter Elements-

316 stainless steel filter elements for the 295S Filter.

2FBX

Coalescing Filter-

Filter with aluminum housing. Recommended for samples containing a very

2CF

light mist and particles > 30 microns.

Spare Filter Elements

for the 2CF.

2CFE

Flowmeter

-Durable one-piece acrylic flowmeter (without flow control adjustment).

2FLM

Flowmeter-

Durable one-piece acrylic flowmeter (with flow control adjustment).

2FLMC

Pressure Regulator-

Aluminum body with a maximum pressure input of 100 psig (7.03kg/cm2).

2LPR

Pressure Regulator-

High capacity stainless steel pressure regulator with a 3000 psig

2PRR

(211 kg/cm2) inlet capacity and an adjustable outlet pressure range of 0 to 5 psig (0 to 0.35 kg/cm2)

(does not include indicating gauge).

Sample Pump

-For applications when the sample pressure is from 12 psia (827 mbar) to

2PMP

14.9 psia (1027 mbar). Maximum sample line limit is 25 feet (7.6 meters). When mounted on the

instrument,the enclosure rating is NEMA 1, general purpose.

High Capacity Sample Pump

- For applications when the sample pressure is from 10 psia (690 mbar)

2PMPH

to 14.9 psia (1027 mbar) or, if the sample line exceeds 25 feet (7.6 meters). Should be used

with the 2FLMC flowmeter. When mounted on the instrument, the enclosure rating is general purpose.

Sensor Heater

-Available with BTX, PTX, and EXX only. Designed to keep the sensor

2HTR

from being damaged due to low temperatures.

Mounting Plate

- Painted aluminum mounting plate ( 16” x 16”) (40cm x 40cm nominally)

2MPL

used for mounting items such as the remote sensor enclosure, flowmeter, sample pump, etc.

Items mounted at factory.

Battery Operation:

Nickel Metal Hydride Battery Pack used to power instrument when AC

2BAT

power is not available. The instrument is equipped with a built-in battery charger.

Internally mounted datalogger

: Capable of storing up to 32,000 oxygen readings.

2DL

Replacement Sensor-

Replacement sensor for the Series 2000 Percent Oxygen Analyzer.

2SEN

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

Page 16

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

Section 5.0

OPERATION

5.1 Preparation for Operation

5.1.1 AC Input Voltage Selection

At the time of shipment, the Series 2000 Percent Oxygen Analyzer is set up to operate on the line

voltage specified in the purchase order. If the line voltage is not specified, the instrument will be

configured for operation on 115 VAC, 50-60Hz. If the instrument is going to be powered from an

external DC power source, move on to the next section.

The input voltage can be changed in the field by changing jumper (S2) located on the lower left

quadrant of the printed circuit board (refer to FIGURE 1.0) When the Series 2000 is configured for

operation on 115 VAC, it contains a 0.5 ampere slow blow fuse (fuse type is Wickman 374050004).

For 230 VAC operation, the same value fuse can be used. However, please refer to item 3 below for

the jumper change required to change AC voltage inputs.

BE SURE TO USE THE APPROPRIATE FUSE RATING IF

THE INSTRUMENT IS CHANGED TO A DIFFERENT AC LINE

VOLTAGE .

Changing the AC input can be done as follows:

1 Disconnect the Series 2000 Percent Oxygen Analyzer from all AC power.

2 Swing out the front panel to gain access to the main printed circuit board

(refer to Section 2.1 for instructions). For explosion proof instruments, removal of the cover bolts

must be done to gain access to the inside of the instrument.

3 Examine the jumpers on the main circuit board. Shown below are the two ways of installing the AC

input selection jumpers at S2.

S2

4

S2

230 115

4. To change the AC configuration, remove the jumpers and place them according to the above

diagram.

5. Remove the fuse located on the main printed circuit board (refer to FIGURE 1.0) and replace it

with one of the proper value for the AC input voltage selected.

6. Reassemble the instrument and proceed to the next section.

Page 17

ALPHA OMEGA INSTRUMENTS CORP.

IT IS HIGHLY RECOMMENDED THAT THE CALIBRATION OF THE

ANALYZER BE CHECKED PRIOR TO INITIAL STARTUP.

NOTE FOR BATTERY OPERATION

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

5.1.2 Initial Set Up

The Series 2000 Percent Oxygen Analyzer is essentially ready to use out of the shipping container.

The analyzer has been calibrated at the factory and, under normal conditions, recalibration should not

be required at initial start-up. However, due to the rigors of shipment, it is possible that settings within

the instrument could change and, as a result, it is highly recommended that the calibration be checked

prior to initial startup.

5.1.3 Mounting Configurations

Bench top/Portable (BTP Configuration) The BTP is the basic Series 2000 Percent Oxygen Analyzer

configuration that has the sensor housing mounted on the rear panel of the electronics enclosure. The

analyzer is designed for either bench top or portable applications. All gas and electrical connections

are located on the instrument's rear panel for ease of access. The power switch is located on the side

of the instrument.

Panel Mounting (PNL)- Like its BTP counterpart, the sensor housing is mounted on the rear panel of

the electronics enclosure. In the PNL configuration, a panel mounting frame is supplied. Make the

appropriate panel modifications as indicated in the drawing.

Remote Sensor Mounting- There are several remote sensor mounting configurations for Series 2000

Percent Oxygen Analyzer. Check the purchase order to determine what mechanical configuration was

specified in the order.

5.1.4 Remote Mounted Sensor Enclosures

For analyzers equipped with remote mounted sensor enclosures, the electronics control unit and

remote mounted sensor enclosures need to be connected via interconnecting cable. If the standard

length of cable is ordered with the instrument (3 feet) (1 meter), wiring to the electronics control unit

has been done at the factory (no wiring is supplied with the explosion proof systems). For all

nonstandard lengths, the cabling will be shipped without being terminated. Please refer to Figure 1.0

to locate the various terminals for connecting the sensor, alarms, outputs, pump, heater, etc.

Optional Battery Operation

If the Series 2000 has been equipped with optional NiMH batteries, it is designed to provide up to eight hours of

operation on a fully charged set of batteries (without pump). With a pump, one may expect to obtain up to 3-4 hours

of continuous operation before charging of the batteries will be necessary. The batteries should be fully charged

upon receipt of the analyzer. If not, the user should recharge the batteries upon initial startup by powering the

analyzer from AC power. NOTE: THE POWER ON SWITCH MUST BE KEPT IN THE “ON” POSITION DURING

CHARGING.

Important: Re-charge batteries 16 hours before initial startup. Batteries are disconnected for

shipment.

The battery option should never be used when the analyzer is powered from a separate DC source. This will cause the batteries to

overcharge which may cause the batteries to explode. Be certain all wiring (alarms, remote sensor, RS-232C, etc.) has been done

before applying AC power to the instrument.

Page 18

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

5.2 Operating Procedures

5.2.1 Power ON

Power to the instrument is applied when the power cord is plugged into an AC outlet. The Series 2000

Percent Oxygen Analyzer has battery backed RAM so when the instrument undergoes a cold start, all

values, set by the user via the front panel or optional RS-232C and RS-485, will be maintained if

switch #8 is set to the "ON" position, otherwise referred to as the user configuration mode (See

section 3.3). The cold boot gives the user the opportunity to make sure the microprocessor, internal

memory, front panel LED's, and the audible alarm are functioning normally. During a cold start

sequence, the instrument's front panel liquid crystal display (LCD) will display a series of dashes in

series like[¯ ¯ ¯ ¯][- - - -][_ _ _ _], each of the three front panel LED's will blink simultaneously for

approximately 5 seconds, and the audible alarm will sound intermittently for as long as the LED's are

blinking. After this, the display will briefly show the onboard switch settings such as [

| | | | | | | |

example, switch #8 is ON and all the others are in the OFF positions.

To perform a warm boot and read the internal switch settings, make sure SW6 - switch # 8 is "OFF"

and push the front panel UP, DOWN, and Alarm 3 buttons simultaneously. Do not hold the buttons

down very long after the display shows the dashes described above. You will see the same sequence

as above, however, switch #8 will indicate low. Powering on with switch #8 in the "OFF" position will

cause the Series 2000 Percent Oxygen Analyzer to default to the specific switch settings.

|]. In this

5.2.2 Front Panel Controls and Indicators

The front panel of the Series 2000 Percent Oxygen Analyzer contains a 4 digit liquid crystal display

(LCD), three (3) alarm set push-button switches, three alarm LED's, and up and down push-button

switches.

Liquid Crystal Display: The primary function of the LCD is to display the concentration of oxygen in

the sample being measured in terms of percent oxygen by volume. Within approximately five seconds

after a cold start, the Series 2000 Percent Oxygen Analyzer will measure and display the oxygen

concentration of the sample gas exposed to the sensor. In addition to displaying oxygen values, the

LCD indicates certain status levels. When setting an oxygen alarm value, it is also possible to toggle

the alarm from high to low to high etc. The display will show [ HI ] or [ LO ], very briefly, upon pressing

the up and down arrows simultaneously, indicating either a high or low alarm. Note: this is a toggle

function, so if it shows the opposite setting desired, just toggle it back. Then exit the alarm set routine

by pressing an alarm button. When the Series 2000 Percent Oxygen Analyzer is equipped with the

Battery Option, the LCD will display [LOBAT ] when battery power has reached the point when

normal instrument operation is in jeopardy. To protect important information stored in the analyzer’s

memory [monitor’s memory], the analyzer [monitor] suspends operation of the microprocessor when

further operation could corrupt that memory. The microprocessor displays the word HALT on the LCD,

then suspends further operation. The microprocessor does not resume operation until power is

reapplied and the battery voltage is verified to be high enough to safely take over operation for a short

time in the event of a recurring power failure.

When calibrating the Series 2000 Percent Oxygen Analyzer, you will notice that upon initiating that mode, the

liquid crystal display momentarily reads [ CAL] and then the value of the oxygen concentration of the gas being

measured is displayed. For further information on calibrating the analyzer, please refer to Section 6.0.

Oxygen Alarms: The Series 2000 Percent Oxygen alarms are set at the factory as low alarms. Any one of

these alarms can be set by the user for operation as high alarms also. Please refer to Section 3.2 "Alarm

Settings" for instructions on how to set Alarm 3 for either high or low operation. Note: All alarms are user

configurable via SW-6, - switch #8 (refer to section 3.3).

Page 19

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

5.2.3 Setting the Alarms

Assuming that no alarms are currently activated (no led's are lit), press the desired alarm switch on

the front panel, "Alarm 1", "Alarm 2", or "Alarm 3" . The numerical value in the LCD is the existing

alarm value associated with that alarm channel. When the alarm switch is pressed, the LED directly

above the switch will light indicating that channel is in the alarm set mode. In addition, the alarm value

in the LCD will be followed by the letter "L" or "H" indicating a low oxygen alarm or a high oxygen

alarm respectively. Any of the three Oxygen Alarms can be changed from low to high or vice versa by

pressing the up and down arrows simultaneously.

To set the oxygen alarm values, using the front panel up and down arrows, press the down arrow to

lower the oxygen alarm value or the up arrow to increase the value. The longer either arrow is held

down, the more rapidly the alarm values will scroll in the display. When the value in the display is close

to the desired oxygen set point value, it is recommended that pressure be released from the switch. To

obtain the final value, apply momentary pressure to the switch to change values in small increments.

When finished setting the alarm, press the associated alarm switch. The LED will go off, and the

display will indicate the actual oxygen concentration. If more than one alarm value is to be changed,

repeat this procedure using the desired alarm channel.

5.2.4 Alarm Processing

When an alarm event takes place, several indications are provided by the Series 2000 Percent

Oxygen Analyzer including:

I. The LED associated with the oxygen channel in question will light.

II. An audible alarm will sound.

III. The relay associated with the oxygen alarm in question will change state.

There are two possible conditions that effect the way the instrument will respond to alarm cancellation.

One is auto-clear operation and the other is manual clear. The mode of operation is determined by the

setting of SW-6 -switch #6.

5.2.4.1 Auto-Clear Operation

In the Auto Clear mode (SW-6 switch #6 is ON), the monitor will automatically reset the 3 indications

mentioned above when the alarm condition clears. Whenever an alarm is active, pressing the

associated front panel push-button (Alarm 1, Alarm 2, or Alarm 3) will silence the audible alarm. To

change the setting for this same alarm, press the button a second time. If more than one alarm is on,

the audible will still be canceled. Please note that the Series 2000 Percent Oxygen Analyzer will not

go into an alarm set mode if an audible alarm is on for that alarm channel. It will for the other

channel(s) that are not in an alarm mode. If, however, you push the alarm button twice for a channel

that is in an alarm condition, it will allow you to change that alarm set point. If you set the alarm to a

value that causes an alarm condition, the audible alarm will immediately come on upon exiting the

alarm set mode.

Note: Under Auto-Clear operation, the silenced audible alarm may automatically come back on if the

O2 reading should go out of alarm range and then back into alarm condition. Also, after silencing the

audible alarm, all alarms must be cleared to re-enable the audible alarm.

Page 20

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

5.2.4.2 Manual Clear Operation

When SW6 switch #6 is in the "OFF" position, the Series 2000 Percent Oxygen Analyzer is in the

Manual Clear mode. In the manual clear mode, whenever the Series 2000 Percent Oxygen Analyzer

senses an alarm condition, it will be indicated by the 3 indications listed in Section 5.2.4. However, if

the oxygen level should return to a non-alarm level, the monitor will not automatically clear. The user

must first cancel the audible alarm by pushing the appropriate alarm button. Only after the audible

alarm has been canceled can the user clear the alarm condition by again pushing the appropriate

alarm button. If the setpoint is to remain the same, simply pushing the appropriate alarm button a

third time will clear the alarm. Note: If the audible alarm is activated, pressing any alarm button that is

not associated with an alarm condition, will temporarily quiet the audible alarm. Upon exiting the alarm

set condition or if the monitor times out because of no user input, the audible alarm will resume

awaiting a manual clear operation as described above.

5.2.4.3 Timing Out

If the user is setting the alarm(s) in the Series 2000 Percent Oxygen Analyzer and no adjustment has

been made for approximately 2 minutes, the analyzer will automatically revert back to normal

operation. This feature helps to prevent the user from inadvertently keeping the analyzer off-line for a

prolonged period of time. If the user is in an alarm setting sequence and the instrument times out, the

alarm value will be that which was last displayed in the LCD. However, under the calibration mode, if

the instrument times out, no changes to the calibration settings will take place.

5.2.5 Over Range

If the oxygen concentration of the gas being measured by the Series 2000 Percent Oxygen Analyzer

exceeds the highest range of the instrument, the LCD will blink "OL" signifying an overload condition

and the audible alarm will sound. The alarm can be shutoff, at any time, using any of the front panel

switches. If left on, it will automatically shutoff once the oxygen concentration has dropped within

range of the analyzer. Note: For the 0-100% range, there is no “OL” signal because oxygen

concentrations cannot exceed 100%.

5.2.6 TTL Signals for Analyzers with Autoranging

As is the case with single range analyzers, all three range analyzers are equipped with two full scale

analog outputs, 4-20 mADC and 0-2 VDC. If a recorder, datalogger, PLC, etc. will be used to monitor

the analog output(s) of the Series 2000 Percent Oxygen Analyzer, TTL (transistor transistor logic)

signals are available to indicate (to the interface device) which of the three oxygen ranges is in use.

For example, a Series 2000 Percent Oxygen Analyzer equipped with three oxygen ranges of 01/10/25% will provide simultaneous analog outputs of 12 mADC and 1 VDC when the oxygen values

are 0.5%, 5.0%, and 12.5%. Without use of the TTL signals, the interface device cannot distinguish

which range is in use. RNG1 represents the lowest of the three ranges, with RNG2 and RNG3

representing the middle and high range respectively. The signals are accessible via three terminals

labeled (RNG1, RNG2 and RNG3) near the top of the main output connector of the Series 2000

Percent Oxygen Analyzer (see figure 1.0). A high TTL signal indicates the specific range in use. When

the lowest range is in use, RNG1 will be high (>2.8 VDC), and RNG2 and RNG3 will be low (<0.8

VDC). When the middle range is in use, RNG2 will be high with RNG1 and RNG3 indicating low, and

when the high range is in use, RNG3 will be high with RNG1 and RNG2 indicating low.

5.2.7 Manual Range Changing

Any three range Series 2000 Percent Oxygen Analyzer can be configured so that the measuring

ranges can be changed manually rather than via autoranging. The default setting from the factory

(unless otherwise specified by the user at the time of order placement) is with autoranging engaged.

Page 21

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

To use manual range change, press Alarm 1 & Alarm 3 keys simultaneously which prompts the

analyzer to display the existing range setting. As indicated previously, the default setting from the

factory is [Auto] and is displayed on the front panel LCD. To toggle to a fixed range, simply continue to

press the Alarm 1 and Alarm 3 keys simultaneously until the range desired is shown in the display at

which point discontinue the toggling action. As an example, if a Series 2000 Percent Oxygen Analyzer

is equipped with three ranges consisting of 0-1/10/25%, pressing A1 and A3 simultaneously will

produce a temporary range indication on the front panel as follows:

Press A1 and A3 simultaneously Display reads: [25.0]

Press A1 and A3 simultaneously Display reads: [10.0]

Press A1 and A3 simultaneously Display reads: [1.0]

Press A1 and A3 simultaneously Display reads: [Auto]

Press A1 and A3 simultaneously Display reads: [25.0] Cycle Repeats.

As is the case with autoranging, if the oxygen concentration exceeds that of the range that is in use,

the instrument will display an [`OL`] condition.

5.2.8 Gas System Pressure Limits

For sample gases and/or calibration gases that are under pressure, it is imperative that the input

pressure to the sensor be kept to under 1 pound per square inch. If the pressure is expected to be in

excess of 1.0 psi, it is advisable to use a pressure regulator (Alpha Omega Instruments Model

Number 2PRR). Flow rates to the analyzer should be between 0.5 to 1.0 liters per minute, never to

exceed 2.0 liters per minute. If the sample pressure is insufficient to move the gas through the sensor

housing, a sample pump may be required (Alpha Omega Instruments P/N 2PMP). If so, the suction

side of the sample pump should be connected to the outlet side of the sensor housing. The pressure

differential should never exceed 1 psi. This could occur if there was a shutoff valve upstream and it

was placed in the off position with the pump on. If the pump has the capacity to create a pressure

drop in excess of 1 psi across the sensor, damage could result. Under no circumstances should the

sensor be operated at a vacuum of less than 12 psia (14.7 psia is atmospheric pressure). Damage to

the sensor will in all likelihood result voiding the remaining warranty.

5.2.9 Sample Connections

All Series 2000 Percent Oxygen Analyzers are normally equipped with quick connect sample gas

fittings on both the sample inlet and outlet to the sensor housing. The Series 2000 Percent Oxygen

Analyzer may be operated without any connections to the output of the sensor housing. Unless the

sample gas is toxic or explosive in nature, it is common for the gas to be vented to atmosphere.

NOTE: All explosion proof analyzers are equipped with inlet and outlet gas flame arrestors.

DO NOT REMOVE THESE ARRESTORS AS DOING SO may produce a potentially hazardous

condition as well as INVALIDATE THE INSTRUMENT WARRANTY.

Page 22

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

Section 6.0

CALIBRATION PROCEDURES

6.1 Initial & Routine Calibration Checks

All Series 2000 Percent Oxygen Analyzers are fully calibrated at the factory prior to shipment.

However, with the potential hazards associated with shipping instrumentation, it is advisable that the

Series 2000 Percent Oxygen Analyzer be given a system calibration check at the time of startup.

Alpha Omega Instruments percent oxygen sensors feature high accuracy and excellent long term

stability characteristics. As a result, routine maintenance is kept to a minimum. As is the case with all

gas analyzers, it is advisable to periodically check the overall system calibration. The frequency of

these checks is often determined by in-house calibration protocols. If none exists, Alpha Omega

Instruments Corp. recommends that a calibration check be made on an average of once every 2-3

months.

6.1.2 Calibration Gas

The oxygen sensor used in the Series 2000 Percent Oxygen Analyzer has a linear output. As a result,

it can be calibrated using a single calibration gas as long as the test is performed accurately. The

calibration gas should contain a defined concentration of oxygen with a balance of nitrogen (N2). The

actual concentration of oxygen should be chosen based on the range(s) of the instrument. For single

range analyzers, choose a calibration gas that is somewhere between 30%-70% of the analyzer's

range. For three range analyzers, use the same rule of thumb choosing the range most often used as

the basis for selecting the calibration gas. If the Series 2000 Percent Oxygen Analyzer is equipped

with a range to measure ambient air (20.9% O2), this is an excellent way to check the instrument

calibration without having to use purchased calibration gases. If there is any reason to question the

composition of the air to be used for calibration, the analyzer should be calibrated next to an open

door or window where there is an ample exchange of fresh air from an outside environment. If the

location of the analyzer precludes the use of a fresh air supply for calibration, compressed air from a

cylinder source is the next best choice (do not use plant air as oil vapors and/or water mist that may

be entrained in the gas stream could damage the oxygen sensor).

6.1.3 Procedure for Checking Calibration

1. Select a cylinder of calibration gas as described in Section 6.1.2.

2. When selecting a pressure regulator to use with the cylinder gas, it is advisable to use a twostage regulator with the second stage capable of delivering a gas sample at a pressure of under

1.0 psig.

3. In addition to the selection of the pressure regulator, care must be given to choose the correct

sample tubing materials. For oxygen measurements below 10%, metal tubing is recommended.

DO NOT USE RUBBER OR PLASTIC TUBING FOR

CALIBRATION BELOW 10%. AIR CONTAINS 20.9%

4. Install a flowmeter on the discharge side of the sensor.

OXYGEN. A SMALL LEAK OF AIR INTO EITHER THE

CALIBRATION GAS OR SAMPLE GAS LINE CAN CAUSE A

SIZABLE ERROR IN READINGS. LEAKAGE CAN BE

THROUGH CRACKS IN THE TUBING OR BY DIFFUSION

THROUGH THE TUBING.

Page 23

ALPHA OMEGA INSTRUMENTS CORP.

The Series 2000 Percent Oxygen Analyzer is equipped with a fourth alarm

relay, referred to as an Instrument Status Alarm. The primary function of

this relay is to alert users when a sensor needs to be changed. During

calibration, if the amount of gain (calibration adjustment) has exceeded a

predetermined limit set at the factory, a message will be shown across the

LCD "change sensor". This message will be displayed only when the instrument has been taken out of calibration mode. In addition to the message,

the instrument status alarm will actuate. If this is the first warning, in all

likelihood, the instrument will still function normally. However, it is an

indication that the sensor should be replaced as soon as possible. Though

the change sensor message will only be displayed once per calibration

cycle (when the preset gain has been exceeded), the alarm relay will stay in

the alarm state until the condition has been cleared. Clearing of the alarm

condition requires changing the sensor.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

5. Power up the Series 2000 Percent Oxygen Analyzer as described in Section 4.2. and set the

calibration gas flow rate to 1.0 liter per minute (LPM). Monitor the analyzer response to the

calibration gas, waiting until a stable reading has been established. (The use of a recorder or

data logger can be very helpful in verifying that the analyzer has reached an equilibrium point.)

6. The reading in the LCD should now display the oxygen concentration of the calibration gas. BE

SURE TO ALLOW THE READING TO COME INTO EQUILIBRIUM BEFORE MAKING ANY

ADJUSTMENTS. If the oxygen value read from the LCD differs from the calibration gas, a span

adjustment should be made so that the value displayed in the LCD is identical to that of the

calibration gas. If a span adjustment is to be made, the instrument must be placed in the

calibration mode. To do so, simultaneously press the front panel buttons labeled Alarm 1, Alarm

2, and Alarm 3. The meter will temporarily display "CAL" and then the oxygen value in the LCD

will appear with a "C" after it indicating the instrument is in the calibration mode. If the oxygen

value displayed is lower than the calibration gas value, press the up arrow to adjust the value in

the LCD upwards. Conversely, if it is higher, use the down arrow to lower the reading. When

finished, once again press Alarm 1, Alarm 2, and Alarm 3 buttons simultaneously and the "C" will

disappear indicating the calibration sequence has been completed. If after initiating a calibration

sequence, it is decided not to make an adjustment, allow the instrument to time out (2 minutes).

In doing so, the previous calibration settings will be used.

6.1.3.2 Zero Adjustment

As discussed in Section 3.0, Alpha Omega Instruments' percent oxygen sensor is very specific for

oxygen. When there is no oxygen present, the output from the sensor is zero. This coupled with the

inherent linear characteristics of the sensor allow the user to use a single point calibration as means of

calibrating the system. NO ZERO CALIBRATION IS REQUIRED.

Page 24

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

Section 7.0

REPLACEMENT OF THE OXYGEN SENSOR

7.1 Procedure for Replacing the Oxygen Sensor

Alpha Omega Instruments oxygen sensor is designed to operate for prolonged periods of time without

needing replacement. However, in time the sensor's output will drop to a level where replacement

becomes the prudent course of action. A good indication of this is a marked increase in calibration

frequency. When this happens, a replacement sensor should be ordered directly from the factory. The

part number for a replacement sensor is 2SEN.

To install a new sensor follow the directions below:

1.0 Remove all power from the instrument.

2.0 Locate the brass sensor housing and sensor located inside the analyzer. Note: For remote

mounted sensor installations, the sensor housing is outside the enclosure. However, access to

the sensor itself can only be accomplished by removing the cover from the remote enclosure.

3.0 Locate the connector on the two sensor leads and disconnect it. Turn the sensor

counterclockwise to unscrew it from its holder. Discard the old sensor (see precautionary note

below) and install the replacement sensor being careful not to over-tighten the sensor. The

sensor has an “O” ring seal that when finger tightened, will provide the required seal. Reattach

the electrical connector and close or reattach the cover to the enclosure.

THE SENSOR CONTAINS A SMALL AMOUNT OF A MILDLY ACIDIC

ELECTROLYTE. WHEN DISCARDING SPENT SENSORS, CARE

SHOULD BE GIVEN NOT TO PUNCTURE THE SENSOR OR TO TAKE

IT APART. DISPOSE OF THE SPENT SENSOR ACCORDING TO

LOCAL, COUNTY, OR STATE GUIDELINES. PLEASE REFER TO THE

MSDS SHEET IN THE BACK OF THIS MANUAL

4.0 Apply power and calibrate according to Section 6.0.

Page 25

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

SECTION 8.0

Serial Communications RS232C & RS485

8.1 Baud Rates

Available Baud Rates are 38400*, 19200*, 9600, 4800, 2400, 1200, 300, and 150. To set the baud rate

please follow the directions below, in the sequence given:

1. Be sure that the unit is fully operational. You can check this by observing that valid oxygen

readings are displayed on the front panel LCD of the instrument.

2. Next, make sure that switch 5 on the Main board Switch Bank is LOW or OFF. This is a factory

switch and should be on only in certain circumstances. Note: if the unit was shipped with SW5

ON, turn it off to set the baud rate. After the baud rate has been set, move SW5 to the on

position to resume normal operation.

3. Press and hold the UP and DN keys simultaneously. An initial beep will be heard followed by a

second beep which confirms that the next step should be taken.

4. At this point, the current setting should be displayed on the front panel. If not, make sure that

you hold the two aforementioned keys long enough.

5. Now press and hold the UP and DN keys to scroll through available settings choosing the

desired baud rate.

With the desired baud rate displayed, push the Alarm 3 button to save it in battery backed memory

8.2 Standard Commands

The following standard commands apply for both the RS-232C OR RS-485 interfaces: Please note

that all letters typed can be upper or lower case. The only exception to this rule is the optional [string].

The Commands below are in upper case for clarity purposes only. Also any user input not in brackets

is shown in lower case. Optional commands or strings are shown within brackets.

Command Description

Aa=[bb.b][L/H] <Enter> Alarm set

Bccccc <Enter> Baud rate select

C[bb.b] <Enter> Calibrate

D[string] <Enter> Disable Security

E[string] <Enter> Enable Security

FSd=[ON/OFF/1/0] <Enter> Fail-safe select

H <Enter> Help Screen

M <Enter> Manual clear toggle

O <Enter> Oxygen Concentration

Q <Enter> Quiet mode (no beeps at all)

S <Enter> Signal mode (beeps audible)

V <Enter> View current Alarms and settings

Where: a = 1, 2, or 3 for different alarms

bb.b = Decimal number signifying the oxygen in %

L/H = Optionally set to 'L'ow or 'H'igh alarm

ccccc = Baud rate number from 150 to 38400

d = Number designating Relay 1 to 4

ON/OFF/1/0 = 'ON' is the same as '1' etc.

name = String for accessing multiple units (see manual)

string = String for security protection (see manual)

* Baud Rates not available on RS485

Page 26

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

An example of each command is as follows:

'A' Command - Alarm set point with low or high alarm option.

Alarm #1 will be set to go off in the case of the oxygen level dropping below 20 %. Type:

A1=20.0L <Enter>

To change Alarm #1 to 18 % instead of 20 % you could type:

A1=18 <Enter>

Note how the 'L'ow alarm is optional unless changing to 'High? As you can see, the decimal point is

optional too, and if left out defaults to '.0'. Note how the command in the help screen says,

"[bb.b]&/or[L/H]"? Examine the following example:

A1=H <Enter>

This is a valid command and will only effect the 'L'ow or 'H'igh status of Alarm 1. To set it back to a

low alarm type:

A1=L <Enter>

'B' Command - Baud change. To change the baud from 300 bps to 9600 (default) bps type the

following:

Make sure the instrument is responding at 300 bps first.

B9600 <Enter>

Note that you may have some garbled data output. Now you must change your terminal's baud rate

and reestablish communication by pressing <Enter>.

'C' Command - Calibrate to known calibration standard (i.e. 2 %).

Using a calibration gas consisting of 2 %, type the following:

C02 <Enter>

Page 27

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

'D' Command - Disable security with optional pass code. (See 'E' Command below for description of

security)

In it's simplest form, to disable security protection type:

D <Enter>

Assuming an 'E' Command had been sent with a pass code of "mypass1" (see next command

example) then type the following to disable the security option:

Dmypass1 <Enter>

Note: typing "DMYPASS1" will not disable the instrument if the original pass code was in lowercase!

That means that the 'D' and 'E' commands are CASE SENSITIVE.

'E' Command - Enable security with optional pass code.

To keep others from changing any system settings, the Enable Command is supplied as an optional

security measure. In it's simplest form type the following:

E <Enter>

In this example, the user would just type 'E' by itself. This would keep people from inadvertently

changing the system settings. However, if the need should arise to change a setting, all that would be

necessary would be a 'D' command with no pass code. The following command shows the use of a

pass code:

Emypass1 <Enter>

This will arm the security system and will ignore any requests for system changes until the user

disarms the system with a 'D' Command followed by the correct pass code (See 'D' command above).

'FS' Command - Fail-safe select.

If the alarm relays should be energized in normal operation and release in the case of a power failure,

type the following:

FS1=ON <Enter>

FS2=1 <Enter>

FS3=on <Enter>

fs4=On <Enter>

Note the individual control over each alarm. Also, ON/on/OFF/off or 1/0 can be used to control the

status of each. Commands are not case sensitive. Example: If only Alarm 2 needs to be in Fail-safe

mode, then type:

FS1=off <Enter>

FS3=0 <Enter>

FS4=Off <Enter>

This turns off the Fail-safe mode for Alarms 1, 3, and 4.

Page 28

ALPHA OMEGA INSTRUMENTS CORP.

SERIES 2000 PERCENT OXYGEN ANALYZER Instruction Manual

'H' Command - Help Screen

Displays a help screen.

H <Enter>

'M' Command - Manually clear all alarms.

This command toggles between Manual and Automatic clearing of alarms. The clearing of an alarm is

simply when the condition causing the alarm has been corrected and the Series 2000 gives no

indication that the alarm was on.

'O' Command - Output Oxygen Concentration

This command is useful for a quick reading of the Oxygen Concentration. All that is returned is the

present reading in percent oxygen.

'Q' Command - Quiet mode (disables the audible alarm. Warning! This disables all sounds - even

from alarms!)

If the instrument is going to be in a test mode for a while, with sensors being removed and replaced

(causing a lot of harmless alarms), you can optionally remove the beeping altogether by typing:

Q <Enter>

This will stay in effect until an 'S' command is received by the Series 2000, or a re-boot is initiated. A

message will appear under the 'V' command displaying the current mode.

'S' Command - Signal mode (enables the audible alarm).

To allow the audible alarms to be heard, simply type the following:

S <Enter>

'V' Command - View current alarms and settings

To view the current status of the Series 2000, type:

V <Enter>

Typical Response: