Page 1

AlphaNet™ IDH4 Series DOCSIS® Status Monitor

for XM2, XM2-HP, and XM2-300HP Series CableUPS™

Installation and Quick Start Guide

The AlphaNet IDH4 Series Embedded DOCSIS Transponder allows monitoring of Alpha power supplies through existing cable network infrastructure.

Advanced networking services provide quick reporting and access to critical powering information.

The IDH4 Series utilizes Simple Network Management Protocol (SNMP) and standard Management Information Bases (MIBs) to provide network

status monitoring and diagnostics. A Web interface enables authorized personnel direct access to advanced diagnostics using a common Web

browser. No custom software or proprietary cables are required.

The transponders can be installed and congured for operation in the XM2, XM2-HP, or XM2-300HP Power Supply.

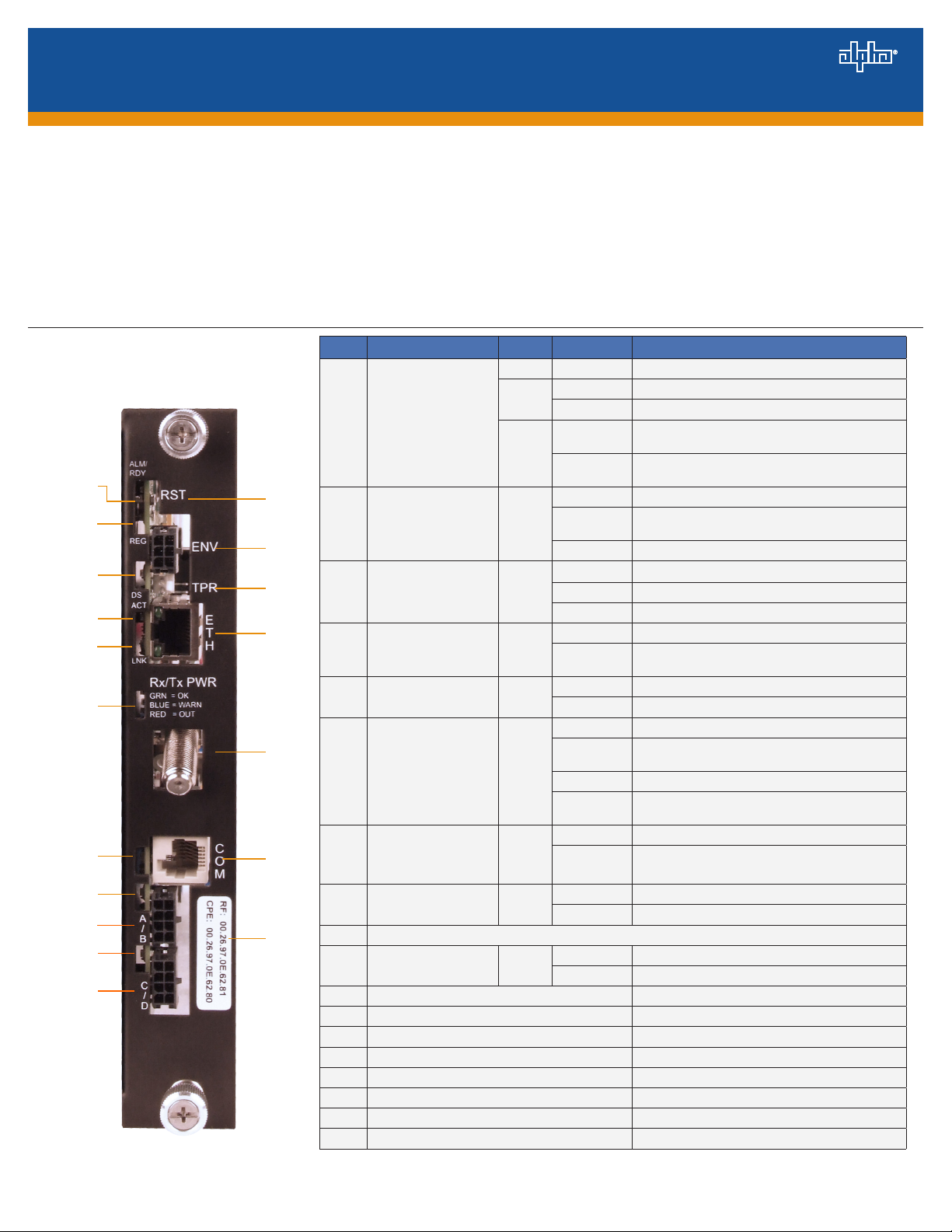

IDH4X DOCSIS Transponder

Item LED or Connector Status Behavior Indication

N/A OFF No power or malfunctioning IDH4 Series

GRN

1 ALM/RDY: Alarm and Ready

RED

1

2

12

2

REG: Upstream ranging and

registration lock

GRN

13

3

14

3

DS: Downstream RF Carrier

detection and lock

GRN

4

15

5

6

4 ACT: CPE Activity status GRN

5 LNK: CPE Link status GRN

16

6

7

17

7

RF Rx/Tx Power Level

Indicator

COM: AlphaBus

communications

TRI

GRN

ON Reset of the IDH4 Series is in process

Steady Blinking Normal operation

Blinking more

OFF than ON

Blinking more

ON than OFF

OFF No power, upstream frequency undetermined

BLINKING

ON CMTS registration completed

OFF No power / downstream carrier

BLINKING Power on, downstream carrier frequency searching

ON Downstream carrier lock

OFF No Ethernet communications activity

BLINKING

OFF No Ethernet link

ON Link on Ethernet Craft port

OFF No RF detected

Blue

Green Rx/Tx RF Power level within tolerance

Red

OFF No AlphaBus Communications

BLINKING Momentary ashes - AlphaBus Port communications active

Minor Alarm

Major Alarm

Power on, downstream locked, upstream frequency ranging,

DHCP request in progress

Momentary ashes during CPE communications via the Ethernet

craft port

Rx/Tx Power at a warning level as set within the SCTE-HMS

Property Table

Rx/Tx Power at an alert level as set within the SCTE-HMS

Property Table

8

9

10

11

746-257-B0-001 Rev. A (2/2014)

ON Battery string(s) connected correctly

OFF Battery string(s) not connected correctly

ON Battery string(s) connected correctly

OFF Battery string(s) not connected correctly

18

8 BAT A/B GRN

9 BAT A/B Connector

10 BAT C/D GRN

11 BAT C/D Connector

12 RST: Reset buttton

13 ENV: Environmental Control connector

14 TPR: Tamper Switch connector

15 ETH: Ethernet connection

16 RF Connection

17 COM: AlphaBus Communications connector

18 RF, CPE MAC Address label

Fig. 1, IDH4X Transponder Front Panel Indicators and Connectors

1

Page 2

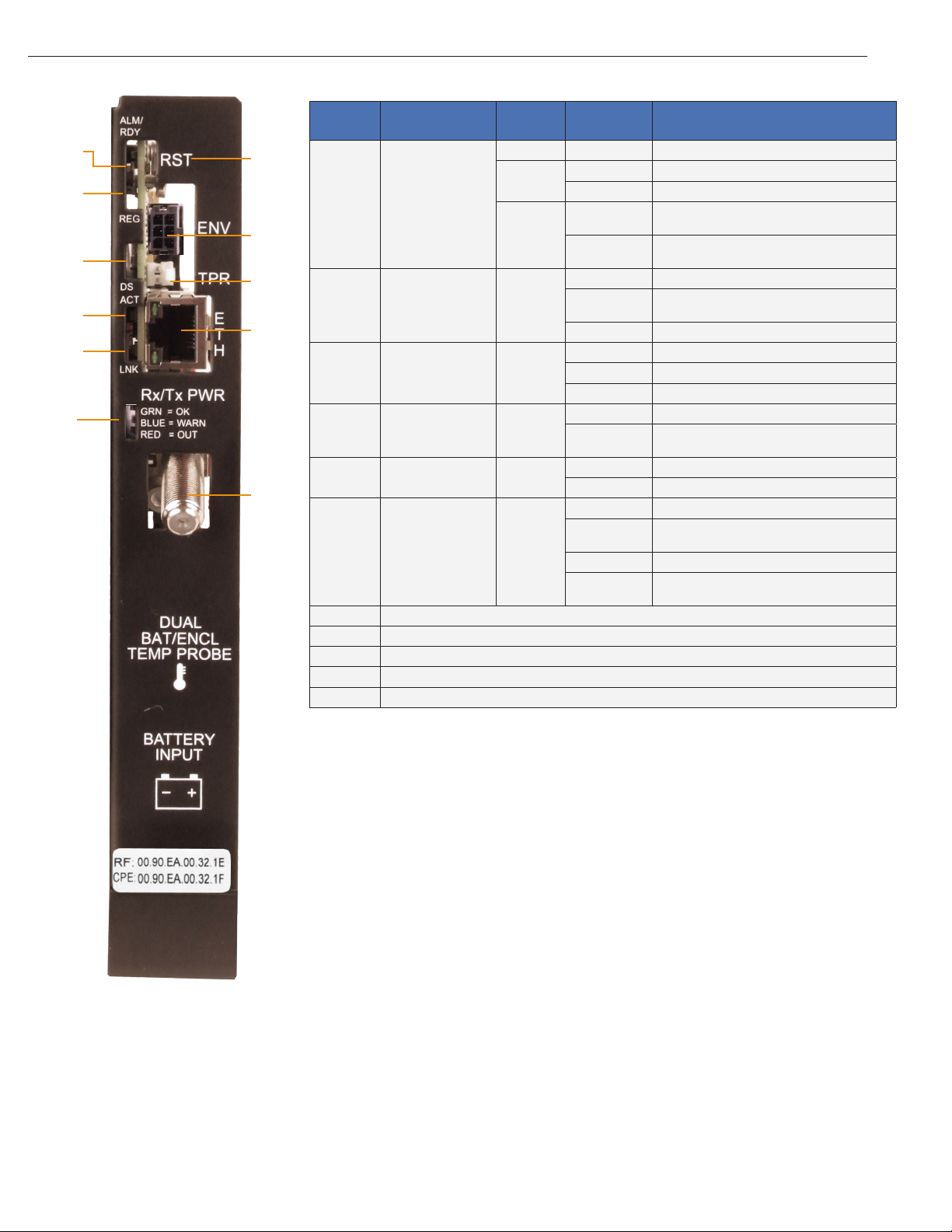

IDH4L DOCSIS Transponder

Item

1

2

7

1

8

3

9

4

2

10

5

3

6

4 ACT: CPE Activity status GRN

5 LNK: CPE Link status GRN

11

6

7 RST: Reset buttton

8 ENV: Environmental Control connector

9 TPR: Tamper Switch connector

10 ETH: Ethernet connection

11 RF Connection

LED or

Connector

ALM/RDY: Alarm and

Ready

REG: Upstream ranging

and registration lock

DS: Downstream RF

Carrier detection and

lock.

RF Rx/Tx Power Level

Indicator

Status Behavior Indication

N/A OFF No power or malfunctioning transponder

GRN

RED

GRN

GRN

TRI

ON Transponder reset in process

Steady Blinking Normal operation

Blinking more OFF

than ON

Blinking more ON

than OFF

OFF No power, upstream frequency undetermined

BLINKING

ON CMTS registration completed

OFF No power / downstream carrier

BLINKING Power on, downstream carrier frequency searching

ON Downstream carrier lock

OFF No Ethernet communications activity

BLINKING

OFF No link

ON Link on Ethernet Craft port

OFF No RF detected

Blue

Green Rx/Tx RF Power level within tolerance

Red

Minor Alarm

Major Alarm

Power on, downstream locked, upstream frequency

ranging, DHCP request pending

Momentary ashes during CPE communications via the

Ethernet Craft port

Rx/Tx Power at a warning level as set within the SCTEHMS Property Table

Rx/Tx Power at an alert level as set within the SCTE-HMS

Property Table

Fig. 2, IDH4L Transponder Front Panel Indicators and Connectors

2746-257-B0-001 Rev. A (2/2014)

Page 3

Overview

CAUTION!

For units in service, backup battery power will not be available during this procedure.

IDH4 Series installation and setup is comprised of three basic steps:

1. Conguring the Network: Provisioning the DHCP Server with the transponder’s MAC Address and assigning it a

DOCSIS Conguration File.

2. Setting Options: The IDH4 Series is designed for out-of-the-box, "plug and play" operation, but non-default settings

such as SNMP trap destination addresses may be required for the Network Management System (NMS). SNMP trap

addresses can be set automatically via the DOCSIS Conguration File per RFC 4639, while IDH4 Series proprietary

options may be set through type-11 TLV entries. The SCTE-HMS and Alpha MIBs may need to be compiled into a MIB

browser before it can be used to monitor or set transponder and power supply parameters. Refer to the IDH4 for XM2

and XM2-HP Technical Manual (Alpha p/n 746-257-B2-001) for details.

3. Installation: Installation of the IDH4 Series into the power supply, connecting the RF Cable, battery sense wire harnesses

(IDH4X only), Environmental, Tamper switch, Ethernet, and verifying operation.

These steps can be performed independently of one another. However, conguring the network prior to eld installation will

allow the installation to be veried while personnel are still on-site. Performing eld installation before network conguration

and before the installation can be veried, might result in additional eld service calls to correct mistakes.

IDH4X Installation / Replacement Procedure in XM2 and XM2-HP Power

Supplies

1. Before removing the Inverter Module (IM), verify the power supply device address is correct.

The power supply device address must not be set to zero and no two power supplies monitored by a single IDH4 Series

can have the same address. Power supplies must have 1, 2, 3, 4 or 5 as an address.

To verify the power supply’s address, go to the LCD display on the inverter module and enter the "Setup" menu. Scroll

to the "Device Address" menu item and verify the device address is set to something other than 0 (Zero).

2. Switch OFF the power supply’s battery breaker.

NOTE:

With the battery breaker in the OFF position, the power supply will not go into inverter mode.

3. Unplug all Inverter Module connections (e.g. battery cable, remote temperature sensor).

4. Loosen the Inverter Module thumbscrews and slide the inverter module out just enough to disconnect the ribbon cable.

Disconnect the ribbon cable.

5. Slide the Inverter Module out of the power supply.

3746-257-B0-001 Rev. A (2/2014)

Page 4

IDH4X Installation / Replacement Procedure in XM2 and XM2-HP Power Supplies,

continued

6. If the Inverter Module is equipped with a communication module, remove it by loosening the two Phillips captive screws.

7. Plug the supplied 18-pin jumper into the header on the back of the IDH4 Series circuit board.

Disconnect here

Captive Screws

Fig. 3, Inverter Module Ribbon Cable

Fig. 4, Captive Screw Locations

NOTE:

To prevent damage to the IDH4X, do not reuse the existing 18-pin connector. Instead, use the jumper supplied with the

transponder.

Fig. 5, Installing 18-pin Jumper

(Alpha p/n 540-286-19)

Fig. 6, Connecting the Transponder to the Inverter Module

8. Line up the 18-pin jumper with the header on the Inverter Module and connect the unit to the Inverter Module.

9. Fasten the IDH4 Series to the Inverter Module by tightening the two captive screws. It is recommended that the screws

be tightened alternately, a few turns at a time so the transponder aligns in parallel to the Inverter Module.

10. Reinstall the Inverter Module and reconnect the ribbon cable. Make front panel connections (tamper, temperature sensor,

battery sense, RF etc.).

11. If not yet done, record the cable modem MAC address from the front of the unit and report it to the network manager for

network provisioning. For Dual IP applications, the CPE MAC address should also be recorded.

4746-257-B0-001 Rev. A (2/2014)

Page 5

IDH4L Installation / Replacement Procedure in XM2-300HP Power Supplies

1. Before removing the Inverter Module (IM), verify the power supply device address is correct.

The power supply device address must not be set to zero and no two power supplies monitored by a single IDH4 Series

can have the same address. Power supplies must have 1, 2, 3, 4 or 5 as an address.

To verify the power supply’s address, go to the LCD display on the inverter module and enter the "Setup" menu. Scroll

to the "Device Address" menu item and verify the device address is set to something other than 0 (Zero).

2. Switch OFF the power supply’s battery breaker.

NOTE:

With the battery breaker in the OFF position, the power supply will not go into inverter mode.

3. Unplug all Inverter Module connections (e.g. battery cable, remote temperature sensor).

Inverter Module

Thumbscrews

Fig. 7, Removing the Inverter Module from the Power Supply

4. Loosen the Inverter Module thumbscrews.

5. Slide the Inverter Module out of the power supply.

6. Loosen the two Phillips captive screws to remove the IDH4L sheet metal from the Inverter Module.

Power Supply

Battery Breaker

Captive Screw

Captive Screw

Fig. 8, Removing the IDH4L Sheet Metal from the Inverter Module

5746-257-B0-001 Rev. A (2/2014)

Page 6

IDH4L Installation / Replacement Procedure in XM2-300HP Power Supplies, continued

7. Plug the supplied 18-pin jumper into the header on the Inverter Module.

NOTE:

To prevent damage to the IDH4L, do not reuse the existing 18-pin connector. Instead, use the jumper supplied with

the transponder.

Fig. 9, Installing 18-pin Jumper

(Alpha p/n 540-581-19)

8. Attach the IDH4L to the sheet metal with the supplied 6-32 screws.

9. Line up the 18-pin jumper with the header on the Inverter Module and connect the unit to the inverter module.

Fig. 10, IDH4L Attached to Sheet Metal

10. Fasten the IDH4L to the Inverter Module by tightening the two captive screws. It is recommended that the screws be

tightened alternately, a few turns at a time so the transponder aligns in parallel to the Inverter Module.

11. Reinstall the Inverter Module and make front panel connections (tamper, temperature sensor, battery, RF, etc.).

12. If not yet done, record the cable modem MAC address from the front of the unit and report it to the network manager

for network provisioning. For Dual IP applications, the CPE MAC address should also be recorded.

Fig. 11, IDH4L Inverter Module Connection

6746-257-B0-001 Rev. A (2/2014)

Page 7

Connecting the RF Drop

CAUTION!

Install a grounded surge suppressor (Alpha P/N 162-028-10 or equivalent).

Connect the RF drop according to the diagram below. The RF drop must have a properly installed ground block in the

power supply enclosure. Recommended downstream RF level is 0 dBmV. Connect any other front panel connections at

this time (e.g. battery strings, tamper switch).

Grounded Surge Protector

(See Caution Above)

RF Cable

to Headend

Fig. 13, Connecting the RF Drop

ECM to SCM Interface

(Alpha P/N 704-709-20)

Linked CableUPS

Serial Interface Cards

B

S

Y

S

C

O

M

A

Comm Port

A

B

System Port

C

Battery Sense Connections

A

S

Y

S

C

O

M

IDH4X in

Primary XM2

B

A

C

AlphaBus Cable

(Alpha P/N 875-190-20 for 6',

-21 for 9', -22 for 18', -23 for 35')

Environmental

connection

Ethernet connection

RF connection

Generator (ECM)

Battery Sense Wire Harness

Connections

Connections with

more than one power

supply

Fig. 14, System Interconnection Diagram

NOTE:

Each power supply must have a unique address. Refer to Intelligent CableUPS technical manual

(Alpha p/n 017-805-B0), or the IDH4 Series Transponder Technical Manual (Alpha p/n 746-257-B2) for

additional information.

7746-257-B0-001 Rev. A (2/2014)

Page 8

Total Power Solutions

Initial Startup and Test / Returning the Unit to Service

1. Plug the power supply into the AC outlet.

2. Switch battery breaker ON.

3. The IDH4 Status LEDs will all blink in unison upon initial power up. The RDY LED will then begin blinking steadily indicating

normal processor activity.

4. Verify the DS and REG LEDs are on solid. This veries the Communications Module has registered an IP address on the

network.

5. Verify the RF LED is solid Green, indicating Upstream and Downstream Power is within the default specied range and the

Upstream RF Power is below the recommended +50 dBmV.

6. Verify no XM2 / XM2-HP / XM2-300HP alarms are active.

RF Power Default Values

LED Color Rx Range (dBmV) Tx Range (dBmV)

Green +10 to -10 0 to +50

Blue +15 to +10 and -10 to -15 +50 to +55

Red >+15 and <-15 >+55

Table 1, RF Power Default Values

Test Connection

With the IDH4 Series Transponder used in conjunction with the XM2-HP power supply, network connectivity can be veried via

the smart display. For other power supply models, verify the network status via the Ethernet port.

Connect a computer’s network port to the transponder’s Ethernet port using a standard network cable. Launch an Internet

browser and enter 192.168.100.1 into the Address. The transponder will return the Web page shown below. The General

Conguration page shown below will appear and display connectivity, power levels, and power supply status information such as

alarms, output voltage, output current, and individual battery voltages. System Name, System Location, System Contact and

Common Logical ID may be edited on this page; when prompted for a User Name and Password, use "Alpha" and "AlphaGet".

Alpha Technologies Inc.

3767 Alpha Way

Bellingham WA 98226

USA

Tel: +1 360 647 236 0

Fax: +1 360 671 493 6

Alpha Technologies

Alpha Technologies Ltd.

7700 Riverfront Gate

Burnaby BC V5J 5M4

Canada

Tel: +1 604 436 5900

Fax: +1 604 4 36 1233

Alpha re serves the r ight to change specicat ions without n otice.

© 2014 Alpha Technologies Inc. All Rights Reserved.

Alpha is a registered t rademark of A lpha Technologi es. 746-257-B0-001 Rev. A (2/2014) For more information visit www.alpha.com

(data values shown for illustration purposes only)

Alpha Technologies Europe Ltd.

Twyford House, Thorley

Bishop’s Stortford,

Hertfordshire

CM22 7PA

United Kingdom

Tel: +44 1279 501110

Fax: +44 1279 659870

Fig. 15, Initial Web Page

Alpha Technologies GmbH

Hansastrasse 8

D 91126 Schwabach

Germany

Tel: +49 9122 79889 0

Fax: +49 9122 7 9889 21

Al phaTe c Lt d.

339 Sai nt Andrews Str eet

Suite 101 Andrea Chambers

3307 Limassol

Cyprus

Tel: +357 25 375675

Fax: +357 25 359595

AlphaTEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1 Ofce 4 03

109028 Moscow

Russia

Tel: +7 495 916 1854

Fax: +7 495 916 1349

member of The Group

Alpha Technologies

Suite 190 3, Tower 1

33 Canton Road, Kowloon

Hong Kong, China

Tel: +852 2736 8 663

Fax: +852 2199 7988

TM

Loading...

Loading...