Page 1

CableUPS® Quick Start Guide

11

10

9

Battery Connector

1

Battery Breaker

2

Precision Temperature Sensor

3

(PTS) Connector

5

2

6

DOCSIS Transponder Battery Sense

Harness Connector

7

RF Connector

8

Tamper Switch Connector

8

7

4

3

6

1

Output 1 (Primary) / Output 2 (AlphaDOC)

LRI Connector

4

Smart Display

5

9

APPs Card

10

Smart AlphaGuard Connector

11

WARNING!

Verify battery voltage, cable color, connection and polarity are correct before proceeding.

Total Power Solutions

Page 2

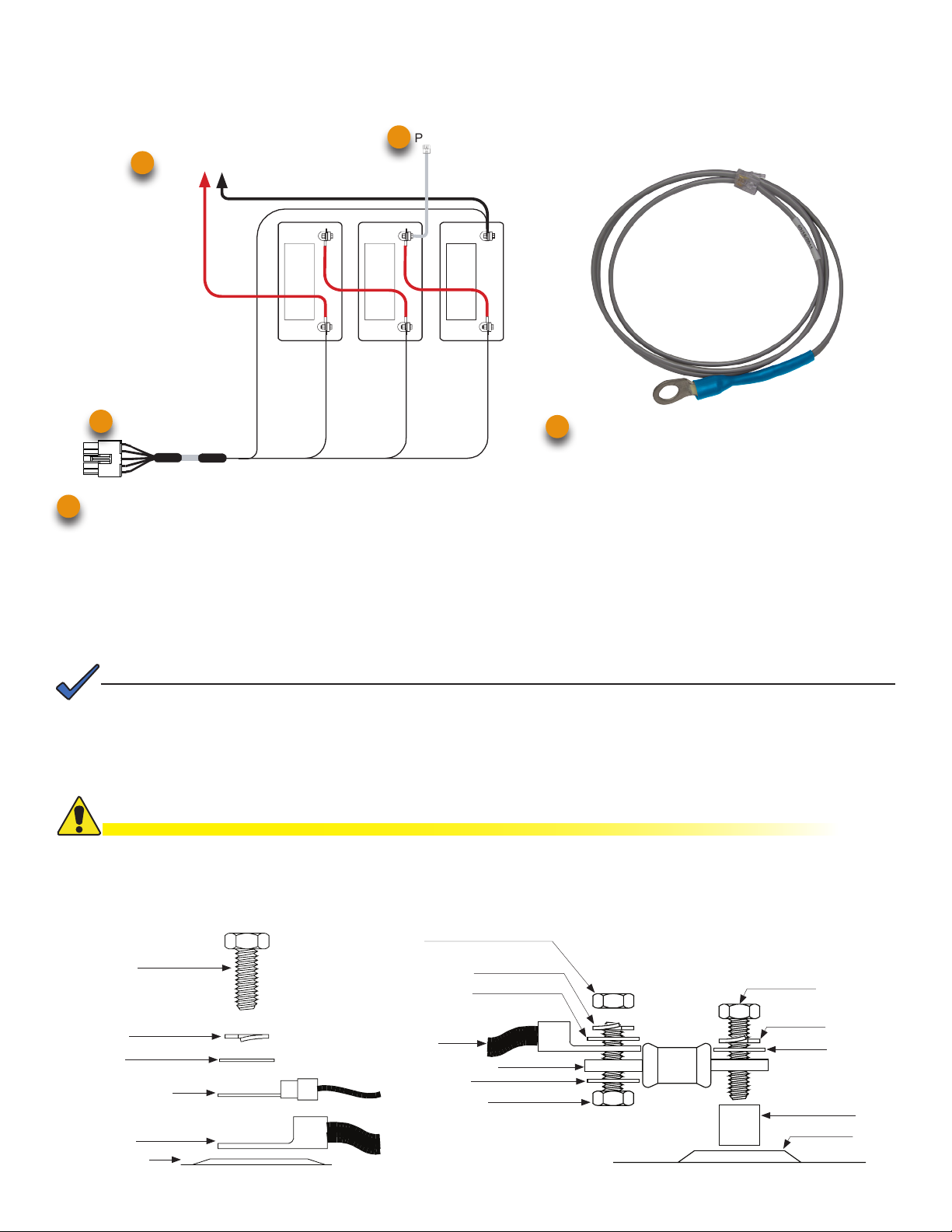

1. Battery Installation and Wiring Diagram

Battery Cable Kit, Precision Temperature Sensor / Smart AlphaGuard or Battery Sense Harness

Load batteries into cabinet with the positive terminals (+) facing forward.

PTS

3

To Power Supply

1

Red

11

Smart AlphaGuard (Embedded) — use Battery Harness, p/n 875-848-20,

11

Black (String -) 0V

36VDC

Black, Pin 5

A/B/C/D NEG

NEG(-) NEG(-) NEG(-)

3A

3A 2A 1A

POS(+)

Red, Pin 9

Vbatt 3A 36V

2A 1A

POS(+) POS(+)

Vbatt 2A 24V

Orange, Pin 4

Vbatt 1A 12V

Brown, Pin 10

Precision Temperature Sensor (PTS), p/n 746-331-20

3

(2 battery strings) — use p/n 875-848-21,

(3 battery strings) — use p/n 875-848-22,

(4 battery strings) — use p/n 875-848-23.

Re-use existing External Alphaguard Battery Sense Harness by installing a retrot kit. External AlphaGuard Battery Sense

Harness to Smart AlphaGuard (1 battery string) — use retrot cable p/n 875-910-20,

(2 battery strings) — use p/n 875-910-21,

(3 battery strings) — use p/n 875-910-22,

(4 battery strings) — use p/n 875-910-23.

NOTE:

The compatibility of the XM3 SAG system with certain vaults is dictated by the length of the SAG harness. Contact

your local sales representative for more information.

Threaded Insert Terminals

CAUTION!

Use 1/4-20 x 3/4” (19mm) bolts for threaded insert terminals. If using a spacer for the in-line fuse link, use 1/4-20 x

1” (25.4mm) bolts.

Torque all nuts and bolts to 110 in-lbs. (12.43N-m)

Nut

3/4" (19mm) x

1/4-20 Bolt

Split Washer

Flat Washer

Battery Sense Cable

or RTS

Battery Cable

Battery Terminal

Split Washer

Flat Washer

Battery

Cable

In-Line Fuse Link

Flat Washer

1" (25.4mm) or

3/4" (19mm) x

1/4-20 Bolt

Fuse

1" (25.4mm) x

1/4-20 Bolt

Split Washer

Flat Washer

Spacer

Battery

Terminal

Page 3

2. Output Voltage Reconguration Procedure

Some systems may require reconguring the output voltage setting. If necessary, follow the steps below to complete the

procedure. If the factory default satises your system requirements, proceed to Section 3.

NOTE:

The output voltage factory default is 89 Volts.

Tools Required:

Small at-blade screwdriver.

1. To access output voltage terminal, remove the Inverter Module.

2. Loosen the terminal screw and move the output voltage wire (Fig. 1)

to the desired output voltage position on the terminal strip.

3. Torque the terminal block screw to 7 in-lbs. (0.79N-m) to secure the

output voltage wire.

4. Replace the Inverter Module.

Fig. 1 - Output voltage wire and terminal bar.

3. DOCSIS Communications Module

Front Panel Connections

1. Connect the Battery Sense Harness to the A/B or C/D Connector (6). For XM3 units with the Smart AlphaGuard

(SAG) option, connect the Battery Harness to the SAG Connector (11) located on the left side of the XM3 Power

Supply.

2. Connect Tamper Switch Wire Harness to the TPR Connector (8).

3. Connect the RF drop to the RF Connector (7).

NOTE:

The DOCSIS specication for downstream power level is 0 dBmV, +/- 15 dBmV. The upstream power level should not

exceed +50 dBmV.

8

TPR Connector

RF Drop

RF Cable

to Headend

To Battery Sense

Harnesses

7

6

Required

Grounded Surge Protector

(Alpha p/n 162-028-10 or equivalent)

Alpha DOCSIS Transponder (1 battery string) — use Battery Sense Harness, p/n 874-842-21.

6

Alpha DOCSIS Transponder (2 battery strings) — use Battery Sense Harness, p/n 874-842-28.

AlphaGuard (external) — use Battery Sense Harness, p/n 875-510-20 (S9) or p/n 875-510-21 (D9).

Page 4

4. Power Module Conguration

Indicates Model

and Output Voltage/Current

Describes Power Supply

Mode of Operation

Describes Status of Functions

Functionality top level menu

PWR, BATT, COMM and APPS

A

B

C

D

A

XM3-918HP 90V/10.0A

B

OPERATION NORMAL

C

OK ALM OK OK

PWR BATT COMM APPS

D

Softkeys (Menu driven

system conguration)

E

E

Installation Procedure

CAUTION!

Before applying power, verify power supply rating is matched to AC input utility. Verify a low-resistance ground is

installed in accordance with the NEC (refer to CableUPS Power Supply technical manual for details).

1. After wiring battery cable kit, battery sense cables and PTS, as shown in

Section 1, verify DC breaker is OFF.

2. Connect the Smart AlphaGuard (SAG) wire harness to SAG port (11). If no

SAG is installed, connect battery sense harness to the transponder (6).

3. Connect PTS to the PTS connector (3).

4. Connect the RF cable and the tamper switch to the transponder.

5. Verify the SPI / ALT Box Switch is in the ALT position.

6. Connect the SPI / ALT Box input cable to the Output 1 Connector (9). If 2nd

SPI / ALT Box is present connect input cable to Output 2 Connector.

7. Connect the LRI to the XM3. For existing LRI installations, use LRI adapter

kit, p/n 875-952-20.

8. Turn ON AC breaker and verify it is the correct utility voltage at the outlet (per

unit’s nameplate voltage). If correct, plug in the line cord into the utility outlet.

9. Verify correct battery voltage and polarity on battery cable connector with a

digital voltmeter, if correct plug into Inverter Module (1).

10. Turn battery breaker ON.

11. Verify no alarms are present after power up initialization. Wait for alarms to

clear (approximately 60 seconds).

12. If no alarms are present, proceed to Step 16.

13. If alarms are present and do not clear after 60 seconds, press the softkey with

ALM (C) to see the ACTIVE ALARM list for the menu item.

14. Press UP (↑) or DOWN (↓) to select the alarm of interest.

15. Press ENTR to select the alarm and display diagnostic information. Press

ESC to return to the alarm list.

16. On the SmartDisplay, press the BATT softkey, enter the BATT CONFIG

menu and select BATT MODEL and NUM BATT STRINGS (Fig. 2).

17. On the SmartDisplay, press BATT softkey, enter BATT CONFIG, enter BATT

MHOs* and DATE Code (Fig. 3).

*Note: Battery MHOs and Date code can only be set after DOCSIS

transponder has registered with CMTS. Please wait 3 minutes after

power up to enter Battery MHOs measurements.

18. Switch SPI / ALT Box Switch to ON, verifying the load on the XM3.

19. Perform a self-test by pressing and holding the Test Button (H) for 1-2

seconds. Wait for self-test completion before proceeding.

20. Perform standby test by shutting OFF utility breaker and verifying it goes into

STANDY MODE and supports the load.

21. Reapply AC power and verify the unit transfers to LINE MODE.

XM3-918HP 90V/0.4A

**ACTIVE ALARM**

OK

PWR

OUTPUT LED (green)

G

SOLID = Operation Normal

FLASHING = Minor Alarm

OFF = Major Alarm

SELF TEST BUTTON

I

Press button to initiate self test.

EDIT USING h i 8 <ESC>

BATT MODEL OTHER

ENTR

BATT A1 DATE 1/10

hi

ENTR to shift eld

ENTR

Fig. 3 - Battery DATE Code and MHOs input

PM

BATT

ALM

COMM

H

h i

Fig. 2 - Battery Model input

ADJUST VALUE

h i

BATT A1 MHOs 1000M

hi

ENTR to save

ENTR

ADJUST VALUE

h i

G

OK

APPS

ALARM LED (red)

FLASHING = Major Alarm

OFF = Minor Alarm

OFF = Operation Normal

ESC

ESC

H

I

ESC

Page 5

5. Alpha DOCSIS Transponder and Smart Alphaguard LED's

5.1 Verify Alpha DOCSIS Transponder operation as indicated below:

LEDs and Indications

Step Communications State ALM/RDY DS REG RF COM

1

2

3

4

Transponder Initializing/Searching for

Downstream DOCSIS channel

DOCSIS Channel locked - Completing

upstream and network registration

Online - Registration Complete Flashing (Green) ON ON

Alpha DOCSIS Transponder fully

functional

LED Color Rx Range (dBmV) Tx Range (dBmV)

Green +10 to -10 0 to +50

* Blue +15 to +10 and -10 to -15 +50 to +55

* Red >+15 and <-15 >+55

* Blue RF LED indicates Rx/Tx Power at a warning level. Make the necessary RF level adjustments.

* Red RF LED indicates Rx/Tx Power at an alert level. Make the necessary RF level adjustments.

NOTE:

Ethernet port LNK and ACT LED’s are on (LNK - Solid, ACT - Flash) only when connected to a laptop.

Flashing (Green) Flashing OFF OFF Flashing

Flashing (Green) ON Flashing

Flashing (Green) ON ON

ON

(Green)

ON

(Green)

ON

(Green)

Flashing

Flashing

Bursts

5.2 Verify Smart AlphaGuard operation as indicated below:

LED State and Indications

LED Name Color State Indication

Off No power to SAG

Unit is on and communicating with power supply or in

Rest mode

Normal operation

No string wires connected

High delta mean

Check battery alarm

String A missing

String miswired

Active Green

STRG A

STRG B

STRG C

STRG D

(ALARMS)

Red

Solid

Flash (90% on / 10% off) Unit is on and operational

Flash (50% on / 50% off) Actively balancing

Flash (10% on / 90% off) Powersave mode

Off

Flash (50% on / 50% off (Minor

Alarm)

Solid (Major Alarm)

5.3 XM3 Smart Display — COMM Menu

COMM-GENERAL

Verify Alpha DOCSIS Transponder communication parameters such as IP Address, RF Power Levels and Signal/

Noise Ratio on the COMM menu of the XM3 Smart Display. Press Enter <ENTR> to open the COMM-GENERAL

Menu enabling the operator to view values for the following parameters. Pressing the up or down arrow softkeys will

show two lines of information for each submenu item.

COMM-GENERAL

CM MAC ADDRESS

00:90:EA:A0:04:99

ESC

Press "Down" arrow softkey to

view next item(s) in menu.

COMM-GENERAL

CM MAC ADDRESS

00:90:EA:A0:04:99

CM IP ADDRESS

192.168.1.121

CM IPV6 ADR PREFIX

2001:123:456:789

CM IPV6 ADR POSTFIX

111:222 :33 3:3 4 3 4

CPE MAC ADDRESS

00:90:EA:00:52:33

Page 6

6.0 Final Verication

Local Web Server Access

The ethernet port of the Alpha DOCSIS Transponder can be used as a local connection point, allowing the user to connect

to the transponder web page.

To access the web page, proceed as outlined below:

NOTE:

A Static IP address (192.168.100.2) may need to be set on your network interface card to connect to the

transponder.

1. Using a standard (CAT5) ethernet cable, connect transponder to the laptop or computer network interface port.

2. Launch a web browser.

3. Enter the transponder’s default IP address (192.168.100.1) into the web browser’s address eld.

4. The transponder’s web server home page will appear.

NOTE:

For the Alpha DOCSIS Transponder, this may take up to 45 seconds when the transponder is initially powered up

with no RF connection.

Remote Web Server Access

To remotely access the Alpha DOCSIS Transponder web server utilizing a web browser:

1. Open a web browser on a computer connected to the same network as the XM3.

2. Enter the Alpha DOCSIS Transponder’s designated IP address (e.g., 192.168.1.124) into the web browser

address eld.

3. The Alpha DOCSIS Transponder ’s web server home page will appear.

Alpha Technologies Inc.

3767 Alpha Way

Bellin gham WA 982 26

USA

Tel: +1 360 647 236 0

Fax: +1 360 671 4936

Alpha Technologies Alpha reserves the right to change specications without notice.

© 2013 Alpha Technologies Inc. All Rights Reserved.

Alpha is a registered trademark of Alpha Technologies. 017-882-B1-001C1 (08/2013) For more information visit www.alpha.com

Alpha Technologies Ltd.

7700 Riverfront Gate

Burnaby BC V5J 5M 4

Canada

Tel: +1 604 436 59 00

Fax: +1 604 4 36 1233

Alpha Technologies Europe Ltd.

Twyford House, Thorley

Bishop’s Stortford,

Hertfordshire

CM22 7PA

United Kingdom

Tel: +44 1279 501110

Fax: +44 1279 659870

Alpha Technologies GmbH

Hansastrasse 8

D 91126 Schwabach

Germany

Tel: +49 9122 7988 9 0

Fax: +49 9122 79 889 21

AlphaTec Ltd.

339 Saint Andrew s Street

Suite 101 Andrea Chambers

3307 Lim assol

Cyprus

Tel: +357 25 375675

Fax: +357 25 3 5959 5

AlphaTEK ooo

Khokh lovskiy Pereulok 16

Stroenie 1 Of ce 403

109028 Moscow

Russia

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alpha Technologies

Suite 190 3, Tower 1

33 Canton Road, Kowloon

Hong Kong

Tel: +852 2736 8663

Fax: +852 219 9 7988

Loading...

Loading...