Page 1

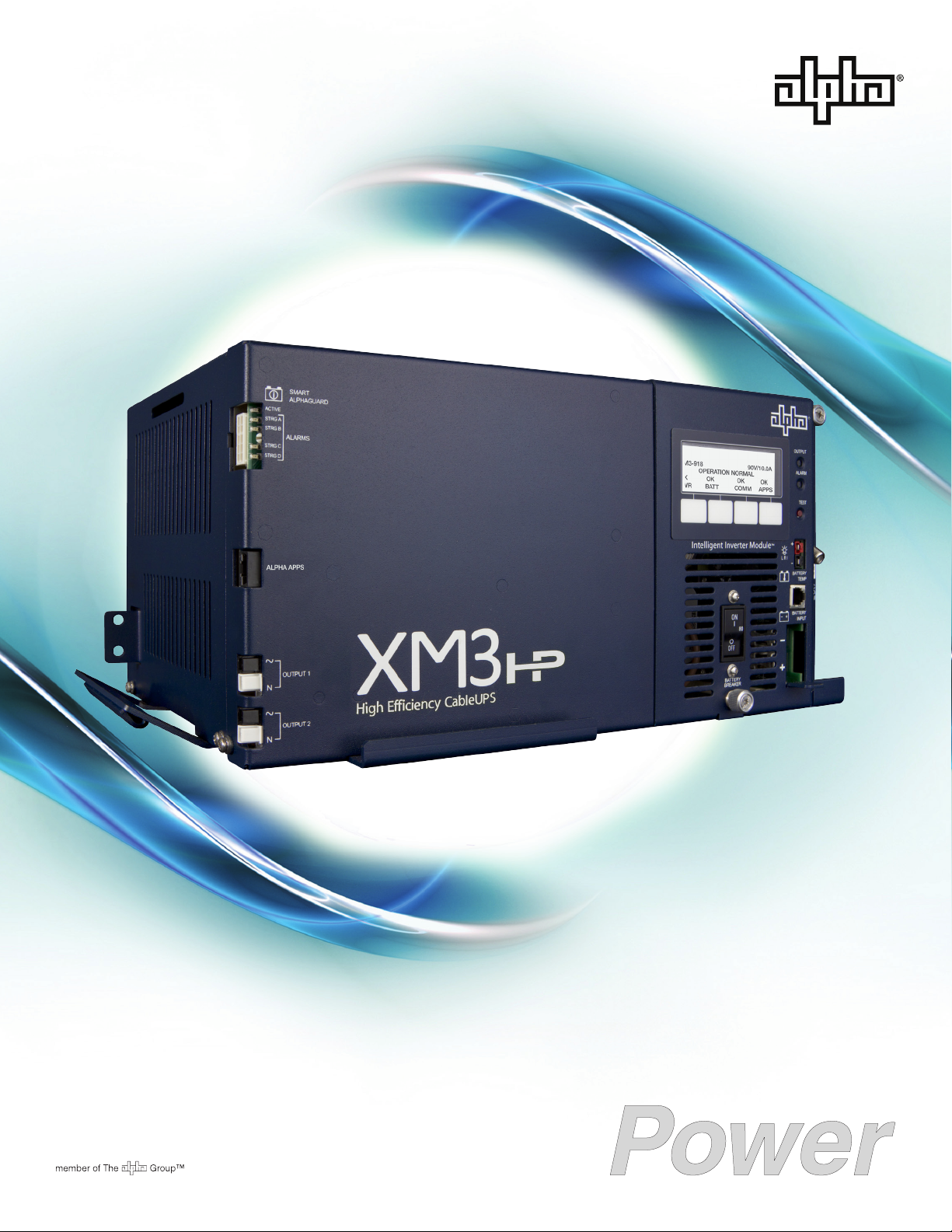

Intelligent CableUPS

Technical Manual

XM3-HP Series

Effective: October 2013

®

Page 2

Alpha Technologies

Power

®

Page 3

Technical Manual

017-882-B0-001, Rev. C2

Effective Date: October 2013

Copyright 2013 Alpha Technologies, Inc.

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match your

installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If there

are questions regarding the safe operation of this powering system, please contact Alpha Technologies or your

nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries or other hardware if used or operated in any manner or subject to any condition not consistent with its

intended purpose or is installed or operated in an unapproved manner or improperly maintained.

Notice of FCC Compliance

Per FCC 47 CFR 15.21:

Changes or modications not expressly approved by the party responsible for compliance could void the user’s authority to

operate the equipment.

Per FCC 47 CFR 15.105:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at their own expense.

Contacting Alpha Technologies: www.alpha.com

or

For general product information and customer service (7 AM to 5 PM, Pacic Time), call

1-800-863-3930

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacic Time or 24/7 emergency support

Page 4

Table of Contents

Safety Notes ......................................................................................................................................................................................... 9

Safety Precautions ............................................................................................................................................................................... 9

Battery Safety Notes........................................................................................................................................................................... 10

Battery Maintenance Guidelines......................................................................................................................................................... 10

Utility Power Connection Notes ...........................................................................................................................................................11

Grounding and Earth Connection Notes............................................................................................................................................. 14

Safety Ground and Earth Connection ......................................................................................................................................... 14

Power Output Return................................................................................................................................................................... 14

Communications Grounding ........................................................................................................................................................ 15

1.0 Introduction.................................................................................................................................................................................. 16

1.1 Alpha XM3-HP Intelligent CableUPS® .................................................................................................................................. 16

1.2 Theory of Operation ............................................................................................................................................................. 17

1.2.1 AC (Line) Operation .................................................................................................................................................. 17

1.2.2 Standby Operation .................................................................................................................................................... 17

1.2.3 Charger Modes of Operation ..................................................................................................................................... 18

1.2.4 Output Voltage Modes of Operation .......................................................................................................................... 22

1.3 Alpha XM3-HP CableUPS® Layout ..................................................................................................................................... 23

1.3.1 Side Panel Connectors ............................................................................................................................................. 23

1.3.2 Front Panel Indicators ............................................................................................................................................... 24

1.3.3 AlphaDOC (PIM) ....................................................................................................................................................... 25

1.3.3.1 Installing the AlphaDOC ........................................................................................................................................ 26

1.3.3.2 Programming the AlphaDOC ................................................................................................................................ 27

1.3.4 Smart AlphaGuard ..................................................................................................................................................... 28

1.3.4.1 Theory of Operation .............................................................................................................................................. 28

1.3.4.2 Connections .......................................................................................................................................................... 29

Table of Contents

1.3.4.3 Alarms ................................................................................................................................................................... 31

1.3.4.4 LEDs ..................................................................................................................................................................... 32

1.3.4.5 Troubleshooting .................................................................................................................................................... 33

1.3.5 Inverter Module Overview ......................................................................................................................................... 34

1.3.6 Optional DOCSIS Status Monitoring Modules........................................................................................................... 35

2.0 Installation ................................................................................................................................................................................... 37

2.1 Installation Procedure .......................................................................................................................................................... 37

2.1.1 Pre-installation Inspection ......................................................................................................................................... 37

2.1.2 Internal Security Screw Kit Installation ...................................................................................................................... 37

2.2 XM3-HP Start-Up Procedure ................................................................................................................................................ 39

2.2.1 Parts and Connections .............................................................................................................................................. 39

2.2.2 Battery Installation Options and Wiring Diagram....................................................................................................... 40

2.2.2.1 Threaded Insert Terminals .................................................................................................................................... 41

2.2.3 120/240V Conguration Procedure ........................................................................................................................... 41

2.2.4 63/89VAC Output Voltage Reconguration Procedure .............................................................................................. 42

2.2.5 Optional AlphaDOC, Smart AlphaGuard, and Alpha APPS Installation ..................................................................... 43

2.2.6 Optional N+1 Congurations ..................................................................................................................................... 44

2.2.7 Communications DOCSIS Status Monitoring ............................................................................................................ 46

2.2.7.1 DOCSIS Status Monitor Front Panel Connections ............................................................................................... 46

2.2.7.2 LED Status Verication ......................................................................................................................................... 47

2.2.8 Power Module Conguration and Installation Procedure .......................................................................................... 48

4

017-882-B0-001 Rev. C2 (10/2013)

Page 5

Table of Contents

2.2.9 Local Verication of DOCSIS Transponder ............................................................................................................... 51

2.2.10 Web Interface ............................................................................................................................................................ 52

2.2.10.1 Local Web Server Access ................................................................................................................................... 52

2.2.11 Remote Web Server Access ..................................................................................................................................... 55

2.2.12 Navigating the Web Page .......................................................................................................................................... 56

2.2.12.1 Web Interface Security Levels ............................................................................................................................ 57

2.2.13 Verifying Communication Parameters ....................................................................................................................... 58

2.2.14 Verifying Power Supply and Battery Parameters ...................................................................................................... 59

2.2.15 Remote Self Tests via the Web Page ........................................................................................................................ 59

3.0 Operation..................................................................................................................................................................................... 60

3.1 Start-Up and Test ................................................................................................................................................................. 60

3.1.1 Self Test Operation .................................................................................................................................................... 60

3.2 Using the Smart Display....................................................................................................................................................... 61

3.3 Smart Display Menus ........................................................................................................................................................... 62

3.3.1 Power Information and Conguration ........................................................................................................................ 63

3.3.2 Battery Information and Conguration....................................................................................................................... 64

3.3.3 Communication Information and Conguration ......................................................................................................... 65

3.3.4 Alpha Applications Information and Conguration..................................................................................................... 68

3.4 AlphaAPPs Overview ........................................................................................................................................................... 69

3.4.1 Display Structure ....................................................................................................................................................... 69

3.4.2 Applications ............................................................................................................................................................... 71

3.5 Active Alarms ....................................................................................................................................................................... 80

3.5.1 Menu Structure/Navigation (from Active Alarms Screen) .......................................................................................... 81

3.5.2 PWR Alarms .............................................................................................................................................................. 82

3.5.3 BATT Alarms ............................................................................................................................................................. 83

3.5.4 COMM Alarms ........................................................................................................................................................... 84

3.5.5 APP Alarms ............................................................................................................................................................... 84

3.6 Smart Display Glossary ........................................................................................................................................................ 84

3.7 Automatic Performance Test ................................................................................................................................................ 88

3.8 Providing Power via Portable Generator or Inverter ............................................................................................................ 89

3.8.1 DC Powering ............................................................................................................................................................. 89

3.8.2 AC Powering ............................................................................................................................................................. 89

3.8.3 Using a Truck-mounted Inverter or Generator........................................................................................................... 90

3.9 Resumption of Utility Power ................................................................................................................................................. 91

Table of Contents

4.0 Maintenance ................................................................................................................................................................................ 92

4.1 Safety Precautions ............................................................................................................................................................... 92

4.2 Required Tools and Equipment ............................................................................................................................................ 92

4.3 Power Supply System Maintenance .................................................................................................................................... 93

4.3.1 Preparing for Maintenance ........................................................................................................................................ 93

4.3.2 Periodic Maintenance Tasks ......................................................................................................................................93

4.3.2.1 Remote Status Monitoring of Power Supply Self Test .......................................................................................... 93

4.3.2.2 On-Site Power Supply Preventive Maintenance ................................................................................................... 93

4.4 Battery Maintenance ............................................................................................................................................................ 96

4.4.1 Battery Notes............................................................................................................................................................. 96

4.4.2 Battery Maintenance Guidelines ............................................................................................................................... 97

4.4.3 Disposal, Recycling and Storage Instructions ........................................................................................................... 98

4.4.4 Capacity .................................................................................................................................................................... 99

4.4.5 Preparing for Maintenance ........................................................................................................................................ 99

017-882-B0-001 Rev. C2 (10/2013)

5

Page 6

Table of Contents

4.4.6 Periodic Maintenance Tasks ....................................................................................................................................100

4.4.6.1 Remote Status Monitoring .................................................................................................................................. 100

4.4.6.2 On-Site Battery Preventive Maintenance ............................................................................................................ 101

4.4.7 Battery Refurbishment Plan .................................................................................................................................... 104

4.4.8 Battery Evaluation Procedures for AlphaCell Batteries ........................................................................................... 105

4.5 XM3-HP System Preventive Maintenance Log .................................................................................................................. 106

5.0 Shut Down ................................................................................................................................................................................. 107

Appendix ........................................................................................................................................................................................ 108

Specications ............................................................................................................................................................................ 108

Safety and EMC Compliance .....................................................................................................................................................110

Simplied Block Diagram ...........................................................................................................................................................111

Battery Spacer Clips...................................................................................................................................................................112

System Options ..........................................................................................................................................................................113

Return and Repair Information ...................................................................................................................................................113

Figures

Fig. 1-1, Alpha XM3-HP Intelligent CableUPS ......................................................................................................................... 16

Fig. 1-2, 3-Stage Charger Modes............................................................................................................................................. 19

Fig. 1-3, 4-Stage Charger Modes............................................................................................................................................. 20

Fig. 1-4, 5-Stage Charger Modes............................................................................................................................................. 21

Fig. 1-5, Front Panel, XM3-HP Power Supply .......................................................................................................................... 23

Fig. 1-6, Side Panel, XM3-HP Power Supply ........................................................................................................................... 23

Fig. 1-7, Detail View, Front Panel Connections and Indicators ................................................................................................ 24

Table of Contents

Fig. 1-8, Output Voltage Terminal Block ................................................................................................................................... 26

Fig. 1-9, AlphaDOC Standoff and Screw Locations ................................................................................................................. 26

Fig. 1-10, 5-Position Output Voltage Terminal Block ............................................................................................................... 27

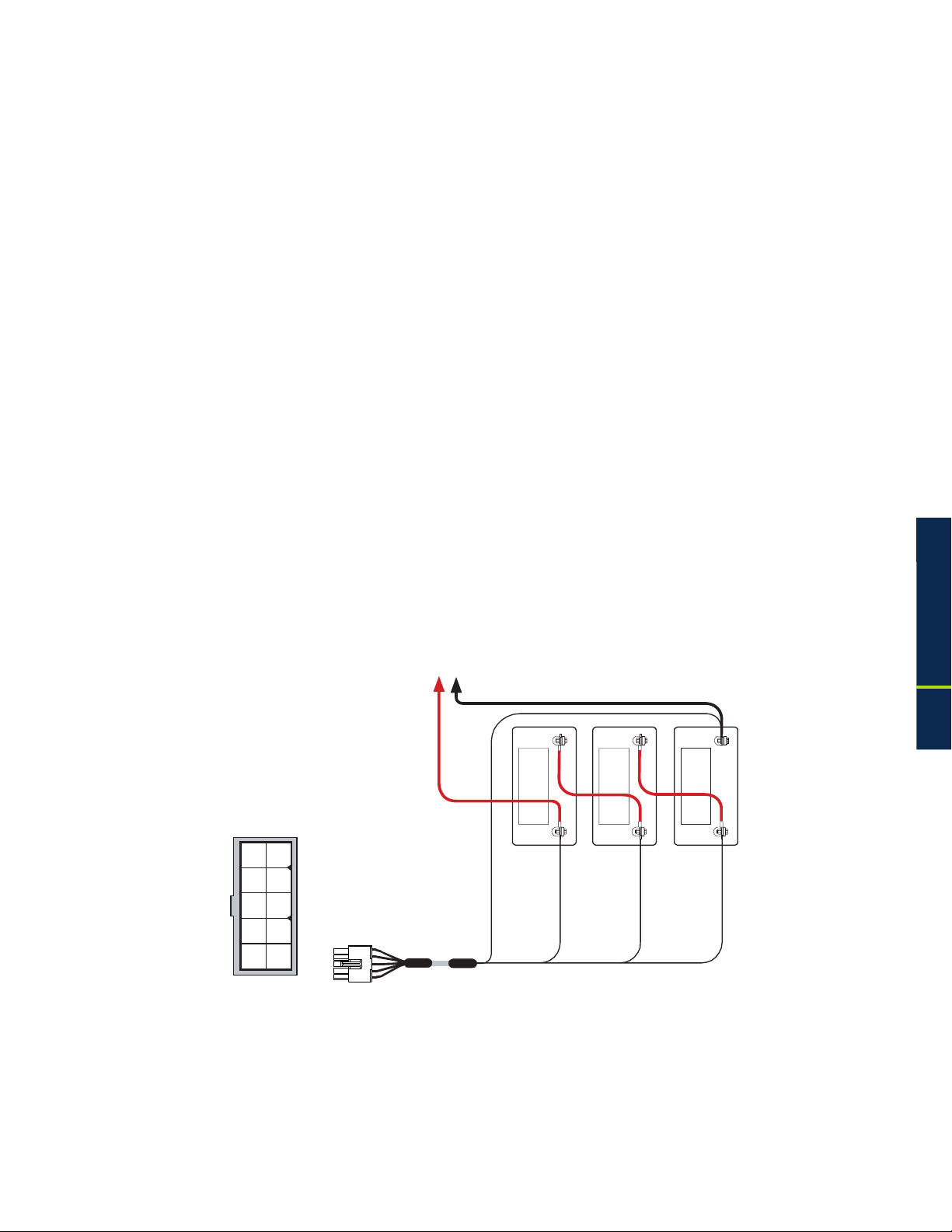

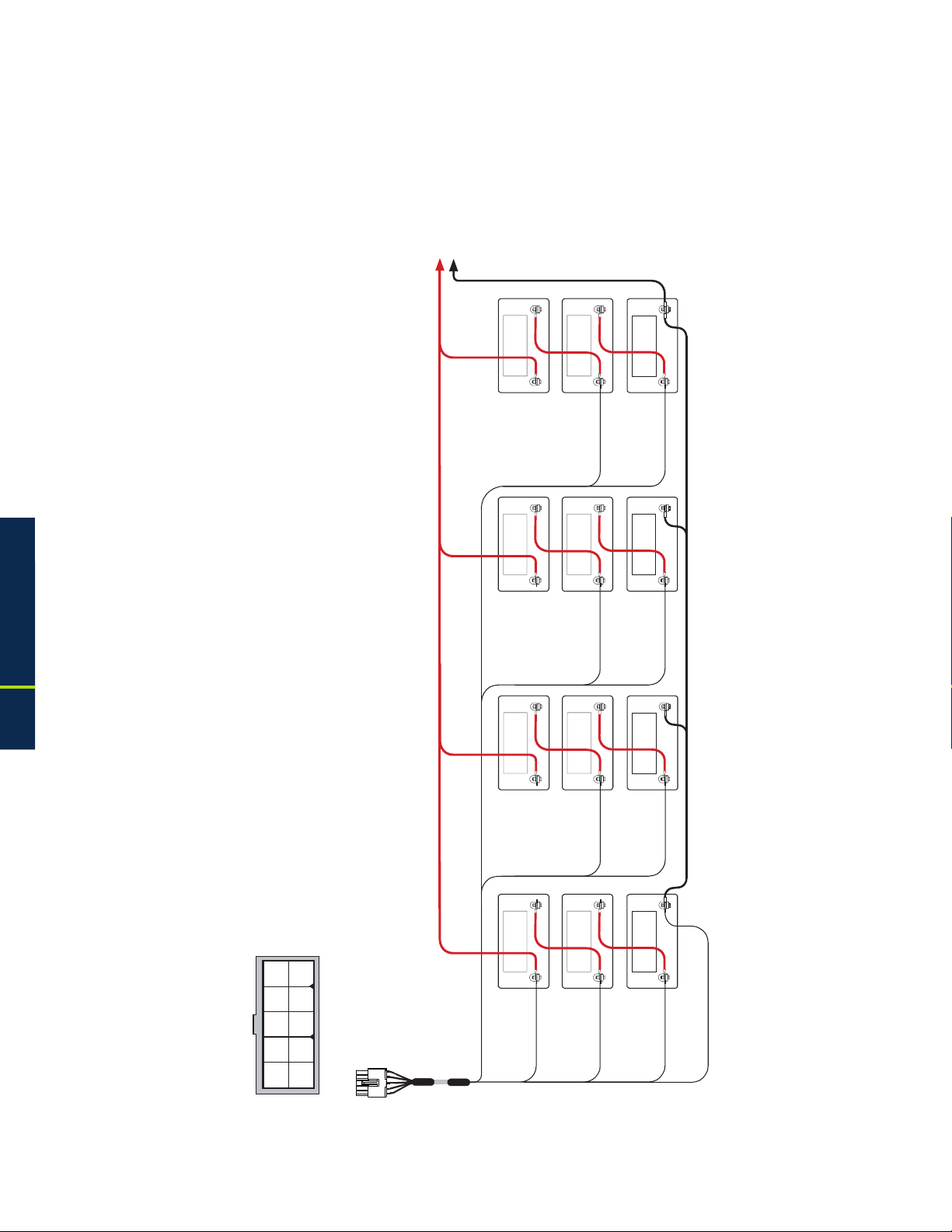

Fig. 1-11, Single Battery String Wiring Diagram (w/ embedded SAG Harness depicted) ........................................................ 29

Fig. 1-12, Multiple Battery String Wiring Diagram (w/ embedded SAG Harness depicted) ..................................................... 30

Fig. 1-13, SAG Front Panel ...................................................................................................................................................... 32

Fig. 1-14, Inverter Module Connections ................................................................................................................................... 34

Fig. 1-15, AlphaNet Series Communication Modules............................................................................................................... 36

Fig. 2-1, Required Materials ..................................................................................................................................................... 38

Fig. 2-2, Security Screw Mounting Location............................................................................................................................. 38

Fig. 2-3, Power Supply/Enclosure Shelf Security Screw Stack Up .......................................................................................... 38

Fig. 2-4, Installation of XM3-HP ............................................................................................................................................... 39

Fig. 2-5, Battery Wiring Diagram (w/ embedded SAG option depicted) ................................................................................... 40

Fig. 2-6, Precision Temperature Sensor (PTS), p/n 746-331-20 .............................................................................................. 40

Fig. 2-7, Battery Terminal Bolt Stack-up ................................................................................................................................... 41

Fig. 2-8, Fuse Bolt Stack-up..................................................................................................................................................... 41

Fig. 2-9, Transformer Harness ................................................................................................................................................. 41

Fig. 2-10, 120/240V Connector ................................................................................................................................................ 41

Fig. 2-11, Line Cord Plugs ........................................................................................................................................................ 42

Fig. 2-12, Input Voltage Setting Screen ................................................................................................................................... 42

6

017-882-B0-001 Rev. C2 (10/2013)

Page 7

Figures

Fig. 2-13, Removing Inverter Module and Output Voltage Terminal Location .......................................................................... 42

Fig. 2-14, Voltage Wire Position .............................................................................................................................................. 42

Fig. 2-15, Front Panel Fastener Locations .............................................................................................................................. 43

Fig. 2-16, APPS Card Standoff, Screw and Ribbon Cable Locations ..................................................................................... 43

Fig. 2-17, SAG Card Standoffs, Screws and Ribbon Cable Locations ................................................................................... 43

Fig. 2-18, SPI, AlphaDOC and SAG Harness Connections .................................................................................................... 44

Fig. 2-19, N+1 Conguration .................................................................................................................................................... 44

Fig. 2-20, Dual Redundancy N+1 Conguration ...................................................................................................................... 45

Fig. 2-21, Active Alarm Screen ................................................................................................................................................. 45

Fig. 2-22, N+1 In Use Alarm Screen ........................................................................................................................................ 45

Fig. 2-23, DOCSIS Status Monitor Front Panel Connections .................................................................................................. 46

Fig. 2-24, Active Alarm Table .................................................................................................................................................... 49

Fig. 2-25, Enter Battery Date Code .......................................................................................................................................... 49

Fig. 2-26, Enter Battery MHOs Reading .................................................................................................................................. 49

Fig. 2-27, Select Language in PWR CNFG Menu.................................................................................................................... 50

Fig. 2-28, COMM Menu Options .............................................................................................................................................. 51

Fig. 2-29, DSM3 Series Web Page .......................................................................................................................................... 52

Fig. 2-30, Local Area Connection Properties Screen, Windows XP ......................................................................................... 53

Fig. 2-31, Internet Protocol (TCP/IP) Properties Screen, Windows XP ................................................................................... 53

Fig. 2-32, Local Area Connection Properties Screen, Windows 7 ........................................................................................... 54

Fig. 2-33, Internet Protocol (TCP/IP) Properties Screen, Windows 7 ...................................................................................... 54

Fig. 2-34, Web Server Home Page .......................................................................................................................................... 55

Fig. 2-35, DSM3 Series Navigation Bar Items ......................................................................................................................... 56

Fig. 2-36, Communication Parameters .................................................................................................................................... 58

Fig. 2-37, Advanced Communication Parameters.................................................................................................................... 58

Fig. 2-38, Power Supply and Battery Parameters .................................................................................................................... 59

Fig. 2-39, Location of "Start" Button for Self Test ..................................................................................................................... 59

Fig. 3-1, Operation Normal Display Screen ............................................................................................................................. 61

Fig. 3-2, Navigating Through Menu Screens ........................................................................................................................... 61

Fig. 3-3, Input Voltage Settings Screen.................................................................................................................................... 62

Fig. 3-4, Active Alarm Table ...................................................................................................................................................... 80

Fig. 3-5, Sample Active Alarm Display, PWR Menu ................................................................................................................. 81

Fig. 3-6, Sample Active Alarm Display, BATT Menu................................................................................................................. 81

Fig. 3-7, Sample Active Alarm Display, COMM Menu .............................................................................................................. 81

Fig. 4-1, XM3-HP System Components ................................................................................................................................... 94

Fig. 4-2, Capacity vs. Storage Time for AlphaCell GXL ........................................................................................................... 98

Fig. 4-3, Capacity vs. Storage Time for AlphaCell HP .............................................................................................................. 98

Fig. 4-4, Available Capacity vs. Ambient Temperature ............................................................................................................. 99

Fig. 4-5, Flow Chart for Remote Status Monitoring .................................................................................................................. 100

Fig. 4-6, Flow Chart for Preventive Maintenance ..................................................................................................................... 101

Fig. 4-7, Flow Chart for Battery Refurbishment Plan ............................................................................................................... 104

Fig. 5-1, Emergency Shutdown ................................................................................................................................................ 107

Fig. A-1, Block Diagram ........................................................................................................................................................... 111

Fig. A-2, Placement of Battery Spacer Clips (for domestic and international 36V battery strings) .......................................... 112

Table of Contents

017-882-B0-001 Rev. C2 (10/2013)

7

Page 8

Tables

Table 1-1, Low Battery Cutoff (EOD) ........................................................................................................................................ 18

Table 1-2, Charger Modes of Operation ................................................................................................................................... 18

Table 1-3, Duration of Load ...................................................................................................................................................... 25

Table 1-4, Smart AlphaGuard LED Alarm States ..................................................................................................................... 32

Table 1-5, Comparative Features, AlphaNet Series Communications Modules ...................................................................... 36

Table 2-1, DSM3 LEDs Behavior ............................................................................................................................................. 47

Table 2-2, DSM3 Series Transponder Security Levels............................................................................................................. 57

Table 3-1, AC Output ................................................................................................................................................................ 60

Table 3-2, Main Menu Functions .............................................................................................................................................. 61

Table 3-3, Logged Events and Alarms ..................................................................................................................................... 72

Table 3-4, PWR Alarms: Classications, Causes and Corrections .......................................................................................... 82

Table 3-5, BATT Alarms: Classications, Causes and Corrections .......................................................................................... 83

Table 3-6, COMMs Alarms: Classications, Causes and Corrections...................................................................................... 84

Table 3-7, APP Alarms: Classications, Causes and Corrections ............................................................................................ 84

Table 4-1, On-Site Battery Preventive Maintenance ................................................................................................................ 103

Table 4-2, AlphaCell Conductance Values, Healthy vs. Suspect Batteries .............................................................................. 105

Table A-1, Product Certications Regarding Safety, EMC Compliance ................................................................................... 110

2.0 Installation

8

017-882-B0-001 Rev. C2 (10/2013)

Page 9

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions regarding

the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha representative. Save this

document for future reference.

To reduce the risk of injury or death and to ensure the continued safe operation of this product, the following symbols have

been placed throughout this manual. Where these symbols appear, use extra care and attention.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to the technician or

user.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure.

ATTENTION:

The use of ATTENTION indicates specic regulatory/code requirements that may affect the placement of equipment

and/or installation procedures.

Safety Precautions

• Only qualied personnel should service the Power Supply.

• Verify the voltage requirements of the equipment to be protected (load), the AC input voltage to the Power Supply

(line) and the output voltage of the system prior to installation.

• Equip the utility service panel with a properly rated circuit breaker for use with this Power Supply.

• When connecting the load, DO NOT exceed the output rating of the Power Supply.

• Always use proper lifting techniques whenever handling units, modules or batteries.

• The Power Supply contains more than one live circuit! Even though AC voltage is not present at the input, voltage

may still be present at the output.

• The battery string, which provides backup power, contains dangerous voltages. Only qualied personnel should

inspect or replace batteries.

• In the event of a short-circuit, batteries present a risk of electrical shock and burns from high current. Observe

proper safety precautions.

• Do not allow live battery wires to contact the enclosure chassis. Shorting battery wires can result in a re or

possible explosion.

• This Power Supply has been investigated by regulatory authorities for use in various Alpha enclosures. If you

are using a non-Alpha enclosure, it is your responsibility to ensure your combination conforms to your local

regulatory requirements and the Power Supply remains within its environmental specications.

9017-882-B0-001 Rev. C2 (10/2013)

Page 10

Battery Safety Notes

Any gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contains diluted sulfuric acid, which is

harmful to the skin and eyes. Emissions are electrolytic and are electrically conductive and corrosive.

To avoid injury:

• Always wear eye protection, rubber gloves, and a protective vest when working near batteries. To avoid

battery contact, remove all metallic objects, (such as rings or watches), from your person.

• Batteries produce explosive gases. Keep all open ames and sparks away from batteries.

• Use tools with insulated handles, do not rest any tools on top of batteries.

• If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your company’s

approved chemical exposure procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with

a solution of one pound bicarbonate of soda to one gallon of water. Report a chemical spill using your

company’s spill reporting structure and seek medical attention if necessary.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

developed on your body.

• Use special caution when connecting or adjusting battery cabling. An improperly or unconnected battery cable

can make contact with an unintended surface that can result in arcing, re, or a possible explosion.

• A battery showing signs of cracking, leaking, or swelling should be replaced immediately by authorized

personnel using a battery of identical type and rating.

Battery Maintenance Guidelines

• During maintenance visits, inspect batteries for the following:

• Signsofbatterycracking,leakingorswelling. The battery should be replaced immediately by

authorized personnel using a battery of the identical type and rating.

• Signsofbatterycabledamage. Battery cable should be replaced immediately by authorized

personnel using replacement parts specied by vendor.

• Loosebatteryconnectionhardware. Refer to documentation for the correct torque and connection

hardware for the application.

• Always replace batteries with those of an identical type and rating. Match conductance, voltage and date codes.

• Do not attempt to remove the vents (valves) from the AlphaCell broadband battery or add water. This is a safety

hazard and voids the warranty.

• Apply NO-OX grease on all exposed connections.

• When necessary, clean up any spilled electrolyte in accordance with all federal, state, and local regulations or codes.

• Follow approved storage instructions.

• Always replace batteries with those of an identical type and rating. Never install untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least 1/2 inch of space between

it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially dangerous gas.

Never place batteries in a sealed enclosure. Extreme caution should be used when maintaining and collecting data on

the battery system. Ensure all enclosure vents and lters are clean and free of debris.

• Spent or damaged batteries are environmentally unsafe. Always recycle used batteries. Refer to local codes for

proper disposal of batteries.

10 017-882-B0-001 Rev. C2 (10/2013)

Page 11

Utility Power Connection Notes

NOTE:

Alpha enclosures are engineered to properly vent the Power Supply. The Power Supplies have been investigated by

regulatory authorities for use in various Alpha enclosures. If you are using a non-Alpha enclosure, it is your responsibility

to ensure your combination conforms to your local regulatory requirements and the Power Supply remains within its

environmental specications.

ATTENTION:

Connecting to the utility should be performed only by qualied service personnel and in compliance with local electrical

codes. Connection to utility power must be approved by the local utility before installing the Power Supply.

Local regulatory authorities may require the use of an approved service entrance and/or service disconnect switch when

the Power Supply is installed in an outdoor enclosure. Alpha enclosures have switch options. The installer may need to

provide these if using a non-Alpha enclosure.

NOTE:

In order to accommodate the high-inrush currents normally associated with the start-up of ferroresonant

transformers (400 Amp, no-trip, rst-half cycle), either a “high-magnetic” or an HACR (Heating, Air Conditioning,

Refrigeration) trip breaker must be used. Do not replace these breakers with a conventional service entrance

breaker. Alpha recommends ONLY Square D breakers because of the increased reliability required in this powering

application. High-magnetic Square D circuit breakers and a BBX option (UL Listed service entrance) are available

from Alpha Technologies.

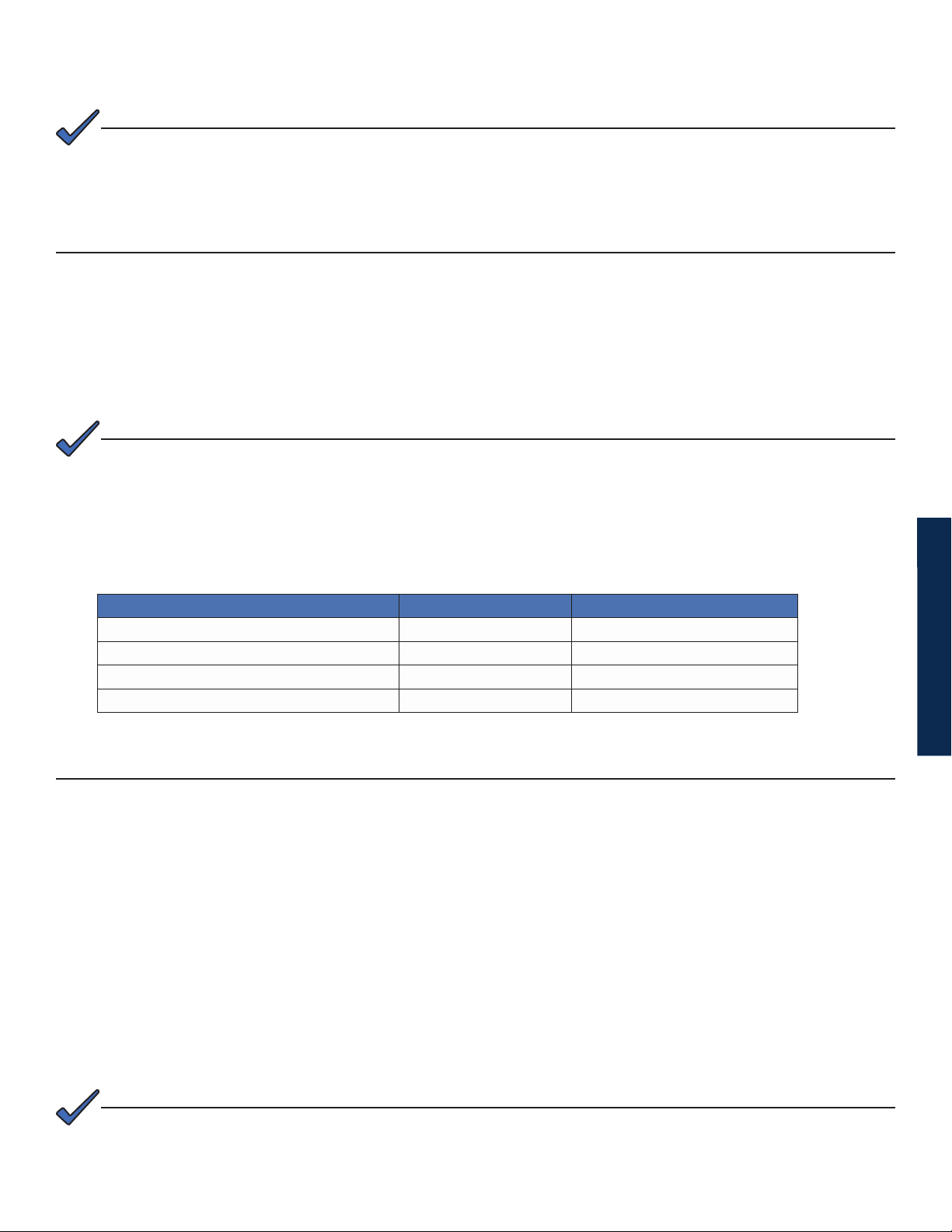

Description Alpha Part Number Square D Part Number

240V Installation - HACR (15A) 470-224-10 QO215

120V Installation - High-magnetic (20A) 470-017-10 QO120HM

BBX - External Service Disconnect 020-085-10 QO2 -4L70RB

BBX - External Service Disconnect 020-141-10 QO8-16L100RB

ATTENTION:

In most cases, the following congurations qualify for service entrance use when wiring a duplex receptacle to a service

disconnect. Other codes may also apply. Always contact your local utility to verify the wiring conforms to applicable codes.

XM3-HP Connections

Proper 120VAC 20A service requires the installation site be:

• Equipped with a 120VAC duplex receptacle which provides power to the Power Supply and peripheral

equipment.

• Have a NEMA 5-20R receptacle protected by a single-pole, 20 Amp High Magnetic (HM) circuit breaker inside

the service entrance.

• Checked to NEC/CEC Code or with your local regulatory authority to verify proper wire AWG (suggested wire

gauge is 12AWG).

• Equipped with a grounding clamp on the enclosure to facilitate dedicated grounding.

NOTE:

When it is required to bond the box to a neutral plate, use the long green bonding screw provided (Alpha P/N

523-011-10, Square D P/N 40283-371-50).

11017-882-B0-001 Rev. C2 (10/2013)

Page 12

Utility Power Connection Notes, continued

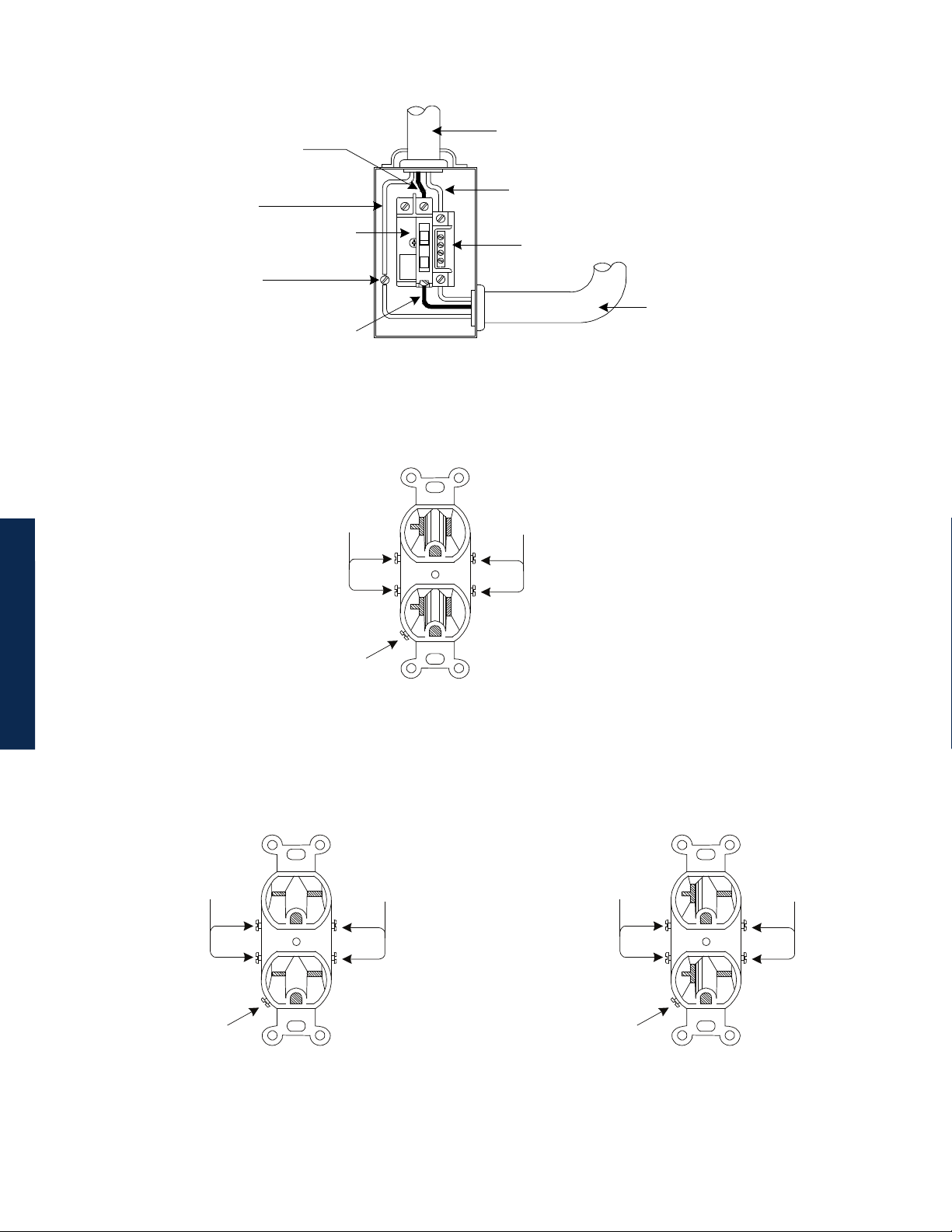

LI (Black)

To Utility

Copper Ground Wire

#8 AWG (Minimum)

Grounding Point Made

to Enclosure Wall

Neutral (White)

Breaker

Neutral Bus

LI (Black)

Typical 120VAC Service Entrance Wiring

Neutral

(White)

LI

(Black)

To Enclosure

Receptacle

Ground

(Green)

Typical 120 VAC 20A Receptacle Wiring, 5-20R

(P/N 531-006-19)

LI

(Black)

L2

(Red)

Ground

(Green)

Typical 240 VAC 20A Receptacle Wiring, 6-15R

(P/N 531-004-19)

LI

(Black)

L2

(Red)

Ground

(Green)

Typical 240 VAC 20A Receptacle Wiring, 6-20R

(P/N 531-008-19)

12 017-882-B0-001 Rev. C2 (10/2013)

Page 13

Utility Power Connection Notes, continued

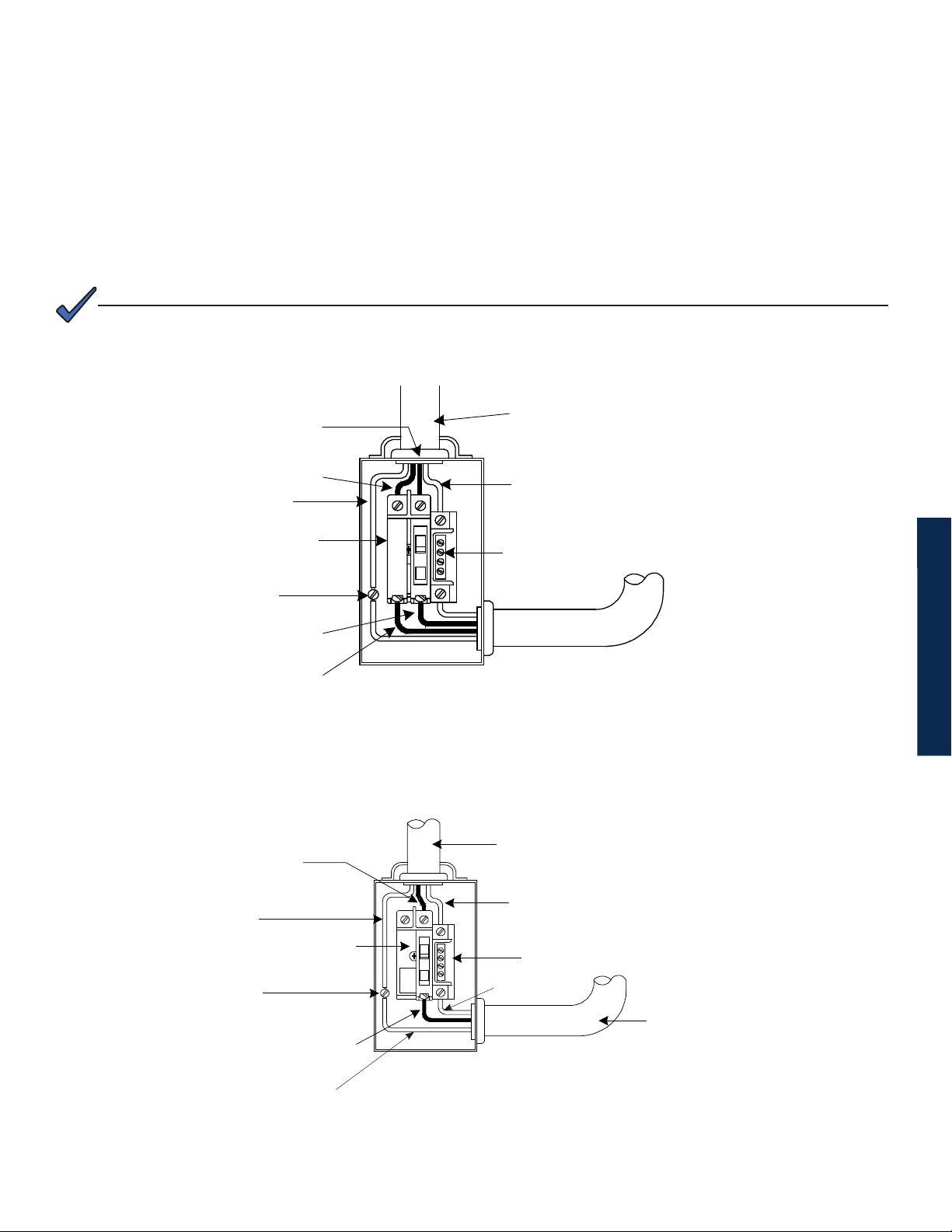

Proper 240VAC 15A service requires the installation site be:

• Equipped with a 240VAC duplex receptacle to provide power to the Power Supply and peripheral equipment.

• Have a NEMA 6-15R receptacle that is protected by a single, 2-pole, common trip 15A circuit breaker inside

the service entrance.

• Checked to NEC/CEC Code or with your local regulatory authority to verify proper wire AWG (suggested wire

gauge is 14AWG).

• Equipped with a grounding clamp on the enclosure to facilitate dedicated grounding.

NOTE:

When it is required to bond the box to a neutral plate, use the long green bonding screw provided (Alpha P/N

523-011-10, Square D P/N 40283-371-50).

LI (Black)

L2 (Red)

Copper Ground Wire

#8 AWG (Minimum)

Breaker

Grounding Point Made

to Enclosure Wall

LI (Black)

L2 (Red)

LI (Brown)

To Utility

Neutral (White)

Neutral Bus

Typical 240VAC 60 Hz Service Entrance Wiring

To Utility

Copper Ground Wire

10mm2 or #8 AWG

(Minimum) (Yellow/Green)

Grounding Point Made

to Enclosure Wall

Copper Ground Wire

(Yellow/Green)

Neutral (Blue)

Breaker

Neutral Bus

Blue

LI (Brown)

Typical 230VAC 50Hz Service Entrance Wiring

To Enclosure

Receptacle

13017-882-B0-001 Rev. C2 (10/2013)

Page 14

Grounding and Earth Connection Notes

In order to provide a ready, reliable source of backup power, it is necessary to connect the Power Supply to an effective grounding

and Earthing system. This not only provides for the safety of the service personnel responsible for its operation and maintenance, but

also facilitates the proper operation and protection of the equipment within the network. Such a grounding system provides protection

with respect to operator safety, system communication and equipment protection.

Lightning strikes, grid switching or other aberrations on the power line and/or communications cable have the potential to cause highenergy transients that can damage the powering or communications systems. The most viable method available to protect the system

from damage is to divert these unwanted high-energy transients along a low-impedance path to earth. A low-impedance path to earth

prevents these currents from reaching high voltage levels and posing a threat to equipment.

The key to the success of lightning protection is single-point grounding so the components of the grounding system appear as a

single point of uniform impedance. Two places recommended by Alpha for single-point grounding are connections in the enclosure

and connections to earth. Single-point grounding in the enclosure is achieved by bonding all electrical connections to the enclosure,

including the connection to earth, as close together on the enclosure as possible. Single-point grounding for the connection to earth

is achieved, for example by the proper bonding of the ground rods.

Safety Ground and Earth Connection

The safety ground and earth is a two-part system, comprised of the utility service and the Alpha system.

1. The utility service;

As a minimum requirement for the protection of Alpha equipment, the local utility service must provide a low-

impedance path for fault current return. In addition, there must be a low impedance bonded path between the

Power Supply ground pin and the enclosure.

2. The Alpha grounding system;

The Alpha grounding system consists of a low-impedance connection between the enclosure and an Earth

Ground (located at least 6’ away from the Utility Earth connection).

This impedance between the enclosure and Earth must be 25 Ohms or less at 60 Hertz as measured by AMPROBE

Model DGC-1000 or equivalent. The measurement should be made on the wire or ground rod after it exits the

enclosure.

Local soil conditions will determine the complexity of the grounding system required to meet the 25 Ohm (maximum)

resistance specied above. For example, a single 8’ ground rod may be sufcient to meet the requirement. In

some cases, a more elaborate system may be required such as multiple ground rods connected by a #6AWG

solid copper cable buried 8-12” below the surface. Where this is not possible, contact a local grounding system

expert for alternate methods that will meet the 25 Ohm (maximum) specication.

All ground rod connections must be made by means of a listed grounding clamp suitable for direct burial or

exothermic welding.

Power Output Return

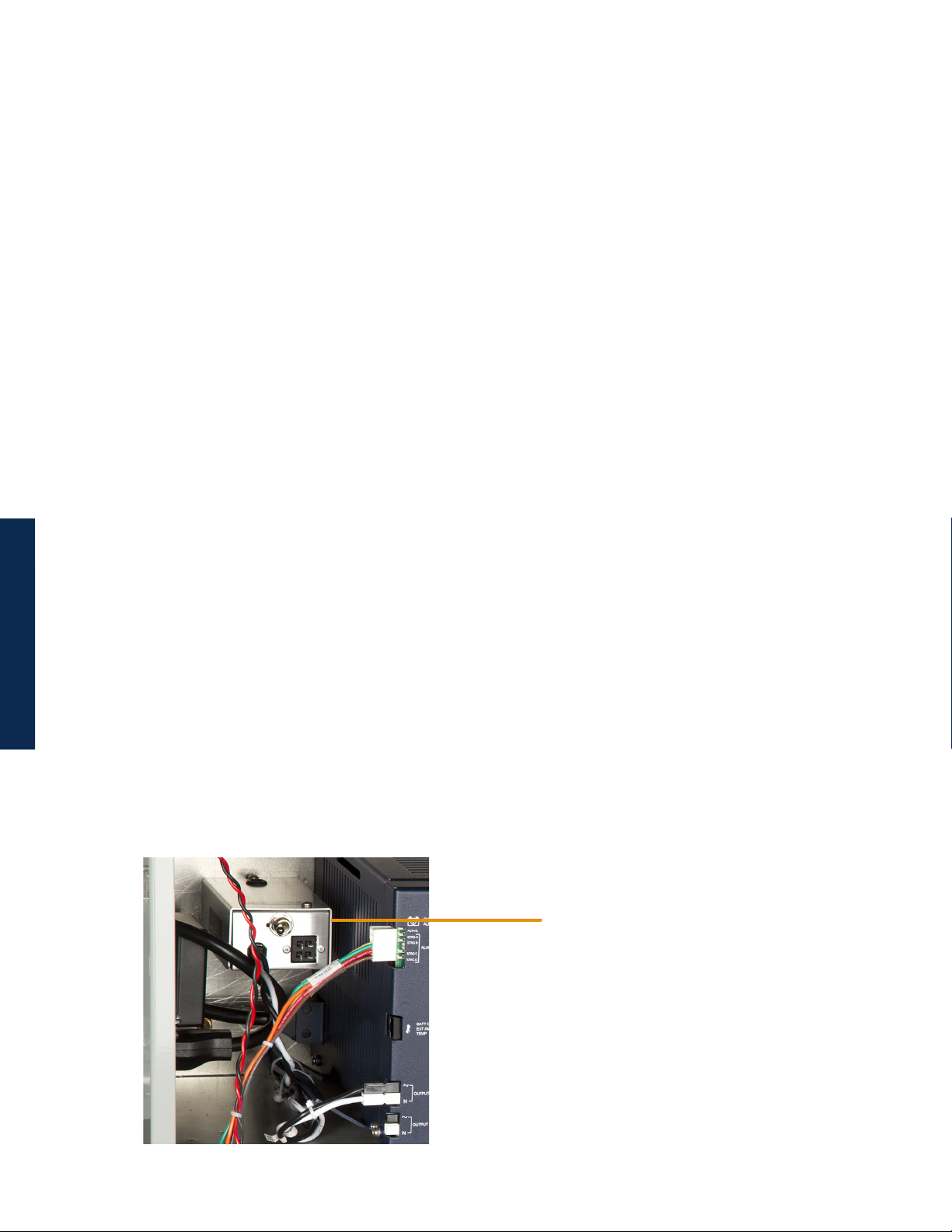

For proper operation, the Service Power Inserter (SPI) must be securely bonded to the enclosure.

SPI

14 017-882-B0-001 Rev. C2 (10/2013)

Page 15

Grounding and Earth Connection Notes, continued

Communications Grounding

For systems using an embedded transponder, the grounding connection is typically made either through a separate chassis ground

block bonded to the enclosure or by means of the internal mounting hardware which bonds the transponder through the CableUPS.

Please refer to the appropriate communications product manual for installation procedures.

For communication cables, Alpha strongly recommends the use of a surge arresting device electrically bonded to the Alpha Enclosure.

WARNING!

Low impedance grounding is mandatory for personnel safety and critical for the proper

operation of the cable system.

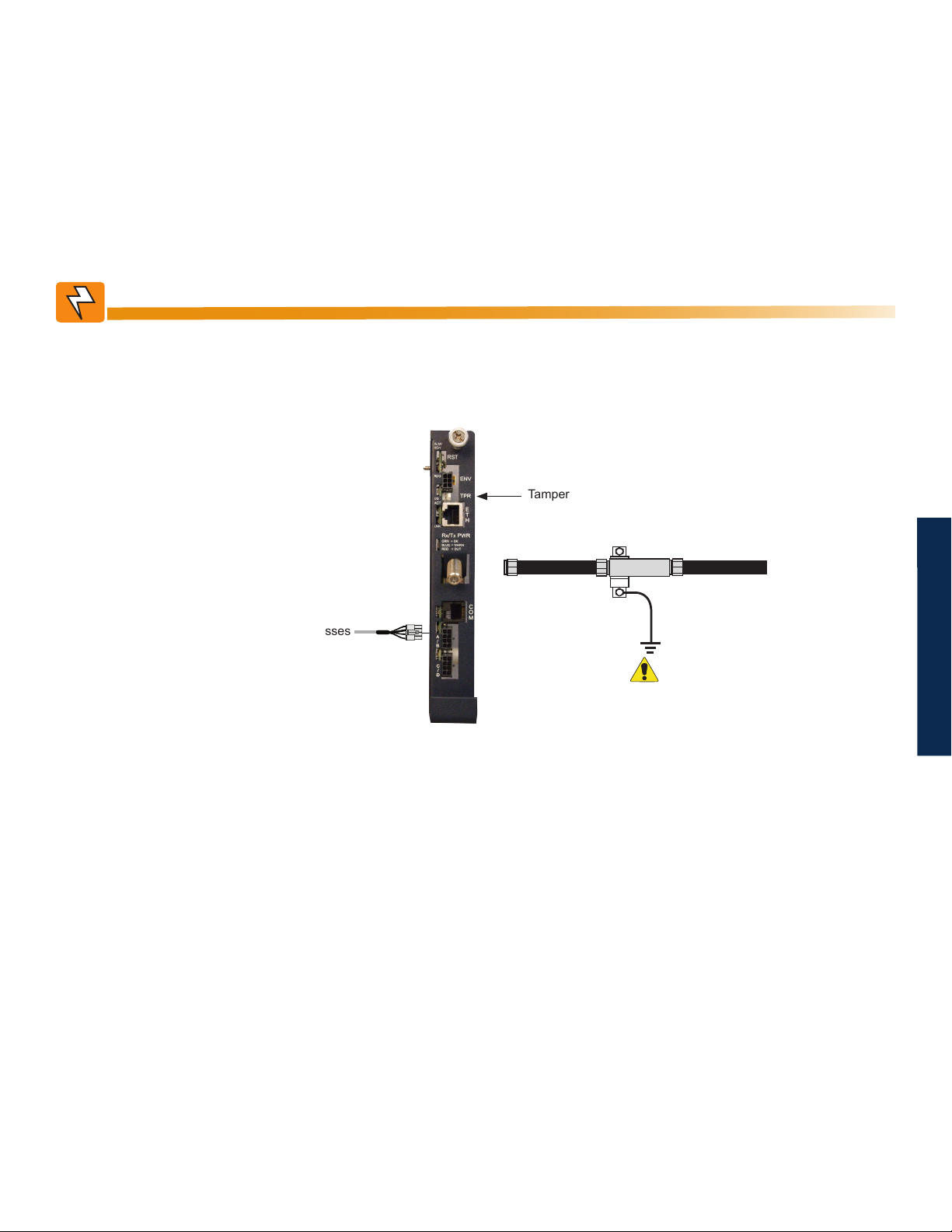

Tamper Switch Connector

To Battery Sense Wire Harnesses

RF Cable to Headend

Required

Grounded Surge Protector

(Alpha p/n 162-028-10 or equivalent)

15017-882-B0-001 Rev. C2 (10/2013)

Page 16

1.0 Introduction

1.0 Introduction

1.1 Alpha XM3-HP Intelligent CableUPS

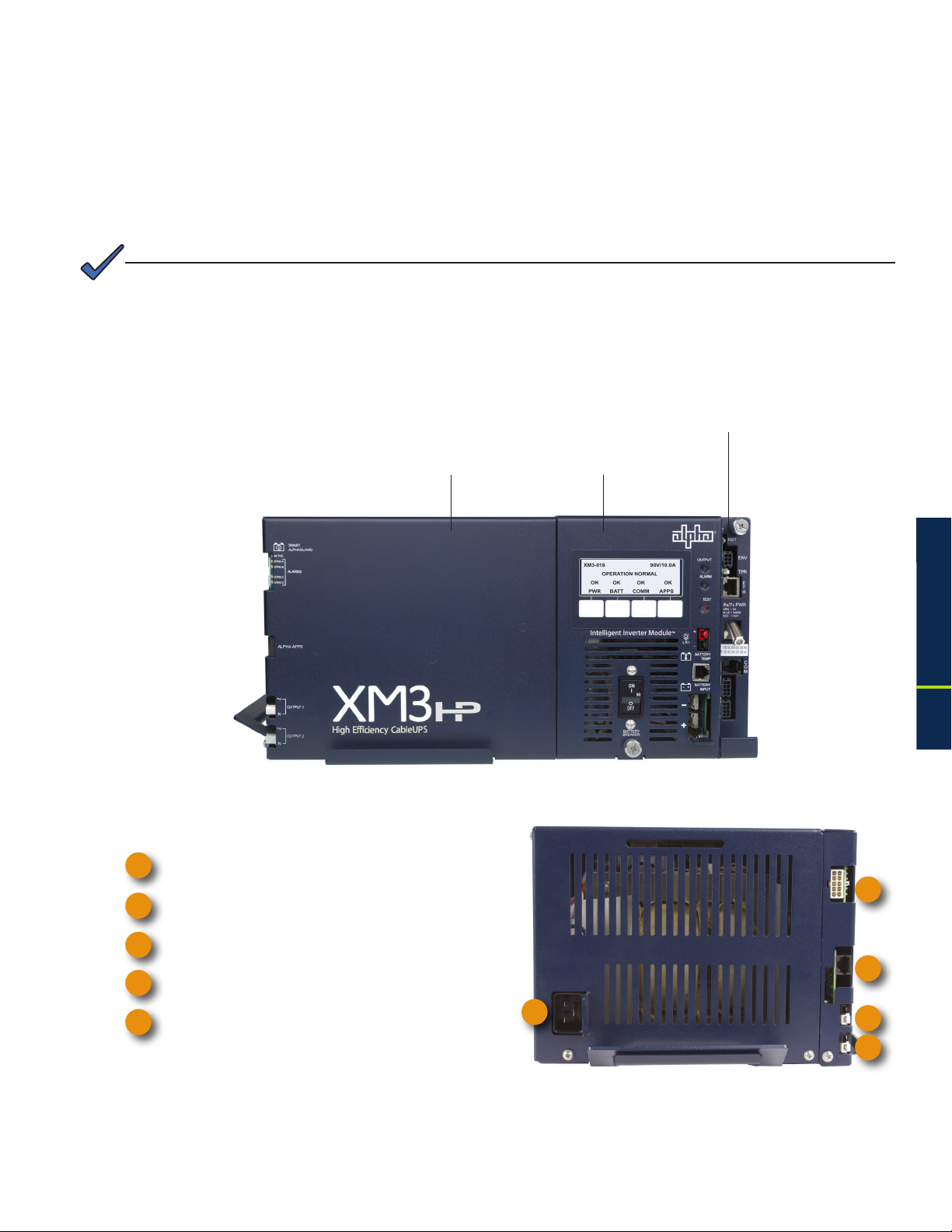

Fig. 1-1, Alpha XM3-HP Intelligent CableUPS

The Intelligent CableUPS® powers signal processing equipment in cable television and broadband LAN

distribution systems. The transformer module provides a critical load with current-limited regulated AC power

that is free of spikes, surges, sags and noise.

During AC line operation, AC power entering the Power Supply is converted into a quasi square wave and is

regulated by a ferroresonant transformer at the required output voltage. The regulated voltage is connected

to the load via the output connectors and some power is directed to the battery charger to maintain a oat

charge on the batteries.

When the incoming AC line voltage signicantly deviates from normal, the Inverter Module automatically

switches to standby operation and maintains power to the load. During the switch to standby operation,

energy in the module’s ferroresonant transformer continues to supply power to the load. In standby mode,

the Power Supply powers the load until the battery voltage reaches a low-battery cutoff point.

When utility power returns, the transformer module waits a short time (approximately 10 to 20 seconds) for the

utility voltage and frequency to stabilize and then initiates a smooth, in phase transfer back to AC line power.

Once the transfer is complete, the battery charger recharges the batteries in preparation for the next event.

NOTE:

®

16

The duration of battery-backed standby operation depends upon the type and number of batteries and the load on

the Power Supply.

The Alpha XM3-HP CableUPS contains the following:

• Smart Display

• Hot-swappable Inverter Module

• Built-in Self Test

• Wide Input voltage range

• High efciency transformer

• Communications menu with DOCSIS®

parameters (only with optional DSM3 or IDH4

installed)

• Optional factory-installed AlphaDOC (PIM)

allows the XM3-HP to provide programmable

current limits for two output channels.

NOTE:

During a no-load start-up, the Power Supply may reduce output voltage to 75-80% of rated output voltage until a

load of greater than 1.5A is applied.

• Optional Smart AlphaGuard (SAG)

• Optional AlphaAPPs (APPS) card

• Via the Smart Display, the operator can

view all of the Power Supply’s operating

parameters.

• Troubleshooting tips automatically display

in the Alarm menu screen.

• Built-in metering circuits measure voltage

and current, without the need for external

test equipment.

017-882-B0-001 Rev. C2 (10/2013)

Page 17

1.0 Introduction, continued

1.2 Theory of Operation

1.2.1 AC (Line) Operation

During AC Line operation, utility power is routed into the primary winding of the ferroresonant

transformer through the contacts of the transfer isolation relay. Simultaneously, in the inverter, power

is directed to the rectier circuitry providing power for the control circuitry. The bidirectional inverter

also serves as a battery charger during line operation. The ferroresonant transformer and an AC

capacitor form the resonant tank circuit, which provides excellent noise and spike attenuation, output

short-circuit current-limiting, and output voltage regulation. The ferroresonant transformer produces

a quasi square wave output which resembles a rounded square wave.

NOTE:

When measuring the output voltage of ferroresonant transformers, use only a true RMS AC voltmeter. NonRMS reading meters are calibrated to respond to pure sine waves and do not provide an accurate reading when

measuring quasi square wave output.

1.2.2 Standby Operation

When the incoming AC line voltage drops or rises signicantly or a complete power outage occurs,

the control logic’s line monitor activates standby operation. During the transfer from AC line to standby

operation, the battery powered inverter comes online as the isolation relay switches to prevent AC

power from back-feeding to the utility. The following changes also occur within the Power Supply:

• The isolation relay opens to disconnect the AC line from the primary winding of the ferroresonant

transformer.

• The control logic switches the inverter FETs on and off. This switching action converts the DC

battery current into AC current in the inverter windings of the ferroresonant transformer, providing

regulated power to the load.

• The control logic, which includes a microprocessor and other circuits to protect the inverter

FETs from overcurrent damage, monitors the condition of the batteries and the inverter during

standby operation. Since a prolonged AC line outage could severely discharge the batteries,

resulting in permanent damage, the control logic disables the inverter when the batteries drop

to a predetermined cutoff voltage.

• The XM3-HP offers two user-selectable EOD options based on either overall string voltage or

individual battery voltage. See Table 1-1 for battery specic EOD settings. Operation is dened

as follows:

• Battery String Voltage Mode which shuts off the inverter when the 36V bus voltage reaches

Low Battery Cutoff Voltage as seen at the inverter.

• Individual Battery Voltage Mode which shuts off the inverter when any battery in any string

(1-4) reaches Low Battery Cutoff Voltage.

• All units will factory default to Battery String Voltage Mode.

• Individual battery EOD will only be available (user-selectable) if individual battery voltages

are being sensed and present at logic card via the Smart AlphaGuard, DSM3 or other

approved status monitor card with individual battery voltage sensing.

1.0 Introduction

• When set to Battery String Voltage Mode the “Low Battery Cutoff” (EOD) is not user adjustable

from the default. See Table 1-1 for more information.

• When set to individual Battery Voltage Mode the “Low Battery Cutoff” (EOD) will automatically

set to default values based on battery type (see Table 1-1). A secondary option is then

offered to the user for manually programming the “Low Battery Cutoff” (EOD), regardless

of battery type, within the range 1.65 to 1.80 V/C.

17017-882-B0-001 Rev. C2 (10/2013)

Page 18

1.0 Introduction, continued

1.2 Theory of Operation, continued

1.2.2 Standby Operation, continued

• When set to Individual Battery Voltage Mode, if individual battery voltage is lost, the unit automatically

reverts back to Battery String Voltage Mode and "Low Battery Cutoff” (EOD) will revert back to default

value based on battery type.

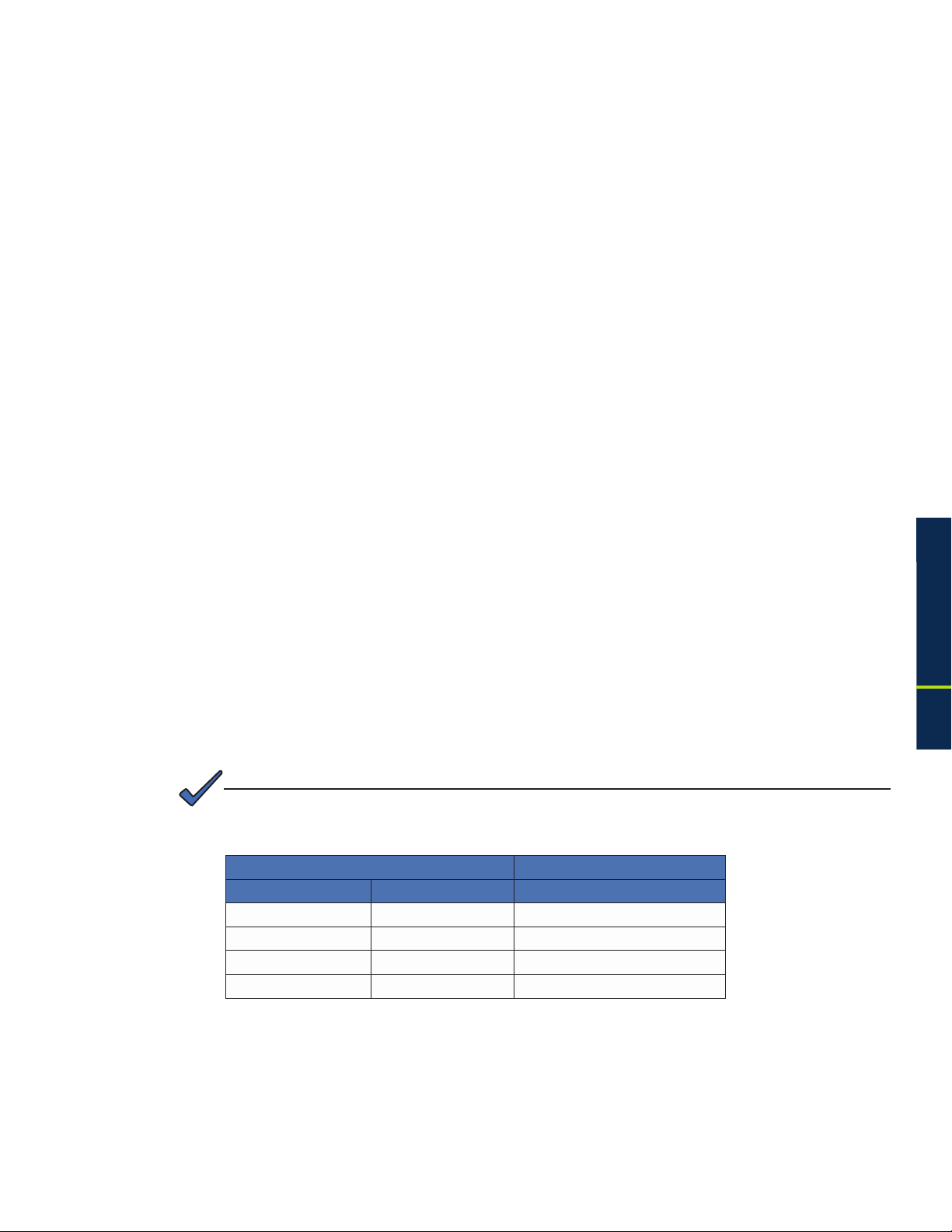

String Low Battery

Cutoff (EOD)

Individual Low

Battery Cutoff

HP Batteries

OTHER Batteries

(EOD)

HP Batteries GXL Batteries OTHER Batteries

Fixed Fixed Fixed

30.6 VDC

(1.70 V/C)

Default Minimum Maximum

10.2 VDC

(1.70 V/C)

10.5 VDC

(1.75 V/C)

10.5 VDC

(1.75 V/C)

31.5 VDC

(1.75 V/C)

9.9 VDC

(1.65 V/C)

31.5 VDC

(1.75 V/C)

10.8 VDC

(1.80 V/C)GXL Batteries

Table 1-1, Low Battery Cutoff (EOD)

1.0 Introduction

• When acceptable AC line voltage returns, the Power Supply returns to AC line operation after a 10

to 20 second lag. This delay lets the AC line voltage and frequency stabilize before the control logic

phase-locks the inverter’s output to the utility input. The control logic then de-energizes the isolation

relay, reconnects the AC line to the primary of the ferroresonant transformer and disables (turns off)

the inverter. This results in a smooth, in-phase transfer back to utility power without interruption of

service to the load. The battery charging circuit then activates to recharge the batteries in preparation

for the next power outage.

1.2.3 Charger Modes of Operation

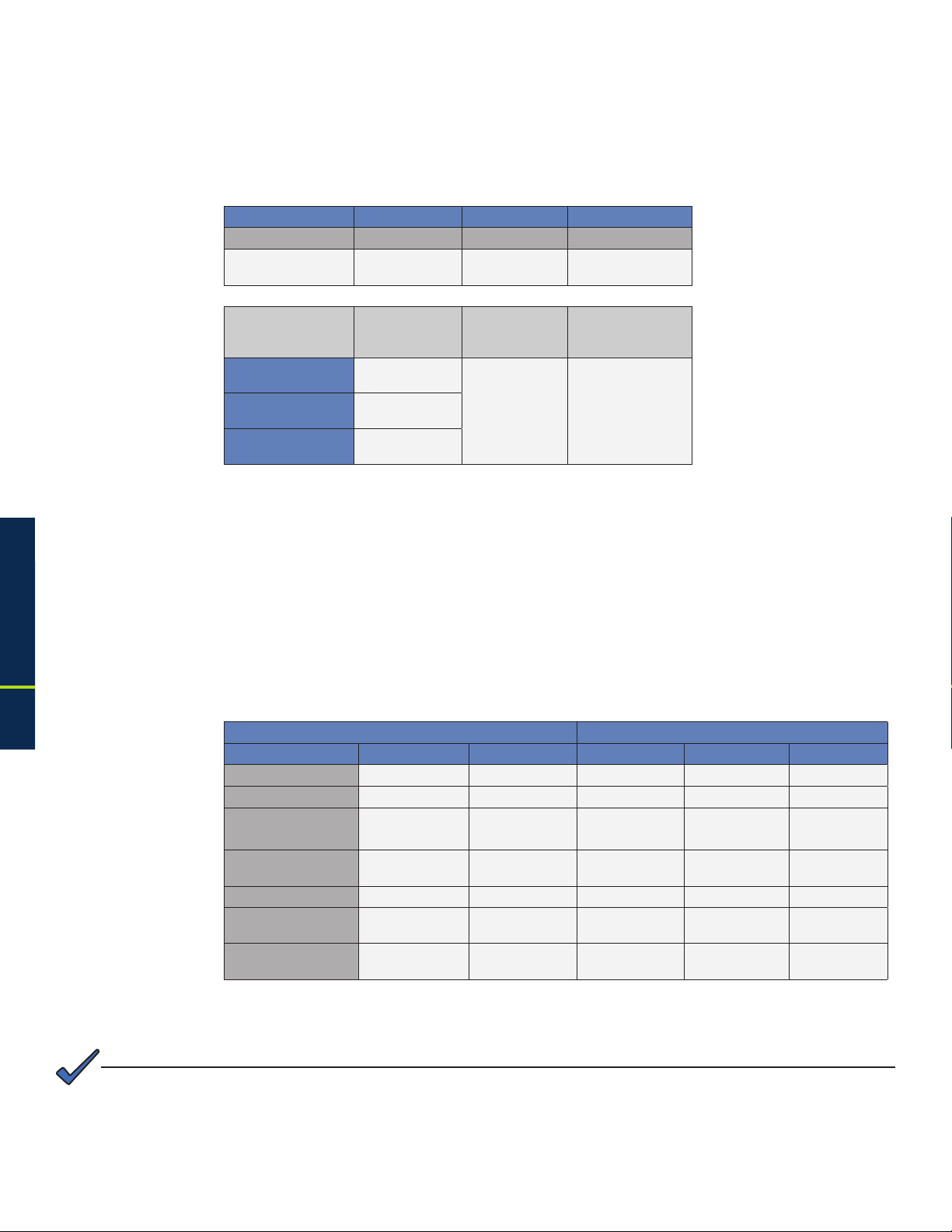

AlphaCell Batteries OTHER Batteries

HP GXL Default Minimum Maximum

Float V/C 2.25 2.27 2.27 2.10 2.35

Accept V/C 2.35 2.40 2.40 2.20 2.45

Automatic 30-Minute

Refresh On/Off

Manual 24-Hour

Refresh On/Off

Refresh V/C 2.45 2.45 2.45 2.40 2.50

Rest On/Off ON OFF

Temperature

Compensation

ON ON OFF OFF OFF

OFF

(Programmable)

-4mV / ºC / cell - 5mV / ºC / cell

OFF

(Programmable)

OFF

(Programmable)

OFF

(Programmable)

-5mV / ºC / cell

(Programmable)

OFF ON

OFF ON

0 mV / ºC / cell -5mV / ºC / cell

18

Table 1-2, Charger Modes of Operation

NOTE:

If a battery type other than an AlphaCell is installed, it is the responsibility of the technician to review the proper

charging specications for the battery used.

017-882-B0-001 Rev. C2 (10/2013)

Page 19

1.0 Introduction, continued

1.2 Theory of Operation, continued

1.2.3 Charger Modes of Operation, continued

The Alpha XM3-HP uses a three-stage (other), four-stage (AlphaCell GXL), or ve-stage

(AlphaCell HP) temperature compensated battery charger as determined by the type of

battery used in the system. During AC line operation, the inverter winding on the ferroresonant

transformer feeds the charger circuit which provides the appropriate charge voltages to the

batteries.

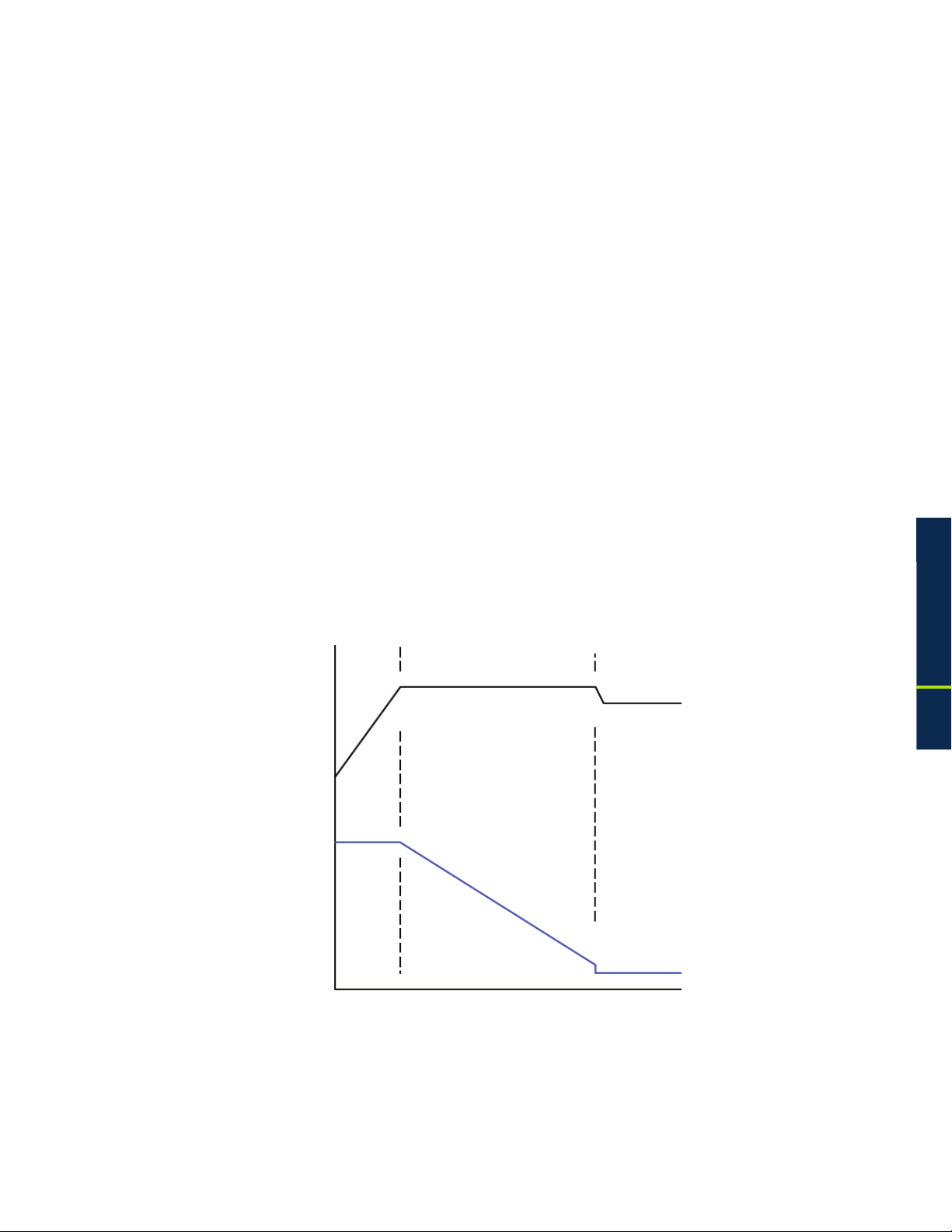

3-Stage Charger Modes (BULK/ACCEPT/FLOAT):

The 3-stage charger is applied when the battery type of OTHER is selected in the Smart Display

menu.

BULK charge is a “Constant Current” charge. The maximum current is 10A. As the charge is

returned to the batteries, their voltage increases to a specic threshold (2.40VDC per cell). The

charger then switches to ACCEPT mode. The BULK charger mode generally returns the battery

charge state to 80 percent of rated battery capacity.

ACCEPT charge is a “Constant Voltage” charge. This voltage, default 2.40VDC (programmable

2.20-2.45VDC) per cell, is temperature-compensated to ensure longer battery life and proper

completion of the charge cycle. This cycle is complete when the charging current into the

batteries becomes less than 0.5A or approximately six hours elapses from the time ACCEPT

mode was entered, at which time the charger switches to the FLOAT mode of operation.

FLOAT charge is a temperature-compensated charge, default 2.27VDC (programmable 2.10-

2.35VDC) per cell. During FLOAT mode, the batteries are fully charged and ready to provide

backup power. The charger provides a small maintenance charge to overcome the batteries selfdischarge characteristics and other minor DC loads within the Power Supply.

Battery Voltage

Battery Current

1.0 Introduction

BULK

Constant

Current Mode

(10A max) until

battery voltage

reaches the

ACCEPT level

(2.40V/cell)

Fig. 1-2, 3-Stage Charger Modes

ACCEPT

Constant Voltage Mode

(2.40V/cell) until battery

current demand drops

below .5A or time out

based on 4 minutes per

Ah battery capacity

FLOAT

Constant

Voltage Mode

(2.27V/cell)

19017-882-B0-001 Rev. C2 (10/2013)

Page 20

1.0 Introduction, continued

1.2 Theory of Operation, continued

1.2.3 Charger Modes of Operation, continued

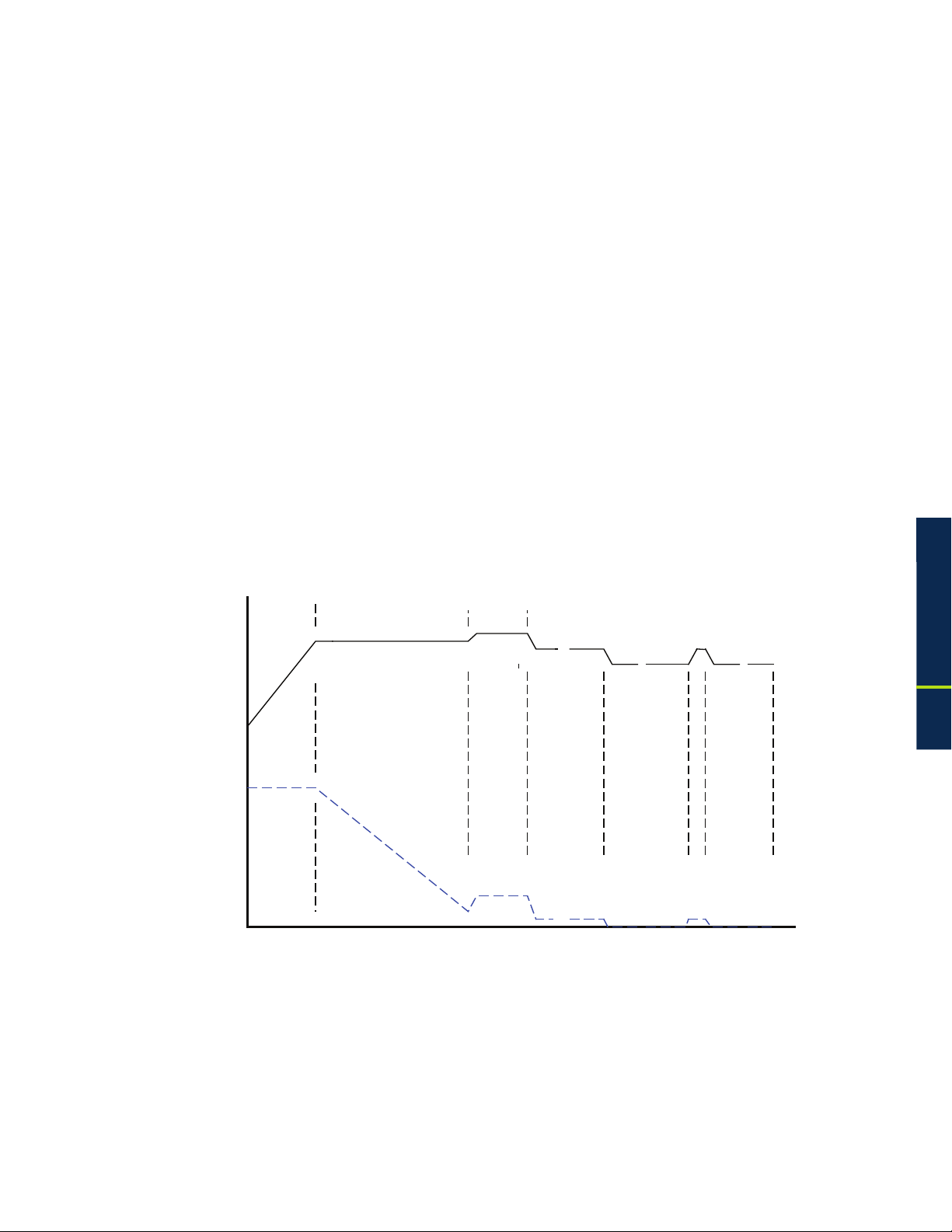

4-Stage Battery Charger (BULK/ACCEPT/REFRESH/FLOAT):

This preset value is applied to AlphaCell GXL batteries when selected in the Smart Display Menu.

A 30-minute REFRESH charge is added, after BULK and ACCEPT states, before dropping down

to FLOAT state, when the batteries are discharged more than 30% and it has been more than 30

days since the last REFRESH charge.

A manual REFRESH charge mode is recommended to be applied to all new batteries upon

installation. This mode “boosts” the individual cell voltage of batteries that may have been in

storage before they were placed on permanent FLOAT. Refresh can be initiated manually via

menu selection or automatically when the battery date code is updated (See Section 3.3.2,

Battery Information and Conguration for further instructions). The REFRESH charge is a one-

time, 24-hour charge to raise individual cell voltage to 2.45VDC, and may bypass the BULK and

ACCEPT states if the batteries are fully charged. The batteries are temperature-compensated at

-0.005VDC per cell per degree C to ensure safe battery cell voltage and maximize battery life.

Battery Voltage

1.0 Introduction

Battery Current

BULK

Constant

Current Mode

(10A max) until

battery voltage

reaches the

ACCEPT level

(2.40V/cell)

ACCEPT

Constant Voltage Mode

(2.40V/cell) until battery

current demand drops

below .5A or time out

based on 4 minutes per

Ah battery capacity

REFRESH

Constant

Voltage Mode

(2.45V/cell)

for 30 minutes

Fig. 1-3, 4-Stage Charger Modes

FLOAT

Constant

Voltage

Mode

(2.27V/cell)

20

017-882-B0-001 Rev. C2 (10/2013)

Page 21

1.0 Introduction, continued

1.2 Theory of Operation, continued

1.2.3 Charger Modes of Operation, continued

5-Stage Battery Charger (BULK/ACCEPT/REFRESH/FLOAT/REST):

This preset value is applied to AlphaCell HP batteries when selected in the Smart Display Menu.

REST: Charger is turned off (if ENABLED) and leaves the batteries without external voltage

applied on the battery. Removing charged voltage and allowing the battery to sit in an open

circuit environment maximizes the battery life by eliminating the chance of overcharging individual

cells inside the 12V battery.

If the Smart AlphaGuard (SAG) is installed and the battery harness is connected, the unit will not

go into REST mode until the SAG indicates that any batteries are less than or equal to 0.3V out of

balance, or until 4 days per string has elapsed, whichever comes rst after the 6 hour oat period.

After any discharge/recharge cycle, once the charger reaches FLOAT mode, it will wait 24 hours

in FLOAT mode before going to REST mode. On a daily basis, without any discharge cycle, the

batteries will be in FLOAT for 25% and REST (charger off) for 75% (6 hours oat, 18 hours rest).

REST mode is terminated if voltage drops to less than 2.12VPC. Upon exiting REST mode due

to a voltage below 2.12VDC, a BULK/ACCEPT cycle will be initiated.

The battery charger voltage is temperature-compensated at -0.004VDC per cell per degree C to

ensure a safe battery cell voltage and to maximize battery life.

BULK

Constant

Current Mode

(10A max) until

battery voltage

reaches the

ACCEPT level

(2.40V/cell)

Battery Voltage

Battery Current

ACCEPT

Constant Voltage

Mode (2.40V/cell)

until battery current

demand drops below

.5A or time out based

on 4 minutes per Ah

battery capacity

Fig. 1-4, 5-Stage Charger Modes

REFRESH

Constant

Voltage

Mode

(2.45V/cell)

for 30

minutes

FLOAT

Constant

Voltage

Mode

(2.27V/cell)

Initial 24

hours

REST

Charger Off

Open Circuit

Voltage

18 hours

1.0 Introduction

FLOAT

AND REST

CYCLES

Charger off for

18 hours

Float for 6

hours

21017-882-B0-001 Rev. C2 (10/2013)

Page 22

1.0 Introduction, continued

1.2 Theory of Operation, continued

1.2.4 Output Voltage Modes of Operation

The XM3-HP can be congured to Fine or Coarse Mode of operation for Output Voltage

Regulation via the Power Conguration Menu (see Section 3.3.1, Power Information and

Conguration).

Fine Mode:

In Fine Mode the power supply will maintain the tightest output voltage regulation possible,

+1/-2.5% for 89V or +1.5/-3.5% for 63V. It will automatically adjust to and from Coarse Override

Mode temporarily if:

a) The unit switches to inverter more than 2 times in a 60-day period;

b) the unit switches tap relays more than 60 times in a 60-day period.

The power supply will automatically adjust back to Fine Mode if there are less than 2 inverter

transfers and less than 15 output tap switches in a 60-day period.

Coarse Mode:

In Coarse Mode the XM3-HP will maintain a wider output voltage regulation window, +1/-5% for

89V or +1.5/-6% for 63V. In this mode the power supply switches taps as few times as possible. It

will never automatically adjust to Fine Mode once Coarse Mode is selected.

1.0 Introduction

22

017-882-B0-001 Rev. C2 (10/2013)

Page 23

1.0 Introduction, continued

1.3 Alpha XM3-HP CableUPS® Layout

The Intelligent CableUPS is comprised of the following:

Transformer module, which acts as a stand-alone line conditioner. The transformer module contains a

ferroresonant transformer, ferroresonant capacitor, line isolation relay, Power Distribution Board, EMC

Filter board and the optional AlphaDOC (PIM) board, Smart AlphaGuard (SAG) and Alpha APPS card.

NOTE:

The option cards require an Inverter Module installed in order to be functional.

Intelligent Inverter Module, which is required for standby operations and contains circuitry needed for

the three-to-ve-stage temperature-compensated battery charger, DC to AC inverter, AC line detectors

and Smart Display.

Optional DOCSIS Communications Module (interfaces to Inverter Module) provides remote status

monitoring and communications.

High Efciency

Transformer Module

Intelligent Inverter

Module

DOCSIS

Communications

Module

®

1.3.1 Side Panel Connectors

1

AC Input Line Cord Connector

Optional Smart AlphaGuard Connector

2

3

Optional APPS Card

4

Output 1 Connector

5

Output 2 Connector

Fig. 1-5, Front Panel, XM3-HP Power Supply

1

Fig. 1-6, Side Panel, XM3-HP Power Supply

1.0 Introduction

2

3

4

5

23017-882-B0-001 Rev. C2 (10/2013)

Page 24

1.0 Introduction, continued

1.3 Alpha XM3-HP CableUPS Layout, continued

1.3.2 Front Panel Indicators

Circuit boards for the optional Smart AlphaGuard (SAG), Alpha APPS card and the two-output

AlphaDOC (PIM) are located behind the removable front panel.

1

Smart AlphaGuard (SAG): Enables the XM3 to gather battery voltage data for up four battery

strings (A through D). Its Charge Management Technology applies excess charge current to

batteries as needed to maintain balanced voltages throughout the string. See Section 1.3.4,

Smart AlphaGuard for connection information and LED functionality.

Alpha APPS Card

2

Output 1 (White = Neutral, Black = Line): The AC output connector is clearly marked and color-

3

coded for easy identication. The Service Power Inserter (SPI) connects directly into the Output 1

connector.

4

Output 2 (White = Neutral, Black = Line): When no AlphaDOC is installed, this output is wired in

parallel to Output 1 and is often used for auxiliary loads. If the AlphaDOC is installed, Output 2

can be isolated from Output 1.

1.0 Introduction

1

2

3

4

Fig. 1-7, Detail View, Front Panel Connections and

Indicators

24

017-882-B0-001 Rev. C2 (10/2013)

Page 25

1.0 Introduction, continued

1.3 Alpha XM3-HP CableUPS Layout, continued

1.3.3 AlphaDOC (PIM)

The optional AlphaDOC adds a second isolated output to the Power Supply. It provides programmable

current limits for two output channels and protects system components by shutting down the load

during overcurrent and short circuit conditions.

The AlphaDOC has a programmable overcurrent threshold (3A-25A) and overcurrent tolerance period

that species the time (20-9900ms) an overcurrent condition is permitted before shutting down.

The programmable retry limit can be programmed to select how many times (0-40) after a

programmable delay (5-301 seconds) the AlphaDOC will attempt to reconnect an output once it

has been shut down. When the limit is reached, the XM3 Power Supply automatically retries once

every 30 minutes until the fault clears.

Adding the AlphaDOC to the Power Supply provides these advantages:

A second isolated output: The main purpose of the AlphaDOC is to limit the impact of a

fault condition in one output channel. If a fault condition occurs in a Power Supply (without

the optional AlphaDOC installed) the entire customer network can be affected. The AlphaDOC

option affords protection to one output should a fault condition exist on the other. This gives

you exibility to isolate Output 1 from Output 2.

A current for critical loads: With the AlphaDOC option, you can designate one output

as the primary connection and the other output as the secondary connection. Commonly,

critical loads are connected to Output 1 as the primary feeder. Using the overcurrent limit

settings, you can ensure the primary output always provides the necessary power. For

example, on a 15 Amp Power Supply, if a customer needs 10 Amps available on Output 1,

the overcurrent limit for Output 2 is set at 5 Amps, so regardless of Output 2, 10 Amps will

remain available for the primary Output 1.

Additional current protection: The standard Power Supply current limit protection is

provided by the fold-back characteristics of the transformer (150% of rated output). The

150% current limit may exceed the ratings of active devices in the cable network and

cause failures. You can lower the maximum current provided at each output by lowering the

overcurrent limit of each respective output. Therefore, to minimize failures due to excess

current supply, set the overcurrent limit to a value below the maximum current the active

components can tolerate.

NOTE:

The table below depicts a condition in which no DOC is installed, or no individual output is above

its trip setting.

Power Supply Load

918

All Other Models

Permitted Duration of Load

>125% >150% 30 seconds

113% to 125% 125% to 150% 10 minutes

108% to 113% 115% to 125% 30 minutes

<108% <115% Several months

Table 1-3, Duration of Load

For example, on a 18A Power Supply, where both outputs are programmed to 10A maximum

and both outputs are supplying 10A, neither output is “in violation” but the total system at 18A

is operating at 111% of its rated output. In this example, after 30 minutes, the Power Supply

will begin a “load shedding” algorithm. The rst action is to disconnect Output 2. If this does not

correct the system overload, the next action is to disconnect Output 1.

1.0 Introduction

25017-882-B0-001 Rev. C2 (10/2013)

Page 26

1.0 Introduction, continued

1.3 Alpha XM3-HP CableUPS Layout, continued

1.3.3 AlphaDOC (PIM), continued

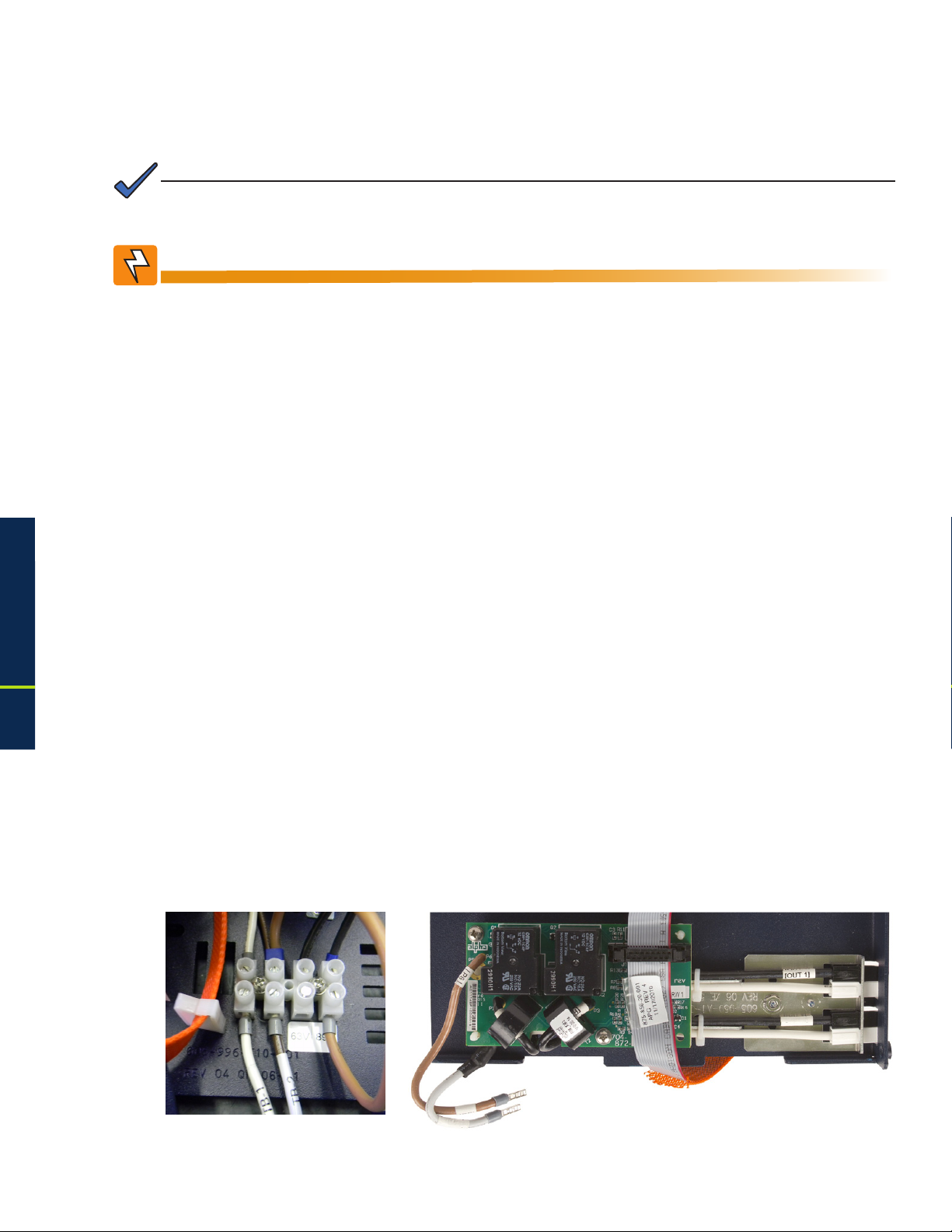

NOTE:

Only qualied personnel should install the AlphaDOC. To install the AlphaDOC you must completely shut

down the Power Supply. To maintain output to the load, consider using either the APP9015S or APP9022S

Service Power Supply during installation.

WARNING!

To avoid exposing the technician to potentially lethal voltages, before you proceed you

must remove all power from the Power Supply; unplug the Power Supply from the AC

power source, remove all front panel connections and disconnect the battery connector.

Tools Required:

3mm slotted screwdriver

#2 Phillips-head screwdriver

To install the AlphaDOC

1. Completely shut down the Power Supply; verify all power is removed. Ensure utility power is off and

battery power is safely secured (or not installed) in the enclosure assembly. All connections and

cables must be removed from the Power Supply. To maintain output to the load, consider using the

APP9015S or APP9022S Service Power Supply when installing the AlphaDOC.

2. To remove the transformer module’s front panel, remove the three front panel screws.

3. Remove the output voltage wires from the terminal block, see Fig. 1-8.

4. Remove the ribbon cable.

5. Lift the front panel up and away from the chassis.

6. Remove the 6-32 KEPS nut securing the single-output wire harness and output connector bracket.

7. Replace with the AlphaDOC board and dual output wire harness assembly.

1.0 Introduction

8. Attach the nomex to the back of the PCB using the two 3/8" circuit board supports

9. Install the output connector bracket using the 6-32 KEPS nut that was removed in Step 6 on the PEM

stud that is farthest from the connectors.

10. Install the PCB using two 6-32 screws, routing the wires under the PCB and nomex as shown.

11. Connect the dual output voltage wires to the output voltage terminal block as shown, see Fig. 1-8.

Torque terminal block screws to 7in-lbs (0.79N-m).

12. Replace the front panel.

13. Replace connections and return the unit to service.

1.3.3.1 Installing the AlphaDOC

26

Fig. 1-8, Output Voltage

Terminal Block

O

O

O

O

Output Voltage