Series 1000 Oxygen Deficiency Monitor

User Manual

IMPORTANT! SET OXYGEN ALARM VALUES PRIOR TO OPERATION!

Alpha Omega Instruments Corp.

40 Albion Road, Suite 100

Lincoln, RI 02865

Toll Free (US & Canada) 800.262.5977

Tel: 001-401-333-8580

Fax: 001-401-333-5550

Email: salescontact@aoi-corp.com

Website: www.aoi-corp.com

Version 3.4 (1/12)

Alpha Omega Instruments

This page doesn't exist

Alpha Omega Instruments

©

COPYRIGHT 2006-2009. Alpha Omega Instruments Corp. All rights reserved including the right to reproduce

manual or any portion thereof in any form.

WARRANTY

Alpha Omega Instruments Corp. warrants that delivered products are free from defects in material and

workmanship at the time of delivery to the FOB point specified in the purchase order. Liability under this warranty

is limited to repairing or replacing, at Alpha Omega Instruments' option, items which are returned to it prepaid

within three years (including sensor) from the date of shipment and found to Seller’s satisfaction to have been

defective.

Alpha Omega Instrument's three (3) year sensor warranty provides protection for three years from the date of

shipment of the Series 1000 Oxygen Deficiency Monitor. Any sensor from a Series 1000 Oxygen Deficiency

Monitor that fails under normal use must be returned to Seller prepaid and, if such sensor is determined by

Seller to be defective, Seller shall provide Buyer with a replacement sensor. Buyer must provide the serial

number of the monitor from which the sensor has been removed. If a sensor is found to be defective and a new

one issued, the warranty of the replacement sensor(s) shall not extend beyond the initial warranty period of the

Series 1000 Oxygen Deficiency Monitor, or for a period of one year, whichever is longer. After this, all

replacement sensors will be warranted for a period of one year from the date of shipment. In no event shall

Alpha Omega Instruments Corp. be liable for consequential damages.

NO PRODUCT IS WARRANTED AS BEING FIT FOR A PARTICULAR PURPOSE AND THERE IS NO

WARRANTY OF MERCHANTABILITY.

This warranty applies only if:

(i) the items are used solely under the operating conditions and manner recommended in this manual, product

specifications, or other product specific literature;

(ii)

the items have not been misused or abused in any manner or unauthorized repairs were attempted thereon;

(iii) written notice of the failure within the warranty period is forwarded to Alpha Omega Instruments Corp. and

the directions received for properly identifying items returned under warranty are followed;

(iv) the return notice authorizes Alpha Omega Instruments Corp. to examine and disassemble returned products

to the extent the Company deems necessary to ascertain the cause of failure.

The warranties stated herein are exclusive. THERE ARE NO OTHER WARRANTIES, EITHER EXPRESSED

OR IMPLIED, BEYOND THOSE SET FORTH HEREIN, and Alpha Omega Instruments Corp. does not assume

any other obligation or liability in connection with the sale or use of said products.

Disclaimer of Warranty

Alpha Omega Instruments makes no representation or warranties, either expressed or implied, by or with

respect to anything in this manual, including, but not limited to, implied warranties of merchantability or fitness for

a particular purpose. In no event will Alpha Omega Instruments Corp. be liable for any damages, whether direct

or indirect, special, consequential, or incidental arising from the use of this manual. Some states in the USA do

not allow the exclusion of incidental or consequential damages. Alpha Omega Instruments Corp. also reserves

the right to make any changes to improve the performance of its products at any time and without notice.

i

Alpha Omega Instruments

Important Safety Information

The following safety notices appear throughout this manual.

This symbol calls attention to an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

This symbol calls attention to a potentially hazardous situation which, if not avoided, may result in

death or serious injury.

This symbol calls attention to a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury. This symbol may also be used to alert against unsafe practices, potential

damage to the instrument or or loss of data.

To avoid the risk of fire or electric shock, do not expose the Series 1000 Oxygen Deficiency Monitor to

rain or water spray unless the enclosure is rated according to the National Electrical Manufacturer's

Association NEMA 4 (IP66)1 rating.

WHEN POWERED, dangerous voltages within the instrument may be of sufficient magnitude to

constitute a risk of electrical shock resulting in injury or death. Leave all servicing to qualified

personnel. Remove ALL Power sources when installing or removing AC power or data signal

connections and when installing or removing the sensor, or electronics.

1

1 The Series 1000 Oxygen Deficiency Monitor complies with National Electrical Manufacturers

Association (NEMA) and IP"XX" European IEC specifications 144 & 529.

ii

Alpha Omega Instruments

RF Disclaimer

This instrument generates and uses small amounts of radio frequency energy, and there may be

interference in a particular installation. If this equipment causes interference to radio or television

reception, try to correct the interference by one of more of the following steps:

1. Reorient the receiving antenna.

2. Relocate the instrument with respect to the receiver.

3. Change the AC outlet of the instrument so the instrument and receiver are on different branch

circuits.

iii

Alpha Omega Instruments

Table of Contents

Important Safety Information.............................................................................................................iii

RF Disclaimer .....................................................................................................................................iv

1 Overview............................................................................................................................................1

1.1 The Series 1000 Oxygen Deficiency Monitor.............................................................................1

1.2 Options and Accessories............................................................................................................2

1.2.1 Battery Backup Option........................................................................................................2

1.2.2 RS-232C Option ................................................................................................................2

1.2.3 RS-485 Option....................................................................................................................2

1.2.4 Remote Mounted Sensor Option........................................................................................3

1.3 Calibration Tool Accessory.........................................................................................................3

1.4 General Specifications...............................................................................................................4

2 Installation.........................................................................................................................................5

2.1 Unpacking the Instrument..........................................................................................................5

2.2 Electrical Installation..................................................................................................................5

2.2.1 Power Source and Line Voltage Setting..............................................................................5

2.2.2 Wiring the AC/DC Power ....................................................................................................6

2.2.3 Wiring the Oxygen Sensor..................................................................................................8

2.2.4 Wiring Alarm Relays...........................................................................................................8

2.2.5 Wiring 4-20 mADC and 0-2 VDC Outputs...........................................................................9

2.2.6 Wiring to the Optional RS-232C or RS-485 Outputs.........................................................10

3 System Description........................................................................................................................11

3.1 Extended Life Electrochemical Sensor ....................................................................................11

3.2 Electronic Data Processing .....................................................................................................12

3.3 Digital Control Center (DCC)....................................................................................................12

3.3.1 Alarms...............................................................................................................................13

3.4 On Board Switch Settings .......................................................................................................14

3.4.1 Fail-Safe Operation ..........................................................................................................14

3.4.2 Alarm 3 Settings ...............................................................................................................14

4 Operation.........................................................................................................................................15

4.1 Preparing for Operation............................................................................................................15

4.2 Selecting AC Voltage...............................................................................................................15

4.2.1 Changing the Voltage Inputs - S2 Jumpers.......................................................................16

4.3 Installing the Monitor................................................................................................................16

4.3.1 Mounting the Monitor on a Wall........................................................................................16

4.4 Operating the Instrument.........................................................................................................16

4.4.1 Power ON........................................................................................................................16

4.4.2 Cold Boot .........................................................................................................................16

4.4.3 Warm Boot........................................................................................................................17

4.5 Battery Backup.........................................................................................................................17

4.6 Operator Controls....................................................................................................................17

4.6.1 Liquid Crystal Display.......................................................................................................17

4.6.2 Oxygen Alarms.................................................................................................................18

4.6.3 Setting the Alarms.............................................................................................................18

4.6.4 Alarm Processing..............................................................................................................18

4.6.4.1 Auto-Clear Operation................................................................................................19

4.6.4.2 Manual Clear Operation...........................................................................................19

iv

Alpha Omega Instruments

4.6.4.3 Timing Out................................................................................................................19

5 Calibrating the Series 1000 Oxygen Deficiency Monitor.............................................................20

5.1 High Altitude Calibration...........................................................................................................20

5.2 Routine Calibration..................................................................................................................20

5.2.1 Calibration with Ambient Air..............................................................................................21

5.2.2 Calibration With Other Gasses.........................................................................................21

5.3 Performing an Initial and/or Routine Calibration Check............................................................21

5.4 Calibration on Ambient Air........................................................................................................22

5.4.1 Calibration Cup (Optional Calibration Tool).......................................................................22

5.4.2 Calibrating from a Gas Cylinder - Effect of Moisture on Calibration .................................23

6 Replacing the Oxygen Sensor ......................................................................................................25

6.1 Replacing the Oxygen Sensor.................................................................................................25

7 Configuring the Optional Remote Sensor.....................................................................................26

8 RS-232C Serial Communications ................................................................................................29

8.1 Baud Rates.............................................................................................................................29

8.2 Standard Commands...............................................................................................................30

8.2.1 'A' Command - Alarm set point with low or high alarm option............................................30

8.2.2 'B' Command - Baud change............................................................................................31

8.2.3 'C' Command....................................................................................................................31

8.2.4 'D' Command ...................................................................................................................32

8.2.5 'E' Command - Enable security with optional passcode....................................................32

8.2.6 'FS' Command - Fail-safe select.......................................................................................32

8.2.7 'H' Command - Help Screen.............................................................................................33

8.2.8 'M' Command - Manually clear all alarms toggle...............................................................33

8.2.9 'O' Command - Output Oxygen Concentration..................................................................34

8.2.10 'Q' Command - Quiet mode (disables the audible alarm)................................................34

8.2.11 'S' Command - Signal mode (enables the audible alarm)................................................34

8.2.12 'V' Command - View current alarms and settings............................................................34

8.3 RS232/485 Connections......................................................................................................35

9 RS-485 - Enhanced Remote Control Command.......................................................................... 36

9.1 RS-485 Protocol......................................................................................................................36

9.2 Enhanced Command Descriptions...........................................................................................37

9.2.1 '\G' Command - Global Set command...............................................................................37

9.2.2 'L' Command - Local name assignment............................................................................39

9.2.3 '\M' Command...................................................................................................................40

9.2.4 “\O' Command - Output Oxygen Concentration................................................................40

9.2.5 '\Q' Command - Quiet Mode select...................................................................................40

9.2.6 '\S' Command - Signal Mode select..................................................................................40

9.2.7 '\U' Command - Use command.........................................................................................40

9.2.8 '\V' Command - View settings...........................................................................................41

10 Internal Data Logger.....................................................................................................................42

10.1 Data Logger Maintenance......................................................................................................42

10.1.1 Replacing the Data Logger Battery.................................................................................42

10.2 Data Logger Software............................................................................................................43

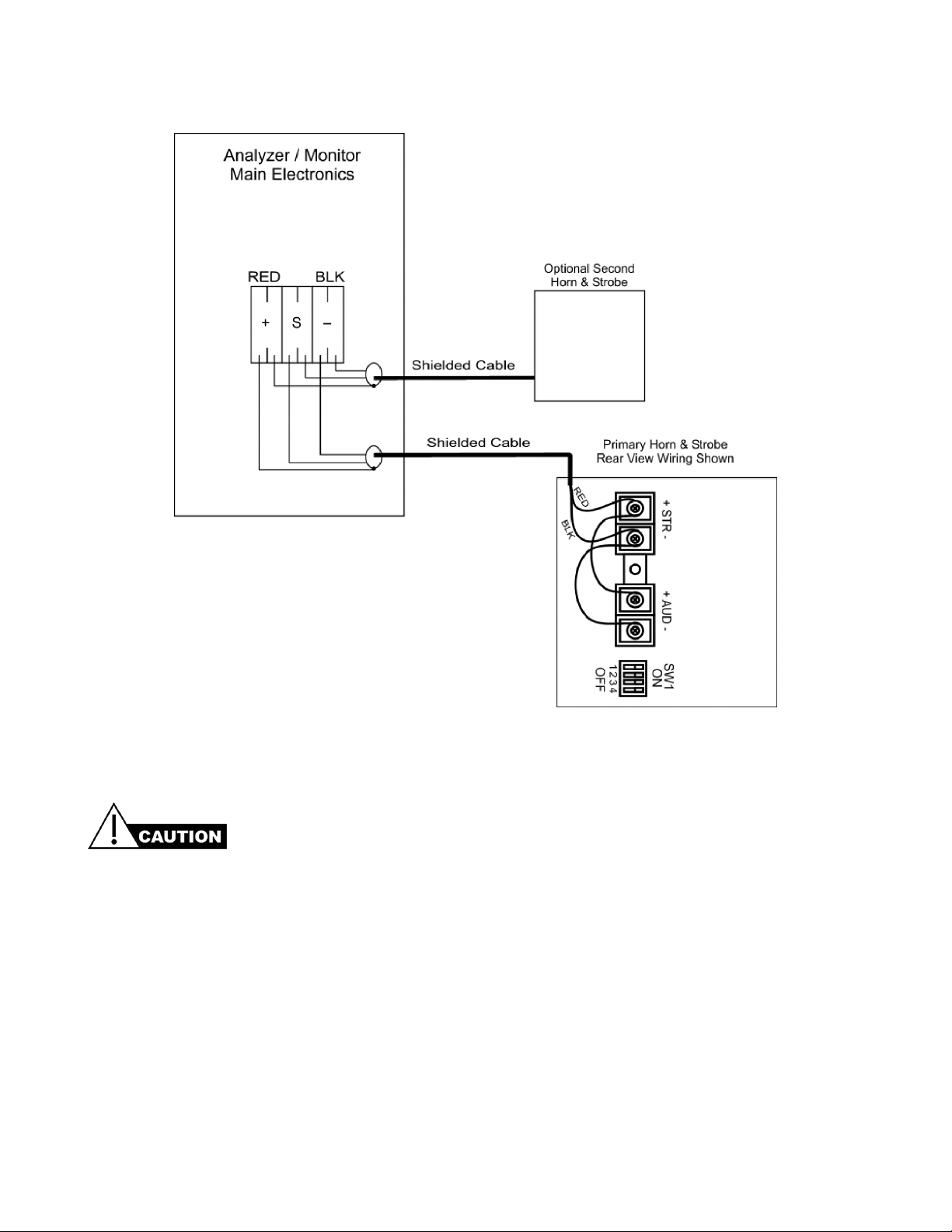

11 Optional 24 VDC Horn/Strobe Alarm...........................................................................................44

11.1 Installation and Wiring............................................................................................................44

11.1.1 Installation.......................................................................................................................44

11.2 Setting the dBA Sound Level..................................................................................................46

v

Alpha Omega Instruments

11.2.1 Selecting the Sound Pattern for the Audible Signal.........................................................47

12 Optional 115 VAC Horn/Strobe Alarm..........................................................................................48

12.1 Installation and Wiring............................................................................................................48

12.1.1 Installation......................................................................................................................49

12.2 Setting the dBA Sound Level.................................................................................................51

12.3 Selecting the Sound Pattern for the Audible Signal................................................................51

Appendix A - ISEN Oxygen Sensor – Material Safety Data Sheet..................................................52

Appendix B - Nickle Hydride Battery Material Safety Data Sheet..................................................57

Appendix C- Effects of Different Oxygen Levels on Humans.........................................................59

vi

Alpha Omega Instruments

1 Overview

1.1 The Series 1000 Oxygen Deficiency Monitor

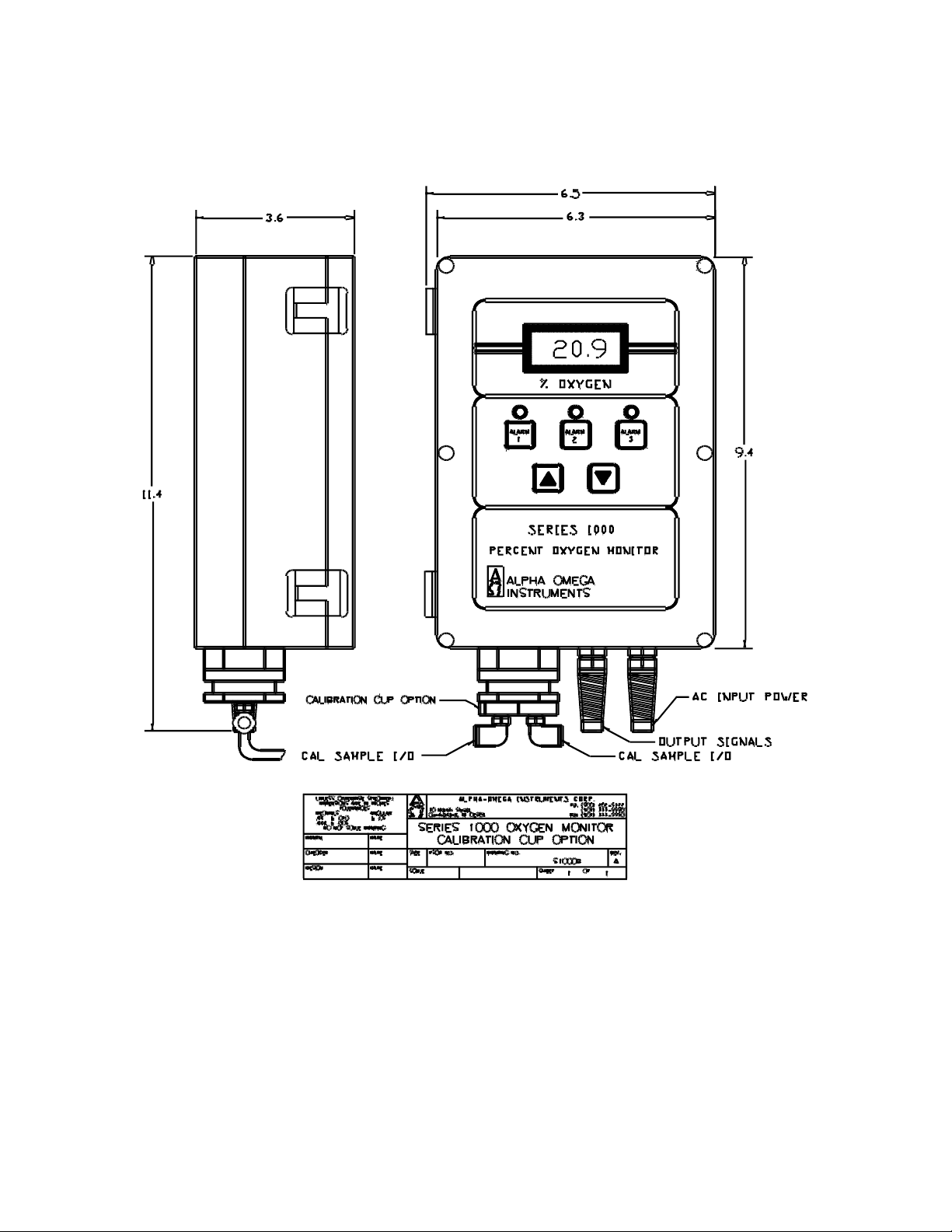

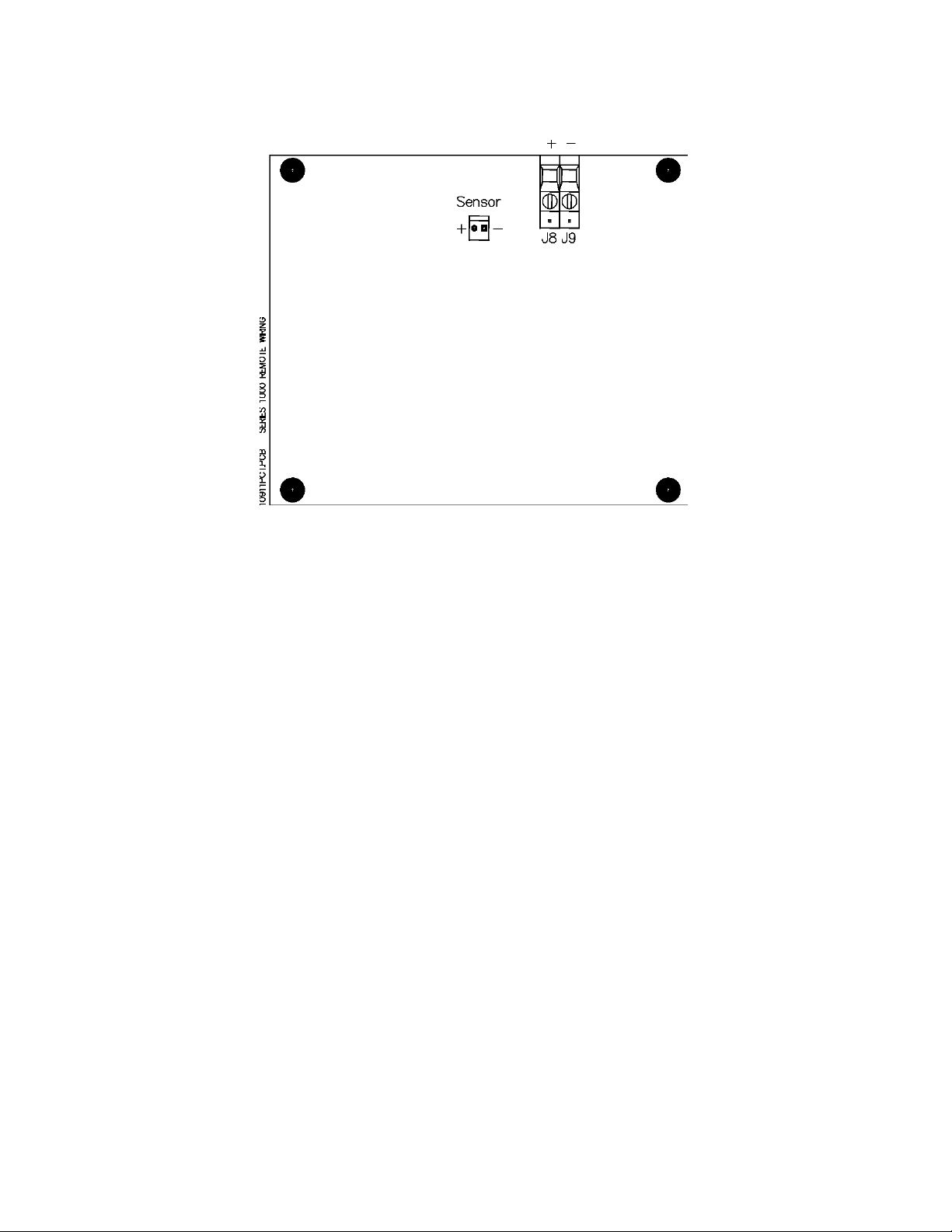

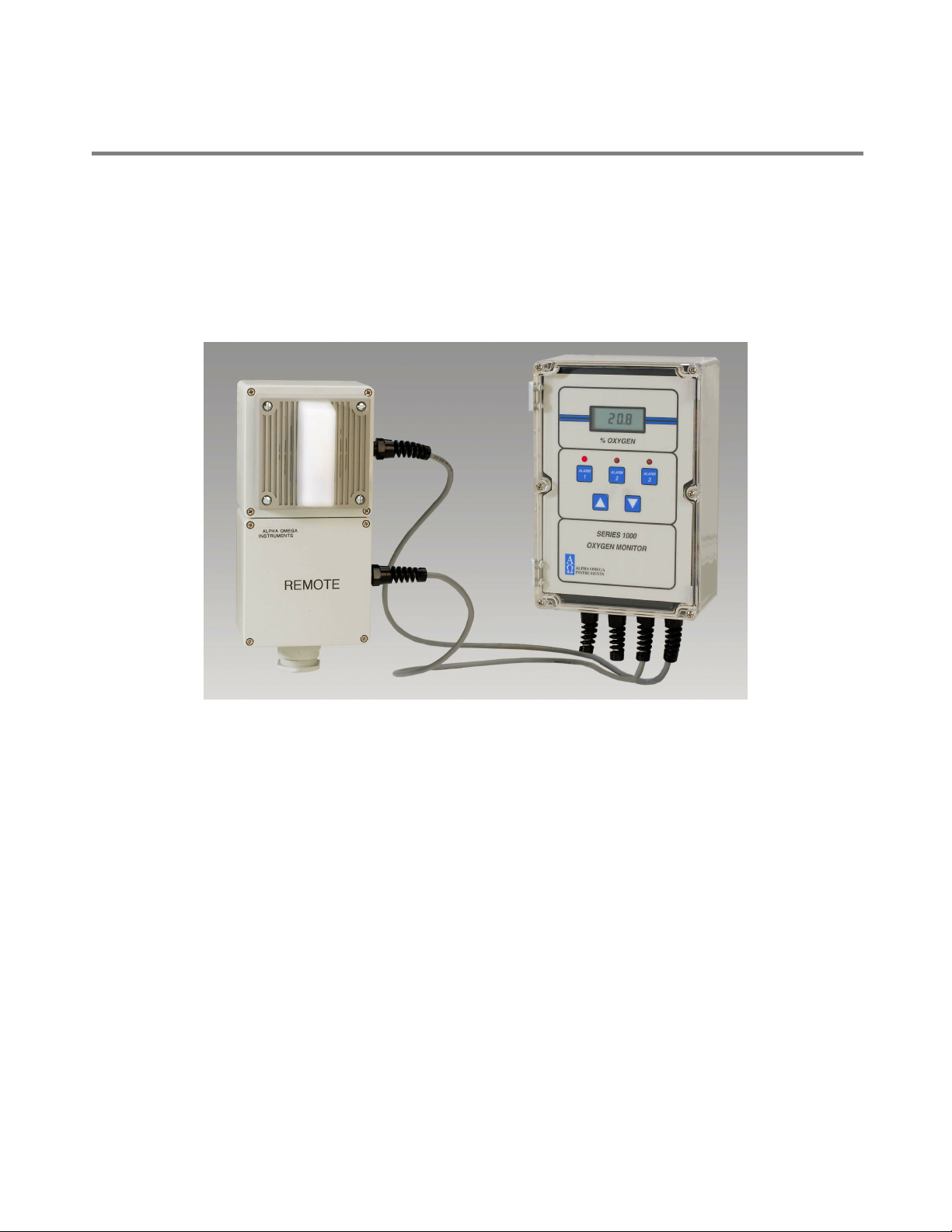

Figure 1-1. The Series 1000 Oxygen Monitor

The Series 1000 Oxygen Deficiency Monitor is a microprocessor controlled instrument with a range of

0-30% . Figure 1-1 shows the standard Series 1000 Oxygen Deficiency Monitor (sensor mounted

integral with electronics).

The microprocessor-controlled instrument includes the following features:

• AC or DC power - 115/230 VAC, 50-60Hz, or with an 18-32 VDC input. Battery backup is

optional (for AC powered instruments only).

• Easy to read liquid crystal display (LCD)

• Polycarbonate enclosure rated general purpose NEMA 1 (IP 30), and watertight, NEMA 4X (IP

66) when used with a NEMA 1 (IP 30) remote sensor enclosure. The optional remote sensor

enclosure can be mounted hundreds of feet from the monitor.

• Easy installation – Holes in the corners of the molded enclosure facilitate installation.

Series 1000 Oxygen Deficiency Monitor Page 1

Alpha Omega Instruments

• Alarm Relays - The instrument is equipped with three oxygen alarm relays and one status

alarm relay. All four relays are Form C (SPDT) types rated at 10 amps at 115/230 VAC and 30

VDC. The relays are user configurable for Fail-safe operation.

• Audible Alarms – The Series 1000 Oxygen Deficiency Monitor has a built-in audible alarm (80

dB) and three red LED's for visual notification of an oxygen alarm condition. Operators can

cancel the audible at any time.

• Standard Analog Outputs - The Series 1000 Oxygen Deficiency Monitor has two standard

analog outputs, 4-20 mADC and 0-2 VDC.

• The Series 1000 Oxygen Deficiency Monitor can also be equipped with optional RS-232C

(maximum transmission distance 50 feet) or RS-485 serial communications for distances of

over 1000 feet.

1.2 Options and Accessories

This section describes available options for the Series 1000 Oxygen Deficiency Monitor.

1.2.1 Battery Backup Option

The factory-installed battery backup option provides backup power to the Series 1000 Oxygen

Deficiency Monitor during a temporary loss of line power. With the backup option installed, the Series

1000 Oxygen Deficiency Monitor will operate for at least 30 minutes under worse case conditions (i.e.

All 4 alarms energized, LED's on, annunciator operating, etc.).

Important: Re-charge batteries 16 hours before initial startup. Batteries are disconnected for

shipment.

The battery pack consists of Nickel Metal Hydride batteries maintained on a trickle charge.

NEVER USE THE BATTERY BACKUP OPTION WHEN THE INSTRUMENT IS POWERED FROM

DC. THIS WILL CAUSE THE BATTERIES TO OVERCHARGE, WHICH MAY CAUSE THE

BATTERIES TO EXPLODE. MAKE SURE ALL WIRING (ALARMS, REMOTE SENSOR, RS-232C,

ETC.) IS COMPLETE BEFORE APPLYING POWER TO THE INSTRUMENT.

1.2.2 RS-232C Option

The factory-installed RS-232C option provides serial communications between the Series 1000

Oxygen Deficiency Monitor and a host system. The maximum distance between monitor and host is

50 feet.

1.2.3 RS-485 Option

The factory-installed RS-485 option provides serial communications between one or several monitors

Series 1000 Oxygen Deficiency Monitor Page 2

Alpha Omega Instruments

and a host system over the same communications channel. The RS-485 format allows both sending

and receiving of signals over distances greater than 50 feet from the host. The maximum distance

recommended between devices is 4,000 feet.

1.2.4 Remote Mounted Sensor Option

This option consists of a factory installed NEMA 1 (IP 30) remote sensor enclosure containing the

oxygen sensor and associated circuitry used to communicate with the read out electronics. When the

remote mounted sensor option is used, the rating for the Series 1000 Oxygen Deficiency Monitor

changes from general purpose, NEMA 1 (IP 30) to NEMA 4X (IP 66) which qualifies it as watertight.

When using the monitor with a battery pack, make sure that all wiring (alarms, remote sensor,

RS-232C, etc.) is complete before applying AC, DC, or battery power to the instrument.

DO NOT USE 24 VDC AS THE SOURCE OF PRIMARY POWER WITH THE BATTERY PACK. THIS

WILL CAUSE THE BATTERIES TO OVERCHARGE WHICH CAN CAUSE THE BATTERIES TO

EXPLODE.

1.3 Calibration Tool Accessory

The optional Calibration Tool is required for calibrating the monitor with gases other than ambient air,

particuarly if there is suspicion that the oxygen concentration in air may be tainted by other gases. The

Calibration Tool contains a tube fitting to deliver the gas, and is designed for low flow conditions (flow

rates of 0.5 to 1.0 liters/minute). The tool attaches to the sensor boss mount to provide a gas tight

inlet.

Series 1000 Oxygen Deficiency Monitor Page 3

Alpha Omega Instruments

1.4 General Specifications

Measurement Range

Accuracy

Sensor Type

Temperature Compensation

Response Time

Sensor Inputs

Sensor Mounting

Display

Input Power

Standard Outputs

Optional Digital Interfaces

Audible Alarm

Audible Alarm Cancel

Oxygen Alarm Relays

Instrument Status Alarm Relay

Open 4-20 mA loop status Alarm

Operating Temperature/Humidity

Electronics Control Unit

Control Unit Dimensions

Optional Remote Sensor Enclosure

Remote Sensor Enclosure

Dimensions

Weight (Control Unit)

Weight (Sensor)

0-30% Oxygen.

±1% of full scale.

Extended Life Electrochemical Sensor.

Standard.

90% of full scale response in <20 seconds.

One.

Either in the electronics enclosure or remotely.

10.2 mm (0.4") high, 4-1/2 digit liquid crystal display.

Resolution 0.1% oxygen.

115/230 VAC, 50-60Hz or 18-32 VDC. Battery backup is

optional for AC powered instruments only.

4-20 mADC and 0-2 VDC.

RS-232C or RS-485 (factory installed).

Internal buzzer (approximately 80dB).

Front panel.

Three (3) SPDT Form C contacts rated 10 A @ 30V

DC/115/230 VAC. Alarm clearing is user configurable for

either manual or automatic.

1 SPDT Form C rated identical to above.

Open collector (drain) output at terminal #10.

5º to 40ºC (40º to 104ºF) and up to 99% (non

condensing).

Light gray polycarbonate with a hinged clear front cover

rated NEMA 1 (IP 30). Available in NEMA 4X (IP 66) with

optional NEMA 1 remote sensor.

239.8 mm (9.44 in.) length, 159.8 mm (6.29 in.) width,

89.9 mm (3.54 in.) height.

Light gray polycarbonate rated NEMA 1 (IP 30).

119.9 mm (4.72 in.) length, 79.8 mm (3.14 in.) width, 84.8

mm (3.34 in.) height.

4.08 kg. (9lbs)

<0.45 kg (<1 lb)

Series 1000 Oxygen Deficiency Monitor Page 4

Alpha Omega Instruments

2 Installation

This chapter describes how to unpack the instrument and perform electrical wiring for power and

monitor options.

2.1 Unpacking the Instrument

To Unpack the Instrument:

1. Carefully remove the instrument from the shipping container and check the outer surfaces for

any damage. Report any damage to Alpha Omega Instruments.

2. Check to make sure all items were shipped. Some items may have been backordered and will

be so noted on the packing slip.

IMPORTANT: Report all damage and missing items to Alpha Omega Instruments within ten

(10) days after receipt of shipment.

3. Locate the screws that attach the clear cover to the polycarbonate enclosure. Loosen the

screws, disengage them, and open the cover to expose the front panel membrane switches.

4. The membrane panel is installed on a hinged metal backing plate that swings out in the same

direction as the cover. Swing out the membrane panel and check for loose or dislodged

components.

NOTE: If there are loose or dislodged components, notify the factory for further instructions.

If all is found to be satisfactory, the installation procedure can begin.

2.2 Electrical Installation

A CERTIFIED ELECTRICIAN SHOULD PERFORM ALL ELECTRICAL INSTALLATION.

ELECTRICAL INSTALLATION MUST COMPLY WITH APPLICABLE FEDERAL, STATE, OR

LOCAL ELECTRICAL SAFETY CODES.

2.2.1 Power Source and Line Voltage Setting

The Series 1000 Oxygen Deficiency Monitor can be powered by a three wire power line cord (included

with shipment) or a conduit into the electrical hub at the bottom of the electronic control unit (conduit

holes can be provided and must be specified at the time of order placement to include diameter size).

Jumper S2 on the printed circuit board determines the line voltage setting. The default setting is for

115 VAC, 50-60Hz operation. If the AC input voltage is changed in the field, please refer to Section

4.2 for instructions.

Series 1000 Oxygen Deficiency Monitor Page 5

Alpha Omega Instruments

2.2.2 Wiring the AC/DC Power

Each connector is equipped with a screw terminal wire holder to facilitate insertion or removal of the

wire from the connector.

To wire the AC/DC Power:

1. Locate the AC Power Terminals - 31, 32, and 33 (refer to Figure 2-1.)

2. Strip away approximately 6.0 mm (1/4 inch) of insulation from each of the three conductors and

then connect AC line, AC neutral, and chassis ground to each connector.

3. Tighten each screw by turning it clockwise to securely fasten each conductor.

4. If the primary power to the instrument is direct current (DC), wire to terminals 29 (BAT+) and 30

(-).

MAKE SURE ALL WIRING (ALARMS, REMOTE SENSOR, RS-232C, ETC.) IS COMPLETE

BEFORE APPLYING ANY POWER TO THE INSTRUMENT.

DO NOT USE 24 VDC AS THE PRIMARY POWER SOURCE WITH THE BATTERY PACK. THIS

CAUSES OVERCHARGING, WHICH MAY CAUSE BATTERIES TO EXPLODE.

Series 1000 Oxygen Deficiency Monitor Page 6

Alpha Omega Instruments

Figure 2-1: Printed Circuit Board

Series 1000 Oxygen Deficiency Monitor Page 7

Alpha Omega Instruments

2.2.3 Wiring the Oxygen Sensor

Oxygen sensor wiring is done at the factory. Refer to section 6.1 Replacing the Oxygen Sensor

regarding how to replace the oxygen sensor.

2.2.4 Wiring Alarm Relays

The Series 1000 Oxygen Deficiency Monitor is equipped with four single pole double throw (SPDT)

Form C contacts rated at 10 amperes @ 30 VDC and 115/230 VAC. All alarm relays are user

configurable with the three oxygen alarms defaulting to factory setting of low oxygen alarms. To

configure any of the three oxygen alarms to be high, see Section 3.4.2 . As a reminder, Alarm 4

which is not displayed as a discrete alarm on the front panel, is the instrument status alarm.

Signal cabling provides access to the control signals generated by the Series 1000 Monitor. The

number of conductors required depends on the number of functions to be monitored.

The technique for wiring to the connectors is identical to that discussed in Section 2.2.2 . The wiring

configuration is as follows:

Terminal Alarm 1 Relay

26 Common Contact

27 Normally Open Contact

28 Normally Closed Contact

Alarm 2 Relay

23 Common Contact

24 Normally Open Contact

25 Normally Closed Contact

Alarm 3 Relay

20 Common Contact

21 Normally Open Contact

22 Normally Closed Contact

Instrument Status Alarm

17 Common Contact

18 Normally Open Contact

19 Normally Closed Contact

Series 1000 Oxygen Deficiency Monitor Page 8

Alpha Omega Instruments

The following table shows wiring configurations for the Series 1000 Oxygen Deficiency Monitor alarms

in both fail-safe and non-fail-safe modes.

Alarm ON

Contacts

shorted for

each Alarm

Fail-safe ON Fail-safe OFF

Relay

High or Low O

Alarm1 /

Relay 1

2

28(NC) to

26(COM)

27(NO) to

26(COM)

High or Low O

Alarm2 /

Relay 2

High or Low O

Alarm3 /

Relay 3

Low Battery or

Instrument

Status/ Relay 4

2

2

25(NC) to

23(COM)

22(NC) to

20(COM)

19(NC) to

17(COM)

24(NO) to

23(COM)

21(NO) to

20(COM)

18(NO) to

17(COM)

To configure the fail-safe or non-fail safe modes, use the DIP switch on the main printed circuit board

(refer to Figure 2-1).

If the instrument is equipped with optional RS-232C or RS-485 communications, the alarms can be

controlled via these comm ports. See the caution note below.

CAUTION:

SHORT THE 4-20MA DC OUTPUT IF NOT IN USE TO AVOID AN OPEN LOOP WARNING VIA

TERMINAL 10 (B-LO)

2.2.5 Wiring 4-20 mADC and 0-2 VDC Outputs

The Series 1000 Oxygen Deficiency Monitor has two standard linear outputs, 4-20 mADC and 0-2

VDC over the instrument's range of 0-30% oxygen. The outputs can be measured simultaneously.

• To wire for the 4-20 mA DC output, wire to terminals 12 (4-20) and 13 (AGND).

• To wire for the 0-2 VDC output, wire to terminals 8 (positive {labeled DAC}) and 9

(negative{labeled AGND}).

Terminals are located on the right side of the printed circuit board (refer to 2-1.)

Note: If a jumper wire is in place between Terminals 12 and 13, remove the jumper wire prior to

using the 4-20 mADC output.

Series 1000 Oxygen Deficiency Monitor Page 9

Alpha Omega Instruments

2.2.6 Wiring to the Optional RS-232C or RS-485 Outputs

The RS-232C and RS-485 options provide serial communications for remote operation and networked

instruments. The monitor can be ordered with either option, but not both.

To wire for either the RS-232C or RS-485, use terminals 14 (TXD) for transmit and 15 (RXD) for

receive. Refer to Chapters 8 and 9 for more information about these options.

Series 1000 Oxygen Deficiency Monitor Page 10

Alpha Omega Instruments

3 System Description

3.1 Extended Life Electrochemical Sensor

The extended life sensor is a lead-oxygen battery that uses a weak acid electrolyte system that

retards passivation of the sensor anode by allowing the products of oxidation to dissolve in the acid

electrolyte. The weak acid electrolyte tolerates over 20 times more lead oxide (PbO) than potassium

hydroxide (KOH) based sensors, renewing the sensor continuously, thereby extending the useful life

of the sensor.

The extended life sensor consists of a lead anode, gold cathode, and a weak acid electrolyte. A gold

electrode is bonded onto a non-porous Teflon® (FEP) membrane. A small amount of oxygen

permeates the membrane and is electrochemically reduced at the gold electrode. A resistor and a

thermistor (for temperature compensation) connects the cathode and anode.

Current flowing through the resistor and thermistor is proportional to the oxygen concentration of the

gas in contact with the Teflon® membrane. The system determines oxygen concentration by

measuring the voltage between the resistor and the thermistor. The two electrode reactions are shown

below:

Cathode: O2 + 4H+ + 4e

Anode: 2Pb + 2H2O

Overall: O2 + 2Pb

The surface of the lead anode is continuously renewed because lead oxide (PbO) is dissolved into the

electrolyte. Since lead oxide generated at the anode is dissolved rather than remaining on the anode,

the output voltage does not decrease.

Lead oxide (PbO) has a maximum solubility level in the weak acid electrolyte. When the electrolyte

becomes saturated with PbO, the sensitivity of the sensor will begin to drop. The system detects this

and notifies the operator that the sensor must be replaced.

In ambient air monitoring applications, carbon dioxide (CO2) that is present will not adversely affect

the sensor's performance. Due to the weak acid electrolyte, CO2 will not react with the electrolyte to

form potassium carbonate as it does with KOH based sensors. As a result, there is no loss in output

due to the presence of CO2.

→

→

→

2H2O

2PbO + 4H+ + 4e

2PbO

Series 1000 Oxygen Deficiency Monitor Page 11

Alpha Omega Instruments

3.2 Electronic Data Processing

Figure 3-1 shown below is a simplified block diagram of the electronics measuring and display systme

for the series 1000 Oxygen Monitor.

Figure 3-1: Electronics Control System

3.3 Digital Control Center (DCC)

The microprocessor-based DCC interfaces with all the inputs and outputs of the system as follows:

• The millivolt output from the oxygen sensor is applied to the input of a buffer amplifier. The

buffer amplifier prevents loading on the sensor and produces a low impedance signal

proportional to the sensor output to the 12 bit analog-to-digital converter input.

• The analog-to-digital converter forms a binary representation of the sensor output for use by

the DCC in all of its decision making functions, and for controlling its outputs. The DCC

processes the sensor input data according to operator inputs as follows:

• The switch bank (SW-6) on the printed circuit board controls the fail-safe condition of

the output alarm relays.

Series 1000 Oxygen Deficiency Monitor Page 12

Alpha Omega Instruments

• The front panel keyboard switches provide controls for adjusting up to three oxygen

level alarm points.

• The optional RS-232C or RS-485 serial interface provides system controls over a network.

• The EPROM (Erasable Programmable Read Only Memory) stores input variables, such as

alarm set points, in a battery backed RAM (Random Access Memory). This RAM stores the

operator-selected alarm set points when power is restored should an AC power outage occur.

• Two analog outputs controlled by the DCC are directly proportional to the sensor output. The

first analog output is an analog voltage output of 0 to 2 VDC, from the digital to analog

converter, over the range of 0 to 30% oxygen. A second analog output tracks the 0 to 2 VDC

output to produce a self-powered 4 to 20 milliamp loop for external data logging and

monitoring. Loop resistance, including wiring, can be as high as 800 ohms even when

operating with the optional Battery Backup. Since the 4 to 20 milliamp loop output chip will

alarm the DCC if an open loop condition exists, this functions connectors must be shorted if

not used.

• A liquid crystal display (LCD) displays the oxygen values over the range of 0 to 30%. The

display also provides operator feedback for setting alarm points and calibrating the monitor.

• An annunciator, also controlled by the DCC, provides audible feedback to the operator

• Three light emitting diodes (LED's) provide visible feedback for system operation.

3.3.1 Alarms

The instrument's audible and visual alarms alert the operator of alarm conditions. The alarm system

consists of:

• Four Form C isolated single pole double throw (SPDT) relays for maximum user flexibility.

• An LED and annunciator for visual and audible alerts. The front panel display and Relay 4

indicate a change in sensor condition and produce an audible alarm.

• If the Series 1000 is equipped with optional battery backup, the sensor status and/or low

battery indication (“LO BATT”) will cause Alarm 4 to change state as well as produce front

panel audible alarms. For loss of AC, (”LOSS OF AC”) and loss of battery (“LOSS OF BATT”),

these conditions will produce an audible alarm but no change in Relay 4.

• An "open collector" output, (open drain output) provides an additional level of operator output

for signaling alarm purposes. This "open drain output", from a 50 volt MOSFET transistor, is

normally open, but will close or short to ground to indicate an alarm condition if the 4 to 20

milliamp loop is open. No audible alarm is associated with an open 4-20 mADC loop.

Series 1000 Oxygen Deficiency Monitor Page 13

Alpha Omega Instruments

3.4 On Board Switch Settings

NOTE: Please perform the field elevation calibration procedure described in Section 5.1 before

changing any switch settings.

The on-board switch settings provide operator control for fail-safe operation and high/low alarms. This

switch bank has eight (8) individual switches for configuring the Series 1000 as shown in Figure 3-2.

Switch 8 is set to OFF at the factory. This default configuration forces the Series 1000 Oxygen

Deficiency Monitor to read the other switches for power-up or a warm-boot. If Switch 8 is ON ("user

configuration" mode), the Series 1000 Oxygen Deficiency Monitor will be configured using batterybacked configuration information. When set to ON, the monitor ignores the switch settings and boots

according to user-configured settings stored in memory (see Chapter 4).

3.4.1 Fail-Safe Operation

Switches 1-4 control the fail-safe operation for each of the four alarm relays. Each switch must be

turned "ON" to be fail-safe as shown in Figure 3-2. When the system is in the fail-safe mode, an alarm

condition changes the state of the corresponding relay from energized to de-energized upon loss of

AC power. Switches 1 - 4 are set to OFF (normal operation or non fail-safe) at the factory.

Figure 3-2: On-Board Switch Settings For Fail-Safe Operation

3.4.2 Alarm 3 Settings

With Switch 8 in the OFF position, the Series 1000 Oxygen Deficiency Monitor defaults to configuring

Oxygen Alarms 1 and 2 as low alarms, and reads Switch 7 to determine if Oxygen Alarm 3 is either

high or low. Alarm 3 can be configured to default as either a high or low oxygen alarm setting upon

power up.

Series 1000 Oxygen Deficiency Monitor Page 14

Alpha Omega Instruments

4 Operation

4.1 Preparing for Operation

The Series 1000 Oxygen Deficiency Monitor is set to the line voltage specified in the purchase order

at the time of shipment. If the line voltage is not specified, the instrument will be configured for

operation on 115 VAC, 50-60Hz. As soon as the instrument is plugged into the properly rated an AC

outlet (or tied into DC power), within seconds the Series 1000 Oxygen Deficiency Monitor is

operational.

4.2 Selecting AC Voltage

This section describes how to set up the instrument for AC voltage. To power the instrument from an

external DC power source, see the following section.

To change the input voltage:

1. Locate the S2 jumper on the lower left quadrant of the printed circuit board (refer to Figure 2-1:

Printed Circuit Board). The 115 VAC configuration uses a 0.5 ampere slow blow fuse (fuse type

is Wickman 374050004). 230 VAC configuration uses the same kind of fuse. Refer to Step 3.

below for the jumper change required to change AC voltage inputs.

To change the AC voltage inputs:

1. Disconnect the Series 1000 Oxygen Deficiency Monitor from all AC or DC power.

2. Swing out the front panel to access to the main printed circuit board Refer to Section 2.1 ,

Unpacking the Instrument, for instructions).

3. Locate the jumpers on the lower left hand side of the printed circuit board (see Figure 2-1:

Printed Circuit Board) The jumpers are protected by an "L" shaped cover.

Figure 4-1 shows two ways of installing the AC input selection jumpers at S2.

Figure 4-1: Changing the Voltage Inputs - S2 Jumpers

Series 1000 Oxygen Deficiency Monitor Page 15

Alpha Omega Instruments

4.2.1 Changing the Voltage Inputs - S2 Jumpers

To change the AC configuration, remove the jumpers and place them (refer to Figure 4-1 above).

1. Remove the fuse located on the main printed circuit board and replace it with one of the proper

value for the AC input voltage selected.

2. Reassemble the instrument and proceed to the next section.

4.3 Installing the Monitor

Install the Series 1000 Oxygen Deficiency Monitor in the vertical position so that the opening to the

oxygen sensor is facing downwards. The extended life oxygen sensor in the Series 1000 Oxygen

Deficiency Monitor uses an open sensor diffuser that allows free movement of air or other gases into

the sensor by natural diffusion. Sample pumps and aspirators are not required.

BE SURE THE OPENING TO THE OXYGEN SENSOR IS NOT BLOCKED OFF OR COVERED.

THIS CAN PRODUCE INCORRECT OXYGEN READINGS!

4.3.1 Mounting the Monitor on a Wall

To mount the Series 1000 Oxygen Deficiency Monitor on a wall:

1. Open the clear polycarbonate lid to expose the mounting holes at each corner of the

enclosure.

2. Drop a screw through each of the four 0.157" (4 mm) diameter holes and screw them into a

vertical surface (i.e. wall, stanchion, etc.) and tighten. It is recommended that all four corners

of the enclosure be fastened to a vertical surface such as a wall, beam, etc.

4.4 Operating the Instrument

4.4.1 Power ON

The Series 1000 Oxygen Deficiency Monitor does not have an Off/On switch. Power is applied

automatically once the instrument is wired to a power source. Refer to Chapter 2 for wiring

instructions.

4.4.2 Cold Boot

A cold boot ensures that the microprocessor, internal memory, front panel LEDs and audible alarm

are functioning normally. The cold boot sequence is as follows:

1. The instrument's front panel liquid crystal display (LCD) displays a series of dashes in

sequence.

[

¯ ¯ ¯ ¯

][- - - -][

Series 1000 Oxygen Deficiency Monitor Page 16

_ _ _ _

]

Alpha Omega Instruments

2. Each of the three front panel LED's blinks simultaneously for approximately 5 seconds, and the

audible alarm will sound intermittently for as long as the LED's are blinking.

3. An onboard switch setting such as [

| | | | | | | |

|

] then appears on the display. In this example,

Switch 8 is ON and all the others are in the OFF positions.

4.4.3 Warm Boot

A warm boot starts the instrument or restarts the instrument while it is powered ON.

To perform a warm boot and read the internal switch settings:

1. Make sure SW6 Switch 8 is set to the OFF position (see Figure 3-2)

2. On the front panel, press the UP, DOWN, and Alarm 3 buttons simultaneously.

You will see the same sequence as above, however, Switch 8 will indicate LOW. Powering on with

switch #8 in the "OFF" position will cause the Series 1000 Oxygen Deficiency Monitor to default to

factory settings (Alarm 1 and 2 are low alarms) and read the switch bank for all other configurations

(fail-safe modes and Alarm 3 mode).

4.5 Battery Backup

Battery backed Random Access Memory (RAM) saves all values set by the operator. When the

instrument undergoes a cold start, all values are maintained if Switch 8 is set to the ON position (user

configuration mode). Section 3.4 provides instructions for the on-board switch settings.

4.6 Operator Controls

The front panel of the Series 1000 Oxygen Deficiency Monitor contains a 4.5 digit liquid crystal display

(LCD), three (3) alarm set push-button switches, three alarm LED's, and up and down push-button

switches.

4.6.1 Liquid Crystal Display

The LCD displays:

• Oxygen percentage. The percentage of oxygen in the sample being measured. Within

approximately ten seconds after a cold start, the Series 1000 Oxygen Deficiency Monitor will

measure and display the oxygen concentration of the sample gas exposed to the sensor.

Ambient air normally contains 20.9% oxygen by volume.

• High/Low Alarm Status levels. When setting an oxygen alarm value, the values will be

followed by either the letter "H" or "L". indicating either a high or low alarm.

• Battery Status. A Series 1000 Oxygen Deficiency Monitor equipped with the Battery Backup

Option, displays the "LOBAT" message when battery power has reached the point when

normal instrument operation is in jeopardy. It also indicates if there is a loss of battery by

displaying "LOSS OF BATT". When calibrating, a "C" in the display signifies Calibration Mode.

Series 1000 Oxygen Deficiency Monitor Page 17

Alpha Omega Instruments

4.6.2 Oxygen Alarms

The Series 1000 Oxygen Deficiency Monitor is equipped with three (3) oxygen alarms. All are set at

the factory as low alarms at 20.0% O2. Any one of these alarms can be set to HIGH. Please refer to

Section 3.4.2 Alarm 3 Settings , for instructions on how to set Alarm 3 for either high or low operation.

All alarms are user configurable use SW-6, - Switch 8 (refer to 3.4 .On Board Switch Settings ).

4.6.3 Setting the Alarms

1. Assuming that no alarms are currently activated (no front panel LEDs are lit), press the desired

alarm switch on the front panel, "Alarm 1", "Alarm 2", or "Alarm 3" .

The numerical value in the LCD is the existing alarm value associated with that alarm channel.

When the alarm switch is pressed, the LED directly above the switch will light indicating that

channel is in the Alarm Set Mode.

The alarm value in the LCD will be followed by the letter L or H indicating a low oxygen alarm or a

high oxygen alarm, respectively.

2. To change any of the three Oxygen Alarms press the UP and DOWN arrows simultaneously.

3. To set the oxygen alarm values, use the front panel up and down arrows, press the DOWN

arrow to lower the oxygen alarm value or the UP arrow to increase the value. The longer either

arrow is held down, the more rapidly the alarm values will scroll in the display. When the value

in the display is within approximately 0.5% of the desired oxygen set point value, release

pressure on the switch.

4. To obtain the final value, apply momentary pressure to the switch to change values in

increments of 0.1 % oxygen.

5. When finished setting the alarm, press the associated alarm switch. The LED will go off, and

the display will indicate the actual oxygen concentration. If you want to change more than one

alarm value, repeat this procedure using the desired alarm channel.

4.6.4 Alarm Processing

When an alarm event occurs, the Series 1000 Oxygen Deficiency Monitor provides the following

alarms:

1. The LED associated with the specific oxygen alarm illuminates.

2. An audible (approximately 80 dB) alarm sounds.

3. The relay associated with the oxygen alarm changes state.

The alarms may be cancelled by either Auto-Clear or the Manual Clear functions, which are set on

Switch 6 of the SW-6.

Series 1000 Oxygen Deficiency Monitor Page 18

Alpha Omega Instruments

4.6.4.1 Auto-Clear Operation

In the Auto Clear mode (SW-6 Switch 6 is ON), the monitor automatically resets the visual and

audible alarms when the alarm condition clears.

To silence an active alarm when the monitor is in Auto-Clear mode:

1. Press the front panel button associated with the alarm (Alarm 1, Alarm 2, or Alarm 3).

2. To change the setting for this same alarm, press the button a second time. If more than one

alarm is on, the audible alarm will still be canceled.

If you set the alarm to a value that causes an alarm condition, the audible alarm will immediately

sound upon exiting the Alarm Set Mode.

Note: Under Auto-Clear operation, the silenced audible alarm may automatically come back

on if the O2 reading should go out of alarm range and then back into alarm condition.

4.6.4.2 Manual Clear Operation

When SW6 Switch 6 is in the OFF position, the Series 1000 Oxygen Deficiency Monitor is in the

Manual Clear mode. In the manual clear mode, whenever the Series 1000 Oxygen Deficiency Monitor

senses an alarm condition, it will be indicated as previously described. However, if the oxygen level

should return to a non-alarm level, the monitor will not automatically clear.

To manually cancel the audible alarm and alarm condition:

1. Cancel the audible alarm by pushing the appropriate alarm button. This silences the alarm.

2. Push the appropriate alarm button again to clear the alarm condition. If the set point is to

remain the same, simply pushing the appropriate alarm button a third time will clear the alarm.

I

4.6.4.3 Timing Out

The Series 1000 Oxygen Deficiency Monitor will time out and resume normal operation if no

adjustments are made for approximately two (2) minutes. This feature helps ensure that the monitor

is not inadvertently left off-line.

Series 1000 Oxygen Deficiency Monitor Page 19

Alpha Omega Instruments

5 Calibrating the Series 1000 Oxygen Deficiency

Monitor

5.1 High Altitude Calibration

All Series 1000 Oxygen Deficiency Monitors are factory calibrated at 72 feet above sea level. At

elevations higher than 500 feet above sea level, it is essential to perform a startup calibration

adjustment. Calibration negates the effects of higher elevations which produce lower than actual

percent oxygen readings.

To adjust calibration for altitude:

1. Power up the instrument at least 30 minutes before calibration, and make sure it is sampling a

fresh source of air.

2. Press and hold the UP and Alarm 2 switches simultaneously. You will hear a series of beeps

and the display will read "20.9F".

3. Continue holding the two switches until the "F" disappears from the display.

4. Once the "F" has disappeared, release the switches and the process is complete

IMPORTANT: Altitude adjustment is a one-time start-up procedure, however, the instrument

must be re-calibrated if it is moved to an altitude 500 feet higher or lower than the initial

location. Alpha Omega recommends that customers document the date, time, location and

person performing the start-up calibration.

Date:

Time:

Location:

Name of Person

5.2 Routine Calibration

The instrument has an extended life sensor with excellent long term stability characteristics for

minimal routine maintenance. As with all gas monitors and analyzers, it is advisable to periodically

check the overall system calibration. The frequency of these checks is often determined by in-house

calibration protocols. If none exists, Alpha Omega Instruments recommends calibration checks be

done approximately every three to six months. In time, if this frequency is extended, it should never go

beyond checking the monitor at least every six months. Given the importance of the requirement,

calibration checks are prudent. It is advisable that a written log be kept to document the frequency of

calibration checks and/or changes.

Series 1000 Oxygen Deficiency Monitor Page 20

Alpha Omega Instruments

5.2.1 Calibration with Ambient Air

The Series 1000 Oxygen Deficiency Monitor has a measurement range of 0-30% that makes ambient

air (20.9% oxygen by volume) a convenient calibration source. However, if using ambient air, it is

essential that the quality of the ambient air used for calibration be untainted. If the composition of the

air is unknown, calibrate the monitor in a location not affected by the leakage of stored gases. A large

office environment is ideal.

5.2.2 Calibration With Other Gases

If a fresh air supply is not available, instrument air or compressed air (oil free) is the next best choice

as is compressed air from a small cylinder. Do not use plant air as oil vapors and/or water mist

may be entrained in the gas stream and could damage the oxygen sensor and/or adversely

affect oxygen readings.

A calibration gas with a specified concentration of oxygen is another alternative to instrument air or a

compressed air cylinder. The factory recommends a composition of 20.9% oxygen/balance nitrogen.

Most major gas manufacturers can readily supply this calibration gas if instrument or plant air is not

available on site. A single calibration point is required provided the calibration is performed accurately.

No zero gas adjustment is required.

IMPORTANT: The Alpha Omega Instruments Optional Calibration Tool is required when using a

pressured gas to check calibration. Purchase the tool (P/N 1CFN) from the factory, and install it on the

mouth of the oxygen sensor. Maintain the sample flow to the inlet of the calibration fixture between 0.3

and 1.0 liters per minute. Please refer to Section 5.4.1

5.3 Performing an Initial and/or Routine Calibration Check

Note: Make sure the instrument is calibrated at the existing altitude. If the Series 1000 Oxygen

Deficiency Monitor is being used at an elevation higher than 500 feet above sea level, the instrument

must be calibrated to the new altitude before routine calibration. If the elevation correction procedure

has been previously performed, do not repeat it unless elevation conditions have changed.

To Perform a Routine Calibration Check

1. Make sure the instrument has been operating for a minimum of 30 minutes.

2. When measuring a fresh source of ambient air, the reading from the front panel should be at

20.9%, + 0.3% (+ 0.3% is the stated error specification of the Series 1000 Oxygen Deficiency

Monitor).

3. If the monitor is reading within acceptable limits, no further action is required. If the monitor is

not reading within these limits, perform a calibration adjustment as described in the next

section.

Series 1000 Oxygen Deficiency Monitor Page 21

Alpha Omega Instruments

5.4 Calibration on Ambient Air

Important: If using a pressurized gas sample for calibration, please refer to 5.4.1 Calibration Cup

(Optional Calibration Tool) before proceeding.

To perform a calibration adjustment on ambient air:

1. Simultaneously press the front panel buttons labeled Alarm 1, Alarm 2, and Alarm 3.

2. On the front panel display, the letter 'C' appears next to the oxygen value being read to

indicate that this step was executed properly.

3. If the oxygen value displayed is lower than the target value of 20.9%, press the up arrow to

bring the value to 20.9%.

4. If the initial value is higher than 20.9%, use the down arrow to lower the reading.

5. Press Alarm 1, Alarm 2, and Alarm 3 buttons simultaneously again. The letter 'C' will

disappear from the display indicating the calibration sequence has been successfully

completed.

5.4.1 Calibration Cup (Optional Calibration Tool)

To perform a calibration check using instrument air, plant air, or a gas cylinder containing 20.9%

oxygen, use the Optional Calibration Tool. The tool attaches to the bottom of the oxygen sensor

holder. Refer to Figure 5-1, Calibration Cup Option.

To Attach the Optional Calibration Tool:

1. Temporarily remove and save the existing sensor retaining nut.

2. Replace the retaining nut with the Calibration Tool.

3. Using 3/16 ID flex tubing, insert the tubing into one of the two quick-connect gas fittings. Make

sure that the tubing delivering the calibration gas is free of cracks, splits, and defects.

4. Before connecting the gas delivery tube to the inlet of the calibration fixture, place a flow meter

somewhere in line. Maintain the flow rate between 0.3 to 1.0 liters per minute.

Important. Establish a sample flow rate of approximately 0.5 liters per minute before

connecting the tubing to the calibration fixture. This prevents inadvertent over pressurization

that may permanently damage the sensor (not covered under warrany).

Once the calibration gas is flowing to the sensor, allow the reading to come into equilibrium before

proceeding with any adjustments. The factory recommends that the calibration gas should be flowing

to the sensor for at least ten (10) minutes before the readings are monitored to determine if

Series 1000 Oxygen Deficiency Monitor Page 22

Alpha Omega Instruments

equilibrium conditions have been established.

When checking the accuracy of the Series 1000 Oxygen Deficiency Monitor, Alpha Omega

Instruments highly recommends using oxygen concentrations of no lower than 20.9%. In all cases, be

sure to obtain a steady reading for at least five minutes before making adjustments to the

calibration.

6. Once equilibrium has been established, simultaneously press the front panel buttons labeled

Alarm 1, Alarm 2, and Alarm 3.

On the front panel display, the letter 'C' next to the oxygen value indicates that the step is

complete.

• If the oxygen value displayed is lower than the target value of 20.9%, press the up arrow to

bring the value to 20.9%.

• If the initial value is higher than 20.9%, use the down arrow to lower the reading.

7. Press Alarm 1, Alarm 2, and Alarm 3 buttons simultaneously.

The letter C disappears from the display, indicating the calibration sequence is complete.

After using the Calibration Tool, be sure to remove it and re-install the sensor retaining nut

before operating the monitor.

5.4.2 Calibrating from a Gas Cylinder - Effect of Moisture on Calibration

When calibrating the monitor from a gas cylinder be sure to understand the effect of moisture

levels on the oxygen readings as explained in the following section.

When calibrating the Series 1000 Oxygen Deficiency Monitor on a calibration gas from a high

pressure cylinder, the gas can be expected to have essentially zero moisture content. When placing

the Series 1000 in service after calibrating, oxygen readings on ambient air may be slightly (approx.

0.2-0.3%) lower than expected (20.9% is the target value on ambient air).

This difference is due to Dalton’s Law of Partial Pressures that states, “the partial pressure of a gas is

equal to its mole fraction in the mixture multiplied by the total pressure.” Variations in the moisture

content of the ambient air will effect the oxygen concentration readings. As the moisture concentration

(partial pressure) increases or decreases, the partial pressures of the other gases (most notably

oxygen and nitrogen) also change based on changes in their respective partial pressures. For this

reason one can expect variations in the oxygen concentration of ambient air based on changes in

moisture levels (dew point temperatures) from day to day. For example, on a warm, humid summer

Series 1000 Oxygen Deficiency Monitor Page 23

Alpha Omega Instruments

day when moisture levels in the air are high, oxygen levels may decrease slightly (approx. 0.2-0.3%)

due to an increase in moisture.

Figure 5-1: Calibration Cup Option

Series 1000 Oxygen Deficiency Monitor Page 24

Alpha Omega Instruments

6 Replacing the Oxygen Sensor

The Alpha Omega Instruments extended life oxygen sensor is designed to operate for several years

without replacement. However, in time, the sensor's output will drop, and the sensor must be replaced.

More frequent calibration is an indication that the sensor will need replacement soon. Change the

sensor when the Change Sensor message appears on the LCD display. During calibration, an alarm

occurs if the amount of gain (calibration adjustment) exceeds a predetermined limit set at the factory.

An alarm sounds and the Change Sensor message appears on the display.

At the first warning, the instrument will probably function normally. However, it is highly recommended

that the sensor be replaced within a few weeks.. Although the message displayed only once per

calibration cycle (when the preset gain is exceeded), the alarm relay will remain in the alarm state until

the condition has been cleared. Order the sensor directly from the factory.

6.1 Replacing the Oxygen Sensor

Replacing the oxygen sensor clears the Change Sensor alarm.

To replace the Oxygen Sensor:

1. Remove all power (AC or DC) from the instrument.

2. Loosen the six screws that fasten the clear front cover to the polycarbonate enclosure. The

screws should be loose enough to disengage from the control unit allowing access to the front

panel containing the membrane switches.

3. Swing out the membrane panel and locate the sensor which is positioned in the lower left side

of the control unit. The membrane panel is installed on a metal backing plate that is hinged and

swings out in the same direction as the cover.

4. Locate the red connector that connects the sensor and the electronics, and disconnect the

connector.

5. Turn the hex nut on the sensor boss mount counterclockwise to loosen the sensor. It is not

necessary to remove the hex nut - just loosen it.

6. Remove the old sensor and install the new one.

7. With power still off, finger tighten the hex nut and reconnect the connector.

CAUTION: To avoid damage to the sensor, do not over tighten the hex nut. Apply power to the

instrument and calibrate the instrument as described in Chapter 5.

Series 1000 Oxygen Deficiency Monitor Page 25

Alpha Omega Instruments

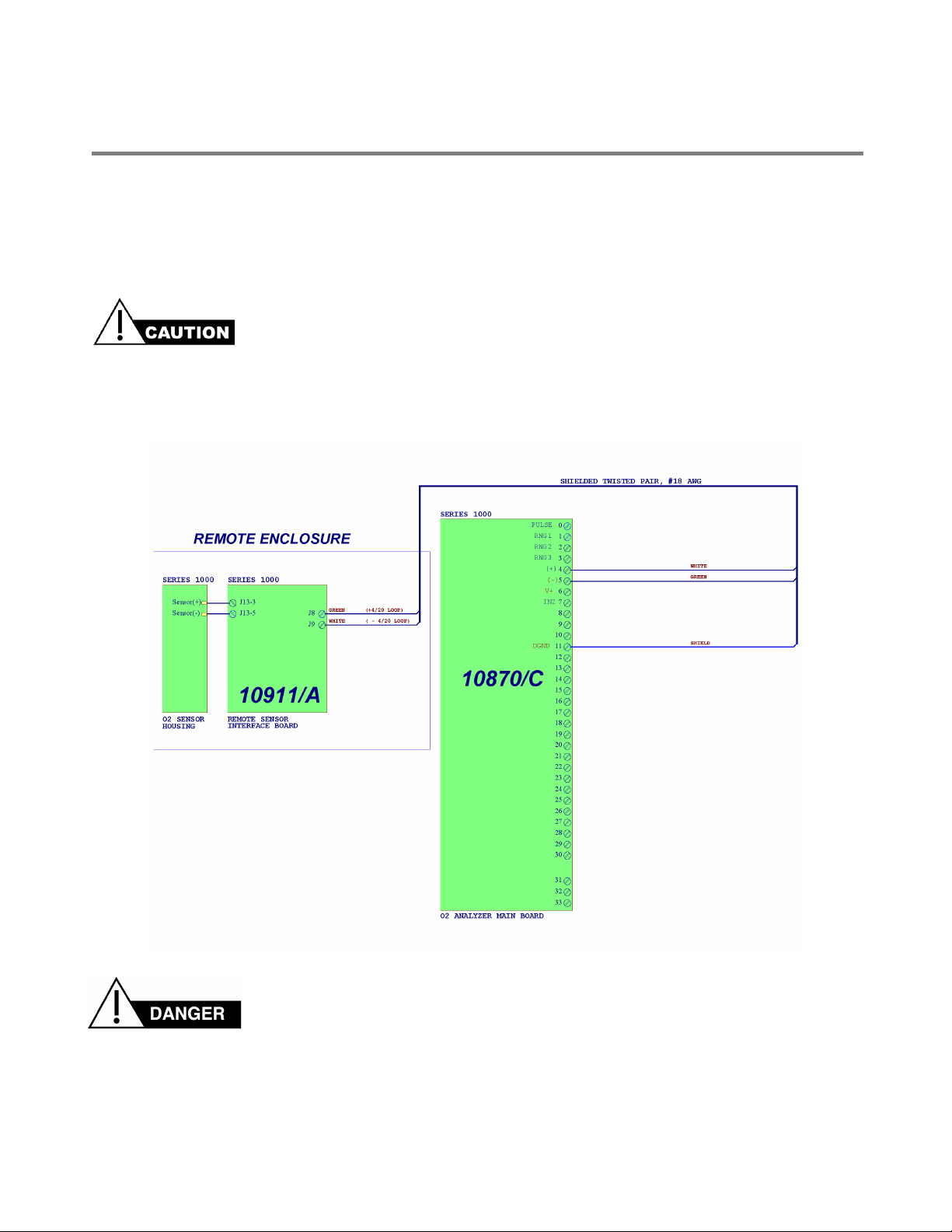

7 Configuring the Optional Remote Sensor

The Optional Remote Sensor is used for applications where the sensor and control electronics are

desired to be in separate locations. The maximum distance between control unit and remote sensor

enclosure is 4,000 feet. If wiring to a remote enclosure, refer to the interconnecting wiring diagram on

the following page (refer to Figures 7-1 and 7-3.

Make sure all wiring (alarms, remote sensor, RS-232C, etc.) are complete before applying AC,

DC, or Battery power to the instrument.

Figure 7-1: Wiring Diagram - Series 1000 Monitor with Remote Sensor

DO NOT USE 24 VDC AS THE SOURCE OF PRIMARY POWER WITH THE BATTERY PACK.

THIS WILL CAUSE THE BATTERIES TO OVERCHARGE. BATTERIES MAY EXPLODE!

Series 1000 Oxygen Deficiency Monitor Page 26

Alpha Omega Instruments

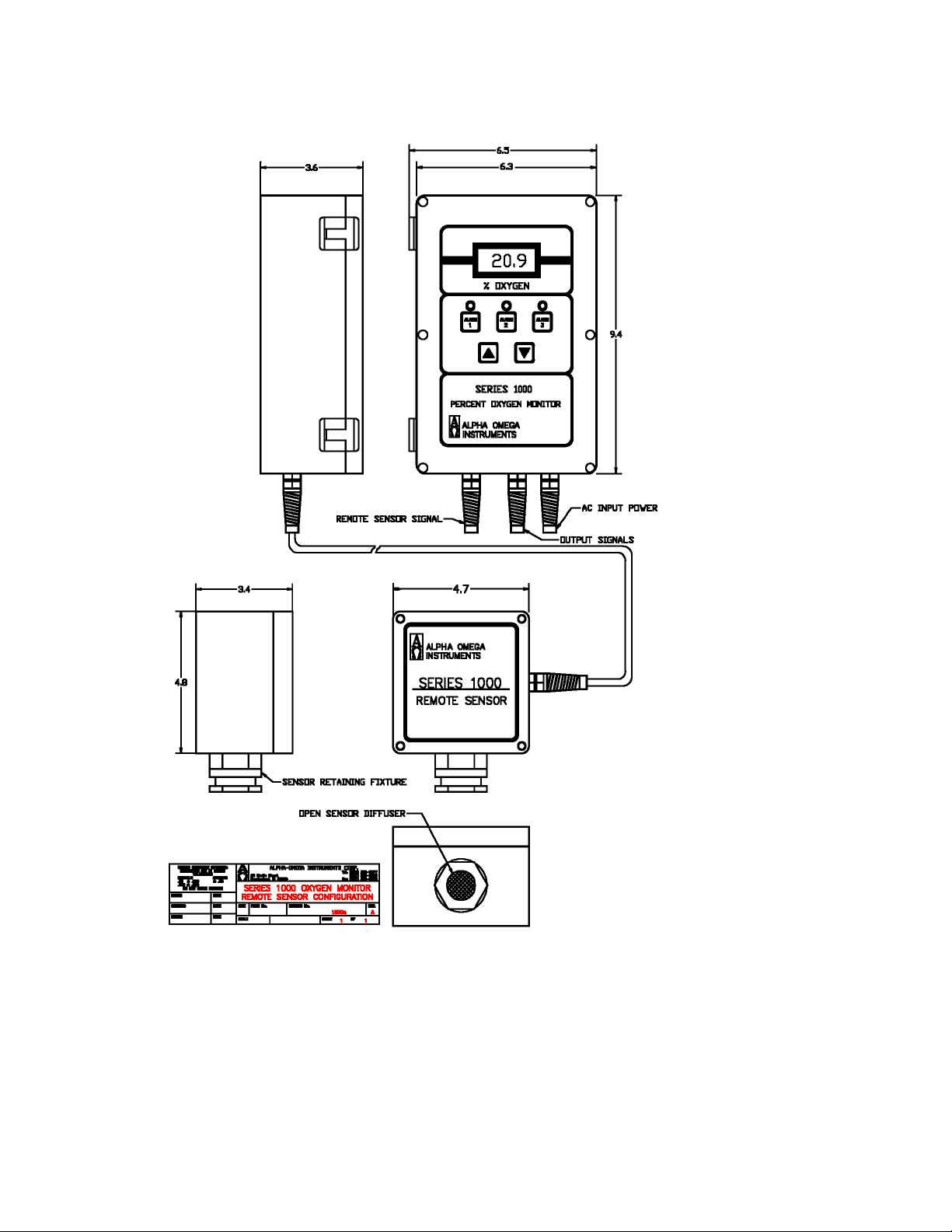

Figure 7-2: Remote Sensor Configuration

Series 1000 Oxygen Deficiency Monitor Page 27

Alpha Omega Instruments

Figure 7-3: Remote Sensor Connections

Series 1000 Oxygen Deficiency Monitor Page 28

Alpha Omega Instruments

8 Optional RS-232C Serial Communications

8.1 Baud Rates

RS-235 Serial communication baud rates are 38400, 19200, 9600, 4800, 2400, 1200, 600, 300, and

150 bps. Rates for RS485, are the same with the exception of 38400 and 19200.

To set the RS-232 baud rate:

1. Make sure that the unit is fully operational. Check for valid oxygen readings on the front panel

LCD of the instrument.

2. Make sure that Switch 5 on the Main board Switch Bank is LOW or OFF. Switch 5 is a factory

switch that should be on only in certain circumstances.

Note: if the unit was shipped with SW5 ON, turn it OFF to set the baud rate. After the baud rate

has been set, move SW5 to the ON position to resume normal operation.

3. Press and hold the UP and DN keys simultaneously. An initial beep followed by a second beep

indicates that the instrument is ready for the next command.

4. The current setting should be displayed on the front panel. If there is no setting indicated,

make sure that you hold the UP and DN keys long enough.

5. Press and hold the UP and DN keys to scroll through available settings choosing the desired

baud rate.

6. When the desired baud rate appears on the display, push the Alarm 3 button to save it in

battery backed memory.

Series 1000 Oxygen Deficiency Monitor Page 29

Alpha Omega Instruments

8.2 Standard Commands

This section describes standard RS-232 commands. Enter letters in either upper or lower case.

Optional strings are case-sensitive.

Standard commands are not case-sensitive. Letters may be in either upper or lower case. The only

exception to this rule is the optional [string] (See note below under the 'D' command description)

Optional commands or strings are shown in brackets. Below is an example Help Screen using the H

Command.

Command Description

Aa=[bb.b][L/H] <Enter> Alarm set

Bccccc <Enter> Baud rate select

C[bb.b] or CAL <Enter> Calibrate ["CAL" defaults to 20.9]

D[string] <Enter> Disable Security

E[string] <Enter> Enable Security

FSd=[ON/OFF/1/0] <Enter> Fail Safe select

H <Enter> Help Screen

M <Enter> Manual clear toggle

O <Enter> Oxygen concentration

Q <Enter> Quiet mode (no beeps at all)

S <Enter> Signal mode (beeps audible)

V <Enter> View current Alarms and settings

Where: a = 1, 2, or 3 for different alarms

bb.b = 0 to 30.0% O2 for alarm setting

L/H = Optionally set to Low or High (H) alarm

ccccc = Baud rate number from 150 to 38400

d = Number designating Relay 1 to 4

ON/OFF/1/0 = 'ON' is the same as '1' etc.

string = String for security protection (see manual)

command

8.2.1

Alarm #1 will be set to go off in the case of the oxygen level dropping below 20%. Type:

A1=20.0L <Enter>

To change Alarm #1 to 18% instead of 20% you could type:

A1=18 <Enter>

Note how the 'L'ow alarm is optional unless changing to 'H'igh? As you can see, the decimal point is

optional too, and if left out defaults to '.0'. Note how the command in the help screen says, "[bb.b]

[L/H]"? Examine the following example:

'A' Command - Alarm set point with low or high alarm option

= Any valid command

Series 1000 Oxygen Deficiency Monitor Page 30

Alpha Omega Instruments

A1=H <Enter>

This is a valid command and will only effect the 'L'ow or 'H'igh status of Alarm 1. To set it back to a

low alarm type:

A1=L <Enter>

The Low alarm is optional unless changing to High. As you can see, the decimal point is optional too,

and if left out defaults to '.0'. Note how the command in the help screen says, "[bb.b][L/H]"? Examine

the following example:

A1=H <Enter>

This is a valid command and will only effect the Low or High (H) status of Alarm 1. To set it back to a

low alarm type:

A1=L <Enter>

8.2.2 'B' Command - Baud change.

To change the baud from 300bps to 9600bps (default), first establish communication at 300bps then

type the following:

B9600 <Enter>

Note that there may be some garbled data output when the instrument responds to the new baud rate.

Now you must change your terminal's baud rate and reestablish communication by pressing <Enter>.

8.2.3 'C' Command

Calibrate to known calibration standard i.e. 5% O2 / balance nitrogen, 15% O2 / balance nitrogen, etc..

Using a calibration gas consisting of 10% O2 / balance nitrogen as an example, type the following:

C10 <Enter>

For room air calibration, take the monitor outside for fresh air or to a known source of 20.9% O2 and

type:

CAL <Enter>

or

C20.9 <Enter>

Note that the monitor defaults to 20.9% if CAL is entered.

Series 1000 Oxygen Deficiency Monitor Page 31

Alpha Omega Instruments

8.2.4 'D' Command

Disable security with optional passcode. (See 'E' Command below for description of security)

In it's simplest form, to disable security protection type:

D <Enter>

Assuming an 'E' Command had been sent with a passcode of "mypass1" (see next command

example) then type the following to disable the security option:

Dmypass1 <Enter>

Note: typing "DMYPASS1" will not disable the instrument if the original passcode was in lowercase!

That means that the 'D' and 'E' commands are CASE SENSITIVE.

8.2.5 'E' Command - Enable security with optional passcode.

To keep others from changing system settings, the 'E'nable Command is supplied as an optional

security measure. In it's simplest form type the following:

E <Enter>

In this example, just type 'E' by itself. This prevents users from inadvertently changing the system

settings. However, if you need to change a setting, type a 'D' command with no passcode. The

following command shows the use of a passcode:

Emypass1 <Enter>

This arms the security system and ignores any requests for system changes until the user disarms the

system with a 'D' Command followed by the correct passcode (See 'D' command above).

8.2.6 'FS' Command - Fail-safe select.

If the alarm relays should be energized in normal operation and released in the case of a power

failure, type the following:

FS1=ON <Enter>

FS2=1 <Enter>

FS3=on <Enter>

fs4=On <Enter>

Note the individual control over each alarm. Also, ON/on/OFF/off or 1/0 can be used to control the

status of each. Commands are not case sensitive. Example: If only Alarm2 needs to be in Fail-safe

mode, then type:

FS1=off <Enter>

FS3=0 <Enter>

FS4=Off <Enter>

This turns off the Fail-safe mode for Alarms 1, 3, and 4.

Series 1000 Oxygen Deficiency Monitor Page 32

Alpha Omega Instruments

8.2.7 'H' Command - Help Screen

Displays a help screen as listed in Section 8.2.

H <Enter>

8.2.8 'M' Command - Manually clear all alarms toggle.

This command toggles between 'M'anual and Automatic clearing of alarms. The alarm is cleared

when the condition causing the alarm has been corrected and the Series 1000 gives no indication that

the alarm was on. The following two examples will explain the difference between 'M'anual and

Automatic clearing of alarms:

Example #1: The Series 1000 monitor is set up to monitor a laboratory full of animals being tested.

In our example, the lab technicians have a suspicion that the reason some animals are expiring

overnight, is because of lack of oxygen! Unfortunately, these technicians don't have any ability to

record the data from the Oxygen monitor, so they set it up for an Alarm 1 set point of 18(L), alarm2 set

point of 19(L), and alarm3 set point of 20%(L). Before they leave for the night, they type:

M <Enter>

The monitor responds with:

Alarms to be cleared Manually

The next morning, the technicians find the monitor reading 20.9%, but alarms are going off! Alarm2

and Alarm3 are both on. This is very meaningful to them, because it means the O2 level in the room

dropped below 19%, but stayed above 18%. This would not have been apparent to them if the alarms

were cleared automatically (See example 2 below)

Example #2: The Series 1000 is set up in an environmental control situation where if the oxygen level

in a room goes below 15%, then a window should automatically open. Also if the oxygen level should

get to 20%, then the window should close and a pump should turn on. First, the user needs to set up

his alarms as follows:

A1=15L <Enter> This sets up a low alarm at 15.0%

A2=20H <Enter> This sets up a high alarm at 20.0%

A3=20H <Enter> This sets up another high alarm at 20.0%

Now the user must toggle the 'M'anual clear command to allow for Automatic clearing:

M <Enter>

Series 1000 responds:

Alarms to be cleared Automatically

Now, assuming the oxygen level to start out at 20.9%, the system could operate as follows:

Alarm1 would be off allowing the window to be closed.

Alarm2 would be on which would tell the window to close.

Series 1000 Oxygen Deficiency Monitor Page 33

Alpha Omega Instruments

Alarm3 would be on which would tell the pump to turn on.

Eventually the oxygen level will drop to under 20% where Alarm 2 and Alarm 3 will automatically shut

off! This could tell the pump to shut off, and allow for the window to be opened by Alarm 1.

Eventually, due to some gas leak in the room, the oxygen level continues to drop below 15% when

Alarm 1 activates and tells the window to open! After a while the oxygen level comes back up past

15% and automatically shuts off Alarm 1. Therefore you have an automatically controlled process.

8.2.9 'O' Command - Output Oxygen Concentration

This command is useful for a quick reading of the Oxygen Concentration. This command returns the

current oxygen reading.

8.2.10 'Q' Command - Quiet mode (disables the audible alarm)

Caution! This disables all sounds - (even from alarms!)

This command is useful if the instrument will be in test mode for awhile, with sensors being removed

and replaced (causing a lot of harmless alarms). Type:

Q <Enter>

This will stay in effect until you type an 'S' command. A message will appear under the 'V'

command displaying the current mode.

8.2.11 'S' Command - Signal mode (enables the audible alarm).

To allow the audible alarms to be heard, simply type the following:

S <Enter>

8.2.12 'V' Command - View current alarms and settings

To view the current status of the Series 1000, type:

V <Enter>

Typical Response:

Alarm Settings

#1:(HI) 22.0 Fail-safe: OFF

#2:(LO) 19.0 Fail-safe: OFF

#3:(LO) 10.0 Fail-safe: ON

#4: N/A Fail-safe: OFF

Channel 1 = 21.0% Oxygen

Series 1000 Oxygen Deficiency Monitor Page 34

Alpha Omega Instruments

Alarm 1 is ON Relay1: Energized

Alarm 2 is OFF Relay2: De-energized

Alarm 3 is OFF Relay3: Energized

Conditions

AC inp: ok 4-20mA: ok Open Collector output: off

Batt: ok (22) Sensor: ok Aux. Relay: De-energized

Alarms to be cleared MANUALLY

Signal Mode

Commands that affect the output of the 'V' command are as follows:

•

• 'A' commands will update the Alarm Settings