Page 1

Intelligent CableUPS

Technical Manual

XM2, XM2-HV, XM2-HP

Effective: January 2013

®

Page 2

Alpha Technologies

Power

®

Page 3

Intelligent CableUPS® Technical Manual

017-805-B0-010, Rev K2

Effective Date: January 2013

Copyright © 2013

Alpha Technologies, Inc.

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose or is installed or operated in an unapproved manner or improperly maintained.

Notice of FCC Compliance

Per FCC 47 CFR 15.21:

Changes or modications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

Per FCC 47 CFR 15.105:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at their own expense.

Contacting Alpha T echnologies: www.alpha.com

or

For general product information and customer service (7 AM to 5 PM, Pacic Time), call

1-800-863-3930

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacic Time or 24/7 emergency support

017-805-B0-010 Rev. K2

3

Page 4

Table of Contents

Safety Notes .....................................................................................................................8

Safety Precautions ...........................................................................................................8

Battery Safety Notes.........................................................................................................9

Utility Power Connection Notes ......................................................................................10

Grounding and Earth Connection Notes.........................................................................13

1.0 Introduction ..........................................................................................................14

1.1 Theory of Operation ..................................................................................15

1.1.1 AC (Line) Operation .......................................................................15

1.1.2 Standby Operation .........................................................................16

1.1.3 Charger Operation .........................................................................17

1.2 Intelligent CableUPS Layout .....................................................................18

1.2.1 Transformer Module Overview .......................................................18

1.2.2 Inverter Module Overview ..............................................................19

1.2.3 Optional Status Monitoring Modules .............................................22

1.3 Recommended Enclosure System Options ..............................................23

2.0 Installation............................................................................................................25

2.1 Installation Procedure ...............................................................................25

2.2 Installing the Optional Indicator Lamps .....................................................26

2.2.1 AC Indicator Lamp .........................................................................26

2.2.2 Local/Remote Indicator ..................................................................27

2.3 Initial Turn Up ............................................................................................29

2.4 Inverter Module Removal and Installation.................................................30

2.5 Protective Interface Module (PIM) ............................................................31

2.6 Installing the PIM ......................................................................................32

2.7 Programming the PIM ...............................................................................35

2.7.1 The Setup Menu.............................................................................36

2.8 N+1 Congurations ...................................................................................37

2.9 Service Power Inserter (SPI) ....................................................................39

3.0 Conguration .......................................................................................................41

3.1 Power Distribution Board (PDB) Setup .....................................................41

3.1.1 Replacing the Metal Oxide Varistors (MOVs) .................................44

3.1.2. Replacing the Line Isolation Relay .................................................45

3.2 AC Input Voltage Reconguration .............................................................46

3.2.1 Reconguration from 120 to 240Vac ..............................................46

3.2.2 Reconguration from 240 to 120Vac ..............................................48

3.3 AC Output Voltage Reconguration ..........................................................50

3.3.1 Output Voltage Switch (SW1) Settings...........................................51

4

017-805-B0-010 Rev. K2

Page 5

Contents, continued

4.0 Operation .............................................................................................................53

4.1 Start-up and Test .......................................................................................53

4.1.1 AC Line Operation..........................................................................53

4.1.2 Self Test Operation .........................................................................54

4.1.3 Standby Operation ........................................................................55

4.2 Using the Smart Display ...........................................................................56

4.3 Smart Display Modes ................................................................................58

4.3.1 Operation Normal ...........................................................................58

4.3.2 Comms Information Display (with DSM2 or later) ..........................59

4.3.3 Setup Menu ....................................................................................60

4.3.4 Menu Structure/Navigation (from Operation Normal screen) .........63

4.3.5 Menu Structure/Navigation (from Active Alarms screen)................64

4.4 Alarm Indications ......................................................................................65

4.5 Smart Display LEDs ..................................................................................71

4.6 Smart Display Glossary ............................................................................72

4.7 Automatic Performance Test .....................................................................74

4.8 Providing Power via Portable Generator or Inverter .................................75

4.8.1 DC Powering ..................................................................................75

4.8.2 AC Powering ..................................................................................75

4.8.3 Using a Truck-mounted Inverter or Generator ...............................76

4.9 Resumption of Utility Power ......................................................................77

5.0 Intelligent CableUPS Maintenance ......................................................................78

5.1 System Information ...................................................................................78

5.2 Battery Charger Voltage............................................................................79

5.3 Battery Terminals and Connecting Wires ..................................................79

5.4 Output Voltage ..........................................................................................79

5.5 Output Current ..........................................................................................79

5.6 Check Output Connections .......................................................................79

5.6.1 Visual Inspection ............................................................................79

5.7 Inverter Module Maintenance ...................................................................80

5.8 Maintenance Log ......................................................................................81

5.9 Repair Record ...........................................................................................82

6.0 Specications.......................................................................................................83

6.1 Intelligent CableUPS North American Models ..........................................83

6.2 Intelligent CableUPS International Models ...............................................84

6.3 Safety and EMC Compliance ....................................................................85

7.0 Return and Repair Information ............................................................................86

7.1 Emergency Shutdown ...............................................................................87

017-805-B0-010 Rev. K2

5

Page 6

Figures and Tables

Fig. 1-1, XM2-HP Power Supply ..........................................................................................................15

Fig. 1-2, Standard XM2 Power Supply .................................................................................................15

Fig. 1-3, Simplied Block Diagram .......................................................................................................16

Fig. 1-4, Charger Modes ......................................................................................................................17

Fig. 1-5, Transformer Module Connections ..........................................................................................18

Fig. 1-6, Inverter Module Voltage Rating Labels ..................................................................................19

Fig. 1-7, Inverter Module Connections .................................................................................................20

Fig. 1-8, Placement of Remote Temperature Sensor (RTS) on battery ...............................................21

Fig. 1-9, Placement of Battery Spacer Clips on 36V and 48V battery strings ......................................21

Fig. 1-10, DSM3x .................................................................................................................................22

Fig. 1-11, IDH3 .....................................................................................................................................22

Fig. 1-12, Standard AlphaGuard ..........................................................................................................24

Fig. 1-13, Potted AlphaGuard ..............................................................................................................24

Fig. 2-1, AC Indicator Lamp .................................................................................................................26

Fig. 2-2, Wire/Housing Assembly .........................................................................................................26

Fig. 2-3, Local/Remote Indicator Lamp ................................................................................................27

Fig. 2-4, Wire/Housing Assembly .........................................................................................................27

Fig. 2-5, ACI/LRI Connection ...............................................................................................................28

Fig. 2-6, Inverter Module Ribbon Cable ...............................................................................................30

Fig. 2-7, Detail of Locking Mechanism .................................................................................................30

Fig. 2-8, PDB Connections ..................................................................................................................32

Fig. 2-9, J6 and J4 connection as seen from rear of Power Distribution Board ...................................33

Fig. 2-10, Location of JP1 on PIM ........................................................................................................34

Fig. 2-11, Jumper in 15A position .........................................................................................................34

Fig. 2-12, Jumper in 22A position ........................................................................................................34

Fig. 2-13, PIM (Protective Interface Module) and PDB (Power Distribution Board) .............................34

Fig. 2-14, N+1 Conguration ................................................................................................................37

Fig. 2-15, Dual Redundancy (N+1) Conguration ................................................................................38

Fig. 2-16, SPI Cover Removal .............................................................................................................39

Fig. 2-17, Coaxial Cable Insertion and Securing .................................................................................39

Fig. 2-18, Cover Replaced, SPI Switched On ......................................................................................40

Fig. 2-19, SPI Grounding Lug ..............................................................................................................40

6

017-805-B0-010 Rev. K2

Page 7

Figures and Tables, continued

Fig. 2-20, Enclosure Ground Bar .........................................................................................................40

Fig. 3-1, Locations of JP1, JP2 and SW1, SW2 on the Power Distribution Board (PDB) ....................42

Fig. 3-2, MOV Replacement ................................................................................................................44

Fig. 3-3, Typical NEMA Receptacles and Plugs ...................................................................................46

Fig. 3-4, Transformer Module Input Jumpers, PDB Jumpers ...............................................................47

Fig. 3-5, SW2 Settings .........................................................................................................................47

Fig. 3-7, Transformer Module Input Jumpers, PDB Jumpers ...............................................................48

Fig. 3-6, Typical NEMA Receptacles and Plugs ...................................................................................48

Fig. 3-8, SW2 Settings .........................................................................................................................49

Fig. 3-9, XM2-615A Transformer Output Tap Connector shown in default setting (63Vac) ..................50

Fig. 3-10, Transformer Output Tap Connector for other XM Series 2 Power Supplies ........................50

Fig. 4-1, Conguration Screen .............................................................................................................53

Fig. 4-2, Smart Display Navigation ......................................................................................................56

Fig. 4-3, Smart Display Panel ..............................................................................................................57

Fig. 4-4, Operation Normal Display ......................................................................................................58

Fig. 4-5, Comms Information Display ...................................................................................................59

Fig. 4-6, Setup Menu Display ..............................................................................................................62

Fig. 4-7, Output and Alarm LEDs .........................................................................................................71

Fig. 7-1 Emergency Shutdown .............................................................................................................87

Table 3-1, Power Distribution Board Setup ..........................................................................................43

Table 3-2, Output Voltage switch settings per Power Supply ...............................................................51

Table 3-3, Output Voltage switch settings for XM2-918HP, XM2-924HP .............................................52

Table 4-1, AC Output ............................................................................................................................54

Table 6-1 Specications for North American Models ...........................................................................83

Table 6-2 Specications for International Models ................................................................................84

Table 6-3, Product Certications ..........................................................................................................85

017-805-B0-010 Rev. K2

7

Page 8

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

ATTENTION:

The use of ATTENTION indicates specic regulatory/code requirements that may affect the placement

of equipment and/or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to

material or equipment.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to the

technician or user.

Safety Precautions

• Only qualied personnel may service the Intelligent CableUPS.

• Verify the voltage requirements of the equipment to be protected (load), the AC input voltage to the power

supply (line) and the output voltage of the system prior to installation.

• Equip the utility service panel with a properly rated circuit breaker for use with this power supply.

• When connecting the load, DO NOT exceed the output rating of the power supply.

• Always use proper lifting techniques whenever handling units, modules or batteries.

• The power supply contains more than one live circuit! Even though AC voltage is not present at the input,

voltage may still be present at the output.

• If batteries are being stored prior to installation, recharge per manufacturer’s specications to ensure

optimum performance and maximum battery service life.

• Reduce the chance of spark and wear on the connectors; always switch the inverter’s battery circuit

breaker off before connecting or disconnecting the battery pack

• The battery pack, which provides backup power, contains dangerous voltages. Only qualied personnel

should inspect or replace batteries.

• In the event of a short-circuit, batteries present a risk of electrical shock and burns from high current.

Observe proper safety precautions.

• Always wear protective clothing, insulated gloves and eye protection (i.e. safety glasses or a face shield)

whenever working with batteries.

• Always carry a supply of water, such as a water jug, to wash the eyes or skin in the event of exposure to

battery electrolyte.

8

017-805-B0-010 Rev. K2

Page 9

Safety Precautions, continued

• Do not allow live battery wires to contact the enclosure chassis. Shorting battery wires can result in a re

or possible explosion.

• Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Avoid using uninsulated tools or other conductive materials when handling batteries or working inside the

enclosure.

• Remove all rings, watches and other jewelry before servicing batteries.

• Spent or damaged batteries are environmentally unsafe. Always recycle used batteries. Refer to local

codes for proper disposition of batteries

• The Intelligent CableUPS has been investigated by regulatory authorities for use in various Alpha

enclosures. If you are using a non-Alpha enclosure, it is your responsibility to ensure your combination

conforms to your local regulatory requirements and the power supply remains within its environmental

specications.

Battery Safety Notes

• Always refer to the battery manufacturer’s recommendation for selecting correct “FLOAT” and “ACCEPT”

charge voltages. Failure to do so can damage the batteries.

• Verify the power supply’s battery charger “FLOAT” and “ACCEPT” charger voltage settings.

• Batteries are temperature sensitive. During extremely cold conditions, a battery’s charge acceptance

is reduced and requires a higher charge voltage; during extremely hot conditions, a battery’s charge

acceptance is increased and requires a lower charge voltage. To compensate for changes in temperature,

the battery charger used in the power supply is temperature compensating. Refer to Section 1.2.2 for

instructions on connecting the Remote Temperature Sensor (RTS).

• If the batteries appear to be overcharged or undercharged, rst check for defective batteries and then

verify the correct charger voltage settings.

• To ensure optimum performance, inspect batteries every three to six months for signs of cracking, leaking

or unusual swelling (note that some swelling is normal).

• Check battery terminals and connecting wires. Clean battery terminal connectors periodically and

retighten to approximately 110 inch-pounds (or to manufacturer’s specications if not AlphaCells). Spray

the terminals with an approved battery terminal coating such as NCP-2.

NOTE:

If installed, disconnect the AlphaGuard prior to measuring battery voltage.

NOTE:

Even with a AG-CMT present in the system, any battery which fails the 0.3V load test must be replaced

with an identical type of battery.

• Check battery voltages UNDER LOAD. Use a load tester if available. Differences between any

battery in the set should not be greater than 0.3Vdc.

• Refer to the battery manufacturer’s recommendation for correct charger voltages and the power

supply operation manual for corresponding charger settings.

• Number the batteries (1, 2, 3, etc.) inside the enclosure for easy identication (refer to the

appropriate enclosure installation guide).

• Establish and maintain a battery maintenance log.

NOTE:

Always verify proper polarity of cables before connecting the batteries to the power module. The

batteries are clearly marked for polarity. If the cables become interchanged at the batteries the battery

breaker will trip.

017-805-B0-010 Rev. K2

9

Page 10

Utility Power Connection Notes

ATTENTION:

Connecting to the utility should be performed only by qualied service personnel and in compliance with local

electrical codes. Connection to utility power must be approved by the local utility before installing the power

supply.

UL and NEC require that a service disconnect switch (UL listed) be provided by the installer and be connected

between the power source and the ALPHA power supply. Connection to the power supply must include an

appropriate service entrance weather head.

NOTE:

In order to accommodate the high-inrush currents normally associated with the start-up of ferroresonant

transformers (400 Amp, no-trip, rst-half cycle), either a “high-magnetic” or an HACR (Heating,

Air Conditioning, Refrigeration) trip breaker must be used. Do not replace these breakers with a

conventional service entrance breaker. Alpha recommends ONLY Square D breakers because of the

increased reliability required in this powering application. High-magnetic Square D circuit breakers and

a BBX option (UL Listed service entrance) are available from Alpha Technologies.

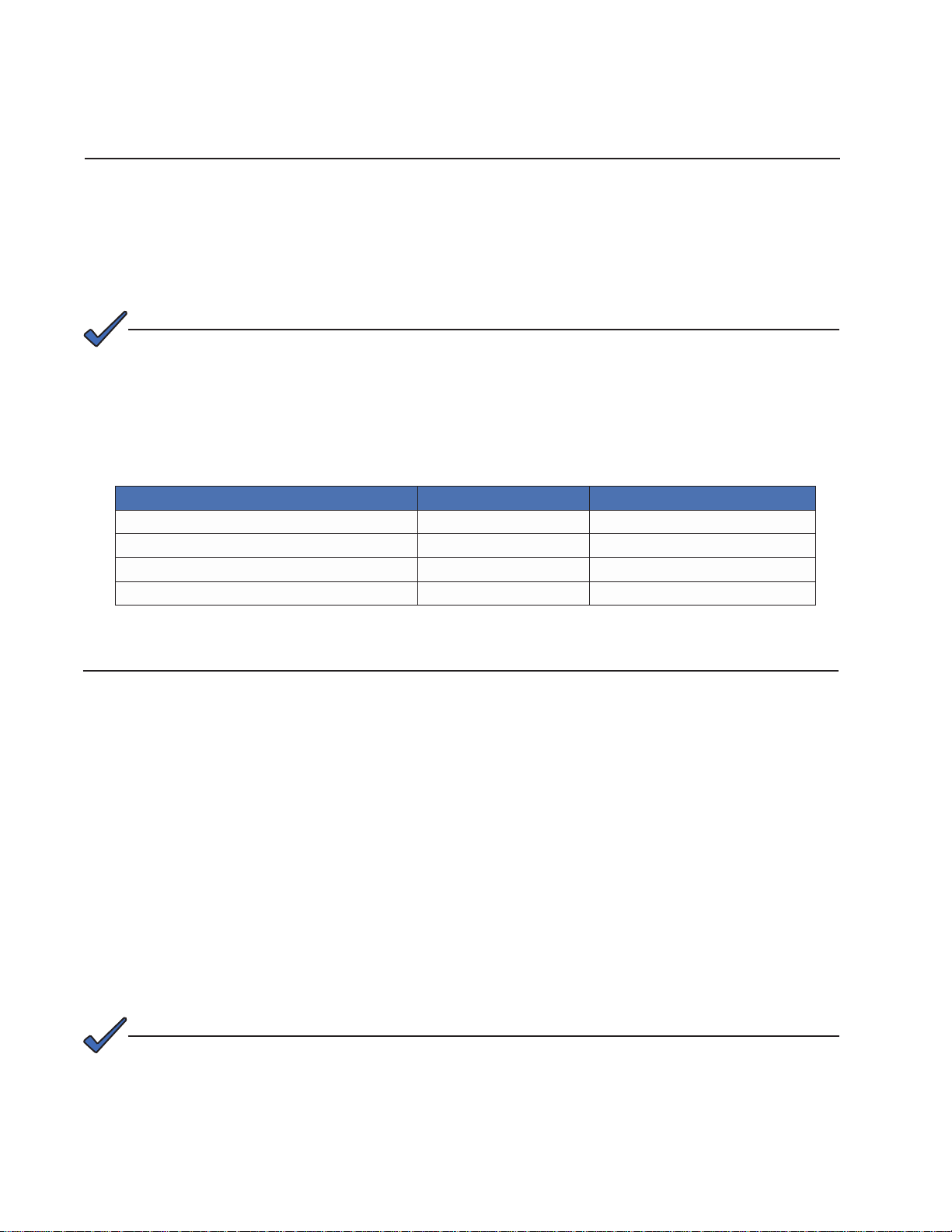

Description Alpha Part Number Square D Part Number

240V Installation - HACR (15A) 470-224-10 QO215

120V Installation - High-magnetic (20A) 470-017-10 QO120HM

BBX - External Service Disconnect 020-085-10 QO2 -4L70RB

BBX - External Service Disconnect 020-141-10 QO8-16L100RB

ATTENTION:

In most cases, the following congurations qualify for service entrance use when wiring a duplex receptacle

to a service disconnect. Other codes may also apply. Always contact your local utility to verify the wiring

conforms to applicable codes.

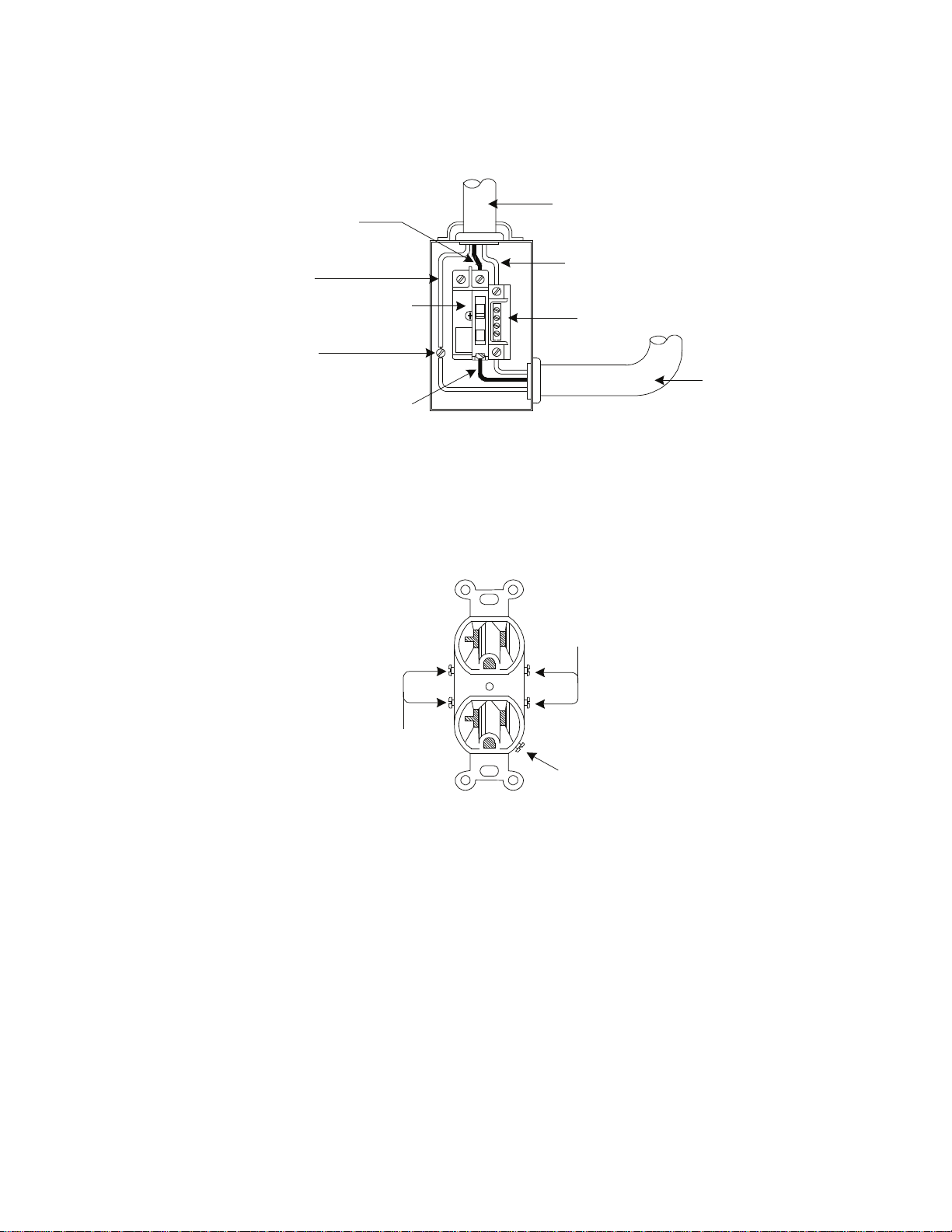

XM2 Connections

Proper 120Vac 20A service requires the installation site be:

• Equipped with a 120Vac duplex receptacle which provides power to the power supply and

peripheral equipment.

• Have a NEMA 5-20R receptacle protected by a single-pole, 20 Amp High Magnetic (HM) circuit

breaker inside the service entrance.

• Checked to NEC CODE to verify proper wire AWG (suggested wire gauge is 12AWG).

• Equipped with a grounding clamp on the enclosure to facilitate dedicated grounding.

NOTE:

When bonding the box to a neutral plate is required, use the long green bonding screw provided (Alpha

P/N 523-011-10, Square D P/N 40283-371-50).

10

017-805-B0-010 Rev. K2

Page 11

Utility Power Connection Notes, continued

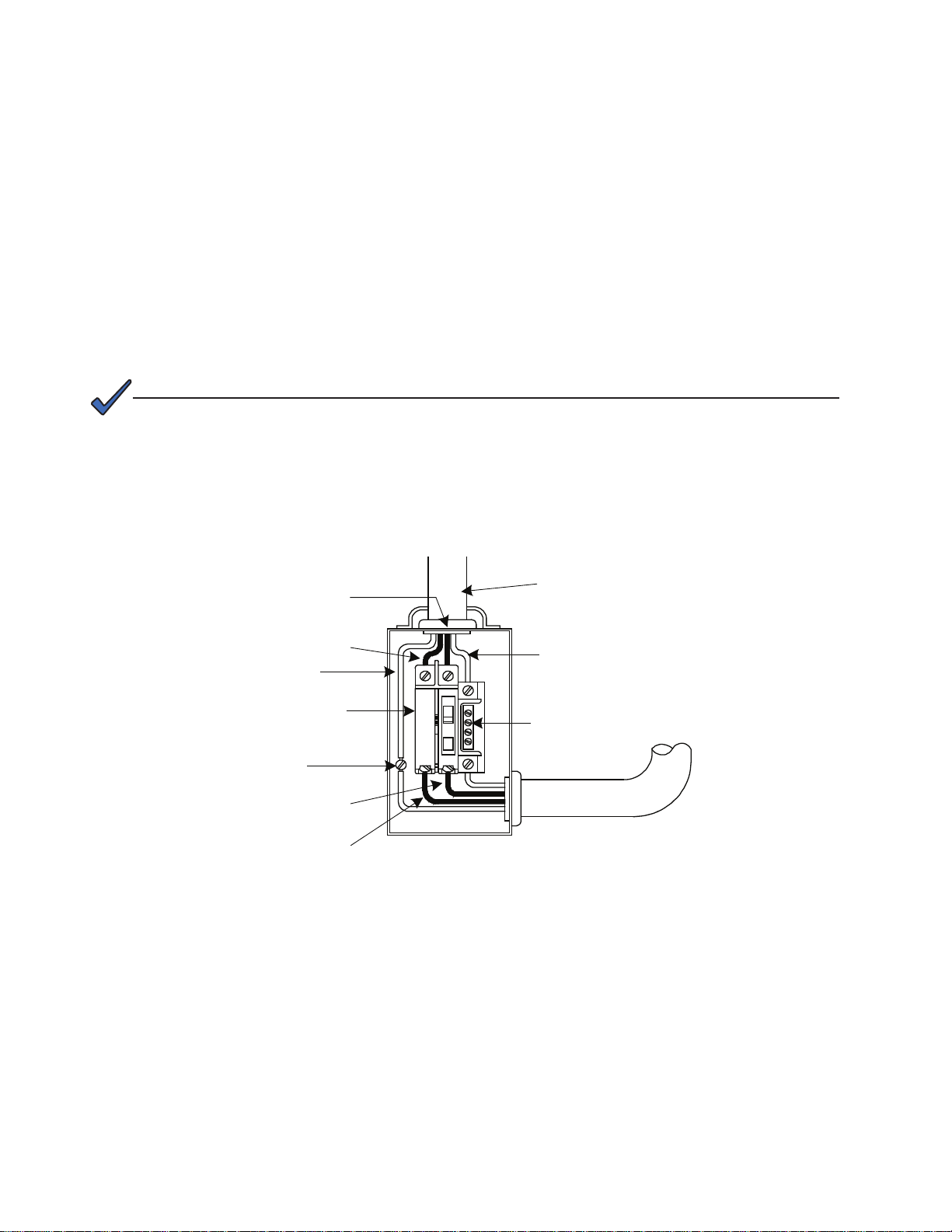

LI Black

Copper Ground Wire

#8 AWG (Minimum)

Grounding Point Made

to Enclosure Wall

Breaker

LI Black

Typical 120Vac Service Entrance Wiring

To Utility

Neutral (White)

Neutral Bus

To Enclosure

Receptacle

LI

(Black)

Neutral

(White)

Typical 120 Vac 20A Receptacle Wiring, 5-20R

(P/N 531-006-10)

Ground

(Green)

017-805-B0-010 Rev. K2

11

Page 12

Utility Power Connection Notes, continued

Proper 240Vac 20A service requires the installation site be:

• Equipped with a 240Vac duplex receptacle to provide power to the power supply and peripheral

equipment.

• Have aNEMA 6-15R receptacle is protected by a single, 2-pole, common trip 15A circuit breaker

inside the service entrance.

• Checked to NEC CODE to verify proper wire AWG (suggested wire gauge is 14AWG).

• Equipped with a grounding clamp on the enclosure to facilitate dedicated grounding.

NOTE:

When bonding the box to a neutral plate is required, use the long green bonding screw provided

(Alpha P/N 523-011-10, Square D P/N 40283-371-50).

LI (Black)

L2 (Red)

Copper Ground Wire

#8 AWG (Minimum)

Breaker

Grounding Point Made

to Enclosure Wall

To Utility

Neutral (White)

Neutral Bus

LI

L2

Typical 240Vac Service Entrance Wiring

12

017-805-B0-010 Rev. K2

Page 13

Grounding and Earth Connection Notes

In order to provide a ready, reliable source of backup power it is necessary to connect the power supply to an

effective grounding and Earthing system that not only provides for the safety of the service personnel responsible for

its operation and maintenance, but also facilitates the proper operation and protection of the equipment within the

network. Such a grounding system provides protection with respect to operator safety, system communication and

equipment protection.

Lightning strikes, grid switching or other aberrations on the power line and/or communications cable have the

potential to cause high-energy transients that can damage the powering or communications systems. The most viable

method available to protect the system from damage is to divert these unwanted high-energy transients along a lowimpedance path to Earth. A low-impedance path to Earth prevents these currents from reaching high voltage levels

and posing a threat to equipment.

The key to the success of lightning protection is single-point grounding so the components of the grounding system

appear as a single point of uniform impedance. Two places recommended by Alpha for single-point grounding are

connections in the enclosure and connections to Earth. Single-point grounding in the enclosure is achieved by bonding

all electrical connections to the enclosure, including the connection to Earth, as close together on the enclosure as

possible. Single-point grounding for the connection to Earth is achieved, for example by the proper bonding of the

ground rods.

Safety Ground and Earth Connection

The safety ground and Earth is a two-part system, comprised of the utility service and the Alpha system.

1. First, utility service;

As a minimum requirement for the protection of Alpha equipment, the local utility service must provide a low-

impedance path for fault current return. In addition, there must be a low impedance bonded path between the Alpha

Power Supply power plug Ground Pin and the Enclosure.

2. Second, the Alpha grounding system;

The Alpha grounding system consists of a low-impedance connection between the enclosure and an Earth Ground

(located at least 6’ away from the Utility Earth connection).

This impedance between the enclosure and Earth must be 25 Ohms or less at 60 Hertz as measured by AMPROBE

Model DGC-1000 or equivalent. The measurement should be made on the wire or ground rod after it exits the

enclosure.

Local soil conditions will determine the complexity of the grounding system required to meet the 25 Ohm (maximum)

resistance specied above. For example, a single 8’ ground rod may be sufcient to meet the requirement. In

some cases, a more elaborate system may be required such as multiple ground rods connected by a #6AWG solid

copper cable buried 8-12” below the surface. Where this is not possible, contact a local grounding system expert for

alternate methods that will meet the 25 Ohm (maximum) specication.

All ground rod connections must be made by means of a listed grounding clamp suitable for direct burial or

exothermic welding.

Power Output Return

For proper operation, the Service Power Inserter (SPI) must be securely bonded to the enclosure.

Communications Grounding

For an external status monitoring transponder, the transponder chassis is typically bonded via a separate ground wire

to the enclosure. For systems using an embedded transponder, the grounding connection is typically made either

through a separate chassis ground block bonded to the enclosure or by means of the internal mounting hardware

which bonds the transponder through the CableUPS. Please refer to the appropriate communications product manual

for installation procedures.

Alpha strongly recommends on communication cables the use of a surge arresting device electrically bonded to the

Alpha Enclosure.

WARNING!

Low impedance grounding is mandatory for personnel safety and critical for the

proper operation of the cable system.

017-805-B0-010 Rev. K2

13

Page 14

1.0 Introduction

The Intelligent CableUPS powers signal processing equipment in cable television and broadband LAN

distribution systems. The transformer module provides a critical load with current-limited regulated,

AC power that is free of spikes, surges, sags and noise.

During AC line operation, AC power entering the power supply is converted into a quasi square wave

and is regulated by a ferroresonant transformer at the required output voltage. The regulated voltage

is connected to the load via the output connectors and some power is directed to the battery charger

to maintain a oat charge on the batteries.

When the incoming AC line voltage signicantly deviates from normal, the inverter module

automatically switches to standby operation and maintains power to the load. During the switch to

standby operation, energy in the module’s ferroresonant transformer continues to supply power to the

load. In standby mode, the Intelligent CableUPS powers the load until the battery voltage reaches a

low-battery cutoff point.

When utility power returns, the transformer module waits a short time (approximately 20 to 40

seconds) for the utility voltage and frequency to stabilize and then initiates a smooth, in phase transfer

back to AC line power. Once the transfer is complete, the battery charger recharges the batteries in

preparation for the next event.

NOTE:

The duration of battery-backed standby operation depends upon the type and number of batteries and

the load on the power supply.

The Intelligent CableUPS contains an impressive list of features, including:

• Smart Display

• Built-in self test

• Battery test

• An optional factory-installed Protective Interface Module (PIM)

Also available is the High Performance Intelligent CableUPS which features:

• A high efciency transformer

• Improved Status menus

• Communications menu with DOCSIS® parameters

• An optional factory-installed Protective Interface Module (PIM)

Via the Smart Display, the operator can view all of the power supply’s operating parameters.

Automatic scrolling (AUTO-SCROLL) is always active so there is no need to press any buttons to

view the power supply’s status or system parameters. In place of operating parameters, active alarms

automatically indicate in the Smart Display so the operator can immediately see what fault is being

detected. Troubleshooting tips automatically display in the Alarm menu screen.

Built-in metering circuits measure voltage and current, without the need for external test equipment.

In legacy models (manufactured prior to July 2006) front panel test points provide access for manual

measurements if desired.

The factory-installed Protective Interface Module (PIM) option allows the Intelligent CableUPS to

function in an N+1 redundant supply system and also provides programmable current limits for two

output channels.

14

CAUTION!

To minimize the possibility of the transformer becoming unstable, a minimum load of at least

1A is required to be connected to the output (for the XM2-906G6 and XM2-906HP, minimum

load is 0.5A). Unstable transformers will self-correct as soon as a load of 1A or greater is

connected to the power supply. DO NOT operate unloaded.

017-805-B0-010 Rev. K2

Page 15

1.1 Theory of Operation

The Intelligent CableUPS is comprised of the:

• Transformer module, which acts as a stand-alone line conditioner. The transformer

module contains a ferroresonant transformer, resonant capacitor, transfer isolation relay,

Power Distribution Board and the optional Protective Interface Module (PIM) board.

• Inverter module, which is required for standby operations and contains circuitry needed

for the three-stage temperature-compensated battery charger, DC to AC converter

(inverter), AC line detectors and Smart Display.

• Optional communications module, used to provide external status monitoring and

communications.

High Efciency

Transformer Module

Fig. 1-1, XM2-HP Power Supply

1.1.1 AC (Line) Operation

Communications

Intelligent Inverter

Module

DOCSIS

Module

®

Transformer Module Intelligent Inverter

Module

DOCSIS

Communications

®

Module

Fig. 1-2, Standard XM2 Power Supply

During AC Line operation, utility power is routed into the primary winding of the

ferroresonant transformer through the contacts of the transfer isolation relay.

Simultaneously, in the inverter, power is directed to the rectier circuitry providing

power for the control circuitry. The bidirectional inverter also serves as a battery

charger during line operation. The ferroresonant transformer and an AC capacitor

form the resonant tank circuit, which provides excellent noise and spike attenuation,

output short circuit current limiting and output voltage regulation. The ferroresonant

transformer produces a quasi square wave output which resembles a rounded

square wave.

NOTE:

When measuring the output voltage of ferroresonant transformers, use only a true RMS AC voltmeter.

Non-RMS reading meters are calibrated to respond to pure sine waves and do not provide an

accurate reading when measuring quasi square wave output.

017-805-B0-010 Rev. K2

15

Page 16

1.1 Theory of Operation, continued

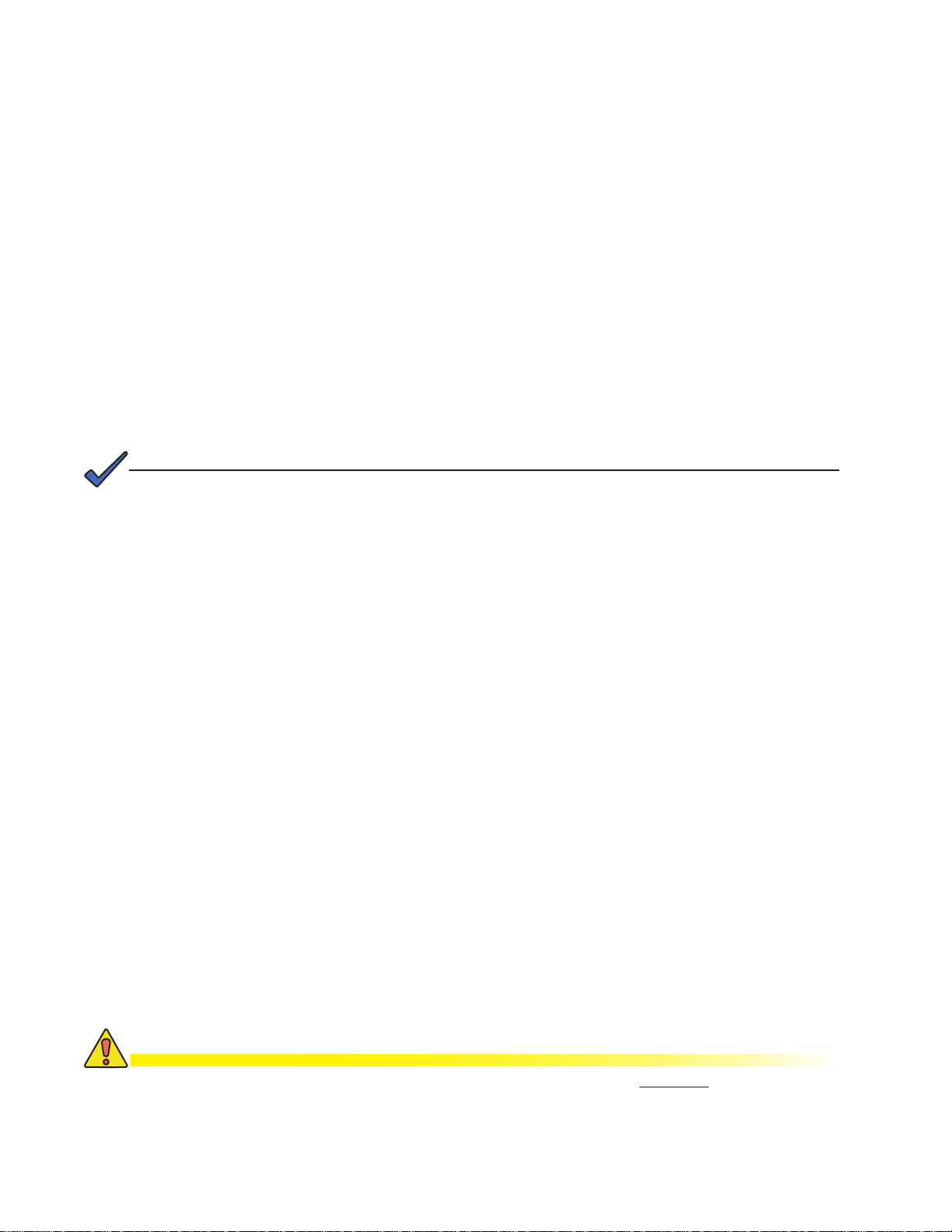

Transformer

K1

RV1

RV3

RV2

63 Vac

75 Vac

C1

(+)

(-)

AC1

AC2

Power Distribution Board

Inverter Module Assembly

Inverter

Relay Control

AC Line Detector

and Control Logic

Circuits

Transponder

Optional

Communications

Card

Batteries

Black

Red

Red

Black

AC Output

Connectors

120Vac Jumper 240Vac Jumper

Input Select

Black

White

Red

Battery Circuit

Breaker

Control Bus

Output 1A

Output 1B

Isolation Relay

Optional Surge Protector -

Replaceable Primary Power Supply

Overvoltage protection

(plugged into upper receptacle

of parallel-wired outlet)

RemoteTemperature

Sensor

Littlefuse V320LA40BP Varistors

Secondary Power Supply Overvoltage protection

Coaxial surge protector (Gas Filled)

Transponder Overvoltage protection

(Alpha p/n 162-028-10)

Surge Protector

Earth Ground (Enclosure)

Black

White

Black

White

Coaxial Cable Power Inserter

(Alpha’s SPI)

Coaxial Network

87/89 Vac

Black

48 Vac

63 Vac

BlackRed

Blue

Transformer AC Output

Output tap connector (shown in default 63Vac position)

Factory-set output tap connector

(settings for 48V/63V models shown below)

XM Series 2 Power Supply Chassis

Status Monitoring

Network

1.1.2 Standby Operation

When the incoming AC line voltage drops or rises signicantly or a complete power

outage occurs, the control logic’s line monitor activates standby operation. During the

transfer from AC line to standby operation, the battery powered inverter comes online

as the isolation relay switches to prevent AC power from back-feeding to the utility.

The energy contained in the ferroresonant transformer continues to supply power to

the load. The following changes also occur within the power supply:

• The isolation relay opens to disconnect the AC line from the primary winding of

the ferroresonant transformer.

• The control logic drives the inverter FETs on and off at line frequency. This

switching action converts the DC battery current into AC current in the inverter

windings of the ferroresonant transformer, providing regulated power to the load.

• The control logic, which includes a microprocessor and other circuits to protect

the inverter FETs from overcurrent damage, monitors the condition of the

batteries and the inverter during standby operation. Since a prolonged AC line

outage would severely discharge the batteries, resulting in permanent damage,

the control logic disables the inverter when the batteries drop to approximately

10.5Vdc per battery (31.5Vdc in a three-battery set or 42.0Vdc in a four-battery

set).

When acceptable AC line voltage returns, the power supply returns to AC line

operation after a 20 to 40 second lag. This delay lets the AC line voltage and

frequency stabilize before the control logic phase-locks the inverter’s output to the

utility input. The control logic then de-energizes the isolation relay, reconnects the

AC line to the primary of the ferroresonant transformer and disables (turns off) the

inverter. This results in a smooth, in-phase transfer back to utility power without

interruption of service to the load. The battery charging circuit then activates to

recharge the batteries in preparation for the next power outage.

NOTE:

The output fuse has been removed from models of the XM2 Power Supply manufactured after July

2006.

Fig. 1-3, Simplied Block Diagram

16

017-805-B0-010 Rev. K2

Page 17

1.1 Theory of Operation, continued

1

2

3

4

5

6

7

8

9

10

2.15

2.25

2.05

2.40

0

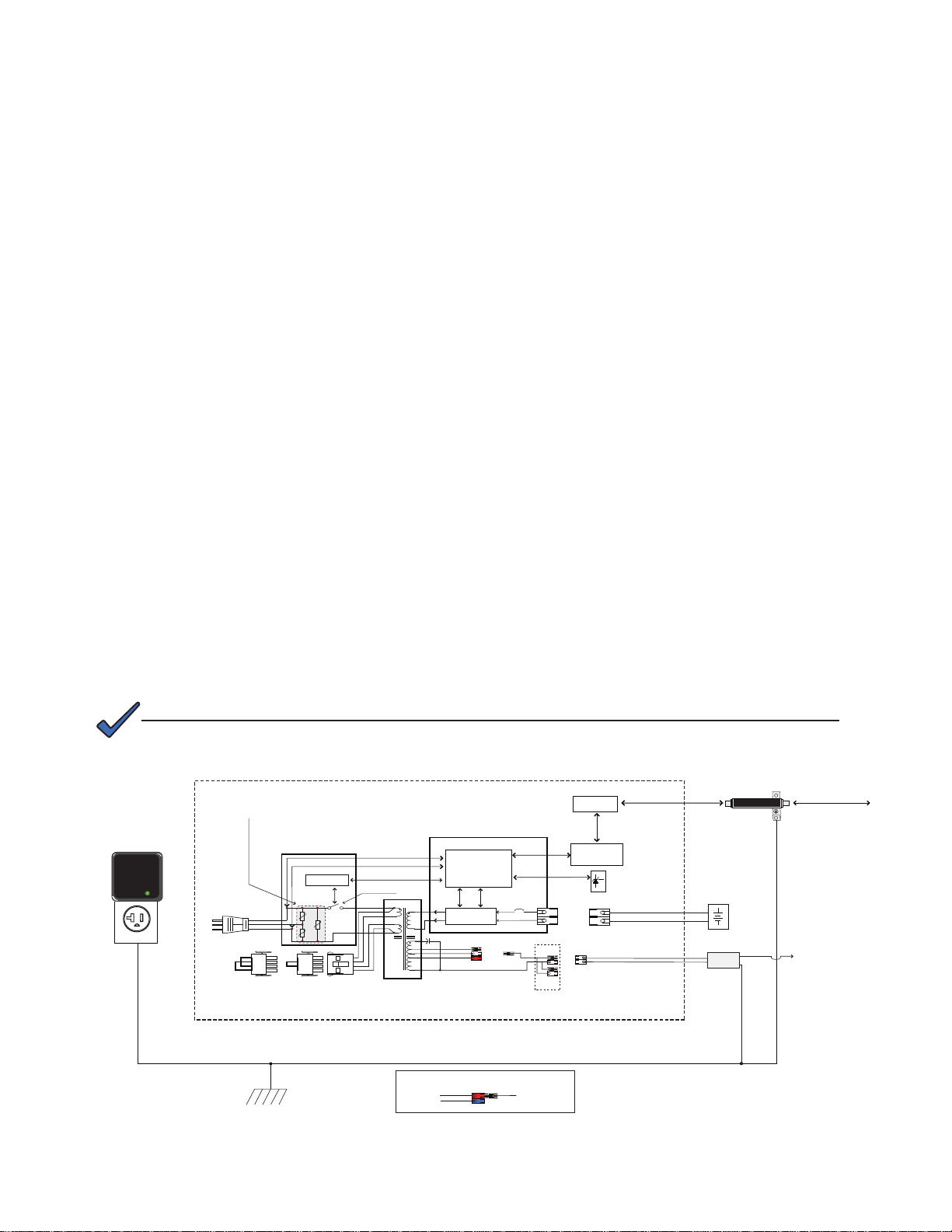

1.1.3 Charger Operation

The Intelligent CableUPS uses a three-stage, temperature-compensated battery

charger. During AC line operation, the inverter winding on the ferroresonant

transformer feeds the charger circuit which provides BULK, ACCEPT and FLOAT

charge voltages to the batteries.

Charger Modes

BULK charge is a “Constant Current” charge. The maximum current is 10A. As the

charge is returned to the batteries, their voltage increases to a specic threshold

(2.27Vdc per cell). The charger then switches to ACCEPT mode. The BULK charger

mode generally returns the battery charge state to 80 percent of rated battery

capacity.

ACCEPT charge is a “Constant Voltage” charge. This voltage, 2.40Vdc (adjustable)

per cell, is temperature-compensated to ensure longer battery life and proper

completion of the charge cycle. This cycle is complete when the charging current into

the batteries becomes less than 0.5A or approximately six hours elapses from the

time ACCEPT mode was entered. When the batteries are fully recharged the charger

switches to the FLOAT mode of operation.

FLOAT charge is a temperature-compensated “pulsed voltage” charge, averaging

about 2.27Vdc (adjustable) per cell. During FLOAT mode, the batteries are

fully charged and ready to provide backup power. The charger provides a small

maintenance charge to overcome the batteries self-discharge characteristics and

other minor DC loads within the power supply. As the battery voltage reaches the “full

charge” level the time delay between pulses increases.

017-805-B0-010 Rev. K2

During ACCEPT and FLOAT modes, the cell voltage is temperature-compensated

at -0.005Vdc per cell per degree C (adjustable) to ensure a safe battery cell voltage

and to maximize battery life.

NOTE:

On HP models, when Alpha Cell is the selected battery type, ACCEPT and FLOAT are pre-set and are

not manually selectable.

Volts Per Cell

Charger Current

Bulk Accept Float

Fig. 1-4, Charger Modes

(dashed lines indicate HV models)

17

Page 18

1.2 Intelligent CableUPS Layout

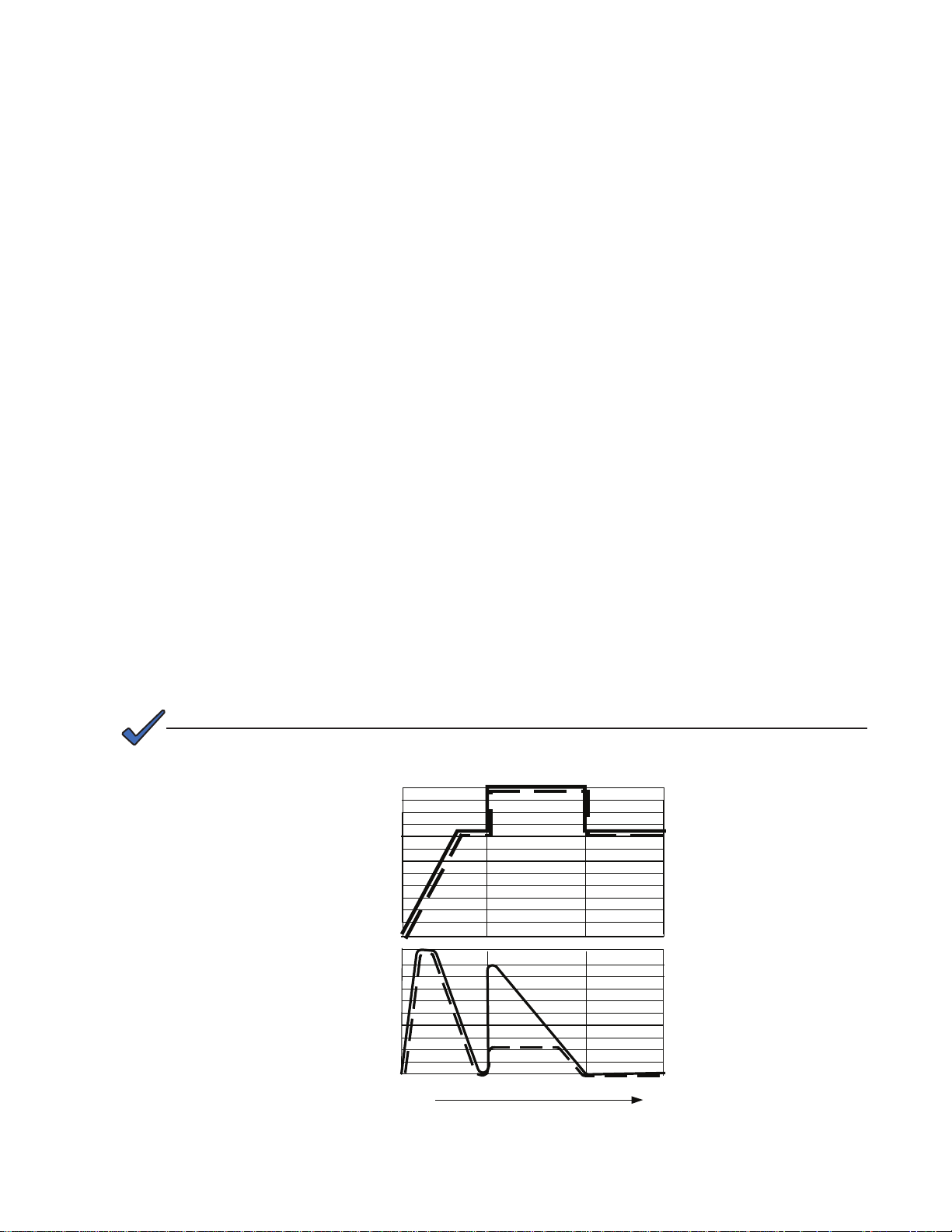

1.2.1 Transformer Module Overview

AC Output Fuse (legacy models only): Legacy XM2 power supplies use either a

20A slow blow or 30A slow blow fuse. To provide increased durability, an integrated

fuse guard protects the fuse.

Output N L (legacy models only): Use the output test point (output N L) to check

the AC output. Use a true RMS AC voltmeter equipped with the proper test probes;

other meters may give false or inaccurate readings.

N+1 (Optional): Use the N+1 ports in redundant system congurations where

multiple power supplies are housed in a single enclosure. If a power supply fails, a

redundant power supply automatically switches into service (8ms delay). This feature

is part of the PIM option.

LRI (Local/Remote Indicator): The LRI lamp option is used in conjunction with

the automatic performance feature and plugs directly into the LRI connector. The

LRI circuit is rated at 12Vdc, 250mA. This option duplicates the function of the red

ALARM LED by illuminating an externally mounted red lamp for standby operation.

Output 1A (White = Neutral, Black = Line): The AC output connector is clearly

marked and color-coded for easy identication. The service power inserter (SPI)

connects directly into the Output 1A connector.

Output 1B (White = Neutral, Black = Line): This output is wired in parallel to Output

1A (Output 1A +1B = Output 1) and is often used for auxiliary loads.

NOTE:

The Smart Display only displays Output 1, which is the sum of Output 1A and Output 1B.

Output 2 (Optional) [White = Neutral, Black = Line]: The AC output connector is

clearly marked and color-coded for easy identication. The SPI, which couples power

to the load, connects directly into the Output 2 connector. This feature is part of the

PIM option.

N+1 Ports

Output 2

18

LRI

Output 1B

Output 1A

Fig. 1-5, Transformer Module Connections

017-805-B0-010 Rev. K2

Page 19

1.2 Intelligent CableUPS Layout, continued

48VOLT

48V

1.2.2 Inverter Module Overview

The removable inverter module provides uninterrupted power to the ferroresonant

transformer (via the batteries) during line failures. During line operation, the inverter

charges the batteries using a three-stage (BULK, ACCEPT and FLOAT) charger.

Each inverter module and transformer module is labeled to indicate its voltage and

current rating. The power supply also carries a voltage and current rating label. It

is very important the inverter module is installed only in a power supply with the

same voltage and current rating. If the labels do not match, do not install the inverter

module. Each unit will bear a label (examples shown below) on the inverter module

and on the inside chassis oor.

Current 36V Inverter Modules bear this yellow label. This

label and the label located on the interior chassis oor must

36V

953-527-10-002 F

match. However, inverter modules carrying this yellow label are

backward compatible with 36V power supplies manufactured

prior to September 2006, which bear yellow labels. Do not install

the inverter module if the voltages do not match.

953-527-12-002 F

1350VA

953-527-11-002 F

Current 48V inverter modules bear this two-color label. This label

and the label located on the interior chassis oor must match.

However, inverter modules carrying this blue/green label are

backward compatible with all 48V power supplies manufactured

prior to September 2006, which bear green labels.

Obsolete-style label for the 1350VA 48V inverter modules.

The current 1350VA 48V inverter module (manufactured after

September 2006) carries a green label. If your legacy power

supply carries this green voltage and current rating label, it is

compatible with the latest blue/green labeled inverter module.

Fig. 1-6, Inverter Module Voltage Rating Labels

017-805-B0-010 Rev. K2

19

Page 20

1.2 Intelligent CableUPS Layout, continued

1.2.2 Inverter Module Overview, continued

Escape

Smart Display

Battery Breaker

Inverter Cooling Fan

Temperature Probe

Connector

Battery Input Connector

Fig. 1-7, Inverter Module Connections

Smart Display: All operational functions, system testing, setup items and alarms are available via the Smart Display panel on the front of the power supply (the Smart Display is

covered in detail in Section 4.2). Display functions are accessible by pressing any of the

four keys: ESCAPE, UP, DOWN or ENTER. Backlighting is activated when any of the four

keys are pressed and stays lit for a period of one hour. There are four levels of menu items

for the standard unit: Operation Normal, Additional Information, Setup and Alarms. For units

equipped with DSM2 (or newer) Communications Modules the four levels are: Operation

Normal, Communication Information, Setup and Alarms. Pressing ENTER will sequence the

display one level lower and pressing ESCAPE will sequence the display one level higher.

Up

Down

Enter

20

Battery Breaker: The battery breaker disconnects the batteries from the inverter module’s

DC circuit. With the battery breaker turned off, the power supply does not transfer to standby

mode, the inverter is disabled and the battery charger cannot charge the batteries. The

breaker trips when an overcurrent is detected in the DC circuitry or the battery polarity is

accidently reversed.

Battery Input Connector: The battery cable connector plugs directly into the inverter

module’s battery input connector. The connector is polarized and ts in one direction only.

NOTE:

Always verify proper polarity of cables before connecting the batteries to the power module.

Reversing the battery polarity can cause permanent damage to the power supply. Polarity is

clearly marked for easy identication.

017-805-B0-010 Rev. K2

Page 21

1.2 Intelligent CableUPS Layout, continued

1.2.2 Inverter Module Overview, continued

Inverter Cooling Fan: The inverter module is equipped with a cooling fan that operates

during standby operation when the inverter heatsink temperature reaches 85°C. The fan

stays on until the temperature drops below 75°C. The fan also operates whenever a self-test

is in progress.

Temp Probe Connector: The Remote Temperature Sensor (RTS) plugs directly into the

temperature probe (RJ-11C type) connector.

Batt Volt (Battery Test Point) [legacy models only]: With the battery breaker on and

battery string(s) connected, DC Output can easily be checked using the inverter module’s

battery test point. Use a DC voltmeter whenever checking the output.

The Remote Temperature Sensor is held in place on the AlphaCell 165, 195, 210 and 220

series batteries by a Battery Spacer Clip. To install, ex the clip and hook the retaining tabs

over the top of the battery and slide the sensor into place in the clip as shown below. For

domestic applications, use one battery clip per 36V battery string and two clips per 48V

battery string for optimal spacing. For International applications use two clips per 36V battery

string and four per 48V battery string. As an option to the Battery Spacer Clip, an RTS with

ring lug can be used (p/n 746-254-XX).

Fig. 1-8, Placement of Remote Temperature Sensor (RTS) on battery

Battery Spacer Clips (Domestic applications)

RTS Ring

Lug option

placement

-

3 2 1 24 13

+

-

+

-

+

-

+

36V battery string

RTS Ring

Lug option

placement

-

+

-

+

48V battery string

-

+

Battery Spacer Clips (International applications)

RTS Ring

Lug option

placement

-

3 2 1 24

+

-

+

-

+

-

+

RTS Ring

Lug option

placement

-

3

+

-

+

-

1

+

Fig. 1-9, Placement of Battery Spacer Clips on 36V and 48V battery strings

(Note: actual placement determined by battery arrangement)

017-805-B0-010 Rev. K2

21

Page 22

1.2 Intelligent CableUPS Layout, continued

1.2.3 Optional Status Monitoring Modules

The power supply supports a number of Alpha Technologies communication modules

which may be ordered factory-installed or as a user-installed eld upgrade.

NOTE:

If communications options are installed, Alpha highly recommends adding the coaxial surge

arrestor for the transponder (See Section 1.3, Recommended Enclosure System Options).

CAUTION!

Handle these modules with extreme care. Circuit boards and logic upgrades are

static-sensitive and susceptible to damage.

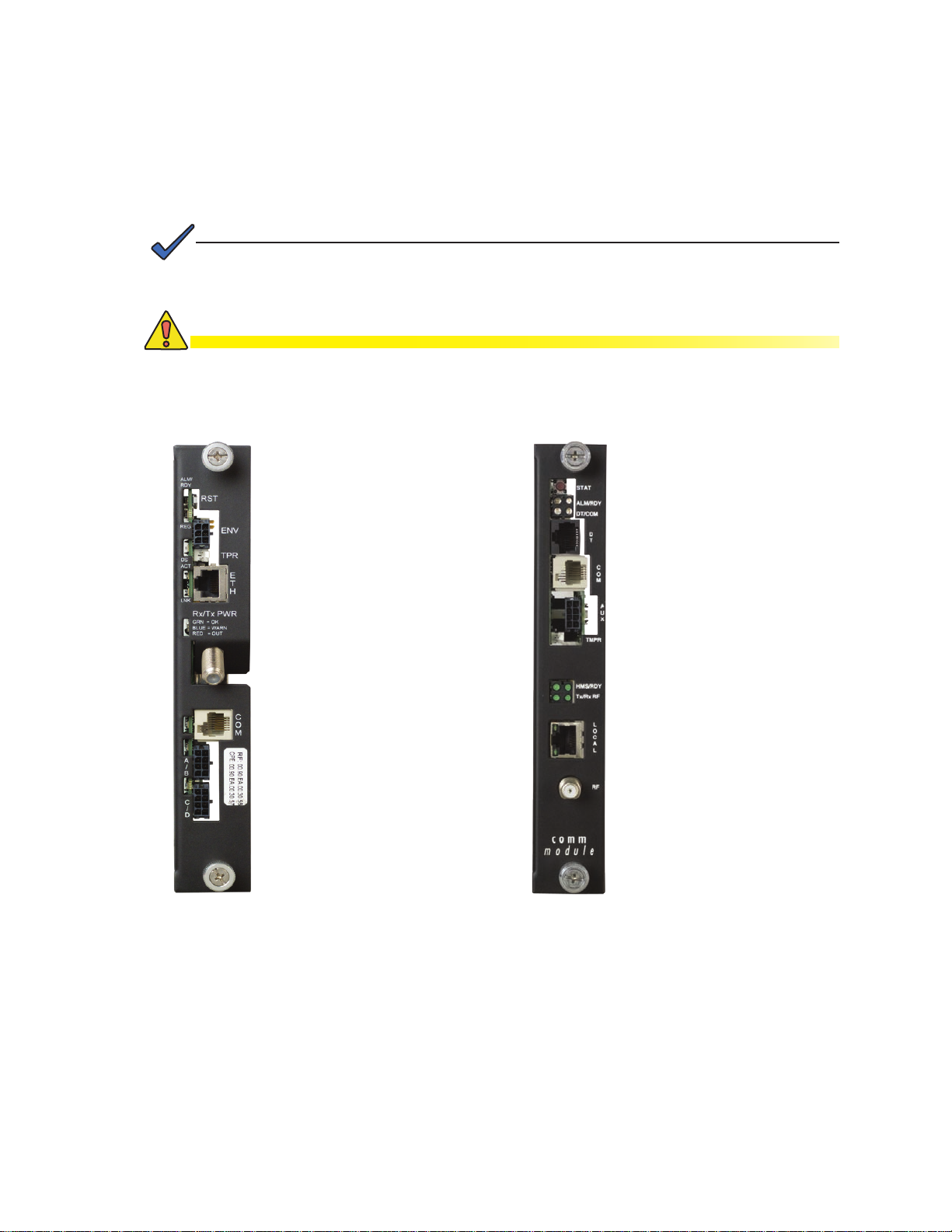

DOCSIS

The AlphaNet DSM3x Embedded

DOCSIS Transponder allows

monitoring of Alpha power supplies

through existing cable network

infrastructure. Multiple power

supplies, batteries and a generator

can be monitored using a single

transponder. Advanced networking

services provide quick reporting

and access to critical powering

information.

The DSM3x utilizes Simple

Network Management

Protocol (SNMP) and standard

Management Information Bases

(MIBs) to provide network status

monitoring and diagnostics. A

Web interface enables authorized

personnel direct access to

advanced diagnostics using a

common Web browser. No custom

software is required.

®

Status Module 3x

DOCSIS

The IDH3 Digital Embedded

DOCSIS Transponder enables

cable operators to manage

their network powering through

the existing cable modem

infrastructure. Multiple power

supplies, batteries and a

generator can be monitored

using a single transponder. Data

is transmitted to a management

system over the network’s

DOCSIS cable modem channels

through the existing CMTS.

Bandwidth utilization is minimized

by using standard SNMP

(Simple Network Management

Protocol) communications.

Status monitoring information

is compatible with ANSI/SCTE

HMS standards.

®

IDH3

22

Fig. 1-10, DSM3x Fig. 1-11, IDH3

017-805-B0-010 Rev. K2

Page 23

1.3 Recommended Enclosure System Options

These options can be factory installed or upgraded in the eld by the user:

Protective Interface Module (PIM)

The PIM protects system components by shutting down the load during overcurrent and short

circuit conditions. The PIM has an operator programmable overcurrent threshold (3A-24A)

and a programmable overcurrent tolerance period, which species the time (1-10 seconds)

an overcurrent condition is permitted before the output shuts down.

Using the programmable retry limit, the operator can select how many times (0-40) after a

programmable delay (5-301 seconds) the PIM will attempt to reconnect an output that has

been shut down. Once the limit is reached, the power supply automatically retries once

every 30 minutes until the fault clears. The PIM also provides N+1 redundancy in system

congurations with programmable dual outputs.

Local and Remote Indicator (LRI)

The LRI (red) lamp is located on the outside of pole-mount enclosures. Using this simple

form of status monitoring operators can check the operational status of the power supply

without having to climb the pole and open the enclosure. During normal AC line operation,

the LRI remains off. The LRI comes on only when the power supply is running in standby

mode. Whenever a fault is detected during self-test, the LRI ashes to indicate that service is

required.

AC Indicator (ACI)

The AC Indicator (green lamp) is located next to the LRI on the outside of pole-mount

enclosures and also acts as a simple form of status monitoring so cable technicians can

check the output status of the power supply without having to climb the pole and open the

enclosure. As long as there is voltage present at the output, the ACI remains on. To provide

much longer life than the original light bulb design, use the ACI-LL (long life LED). Models for

60V and 90V are available. Do not use ACIs for ground mount enclosures.

LA-P+, LA-P-120T 120V, 240V (Lightning Arrestor)

The LA-P+ plugs directly into the enclosure’s convenience outlet and provides additional

protection from voltage spikes caused by lightning and other power disturbances. It

eliminates the need for hard-wired MOVs. No additional wiring is necessary.

LA-P+ With Status Monitoring

Incorporates the same features as the LA-P+, with the additional benet of Status Monitoring

capability.

Co-axial Surge Arrestor

Alpha recommends using coaxial surge suppression for enclosure protection. The Coax

Surge Protector (Alpha P/N 162-028-10) includes 75 ohm surge suppressor and mounting

hardware.

APP90S /APP9022S (Service Power Supply)

The APP90S/APP9022S is a portable, non-standby power supply that provides conditioned

AC power to the load when the main power module is out of service. An internal tap lets the

APP90S/APP9022S be set for 90/75/60Vac applications. Use a 15A or 25A SPI (Service

Power Inserter) to transfer power from the APP9015S/APP9022S to the load.

017-805-B0-010 Rev. K2

23

Page 24

1.3 Recommended Enclosure System Options, continued

AlphaGuard™ Battery Charge Management System

The AlphaGuard

Battery Charge Management System extends battery life by

providing the precise voltage required for each battery. 36V (3 battery) and 48V (4

battery) versions are available. The AlphaGuard performs electrical compensation

for differences in individual batteries in the string. You can congure the unit to pass

measurements from the battery string to a status monitoring device, such as the

EDSM card or DOCSIS transponder, using an interface cable. See the AlphaGuard

System Installation Instructions, (P/N 012-306-C0), for detailed information (www.

alpha.com).

Fig. 1-12, Standard AlphaGuard Fig. 1-13, Potted AlphaGuard

24

017-805-B0-010 Rev. K2

Page 25

2.0 Installation

2.1 Installation Procedure

The Intelligent CableUPS can be shelf-mounted within a variety of Alpha enclosures.

Complete the pre-installation instructions in Section 2.0 and the preliminary inspection and

self-test procedure before you install the power supply.

CAUTION!

Read the Safety Precautions, Utility Power Connection Notes and Grounding Connection

Notes (pages 8-13) before you install the power supply.

Pre-installation Inspection

1. Remove the power supply from the shipping container. Conrm the power supply, including the

Remote Temperature Sensor and all other ordered options are included.

2. During shipping, components might shift. Carefully inspect the power supply and other contents

for possible shipping-related failures, such as loosened or damaged connectors. If any items are

damaged or missing, contact Alpha Technologies or the shipping company immediately. Most

shipping companies have a short claim period.

3. Do not attempt to install a damaged power supply without rst passing a complete pre-installation

inspection and start-up test.

NOTE:

See the “Preliminary Inspection/Pre-Service Checklist” (Alpha P/N 017-805-B5) that accompanies

each power supply. SAVE THE ORIGINAL SHIPPING CONTAINER.

Use the original shipping container if the power supply needs to be returned for service. If the original

container is not available, make sure the unit is well packed with at least three inches of shockabsorbing material to prevent shipping damage.

CAUTION!

Do not use popcorn-type material. Alpha Technologies is not responsible for damage caused

by improper packaging of returned units.

017-805-B0-010 Rev. K2

25

Page 26

2.2 Installing the Optional Indicator Lamps

2.2.1 AC Indicator Lamp

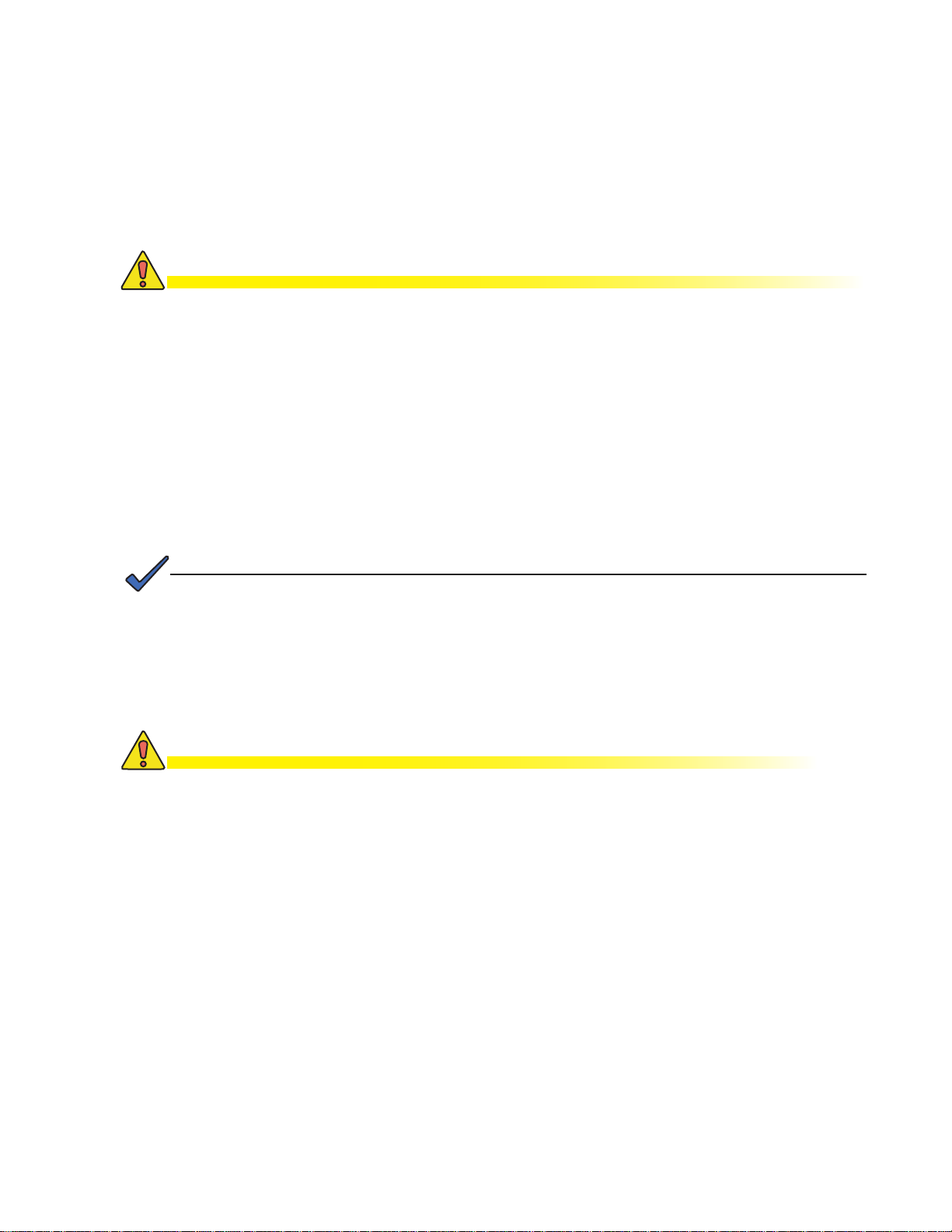

The AC indicator (green lamp) is located on the outside of the enclosure. When lit,

it indicates AC power is available at the power supply output and enables service

personnel to determine the status of the power supply without having to climb the

pole.

Installation Procedure:

1. Remove the rear-most knockout (see Fig. 2-5).

2. Feed ACI wires through the hole.

3. Slide locking nut over the wires and thread onto lamp body (see Fig. 2-1).

4. Insert the crimped contacts into the plastic connectors. The BLACK wire must

always go into the BLACK housing. Insert the remaining wire (this may be white,

yellow or blue) into the WHITE housing (see Fig. 2-2).

5. Connect the shorter BLACK/WHITE set of wires to the BLACK/WHITE wires

leading from the SPI. The remaining set of longer wires connects to the Output

1A connector on the front of the power supply (Fig. 2-5).

To SPI

To Output 1A

Fig. 2-1, AC Indicator Lamp

CAUTION!

Secure the contact. If you do not properly position the contact, overheating and cable

assembly failure can result.

NOTE:

To remove the wire from the plastic housing, use a small screwdriver to depress the metal retainer

and slide out the wire.

Top View

White Housing

Black Housing

White, Yellow or Blue Wire

Black Wire

26

Verify contact snaps

over metal retainer

Fig. 2-2, Wire/Housing Assembly

Side View

017-805-B0-010 Rev. K2

Page 27

2.2 Installing the Optional Indicator Lamps, continued

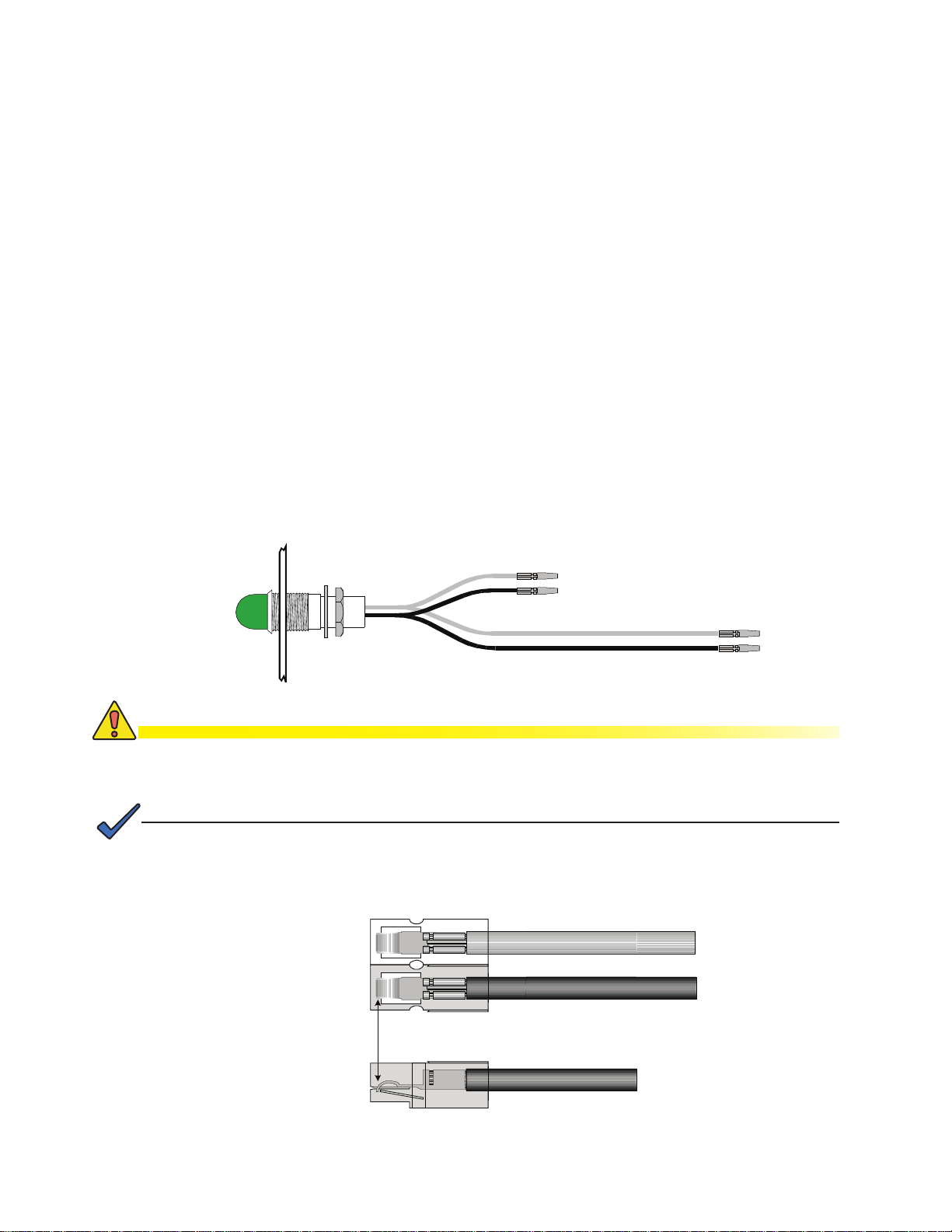

2.2.2 Local/Remote Indicator

The Local/Remote indicator (Red lamp) is located on the outside of the enclosure.

During normal AC operation, the lamp remains OFF. The lamp comes ON only when

the power supply is running in Standby Mode. In the event a major alarm is detected,

the lamp ashes to indicate service is required. The LRI is a simple form of status

monitoring which allows the operational status of the power supply to be veried from

the ground.

Installation Procedure:

1. Remove the front-most knockout (see Fig. 2-5).

2. Feed LRI wires through the hole.

3. Slide locking nut over the wires and thread onto lamp body (see Fig. 2-3).

4. Insert the crimped contacts into the plastic connectors. The BLACK wire must

always go into the BLACK housing and the RED wire into the RED housing (see

Fig. 2-4).

5. Connect the wire harness into the LRI connector on the front panel of the power

supply.

Fig. 2-3, Local/Remote Indicator Lamp

CAUTION!

Secure the contact. If you do not properly position the contact, overheating and cable

assembly failure can result.

NOTE:

To remove the wire from the plastic housing, use a small screwdriver to depress the metal retainer

and slide out the wire.

Top View

Black Housing

Red Housing

Verify contact snaps

over metal retainer

Fig. 2-4, Wire/Housing Assembly

Black Wire

Red Wire

Side View

017-805-B0-010 Rev. K2

27

Page 28

LRI

Output 1A

LRI

ACI

SPI

2.2 Installing the Optional Indicator Lamps, continued

Installation is complete. Go to Start-up Test (Section 4.1, Start-up and Test).

ATTENTION:

See Section 5.6, Check Output Connections, for inspection guidelines.

28

Fig. 2-5, ACI/LRI Connection

017-805-B0-010 Rev. K2

Page 29

2.3 Initial Turn Up

NOTE:

Alpha enclosures are engineered to properly vent the power supply. The power supplies have been

investigated by regulatory authorities for use in various Alpha enclosures. If you are using a nonAlpha enclosure, it is your responsibility to ensure your combination conforms to your local regulatory

requirements and the power supply remains within its environmental specications.

CAUTION!

Batteries are an important part of the power supply. Properly install and test all batteries,

battery connections and battery cables before you connect them to the power supply.

1. Verify the Inverter Module’s battery breaker is OFF.

2. Connect battery cables to battery input connector.

3. Insert temperature probe cable.

4. Insert Local/Remote Indicator (LRI) cable. (Optional)

5. Connect status monitoring connectors, including tamper switch (if installed).

6. Verify SPI switch is in “ALT” position.

7. Connect the SPI (network load) to the Output 1A connector.

8. Connect an auxiliary load (i.e. fan) to the Output 1B connector (If optional

factory installed PIM has been installed).

9. Turn on AC breaker (located on enclosure) and verify correct (per unit’s

nameplate voltage) utility voltage at outlet; if correct, plug in XM2 line cord

to the utility outlet.

10. Switch the Inverter Module’s battery breaker ON.

11. Verify no alarms are present (it may take up to 60 seconds for alarms to

clear).

12. Perform self-test. Initiate the self-test by simultaneously pressing the DOWN

arrow key and ENTER key. Wait for Self-test completion before proceeding.

13. Perform this live inverter test procedure:

a.) Turn AC input breaker OFF.

b.) Verify power supply transfers to “Inverter” mode.

c.) Turn AC input breaker ON.

d.) Verify power supply transfers back to utility.

14. Verify Service Power Inserter (SPI) toggle switch in ON position (not ALT).

NOTE:

Output 2 is available only if the optional PIM is installed.

Use Output 1B to power auxiliary loads, such as cooling fans.

017-805-B0-010 Rev. K2

29

Page 30

2.4 Inverter Module Removal and Installation

The Intelligent CableUPS comes with a eld-replaceable inverter module assembly containing

the inverter and control logic. The inverter module accepts optional communications modules

to facilitate remote status monitoring. The removable module is located on the front, righthand side of the unit.

CAUTION!

ALWAYS switch the battery breaker off before removing or installing the inverter module

assembly.

Handle the inverter module with extreme care. Circuit boards and logic upgrades are static-

sensitive and susceptible to damage.

NOTE:

You can remove the inverter module assembly while the power supply is running on line power. The

power supply will continue to operate as a non-voltage regulated power supply.

Removal Procedure:

1. Turn off the battery breaker.

2. Disconnect the battery input and temp probe cables

from the inverter module and the TMPR and XPDR

cables from the communication module.

3. Loosen the thumbscrews.

4. Grasp the handle on the right side of the inverter

module. Pull rmly to release the module from the

inverter connector. Gently slide the module assembly

straight out until the inverter module ribbon cable

connector is accessible. Move the retaining clips

apart and the ribbon cable will come free from the

connector.

Installation Procedure:

1. Reconnect the inverter module ribbon cable

to the Inverter Module circuit board by seating

the cable into the connector (the locking tabs

will automatically engage). Engage the sheet

metal in the upper and lower guides and slide

the inverter module back onto the connector. It

is important the sheet metal is properly seated

in the card guides and fully inserted into the

housing.

Disconnect here

Fig. 2-6, Inverter Module Ribbon Cable

30

2. Tighten the thumbscrews.

3. Verify the battery breaker is off. Reconnect the

battery input, temp probe cables, TMPR and

XPDR cables. Turn the battery breaker on.

Fig. 2-7, Detail of Locking Mechanism

017-805-B0-010 Rev. K2

Page 31

2.5 Protective Interface Module (PIM)

The optional (PIM) adds a second isolated output so the Intelligent CableUPS can function

as an N+1 redundant supply system. It provides programmable current limits for two output

channels and protects system components by shutting down the load during overcurrent and

short circuit conditions.

The PIM has a programmable overcurrent threshold (3A-24A) and overcurrent tolerance

period that species the time (1-10 secs) an overcurrent condition is permitted before shutting

down.

You can use the programmable retry limit to select how many times (0-40) after a

programmable delay (5-301 seconds) the PIM will attempt to reconnect an output once it has

been shut down. When the limit is reached, the XM2 power supply automatically retries once

every 30 minutes until the fault clears. The PIM also provides N+1 redundancy in system

congurations and programmable dual outputs.

Adding the PIM to the Intelligent CableUPS provides these advantages:

• A second isolated output: The main purpose of the PIM is to limit the impact of a fault

condition in one output channel. If a fault condition occurs in an Intelligent CableUPS

(without the optional PIM installed) the entire customer network can be affected. The PIM

option affords protection to one output should a fault condition exist on the other. This

gives you exibility to isolate Output 1A and 1B from Output 2.

• A current for critical loads: With the PIM option, you can designate one output as the

primary connection and the other output as the secondary connection. Commonly, critical

loads are connected to Output 1A as the primary feeder. Using the overcurrent limit

settings, you can ensure the primary output always provides the necessary power. For

example, on a 15 Amp power supply, if a customer needs 10 Amps available on Output

1A, the overcurrent limit for Output 2 is set at 5 Amps, so regardless of Output 2, 10

Amps will remain available for the primary Output 1.

• Additional current protection: The standard power supply current limit protection is

provided by the fold-back characteristics of the transformer (180% of rated output). The

180% current limit may exceed the ratings of active devices in the cable network and

cause failures. You can lower the maximum current provided at each output by lowering

the overcurrent limit of each respective output. Therefore, to minimize failures due to

excess current supply, set the overcurrent limit to a value below the maximum current the

active components can tolerate.

Power Supply Load Permitted Duration of Load

>150% 10 seconds

125% to 150% 10 minutes

115% to 125% 30 minutes

<115% Many months

For example, on a 15A power supply, where both outputs are programmed to 10A maximum

and both outputs are supplying 9A, neither output is “in violation” but the total system at 18A

is operating at 120% of its rated output. In this example, after 30 minutes, the power supply

will begin a “load shedding” algorithm. The rst action is to disconnect Output 2. If this does

not correct the system overload, the next action is to disconnect Output 1A and Output 1B (if

used).

017-805-B0-010 Rev. K2

31

Page 32

2.6 Installing the PIM

NOTE:

Only qualied personnel should install the PIM. To install the PIM you must completely shut down

the power supply. To maintain output to the load, consider using either the APP9015S or APP9022S

Service Power Supply during installation.

WARNING!

To avoid exposing the technician to potentially lethal voltages, before you proceed

you must remove all power from the power supply; unplug the power supply from the

AC power source, remove all front panel connections (such as N+1) and disconnect

the battery connector.

Tools Required:

• 90° Torque driver with #2 Phillips-head bit (set to 14 inch-pounds)

• 9/32” Nut driver

To install the PIM

1. Completely shut down the Intelligent CableUPS, verify all power is removed. Ensure

utility power is off and battery power is safely secured (or not installed) in the enclosure

assembly. All connections and cables must be removed from the power supply. To

maintain output to the load, consider using the APP9015S or APP9022S Service Power

Supply when installing the PIM.

2. To remove the transformer module’s front panel, remove the ve front panel screws. Lift

the front panel up and away from the chassis. The front handle remains in place.

3. For Legacy models: Use a right-angled (90°) Phillips-head screwdriver to remove the

fuse wire (A). This wire may be connected to the power distribution board (PDB) by either

a standoff (Fig. 2-8) or “Fast-On” connector.

4. Remove the transformer wire (B). This wire may be connected to the PDB by either a

standoff (Fig. 2-8) or “Fast-On” connector.

5. Remove the factory-installed bus bar (E) between standoffs P13 (D) and P16 (C).

A CD E

B

(may be yellow with

black trace on older models)

32

Fig. 2-8, PDB Connections

017-805-B0-010 Rev. K2

Page 33

2.6 Installing the PIM, continued

6. Install the PDB header in the J4 connector of the PIM circuit board.

7. Align the PIM circuit board holes labeled P3, P5 and P4 with the standoffs (P13, P15

and P16) on the PDB. Place the PIM circuit board on the standoffs, making the J6/J4

connection. Verify the J6 pins are aligned correctly and completely seated in J4.

8. Using the provided 6-32 hardware, re-attach the:

• Fuse/ output voltage selection block wire at P5 (on PIM board in legacy units)

• 0-Volt wire from the transformer to P4*

9. Torque the three 6-32 screws (P3, P5 and P4) fastening the PIM circuit board to the

power distribution circuit board to 14 inch-pounds (P13, P15 and P16).

10. Replace the front panel.

11. Program the PIM. See Section 2.6 for instructions.

* For installation assistance, call Alpha Technologies technical support, 1-800-863-3364

CAUTION!

Torque the 6-32 fastening hardware (with or without standoff) to 14 inch-pounds to avoid arcing or

board failure.

NOTE:

The PIM header (Alpha P/N 545-739-10) is shipped uninstalled. Locate the header and install it

between J6 on the PDB board and J4 on the PIM board.

J4

PIM to PDB Header

Connection

J6

Fig. 2-9, J6 and J4 connection as seen from rear of Power Distribution Board

017-805-B0-010 Rev. K2

33

Page 34

2.6 Installing the Optional PIM, continued

NOTE:

The output current limit for the PIM is set by the position of the jumper on JP1. Congure JP1 to the

proper current setting; either 15A or 22A.* For the 918HP and 924HP Cable UPS models, set this

jumper to the 22A position

* For additional conguration assistance, call Alpha Technologies Technical

Support, 1-800-863-3364

Fig. 2-10, Location of JP1 on PIM

Line Isolation Relay

Fig. 2-11, Jumper in 15A position Fig. 2-12, Jumper in 22A position

J4

15/22A

Jumper

Replaceable

P3

P4

P5

(Front of Power Supply)

34

Fig. 2-13, PIM (Protective Interface Module) and PDB (Power Distribution Board)

017-805-B0-010 Rev. K2

Page 35

2.7 Programming the PIM

Programmable parameters (with PIM installed) are:

Channel 1 Overcurrent Limit: The RMS current level that causes the Output 1 protection

relay to trip after a specied delay (overcurrent tolerance period).

Channel 2 Overcurrent Limit: The RMS current level that causes the Output 2 protection

relay to trip after a specied delay (overcurrent tolerance period).

Retry Delay: The time between each attempt to restart an output in the event of an

overcurrent event.

Retry Limit: The number of times the CableUPS attempts to restart an output connection.

Once the RETRY LIMIT is exceeded, standard models attempt to restart the output

connection every 30 minutes (HV models do not attempt to restart after the retry limit is

exceeded). Set this parameter to “zero” to disable the “automatic retry” function.

Overcurrent Tolerance Period (1-10 seconds): In the event of an overcurrent episode,

the amount of time an output overcurrent condition is permitted on either output connection.

Once this time expires, the output protection relay disables its output feeder.