SERIES 1300

OXYGEN DEFICIENCY MONITOR

USER MANUAL

CAUTION

Please read this manual before using the Series 1300 Oxygen Deficiency Monitor. Instructions

within the manual are essential for the proper operation of this product.

40 Albion Road, Lincoln, RI, USA 02865

Tel: (001) (401) 333-8580

Fax: (001) (401) 333-5550

Email: contact@aoi-corp.com

Website: www.aoi-corp.com

Rev 1.0915, September 2017

© COPYRIGHT 2014. Alpha Omega Instruments Corp. All

rights reserved including the right to reproduce this

manual or any portion thereof in any form.

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

WARRANTY

Alpha Omega Instruments Corp. warrants that delivered products are free from defects in material

and workmanship at the time of delivery to the FOB point specified in the purchase order. Liability

under this warranty is limited to repairing or replacing, at Alpha Omega Instruments' option, items

which are returned to it prepaid within four years (including sensor) from the date of shipment and

found to Seller’s satisfaction to have been defective.

Alpha Omega Instrument's four (4) year sensor warranty provides protection for four years from the

date of shipment of the Series 1300 Oxygen Deficiency Monitor. Any sensor from a Series 1300

Oxygen Deficiency Monitor that fails under normal use must be returned to Seller prepaid and, if such

sensor is determined by Seller to be defective, Seller shall provide Buyer with a replacement sensor.

Buyer must provide the serial number of the monitor from which the sensor has been removed. If a

sensor is found to be defective and a new one issued, the warranty of the replacement sensor(s) shall

not extend beyond the initial warranty period of the Series 1300 Oxygen Deficiency Monitor, or for a

period of one year, whichever is longer. After this, all replacement sensors will be warranted for a

period of one year from the date of shipment. In no event shall Alpha Omega Instruments Corp. be

liable for consequential damages.

NO PRODUCT IS WARRANTED AS BEING FIT FOR A PARTICULAR

PURPOSE AND THERE IS NO WARRANTY OF MERCHANTABILITY.

This warranty applies only if:

(i) the items are used solely under the operating conditions and manner recommended in this manual, product

specifications, or other product specific literature;

(ii) the items have not been misused or abused in any manner or unauthorized repairs were attempted thereon;

(iii) written notice of the failure within the warranty period is forwarded to Alpha Omega Instruments Corp. and, the

directions received for properly identifying items returned under warranty are followed;

(iv) the return notice authorizes Alpha Omega Instruments Corp. to examine and disassemble returned products to the

extent the Company deems necessary to ascertain the cause of failure.

The warranties stated herein are exclusive. THERE ARE NO OTHER WARRANTIES, EITHER

EXPRESSED OR IMPLIED, BEYOND THOSE SET FORTH HEREIN, and Alpha Omega Instruments

Corp. does not assume any other obligation or liability in connection with the sale or use of said

products.

Disclaimer of Warranty

Alpha Omega Instruments Corp. makes no representation or warranties, either expressed or implied, by or with respect to

anything in this manual, including, but not limited to, implied warranties of merchantability or fitness for a particular purpose.

In no event will Alpha Omega Instruments Corp. be liable for any damages, whether direct or indirect, special, consequential,

or incidental arising from the use of this manual. Some states in the USA do not allow the exclusion of incidental or

consequential damages. Alpha Omega Instruments Corp. also reserves the right to make any changes to improve the

performance of its products at any time and without notice.

Series 1300 Oxygen Deficiency Monitor PAGE i

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

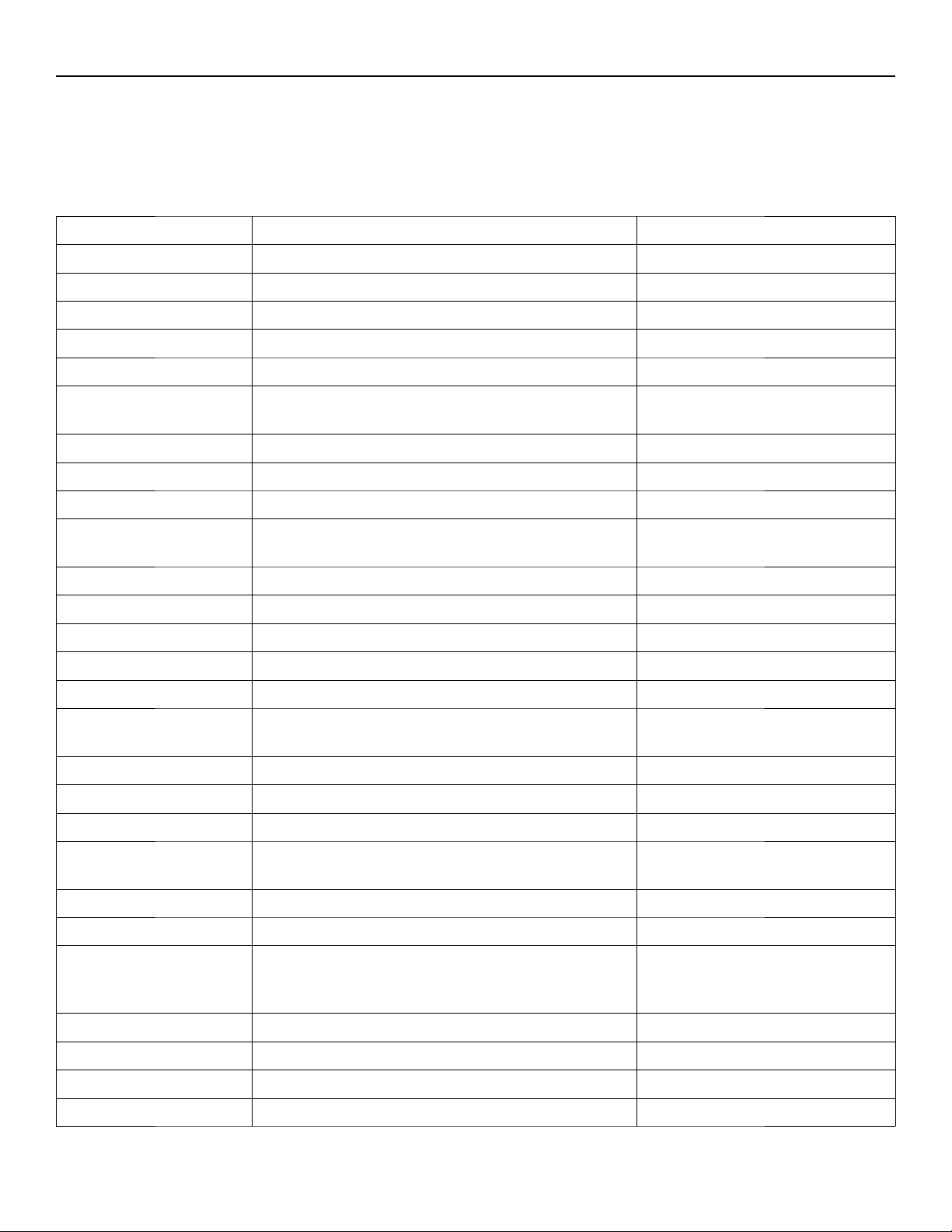

Table of Contents

WARRANTY..............................................................................................................................................i

1 Overview...............................................................................................................................................1

1.1 Explanation Of Graphic Symbols...................................................................................................1

1.2 Instrument Description...................................................................................................................1

1.2.1 Features.................................................................................................................................2

1.3 Mounting........................................................................................................................................2

1.4 Oxygen Sensor..............................................................................................................................2

1.5 Description Of Optional Equipment...............................................................................................3

1.6 Standard Features.........................................................................................................................4

1.7 Optional Features..........................................................................................................................4

1.8 General Specifications...................................................................................................................5

2 Installation.............................................................................................................................................6

2.1 Unpacking The Instrument.............................................................................................................6

2.2 Electrical Installation......................................................................................................................7

2.3 Mechanical Configuration..............................................................................................................7

2.3.1 Main Enclosure.......................................................................................................................8

2.3.2 Remote Oxygen Sensor Enclosure........................................................................................9

3 Wiring..................................................................................................................................................10

3.1 Local Oxygen Sensor...................................................................................................................11

3.1.1 Local Oxygen Sensor Installation.........................................................................................12

3.2 Power (TB1).................................................................................................................................13

3.3 Remote Oxygen Sensors.............................................................................................................14

3.3.1 Remote Oxygen Sensor Installation Procedure...................................................................15

3.4 Horn And Strobe...........................................................................................................................16

3.4.1 Horn and Strobe PCB...........................................................................................................17

3.4.2 Horn and Strobe Daisy Chain Configuration........................................................................18

3.4.3 Horn and Strobe Star Configuration.....................................................................................19

3.4.4 Horn and Strobe External Power..........................................................................................19

3.4.5 Horn and Strobe Relay Wiring..............................................................................................20

3.4.6 Horn and Strobe Switch Settings..........................................................................................20

3.4.7 Horn and Strobe Maximum Distance...................................................................................21

3.5 Analog Outputs.............................................................................................................................22

3.6 Alarm Relays................................................................................................................................22

3.6.1 Fail Safe................................................................................................................................23

3.7 RS-232/485 Communications......................................................................................................23

4 Operation.............................................................................................................................................24

4.1 Power ON.....................................................................................................................................24

4.2 Panel Description.........................................................................................................................24

4.3 Navigating The Screens...............................................................................................................24

4.3.1 Home Screen........................................................................................................................24

4.3.1.1 Three Line "Home" Screen................................................................................................25

4.3.1.2 Large Font Home Screen..................................................................................................25

4.3.2 Alert Screen..........................................................................................................................25

4.3.2.1 Navigating the Alert Screens.............................................................................................26

4.3.3 Active Alarms Screen............................................................................................................28

4.3.4 Alarm Status Screen.............................................................................................................28

PAGE ii Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

4.3.5 Main Menu Screen................................................................................................................29

4.4 Alarm System...............................................................................................................................29

4.4.1 Alarm System Menu Settings...............................................................................................30

4.4.2 Default Alarm Settings..........................................................................................................31

4.4.3 Default Alarm Activation Behavior........................................................................................31

4.4.4 Low Alarms vs High Alarms..................................................................................................31

4.4.5 Alarm Latching......................................................................................................................31

4.4.6 Relay Fail-safe Operation.....................................................................................................32

4.4.7 Navigating Alarms.................................................................................................................32

4.5 Horn And Strobe...........................................................................................................................33

4.5.1 Horn and Strobe Naming......................................................................................................34

4.6 Analog Outputs.............................................................................................................................34

4.6.1 Analog Output Sensor Association.......................................................................................34

4.6.2 Analog Output Range...........................................................................................................34

4.6.3 Analog Output Offset............................................................................................................35

4.6.4 Voltage Output Mode............................................................................................................35

4.7 Navigating The Menu...................................................................................................................36

4.7.1 Timing Out.............................................................................................................................36

4.8 Main Menu...................................................................................................................................37

4.8.1 Passcode..............................................................................................................................39

4.8.2 CALIBRATE..........................................................................................................................39

4.8.3 SENSOR SETUP..................................................................................................................39

4.8.3.1 Sensor Naming..................................................................................................................39

4.8.4 ALARM SETUP.....................................................................................................................39

4.8.4.1 Setting the Alarm Sensor...................................................................................................39

4.8.4.2 Setting the Alarm Set point................................................................................................40

4.8.4.3 Setting the Alarm High or Low...........................................................................................40

4.8.4.4 Setting the Alarm Latch.....................................................................................................40

4.8.4.5 Clearing a Latched Alarm..................................................................................................40

4.8.4.6 Activating Alarm Relays and Horn and Strobes................................................................40

4.8.5 FAILSAFE SETUP................................................................................................................41

4.8.6 OUTPUTS SETUP................................................................................................................41

4.8.6.1 Sensor................................................................................................................................41

4.8.6.2 Scale Low & Scale High....................................................................................................41

4.8.6.3 Analog Output Offset.........................................................................................................42

4.8.7 HORN & STROBES..............................................................................................................42

4.8.7.1 Naming the horn and strobe..............................................................................................42

4.8.8 DATA LOGGER.....................................................................................................................43

4.8.9 MISCELLANEOUS...............................................................................................................43

4.8.10 Field Elevation Adjustment.................................................................................................44

4.8.11 System Information (“SYSTEM INFO”)...............................................................................44

5 Data Logger.........................................................................................................................................45

5.1 Logger Operation.........................................................................................................................45

5.1.1 Logger State.........................................................................................................................45

5.1.2 Logger Mode.........................................................................................................................45

5.2 Sample Interval............................................................................................................................46

5.3 Date And Time..............................................................................................................................46

5.4 Sensor Selection..........................................................................................................................46

Series 1300 Oxygen Deficiency Monitor PAGE iii

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

6 Sensor Setup.......................................................................................................................................47

6.1 Sensor Removal...........................................................................................................................47

7 Calibration Procedures........................................................................................................................48

7.1 Routine Calibration Check...........................................................................................................48

7.2 Oxygen Calibration......................................................................................................................48

7.2.1 Calibration with Ambient Air..................................................................................................48

7.2.2 Calibration With Other Gases...............................................................................................48

7.2.3 Procedure for Checking Oxygen Calibration........................................................................49

7.3 Calibration On Ambient Air...........................................................................................................49

7.4 Optional Calibration Fixture.........................................................................................................49

7.5 NO Zero Adjustment....................................................................................................................50

7.6 Change Oxygen Sensor Notice...................................................................................................50

7.6.1 Replacing a Sensor..............................................................................................................50

8 Battery Backup....................................................................................................................................52

8.1 Battery Backup HALT...................................................................................................................52

8.2 Battery Backup Time....................................................................................................................53

8.3 Battery Status Screen..................................................................................................................54

9 Warnings..............................................................................................................................................55

9.1 Alarm Warnings............................................................................................................................55

9.2 Sensor Removal Warnings..........................................................................................................56

9.2.1 Scenario 1 – Dangerous Low Oxygen Level........................................................................56

9.2.2 Scenario 2 – Disconnected Oxygen Sensor.........................................................................56

9.3 Horn And Strobe Warnings..........................................................................................................56

9.3.1 Horn and Strobe Removal....................................................................................................56

9.3.2 Horn and Strobe Address Change........................................................................................56

10 Maintenance and Troubleshooting....................................................................................................57

10.1 User Maintenance......................................................................................................................57

10.2 Serviceable Items......................................................................................................................57

10.3 System Messages.....................................................................................................................57

11 Serial Communications......................................................................................................................59

11.1 Baud Rates.................................................................................................................................59

11.1.1 Setting the Baud Rate.........................................................................................................59

11.2 Line Endings...............................................................................................................................59

11.3 RS Echo.....................................................................................................................................59

11.4 Addressing..................................................................................................................................59

11.4.1 Address...............................................................................................................................60

11.5 Standard Commands.................................................................................................................60

11.5.1 Read....................................................................................................................................60

11.5.2 Write....................................................................................................................................61

11.6 RS485.........................................................................................................................................61

11.7 RS Security................................................................................................................................61

11.8 Variable Registers Table.............................................................................................................61

11.9 RS Data Logger..........................................................................................................................65

12 APPENDIX A – Main Enclosure Template.........................................................................................66

13 APPENDIX B – Remote Enclosure Template...................................................................................67

14 APPENDIX C – Terminal Block Reference.......................................................................................68

14.1 Standard AC Connections..........................................................................................................68

14.2 Remote Sensor And Horn And Strobe Connections..................................................................68

PAGE iv Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

14.3 PCB Connectors........................................................................................................................69

15 APPENDIX D – Horn and Strobe(s)..................................................................................................70

15.1 Externally Powered Horn And Strobe(s)....................................................................................70

15.2 Horn And Strobe Sound Switch Settings...................................................................................70

15.3 Horn And Strobe Tone Settings..................................................................................................71

15.4 Horn And Strobe Mechanical Details.........................................................................................72

15.5 Horn And Strobe PCB Detail......................................................................................................73

16 APPENDIX E – Remote with Calibration Fixture..............................................................................73

17 APPENDIX F – Oxygen Sensor Material Safety Data Sheet............................................................74

18 APPENDIX G – Battery Backup........................................................................................................78

18.1.1 Battery Temperature...........................................................................................................78

18.1.2 Battery Testing....................................................................................................................78

18.2 Battery Installation/Replacement...............................................................................................78

Figures

Figure 1 - Oxygen Sensor........................................................................................................................2

Figure 2 - Main Enclosure........................................................................................................................8

Figure 3 - Remote Oxygen Sensor Enclosure.........................................................................................9

Figure 4 - Bottom View 1 Of Series 1300...............................................................................................10

Figure 5 - Bottom View 2 Of Series 1300...............................................................................................11

Figure 6 - Oxygen Sensor......................................................................................................................11

Figure 7 - Local Oxygen Sensor Installation..........................................................................................12

Figure 8 - Local Oxygen Sensor Installation & Wiring...........................................................................13

Figure 9 - Remote Oxygen Sensor Enclosure.......................................................................................14

Figure 10 - Remote Oxygen Sensor Enclosure & PCB.........................................................................15

Figure 11 - Remote Oxygen Sensor.......................................................................................................15

Figure 12 - Horn And Strobe With PCB..................................................................................................17

Figure 13 - Horn And Strobe PCB..........................................................................................................17

Figure 14 - Wiring Horn And Strobes In Series (Daisy Chained)...........................................................18

Figure 15 - Wiring Horn And Strobes Individually..................................................................................19

Figure 16 - Externally Powered Horn And Strobes................................................................................19

Figure 17 - Wiring Horn And Strobes Using A Relay..............................................................................20

Figure 18 - SW1 Detail On Horn And Strobe PCB.................................................................................20

Figure 19 - Three Line Home Screen.....................................................................................................25

Figure 20 - Large Font Home Screen....................................................................................................25

Figure 21 - Main Alert Screens...............................................................................................................26

Figure 22 - Active Alarms Screen...........................................................................................................28

Figure 23 - Modified Active Alarms Screen............................................................................................28

Figure 24 - Alarm Status Screens..........................................................................................................28

Figure 25 - Main Menu Screen...............................................................................................................29

Figure 26 - Setting An Alarm..................................................................................................................30

Figure 27 - Horn And Strobe Detected...................................................................................................33

Figure 28 - Horn And Strobe Removed..................................................................................................33

Figure 29 - Main Menu...........................................................................................................................36

Figure 30 - Main Enclosure Template....................................................................................................66

Figure 31 - Remote Enclosure Template................................................................................................67

Series 1300 Oxygen Deficiency Monitor PAGE v

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

Figure 32 - Horn And Strobe PCB Wiring Diagram................................................................................70

Figure 33 - Horn And Strobe Mechanical Details...................................................................................72

Figure 34 - Horn And Strobe PCB Detail...............................................................................................73

Figure 35 - Remote Oxygen Sensor Enclosure & Optional Calibration Fixture.....................................73

Tables

Table 1 - Power Connections (Terminal Block 1)...................................................................................13

Table 2 - Remote Oxygen Sensor Connections (Terminal Block 1).......................................................14

Table 3 - Horn And Strobe Connections (Terminal Block 1)...................................................................16

Table 4 - Horn And Strobe PCB Switch Settings....................................................................................21

Table 5 - Analog Output Connections.....................................................................................................22

Table 6 - Relay Connections..................................................................................................................22

Table 7 - Fail Safe Logic.........................................................................................................................23

Table 8 - RS232/485 Communications Wiring.......................................................................................23

Table 9 - Alert Screens...........................................................................................................................27

Table 10 - Overview Of Alarm Settings..................................................................................................30

Table 11 - Default Alarm Settings...........................................................................................................31

Table 12 - Alarm Status Screens............................................................................................................32

Table 13 - Analog Output Factory Default Settings................................................................................34

Table 14 - Main Menu.............................................................................................................................38

Table 15 - Data Logger Settings.............................................................................................................43

Table 16 - Miscellaneous Settings..........................................................................................................43

Table 17 - System Information...............................................................................................................44

Table 18 - Battery Backup Minimum Operating Times...........................................................................53

Table 19 - Battery Status Screens..........................................................................................................54

Table 20 - System Messages.................................................................................................................58

Table 21 - Variable Registers.................................................................................................................64

Table 22 - Logger Time / Interval Estimates...........................................................................................65

Table 23 - Logger RS Commands..........................................................................................................65

Table 24 - Horn And Strobe Sound Switch Settings...............................................................................71

PAGE vi Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

1 Overview

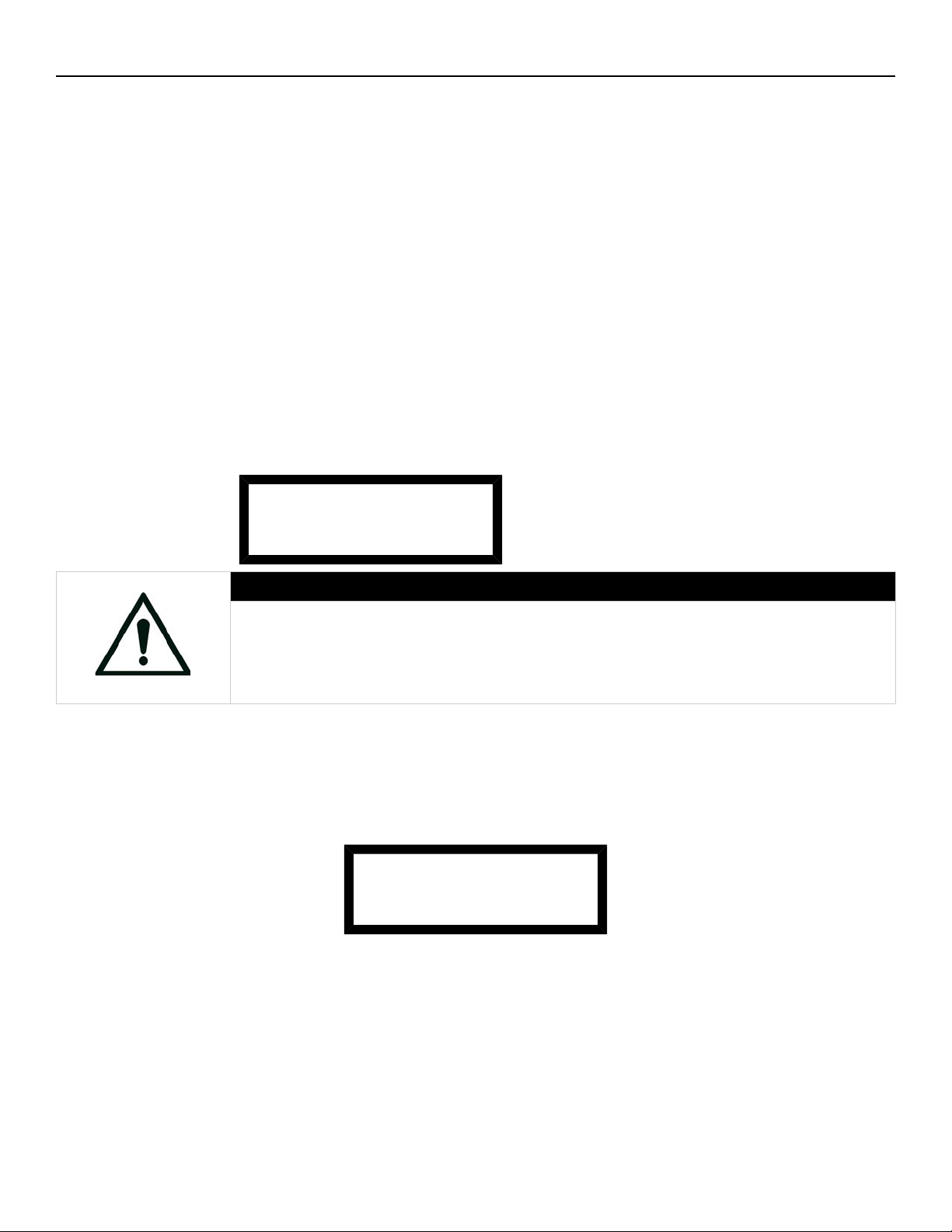

1.1 Explanation Of Graphic Symbols

The information listed below is essential to the proper operation of the monitor. Please review the

following safety precautions prior to using the monitor. Cautionary notes are included throughout this

manual.

WARNING MESSAGE

THIS SYMBOL IS INTENDED TO ALERT THE USER ABOUT GENERAL WARNINGS

AND IMPORTANT OPERATING AND MAINTENANCE INSTRUCTIONS.

WARNING

HAZARDOUS VOLTAGE. CONTACT MAY CAUSE ELECTRIC SHOCK OR BURN.

TURN OFF & LOCK OUT SYSTEM BEFORE SERVICING.

THIS SYMBOL IS INTENDED TO ALERT THE USER TO POTENTIALLY

DANGEROUS SITUATIONS.

1.2 Instrument Description

The Series 1300 Oxygen Deficiency Monitor allows for the simultaneous monitoring of breathing air

oxygen using up to three (3) separate oxygen sensors. For monitoring of a single location, the Series

1300 supports either a “Local Sensor” (located within the main electronics enclosure) or a “Remote

Sensor” (located in a separate remote electronics enclosure). For monitoring of multiple locations, up

to two (2) “Remote Sensors” can be added to the “Local Sensor” for a total of three (3) monitoring

locations. The standard input power to the Series 1300 instrument is 88-264VAC, 47-63Hz (Hertz).

Available power options include 12VDC or 18-36VDC (24VDC) and must be specified at the time of

order placement.

The Series 1300 Oxygen Deficiency Monitor is housed in a NEMA 1 equivalent enclosure rated for

general purpose indoor use. Oxygen values for all sensors are displayed on a 4 line by 20 character

liquid crystal display (LCD) with a total height of 0.81" (20.8 mm). Various display modes are available

that allow for viewing all sensors simultaneously or having the sensor oxygen values cycle in a large

font display mode. The front panel includes a membrane panel with seven buttons that provide

access to the monitor's settings. The monitor is equipped with four alarm relays (see specifications)

which are user configurable and can be set for fail-safe operation. Also included, is a built-in audible

indication of an oxygen alarm condition.

The Series 1300 Oxygen Deficiency Monitor comes equipped with two direct current (DC) analog

outputs. The analog outputs can be independently configured for 0-20mA or 4-20mA. Both are

scalable over the operating range of the monitor. Using a terminating resistor on either of these

outputs will provide an analog voltage up to 5 volts full scale up to a maximum of 1,000 feet.

The Series 1300 Oxygen Deficiency Monitor comes equipped standard with a data-logger and a

serial interface commonly referred to as RS-232. The interface is compatible with EIA/TIA-232E.

Optional addresses from 1 to 32 may be assigned to each monitor for communicating with up to 32

instruments on the RS-2321 or RS-485 bus.

1

The built in standard RS-232 by definition does not allow for more than one instrument on the same physical wires. An

external RS-232 to RS-485 adapter or an “Ethernet Serial server” can be used to allow addressing multiple RS-232 units by

converting the RS-232 signals to an alternate bus.

Series 1300 Oxygen Deficiency Monitor PAGE 1

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

1.2.1 Features

Standard Features:

• Easy to use and configure.

• Capable of monitoring up to three oxygen

sensors simultaneously.

• Automatically senses and configures new

sensors.

• Multiple monitoring screens: detailed or

large font versions.

• Alarm status is clearly displayed on the

screen with pop-up for active alarms

• Scrolling collapsible menu system is easy

to navigate.

• Wide range of configurable settings.

• Any sensor can be assigned to any output.

Standard Features (continued):

• Any Alarm can be assigned to any sensor.

• Any Alarm can activate any combination

of relays, horns, and strobes.

• Isolated digital communications (RS-232

or RS485).

• Built-in data-logger.

Optional Features:

• Battery backup.

• Isolated process outputs.

• Extended memory Data-logger (capable

of almost 4x more logging capacity).

1.3 Mounting

Wall Mount (WMT) is the basic configuration for the Series 1300 Oxygen Deficiency Monitor. All

electrical connections are located on the bottom of the monitor. See APPENDIX A – Main Enclosure

Template on page 66 for detailed dimensional drawings.

1.4 Oxygen Sensor

The Series 1300 Oxygen Deficiency Monitor features an ambient temperature electrochemical sensor

with an Enhanced Electrolyte System (EES). The EES, significantly extends the useful life of the

oxygen sensor as well as providing exceptional measurement stability.

Figure 1 - Oxygen Sensor

PAGE 2 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

1.5 Description Of Optional Equipment

The Series 1300 Oxygen Deficiency Monitor incorporates a host of standard features. For certain

requirements, user's may desire to augment the capabilities of the monitor by ordering the monitor with one or

more available options described below.

1.5.1 Battery Backup P/N 13-BAT

The Battery Backup option provides backup power to the Series 1300 Oxygen Deficiency Monitor during a

temporary loss of main power. Please see section 8 Battery Backup for more information on this option.

1.5.2 RS-485 P/N 13-485

The factory installed RS-485 is an optional upgrade to the factory default of RS-232 and offers the ability to

extend the distance from 50 feet maximum up to 4,000 feet between the monitor and the host system. This

option also provides serial communications (both sending and receiving ) between several monitors up to a

maximum of 32 on one RS-485 three wire communications channel.

1.5.3 Replacement Oxygen Sensor P/N 13-SEN

This option consists of just the sensor (no enclosure or electronics). This option should be ordered in the event

that the sensor is damaged or needs replacement due to end of life.

1.5.4 Remote Mounted Sensor Enclosure P/N 13-RSEN

This option consists of a NEMA 1 (IP 30) remote sensor enclosure containing the oxygen sensor and

associated circuitry used to communicate with the read out electronics. The remote sensors may be added to

the Series 1300 Oxygen Deficiency Monitor in the field by the user. See section 3.3 Remote Oxygen Sensors.

1.5.5 Analog Output Isolation P/N 13-ISO

Installed at the factory, this option provides galvanic isolation of both analog outputs. This eliminates any

potential ground loops when connecting to earth grounded inputs or powering from DC where the power return

could create a ground loop with the output grounds or the input and output grounds are tied to chassis ground.

The isolation also allows for a higher maximum load resistance up to 1200 ohms (24V @ 20mA) as opposed to

the 12V maximum of 300 ohms (6V @ 20mA).

1.5.6 Calibration Fixture P/N 13-CFN

The optional calibration fixture is recommended for checking the calibration of the Series 1300 Oxygen

Deficiency Monitor. Ideally, the source of the calibration gas should be compressed air (clean, dry, and oil free).

Most industrial gas suppliers can provide the compressed air in small hand-held cylinders. The calibration

fixture is designed to easily install over the gas opening of the Series 1300 oxygen sensor making a tight seal.

The fixture is equipped with ¼ inch tube fittings to deliver the compressed air through a 1/4" OD plastic tube

(not supplied). The sample pressure to the fixture should never exceed 1.5 pounds per square inch (PSIG) at a

corresponding sample flow rate of between 0.2 to 1.0 standard cubic feet per hour (SCFH) or 0.1 to 0.5 liters

per minute (LPM).

1.5.7 12VDC Power P/N 13-12V

Allows for a user supplied regulated 12V as the main source of power to the instrument. Minimum power

requirement is 25.2 Watts.

1.5.8 24VDC Power (18 To 36V) P/N 13-24V

Allows for 18 to 36VDC (nominal 24VDC) as the main source of power to the instrument. Minimum power

requirement is 35 Watts.

1.5.9 Extended Logger P/N 13-LOG

Adds almost four times the logging capacity to the existing built in logger. This option is installed at

the factory. Consult factory.

Series 1300 Oxygen Deficiency Monitor PAGE 3

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

1.6 Standard Features

Analog Outputs: (2) DC mA (direct current milliampere) loop outputs.

User selectable for either 0 to 20mA or 4 to 20mA.

User configurable for any oxygen sensor.

Non-isolated Maximum load resistance: 300 ohms max @ 25C

Isolated Option Maximum load resistance: 1200 ohms max @ 25C

Alarm Relays: (4) SPDT (single pole-double throw) Form C contacts rated at:

10 A (250 VAC) / 5A (100 VDC).

Alarms are user configurable for automatic clearing or latching

(requires manual clearing at the instruments panel).

Alarms: (9) individually configurable alarms that can be setup to activate any

relay, any Horn/Strobe combination, and assignable to any sensor.

Each alarm can be configured as either a “high alarm” or a “low alarm”.

Input Power: Universal 90-264 VAC, 47-63 Hz.

12VDC optional and must specify at time of order.

24VDC (18-36VDC) optional and must specify at time of order.

RS

Communications:

Data Logger: 1 to 60 second interval time. Selectable sensors. 0-30% O2 logging.

Audible Alarms: Internal audible alarm rated at 85 decibels at 10 centimeters

Operating

Temperature:

RS-232 Communications standard. Compatible to EIA/TIA-232E. User

selectable baud from 2400 to 115.2k bps. Optional assignable address

from 1 to 32. Maximum of 50 feet from host system to monitor.

Included real time clock allows selectable time stamp.

Individually select which available sensors to log.

Output in easy to graph character separated values (CSV) for

importing into spreadsheets or data visualization programs.

See section Section 5 “Data Logger” for details.

50° to 104°F (10° to 40°C)

0 to 90% relative humidity (RH), non-condensing

1.7 Optional Features

The Series 1300 Oxygen Deficiency Monitor can be ordered with the following options:

Analog Outputs: Isolated, longer driving distance.

Input Power: 12V@25.2W or 24V nominal @35W (18 to 36V).

RS Communications: RS-485 add on to extend the distance from host to monitor from

50 feet to 4000 feet. Also allows for up to 32 monitors on one bus.

Data Logger: Factory installed extended memory for longer logging (almost 4x).

Audible Alarms: Up to 8 horn and strobes (factory ready).

PAGE 4 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

1.8 General Specifications

Measurement Range: Percent Oxygen: 0 to 30%.

Resolution: 0.1%

Sensor Type: Long-life electrochemical sensor (5 years typical).

Accuracy: ±1% of full scale.

Response Time: 90% of full scale in < 20 seconds.

Start Up Time:

(after initial installation)

Calibration Sample Flow Rate: 0.2 to 1.0 standard cubic feet per hour (SCFH)

Calibration: Ambient air or oil-free compressed air.

2

< 1 minute.

0.1 to 0.5 liters per minute (LPM)

Optimum flow using Alpha Omega Instruments

calibration fixture.

Enclosures:

Polycarbonate, equivalent to NEMA 1 (IP 30)

(Main & Remotes)

Main Enclosure Dimensions:

Nominal

10.94 Inches (277.8 mm) – height.

6.3 Inches (160 mm) – width.

3.6 inches (91 mm) – depth.

Remote Enclosure Dimensions:

Nominal

6.2 Inches (158 mm) – height.

5.83 Inches (148 mm) – width.

3.49 inches (89 mm) – depth.

With calibration fixture:

7.3 Inches (158 mm) – height

Sample Delivery: Open diffuser-no pump required.

Display: 4 Line by 20 character LCD.

Remote Sensor Max Distance: Over 1000 feet (305 meters) using 22 AWG wire.

Longer lengths available using larger diameter

wire.

2

General specifications are at standard temperature, pressure, and humidity. Unless specified otherwise.

Series 1300 Oxygen Deficiency Monitor PAGE 5

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

2 Installation

DANGER

POTENTIALLY HAZARDOUS AC VOLTAGES EXIST WITHIN THE INSTRUMENT. IF

NOT AVOIDED, THESE VOLTAGES COULD POTENTIALLY RESULT IN SERIOUS

INJURY OR DEATH. DISCONNECT ALL SOURCES OF POWER AND EXTERNAL

CONNECTIONS BEFORE REMOVING THE COVER TO THE MONITOR.

RISK OF SHOCK

TO AVOID THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THE

SERIES 1300 OXYGEN MONITOR TO RAIN, WATER SPRAY, OR ANY OTHER

LIQUIDS.

2.1 Unpacking The Instrument

Upon opening the shipping container, carefully unpack the instrument to check if the outer surfaces

have been damaged. If so, report the findings immediately to Alpha Omega Instruments who will, in

turn, provide further instructions.

If there is no apparent damage, check the contents to ensure all items were shipped. In some cases,

items may be back ordered.

NOTE: IF DAMAGE HAS BEEN FOUND, DO NOT PROCEED FURTHER, BUT INSTEAD, CONTACT THE

FACTORY.

All damage and shortage claims must be made known to Alpha Omega Instruments within 10 days

after receipt of shipment.

Carefully rotate the monitor and check to make sure no components have been loosened or

dislodged.

If there are any loose or dislodged components (rattling of any kind), contact the factory for further

instructions.

If there is no evidence of loose or dislodged components, the installation procedure can begin.

PAGE 6 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

2.2 Electrical Installation

WARNING

ELECTRICAL INSTALLATION SHOULD BE PERFORMED BY A QUALIFIED

PERSON AND SHOULD COMPLY WITH APPLICABLE FEDERAL, STATE, OR

LOCAL ELECTRICAL SAFETY CODES.

The standard Series 1300 Oxygen Deficiency Monitor accepts a universal AC power input of 90-264

VAC, 47-63 Hz. In this configuration, the unit is shipped with a standard North American power cord

NEMA style 5-15P. The power cord is wired to an AC terminal block labeled “TB1” within the

enclosure. If the installation requires hard wiring, simply replace the power cord with the appropriately

rated wire. Use of #18 AWG is recommended. See section Wiring on page 10.

For DC operation the terminal block labeled “TB1” will still be used, however the labeling will indicate

the configured power.

2.3 Mechanical Configuration

The Series 1300 Oxygen Deficiency Monitor can be configured as a single stand alone enclosure with

a single (local) sensor located within the main enclosure. The sensor is mounted at the bottom of the

main enclosure and is exposed to the surrounding atmosphere the monitor has been installed in.

The Series 1300 Oxygen Deficiency Monitor can also be configured with a Remote Oxygen Sensor

that is housed in it's own separate smaller enclosure. The Series 1300 Oxygen Deficiency Monitor

can accept a maximum of two remote oxygen sensors that can be placed at different locations away

from the main electronics.

The Series 1300 Oxygen Deficiency Monitor main enclosure is fabricated from a polycarbonate

enclosure with a cover that is secured by six (6) screws. Access to the wiring and membrane switch

control panel is available by removing the cover using a standard Philips type screw driver with a #2

style point. Please exercise caution when removing the cover as it is not hinged.

Mounting holes are also accessed by removing the cover. See the following pages for more

information and also APPENDIX A – Main Enclosure Template on page 66 and APPENDIX B –

Remote Enclosure Template on page 67 for mounting templates.

Series 1300 Oxygen Deficiency Monitor PAGE 7

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

2.3.1 Main Enclosure

Figure 2 - Main Enclosure

PAGE 8 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

See section 3 “Wiring“ on page 10 for wiring details.

WARNING

THE SERIES 1300 OXYGEN DEFICIENCY MONITOR AND THE REMOTE OXYGEN

SENSOR ENCLOSURES SHOULD BE KEPT IN THEIR DESIGNED WALL

MOUNTED ORIENTATION WITH THE SENSOR FACING DOWNWARDS.

2.3.2 Remote Oxygen Sensor Enclosure

The Remote Oxygen Sensor enclosure is configured similarly in a polycarbonate enclosure with a

cover secured by four (4) screws. Remove the cover of the Remote Oxygen Sensor enclosure to gain

access to both the printed circuit board connections and the mounting holes. See APPENDIX B –

Remote Enclosure Template on page 67 for a mounting template.

Wiring will be through the strain relief located on the right side of the remote enclosure. See section

3.3 “Remote Oxygen Sensors” on page 14 for details.

Figure 3 - Remote Oxygen Sensor Enclosure

CAUTION

DO NOT OPERATE THE SERIES 1300 OXYGEN DEFICIENCY MONITOR OR THE

REMOTE OXYGEN SENSORS IN ANY POSITION OTHER THAN WITH THE

SENSOR MOUNTED DOWNWARD AS SHOWN. A DIFFERENT ORIENTATION MAY

ADVERSELY AFFECT THE OXYGEN VALUES.

Series 1300 Oxygen Deficiency Monitor PAGE 9

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

3 Wiring

The Series 1300 Oxygen Deficiency Monitor main enclosure is designed to accept a number of inputs

and outputs. Please reference Figure 4 below to wire to the following hardware. Note: Following this

page are detailed instruction for each of the following items:

Oxygen Sensor A single “Local Oxygen Sensor” mounted at the bottom center of the enclosure. This is a

two (2) wire interface located on the left side, inside the main enclosure.

Power AC or DC power via terminal block (TB1). Labeled at the factory. Figure 4 - Bottom View 1

of Series 1300 below Shows the AC version labeled “L”, “N”, and “G” for Line, Neutral, and

Ground respectively. For DC operation these will be “+”, “-”, and “G” respectively.

Remote Sensors One (1) or Two (2) Remote Oxygen Sensors via terminal block TB1, terminals 1 thru 6. See section 3.3

Horn and Strobes Up to eight (8) horn and strobes (where four can be powered directly without external

power supplies) via terminal block TB1, terminals 7 thru 11.

Analog Outputs Removable printed circuit board (PCB) terminal block TB2 See section 3.5

Alarm Relays Removable printed circuit board (PCB) terminal blocks TB3 & TB4 See section 3.6

Digital Communications (RS-232 or RS-485) via terminal block TB1, terminals labeled “T”, “R”, and “G”. See section 3.7

See section 3.1

See section 3.2

See section 3.4

Figure 4 below shows a cut-away view of the internal terminal block TB1.

Figure 4 - Bottom View 1 Of Series 1300

PAGE 10 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

Figure 5 below shows a cut-away line drawing showing the PCB terminal blocks TB2, TB3, and TB4.

Figure 5 - Bottom View 2 Of Series 1300

3.1 Local Oxygen Sensor

If ordered with a Local Oxygen Sensor, the Series 1300 Oxygen Deficiency Monitor will have a large

gland that is centrally located on the bottom of the enclosure as shown above. This hole will be

plugged when the Series 1300 Oxygen Deficiency Monitor is ordered without a Local Oxygen Sensor.

Figure 6 - Oxygen Sensor

Series 1300 Oxygen Deficiency Monitor PAGE 11

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

3.1.1 Local Oxygen Sensor Installation

To install the replaceable local sensor, simply open the front cover and slide the sensor down into the

large gland designed to hold the sensor. Gently tighten the nut while holding the sensor in place from

the top and the bottom at the same time as shown.

Figure 7 - Local Oxygen Sensor Installation

PAGE 12 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

The sensors wired connector should then be pressed together with the mating connector already

supplied inside the main enclosure down at the bottom on the left. The mating connector is in the

form of a cable with a two pin male connection as shown below before and after connection:

Before After

Figure 8 - Local Oxygen Sensor Installation & Wiring

3.2 Power (TB1)

Power the Series 1300 Oxygen Deficiency Monitor by wiring to terminal block TB1. Please Note that

the terminal blocks are color coded. The two primary power connectors are blue and the ground

returns are a yellow/green color.

Universal AC

90-264 VAC, 47-63 Hz.

TB1

LabelACSignal

L Line + Positive (12V) Positive (24V)

N Neutral - Negative (12V Return) Negative (24V Return)

G Ground G Chassis Ground Chassis Ground

TB1

Label

12V

Signal

Table 1 - Power Connections (Terminal Block 1)

DC

24V (18 to 36V)

Signal

Series 1300 Oxygen Deficiency Monitor PAGE 13

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

3.3 Remote Oxygen Sensors

The interface to the “Remote Oxygen Sensor”s are located at terminal block TB1 (Refer to Figure 4)

inside the main enclosure. The Remote Oxygen Sensors are connected using a twisted shielded pair

of wires. The connections within the main electronics enclosure are located on a terminal block

located in the bottom of the enclosure labeled “TB1”. See Table 2 below for reference. Terminals 1-6

are used to connect to the Remote Oxygen Sensors as shown in the table below. These connections

are terminated at the Remote Oxygen Sensor enclosure by means of another terminal block (also

labeled TB1) located within the remote electronics enclosure. See Figure 10 - Remote Oxygen

Sensor Enclosure & PCB.

Connects

from:

Main

Electronics

TB1

Label Signal

1 Shield

2 Positive 2 Positive, source of current loop

3 Return 3 Return, Negative return of current loop

4 Shield

5 Positive 2 Positive, source of current loop

6 Return 3 Return, Negative return of current loop

Connects

to:

Remote

Oxygen

Sensor 1

Remote

Oxygen

Sensor 2

TB1

Label Detail

1 Shield

1 Shield

Table 2 - Remote Oxygen Sensor Connections (Terminal Block 1)

Figure 9 - Remote Oxygen Sensor Enclosure

Inside the Remote Oxygen Sensor enclosure is a PCB as shown in Figure 10 below.

PAGE 14 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

3

TB1

2

1

Figure 10 - Remote Oxygen Sensor Enclosure & PCB Figure 11 - Remote Oxygen Sensor

The sensor is connected to P1 with the red wire towards the edge of the PCB. The connector is a two

(2) pin Molex style. Note that only the “+” and “-” pins are used.

3.3.1 Remote Oxygen Sensor Installation Procedure

Follow the procedure below for connecting the first Remote Oxygen Sensor.

CAUTION

REMOVE ANY POWER FROM THE INSTRUMENT BEFORE PERFORMING ANY

WIRING ON THE MAIN INSTRUMENT OR THE REMOTE OXYGEN SENSOR.

NOTE: For best results it is recommended to use a twisted shielded pair to connect to the Remote

Oxygen Sensors. Using #22 AWG (American Wiring Gauge) will allow distances up to 1000'. Longer

lengths available with larger diameter wire (consult factory). In most cases the proper cable is

specified at time of order and will be supplied by the factory.

Connecting Remote Oxygen Sensor #1 (refer to Table 2 - Remote Oxygen Sensor Connections

(Terminal Block 1) on page 14 above):

1. Connect the SHIELD wire of the twisted pair shielded cable to TB1, terminal 1 of the main

electronics. This wire should terminate at terminal block TB1, terminal 1 inside the Remote Oxygen

Sensor. Make sure all wires are put through the strain relief first.

2. Connect the POSITIVE wire of the twisted pair shielded cable to TB1, terminal 2 of the main

electronics. This wire should terminate at terminal block TB1, terminal 2 inside the Remote Oxygen

Sensor.

3. Connect the RETURN wire of the twisted pair shielded cable to TB1, terminal 3 of the main

electronics. This wire should terminate at terminal block TB1, terminal 3 inside the Remote Oxygen

Sensor.

Series 1300 Oxygen Deficiency Monitor PAGE 15

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

Repeat the above procedure to connect the second Remote Oxygen Sensor if applicable but

substitute the terminals as follows:

1. Connect the SHIELD (TB1, terminal 4) of the main electronics to TB1, terminal 1 inside the 2

Remote Oxygen Sensor.

2. Connect the POSITIVE (TB1, terminal 5) of the main electronics to TB1, terminal 2 inside the 2

Remote Oxygen Sensor

3. Connect THE RETURN (TB1, terminal 6) of the main electronics to TB1, terminal 3 inside the 2

Remote Oxygen Sensor

nd

nd

nd

After connection to the Remote Oxygen Sensor(s) has been completed, power the instrument and

wait for it to initialize. The display should now show each sensor being initialized. Please reference

section 6 “Sensor Setup” on page 47 for more information on setting up the sensor(s).

NOTE: Remote Oxygen Sensors do not need to be connected to the unit sequentially. They will be

detected based on the terminals they are connected to.

3.4 Horn And Strobe

The interface to the Horn and Strobes is located at terminal block TB1 (Refer to Figure 4) inside the

main enclosure. The Series 1300 Oxygen Deficiency Monitor is capable of supporting up to 8 horn and

strobes. The horn and strobes use a 3 wire connection3 consisting of power, ground return, and data.

The connections within the main electronics enclosure are located on a terminal block located in the

bottom of the enclosure labeled “TB1”. See Table 3 below for reference.

Main Enclosure Horn and Strobe PCB

Terminal

Block

TB 1 Signal Name on PCB Detail

7 Shield

8 Shield “SH” Shield

9 Positive “V+” Positive Power (typically 12V)

10 Data “DAT” Data communications line

11 Return “GND” Power Return

Table 3 - Horn And Strobe Connections (Terminal Block 1)

Follow the procedure below for connecting a horn and strobe that will be powered from the Series

1300 Oxygen Deficiency Monitor.

1. Connect the 1st wire of the shielded cable to TB1 terminal 9 (POSITIVE), inside the main enclosure.

Terminate this wire to one of the terminals on the horn and strobe PCB labeled “V+”.

2. Likewise connect the 2nd wire of the shielded cable to TB1 terminal 10 (DATA). Terminate this wire

to one of the terminals on the horn and strobe PCB labeled “DAT”.

3. Connect the 3rd wire of the shielded cable to TB1 terminal 11 (RETURN). Terminate this wire to one

of the terminals on the horn and strobe PCB labeled “GND“.

4. Connect the shield of the shielded cable to TB1 terminal 8 (SHIELD). Terminate this shield to one of

the terminals on the horn and strobe PCB labeled “SH”.

Note: it is only necessary to connect the shield at the horn and strobe PCB when daisy-chaining4. In a

star-point configuration, simply leave it disconnected.

3

Horn and Strobes can be wired directly to the relay contacts using only two (2) wires. The Series 1300 Oxygen Deficiency

Monitor will not be able to warn the user of any disconnect or wiring problem without the use of the “DAT” line.

PAGE 16 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

Follow the same procedure to connect multiple horn and strobe units to the Series 1300. The main

enclosure and the horn and strobe unit both have multiple terminals that can accept more than a

single wire twisted together if necessary. If daisy-chaining, then simply connect to the second set of

terminals supplied on the horn and strobe unit.

When powered from 90-264 VAC, 47-63 Hz., the instruments default DC output power is capable of

driving up to 4 horn and strobes simultaneously. If more than 4 are required, the additional horn and

strobes need to be powered from either an independent DC power source or an upgraded power

supply that can handle the extra horn and strobes. The maximum length of cable for a single horn

and strobe wired with the recommended #18 AWG wire can be up to 1,000 feet away from the main

electronics. However, each additional horn and strobe wired in SERIES (daisy-chained) on the SAME

wire will reduce the maximum length by approximately half. The maximum voltage drop in any single

chain of wire must be less than or equal to 3V. There must be a minimum of 9V at the end of the wire.

CAUTION

THE MAX CABLE CAPACITANCE OF 0.15UF MUST BE ADHERED TO OR THE

HORN AND STROBES MAY NOT WORK CORRECTLY AND/OR CAUSE

UNWANTED BEHAVIOR. PLEASE CONTACT THE FACTORY FOR ANY

APPLICATIONS REQUIRING LONGER LENGTHS.

Figure 12 below shows a horn and strobe and the associated printed circuit board (PCB).

Figure 12 - Horn And Strobe With PCB

3.4.1 Horn And Strobe PCB

The printed circuit board has 8 terminals located on the front edge as shown in Figure 13 - Horn and

Strobe PCB on page 17. The signals are labeled on the board as “DAT” for data, “V+” for positive

power, “GND” for power return, and “SH” for shield. Each signal has two connections to allow daisychaining. If daisy-chaining multiple horn and strobes, the connectors are sized to allow for twisting

two wires together before inserting into the screw terminal.

Figure 13 - Horn And Strobe PCB

4

Daisy-chaining is when another Horn and Strobe is connected to the first in series. As opposed to being connected to the

main enclosure in parallel (or star-point).

Series 1300 Oxygen Deficiency Monitor PAGE 17

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

Series 1300

Optionally wire

up to (4) more.

This requires

external Power

or a higher

rated internal

power supply.

CAUTION

J1 TO J4 SUPPORT A MAXIMUM OF FOUR (4) HORN AND STROBES UNLESS

USING A SPECIAL HIGH POWERED MAIN POWER SUPPLY. NEVER CONNECT

AN EXTERNAL POWER SUPPLY TO THE “V+” TERMINALS.

Note, that if powering the instrument from an external power supply, it is imperative that the power

supplied be sufficient for the number of horn and strobes connected at any given time. (5) or more

horn and strobes will require remote power or a higher wattage upgrade to the internal power supply.

The additional external power needed to handle up to four (4) standard horn and strobes is

approximately 20W. Therefore, using a 45W, 12V power supply would be able to power the Series

1300 Oxygen Deficiency Monitor as well as all eight (8) horn and strobes.

When externally powered, connect only the “DAT” and “GND” terminals back to the main electronics

enclosure. The “V+” terminal can be omitted in this case as it is not powered from the main

electronics. The external power supply connects to “EXT PWR” terminal located on the right hand

side labeled “J5”.

CAUTION

REMOVE POWER BEFORE PERFORMING ANY WIRING ON THE INSTRUMENT

OR HORN AND STROBE(S). IF EQUIPPED WITH BATTERY BACKUP, INSURE THE

BATTERY TERMINAL INSIDE THE MAIN ENCLOSURE IS DISCONNECTED.

3.4.2 Horn And Strobe Daisy Chain Configuration

This configuration shows how the wiring can be configured in a serial fashion or “daisy chain”. The

source wiring comes in on one set of connectors and the next horn and strobe is wired to the other

set of connectors as shown below.

Figure 14 - Wiring Horn And Strobes In Series (Daisy Chained)

As shown above, using four (4) horn and strobes and #18 AWG cable wire, the maximum distance to the last

horn and strobe in the chain is 250 feet.

PAGE 18 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

Series 1300

Series 1300

12V

3.4.3 Horn And Strobe Star Configuration

Shown below is a Series 1300 Oxygen Deficiency Monitor wired to four (4) horn and strobes.

Figure 15 - Wiring Horn And Strobes Individually

As shown above, using four (4) horn and strobes and #18 AWG cable wire, the maximum distance fore each

single horn and strobe is 1,000 feet.

3.4.4 Horn And Strobe External Power

Adding more than four (4) horn and strobes with the standard power supply requires external power.

Shown below is the wiring for externally powered horn and strobes. Note the added 12V power

supply that is connected to a separate connector.

CAUTION

DO NOT CONNECT EXTERNAL POWER TO THE V+ TERMINAL. EXTERNAL

POWER SHOULD ONLY BE APPLIED TO THE “EXT PWR” CONNECTOR

LABELED “J5”

Figure 16 - Externally Powered Horn And Strobes

Wiring of the V+ is optional and shown as a dashed line in the picture.

Series 1300 Oxygen Deficiency Monitor PAGE 19

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

Horn Strobe

12V

Customer

Supplied

Series

1300

ENABLE

1

2

3

4

3.4.5 Horn And Strobe Relay Wiring

The horn and strobe can be wired through any alarm relay as shown. The Horn and Strobe can be

individually enabled by adding a jumper plug where shown labeled “HN” for Horn and “SB” for Strobe.

Placing a jumper on the ENABLE pin(s) – labeled “EN” – will activate that particular output as soon as

power is applied.

NOTE

IT IS NOT NECESSARY TO CONNECT ANY OTHER WIRES IN THE TWO WIRE

RELAY ACTIVATED MODE AS SHOWN BELOW IN FIGURE 17 - WIRING HORN

AND STROBES USING A RELAY.

Figure 17 - Wiring Horn And Strobes Using A Relay

CAUTION

THE SERIES 1300 TWO WIRE CONFIGURATION SHOWN ABOVE DOES NOT

ALLOW FOR THE INSTRUMENT TO ALERT THE USER OF ANY WARNINGS

ASSOCIATED WITH HORN AND STROBES.

3.4.6 Horn And Strobe Switch Settings

SW1 Switch Bank

Each horn and strobe requires a unique address and this address is configured using a DIP style

Figure 18 - SW1 Detail On Horn And Strobe PCB

switch bank labeled “SW1” located on the printed circuit board mounted within the horn and strobe

enclosure. To turn an individual switch “ON”, simply move the switch position away from the text label

“SW1” and towards the text label “ON”. See FIGURE X below and Table 4 below for details on setting

the correct address.

SW1.4 Not Used

SW1.3 Bit 2

SW1.2 Bit 1

SW1.1 Bit 0

PAGE 20 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

SW1 – Horn and Strobe PCB (11751)

SW1.1 SW1.2 SW1.3 Address/Number

OFF OFF OFF 1

ON OFF OFF 2

OFF ON OFF 3

ON ON OFF 4

OFF OFF ON 5

ON OFF ON 6

OFF ON ON 7

ON ON ON 8

Table 4 - Horn And Strobe PCB Switch Settings

CAUTION

EACH HORN AND STROBE UNIT MUST BE SET FOR A DIFFERENT ADDRESS

BEFORE CONNECTING IT TO THE MAIN ENCLOSURE OR AN ERROR WILL

OCCUR AND POSSIBLY SET OFF UNWANTED ALARMS!

All horn and strobes are detected based on the address assigned by the switch settings on each horn

and strobe PCB. Table 4 above shows all the possible configurations and the corresponding

addresses.

After installation of the horn and strobe(s) has been completed, power the instrument and follow the

on screen instructions for enabling the horn and strobes. The system will keep displaying alert

messages until either the horn and strobe is enabled or it's removed. Once all horn and strobes are

enabled, consider setting up the horn and strobe activations under the “Main Menu“. See page 37

under “Activating Alarm Relays and Horn and Strobes“.

3.4.7 Horn And Strobe Maximum Distance

Each single horn and strobe can be up to 1,000 feet away from the main electronics. Any additional

horn and strobe on the same cable reduces the maximum length as shown below.

# of horn and

strobes on a

Configuration

5

Star

single cable

1 450 feet 1000 feet 1800 feet

Daisy Chain 2 200 feet 550 feet 900 feet

Daisy Chain 3 150 feet 350 feet 600 feet

Daisy Chain 4 100 feet 250 feet 450 feet

Note: combinations of the above are acceptable. Example, using #18 AWG cable wire, three (3) horn and

strobes at 350 feet max and one (1) horn and strobe at 1,000 feet will work. The appropriate wire is typically

supplied by the factory based on the customer's application. Using smaller wire diameters will significantly

reduce the wiring lengths. Example, #22 AWG with 4x Horn and Strobes is 100 feet Max.

Cable Wire

Gauge #22

Cable Wire

Gauge #18

Cable Wire

Gauge #16

5

Four (4) separate horn and strobes can be wired at 1000 feet each as long as they are wired in a “Star” configuration where

each cable is connected to a single horn and strobe and is terminated at the main enclosure.

Series 1300 Oxygen Deficiency Monitor PAGE 21

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

3.5 Analog Outputs

Access to the Series 1300 Oxygen Deficiency Monitor's analog outputs and alarm relays is

accomplished through the user interface connectors within the main electronics enclosure. These

connectors are shown in the graphic in Figure 4 on page 10 and are labeled “TB2”, “TB3”, and “TB4”.

Table 5 shows the pin outs and the connections associated with these signals. located on the printed

circuit board.

Terminal

Block Pin Signal Description

TB2

1

Analog

2 Positive

Output 1

3 Shield

4

Analog

5 Positive

Output 2

6 Shield

Return

Return

Table 5 - Analog Output Connections

3.6 Alarm Relays

The Series 1300 Oxygen Deficiency Monitor is equipped with four (4) single pole double throw

(SPDT) relays. To configure the alarm relays, please refer to section 4.4 Alarm System on page 29.

Access to the Series 1300 Oxygen Deficiency Monitor's alarm relays is accomplished through the

user interface connectors within the main electronics enclosure. These connectors are shown in the

graphic in Figure 4 and are labeled “TB2”, “TB3”, and “TB4”. Table 6 below shows the pin outs and

the connections associated with the relays.

Terminal

Block Pin Signal Description

TB3

TB4

1

Relay 1

2 Common Contact

3 Normally Open Contact

4

Relay 2

5 Common Contact

6 Normally Open Contact

1

Relay 3

2 Common Contact

3 Normally Open Contact

4

Relay 4

5 Common Contact

6 Normally Open Contact

Normally Closed Contact

Normally Closed Contact

Normally Closed Contact

Normally Closed Contact

Table 6 - Relay Connections

PAGE 22 Series 1300 Oxygen Deficiency Monitor

ALPHA OMEGA INSTRUMENTS CORP. USER MANUAL

3.6.1 Fail Safe

Fail safe is individually selected for each of the (4) relays. When enabled (“ON”), the relay will be

energized when there is no active alarm associated with the relay. The factory default for fail safe is

“OFF”.

Contacts shorted

for each Active

Alarm Relay

Relay 1

Relay 2

Relay 3

Relay 4

Alarm ON

Fail-safe ON

NC (TB3-1) to COM

(TB3-2)

NC (TB3-4) to COM

(TB3-5)

NC (TB4-1) to COM

(TB4-2)

NC (TB4-4) to COM

(TB4-5)

Fail-safe OFF

(shipped from factory)

NO (TB3-3) to COM

(TB3-2)

NO (TB3-6) to COM

(TB3-5)

NO (TB4-3) to COM

(TB4-2)

NO (TB4-6) to COM

(TB4-5)

Table 7 - Fail Safe Logic

Table 7 illustrates the various wiring configurations for the four alarm relays in the Series 1300

Oxygen Deficiency Monitor based on whether the alarm relays are going to be configured for fail-safe

or non fail-safe operation. Please refer to Relay Fail-safe Operation on page 32.

3.7 RS-232/485 Communications

RS Communications is a three (3) wire interface for both RS-232 and RS-485. Refer to the table

below for wiring.

Terminal

Block

TB 1 Label

T TxD / + RxD / +

R RxD / - TxD / -

G Isolated Ground

Signal

RS-232 / 485

Connects to:

RS-232 / 485

Table 8 - RS232/485 Communications Wiring

Note: If you have an RS485 output and have trouble communicating, try swapping over the input and

output lines. Some are called T+ / T- or maybe A / B. Whatever the case, the communications link will

not work unless these are correct. The COM (or ground) pin MUST be connected to insure proper

communications.

Series 1300 Oxygen Deficiency Monitor PAGE 23

USER MANUAL ALPHA OMEGA INSTRUMENTS CORP.

4 Operation

The Series 1300 Oxygen Deficiency Monitor is ready to be used out of the shipping container. Simply

verify that the proper power is available and wire accordingly (See section 3 Wiring on page 10). The

monitor has been calibrated at the factory and re-calibration is not required at initial start up. When

powering the instrument for the first time, any sensors will be automatically detected and initialized.

This initial detection and initialization will take approximately 30 minutes. This is a one-time

initialization.

4.1 Power ON

The Series 1300 Oxygen Deficiency Monitor has non-volatile flash memory so that all the values set

by the user via the front panel will be maintained. Upon powering the Series 1300 Oxygen Deficiency

Monitor, the monitor will show “BOOTING” on the screen for approximately fifteen (15) seconds then

immediately start to display the oxygen level detected by all attached sensors. This assumes the

instrument has been initialized. When using the data logger, the instrument may pause with a

message “Logger updating” which indicates a power outage while logging. The logger will recover

automatically. The longer the power was interrupted the longer the initialization will be. The first

screen that displays the oxygen values is called the “Home” screen. See sections 4.3.1.1 and 4.3.1.2

starting on page 25.

4.2 Panel Description

The front panel of the Series 1300 Oxygen Deficiency Monitor contains a 4 Line liquid crystal display

(LCD) and seven (7) membrane panel buttons, “STATUS”, “ESCAPE”, UP, DOWN, LEFT, RIGHT,

and “ENTER”. There is an audible indicator located inside one of the strain reliefs on the bottom of

the monitor. The 4 Line LCD display shows the concentration of oxygen in the environment being

measured in terms of percent oxygen and also displays messages or alerts from the microprocessor.

4.3 Navigating The Screens